Method for testing sheet resistance in preparation process of selective transmission electrode battery

A technology of emitter electrode and preparation process, applied in the direction of measuring resistance/reactance/impedance, measuring device, measuring electrical variables, etc., can solve problems such as test error, difficulty in process adjustment and optimization, and easy pressure of probes to grid lines, etc. Accurately identify test points, save test time, and simplify the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

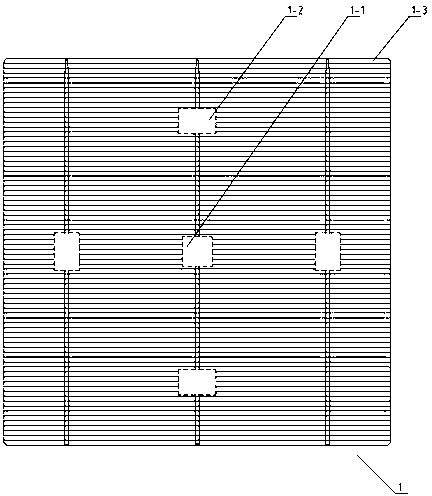

[0014] A method for testing square resistance during the preparation of selective emission electrode batteries. The steps of the method are as follows: 1) designing grating patterns; 2) selecting substrates 1-3 of the same batch of selective emission electrode batteries , and open a positioning hole 1-1 at the center of the substrate substrate 1-3, the center position of the four probes of the four-probe tester is centered on the axis of the positioning hole 1-1, and the Probe areas corresponding to four probes are respectively formed on the bottom 1-3, and probe positioning holes 1-2 are respectively opened on the four probe areas of the substrate substrate 1-3 to form a monitoring chip substrate; 3 ) Coating photoresist on the monitor sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com