Novel belt type vibratory rolling filtering device

A filter device and vibrating roller technology, which is applied in the direction of moving filter element filter, filter separation, separation method, etc., can solve the problems of large water consumption for cleaning filter cloth, large consumption of flocculant, and inability to wash filter cake, etc., to prevent Effects of running mixed filtrate, reducing energy consumption and cost, and improving solid-liquid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

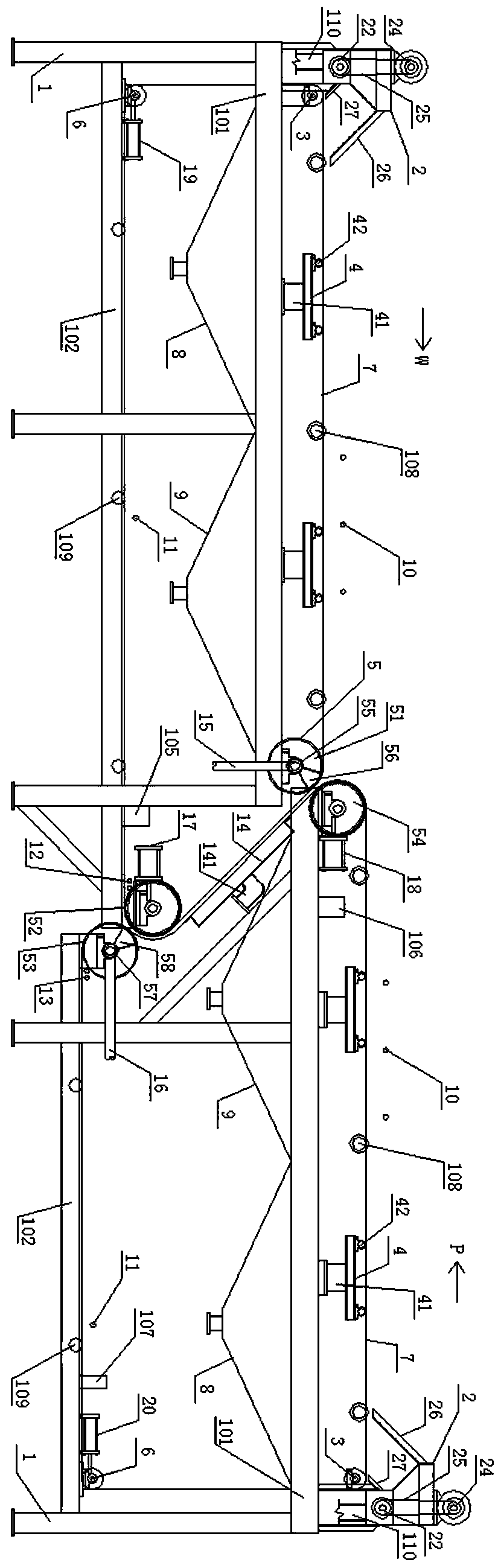

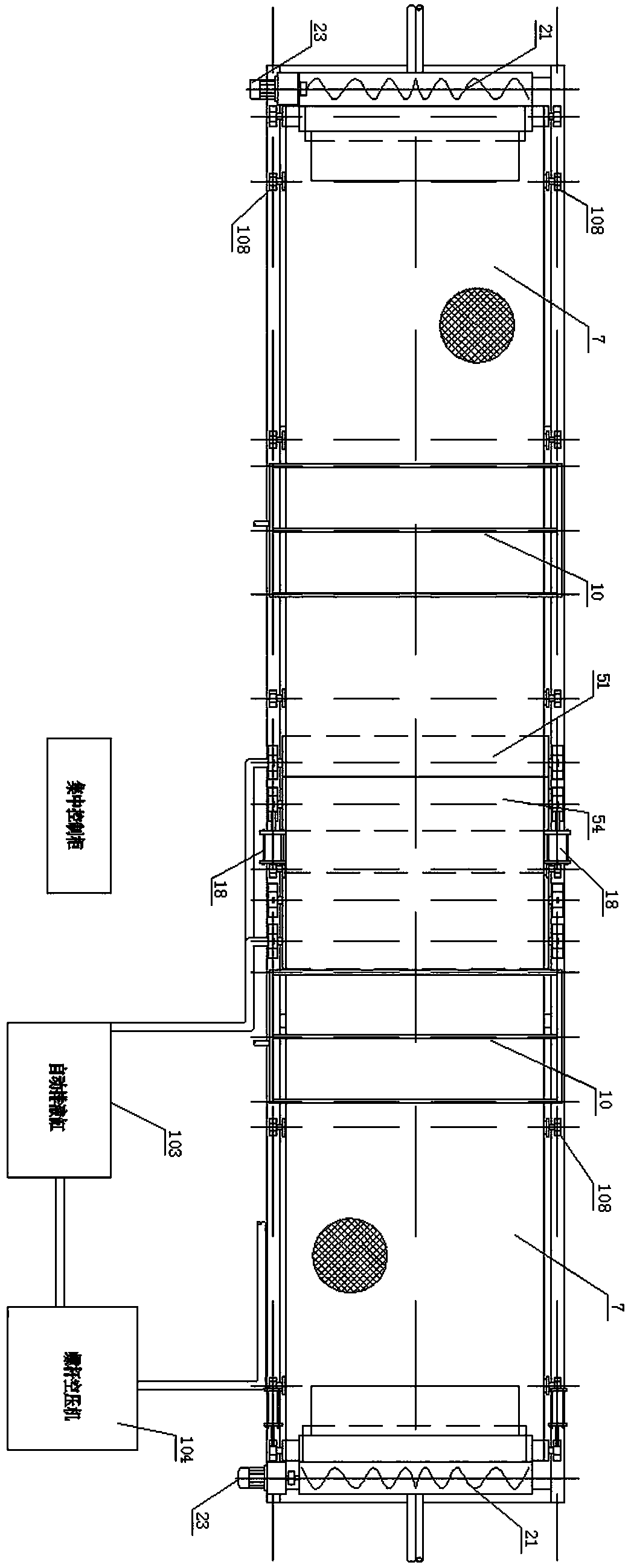

[0038] Such as figure 1 and figure 2 As shown, the novel belt-type vibrating roll-press filter device of the present invention comprises belt-type vibrating-roll-press filters arranged side by side relative to each other, and the belt-type vibrating roll-press filters each include a frame 1, including a horizontally arranged upper support frame 101 And the lower support frame 102, the upper end of the upper support frame 101 is provided with a layered distributor 2, along the flow direction of the material, the frame 1 is successively provided with a guide roller 3, a vibrating part 4, a driving roller press part 5 and a tensioning part. Roller 6, the layered distributor 2 is located upstream of the guide roller 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com