Patents

Literature

35results about How to "Will not complicate the structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

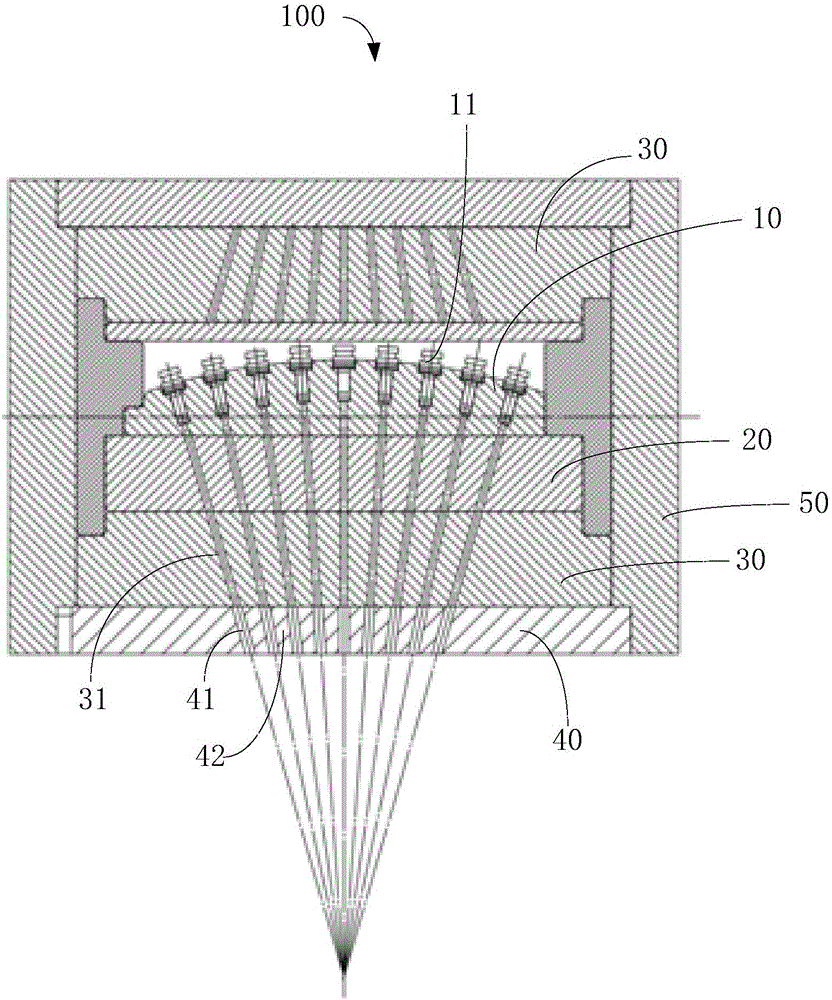

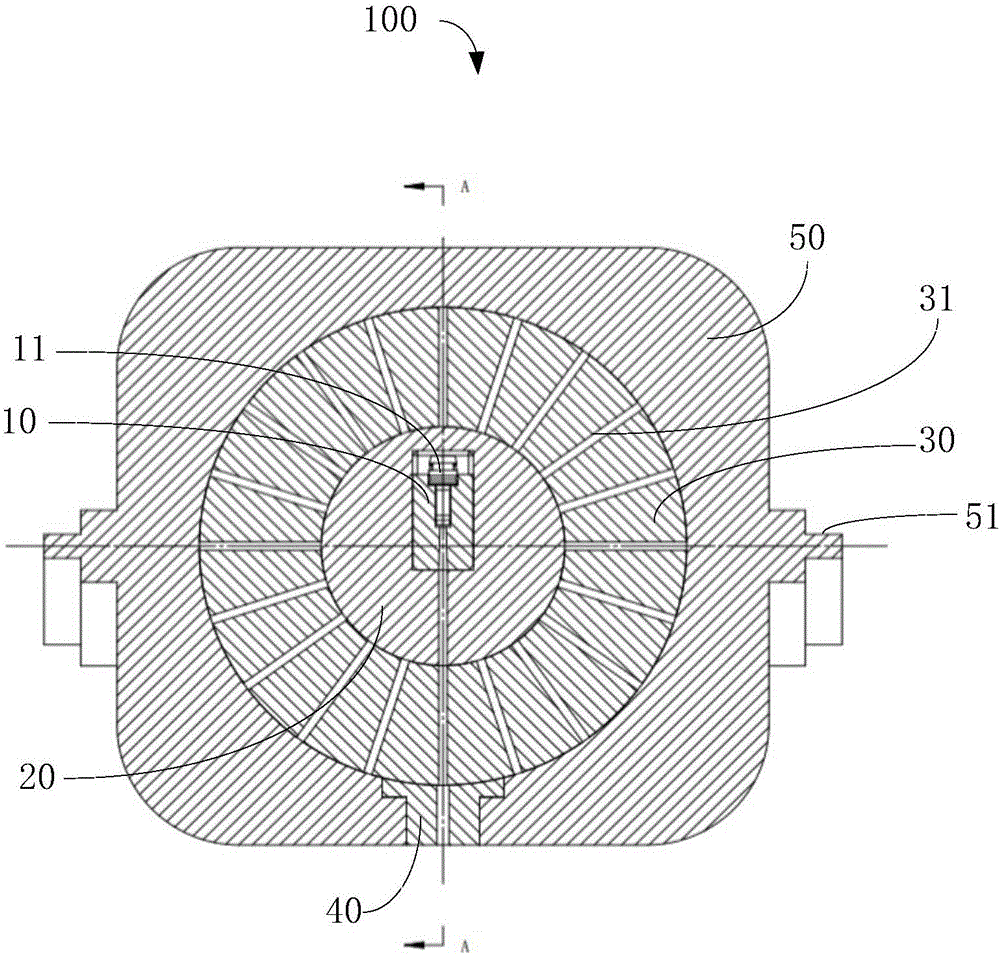

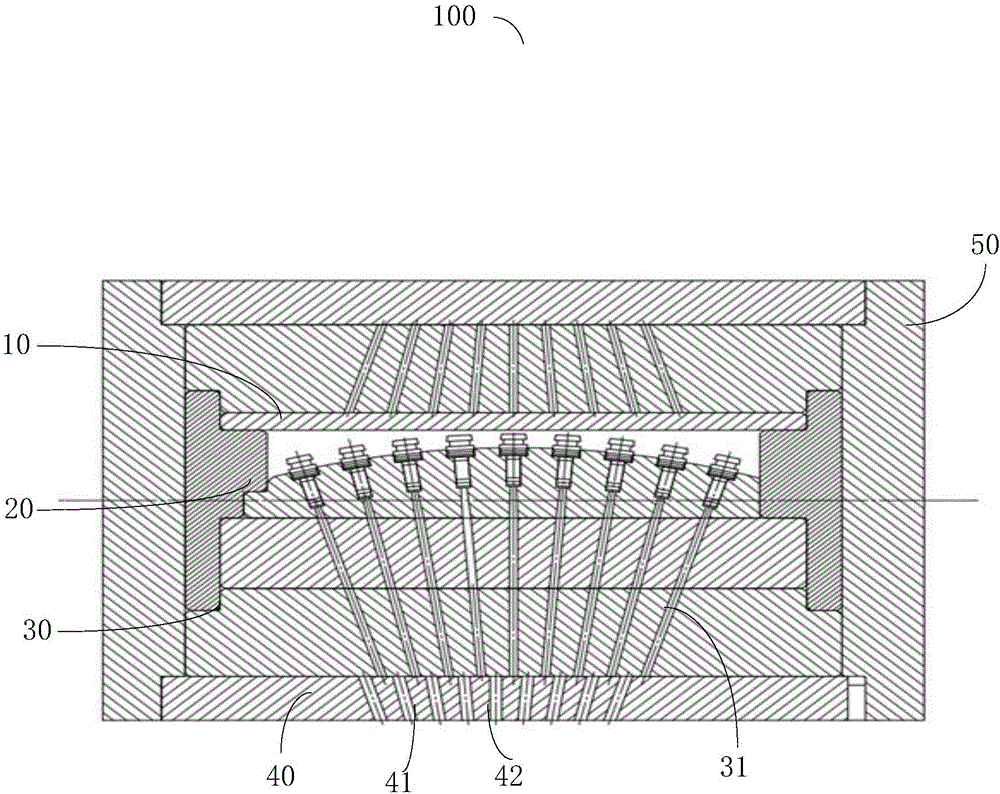

Focussed radiotherapy apparatus and radiation therapy device

ActiveCN106456991AWill not complicate the structureRich combination numberTomographyRadiation diagnosticsField sizeRadiation therapy

Owner:CYBERMED TECH XIAN

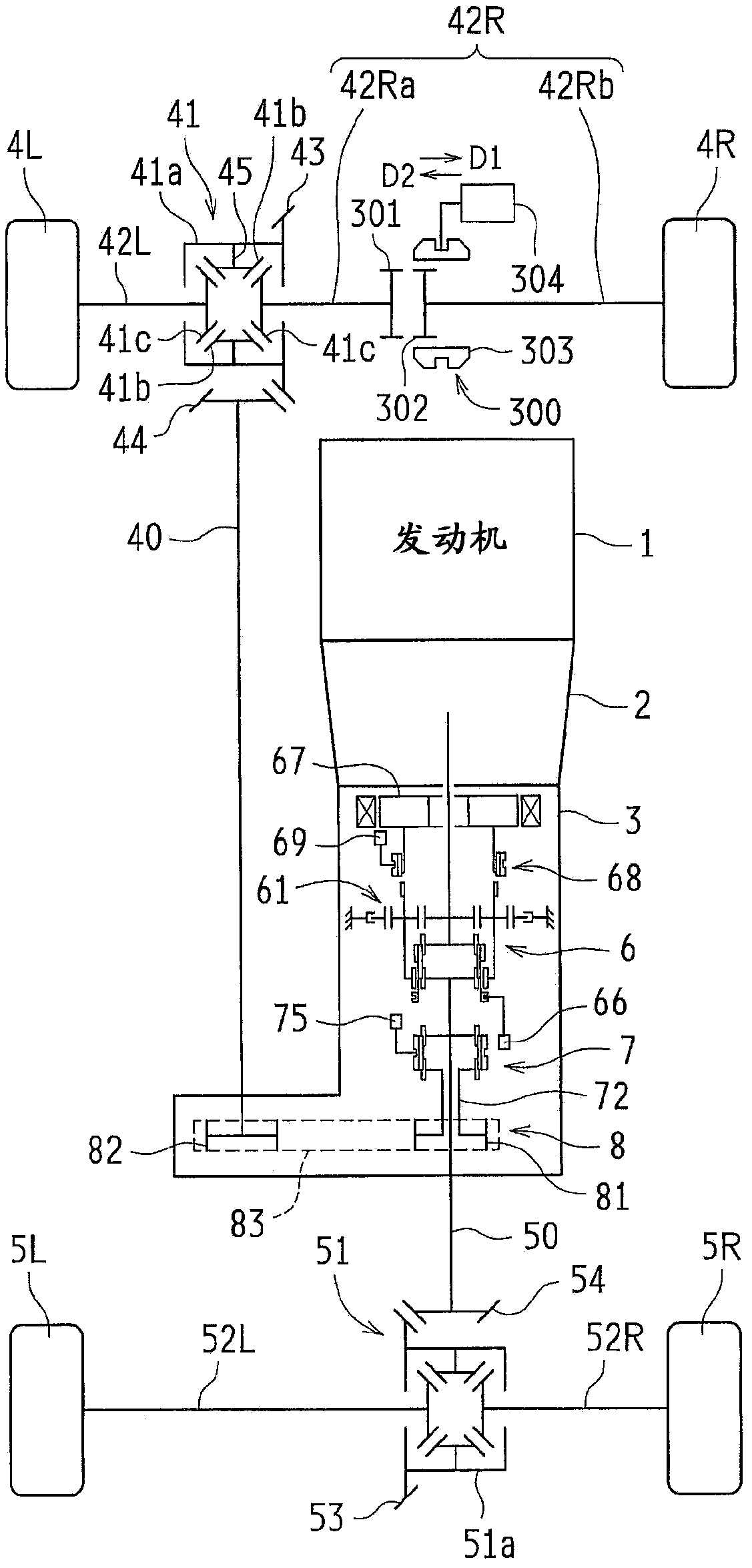

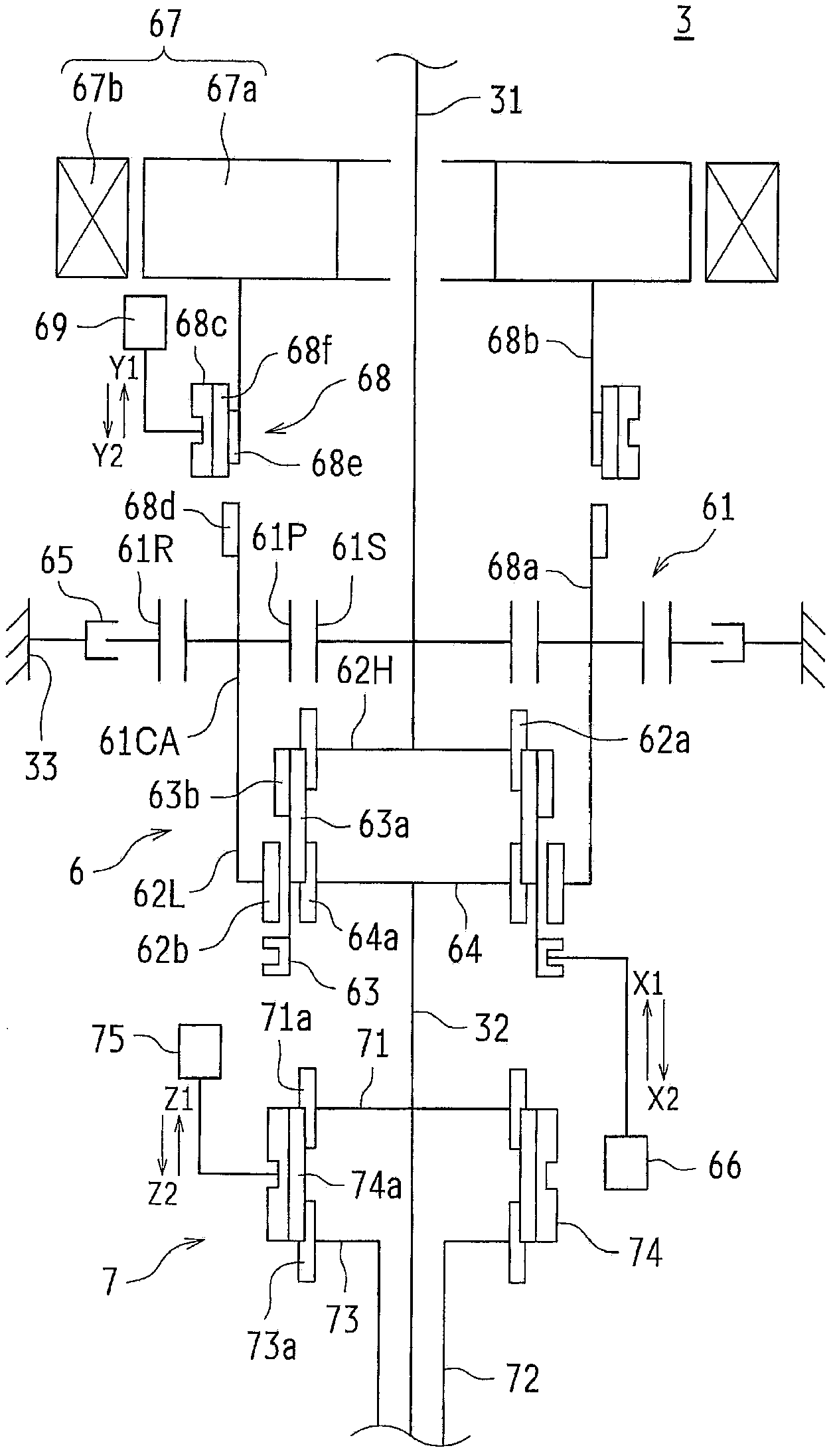

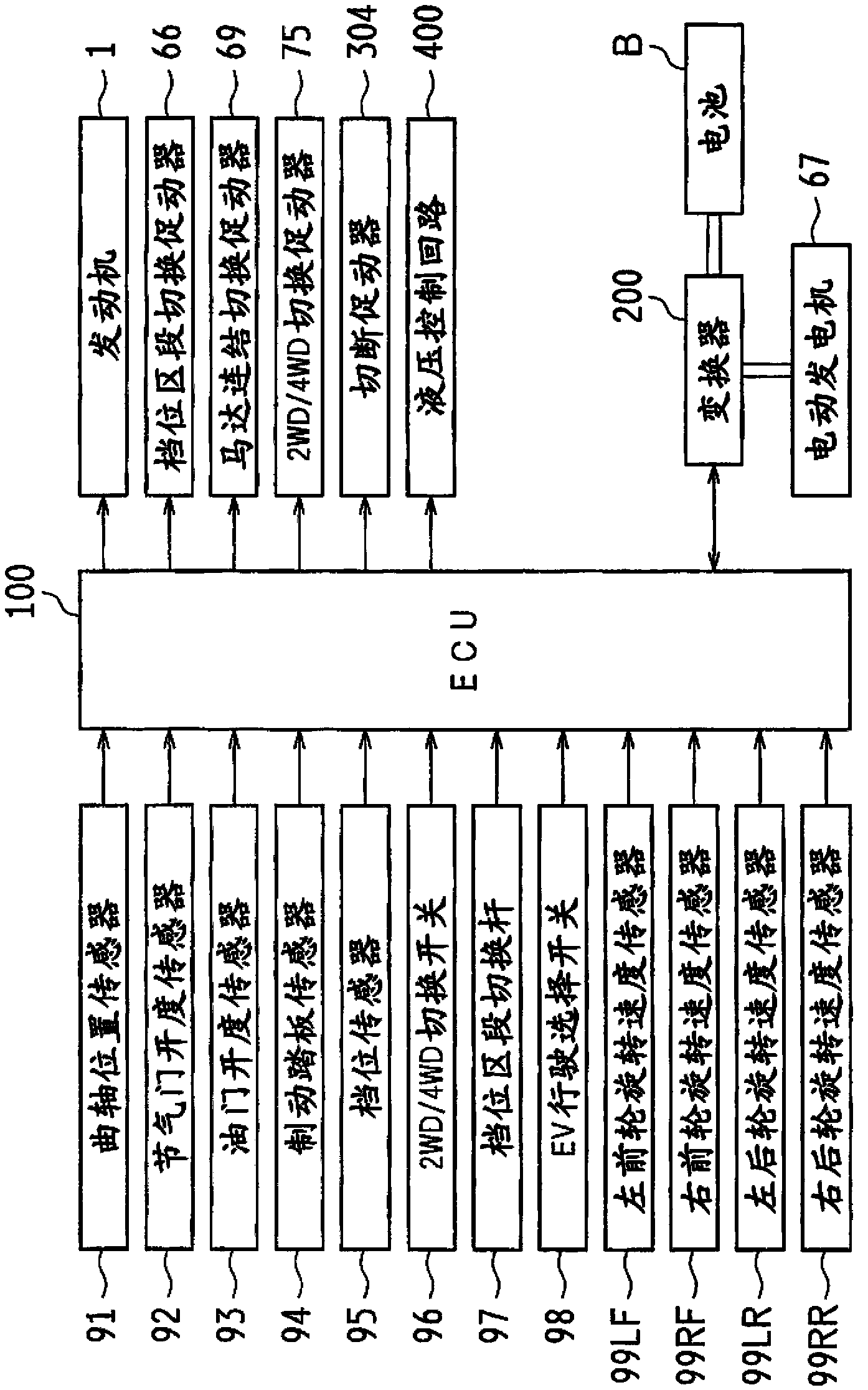

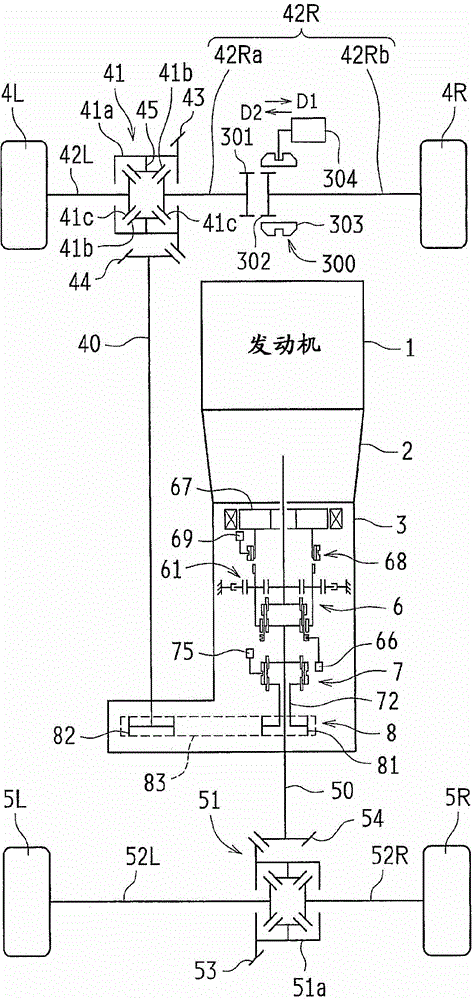

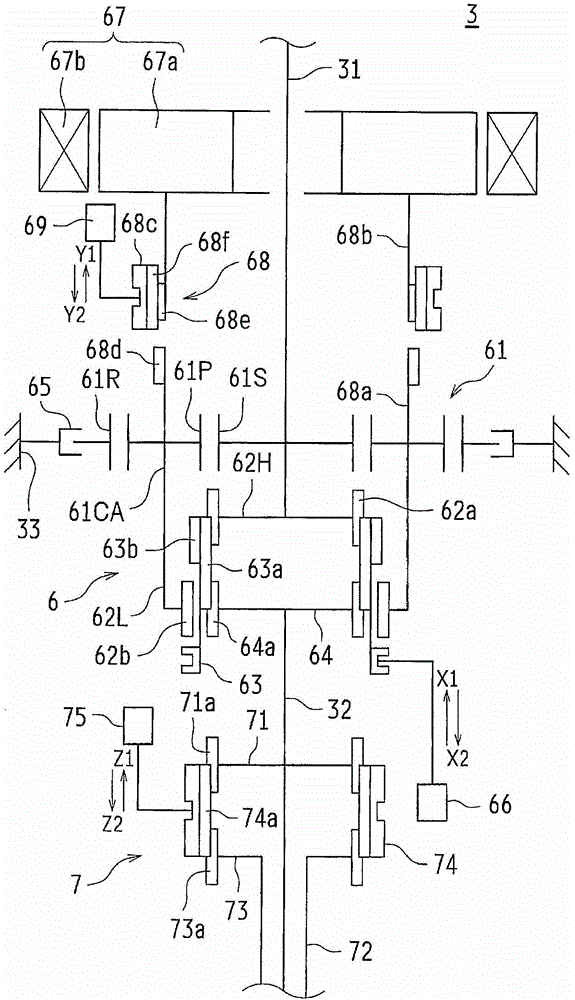

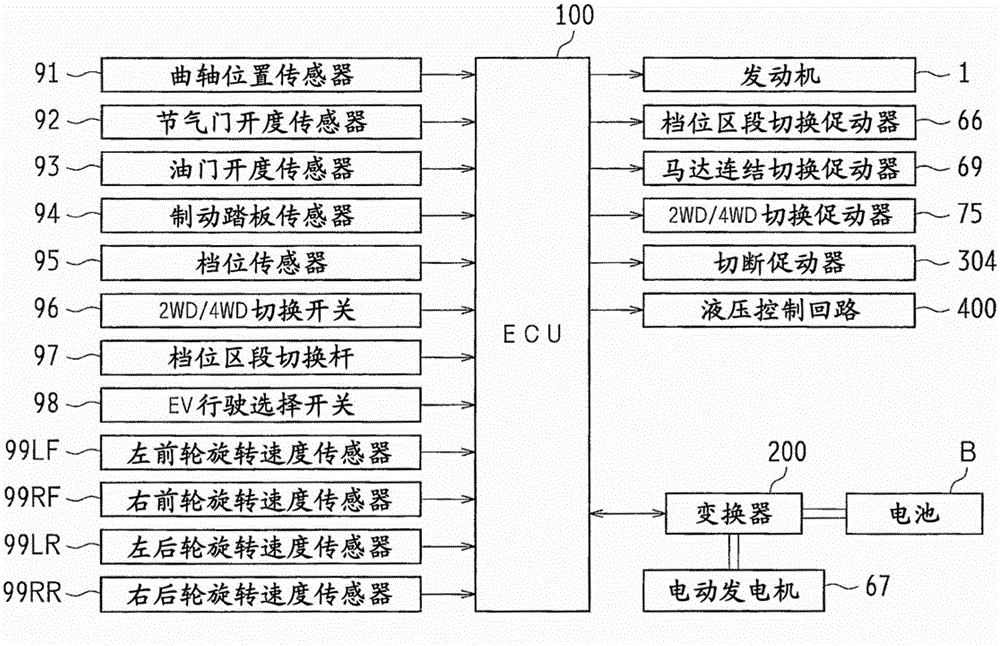

Vehicle power transmission system

ActiveCN103998828AIncrease rotation speedShift downToothed gearingsPropulsion using engine-driven generatorsElectric power transmissionLow speed

A motor generator (67) is connected to carriers (61CA) of an auxiliary transmission mechanism (6) capable of switching between a high-speed range and a low-speed range, in a manner that enables power to be transmitted to a vehicle provided with said auxiliary transmission mechanism (6). When switching from the high-speed range to the low-speed range, the rotational speed of the carriers (61CA) is increased by the motor generator (67) so as to synchronize the rotational speed of low-speed range pieces (62L) with the rotational speed of an input shaft (31). When switching from the low-speed range to the high-speed range, the rotational speed of the carriers (61CA) is increased by the motor generator (67) so as to synchronize the rotational speed of an output shaft (32) with the rotational speed of the input shaft (31). Thus, range switching can be performed while reducing transmission shocks, even while the vehicle is moving.

Owner:TOYOTA JIDOSHA KK

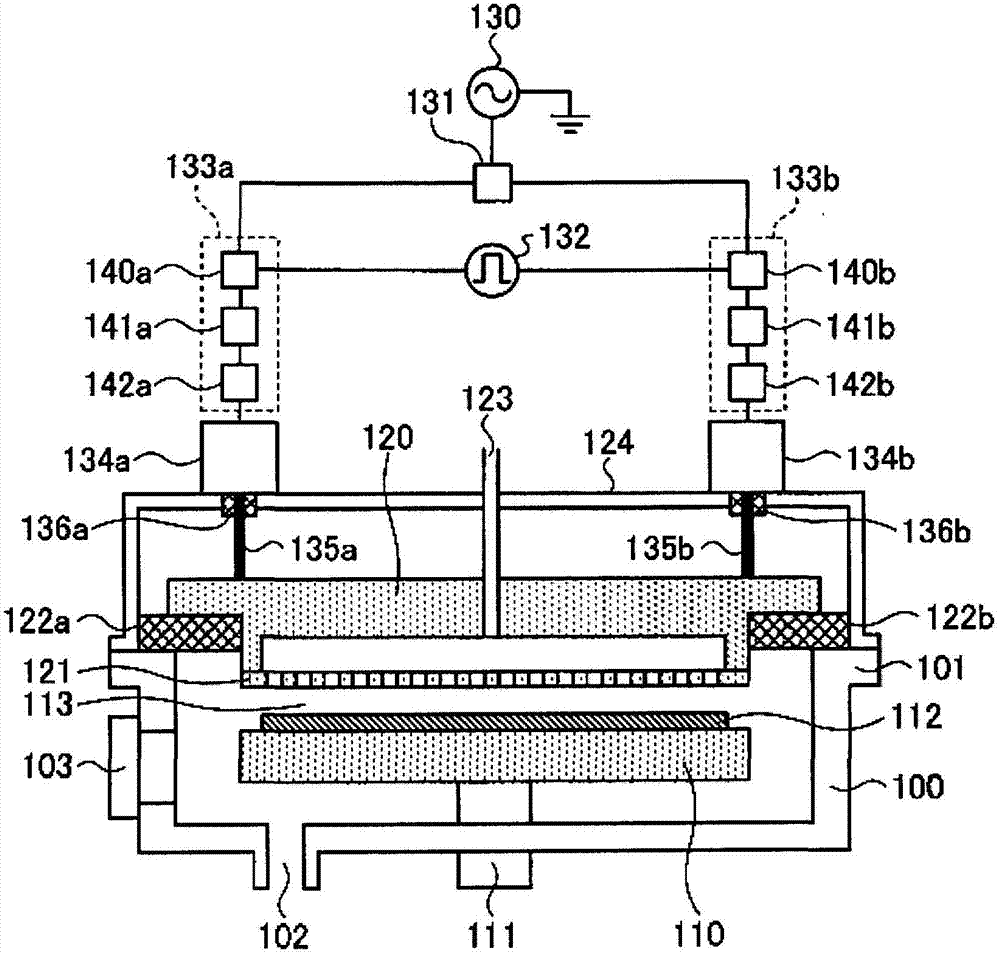

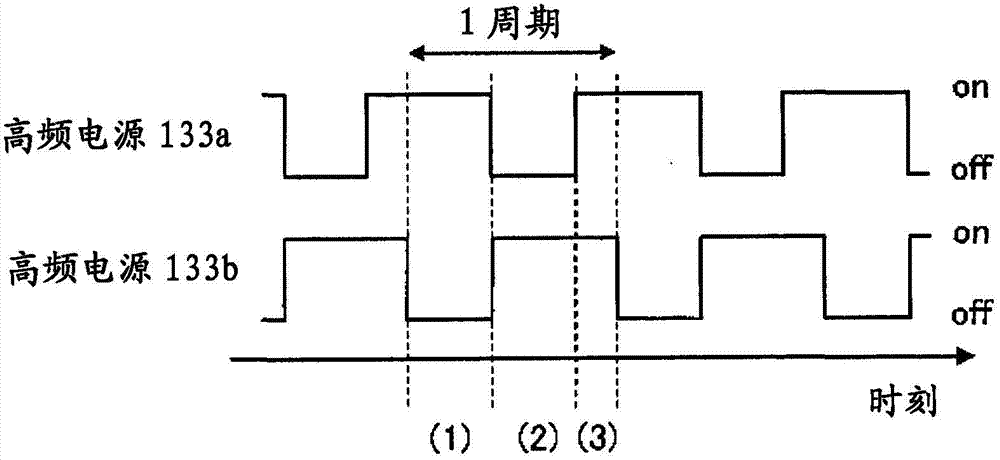

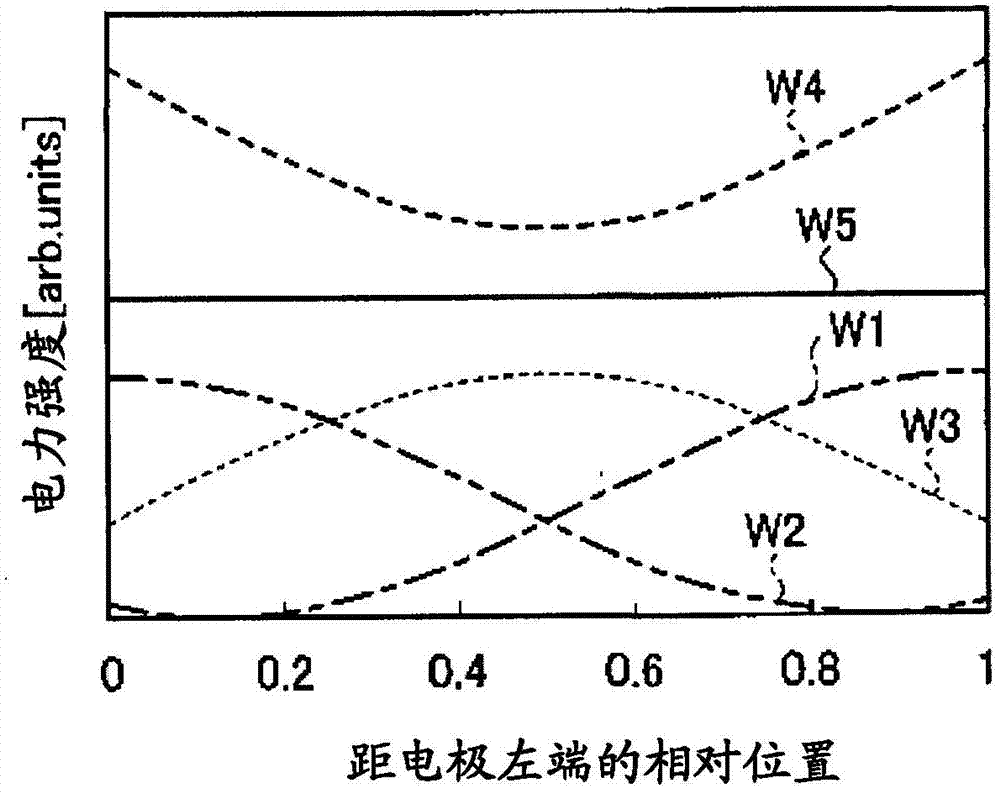

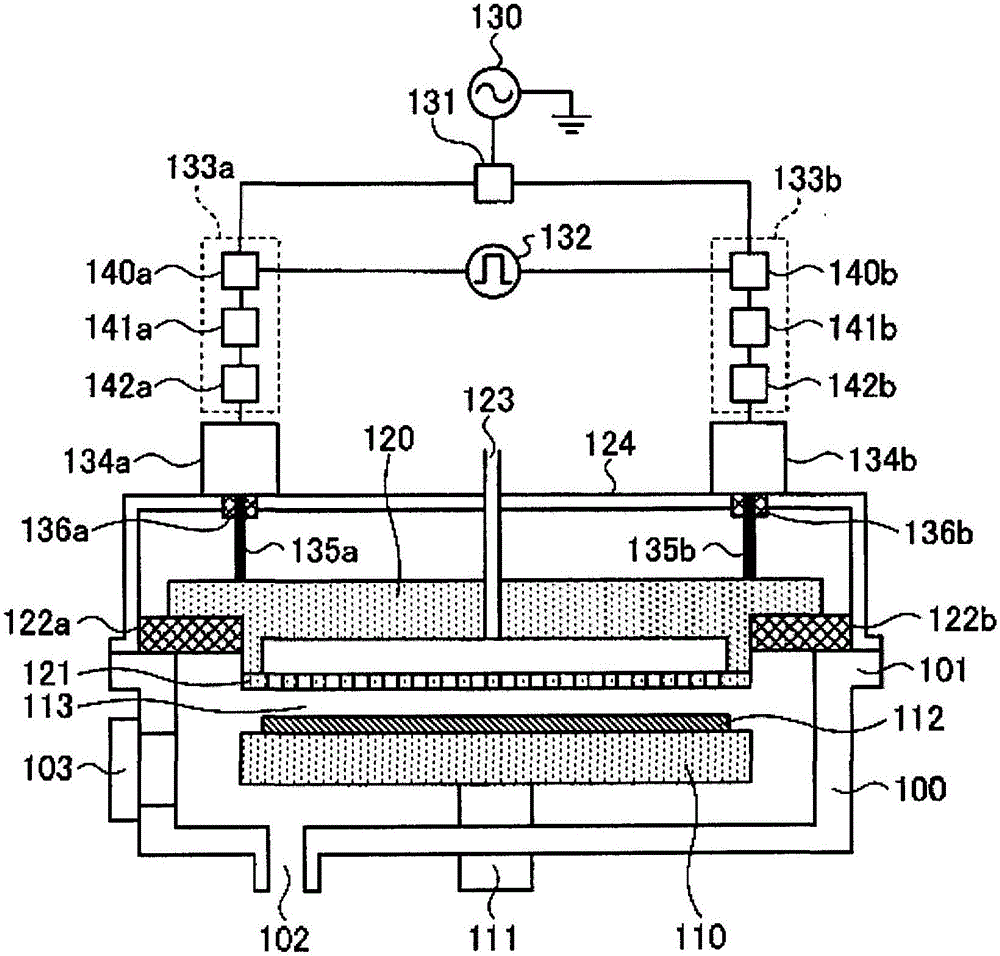

High-frequency power supply device, plasma processing device and method for producing thin film

InactiveCN103098559AUniform power intensity distributionWill not complicate the structureElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma processingElectricity

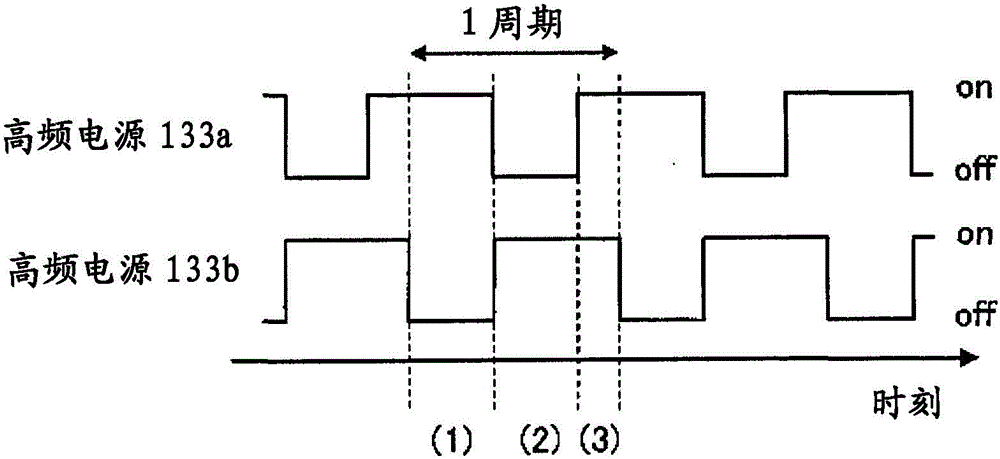

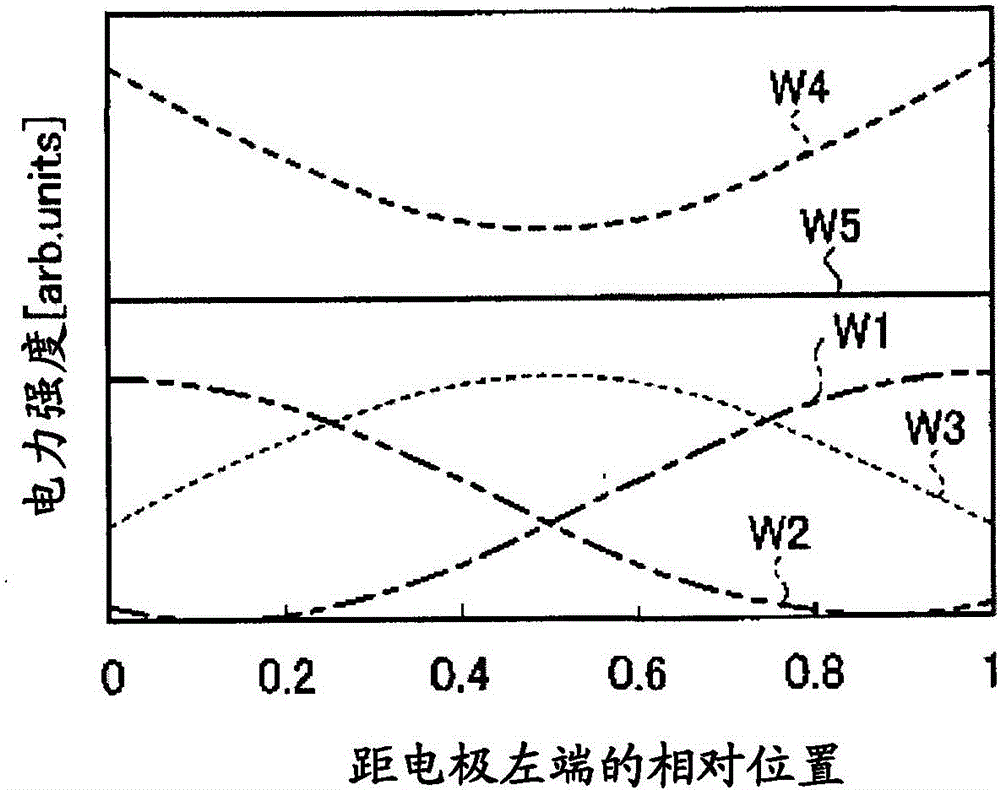

A high-frequency power supply device for supplying high-frequency power to parallel planar electrodes, the high-frequency power supply device comprising: high-frequency power sources (133a, 133b) for supplying high-frequency power to positions spaced apart from each other in the electrode; and a pulse generator for pulse-modulating the power supplied from the high-frequency power sources (133a, 133b) such that the power changes at a plurality of levels including a high level and a low level, the pulse generator instructing switching of levels to include a period (1) during which the supplied power from the high-frequency power source (133a) is at the high level and the supplied power from the high-frequency power source (133b) is at the low level, a period (2) during which the supplied power from the high-frequency power source (133b); is at the high level and the supplied power from the high-frequency power source (133a) is at the low level, and a period (3) during which the supplied power from each of the high-frequency power sources (133a, 133b) is at a level higher than the low level.

Owner:MITSUBISHI ELECTRIC CORP

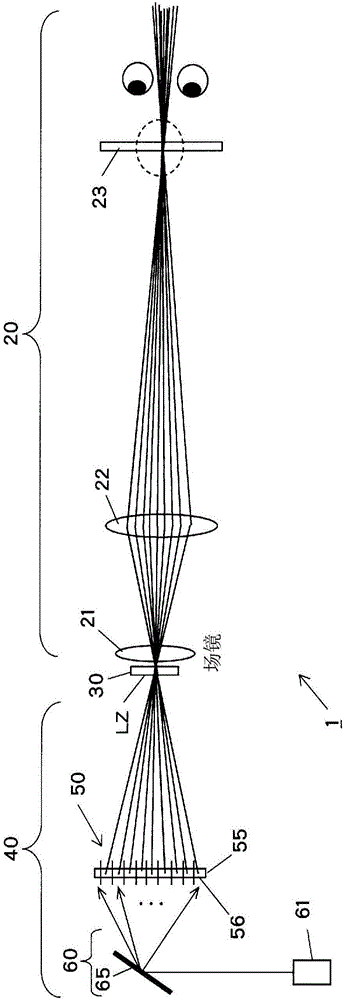

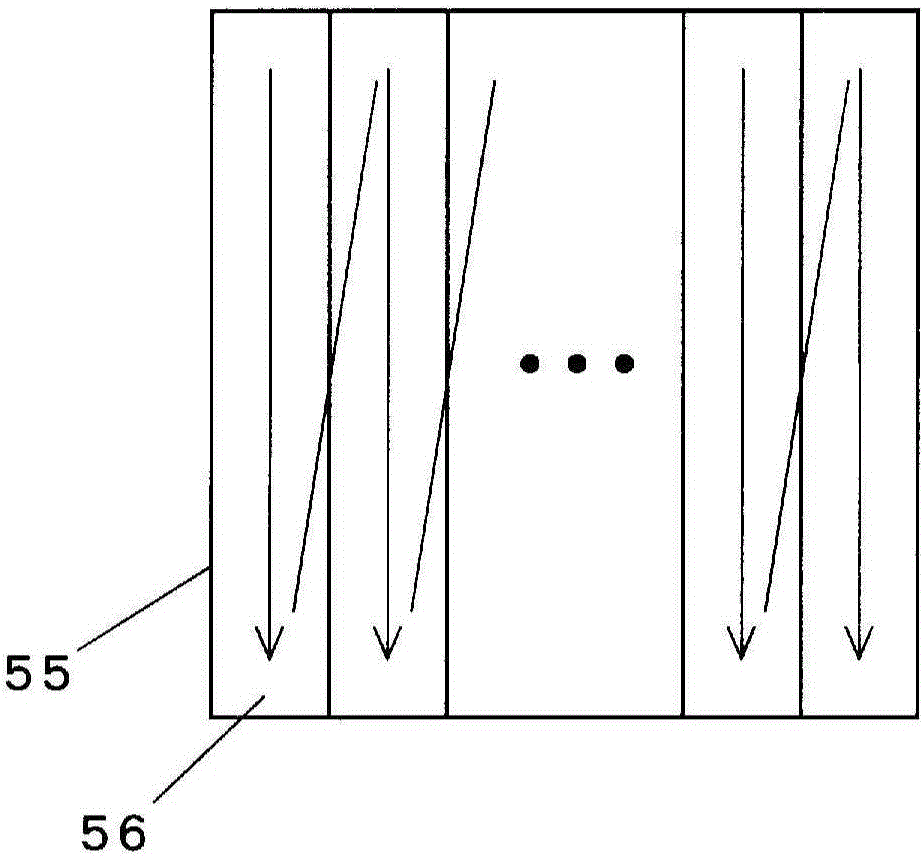

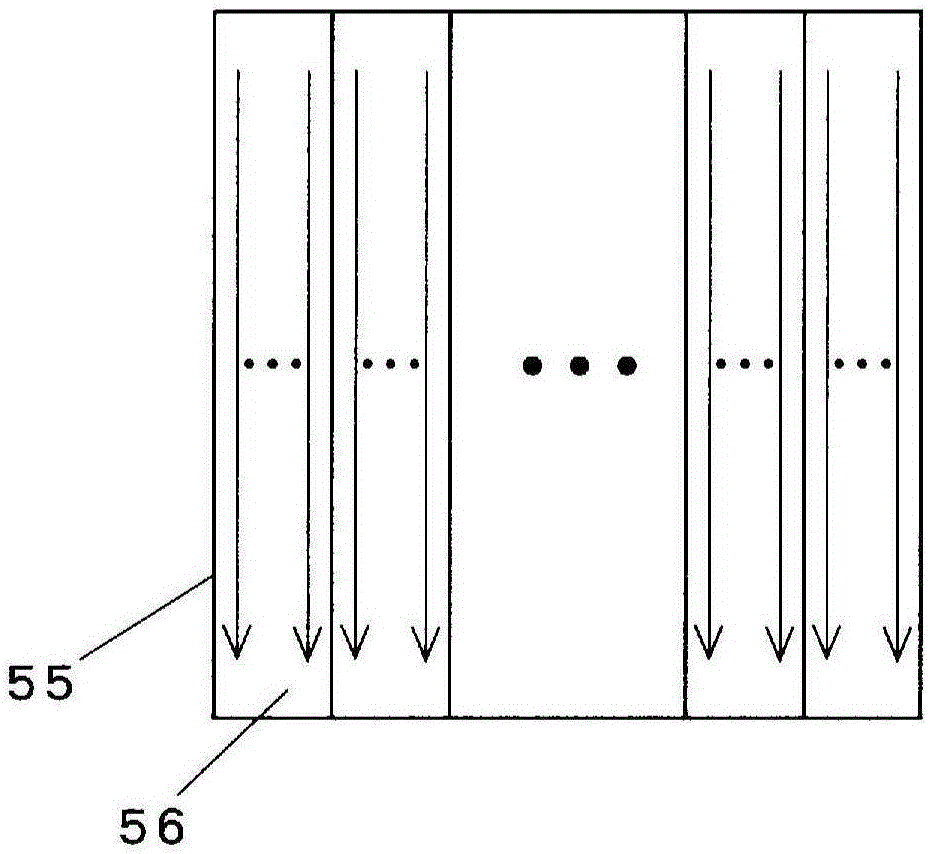

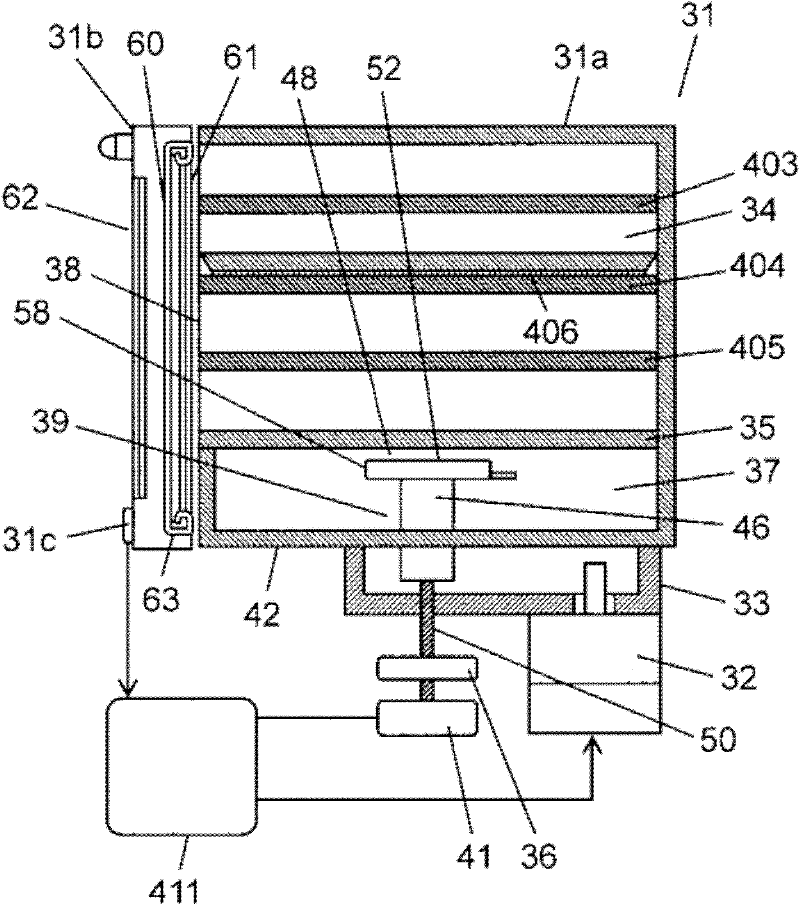

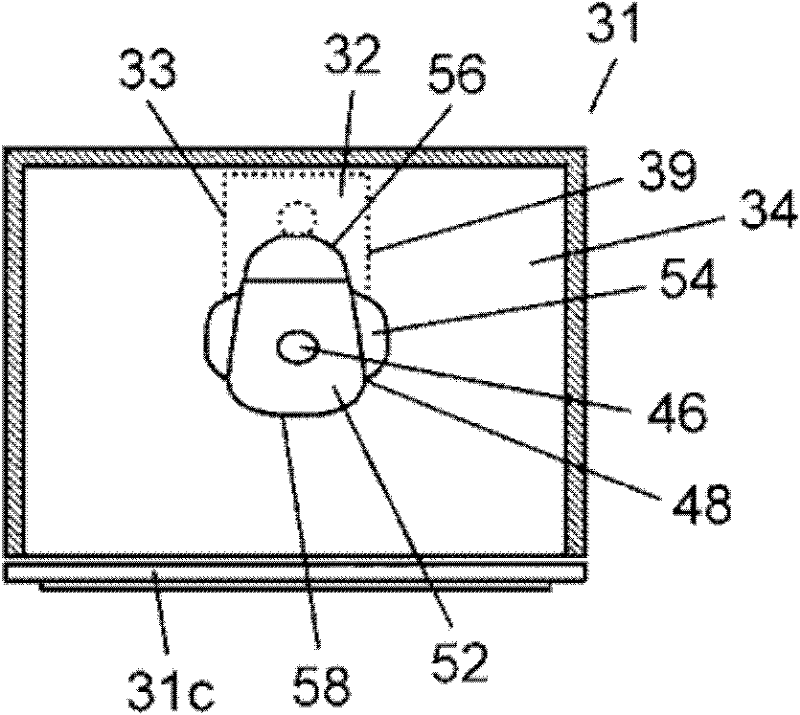

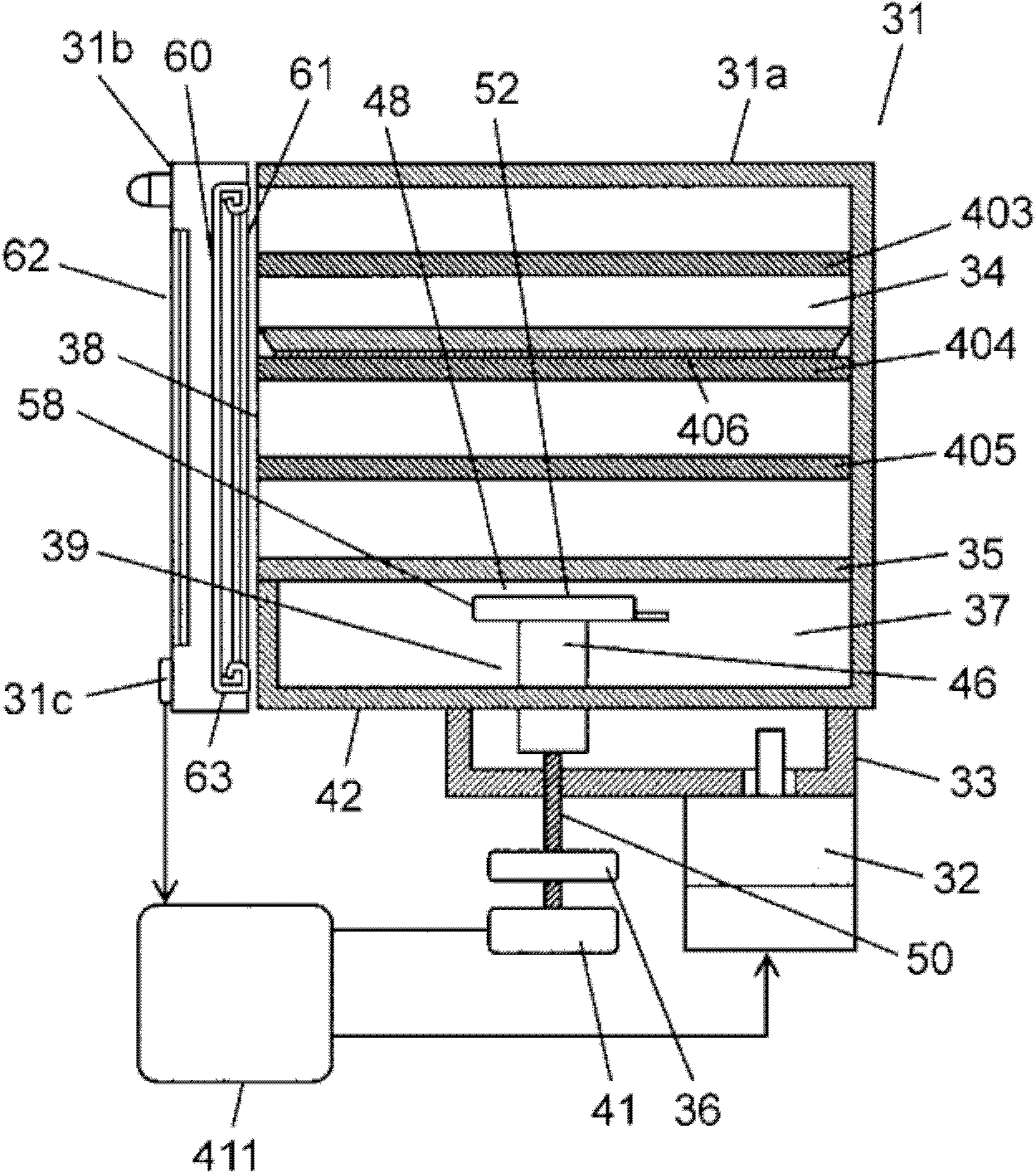

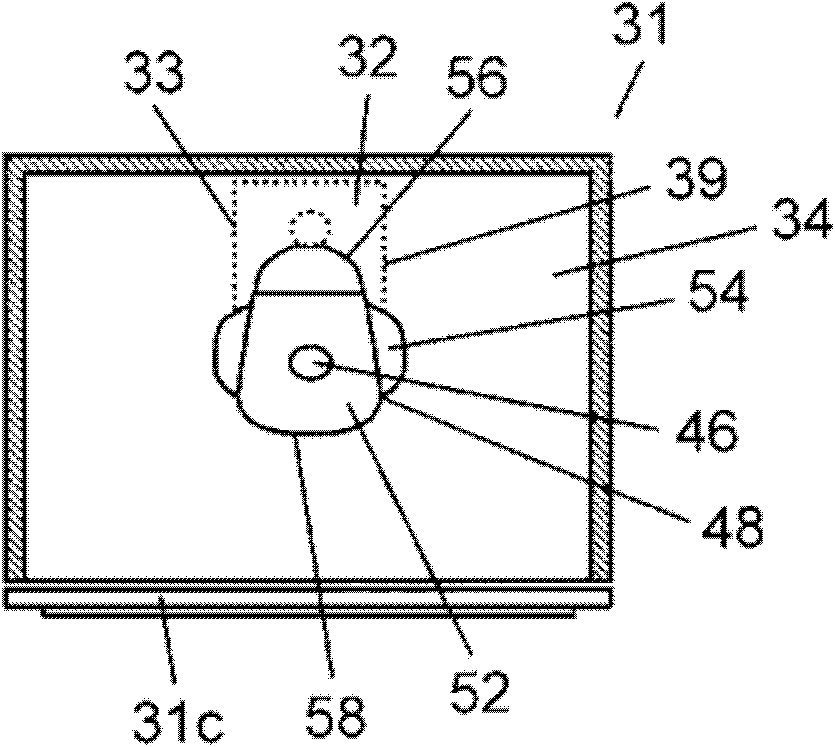

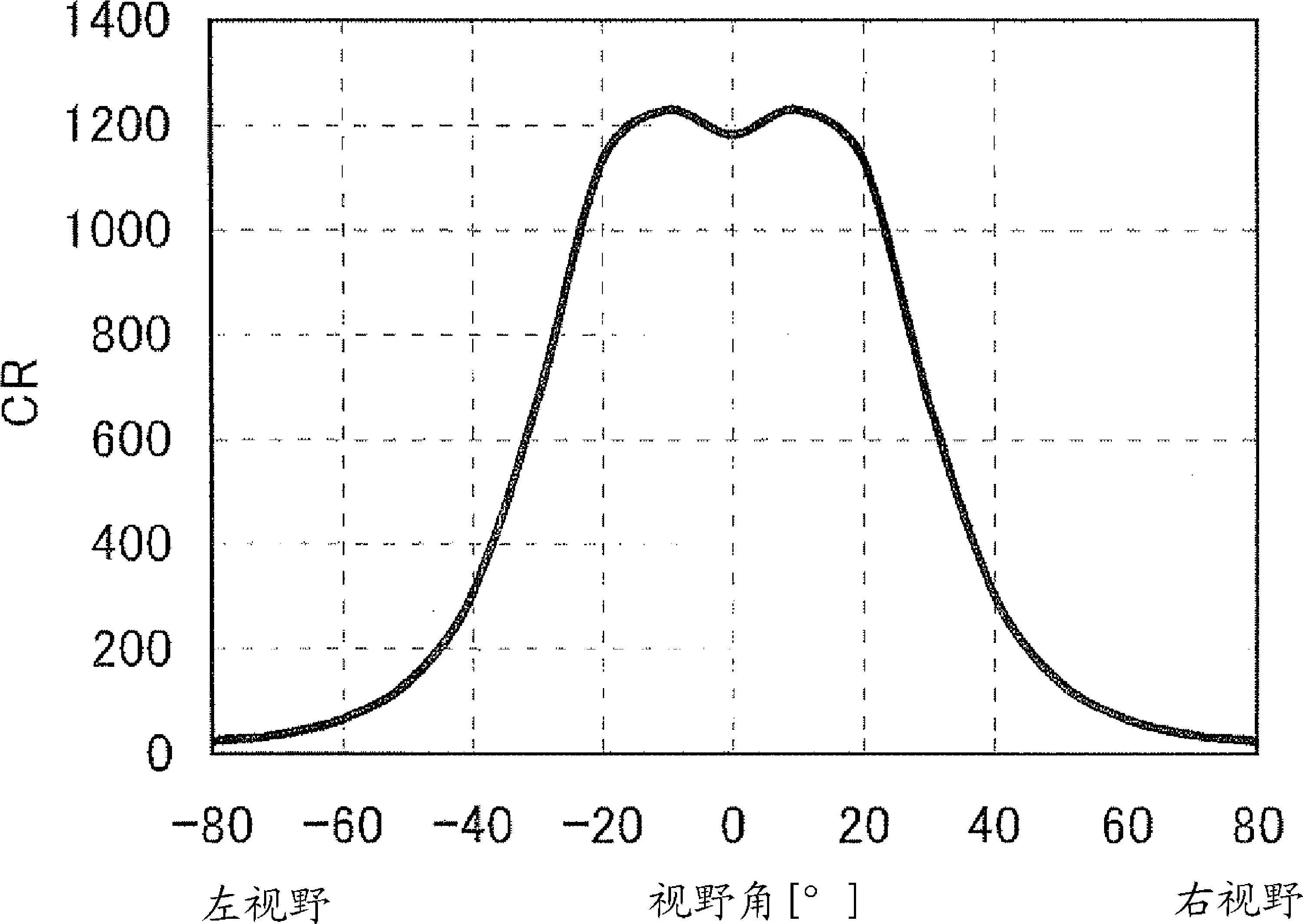

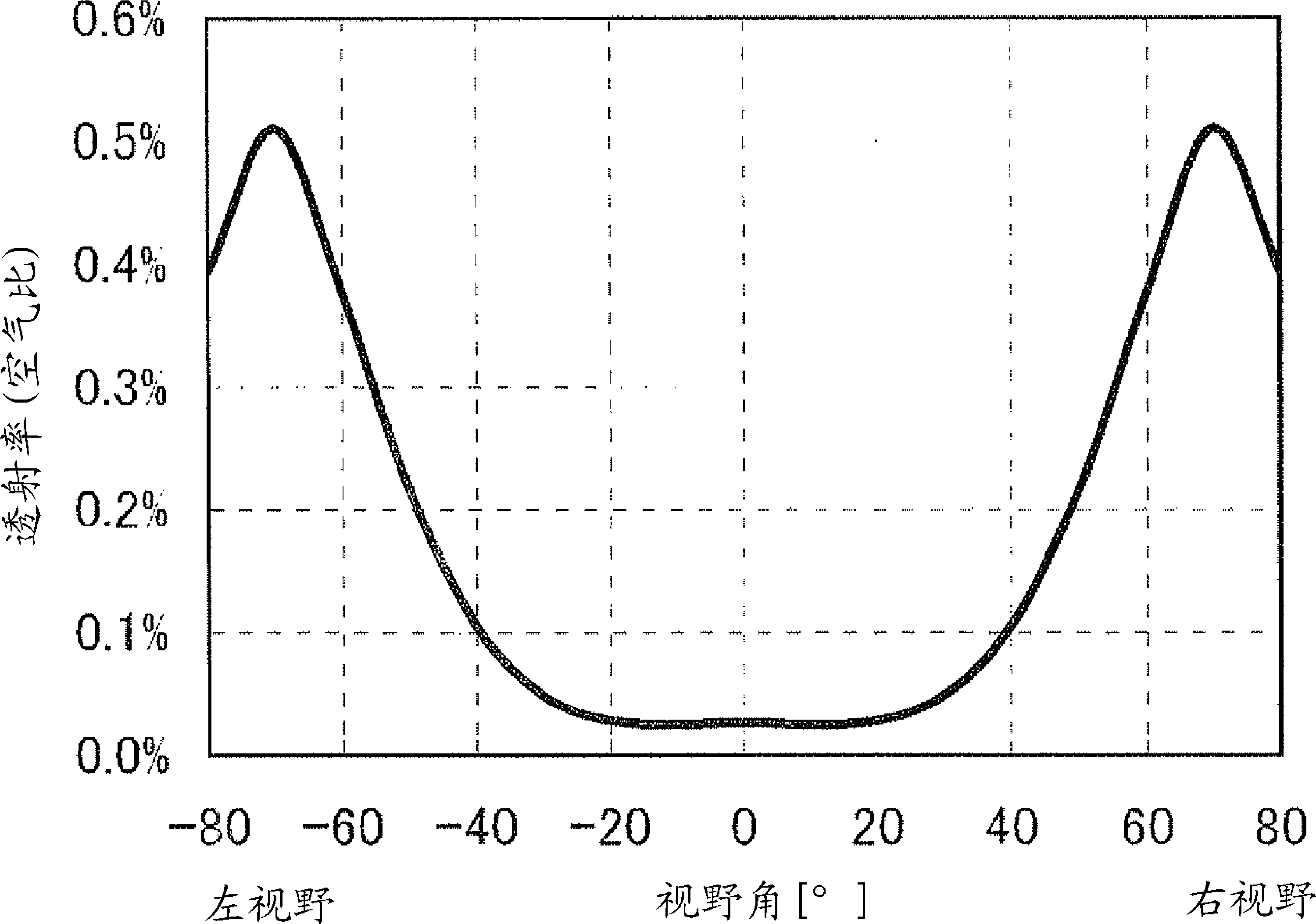

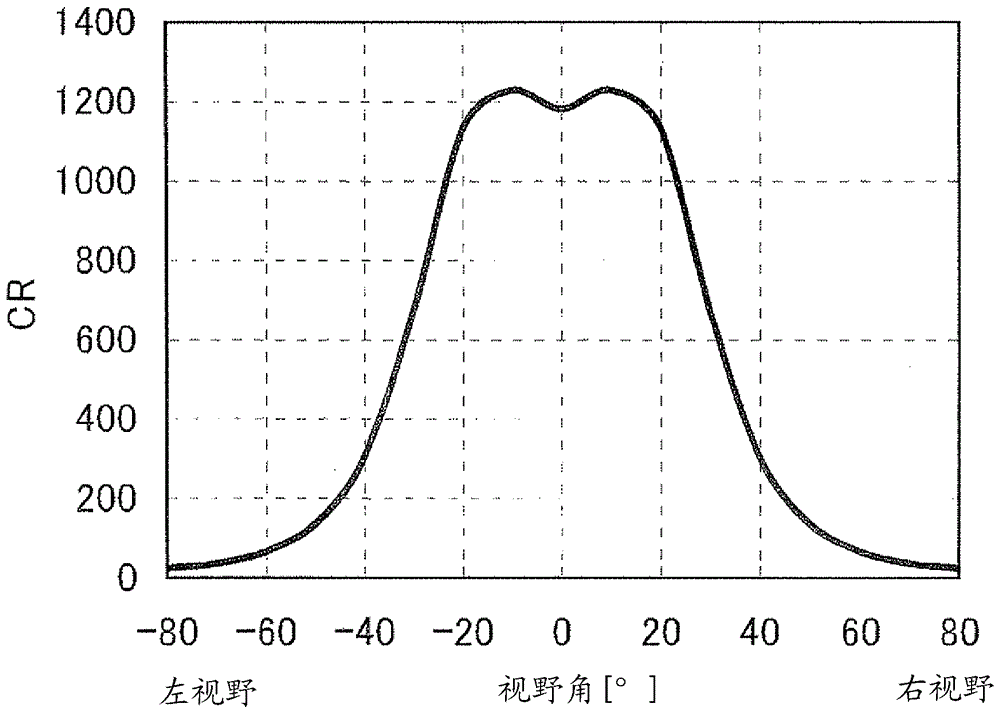

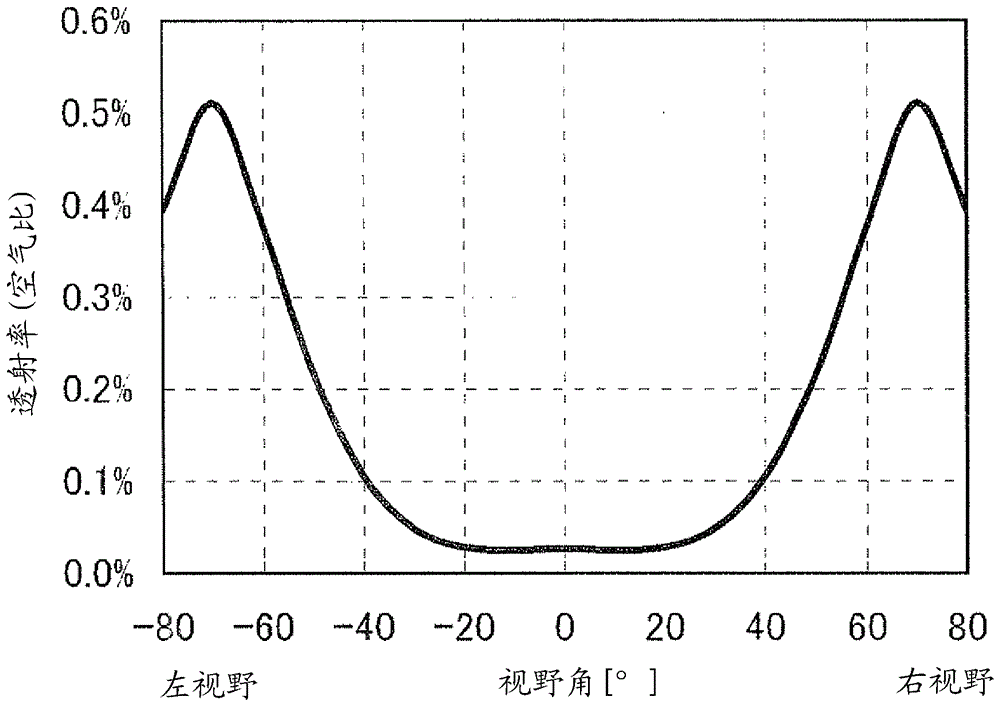

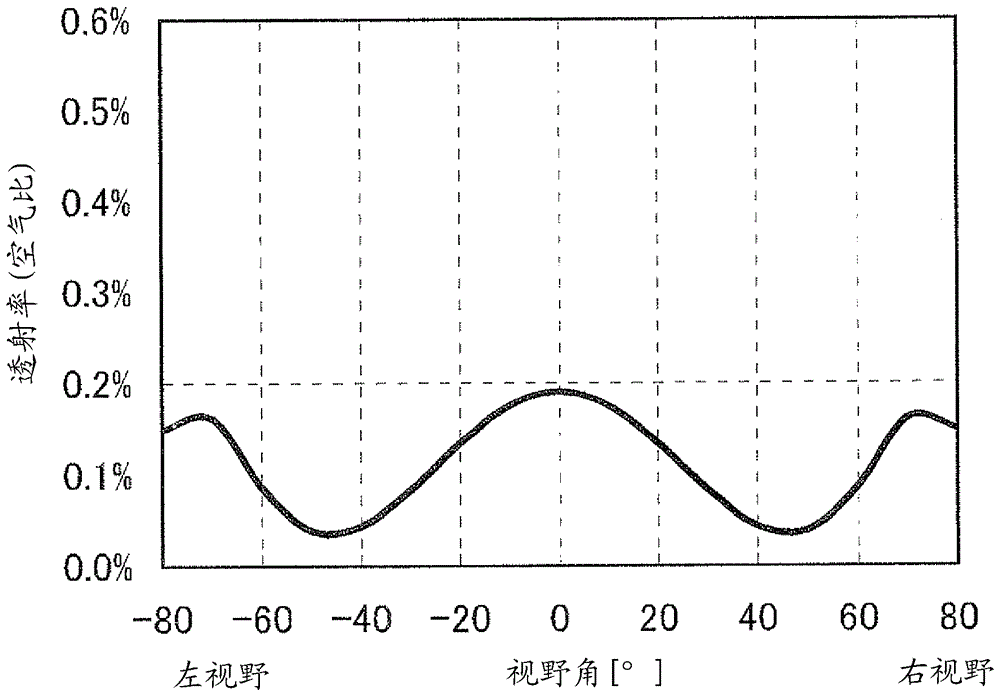

Stereoscopic image display device

InactiveCN105008984AWill not complicate the structureColor television detailsStereoscopic photographyDiffusionParallax

[Problem] To provide a stereoscopic image display device that makes images with disparity viewable over a wide range of a diffusion surface. [Solution] A stereoscopic image display device (1) is provided with: an optical element (50) having n regions provided so as to correspond to each of n (n being an integer of 2 or higher) images with disparity for obtaining diffusing coherent light for each; an irradiating device (60) that irradiates the optical element with coherent light and scans the n regions with the coherent light; an optical modulator (30) that is illuminated by the diffused coherent light incident to each position on the optical element from the irradiation device, synchronizes for scanning the n regions with the coherent light, and generates modulated images corresponding to each of the n regions; and a projection optical system (20) that superimposes and projects each of the n images with disparity that have been generated by the modulated images onto the same surface at different angles.

Owner:DAI NIPPON PRINTING CO LTD

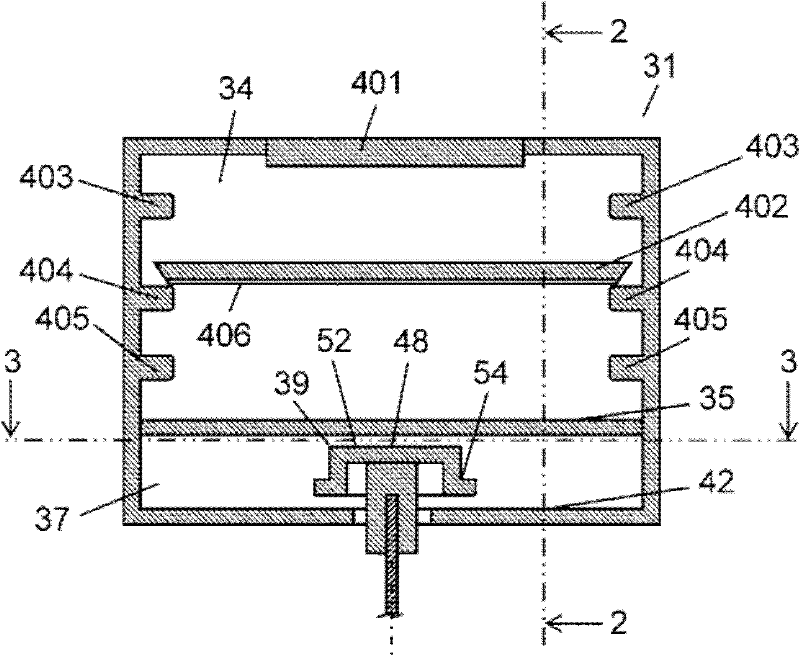

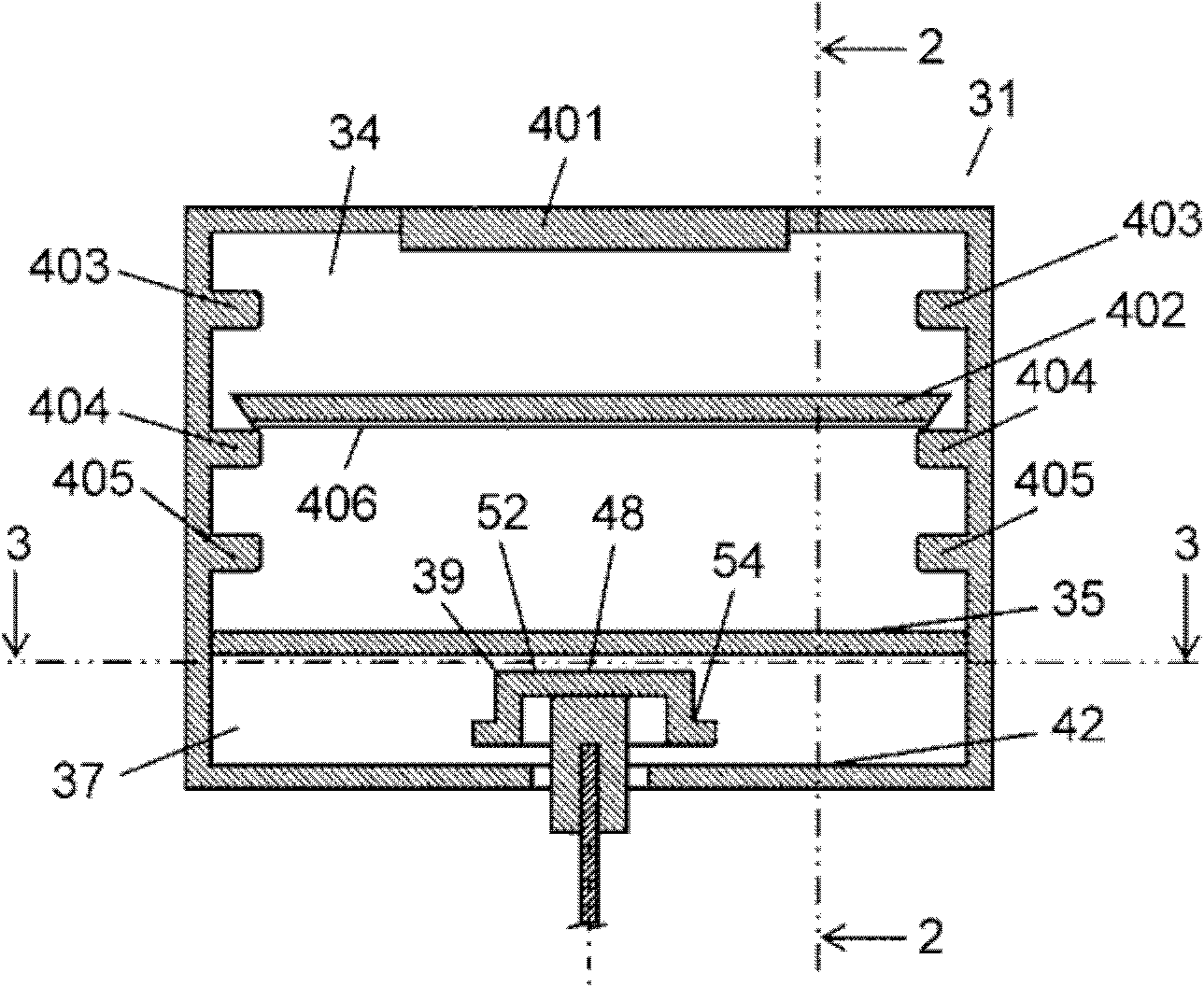

Microwave heating cooker

ActiveCN102265092AIncrease the amount of windingWill not complicate the structureDomestic stoves or rangesLighting and heating apparatusDirectivityCooker

The present invention relates to a microwave cooking device comprising: a heating chamber (34) which is provided with a glass-equipped door (31b) located at the front face opening and is adapted to contain an object to be heated; a waveguide tube (33) for transmitting to the heating chamber (34) a microwave emitted from a microwave generating section (32); an electricity supply section (39) having directivity and supplying the microwave from the waveguide tube (33) to the heating chamber (34); a drive section (41) for rotationally driving the electricity supply section (39); and a control section (411) for controlling the drive section (41) such that the microwave is supplied to a space above a tray, with the electricity supply section (39) directed to the door, using the inside of the glass as the main transmission path for the microwave. A thaw function and a grill function can be automatically and continuously performed without operation by the user.

Owner:PANASONIC CORP

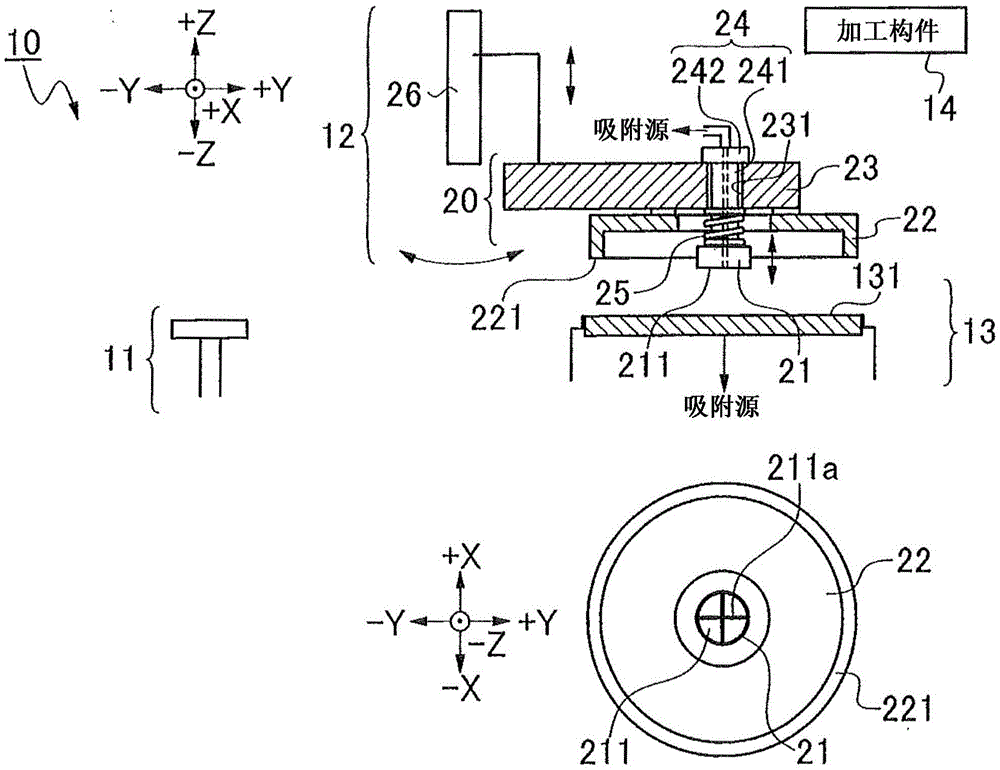

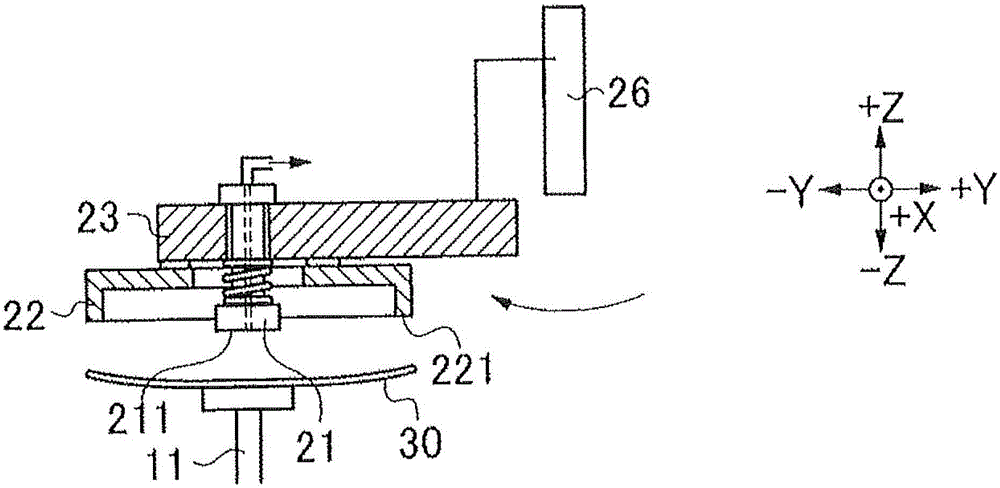

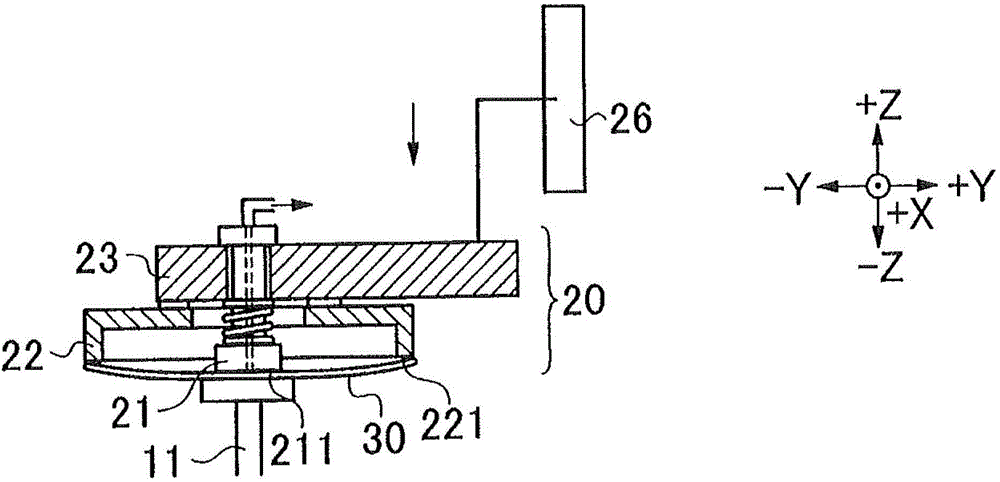

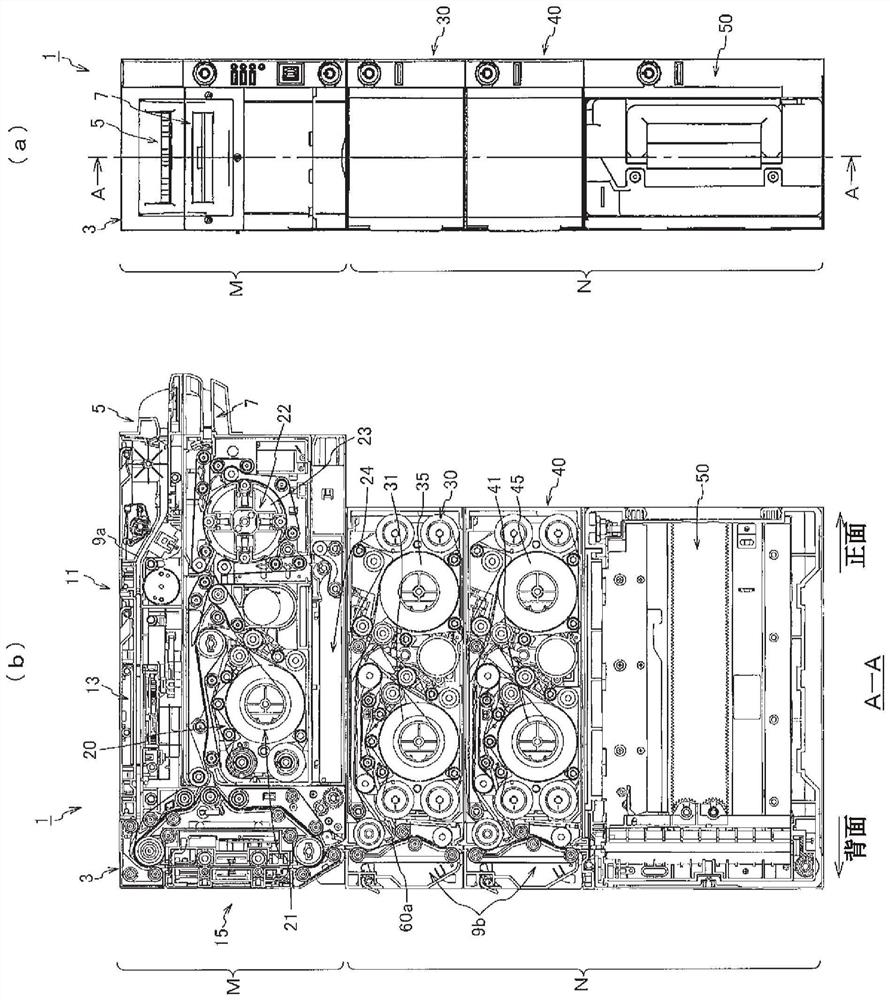

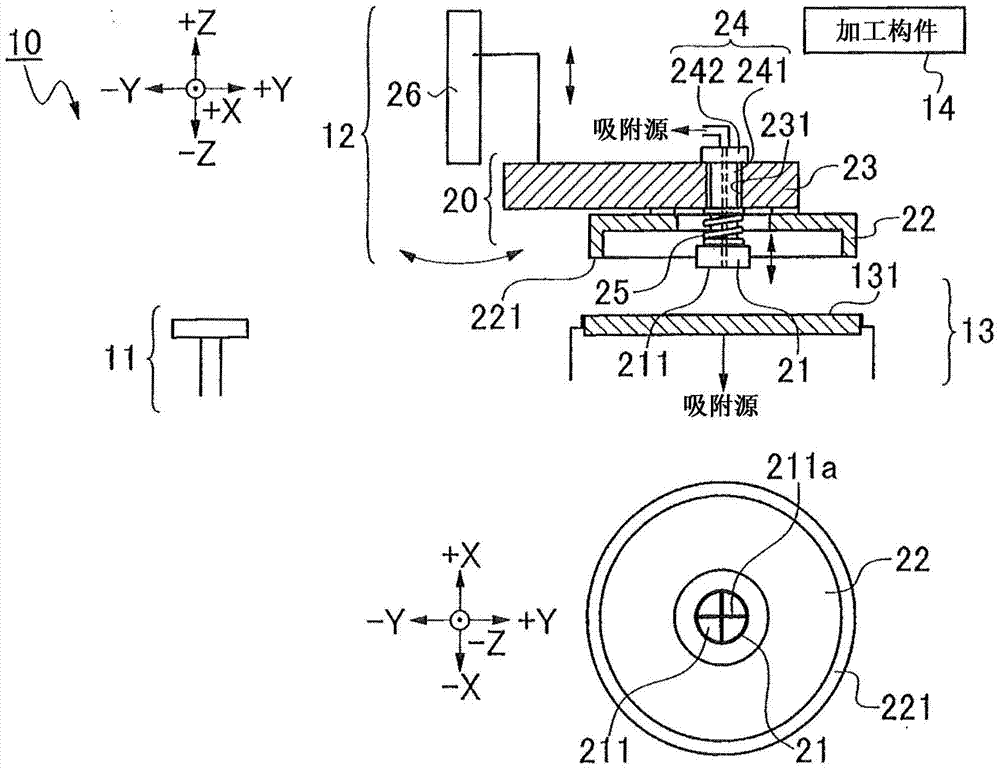

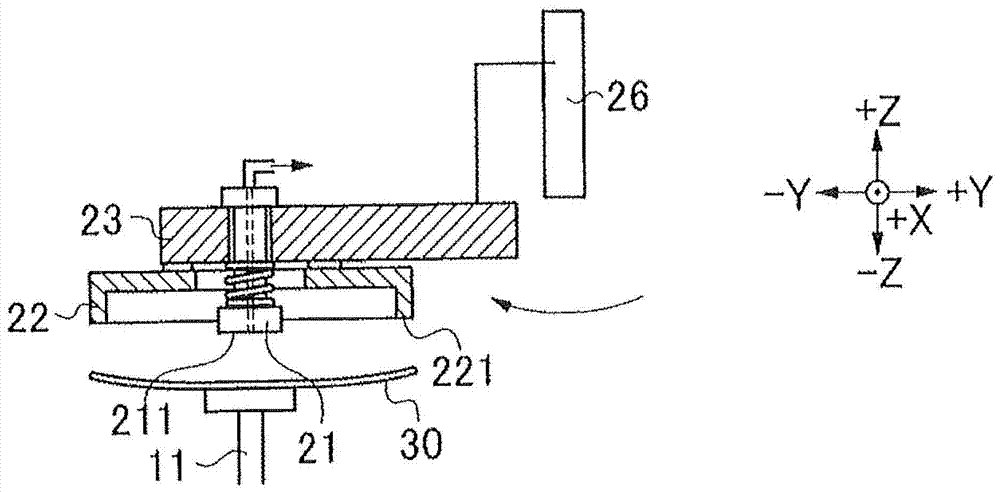

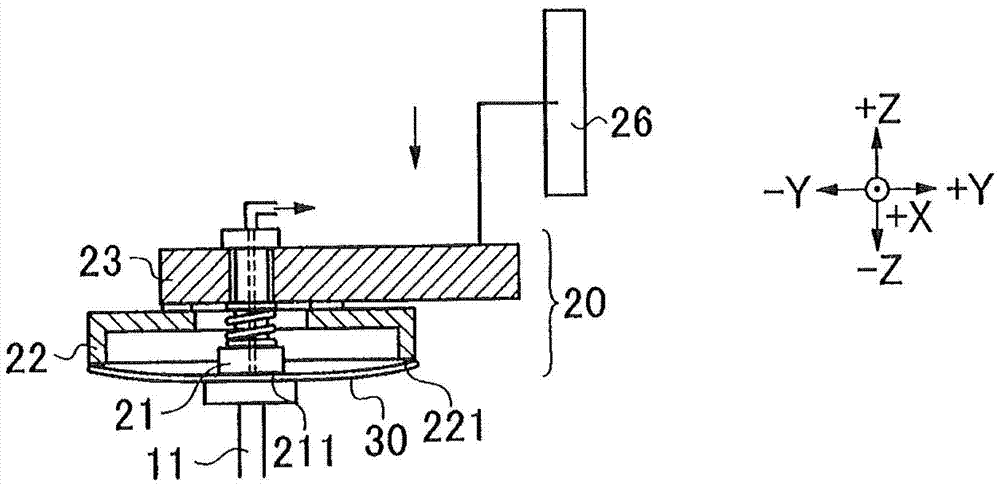

Processing Device

ActiveCN104647204AWill not complicate the structureCorrect warpingWork carriersGrinding work supportsEngineeringMechanical engineering

The present invention provides a processing device which can correct the warping of a workpiece without complicating the structure of the device, and can keep the workpiece on a chuck workbench reliably. A conveying pad (21) possesses an absorption surface (211) of absorbing and keeping the central part of the workpiece, a pressing part (22) possesses an annular pressing surface (211) with an internal diameter greater than the external diameter of the conveying pad (21), and a forwarding and withdrawing part penetrates a hole (231) and a shaft (24) and enables the conveying pad (21) to forward and withdraw along a direction vertical with the absorption surface (211) between a position of the absorption surface (211) protruding towards the pressing surface (221) and the position at which the absorption surface (211) and the pressing surface (221) are located in a same plane. A lifting component (26) enables a keeping mechanism (20) keeping the workpiece to move towards the direction of the chuck workbench (13), thereby pressing the workpiece against the chuck workbench (13). Therefore, the forwarding and withdrawing part acts, so that the absorption surface (211) is positioned in the plane same with the pressing surface (221), the warping of the workpiece is corrected, and the chuck workbench (13) keeps the workpiece.

Owner:DISCO CORP

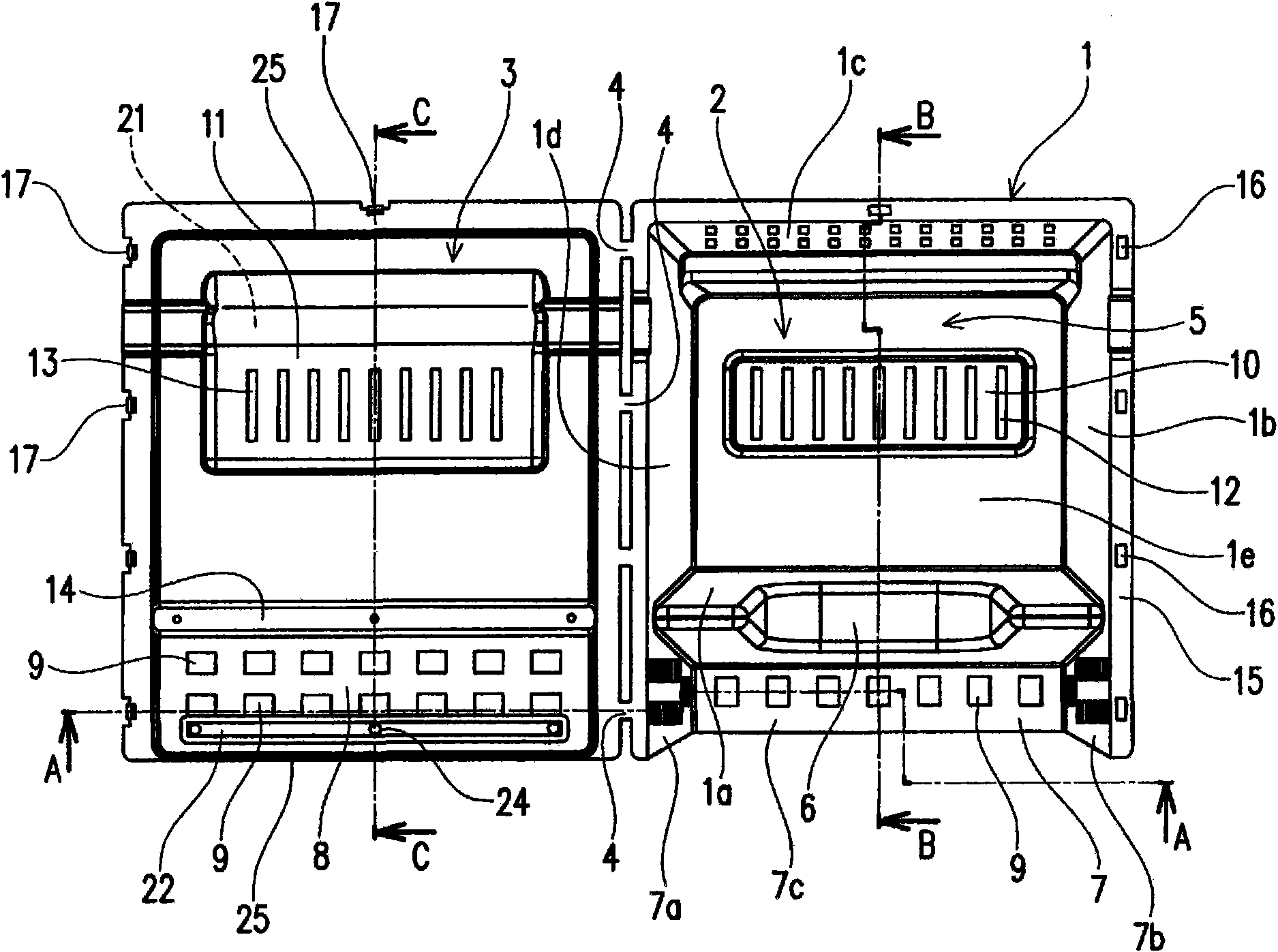

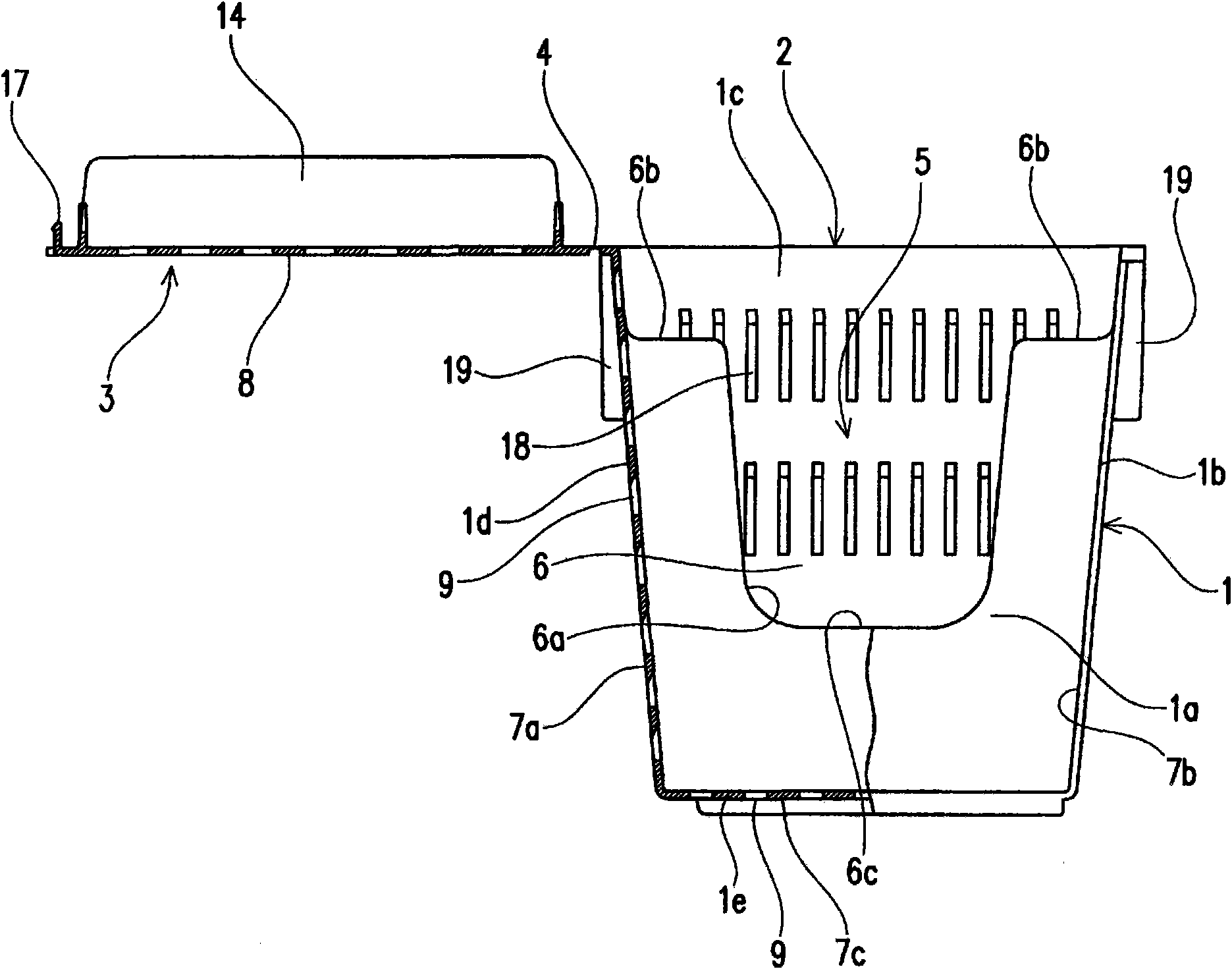

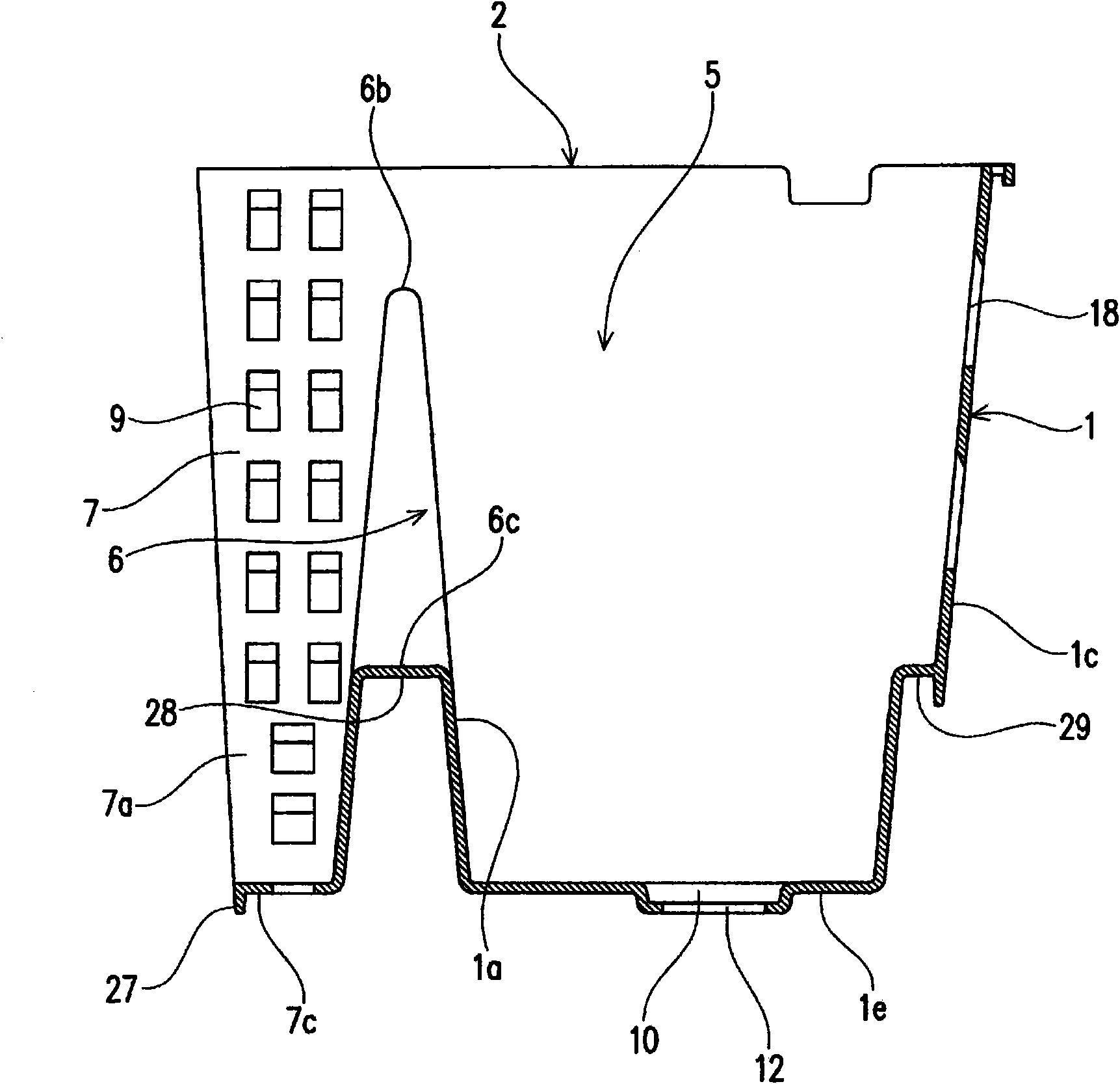

Container unit for greening and greening technique using the container unit

InactiveCN101909426AEasy to operateShort construction periodSelf-acting watering devicesCultivating equipmentsGreeningEngineering

Relating to a container unit for greening, for example, wall surface and a greening technique using the container unit, this object aims to provide a container unit for greening which can be easily handled, makes it possible to very easily undertake greening of, for example, wall surface within a short period of time, and has a low production cost; and a greening technique. A container unit is characterized in that an opening, through which a part of the plant body of a potted plant seedling to be packed in a container unit body can be guided outside, is formed in the one face side of the container unit body in which a planting base such as soil and the potted plant seedling can be packed. Separately from the opening through which a part of the plant body of the potted plant seedling can be guided outside, it is possible to form another opening for packing the planting base and the potted plant seedling in the container unit body.

Owner:TOHO LEO

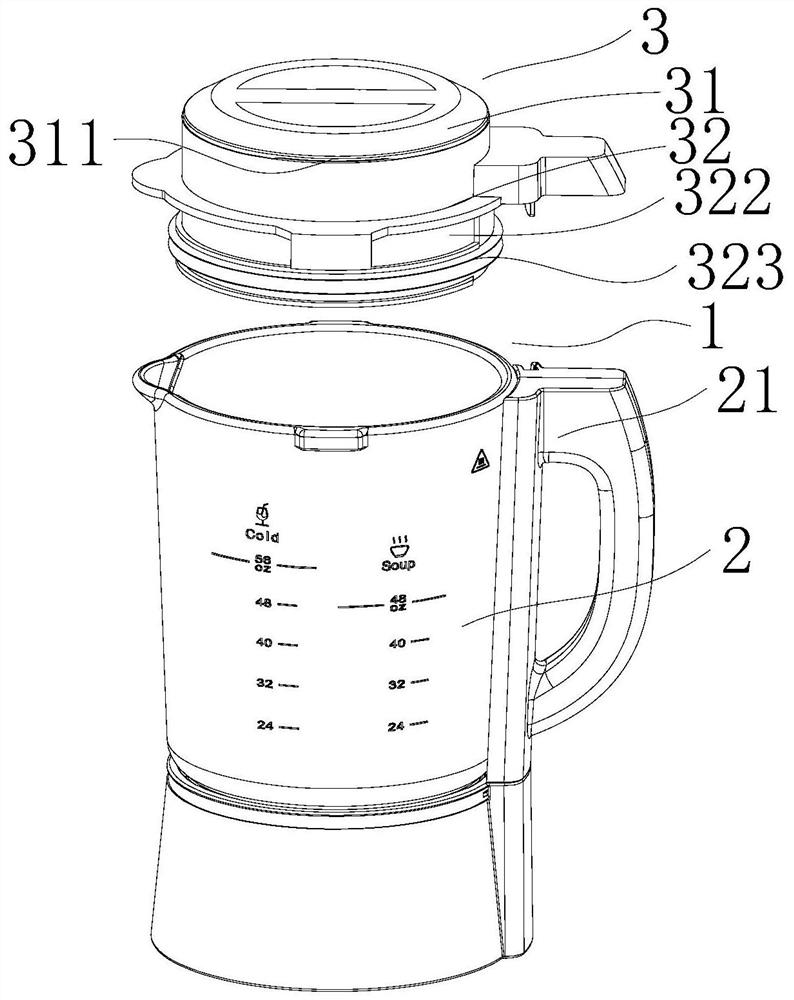

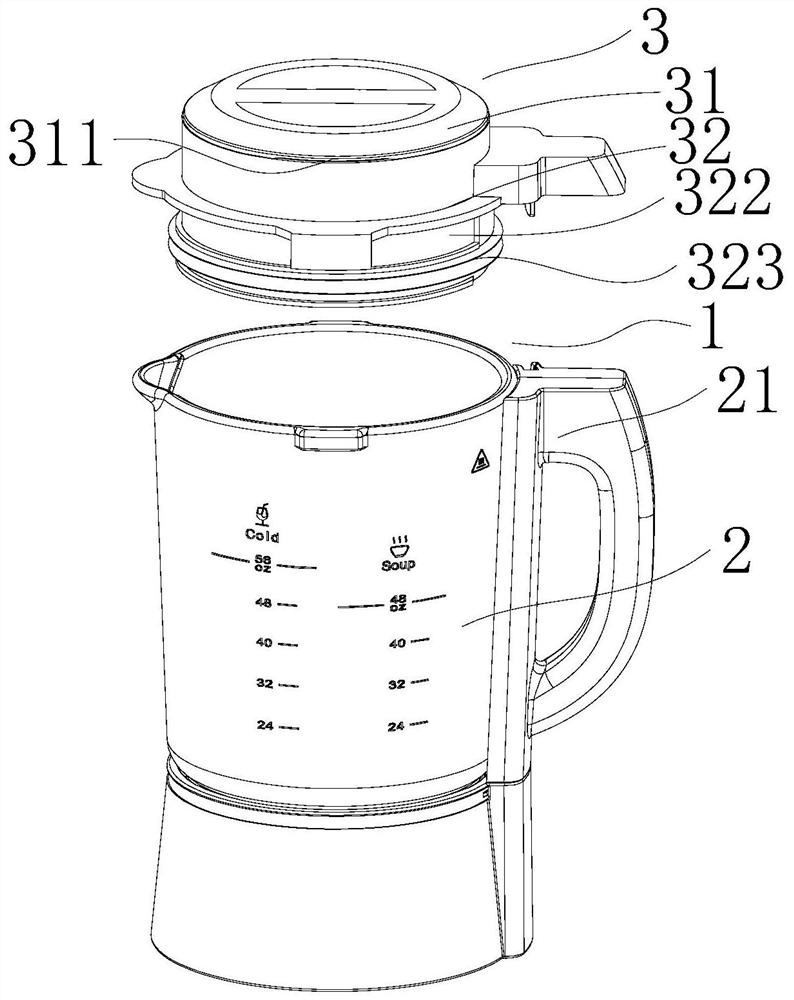

Food processor with good spill-proof effect

ActiveCN111820778AAvoid enteringEasy to overflowKitchen equipmentElectric machineryStructural engineering

Owner:JOYOUNG CO LTD

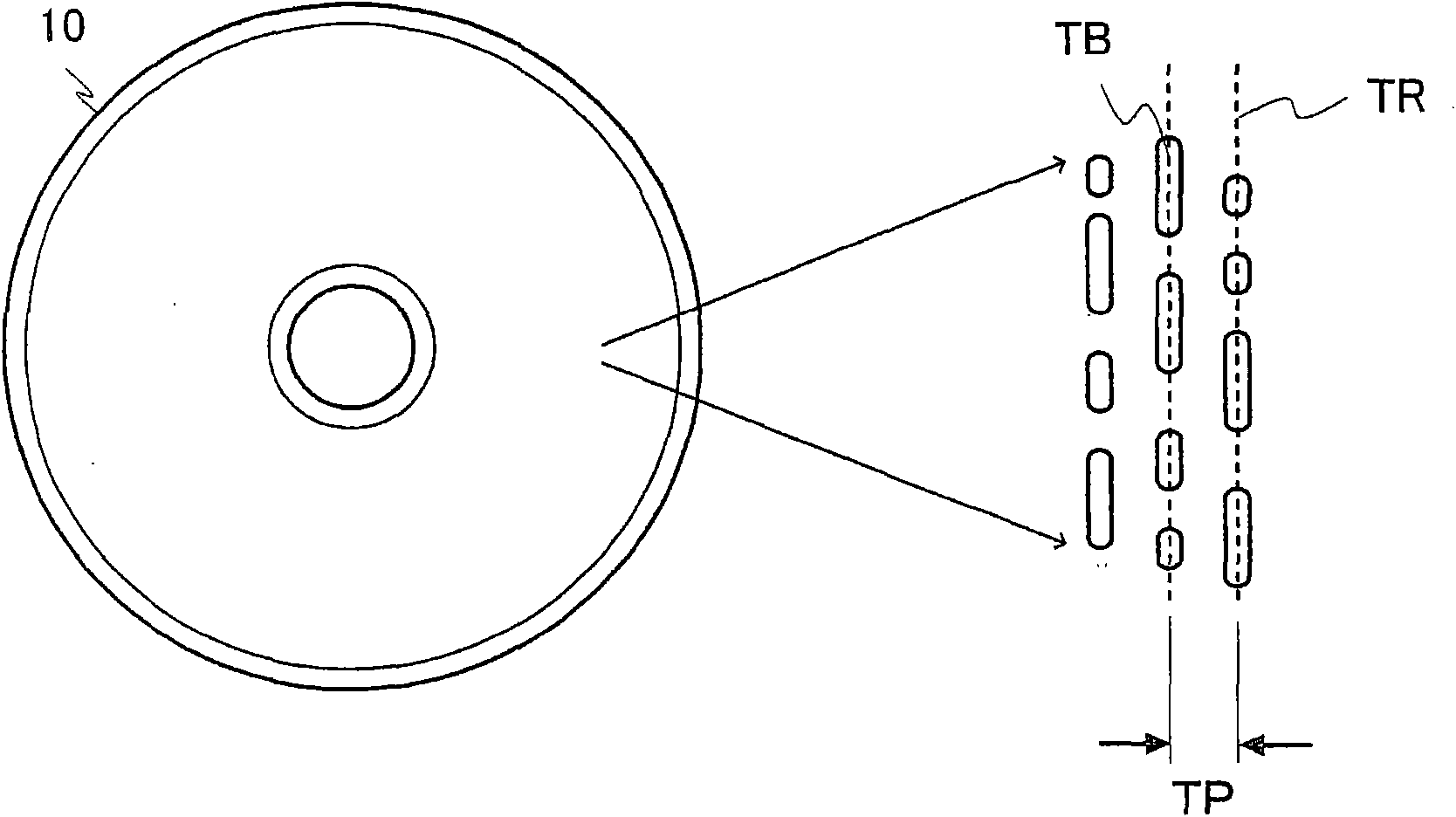

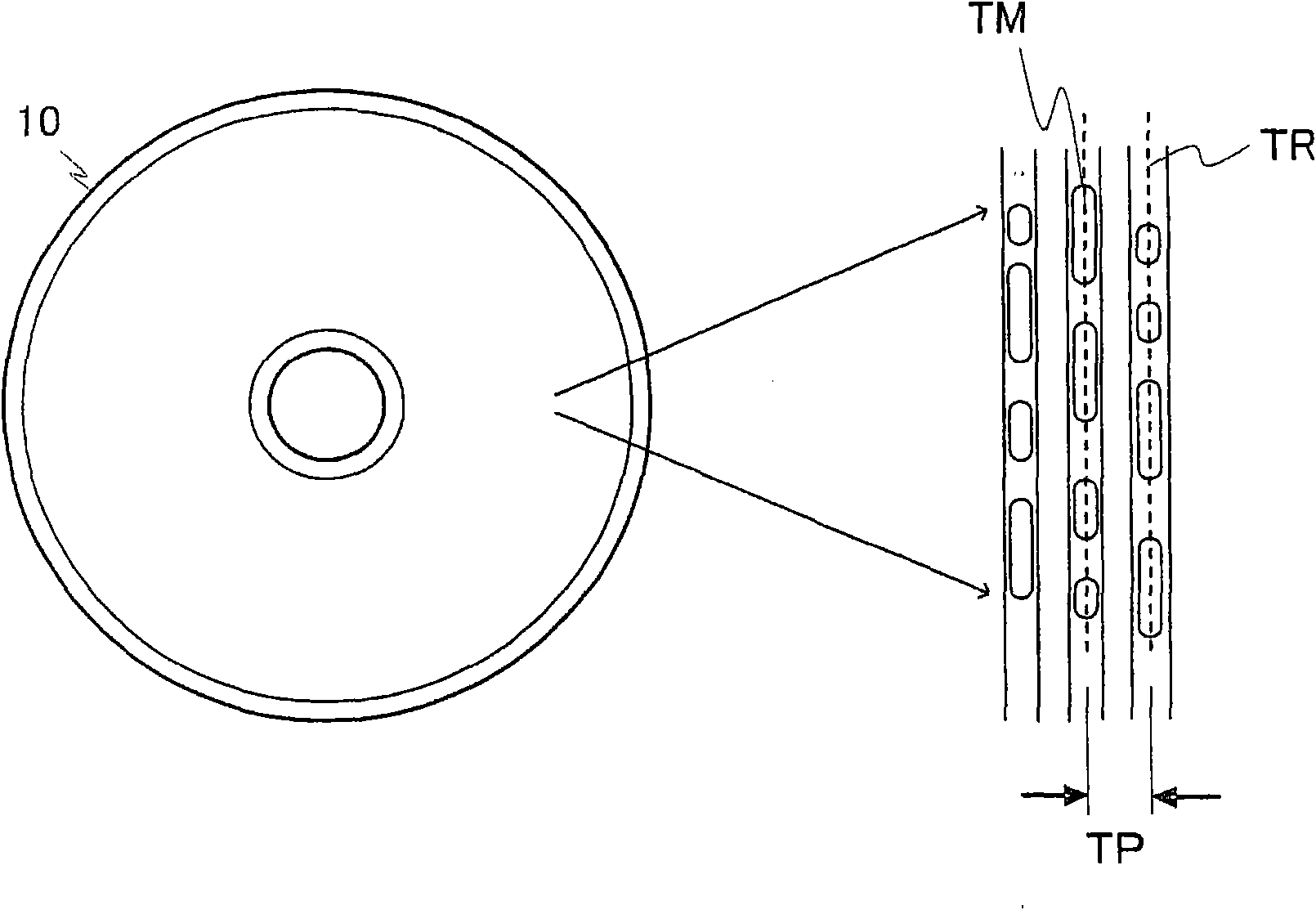

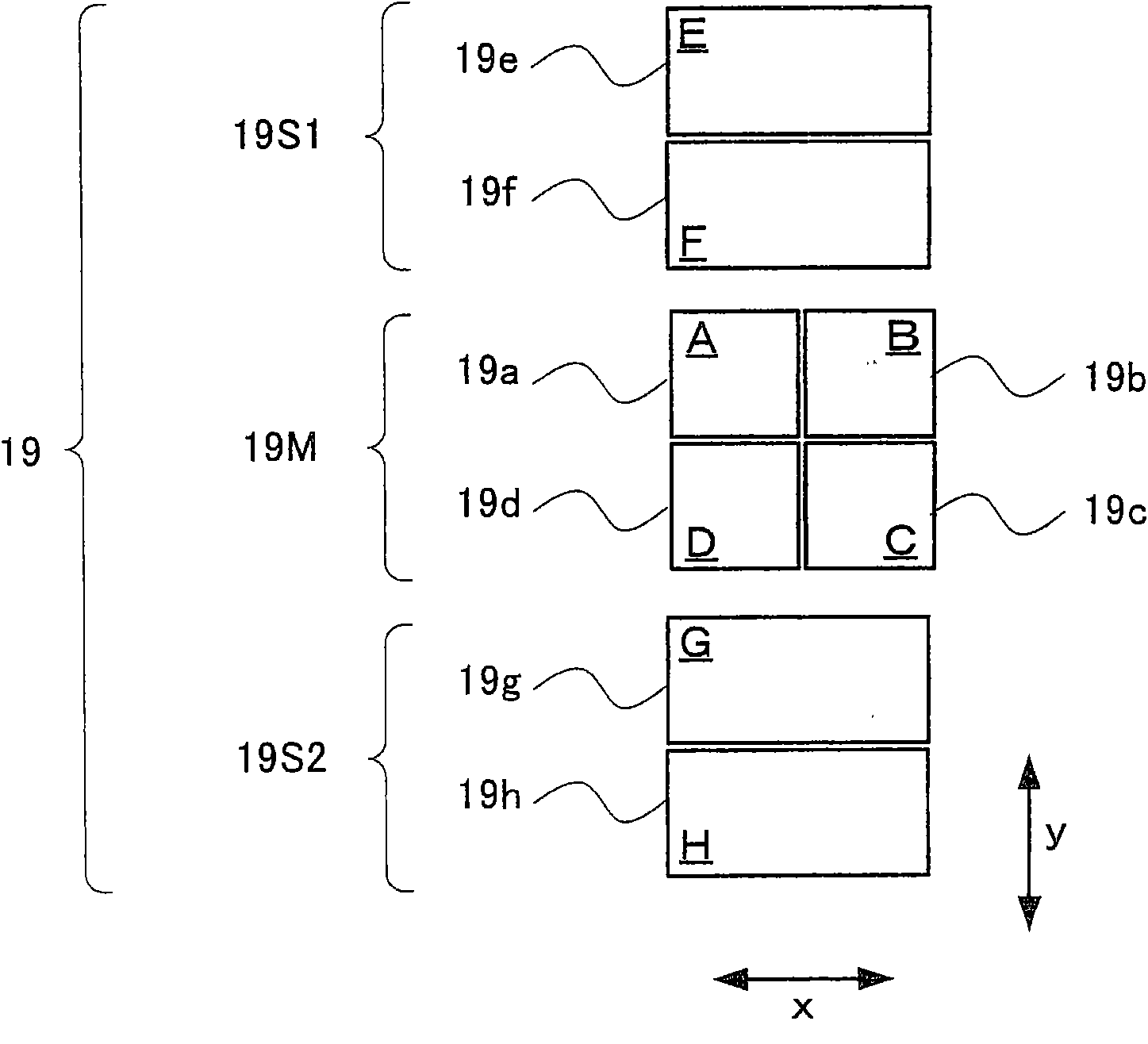

Optical head device and optical disc device

ActiveCN101681642AImprove reliabilityMitigating the Effects of Push-Pull SignalsOptical detectorsRecord information storageOptical detectorsOptical detector

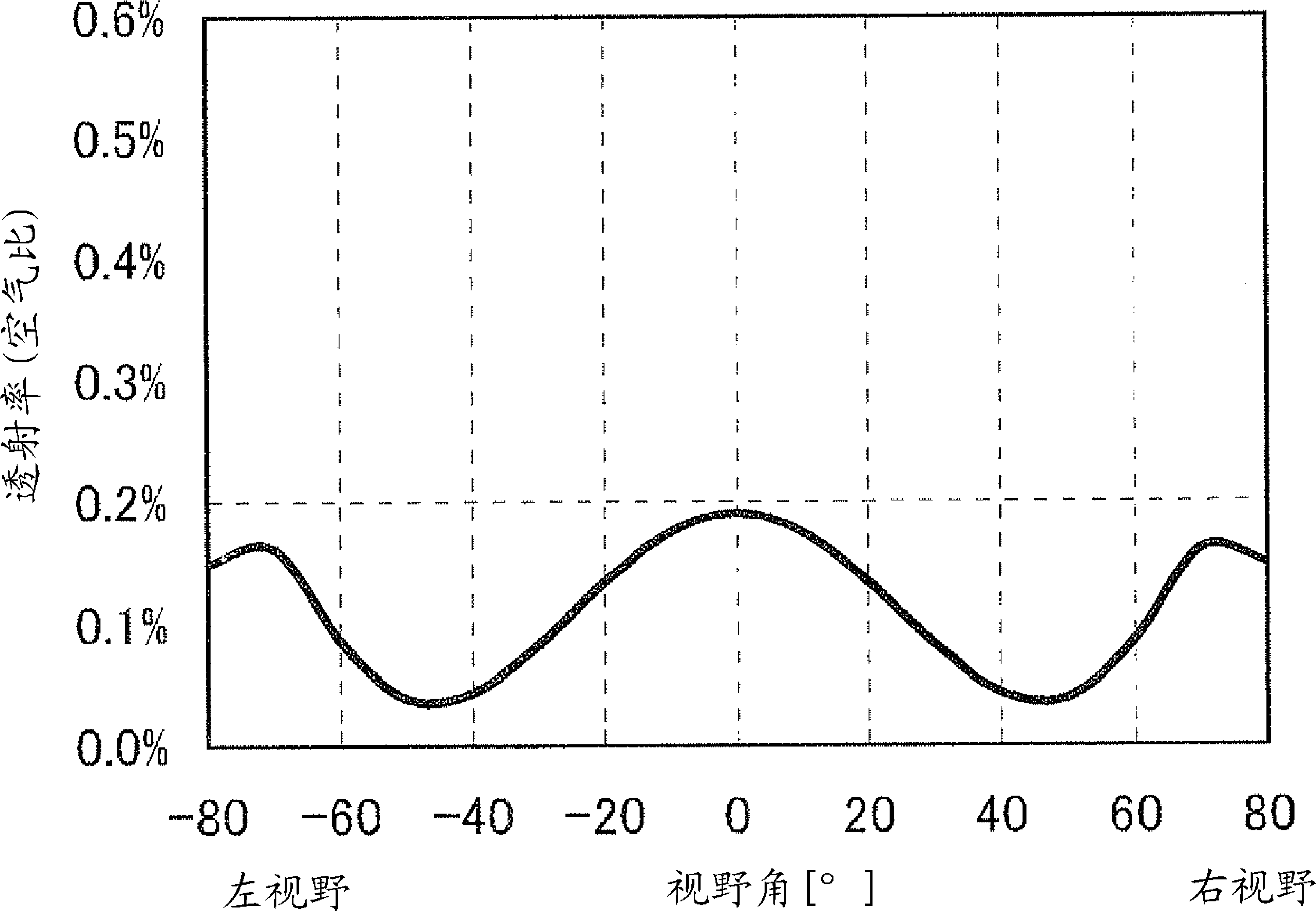

In an optical head device and an optical disc device, which make it possible to reduce an influence of a differential push-pull signal by stray light without making the structure complicated, reflective light of zero-order diffracted light by other information recording surfaces than an access subject information recording surface, reflective light of + first-order diffracted light by other information recording surfaces than an access subject information recording surface, and reflective light of - first order-order diffracted light by other information recording surfaces than an access subject information recording surface form an interference fringe on an optical detector (9). If a length in a y-direction of one period of the interference fringe is Ty, a positive integer is N1, and lengths in the y-direction of divided receiving elements (9e, 9f, 9g, 9h) are Uy, respectively, then they satisfy the following: Uy=Ty x N1. Further, if a positive integer is N2, a distance from the center of a main beam light receiving unit (9M) to the divided receiving elements (9e, 9f, 9g, 9h) and a distance from the center of the main beam light receiving unit (9M) to a dividing line of the divided receiving elements (9g, 9h) are Vy, then they satisfy the following: Vy = (Ty / 2) x {N2 - (1 / 2)}.

Owner:MITSUBISHI ELECTRIC CORP

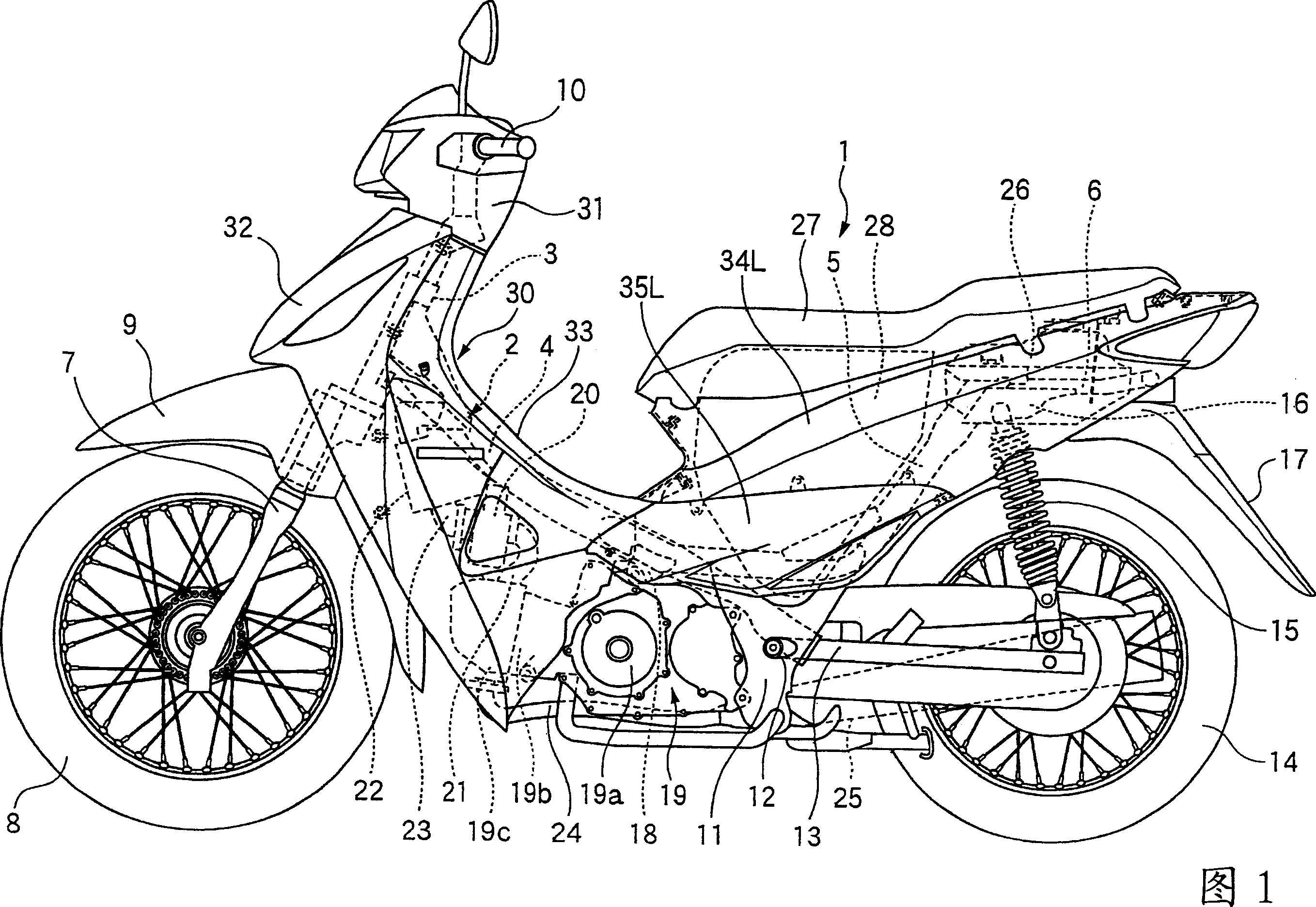

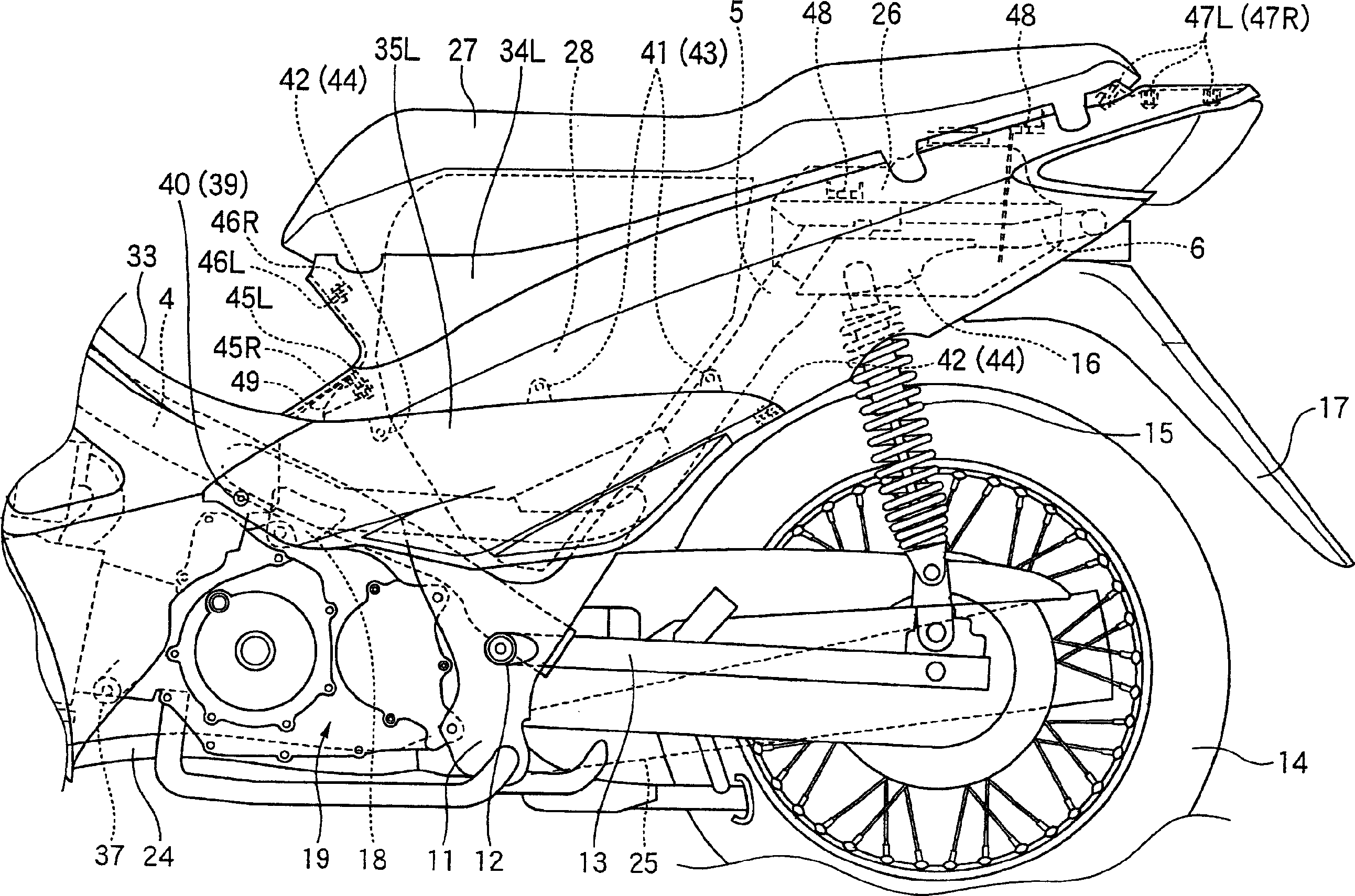

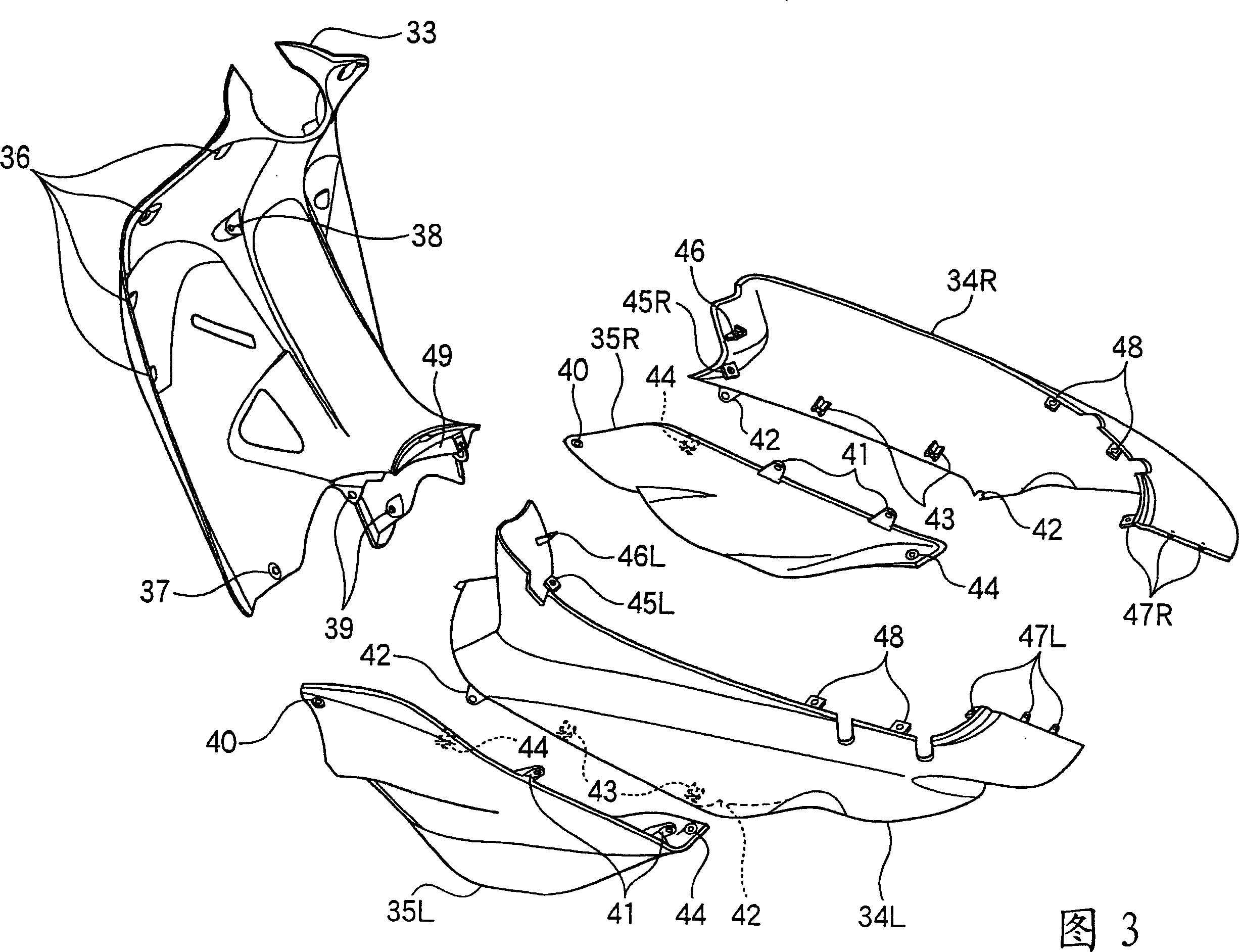

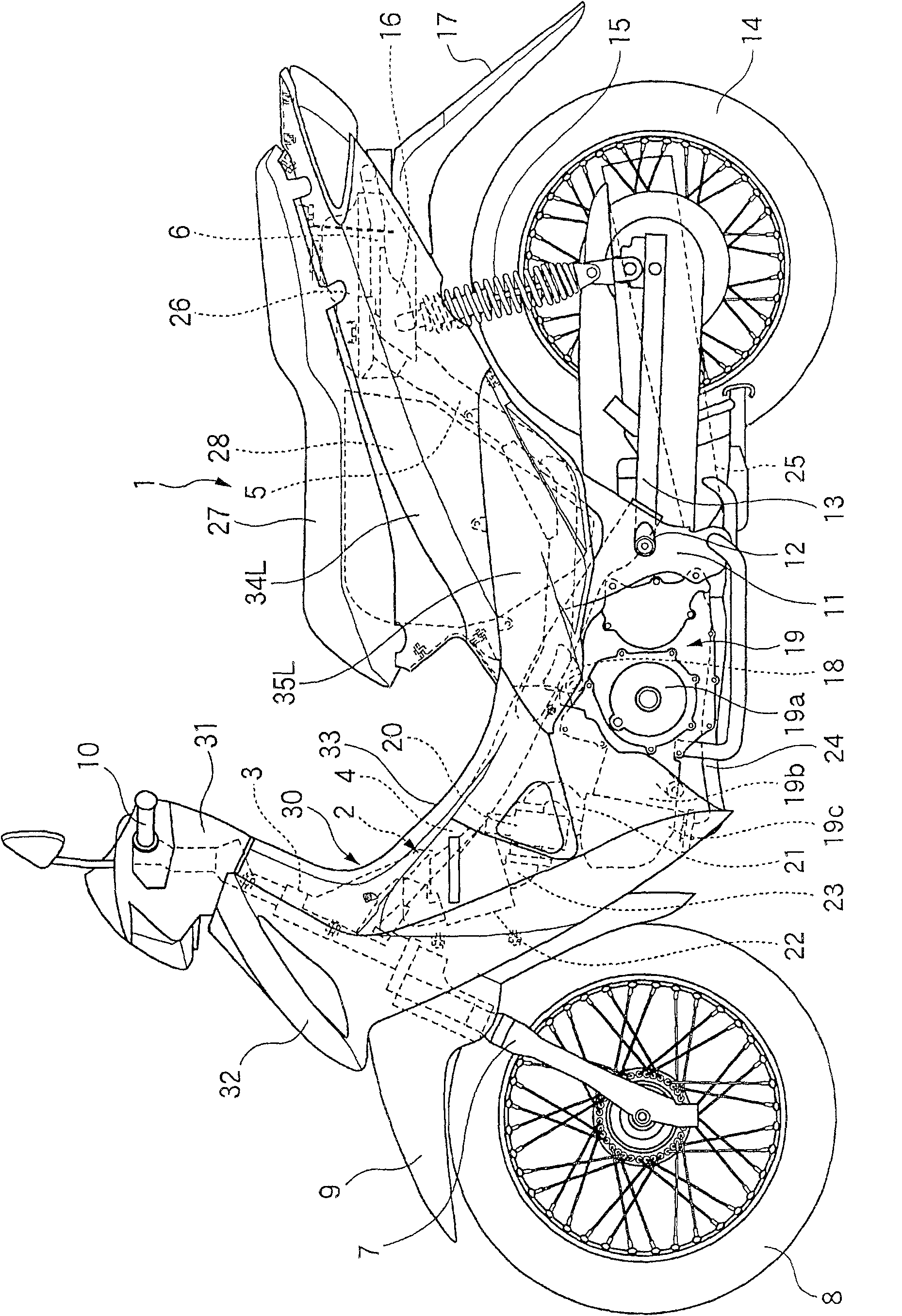

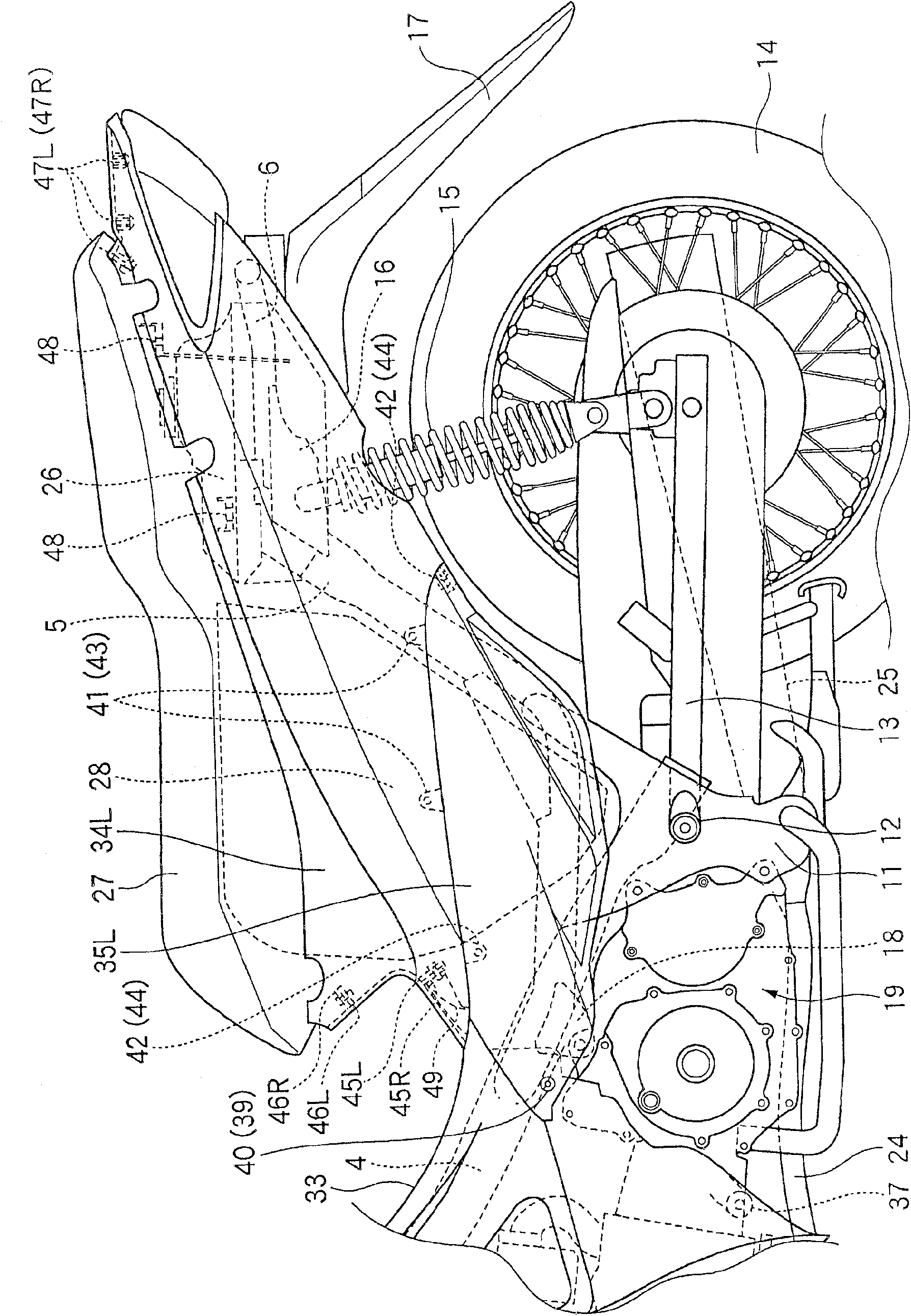

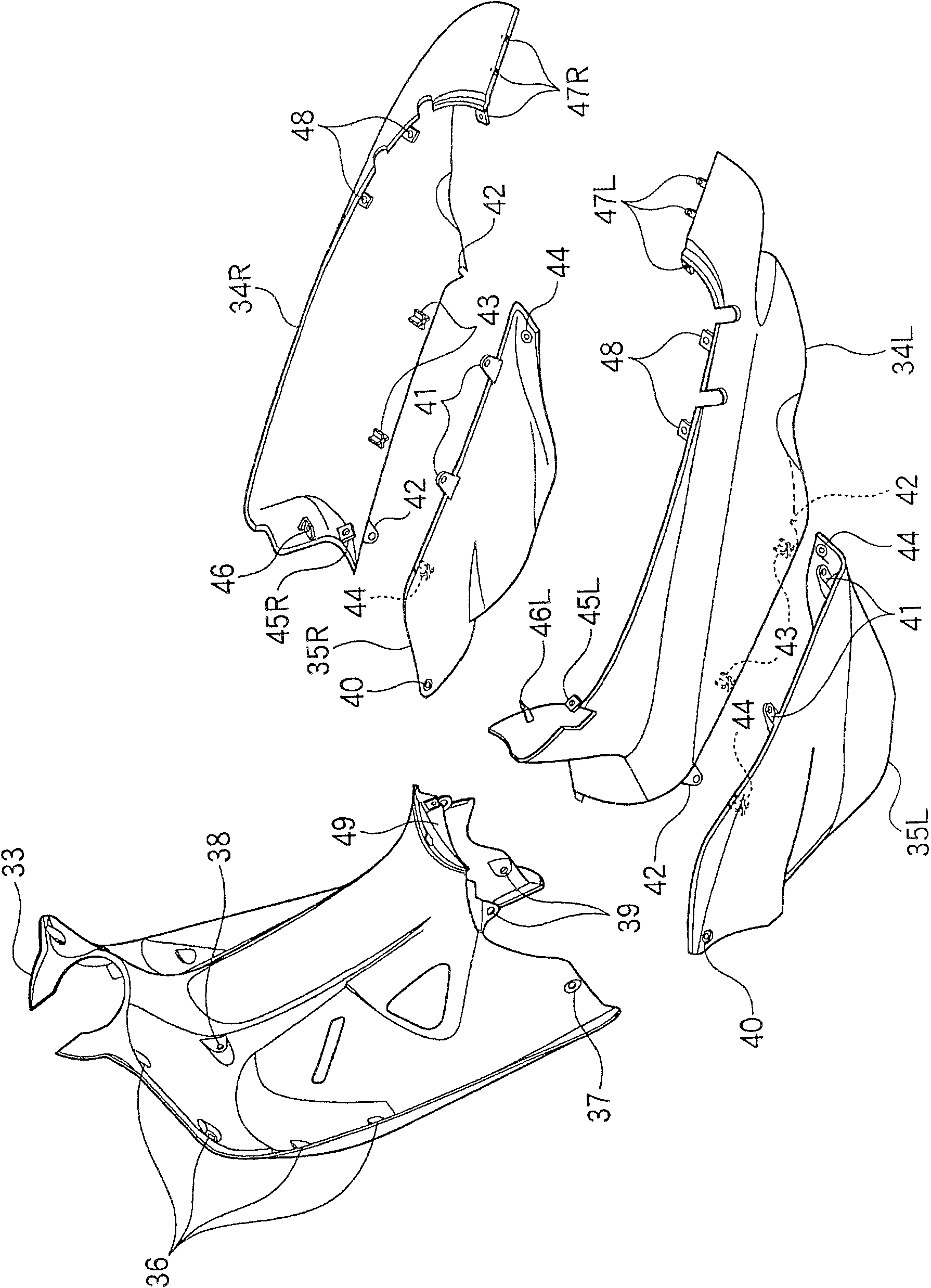

Body hood mounting structure of automatic two-wheeled bicycle

InactiveCN1754747AEasy to connectReduce in quantityMotorised scootersWeather guardsMan-hourEngineering

To provide a body cover mounting structure of a motorcycle capable of enhancing the producibility through a decrease in the man-hours for assembly and reducing the cost by means of simplification of the construction. A pair of body covers 34L and 34R are equipped with front engaging pieces 58 installed in the front part and cover mounting pieces 45L and 45R installed inside, respectively, and a leg shield 33 is provided with an engaging hole 51 to engage the front engaging pieces 58 and rear mounting pieces 49 extending backward inside the body covers 34L and 34R and fastened together with the two cover mounting pieces 45L and 45R.

Owner:HONDA MOTOR CO LTD

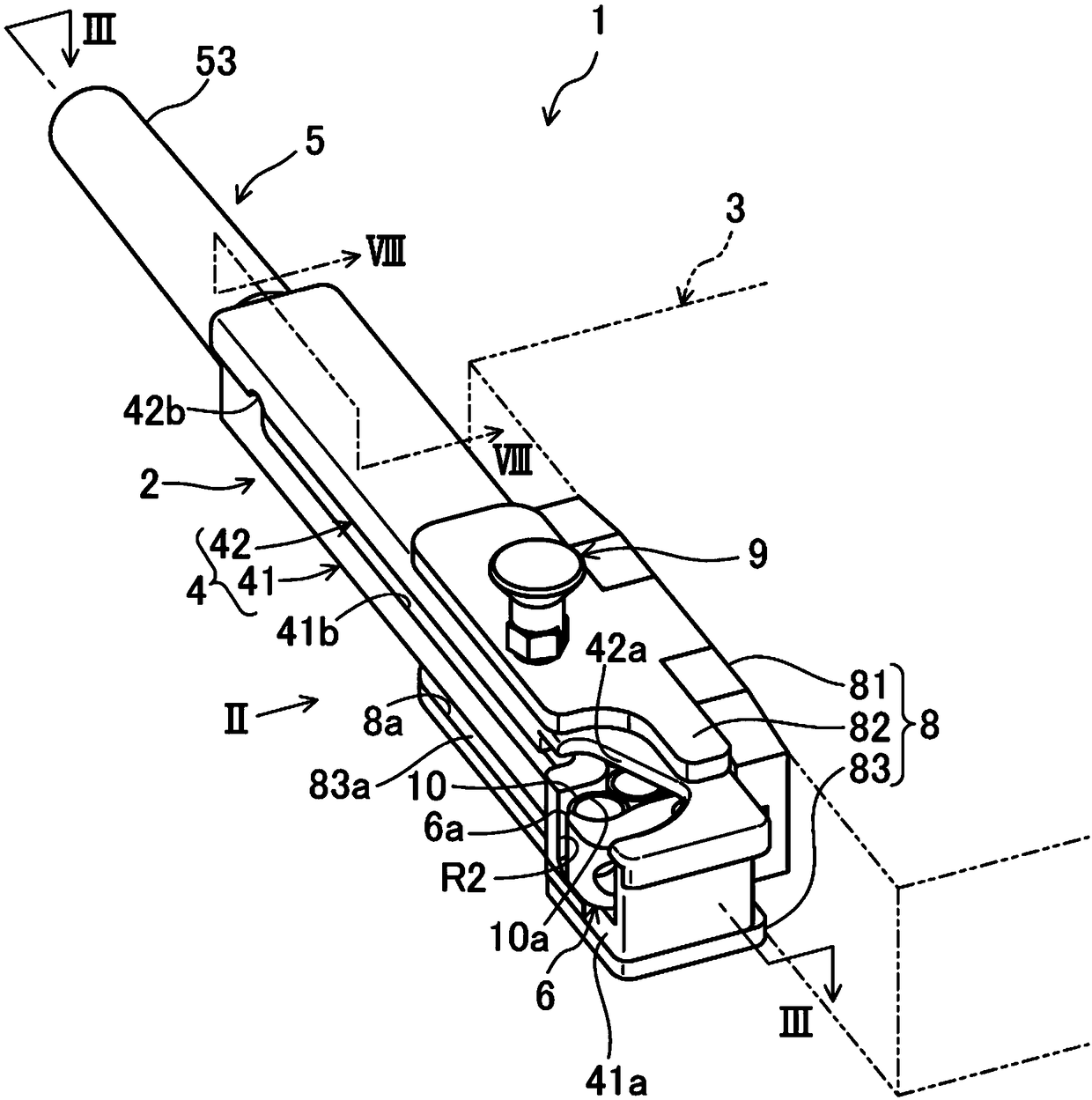

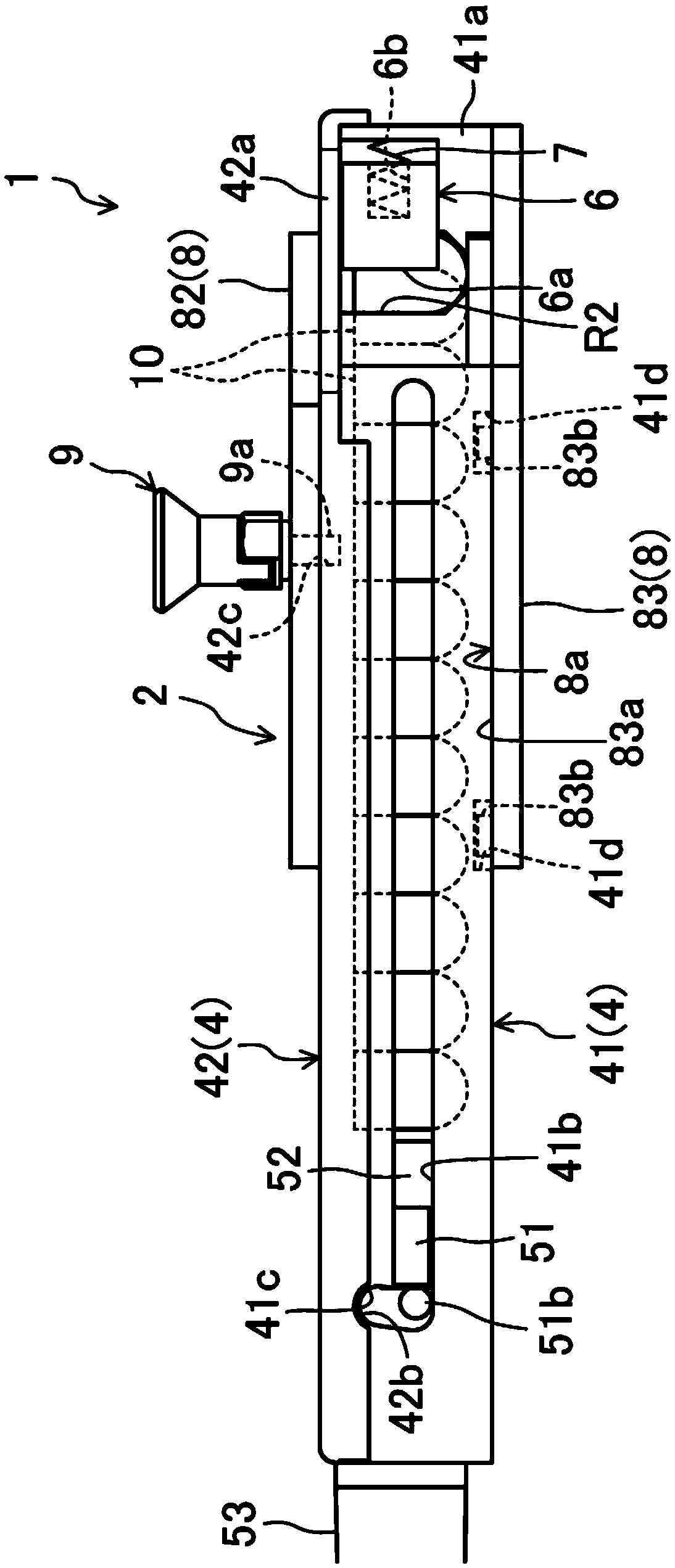

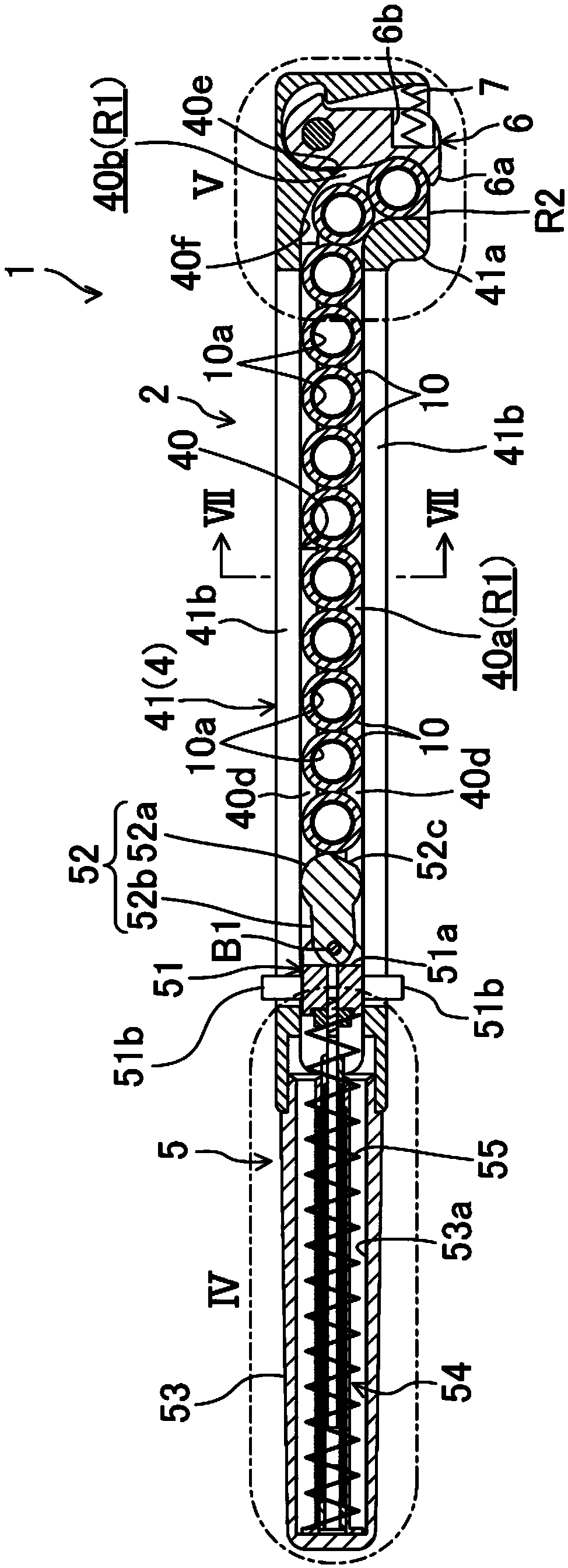

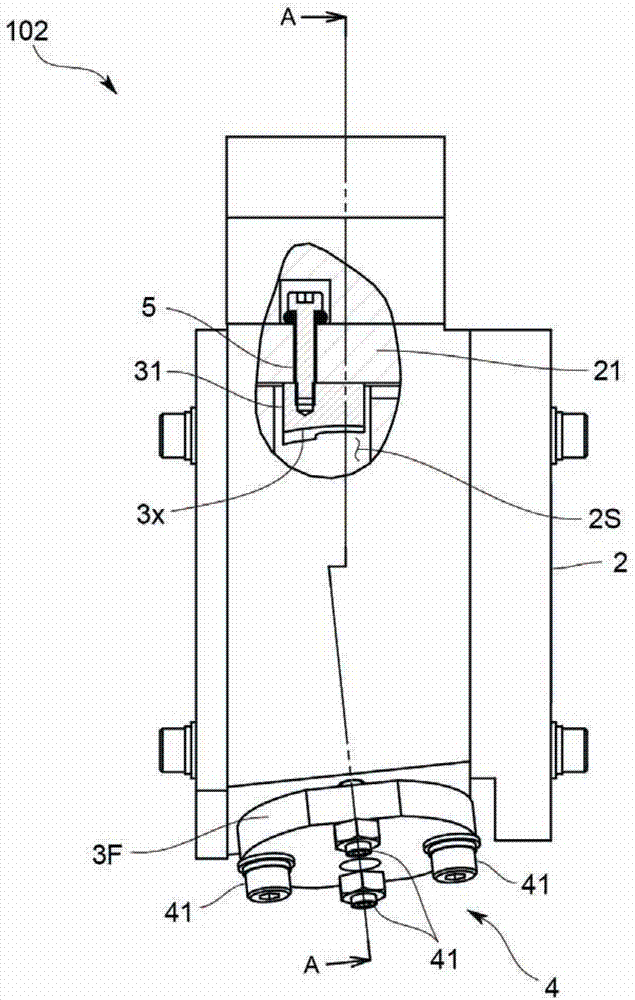

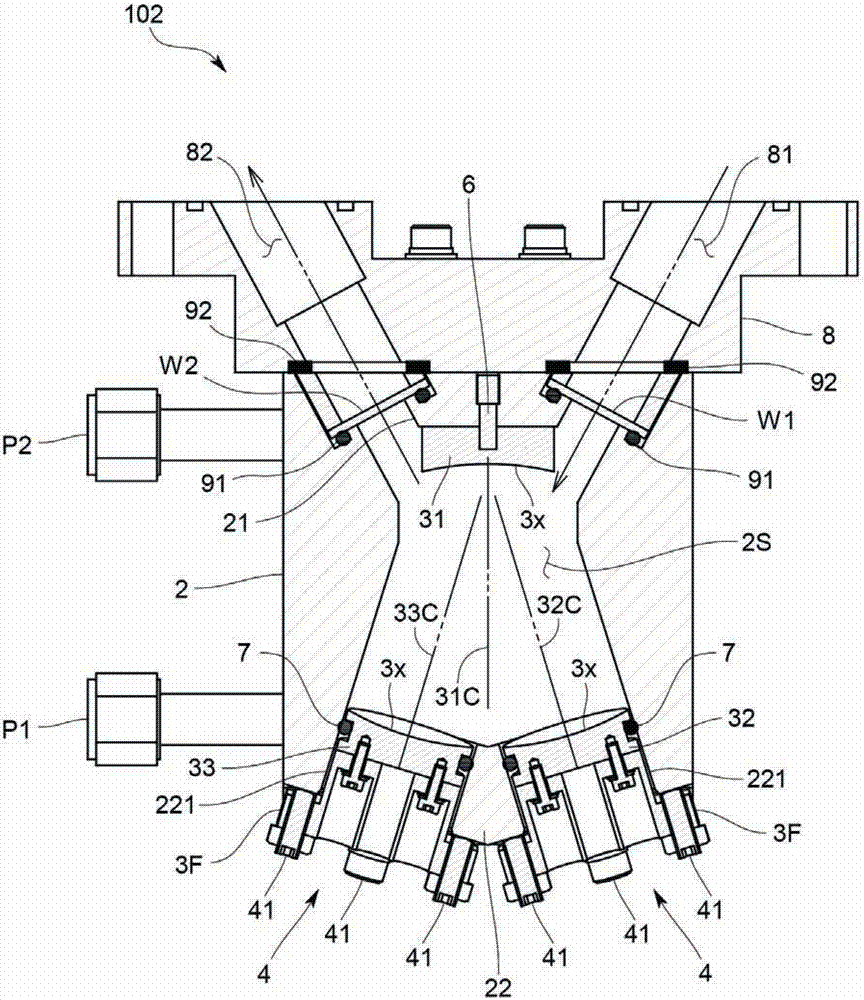

Electrode housing device for spot welding

ActiveCN109311117AReduce work failurePrevent immobilityNon-shielding electrode holdersElectrode featuresCoil springEngineering

An accommodating case (4) has an accommodating passage (R1) that linearly accommodates a plurality of electrodes (10) in the interior thereof. An electrode outlet (R2) that communicates with the accommodating passage (R1) is formed in one end of the accommodating case (4). A pressing unit (5) presses the plurality of electrodes (10), which are in a state of being set in a row accommodated in the accommodating passage (R1), toward one end of the accommodating passage (R1). A lever member (6), by swinging, switches unloading of the electrodes (10) from the electrode outlet (R2) between a regulated state and an open state. A regulating coil spring (7) biases the lever member (6) so as to swing in one direction.

Owner:KYOKUTOH

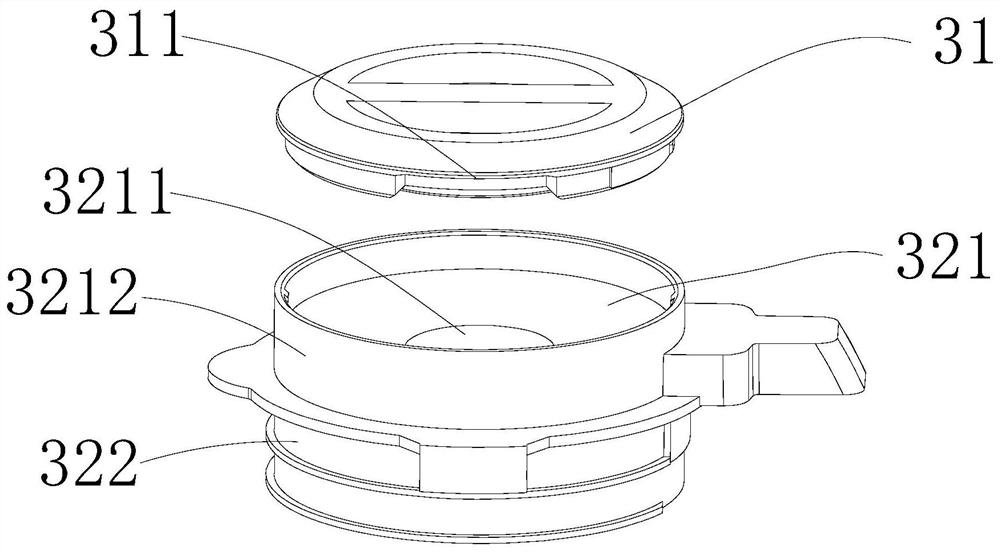

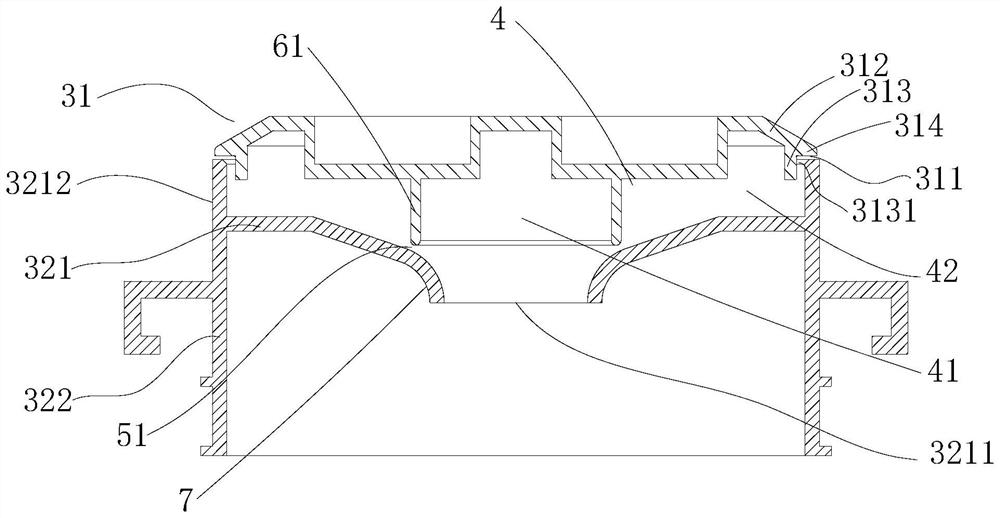

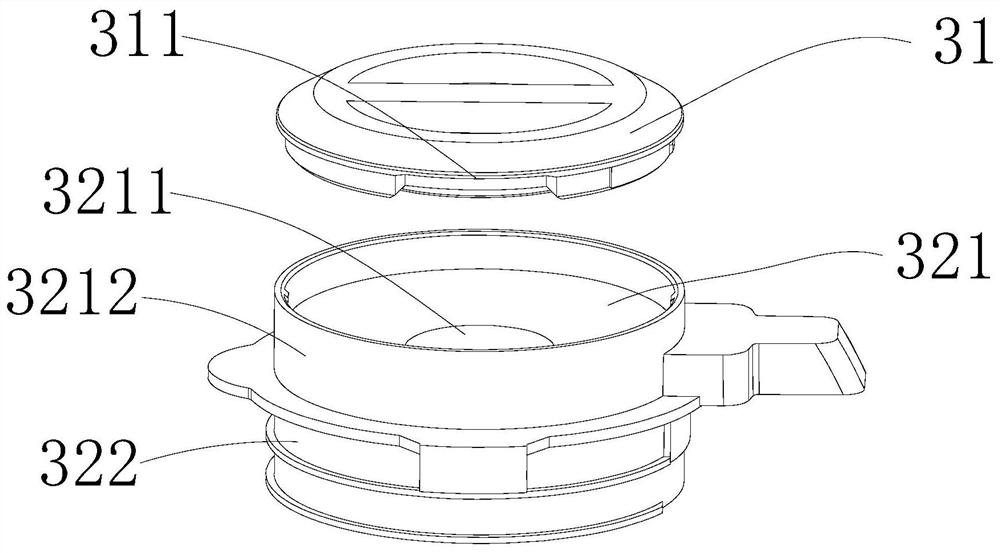

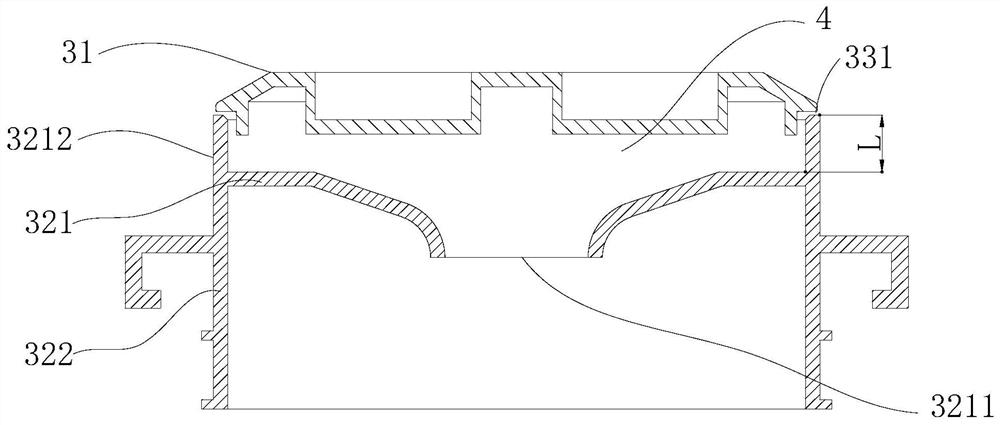

Low-noise food processor

ActiveCN111820779ASimple structureReduce noiseKitchen equipmentElectric machineryStructural engineering

The invention discloses a low-noise food processor. The low-noise food processor comprises a base and a stirring cup arranged on the base, a motor and a circuit board are arranged in the base; the stirring cup comprises a cup body and a cup cover; a crushing cutter is arranged in cup body, a motor drives the crushing cutter, the cup cover comprises an upper cover and a lower cover; the lower covercomprises a lower cover top wall, a lower cover side wall and a sealing ring; at least part of the side wall of the lower cover extends into the cup body, the sealing ring is arranged between the side wall of the lower cover and the cup body, a through hole is formed in the top wall of the lower cover, an upward surrounding edge is arranged on the edge of the top wall of the lower cover, the upper cover covers the surrounding edge, and a silencing cavity is defined between the upper cover and the lower cover and communicated with the outside through an exhaust gap which is arranged at the upper cover. After noise generated in the cup body enters the silencing cavity from the through hole, the noise pressure is released and attenuated, and then the noise is further attenuated through the exhaust gap and discharged, so that the discharged noise is greatly attenuated, and the noise is greatly reduced.

Owner:JOYOUNG CO LTD

Microwave cooking device

ActiveCN102265092BIncrease the amount of windingWill not complicate the structureDomestic stoves or rangesLighting and heating apparatusMicrowaveTransmission channel

Owner:PANASONIC CORP

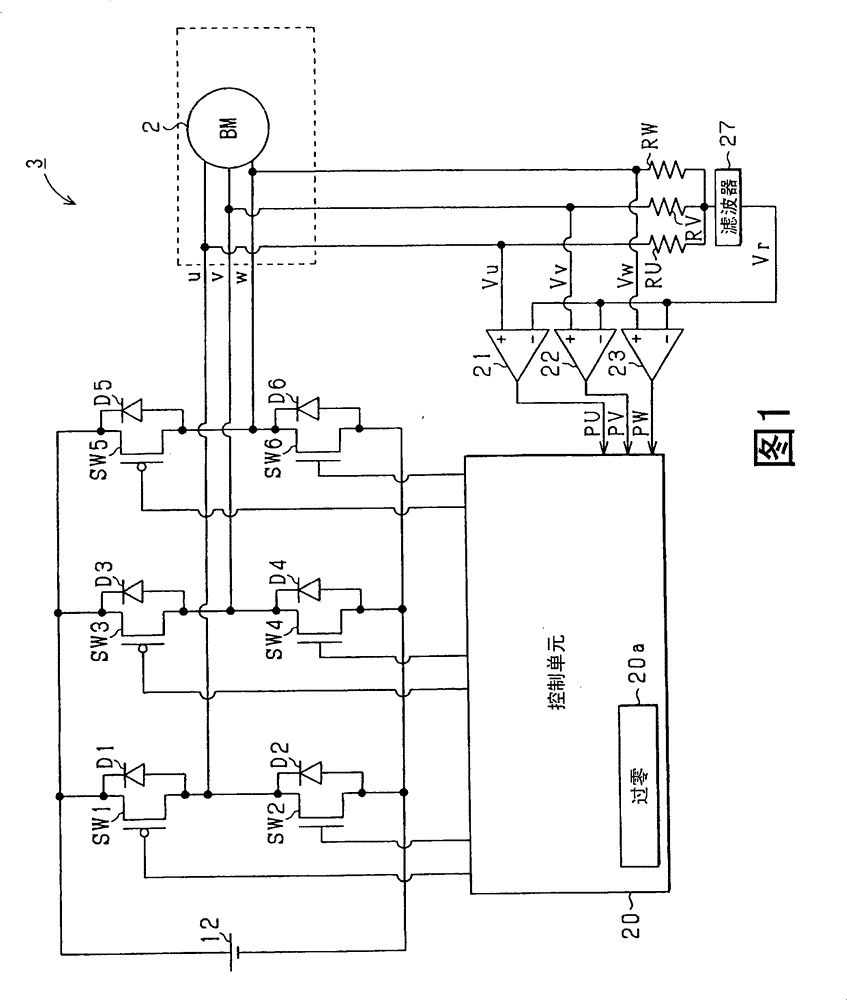

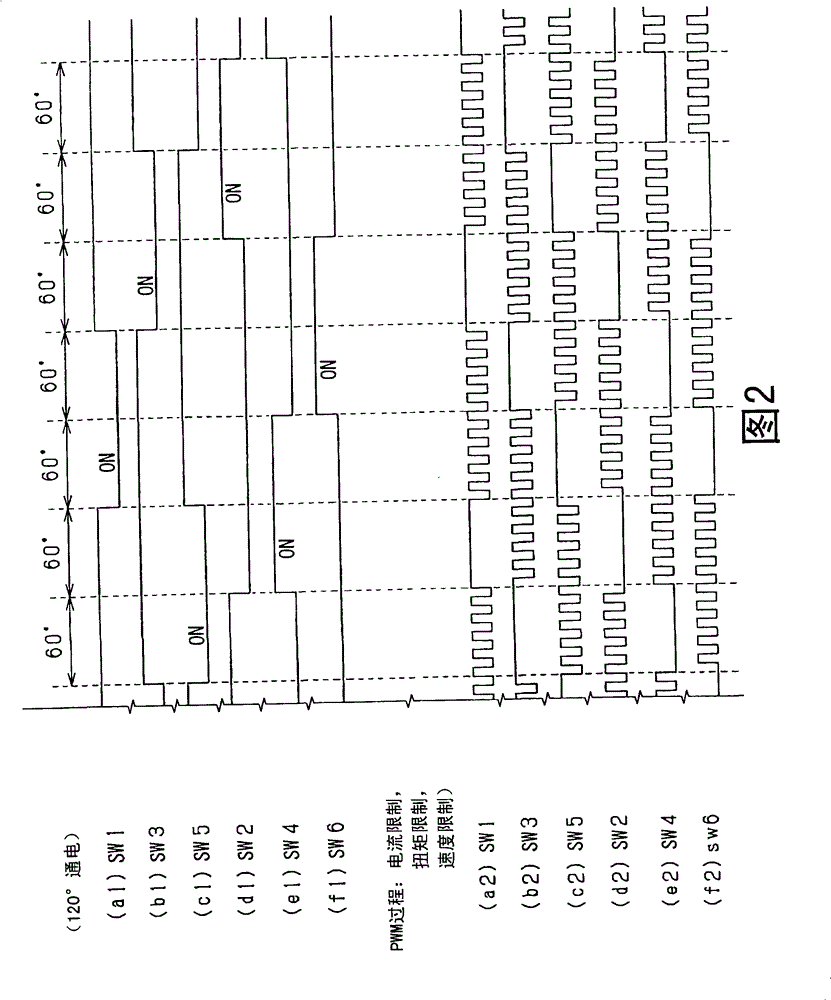

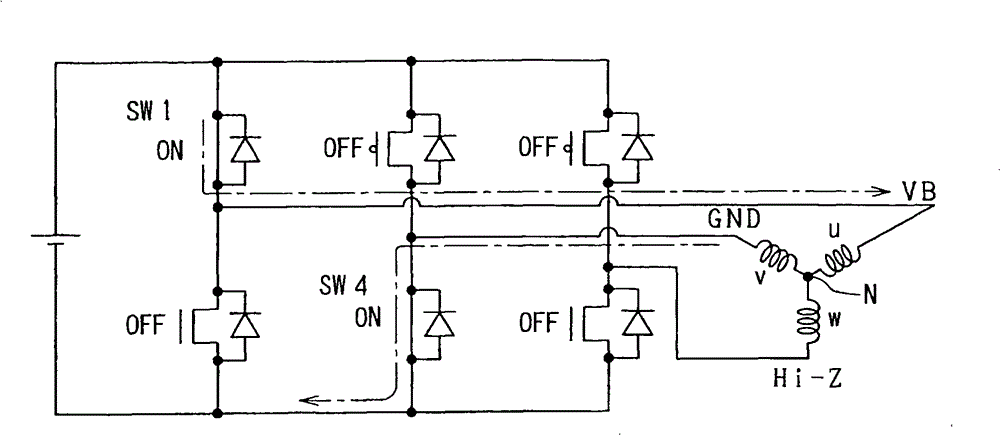

Control system for multiphase electric rotating machine

ActiveCN101483403BSuppress noiseAppropriate startSingle motor speed/torque controlElectronic commutatorsControl systemEngineering

A control system controls a multiphase rotating machine by a 120 DEG energization process and a PWM process. In the 120 DEG energization process, respective ones of switching elements of a high side arm and switching elements of a low side arm of a power conversion circuit are turned on. In the PWM process, the switching elements of the power conversion circuit turn on / off so that two phases that are connected to the switching elements that are in the on-state are alternately rendered conductive to the high potential side input terminal and the low potential side input terminal of the power conversion circuit.

Owner:DENSO CORP

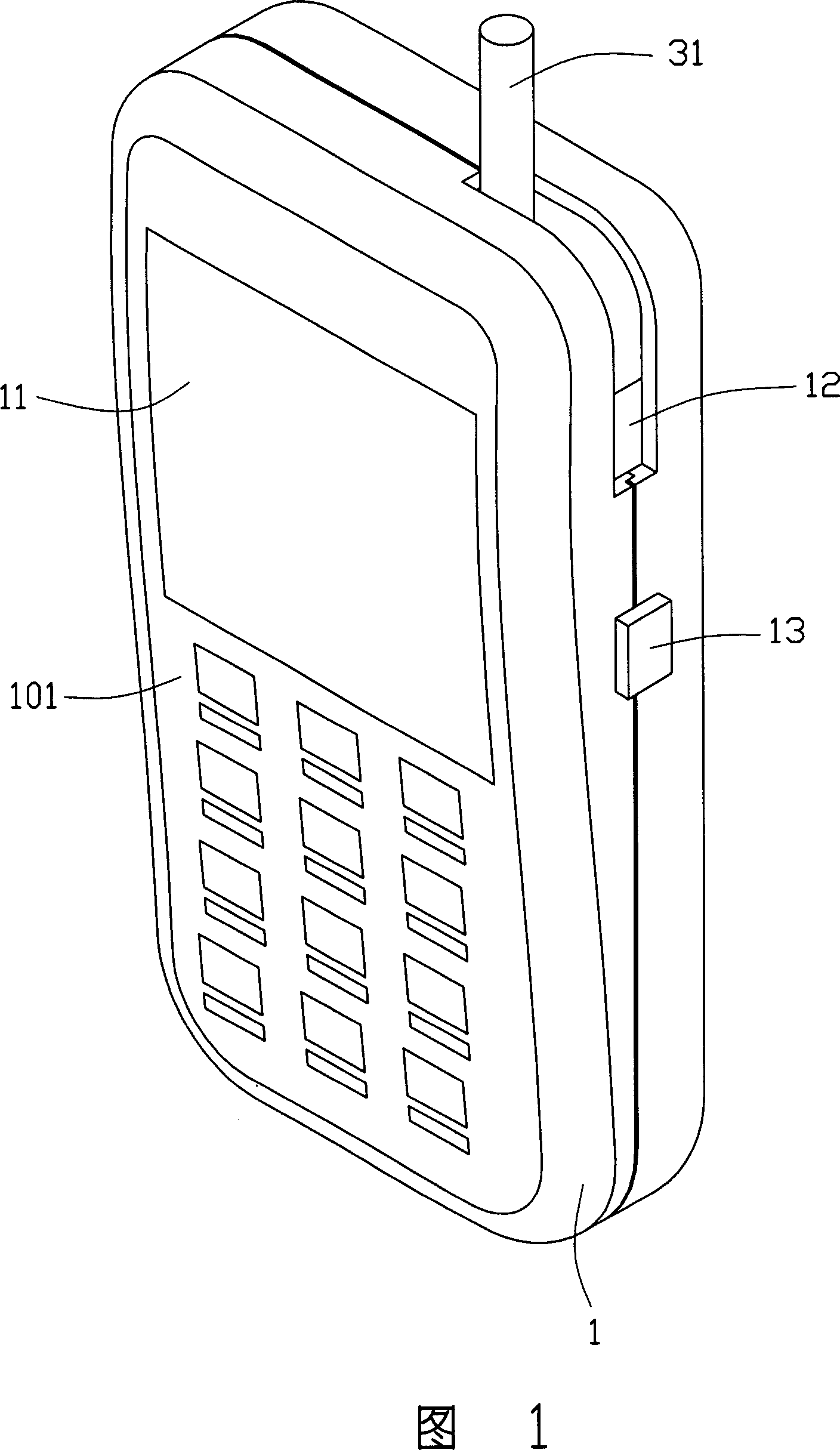

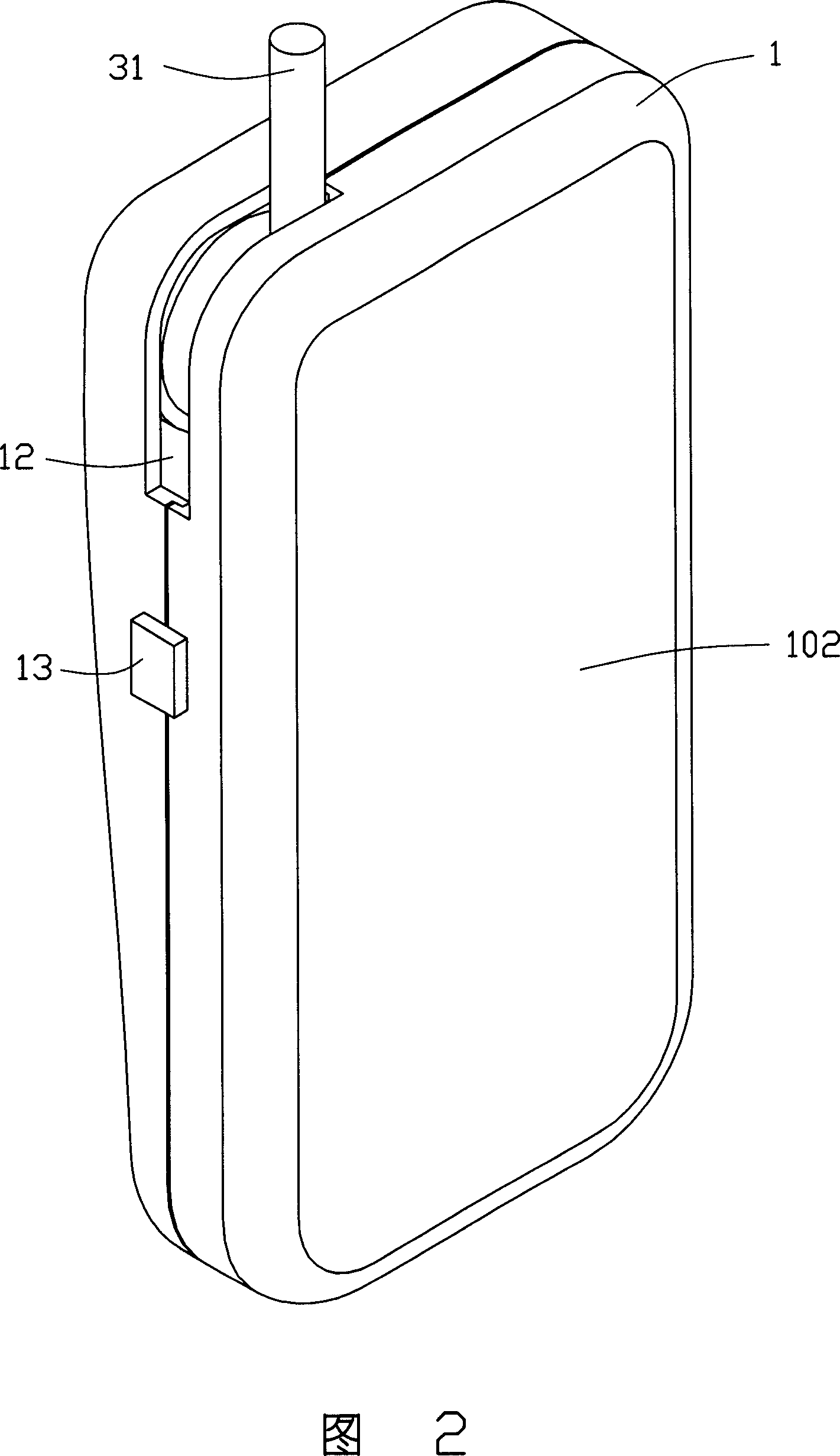

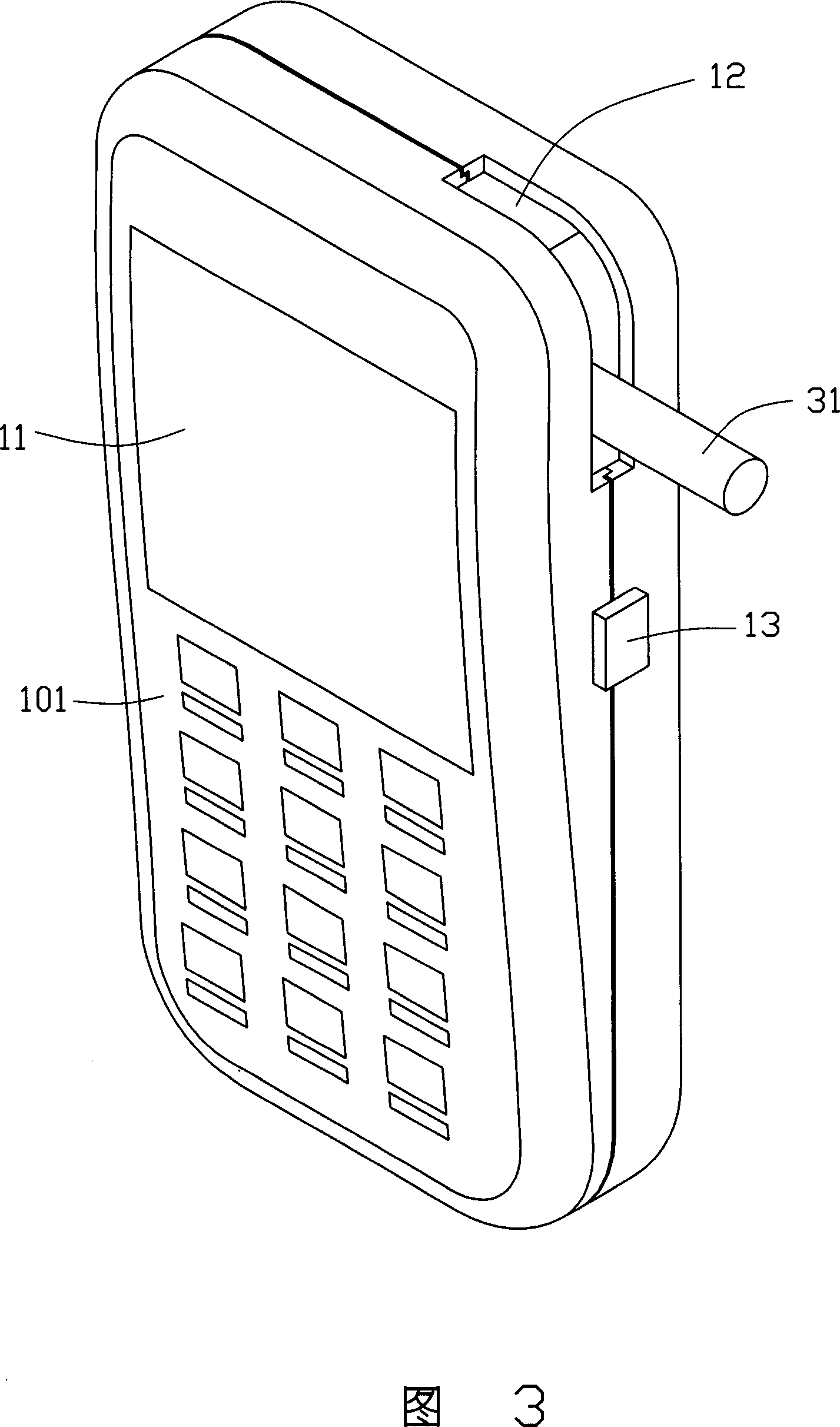

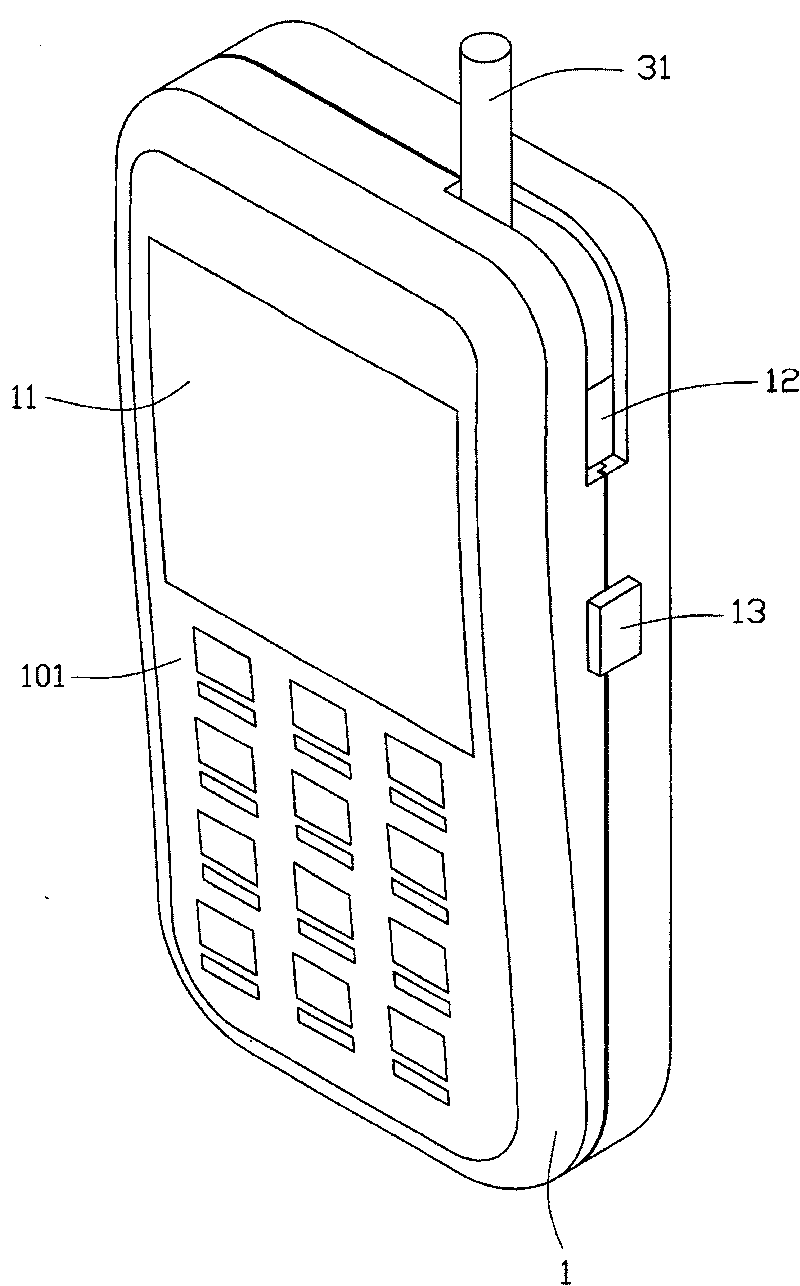

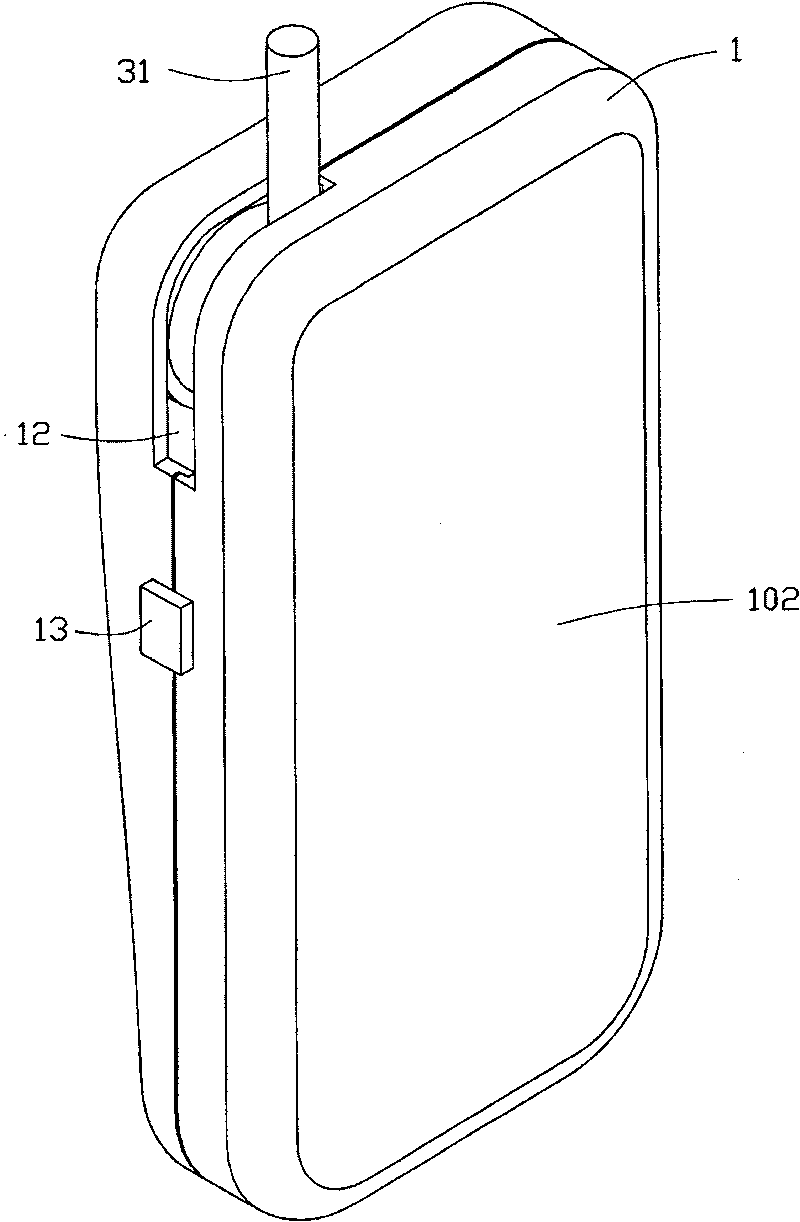

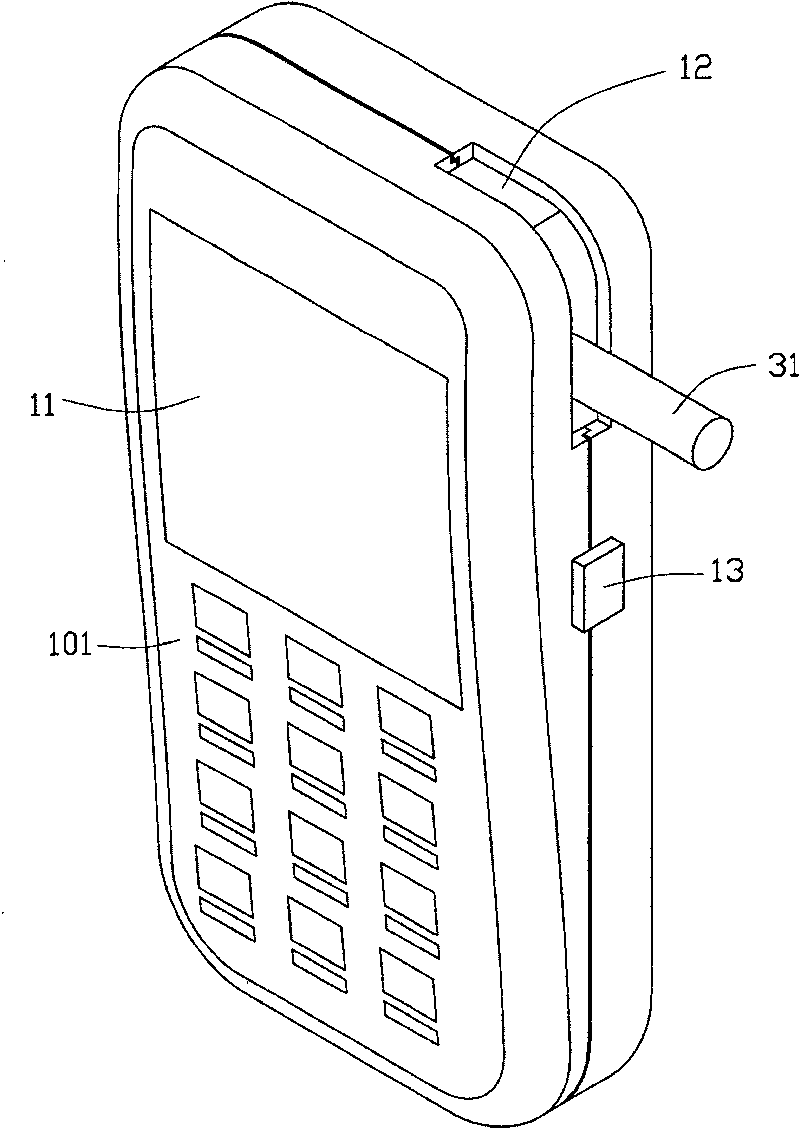

Mobile phone with game function

InactiveCN1964371AEasy to operateWill not complicate the structureRadio/inductive link selection arrangementsVideo gamesRocker armEngineering

The mobile phone with game function comprises: a rocker arm arranged on phone body to operate e-game, and the antenna for phone signal emission built in the rocker arm. This invention combines mobile phone and e-mage to introduce much convenience for user without complex structure.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

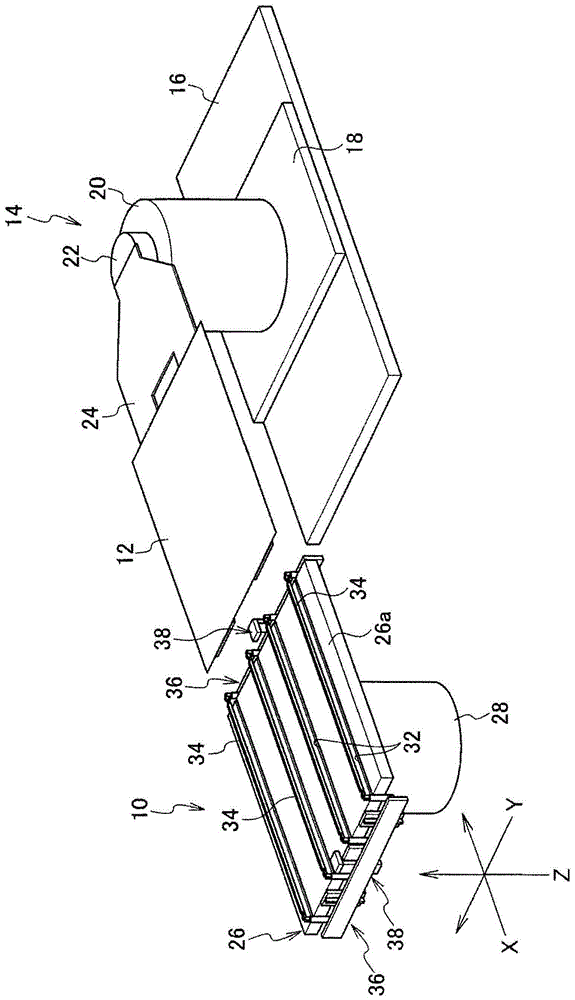

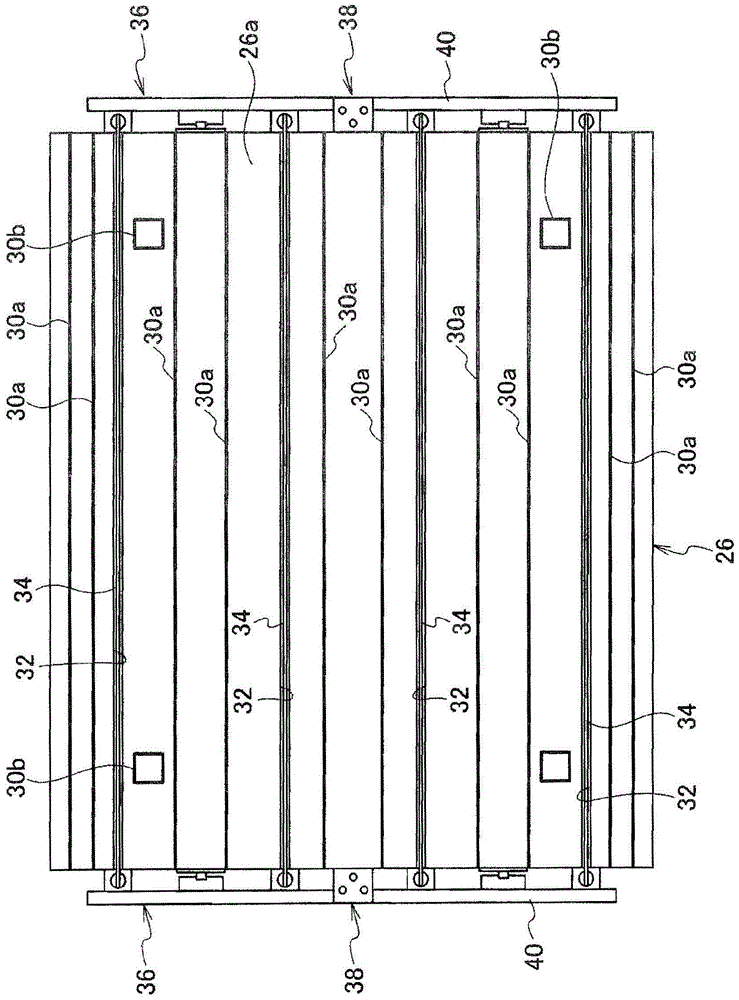

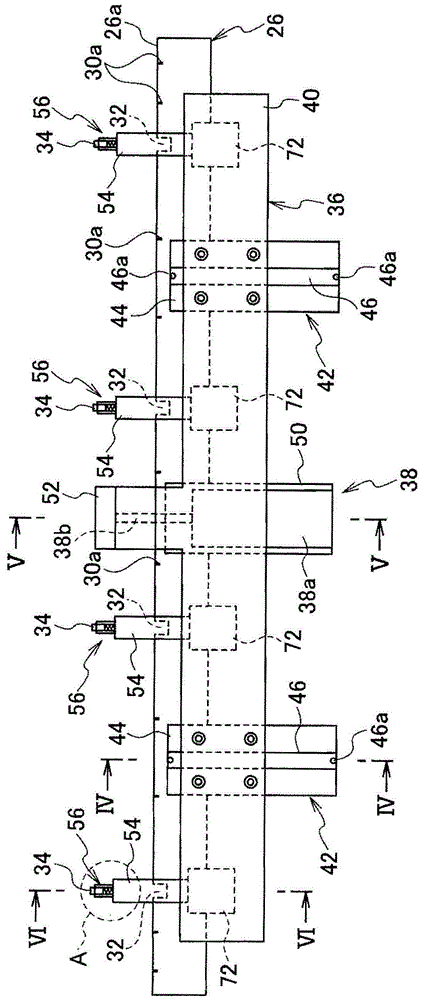

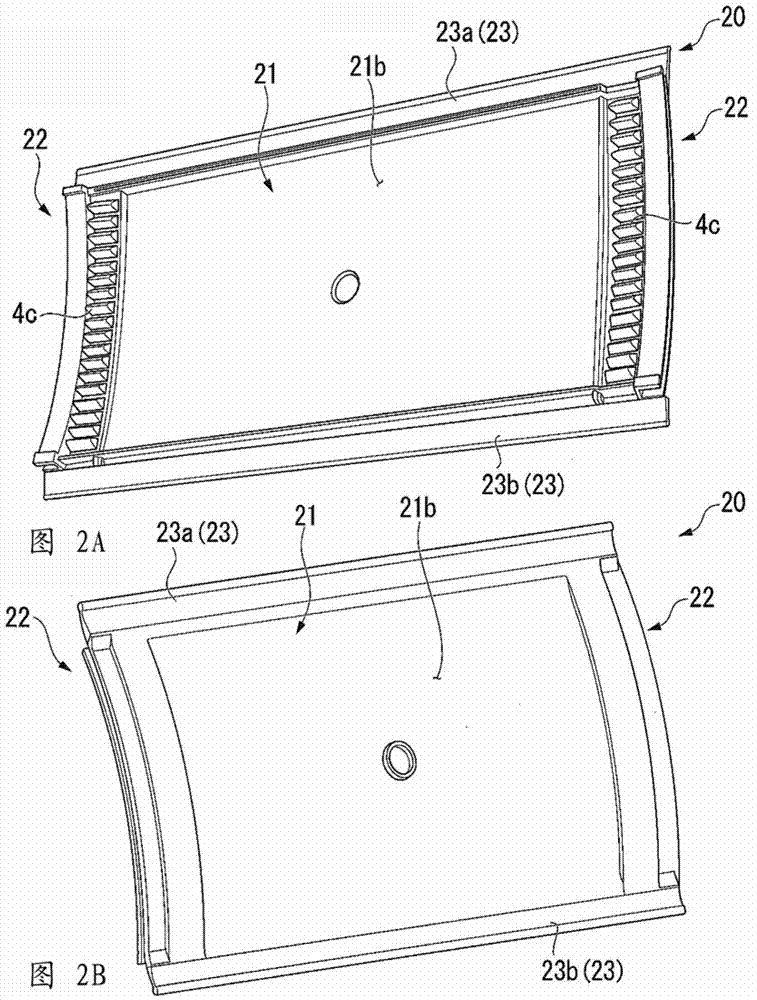

Adsorption table

ActiveCN103681436BWill not complicate the structureCheap offerSolid-state devicesSemiconductor/solid-state device manufacturingSuction surfaceSurface plate

PROBLEM TO BE SOLVED: To provide a suction table which can lift a display panel on a suction surface at delivery without having a complicated configuration nor locally applying strong stress on the display panel.SOLUTION: A suction table holds a display panel and includes a support board having a suction surface in which negative pressure openings open, a plurality of lift bars disposed across the suction surface, a plurality of recesses arranged in parallel with each other on the suction surface so as to house the lift bars in the support board without being protruded form the suction surface, support mechanisms that support the lift bars in a vertically movable manner at sides of the support board in which the plurality of recesses open, and lifting devices arranged in relation with the support mechanisms so as to lift the lift bars between an ascent position where the lift bars are protruded from the recesses and a descent position where the lift bars are housed in the recesses. The support mechanisms comprise support pillars for supporting the lift bars at both ends, guide pins supported by the support pillars, and slots arranged in the lift bars so as to allow the guide pins to penetrate therethrough.

Owner:NIHON MICRONICS

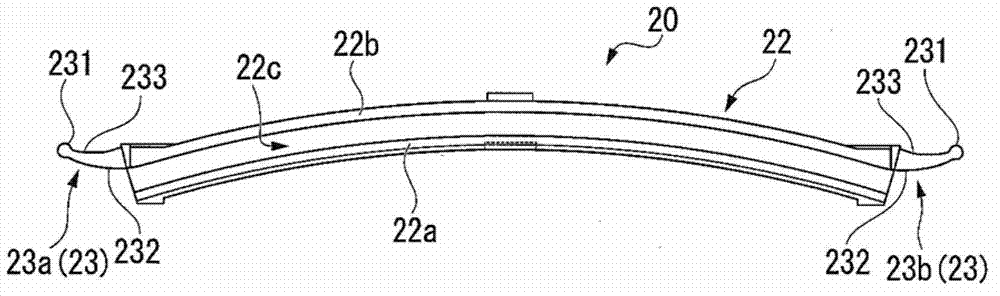

Air conditioning apparatus for vehicle

InactiveCN103158493AReduce gapWill not complicate the structureAir-treating devicesHeating and ventilation casings/coversEngineeringAir conditioning

An air conditioning apparatus for a vehicle that includes a frame having an opening through which an airflow passes, and a sliding door which adjusts an aperture ratio of the opening by being slid along a wall surface formed with the opening of the frame in an upstream side of the opening, wherein the sliding door includes: a shield plate to shield the airflow; and a seal member which extends from the shield plate in a sliding direction of the sliding door and is more easily bent than the shield plate, and which is bent by receiving the airflow, thereby coming into contact with the wall surface of the frame.

Owner:KEIHIN CORP

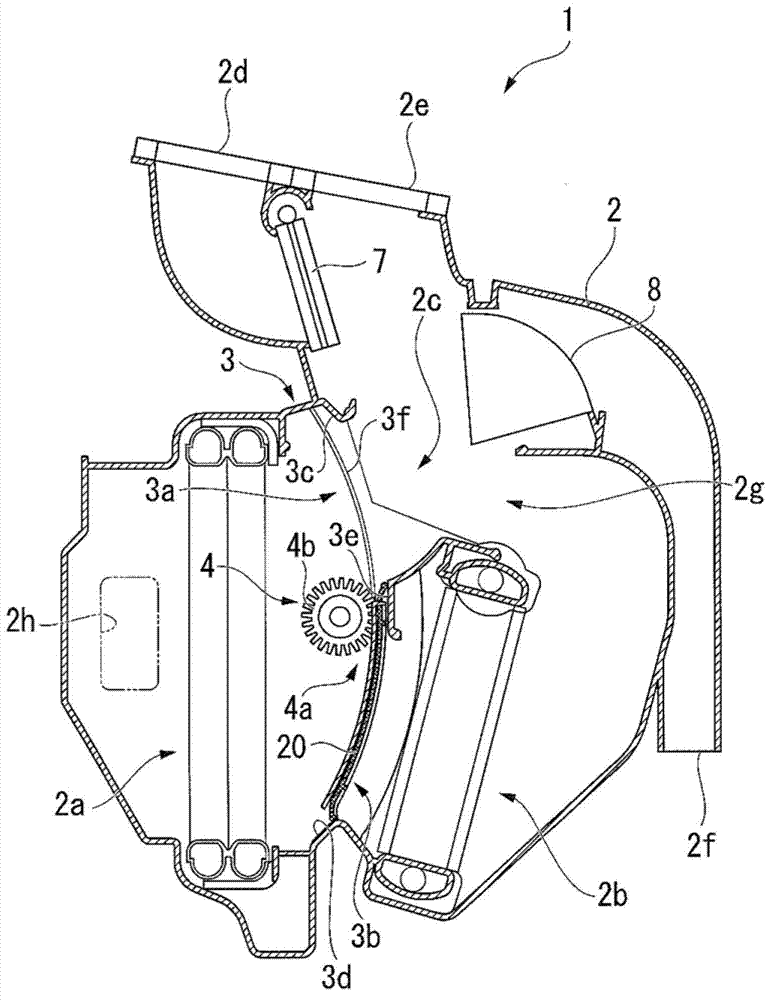

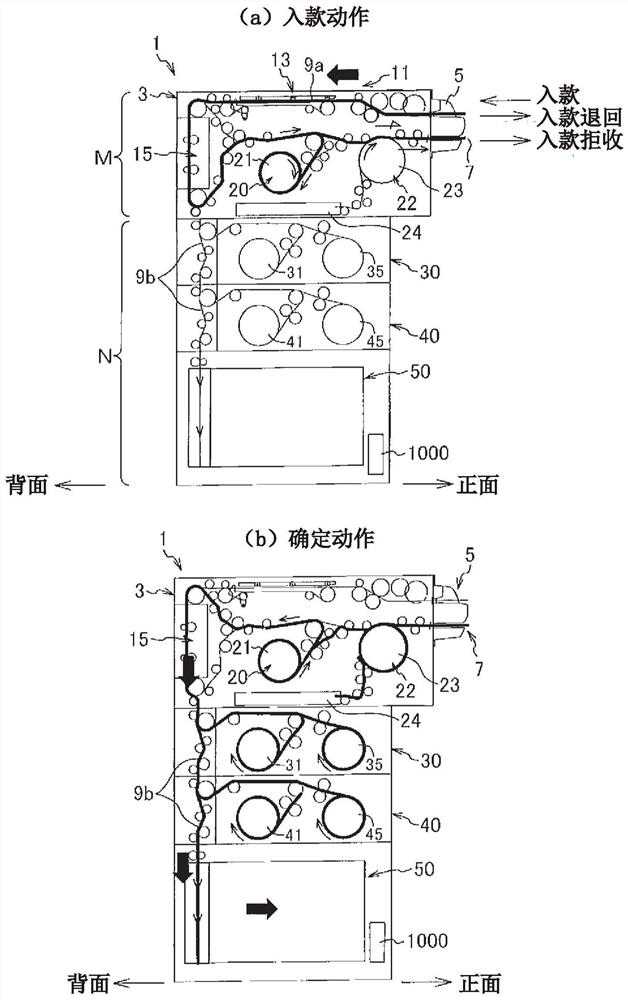

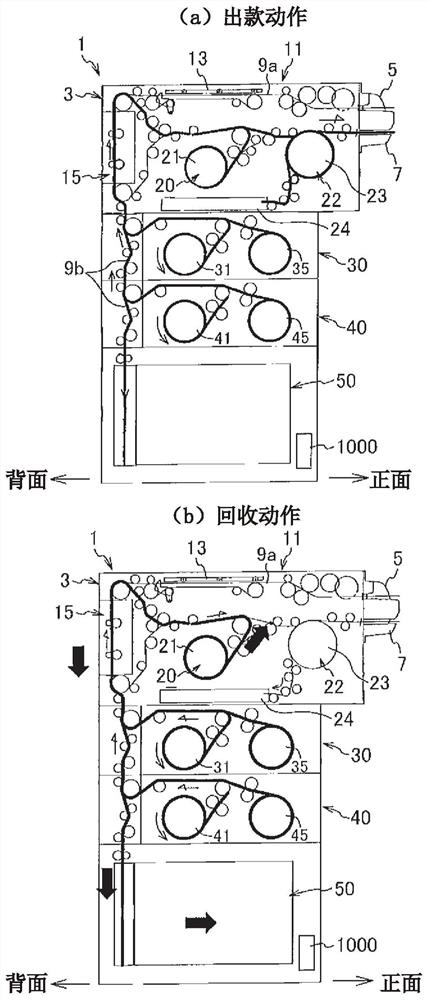

Drive transmission switching mechanism, paper sheet storage unit, and paper sheet processing device

ActiveCN111867952AWill not complicate the structureCoin countersCoin/currency accepting devicesControl engineeringPaper sheet

Provided is a drive transmission switching mechanism that can switch and drive two circulation units with one motor in response to an operation that switches a paper conveyance direction. This invention comprises: a first circulation unit 100 and a second circulation unit 200 that each receive a drive force from a single motor 302 and function to receive individual paper sheets that are conveyed and to feed out paper sheets that are stored; a distributing means 310 that distributes the paper sheets to either of the circulation units; and a drive transmission switching mechanism 400 that transmits the drive force from the motor to either one of the circulation units. The drive transmission switching mechanism is actuated in coordination with an operation that changes a posture of the distributing means such that the drive transmission switching mechanism switches and transmits the drive force to the either one of the circulation units.

Owner:JAPAN CASH MASCH CO LTD

Body hood mounting structure of automatic two-wheeled bicycle

InactiveCN100572181CEasy to connectReduce in quantityMotorised scootersWeather guardsMan-hourEngineering

The invention provides a body cover mounting structure of a motorcycle capable of enhancing the producibility through a decrease in the man-hours for assembly and reducing the cost by means of simplification of the construction. A pair of body covers 34L and 34R are equipped with front engaging pieces 58 installed in the front part and cover mounting pieces 45L and 45R installed inside, respectively, and a leg shield 33 is provided with an engaging hole 51 to engage the front engaging pieces 58 and rear mounting pieces 49 extending backward inside the body covers 34L and 34R and fastened together with the two cover mounting pieces 45L and 45R.

Owner:HONDA MOTOR CO LTD

Processing device

ActiveCN104647204BWill not complicate the structureCorrect warpingWork carriersGrinding work supportsEngineeringMechanical engineering

Owner:DISCO CORP

Mobile phone with game function

InactiveCN1964371BWill not complicate the structureEasy to operateVideo gamesTelephone set constructionsEngineeringRocker arm

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

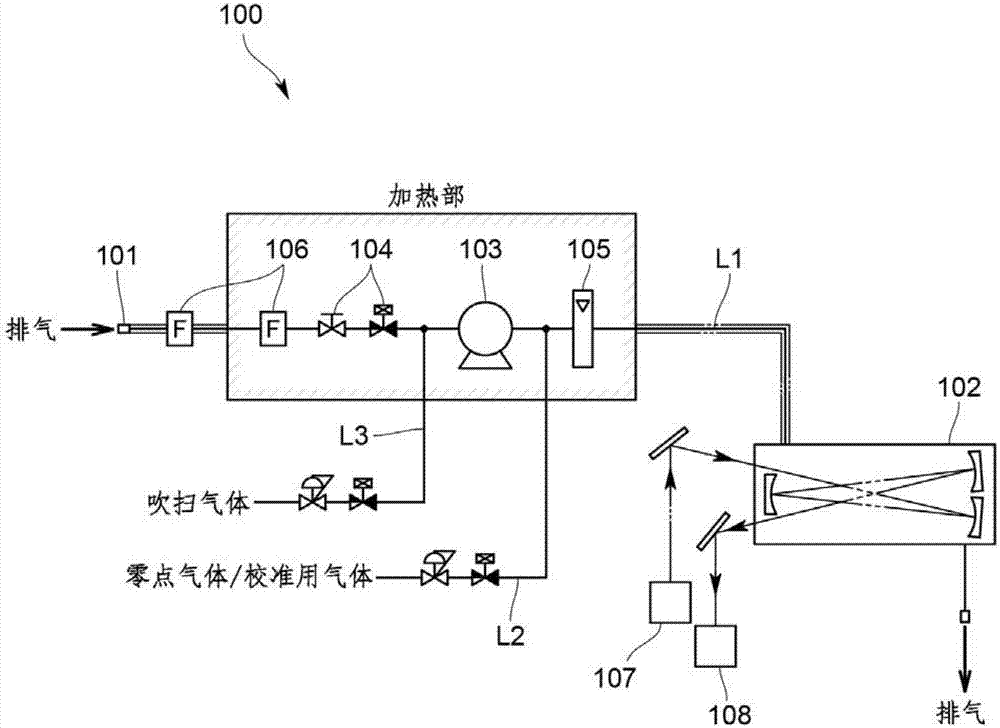

Multiple reflection type cell and analyzer

ActiveCN107389583AWill not complicate the structureReduce dead spaceMaterial analysis by optical meansGas analyser construction detailsCell bodiesOptical path length

This invention is a multiple reflection type cell that makes it possible to reduce a dead space resulting from a position adjusting mechanism and to adjust the light to a desired optical path length without complicating a structure. The multiple reflection type cell comprises a cell body where a cell chamber is formed, two or more reflecting members that are mounted on the cell body and whose reflecting surfaces locate in the cell chamber, and a position adjusting mechanism that adjusts a position of the reflecting member relative to the cell body. The cell body has a mounting part that communicates the cell chamber and the outside and on which the reflecting members are mounted. A seal member that seals a gap between the cell chamber and the outside of the cell body is arranged between the reflecting member mounted on the mounting part and the cell body so that the gap between the cell chamber and the outsider of the cell body is sealed by the seal member.

Owner:HORIBA LTD

Liquid crystal display apparatus

ActiveCN103713423AWill not complicate the structureReduce crosstalkNon-linear opticsOptical elementsOptical axisAngular degrees

In a liquid crystal display apparatus in which a liquid crystal layer is twist-aligned when no electric field is applied, [Delta]nd value of a liquid crystal layer in a wavelength of 550 nm is 300 to 400 nm, each of directions of polarizing axes of pair of linear polarizers is substantially parallel or vertical to the alignment direction of liquid crystal molecules in each end face of the liquid crystal layer that is closer to each of linear polarizers, and the angle between polarizing axes of the pair of linear polarizers is 85 DEG or larger and smaller than 90 DEG . In a liquid crystal display apparatus in which a liquid crystal layer is aligned to be substantially vertical when no electric field is applied, the angle between polarizing axes of the pair of linear polarizers is 85 DEG or larger and smaller than 90 DEG. In a liquid crystal display apparatus of a lateral electric field drive system, a uniaxial alignment angle of a liquid crystal layer when no electric field is applied is larger than -45 DEG and -40 DEG or smaller, or +40 DEG or larger and smaller than +45 DEG. (the "angle" here is a value based on 0[deg.] which is the direction of three-o'clock of a clock seen from a front with respect to a display screen, the counterclockwise direction from 0[deg.] being "+", and the clockwise direction from 0[deg.] being "-")

Owner:MITSUBISHI ELECTRIC CORP

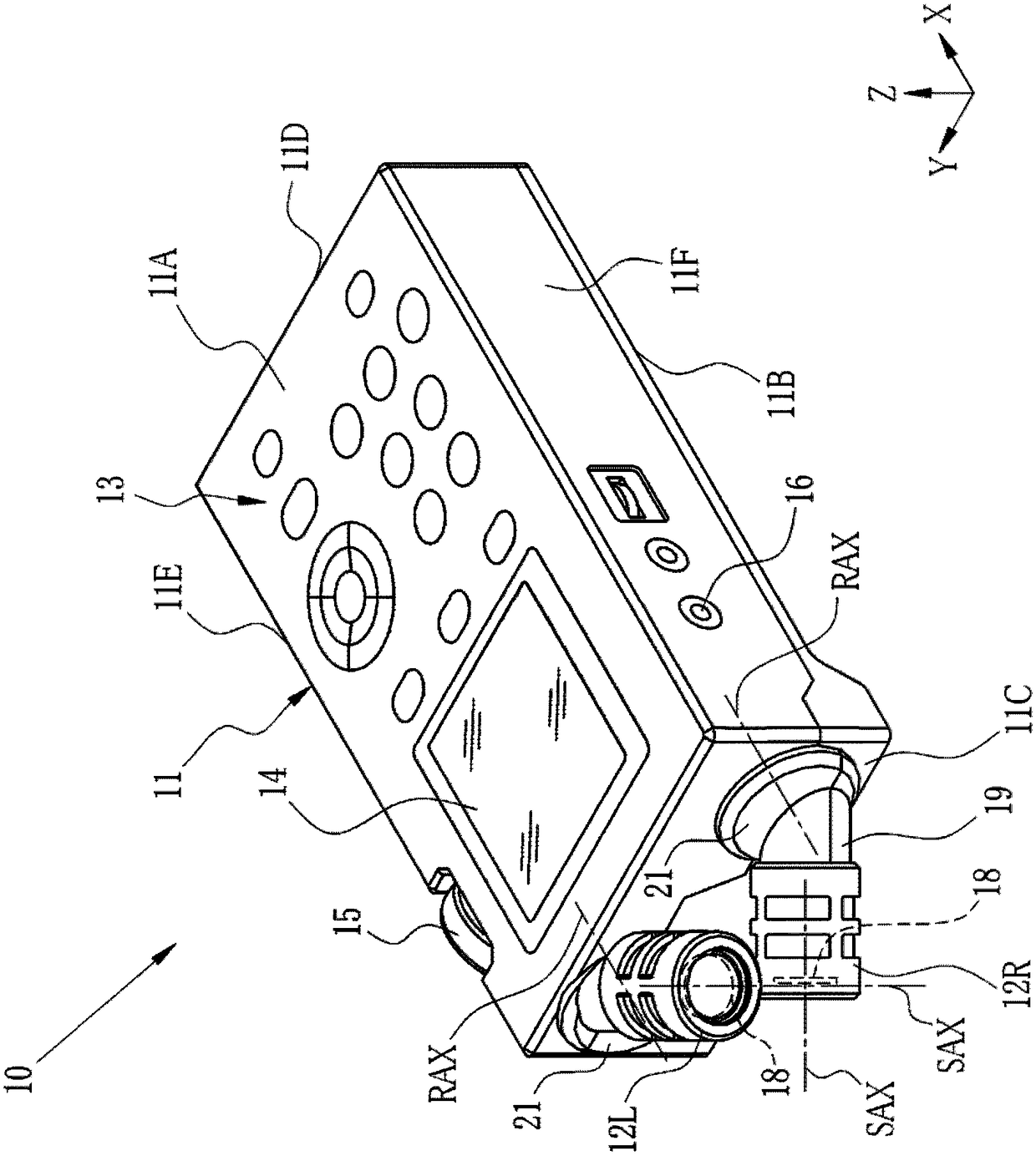

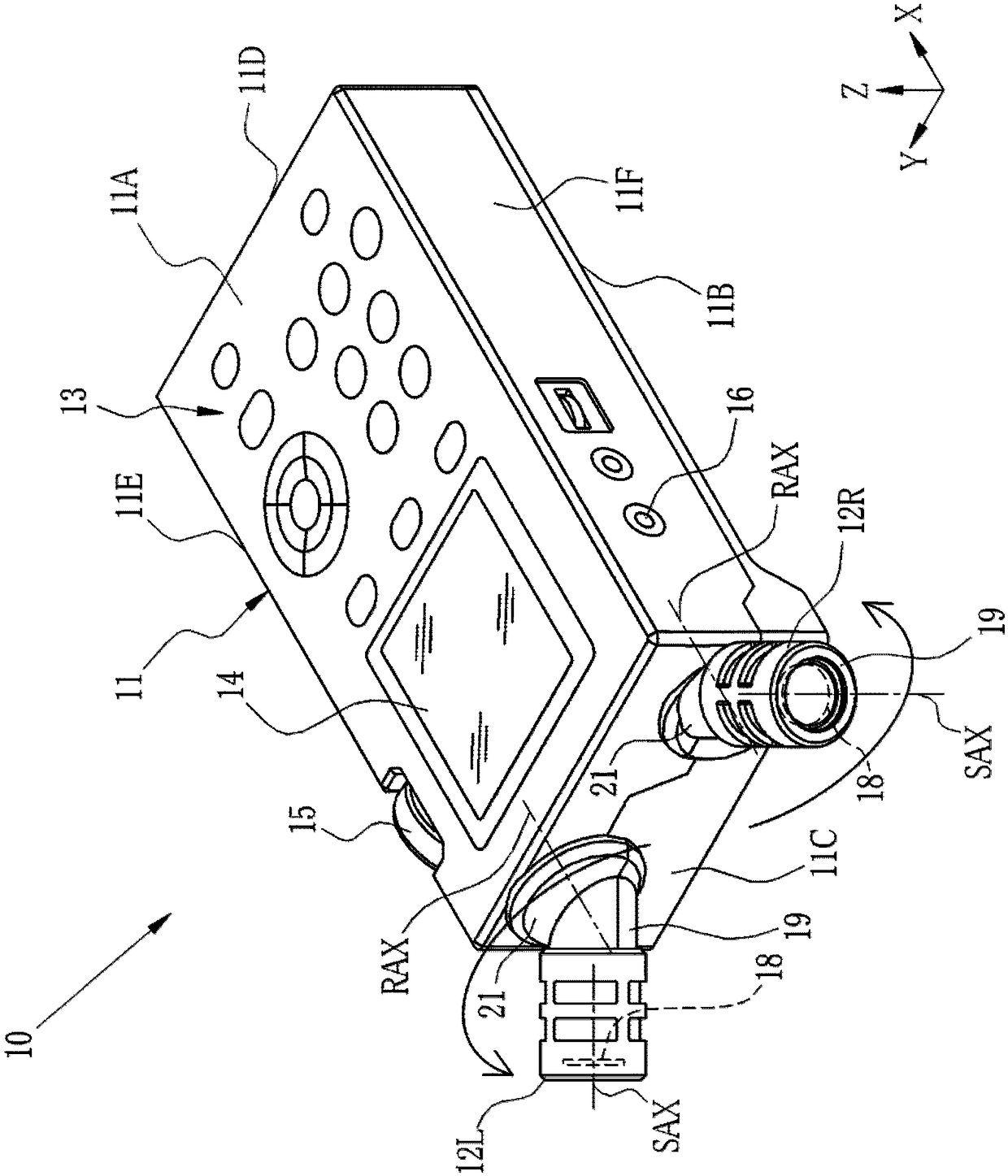

sound recorder

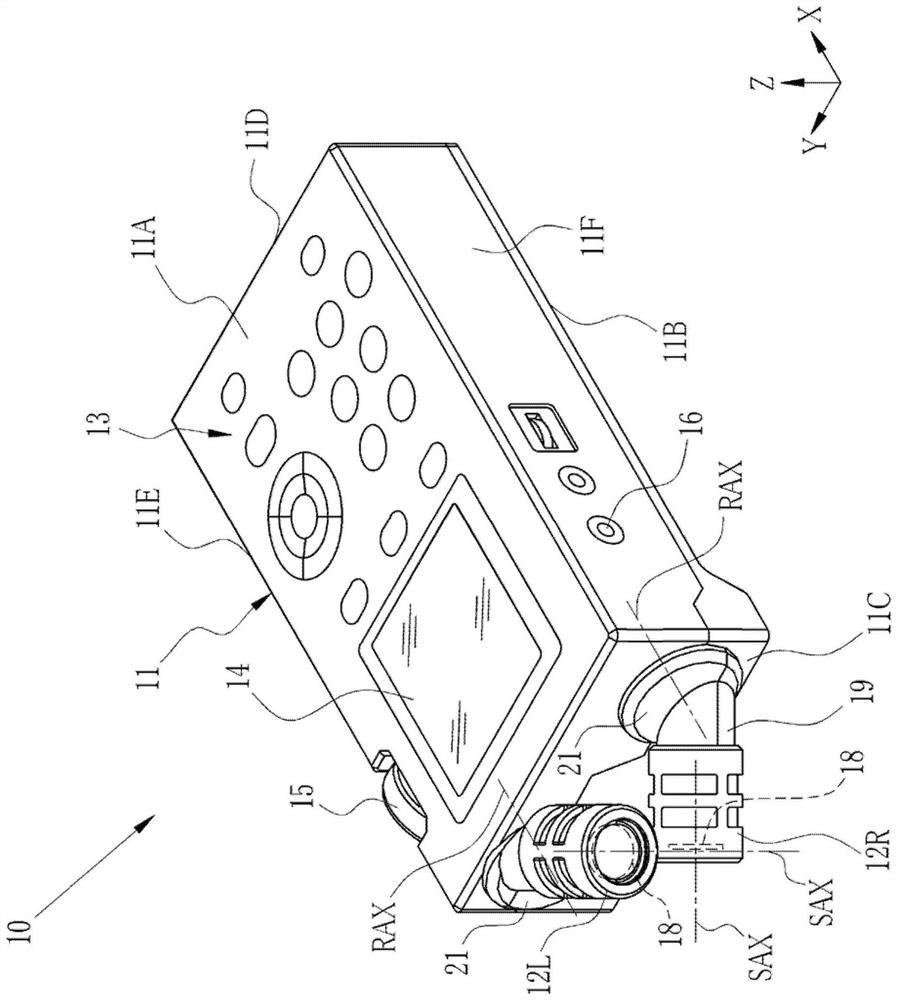

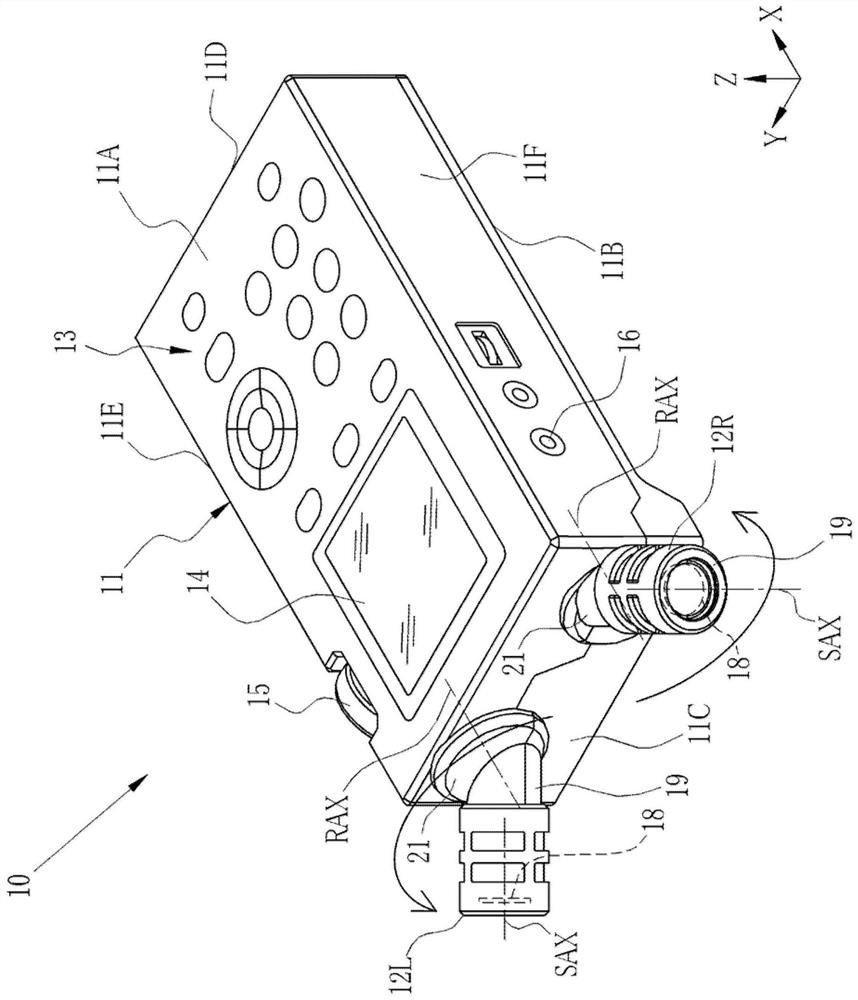

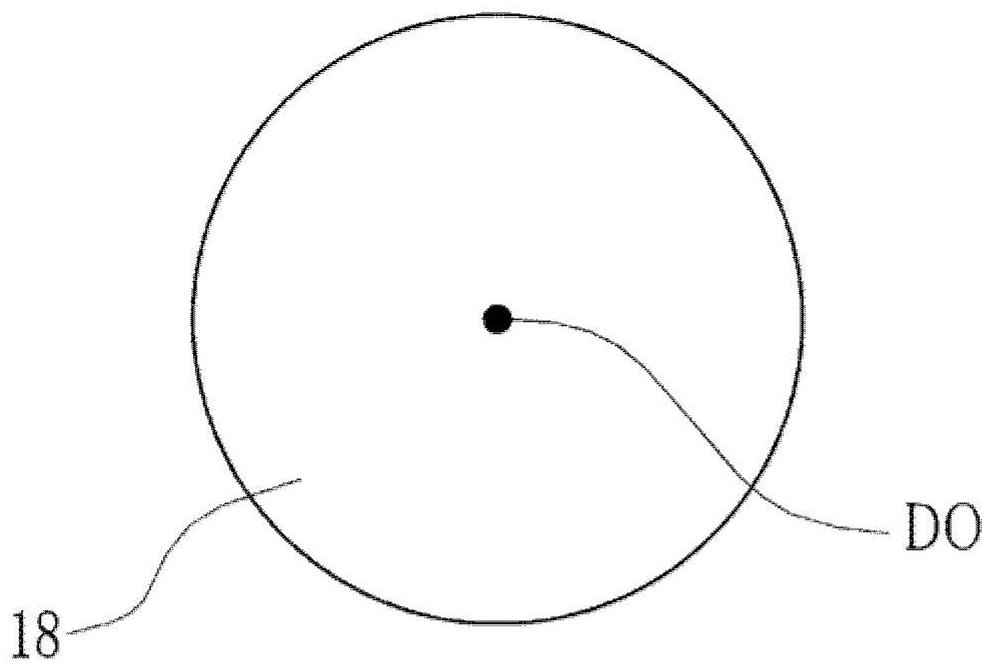

ActiveCN108574907BNot cumbersomeWill not complicate the structureSignal processingMicrophones signal combinationRotational axisMicrophone

The present invention provides a voice recorder that can be switched between an inward posture and an outward posture with a small phase difference in a voice recorder provided with a pair of left and right microphones without complicating the operation and compromising the structure. complication. The voice recorder (10) includes a pair of left and right microphones (12L, 12R). Each microphone (12L, 12R) is respectively fixed to a bracket (21) rotatable about a rotation axis (RAX), and each sound collection axis (SAX) is inclined with respect to the rotation axis (RAX). When each stand (21) is rotated by 180°, the posture is switched between an inward posture in which the sound collection axes (SAX) of each microphone cross and an outward posture in which the sound collection axes (SAX) do not cross. The microphones are disposed on the brackets (21) in an inward posture, offset from each rotation axis (RAX) toward each sound collection axis (SAX) in a direction separated from each other in the height direction (Z direction).

Owner:TEAC CORP

Liquid crystal display device

ActiveCN103713423BWill not complicate the structureReduce crosstalkNon-linear opticsOptical elementsOptical axisPolarizer

The present invention relates to a liquid crystal display device, and provides a liquid crystal display device with good visibility. In a liquid crystal display device in which the liquid crystal layer is twisted and aligned in the state where no electric field is applied, the Δnd value of the liquid crystal layer at 550 nm is 300 nm to 400 nm, and the polarization axis directions of a pair of linear polarizers are respectively relative to the end faces on the near side of the liquid crystal layer. The alignment direction of the liquid crystal molecules is approximately parallel or approximately vertical, and the angle formed by the polarization axes of a pair of linear polarizers is designed to be greater than 85° and less than 90°. In a liquid crystal display device in which the liquid crystal layer is aligned substantially vertically in a state where no electric field is applied, the angle formed by the polarization axes of the pair of linear polarizers is 85° or more and less than 90°. In a liquid crystal display device driven by a transverse electric field, the uniaxial orientation angle of the liquid crystal layer in a state where no electric field is applied is greater than -45° and less than -40°, or greater than +40° and less than 45° (here, " "Angle" means that when viewed from the front with respect to the display screen, the 3 o'clock direction of the clockwise direction is set to 0°, the counterclockwise direction from there is set to "+", and the clockwise direction is set to "-").

Owner:MITSUBISHI ELECTRIC CORP

vehicle power transmission

ActiveCN103998828BWill not complicate the structureReduce shift shockToothed gearingsPropulsion using engine-driven generatorsControl theoryMotor–generator

In a vehicle that includes an auxiliary transmission mechanism 6 where a high-speed range and a low-speed range are switchable, a carrier 61 CA of an auxiliary transmission mechanism 6 is coupled to a motor-generator 67 to allow power transmission. When switching from the high-speed range to the low-speed range, the motor-generator 67 increases a rotational speed of the carrier 61CA such that a rotational speed of a low-speed range piece 62L is synchronized with a rotational speed of an input shaft 31. When switching from the low-speed range to the high-speed range, the motor-generator 67 increases a rotational speed of the carrier 61CA such that a rotational speed of an output shaft 32 is synchronized with a rotational speed of the input shaft 31. This allows range switch with a reduced gear change shock even while the vehicle is running.

Owner:TOYOTA JIDOSHA KK

Voice recorder

ActiveCN108574907ANot cumbersomeWill not complicate the structureSignal processingMicrophones signal combinationPhase differenceEngineering

The present invention provides a voice recorder with a right-and-left pair of microphones, which can change over between an inward position with little phase difference and an outward position, without any intricate operation or complicated structure. The voice recorder (10) includes a right-and-left pair of microphones (12L, 12R). Each microphone (12L, 12R) is fixed to a holder (21) that is rotatable about a rotation axis (RAX), and a sound-collection axis (SAX) of each microphone is tilted to the rotation axis (RAX). Turning each holder (21) by 180 degrees allows each microphone to change over between an inward position where the sound-collecting axes (SAX) of the microphones intersect and an outward position where the sound-collecting axes (SAX) do not intersect. Each microphone is placed offset from the rotation axis (RAX) on each holder (12) in such a direction that the sound-collecting axes (SAX) are spaced apart from each other in a height-direction (Z-direction) while the microphones are in the inward position.

Owner:TEAC CORP

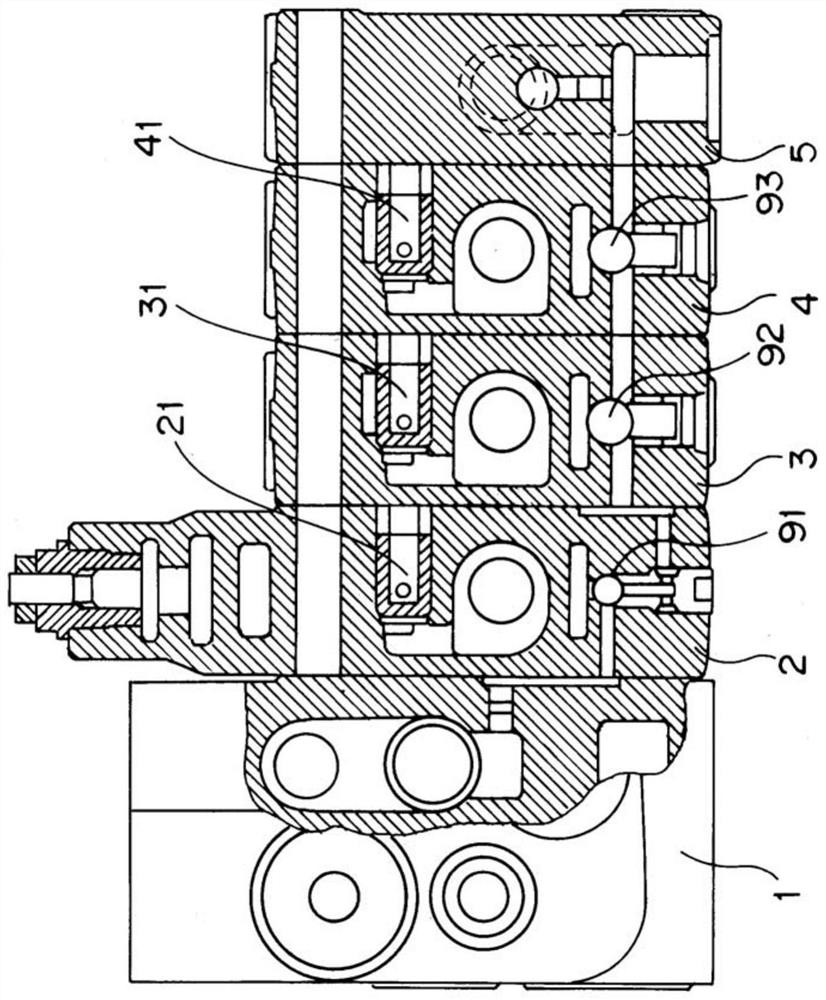

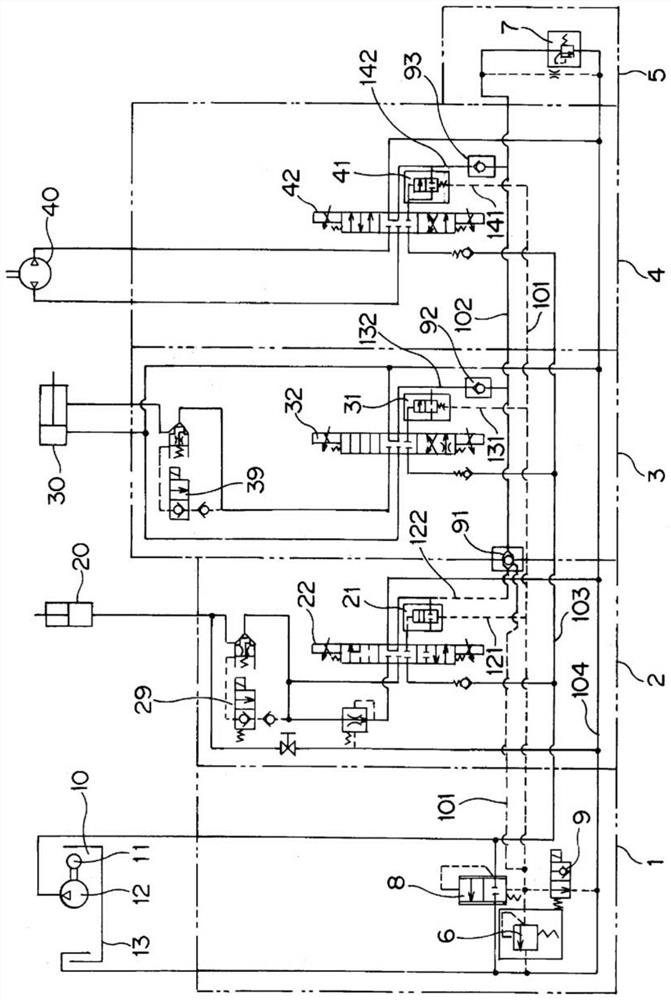

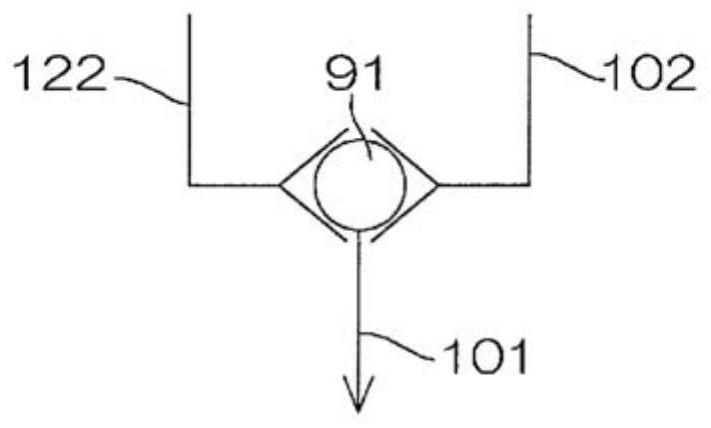

Fluid control device

ActiveCN113286951AWill not complicate the structureServomotorsServometer circuitsFluid controlEngineering

During opening and closing operations of a fluid control valve (2), the port pressure in the fluid control valve (2) is guided to a main relief valve (6) via a first passage (101) and the maximum pressure thereof is controlled by the main relief valve (6). In addition, the port pressure in the fluid control valve (2) is simultaneously guided to pressure compensation valves (21), (31), (41) of fluid control valves (2), (3), (4). Thus, even in the case when functions with different load pressures are simultaneously operated in the fluid control valves (2), (3), (4), it is possible always to guarantee constant operability regardless of the pressure load. In addition, during opening and closing operations of the fluid control valve (3) that drives a tilt cylinder (30) for a function to tilt a fork, the port pressure of the fluid control valve (3) is guided to a secondary relief valve (7) via a second passage (102), is guided to the main relief valve (6) via the first passage (101), and is guided to the pressure compensation valves (21), (31), (41) of the fluid control valves (2), (3), (4).

Owner:SHIMADZU SEISAKUSHO CO LTD

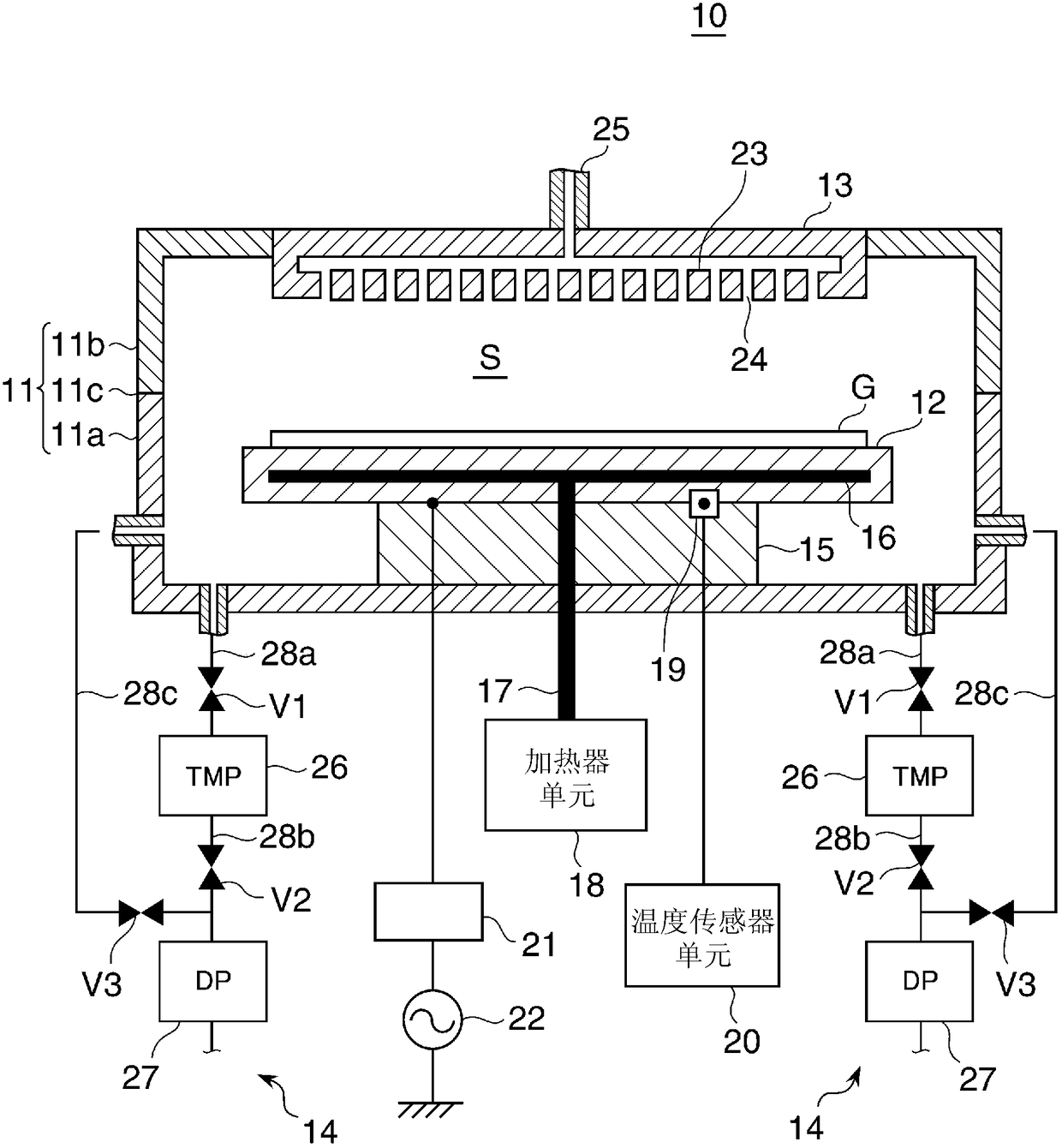

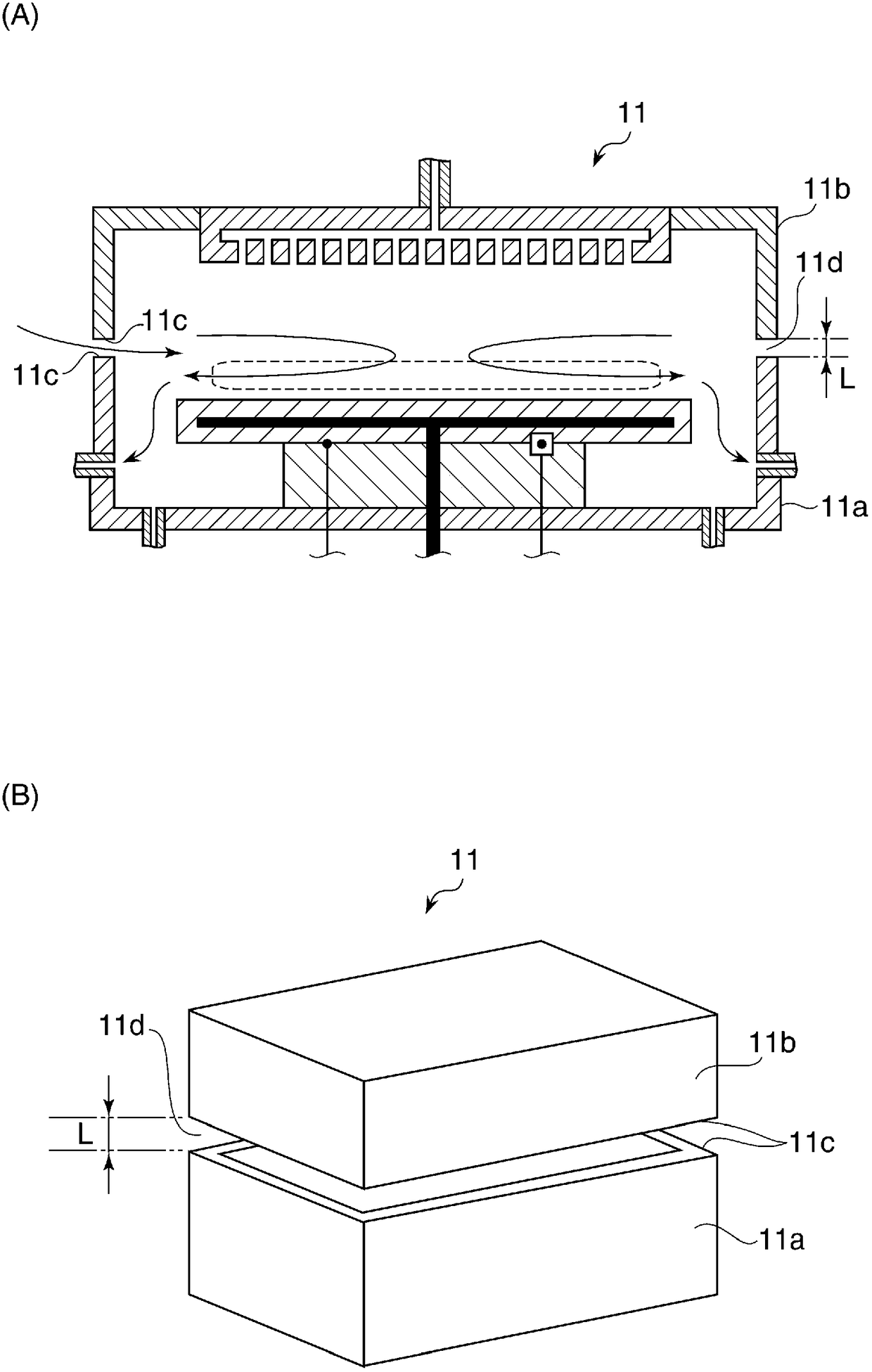

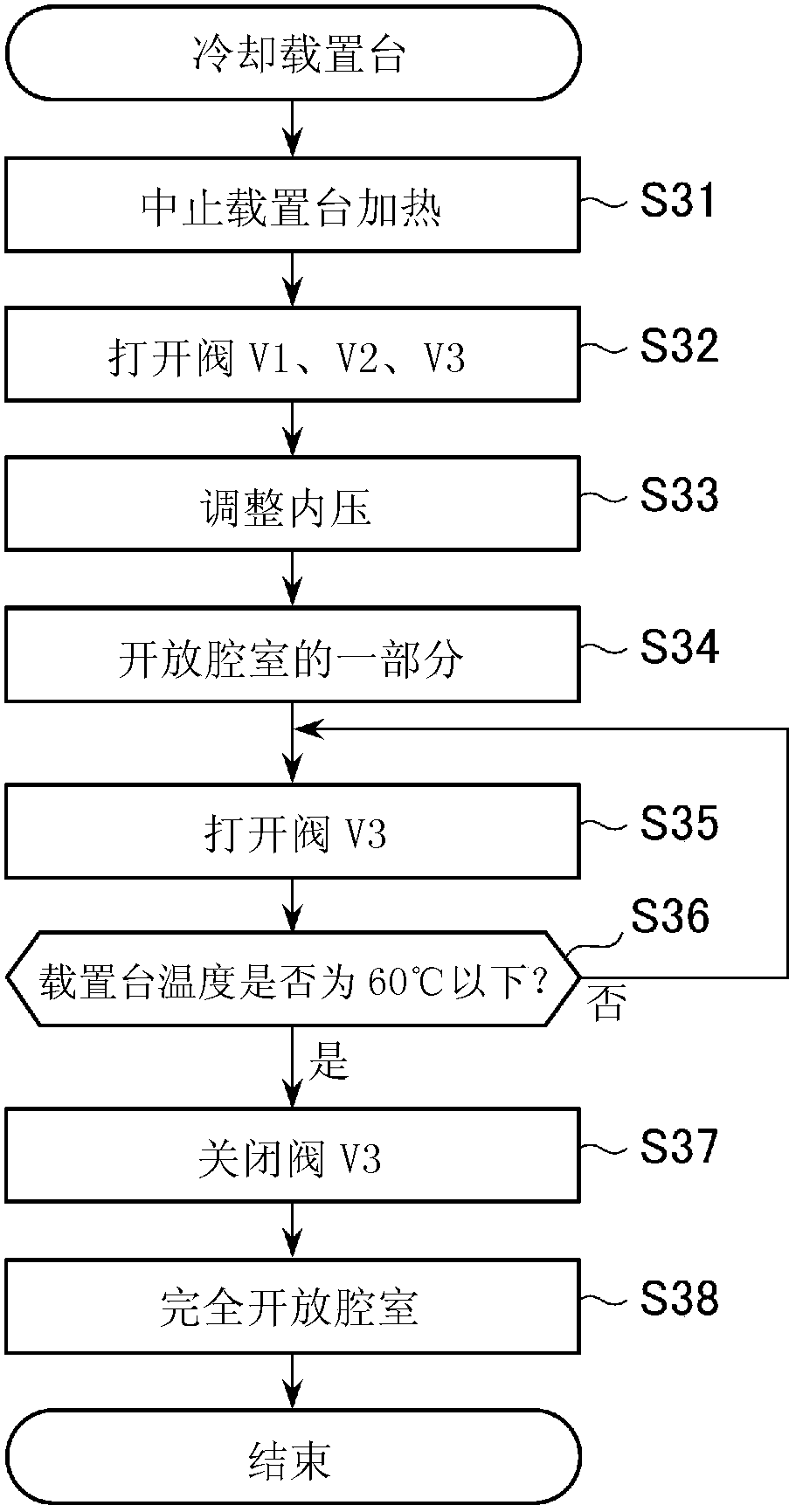

Cooling method for processing indoor parts

ActiveCN103311152BRapid coolingReduce transfer efficiencySemiconductor/solid-state device manufacturingEngineeringDry etching

The present invention provides a cooling method for components in a processing chamber that can quickly cool components in the processing chamber without complicating the structure of a substrate processing apparatus. In a substrate processing apparatus (10) for dry etching a substrate (G), a mounting table disposed in a chamber (11) composed of a base portion (11a) and a lid portion (11b) that can be separated from each other (12) When cooling, adjust the pressure in the chamber (11) to atmospheric pressure, separate the cover (11b) and the base (11a), and form an open portion around the entire circumference of the side wall of the chamber (11). (11d), thereby connecting the chamber (11) to the atmosphere, using the exhaust system (14) to form airflow in the chamber (11), and when it is determined that the temperature of the mounting table (12) is below 60°C , stop the work of the exhaust system (14) and stop the air flow in the chamber (11).

Owner:TOKYO ELECTRON LTD

High-frequency power supply device, plasma processing device and method for producing thin film

InactiveCN103098559BUniform power intensity distributionWill not complicate the structureElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityPlanar electrode

A high-frequency power supply device for supplying high-frequency power to parallel planar electrodes, the high-frequency power supply device comprising: high-frequency power sources (133a, 133b) for supplying high-frequency power to positions spaced apart from each other in the electrode; and a pulse generator for pulse-modulating the power supplied from the high-frequency power sources (133a, 133b) such that the power changes at a plurality of levels including a high level and a low level, the pulse generator instructing switching of levels to include a period (1) during which the supplied power from the high-frequency power source (133a) is at the high level and the supplied power from the high-frequency power source (133b) is at the low level, a period (2) during which the supplied power from the high-frequency power source (133b) is at the high level and the supplied power from the high-frequency power source (133a) is at the low level, and a period (3) during which the supplied power from each of the high-frequency power sources (133a, 133b) is at a level higher than the low level.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com