Patents

Literature

579results about How to "Prevent extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

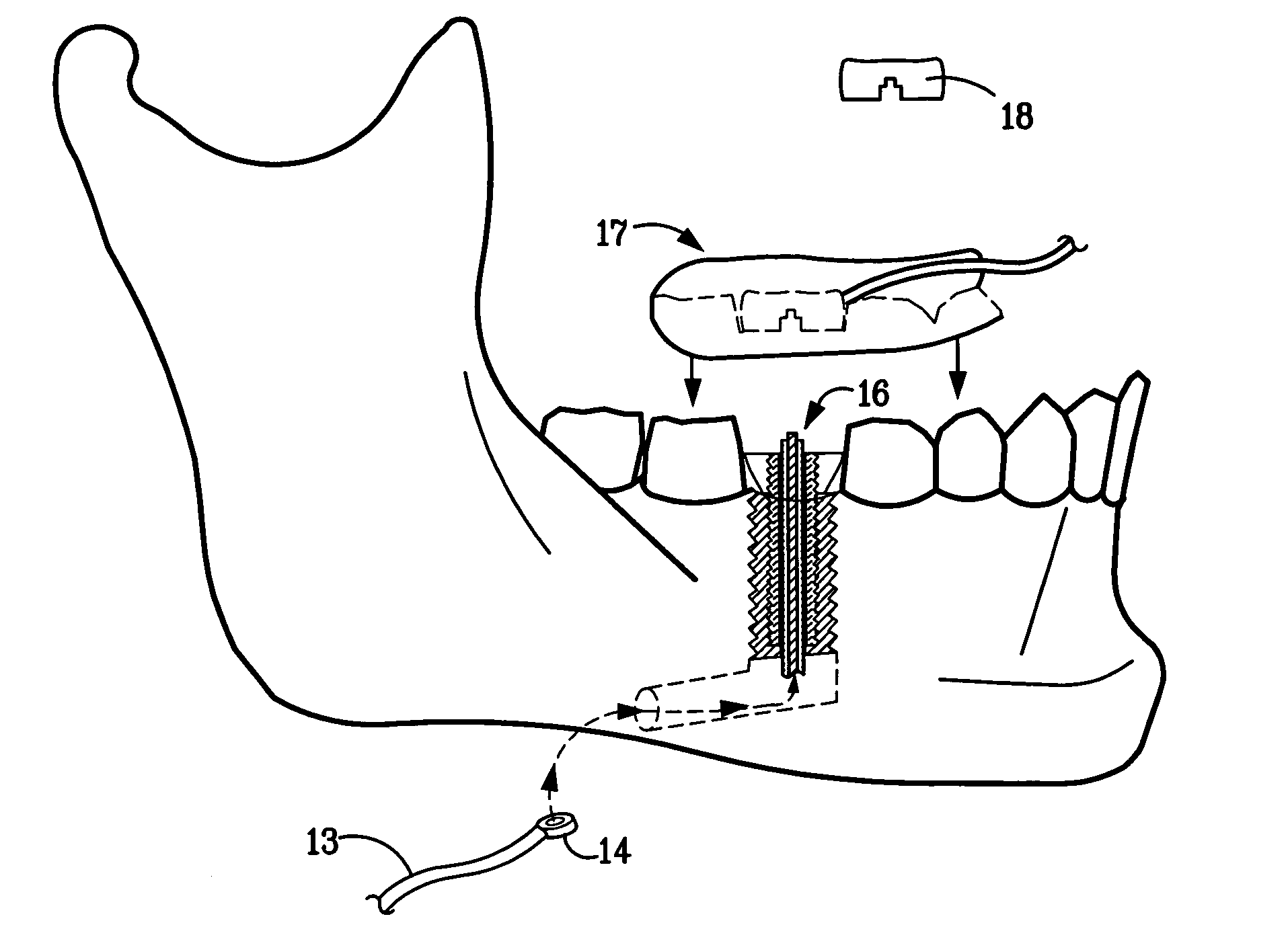

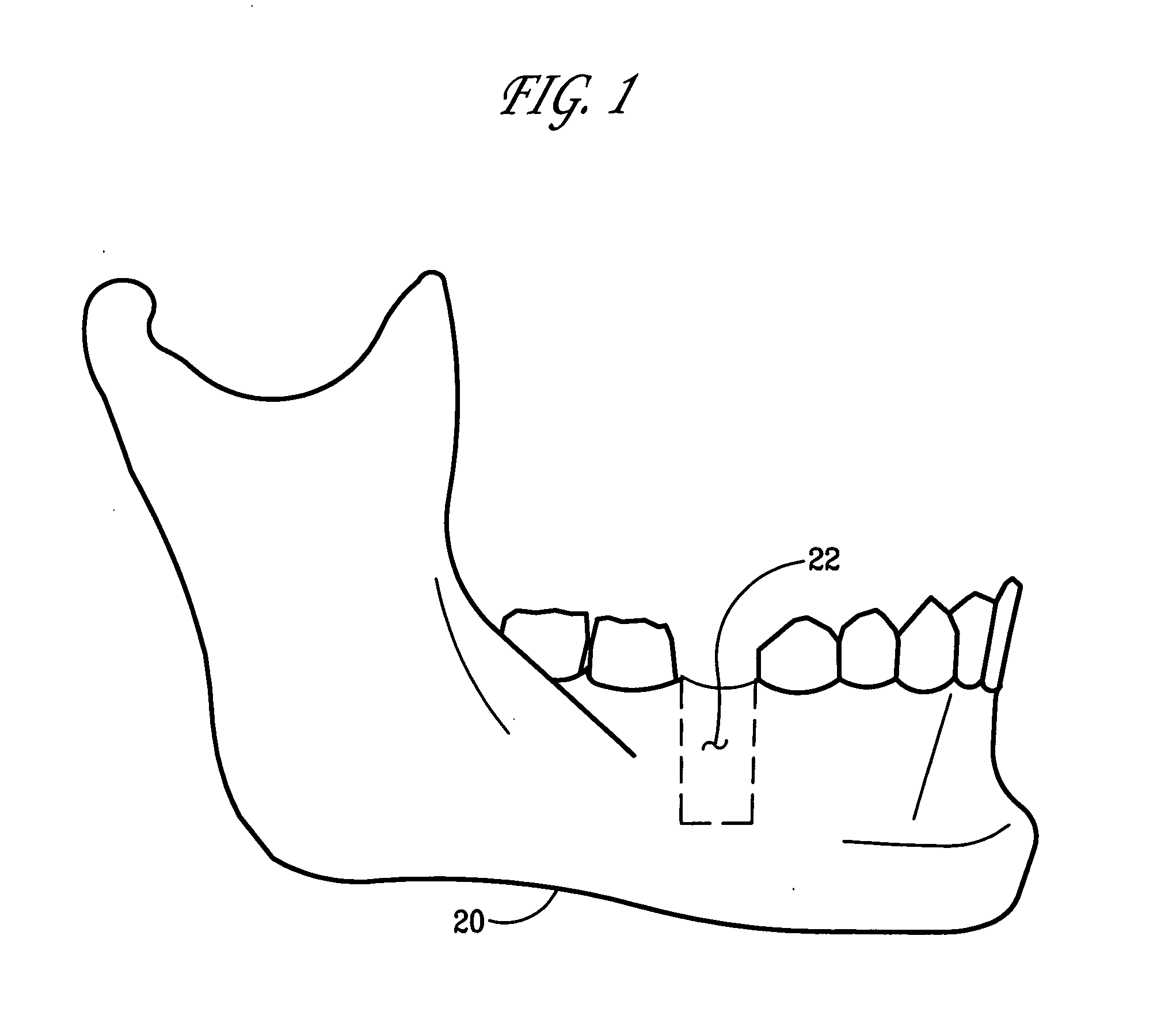

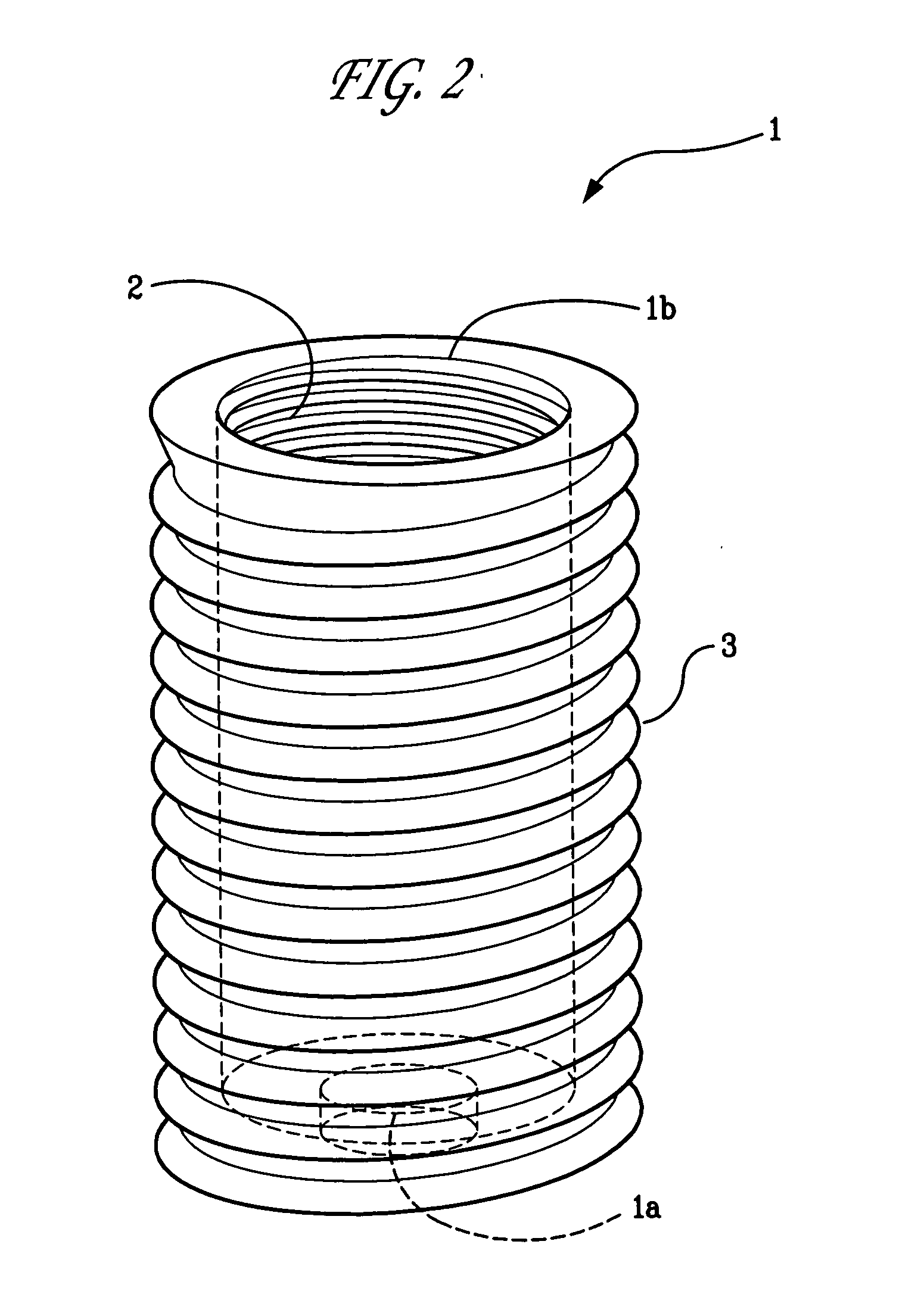

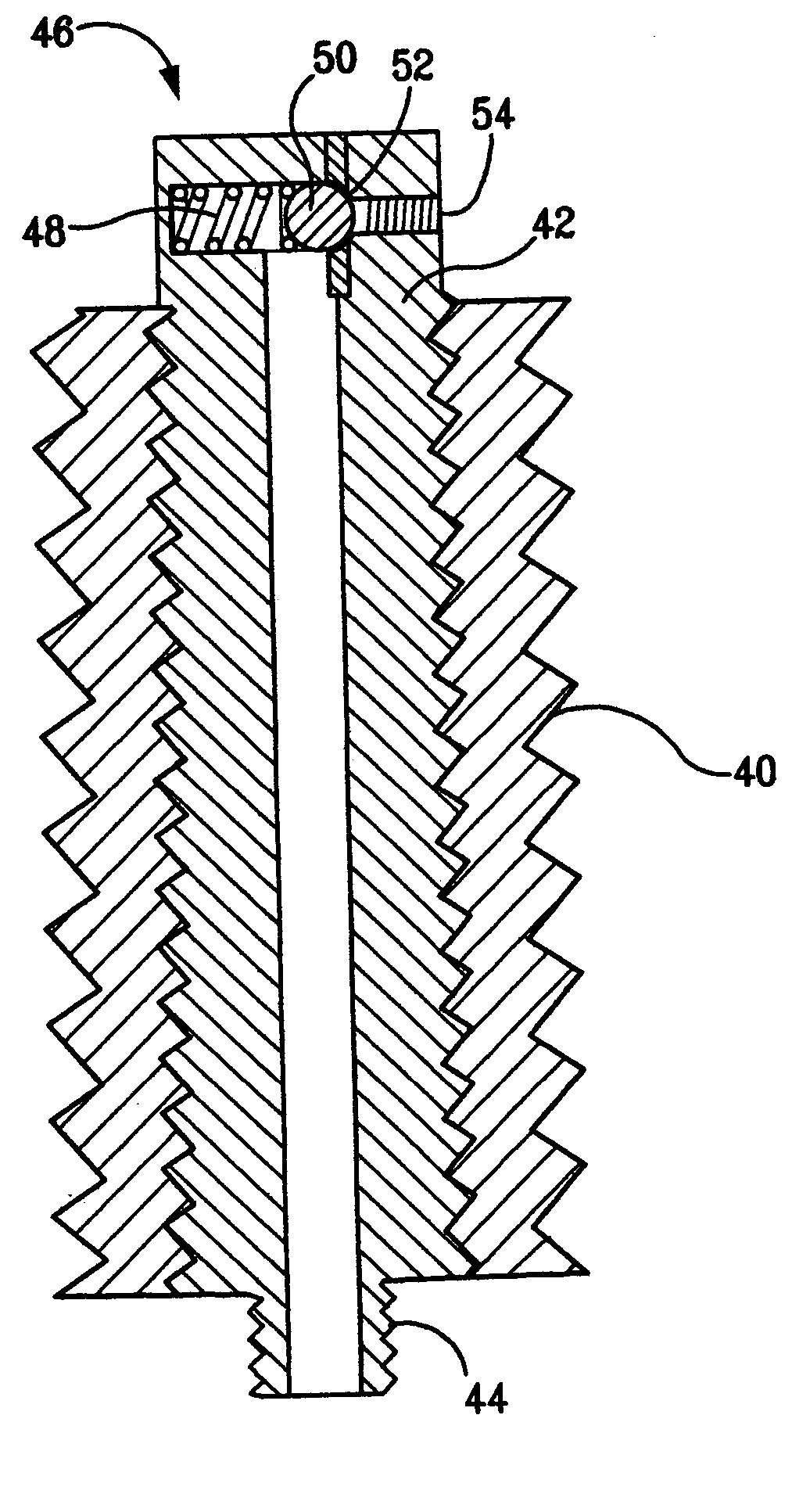

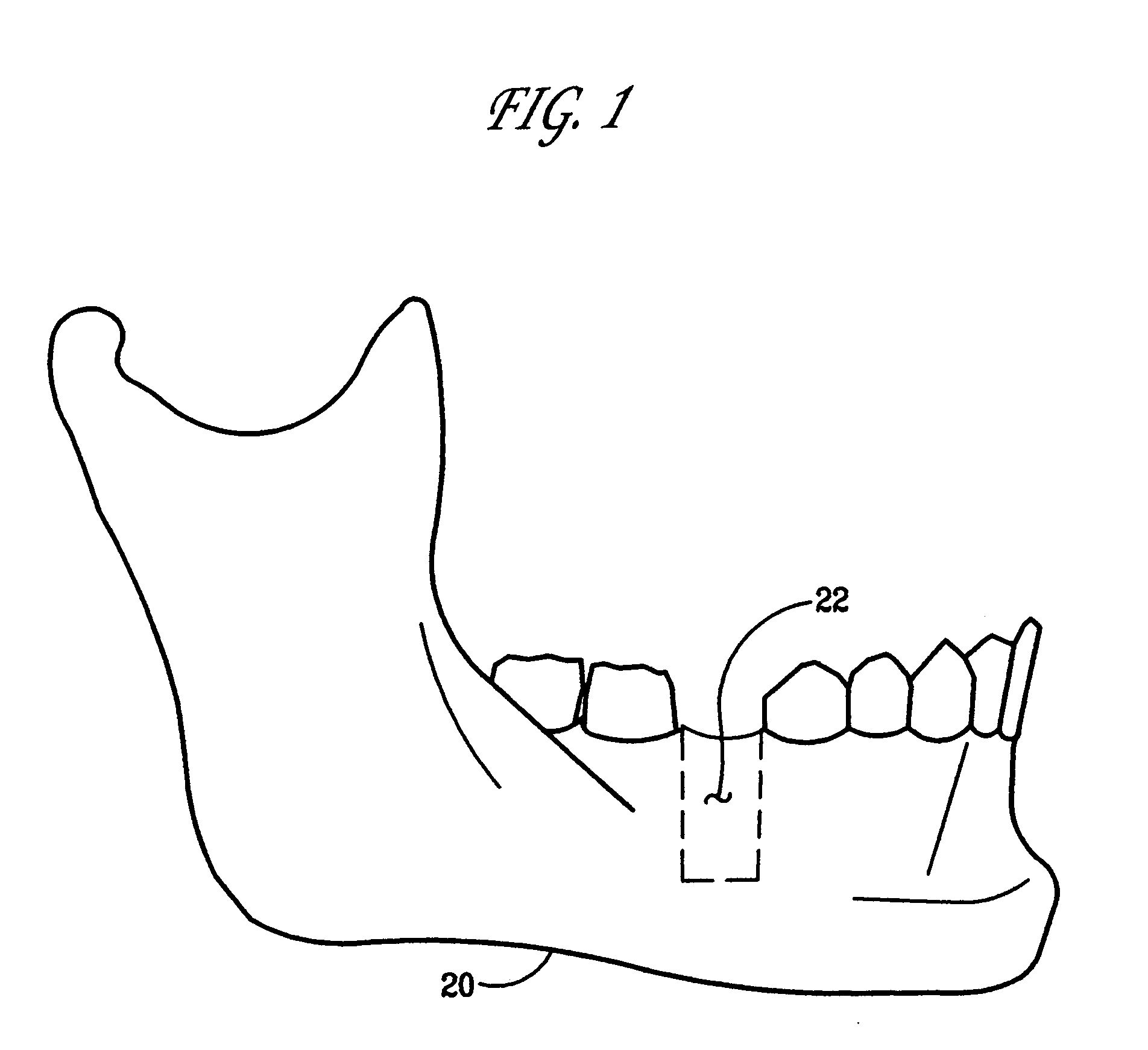

Apparatus and method for using an intraosseous space for moving fluid into and out of the body

InactiveUS20080215010A1Eliminate riskReduce necessityDental implantsMedical devicesPharmaceutical drugDiabetic patient

An apparatus for communication between a site within a body and a source, depot, reservoir, device or machine external to the body via the mouth of the body, comprising an implant for placement in tooth-supporting bone, the implant having a first portion extending into the mouth external to the tooth-supporting bone, a second portion for being embedded in the tooth-supporting bone, and an opening extending along the implant from the first portion to the second portion. A sealing cap containing an antimicrobial substance may be provided to provide a seal when the apparatus is not in use. An external pump may infuse various medications or liquids, including those required by a person having a diabetic condition.

Owner:SILVER THEODORE A +1

Apparatus and method for movement of electricity or fluid into and out of the body

InactiveUS20050256540A1Eliminate riskEliminate necessityDental implantsElectrotherapyElectricityCatheter

An apparatus for communication between a site within a body deep to the skin and a source, depot, reservoir, device, machine, or power source external to the body via the mouth of the body, comprising an implant for placement in tooth-supporting bone, the implant having a first portion extending into the mouth external to the tooth-supporting bone, a second portion for being embedded in the tooth-supporting bone, and an opening extending along the implant from the first portion to the second portion; and a conduit for coupling to the second portion of the implant when the implant is implanted in the tooth-supporting bone so that the conduit is in communication with the opening, the conduit being for extending from the implant to the site in the body.

Owner:SILVER THEODORE A +1

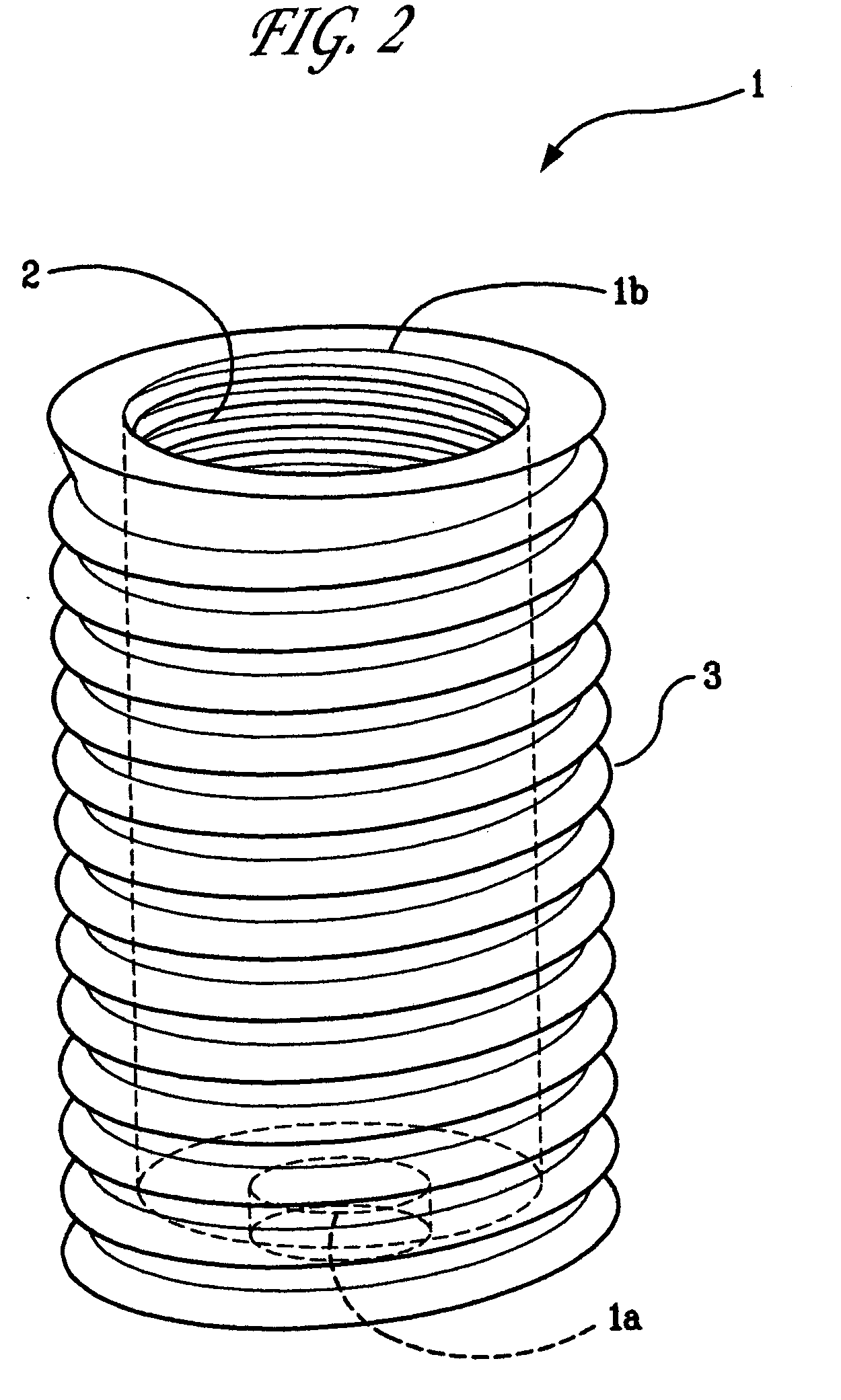

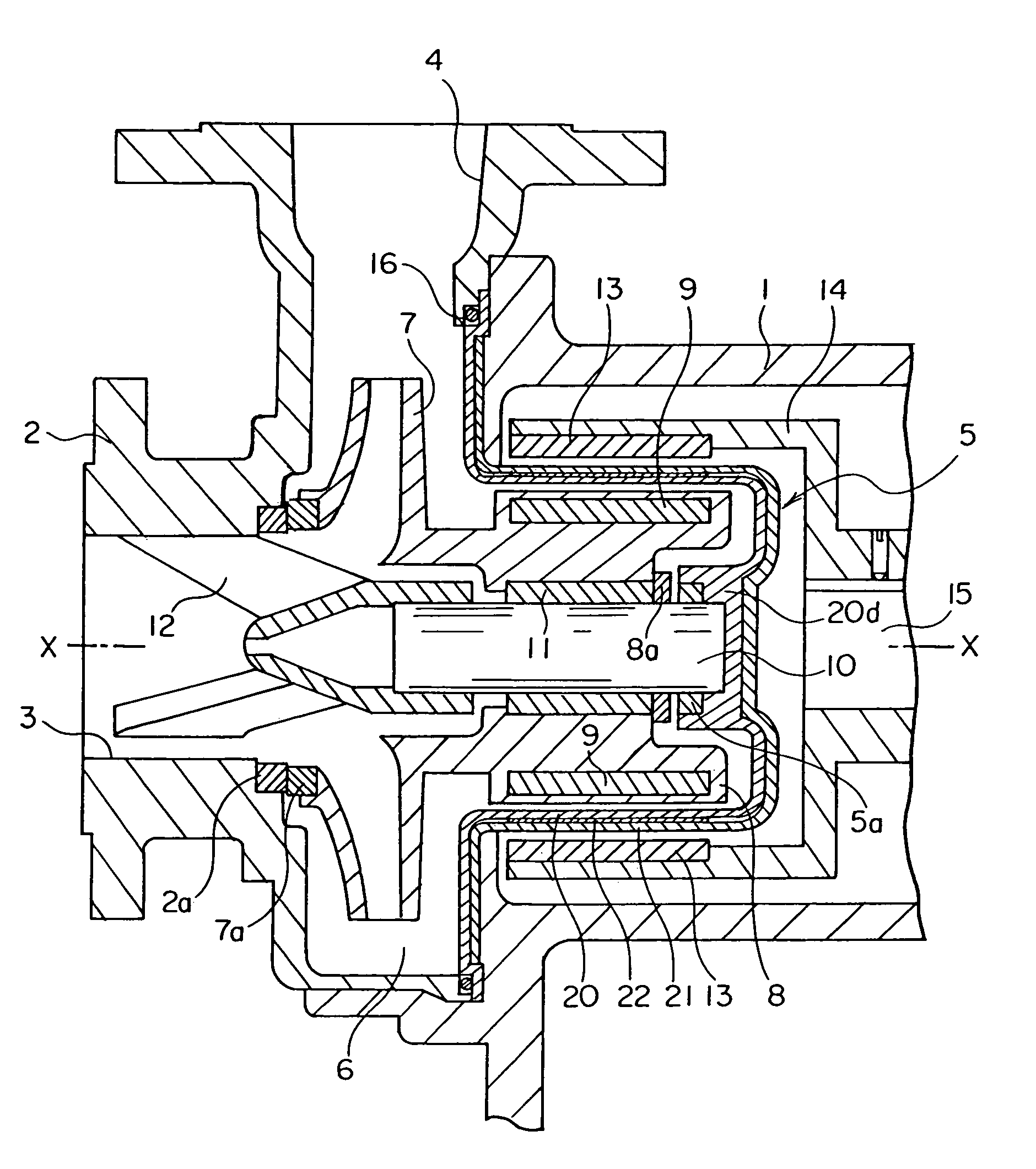

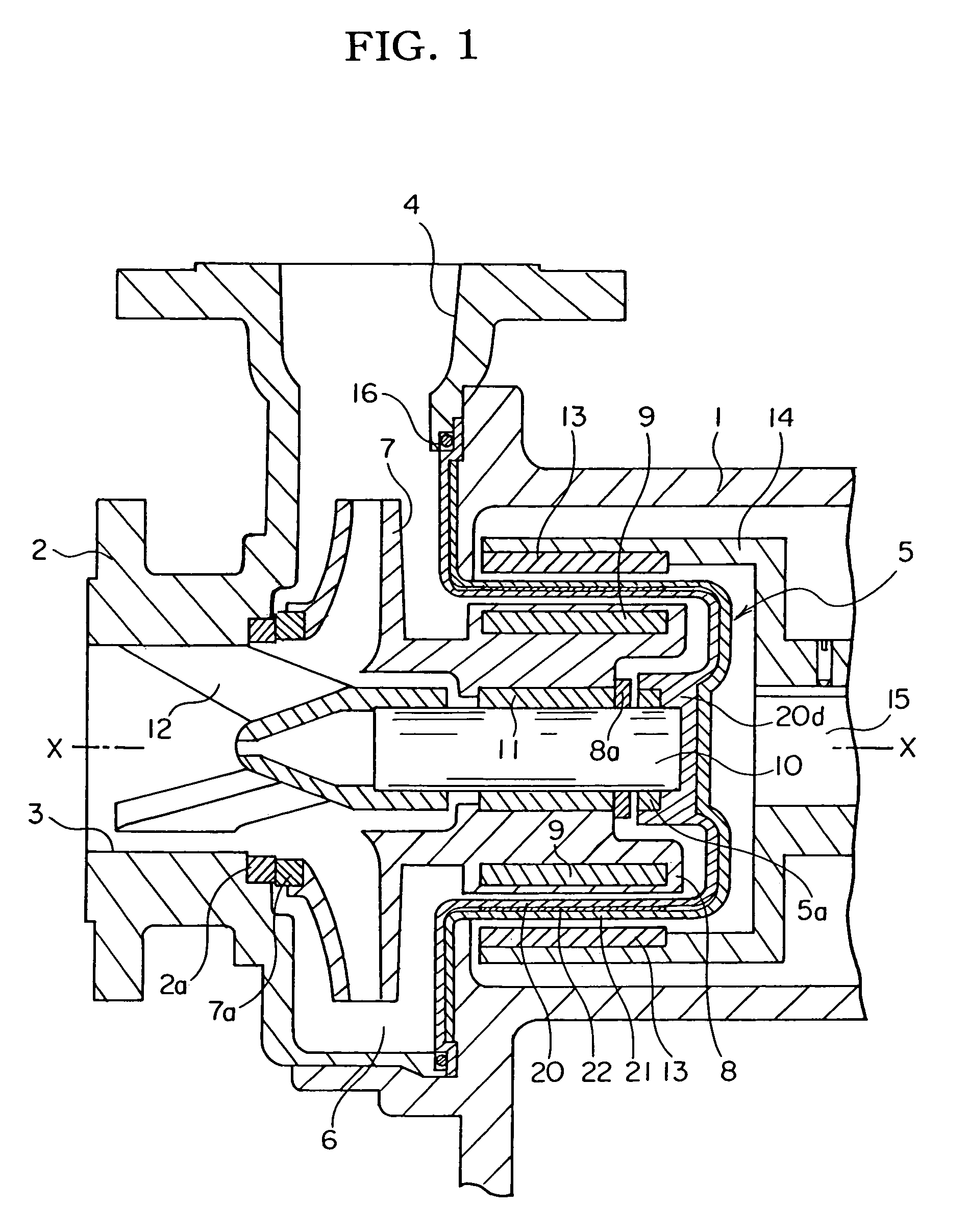

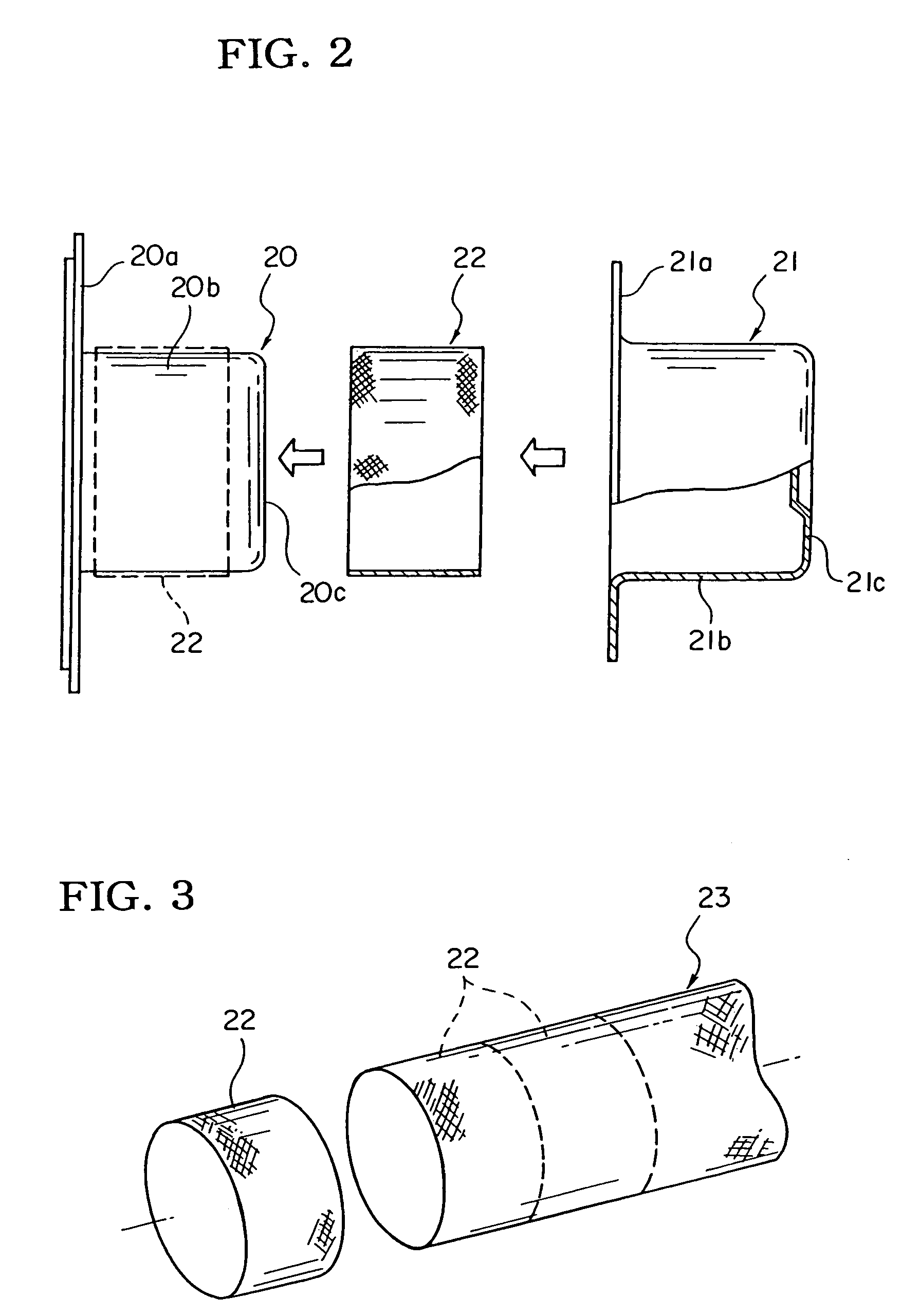

Rear casing arrangement for magnetic drive pump

ActiveUS7249939B2Improve reinforcement effectAvoid deformationPositive displacement pump componentsPump installationsHeat resistanceBand shape

It is sought to provide a rear casing arrangement for a magnetic drive pump, which can sufficiently provide such functions pressure resistance and heat resistance, which give rise to problems in the case of manufacturing the rear casing from a material based on a synthetic resin, and can also be manufactured at low cost.A reinforcing belt-like ring member is woundly fitted on the outer periphery of a cylindrical barrel part of an inner casing member constituting a rear casing. The belt-like ring member has a width smaller than the length of the barrel part. A casing cover member is fitted on the belt-like ring member in the above fitted state. Alternatively, it is possible to fit the belt-like ring member on the outer periphery of a barrel part of the casing cover member. These parts can be disassembled.

Owner:IWAKI

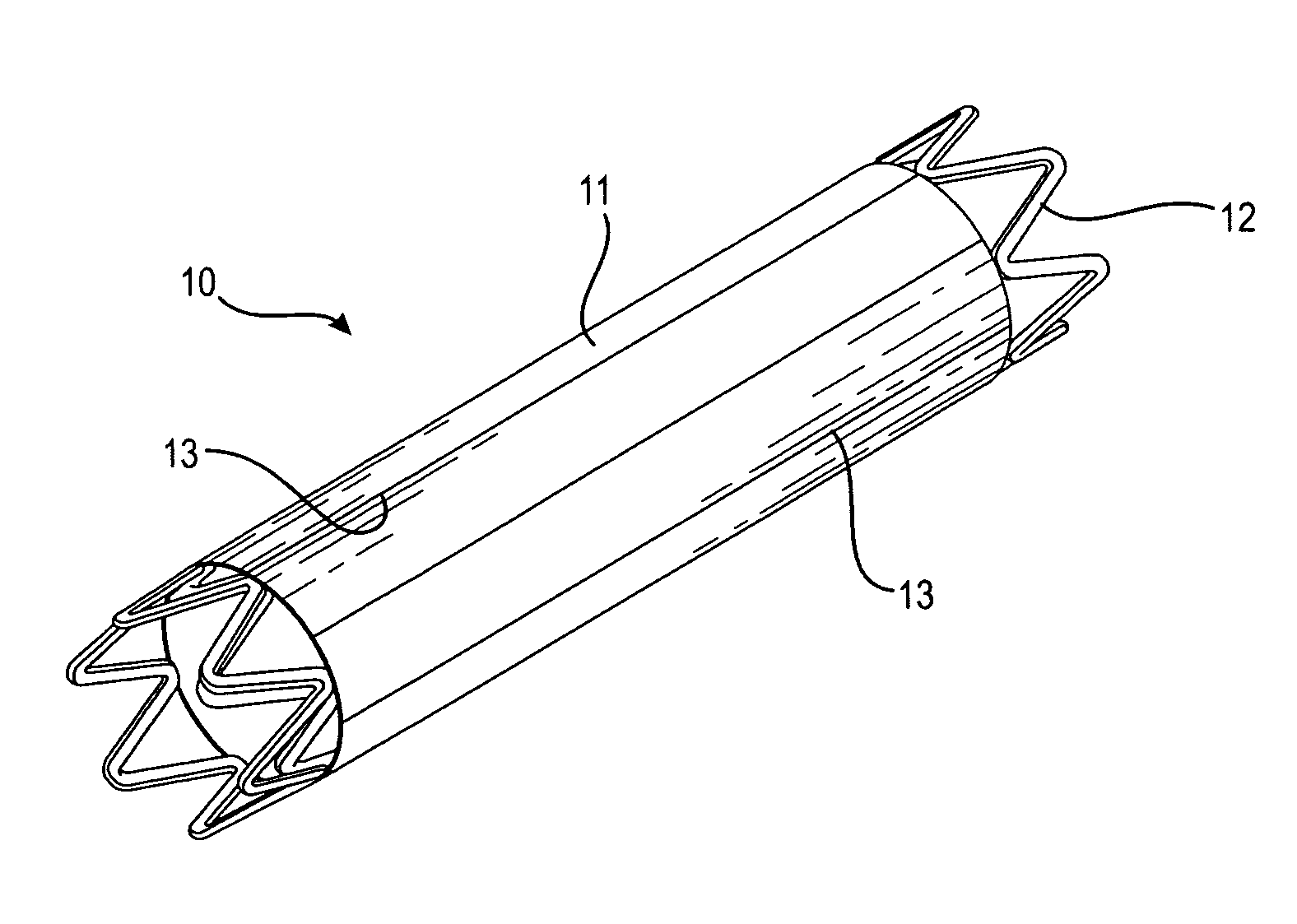

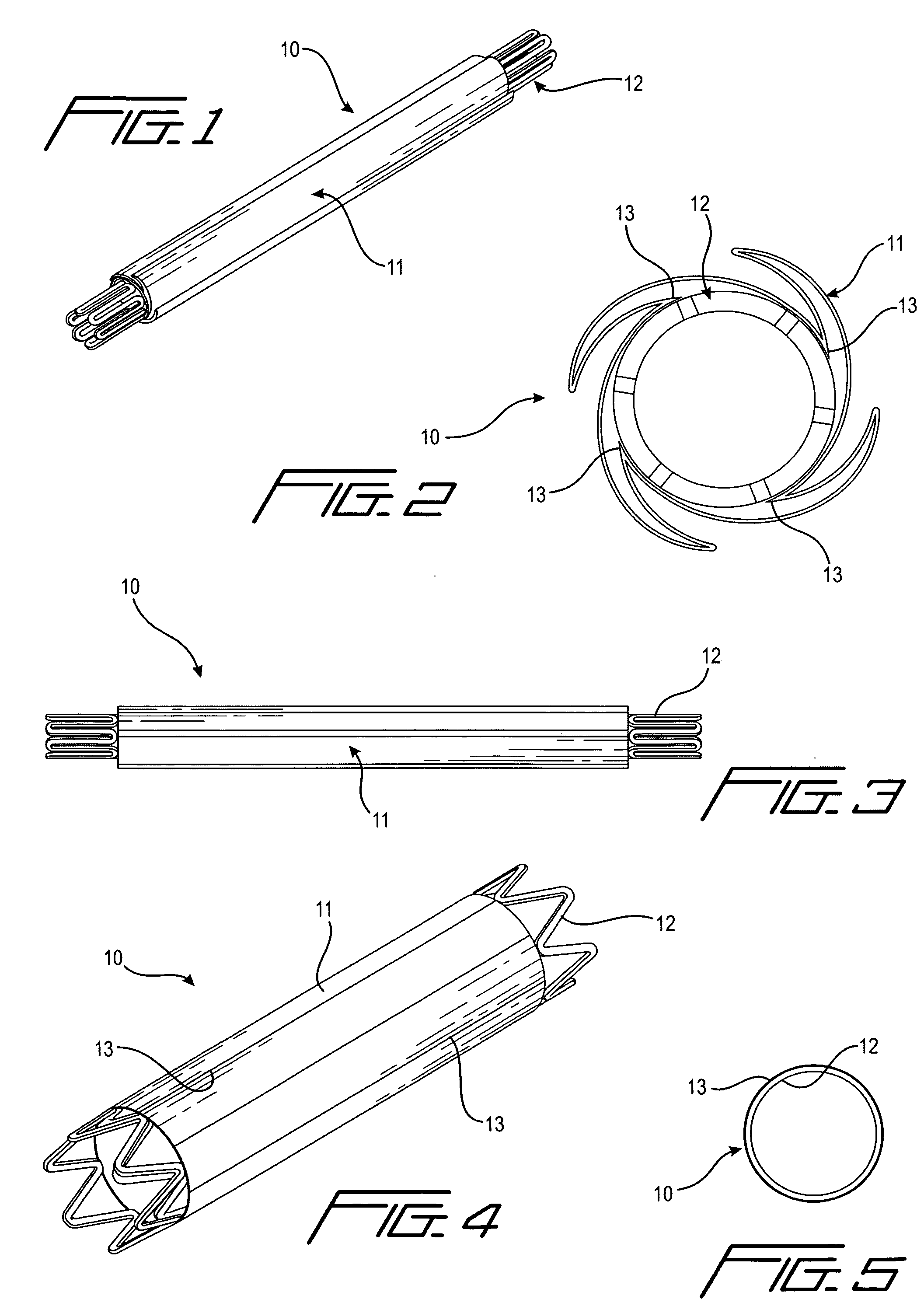

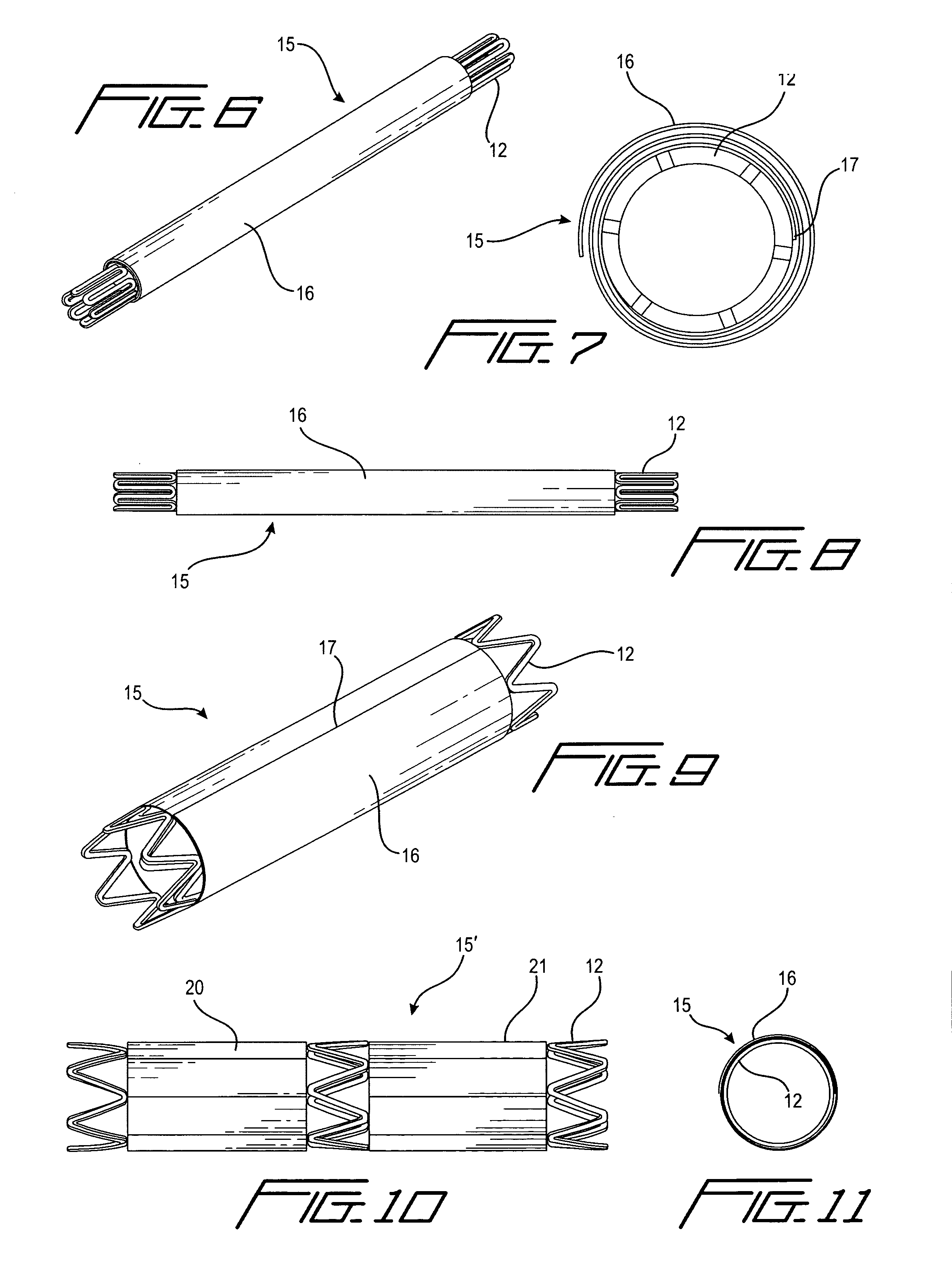

Medical stent and devices for localized treatment of disease

Owner:KRAUSE ARTHUR A +1

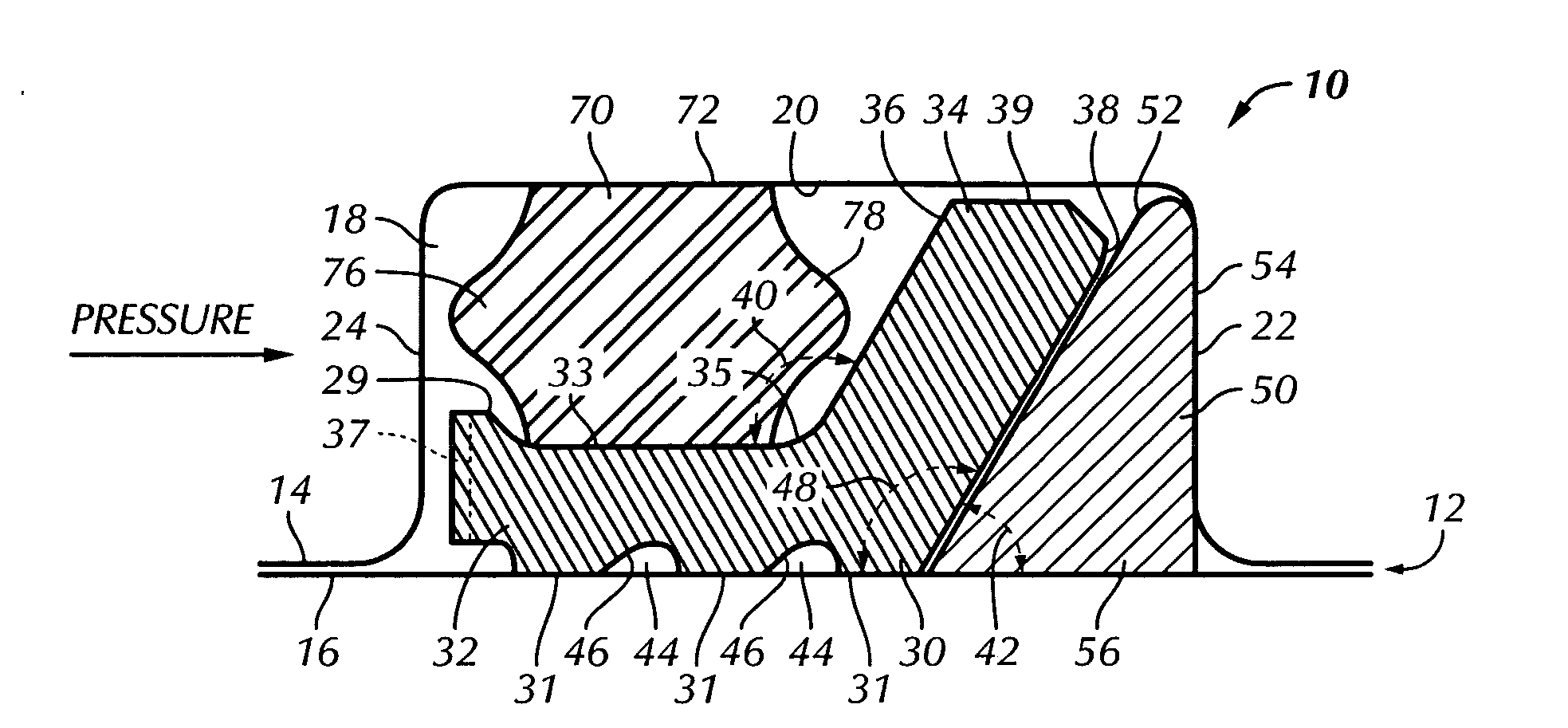

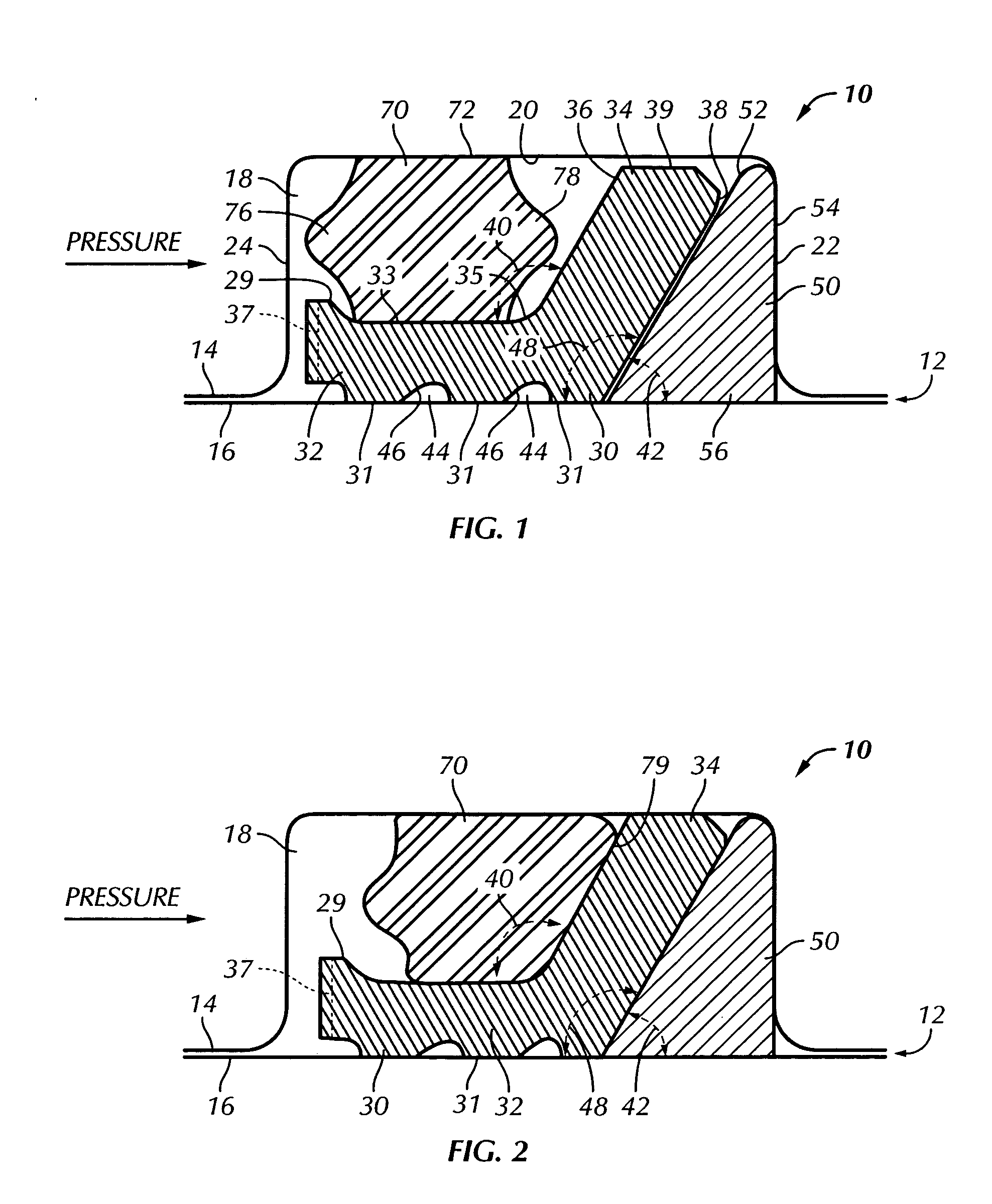

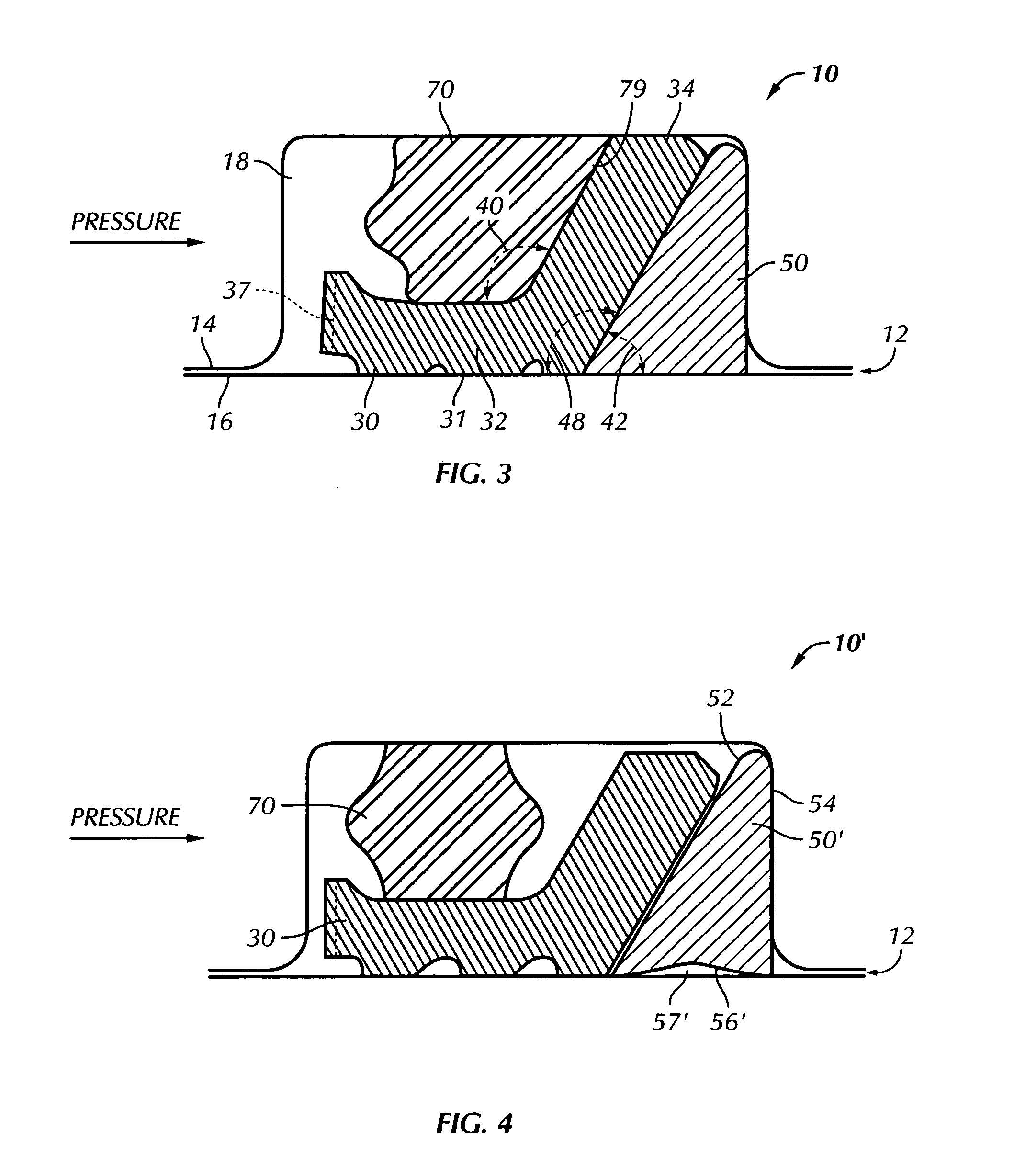

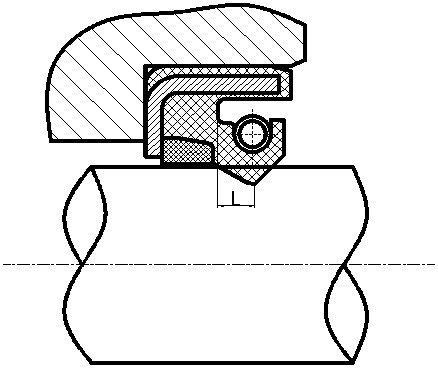

Cammed seal assembly with elastomeric energizer element

A seal assembly seals first and second operational surfaces spaced apart by a gap. The first surface includes a seal groove having a base surface and first and second side surfaces. A sealing element in the seal groove has a foot portion extending parallel to the base surface which engages the second operational surface. A leg portion extending from the foot portion toward the base surface has first and second surfaces. A back-up ring adjacent to the sealing element prevents extrusion of the sealing element into the gap. A first side of the back-up ring mates with the second surface of the leg portion, and a second side mates with one of the first and second side surfaces of the seal groove. An energizer element located between the base surface and the foot portion applies uniform pressure to the leg and foot portions when the energizer element is compressed.

Owner:GREENE TWEED TECH

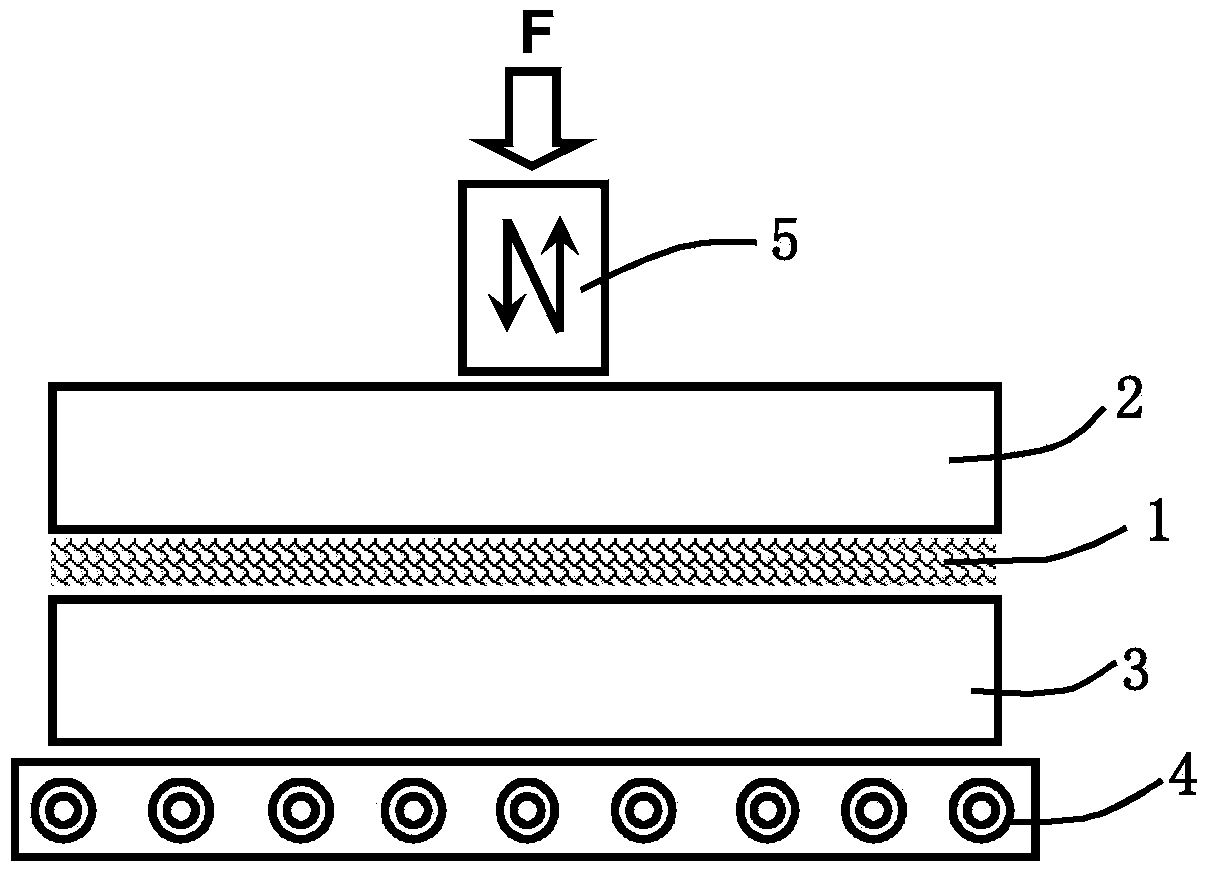

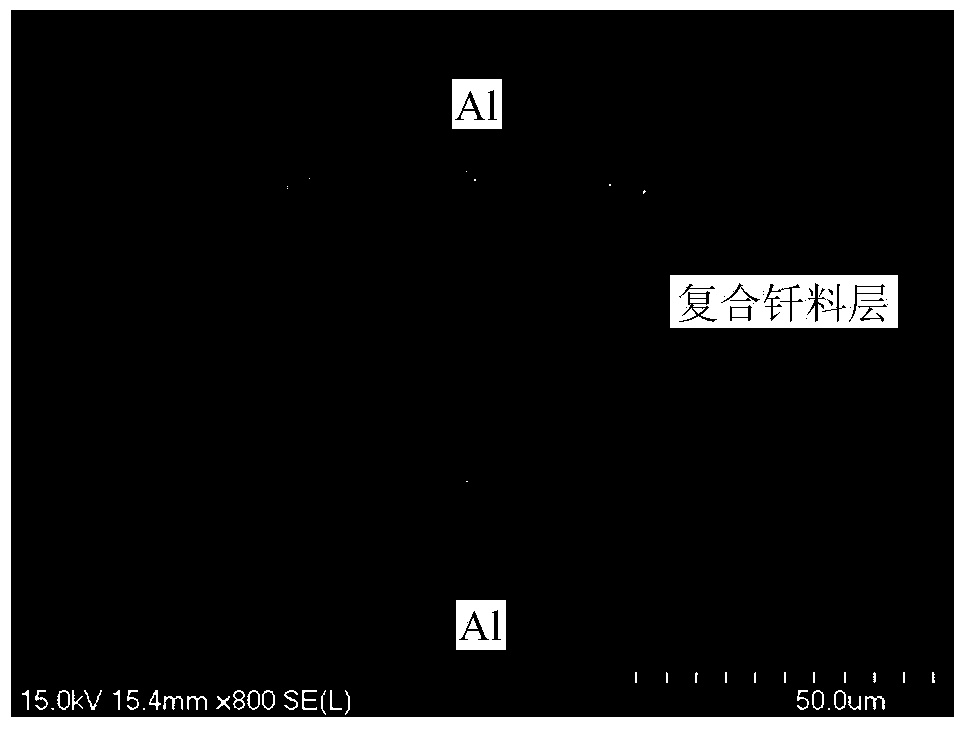

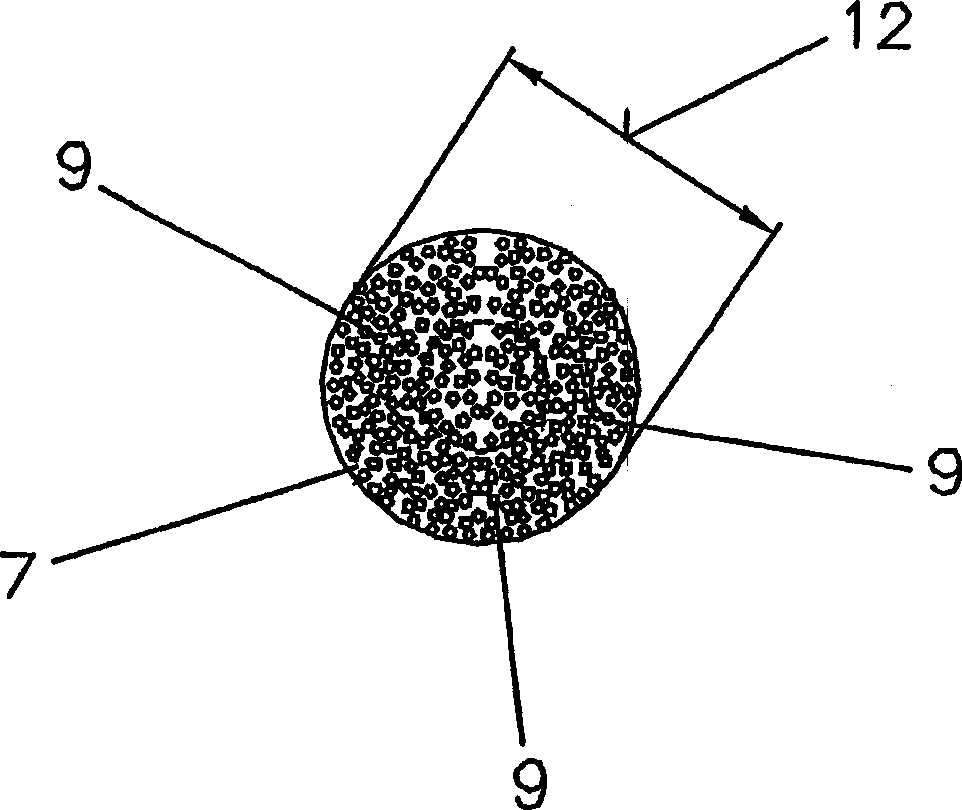

Preparing method for porous metal matrix compound brazing filler metal alloy soldering head

ActiveCN104191057ASuitable for brazingHigh strengthSoldering apparatusThermal dilatationUltrasonic vibration

The invention discloses a preparing method for a porous metal matrix compound brazing filler metal alloy soldering head. The method adopts porous metal matrix compound brazing filler metal alloy filled up with brazing filler metal alloy, a compound brazing filler metal layer is prefabricated between hard base metal, then the brazing filler metal alloy filled into the porous metal layer is heated to melt, and a tool head of an ultrasonic vibrating device acts on the surface of the base metal and exerts certain-pressure certain-time ultrasonic vibration on the surface of the base metal to finish a brazing process. When the method is used for preparing the brazing soldering head, the porous metal with high melting point can have a supporting function to a soldering seam layer in a brazing soldering process, the liquid-phase brazing filler metal alloy is prevented from being extruded out excessively in the ultrasonic vibration action. Thus, the preparation of the brazing soldering head with a large fuse face is achieved. In addition, the porous metal layer in the brazing seam layer can reduce the thermal expansion coefficients of the brazing seam layer, and the strength of the brazing seam layer and the strength of the connection interface between the brazing seam layer and the base metal are improved.

Owner:CHINA NAT ELECTRIC APP RES INST +1

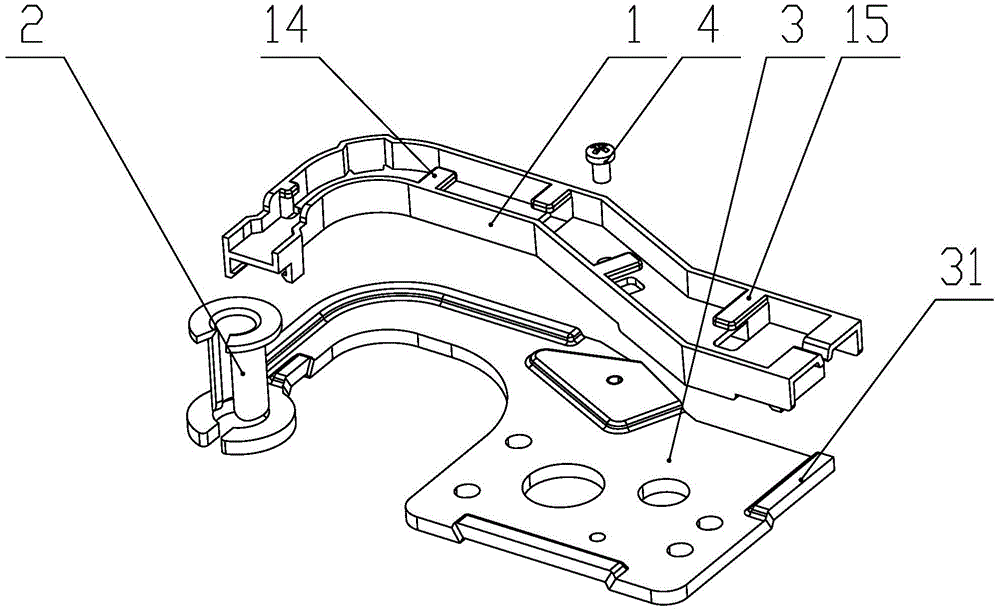

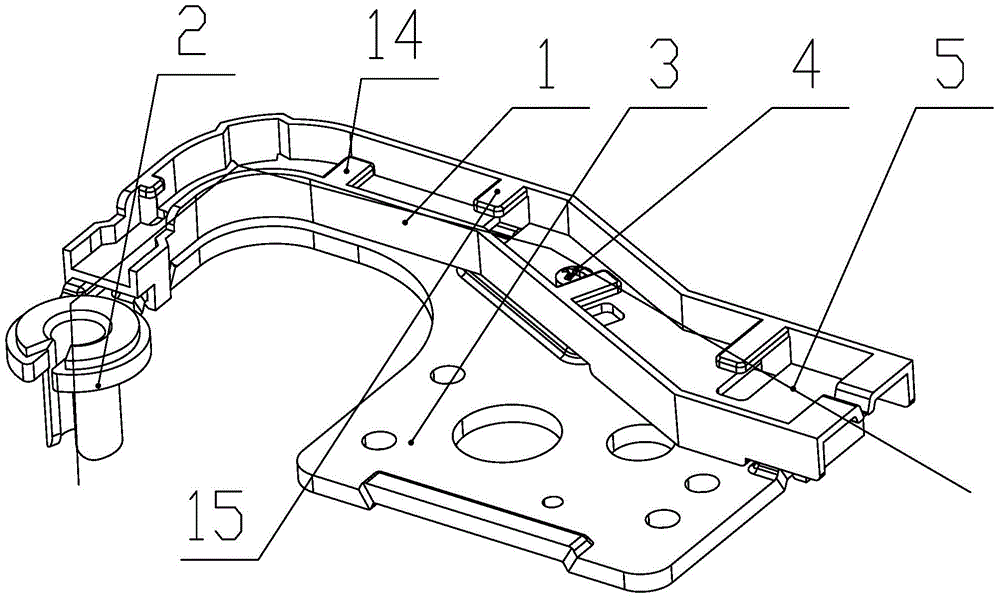

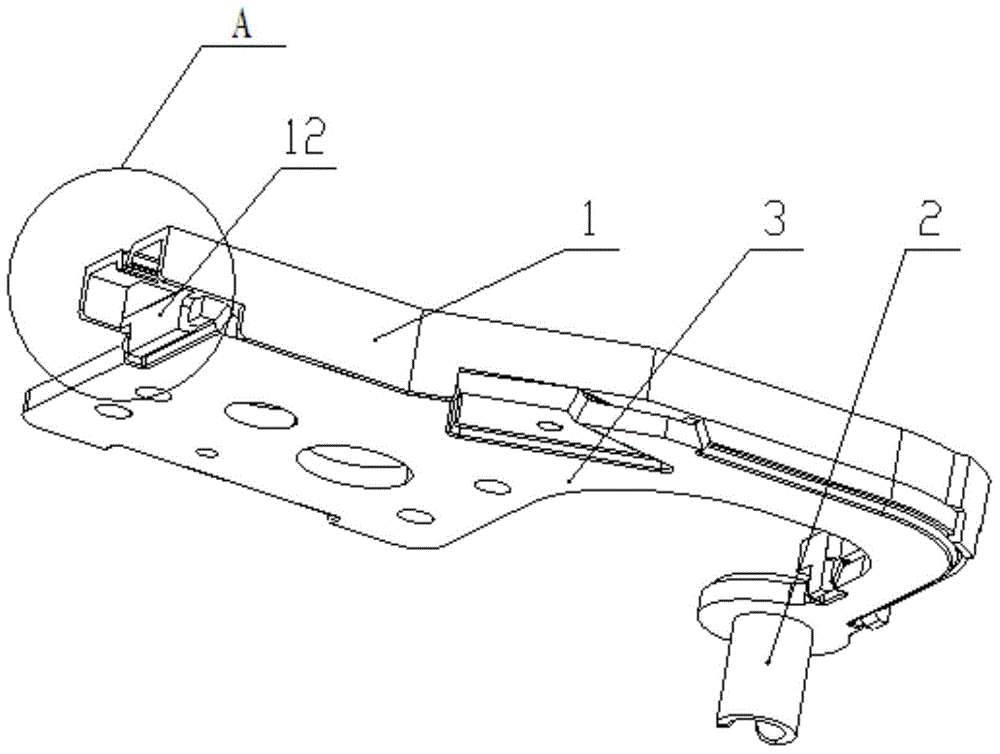

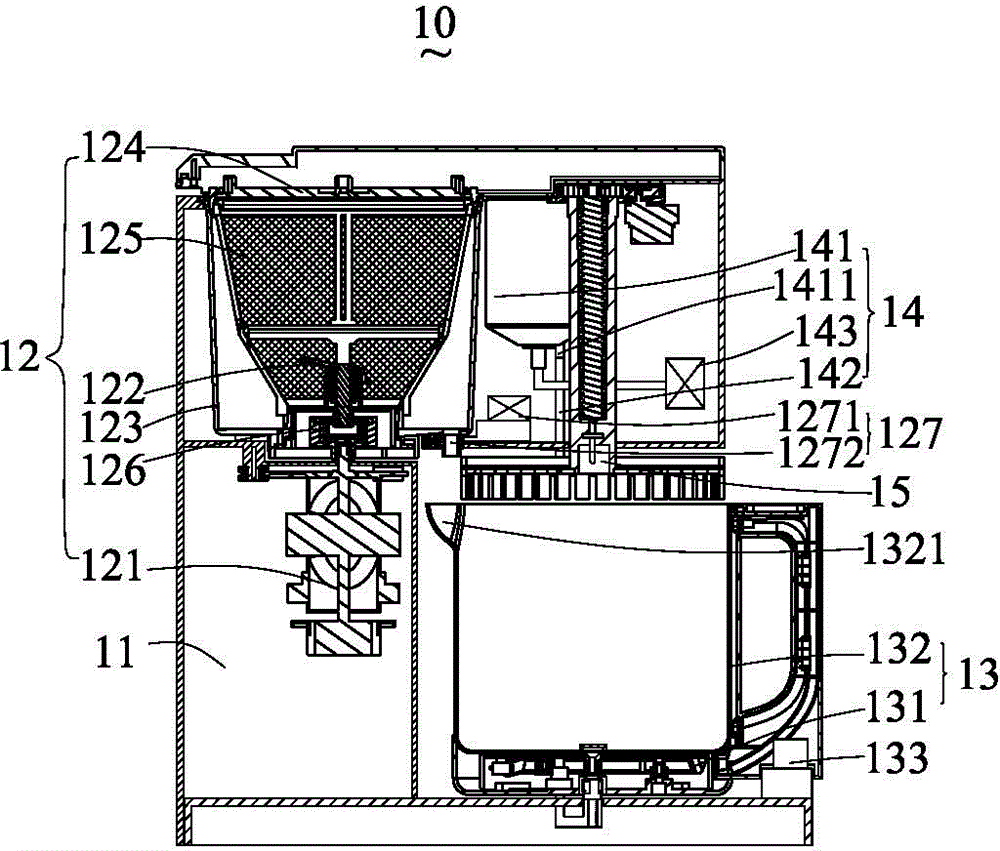

Door hinge wire harness restraining structure and refrigerator

ActiveCN104466826AHigh strengthIncreasing the thicknessElectrical apparatusHingesMechanical engineeringRefrigerated temperature

The invention relates to the field of refrigerators and discloses a door hinge wire harness restraining structure and a refrigerator. The door hinge wire harness restraining structure comprises an upper hinge plate and an upper hinge shaft which are fixedly connected together and further comprises a wiring box installed on the upper surface of the upper hinge plate. At least part of the interior of the wiring box forms a containing space for containing wire harnesses. The wiring box and the upper hinge plate are located and installed in a clamped mode. According to the structure, the wire harnesses are supported and restrained through the upper hinge plate and the wiring box, the upper hinge plate and the wiring box are separately arranged, and compared with a mode that the upper hinge plate and the wiring box are integrated in the prior art, the wire harness fixing effect is better, the wire harness assembly process is simpler, and the use effect is better.

Owner:GREE ELECTRIC APPLIANCES INC

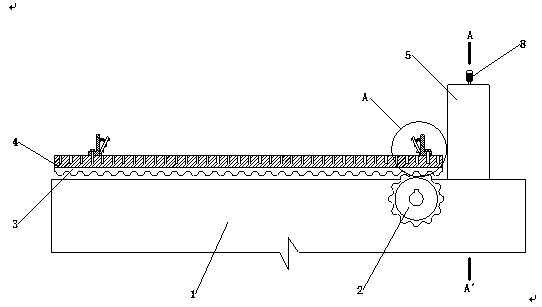

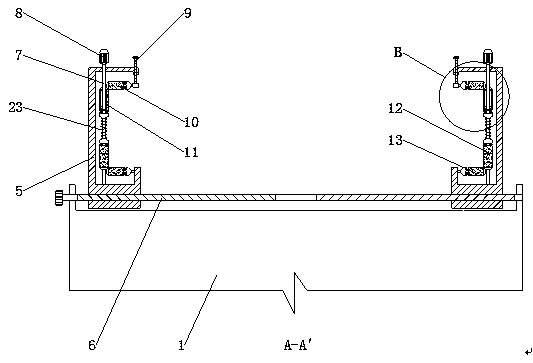

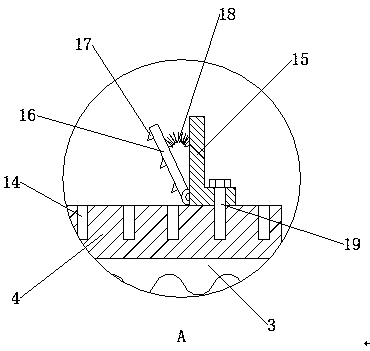

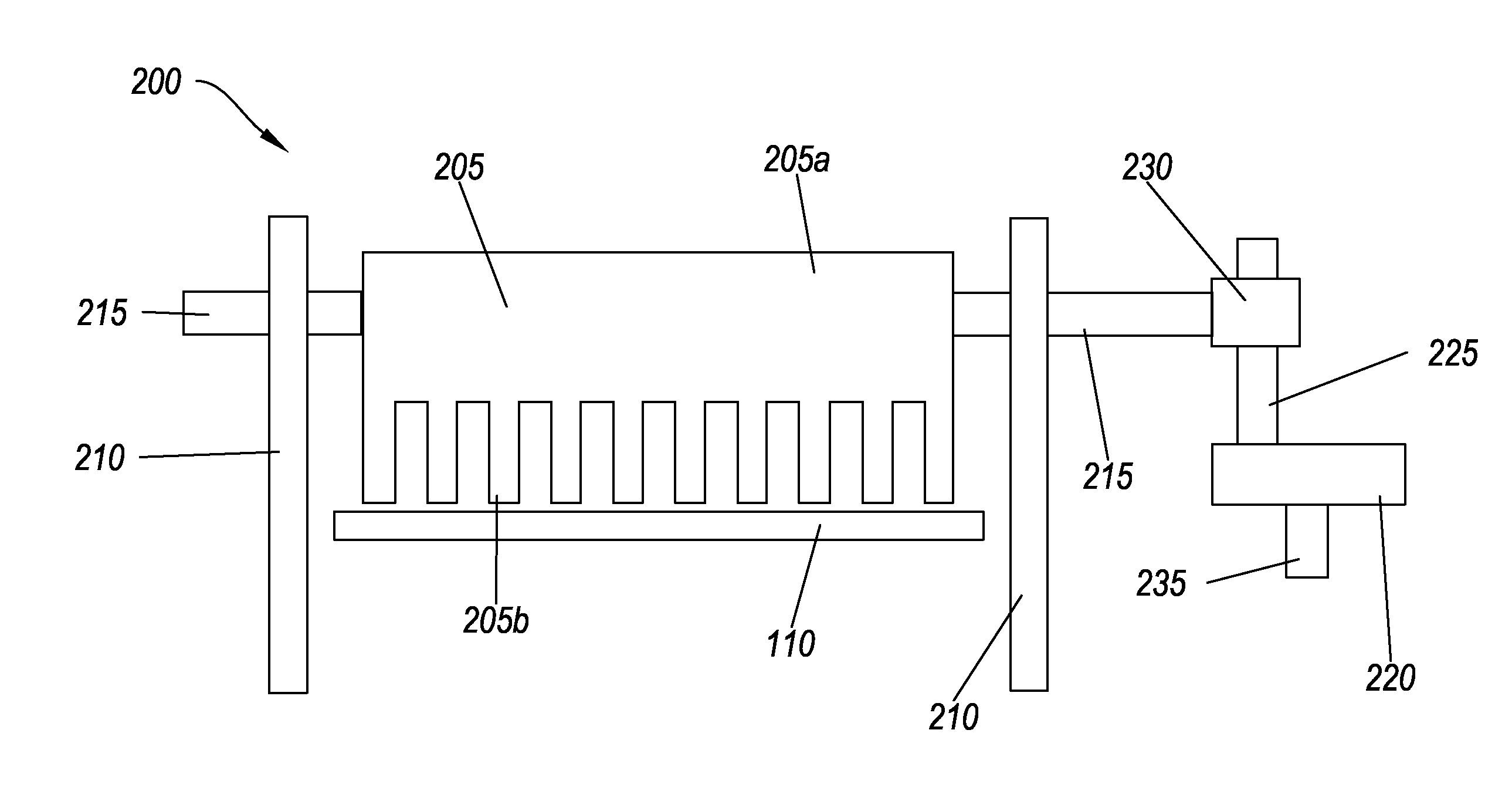

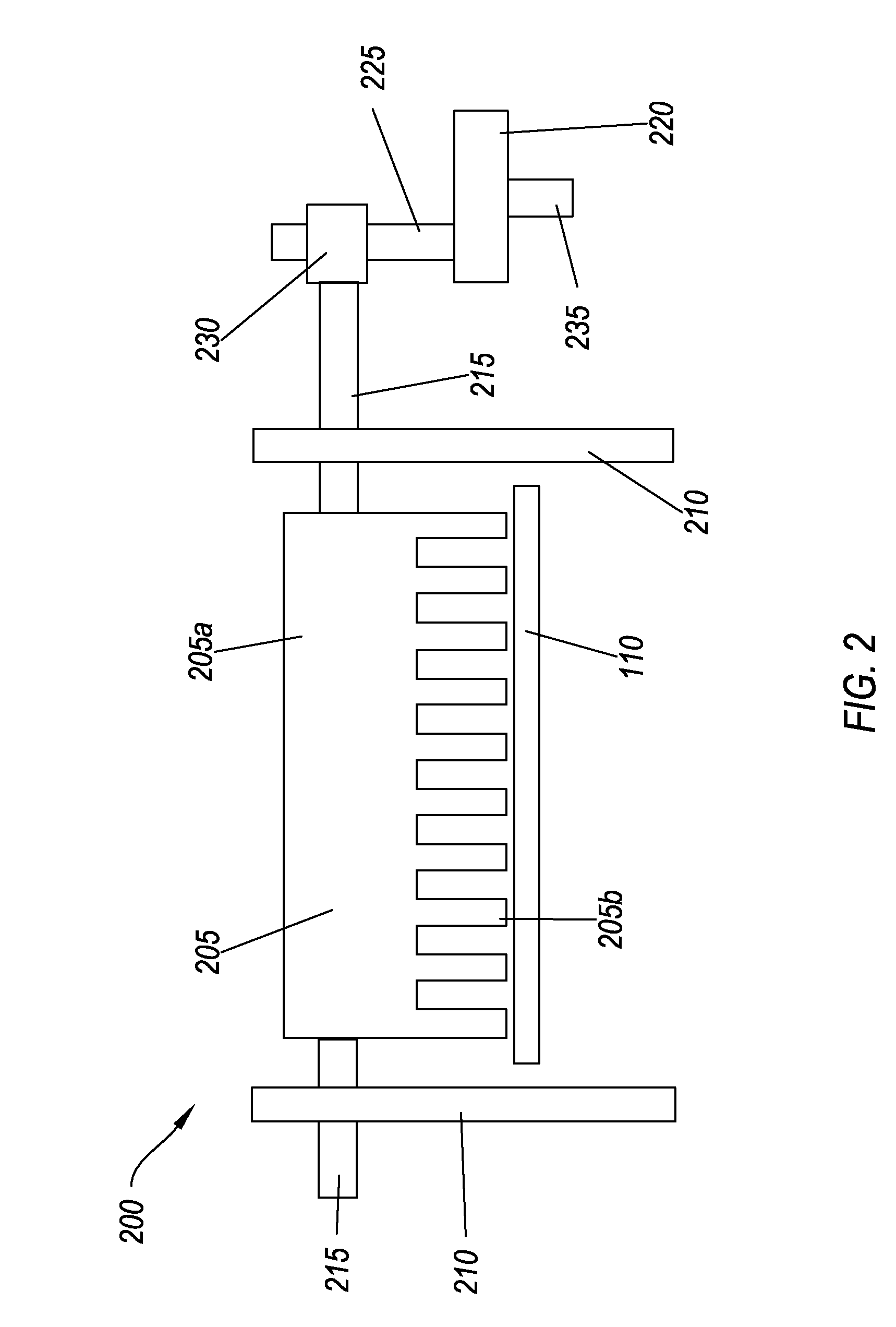

Deburring device for wood board processing

InactiveCN109732436AAvoid affecting the working environmentQuick clampingEdge grinding machinesGrinding drivesFurringPulp and paper industry

The invention provides a deburring device for wood board processing. The deburring device includes a workbench, a feeding flat board, two deburring frames, a moving transverse-grinding roller, a moving vertical-grinding roller, a fixed vertical-grinding roller and a fixed transverse-grinding roller, the feeding flat board is slidably arranged at the upper portion of the workbench, a rack is fixedly connected with the bottom of the feeding flat board, two L-shaped supporting boards are fixedly connected with the upper portion of the feeding flat board, and an elastic splint is rotatably connected with the inner side of each L-shaped supporting board; and a return stopping strip is fixedly connected with the surface of each elastic splint, the two deburring frames are movably arranged at oneend of the workbench, the moving vertical-grinding roller is slidably connected with the upper end of a rotating shaft, the moving transverse-grinding roller meshes with outer periphery of a cone gear, a fixed vertical-grinding roller is fixedly connected with the outer periphery of the lower end of the rotating shaft, and the fixed transverse-grinding roller meshes with the bottom of the fixed vertical-grinding roller. According to the deburring device, the feeding flat board is matched with the deburring frames, the wood board can be fixed on the feeding flat board through the elastic splints and the L-shaped supporting boards, so that the side end surface of the wood board can be scraped and polished in a reciprocating mode, and the deburring effect is improved.

Owner:江山市标龙装饰材料有限公司

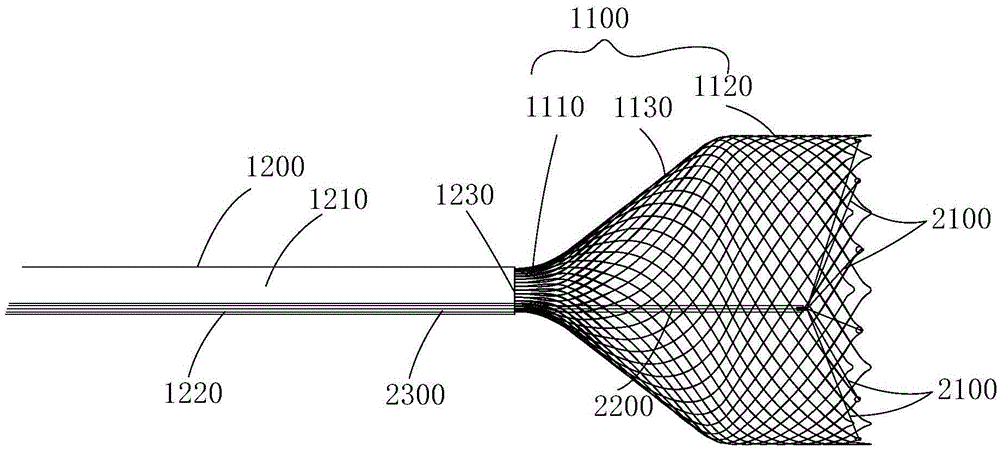

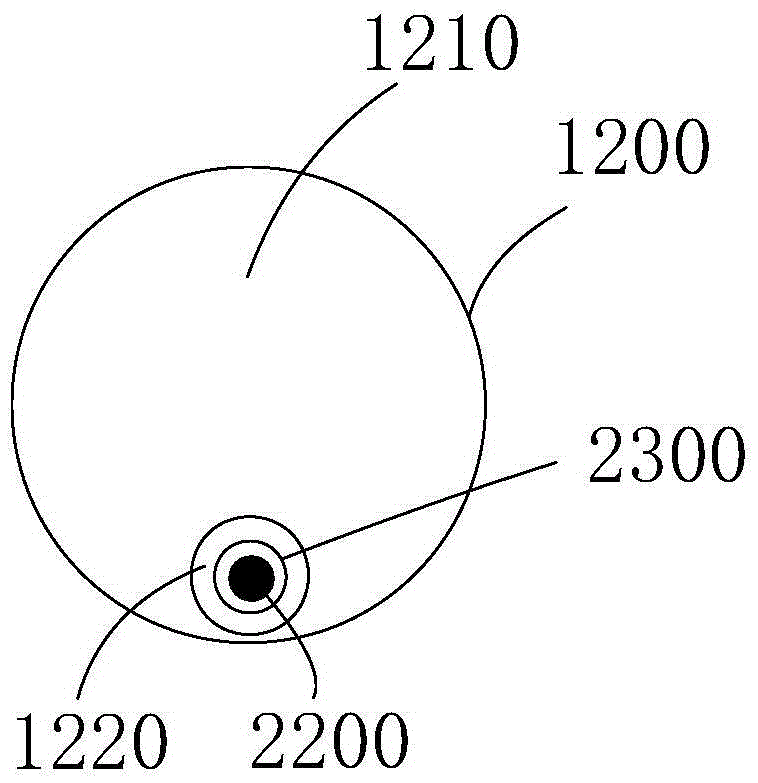

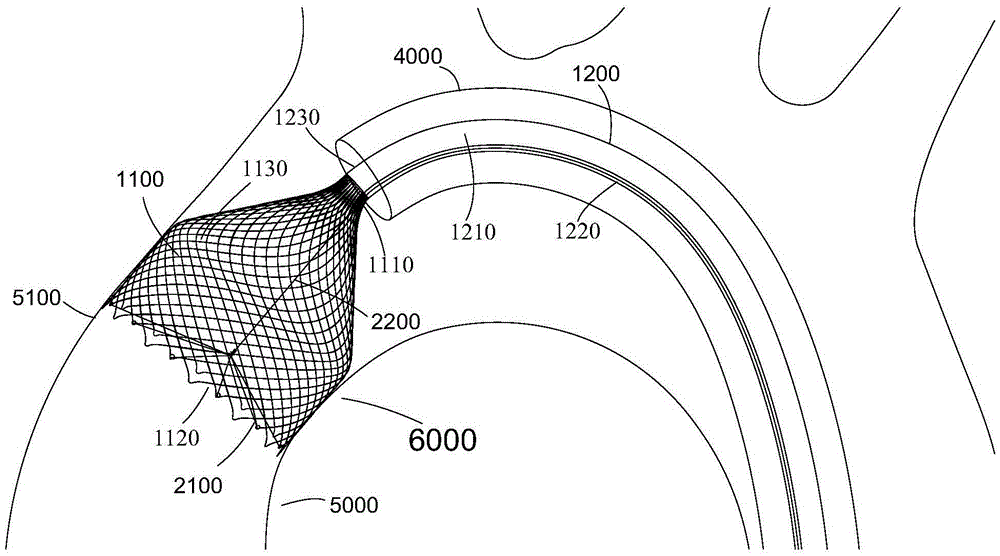

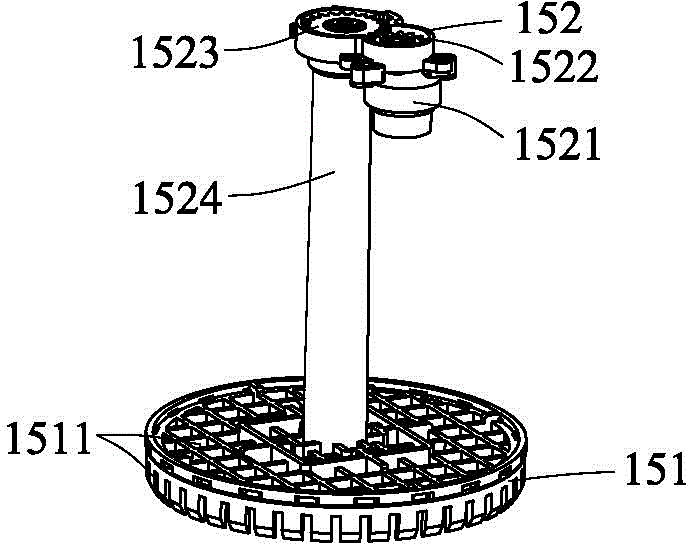

Thrombus filter

The invention discloses a thrombus filter which comprises a handle, a filter umbrella for capturing thrombi, a push catheter, and a folding device for shrinking and folding the filter umbrella, wherein the filter umbrella adopts a meshy elastically-recoverable funnel-shaped structure; a neck part of the filter umbrella is fixedly connected with the push catheter; an inner cavity is axially formed in the push catheter; a cavity enclosed by the filter umbrella is communicated with the inner cavity of the push catheter; the folding device comprises a take-up unit and a drawing mechanism for drawing the take-up action; the take-up unit is connected with an opening part of the filter umbrella and draws the opening part to be folded, so that the filter umbrella becomes a closed space; the drawing mechanism penetrates the inner cavity of the push catheter, extends towards the opening part of the filter umbrella and is connected with the take-up unit; the push catheter and the drawing mechanism are connected with the handle; the actions of the push catheter and the drawing mechanism are controlled by the handle. The thrombus filter can effectively block exfoliated plaques or emboli, and is simple in structure, small in push resistance and smooth in operation.

Owner:VENUS MEDTECH (HANGZHOU) INC

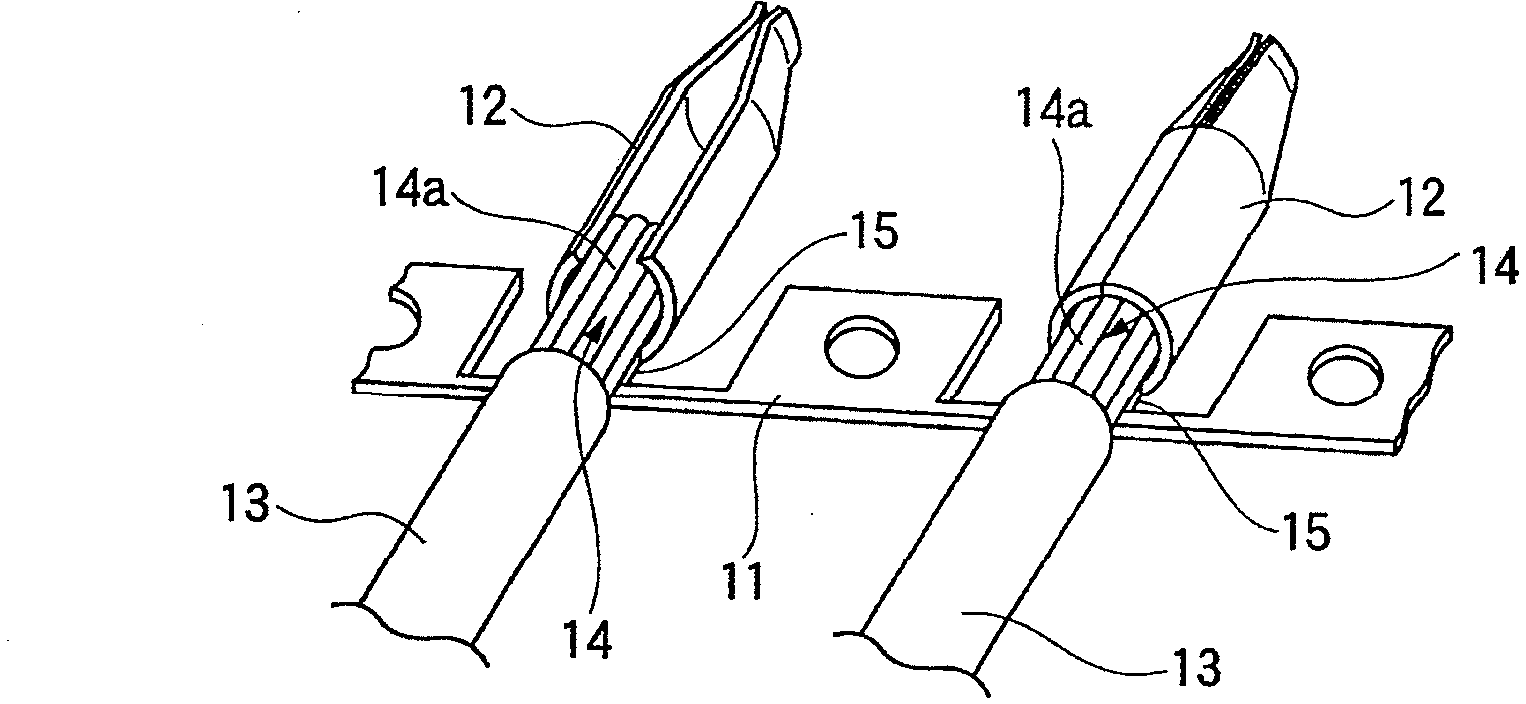

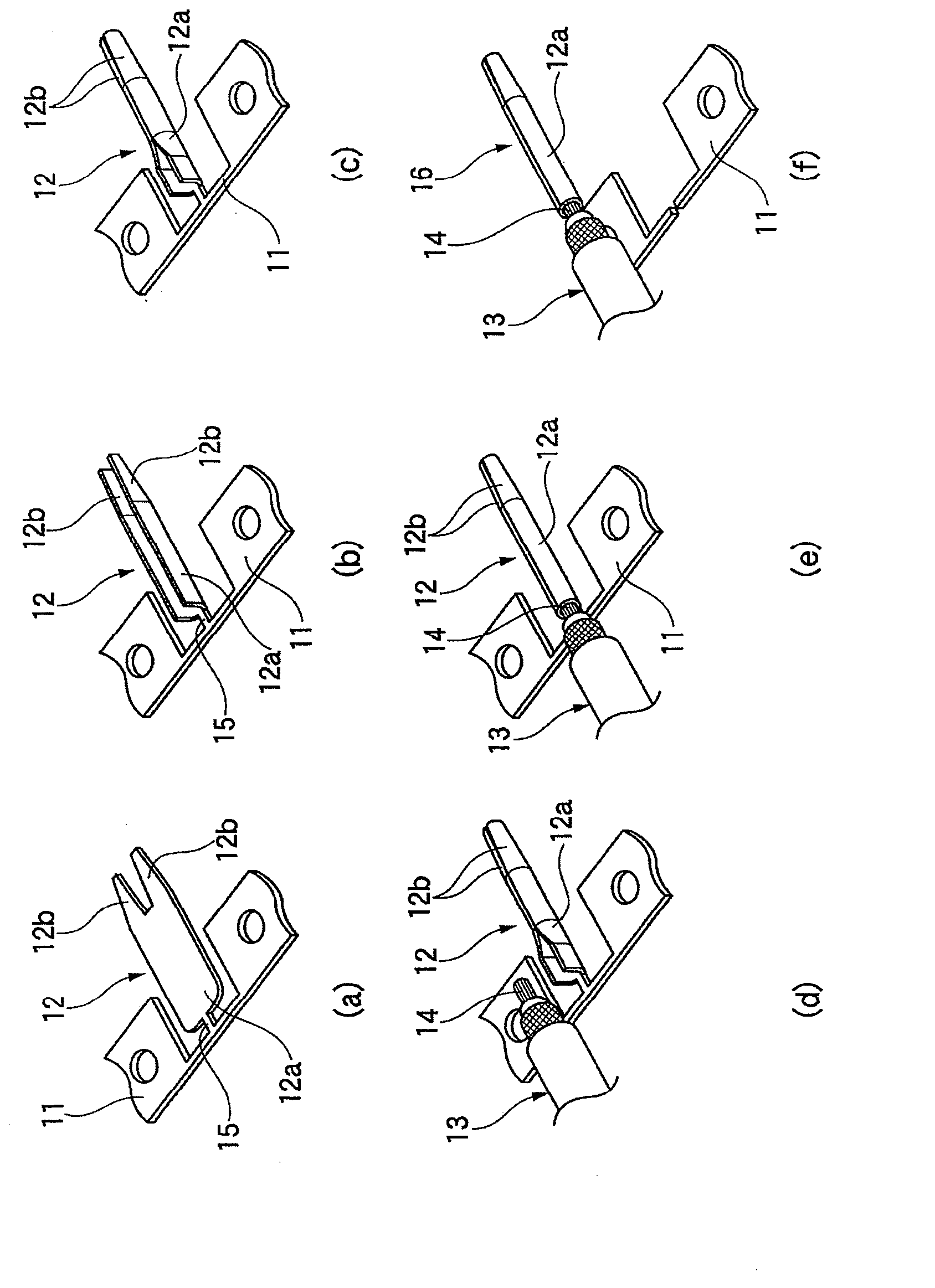

Dies and crimping method

InactiveCN103004038APrevent extrusionLine/current collector detailsConnections effected by permanent deformationElectrical conductorWrap around

The purpose of the present invention is to provide dies and a crimping method, wherein, when caulking a signal conductor of a wire placed on a terminal forming piece so as to wrap around the signal conductor, the signal conductor can be made not to bulge out from in-between both ends of the terminal forming piece. An upper die (18) of the present invention comprises a bulging-out preventing protrusion (17) that protrudes towards a signal conductor (14) arranged on the upper side of a terminal forming piece (12) placed on a lower die (19); and inner-die wall faces (18a) that are positioned at both sides of the bulging-out preventing protrusion (17), and that are for bending the terminal forming piece (12). When crimping the terminal forming piece (12) onto the signal conductor (14) with the upper die (18) and the lower die (19), the bulging-out preventing protrusion (17) presses the signal conductor (14) in the downward direction, and the inner-die wall faces (18a) bend the terminal forming piece (12) such that both end-sections of the terminal forming piece (12) will come near the bulging-out preventing protrusion (17).

Owner:YAZAKI CORP

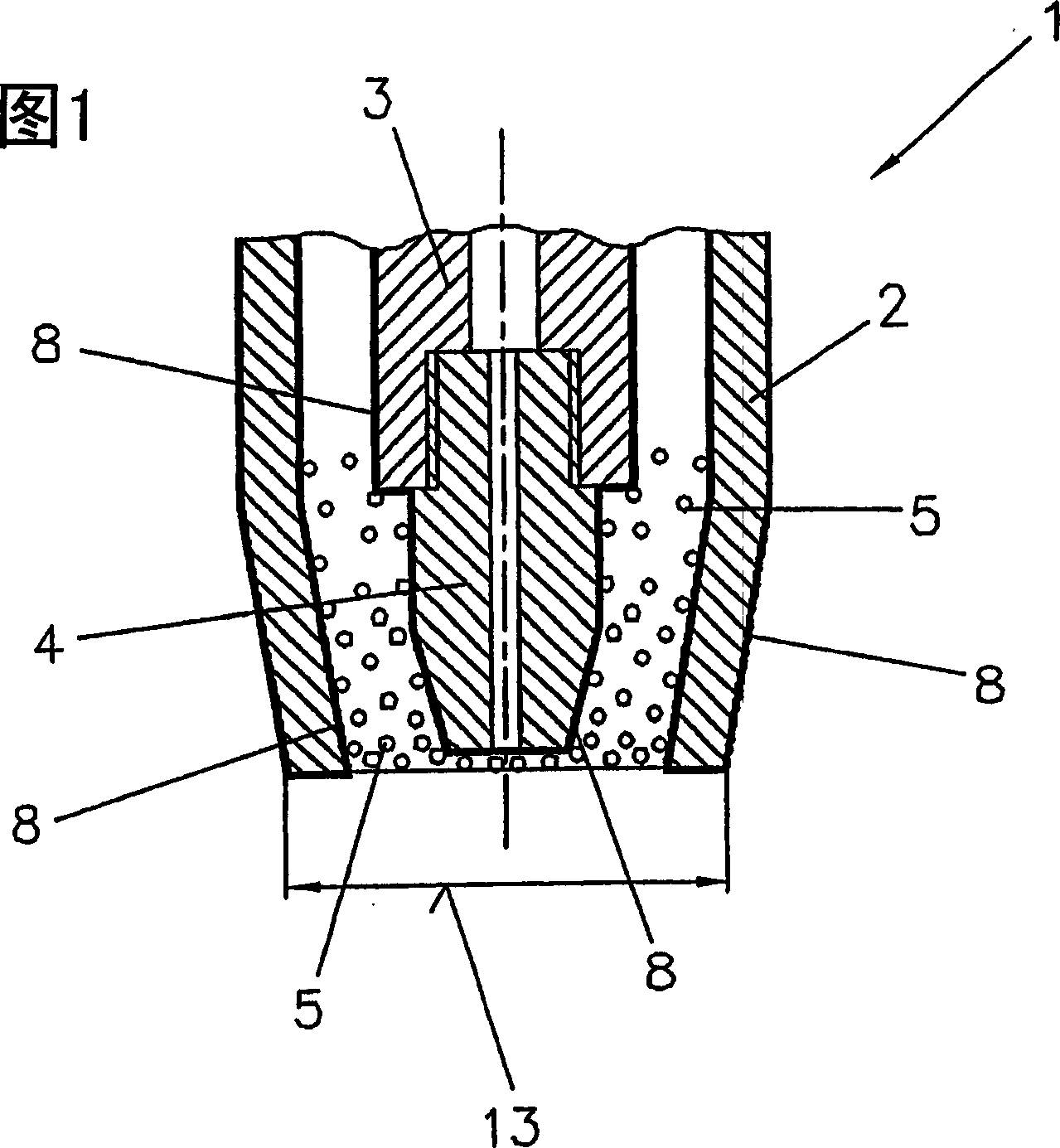

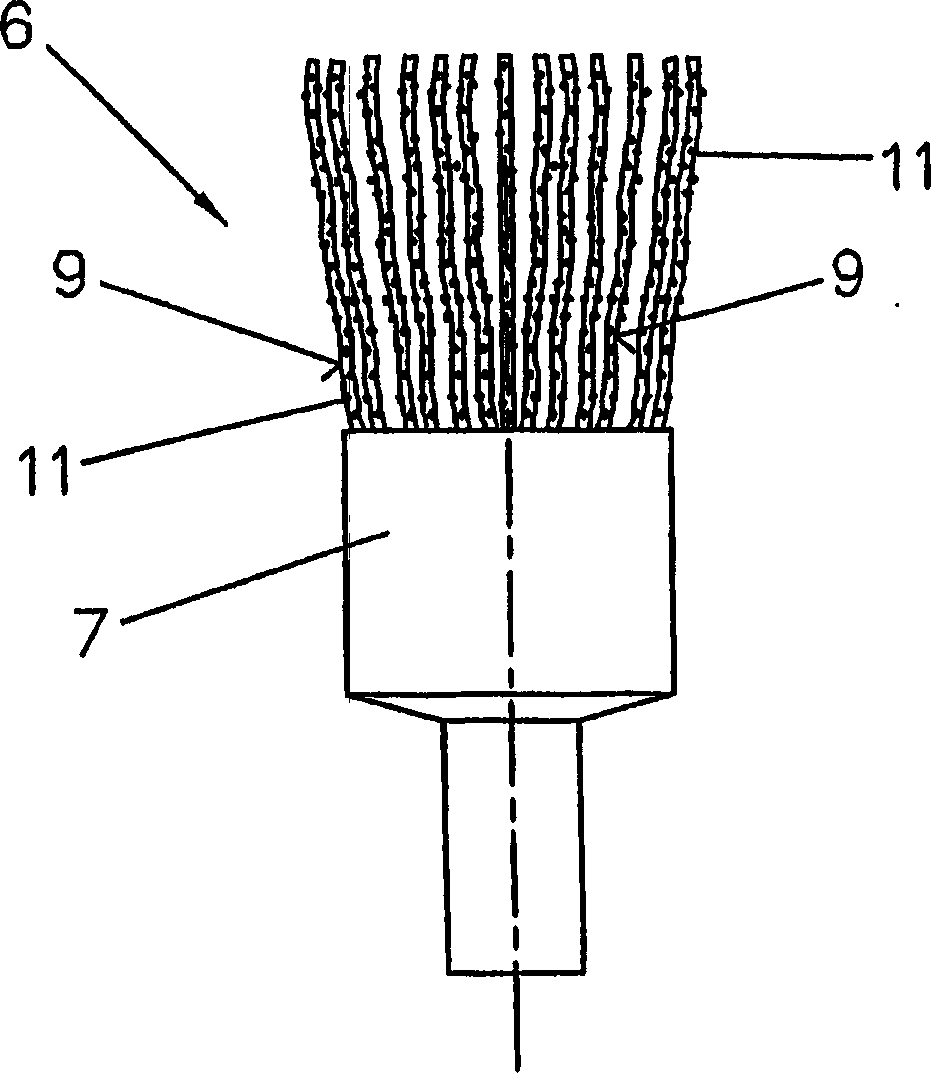

Gas nozzle for a welding torch, welding torch having a produced patina layer; cleaning device for a welding torch having bristles made of a soft elastic material and abrasive grains embedded in these

The invention relates to a gas nozzle (2) and a welding torch (1) equipped with said gas nozzle (2), a nozzle assembly (3) and a conductive tube (4), said gas nozzle (2), nozzle The component ( 3 ) and the conductive tube ( 4 ) have an artificially produced patina ( 8 ) on at least a partial area of their surface for the purpose of reducing the adhesion of welding spatter. The invention also relates to a cleaning device for a welding torch (1) having a brush with bristles. These bristles are made of a very soft elastic material, preferably plastic, and abrasive particles are embedded in said bristles.

Owner:FRONIUS INTERNATIONAL GMBH

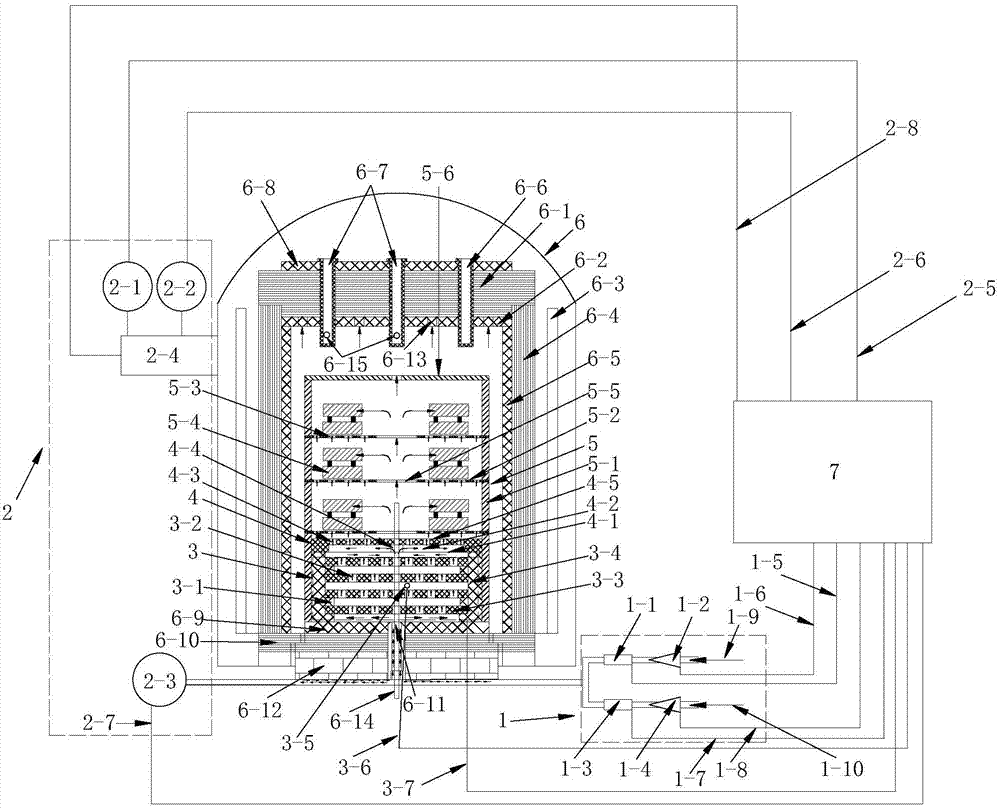

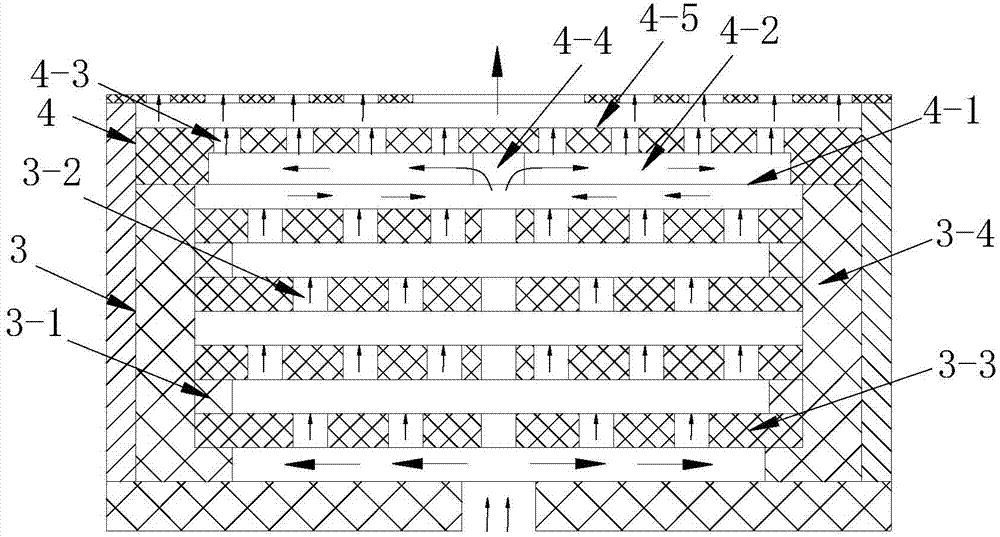

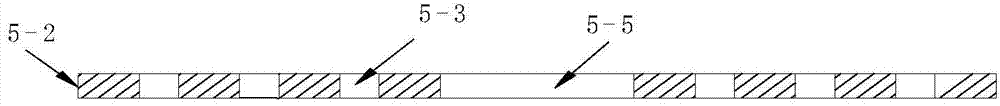

Carbon/carbon composite component chemical vapor infiltration device

ActiveCN104498891AWell mixedIncrease profitChemical vapor deposition coatingPressure controllerCarbon composites

The invention brings forward a carbon / carbon composite component chemical vapor infiltration device and aims to provide a device for solving problems of low reactant gas utilization rate and low infiltration efficiency existing by chemical vapor infiltration in the prior art. The invention is realized by the following technical scheme: a gas mixing and preheating device for primary control of reactant gas diversion direction and a temperature sensor for monitoring preheating temperature of reactant gas are arranged below a deep gas-mixing and outgassing device connected with a sealed infiltration chamber; the regulated and controlled reactant gas enters a gas mixing and preheating device from the bottom of a chemical vapor deposition furnace body through a gas supply device, and a controller automatically regulates electric power on a heater to obtain required preheating temperature; and the preheated reactant gas enters the sealed infiltration chamber and passes through a porous graphite liner plate to infiltrate through a composite preform placed inside the sealed infiltration chamber, and chemical vapor infiltration is performed under constant values by pressure control of a furnace pressure controller and temperature control of a temperature control sensor.

Owner:PLA NO 5719 FACTORY

Manufacture of kinesiology tape

InactiveUS20110271854A1Prevent extrusionLiquid surface applicatorsInking apparatusKinesiologyEngineering

One example embodiment includes a continuous feed variable depth die cut. The die cut includes a housing, including a first opening configured to allow kinesiology tape to enter the housing and a second opening configured to allow the kinesiology tape to exit the housing. The die cut also includes a roller inside the housing, where the roller is configured to rotate as the kinesiology tape passes over the roller and a die formed on the outer surface of the roller, where the die includes a cutting edge for cutting the kinesiology tape and where the cutting edge is formed in the shape of the strip of kinesiology tape to be cut. The shape is approximately rectangular and includes rounded exterior corners. The die cut further includes a surface inside the housing, where the kinesiology tape passes over the surface when the kinesiology tape is cut.

Owner:LUMOS

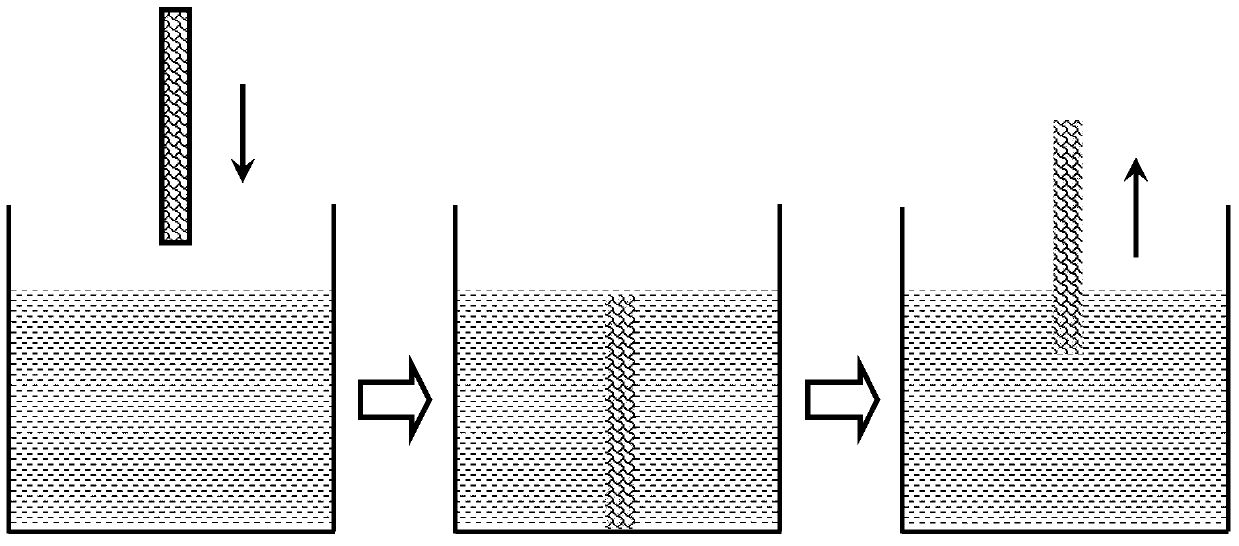

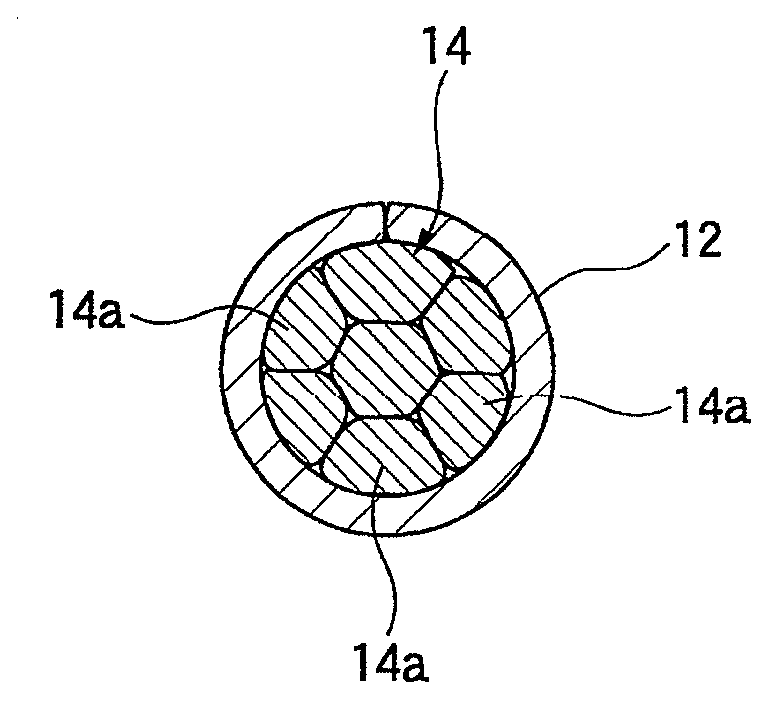

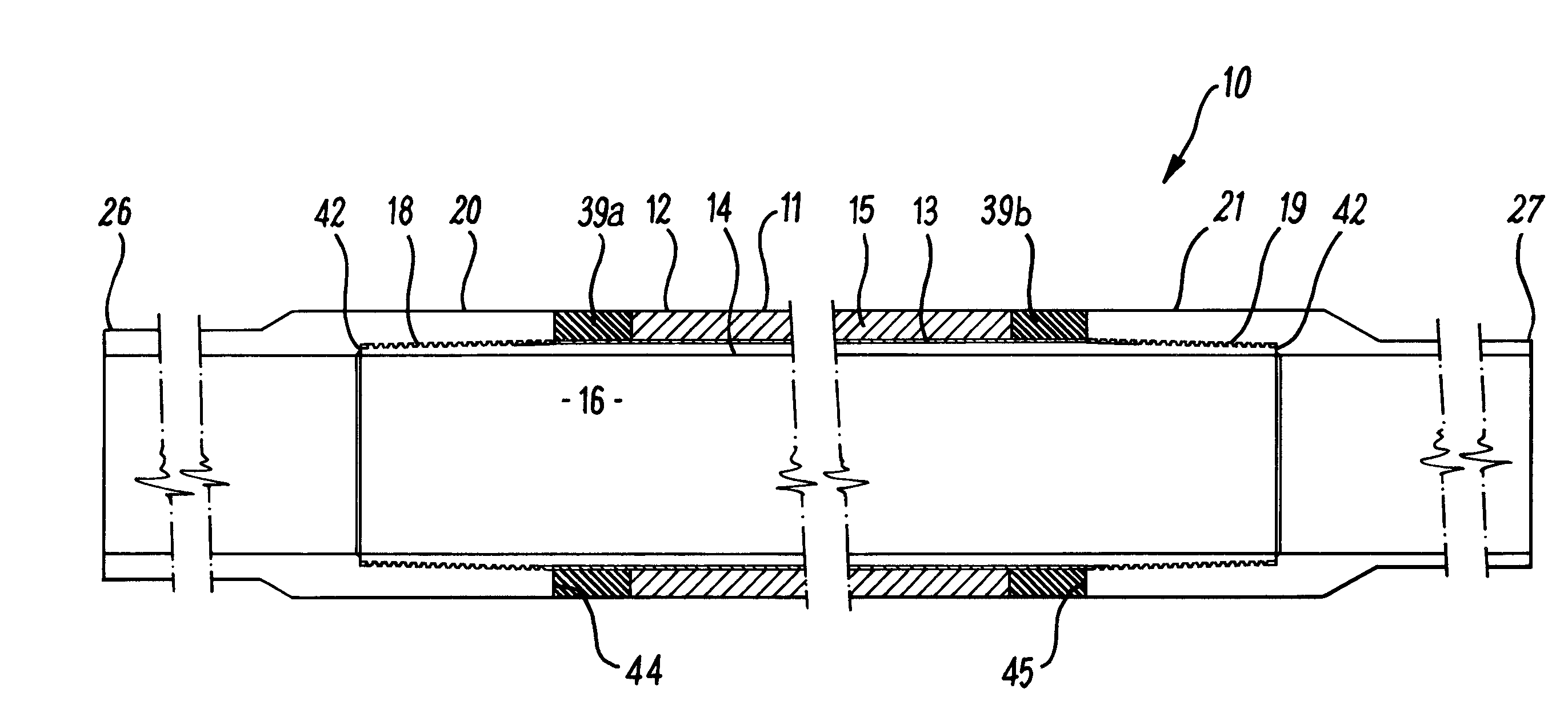

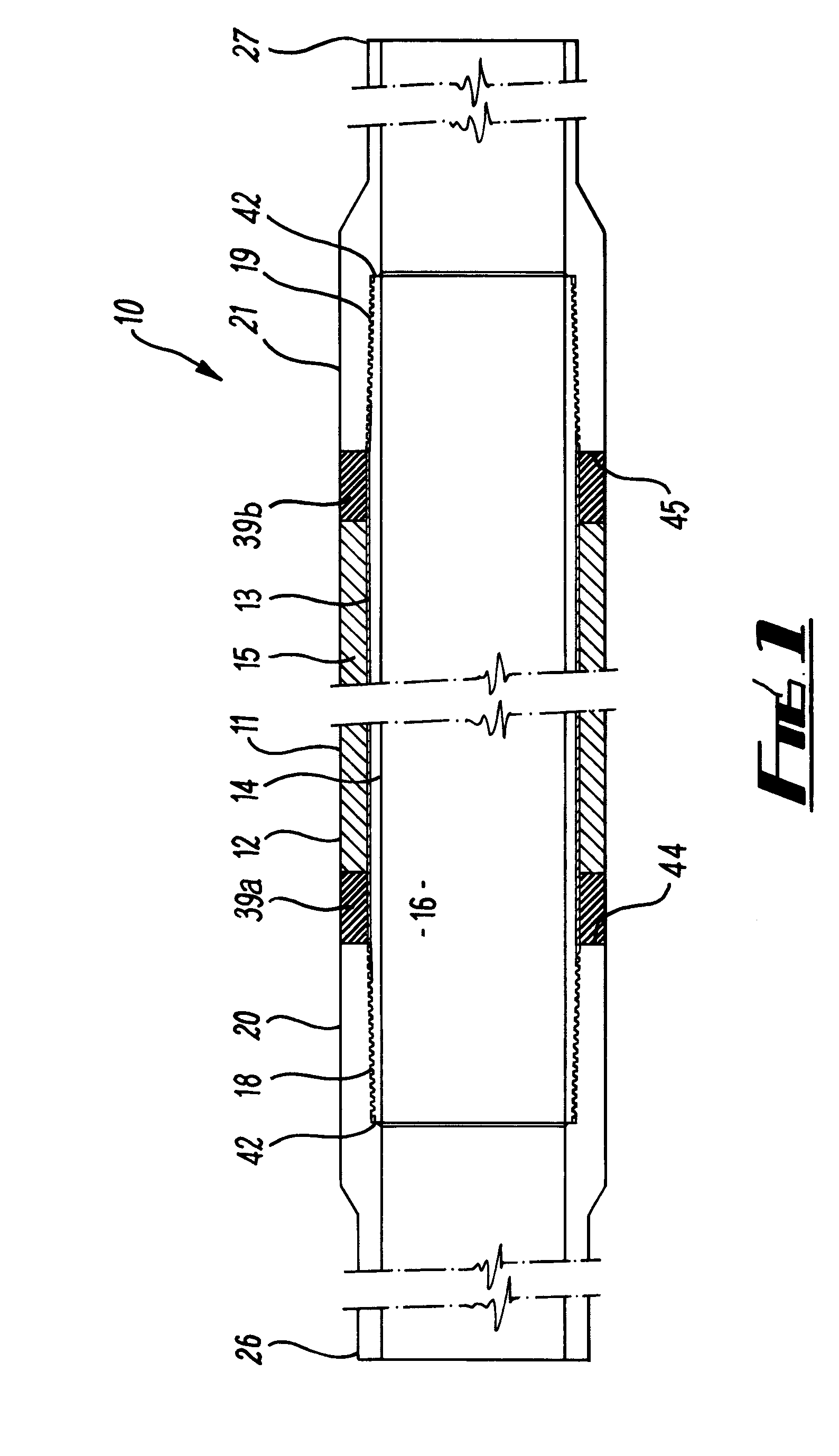

Ring member for a swellable downhole packer

InactiveUS20090260801A1Prevent extrusionGood resistanceDrilling rodsFluid removalEngineeringCoupling

A ring member for a downhole apparatus including a swellable material selected to increase in volume on exposure to at least one triggering fluid is described. The ring member is configured to cooperate with a swellable member disposed on a body of the apparatus, and may, for example, function as a gauge ring or a retaining member. The ring member is secured to the apparatus via a coupling arrangement which couples the body to an adjacent well string section. In one embodiment, the ring member is threaded into the well string. In another, it is disposed over an upstanding formation such as a coupling sleeve, for example, by clamping. An assembly and a method of assembly are also described.

Owner:WEATHERFORD U S INC

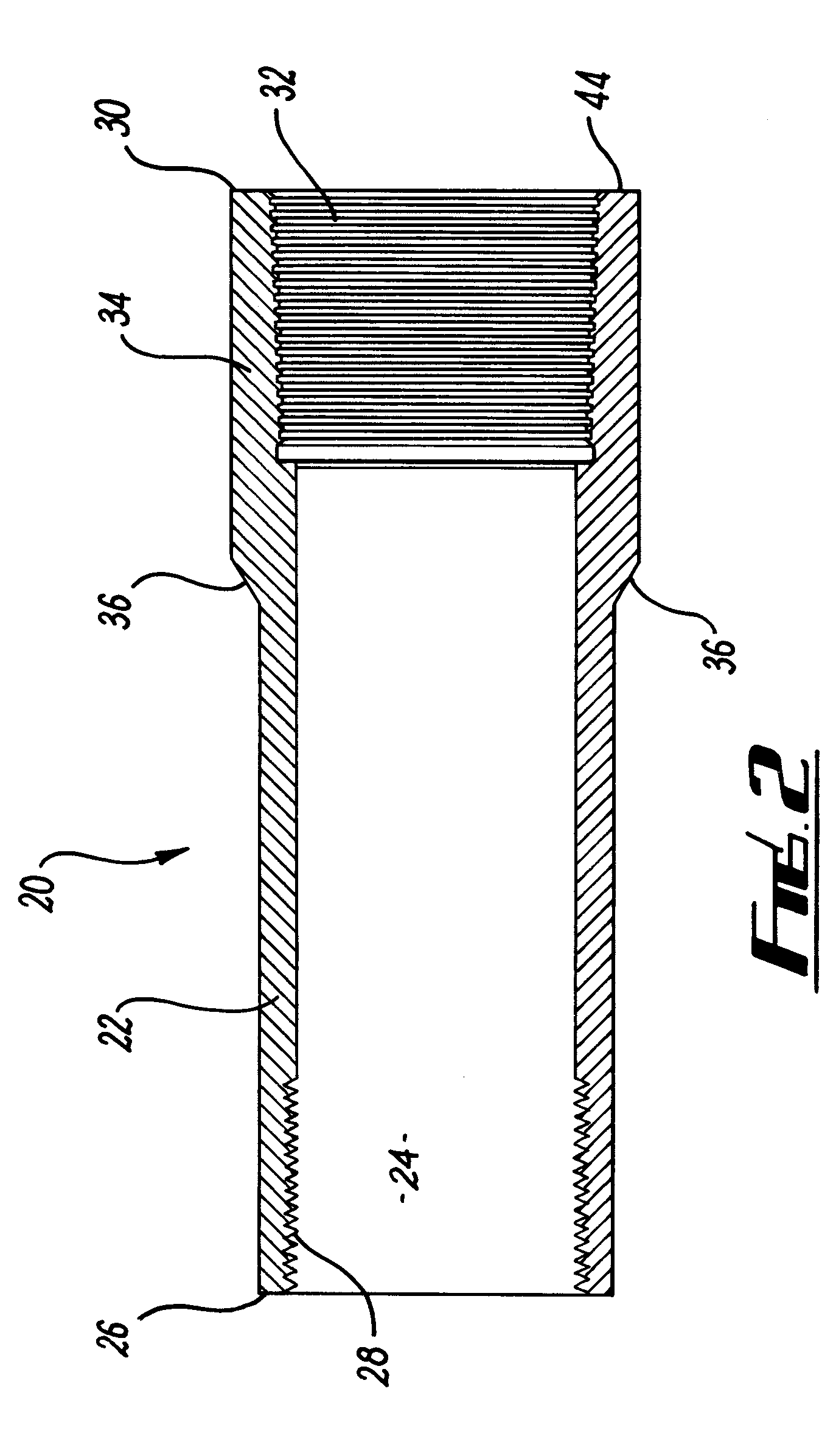

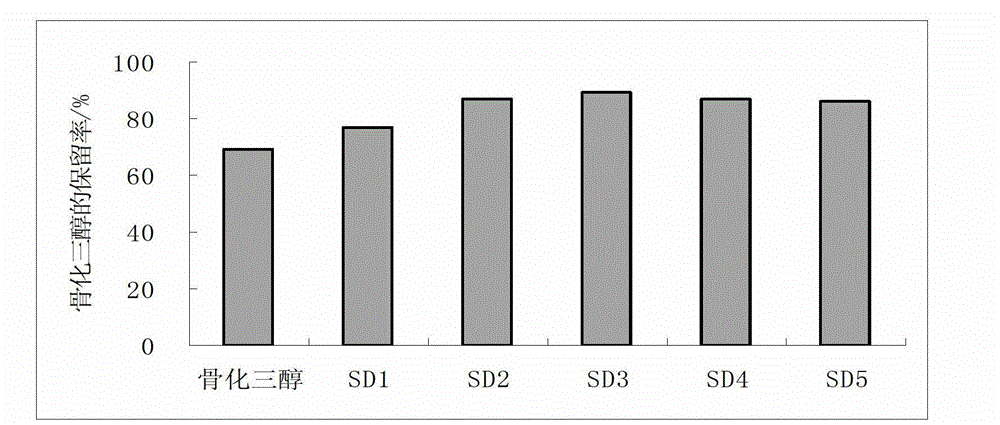

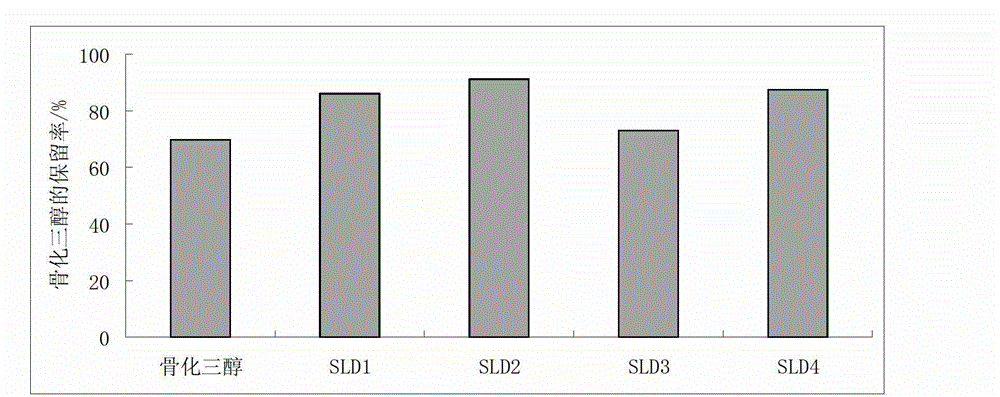

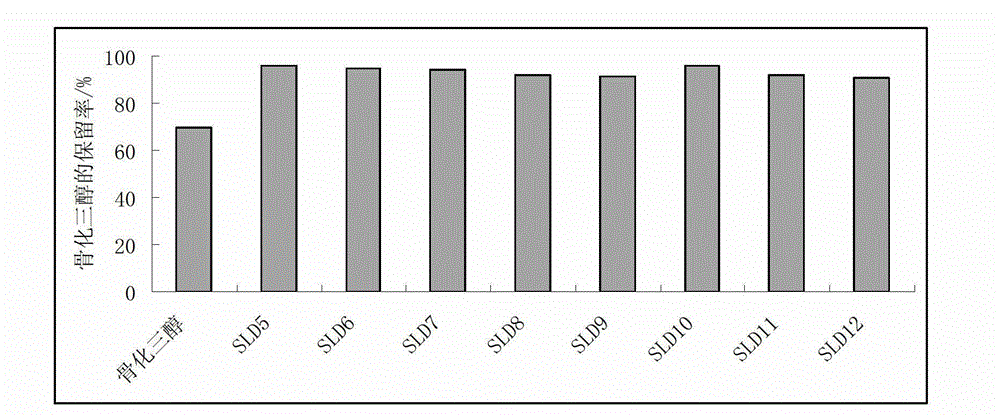

Calcitriol solid lipidic dispersion and preparation method thereof

ActiveCN102973528AImprove stabilityImprove drug stabilityOrganic active ingredientsSkeletal disorderVitamin E AcetatePolyethylene glycol

The invention discloses a calcitriol solid lipidic dispersion and a preparation method thereof. Raw materials of the calcitriol solid lipidic dispersion comprise calcitriol, one or more lipidic carriers and solid carriers, wherein a mass ratio of calcitriol to the one or more lipidic carriers is 1: (90-200000); a mass ratio of the one or more lipidic carriers to the solid carriers is (1-2): 1; and the one or more lipidic carriers are selected from caprylic triglyceride, capric triglyceride, caprylic / capric triglyceride, laurin, caprylic dilaurin, capric dilaurin, vitamin E, vitamin E succinate, vitamin E polyethylene glycol succinate and vitamin E acetate. The calcitriol solid lipidic dispersion has high drug stability and can keep a constant treatment level. The preparation method does not adopt an inorganic solvent, is suitable for industrial production and is conducive to storage and taking. An experiment proves that the calcitriol solid lipidic dispersion has good stability and dispersion uniformity satisfying requirements.

Owner:SUN YAT SEN UNIV

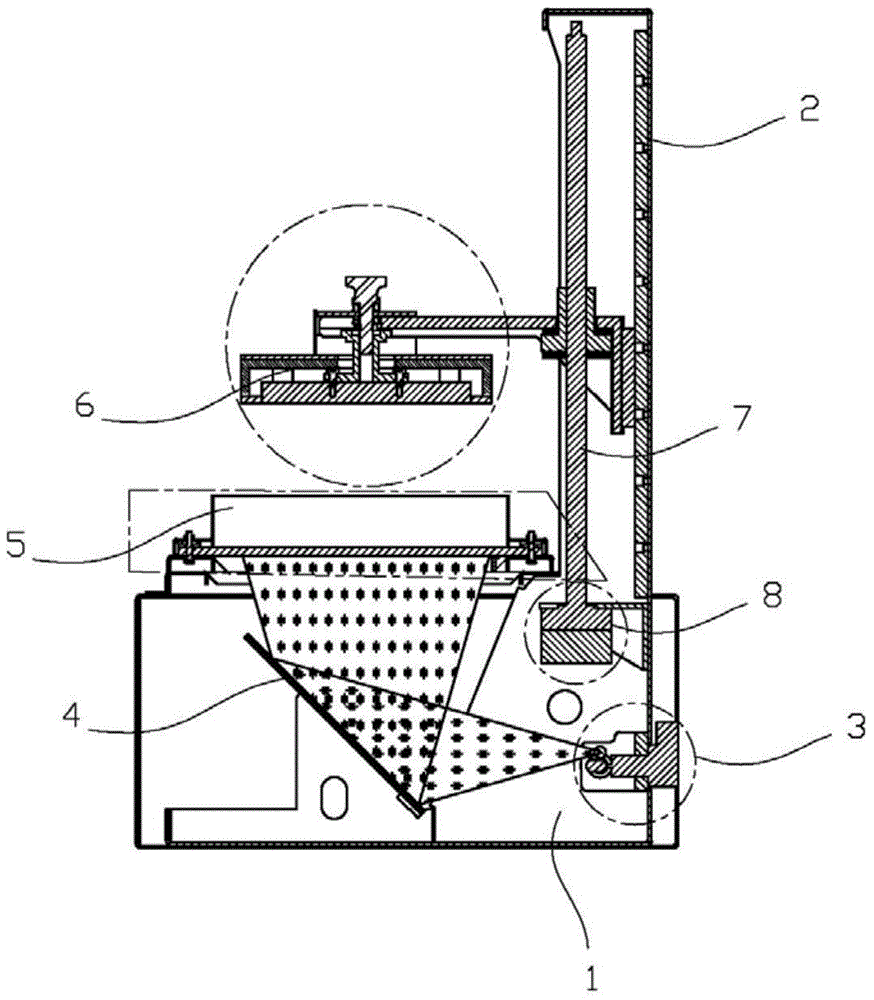

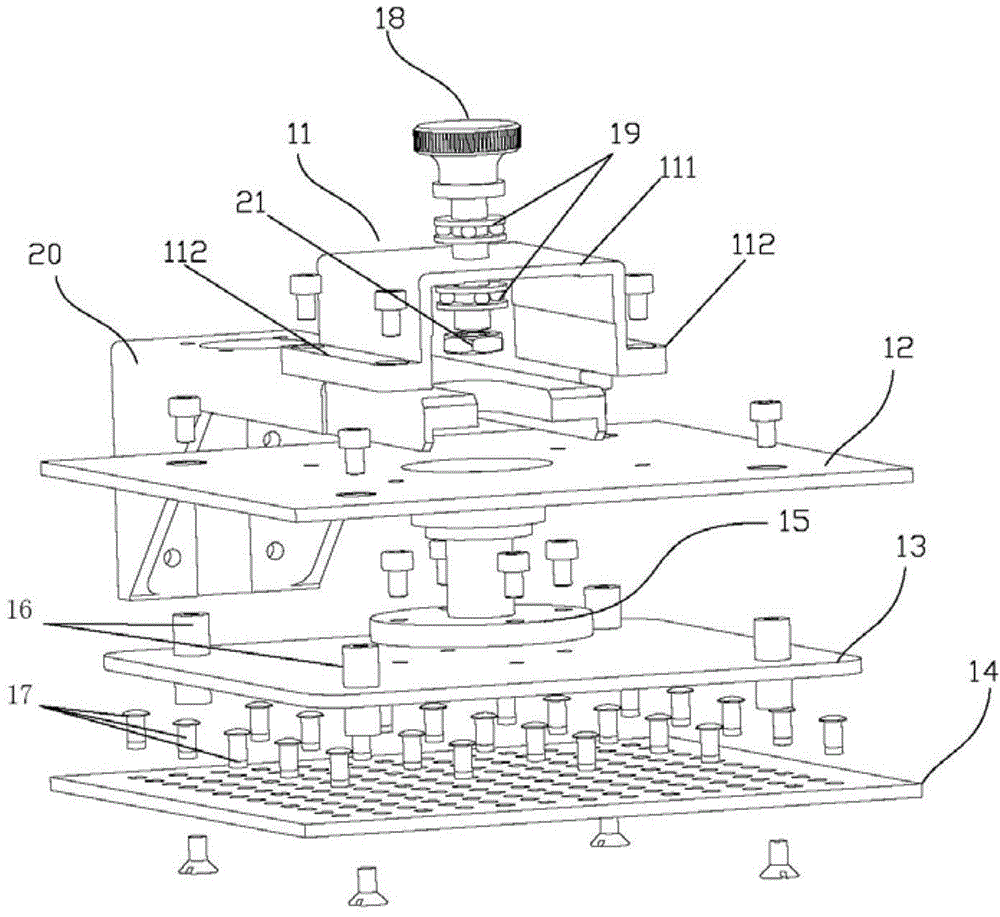

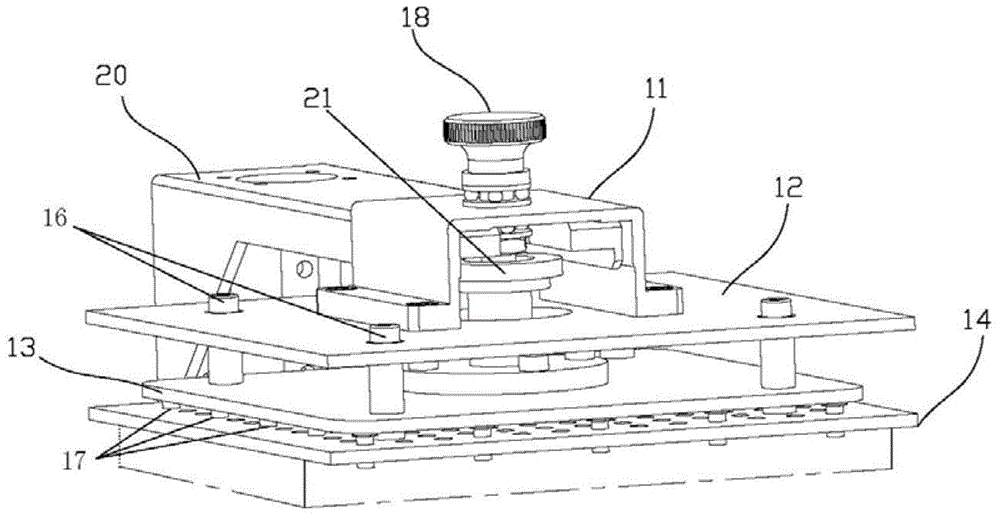

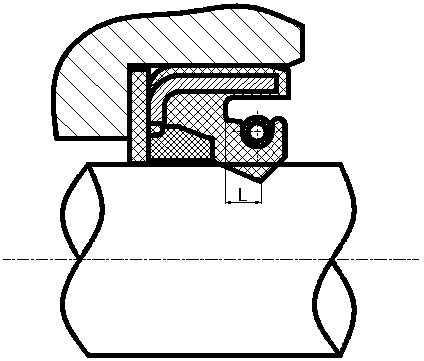

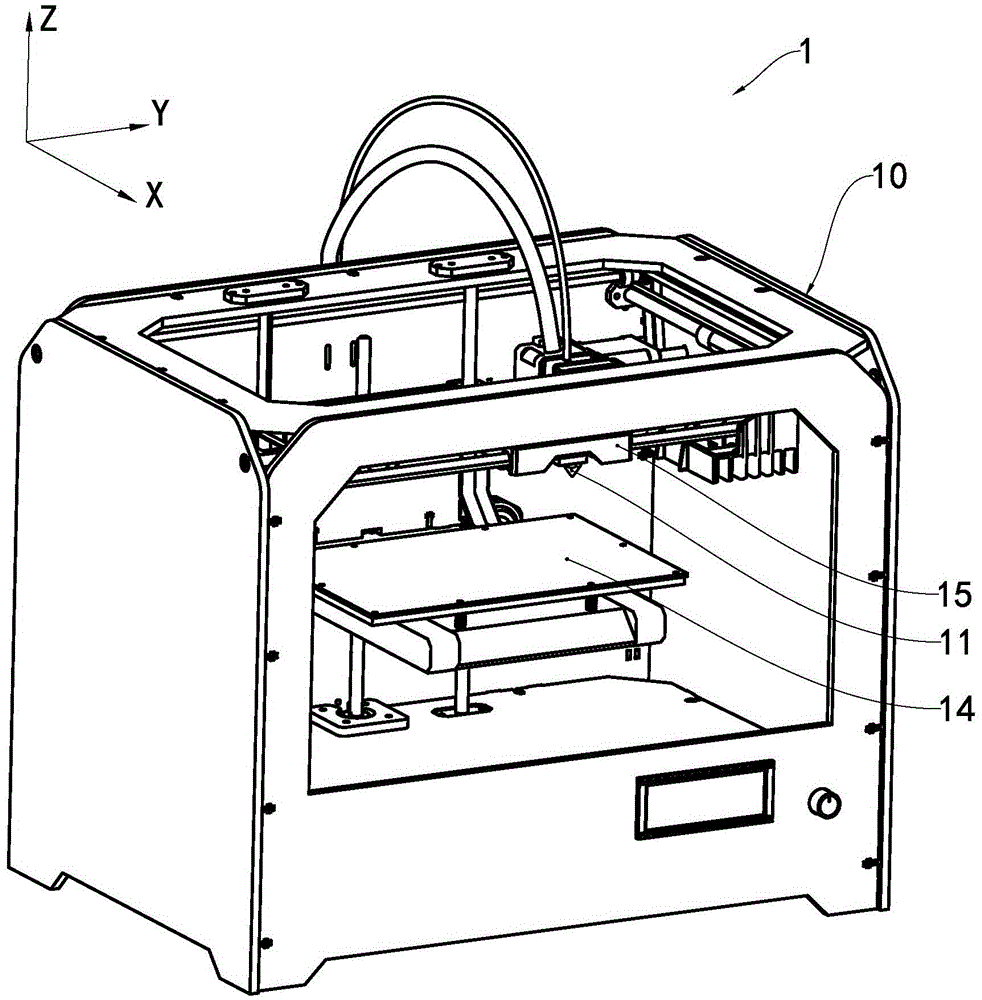

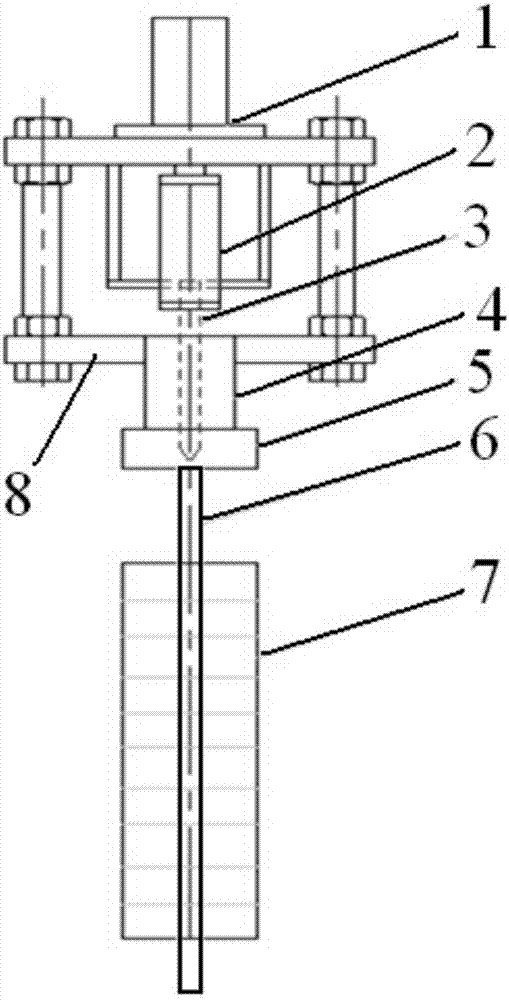

Model separation device for 3D printer

ActiveCN104608387AEasy to separateSafe separationAdditive manufacturing apparatusFixed bearing3d print

The application provides a model separation device for a 3D printer, wherein the 3D printer is capable of printing a solid-state model. The model separation device comprises a fixed bearing plate used for bearing the model and provided with a plurality of through holes, and a movable extrusion plate arranged in parallel relative to the bearing plate, wherein a plurality of extrusion components are arranged between the plate body of the extrusion plate and the bearing plate, and the extrusion plate and the extrusion components are configured as follows: the extrusion components are capable of gradually stretching out from the through holes with the movement of the plate body of the extrusion plate towards a direction approaching to the bearing plate. According to the model separation device for the 3D printer provided by the application, the purpose of rapidly, safely and accurately separating the printing model is achieved by virtue of the principle of generating an axial force by thread rotation by reasonably designing structures among the various components. Meanwhile, the working efficiency is increased, and the integrity and beauty of the printing model are ensured.

Owner:GOLD ARRAY TECH BEIJING LLC

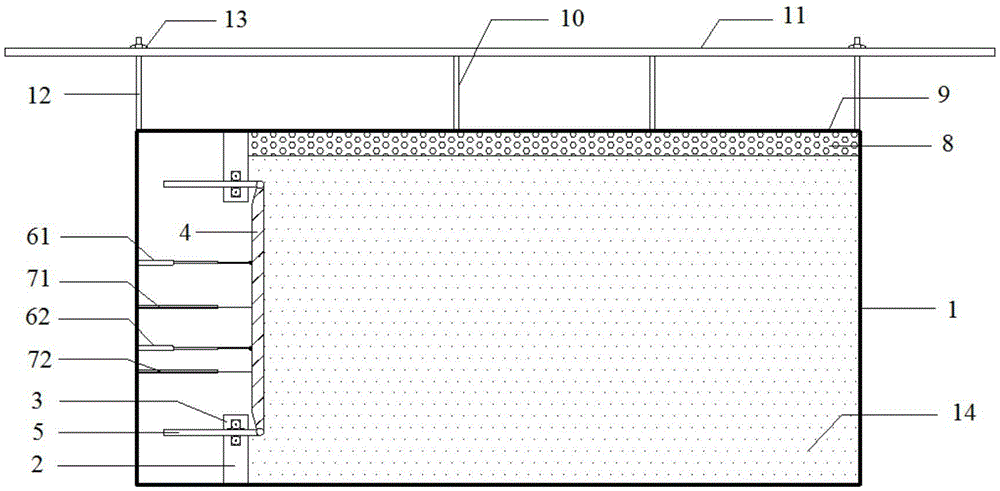

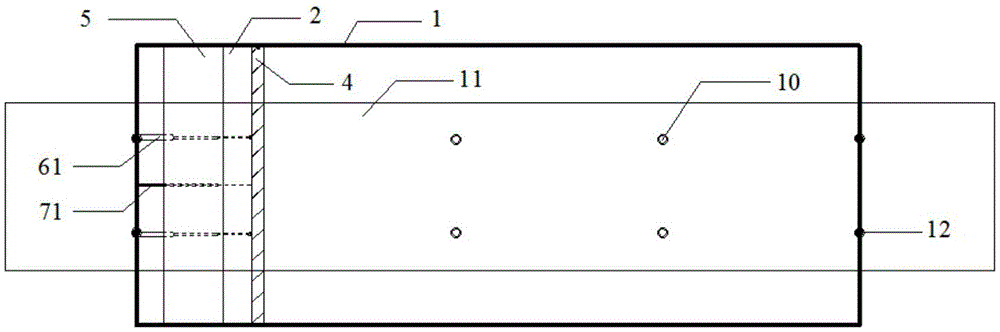

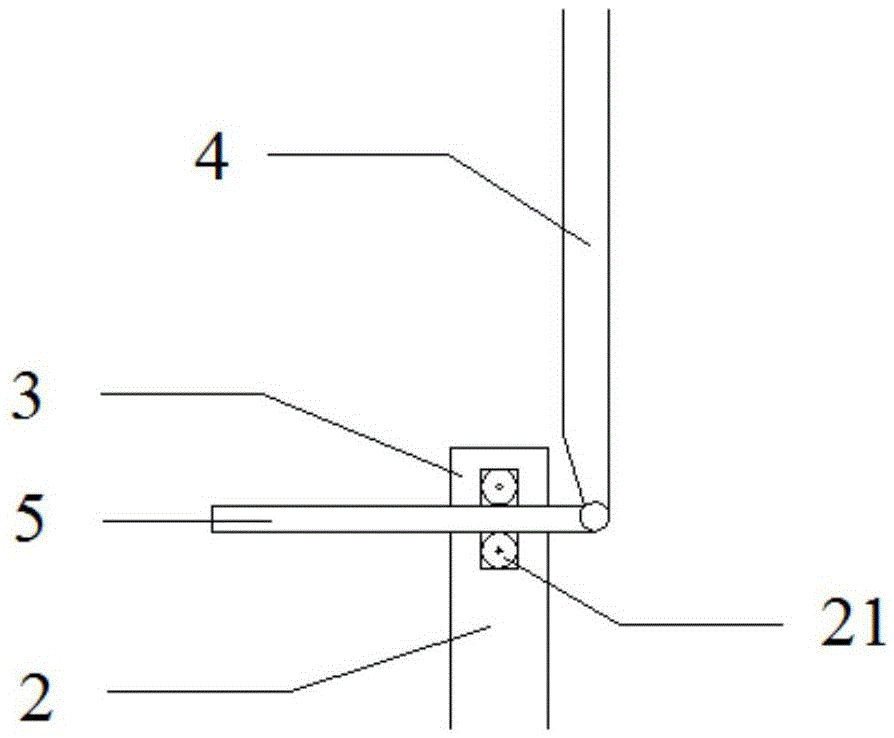

Device for detecting pressure of translating and rotating rigid barricade soil

ActiveCN105547847AReduce the impactPrevent extrusionMaterial strength using tensile/compressive forcesDistribution ruleEngineering

The invention discloses a device for detecting pressure of translating and rotating rigid barricade soil. A sliding base plate and a sliding bracket are welded between front and rear lateral plates at the bottom and top of a box; a flange is hinged with the top end and the bottom end of a rigid baffle; the flange horizontally passes through the space between the sliding base plate and the sliding bracket; a horizontal actuator is horizontally arranged between the rigid baffle and the box; a displacement sensor is horizontally connected between the left side of the box and the rigid baffle; soil is filled in the rigid baffle and the box; a rigid pressing plate and a water bag are pressed on the top surface of the soil; the rigid pressing plate is connected with a counterforce frame; and a film type pressure sensor is arranged on the side of the rigid baffle facing to the soil. The device can meet the research requirement for the soil pressure distribution rule under different ground loading conditions and different displacement modes of the rigid barricade, and has important significance in the development of soil pressure theory and the promotion of the engineering technology level.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

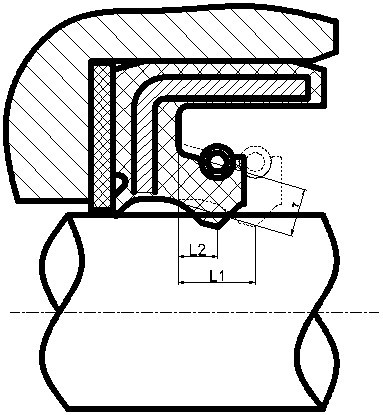

Assembled half-exposed framework high-pressure seal ring

ActiveCN102537360AImprove carrying capacityIncrease stiffnessEngine sealsVulcanizationMetal framework

The invention discloses an assembled half-exposed framework high-pressure seal ring, which not only can seal in a rotating way, but also can seal in a reciprocating way. The seal ring includes a rubber body with a sealing lip, a metal framework vulcanized in the rubber, and a half-exposed framework, a pressure bearing ring taking a metal or non-metal composite material and a spring that are assembled on the rubber body. The half-exposed framework, the composite material pressure bearing ring and the rubber body of the seal ring are designed in an assembling way; and the composite material pressure bearing ring is arranged between the half-exposed framework and the sealing lip, and the pressure bearing ring bears a large amount of working pressure. The assembled half-exposed framework high-pressure seal ring has extremely high high-pressure resistance, outstanding and stable extrusion resistance, excellent heat dissipation and friction lubricating property, good eccentricity adaptability, extremely long service life, simple process, and efficient and stable machining.

Owner:重庆杜马斯克科技有限公司 +2

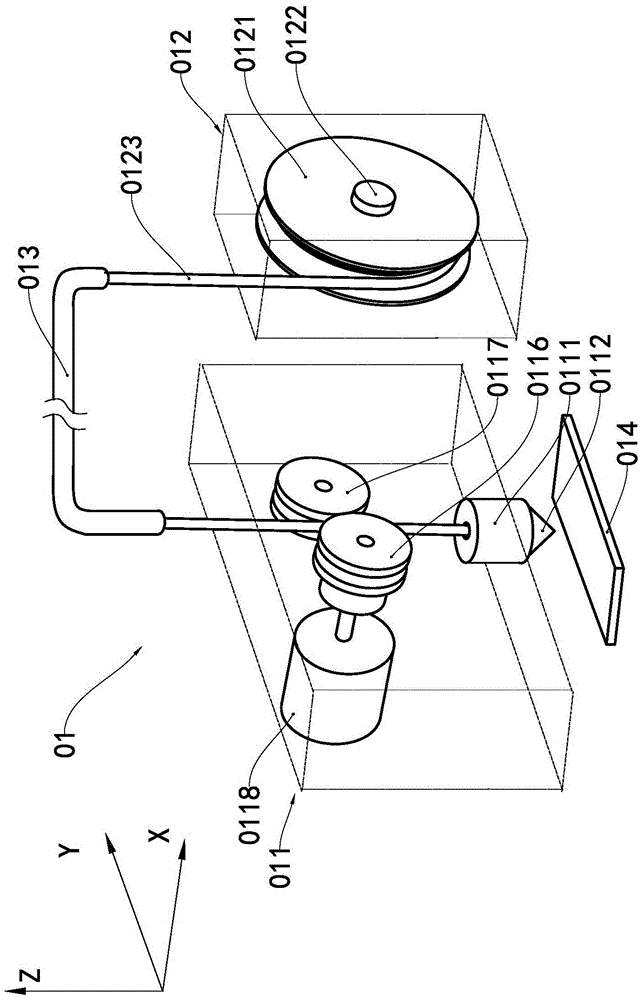

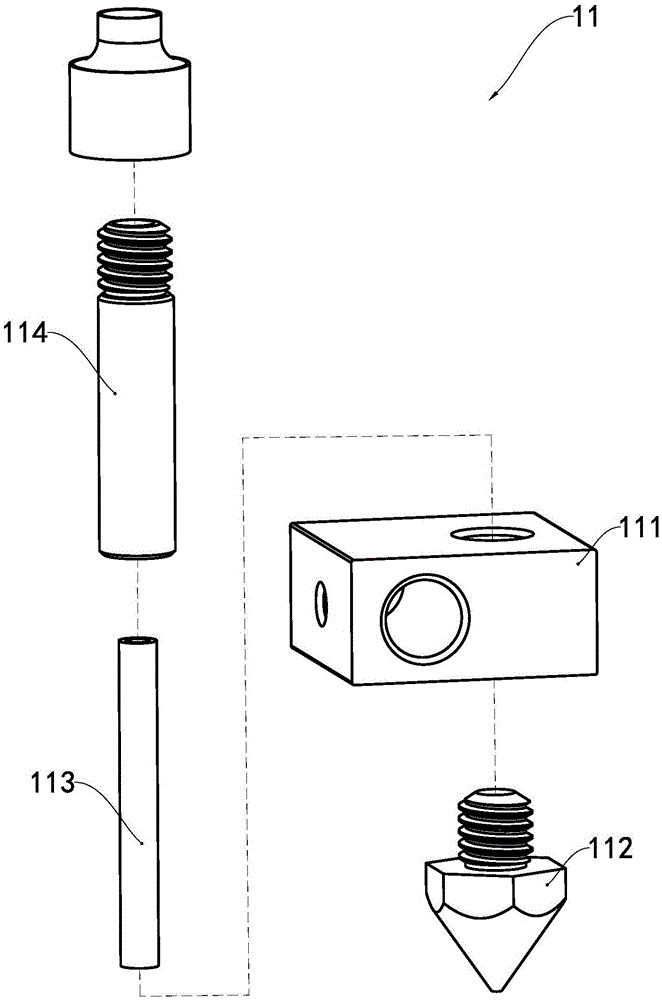

Printing head and three-dimensional printer

ActiveCN105459402APrevent adhesionAvoid condensationAdditive manufacturing apparatusEngineeringElectrical and Electronics engineering

The invention relates to a printing head for a three-dimensional printer. The printing head comprises a heating block, a throat tube fixedly connected with the heating block and a spraying nozzle, and further comprises a Teflon pipe located in the throat tube in the mode of being coaxial with the throat tube. The section, near a spraying opening, of a melting pipe of the spraying nozzle is a hole expanding outwards. The printing head can effectively prevent extruded fuse wires from adhering and agglomerating to the periphery of the spraying opening, improve printing accuracy and guarantee the forming effect of a three-dimensional object. The invention further provides the three-dimensional printer including the printing head.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

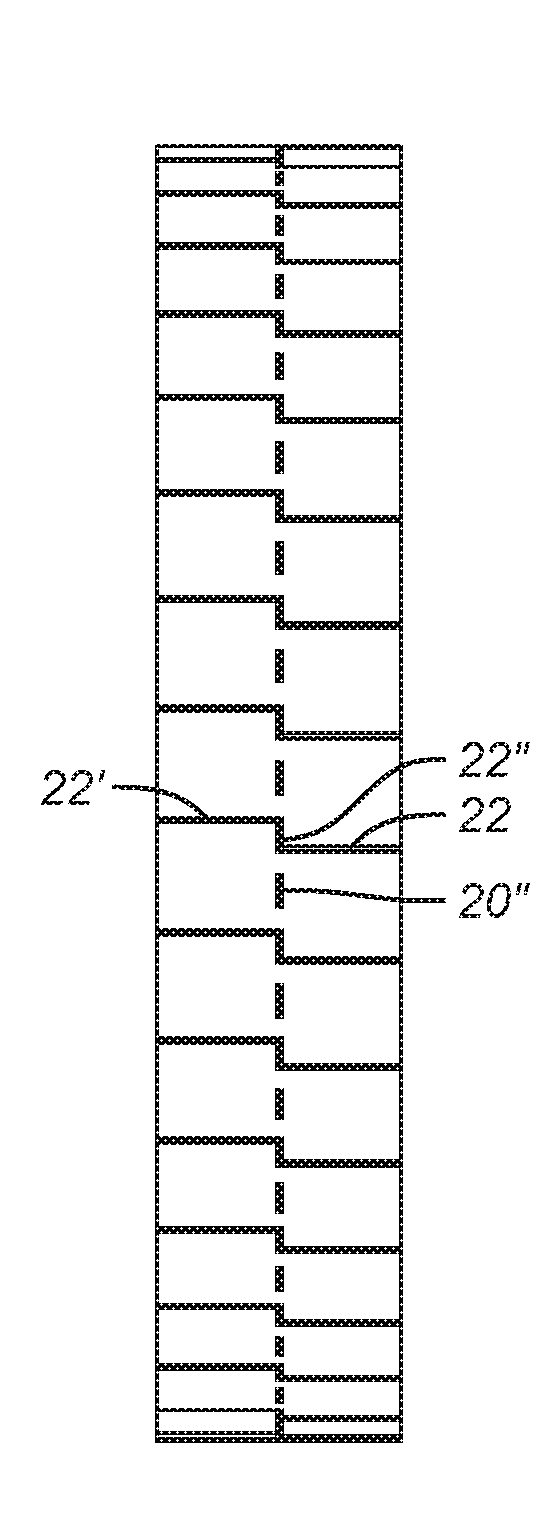

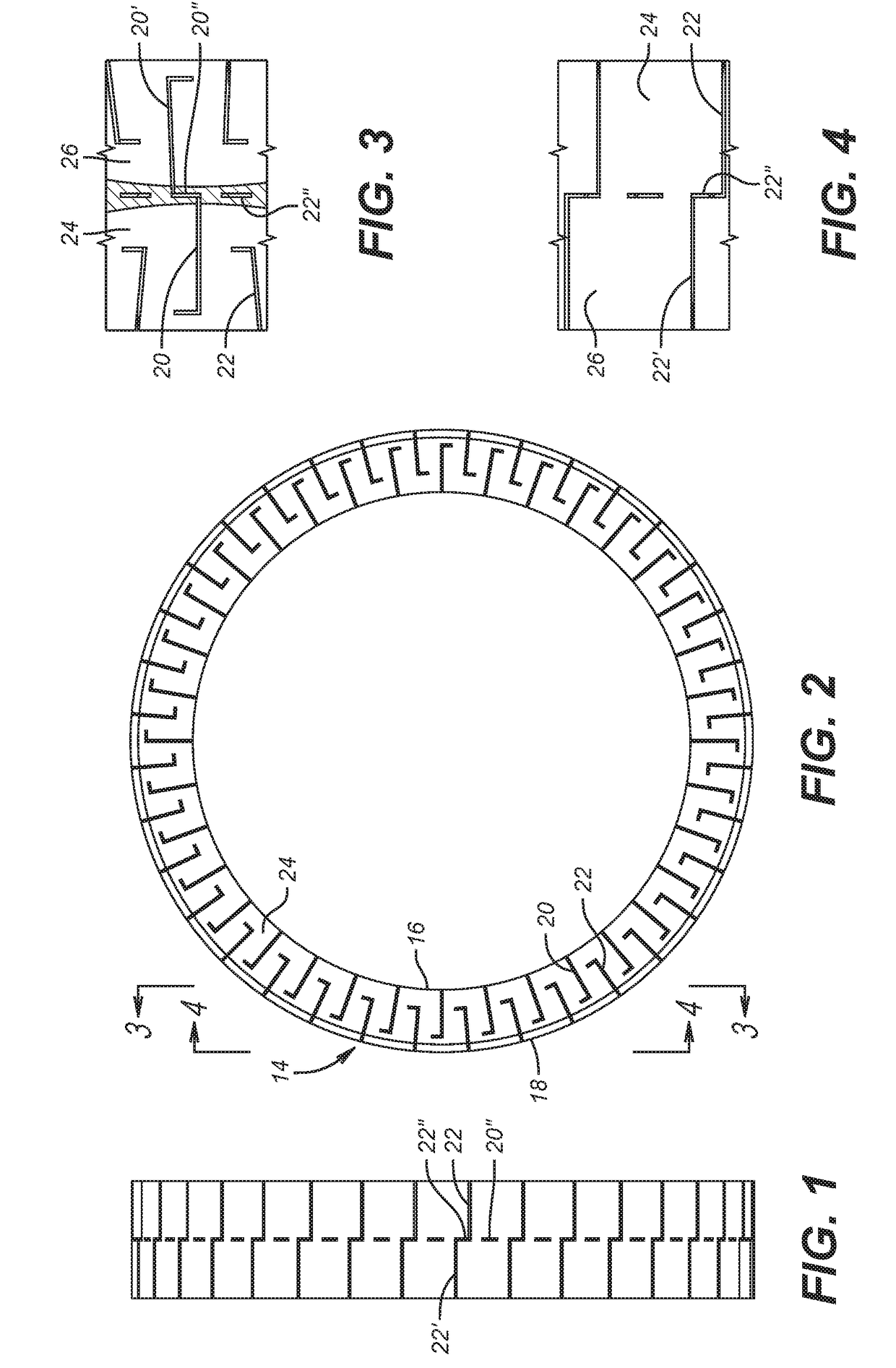

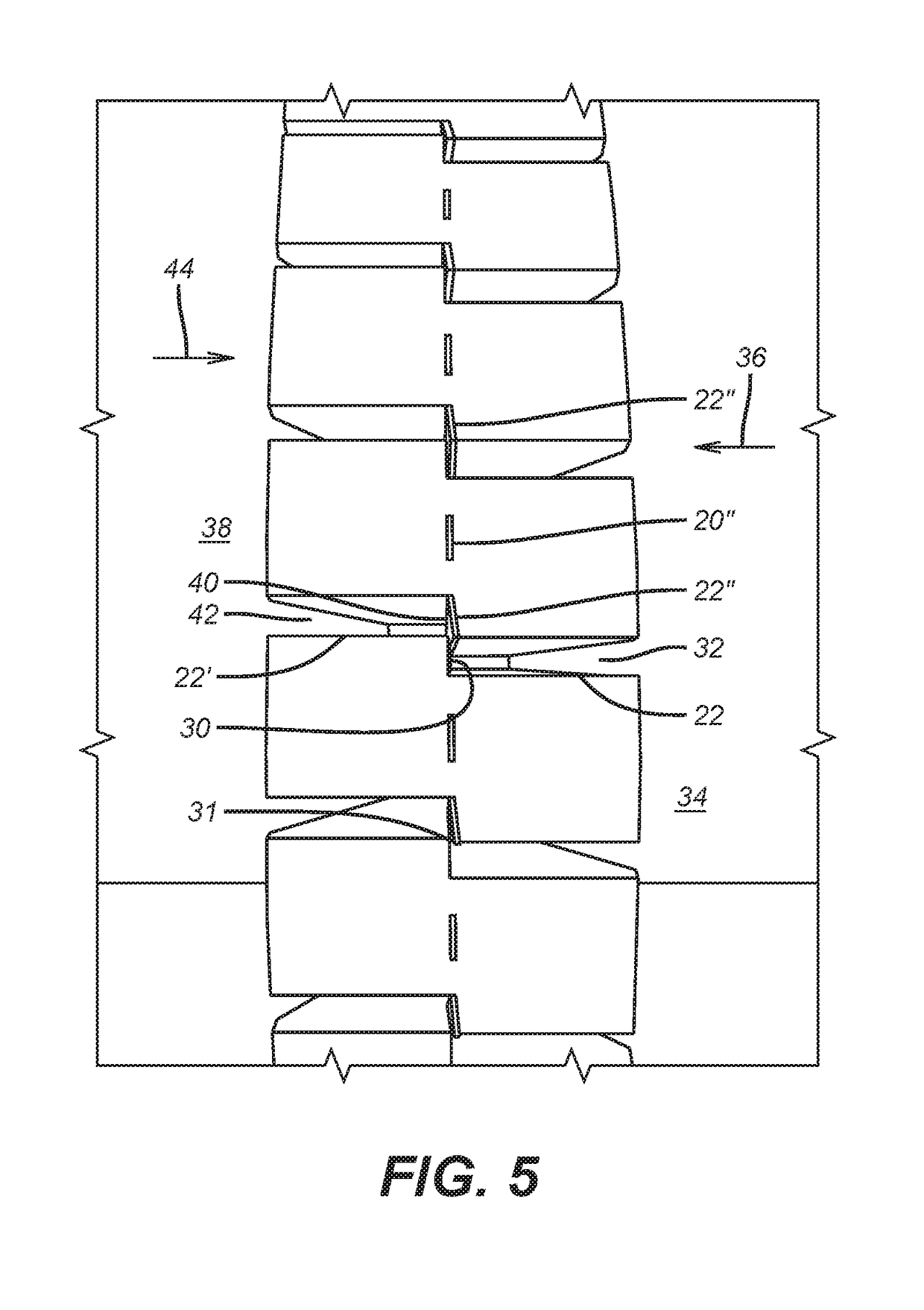

Packer Backup Ring with Closed Extrusion Gaps

Alternating l-shaped side slots are cut into opposed sides of a backup ring and are circumferentially offset and alternately extend from the inside and outside dimension. An oval shaped opening connects adjacent circumferentially offset slots so that on ring expansion the inside and outside diameters increase as the openings are sheared at one end to place a barrier in opened side slot to prevent extrusion of the adjacent sealing element.

Owner:BAKER HUGHES INC

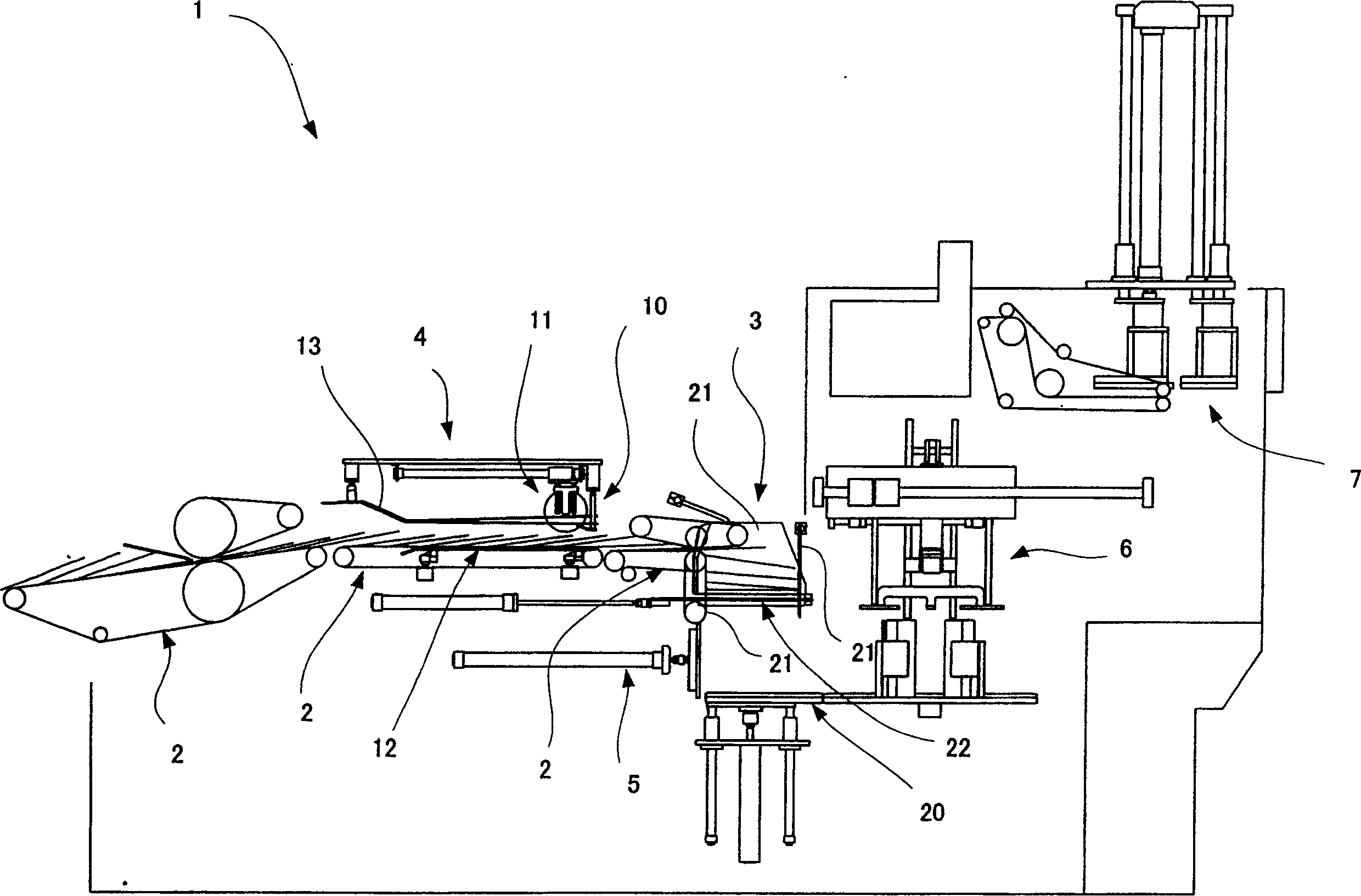

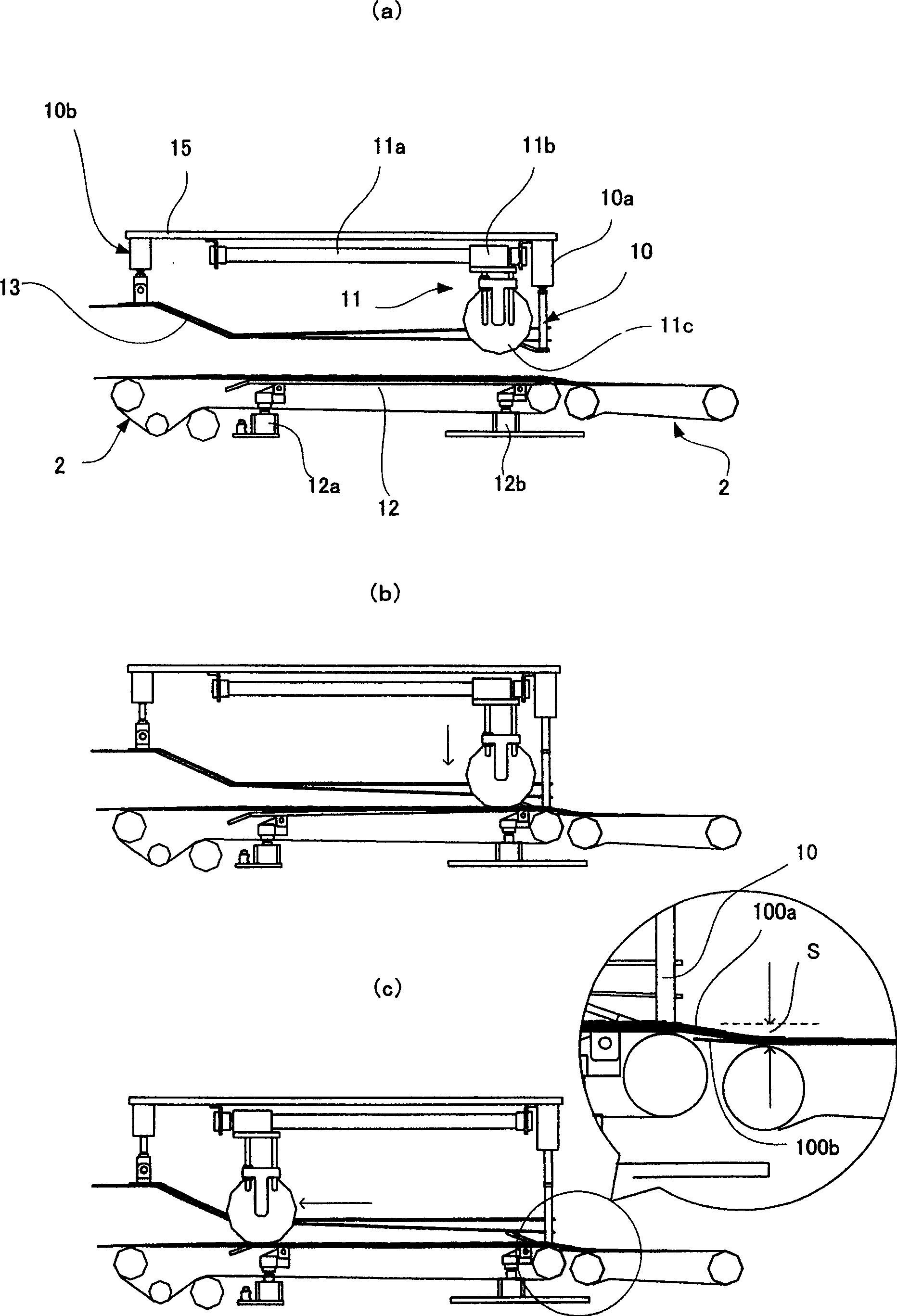

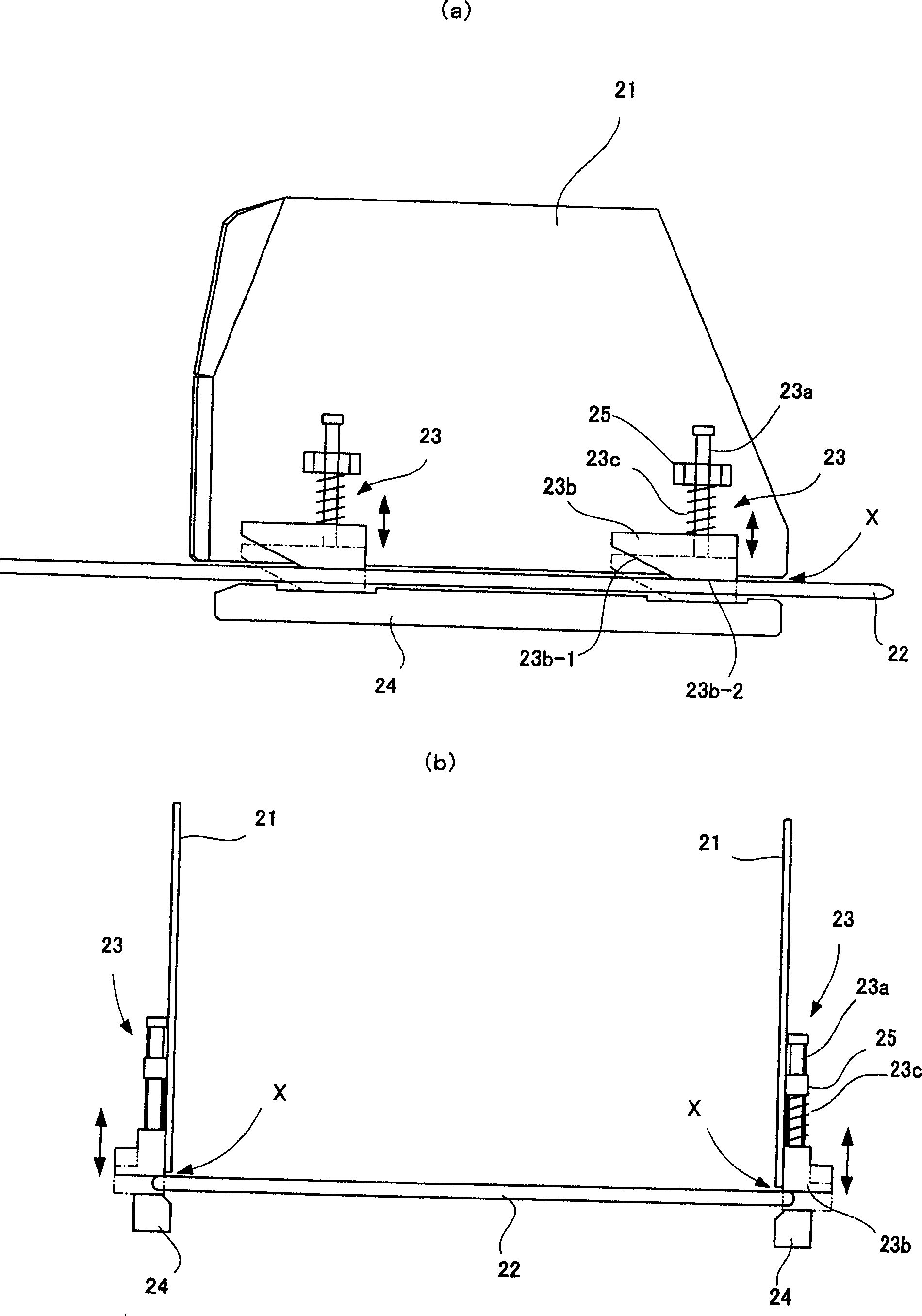

Stack binding machine and control method thereof

InactiveCN1597481APrevent cumulative overlapExtended temporary stopPile receiversArticle deliveryEngineeringStacker

Provided is a stacker bundler capable of solving paper jam and non-alignment of signature. The stacker bundler is constituted such that a lifting plate 12 of an end device 4 is inclinably supported by at least a pair of lifting driving devices 12a, 12b independently driven, when the lifting plate 12 is raised, the lifting driving device 12b in a downstream side is drivingly raised at a position where a press roller 11 pushes and strokes the stream of the signature accompanying with rolling of the press roller 11 so as to lift up the signature, and a little bit thereafter the lifting driving device 12a on the upstream side is drivingly raised.

Owner:GUNZE LTD

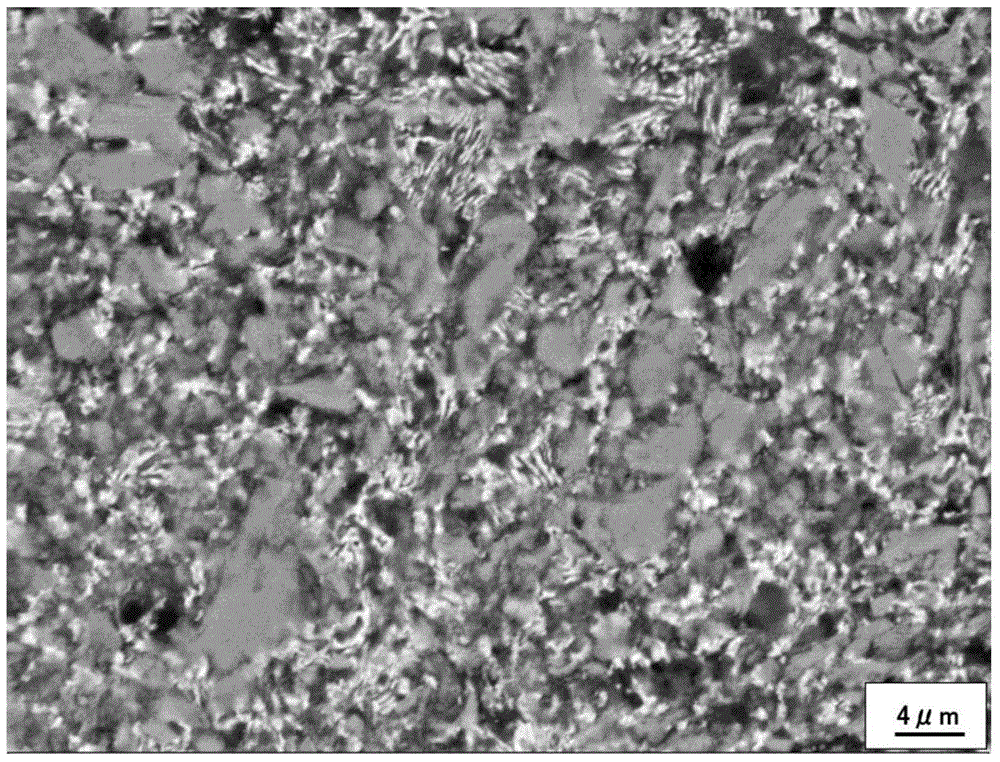

Pressureless sintering-pressurized densifying preparation method for titanium-aluminum-carbon particle enhanced zinc-aluminum matrix composite

The invention discloses a pressureless sintering-pressurized densifying preparation method for a titanium-aluminum-carbon (Ti3AlC2) particle enhanced zinc-aluminum matrix composite. The method comprises two steps of sintering and densifying. The method comprises the following steps: sintering mixed powders of titanium aluminum carbon and zinc-aluminum alloy at a relatively high temperature; conducting pressurized densifying at a relatively low temperature. Sintering at the relatively high temperature can obviously improve the interface bonding force between the titanium aluminum carbon enhanced phase and the zinc-aluminum alloy matrix, and pressurized densifying at the relatively low temperature can prevent zinc-aluminum alloy liquids from being extruded out because of pressurization; the titanium-aluminum-carbon particle enhanced zinc-aluminum matrix composite is uniform and compact in organization, less in defects and close in combination between the matrix and the enhanced phase, and has good physical properties and mechanical properties.

Owner:BEIJING JIAOTONG UNIV

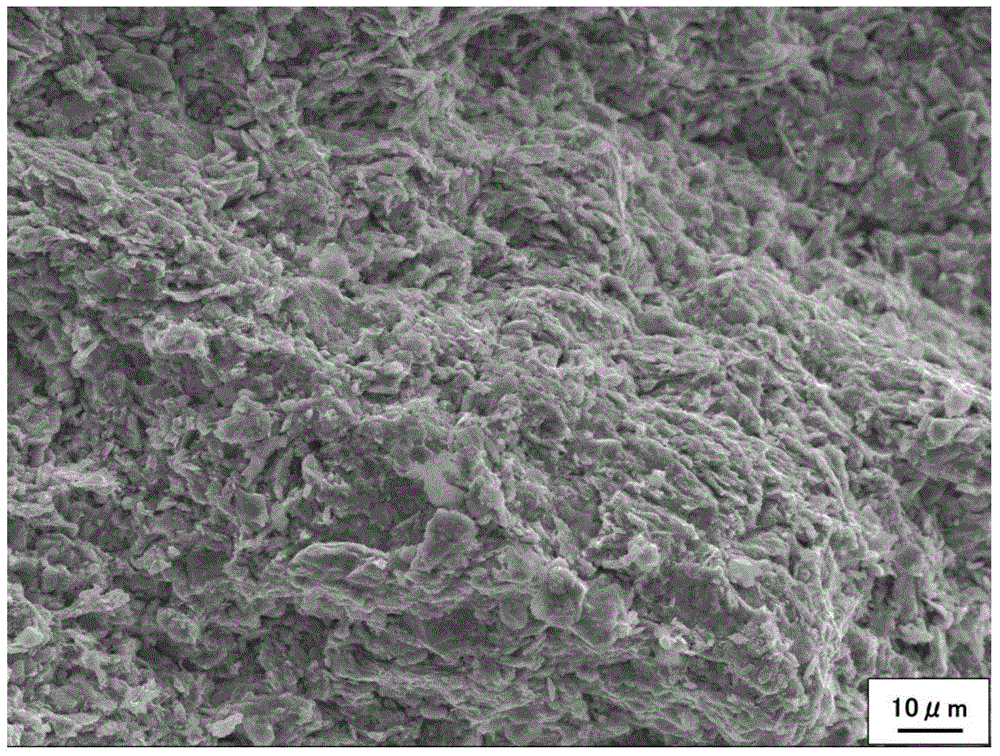

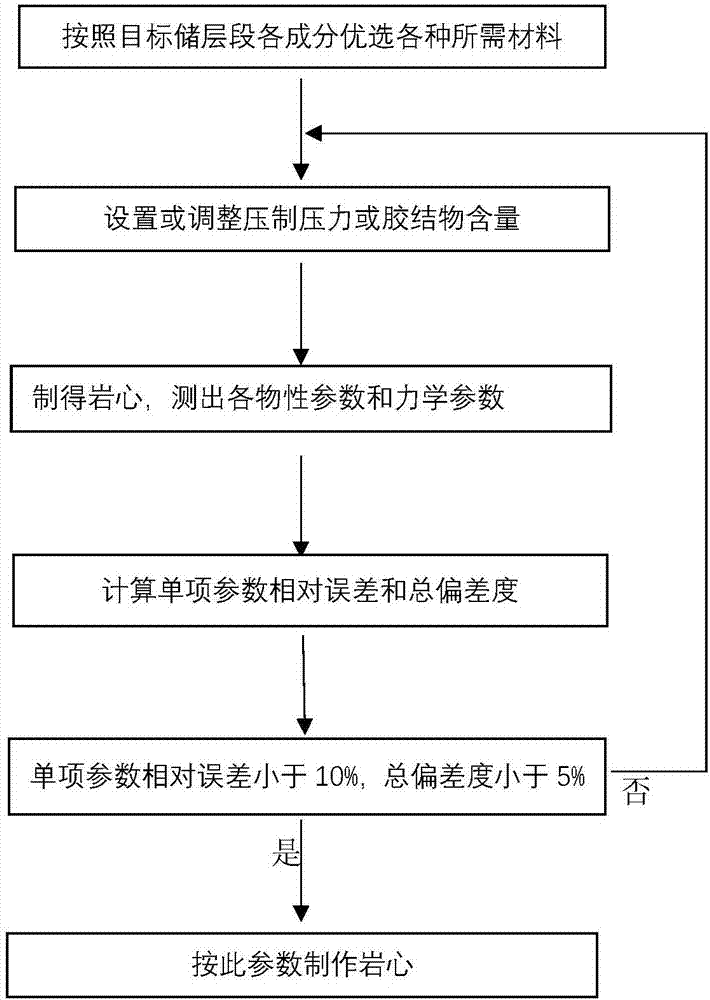

Manufacturing method for muddy loosing sand stone core

The invention relates to the field of petroleum exploitation and specifically relates to a manufacturing method for a muddy loosing sand stone core. The method comprises the following steps: firstly, acquiring mineral composition and proportion, grain size and stratum water component of a target reservoir section; selecting corresponding raw materials; confirming pressing pressure according to the overlying rock pressure of the stratum of the core; adopting epoxy resin cementation for manufacturing the core; acquiring porosity, permeability, Young modulus, uniaxial compressive strength and poisson ratio of the core of the target reservoir section; endowing a weighting coefficient; determining the porosity, permeability, Young modulus, uniaxial compressive strength and poisson ratio of an artificial core; acquiring the relative errors and total deviation by comparing with various parameters of the true core; if the deviation is larger, adjusting the pressing pressure and the cement content till the core parameters meet the simulation requirement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

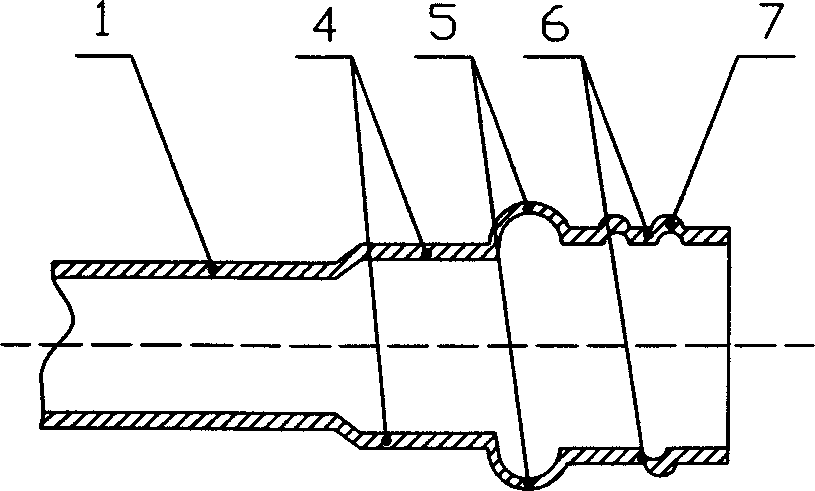

Thin-wall metal pipe quick-locking connection structure

InactiveCN1851308AImprove sealingImprove tensile propertiesJoints with sealing surfacesSet screwPipe fitting

The invention offers thin wall metal pipe fitting fast locking type bonded structure. It includes pipe fitting joint, pipe body, seal ring, external pressure screw cap and roof pressure ring. The pipe fitting joint is set pipe body inner shoulder-hole, convex annular and roof pressure ring inner shoulder hole. Its end out side is set screw thread external tapping. Pipe body cover is set in the pipe fitting joint. It has the advantages of high compressive strength, good seal performance, and low cost. And it can be mainly used in water supply, drinking water or conveyance of fluids industries.

Owner:卜莹

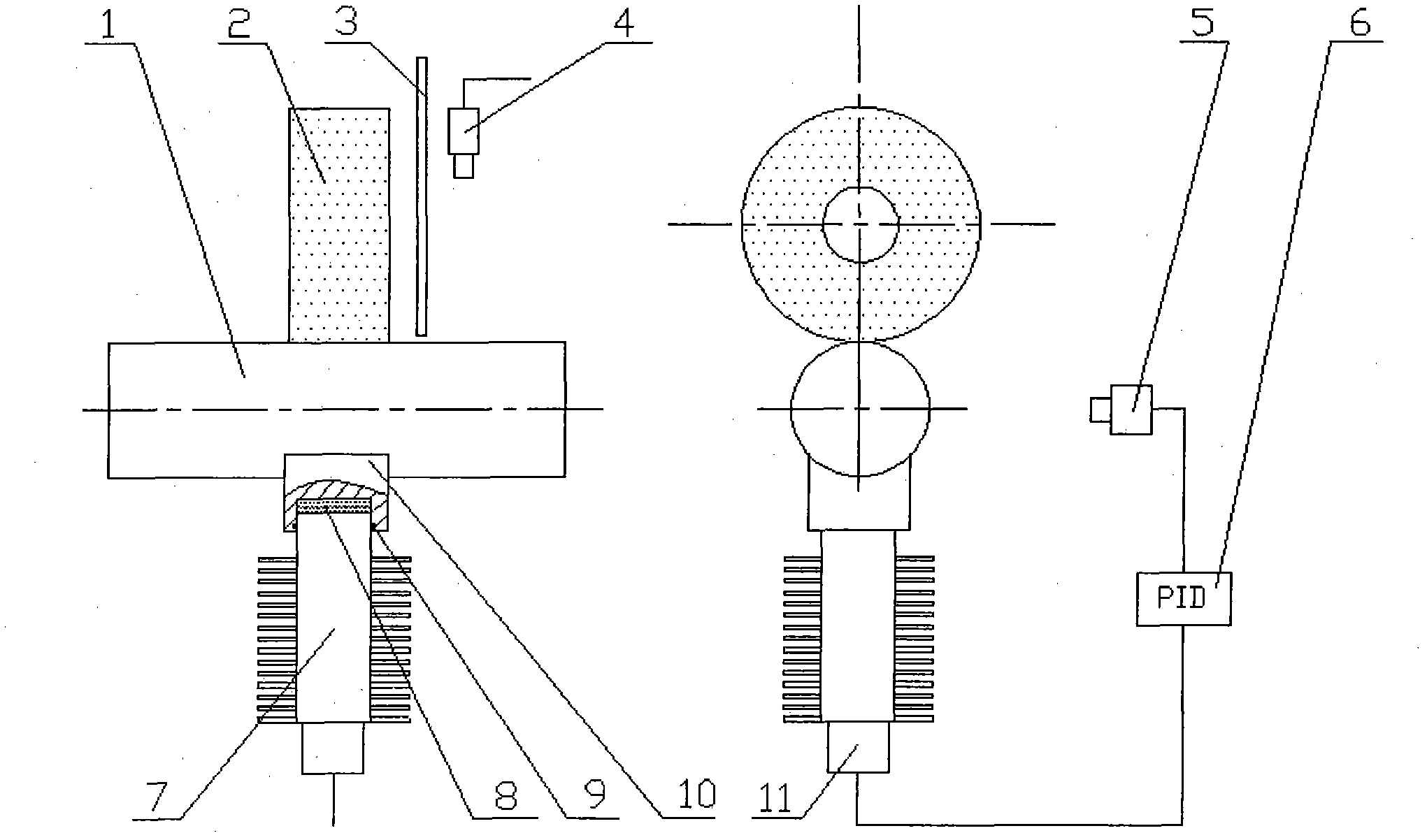

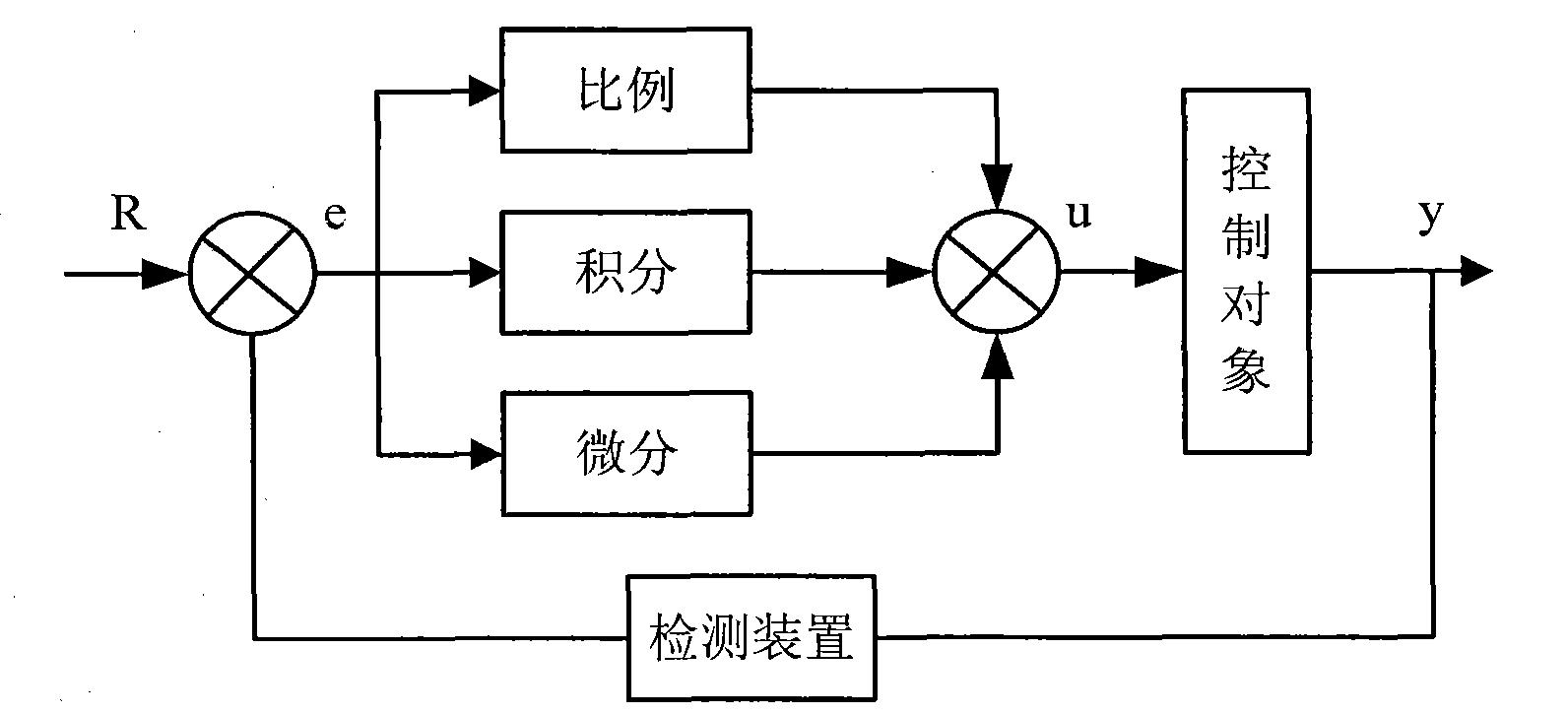

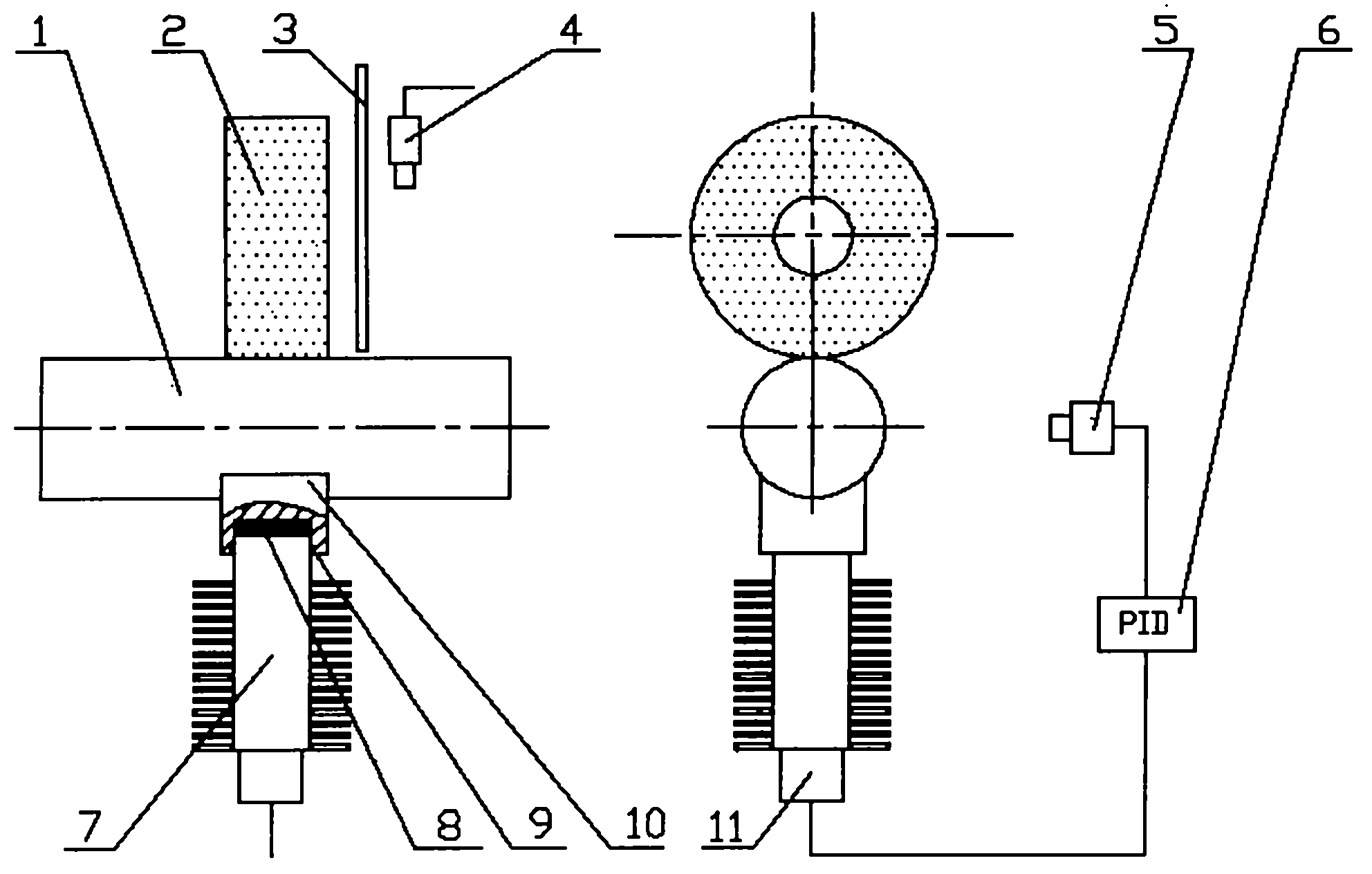

Part temperature control device for grinding processing

InactiveCN102303285AAvoid wear and tearAvoid outgoingAutomatic grinding controlAutomatic controlDirect effects

The invention relates to a part temperature control device for grinding processing. In a grinding quench hardening processing course, the change of the surface temperature of a part directly affects the quality of a heat-treated layer on the surface of the part. A high-temperature heat pipe is a good device for controlling heat transfer; in order to keep the temperature change of the part in the grinding quench hardening processing course low, the high-temperature heat pipe comes into contact with a part to be ground; the surface temperature of the part is detected in real time during grinding processing by means of an infrared radiation thermodetector; the contact area of the high-temperature heat pipe with a connection block and a thermal conductive adhesive is adjusted by driving a transmission structure unit using a PID (Proportion Integration Differentiation) controller, so that thermal contact resistance is reduced to transfer excessive heat outwards; therefore, the surface temperature of the part is adjusted, the requirement of controlling surface quenching is met, and technical support and foundation are provided for realizing automatic control of grinding process; and theapplication of the device may produce excellent economic and social benefits.

Owner:JIANGSU UNIV +1

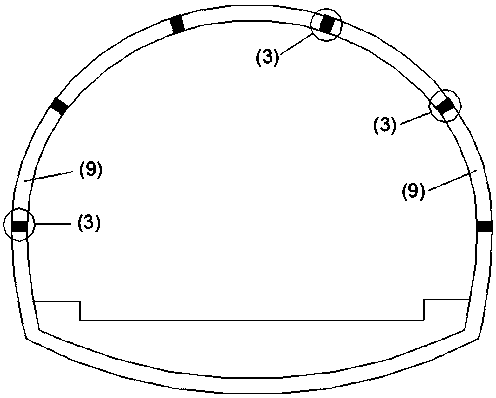

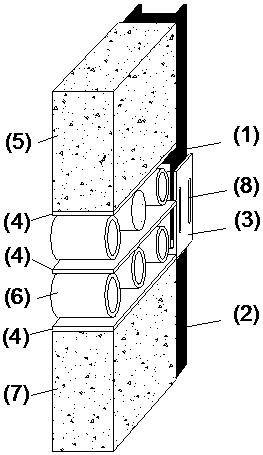

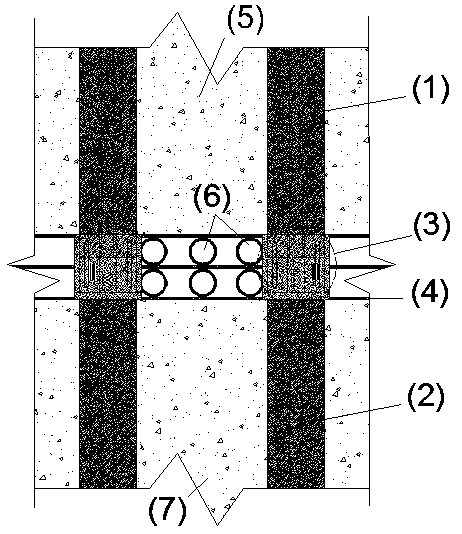

Large-deformation preliminary bracing system for high-ground-stress soft rock

The invention relates to a large-deformation preliminary bracing system for a high-ground-stress soft rock. The large-deformation preliminary bracing system comprises multiple circles of H-shape-steelsteel arch centers, wherein the multiple circles of H-shape-steel steel arch centers are longitudinally arranged in parallel; two longitudinal steel arch centers are connected by adopting a longitudinal connecting steel bar or channel steel; a single steel arch center is circumferentially divided into multiple segments; nodal points are connected through socket and spigot steel arch center joints; a longitudinal groove is reserved in a preliminary bracing sprayed concrete layer between the nodal points of two adjacent steel arch centers; compressible steel tubes are arranged in the longitudinal grooves. According to the large-deformation preliminary bracing system, by utilizing the compressible steel tubes which are longitudinally embedded into precast sprayed concrete and can provide resistance and spigot and socket section-steel steel frame joints corresponding to the compressible steel tube, the concession is carried out while the resisting is carried out; the deformation is enabled to be controllable; the deformation pressure borne of a preliminary bracing is released and the structural stableness of the preliminary bracing is realized.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

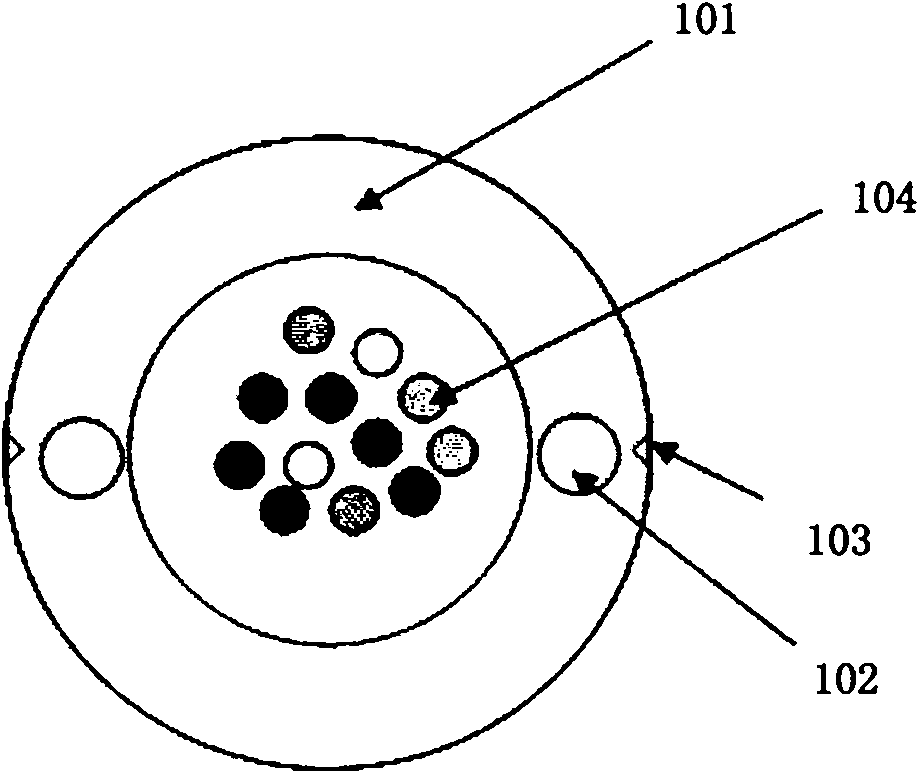

Cable and cable system

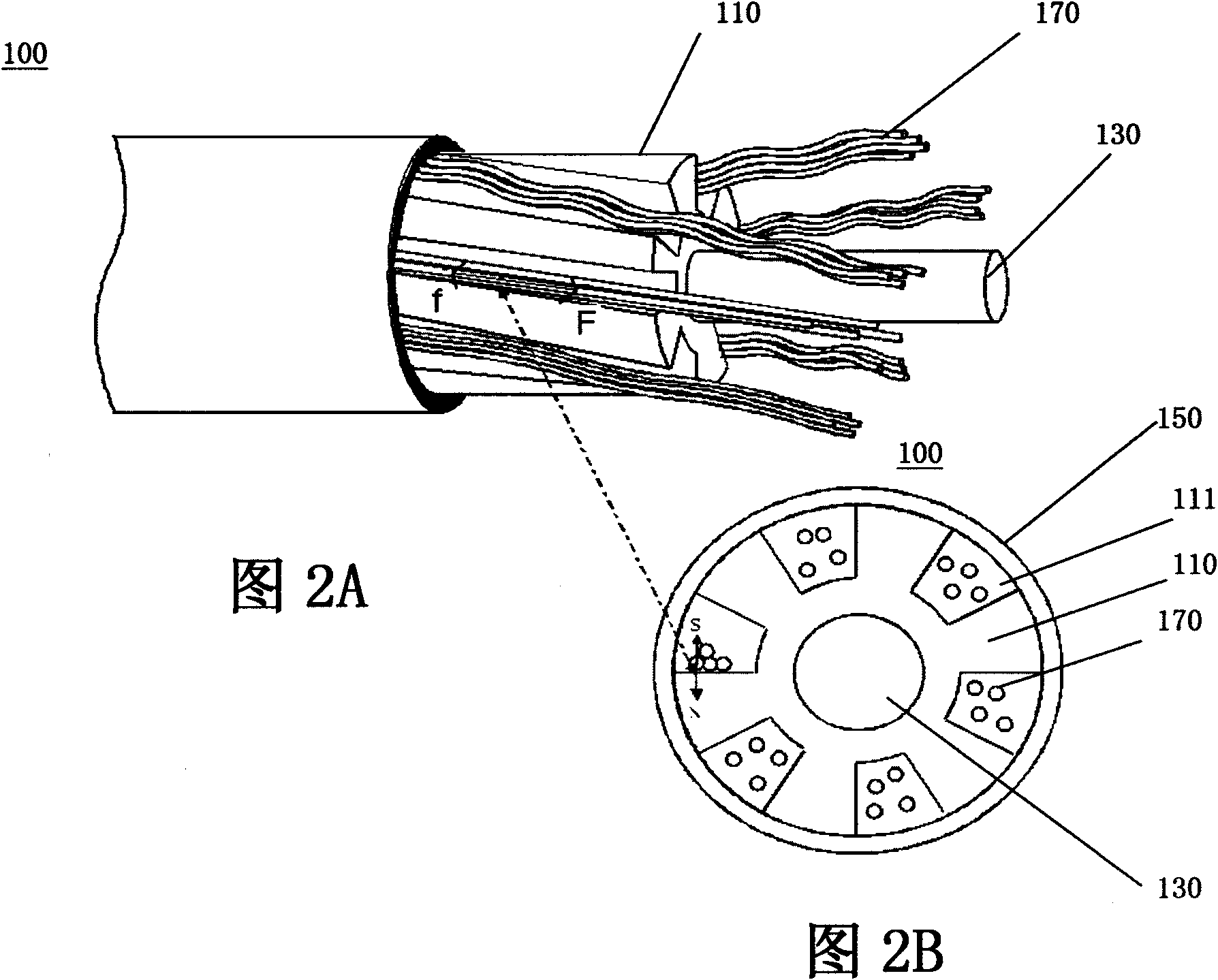

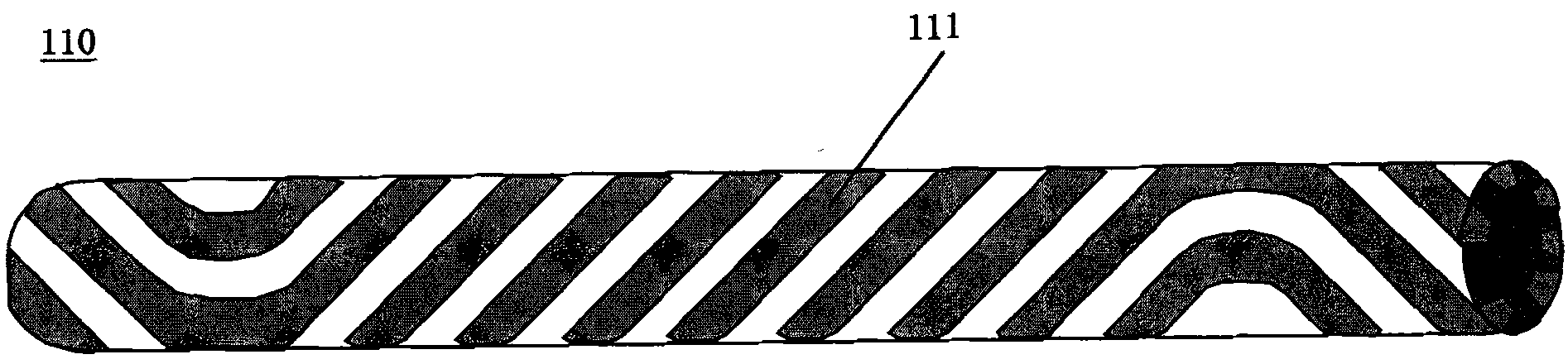

InactiveCN101943775AExtended service lifeEasy wiringOptical fibre/cable installationFibre mechanical structuresFiberEngineering

The invention discloses a cable and a cable system. The cable comprises an SZ (String Zero)-type cable frame and a plurality of fiber units, wherein a plurality of frame grooves are arranged in a concave mode on the outer periphery of the frame, and the plurality of fiber units in the cable are grouped and respectively arranged in the corresponding frame grooves so as to have the advantages of easy stripping and extraction, high reliability and long service life. The cable in mounting not only avoids connecting bifurcation among floors, shortens the welding / terminating time, simplifies the cable distribution, greatly decreases the deployment cost of an ODN (Optical Distribution Network) and accelerates the scaled deployment of FTTX (Cable to the) ODN, but also avoids the mutual interference of fibers in extraction and improves the fiber reliability after mounting.

Owner:HUAWEI TECH CO LTD

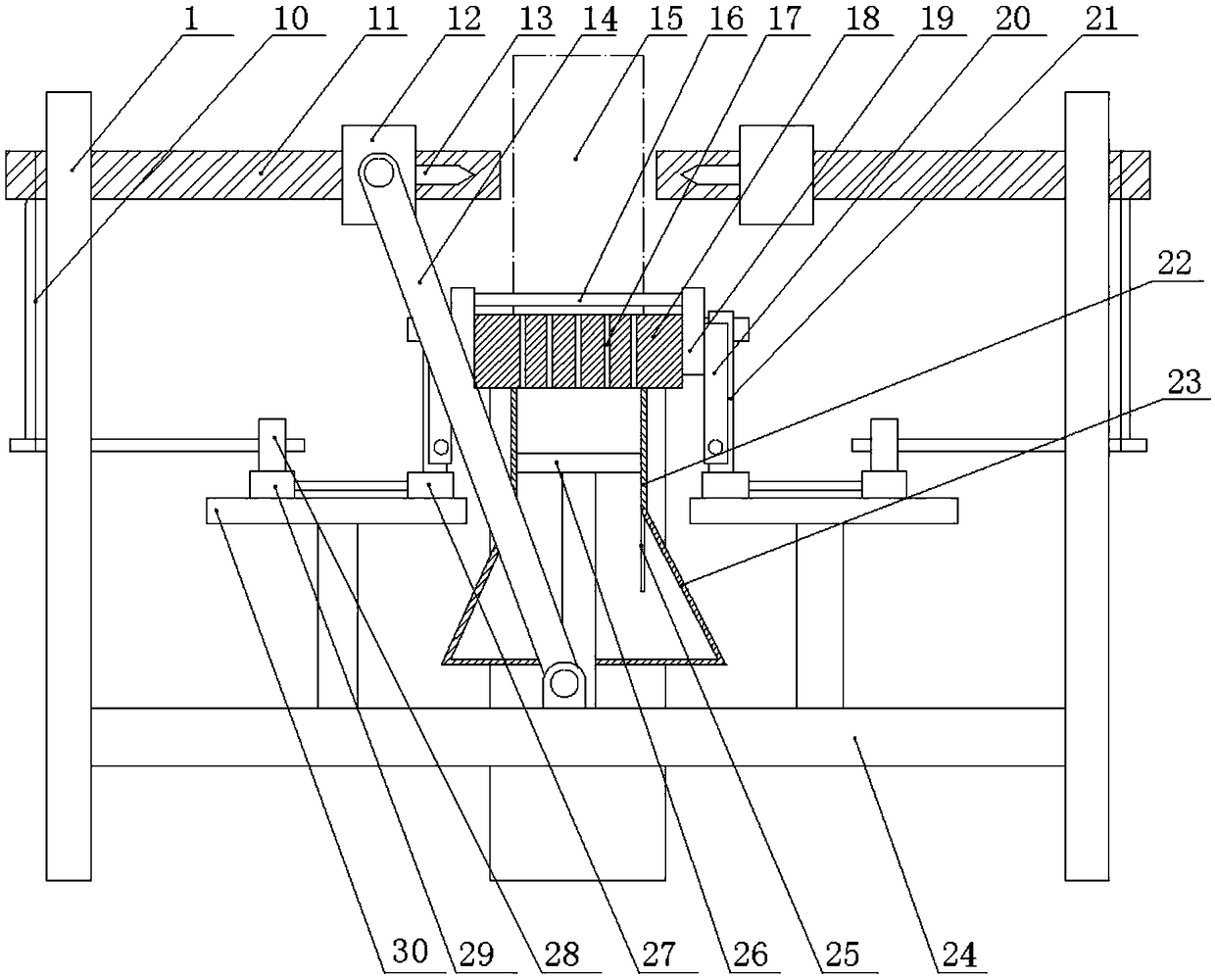

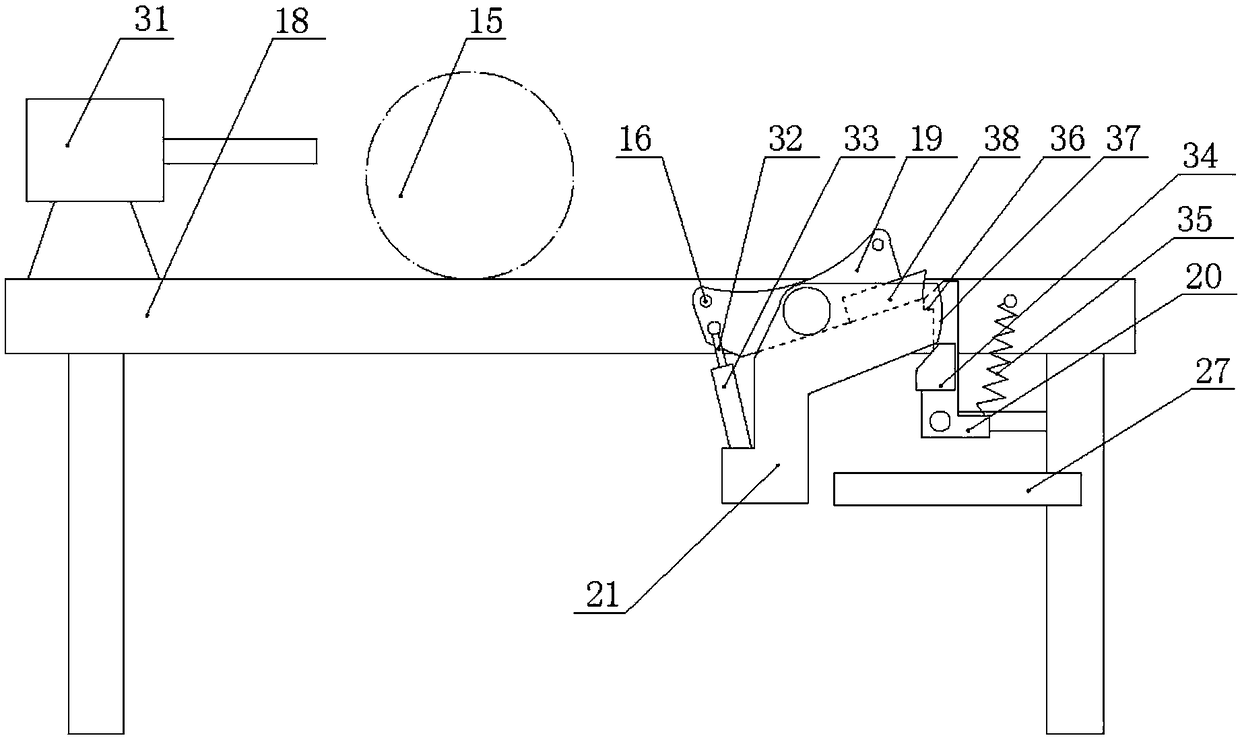

Production equipment for household furnishings

PendingCN108405900AImprove processing efficiencyReduce the amount of manual laborMaintainance and safety accessoriesBoring/drilling machinesEngineeringThreaded rod

The invention relates to the technical filed of fixture decoration processing and manufacturing, in particular to production equipment for household furnishings. The production equipment comprises a processing table with two sides symmetrically provided with fixing plates, the middle portions of the fixing plates are connected in a hinged mode to the side walls of the processing table, and a displacement limiting bar is arranged between the fixing plates. Each fixing plate is provided with a first wedge block, a wedge rod is arranged at one side of each fixing plate, each wedge rod is providedwith a clamping surface, and the first wedge blocks cooperate with the wedge rods intermittently. The wedge rods are connected in a hinged mode to the processing table, reset springs are arranged between the wedge rods and the processing table, and the wedge rods are provided with second wedge blocks. A pushing plate is coaxially and rotationally connected to each fixing plate, one end of each pushing plate is connected to the corresponding fixing plate by a telescopic rod, and an incline plane is arranged at the other end of each pushing plate to be intermittently matched with the corresponding second wedge block. Supporting columns are arranged at two sides of the processing table, the supporting columns are rotationally connected with threaded rods, the threaded rods are connected to sliding sleeves by threads, and the opposite sides of the sliding sleeves are provided with perforating knifes. The production equipment for the household furnishings solves the problem that an existing perforating machine is unable to perforate both sides of a workpiece at the same time.

Owner:重庆木头木脑文化创意有限公司

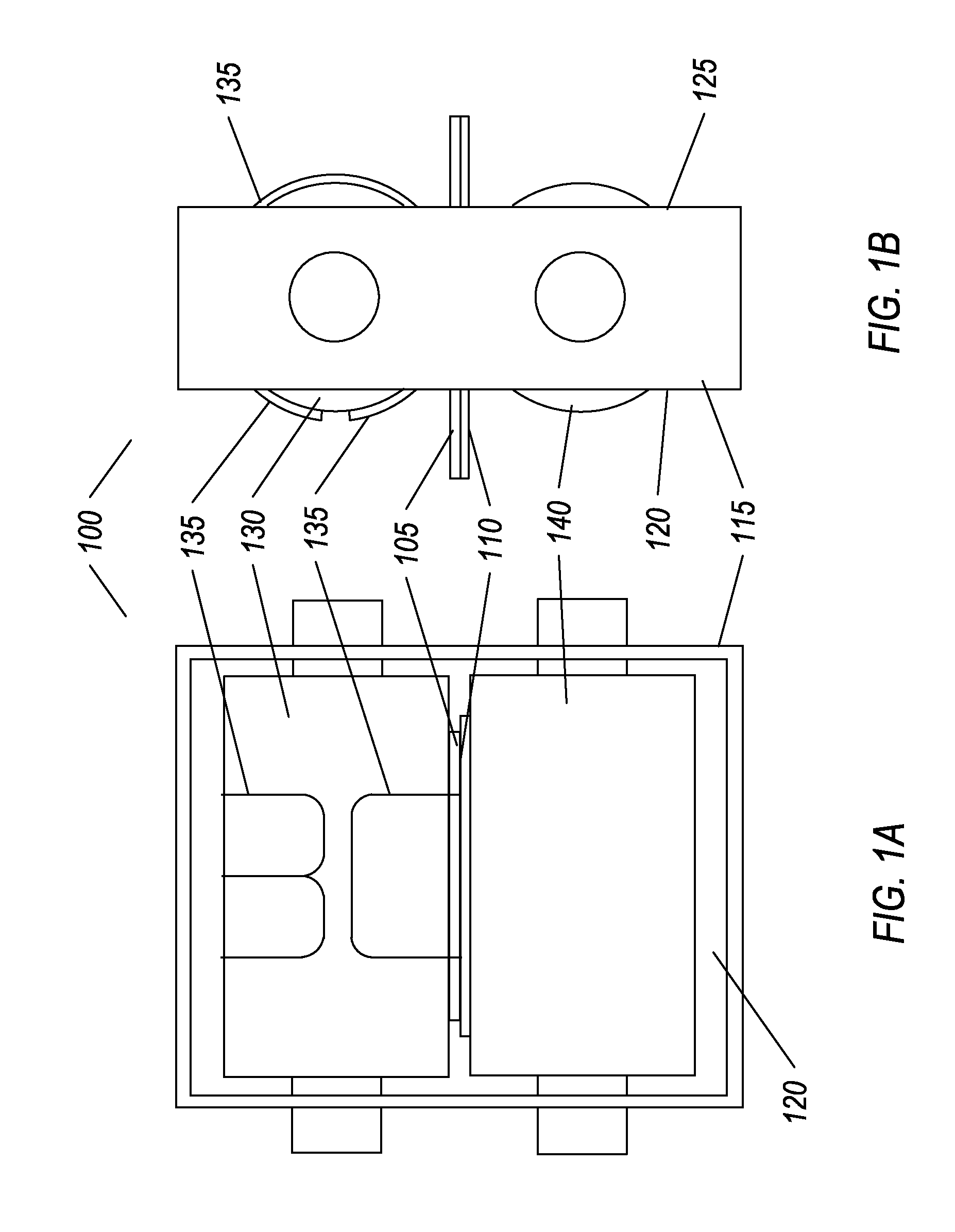

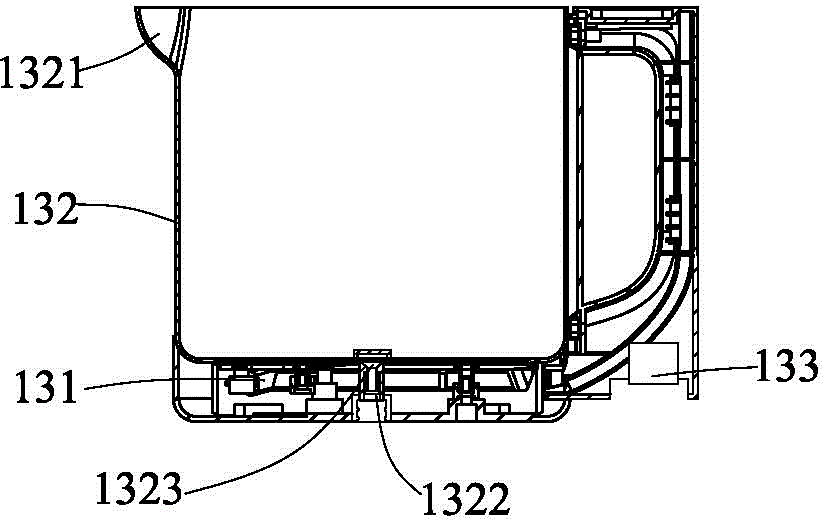

Technology for preparing bean curd/uncongealed bean curd by virtue of household bean curd machine

ActiveCN104642558ALong storage timeSimple structureCheese manufactureFood scienceElectric machinerySlurry

The invention relates to a technology for preparing bean curd / uncongealed bean curd by virtue of a household bean curd machine. The technology comprises the following steps: (a) in a crushing stage, adding water and materials to a crushing cup, wherein the motor drives a crushing tool to rotate and crush the materials into slurry, and the crushed slurry is filtered through a filter and then is discharged into a slurry boiling cup; (2) in a slurry boiling stage, heating the slurry in the slurry boiling cup by virtue of a heating element until the slurry is cooked, and cooling the slurry to a certain temperature; (c) in a marinating and solidifying stage, discharging the a marinating agent in a marinating box into the slurry boiling cup, marinating and then standing for a certain period of time; and (d) in a pressing stage, driving a pressure plate to advance along the inner wall of the slurry boiling cup by a drive mechanism, infiltrating yellow serofluid into the position above the pressure plate through a drainage groove and / hole in the pressure plate, and forming the bean curd below the pressure plate. Therefore, water sealing is achieved above the bean curd to be isolated from air; the bean curd is prevented from being polluted by bacteria; the storage time of the bean curd is relatively long; and meanwhile, the yellow serofluid can also play a role in natural heat preservation.

Owner:JOYOUNG CO LTD

Extrusion preparation method and extrusion equipment for extra-large-orifice PTFE pipe fitting paste

The invention discloses an extrusion preparation method for extra-large-orifice PTFE pipe fitting paste. The extrusion preparation method comprises the following steps of: mixing raw materials; pre-forming the raw materials; extruding and forming the raw materials; tracing extrusion speed and a position of an extruded pipe fitting, controlling an extruder through a feedback signal; sintering and forming; performing position measuring and feedback control on the position of a sintered extra-large-orifice PTFE pipe fitting product; and enabling polytetrafluoroethylene dispersion resin tube to form a product. The invention further discloses extrusion equipment for extra-large-orifice PTFE pipe fitting paste. The extrusion equipment comprises an extrusion drive part, a pushing-pressing assembly, a mandrel assembly, a raw material barrel, an extrusion mould and a thermal forming assembly which are sequentially connected coaxially, wherein the extrusion drive part is mounted on the tail part of the rack; one end of the pushing-pressing assembly is connected with the extrusion drive part; the other end of the pushing-pressing assembly is connected with one end of the mandrel assembly; the raw material barrel is mounted on the front part of the rack; the extrusion mould is mounted at an outlet end of the raw material barrel; the mandrel assembly passes through the center of the raw material barrel and the center of the extrusion mould; and the thermal forming assembly is supported in front of the rack and is concentric with the raw material barrel.

Owner:JIANGNAN FLUOROPLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com