Part temperature control device for grinding processing

A temperature control device and grinding processing technology, applied in the direction of automatic grinding control devices, grinding machine parts, metal processing equipment, etc., can solve the problems of large thermal resistance, decreased strength of grinding wheels, poor thermal conductivity, etc., and achieve high Effects of heat transfer efficiency, avoidance of direct friction, and excellent temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

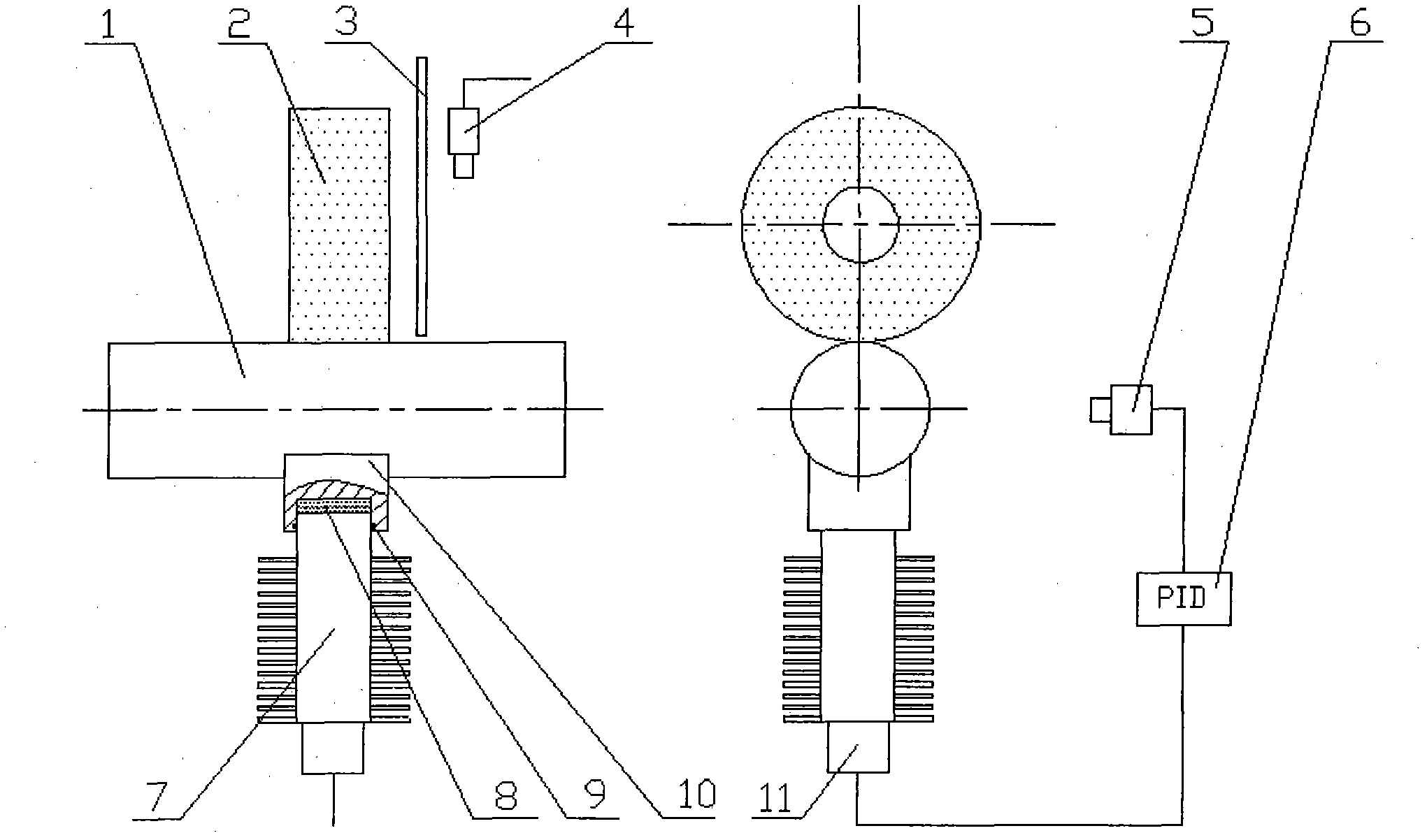

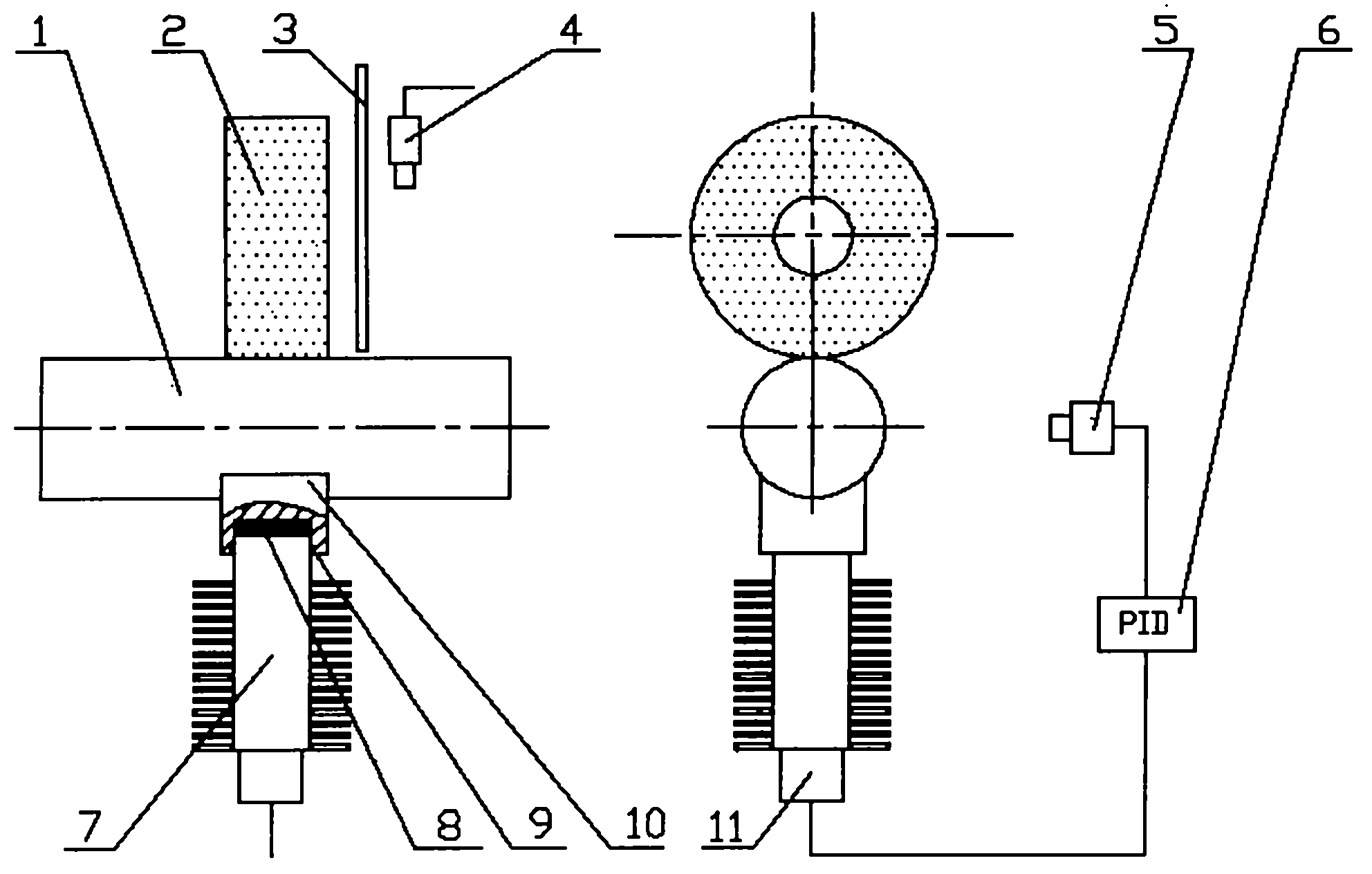

[0011] Such as figure 1 As shown, the external cylindrical grinding and hardening process is taken as an example. When rough grinding the external circle, the grinding wheel 2 uses suitable process parameters to grind the part 1 so that the surface temperature of the part 1 is near the upper limit of the quenching critical temperature range. A connecting block 10 is used on the outer circle surface of part 1 to tightly contact with part 1. The connecting surface on one side of the connecting block 10 is an arc surface with the same basic size as the outer circle diameter of part 1. The heat transfer end of the high temperature heat pipe 7 Then it forms a clearance fit contact with the hole on the other side of the connecting block 10, and a certain amount of thermally conductive glue 8 is filled at the contact junction. A sealing ring 9 is used between the high temperature heat pipe 7 and the connecting block 10 to prevent the thermally conductive glue 8 from extruding from the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com