Strain-Temperature Variation Dual Parameter Measurement Method Based on Chirped Grating

A technology of chirped grating and measurement method, applied in the field of sensors, can solve the problem of external force of fiber grating, and achieve the effect of high integration, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

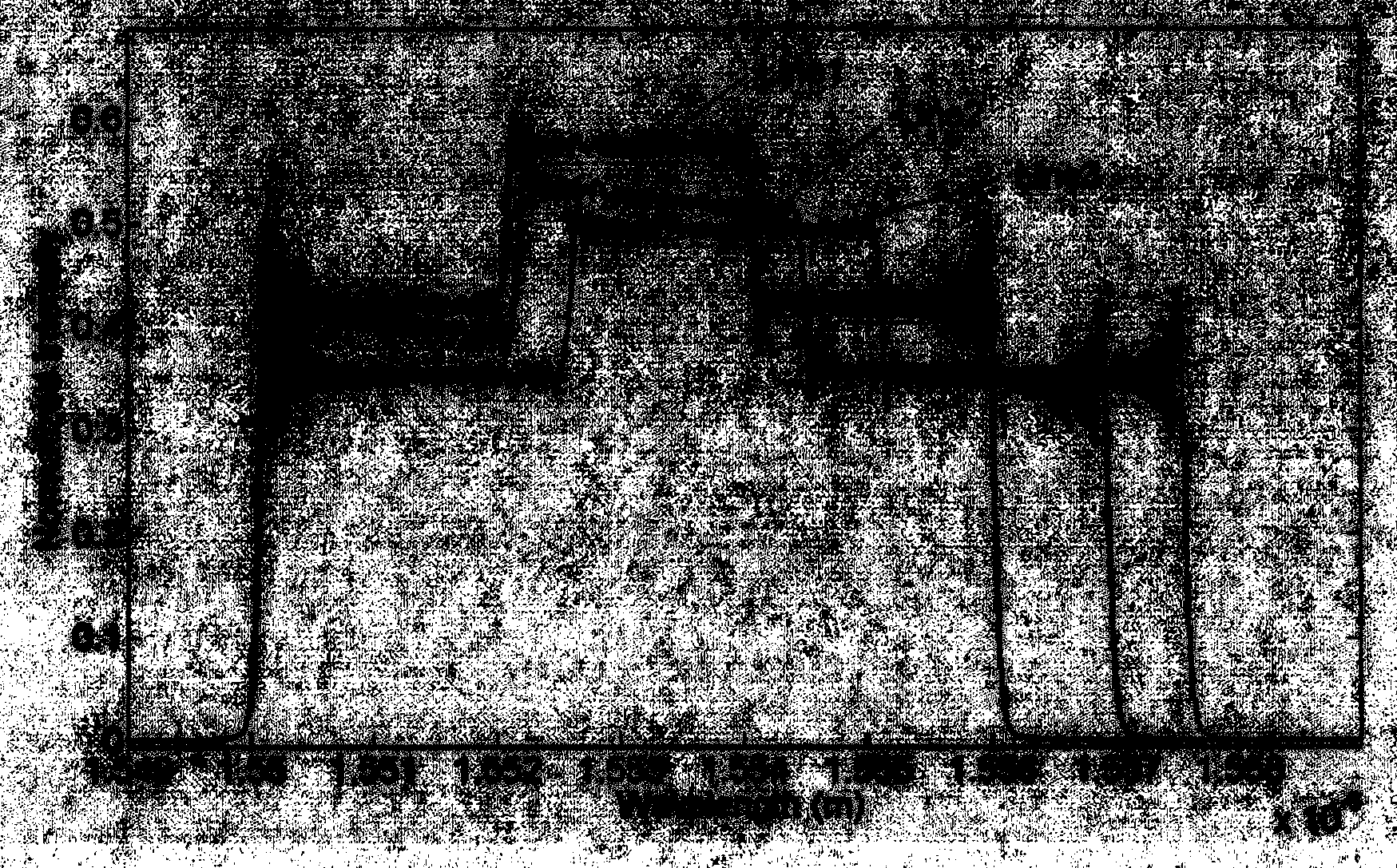

[0090] In this embodiment, the reflectivity of the three segments of the convex chirped grating is 43%, 58% and 43%, respectively. When the grating is subjected to a strain in the form of a linear function along the axial direction, that is, ε z = K 1 z+K 0 , K is a constant, K 0 It can be obtained from the spectral wavelength value when z=0, in image 3 , the starting wavelength coincides with the wavelength of the original spectrum, that is, K0 =0. The three-segment spectral broadening of the convex grating spectrum is exactly the same, so the K value can be calculated from the end value of the reflection spectrum wavelength of any of the three segments, the end value of the spectral wavelength when the grating is not subjected to external force, and the grating length. Such as image 3 As shown in Line3, taking the end wavelength value of the first spectrum as an example, the current end value of the first spectrum wavelength is 1552.5nm, and it is 1552nm when no exter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com