Patents

Literature

61 results about "Probe tester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

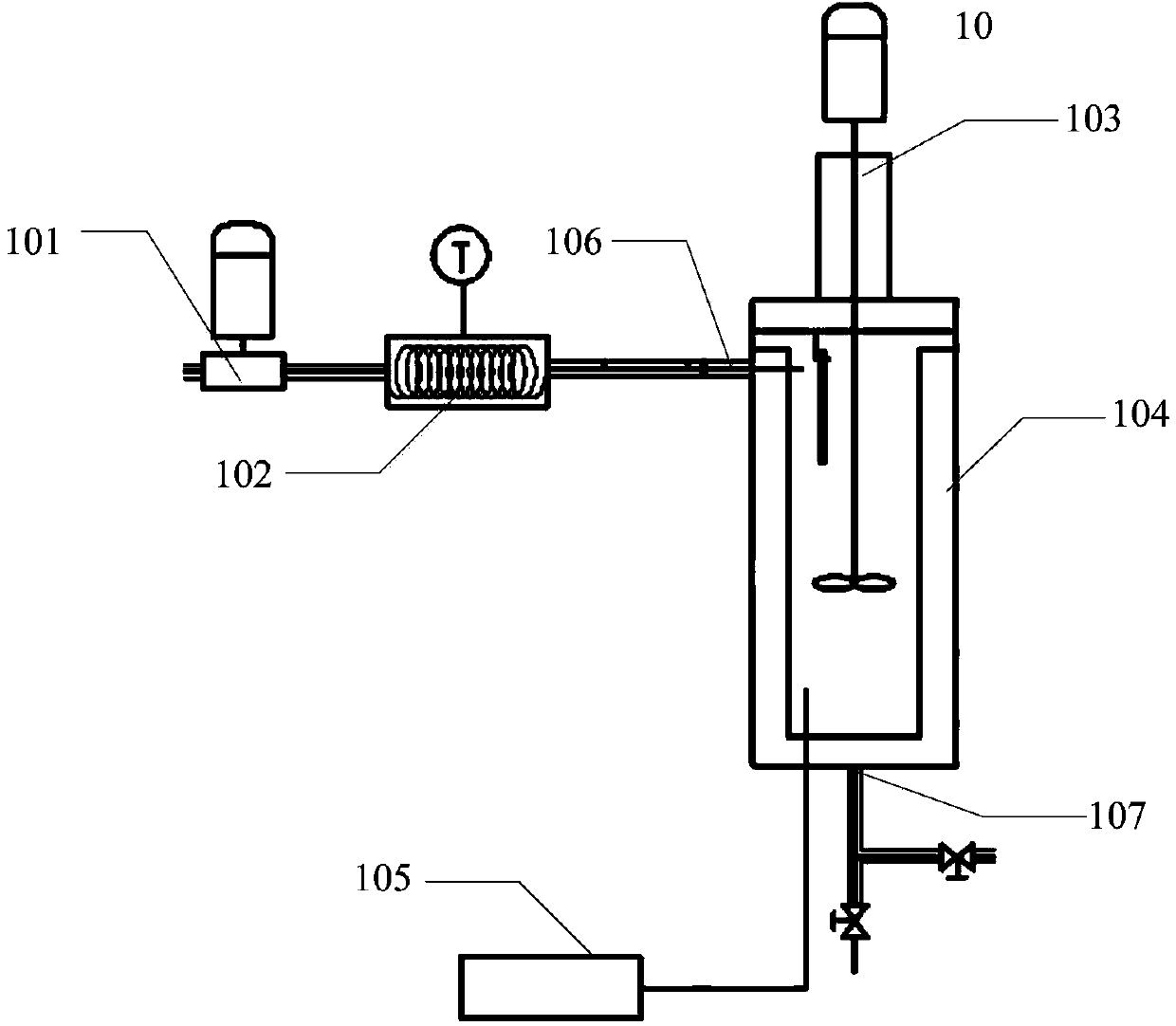

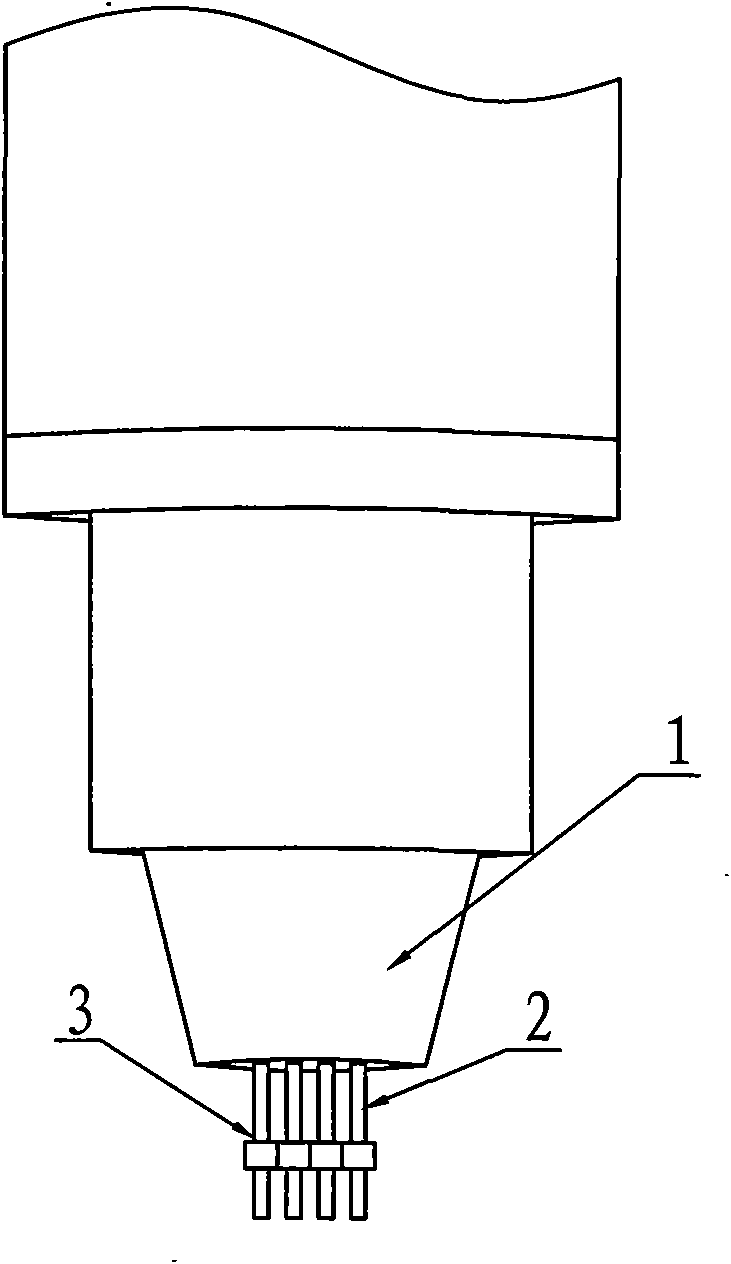

Device for testing high-temperature and high-pressure corrosion rate of multi-phase medium

ActiveCN104215572AReal-time acquisition of corrosion rateWeather/light/corrosion resistanceMagnetic tension forceEngineering

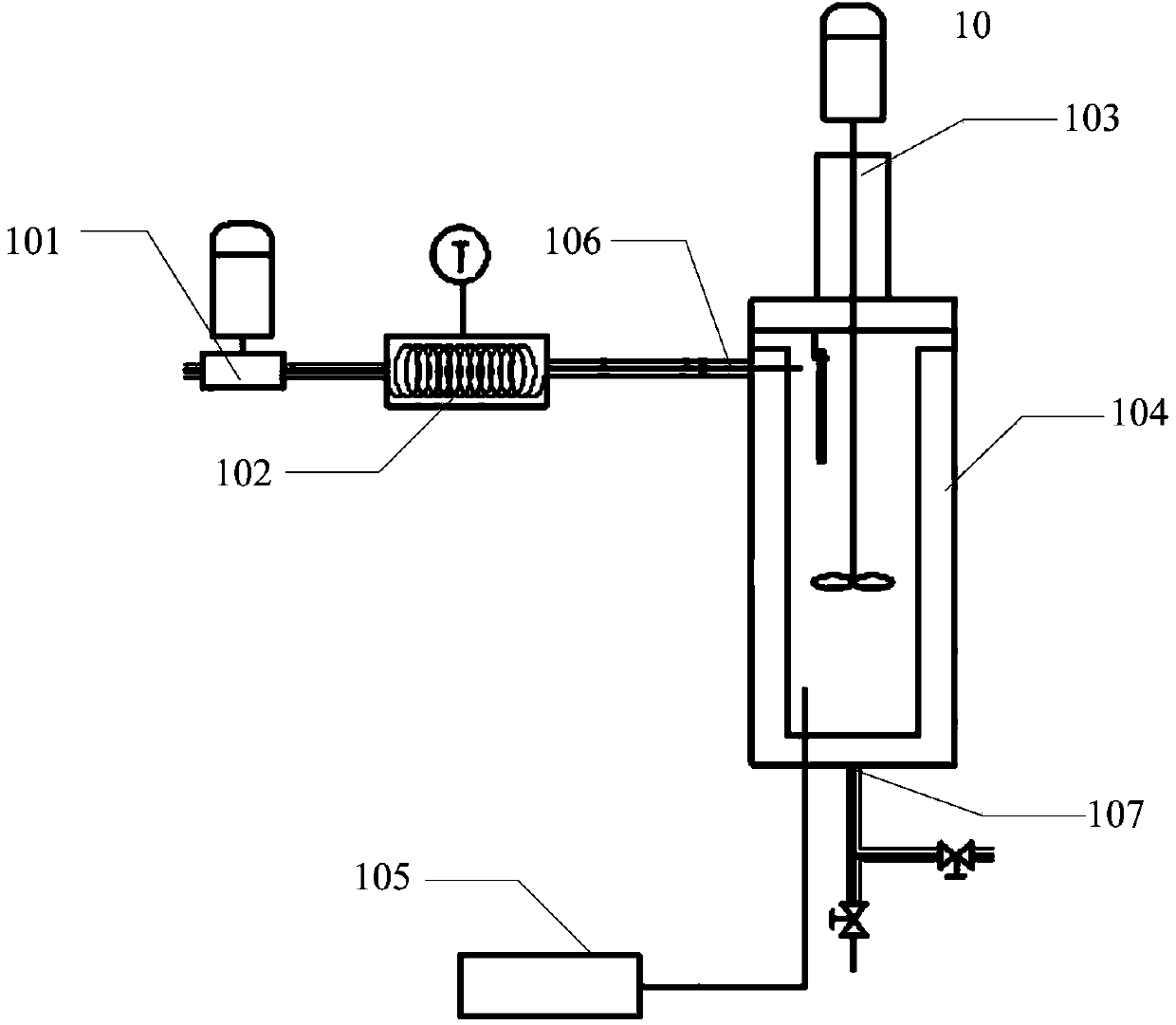

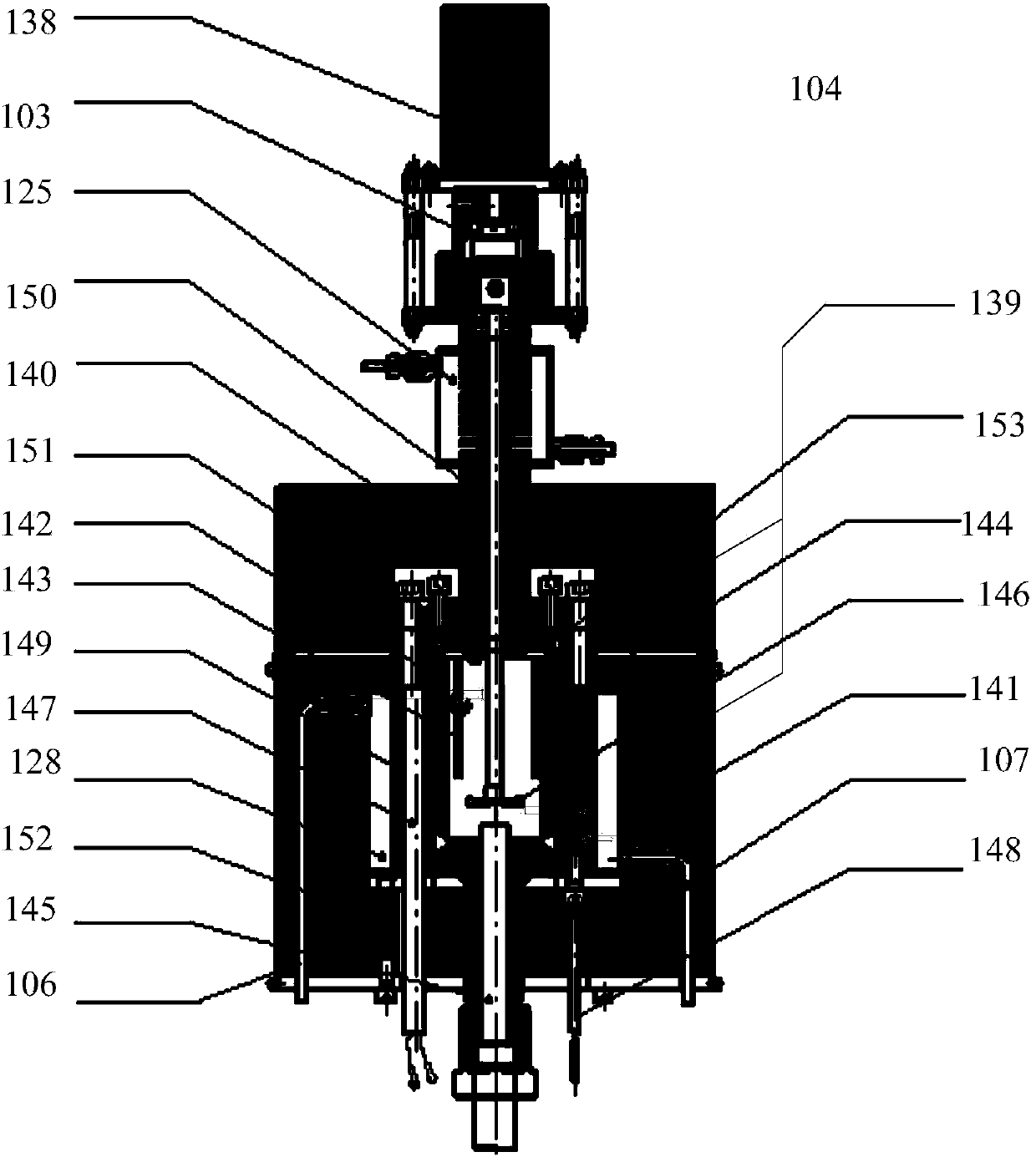

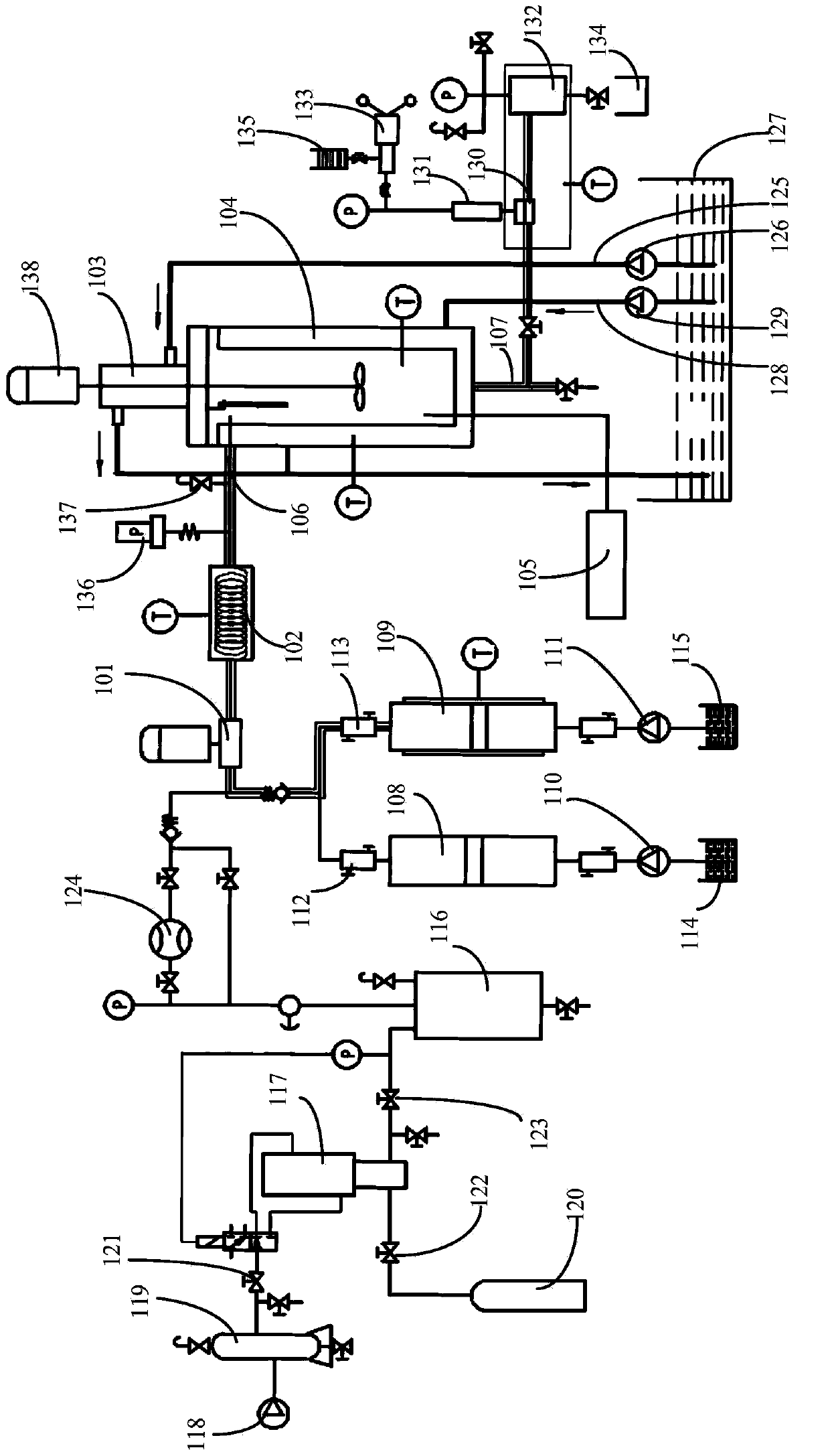

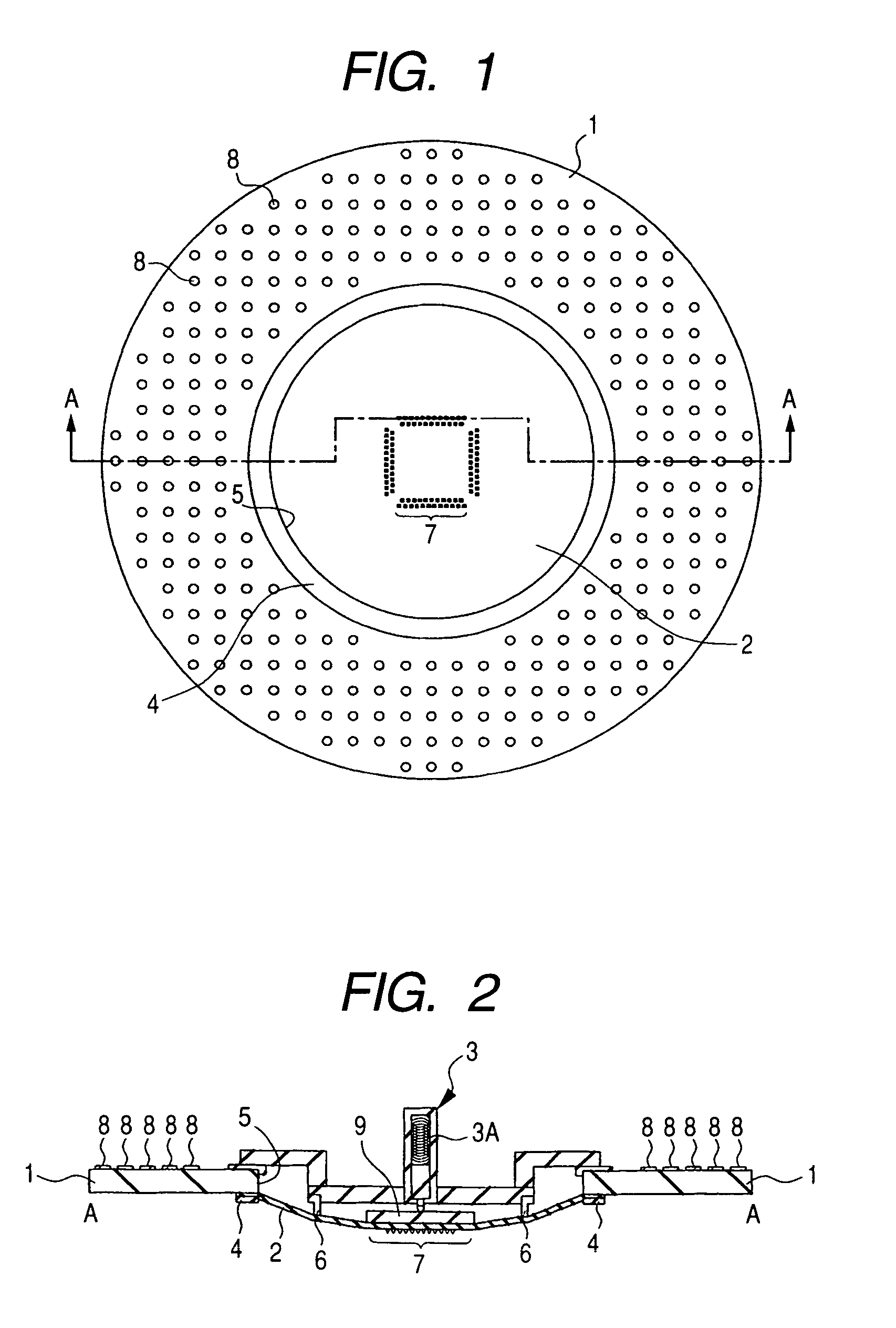

The invention discloses a device for testing a high-temperature and high-pressure corrosion rate of a multi-phase medium and relates to the technical field of corrosion rate testing, and the device comprises a gas-liquid stirring device, a preheater, a high-temperature and high-pressure reactor connected with a magnetic force stirring mechanism, and an inductance probe tester extended into the high-temperature and high-pressure reactor; the upper end of the high-temperature and high-pressure reactor is connected with a gas-liquid mixture injection pipeline which is further connected with the preheater, and the lower end of the high-temperature and high-pressure reactor is connected with a gas-liquid mixture discharge pipeline. The device can solve the problems that: because the reactor in the present technology is in static environment, the corrosion test only can be executed in static environment, so that dynamic environment in a pit is difficultly simulated, tested data isn't sufficiently accurate and the measuring speed is slower when hanging sheets are arranged the reactor, and only the average corrosion rate in longer time can be obtained.

Owner:PETROCHINA CO LTD

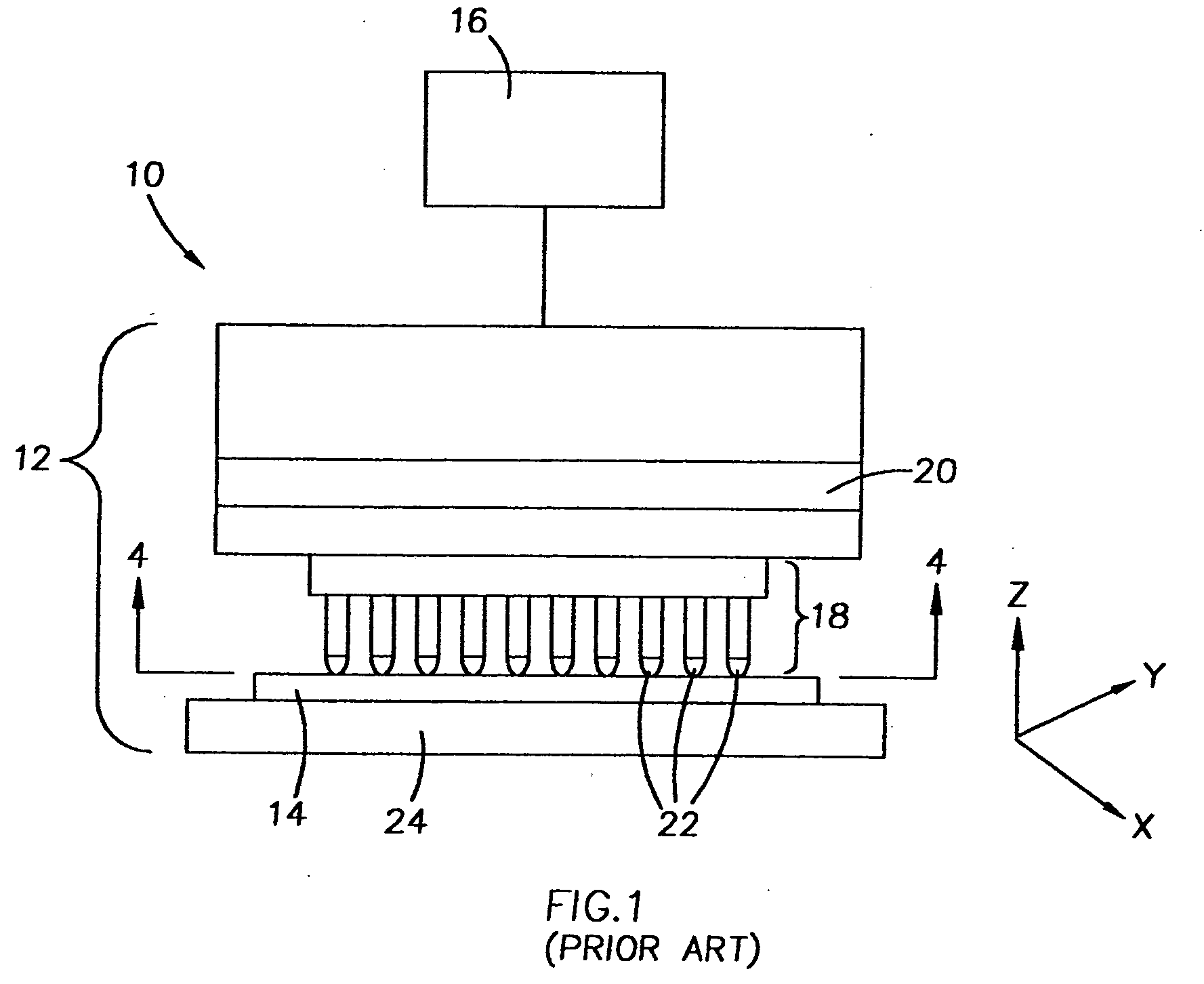

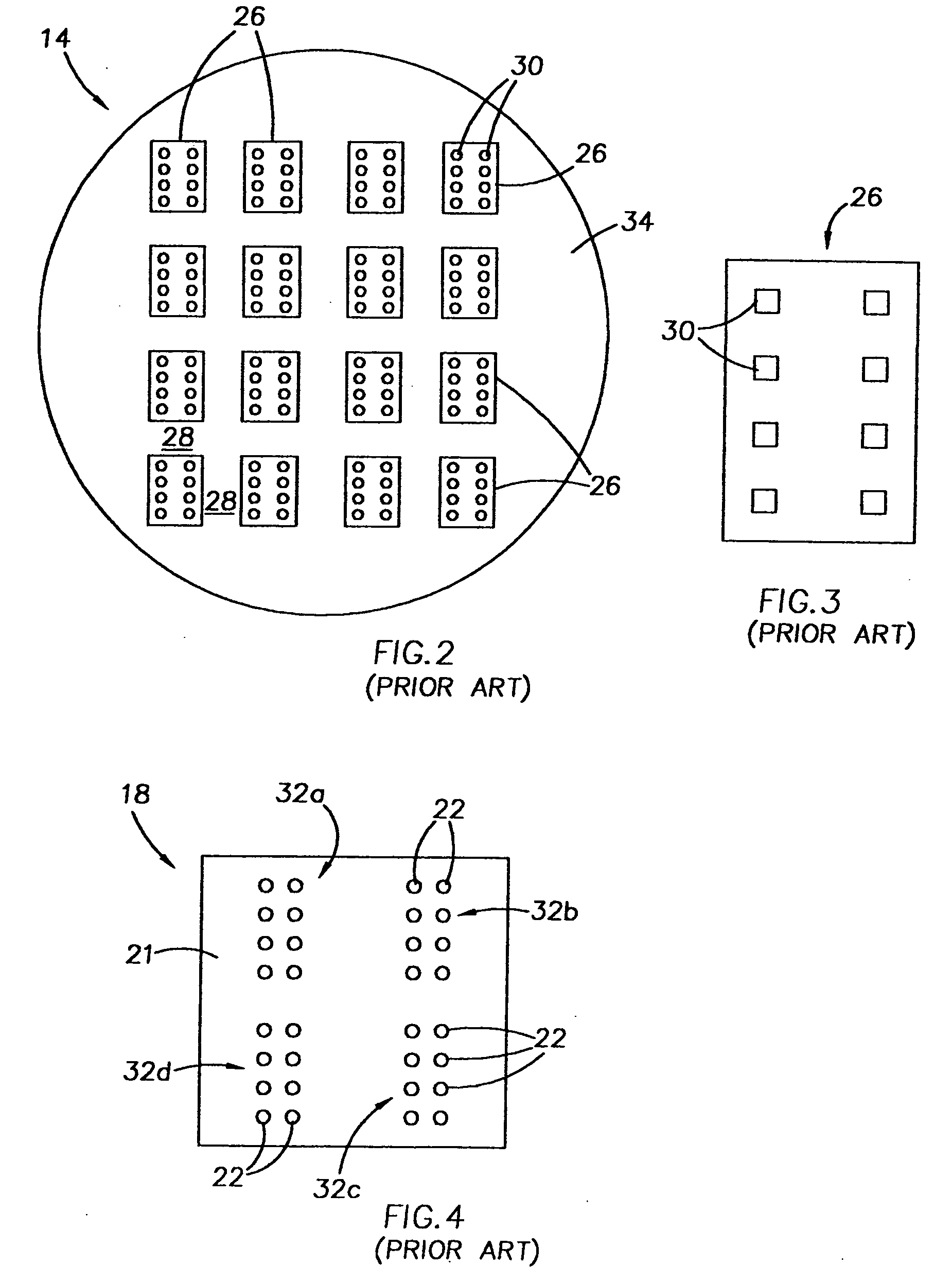

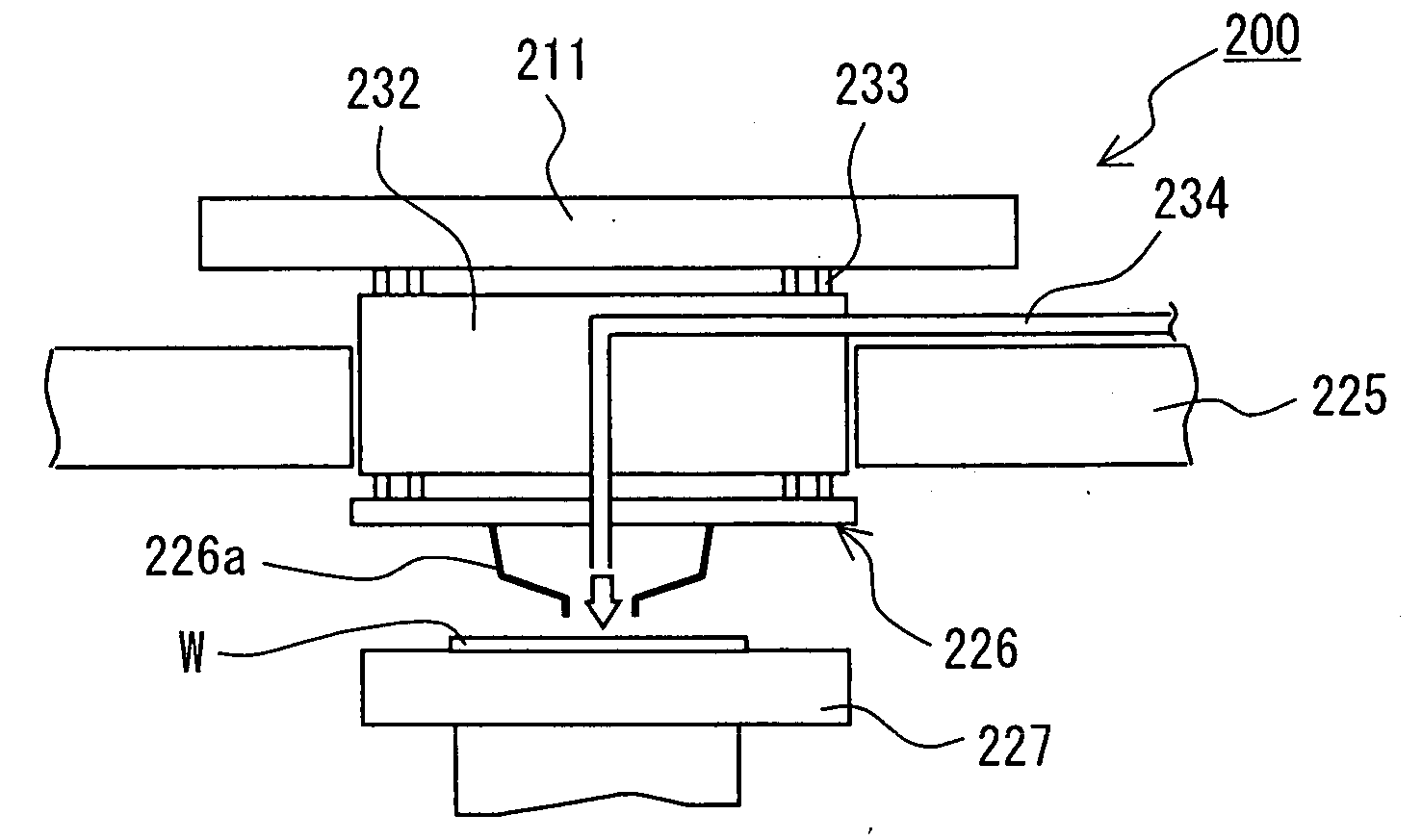

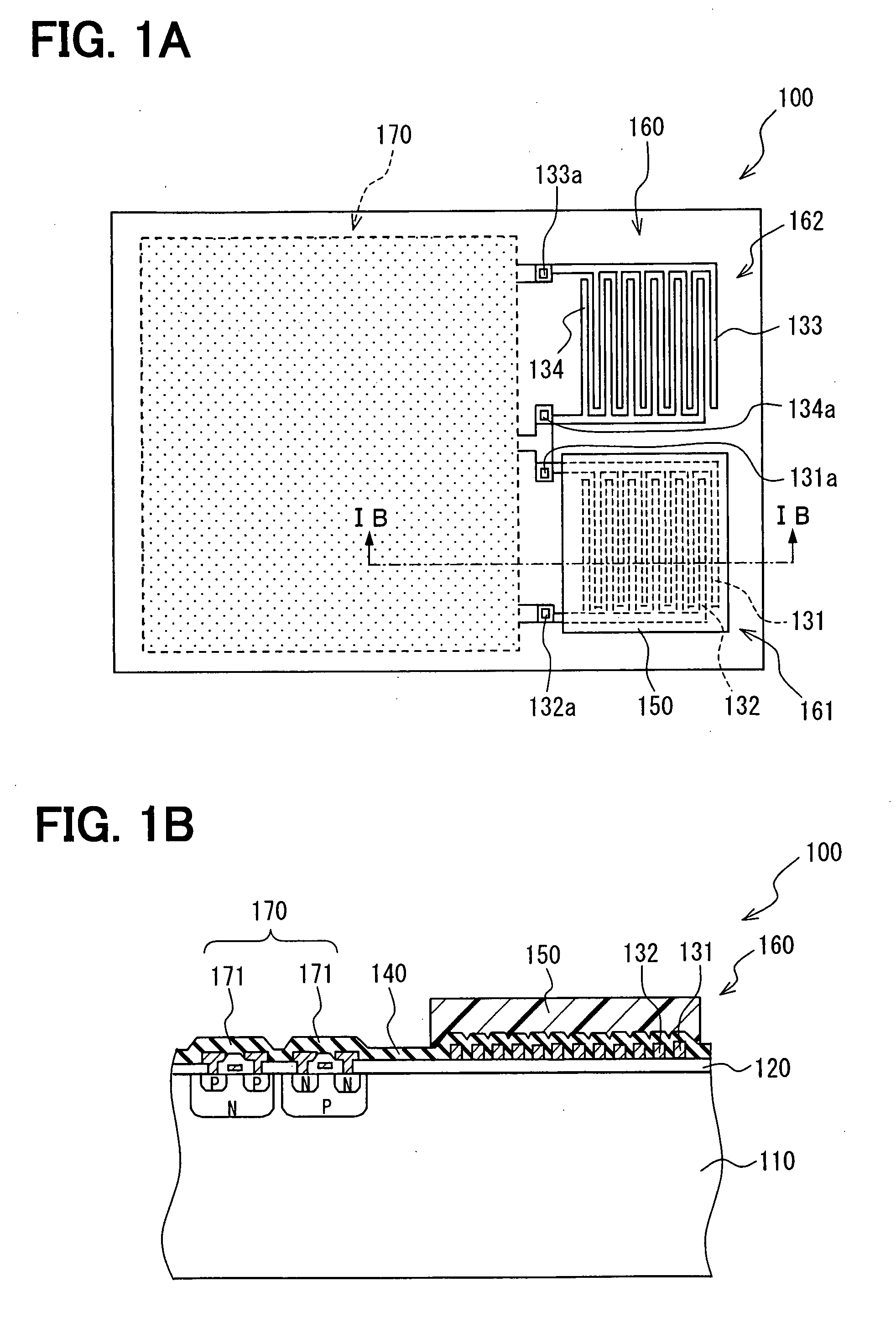

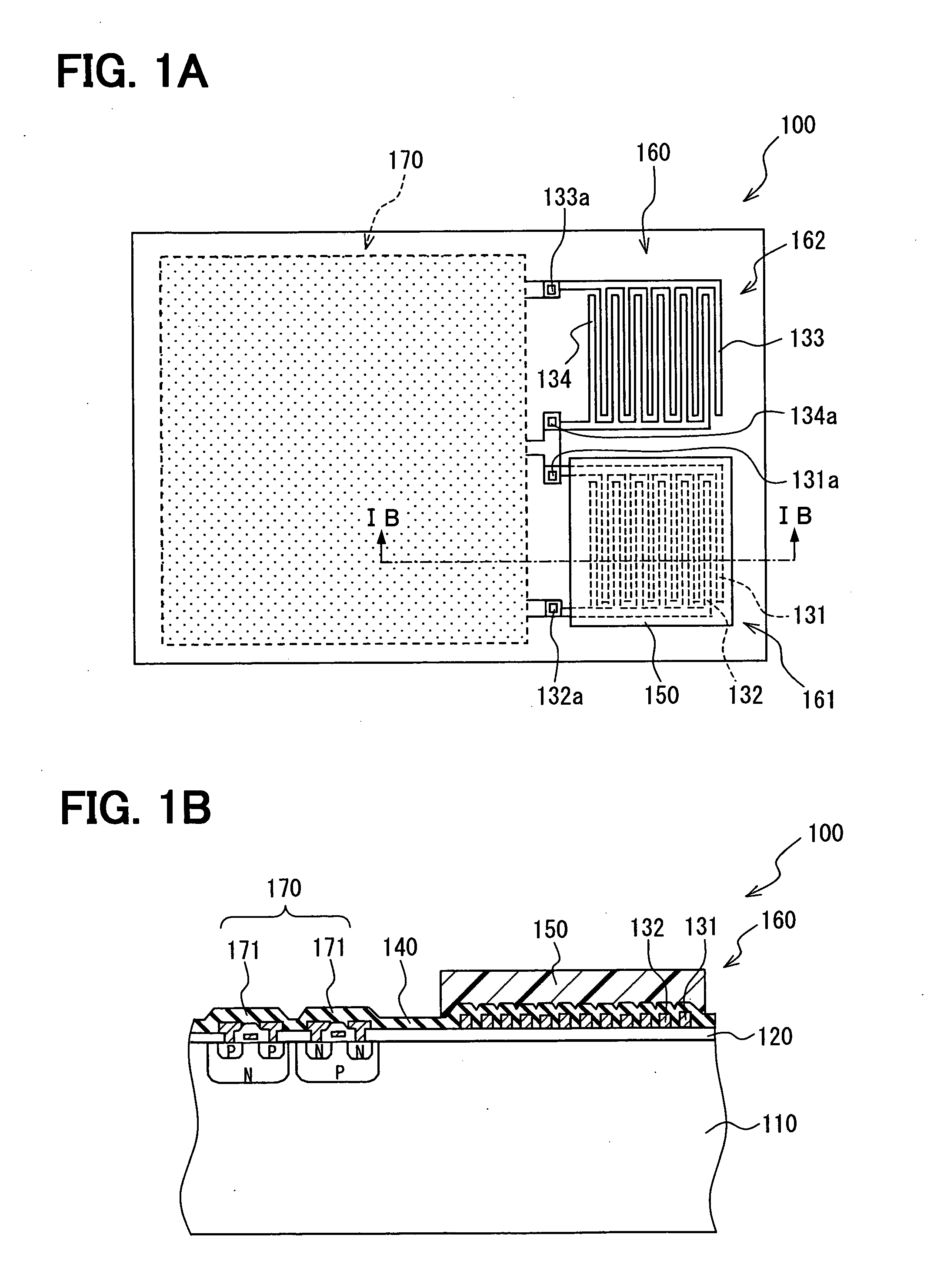

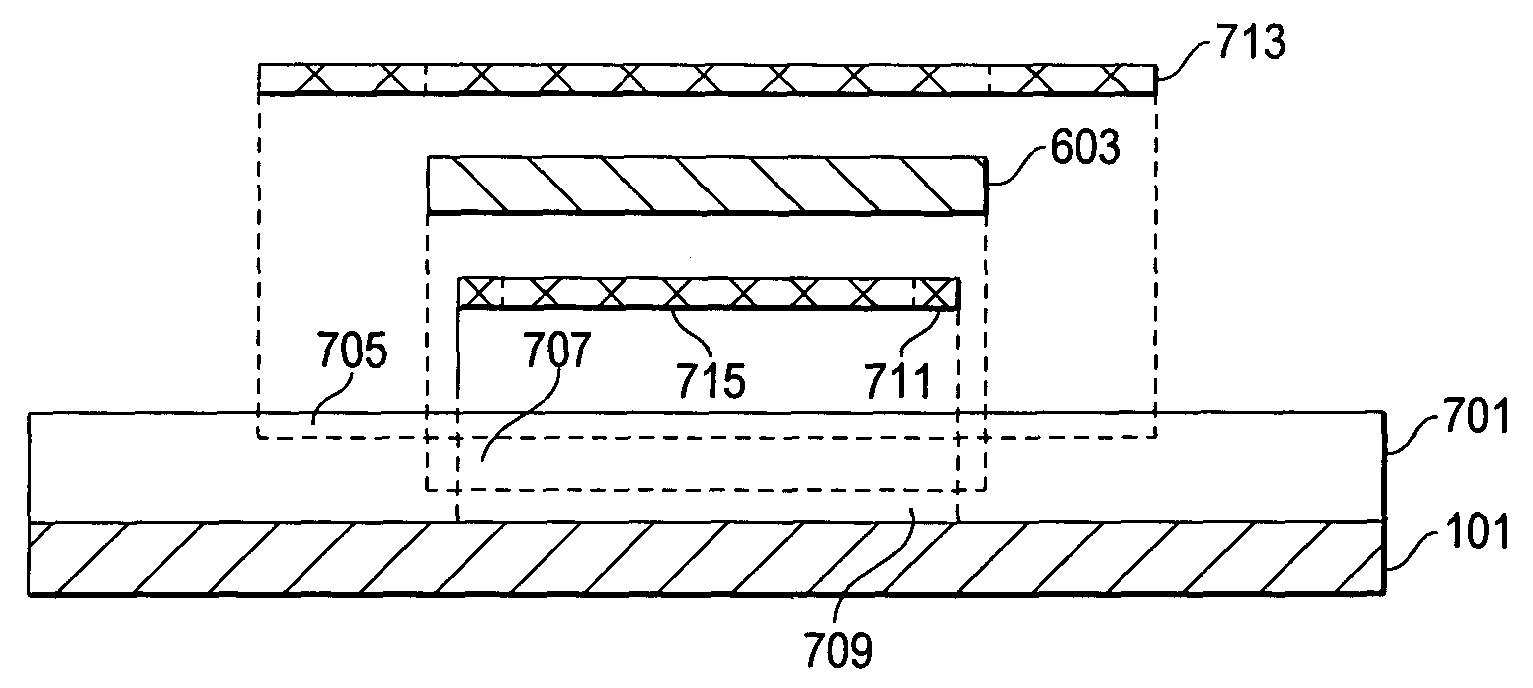

Fabrication method of semiconductor integrated circuit device

InactiveUS7544522B2Reduce manufacturing costIncrease the number ofSemiconductor/solid-state device testing/measurementElectronic circuit testingForeign matterProbe card

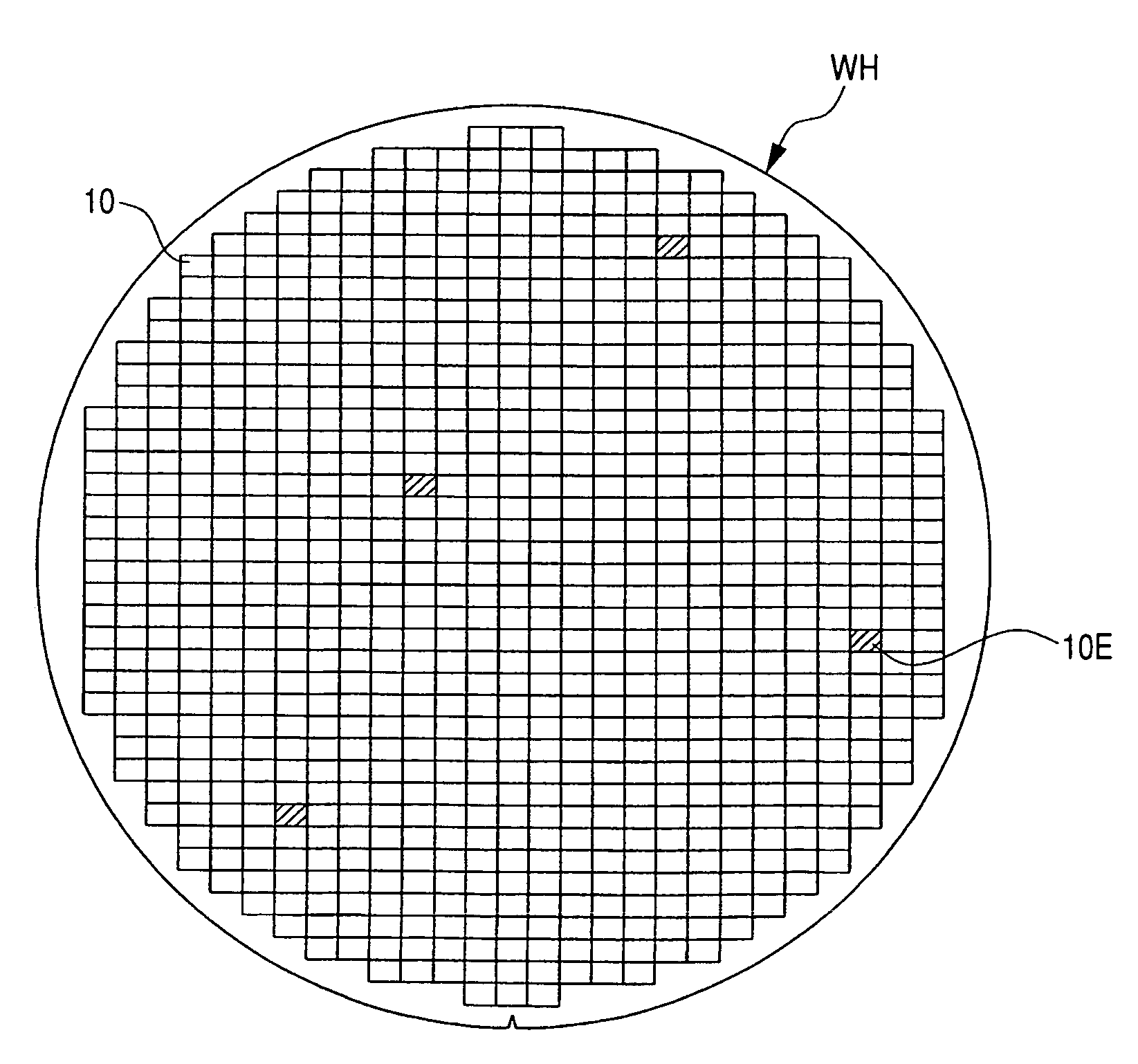

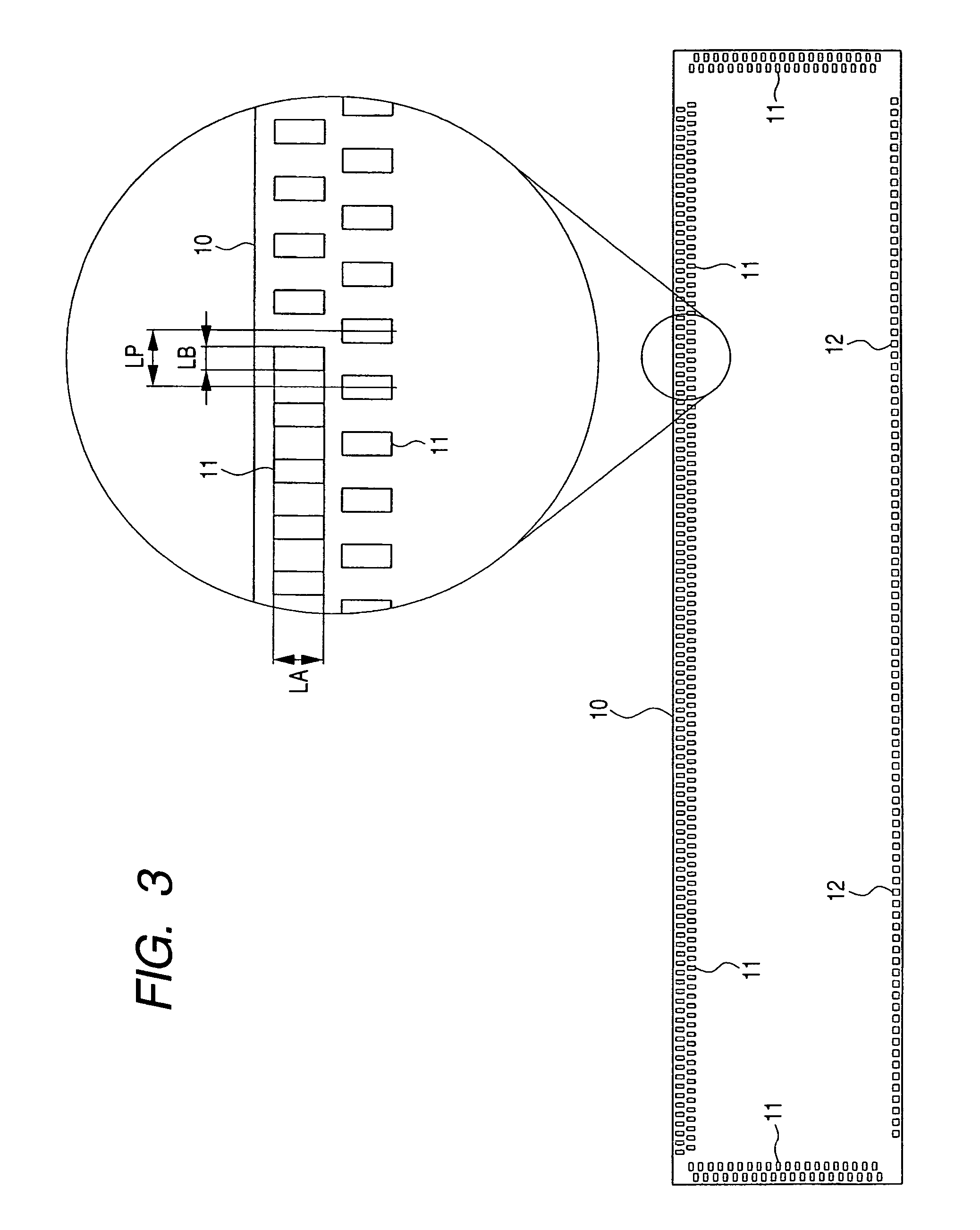

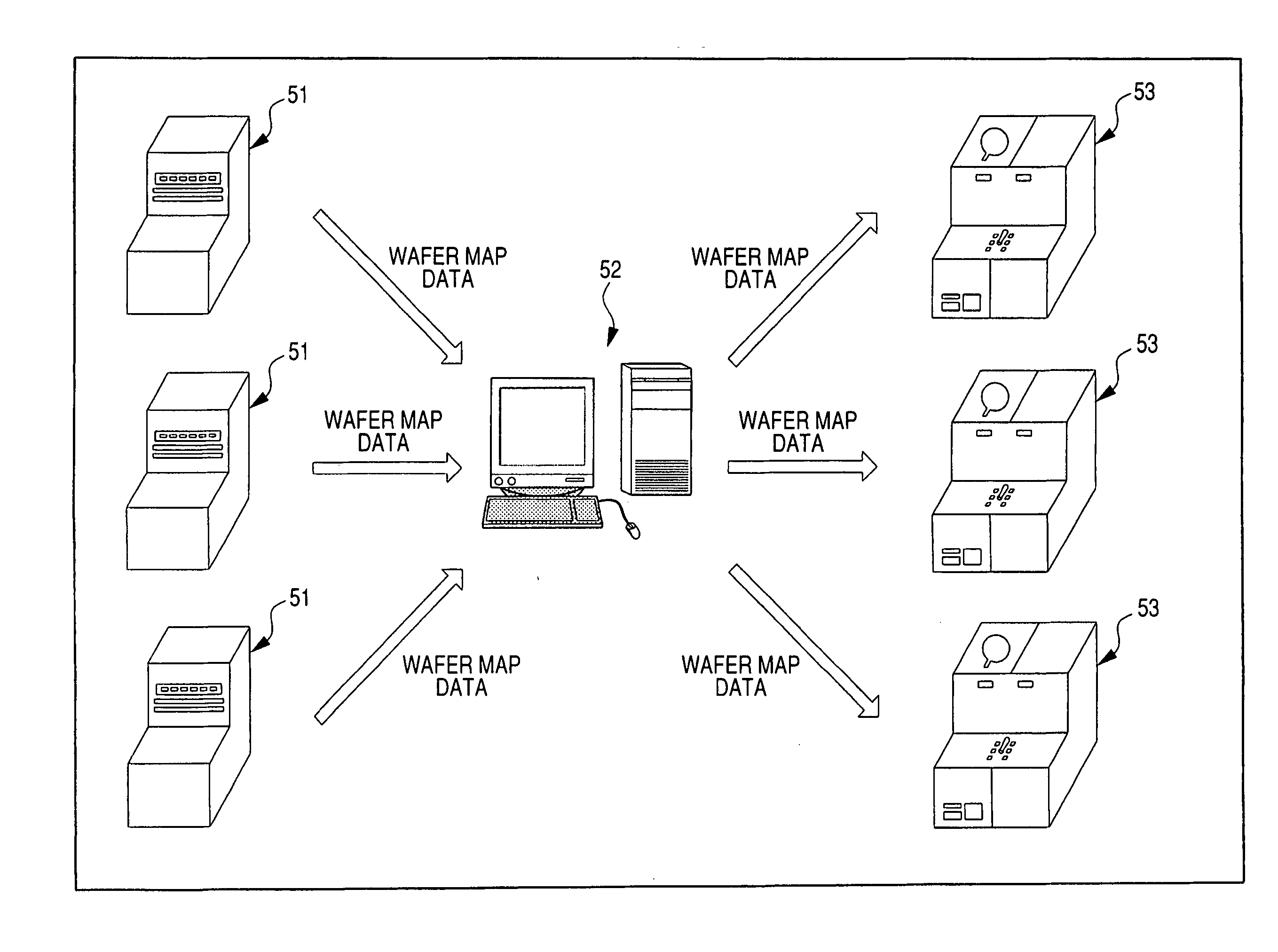

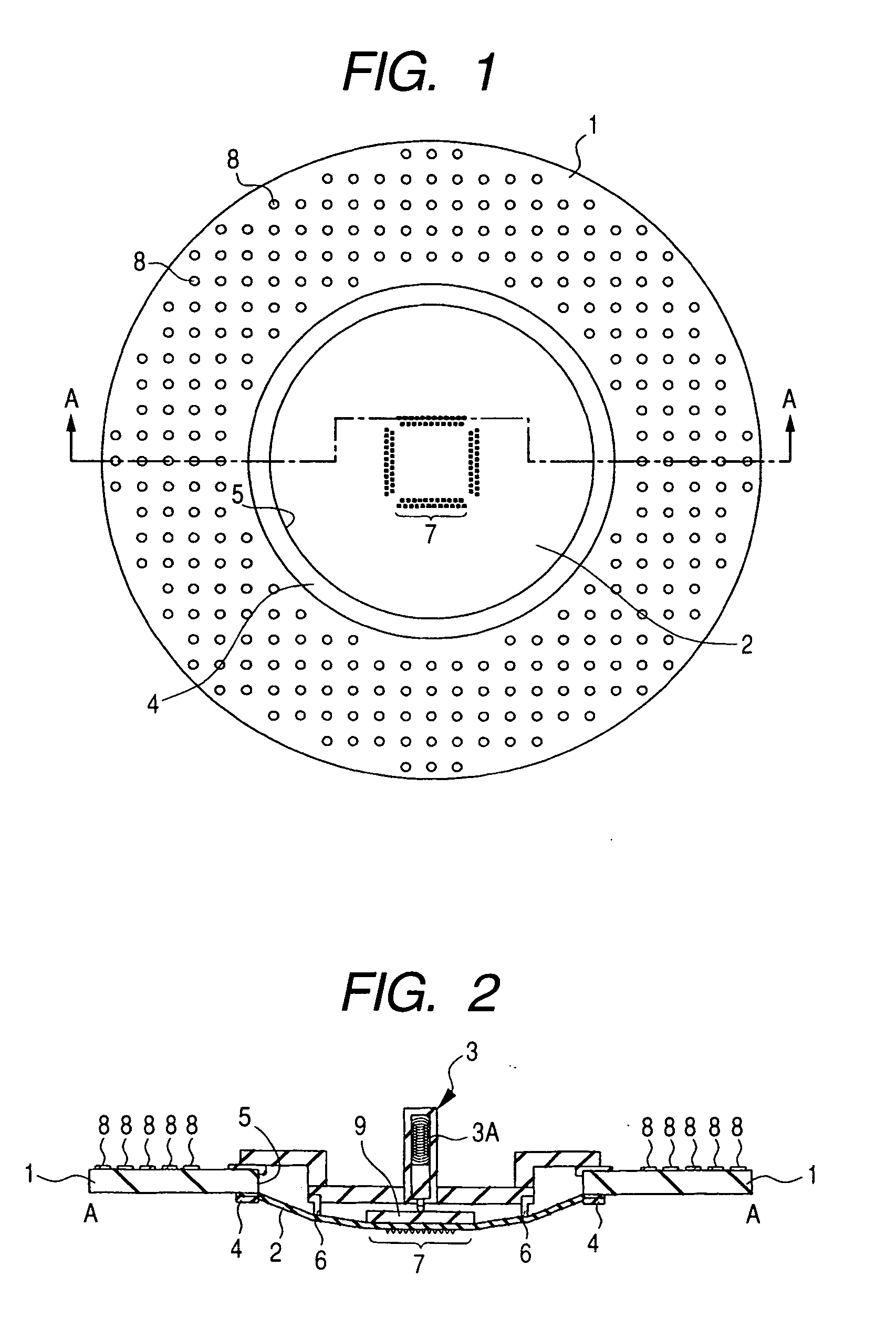

To prevent breakage of a membrane probe during a probe test using a probe card having the membrane probe, appearance of a main surface of a wafer as a test object is tested by an appearance tester 51, and results of bad appearance such as adhesion of a foreign substance to the main surface of the wafer and abnormality in shape of bump electrodes over the main surface of the wafer are collected as wafer map data according to arrangement of respective chips in a plane of the wafer, then the wafer map data are transmitted to a probe tester 53 via a server 52, and the probe tester 53 omits the probe test for chips in which bad appearance was detected, and concurrently performs the probe test to other chips in which bad appearance was not detected, based on the wafer map data.

Owner:RENESAS ELECTRONICS CORP

Method for testing high-temperature and high-pressure corrosion rate of multi-phase medium

ActiveCN104215571AFast measurementReal-time acquisition of corrosion rateWeather/light/corrosion resistanceForming gasProduct gas

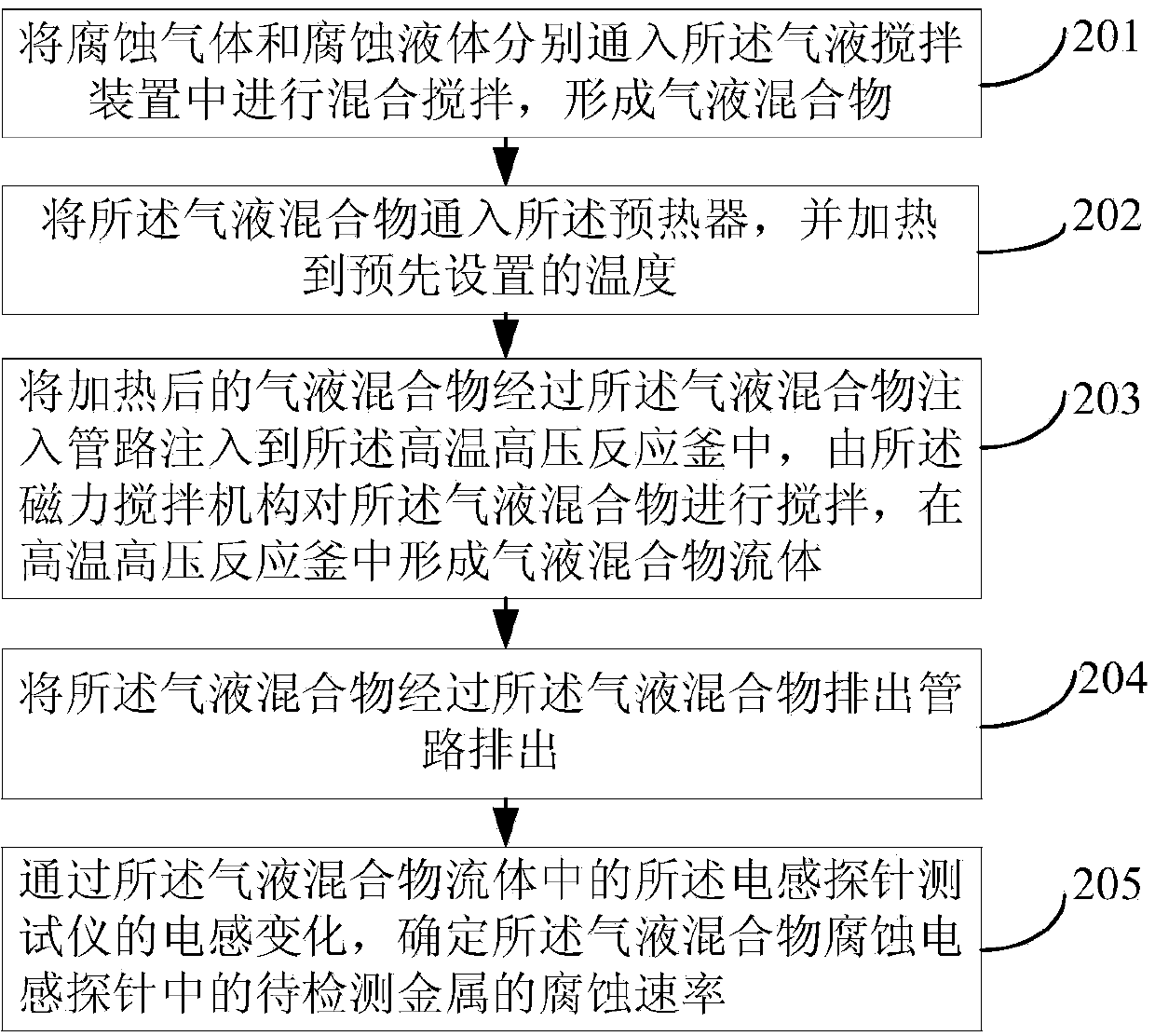

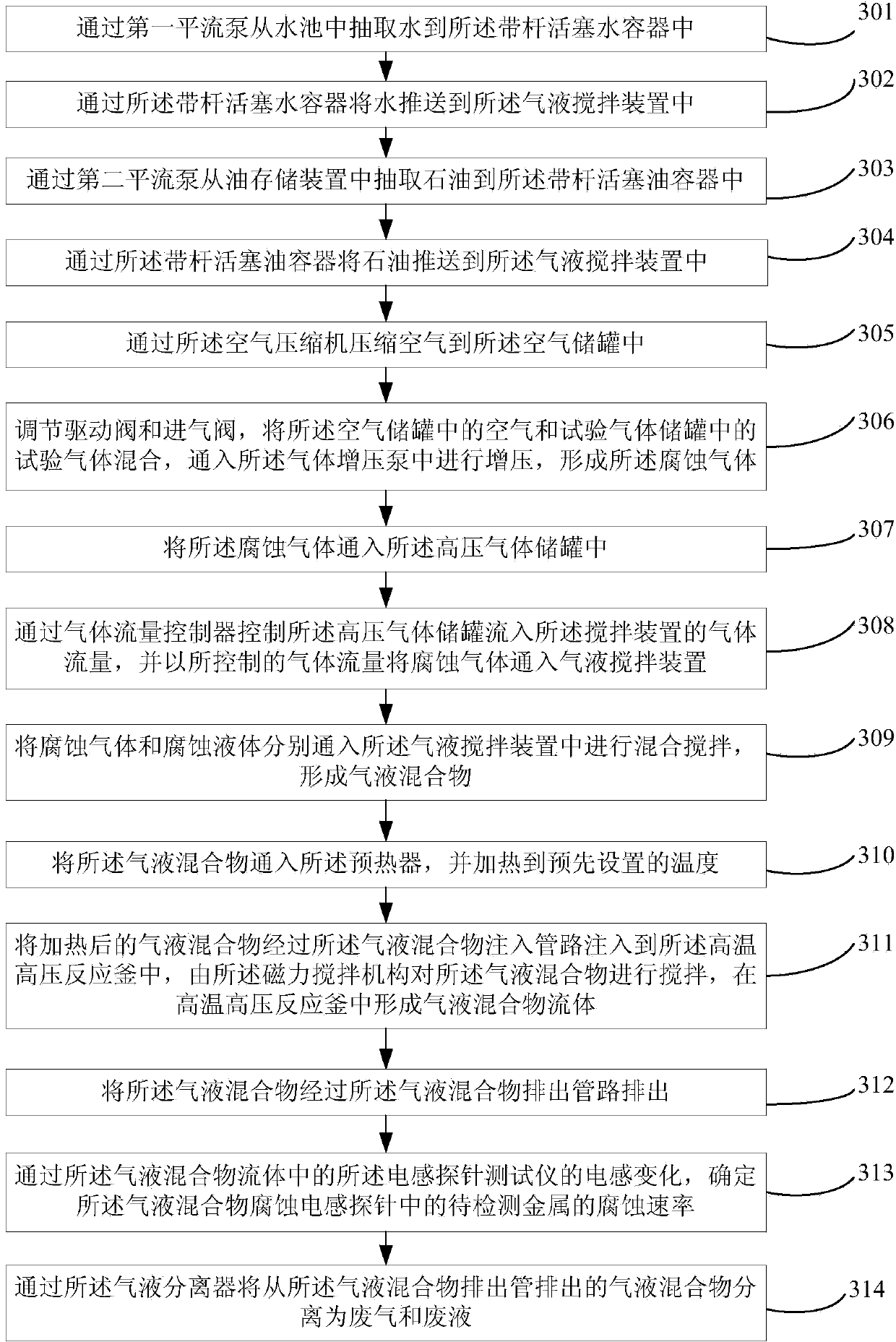

The invention discloses a method for testing a high-temperature and high-pressure corrosion rate of a multi-phase medium and relates to the technical field of corrosion rate testing, and the method is applied to a device for testing the high-temperature and high-pressure corrosion rate of the multi-phase medium and comprises the following steps of: respectively accessing corrosive gas and corrosive liquid into a gas-liquid stirring device and mixing them to form a gas-liquid mixture, accessing them into a preheater to be heated to the preset temperature; injecting the gas-liquid mixture into a high-temperature and high-pressure reactor through a gas-liquid mixture injection pipeline, and discharging it by a gas-liquid mixture discharge pipeline to form gas-liquid mixture fluid; confirming the corrosion rate of the to-be-detected metal in a gas-liquid mixture corrosion inductance probe through inductance change of an inductance probe tester. The method can solve the problems that the corrosion test in the present technology only can be executed in static environment so that dynamic environment in a pit is difficultly simulated, tested data isn't sufficiently accurate and the measuring speed is slower, and only the average corrosion rate in longer time can be obtained.

Owner:PETROCHINA CO LTD

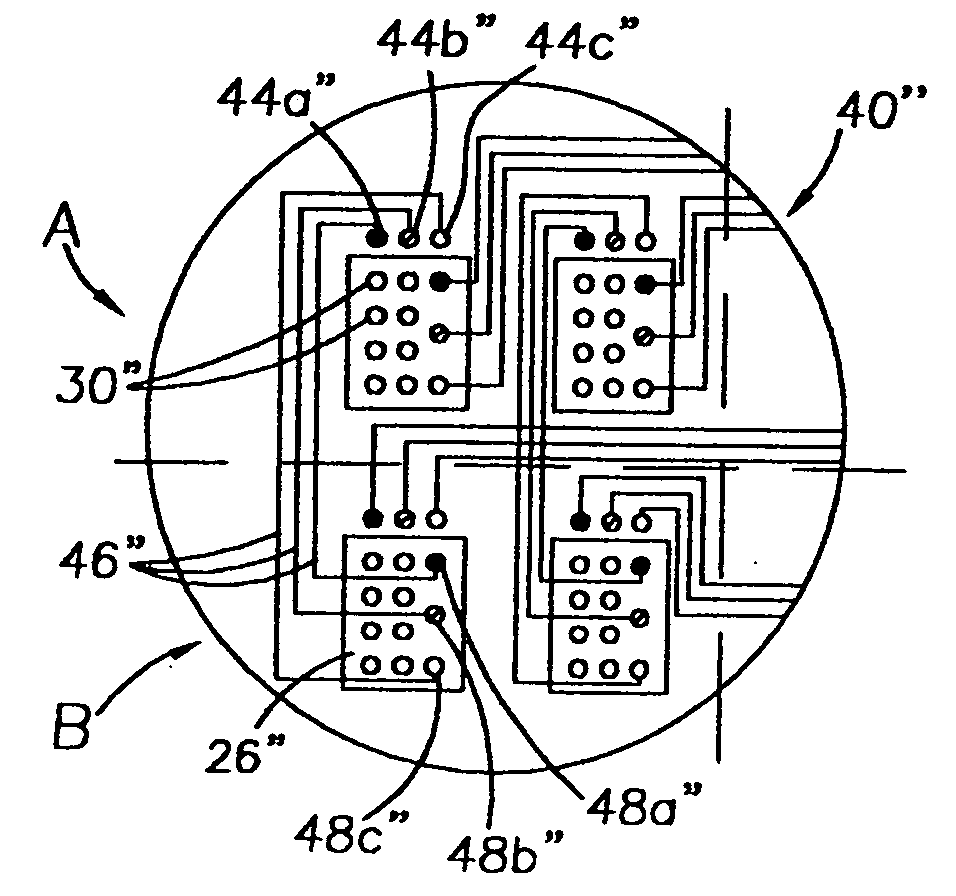

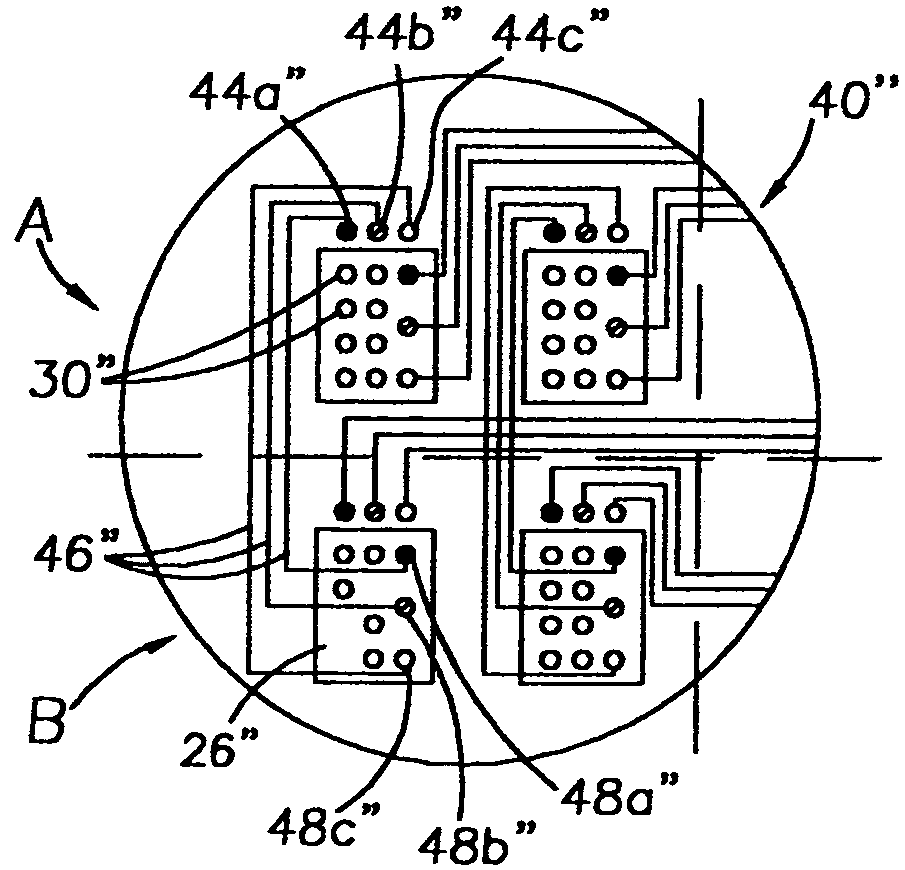

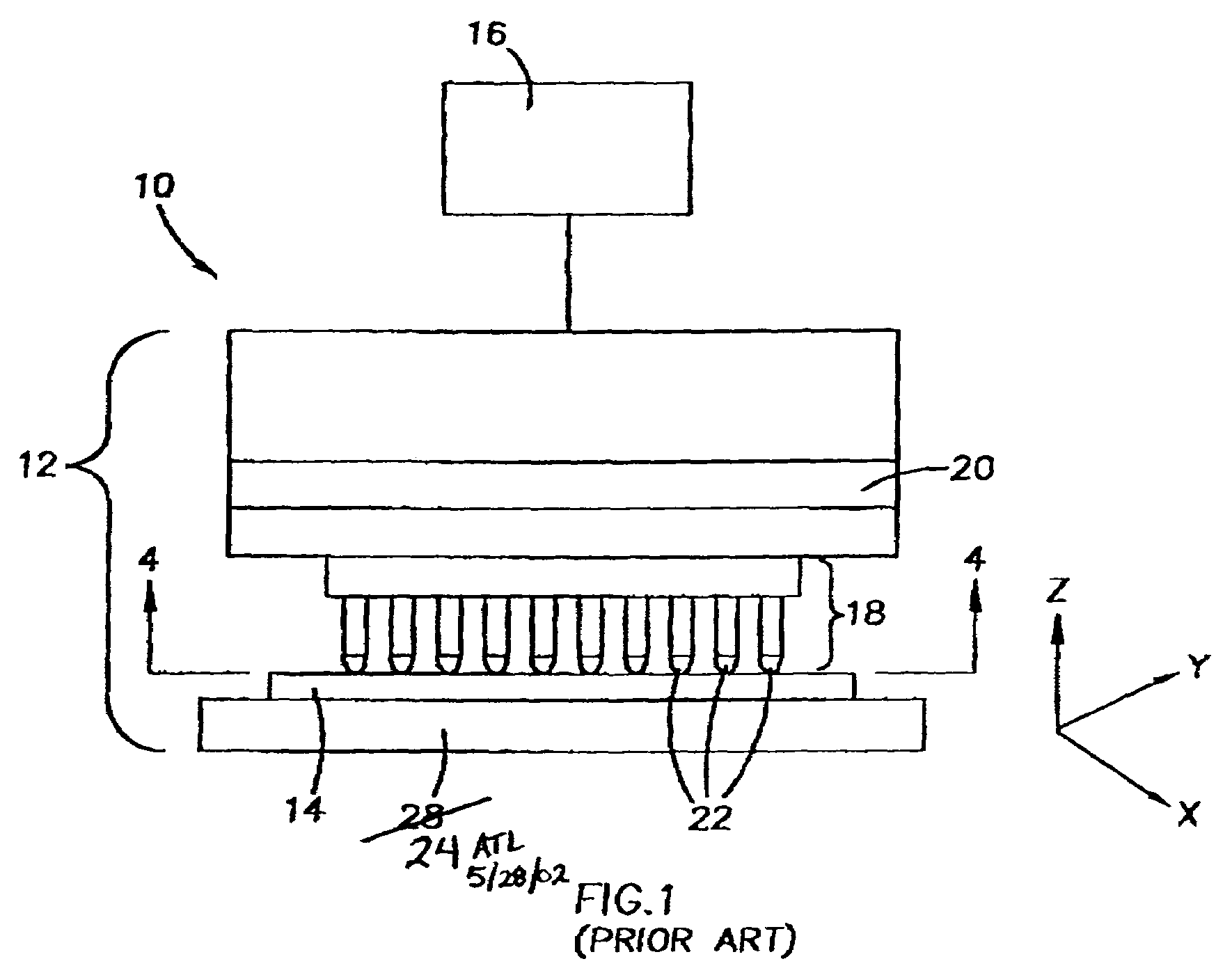

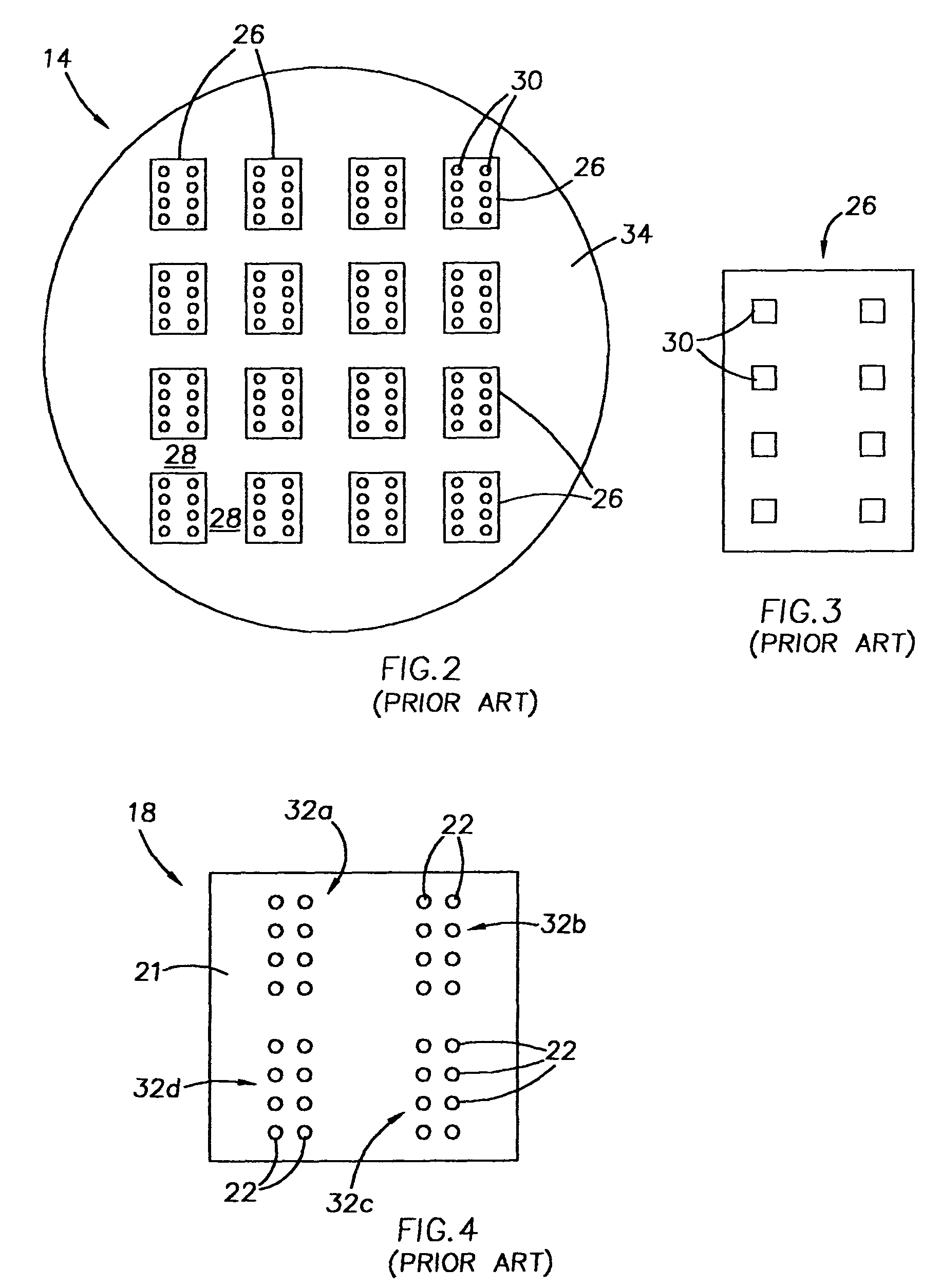

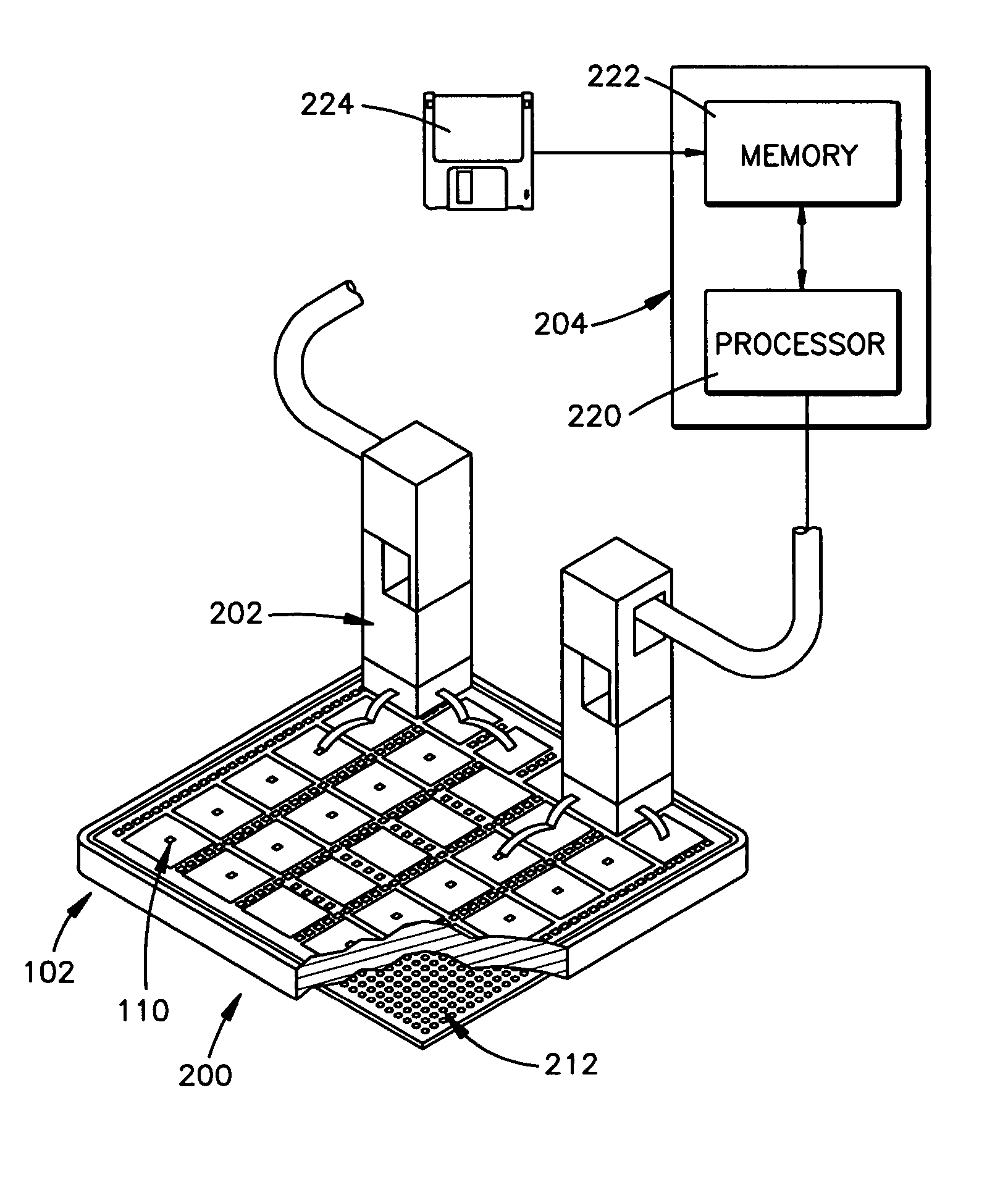

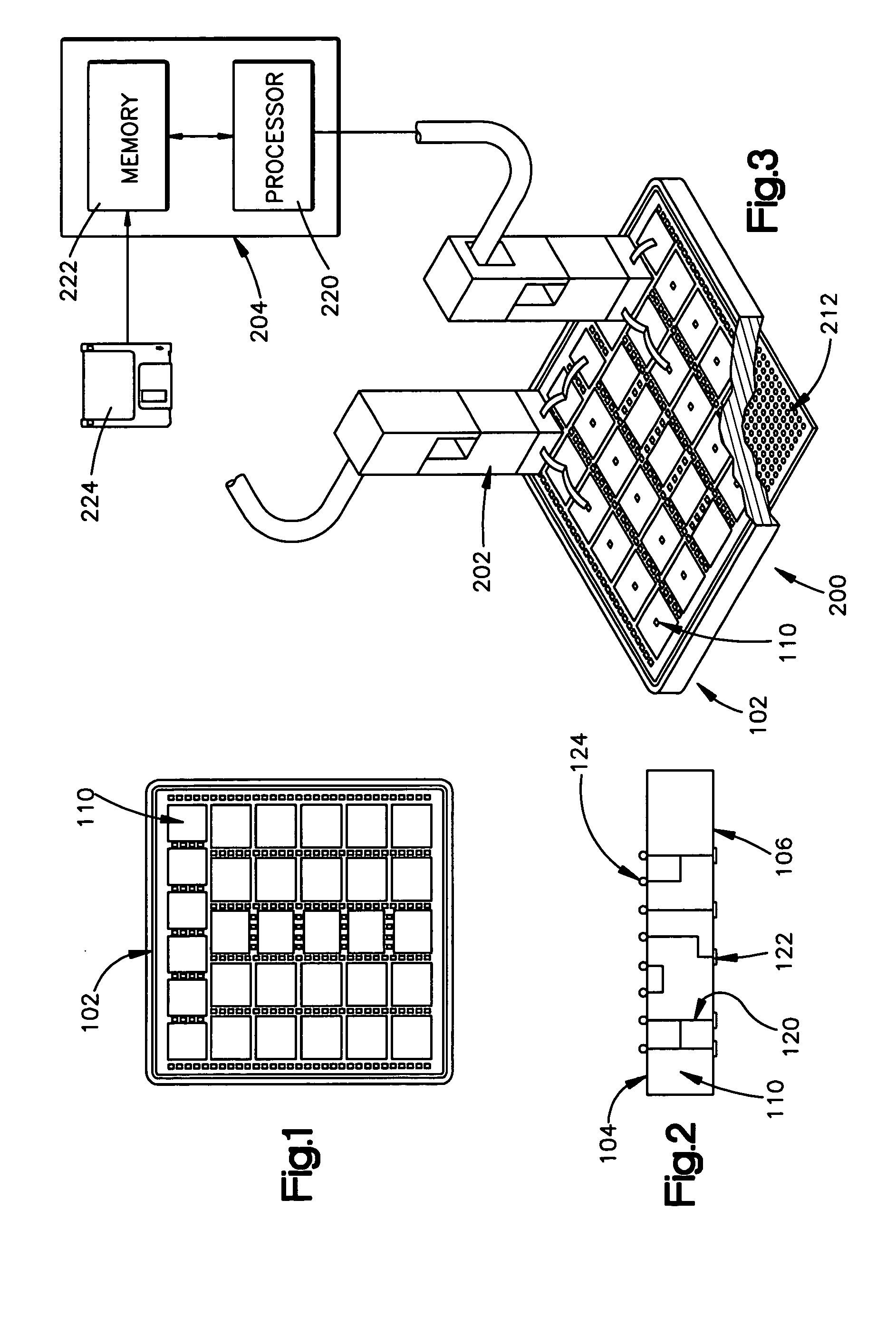

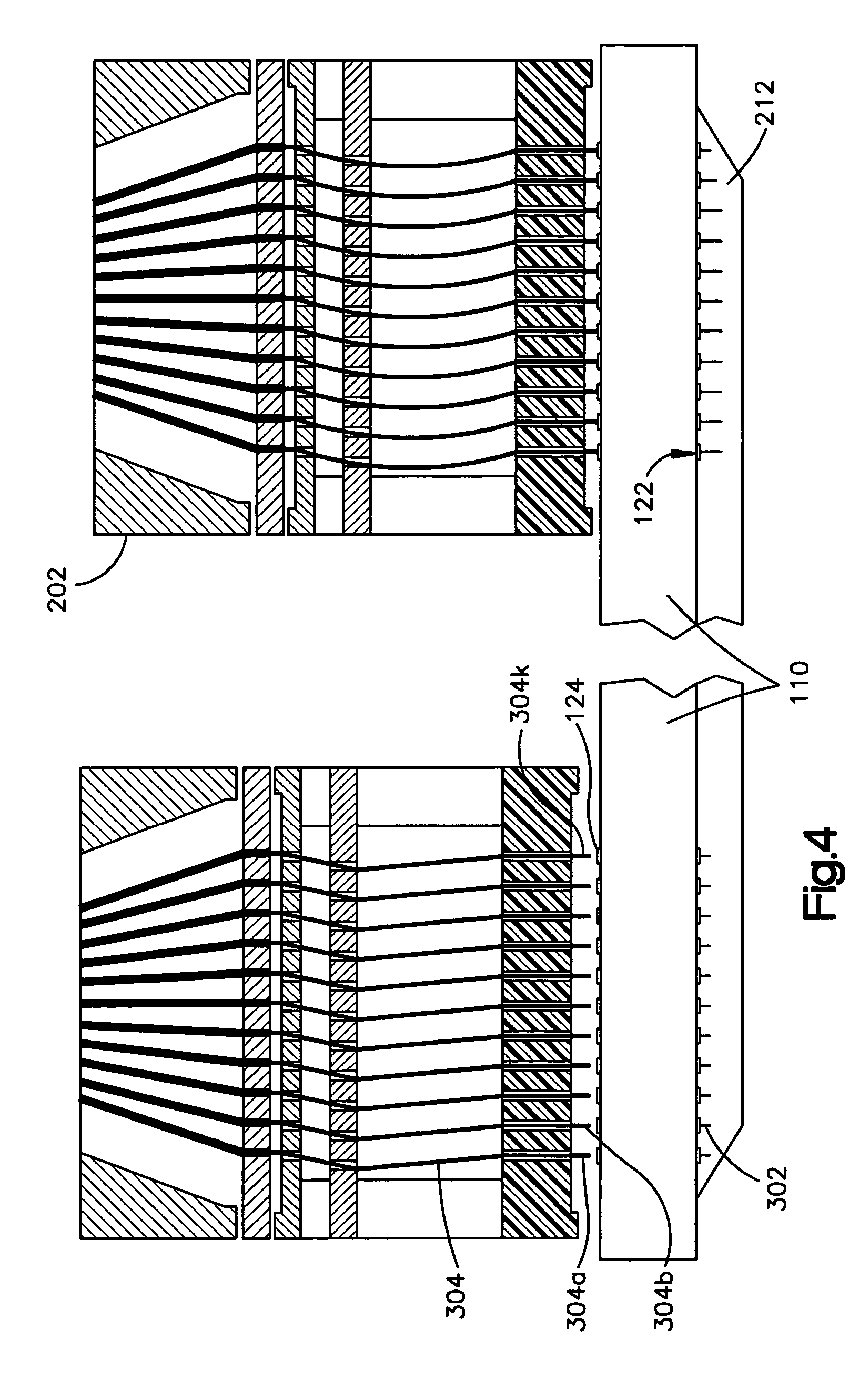

Probe look ahead: testing parts not currently under a probehead

InactiveUS20060113535A1Reduce and eliminate needImprove life expectancySemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardRedistribution layer

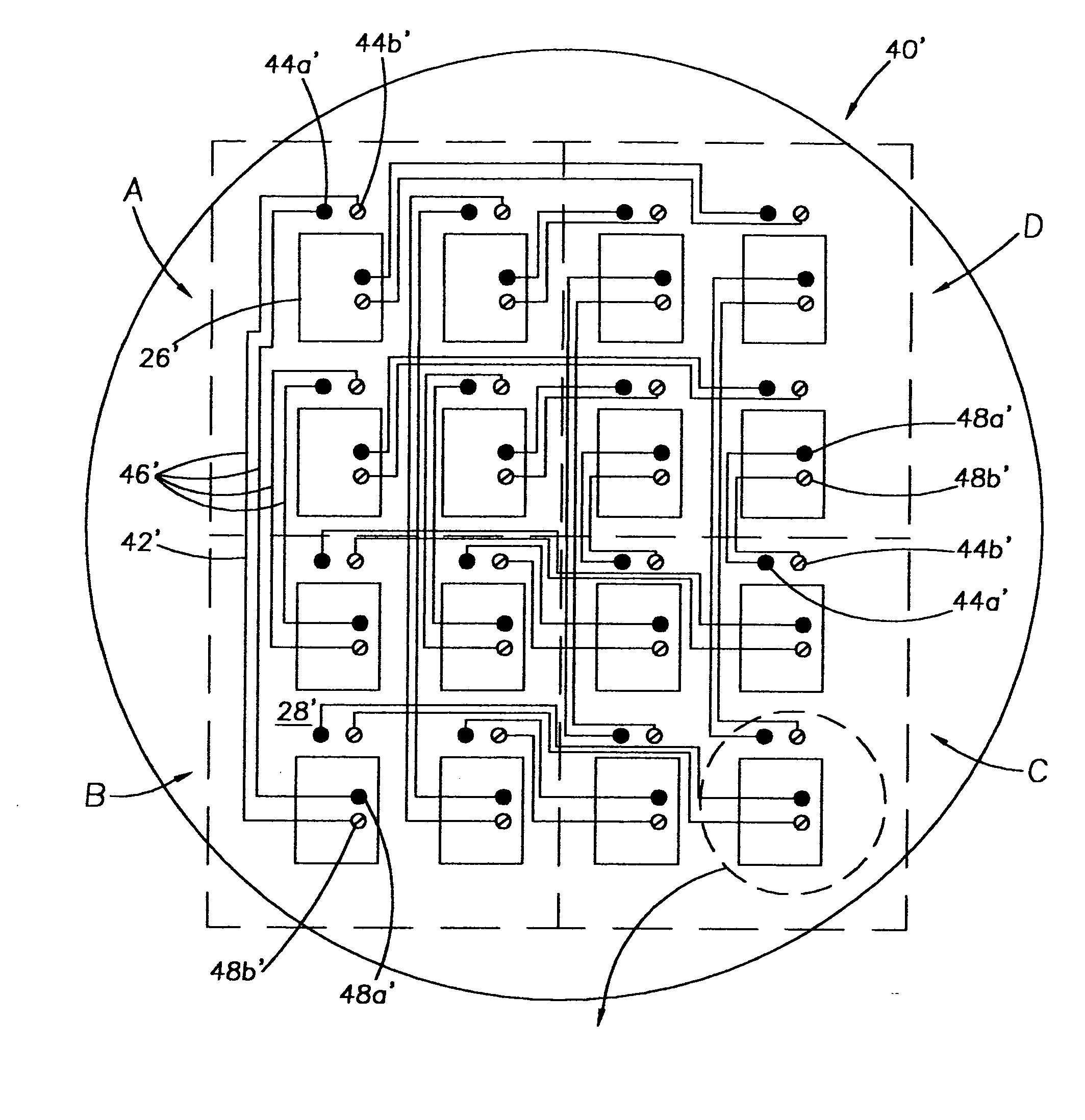

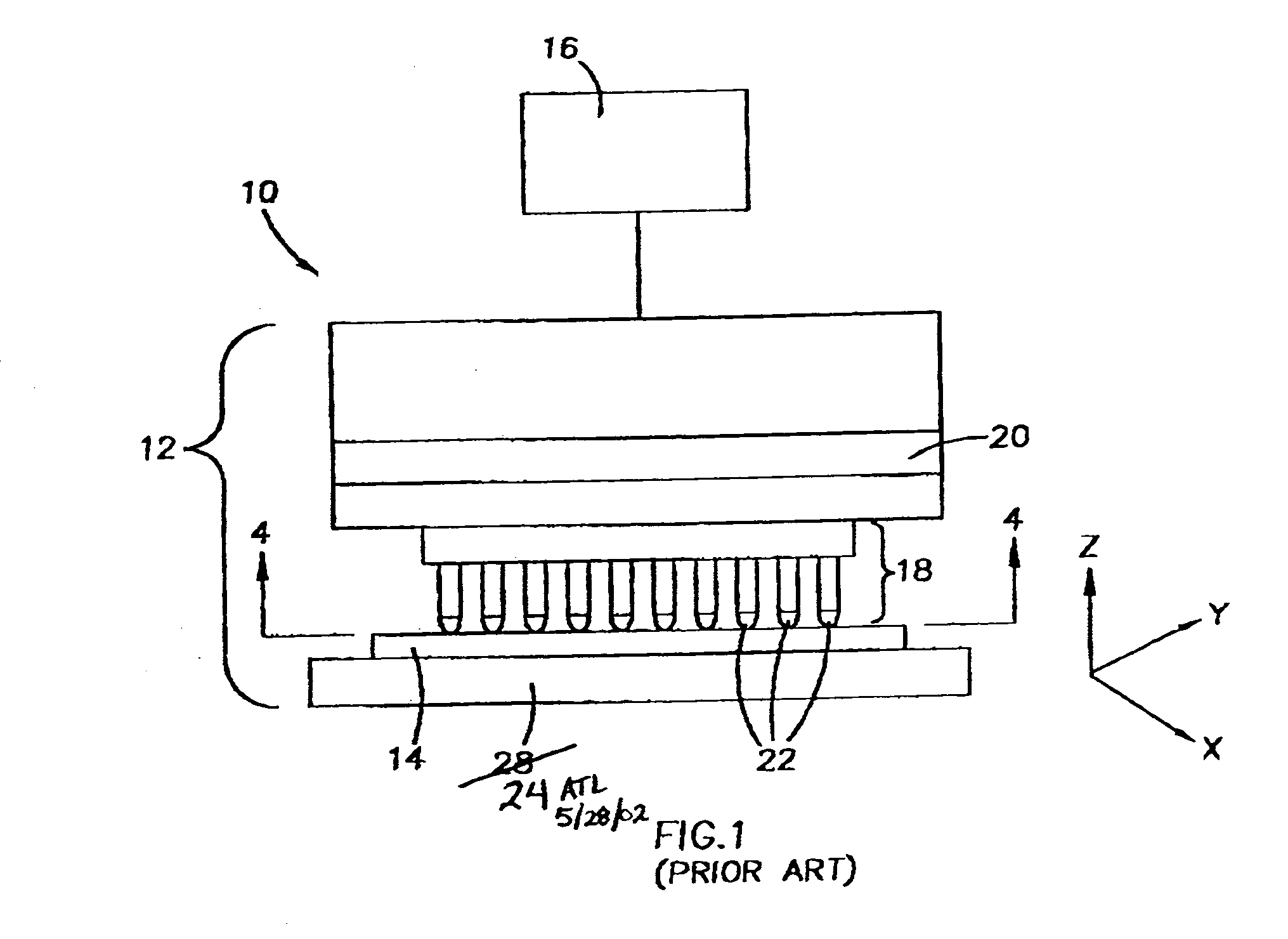

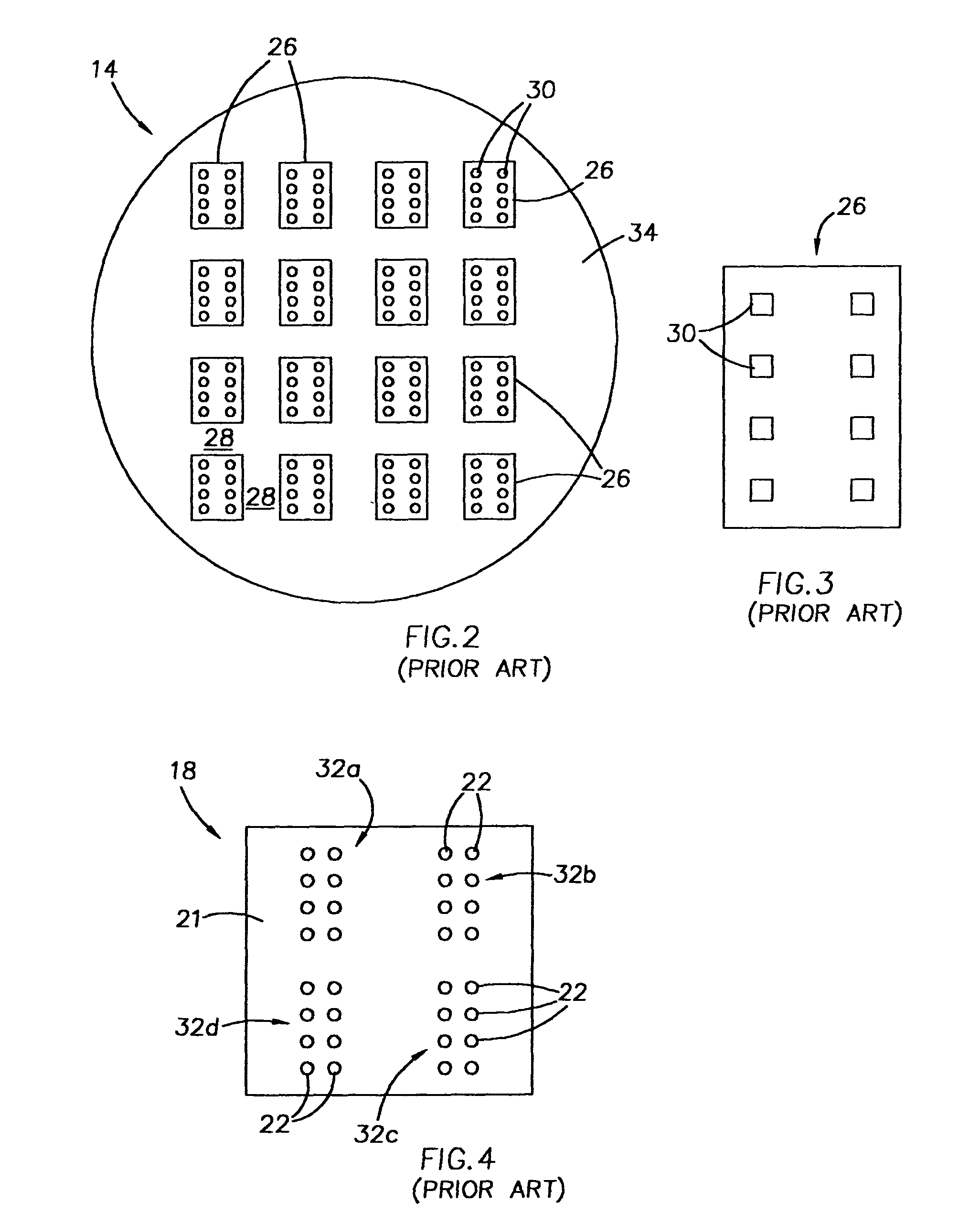

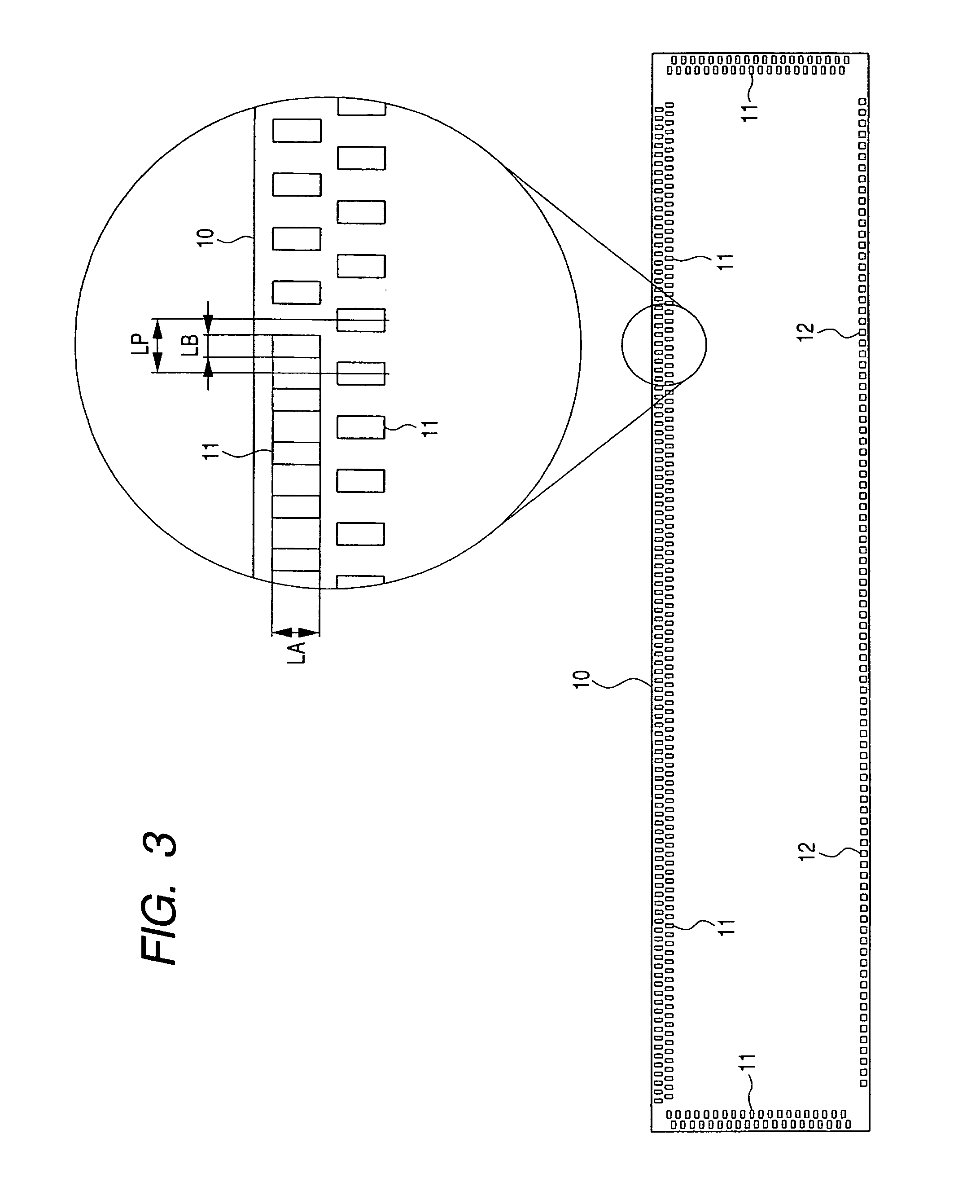

A semiconductor substrate, probe card, and methods for stressing and testing dies on a semiconductor substrate are provided. The semiconductor substrate, typically a semiconductor wafer, comprises dies disposed thereon and a redistribution layer (RDL) for routing signals from a test circuit into dies on the substrate that are not currently under probe. The RDL includes look-ahead contacts associated with a first die set that are electrically connected by traces to dies of a second die set. Upon contact of elements of the probe tester with the look-ahead contacts, required Vcc power, GND ground potential and signals from the probe tester are routed through the traces to the die of the die set not currently under probe. The dies can comprise a built-in self-stress (BISS) circuit and / or a built-in self-test (BIST) circuit for implementing a stress or test sequence. The look-ahead contacts allow for overlapping or substantially simultaneously stressing and / or testing dies of dies of a die set currently under probe and dies of a second die set located prior to or after the current probe head position (i.e., not under probe).

Owner:MICRON TECH INC

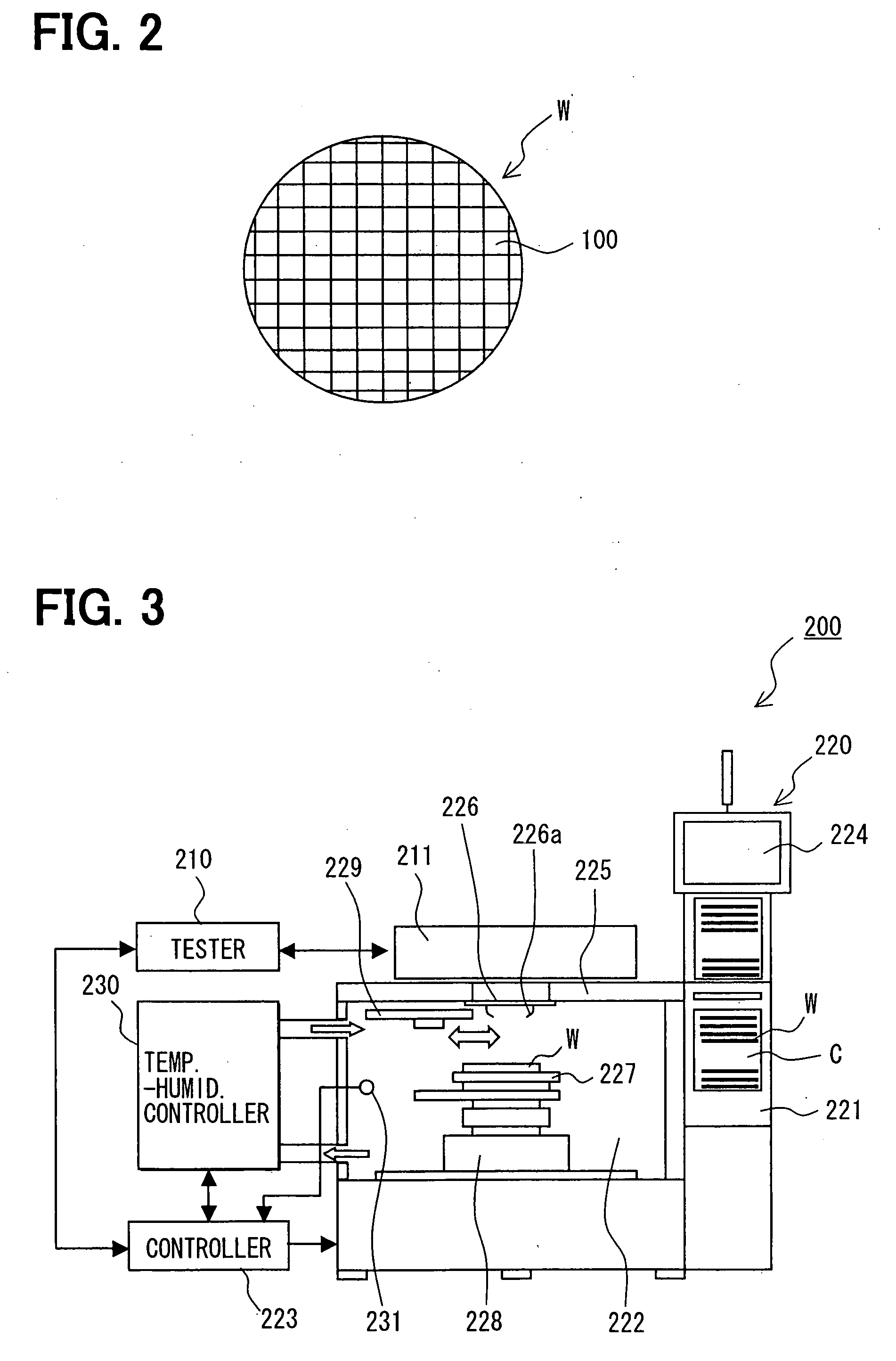

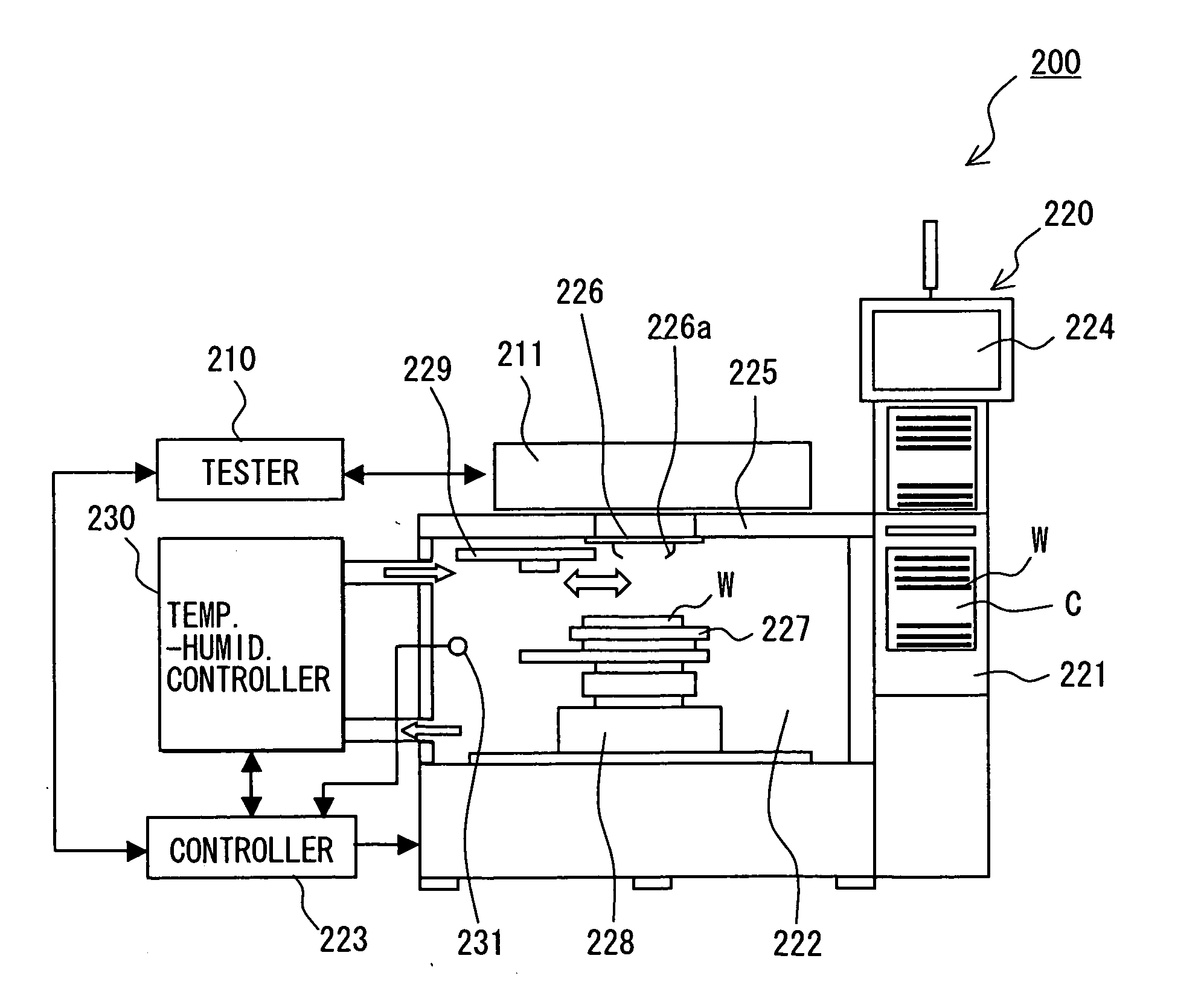

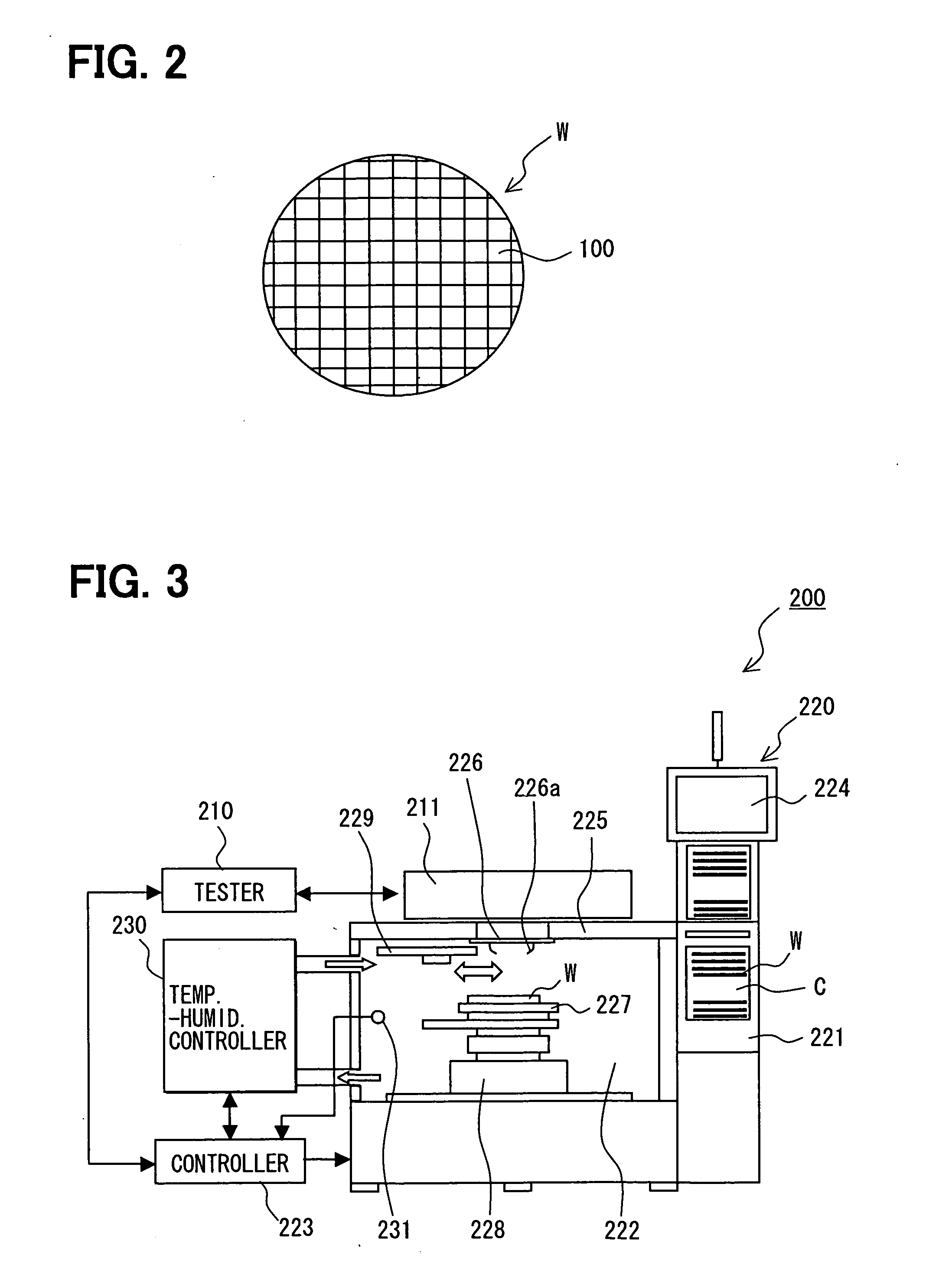

Inspection device for humidity sensor and method for adjusting sensor characteristics of humidity sensor

InactiveUS20070169535A1Reduce manufacturing costSensor characteristics of the humidity sensor are inspected effectivelyMaterial analysis by optical meansStructural/machines measurementEngineeringMoisture sensor

An inspection device inspects a humidity sensor having a sensor portion and a circuit portion, which are integrated into one chip. The inspection device includes: an inspection chamber for accommodating a wafer, in which a plurality of humidity sensors are disposed as a sensor chip in a wafer state; a probe for contacting an electrode pad of the circuit portion; a tester electrically connected to the probe for inspecting electric properties of the humidity sensor; and a temperature-humidity control portion for controlling a temperature and a humidity in the inspection chamber.

Owner:DENSO CORP +1

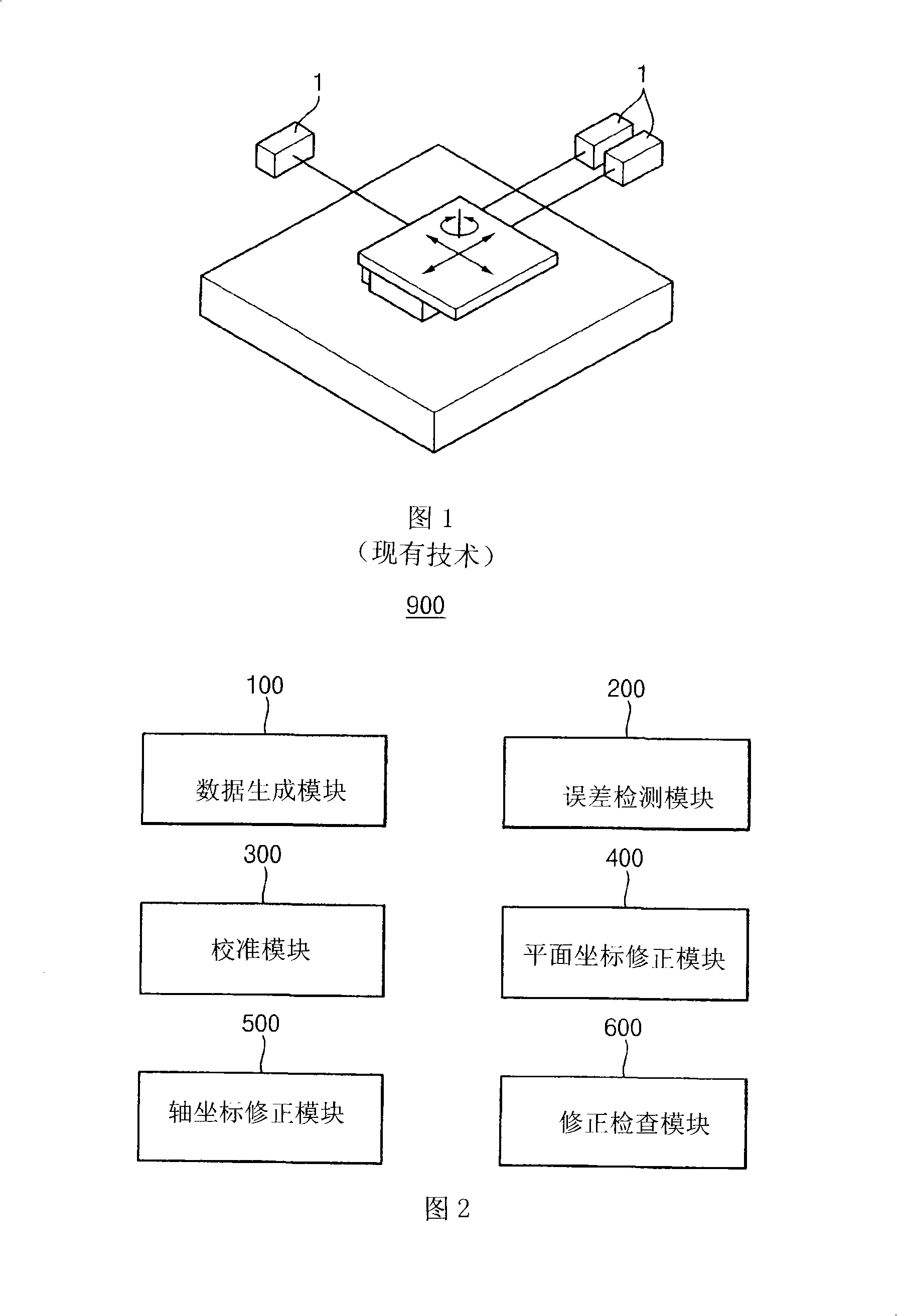

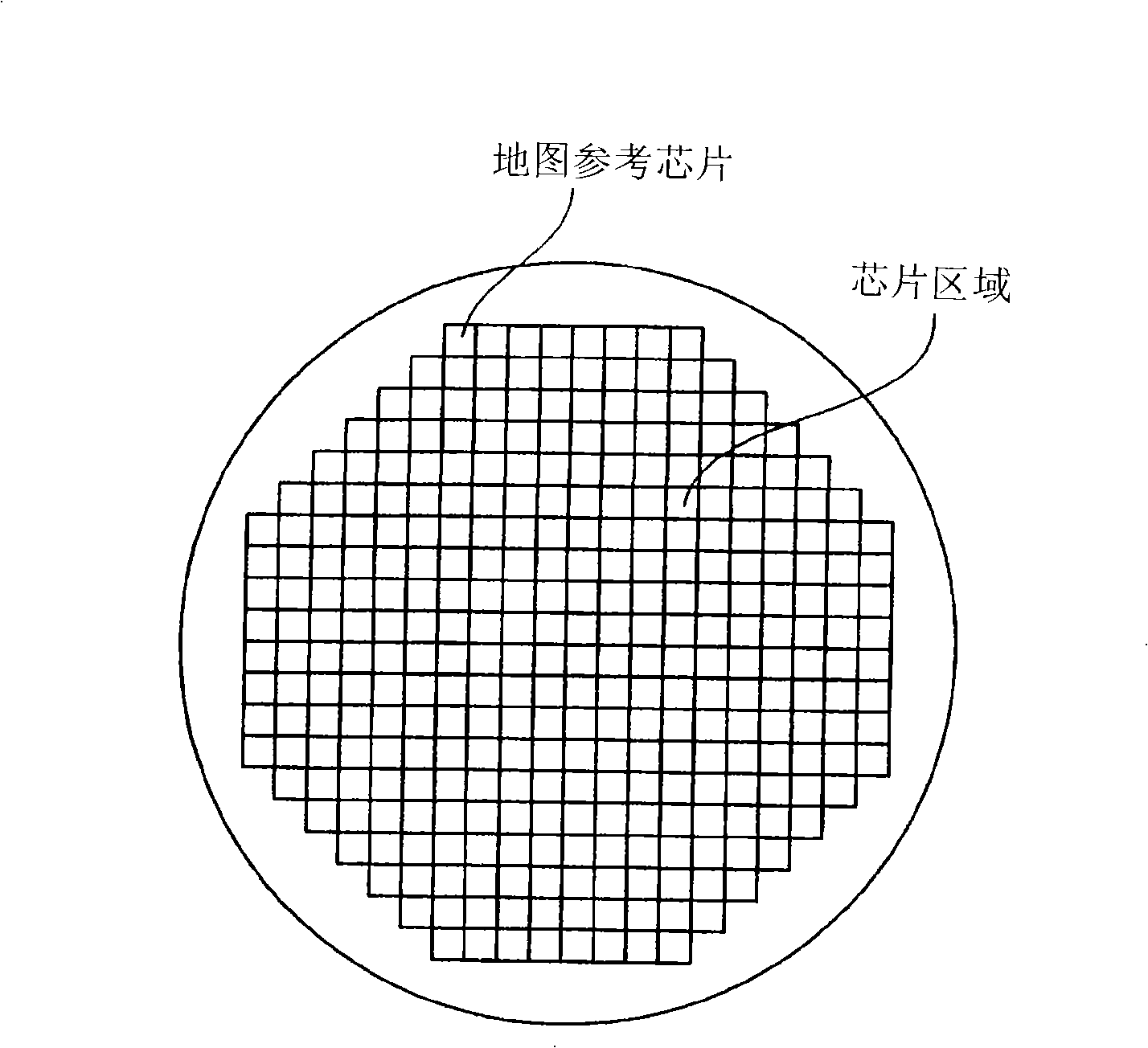

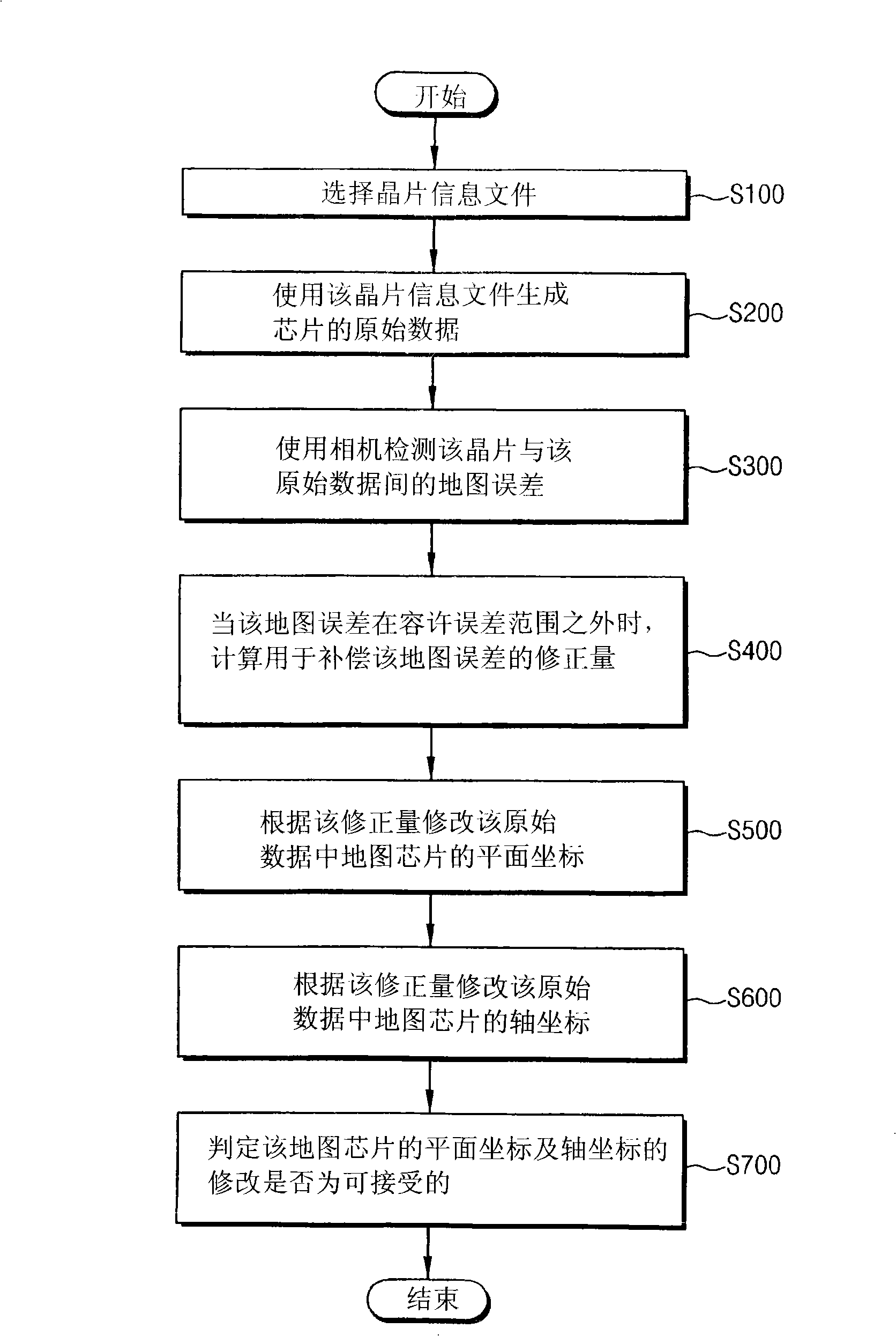

Device and method for generating probe tester map data

ActiveCN101311668ANo additional manual operation requiredImprove detection efficiencySemiconductor/solid-state device testing/measurementElectronic circuit testingOriginal dataComputer science

Provided is a device for generating map data of a probe tester and a method, comprising a data generating module, for generating original data of a wafer by using a wafer information file, wherein the file includes a plurality of characteristics of the wafer; an error detecting module, for detecting map error between a first coordinate of a chip and a second coordinate of the map chip in the original data corresponding to the chip on the wafer; a calibrating module, for computing correction, for compensating the map error between the first coordinate of the chip and the second coordinate of the map chip; and a coordinate correcting module, for correcting the coordinate of the map chip in the original data according to the correction. Therefore, no additional manual operation is required based on the original data related to the wafer to generate precise map data.

Owner:SEMES CO LTD

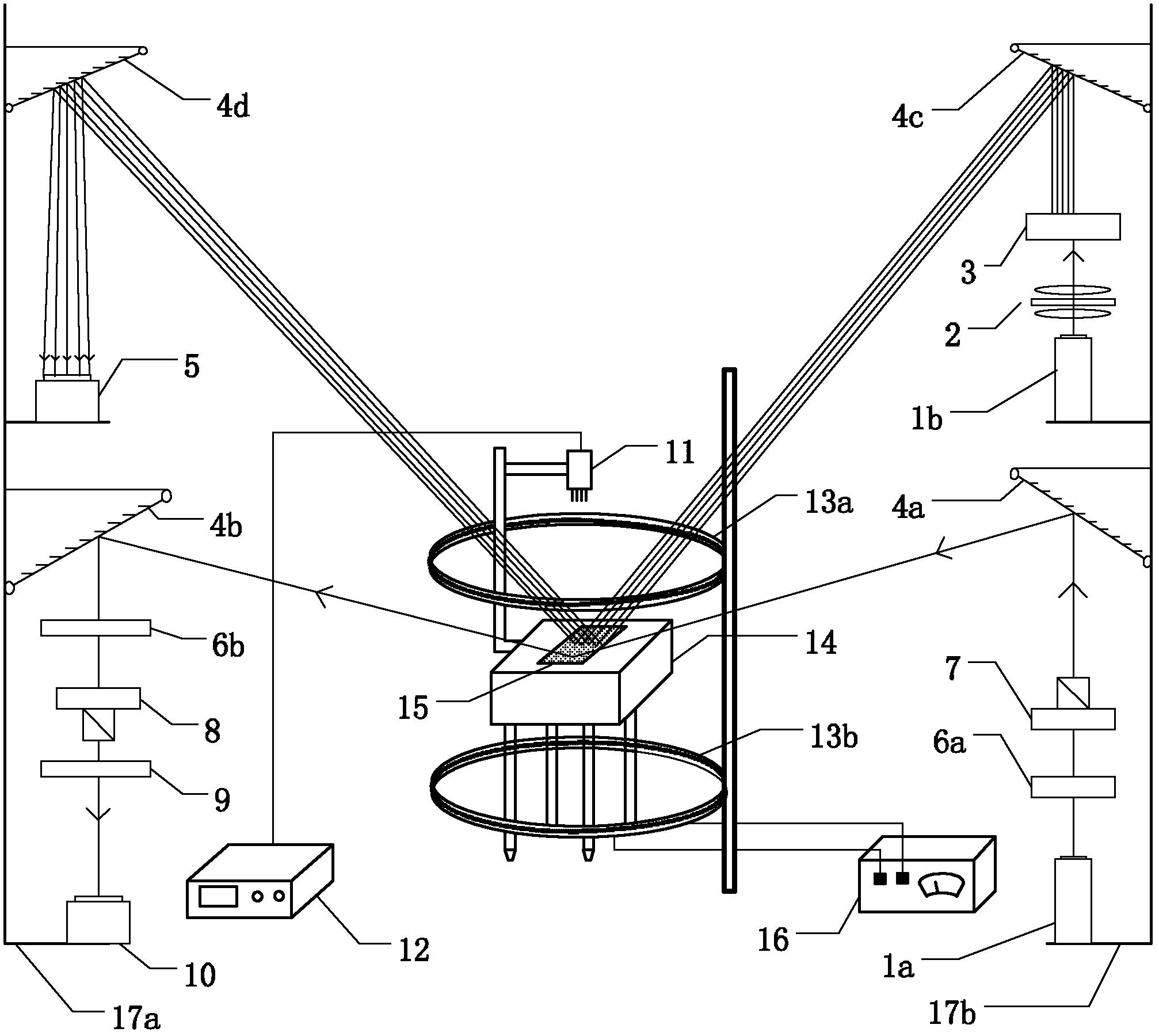

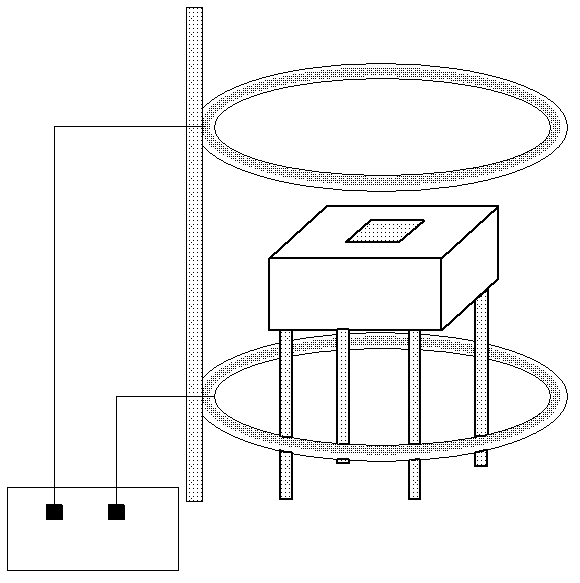

Device and method for detecting force electromagnetic coupling behavior of giant magneto resistive film

ActiveCN102508179ARealize online simultaneous measurementUniform magnetic fieldResistance/reactance/impedenceForce measurement by measuring optical property variationHysteresisFilm resistance

The invention discloses a device and a method for detecting the force electromagnetic coupling behavior of a giant magneto resistive film, and belongs to the technical field of engineering materials, structural deformation, mechanics experiment and electrical experiment. The device comprises a magnetic field generator, a giant magneto resistive film hysteresis loop measurement optical path, a film stress measurement optical path, and a film resistance probe tester. The giant magneto resistive film hysteresis loop measurement optical path comprises a laser, diaphragms, reflectors, a polarizer, an analyzer, a lens and a photoelectric detector; and the film stress measurement optical path comprises a laser, a spatial filter, a calibrator, reflectors, and a charge couple device (CCD) camera. A uniform magnetic field is provided by the magnetic field generator; the hysteresis loop is measured according to a magneto-optic Kerr effect; curvature of the surface of the film is measured by a multi-beam optical stress sensitivity technology; the stress of the film is obtained according to the relation expression of the curvature and the stress; the resistivity of a film material is measured by the film resistance probe tester; and coupling relational expressions of the resistance of the giant magneto resistive film and the magnetic induction density and stress of the film can be obtained finally.

Owner:TSINGHUA UNIV

Probe look ahead: testing parts not currently under a probehead

InactiveUS20050099862A1Reduce and eliminate needLow costSemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardRedistribution layer

A semiconductor substrate, probe card, and methods for stressing and testing dies on a semiconductor substrate are provided. The semiconductor substrate, typically a semiconductor wafer, comprises dies disposed thereon and a redistribution layer (RDL) for routing signals from a test circuit into dies on the substrate that are not currently under probe. The RDL includes look-ahead contacts associated with a first die set that are electrically connected by traces to dies of a second die set. Upon contact of elements of the probe tester with the look-ahead contacts, required Vcc power, GND ground potential and signals from the probe tester are routed through the traces to the die of the die set not currently under probe. The dies can comprise a built-in self-stress (BISS) circuit and / or a built-in self-test (BIST) circuit for implementing a stress or test sequence. The look-ahead contacts allow for overlapping or substantially simultaneously stressing and / or testing dies of dies of a die set currently under probe and dies of a second die set located prior to or after the current probe head position (i.e., not under probe).

Owner:MICRON TECH INC

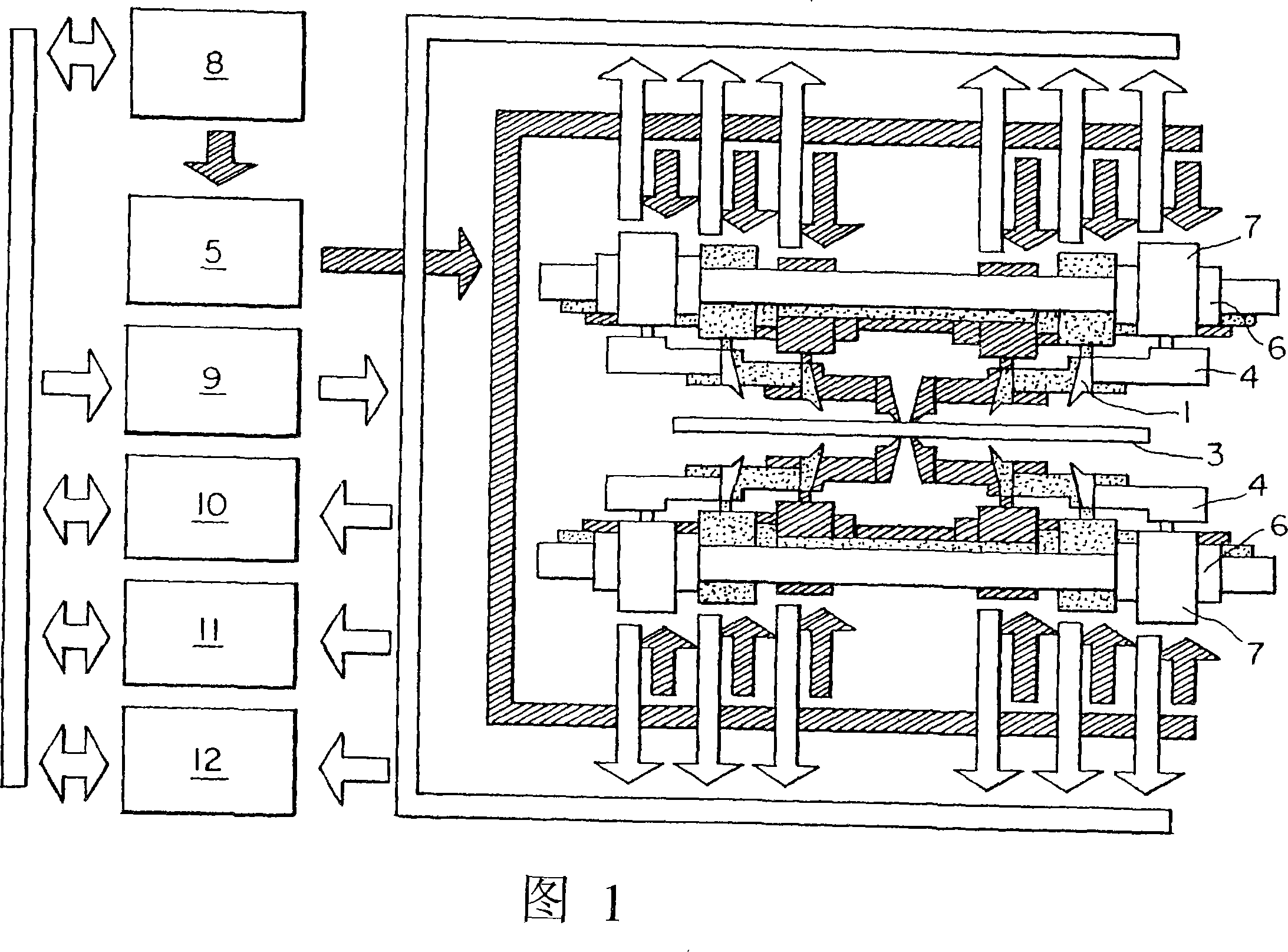

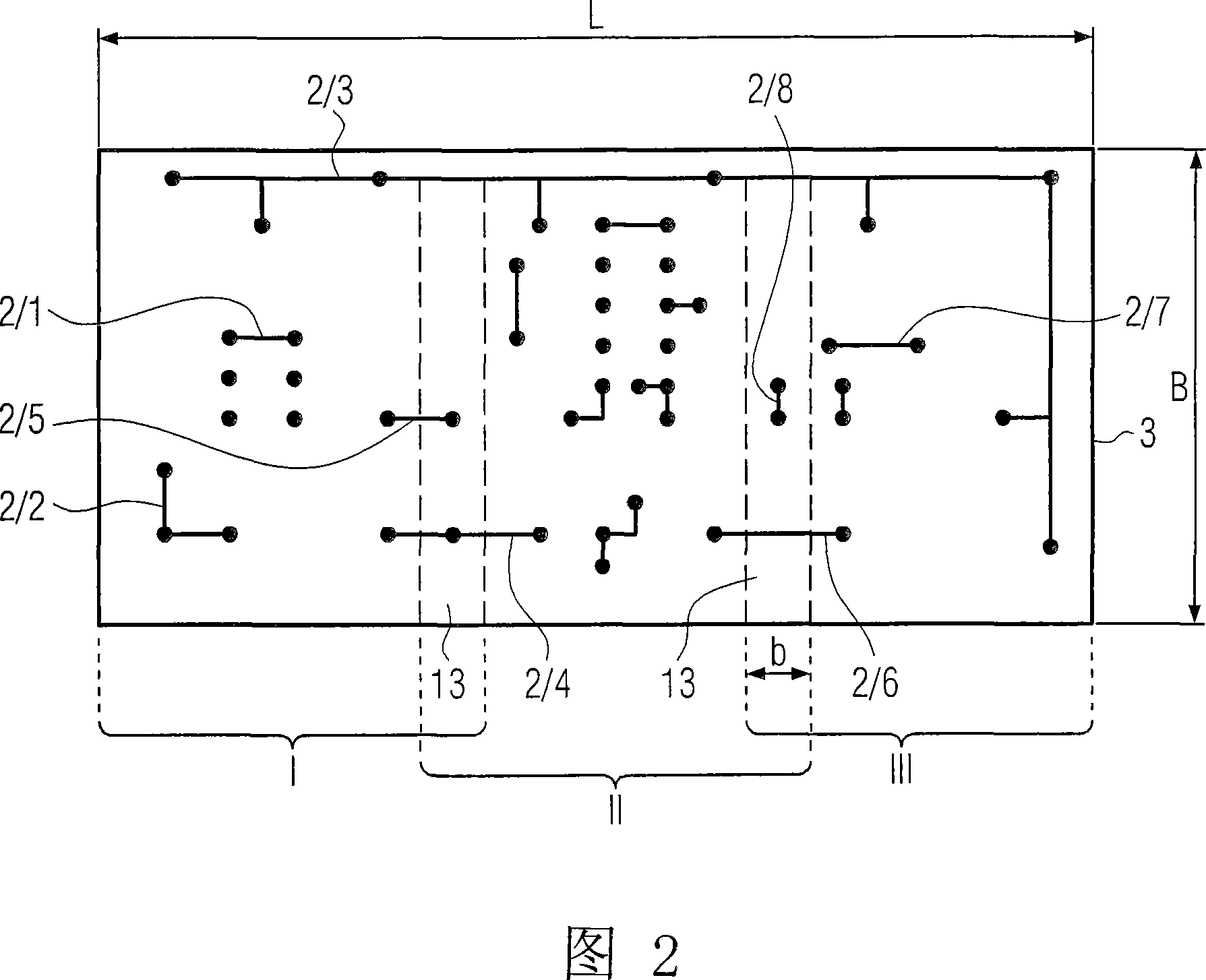

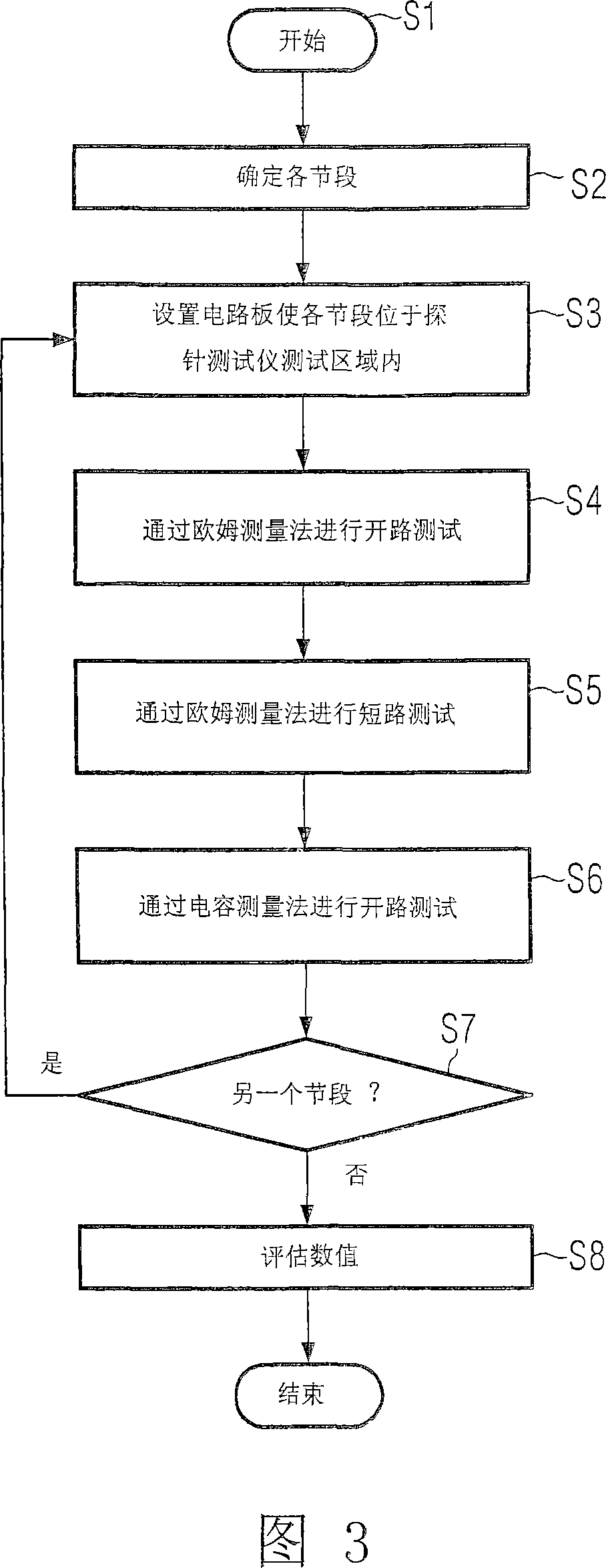

Method of testing unloaded, large-area printed circuit boards with a finger tester

InactiveCN101198879APrinted circuit testingContactless circuit testingElectrical conductorTester device

The invention relates to a method of testing unloaded, large-area printed circuit boards having conductor tracks with a finger tester. According to the method according to the invention, the printed circuit boards are tested when subdivided into a number of segments, conductor tracks that extend beyond one segment being tested by means of capacitive measurement of the end points located in the respective segment, an interruption of the conductor track being established if one measured value of the capacitive measured values belonging to one conductor track differs significantly from other measured values.

Owner:ATG LUTHER & MAELZER GMBH

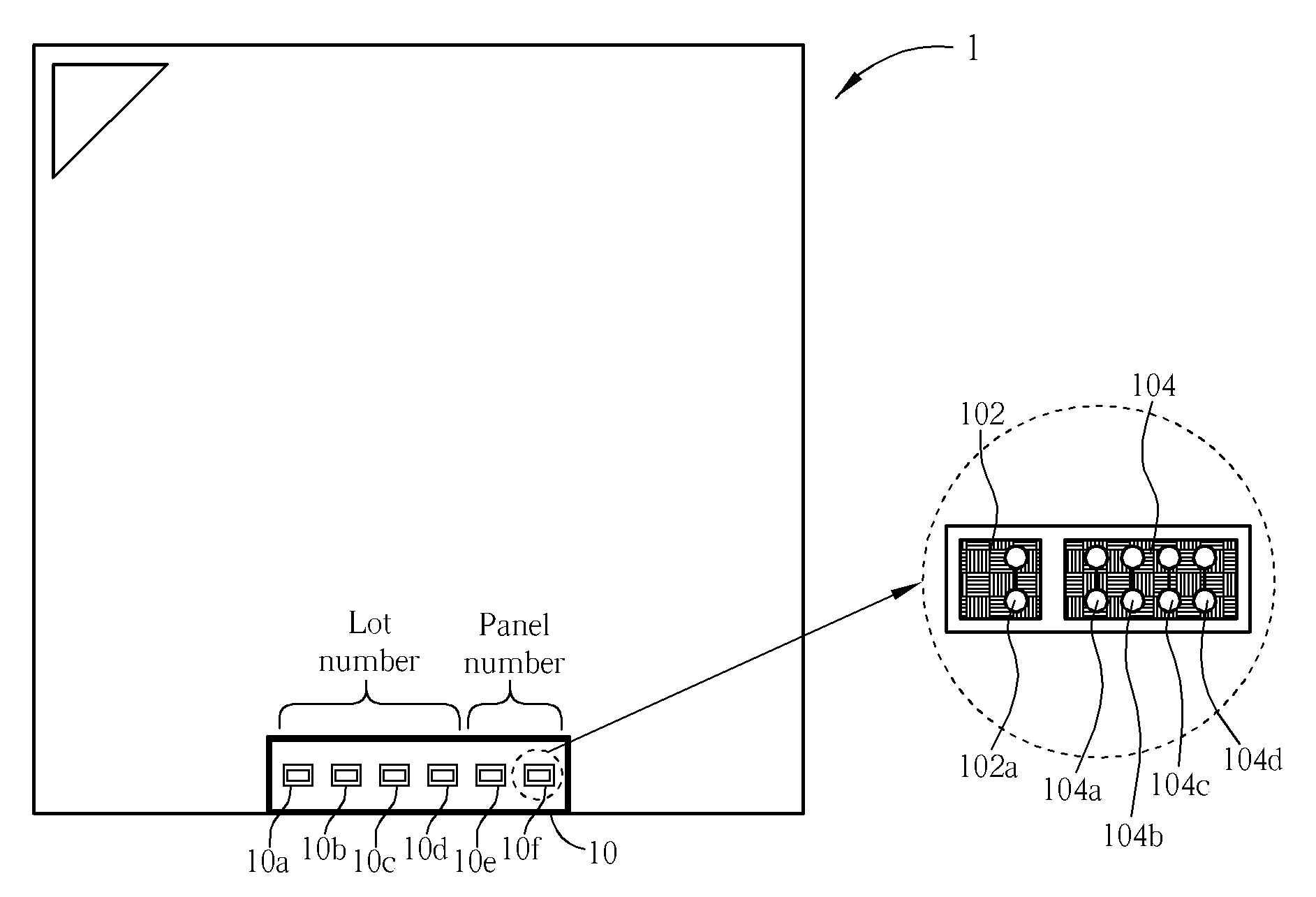

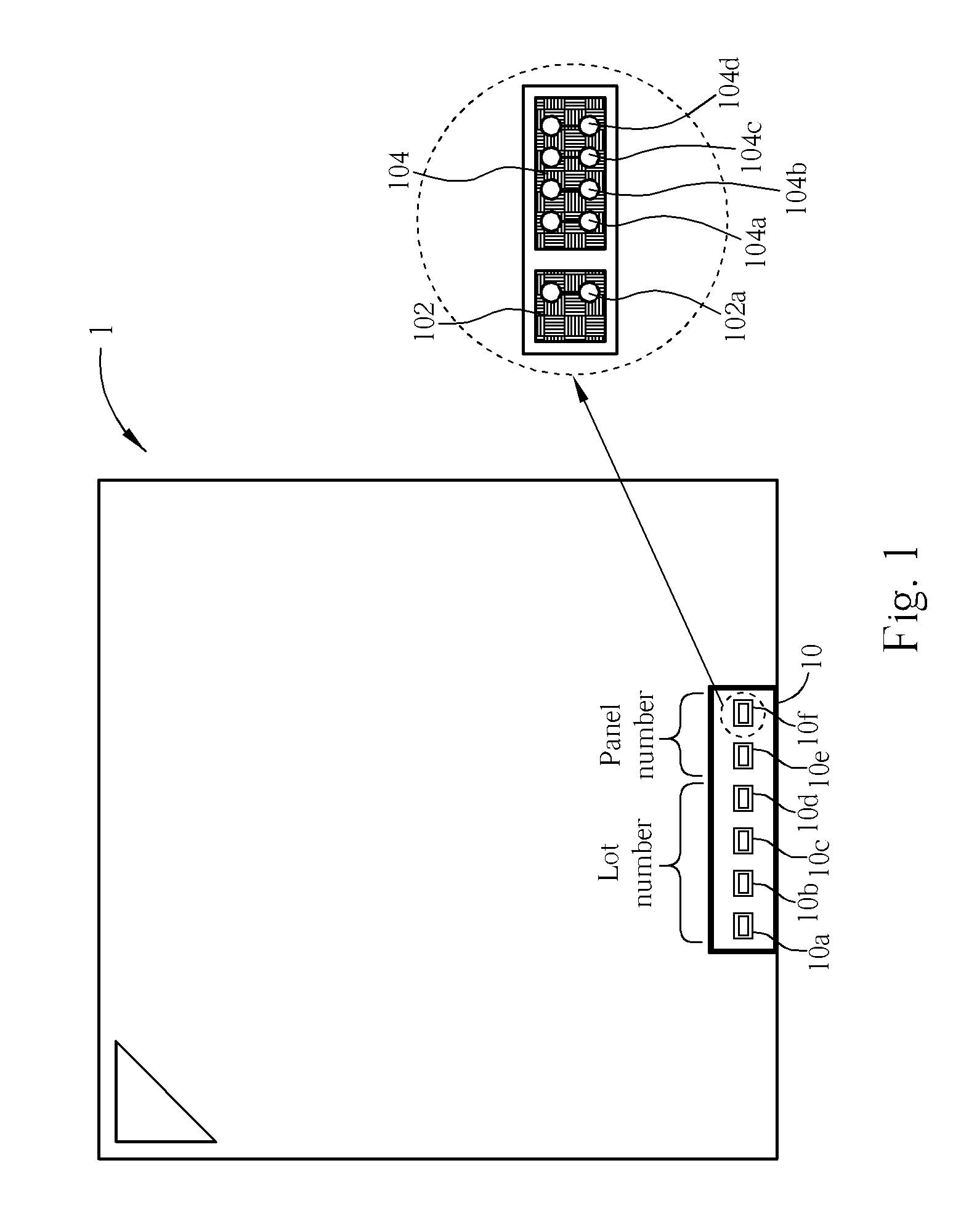

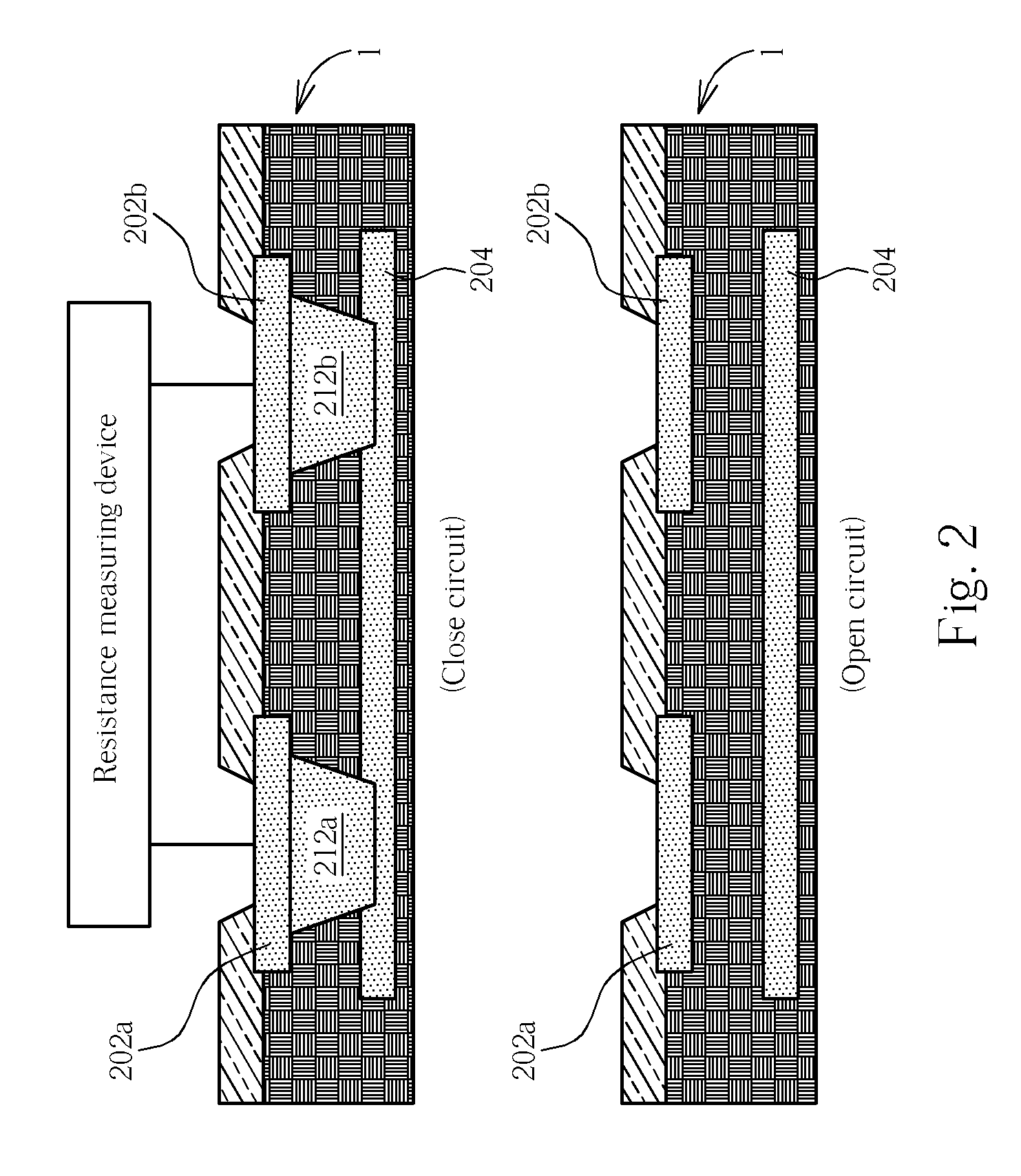

Lot traceable printed circuit board

ActiveUS20080149732A1Printed circuit aspectsInspection/indentification of circuitsElectrical resistance and conductanceTester device

A lot traceable printed circuit board (PCB) includes a substrate having thereon a patterned circuit layer and a working zone carrying production information related to the PCB itself. The working zone includes a plurality of code boxes, wherein each of the code boxes has a first probe region and second probe region. A single set of resistance test loop is disposed within the first probe region. Four sets of resistance test loops are disposed within the second probe region. A frying probe tester is used to probe the set of resistance test loops respectively for abstracting the production information recorded in the working zone.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

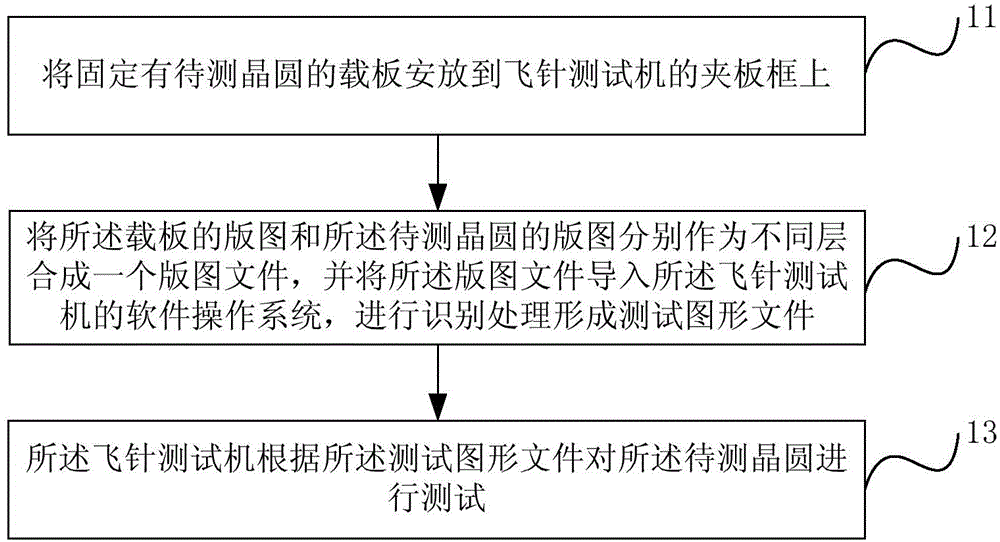

Wafer testing system and method

ActiveCN104459508AIncrease flexibilityImprove test efficiencyIndividual semiconductor device testingProbe cardEngineering

The invention discloses a wafer testing system and method. The system comprises a flying-probe tester and a carrier plate, the flying-probe tester is used for testing a wafer to be tested, the carrier plate is used for bearing the wafer to be tested on the flying-probe tester and providing an alignment mark corresponding to a clamping plate frame of the flying-probe tester and the domain of the carrier plate, the domain of the carrier plate and the domain of the wafer to be tested are matched to form a domain file to be tested, and after the domain file to be tested is led into a software operation system of the flying-probe tester, a testing figure file is formed. According to the wafer testing system and method, various pinboard wafers or wafers of passive integrated devices can be automatically tested through the flying-probe tester, an automatic probe table does not need to be bought for testing the wafer with different domains, corresponding expansive probe cards do not need to be customized according to the wafers to be tested with the different domains, the flexibility is improved, the cost is lowered, the period is shortened, and the industrialization process of the wafer pinboarrds such as TSV and TGV and an IPD technology is promoted.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

Inspection device for humidity sensor and method for adjusting sensor characteristics of humidity sensor

InactiveUS20060201232A1Reduce manufacturing costSensor characteristics of the humidity sensor are inspected effectivelyMaterial analysis by electric/magnetic meansMaterial analysis by optical meansEngineeringMoisture sensor

An inspection device inspects a humidity sensor having a sensor portion and a circuit portion, which are integrated into one chip. The inspection device includes: an inspection chamber for accommodating a wafer, in which a plurality of humidity sensors are disposed as a sensor chip in a wafer state; a probe for contacting an electrode pad of the circuit portion; a tester electrically connected to the probe for inspecting electric properties of the humidity sensor; and a temperature-humidity control portion for controlling a temperature and a humidity in the inspection chamber.

Owner:DENSO CORP +1

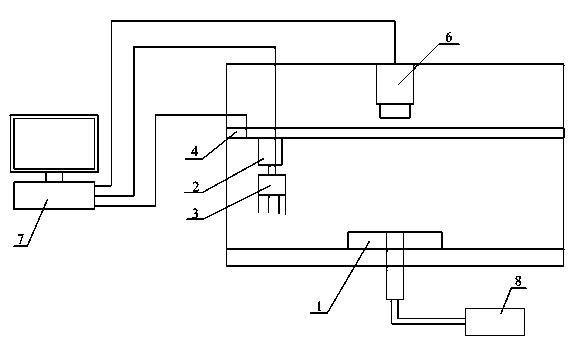

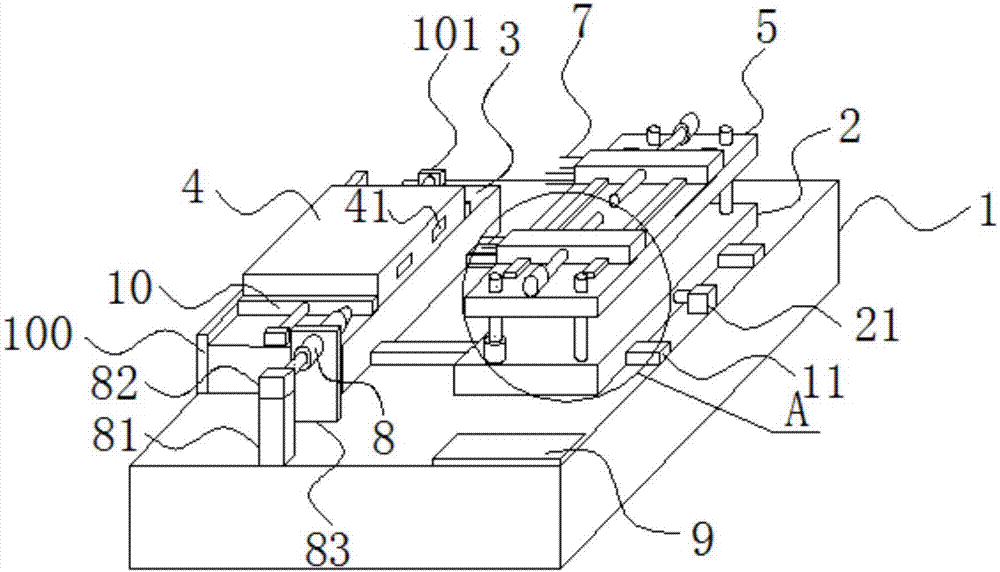

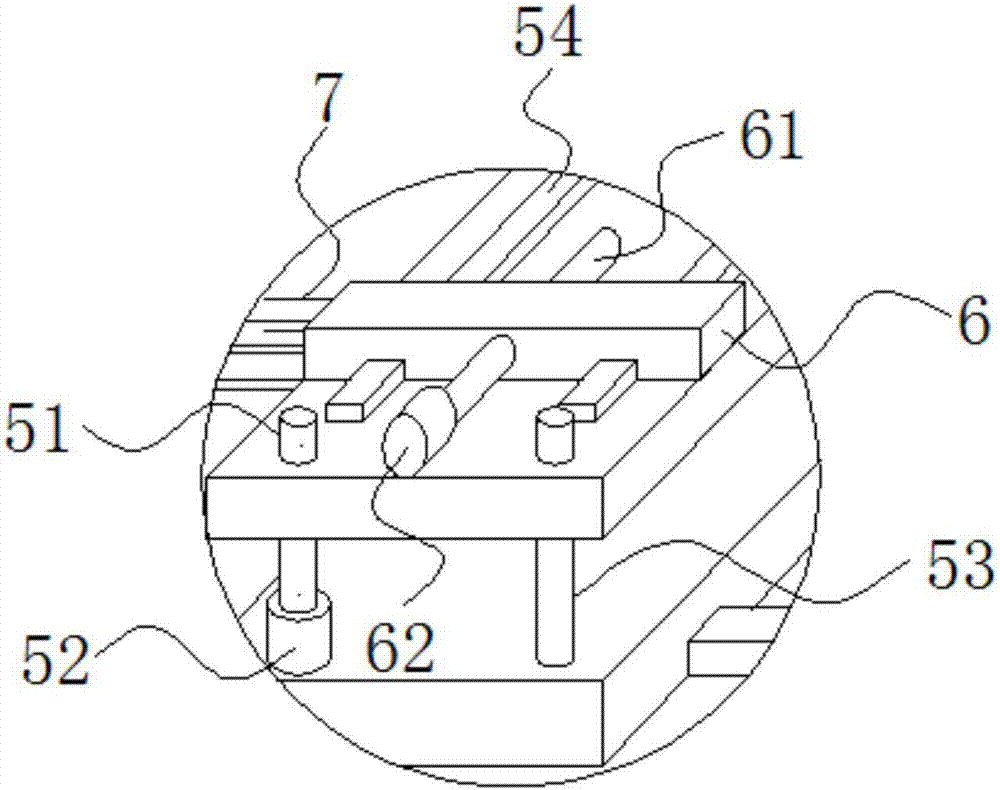

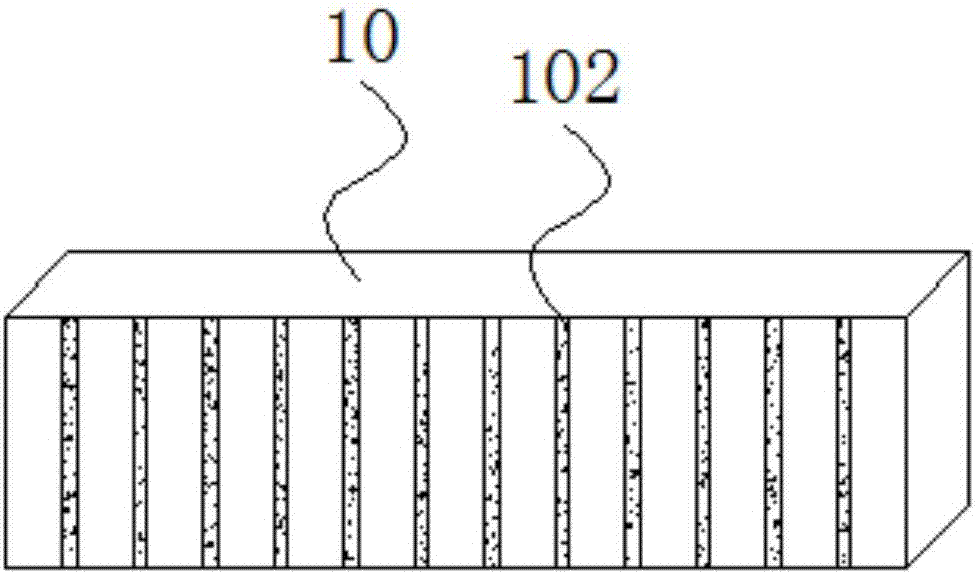

Multifunctional automatic four-point probe tester

InactiveCN103472303APrevent movementImplement the fragmentation functionResistance/reactance/impedenceElectrical measurement instrument detailsControl signalTester device

A multifunctional automatic four-point probe tester comprises a vacuum suction sheet bearing table, a four-point probe assembly, a three-shaft driving mechanism, a camera and a main control computer. The four-point probe assembly is arranged on the three-shaft driving mechanism. The shooting direction of the camera right faces the vacuum suction sheet bearing table. The signal output end of the camera and the signal output end of the four-point probe assembly are connected with the signal input end of the main control computer. The control signal input end of the three-shaft driving mechanism is connected with the control signal output end of the main control computer. The suction sheet bearing table of the multifunctional automatic four-point probe tester can be used for fixing broken silicon wafer samples, so that the tester is made to have the function of fixing samples and prevent samples form moving in the testing process. The camera is used for shooting the position and the shape of a silicon wafer, and images can be used for locating, so that the fragment processing function of the equipment is achieved. A four-point probe three-dimensional driving mechanism is controlled to enable a four-point probe to move and be located in the suction piece bearing table. Moreover, the driving mechanism is downward pressed through a Z-axis to enable the probe to be automatically pressed downward to realize automatic measuring.

Owner:NANTONG UNIVERSITY

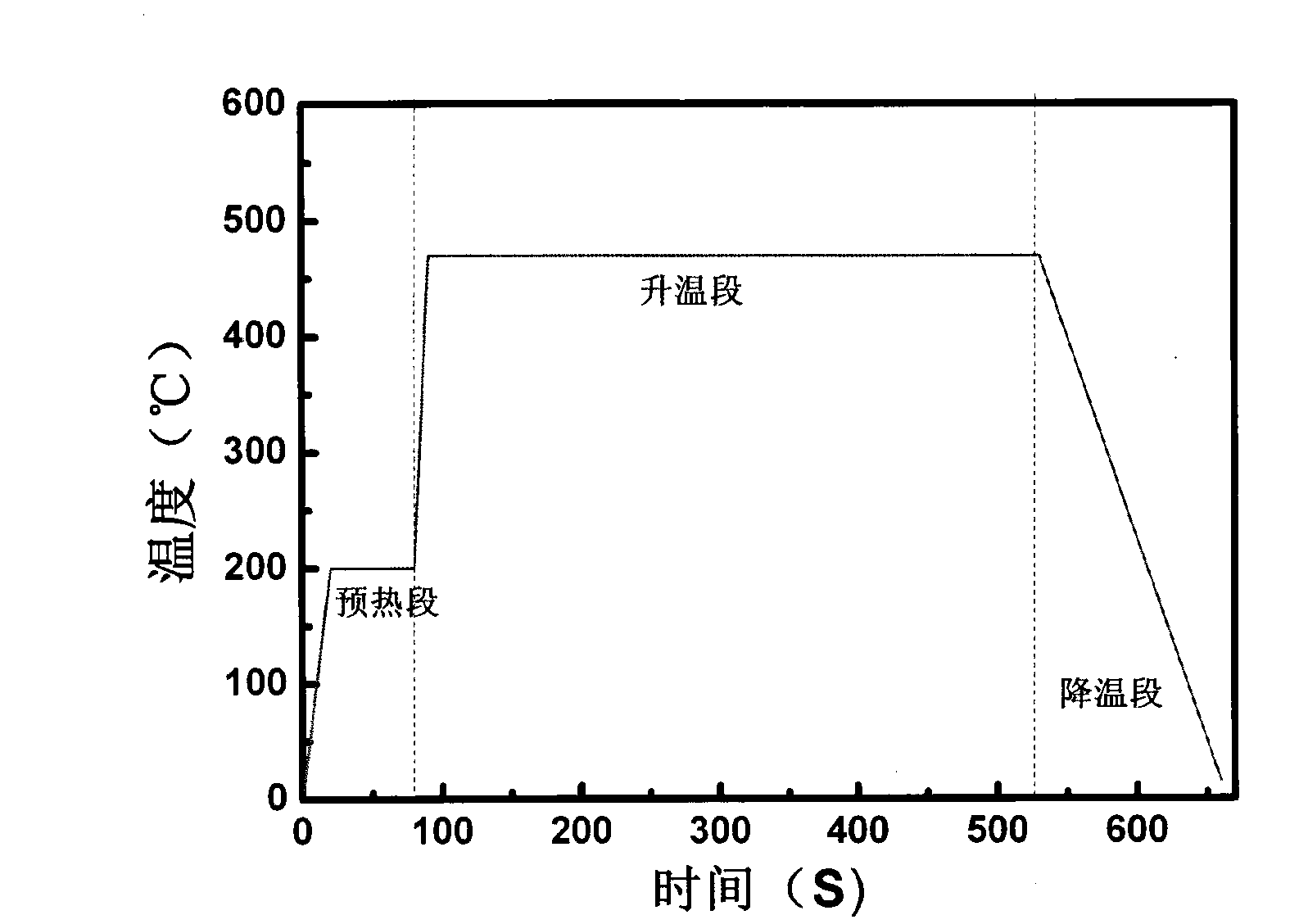

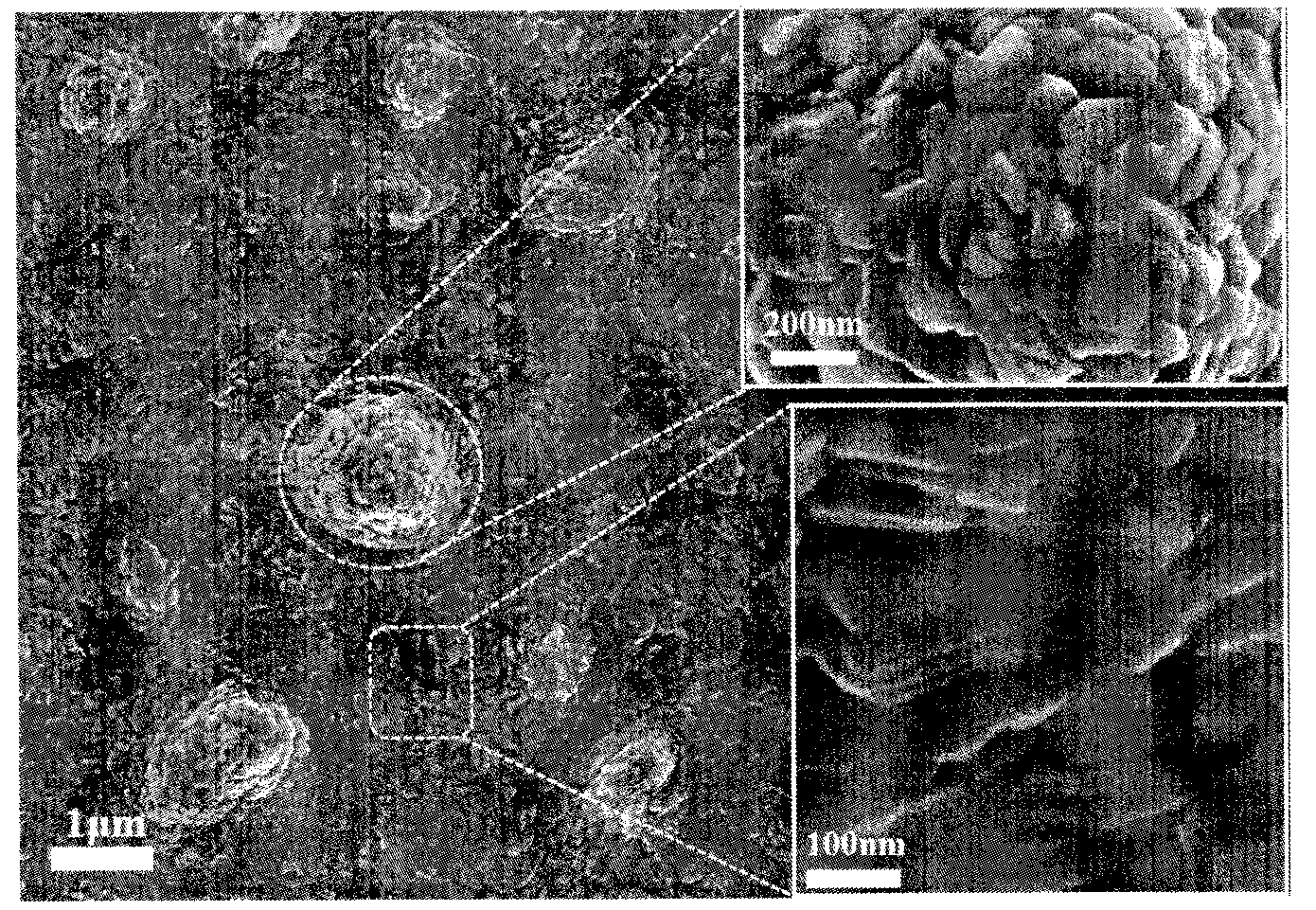

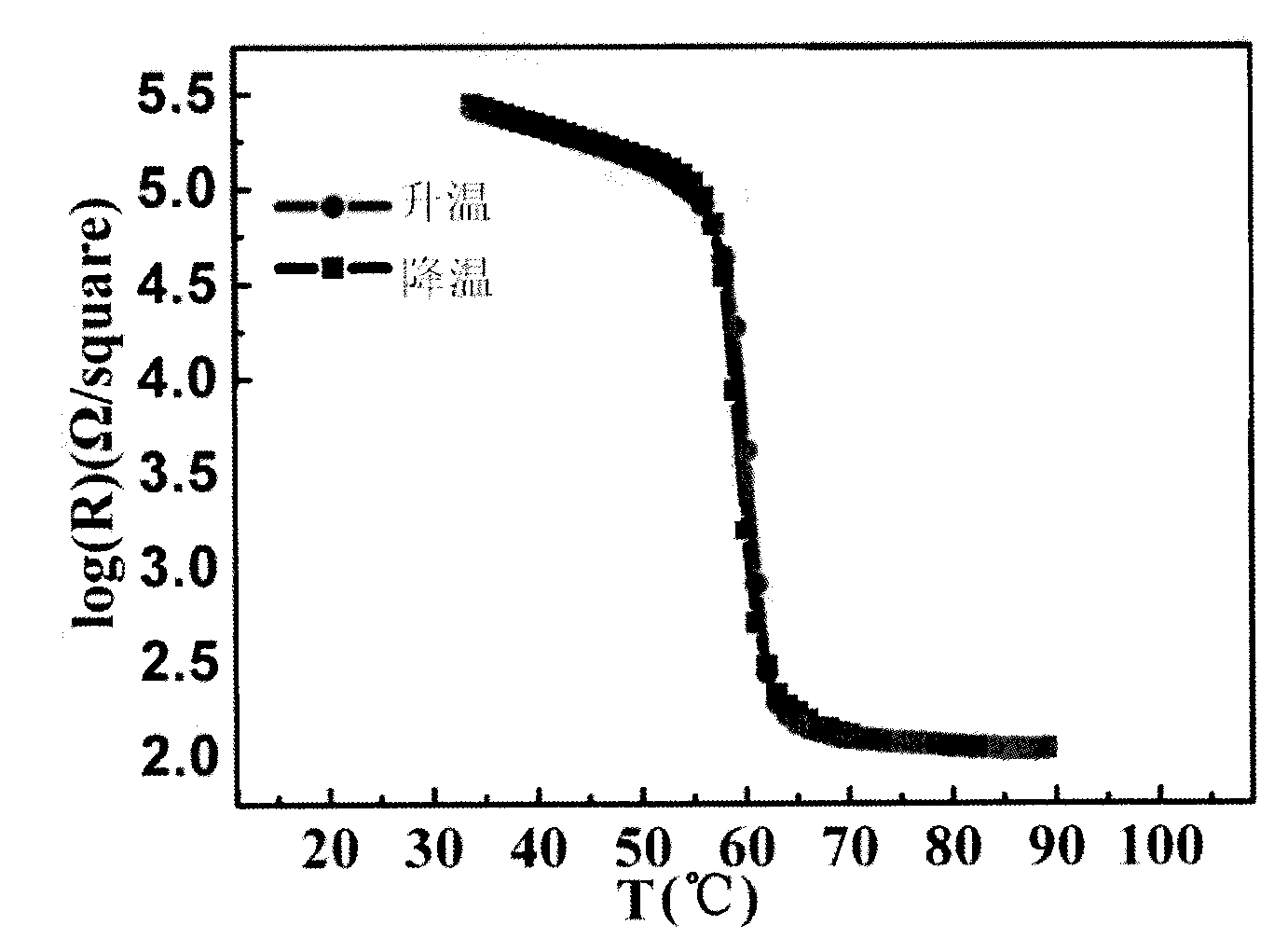

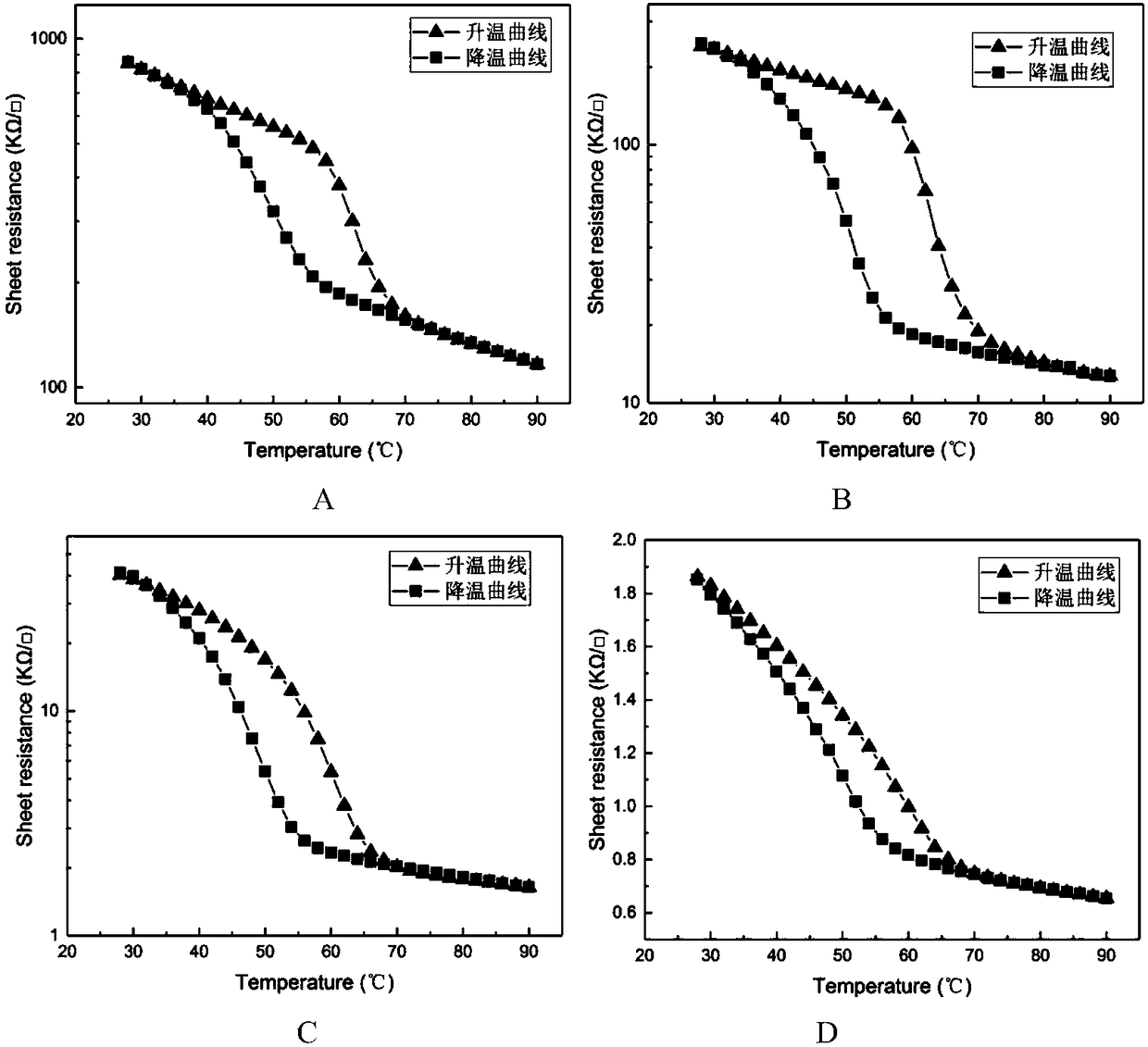

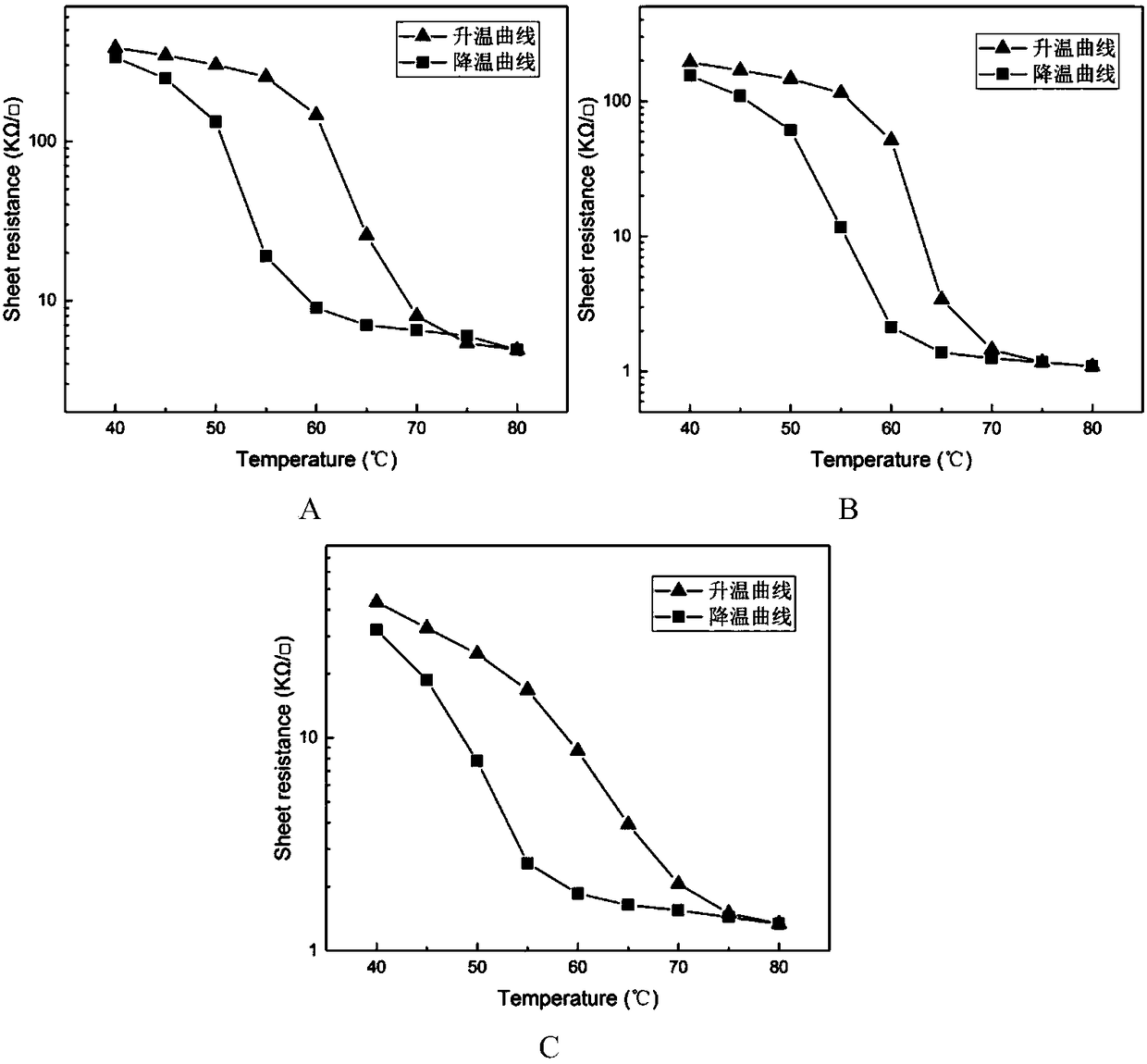

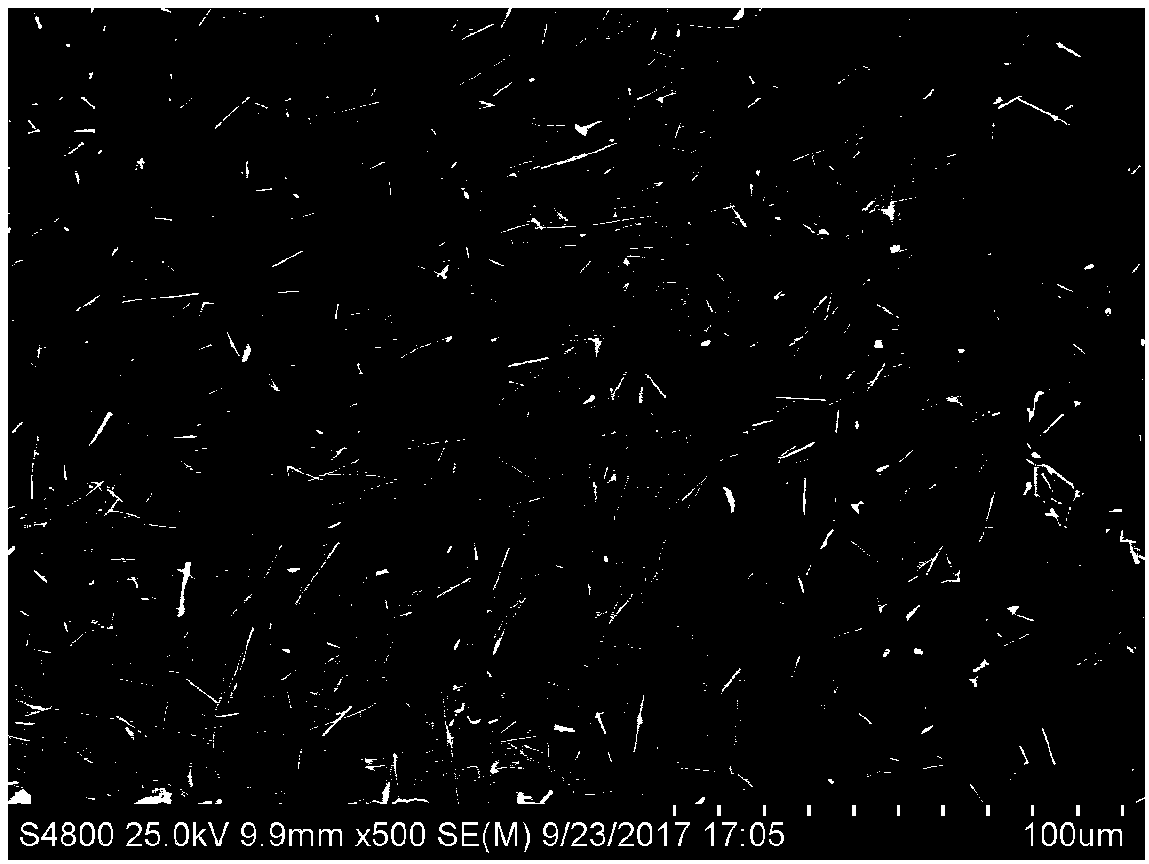

Preparation method of vanadium dioxide thin film of extremely narrow hysteretic curve width and high temperature coefficient of resistance

InactiveCN102703873ASimple manufacturing methodGood repeatabilityVacuum evaporation coatingSputtering coatingVanadium dioxideElectrical resistance and conductance

The invention provides a preparation method of a vanadium dioxide (VO2) thin film of extremely narrow hysteretic curve width and high temperature coefficient of resistance (TCR). The preparation method is characterized by comprising the following two steps of: 1, performing direct current sputtering on an Al2O3 substrate by using a metal vanadium target of a magnetron sputtering coating instrument to prepare a metal vanadium thin film; and 2, placing the metal vanadium film in a quick annealing furnace to perform oxidation treatment, then taking the oxidized metal vanadium thin film out and placing in air to naturally cool to obtain a polycrystalline VO2 thin film. The preparation method of the VO2 thin film of extremely narrow hysteretic curve width and high temperature coefficient of resistance provided by the invention is simple and practical and has high repeatability; and the analysis of a scanning electron microscope and a four-probe tester shows that the prepared VO2 thin film has a nano flaky structure, the hysteretic curve width is only about 0.4 DEG C, almost overlapping is realized and the thin film has extremely high TCR.

Owner:DONGHUA UNIV

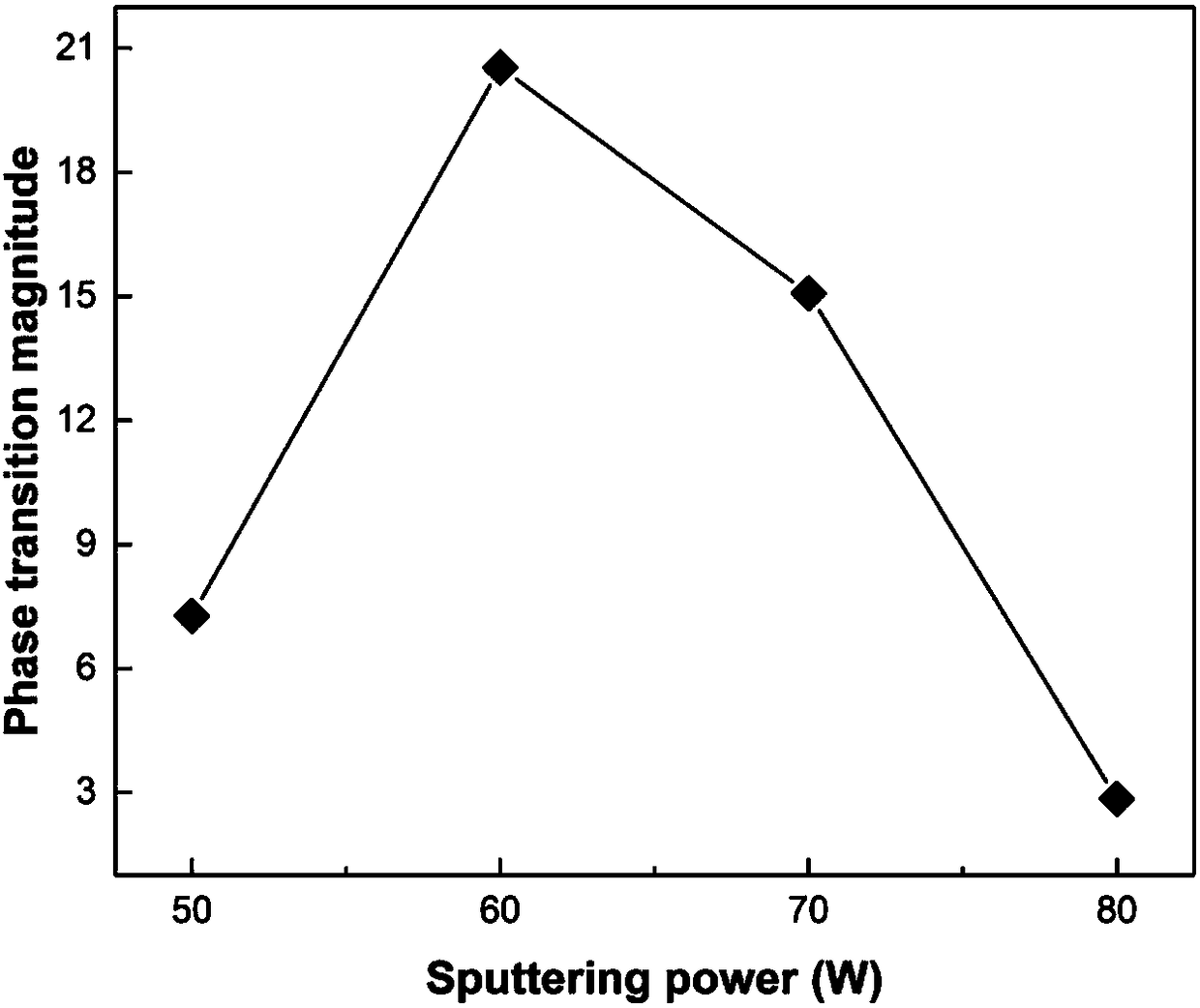

Method for improving vanadium dioxide phase change amplitude by regulating sputtering power

InactiveCN108179394AEasy to prepare stablyEasy to controlVacuum evaporation coatingSputtering coatingVanadium dioxideSputtering

Owner:TIANJIN UNIV

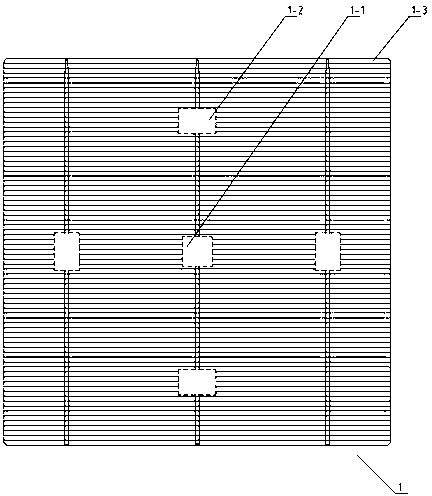

Method for testing sheet resistance in preparation process of selective transmission electrode battery

ActiveCN103235185AAvoid errorsAvoid false positivesResistance/reactance/impedenceScreen printingGrating

The invention discloses a method for testing a sheet resistance in a preparation process of a selective transmission electrode battery. The method comprises the following steps of 1, designing a grid pattern; 2, producing a monitor plate substrate; 3, coating photoresist on the monitor plate substrate, and masking a positioning hole and four probe positioning holes by utilizing the photoresist in identical thickness; 4, producing a monitoring screen printing plate; 5, adopting the monitoring screen printing plate to print a monitor plate according to a battery piece production process; 6, etching and washing a non-mask area of the monitor plate; 7, adopting a four-probe tester, inserting four probes into the corresponding probe positioning holes, and testing the sheet resistance of the non-mask area of the monitor plate; 8, adjusting the washing parameter of the selective transmission electrode battery according to the tested sheet resistance result, and repeating the washing step in step 6 and the step 7 until the sheet resistance value of the monitor plate is standard, thereby determining the washing parameters of the selective transmission electrode battery. Due to the adoption of the method, the test error phenomenon caused by pressing a grid line part in the test process can be avoided, the test process is fast and convenient, the test flow is simplified, and the test time is saved.

Owner:盐城天合国能光伏科技有限公司

Fabrication Method of Semiconductor Integrated Circuit Device

InactiveUS20070231936A1Reduce manufacturing costIncrease the number ofSemiconductor/solid-state device testing/measurementElectronic circuit testingForeign matterProbe card

To prevent breakage of a membrane probe during a probe test using a probe card having the membrane probe, appearance of a main surface of a wafer as a test object is tested by an appearance tester 51, and results of bad appearance such as adhesion of a foreign substance to the main surface of the wafer and abnormality in shape of bump electrodes over the main surface of the wafer are collected as wafer map data according to arrangement of respective chips in a plane of the wafer, then the wafer map data are transmitted to a probe tester 53 via a server 52, and the probe tester 53 omits the probe test for chips in which bad appearance was detected, and concurrently performs the probe test to other chips in which bad appearance was not detected, based on the wafer map data.

Owner:RENESAS ELECTRONICS CORP

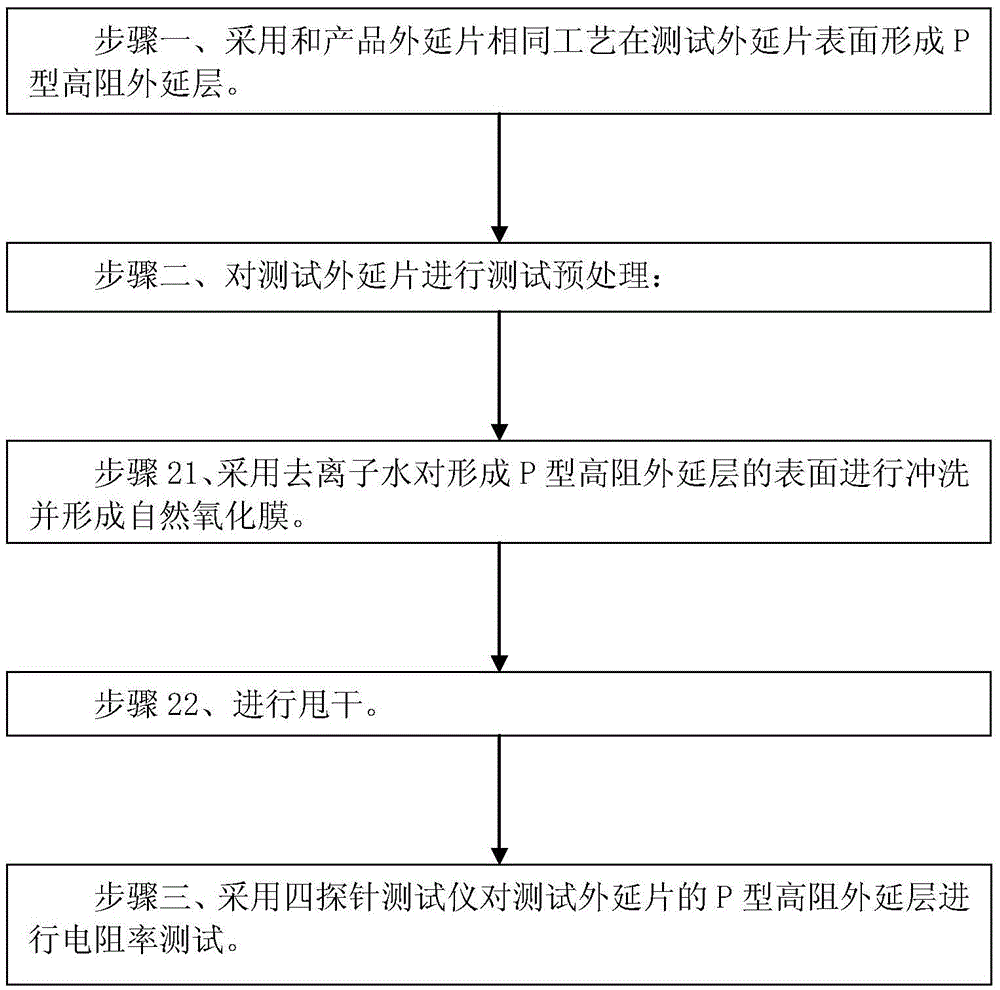

Resistivity monitoring method used in P type epitaxial wafer production

ActiveCN105552003AImprove test efficiencyEliminate distractionsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest efficiencyIon

The invention discloses a resistivity monitoring method used in a P type epitaxial wafer production. The resistivity monitoring method comprises the following steps of step 1, forming a P type epitaxial layer on the surface of a test epitaxial wafer by adopting a same process as the product epitaxial wafer; step 2, performing test preprocessing on the test epitaxial wafer: step 21, washing the surface of the formed P type epitaxial layer by deionized water and forming a natural oxide film; step 22, performing spin-drying; and step 3, performing resistivity test for the P type epitaxial layer of the test epitaxial wafer by a four-point probe. According to the resistivity monitoring method, test error can be lowered, the test efficiency for resistivity can be improved, and the test cost can be lowered; and meanwhile, the production efficiency of products can be relatively improved, and the production cost can be relatively lowered.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

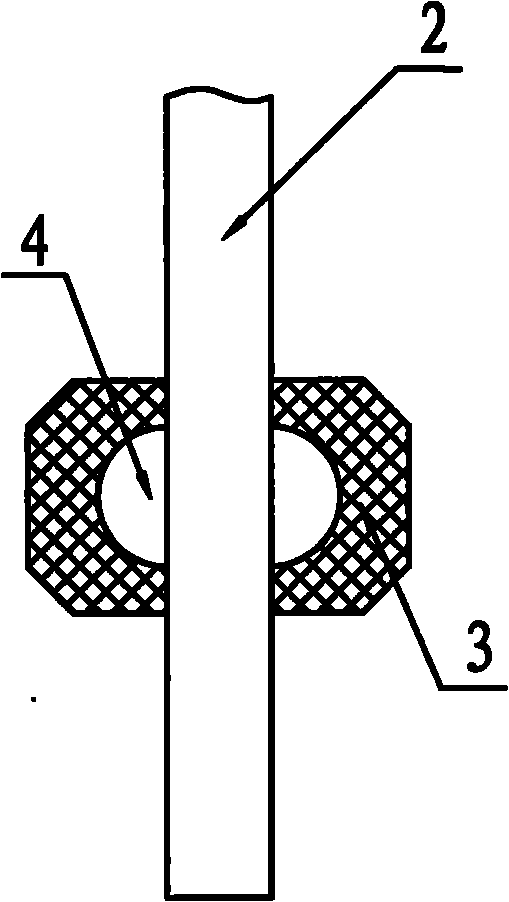

Probe positioning structure of four-probe instrument

ActiveCN101968497AHigh strengthPrecise Control of IntensityResistance/reactance/impedenceElectrical testingUltimate tensile strengthBiomedical engineering

The invention discloses a probe positioning structure of a four-probe instrument, which comprises an insulated probing head and four probes, wherein each probe is fixedly sleeved an elastic insulated spacer ring the inner diameter of which is matched with the diameter of the probe, the sum of wall thicknesses of the elastic insulated spacer rings sleeved on two adjacent probes is equal to the value obtained by subtracting the diameter of one probe from the center distance between the two adjacent probes; and four elastic insulated spacer rings are arranged at the same height on the probes, the distance from the elastic insulated spacer ring to the lower end of the metal probe accounts for 1 / 4 to 1 / 2 of the total length of the probe; simple technology, high spacer ring precision and low cost can be achieved in case that the probe spacer rings are made of tetrafluoro elastic insulated material, and each probe is sleeved with the tetrafluoro elastic insulated ring, thereby not only separating the four probes from each other quite stably and increasing the strength of the probes, but also precisely controlling the mechanical shift of the probes to further guarantee the electric insulating property between the probes as well as the constant pressure elasticity and excellent electric contact of the probes.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Probe look ahead: testing parts not currently under a probehead

InactiveUS7122829B2Reduce and eliminate needImprove life expectancySemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardRedistribution layer

Owner:MICRON TECH INC

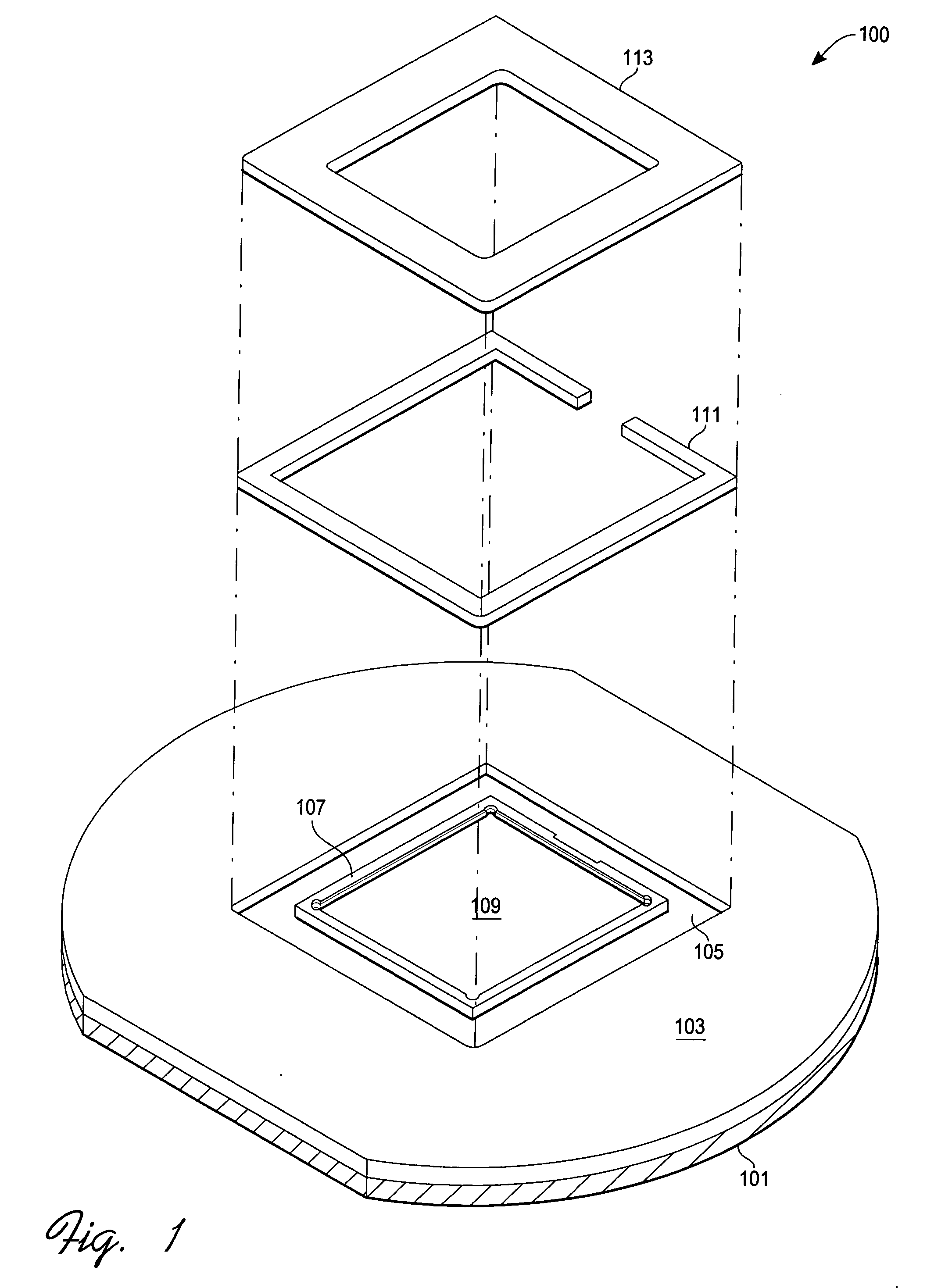

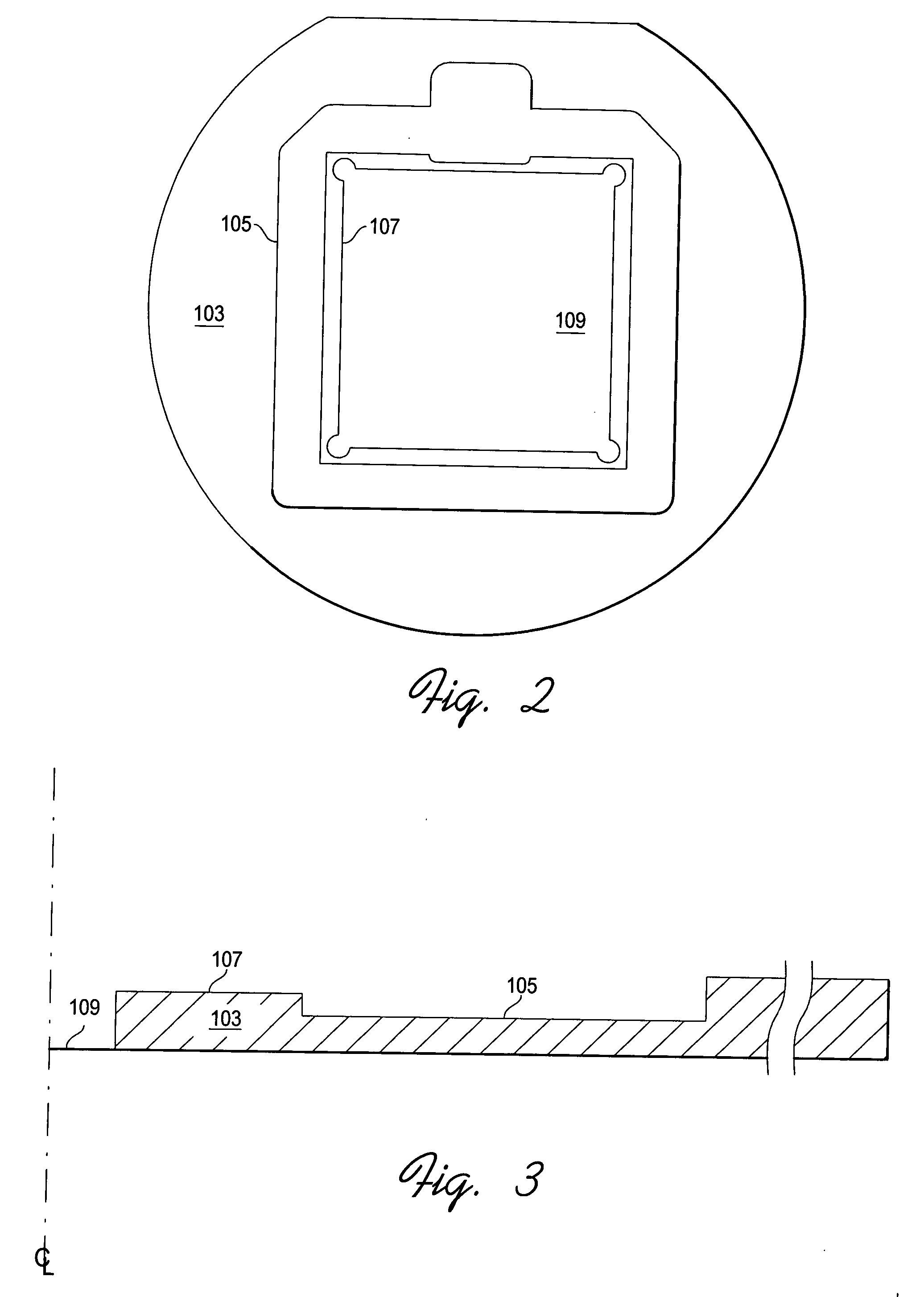

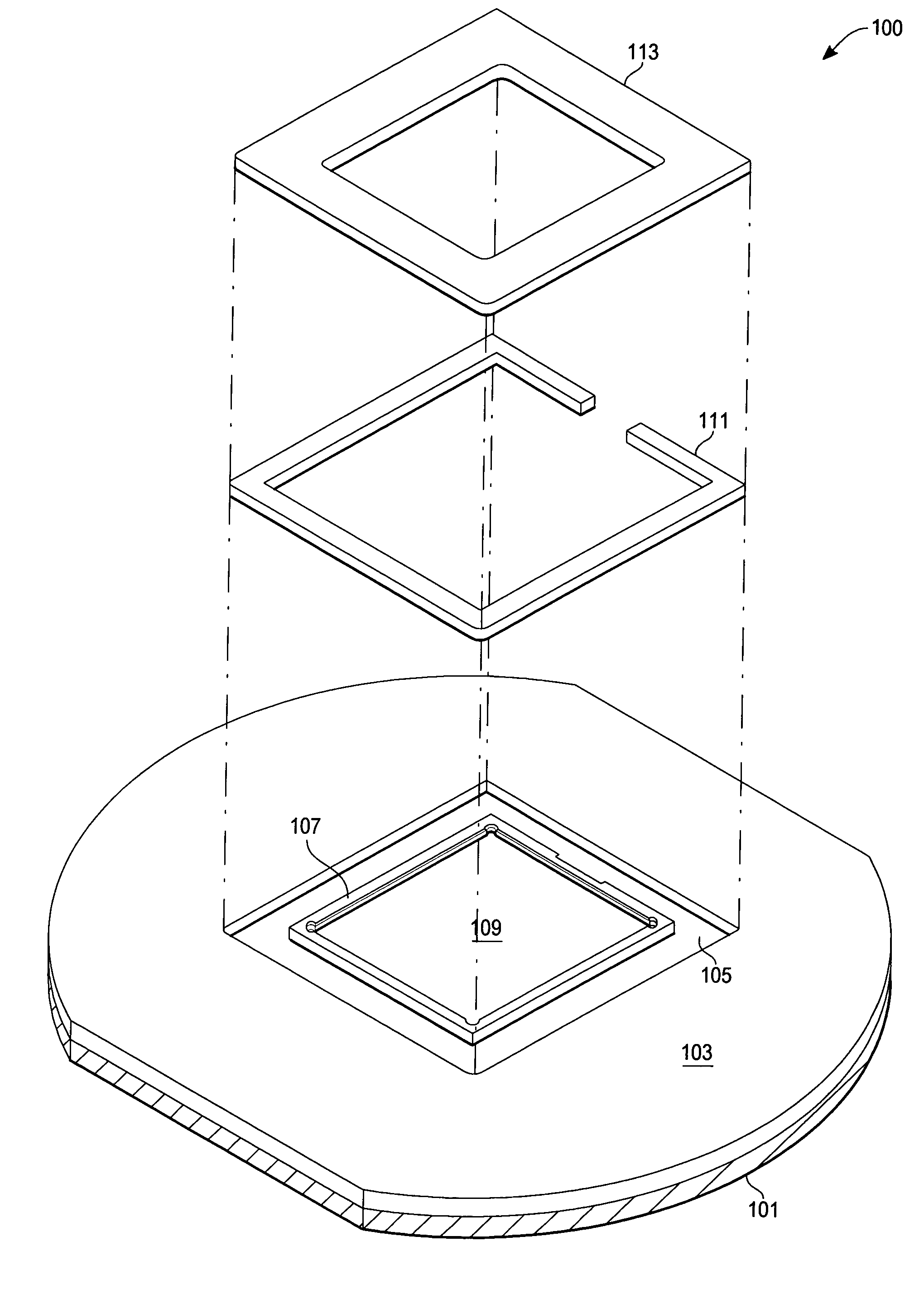

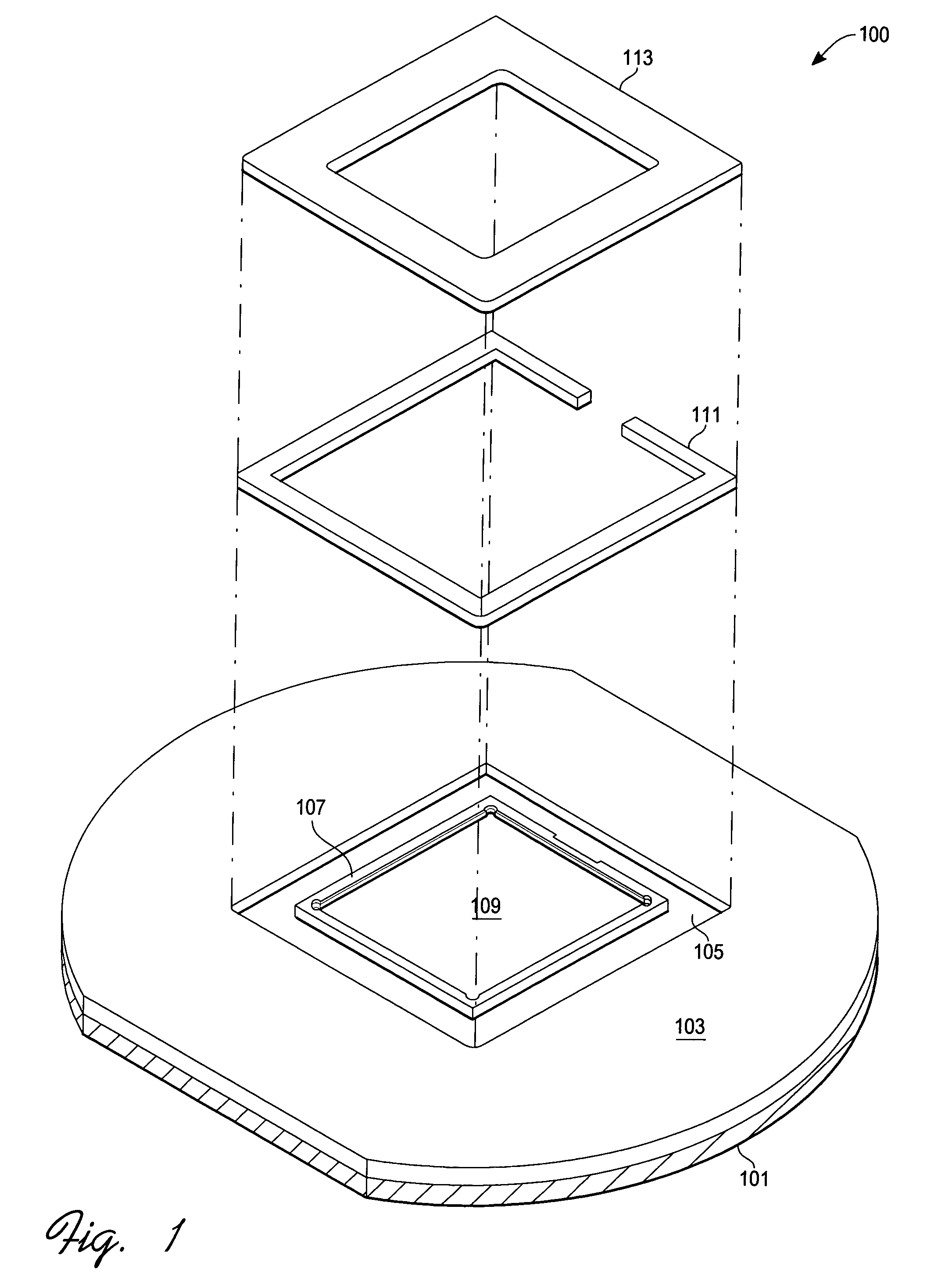

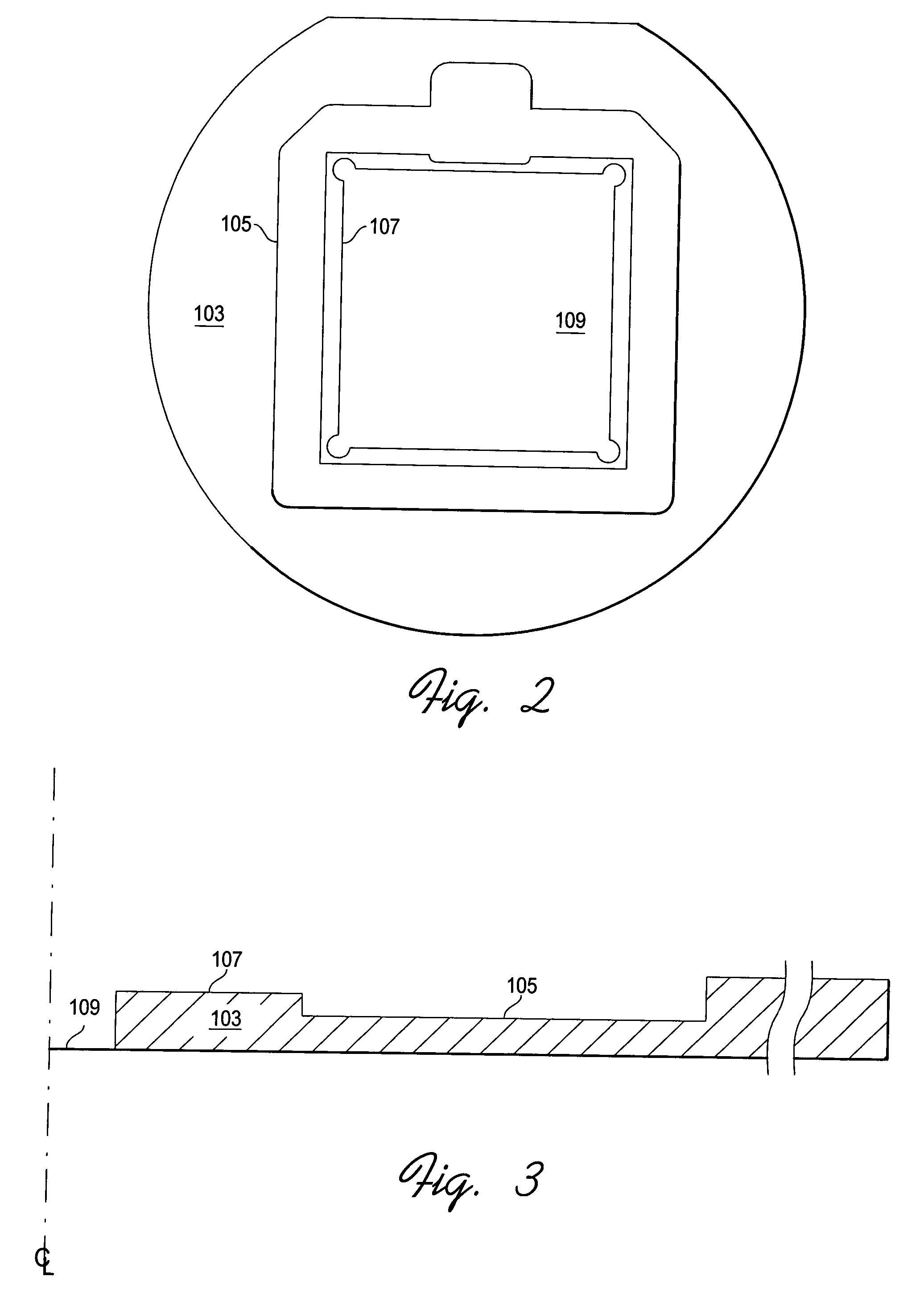

Low profile carrier for non-wafer form device testing

InactiveUS20050060115A1Low-profileResistance/reactance/impedenceElectrical measurement instrument detailsMeasurement deviceEngineering

The present invention allows non-wafer form devices to be tested on a standard automatic wafer-probe tester or other automated test or measurement device commonly employed in semiconductor or allied industries (e.g., flat panel display, data storage, or the like) processes. The present invention accomplishes this by providing a low-profile carrier for temporarily mounting a non-wafer form device. The low-profile carrier holds the non-wafer form device (e.g., an integrated circuit chip, a thin film head structure, one or more molded array packages, etc.) magnetically into recesses which are machined or otherwise formed in the low-profile carrier.

Owner:ATMEL CORP

FCT probe testing instrument

PendingCN107957545AImprove detection efficiencyReduce testing costsElectric testing/monitoringPrinted circuit testingEngineeringBlock match

Owner:SUZHOU RUI AI DI AUTOMOTIVE TECH CO LTD

Low profile carrier for non-wafer form device testing

InactiveUS6972486B2Resistance/reactance/impedenceElectrical measurement instrument detailsMeasurement deviceFlat panel display

Owner:ATMEL CORP

Method and system of testing complex MCM's

A system and method for utilizing a multi-probe tester to test an electrical device having a plurality of contact pads. Multi-probe tester test probes and electrical device contact pads are arrayed in a common distribution pitch, and a means for masking test probes masks at least one test probe, thereby preventing the at least one test probe from returning a test result to the testing apparatus. In one embodiment the means for masking test probes is a mask membrane physically preventing at least one test probe from making contact with the electrical device. In another embodiment, the means for masking is at least one software command configured to cause an input from at least one test probe to be disregarded during a test routine. Another embodiment features both mask membrane and software command probe masking.

Owner:INTELLECTUAL DISCOVERY INC

Novel graphene heating material

The invention discloses a novel graphene heating material. A nano-metal material is doped into graphene to reduce the resistivity of a pure graphene circuit. The shape and form of a nanowire are observed by using an optical microscope and a scanning electron microscope; and the electrical performance of an obtained sample is tested and analyzed by using a four-probe tester. According to the novelgraphene heating material, the silver nanowire is doped between graphene layers, and sintering and pressing operations are carried out, so that the interface resistance and electron transport barriersof graphene sheets are reduced and the resistivity of graphene / silver nanowire composite ink is reduced to 1 / 18 of the original resistivity; and meanwhile, the resistivity of graphene / copper nanowirecomposite ink is also reduced to 1 / 5 of the original resistivity through doping a copper nanowire between the graphene layers. According to a method disclosed by the invention, graphene instead of graphene oxide is adopted, so that the resistivity of the circuit can be obviously greatly reduced, and the method has the advantages of being simple in experimental operation, low in cost, short in preparation period, high in feasibility, nontoxic and free of pollution, and can be operated at room temperature.

Owner:HANGZHOU DIANZI UNIV

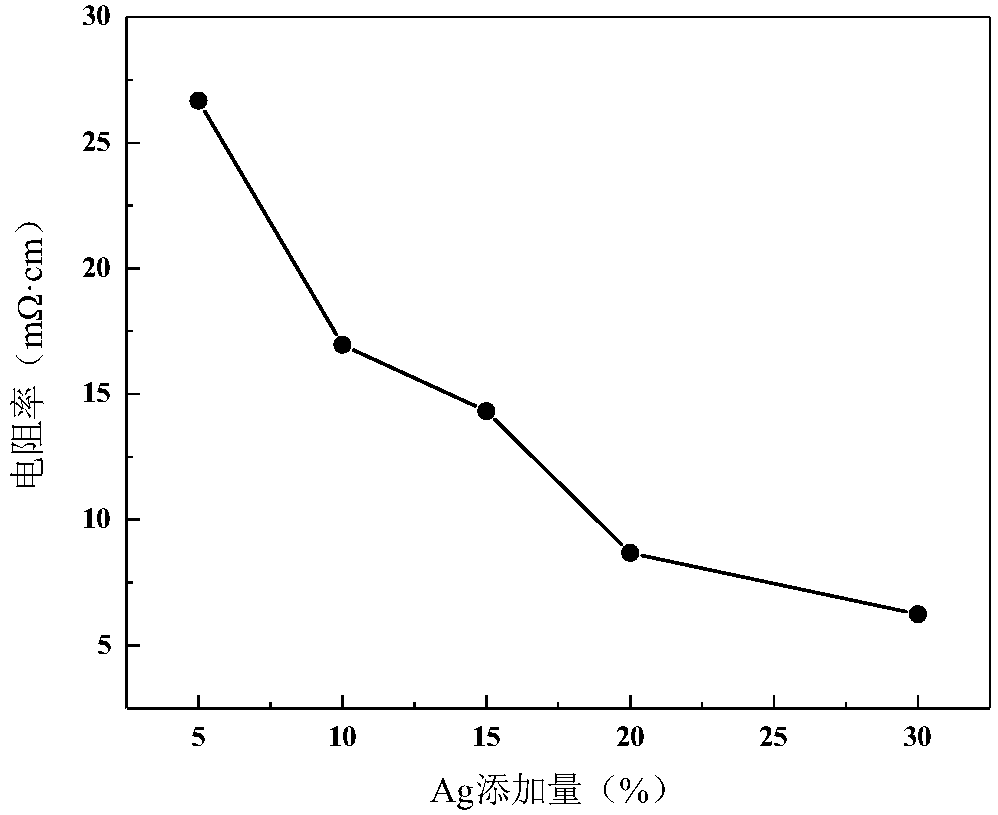

Liquid phase sintering method of Si3N4-TiZrN2-TiN composite conductive ceramic

Provided is Si3N4-TiZrN2-TiN composite conductive ceramic. Raw materials for synthesizing the composite conductive ceramic comprise Si3N4, ZrN, TiN, Y2O3, La2O3 and AlN. The final product of the composite conductive ceramic comprises an Si3N4 phase, a TiN phase and a solid solution TiZrN2 phase of metal nitride. Due to addition of AlN, volatilization caused by adding of Al2O3 in a conventional mode is avoided, and the surface of the final product to which AlN is added can be smoother than that of the product to which Al2O3 is added. The invention further provides a liquid phase sintering method of the Si3N4-TiZrN2-TiN composite conductive ceramic. The Si3N4-TiZrN2-TiN composite conductive ceramic has the advantages that electrical resistance is low, wherein the sample resistance tested by an SX1944 four-probe tester for the composite conductive ceramic is at the 10-2 omega.cm order which is far lower than that of like products; the mechanical strength is high, wherein the load of the composite conductive ceramic is 10 kg, the pressurizing time is 5 s, the measured Vickers hardness of the sample is 14.7 GPa, the sample breaking tenacity calculated through the hardness indentation quadrangle expansion crack length is 7.8 MPa.m 0.5, and the original strength and hardness of silicon nitride ceramic are kept.

Owner:BEIFANG UNIV OF NATITIES

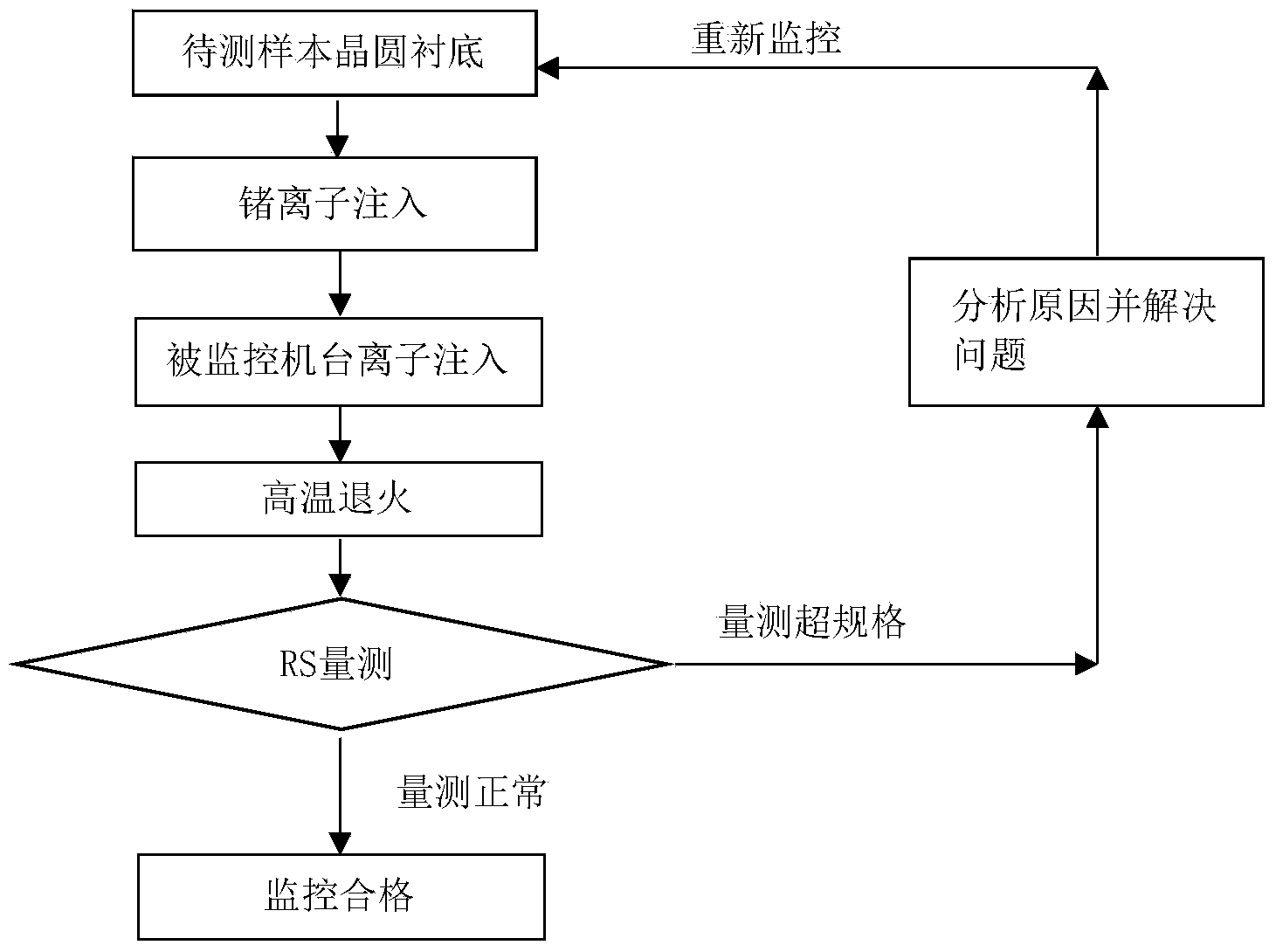

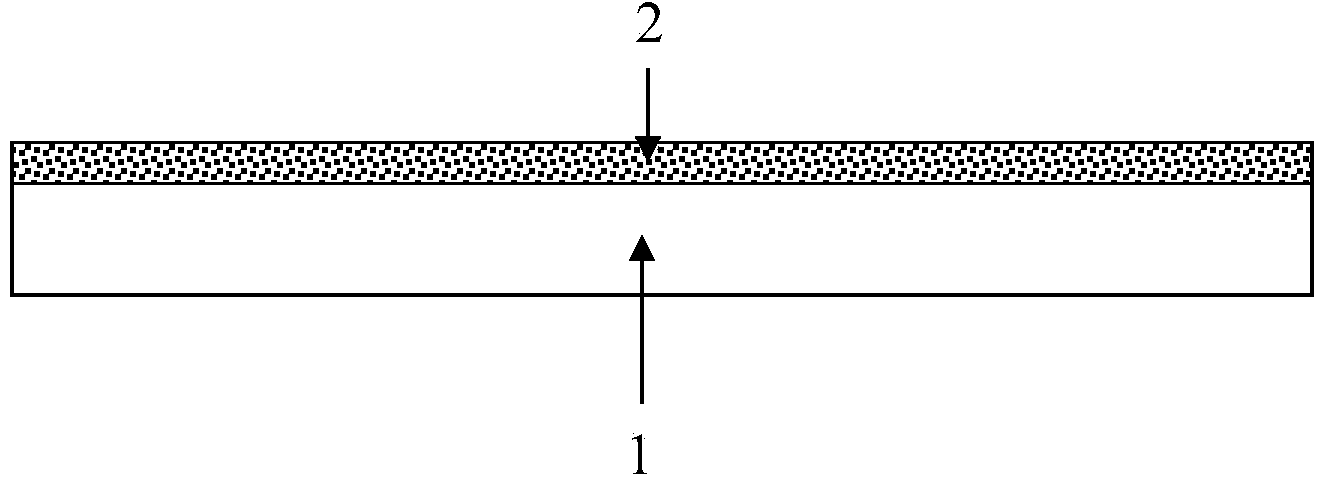

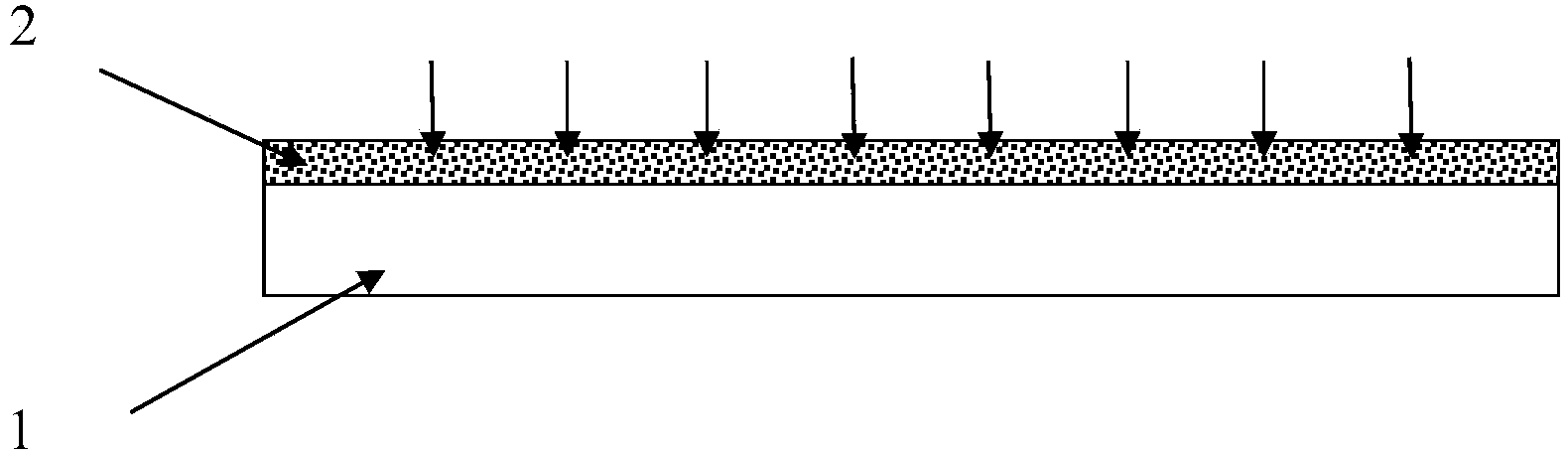

Method for monitoring stability and uniformity of ion implanter

ActiveCN103904009AReduce the injection depthAccurately Monitor StabilitySemiconductor/solid-state device manufacturingDowntimeAlloy

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for quickly detecting open-circuit and short-circuit functional defects of PCB micro pad with minimum width of 1 mil

ActiveCN107356857ANo collisionEasy to operateElectronic circuit testingElectrical measurement instrument detailsOperabilityFlying probe

The invention discloses a method for quickly detecting the open-circuit and short-circuit functional defects of a PCB micro pad with a minimum width of 1 mil. The method comprises the following steps of: firstly, automatically generating a test file by using engineering software, and manually and locally adjusting the test position of the micro pad in the test file according to the shape of the pad, and generating a test file; selecting a high-precision flying probe tester with a lead screw movement system and selecting the optimal flying probe tester; replacing a micro test tool and performing accuracy correction, replacing a conventional cutter-type test probe on the flying probe tester with a micro probe which is a needle-type test probe dedicated to the micro pad; performing micro-pad alignment design, using the micro pad as an alignment point and performing alignment by using a micro pad center direct alignment method; and setting tester operating parameters. The method for quickly detecting the open-circuit and short-circuit functional defects of a PCB micro pad with a minimum width of 1 mil has good operability, low production difficulty, high efficiency and guaranteed quality.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

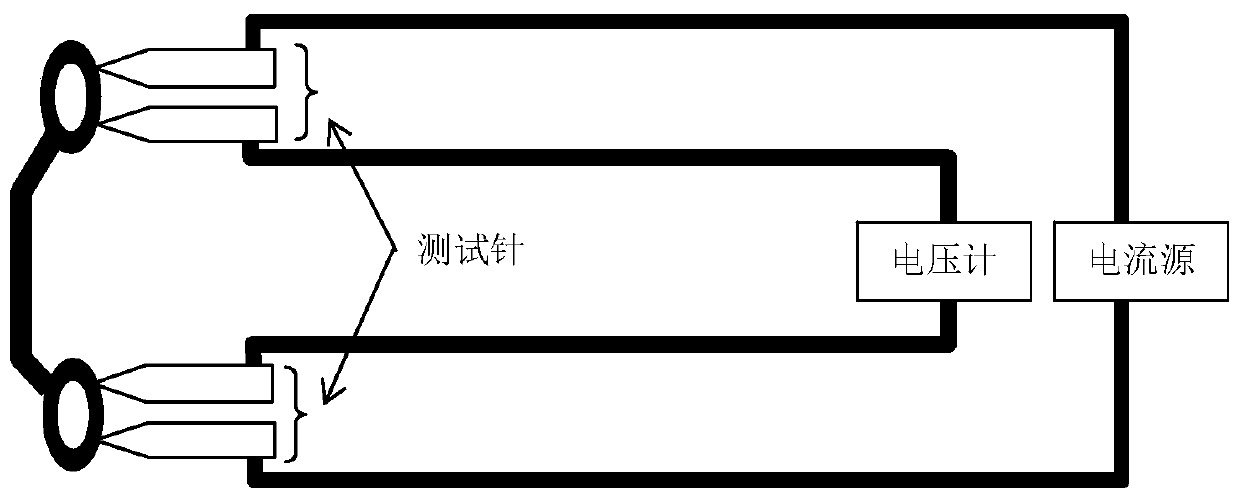

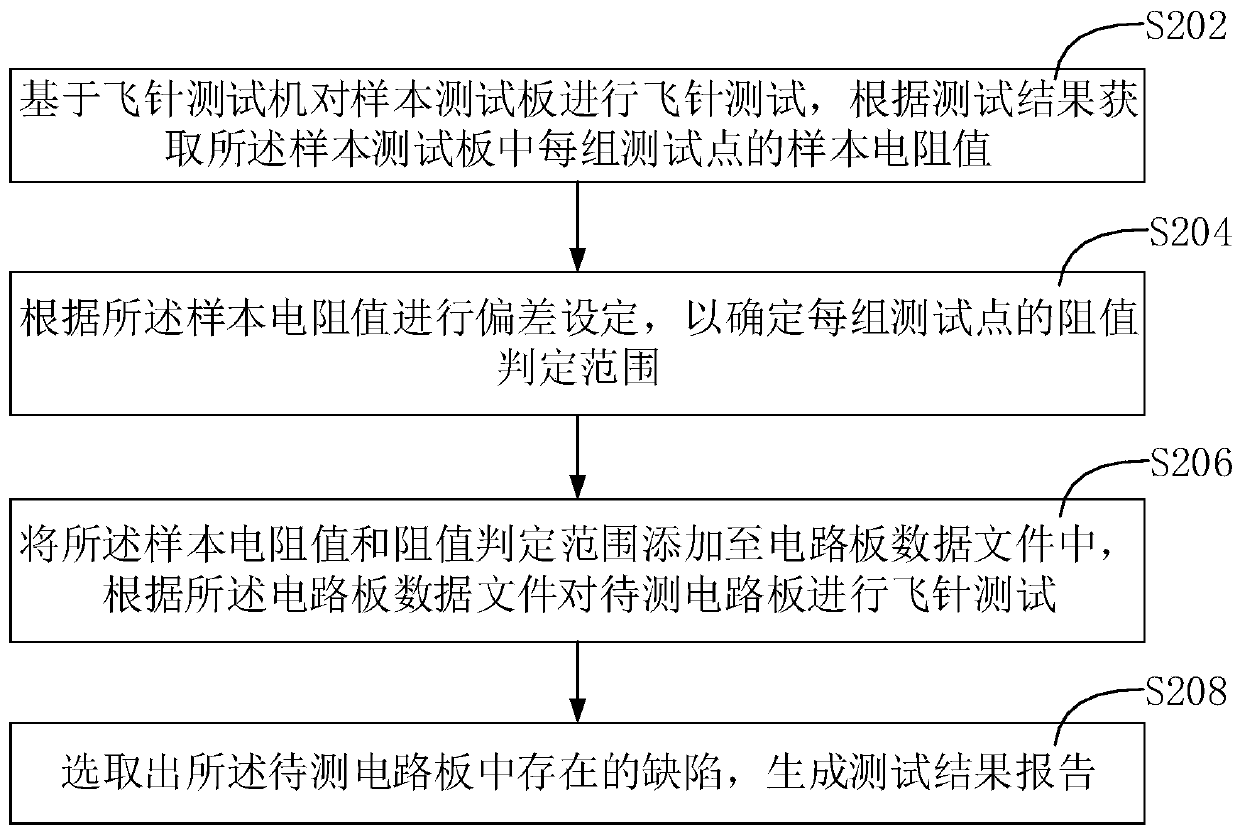

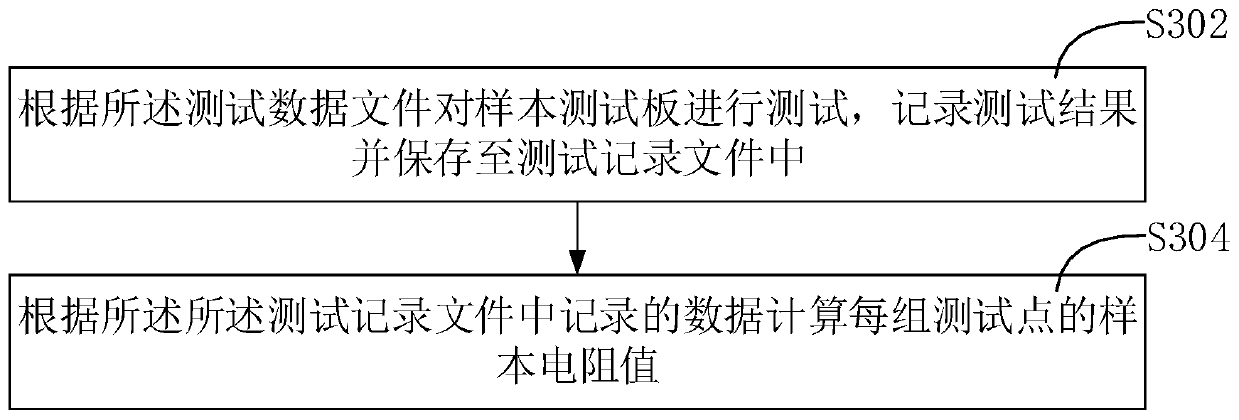

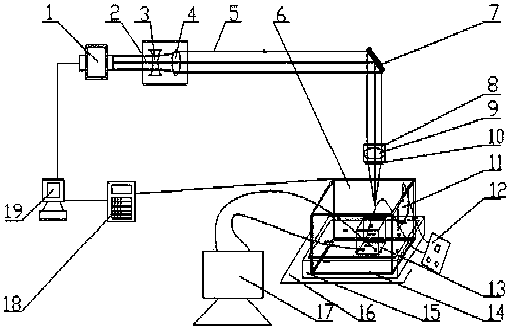

Test method and device of flying-probe tester

InactiveCN109696616AImprove test accuracyTest accurateElectronic circuit testingData fileLab test method

The embodiment of the invention discloses a test method and device of a flying-probe tester. The method comprises the steps of conducting a flying-probe test on a sample test board based on the flying-probe tester, and acquiring sample resistance values of each group of test points in the sample test board according to the test result; setting the deviation according to the sample resistance values so as to determine the resistance judgment range of each group of test points; adding the sample resistance values and the resistance judgment ranges to a circuit board data file, and conducting a fly-probe test on a circuit board to be tested according to the circuit board data file; and selecting defects in the circuit board to be tested, and generating a test result report. According to the method, the specific resistance value of each test point of the circuit board can be accurately measured, the test accuracy of the circuit board can be improved, and the defects of the low-resistance circuit can be accurately tested.

Owner:HANS CNC SCI & TECH

Experimental detection device and method for preparing graphene by laser

InactiveCN109444202ASuitable temperatureThe temperature is suitable for the best preparation of grapheneMaterial thermal analysisEngineeringGraphene

The invention relates to an experimental detection device and method for preparing graphene by a laser. The device comprises a movable platform, a reaction vessel is arranged on the movable platform and integrally positioned in a heating cover, a powered-on electrode and a large electrode block are arranged in the reaction vessel, the powered-on electrode is connected with a voltage controller, the large electrode block is connected with a double-electric-logging four-probe tester, and a laser generation system is arranged on the upper portion of the reaction vessel. According to the device, laser-shocked plasmas can sufficiently contact with an electrode base and are deposited on the electrode base. The temperature of water in the reaction vessel is gradually increased by the heating cover, and generation experiments of the graphene are detected in real time, so that optimal temperature suitable for preparing the graphene is acquired.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com