Packer Backup Ring with Closed Extrusion Gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

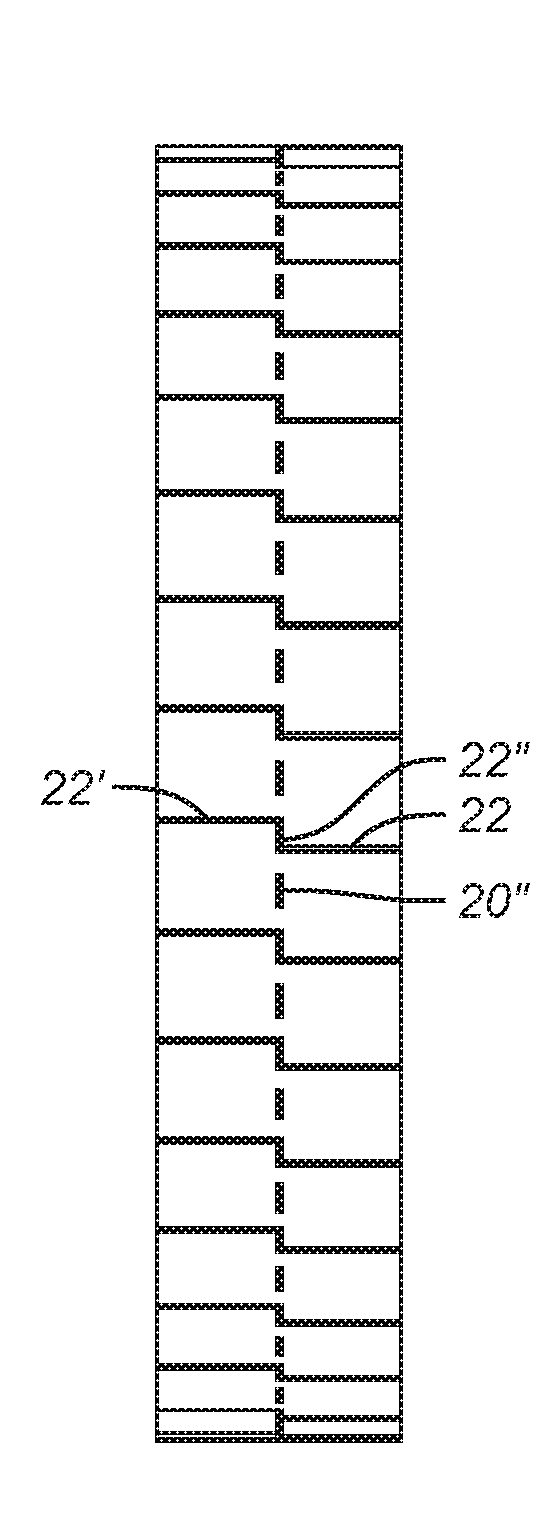

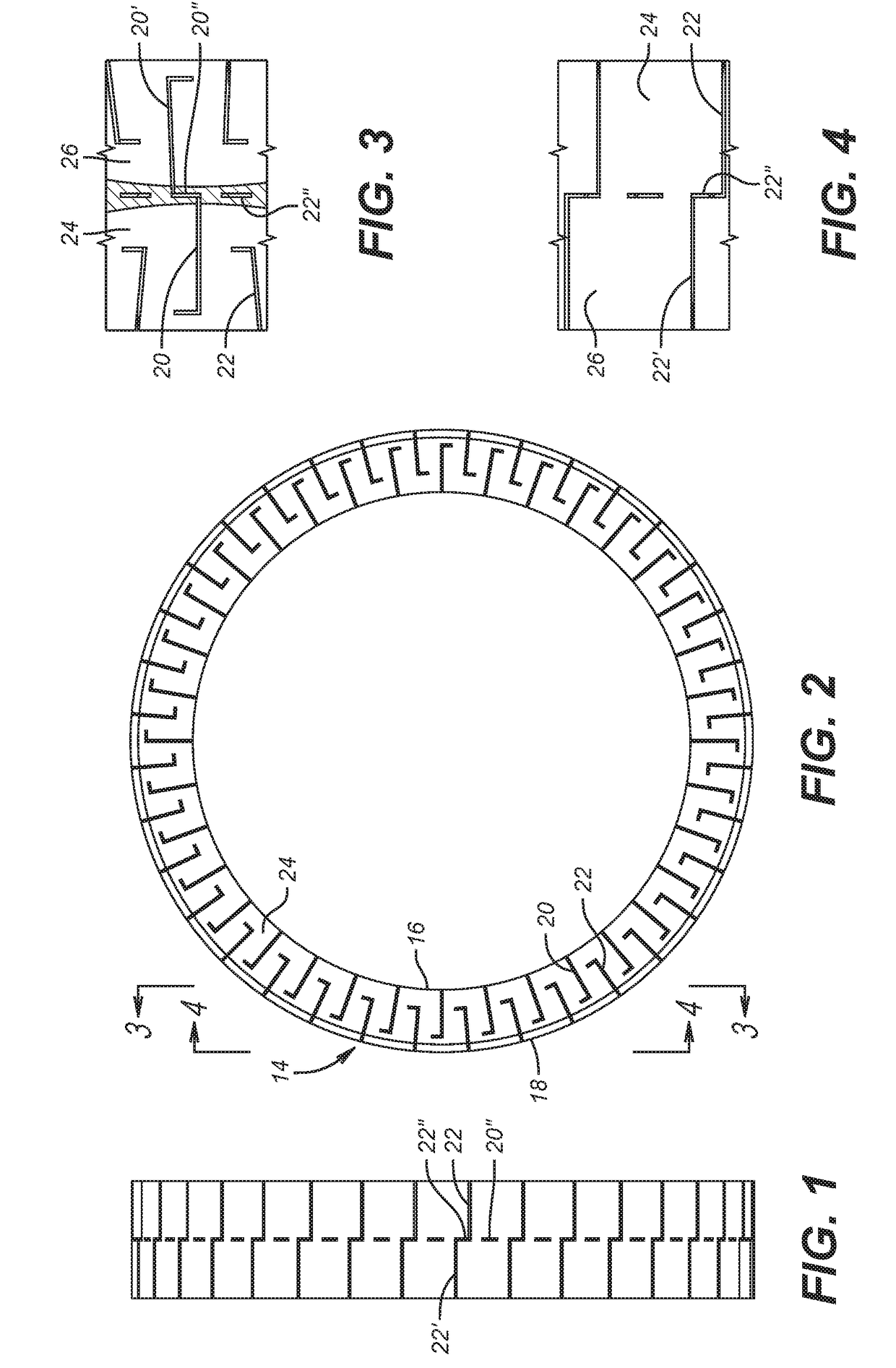

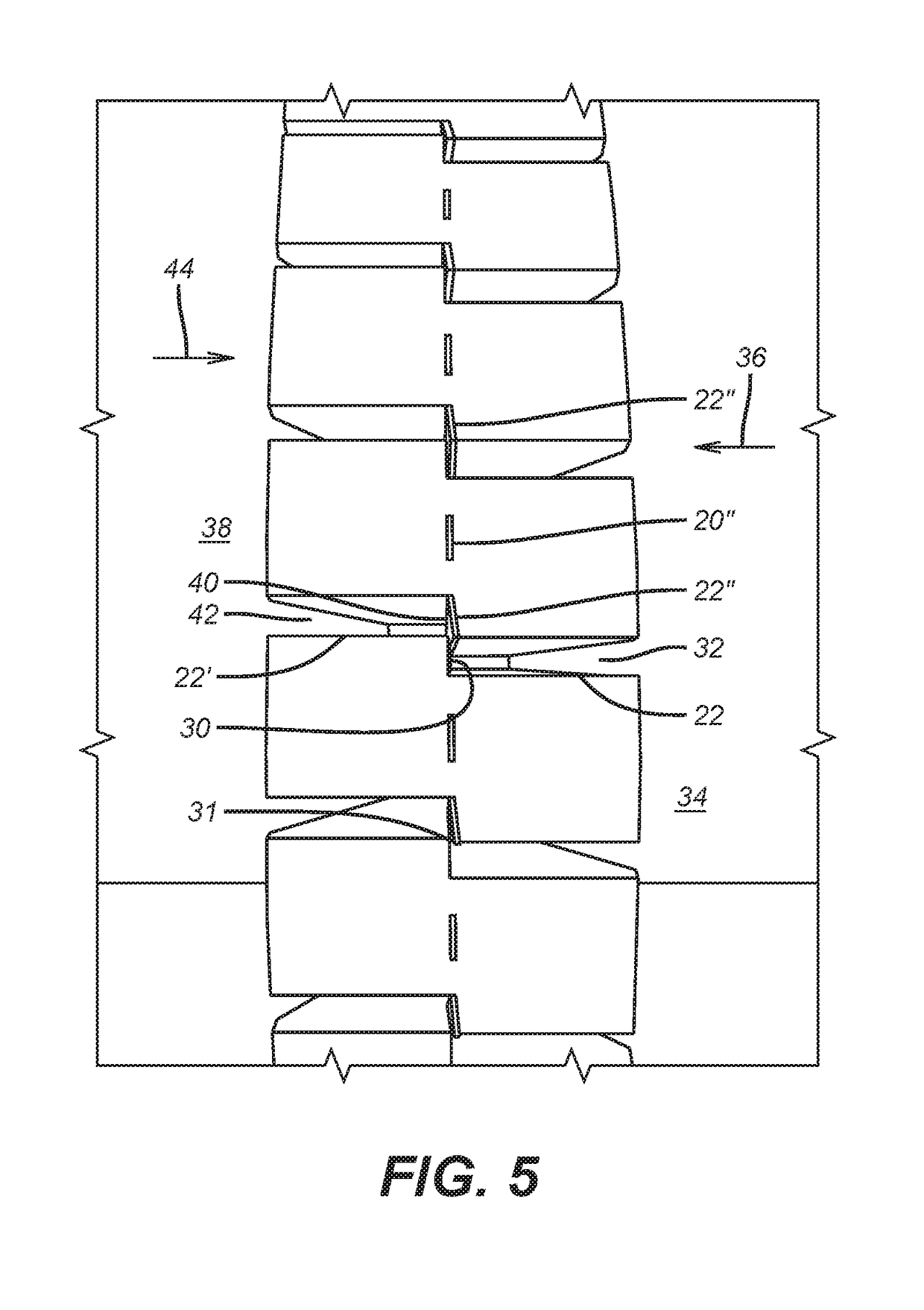

[0029]FIGS. 10 and 11 illustrate the juxtaposition of a sealing element 10 next to a backup ring 12. FIG. 2 shows an end view of a continuous single ring 14 that can be disposed next to a sealing element 10. Ring 14 has an inside diameter 16 and an outside diameter 18. There are alternating l-shaped slots 20 and 22 that start at the outside diameter 18 and at the inside diameter 16. FIG. 2 shows a tapered or sloping side 24 and slots 20 and 22 that alternate as to the location of the long dimension of the l-shaped slot. Sloping side 26 is not seen in FIG. 2 but is shown as FIG. 3 as well as the cylindrically shaped inside surface 28 that defines the inside diameter 16. FIGS. 1 and 4 both show an outside view where it is seen that slot 22 is a segment that goes to outside diameter 18 has a continuation slot segment 22′ that is circumferentially offset a few degrees. Slots 22 and 22′ are at opposed ends of an oblong bore 22″ that may have internal supports. Bore or opening 22″ is seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com