Electrode housing device for spot welding

一种收纳装置、电极的技术,应用在电极支撑装置、电极特征、不提供电极屏蔽的电极夹等方向,能够解决电极损耗等问题,达到减少工作故障、外观良好、优异设计性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. It should be noted that the following description of the preferred embodiments is exemplary only in nature.

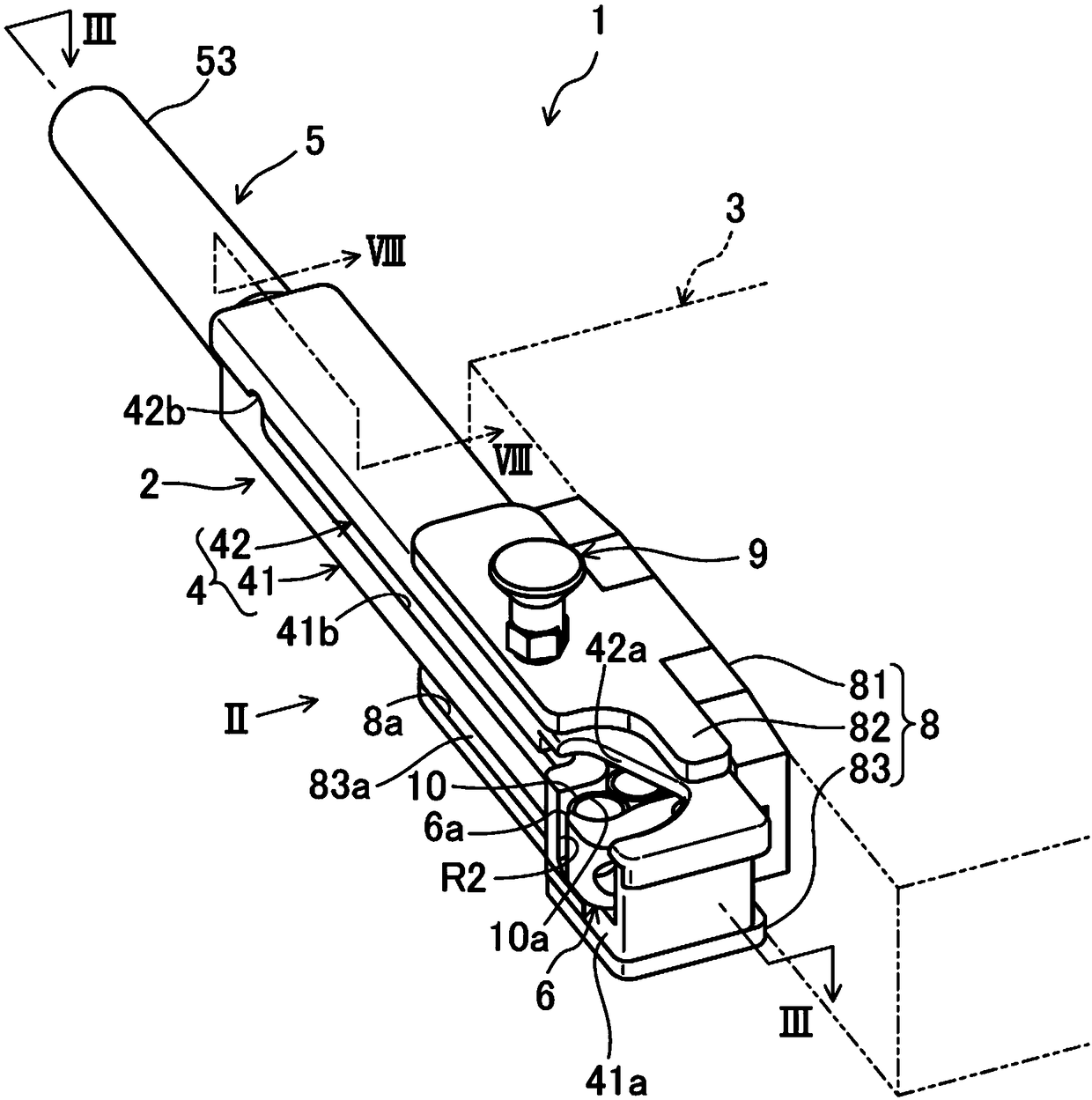

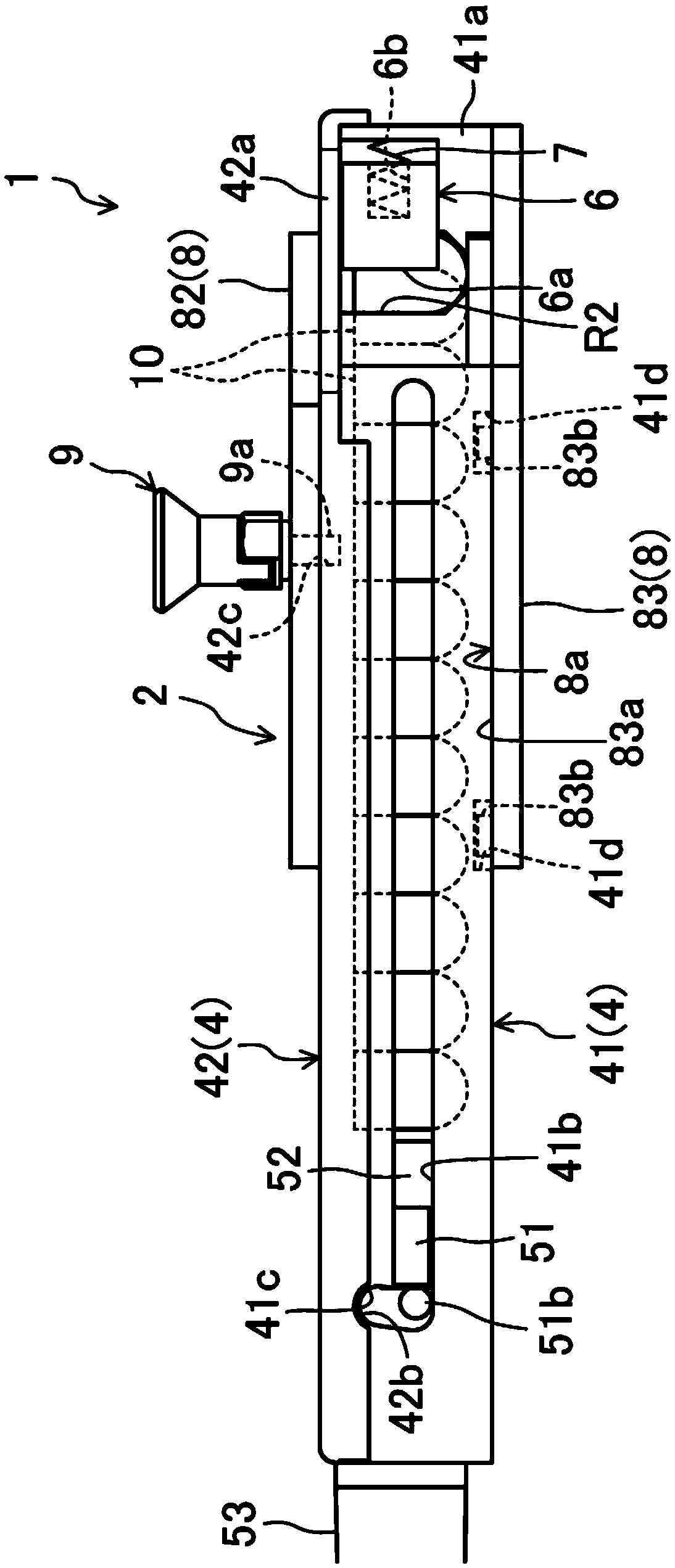

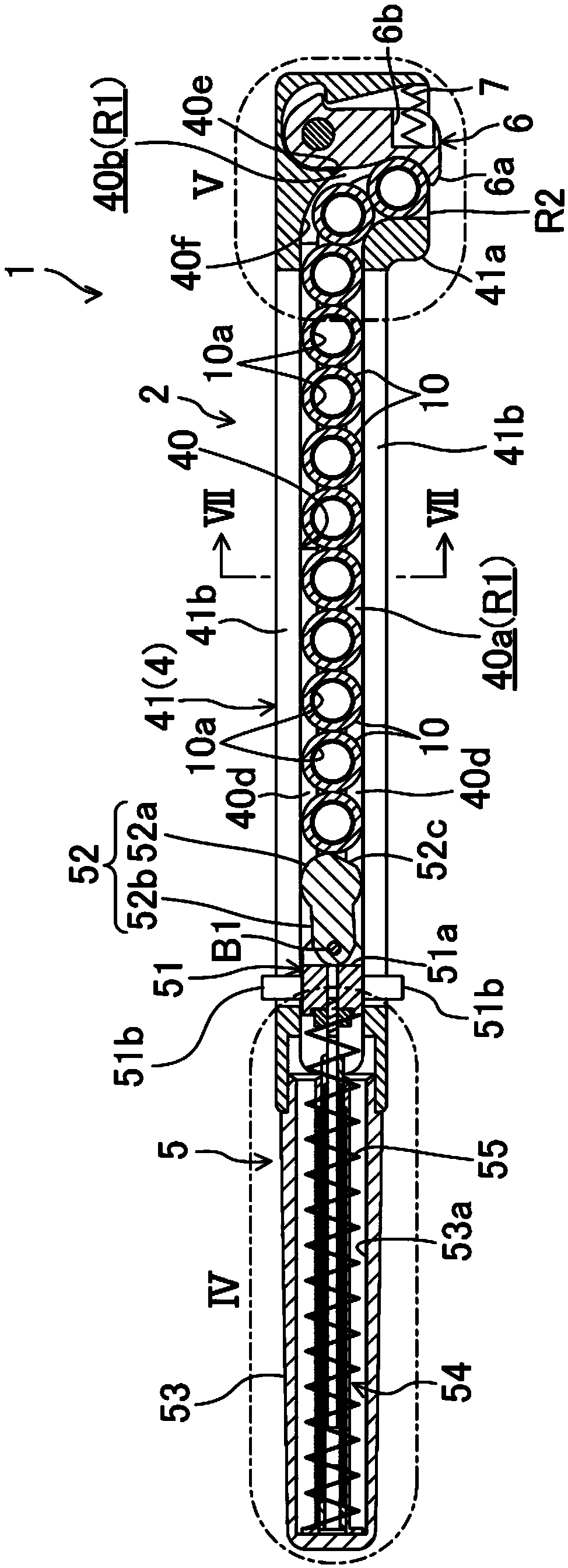

[0041] figure 1 and figure 2 The electrode storage device 1 for spot welding according to the embodiment of the present invention is shown. This electrode accommodating device 1 is arranged on the side of the vehicle body assembly passage in the automobile production line, so that the spot welding electrode 10 can be installed on the handle 11 of the welding torch held by the welding robot (refer to Figure 5 ) form accommodates a plurality of the electrodes 10.

[0042] The electrode storage device 1 includes a device main body 2 extending linearly, and the device main body 2 has a housing case 4 in an approximately rectangular cylindrical shape.

[0043] The receiving case 4 includes a U-shaped case body 41 with a U-shaped cross section on the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com