Adsorption table

A technology of adsorption table and adsorption surface, which is applied in the direction of instruments, electrical components, measuring electronics, etc., can solve the problems of high price, complicated structure of adsorption device, complicated structure of supporting table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

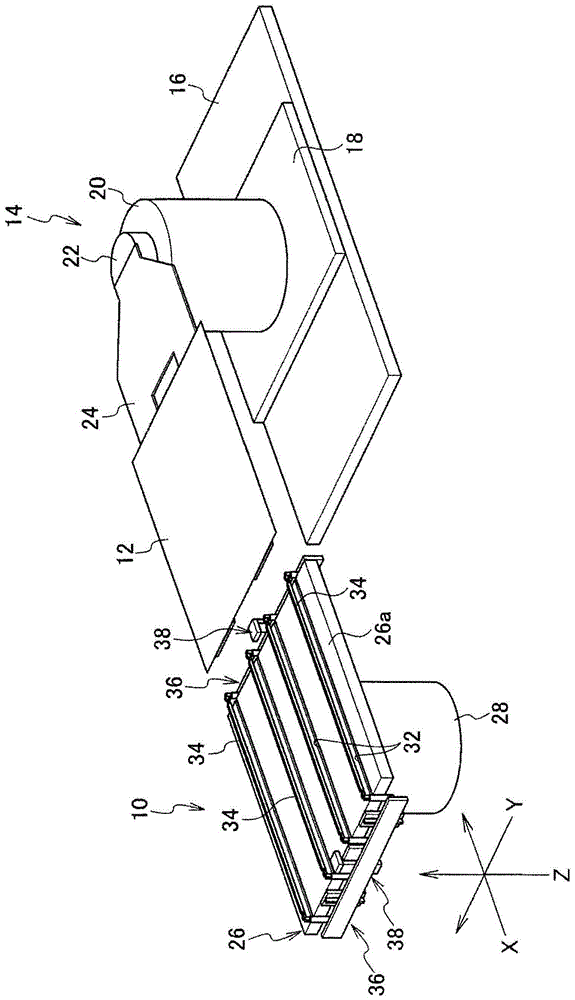

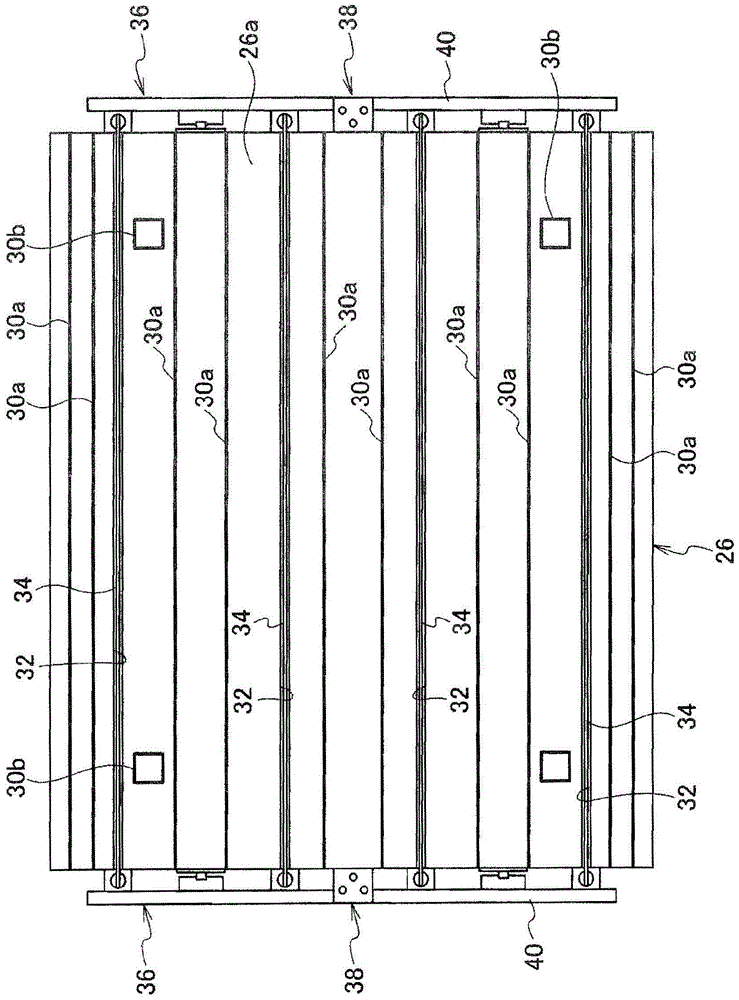

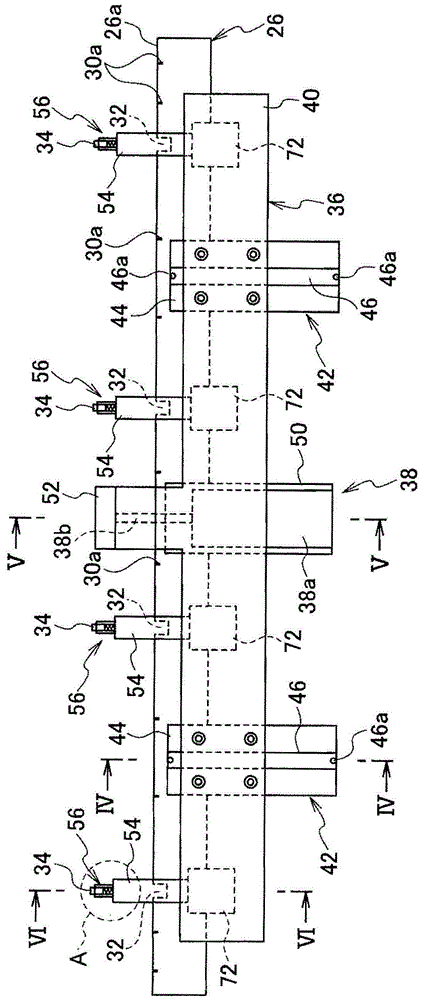

[0038] Such as figure 1 As shown, the suction table 10 of the present invention is assembled and used in a detector (not shown) for inspecting a display panel 12 such as a liquid crystal panel or an organic light emitting panel. exist figure 1 An example in which the inspection object 12 is delivered between the adsorption table 10 and the transfer robot 14 is shown in .

[0039] As known in the past, the delivery robot 14 includes: a movable table 18, which can move toward the adsorption table 10 on the base 16 and move along the direction away from the adsorption table 10; The pillar 20 on the table is coaxially supported by the pillar 20, and the shaft member 22 rotates around the axis and expands and contracts relative to the pillar 20 along the axis. As conventionally known, a fork-shaped robot arm 24 for placing the object 12 to be inspected is fixed to the shaft member 22 capable of the rotational movement and the telescopic movement.

[0040] For example, when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com