Model separation device for 3D printer

A 3D printer and separation device technology, applied in the direction of additive processing, etc., can solve the problems of fragile model integrity, time-consuming and labor-intensive, low work efficiency, etc., and achieve the effect of improving work efficiency and ensuring complete and accurate separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

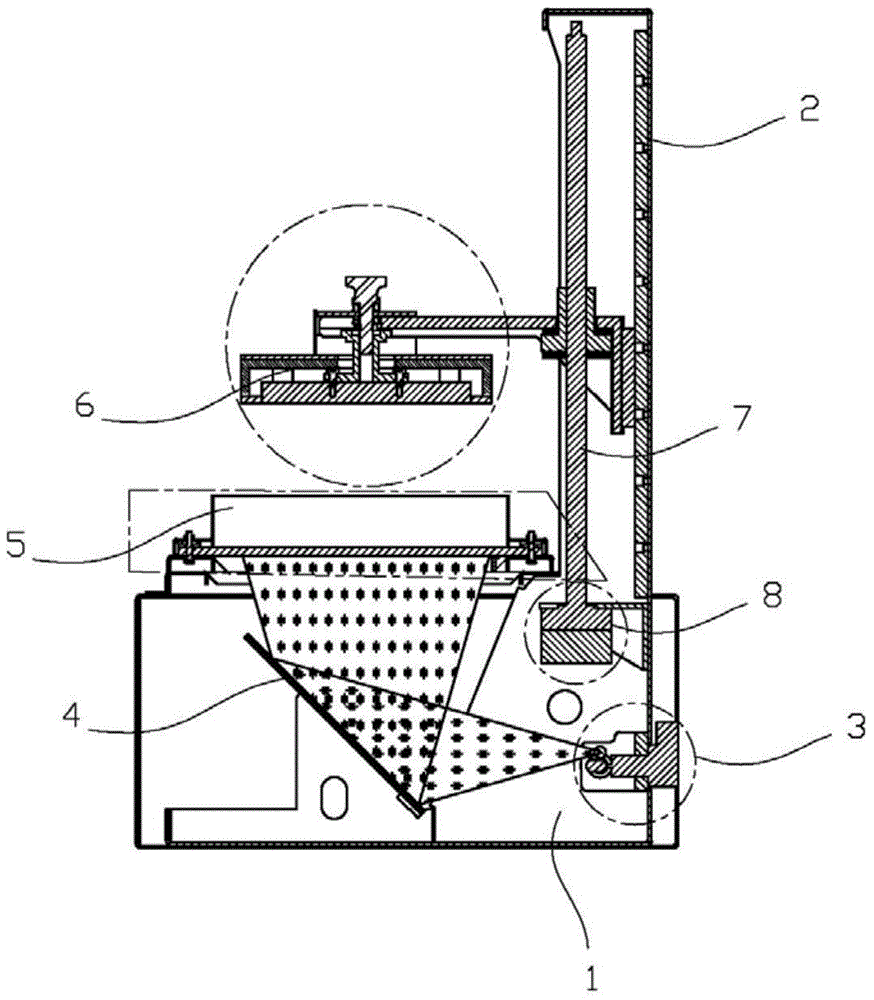

[0024] Such as figure 1 A rapid prototyping 3D printer is shown, including a hollow base 1 and a column 2 extending upward along one side of the base 1 , and a laser emitting device 3 and a reflector 4 are arranged in the base of the cabinet. The upper surface of the base 1 is also provided with a photosensitive resin pool 5, and the bottom surface of the photosensitive resin pool 5 is fixed with high-transmittance quartz glass. The mirror 4 can reflect the laser light emitted by the laser emitting device 3 to the position of the photosensitive resin pool 5 , so that the laser light can irradiate the liquid photosensitive resin in the photosensitive resin pool 5 . The model separating device 6 in the embodiment of the present invention is connected with the column 2 through a ball screw 7 . The ball screw 7 is connected with the driving motor 8 arranged in the base 1 . When the drive motor 8 drives the ball screw 7 to rotate, the model separating device 6 can move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com