Technology for preparing bean curd/uncongealed bean curd by virtue of household bean curd machine

A tofu machine and household technology, used in applications, dairy products, cheese substitutes, etc., can solve the problems of cumbersome use, secondary pollution, and bulky machines, reducing manual participation, improving user experience, and reducing cleaning parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

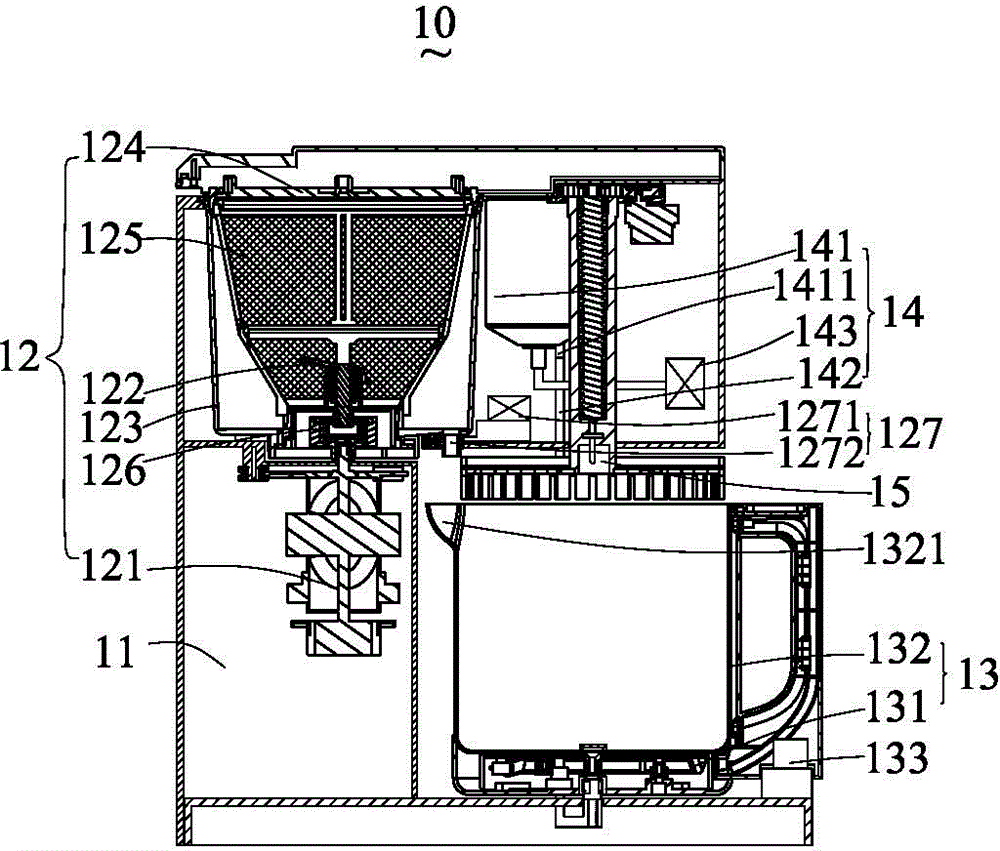

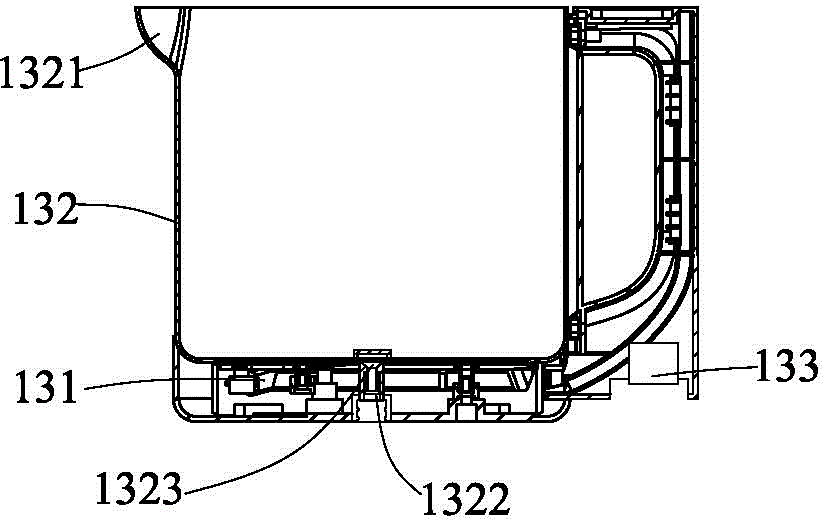

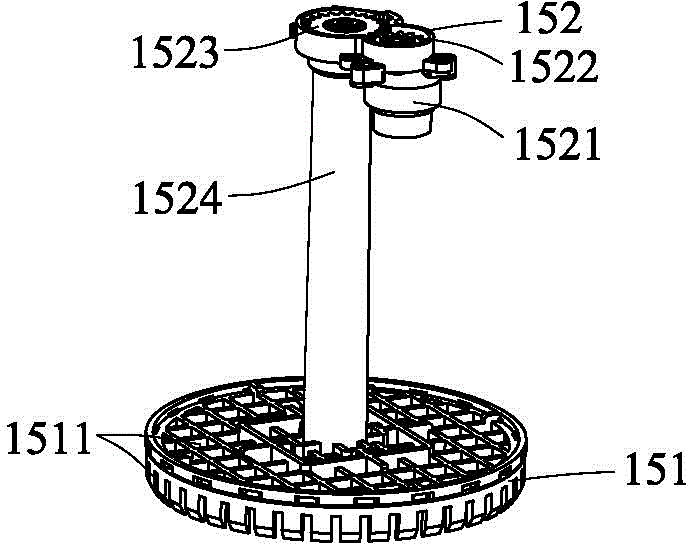

[0041] see figure 1 The schematic diagram of the domestic tofu machine used in the first preferred embodiment of making tofu and bean curd flower / brain, the household tofu machine 10 includes a machine base 11, a crushing module 12, a cooking module 13, a marinating module 14, a pressing The module 15 and the circuit control module (not shown in the figure), the pulverizing module 12, the pulp cooking module 13, the halogen point module 14, the pressing module 15 and the circuit control module are respectively arranged on the machine base 11.

[0042] The crushing module 12 includes a motor 121, a crushing cutter 122, a crushing cup 123, a crushing cup cover 124 fastened with the crushing cup 123, and a filter screen 125 located in the crushing cup 123. The motor 121 is electrically connected to the circuit control module. The motor 121 drives the crushing cutter 122 to rotate and crush into a slurry, and the crushing cutter 122 is located in the filter screen 125 . In this e...

Embodiment approach 2

[0065] see Figure 5 The schematic diagram of the domestic tofu machine used in the second preferred embodiment of making tofu and tofu flower / brain. The difference between the household tofu machine 20 and the household tofu machine 10 is that the stew making module 21 also includes an air pump 211, The air pump 211 communicates with the pulp cooking cup 132 or the halogen point box 141 through the reversing valve 212, and the air pump 211 communicates with the halogen point box 141 so that the air pump 211 blows into the halogen point box 141 to press the halogen point into the halogen point box 141. In the pulp cooking cup 132, the air pump 211 communicates with the pulp cooking cup 132 so that the air pump 211 blows air into the pulp cooking cup 132 to cool down the slurry.

[0066] In this way, not only is there a stirring effect on the slurry during the stewing process, so that the stewing is more uniform; When the temperature of the slurry is 75 to 95 degrees Celsius, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com