Patents

Literature

41results about "Non-shielding electrode holders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

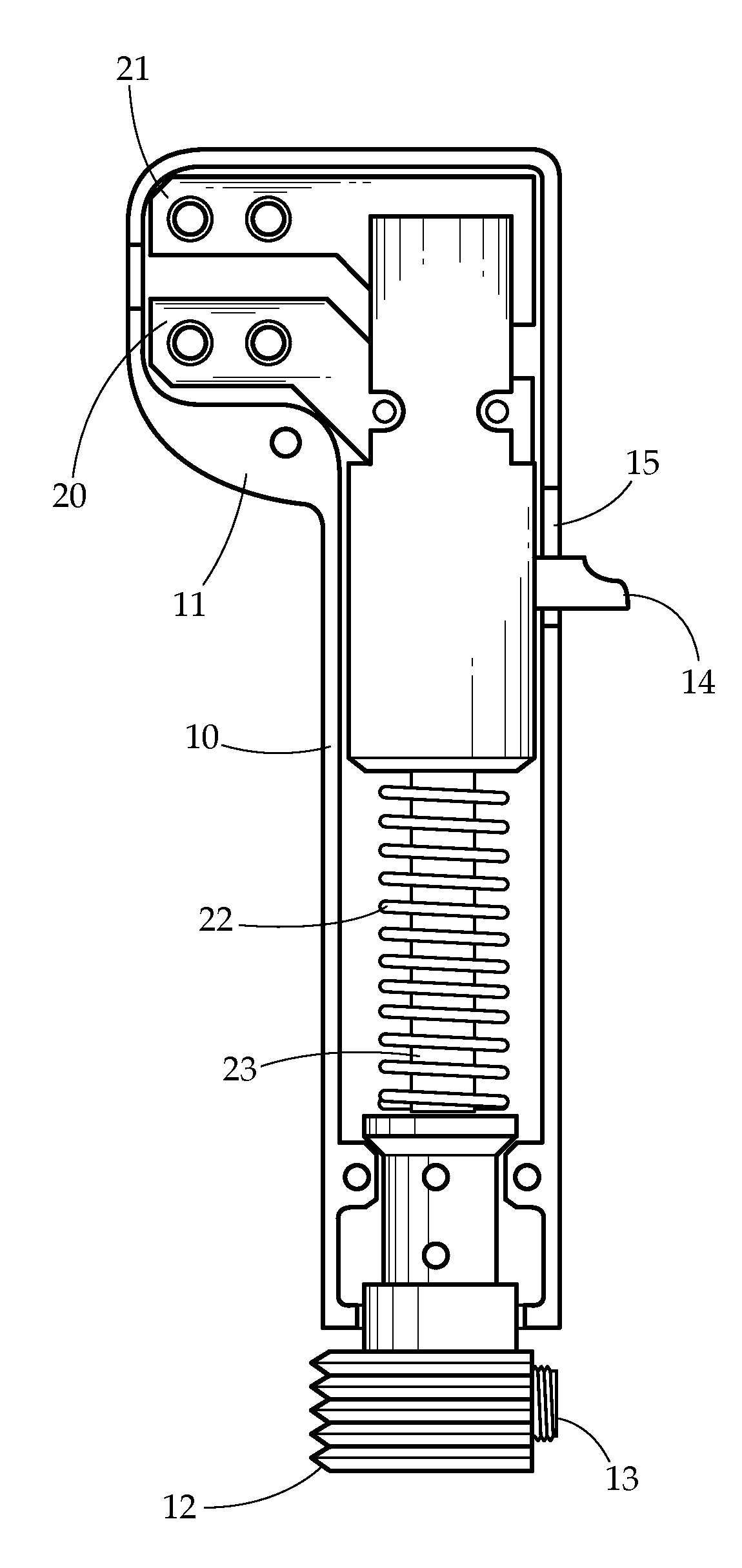

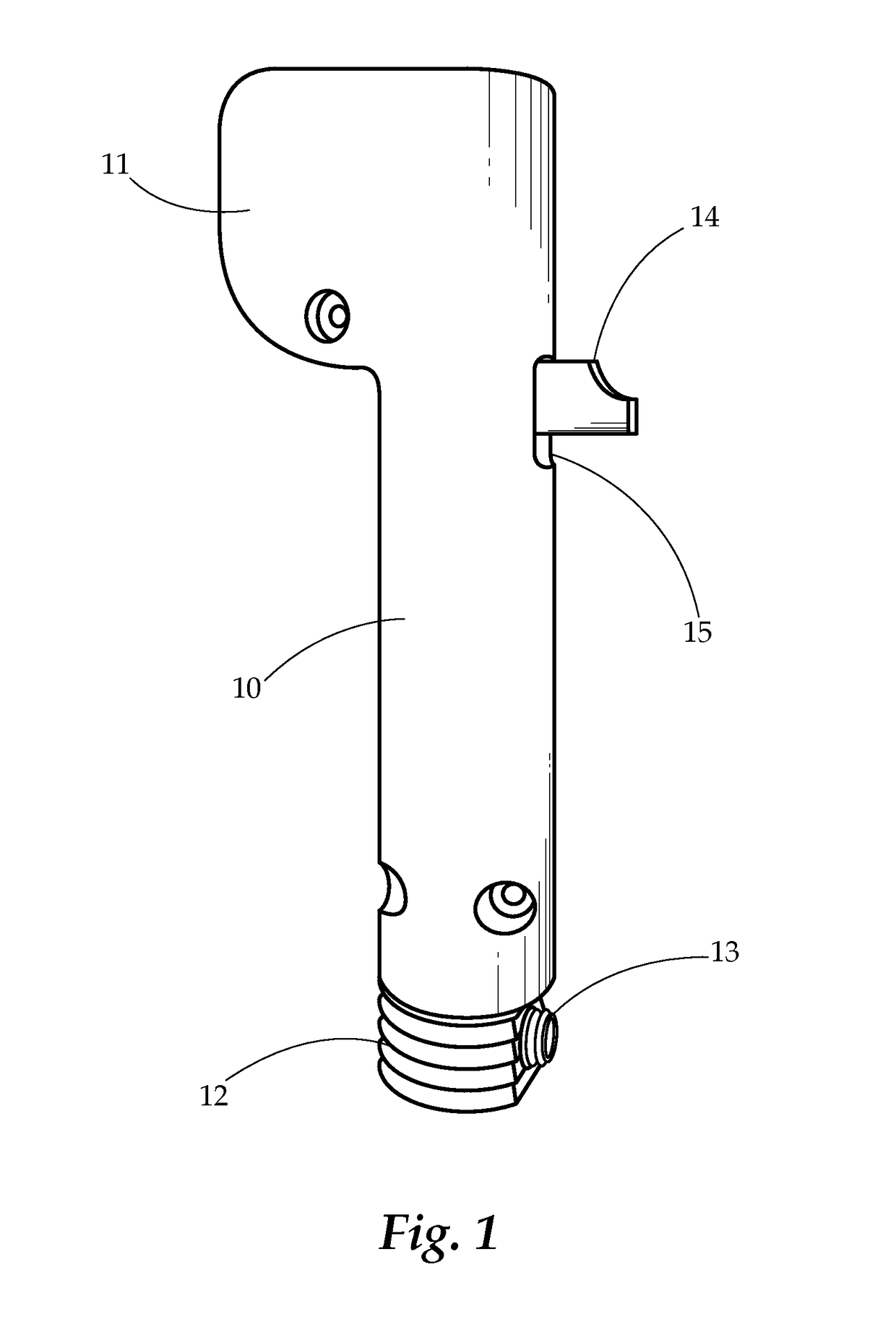

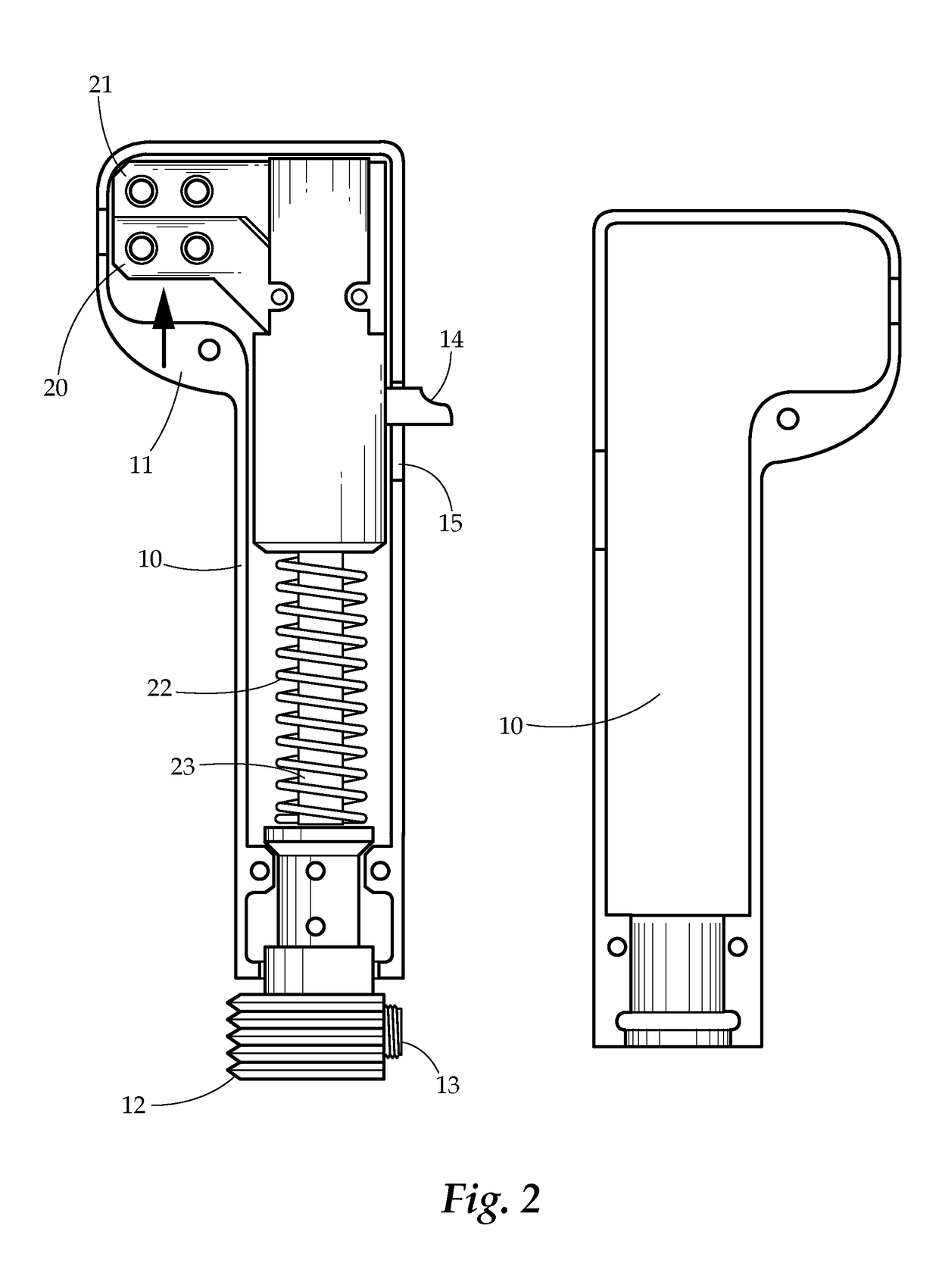

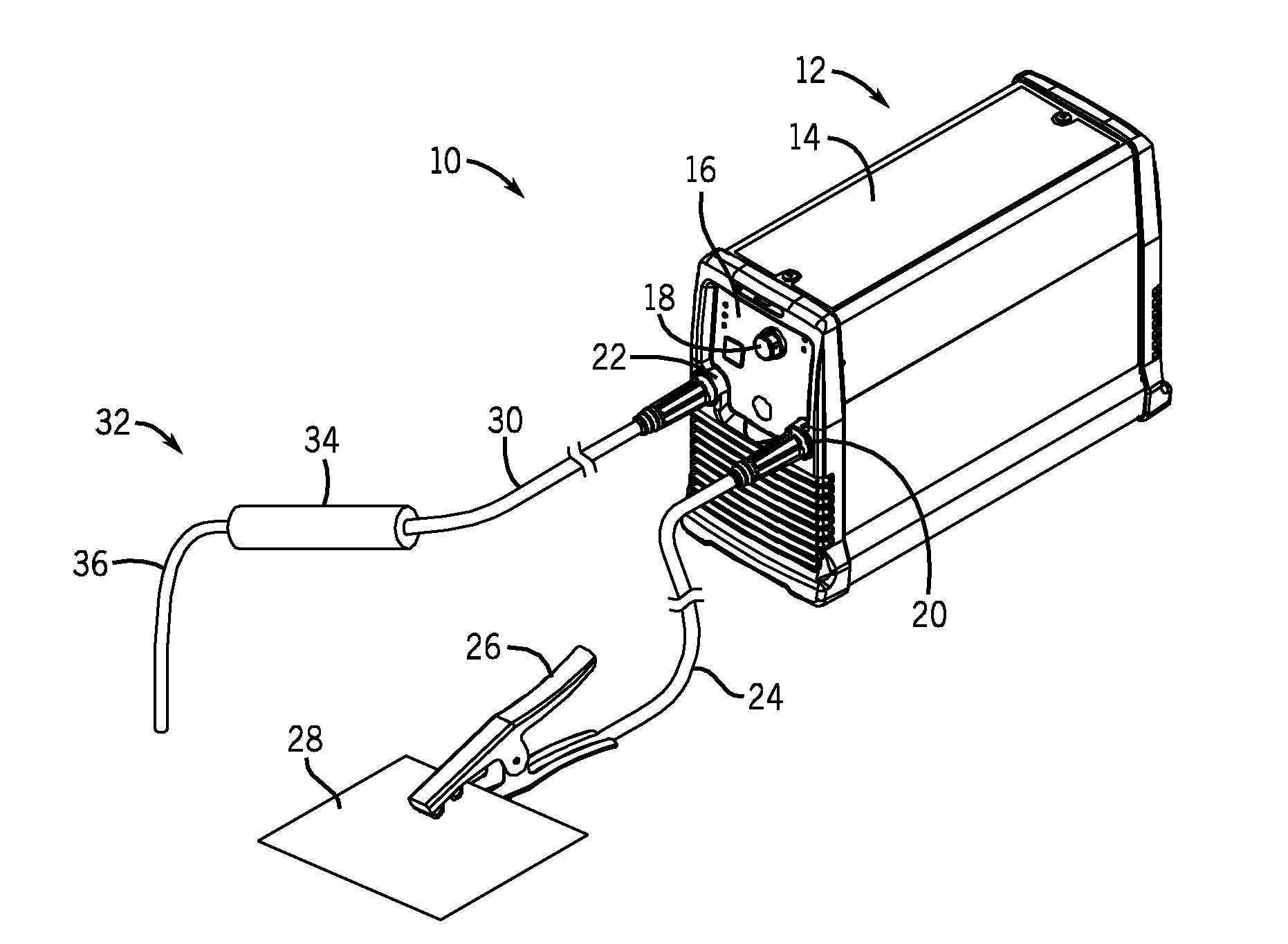

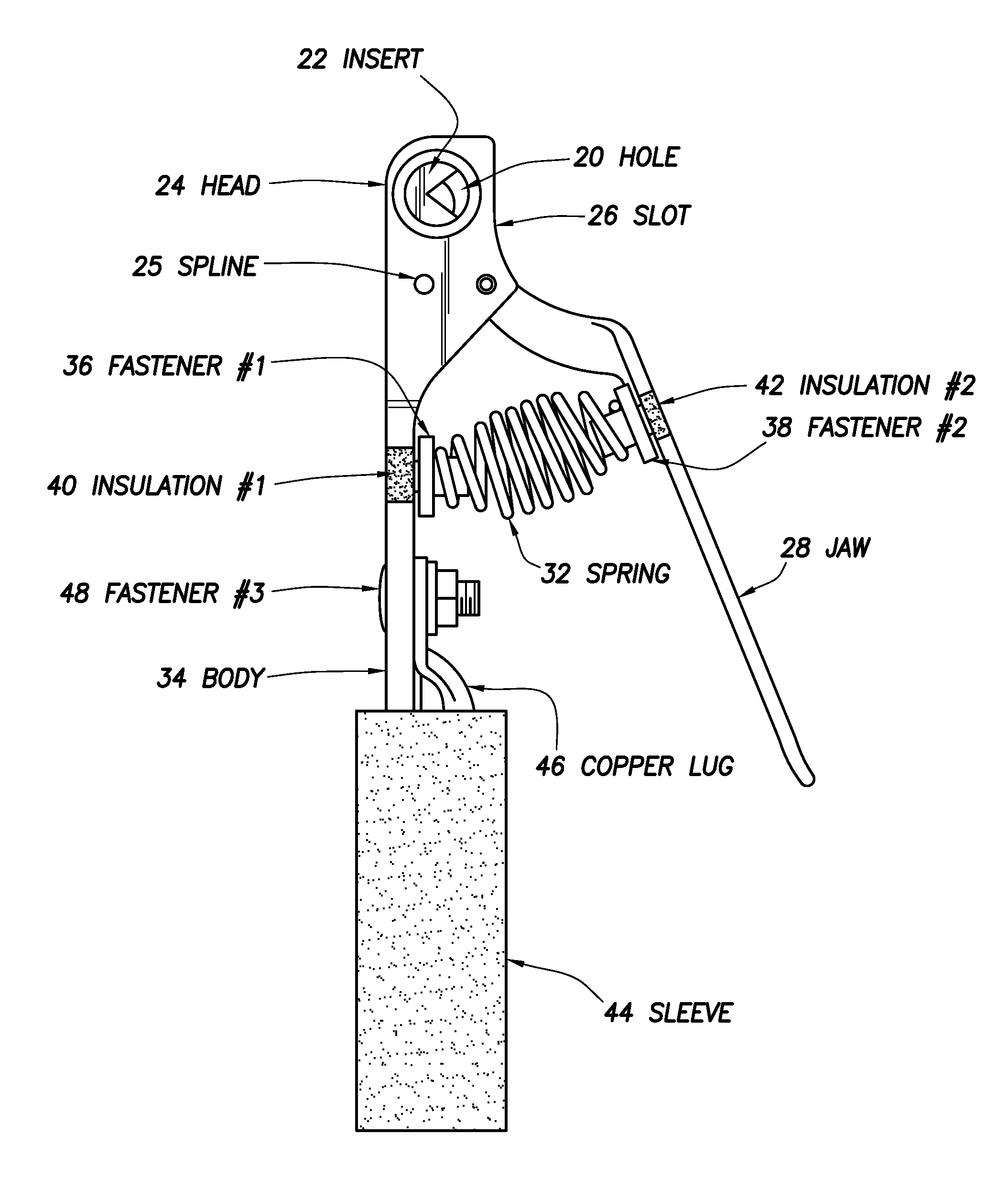

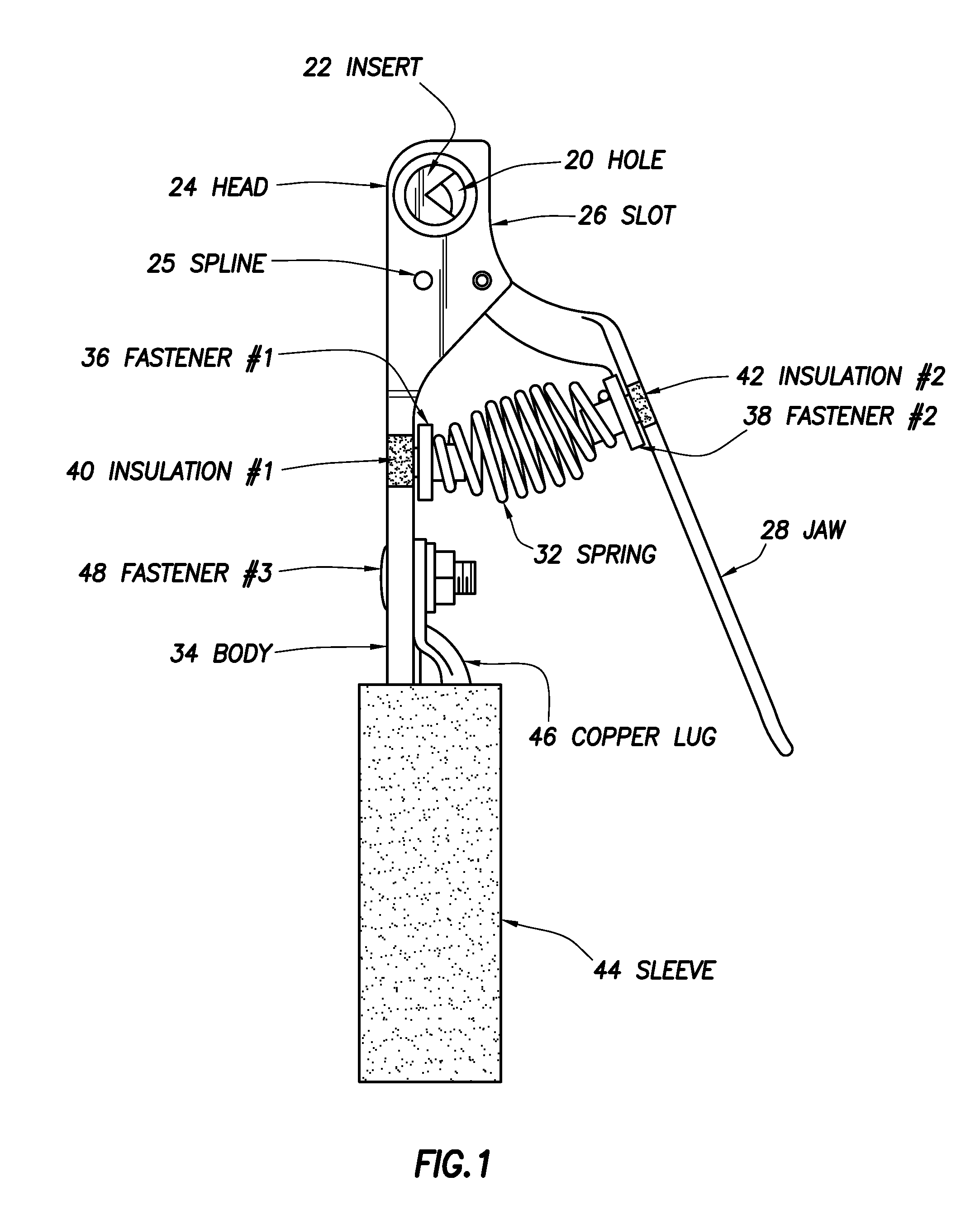

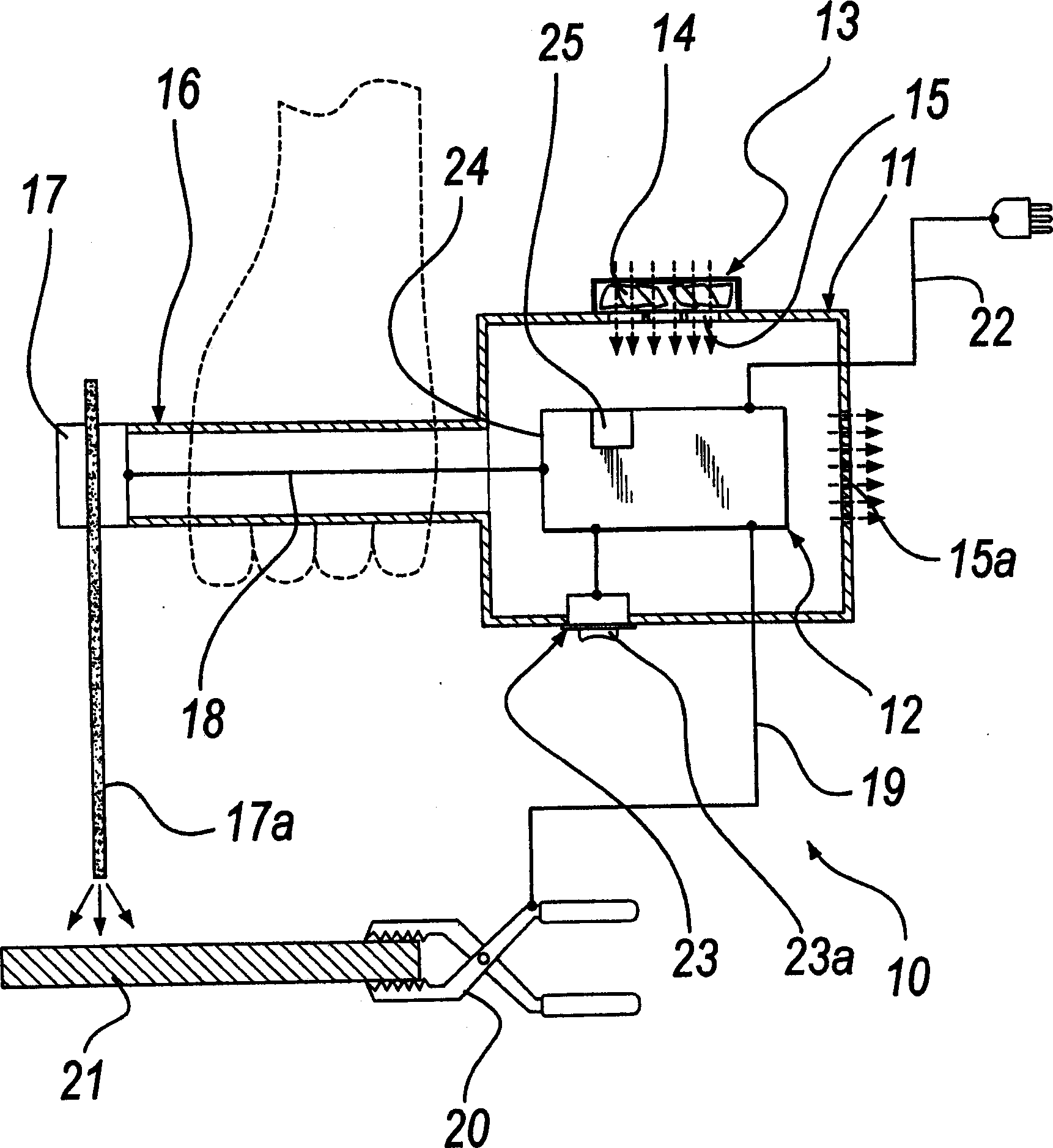

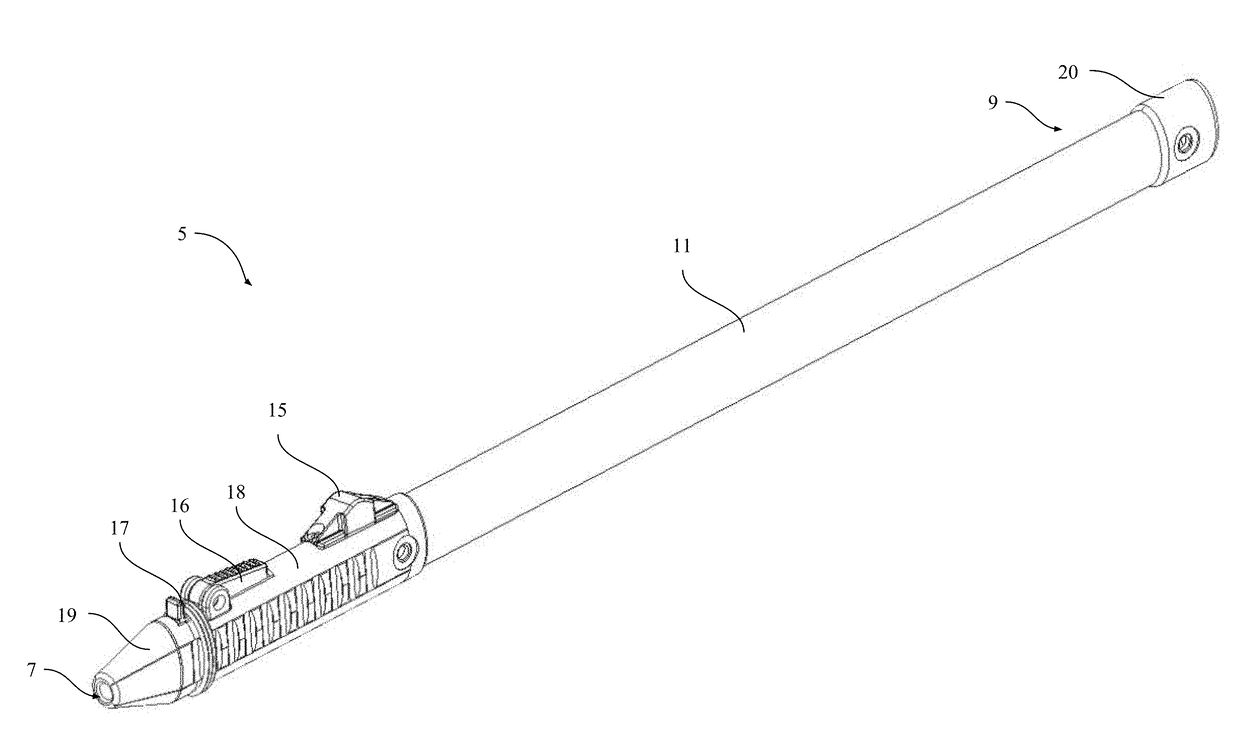

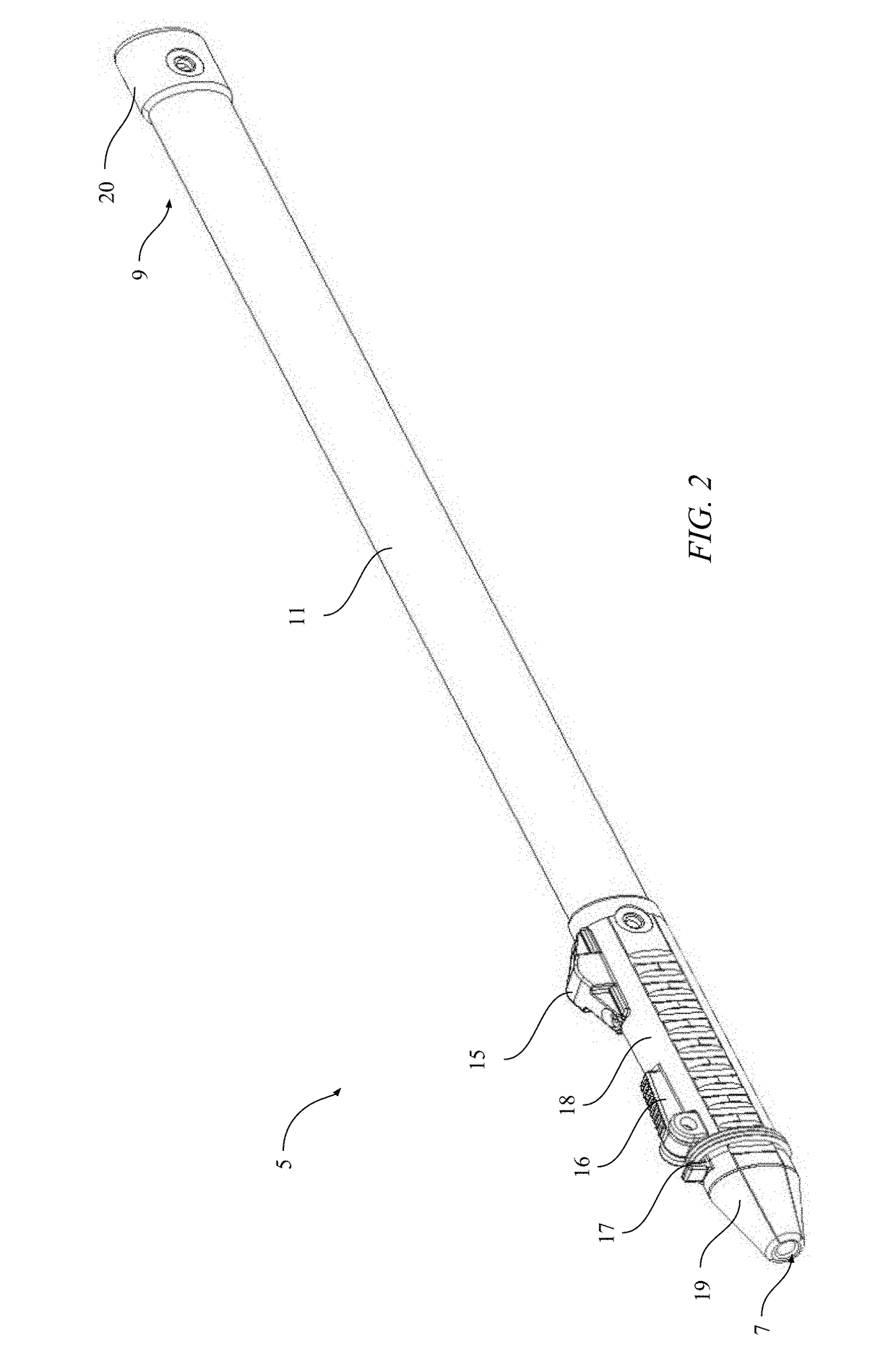

Electrode Holder with Automatic Power Cutoff

InactiveUS20140131337A1Avoiding accidental electrocutionMinimize shock hazardElectric discharge heatingNon-shielding electrode holdersElectricityElectrical and Electronics engineering

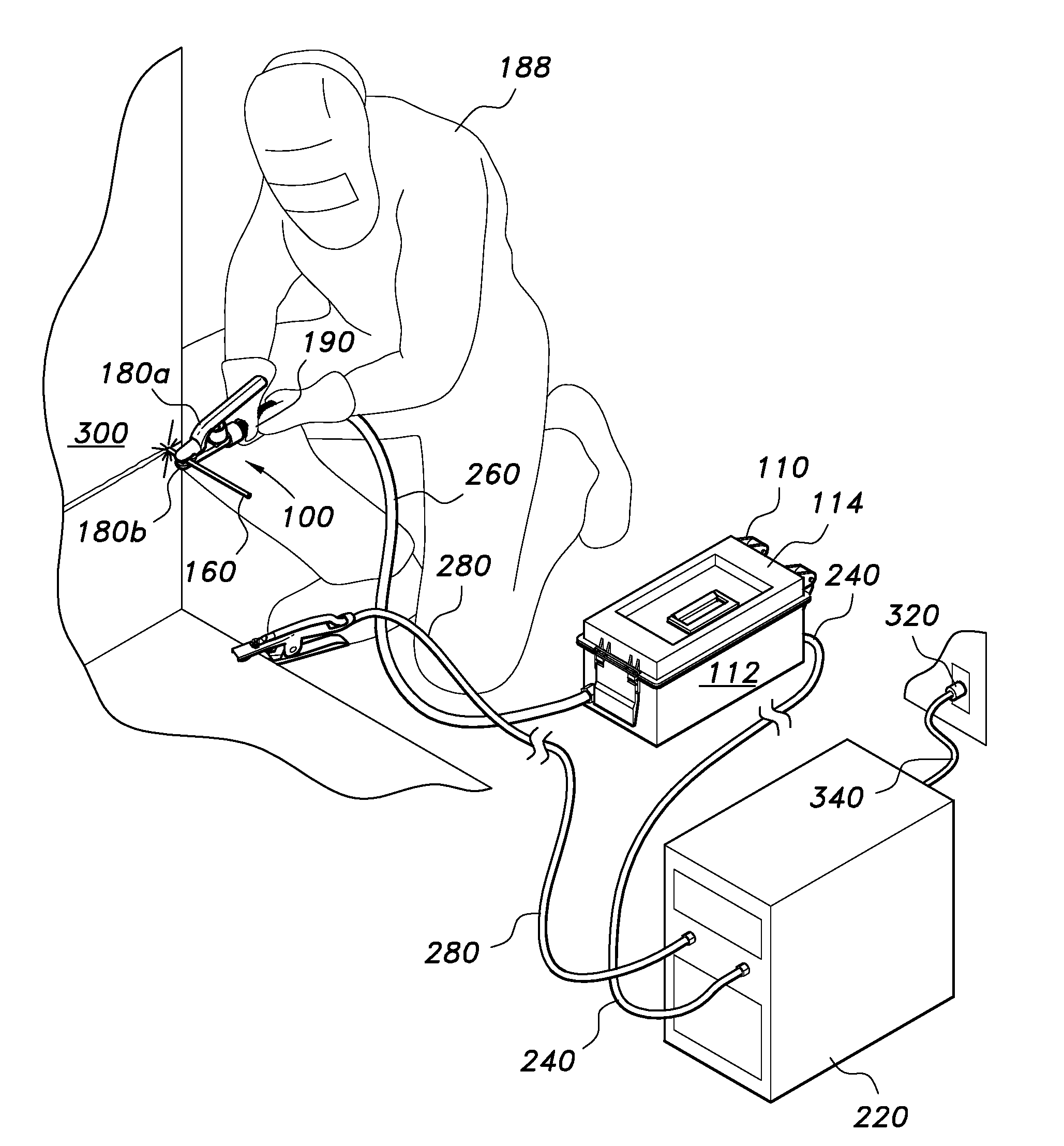

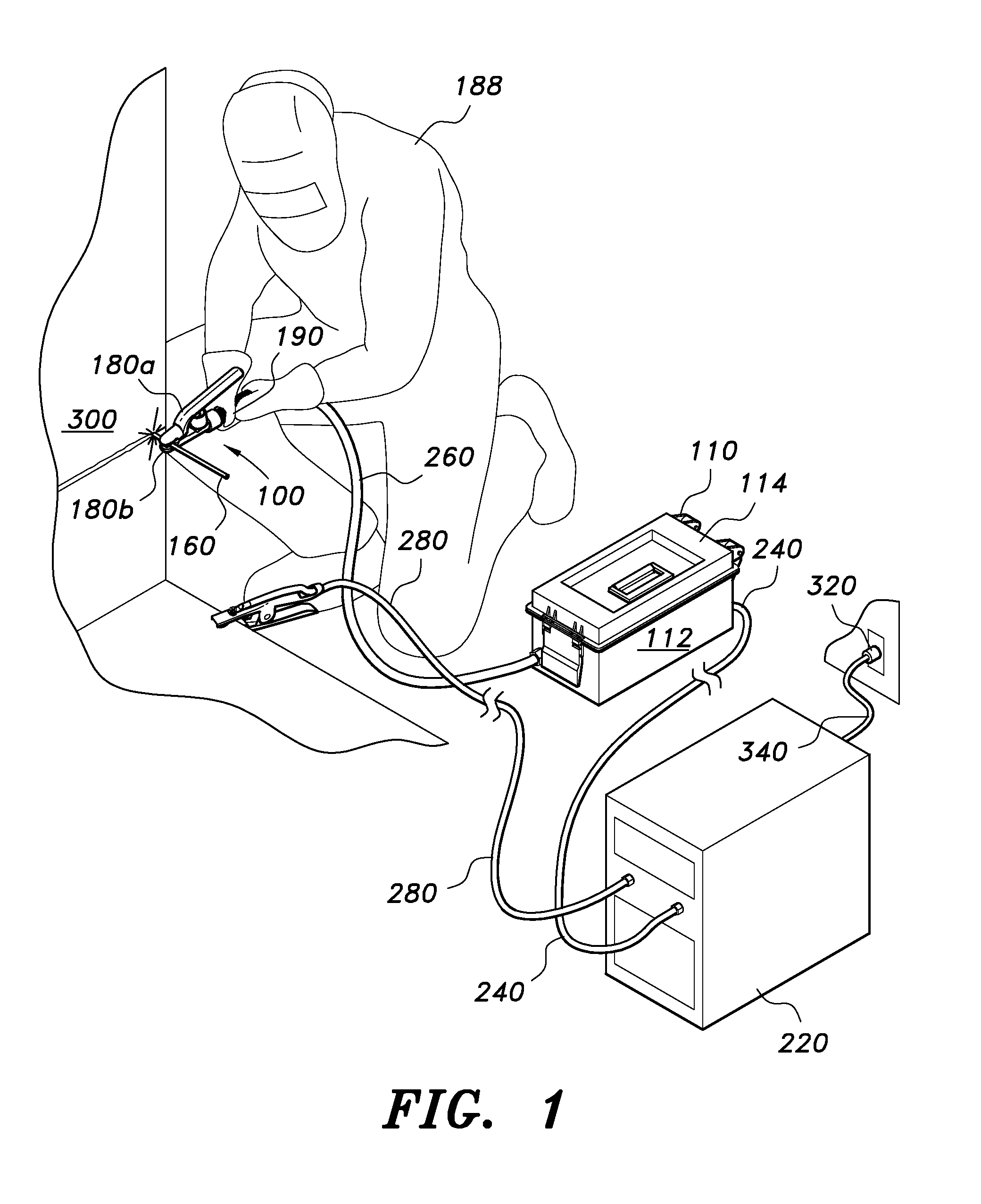

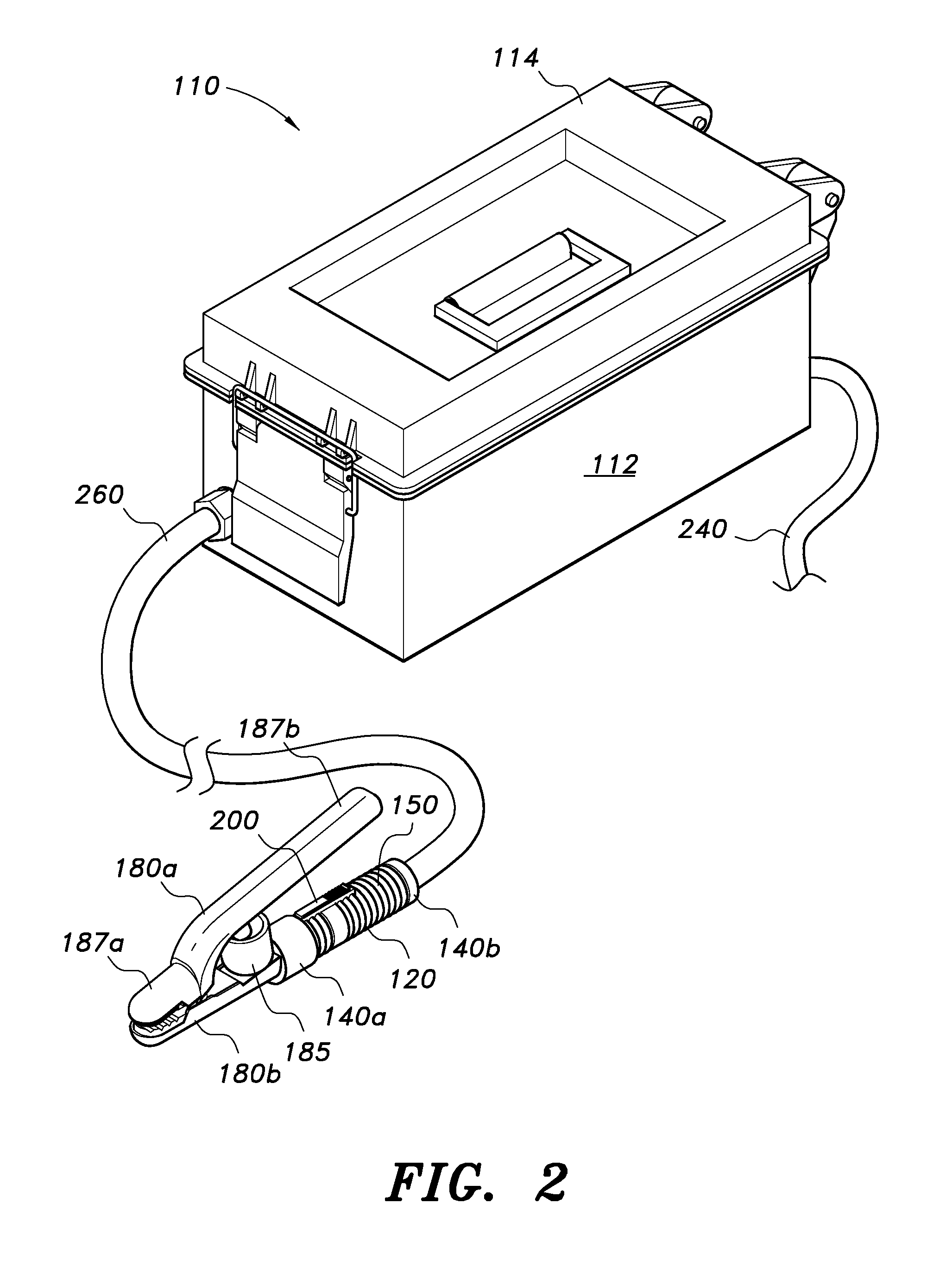

An electrode holder is provided for use in stick welding. The electrode holder comprises a handle, and an electrode gripping mechanism fitted to the first opposite end of the handle. The electrode gripping mechanism comprises upper and lower jaw members. The upper jaw member extends above the handle for a distance from one end of the handle. In one non-limiting embodiment a handle switch is located on the handle and below the upper jaw member. The handle switch is in operable communication with a power shutoff located between the electrode holder and a power supply. The location of the handle switch obviates the need for conscious effort on the part of a user to electrically isolate the electrode holder when changing an electrode.

Owner:WILLIAMS DONNY R

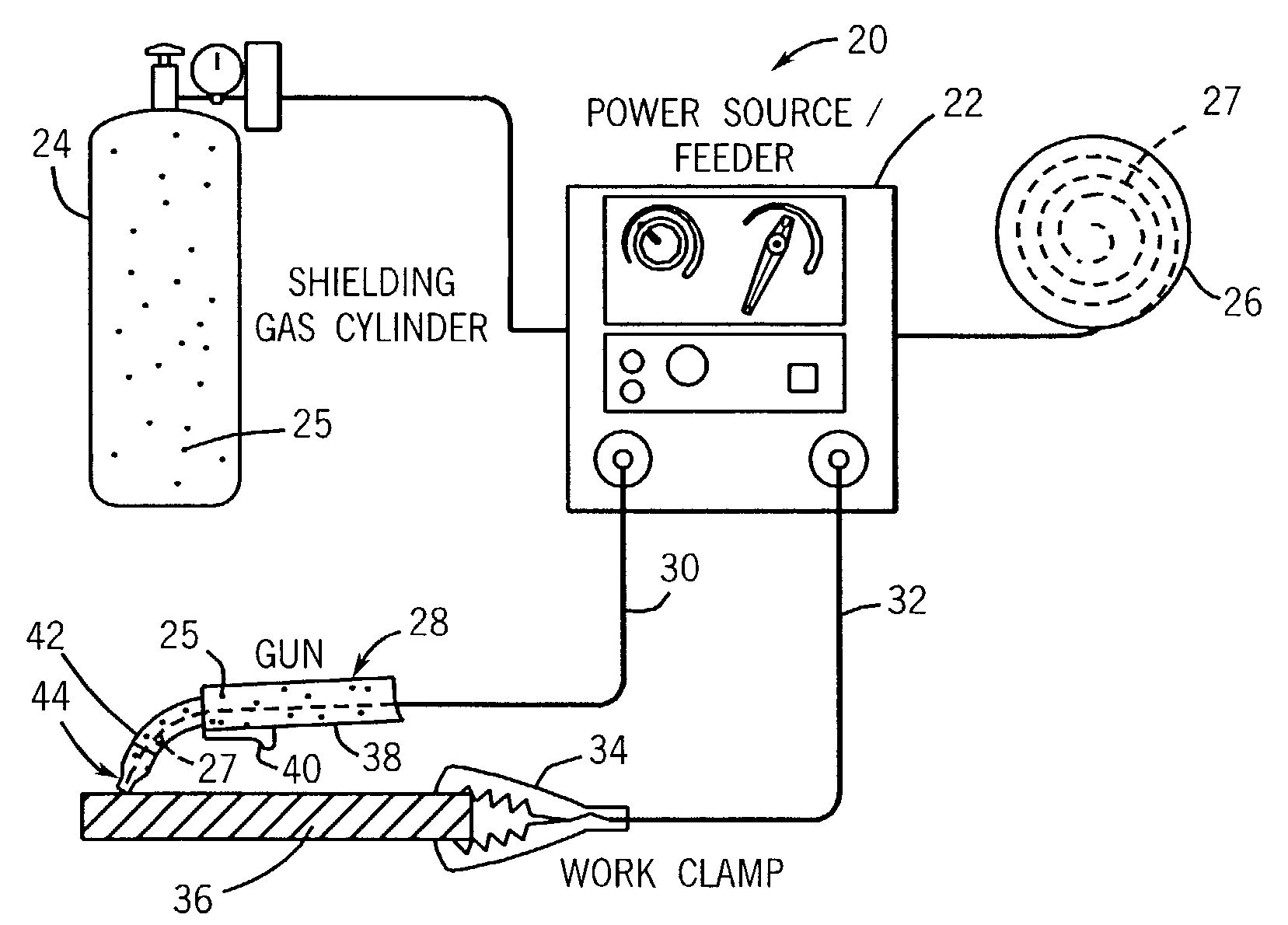

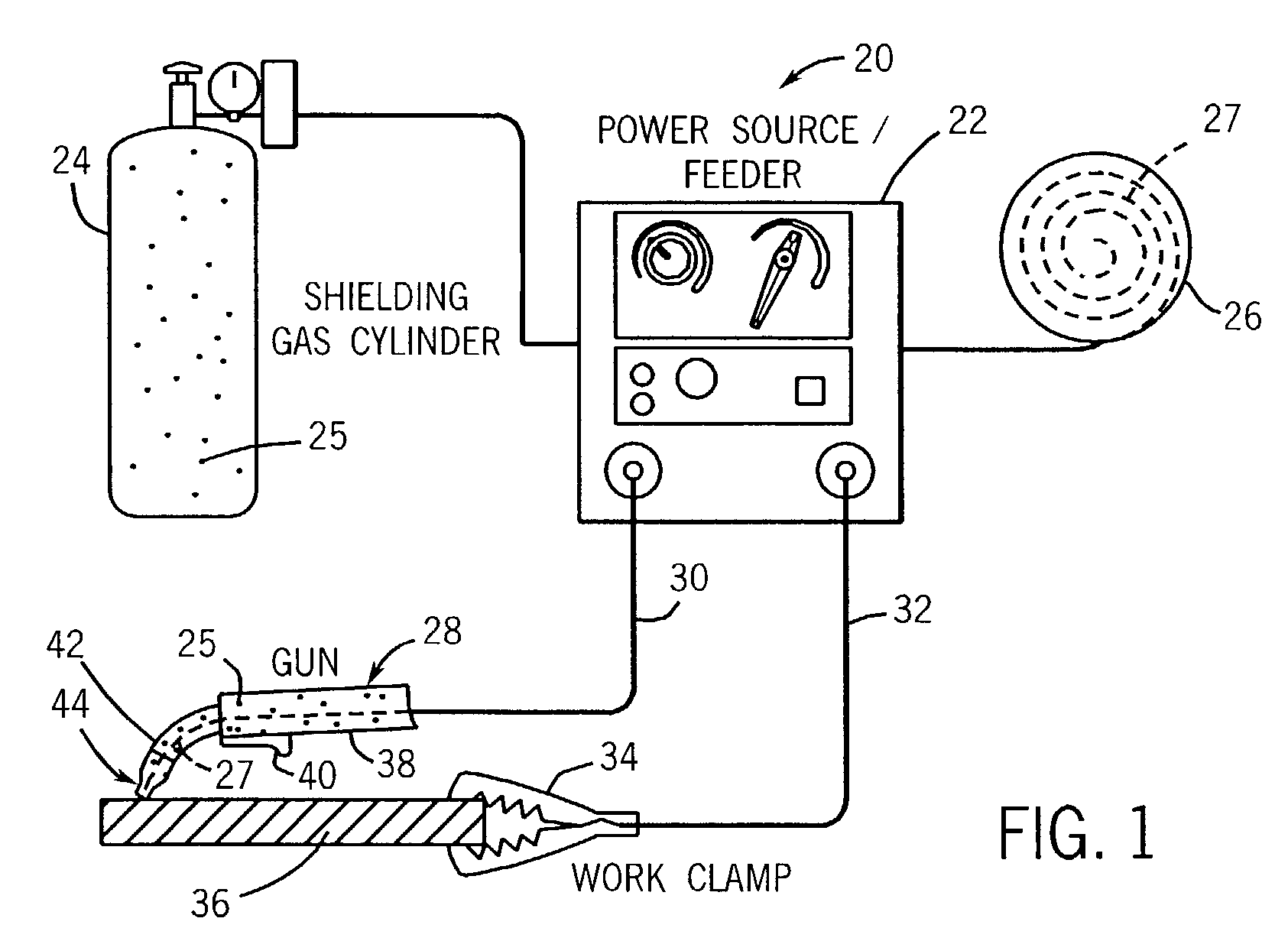

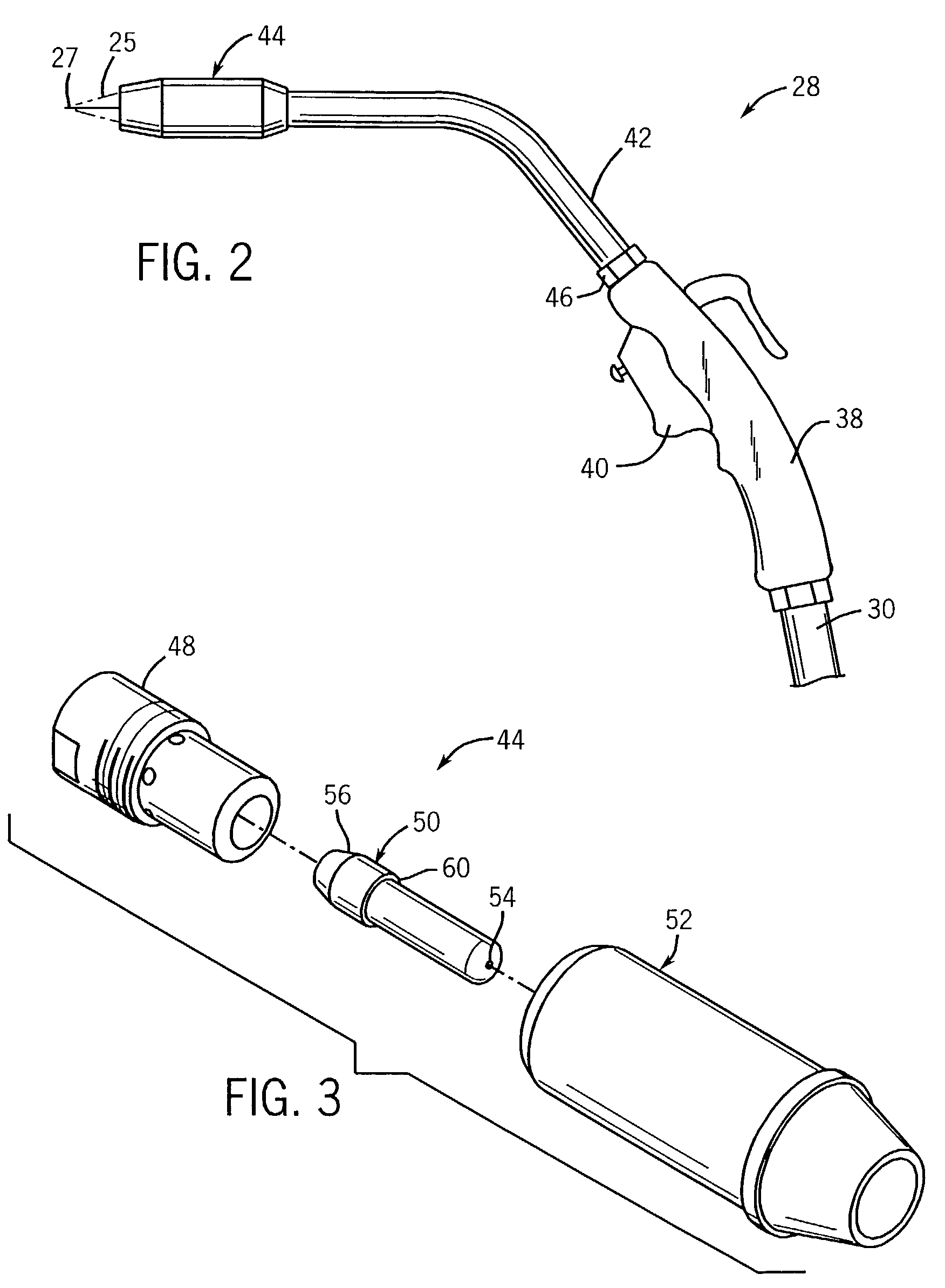

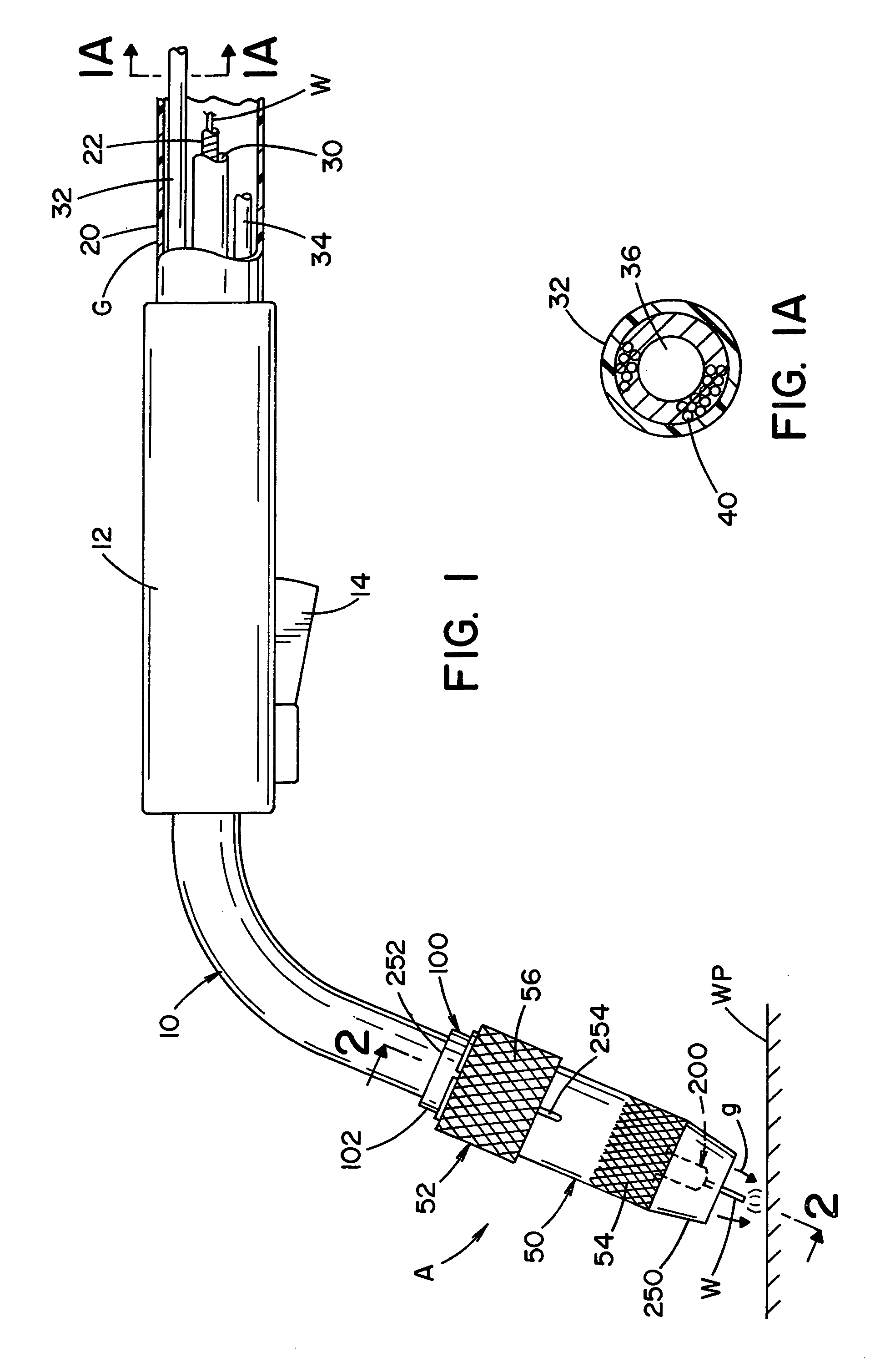

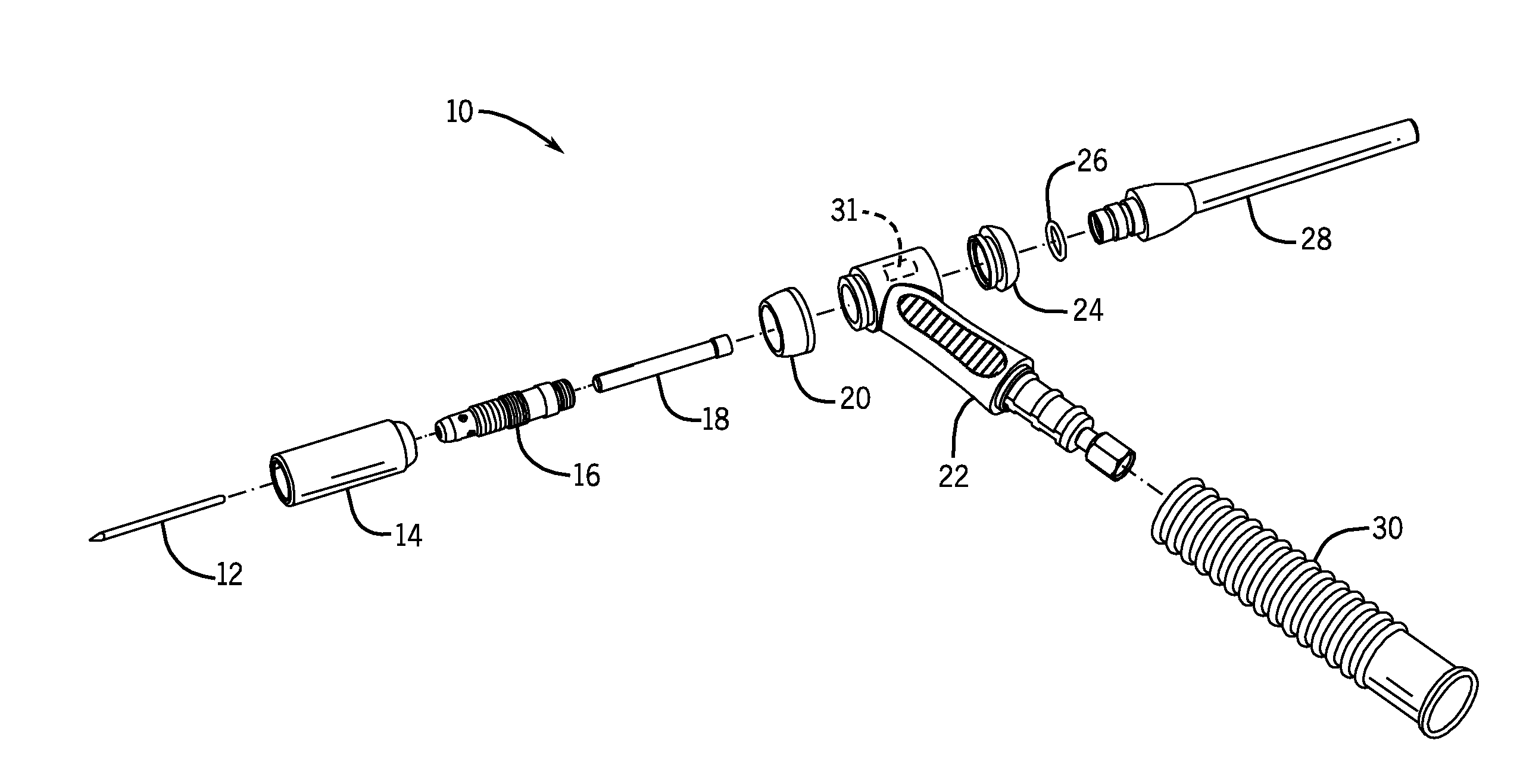

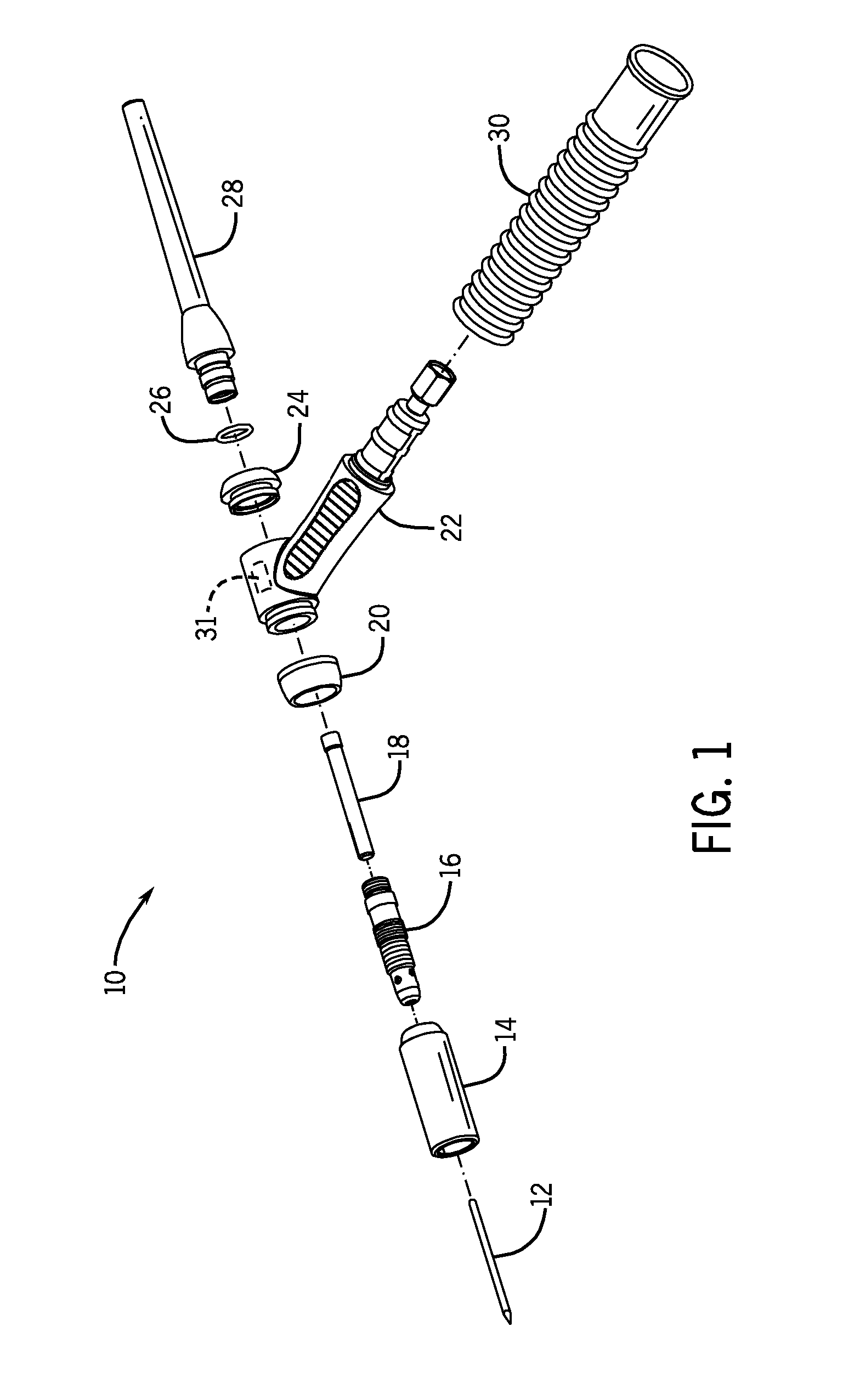

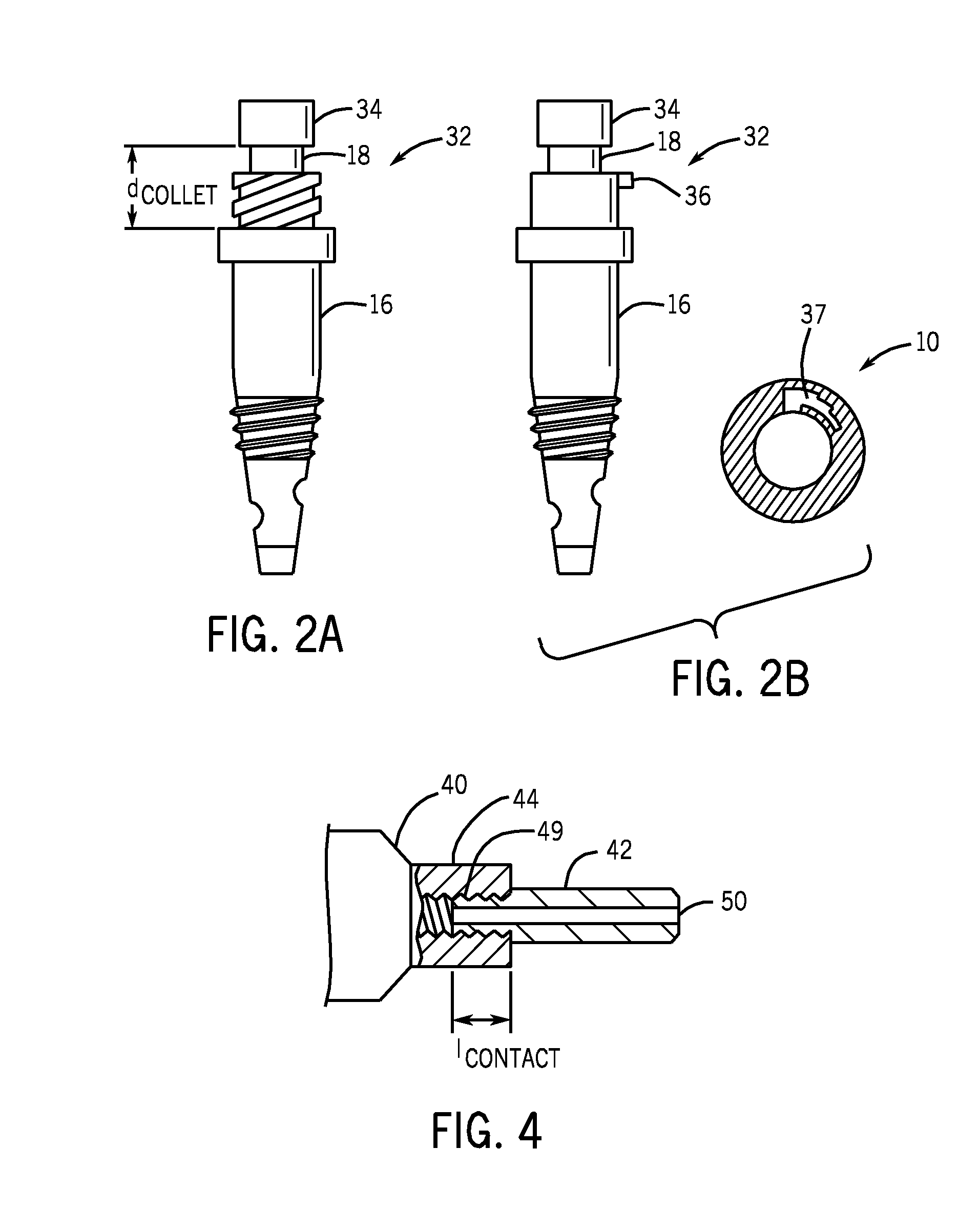

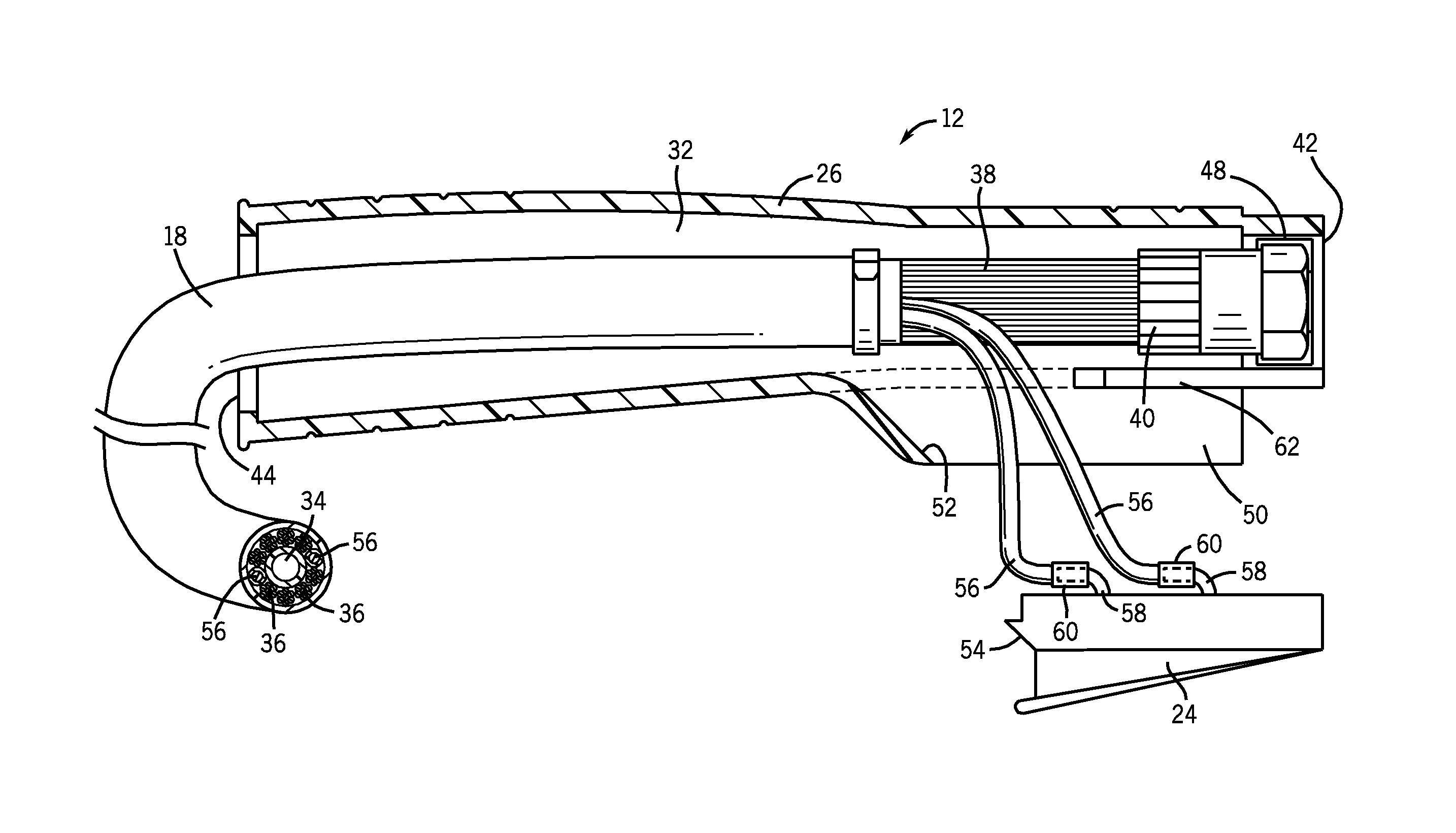

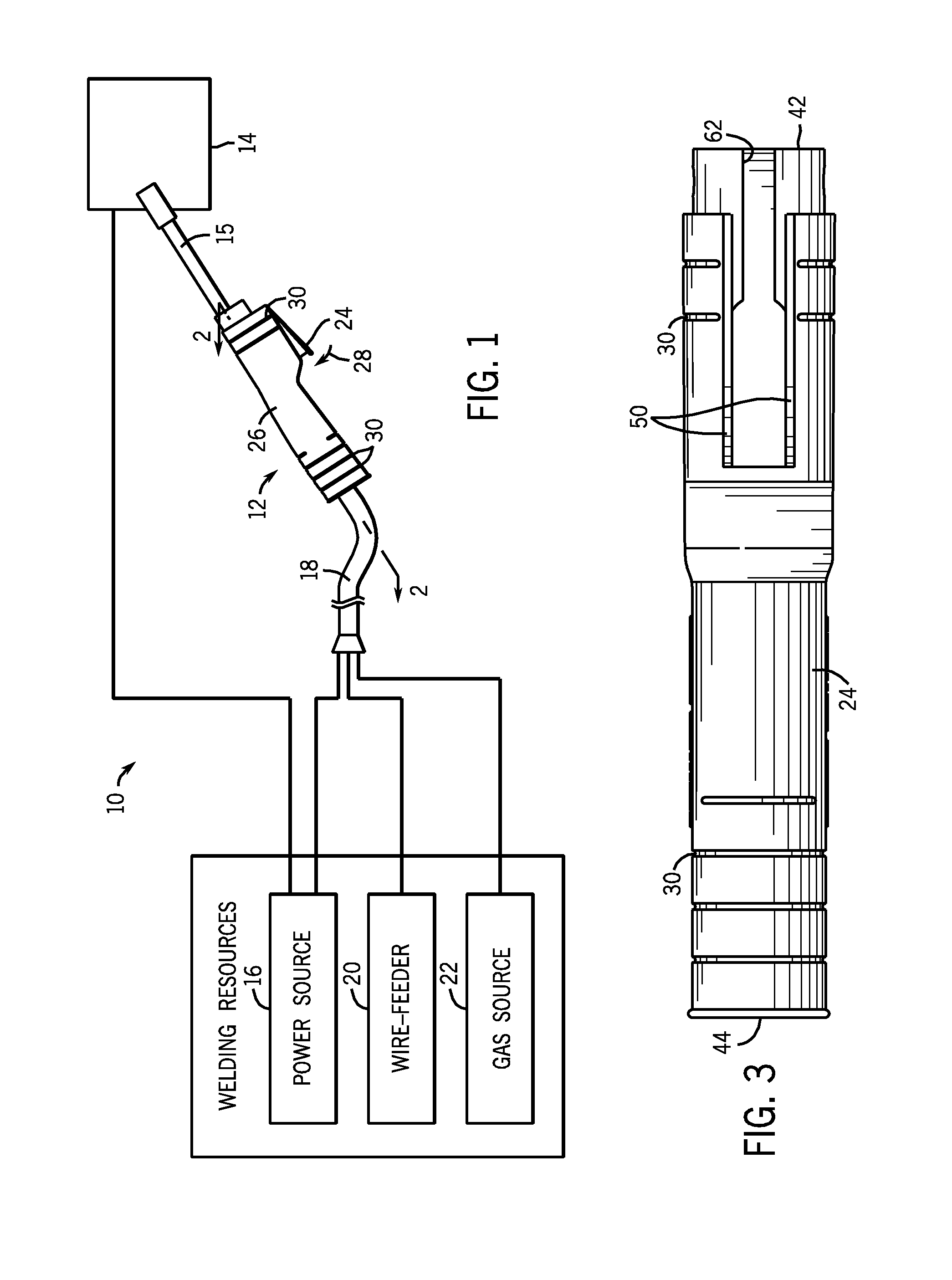

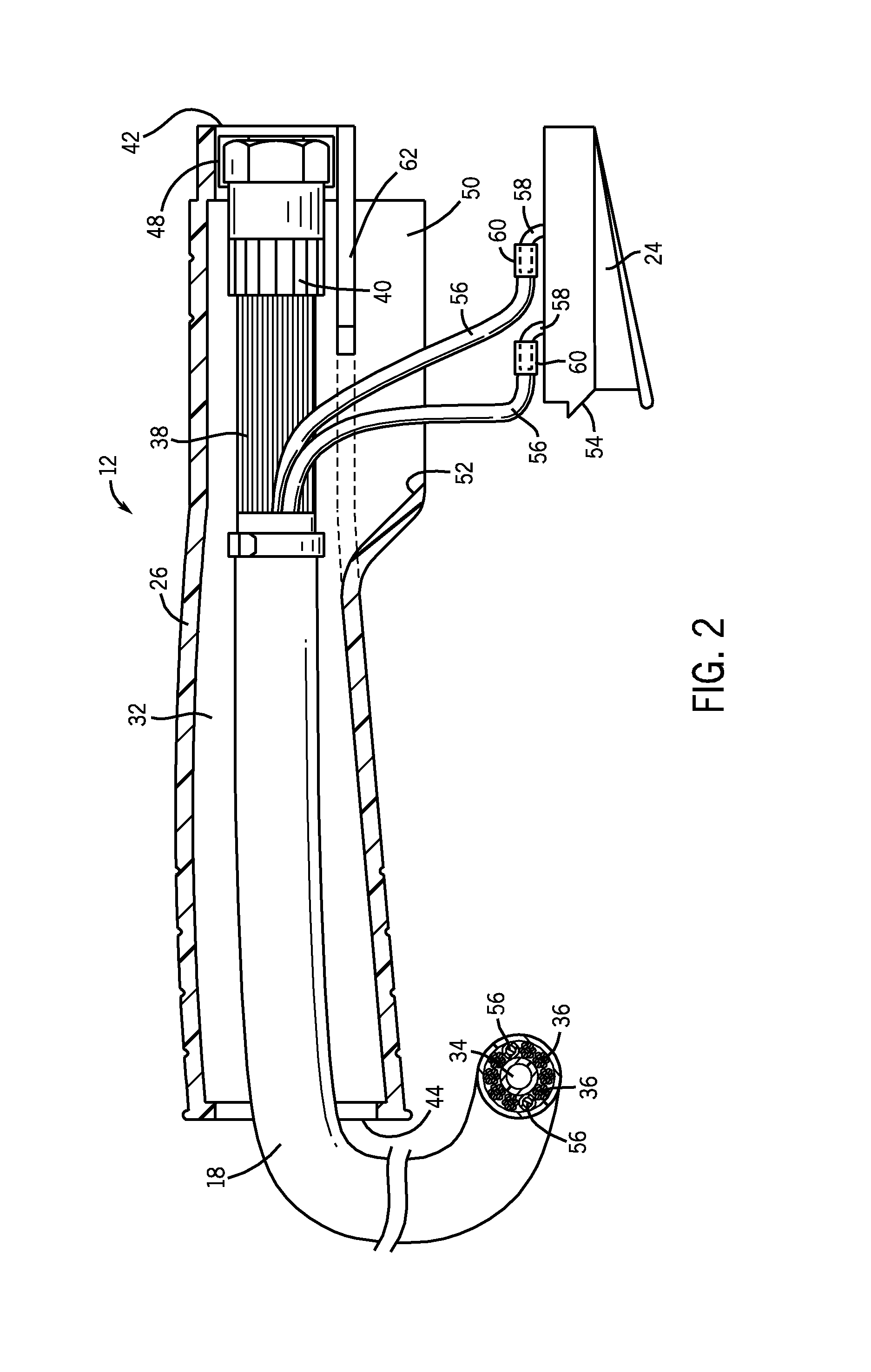

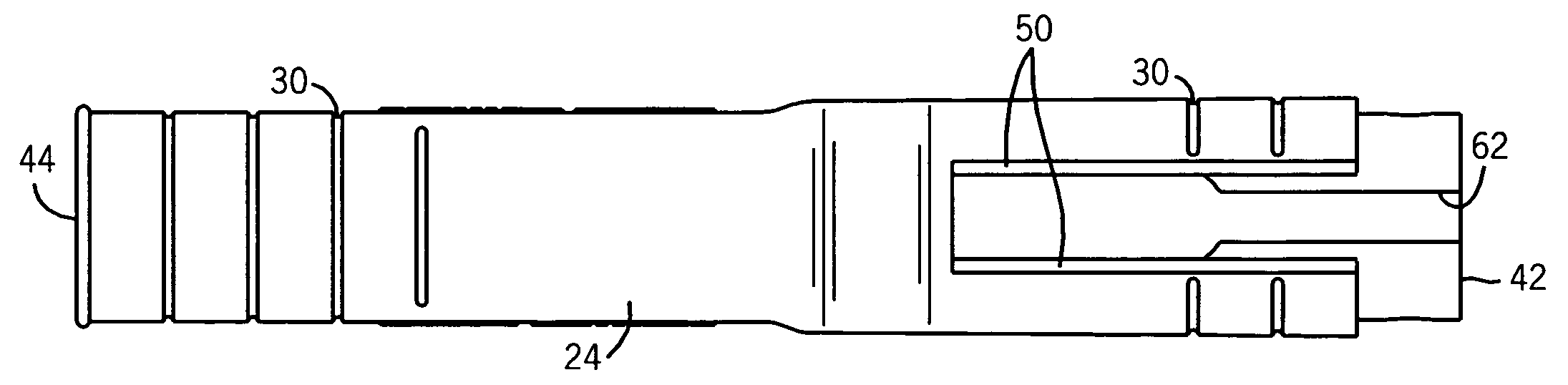

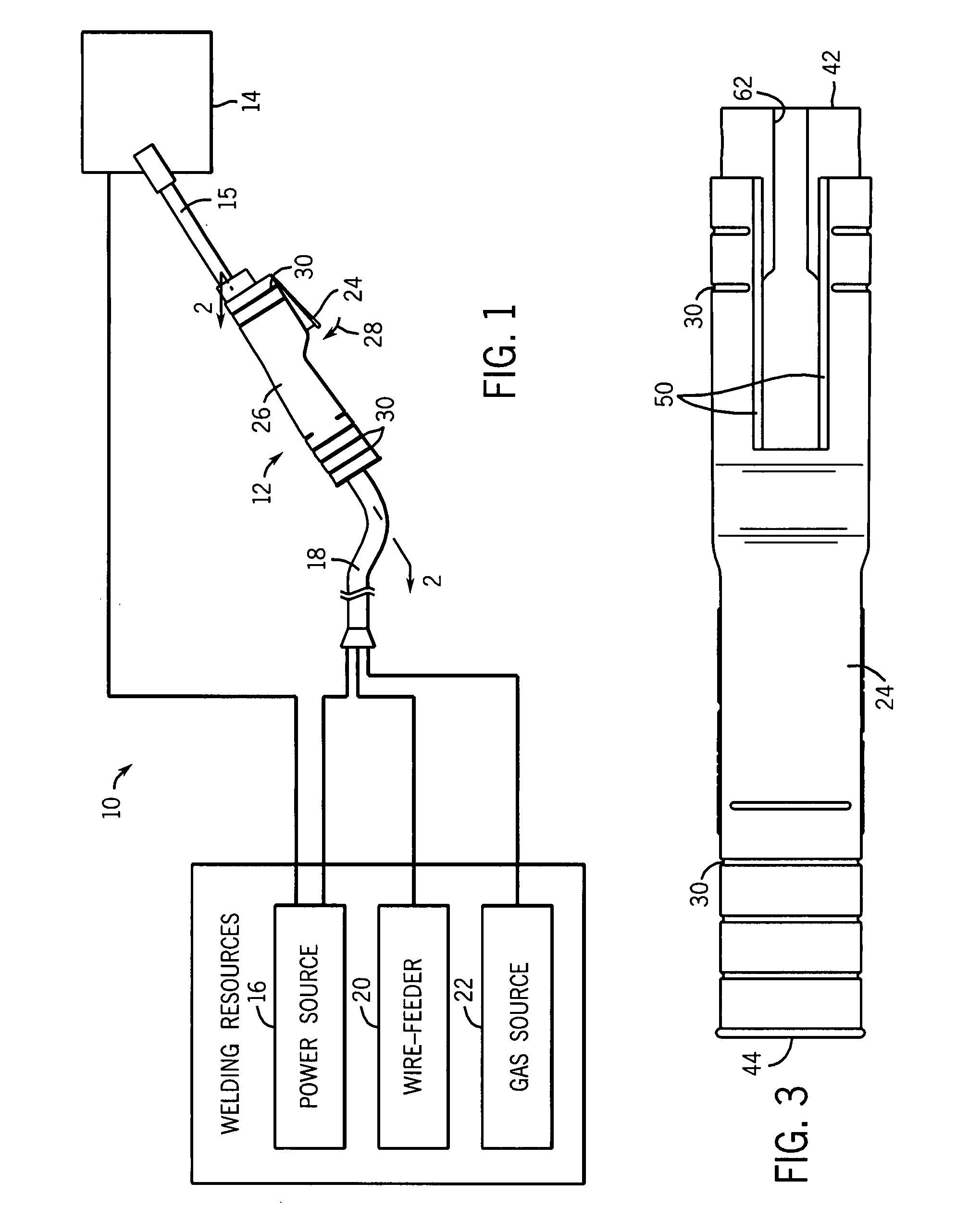

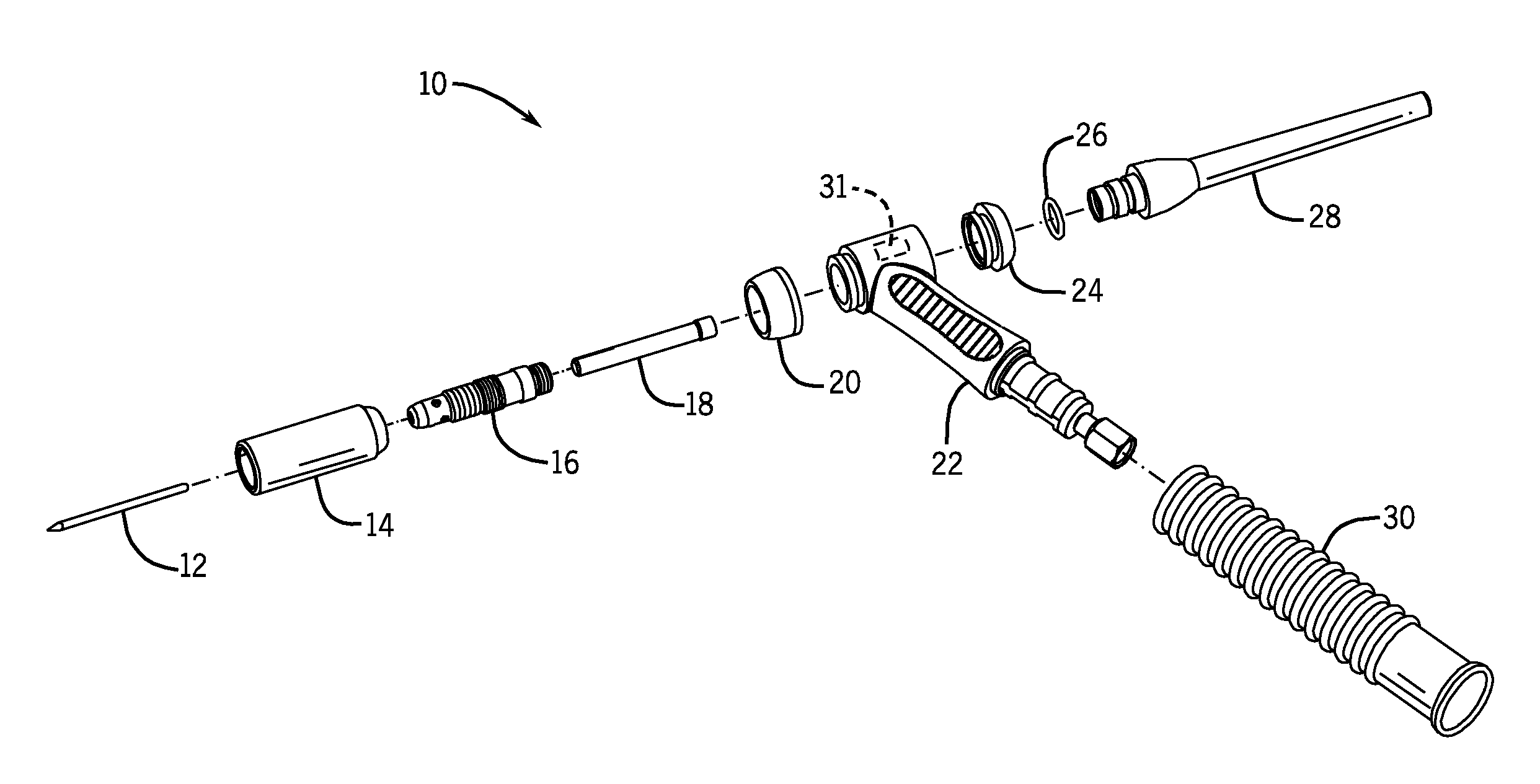

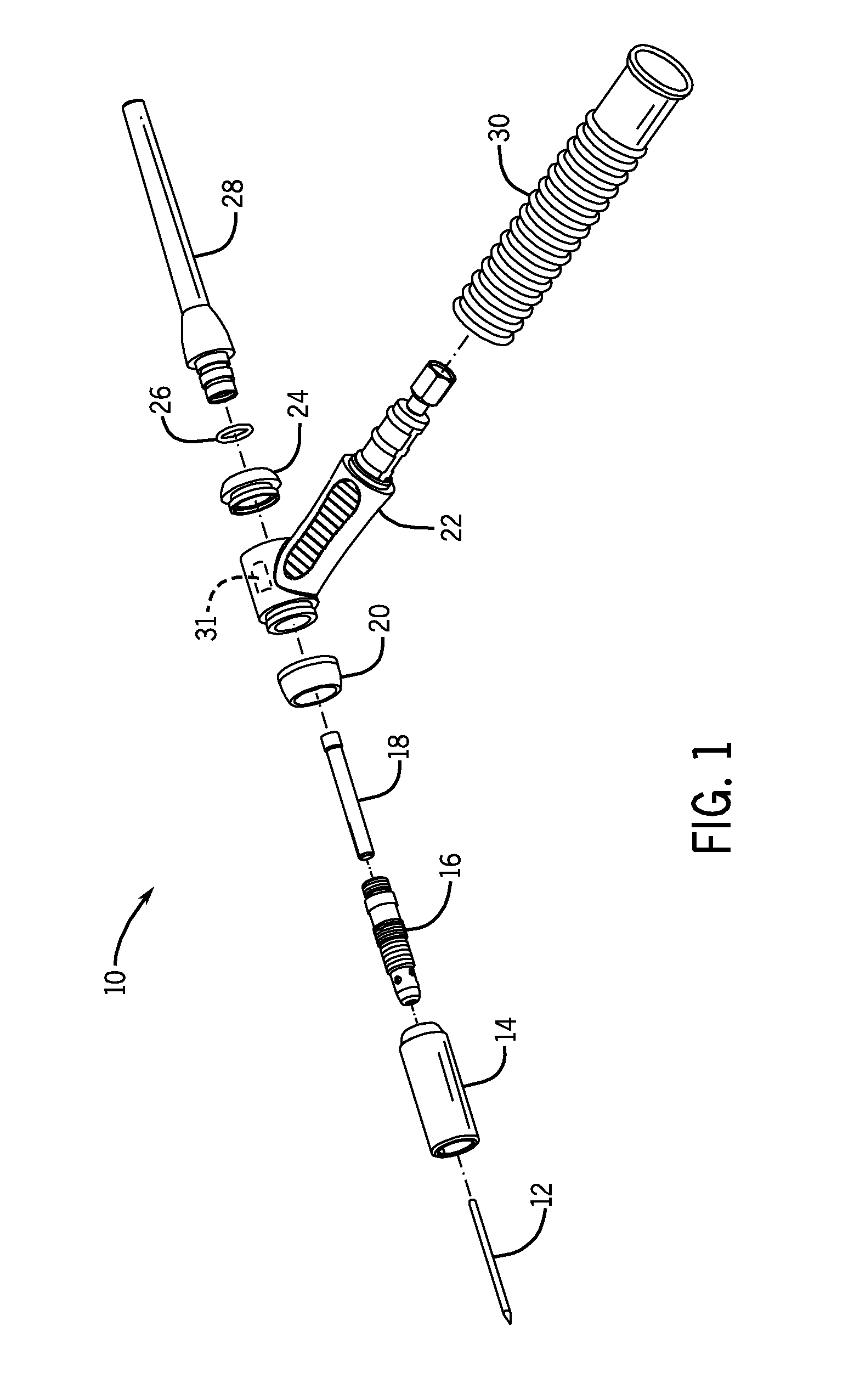

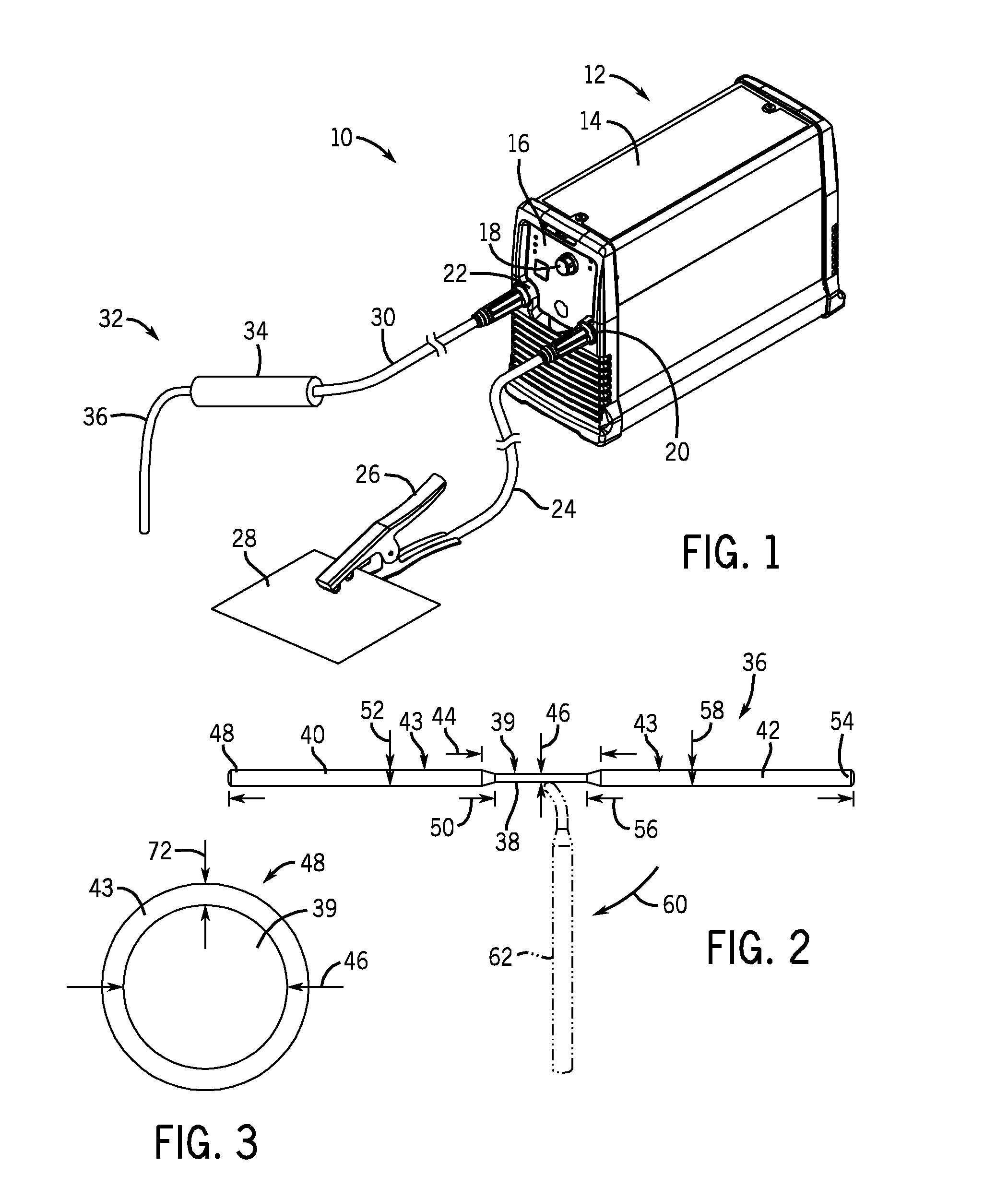

Welding gun having contact tip and method of operating same

InactiveUS7105775B2Support devices with shieldingNon-shielding electrode holdersAbutmentBiomedical engineering

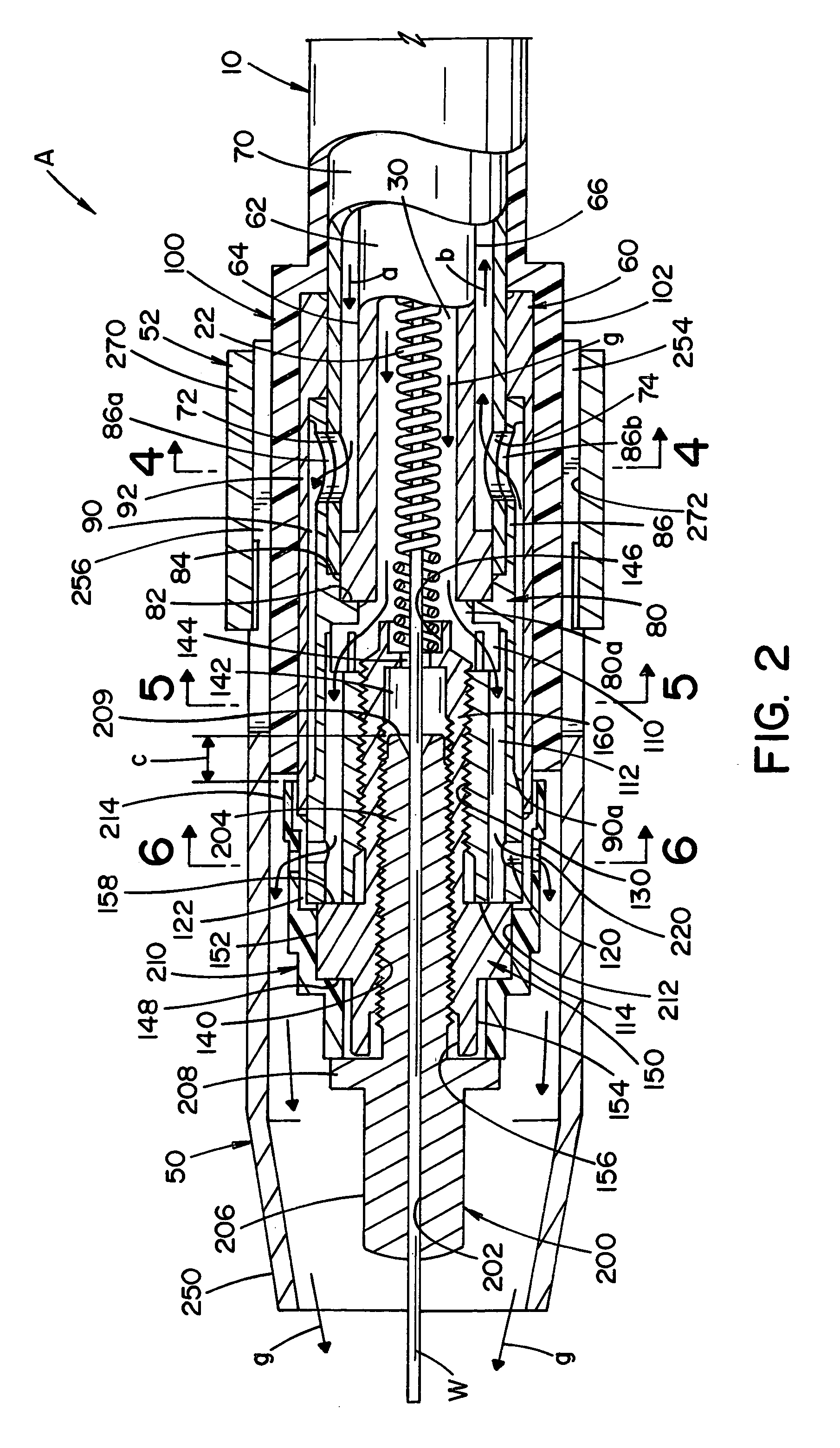

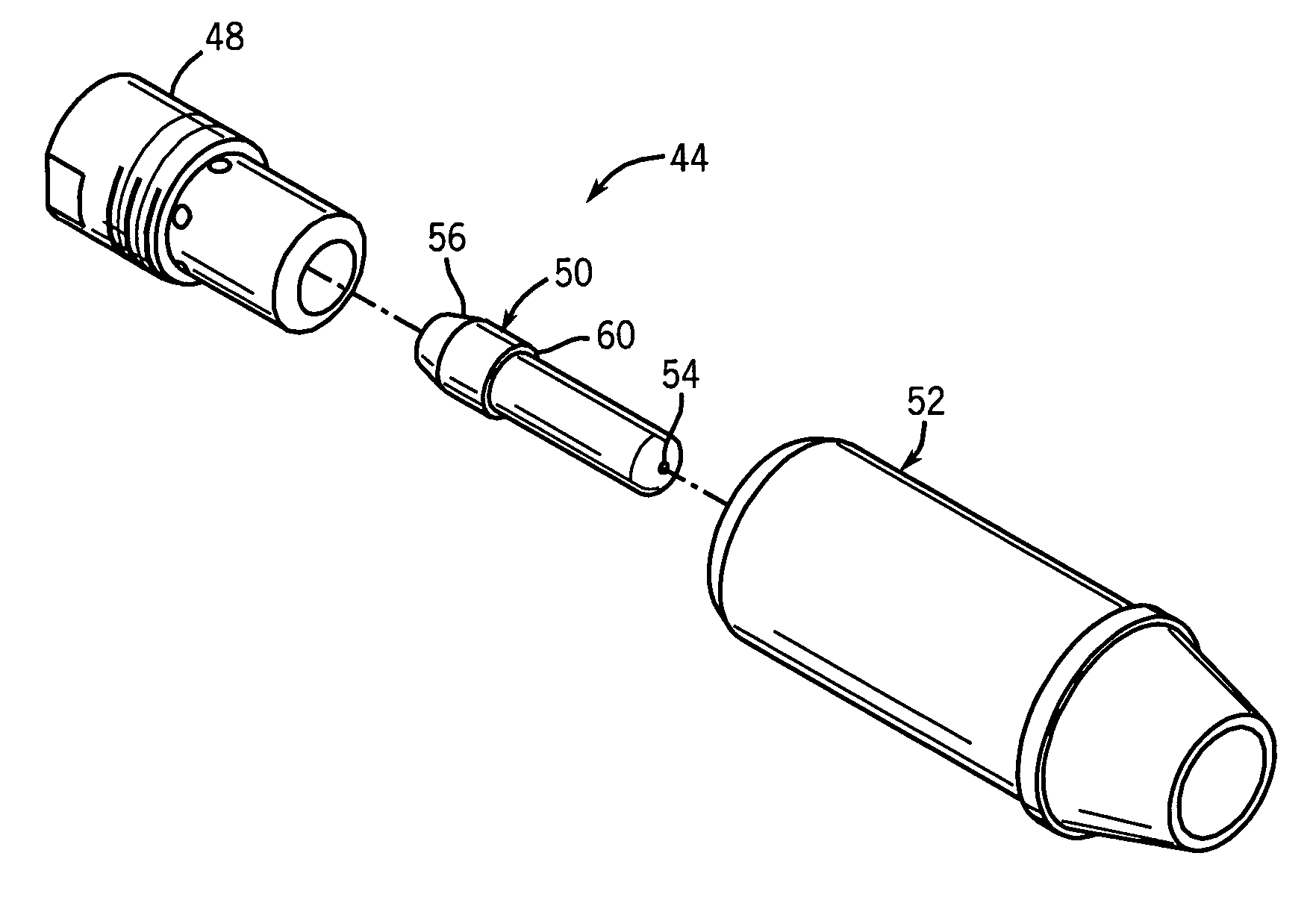

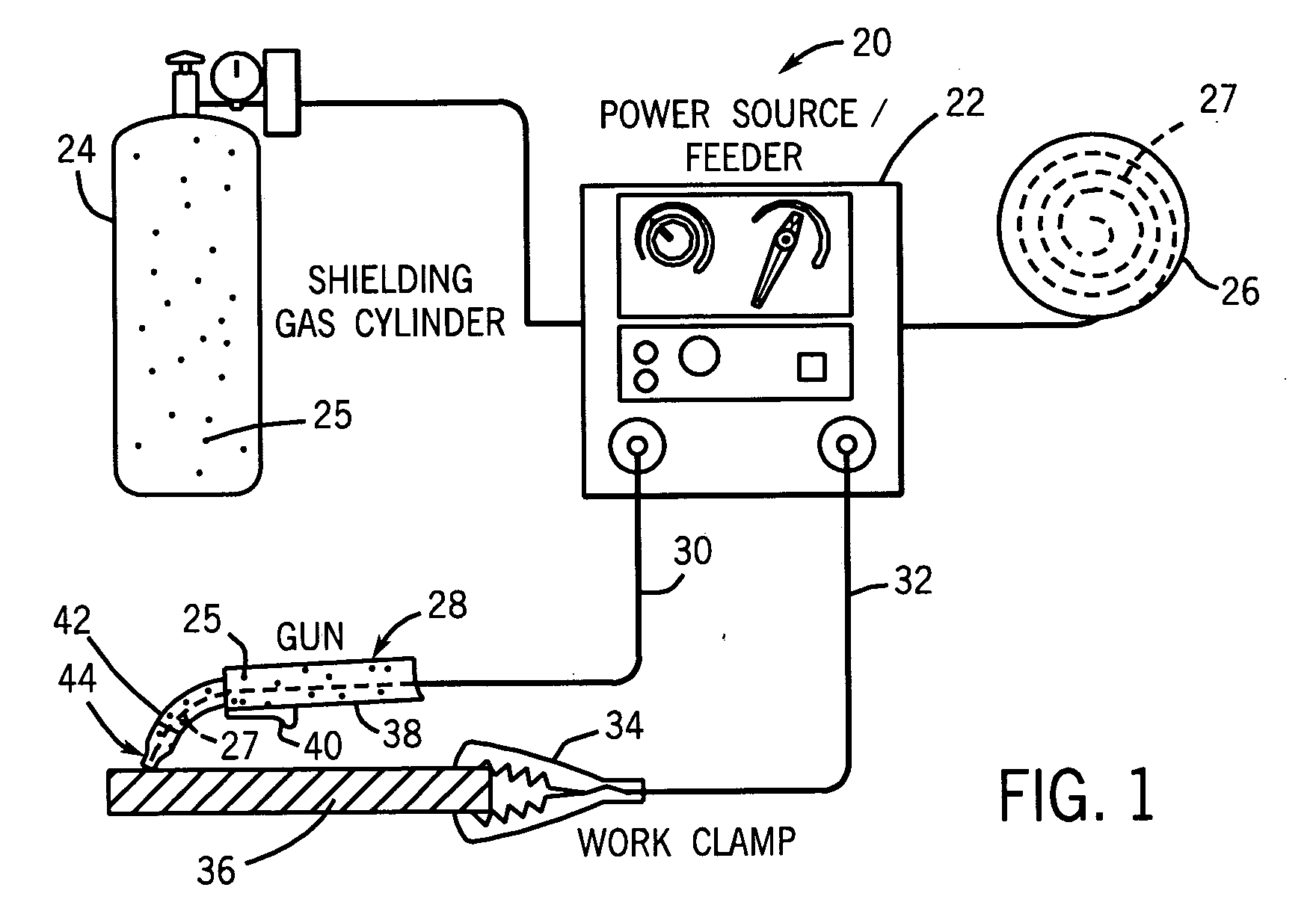

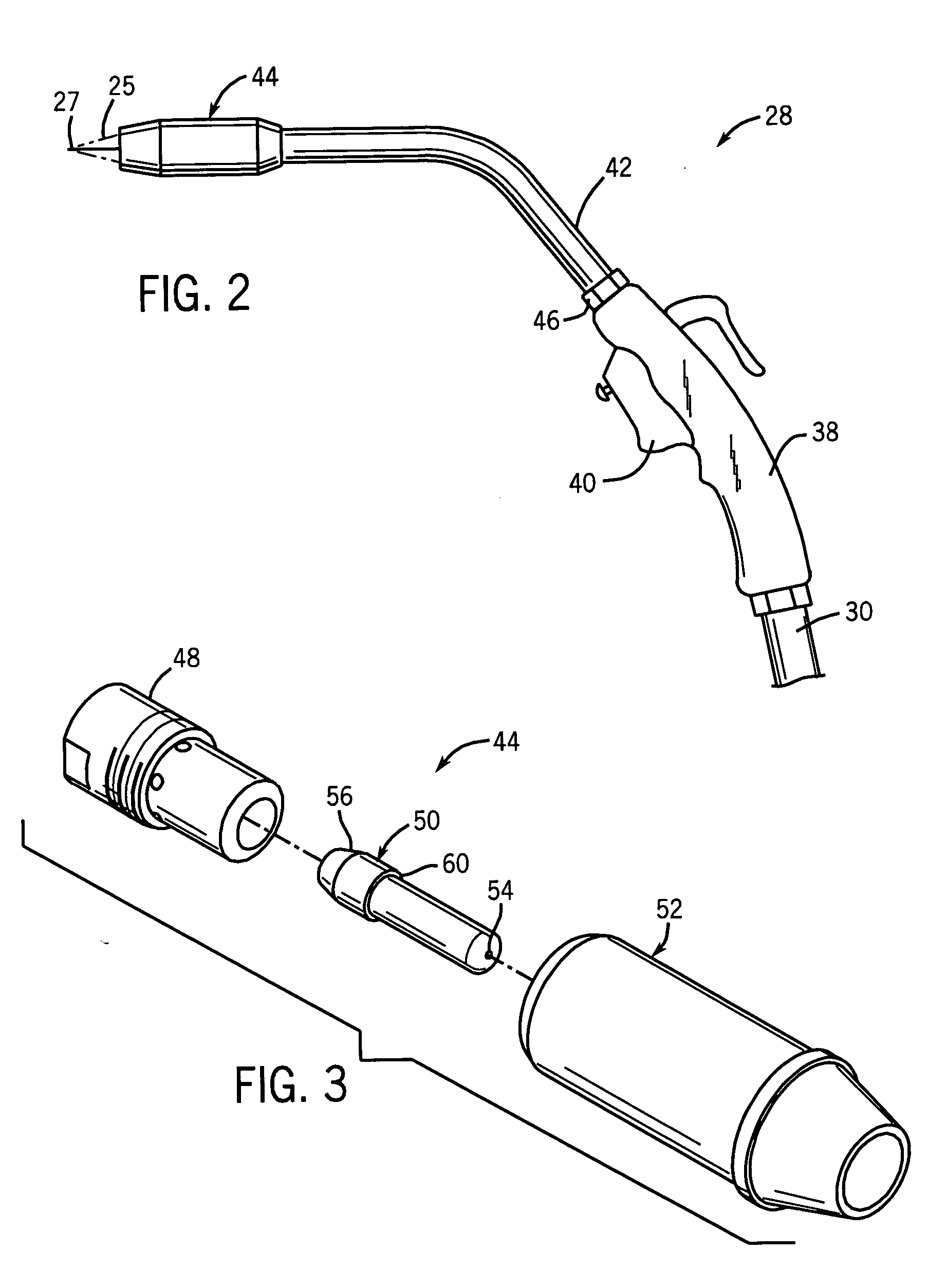

A welding gun adapted to secure a contact tip within the welding gun without threading the contact tip and without the use of tools. The contact tip may be adapted to abut a surface of a first member disposed within the welding gun. The surface may be a surface of a gas diffuser. The surface may be adapted to abut the contact tip. The contact tip also may be adapted for abutment with a second member to urge the contact tip toward the first member. The second member may be a portion of a nozzle adapted to abut the contact tip to urge the contact tip toward the surface of the first member. A method of assembling a welding gun also is provided. The method may comprise disposing a contact tip between a first and a second member and capturing the contact tip between the first and second members.

Owner:ILLINOIS TOOL WORKS INC

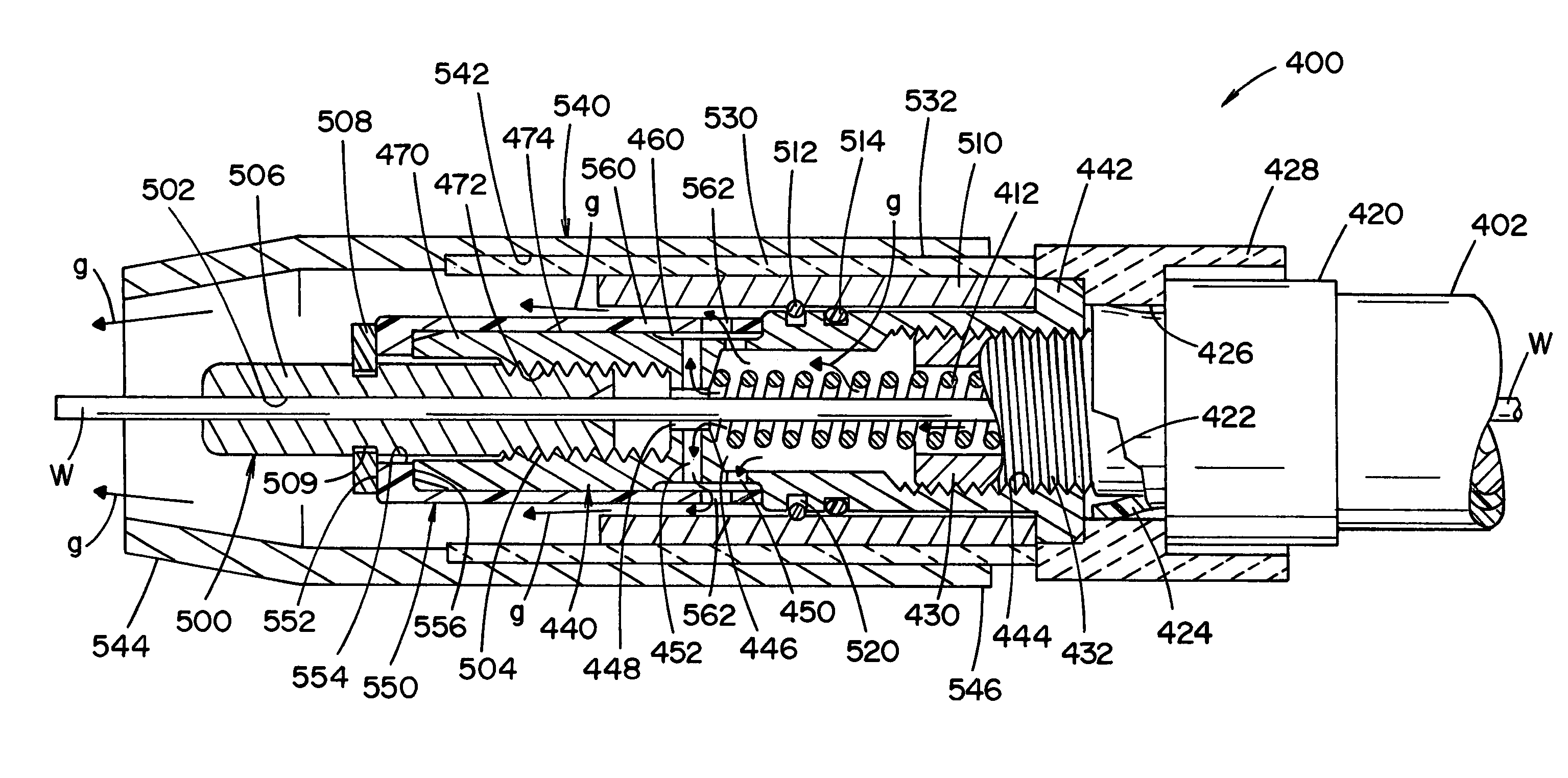

Torch for arc welding gun

InactiveUS8552341B2Heat deteriorationInsulate from heatNon-shielding electrode holdersCooled electrode holdersShielding gasFlange

A welding torch comprising: a main cylindrical conductive assembly with a front diffuser section having a plurality of circumferentially spaced shielding gas diffuser orifices for directing shielding gas radially outwardly from the assembly, a forwardly facing threaded bore extending through a cylindrical support nose and an elongated wire passageway coaxial with the threaded bore and opening at the rear end of the assembly. An insulated, cylindrical protective sleeve fitted around both the support nose and the diffuser orifices where the sleeve has a front clearance opening and circumferentially spaced openings communicated with the diffuser orifices and a contact tip having a central wire guide bore with a diameter only slightly larger than the diameter of the welding wire, a threaded rear body, a front extension passing through the front clearance opening and a radially extending flange between the rear body and the front extension to hold the protective sleeve around the nose when the body is screwed into the threaded bore of the main assembly.

Owner:LINCOLN GLOBAL INC

Welding gun having contact tip and method of operating same

InactiveUS20070000895A1Support devices with shieldingNon-shielding electrode holdersAbutmentBiomedical engineering

A welding gun adapted to secure a contact tip within the welding gun without threading the contact tip and without the use of tools. The contact tip may be adapted to abut a surface of a first member disposed within the welding gun. The surface may be a surface of a gas diffuser. The surface may be adapted to abut the contact tip. The contact tip also may be adapted for abutment with a second member to urge the contact tip toward the first member. The second member may be a portion of a nozzle adapted to abut the contact tip to urge the contact tip toward the surface of the first member. A method of assembling a welding gun also is provided. The method may comprise disposing a contact tip between a first and a second member and capturing the contact tip between the first and second members.

Owner:ILLINOIS TOOL WORKS INC

Welding Electrode Holder

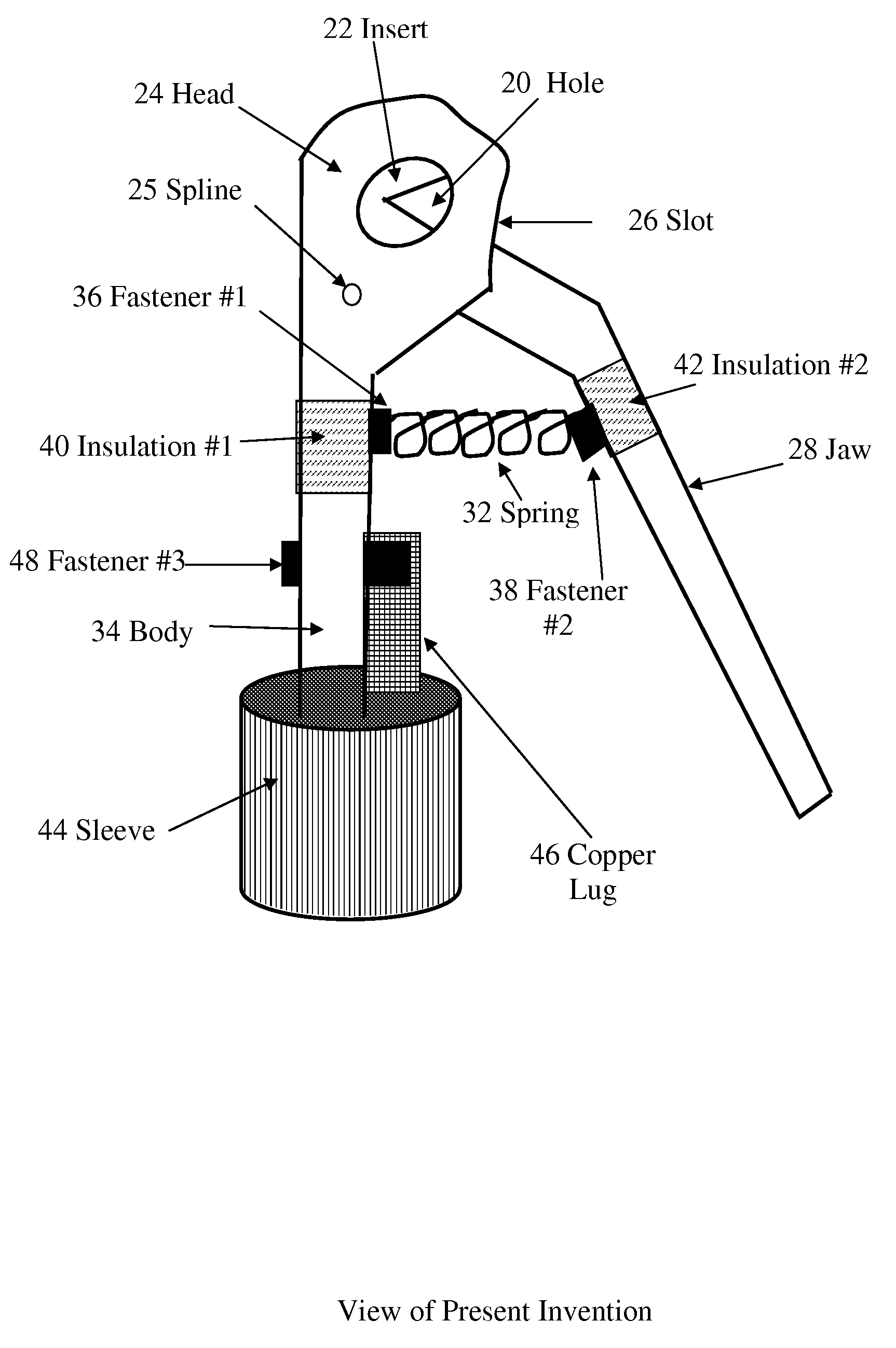

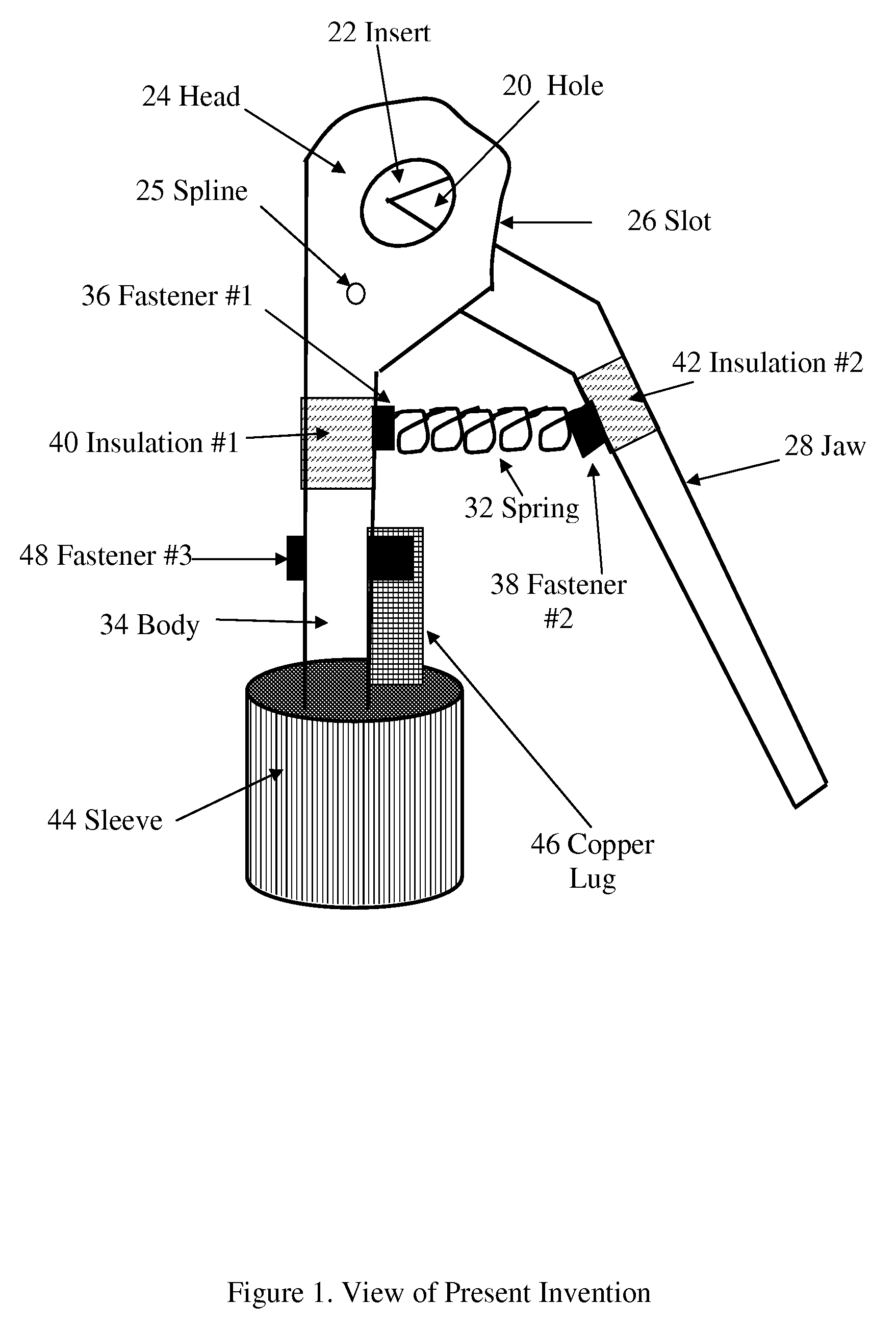

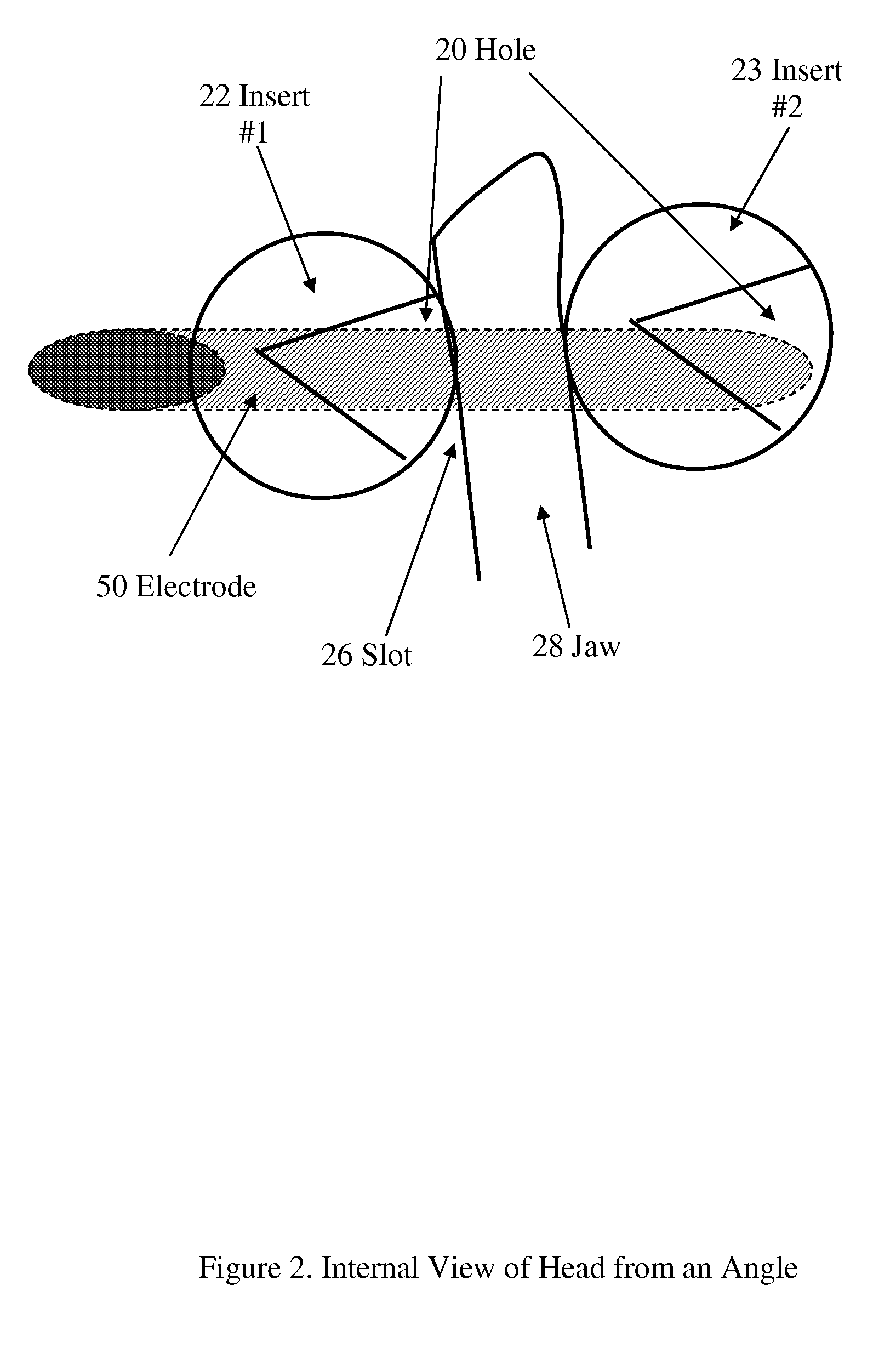

ActiveUS20170087658A1Gripped comfortably and safely by the userElectric discharge heatingNon-shielding electrode holdersEngineeringMechanical engineering

Owner:TOWNSEND CARL

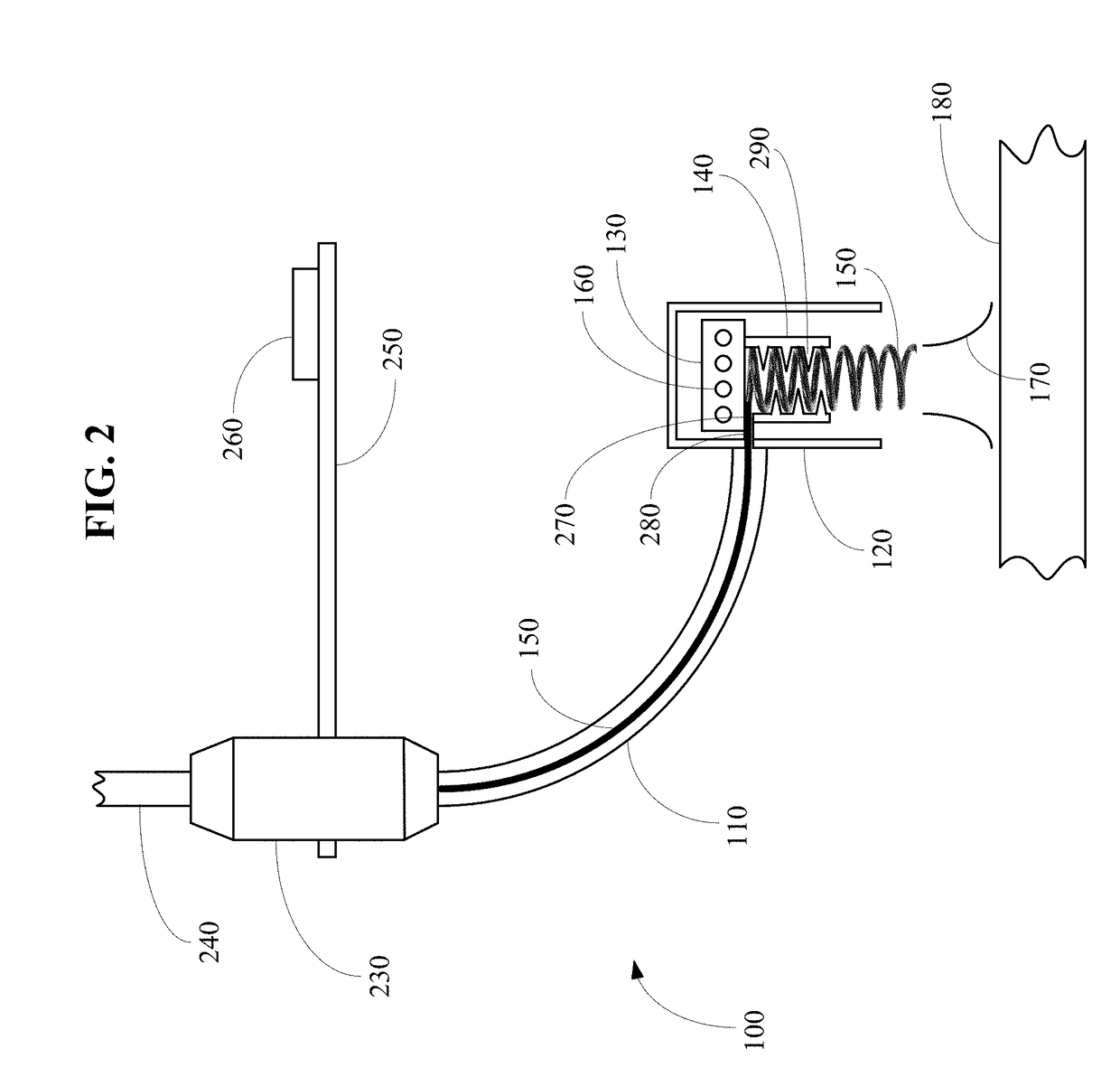

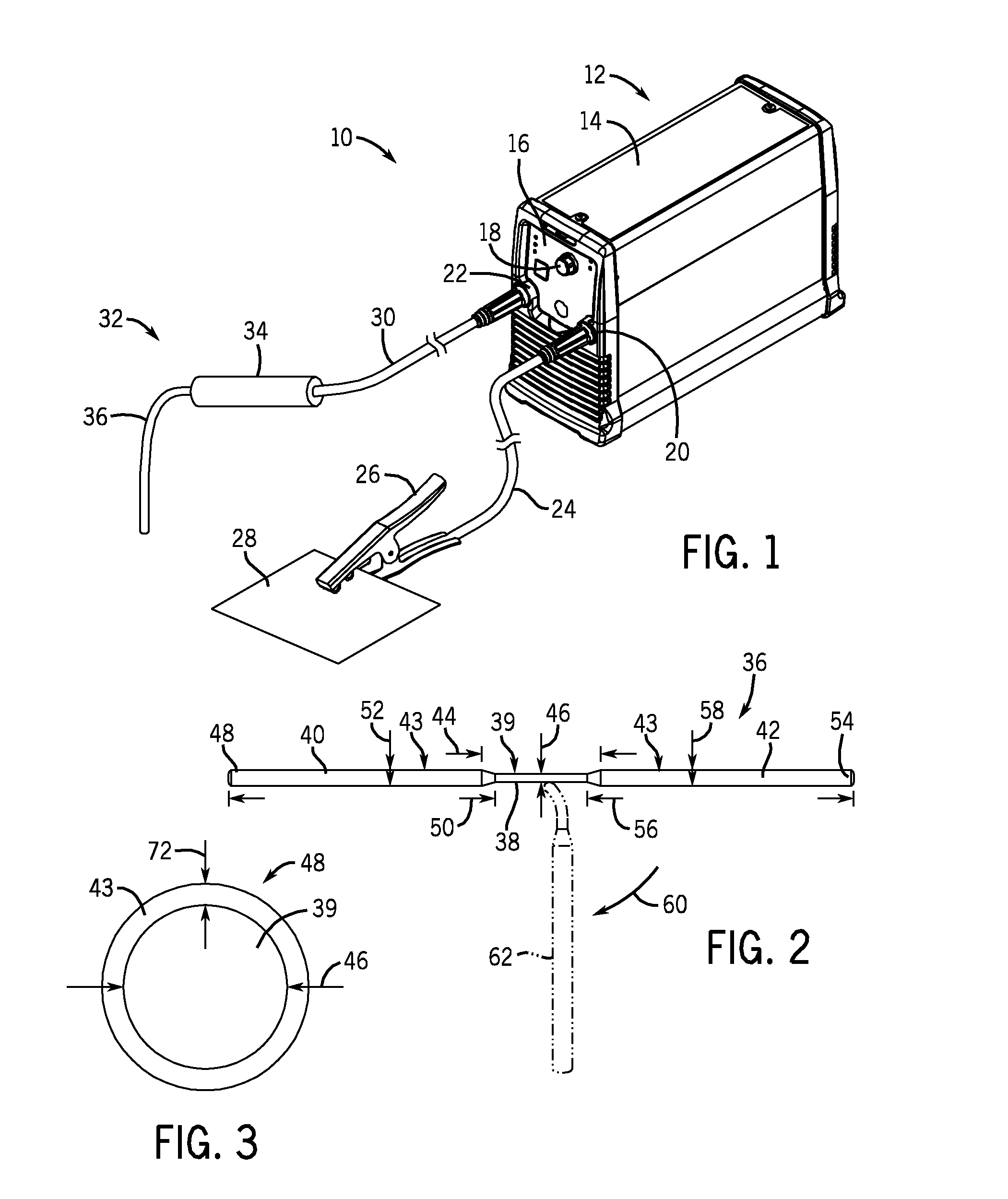

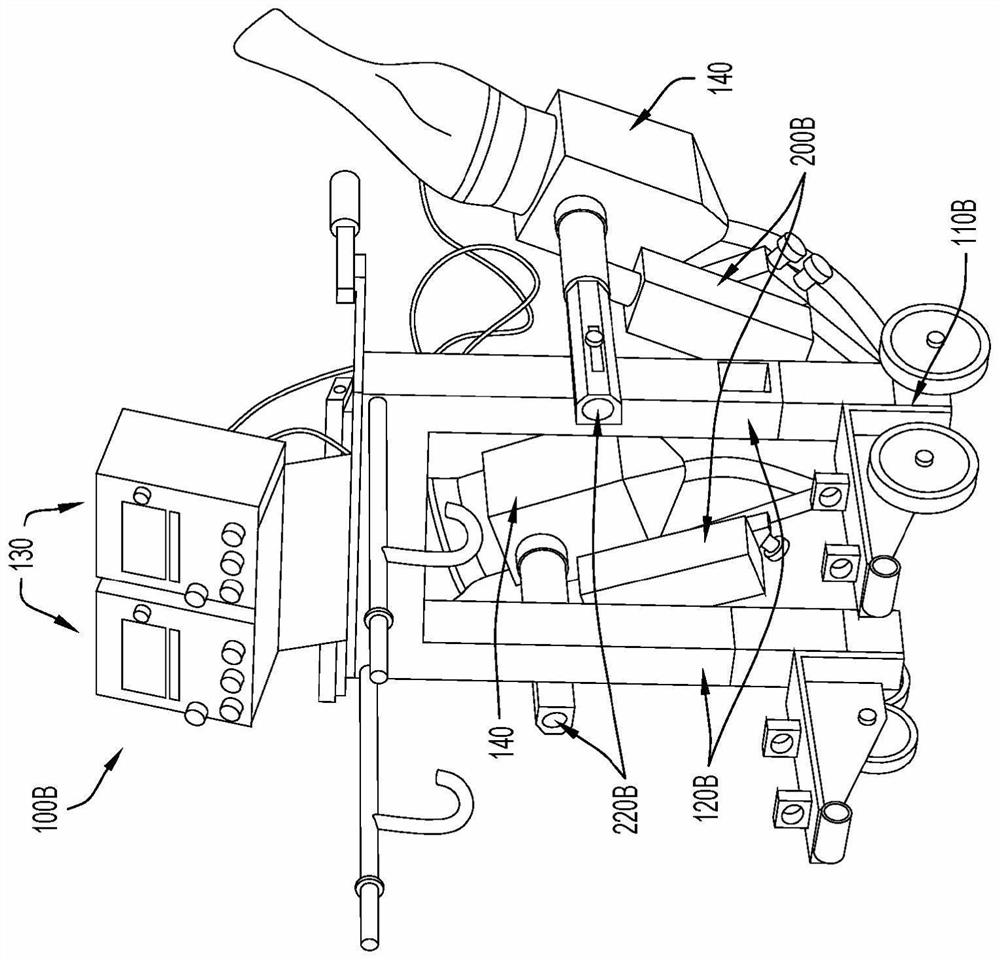

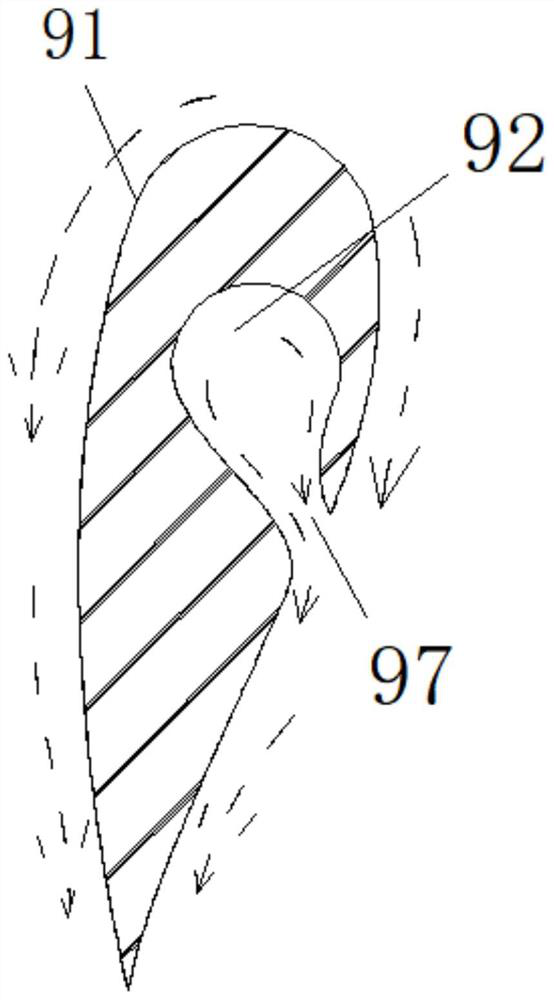

Helical welding wire and helix forming welding torch

ActiveUS20180079024A1Non-shielding electrode holdersWelding/cutting media/materialsEngineeringWelding torch

Systems and methods are disclosed that provides a helical wire for use in welding applications. A torch can be adapted to form the helical wire from a straight wire and to provide the helical wire as a consumable electrode in a welding or cladding application. The helical wire can be, for example, solid, tubular, or seamless tubular. The torch concurrently forms the helical wire and provides welding current for the welding or cladding application.

Owner:ILLINOIS TOOL WORKS INC

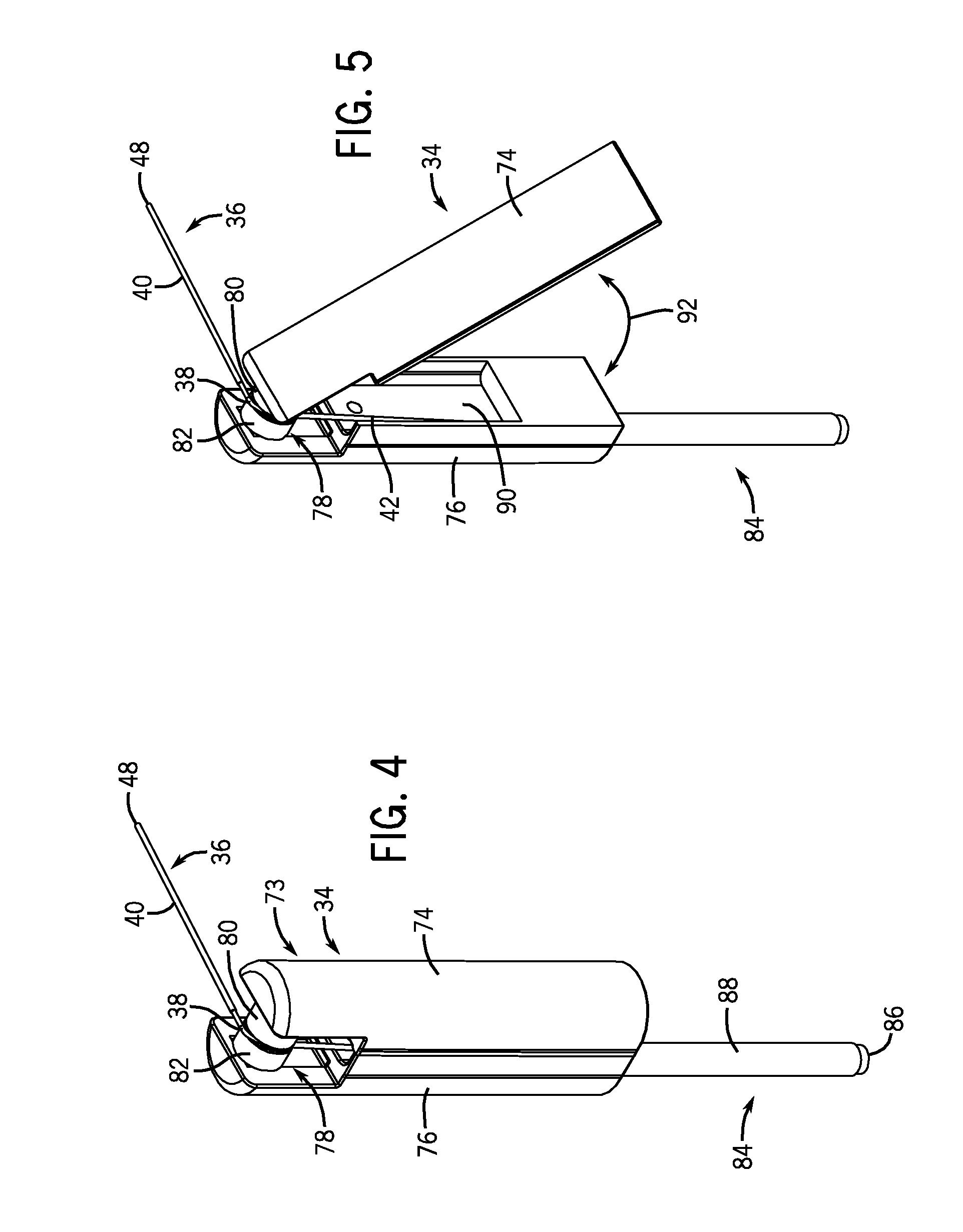

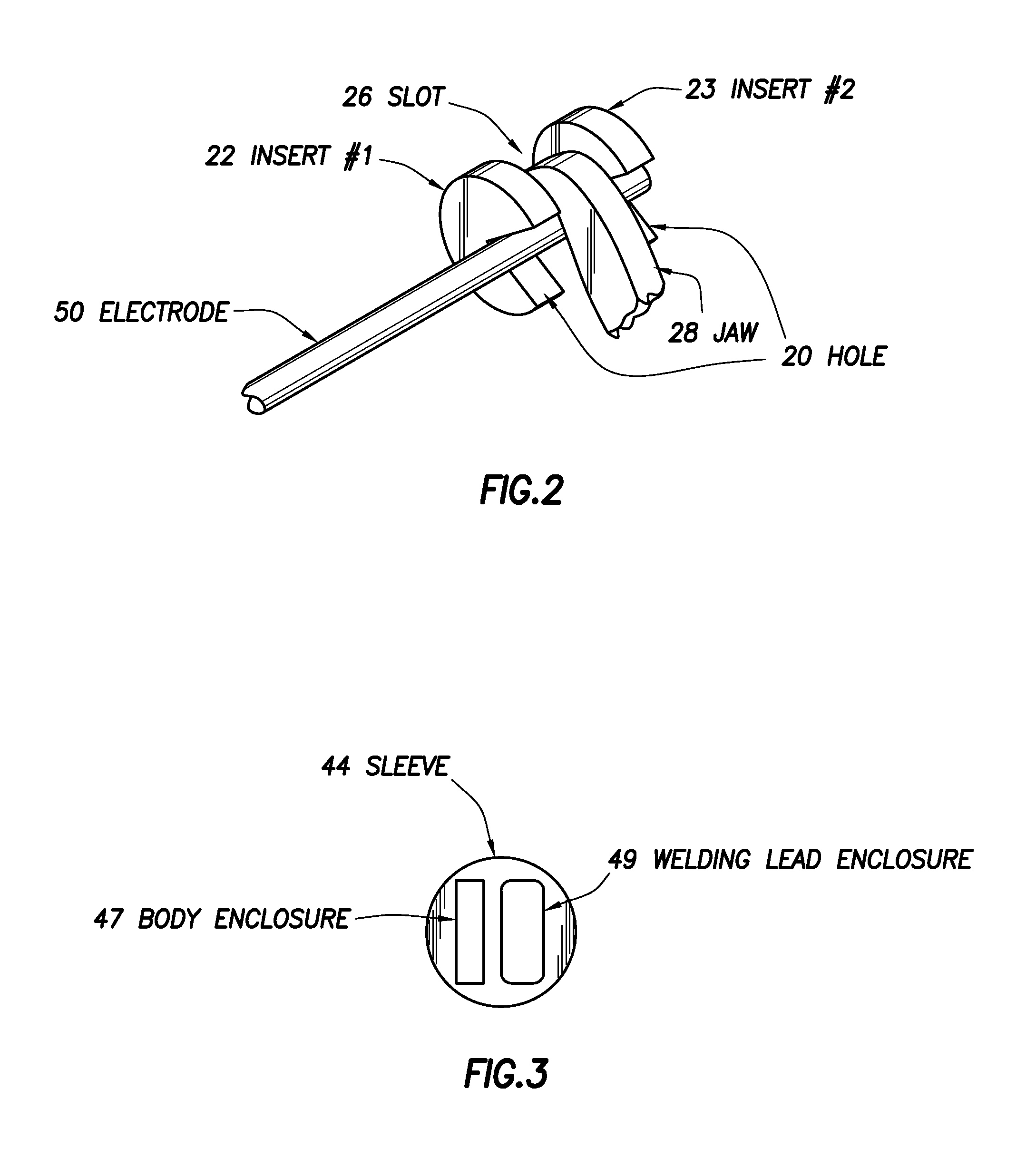

Welding consumables and consumable holders

ActiveUS20110284513A1Non-shielding electrode holdersWelding/cutting media/materialsElectrical contactsConsumables

A welding torch with a welding electrode and a welding electrode holder is provided. One welding torch includes a securing mechanism and an insulated grip. The securing mechanism is configured to secure an exposed central portion of a welding rod bounded by flux covered first and second sides. The securing mechanism is also configured to make electrical contact with the central portion of the rod for arc welding with the first side. The insulated grip is configured to cover the second side of the welding rod.

Owner:ILLINOIS TOOL WORKS INC

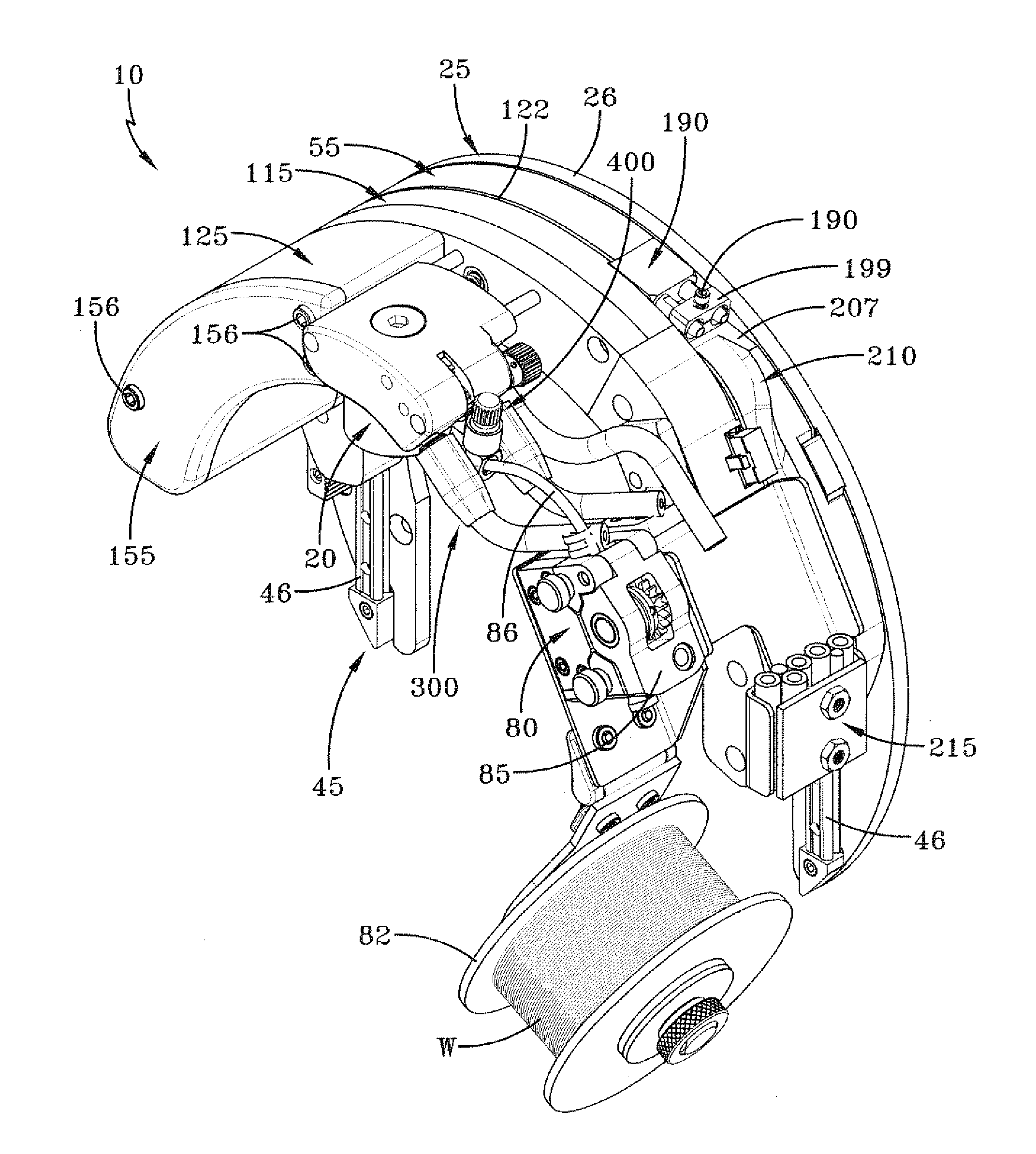

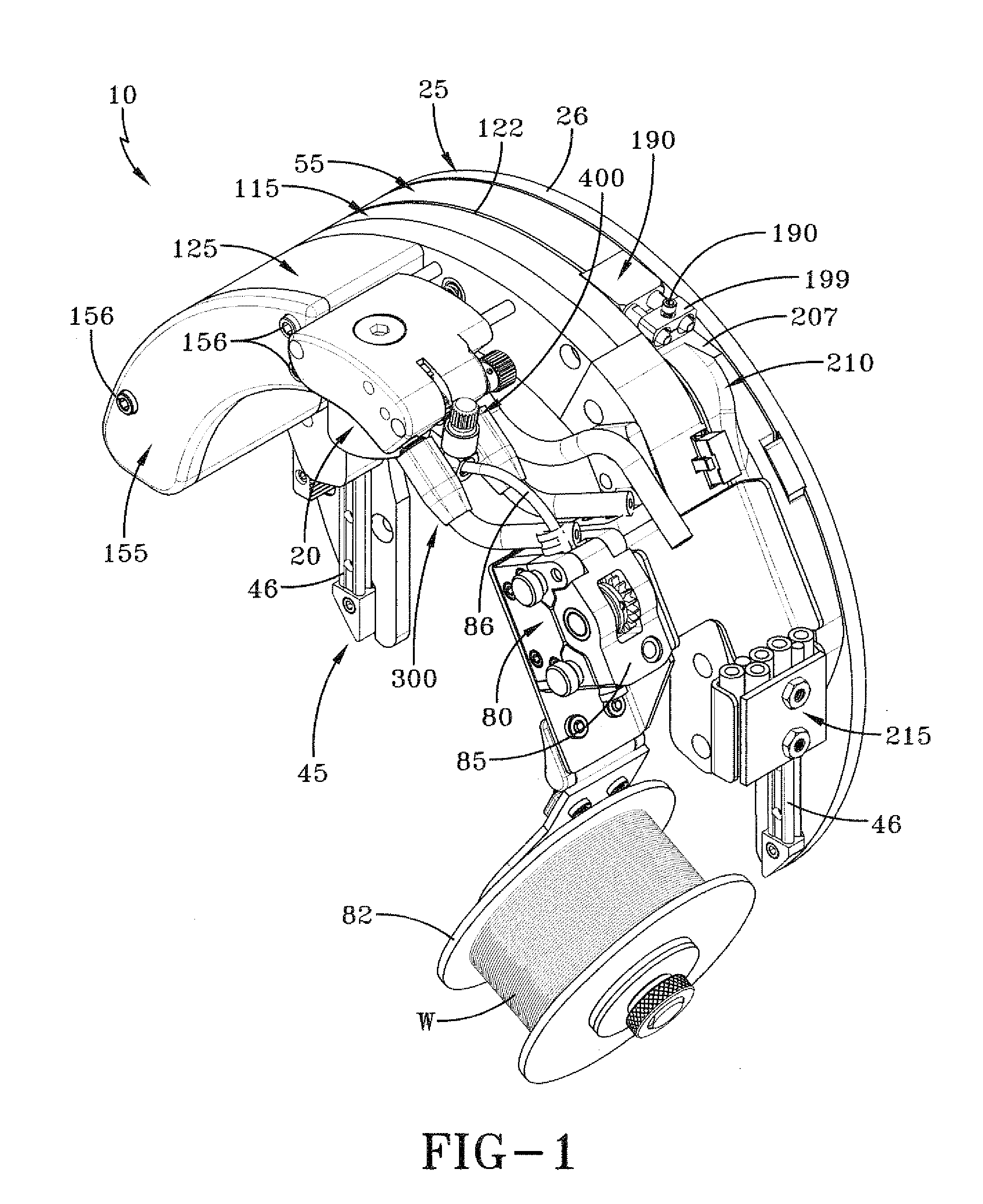

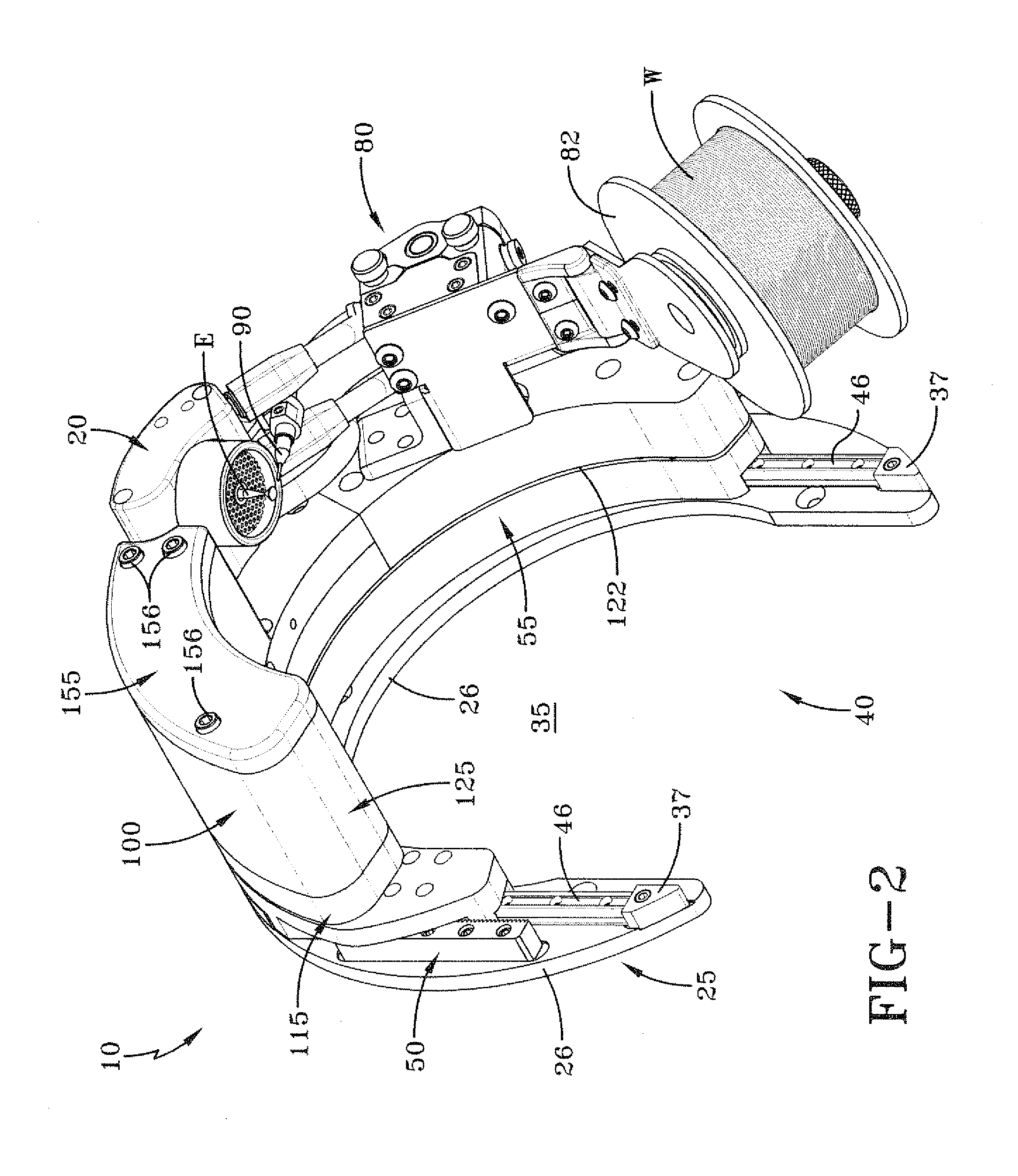

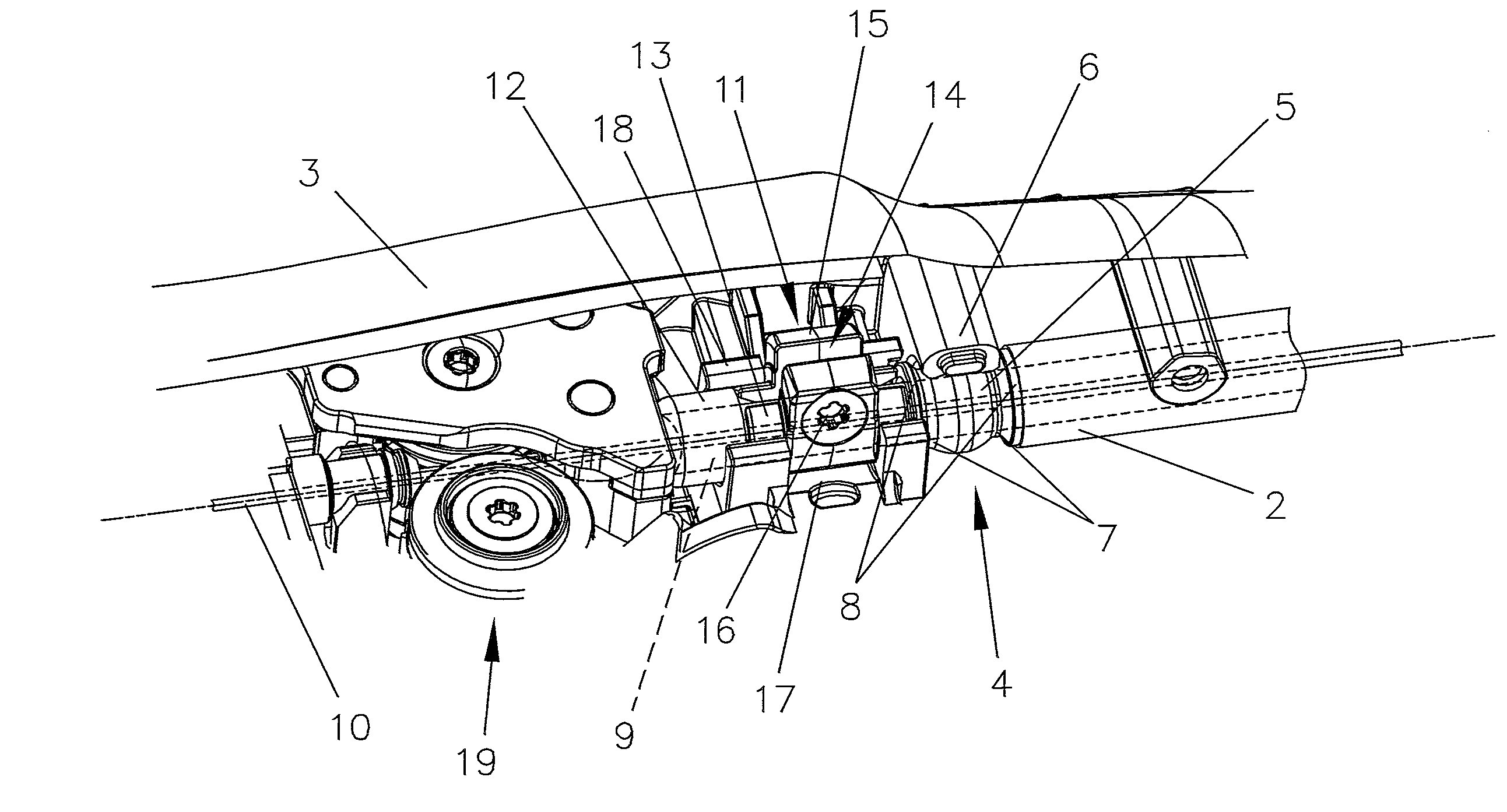

Multi-fuction orbital welding system

InactiveUS20140263257A1Electric discharge heatingNon-shielding electrode holdersEngineeringMechanical engineering

A torch head in a welding system for applying a weld to a workpiece, the torch head including a torch head body having a first side, a second side, an inward side and a outer side, the torch head body further including a lower surface and a top surface forming a solid; the torch body defining a slot extending from the lower surface to the top surface on the first side; an electrode assembly including an electrode mounted on the torch body, the electrode extending downward relative to the lower surface of the torch body; a wire adjustment assembly including a bracket supporting a wire guide that receives a wire from a wire supply; the bracket being attached to a rack and pinion supported within the slot, the rack being located inward of the pinion and slideable within the slot, the pinion being rotatable within the slot, and engaged with the rack to move the bracket vertically upon rotation of the pinion to adjust the vertical position of the wire.

Owner:LINCOLN GLOBAL INC

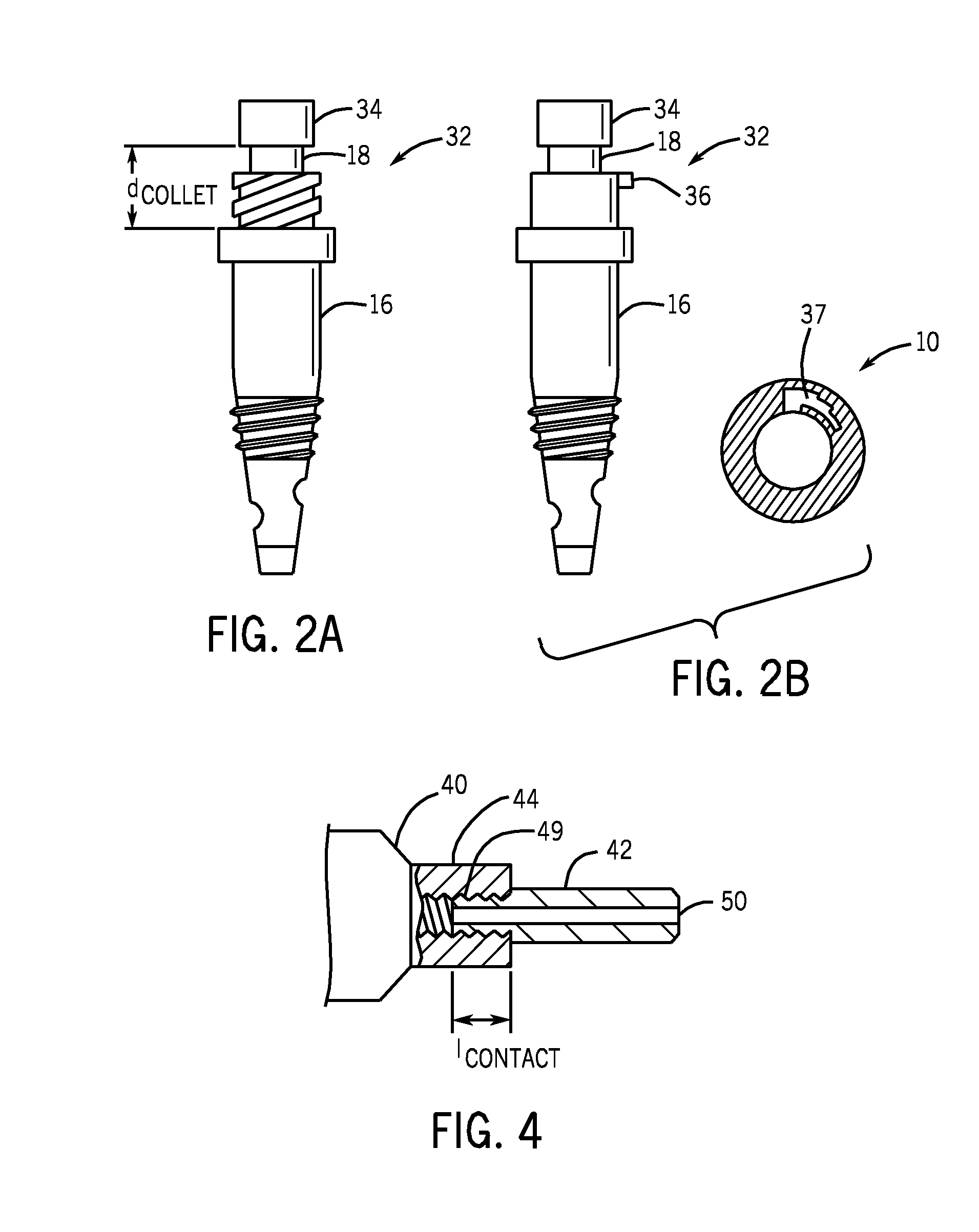

Electrode diameter sensing consumables

ActiveUS20130327746A1Non-shielding electrode holdersElectrode holder supportersIndustrial engineeringWelding torch

The present disclosure provides a welding system capable of detecting a size of a welding material and automatically implementing appropriate arc starting parameters. The welding system includes a welder, a welding torch, and a sensor, in which the sensor is configured to detect the size of the welding material, directly or indirectly. The welder is automatically configured to produce an arc having the arc starting parameters determined from the size of the welding material detected by the sensor. The present disclosure decreases operational error by automatically changing arc starting parameters and / or welding parameters based upon a change in welding material size, rather than requiring an operator to manually change the arc starting parameters and / or welding parameters.

Owner:ILLINOIS TOOL WORKS INC

Welding torch handle utilizing slot for trigger attachment

InactiveUS8952294B2Enhanced couplingSupport devices with shieldingNon-shielding electrode holdersElectrical conductorCoupling

Owner:ILLINOIS TOOL WORKS INC

Welding torch handle

InactiveUS20080290072A1Enhanced couplingNon-shielding electrode holdersWelding/cutting media/materialsElectrical conductorCoupling

In accordance with one embodiment, the present technique relates to a welding torch handle that has an unenclosed slot extending from one end thereof. This unenclosed slot provides a mechanism through which insulated signal leads of a conductor can extend from the interior of the handle to connect with a trigger disposed outside the handle. As one advantage, the unenclosed nature of the slot facilitates this coupling without the need for threading of the leads, which can damage the leads.

Owner:ILLINOIS TOOL WORKS INC

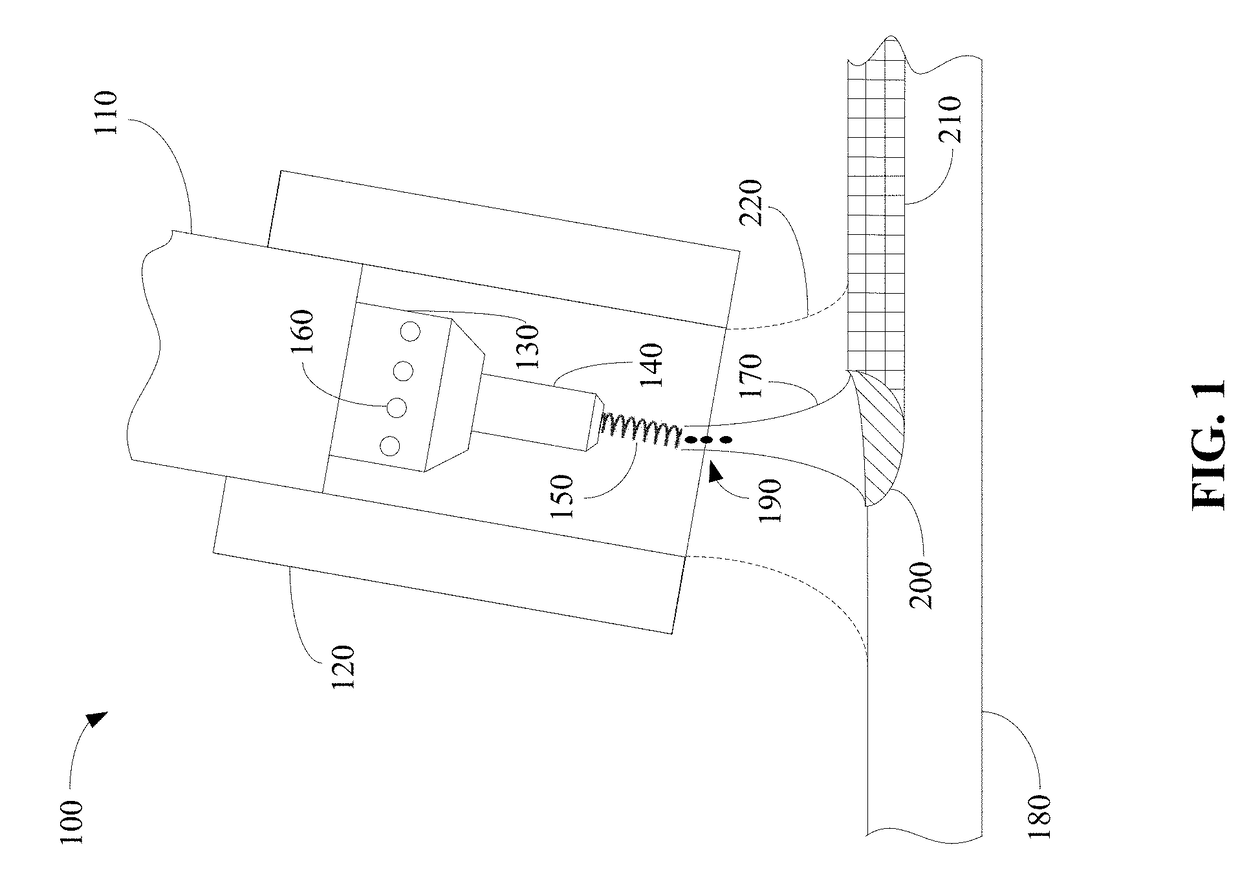

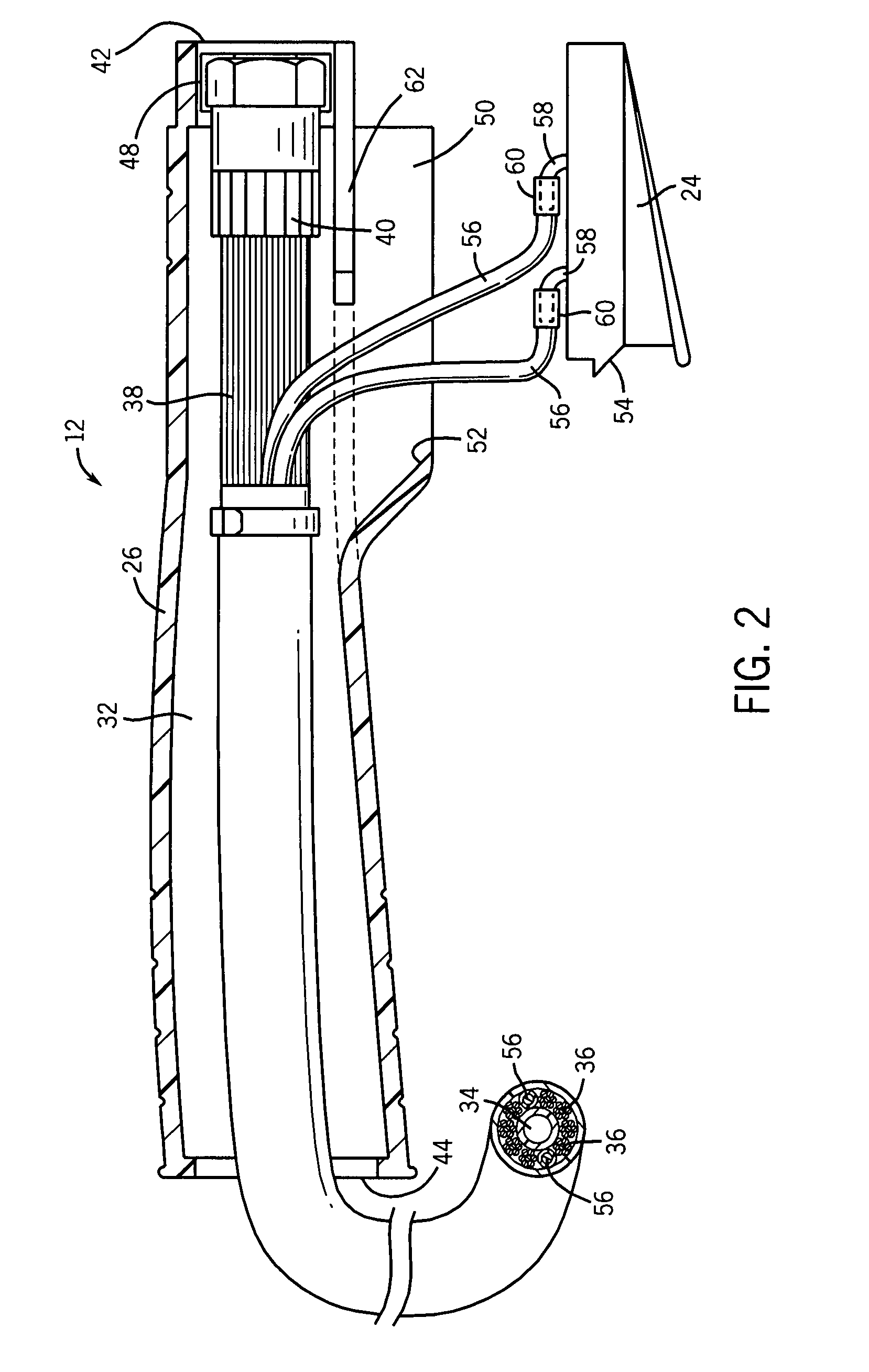

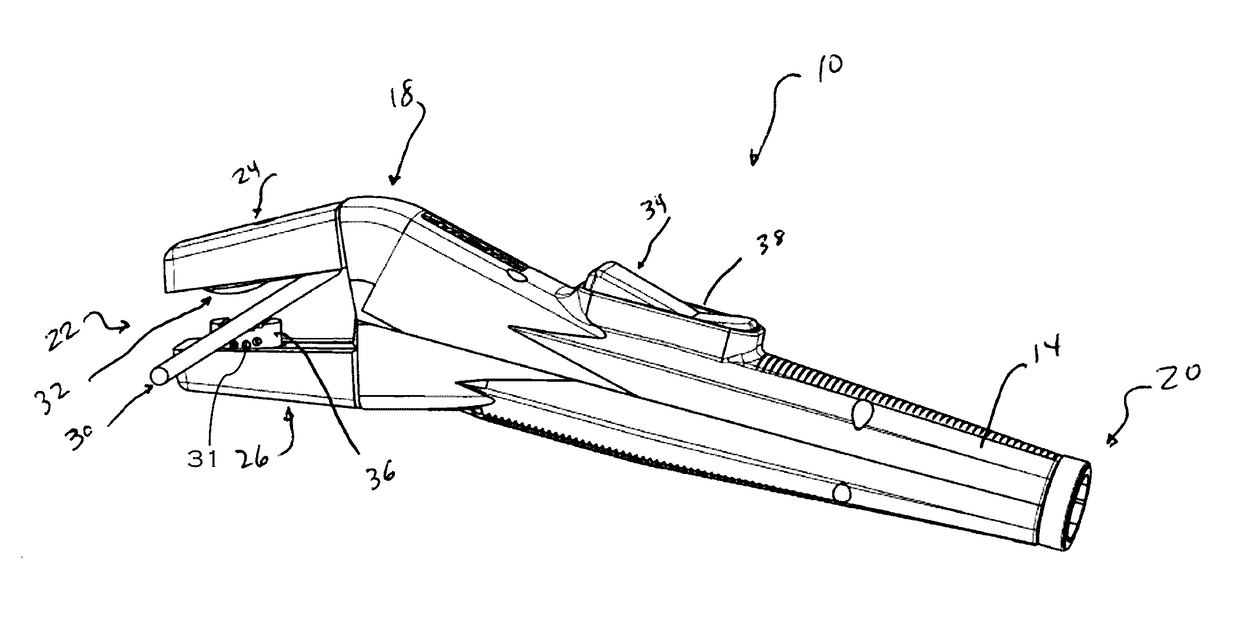

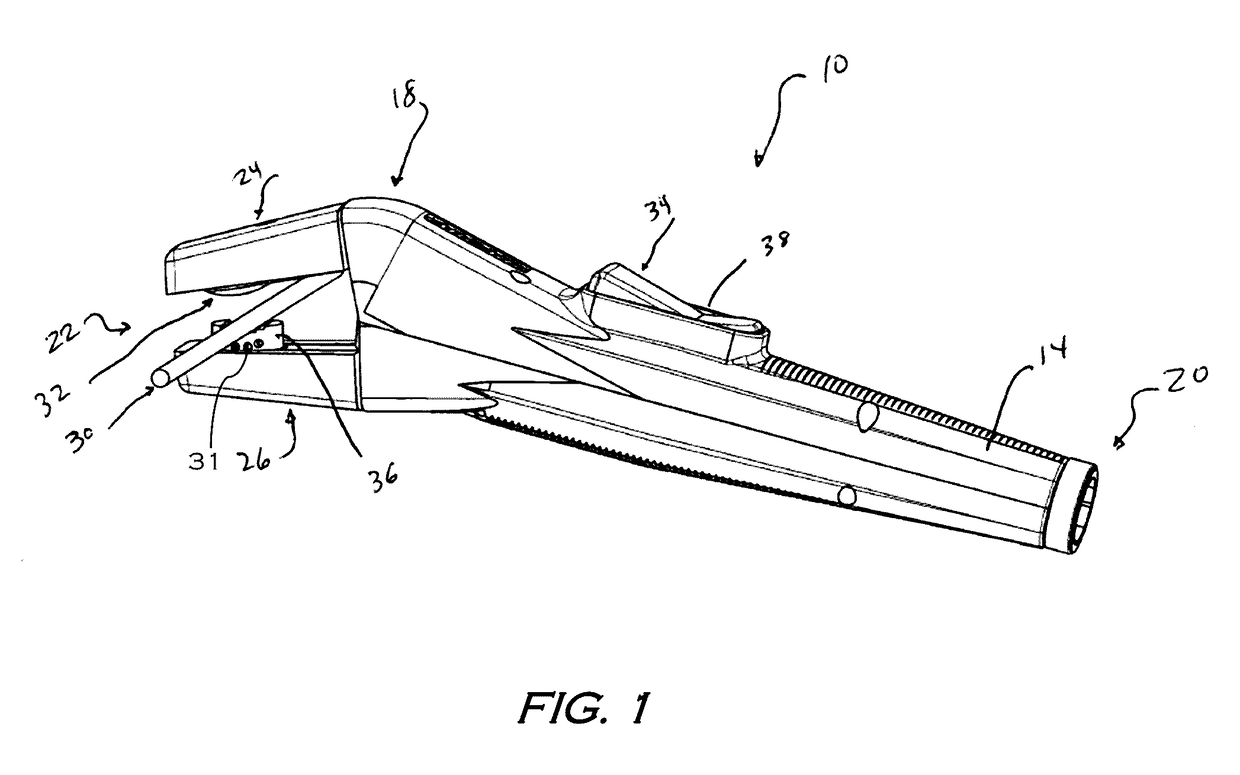

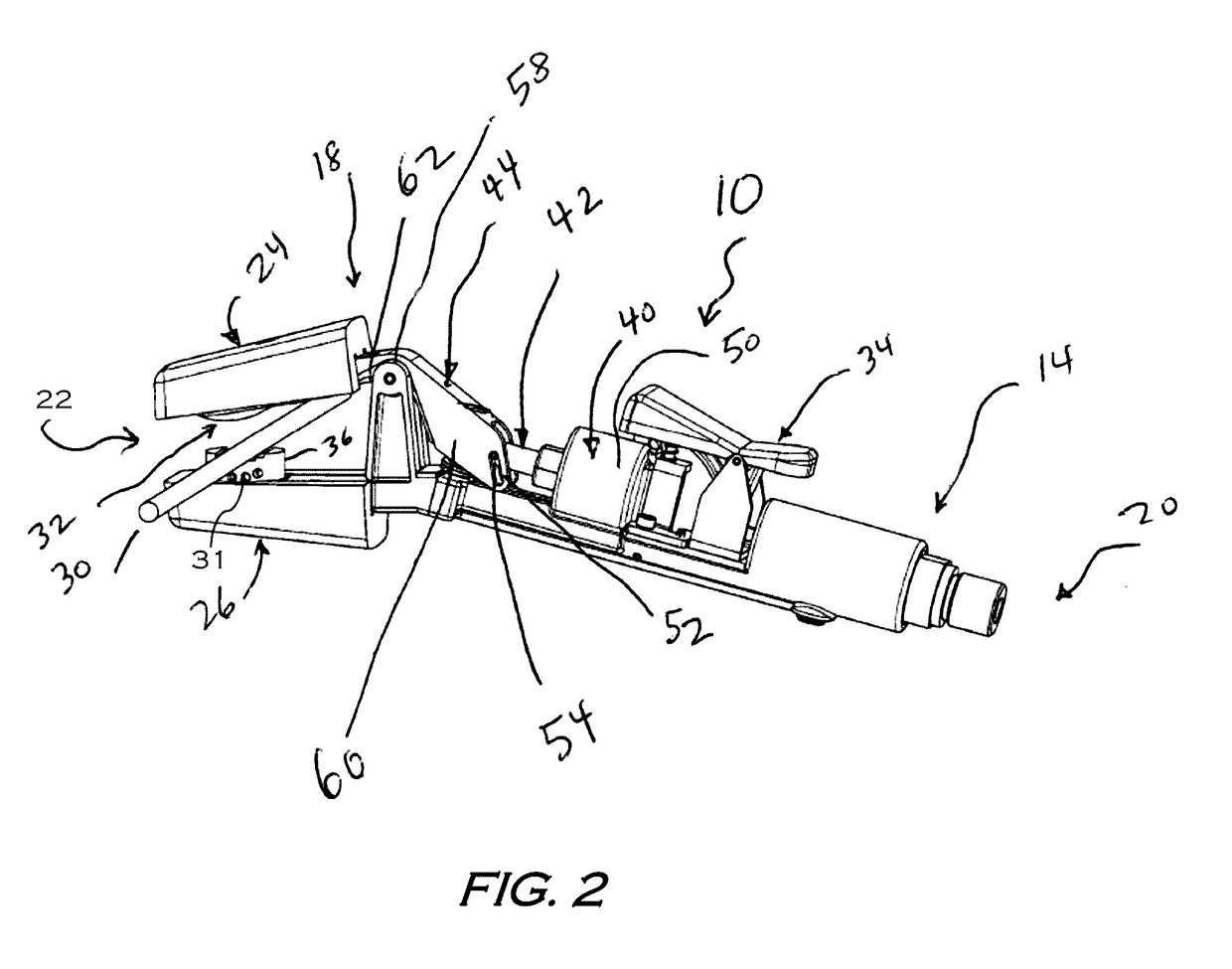

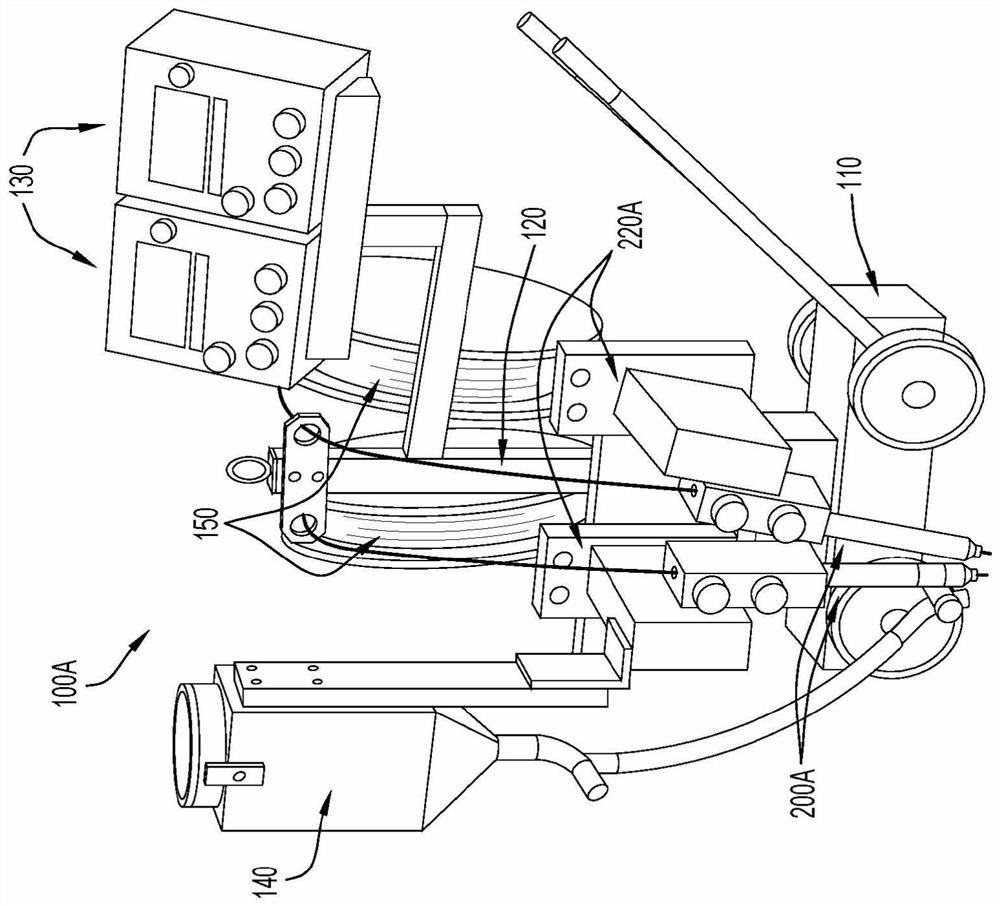

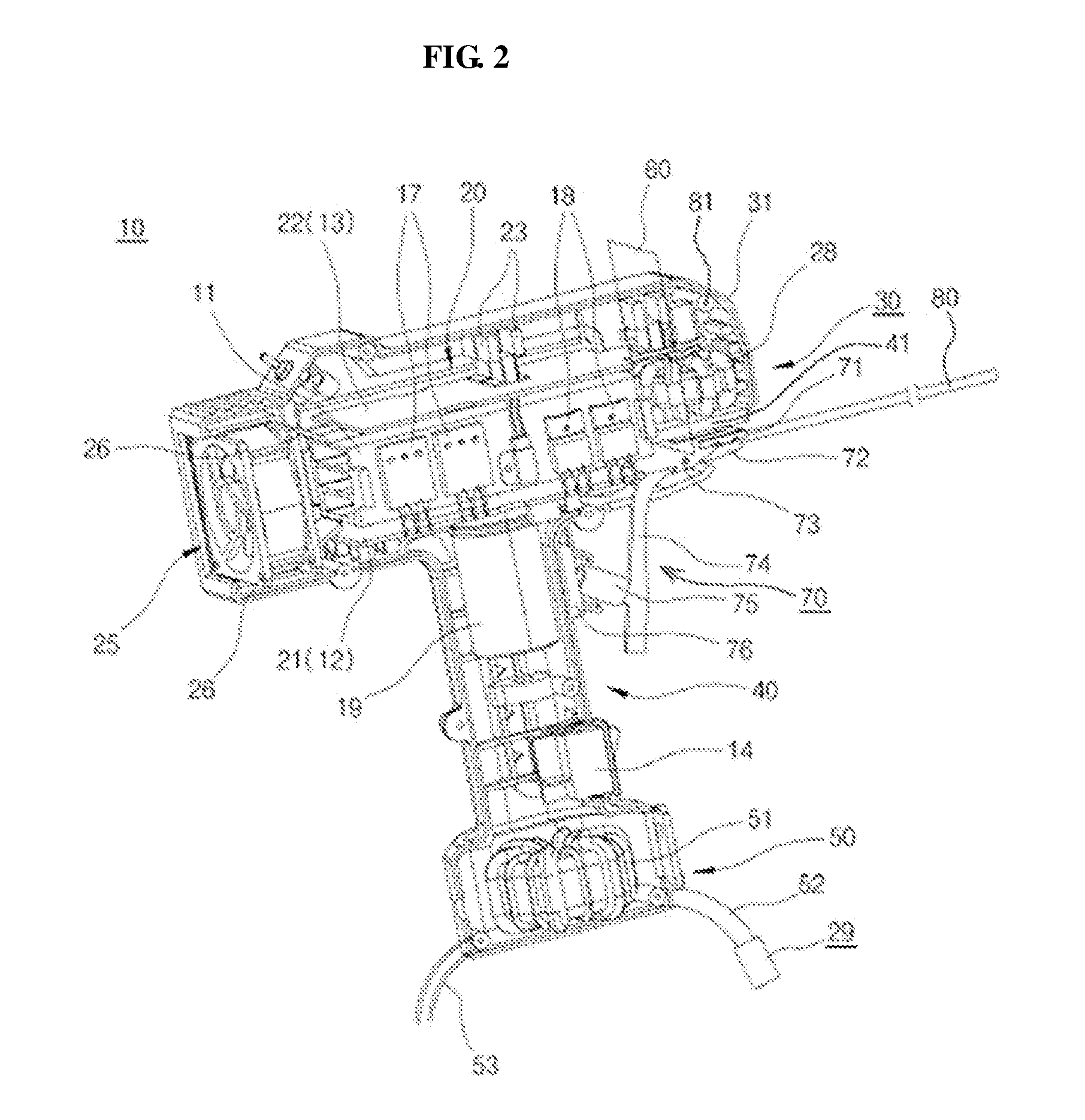

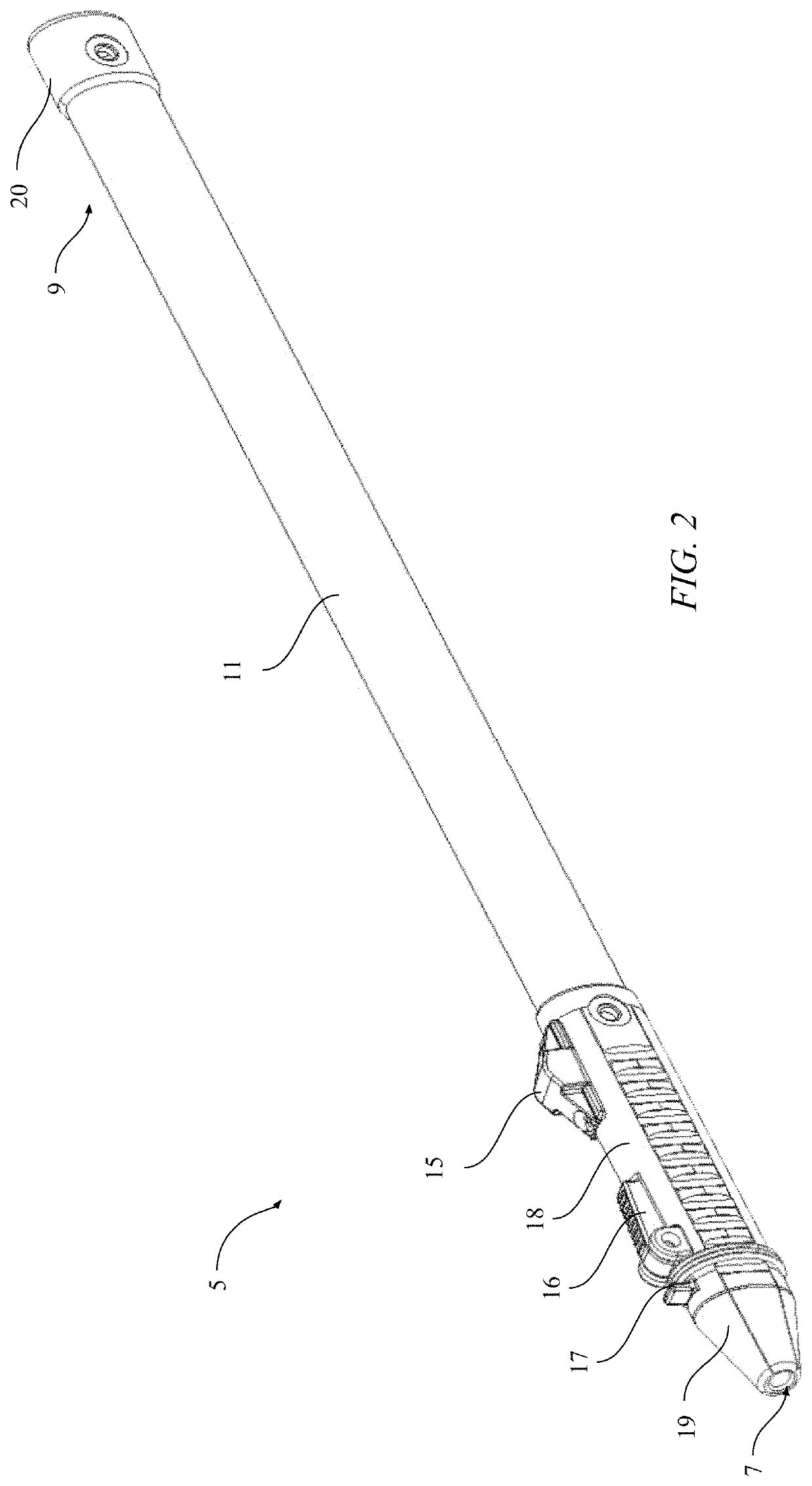

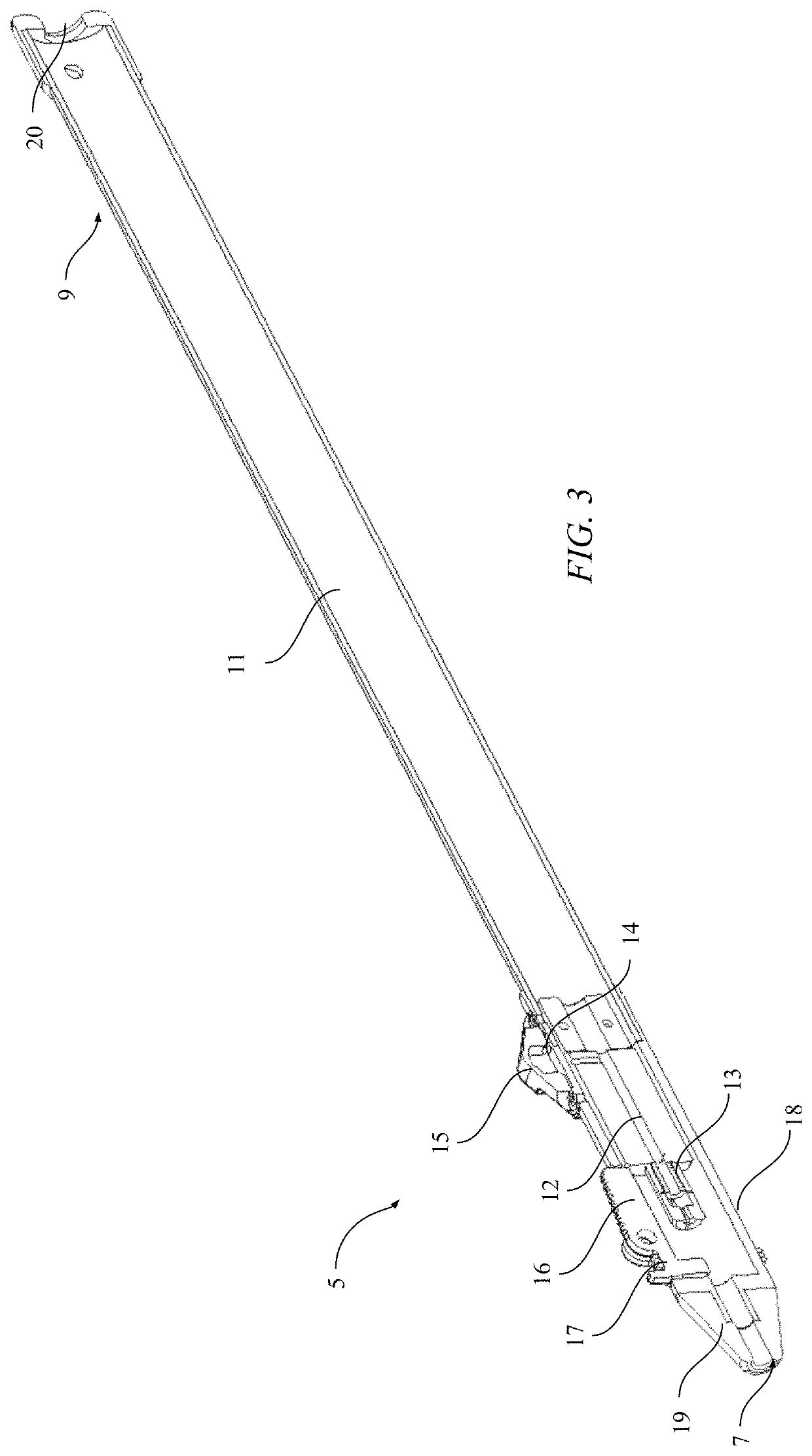

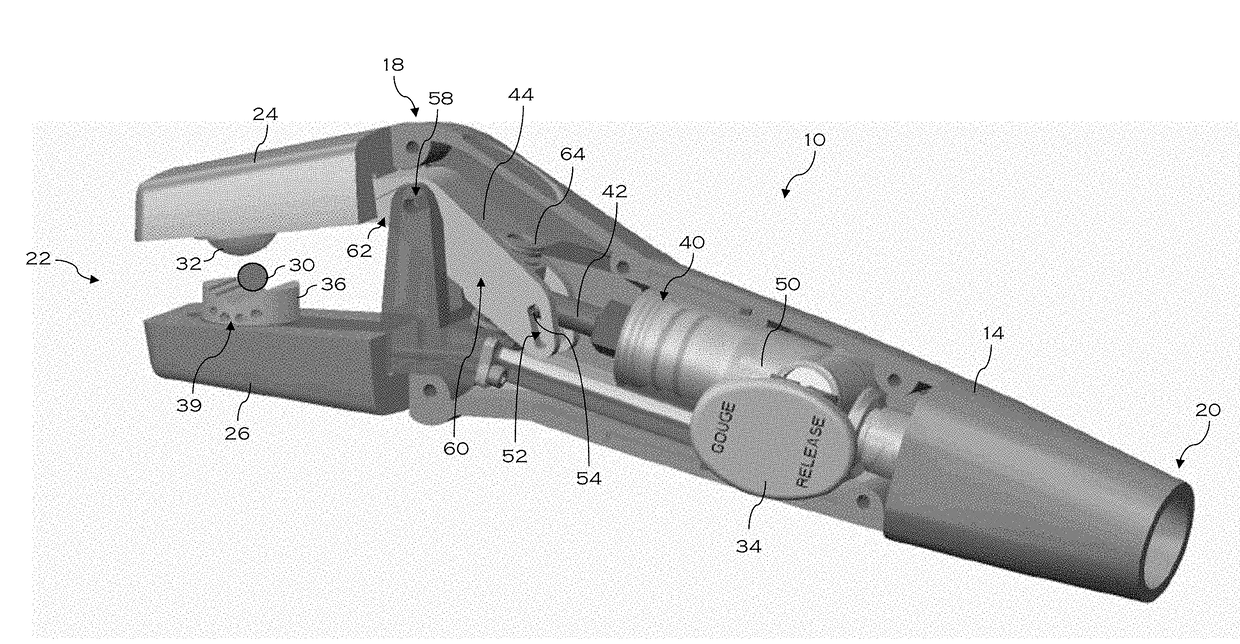

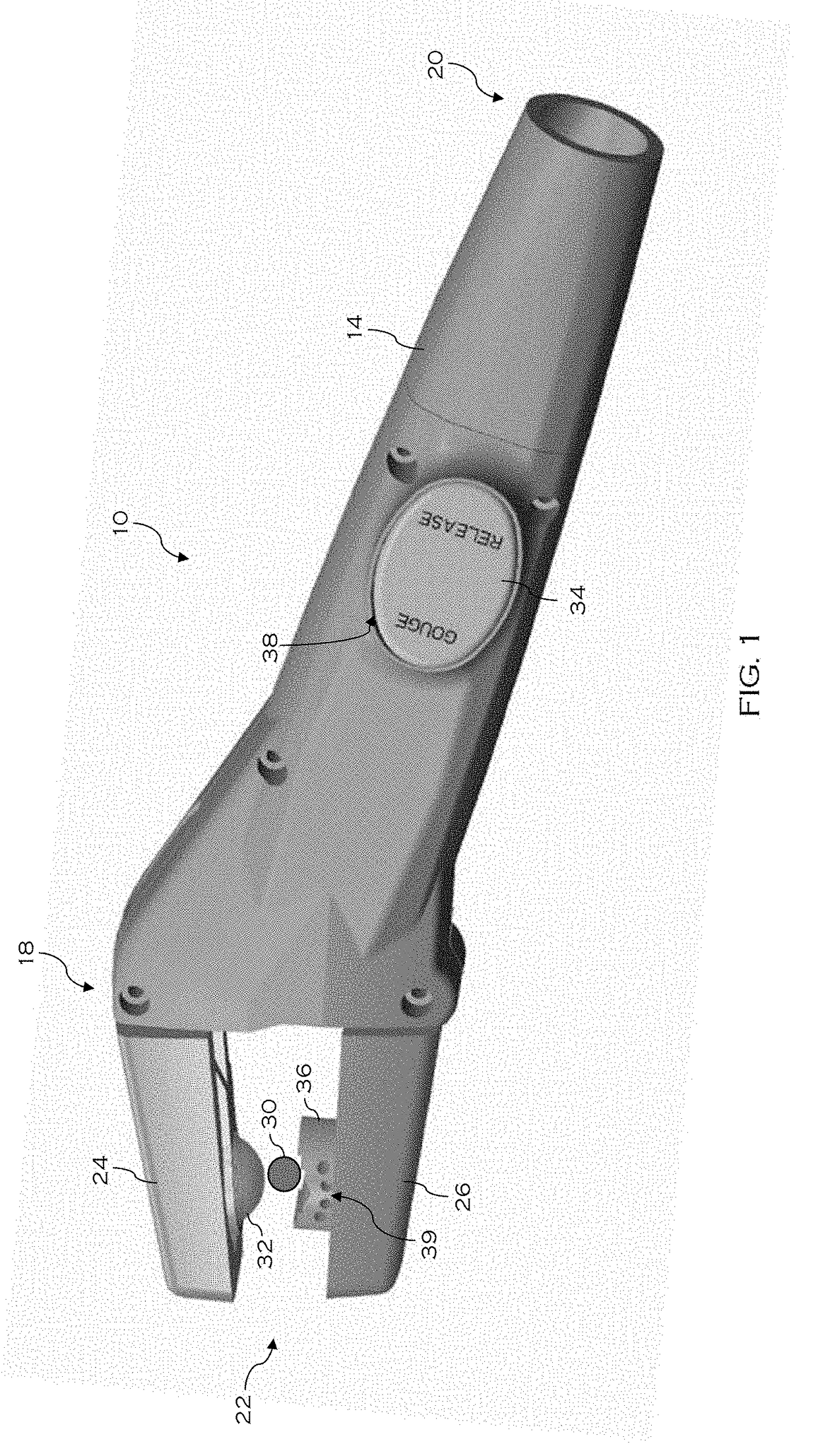

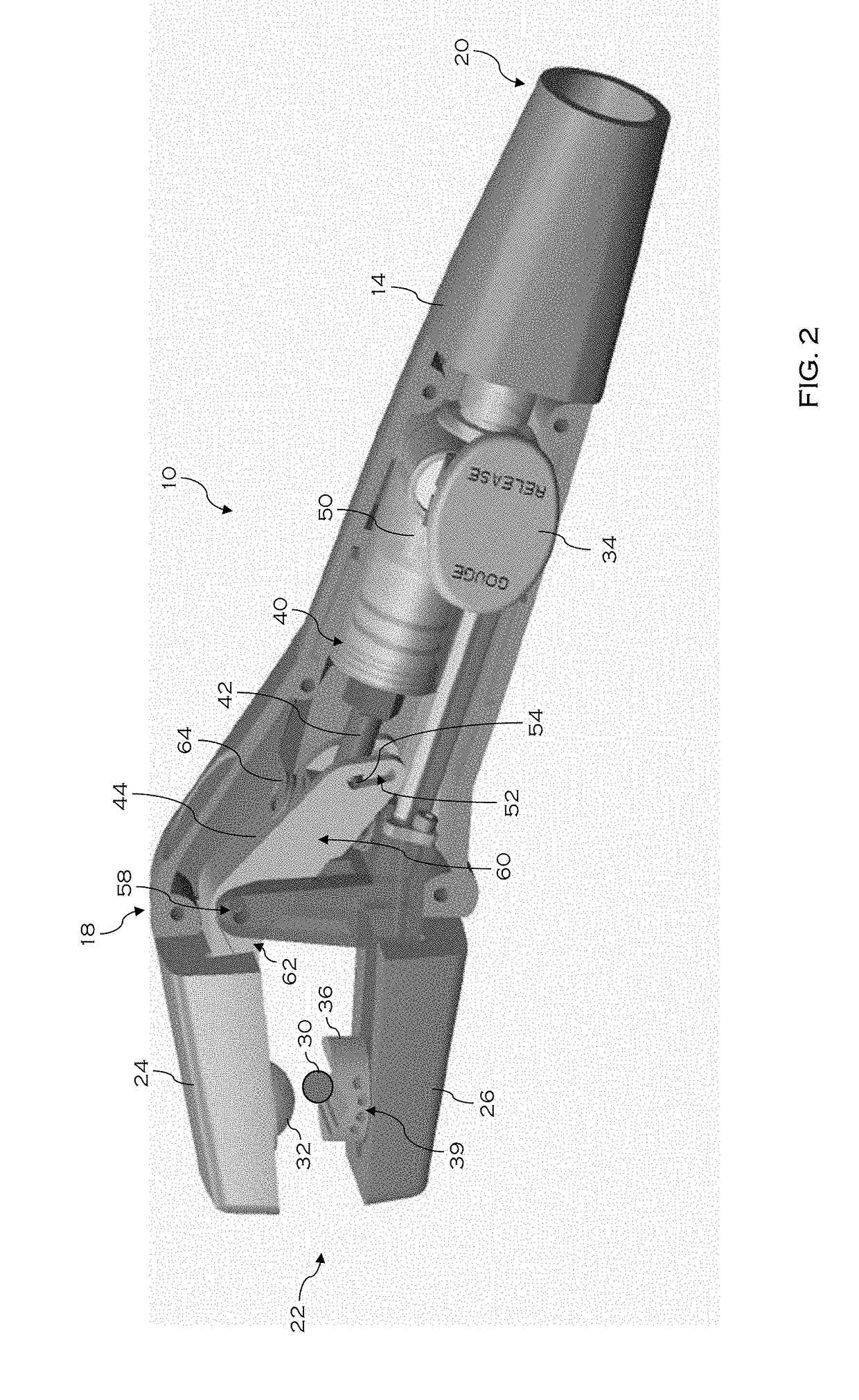

Torch handle including pneumatically operated jaw

ActiveUS20170144244A1Grip force decreaseReduce forceNon-shielding electrode holdersElectrode holder supportersTorchPneumatic cylinder

Approaches herein provide a torch handle including a pneumatically controlled jaw operable to engage an electrode. In one approach, a system is provided for distributing gas within the torch handle, the system including a pneumatic cylinder within a main housing of the torch handle. The pneumatic cylinder is coupled to a shaft for actuating first and second members of the jaw. The system further includes a gas passageway through the main housing, the gas passageway extending to an exit orifice disposed within the second member. A flow controller, including first and second valves, is operable to direct a flow of a gas to either the pneumatic cylinder or the gas passageway. In one approach, the first member is actuated towards the second member when the gas is directed through the gas passageway, and actuated away from the second member when the gas is directed to the pneumatic cylinder.

Owner:VICTOR EQUIP

Closed-End Welding Electrode Holder

ActiveUS20100126977A1Avoid problemsClamp tightlyElectric discharge heatingNon-shielding electrode holdersEngineeringElectrode

Owner:LANGLEY CHARLES MARK

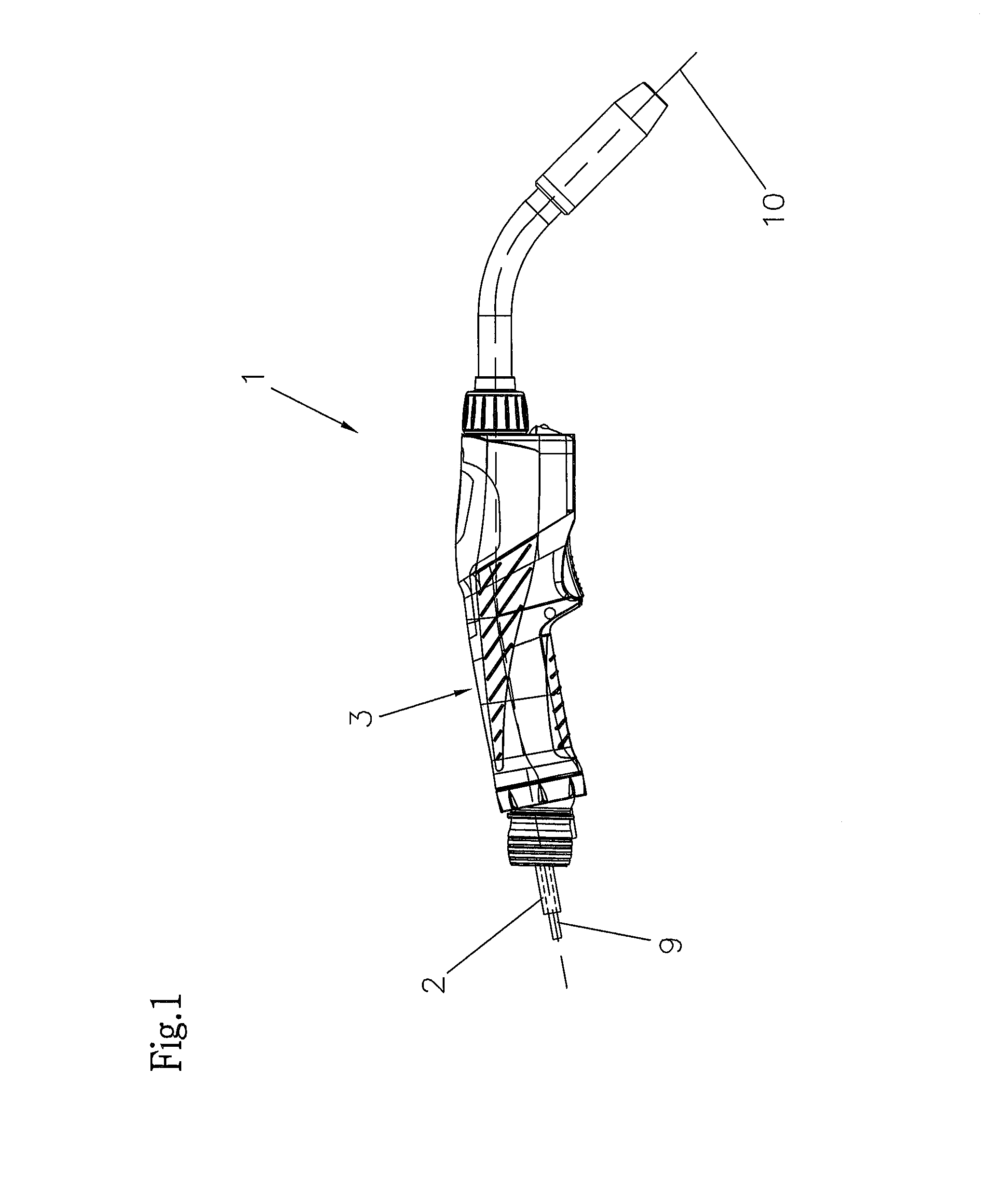

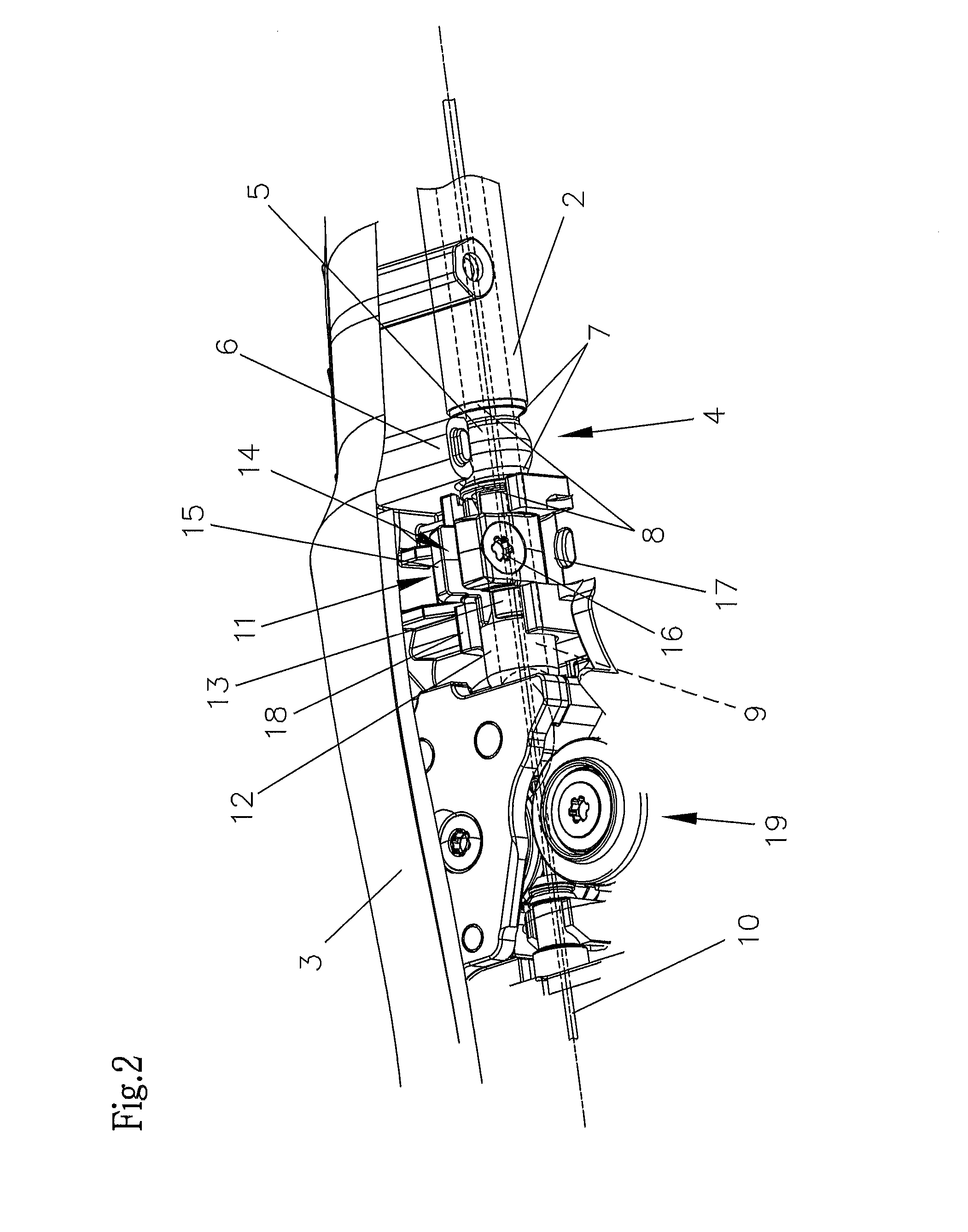

Welding torch

ActiveUS20150069041A1Reduce the burden onStable positionElectric discharge heatingNon-shielding electrode holdersEngineeringWelding torch

A welding torch, in particular a handheld welding torch, for a melting welding wire, which is guided in a wire core arranged within a protective hose, fastens the protective hose and the welding core within a torch housing of the welding torch independently from one another. For minimizing stresses on the welding torch by the hose package, the protective hose is fastened rotatably and pivotably and the wire core is fastened rotatably to the torch housing.

Owner:FRONIUS INTERNATIONAL GMBH

Closed-end welding electrode holder

ActiveUS8450648B2Prevents gripping problemClamp tightlyElectric discharge heatingNon-shielding electrode holdersEngineeringElectrode

Owner:LANGLEY CHARLES MARK

Electrode diameter sensing consumables

The present disclosure provides a welding system capable of detecting a size of a welding material and automatically implementing appropriate arc starting parameters. The welding system includes a welder, a welding torch, and a sensor, in which the sensor is configured to detect the size of the welding material, directly or indirectly. The welder is automatically configured to produce an arc having the arc starting parameters determined from the size of the welding material detected by the sensor. The present disclosure decreases operational error by automatically changing arc starting parameters and / or welding parameters based upon a change in welding material size, rather than requiring an operator to manually change the arc starting parameters and / or welding parameters.

Owner:ILLINOIS TOOL WORKS INC

Portable welder gun

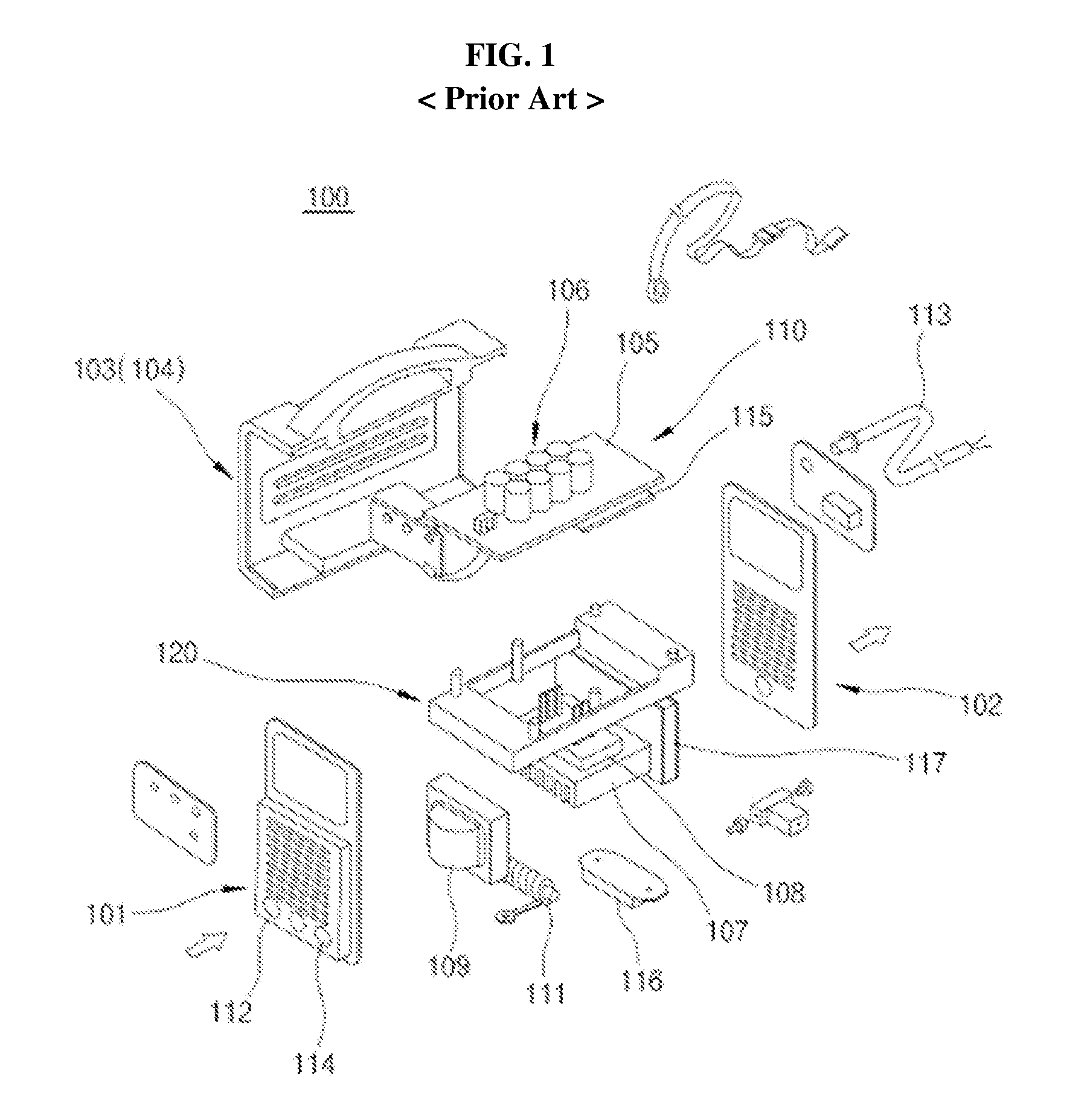

InactiveCN1822914ANon-shielding electrode holdersWelding coupling meansEngineeringMechanical engineering

The portable welding apparatus includes one box shaped body with one welding generator connected to one cooling device, and the welding generator is connected functionally to one electrode holding clip, one earthing clip and one power source system. One handle for holding the welding apparatus and determining the direction of the welding apparatus is stretched from the box shaped body; and the electrode holding clip is connected rigidly to the free end of the handle.

Owner:SELCO SRL

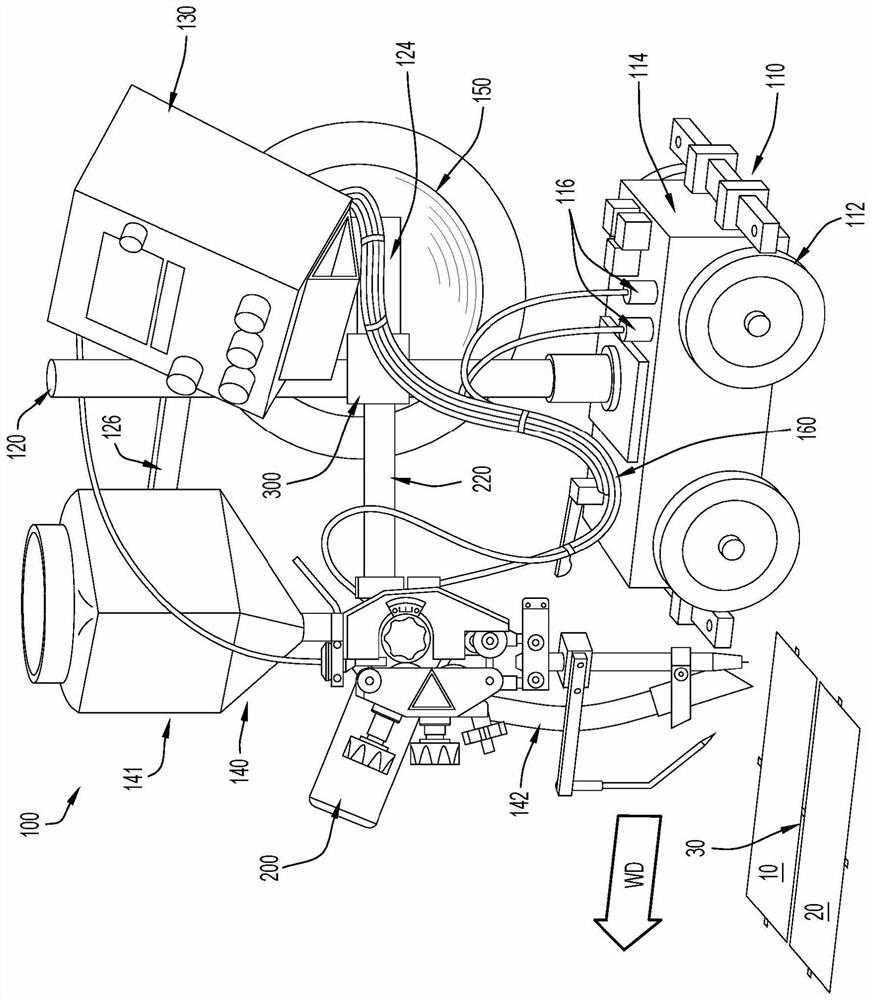

Automated welding system for interchangeable welding heads

InactiveCN112469524ASimplify the configuration processNon-shielding electrode holdersWelding/cutting auxillary devicesEngineeringPhysics

An automated welding system includes a support structure, a plurality of welding heads, and a controller. The plurality of welding heads are each removably, mechanically coupleable to the support structure. The controller is configured to control welding operations of the automated welding system based on an identity of a particular welding head of the plurality of welding heads that is mechanically coupled to the support structure and operably coupled to the controller.

Owner:ESAB AB

Welding consumables and consumable holders

ActiveUS8890029B2Electric discharge heatingNon-shielding electrode holdersEngineeringElectrical contacts

A welding torch with a welding electrode and a welding electrode holder is provided. One welding torch includes a securing mechanism and an insulated grip. The securing mechanism is configured to secure an exposed central portion of a welding rod bounded by flux covered first and second sides. The securing mechanism is also configured to make electrical contact with the central portion of the rod for arc welding with the first side. The insulated grip is configured to cover the second side of the welding rod.

Owner:ILLINOIS TOOL WORKS INC

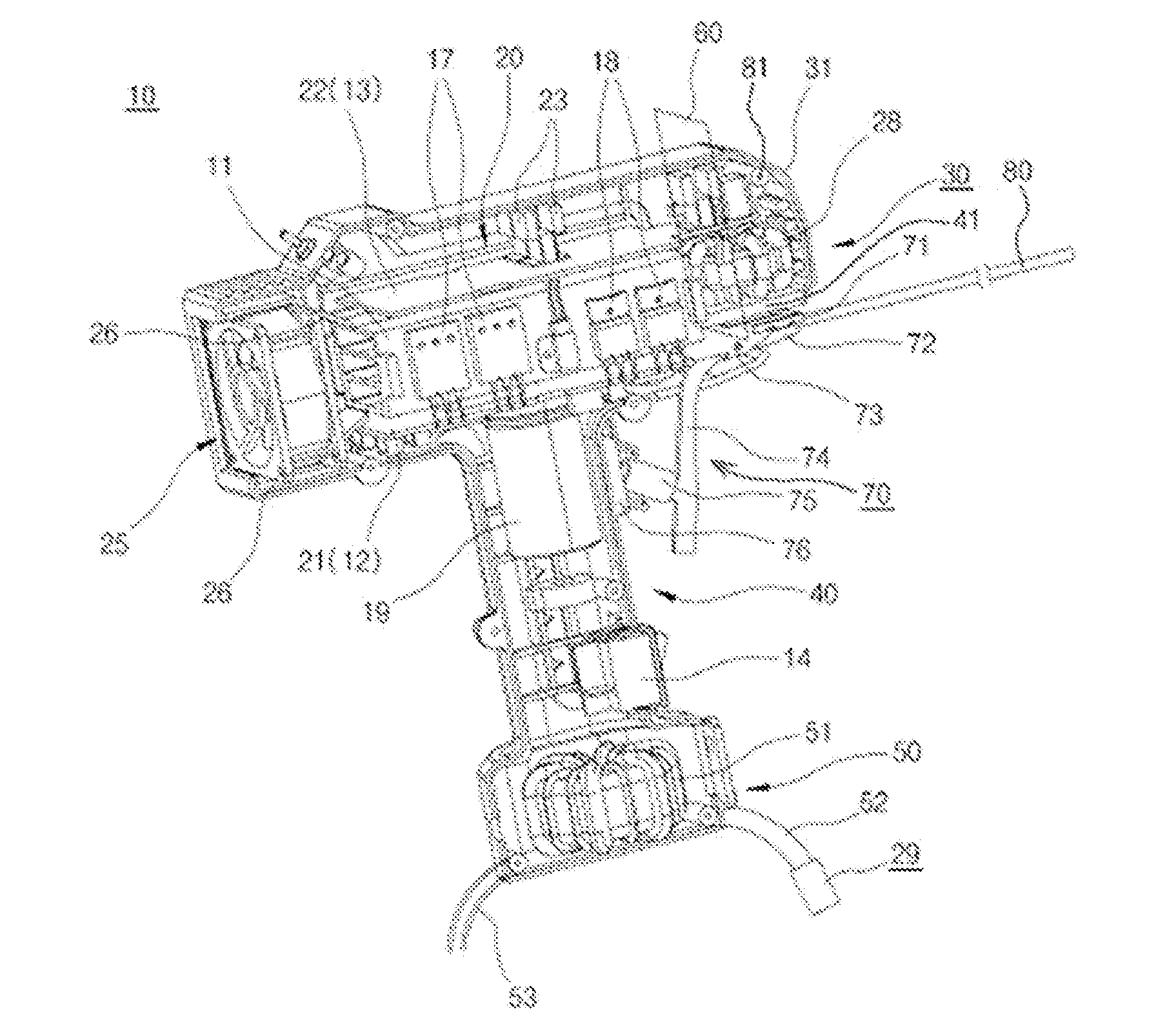

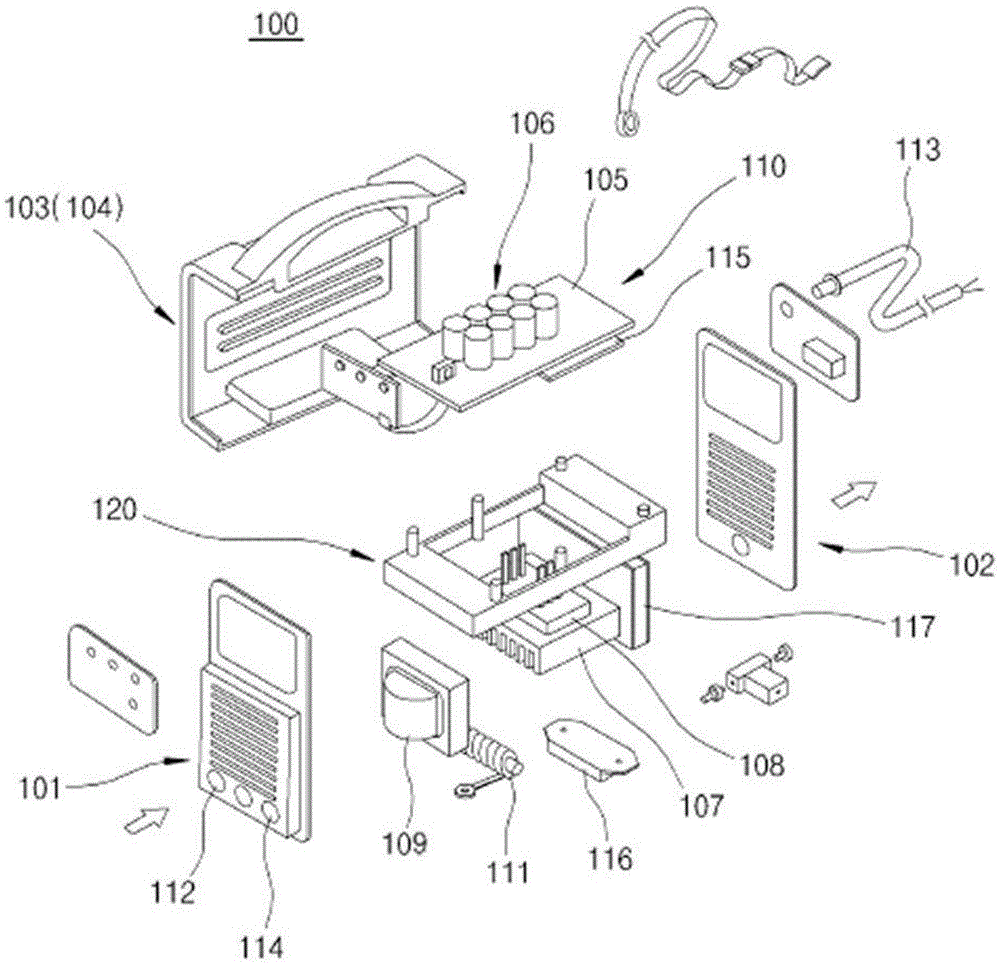

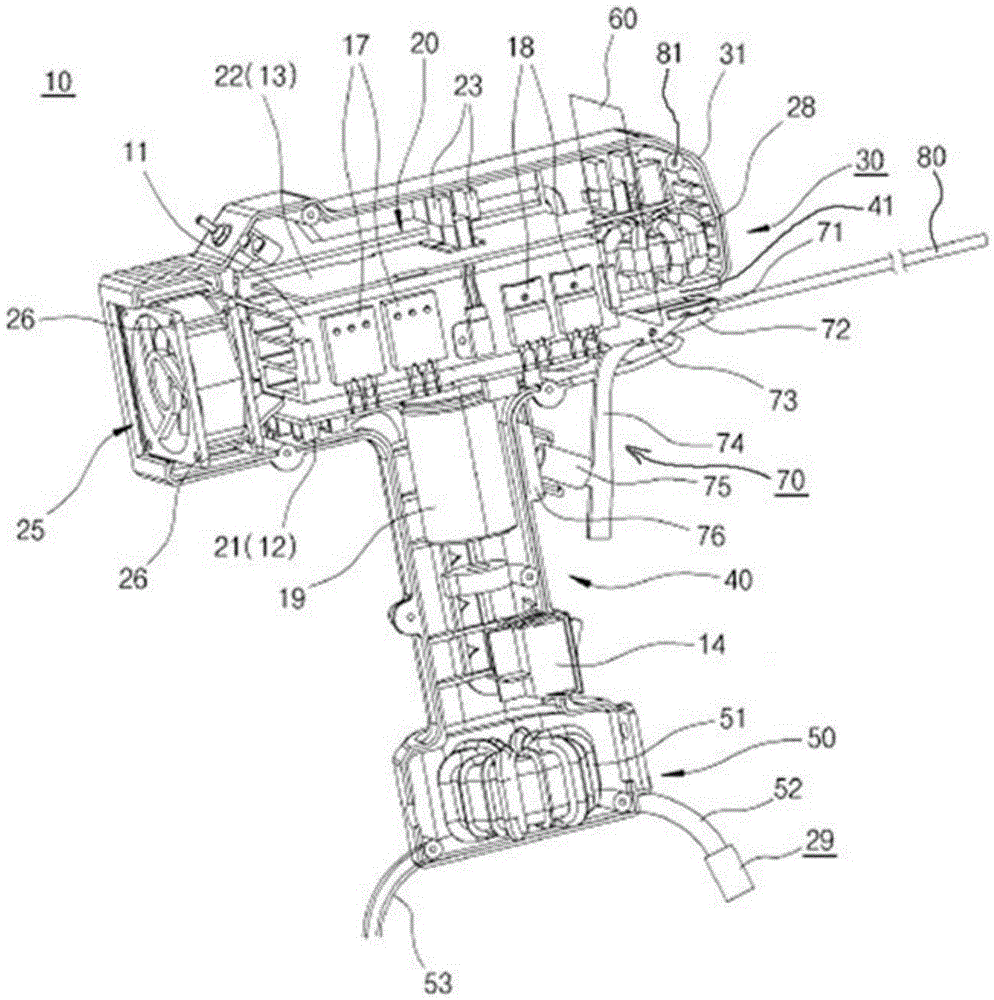

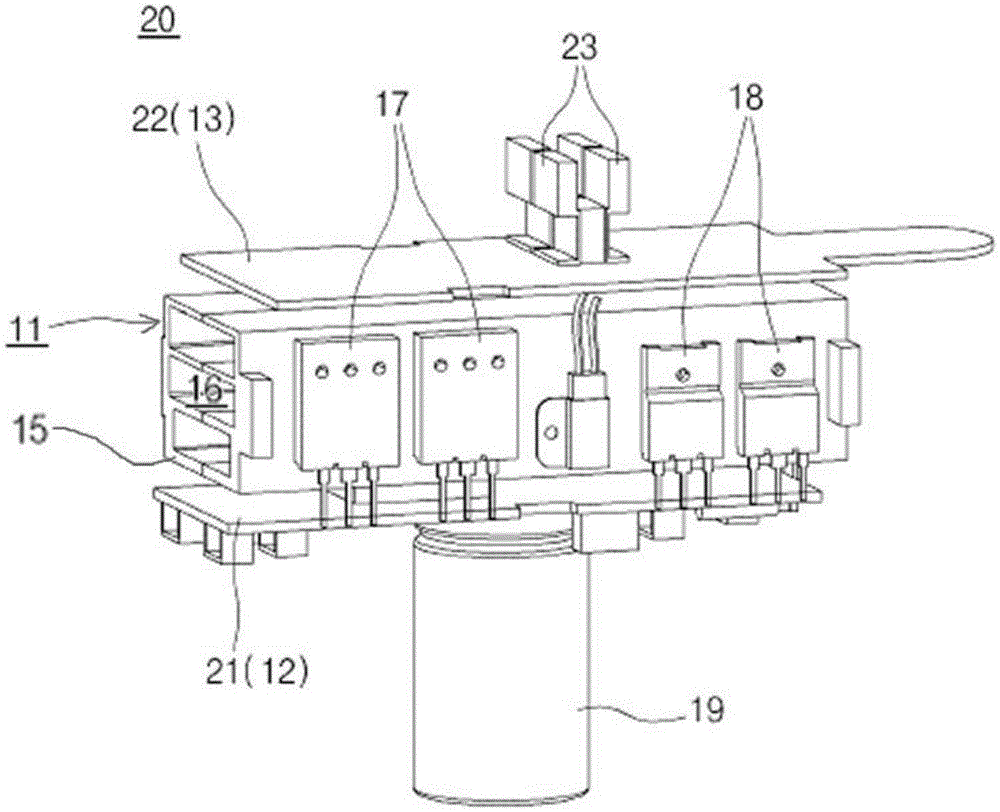

Integrated single body compact welder

InactiveUS20160221103A1Effectively act for load of systemTake its balanceNon-shielding electrode holdersWelding/cutting auxillary devicesControl systemDirect current

An integrated single body compact welder comprises a single unit constructed as one body in a centralized arrangement, a body portion mounting the single unit therein, an handle portion integrated to the body portion and a welding rod holder mounted on a support portion which is fixed to the body portion, in which the body portion comprises a heat sink, a power input / output circuit portion including a rectifying portion and an inverter circuit constituted by mounting parts on a first print circuit board positioned on the lower surface of the heat sink; and a system operating control portion including a system direct current supply portion and a control portion including a pulse width modulation circuit for controlling a system output power, which are constituted by mounting parts on a second print circuit board positioned on the upper surface of the heat sink.

Owner:REXWELL CO LTD

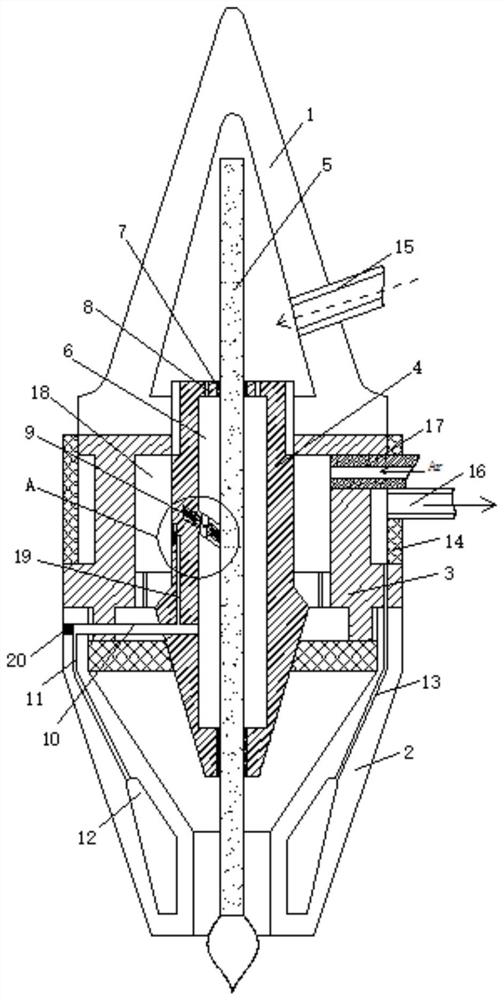

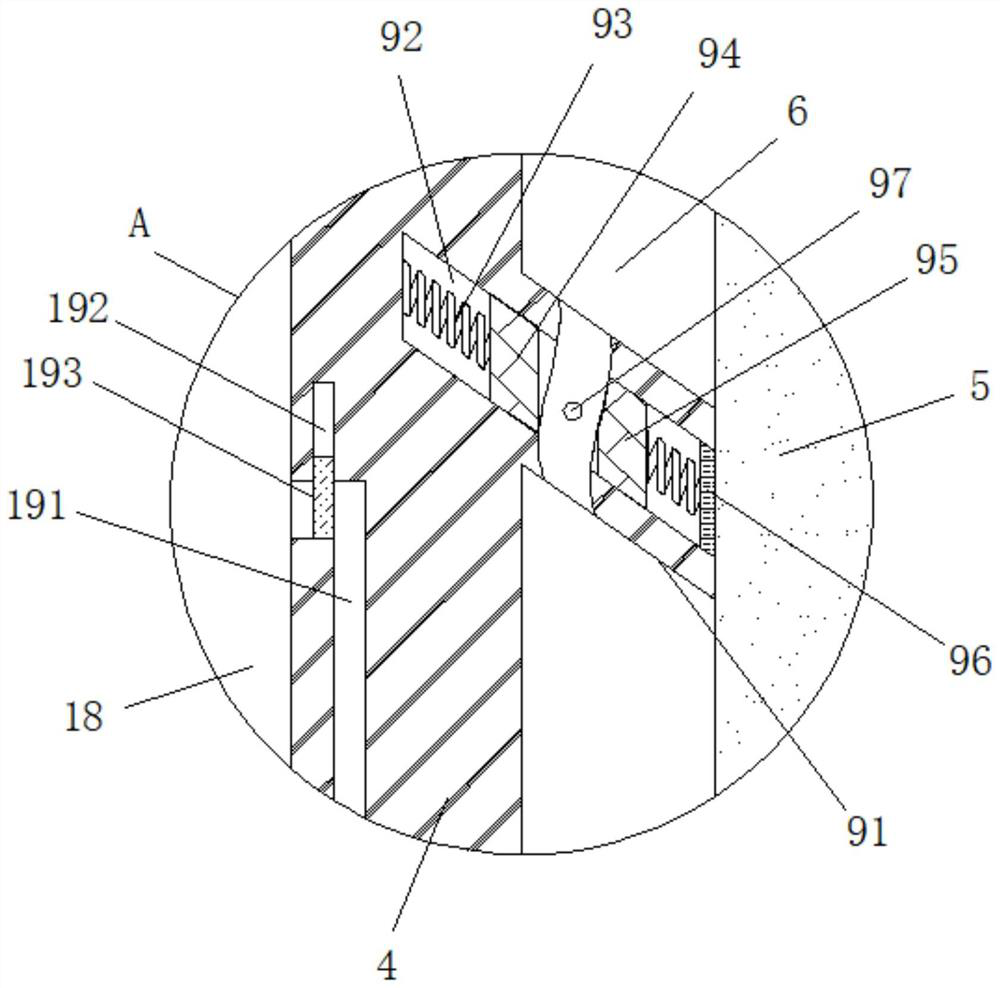

Tungsten electrode argon arc welding gun

PendingCN114147326AAvoid ablationAvoid damageNon-shielding electrode holdersElectrode accessoriesWater flowCold area

The invention relates to the technical field of arc welding equipment, and discloses an argon tungsten-arc welding gun which comprises an upper gun body, a middle insulator and a lower gun body, the upper gun body, the middle insulator and the lower gun body are arranged in an upper-middle-lower mode to form the complete welding gun, and a chuck is fixedly installed in the middle of the lower gun body. The liquid cooling cavity is formed in the chuck, water cooling used for cooling the chuck directly acts on the tungsten electrode bar, compared with original indirect action, the tungsten electrode bar can be more effectively prevented from being ablated, meanwhile, the power control device is arranged in the liquid cooling cavity, two different flowing states of water flow during water supply and water cut-off are used as conditions, and the energy consumption is reduced. And once water cooling is stopped, power supply is stopped immediately, and the tungsten electrode bar does not work any more, so that the situation that the tungsten electrode bar is ablated before the welding gun is closed due to the lack of the cold area effect of water cooling during water supply is effectively prevented, the ablation and damage of the welding gun are avoided, and the replacement cost of the welding gun is effectively reduced.

Owner:黄培

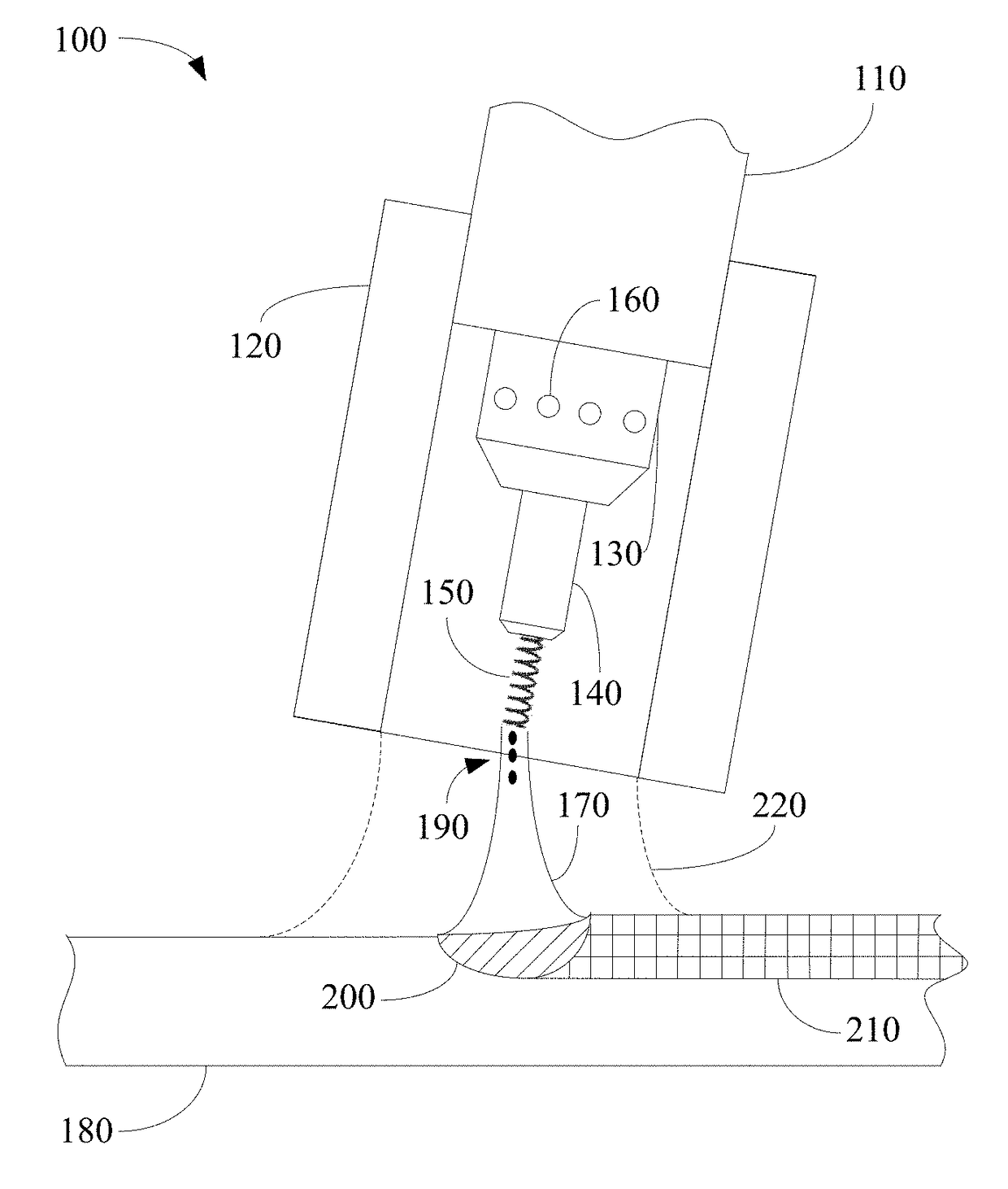

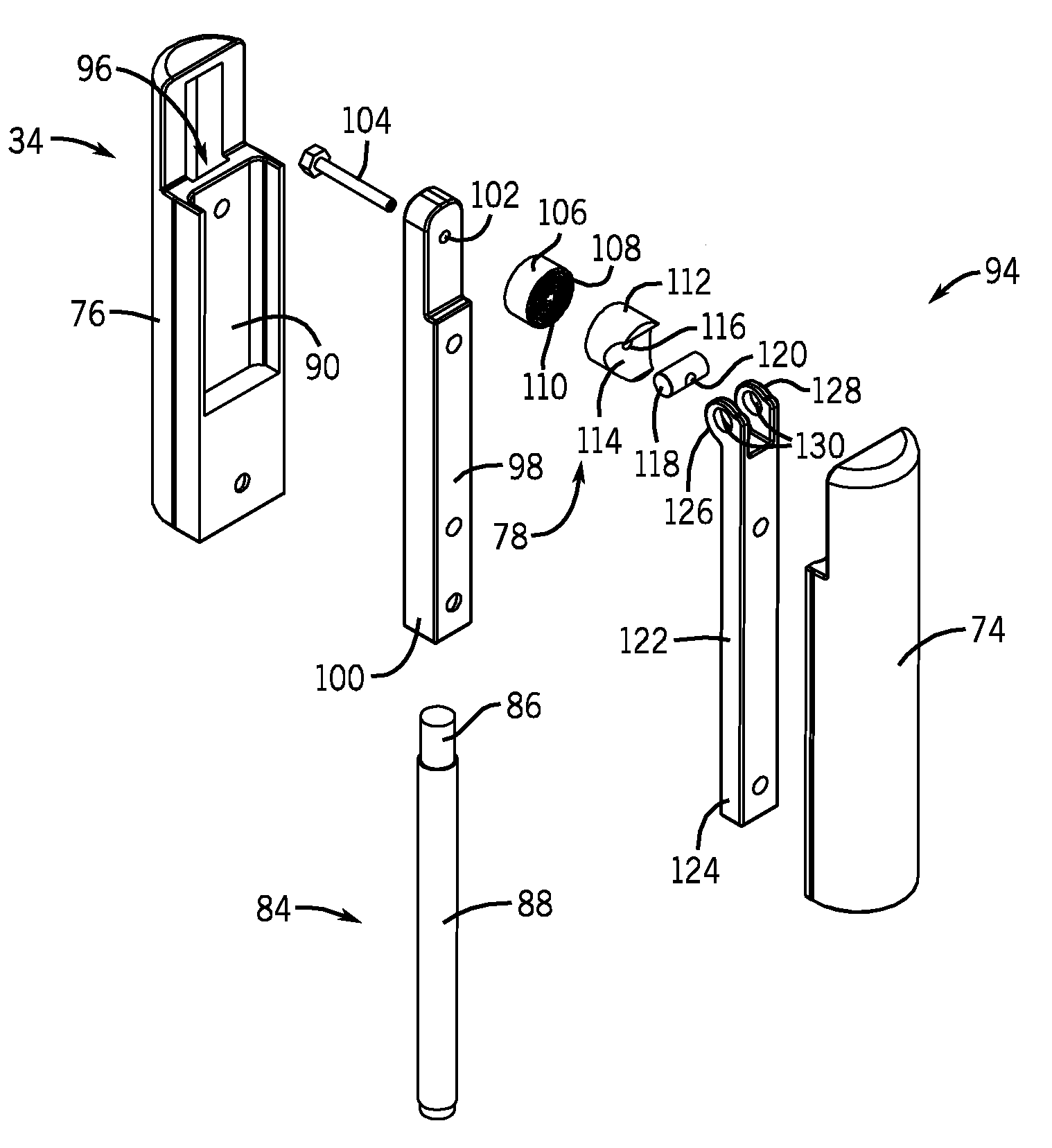

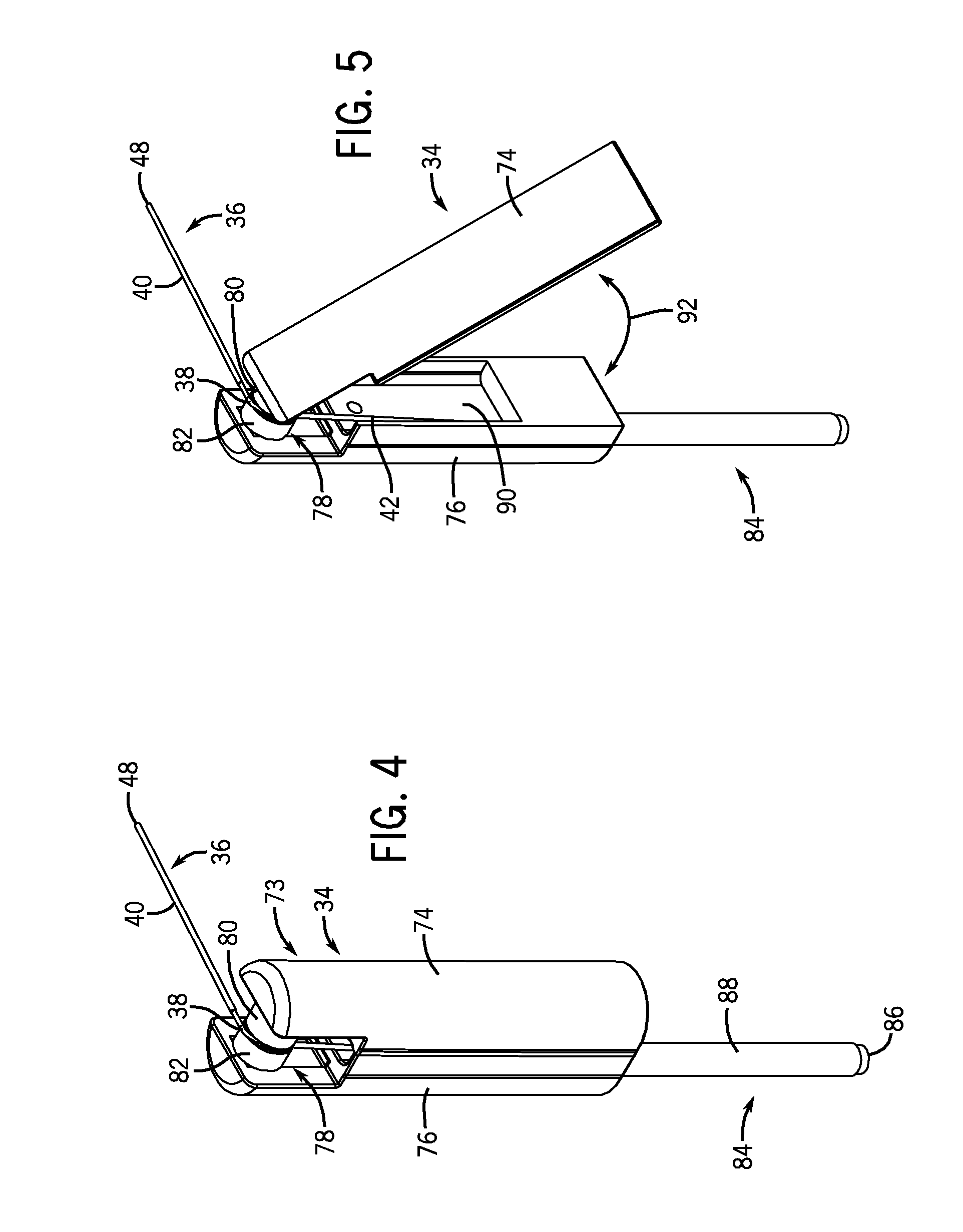

Hand held arc welding rod holder with integral arc welding lead contact and automatic arc welding rod feed mechanism

According to an embodiment of the disclosure, a welding rod holder comprises a body, an electrical contact tip, a slider, and a biasing mechanism. The body has a lower end and an upper end. The electrical contact tip is coupled to the body and is configured to electrically contact a welding rod. The slider is configured to allow the welding rod to move with respect to the body. The biasing mechanism is configured to move the welding rod out of a lower end of the body. The hand brake is configured to selectively allow the biasing mechanism to move the welding rod out of a lower end of the body. The movement of the welding rod out of a lower end of the body is configured to allow a substantially similar distance between the body and a welding work as the welding rod is exhausted.

Owner:VAN STEENBURG MICHAEL

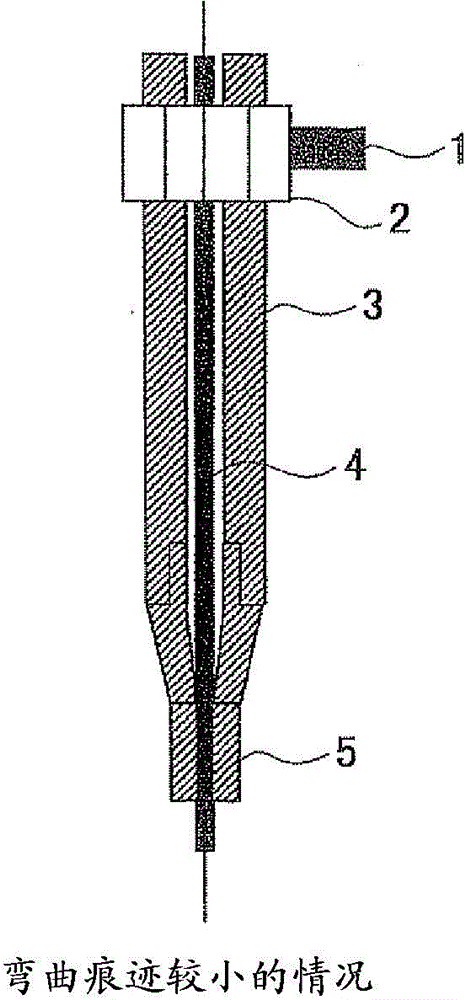

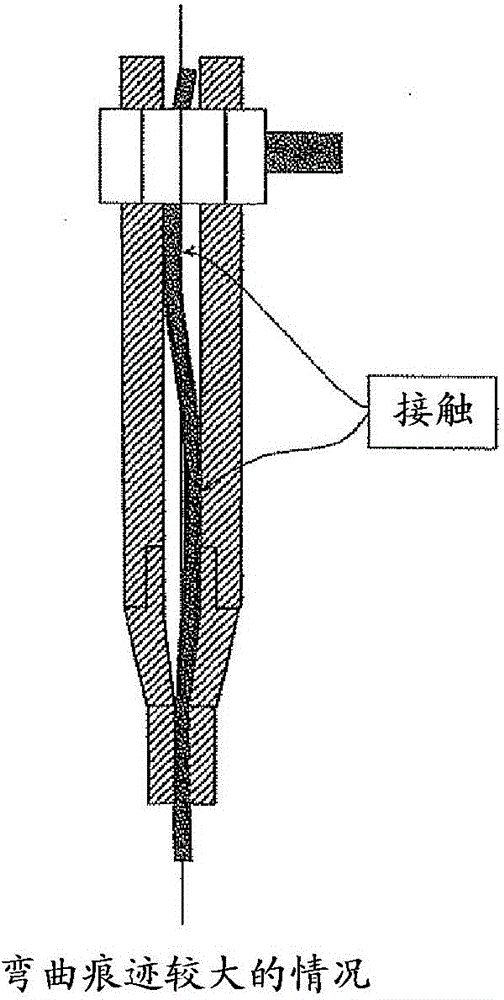

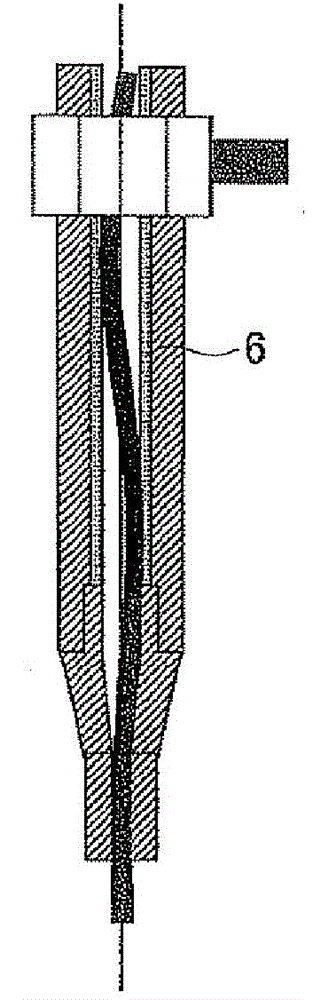

Welding torch for first electrode for multi-electrode submerged arc welding and welding method using same

InactiveCN104159694AGood effectImprove qualityNon-shielding electrode holdersElectrode accessoriesConductor CoilWelding torch

The present invention provides a welding technique for multi-electrode submerged arc welding that is stable even if a small-diameter wire is used with a first electrode, in particular if welding is being carried out under welding conditions where the wire feed speed increases or if there is considerable kinked winding, even after correction, with a flux cored wire. A welding torch for a first electrode for multi-electrode submerged arc welding and a method for multi-electrode submerged arc welding using the same are characterized by comprising a means for insulating, from an electrode wire, a tubular electric conductor that is arranged between a power supply chip and a connecting part of a power supply cable.

Owner:JFE STEEL CORP

Single-body concentration-type small welding machine

InactiveCN105834555AEasy to carryImprove cooling effectNon-shielding electrode holdersWelding/cutting auxillary devicesControl systemSystem configuration

A single-body concentration-type small welding machine comprises: a single unit constructed in a single-body integration type; a main body unit on which the single unit is installed; a handle unit integrally coupled to the main body unit; and welding rod holders installed on a support unit, which is fixed to the main body unit, wherein the main body unit is made compact by the single unit comprising a heat sink, a power input / output circuit unit comprising a rectification unit and inverters on a single first printed board installed on the lower surface of the heat sink, a system direct current supply unit comprising components for rectifying commercial power mounted on a different single second printed board installed on the upper surface of the heat sink, and system operation control units comprising a control unit having a pulse width modulation (PWM) circuit for controlling the system output power. System components are divided into a heat-generating component group and a non-heat-generating component group, thereby improving the heat-radiating effect, and proper arrangement of independent components not only diversifies the overall system configuration, but also makes the design simple and compact, thereby providing an integrated small welding machine that can be carried conveniently.

Owner:株式会社热士威

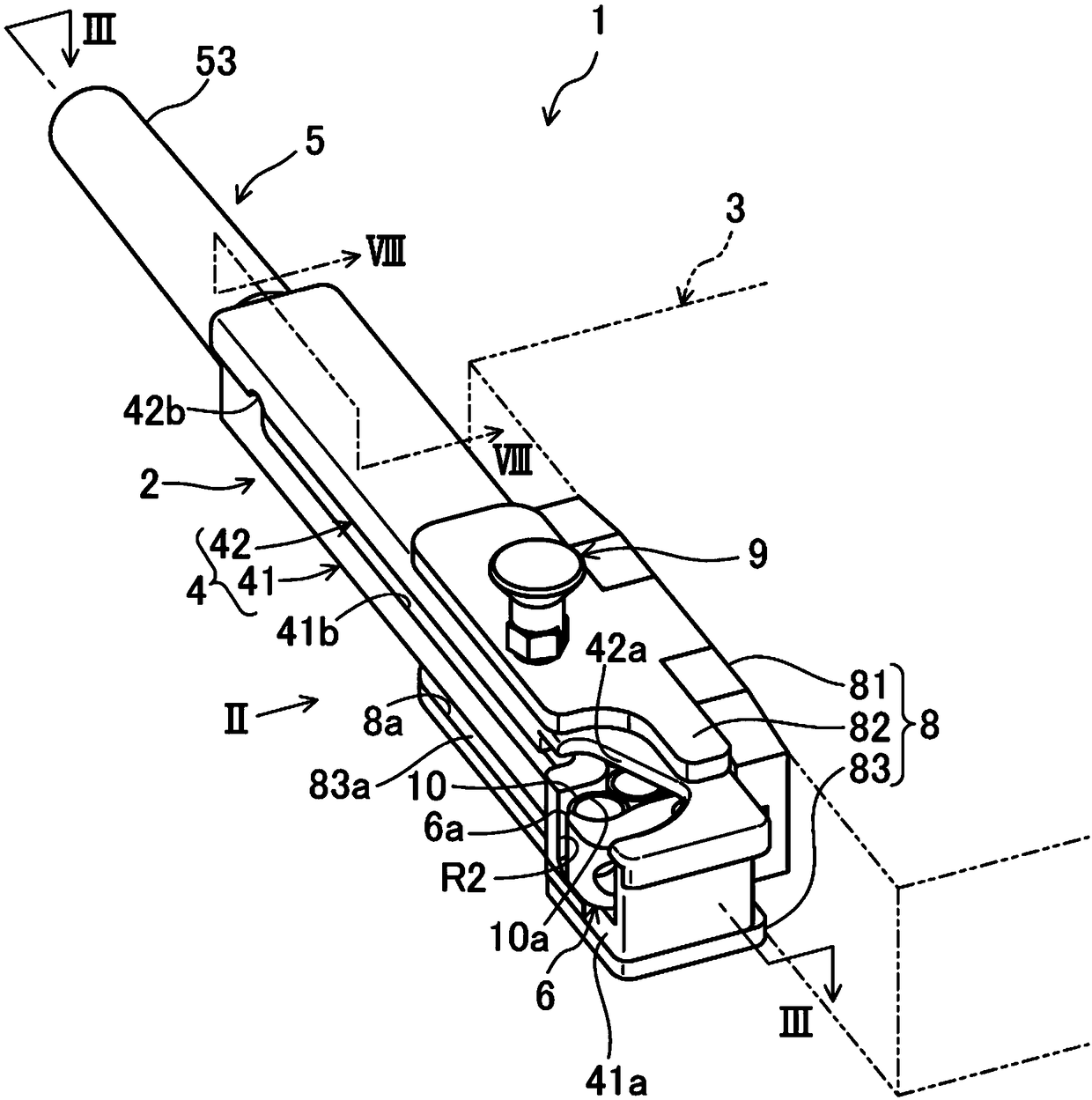

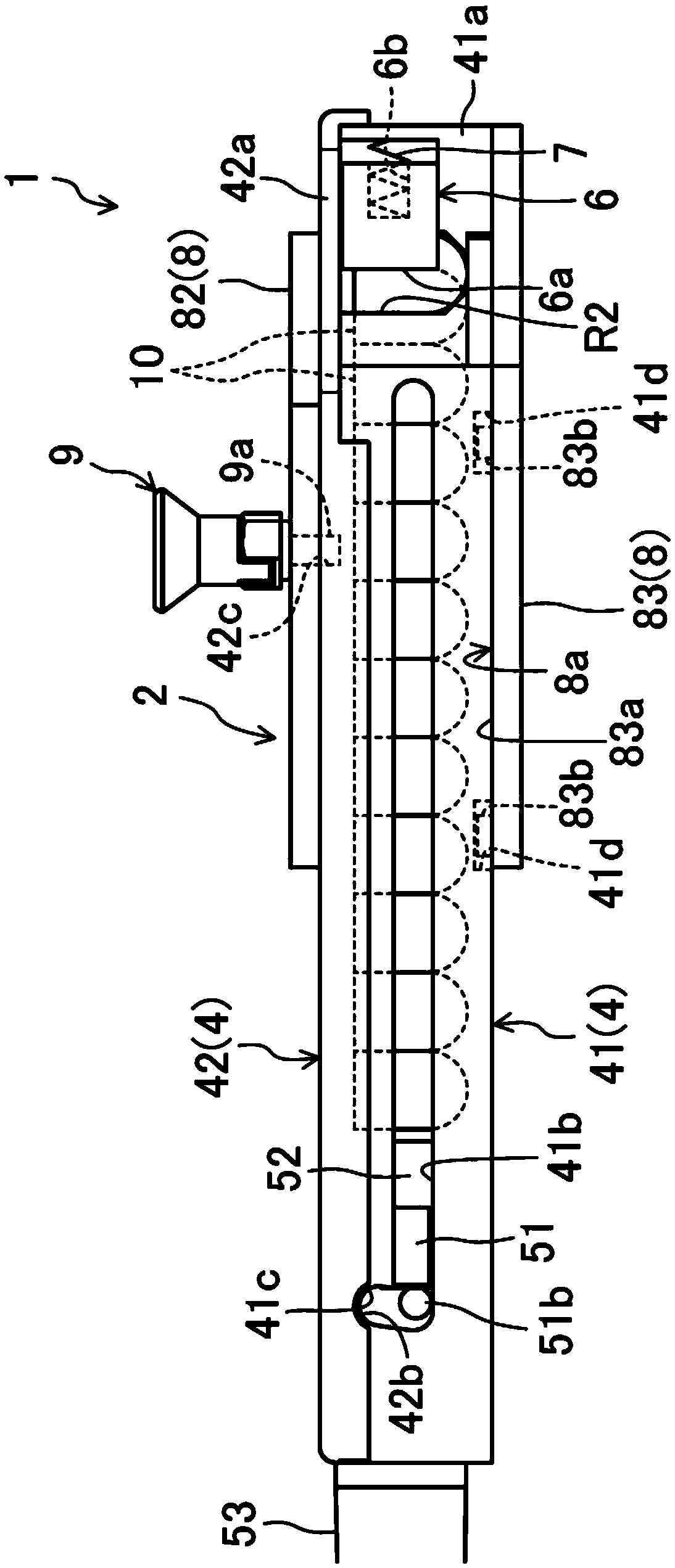

Electrode housing device for spot welding

ActiveCN109311117AReduce work failurePrevent immobilityNon-shielding electrode holdersElectrode featuresCoil springEngineering

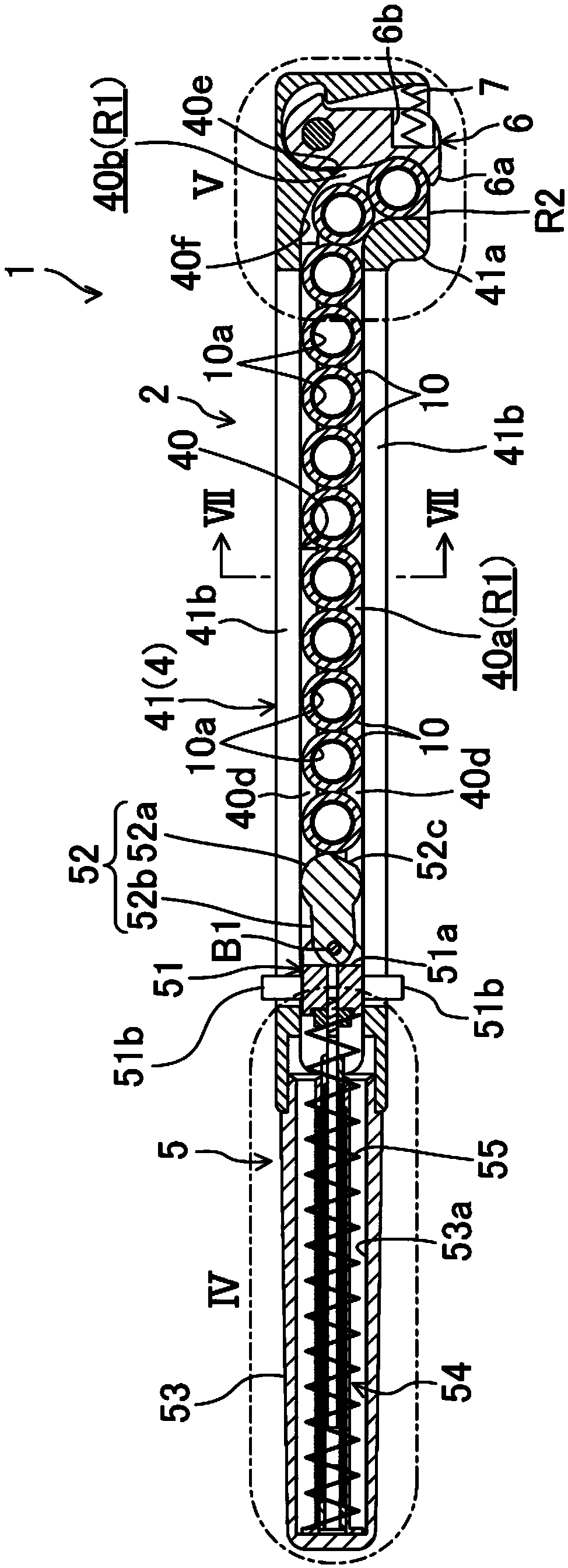

An accommodating case (4) has an accommodating passage (R1) that linearly accommodates a plurality of electrodes (10) in the interior thereof. An electrode outlet (R2) that communicates with the accommodating passage (R1) is formed in one end of the accommodating case (4). A pressing unit (5) presses the plurality of electrodes (10), which are in a state of being set in a row accommodated in the accommodating passage (R1), toward one end of the accommodating passage (R1). A lever member (6), by swinging, switches unloading of the electrodes (10) from the electrode outlet (R2) between a regulated state and an open state. A regulating coil spring (7) biases the lever member (6) so as to swing in one direction.

Owner:KYOKUTOH

Welding torch

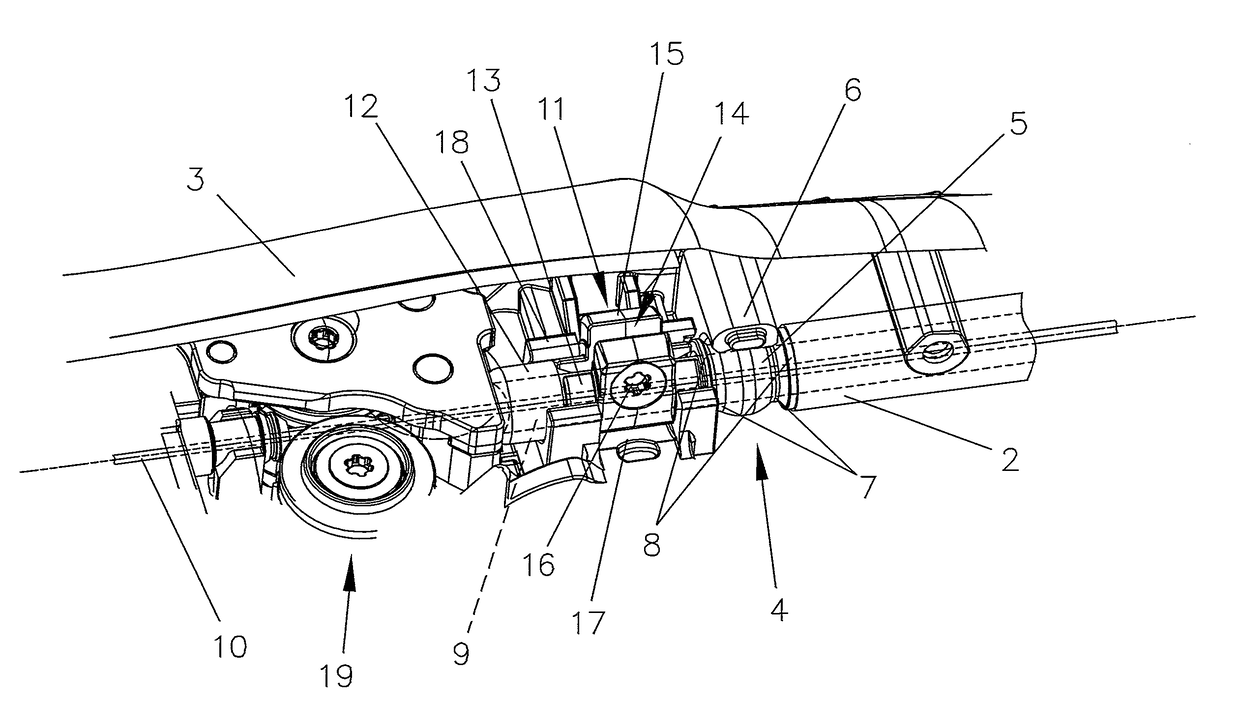

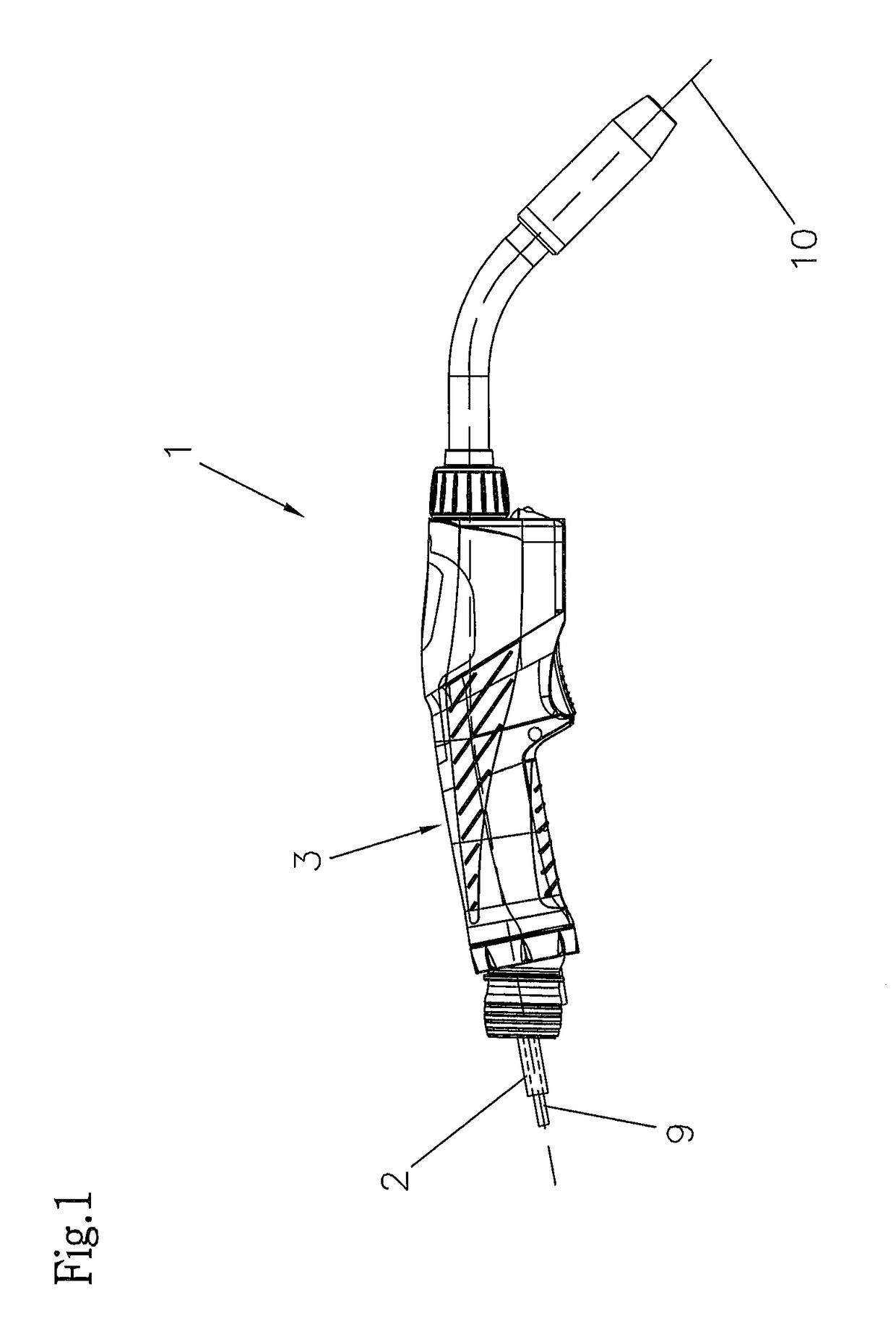

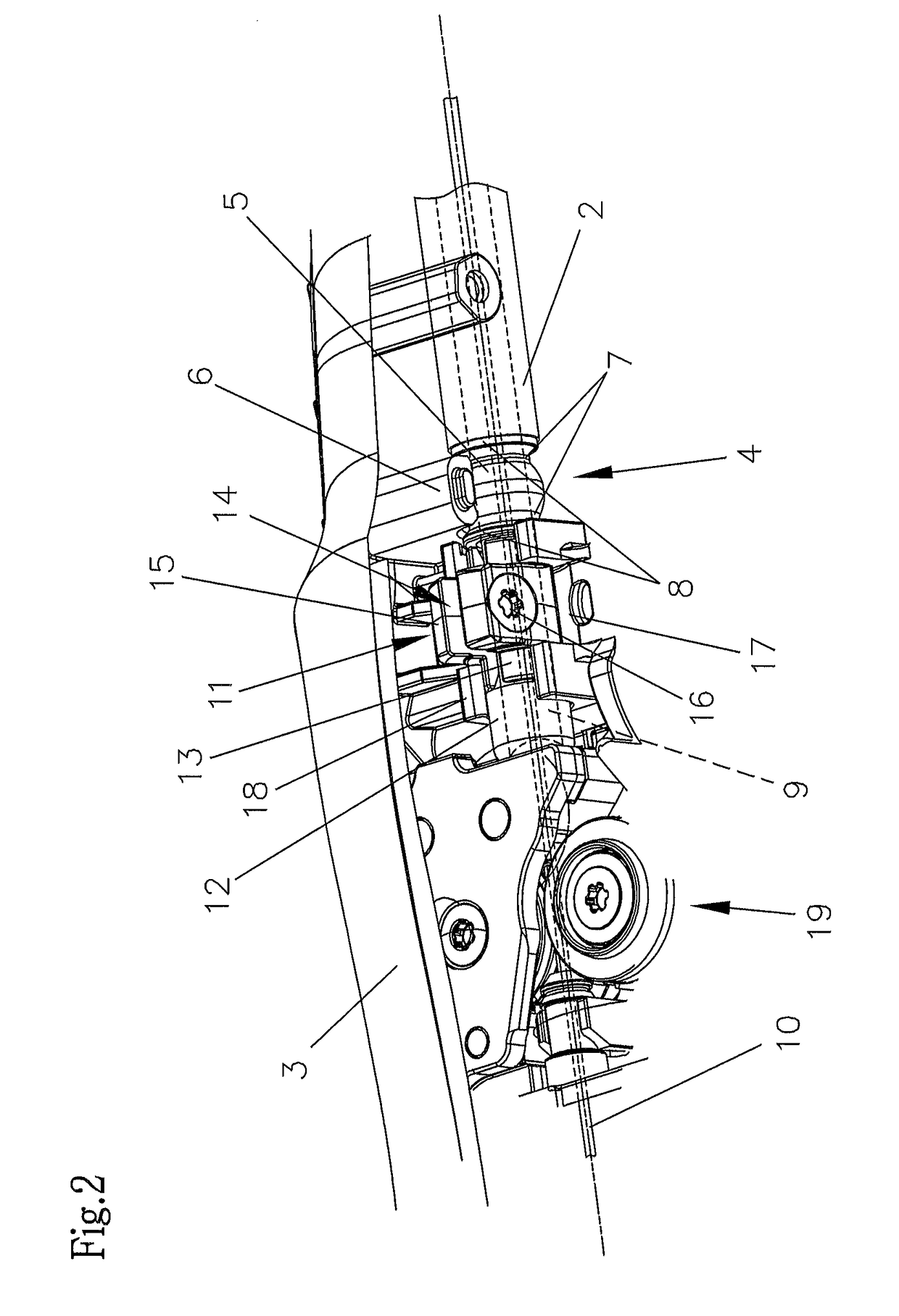

ActiveUS9610647B2Reduce the burden onEasy to handleSupport devices with shieldingNon-shielding electrode holdersWelding torchWelding

A welding torch, in particular a handheld welding torch, for a melting welding wire, which is guided in a wire core arranged within a protective hose, fastens the protective hose and the welding core within a torch housing of the welding torch independently from one another. For minimizing stresses on the welding torch by the hose package, the protective hose is fastened rotatably and pivotably and the wire core is fastened rotatably to the torch housing.

Owner:FRONIUS INTERNATIONAL GMBH

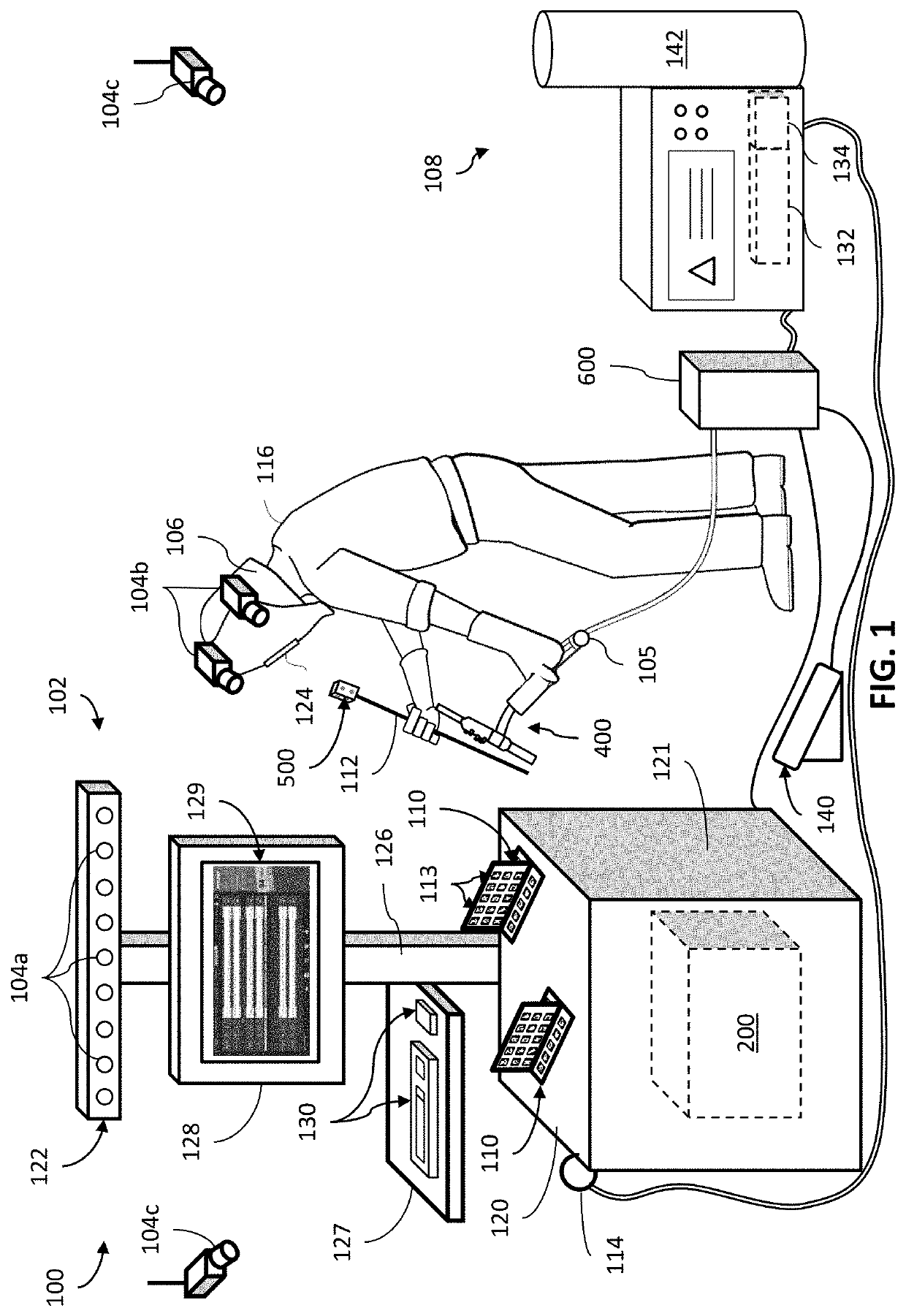

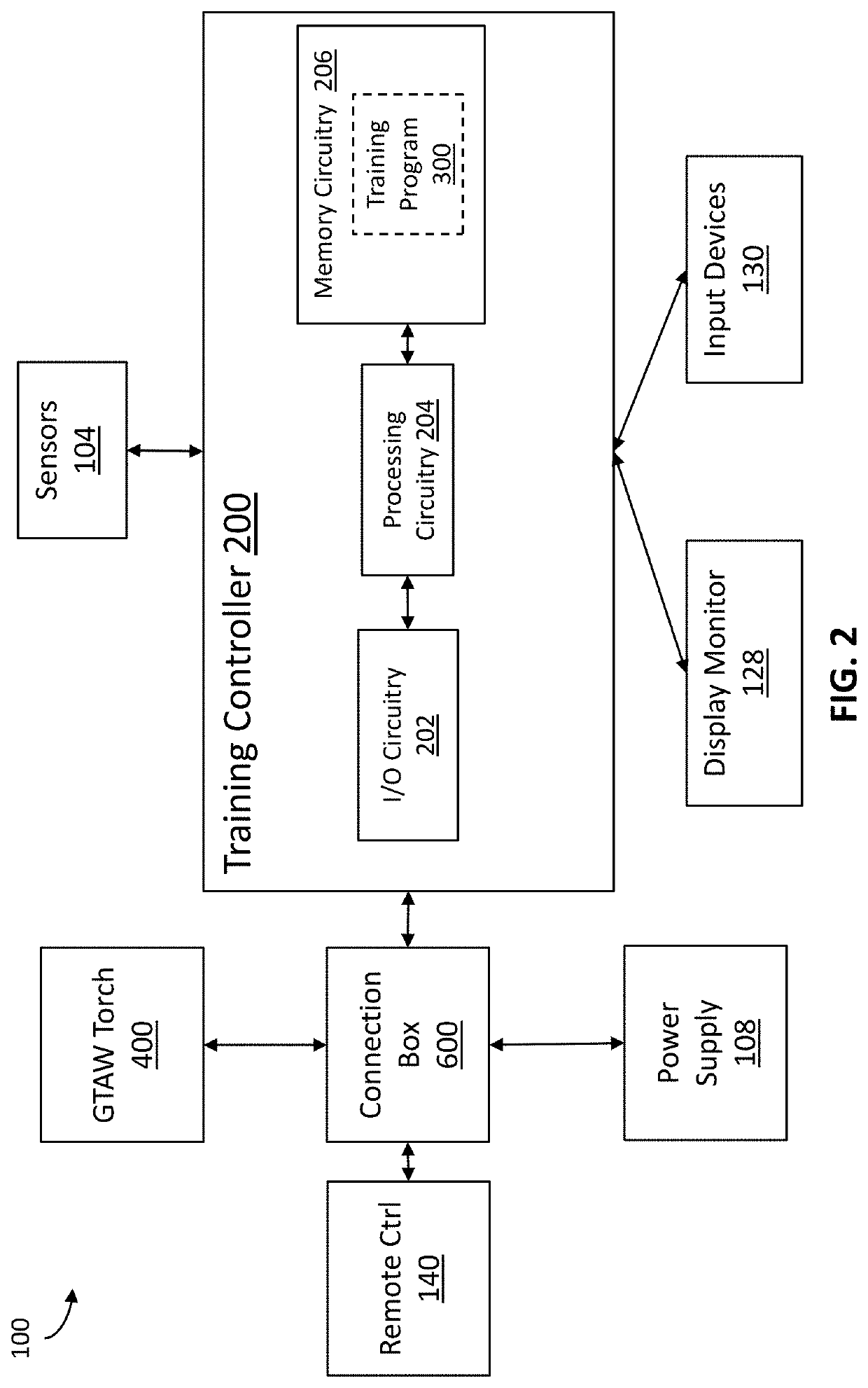

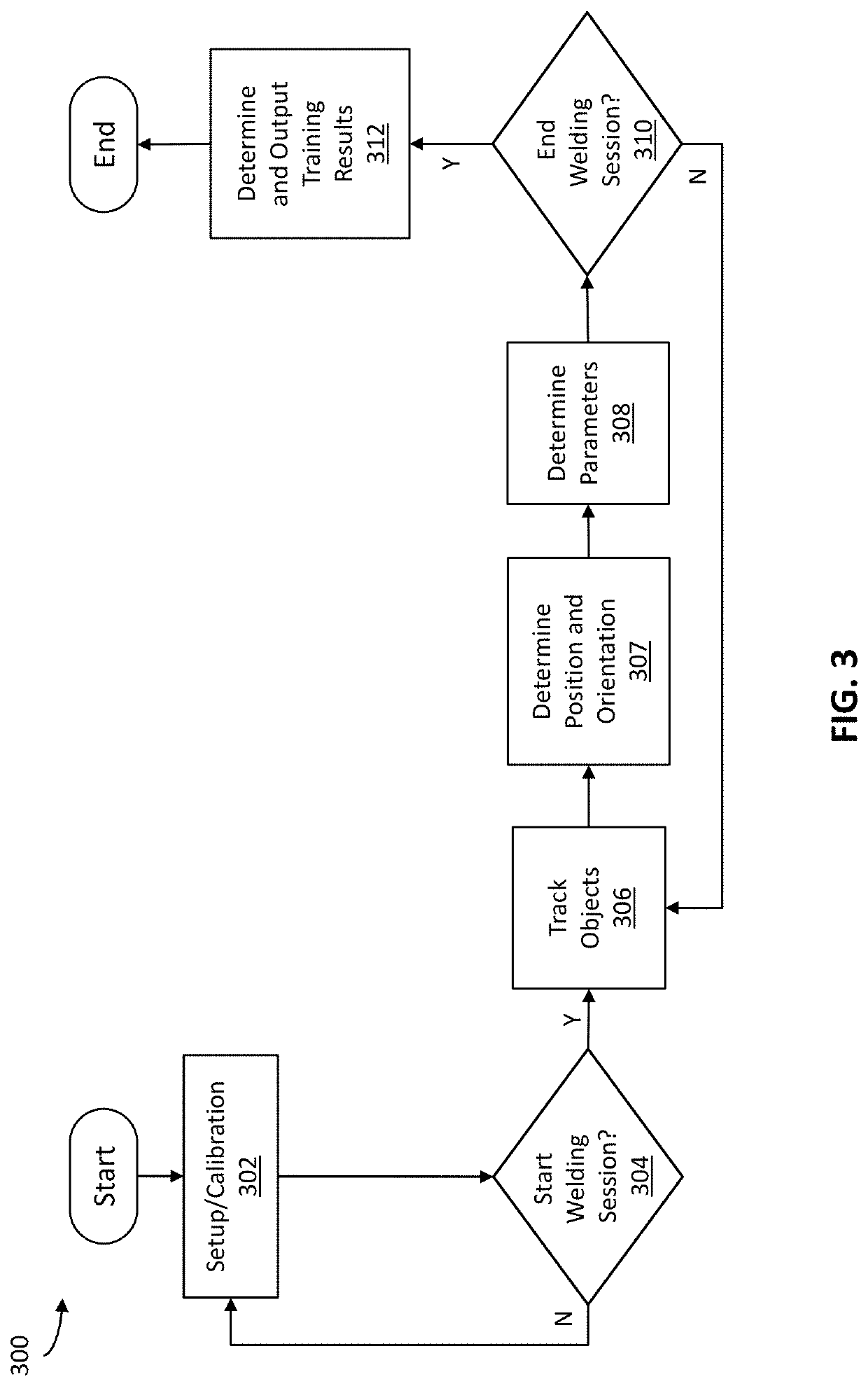

Connection boxes for gas tungsten arc welding training systems

ActiveUS20210027657A1Cosmonautic condition simulationsNon-shielding electrode holdersRemote controlProcess engineering

Connection boxes for gas tungsten arc welding (GTAW) training systems are described. In some examples, a connection box of the GTAW training system coordinates delivery of welding-type power to a GTAW torch during training. In some examples, a remote control (e.g., foot pedal) may be activated at different levels to command different levels of welding-type power be delivered to the GTAW torch from a welding-type power supply. In some examples, the connection box may selectively enable or disable communication between the remote control and welding-type power supply during training. In some examples, this selective enablement / disablement may be based on whether the GTAW training system is in a live-arc mode or simulation mode

Owner:ILLINOIS TOOL WORKS INC

Hand held arc welding rod holder with integral arc welding lead contact and automatic arc welding rod feed mechanism

According to an embodiment of the disclosure, a welding rod holder comprises a body, an electrical contact tip, a slider, and a biasing mechanism. The body has a lower end and an upper end. The electrical contact tip is coupled to the body and is configured to electrically contact a welding rod. The slider is configured to allow the welding rod to move with respect to the body. The biasing mechanism is configured to move the welding rod out of a lower end of the body. The hand brake is configured to selectively allow the biasing mechanism to move the welding rod out of a lower end of the body. The movement of the welding rod out of a lower end of the body is configured to allow a substantially similar distance between the body and a welding work as the welding rod is exhausted.

Owner:VAN STEENBURG MICHAEL

Torch handle including pneumatically operated jaw

ActiveUS20180169782A1Reduce forceNon-shielding electrode holdersElectrode holder supportersTorchEngineering

Approaches herein provide a torch handle including a pneumatically controlled jaw operable to engage an electrode. In one approach, a system is provided for distributing gas within the torch handle, the system including a pneumatic cylinder within a main housing of the torch handle. The pneumatic cylinder is coupled to a shaft for actuating a first member of a jaw relative to a second member of the jaw. The system further includes a gas passageway through the main housing, the gas passageway extending to an exit orifice disposed within the second member. A flow controller is operable to direct a flow of a gas to either the pneumatic cylinder or the gas passageway. In one approach, the first member is actuated towards the second member when the gas is directed through the gas passageway, and actuated away from the second member when the gas is directed to the pneumatic cylinder.

Owner:VICTOR EQUIP

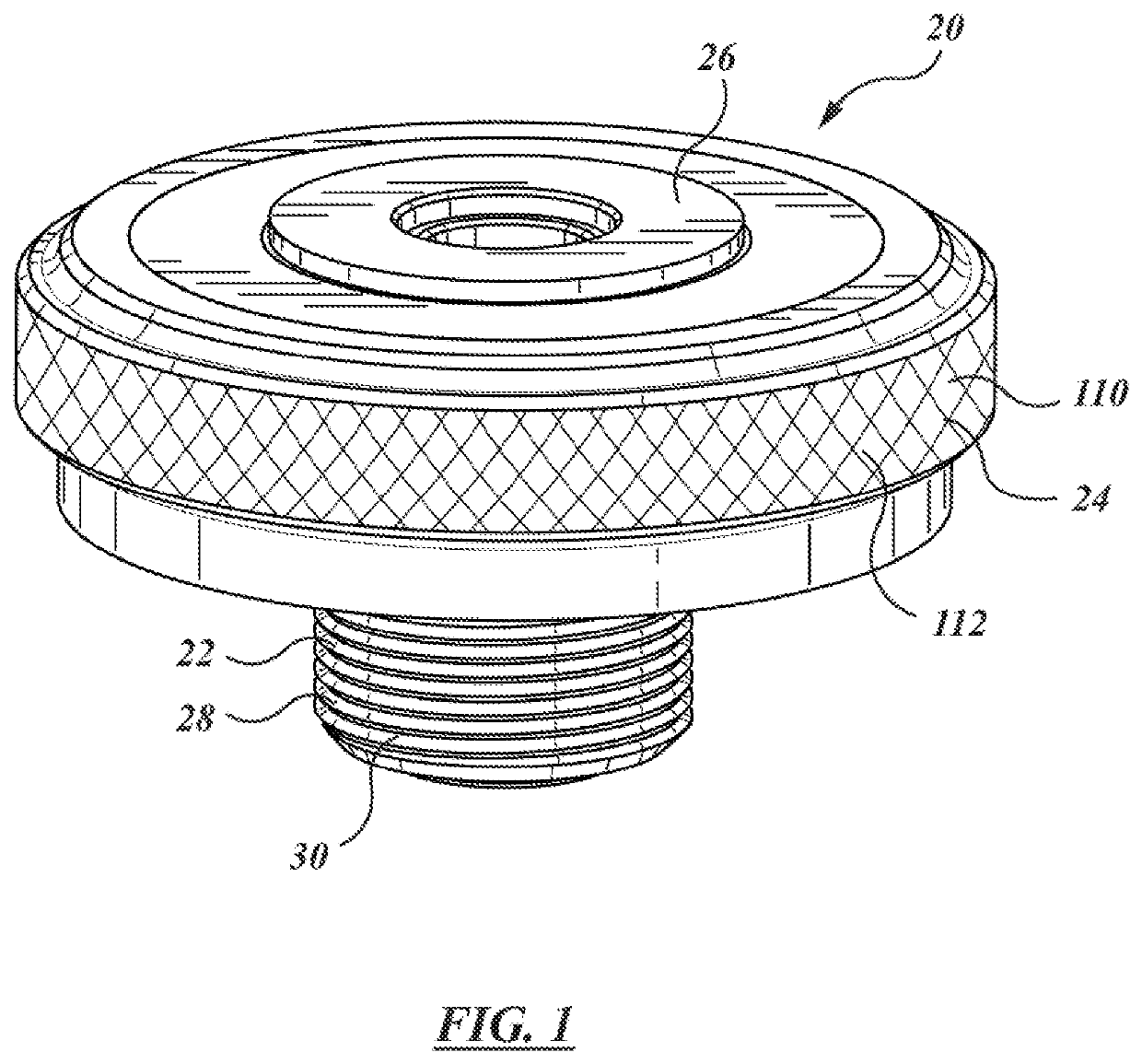

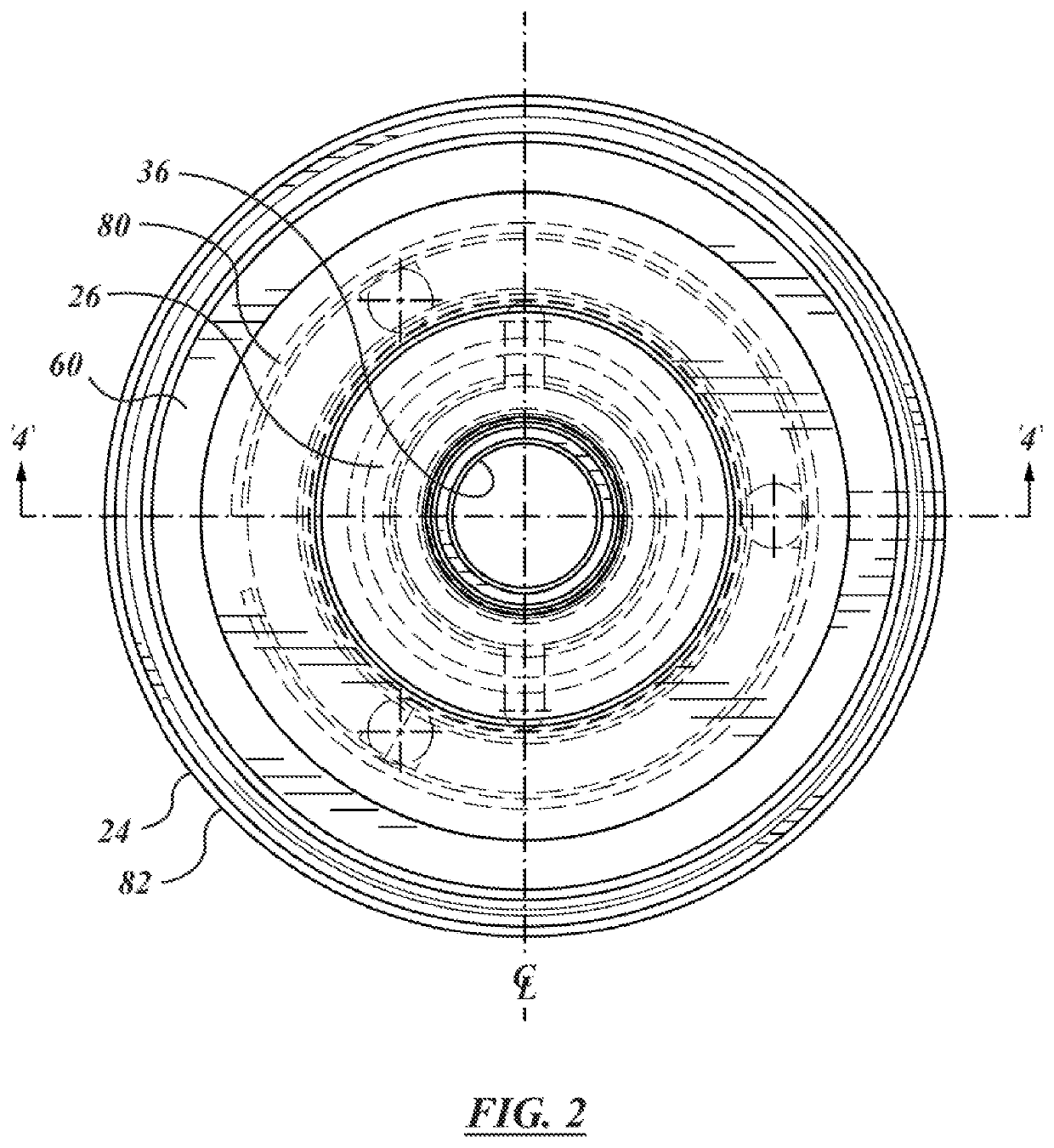

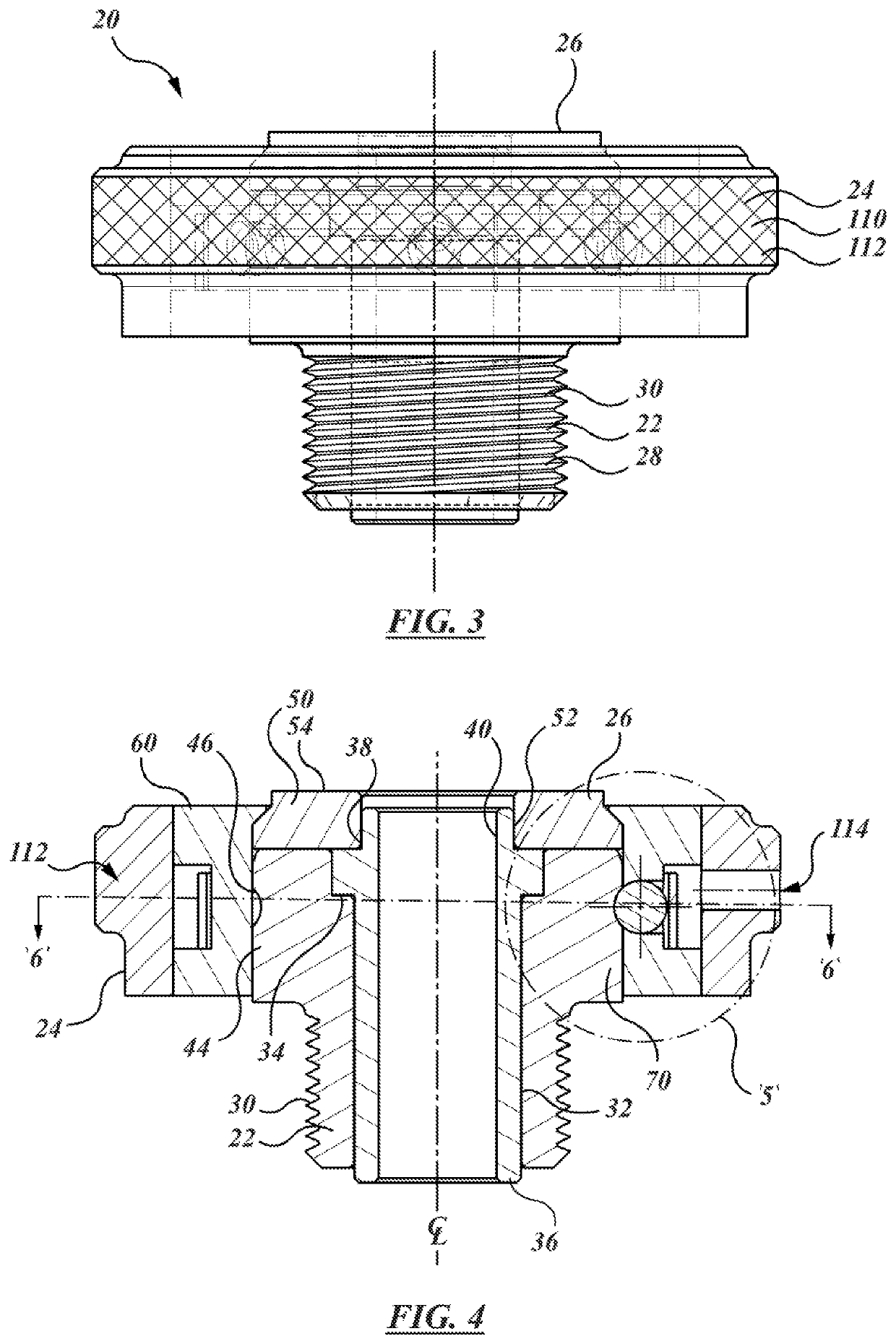

Welding apparatus

ActiveUS10974342B2Non-shielding electrode holdersWelding/cutting media/materialsBall bearingEngineering

A welding electrode apparatus has a base member and a locking ring for clamping a consumable electrode tip to the electrode base. The base and the tip are predominantly made of copper, or a copper alloy. The base member has a first end that is threaded to fit a welding head that supplies electric current; and an electrically conductive second end to which the electrode tip is mounted. The second portion has an externally facing, axially extending cylindrical wall. A circumferential groove is formed in the wall. The locking ring has a quick-disconnect feature in the form of an array of spring-loaded stainless steel ball bearing detents that deflect to ride upon the cylindrical wall, and spring inwardly to seat in the circumferential groove.

Owner:HUYS IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com