Container unit for greening and greening technique using the container unit

A construction method and container technology, applied in container cultivation, botany equipment and methods, applications, etc., can solve the problems of increased manufacturing cost, large number of parts, complex structure, etc., shorten the construction period, reduce manufacturing cost, and be easy to dismantle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

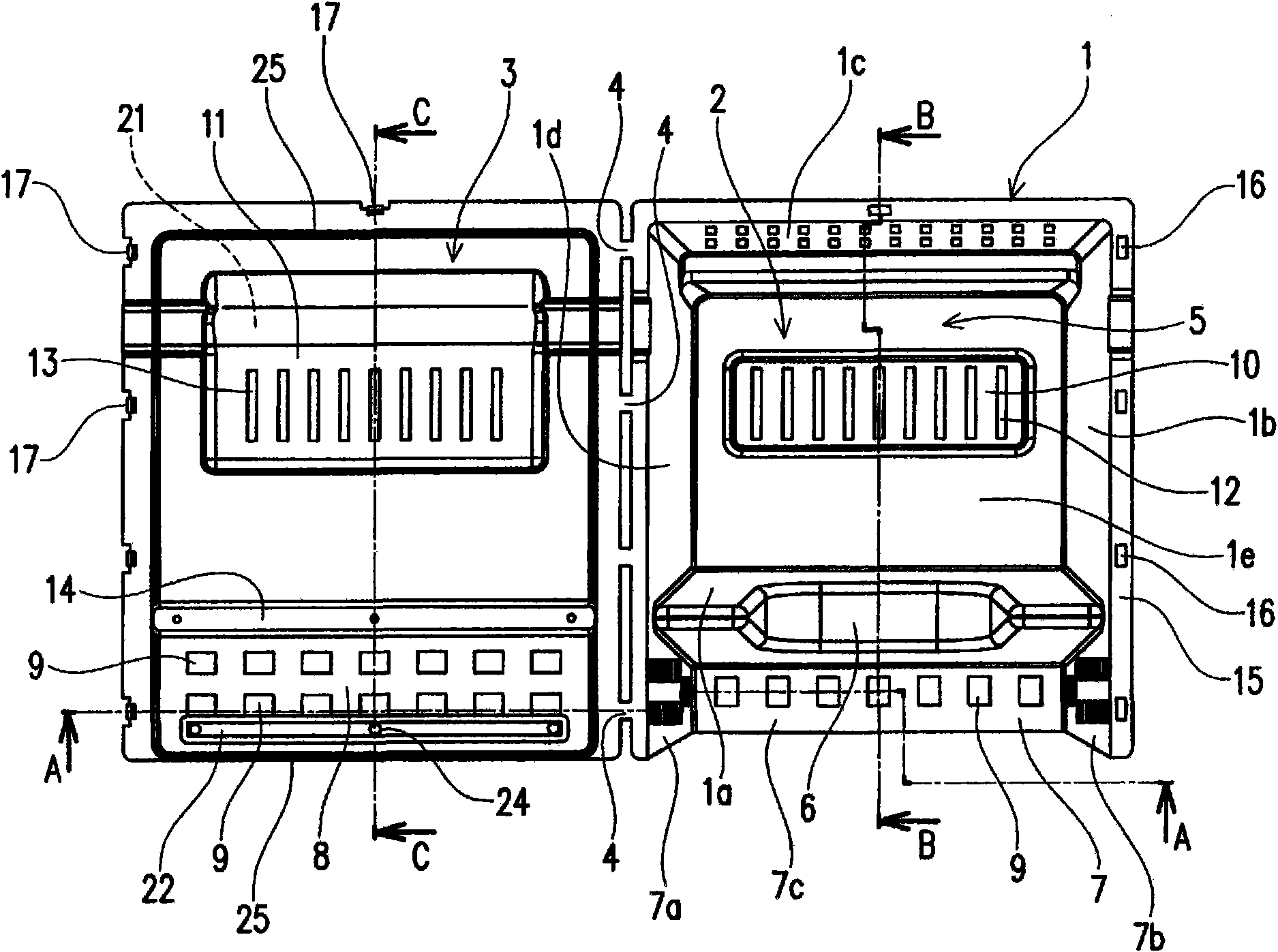

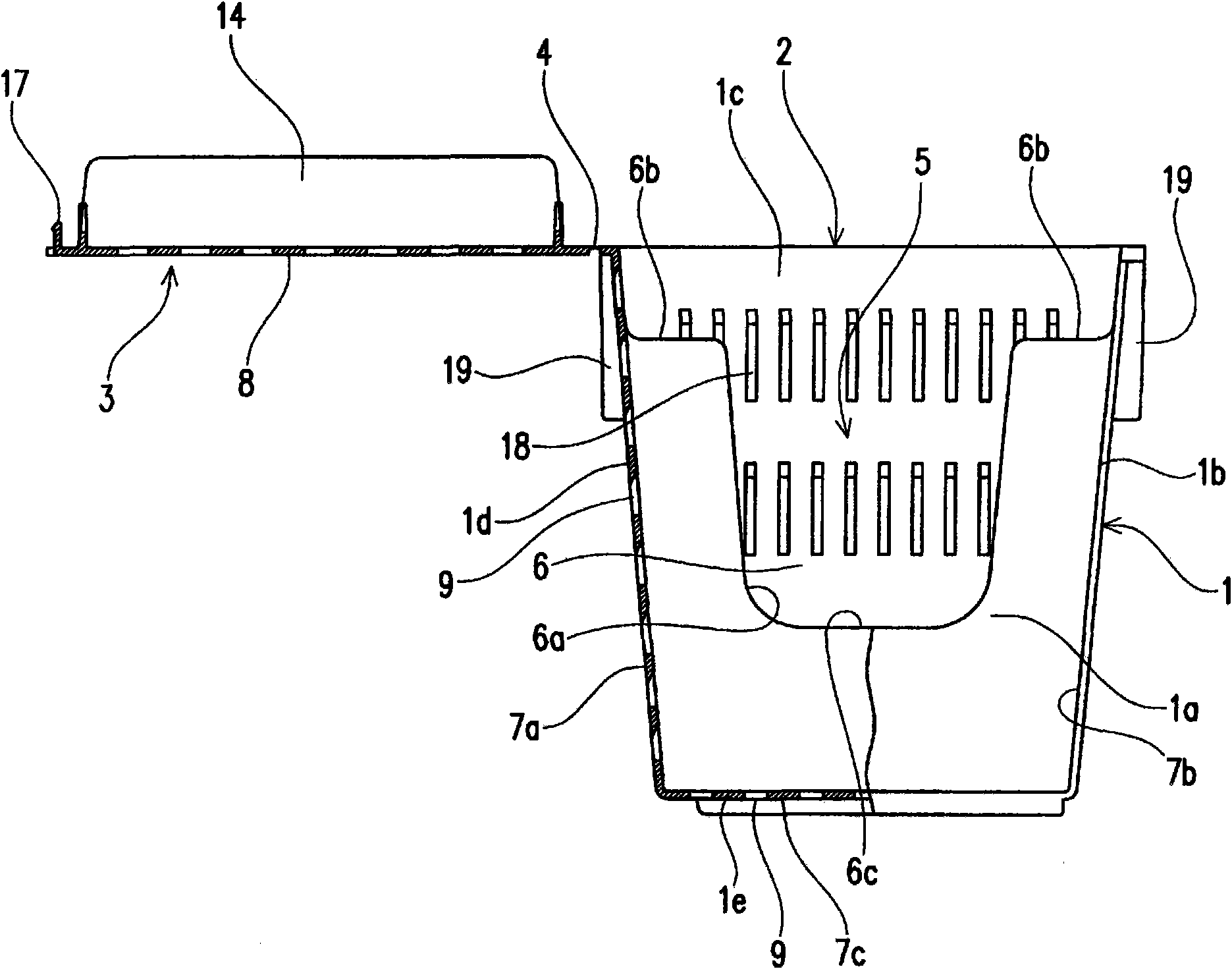

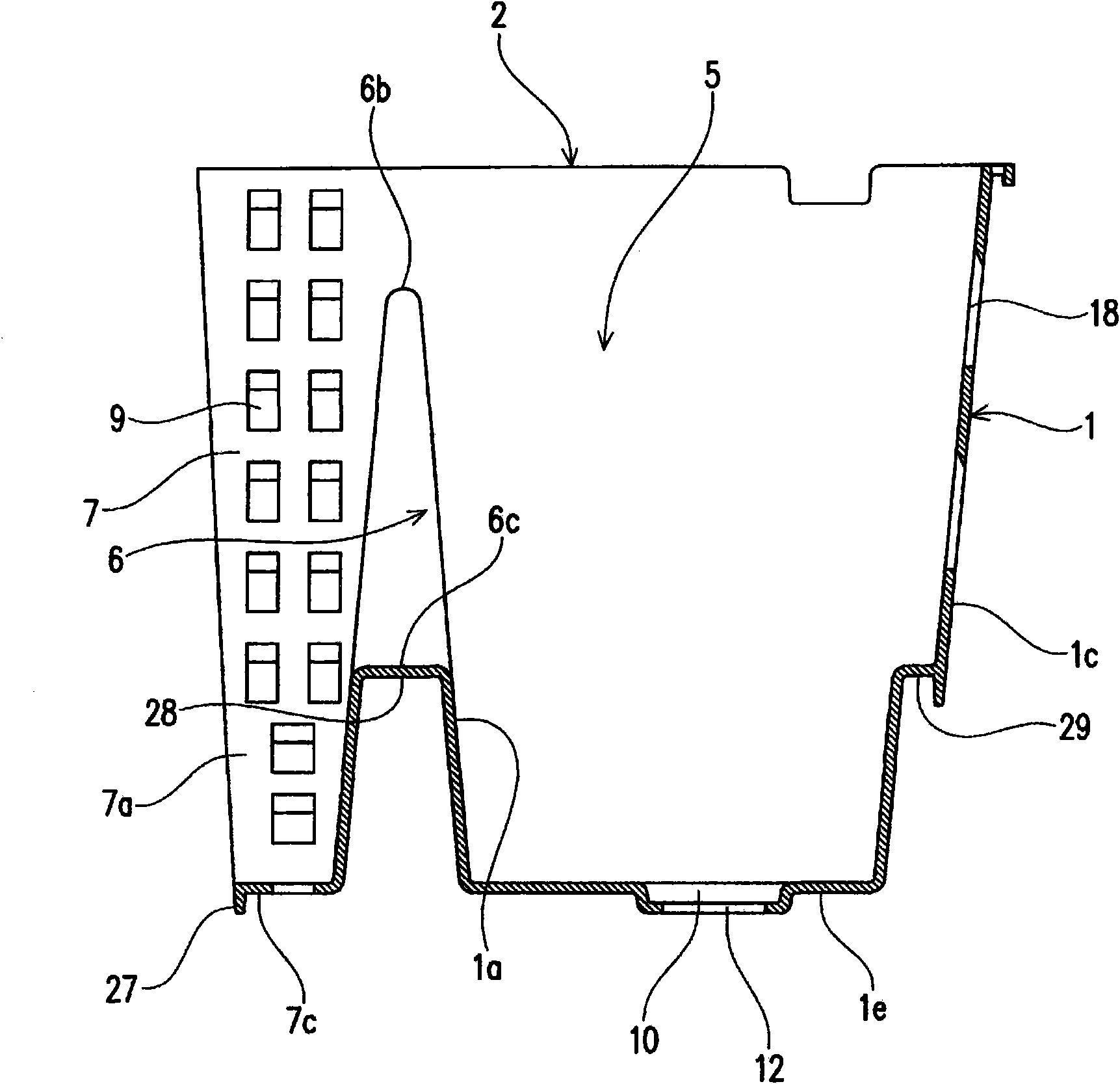

[0079] Such as Figure 1 to Figure 4 As shown, the container unit for greening in this embodiment is composed of a container unit body 1 of a top-opening type and a cover body 3 capable of opening and closing the top opening 2 of the container body 1 . The container unit body 1 and the cover body 3 are connected and arranged through a hinge part 4 . In addition, the container unit main body 1 , the lid body 3 and the hinge part 4 are all formed integrally with synthetic resin. The type of synthetic resin constituting the container unit body 1 , lid body 3 , and hinge portion 4 is not particularly limited, and general-purpose synthetic resins such as polyethylene, polypropylene, polystyrene, and polyester can be appropriately used. Especially preferred is the use of weather-resistant polypropylene.

[0080] As mentioned above, the container unit body 1 is of the upper opening type, such as Figure 1 to Figure 3 As shown, it is composed of the surrounding side parts 1a, 1b, 1...

no. 2 approach

[0113] In the present embodiment, the container unit 20 having the same structure as that of the above-mentioned first embodiment is used, but in the state where a plurality of container units 20 are hooked on the holder 34, the container units 20 adjacent to each other up and down are not as in the above-mentioned first embodiment. stacked as described in one embodiment, but as Figure 16 As shown, the bottom portion 1e of the upper container unit 20 and the lid body 3 of the lower container unit 20 which are vertically adjacent to each other form a separated state with a small gap. This point is different from the above-mentioned first embodiment in which the bottom portion 1e of the upper container unit 20 and the lid body 3 of the lower container unit 20 are in surface contact.

[0114] In this way, even if the bottom portion 1e of the container unit 20 on the upper side and the lid body 3 of the container unit 20 on the lower side form a separated state with a small gap, ...

no. 3 approach

[0123] This embodiment is another embodiment of the arrangement form of the container unit 20 . In this embodiment, the container unit 20 is not arranged in a Figure 12 to Figure 14On all grid frames between the vertical frame 36 and the horizontal frame 37 of the shown holder 34, but as Figure 17 As shown, the container unit 20 is not provided on a part of the lattice frame, and the void portion 41 of the lattice frame is maintained.

[0124] In this embodiment, if Figure 17 As shown, on the entire holding body 34 having a plurality of lattice frames horizontally and vertically, a void portion 41 is formed on every left and right column of lattice frames. It is installed obliquely to the lower right side. And the container unit 20 is provided in the part of each lattice frame other than the cutout part 41 provided obliquely in this way. This point is different from the above-mentioned first embodiment in which container units 20 are provided in all lattice frame parts....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com