Device and method for detecting force electromagnetic coupling behavior of giant magneto resistive film

A technology of electromagnetic coupling and giant magnetoresistance, applied in the fields of electrical experiments, engineering materials, structural deformation and mechanical experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

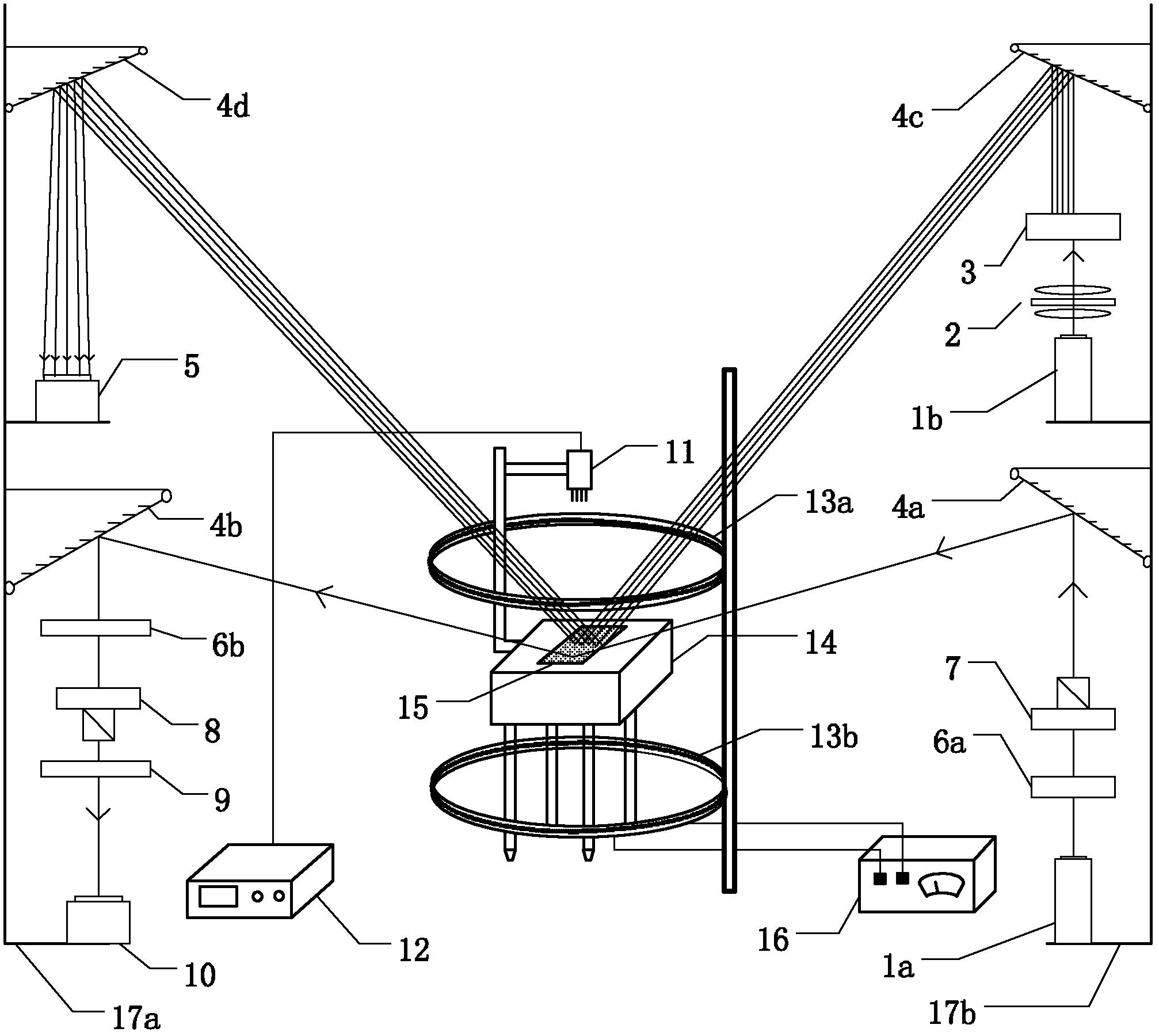

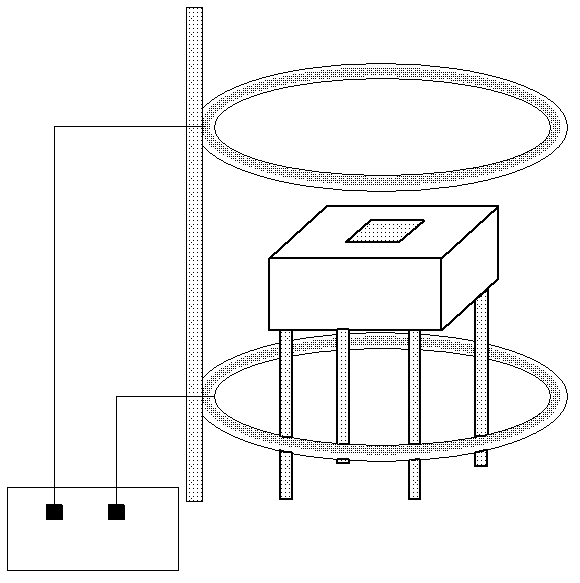

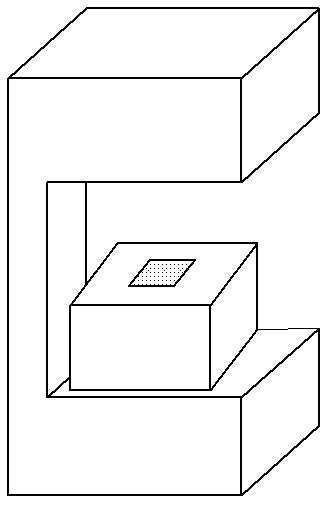

[0039] figure 1 It is a schematic diagram of a detection device for the force-electromagnetic coupling behavior of the giant magnetoresistive material of the present invention. The device includes a magnetic field generator for generating uniform magnetic fields of different intensities, a giant magnetoresistance thin film hysteresis loop measurement optical path, a thin film stress measurement optical path, an optical shock absorption and force loading platform 14 for placing the test piece, and a thin film resistance probe Measuring instrument12.

[0040] The giant magnetoresistive film hysteresis loop measurement optical path includes the first laser 1a, the first aperture-shaped adjustable diaphragm 6a, the polarizing prism 7, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com