Patents

Literature

815 results about "Capacitive measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capacitance is measured in units called farads (abbreviated F). The definition of one farad is deceptively simple. ... One ampere per second corresponds to the standard unit for measuring electric charge, called the coulomb. So another way of stating the value of one farad is to say that it’s the amount of capacitance that can store one coulomb with a voltage of one volt across the plates.

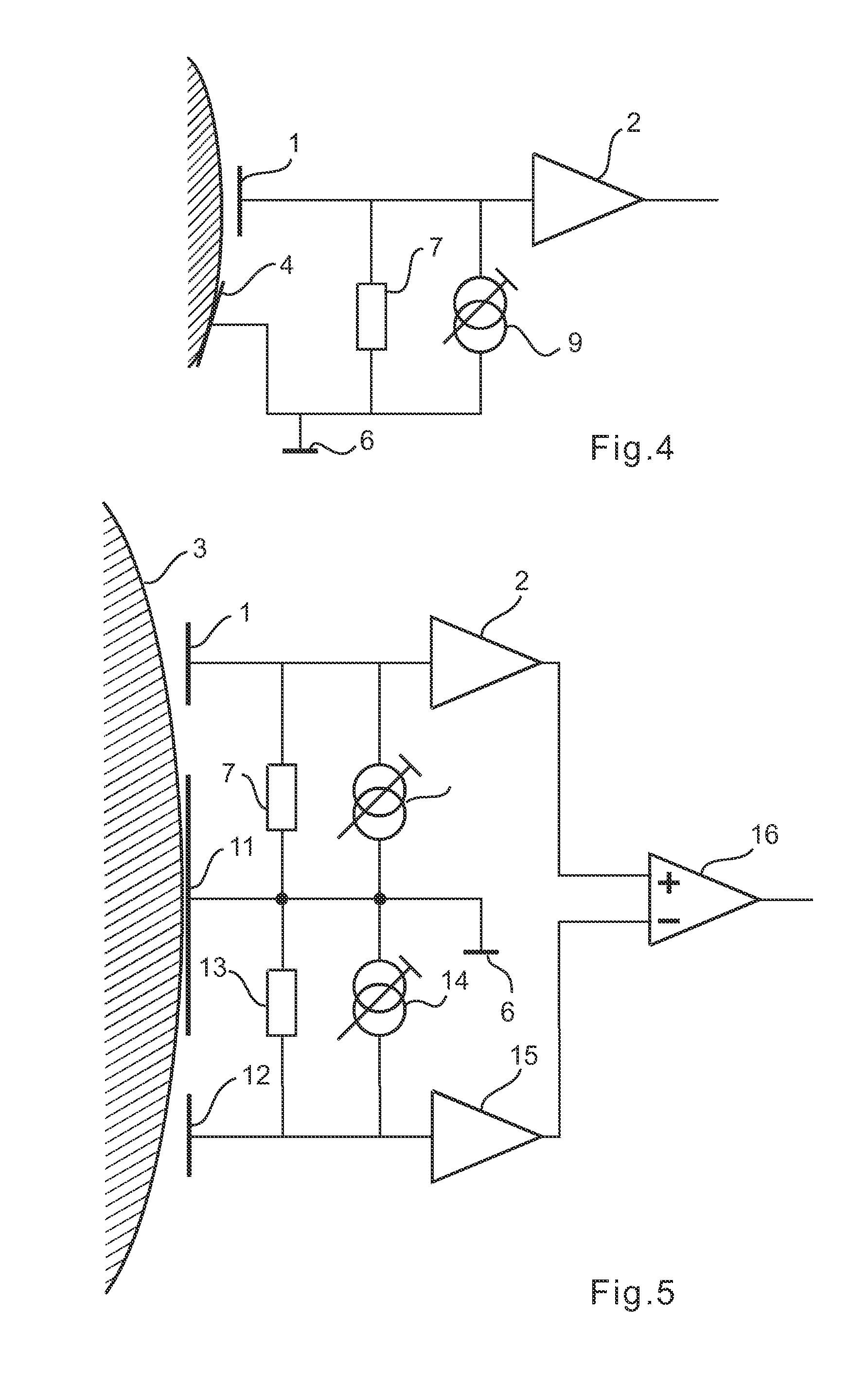

Linear capacitance measurement and touchless switch

InactiveUS7498822B2Improve accuracyHigh sensitivityResistance/reactance/impedenceElectronic switchingNegative feedbackProximity sensor

Owner:LEE YING LAU

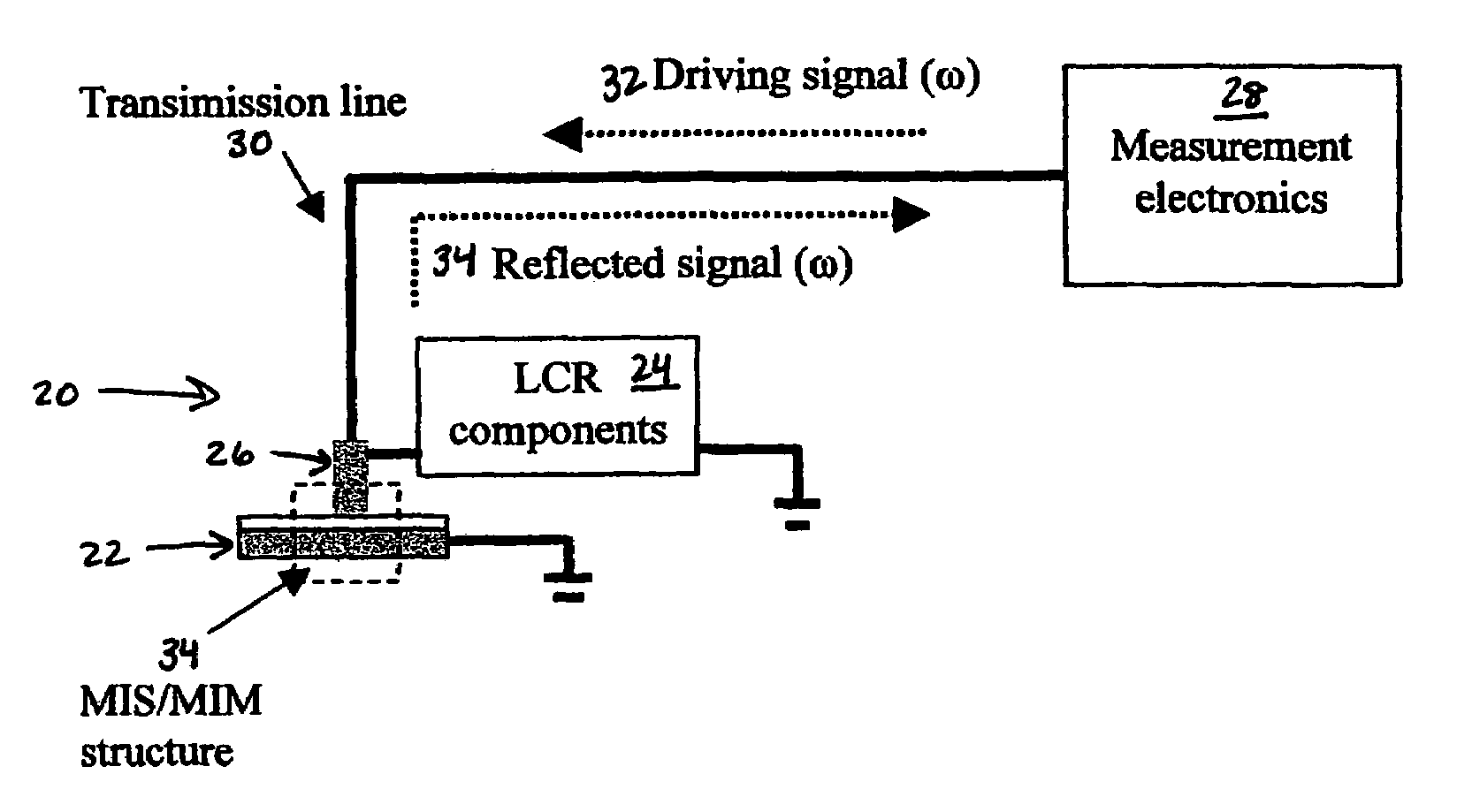

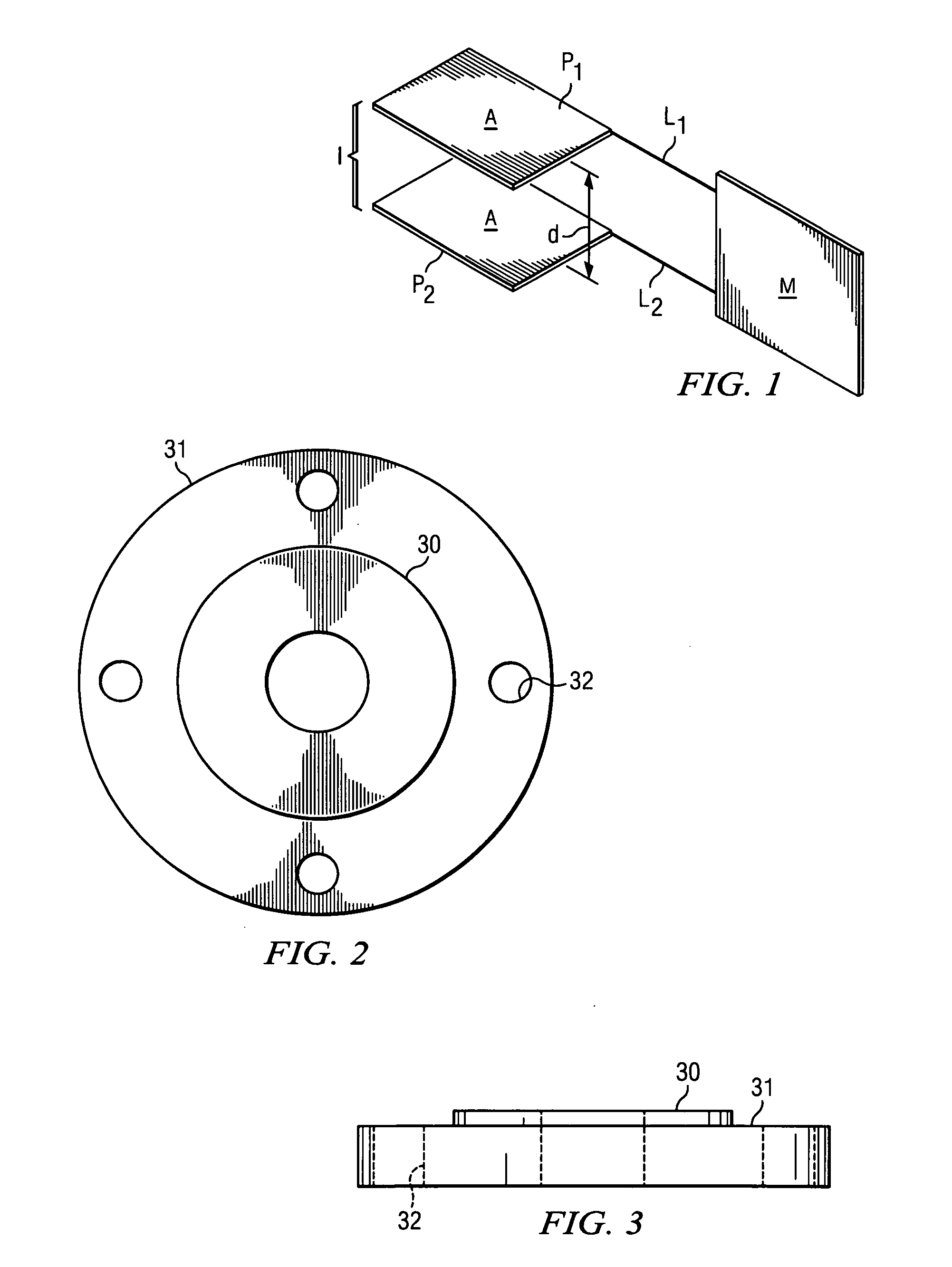

Capacitance probe for thin dielectric film characterization

ActiveUS7001785B1Semiconductor/solid-state device testing/measurementResistance/reactance/impedenceElectrical conductorCapacitive measurement

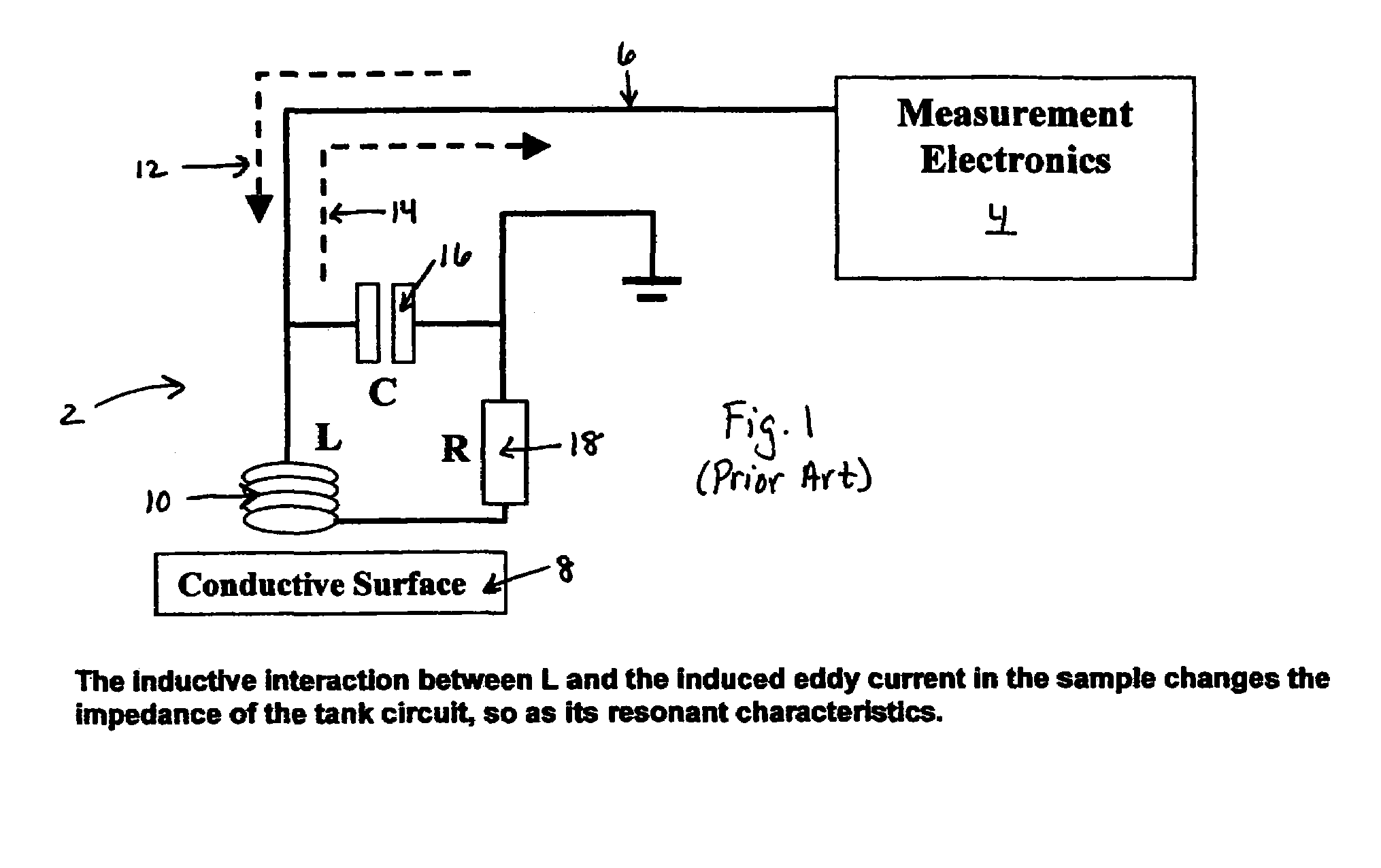

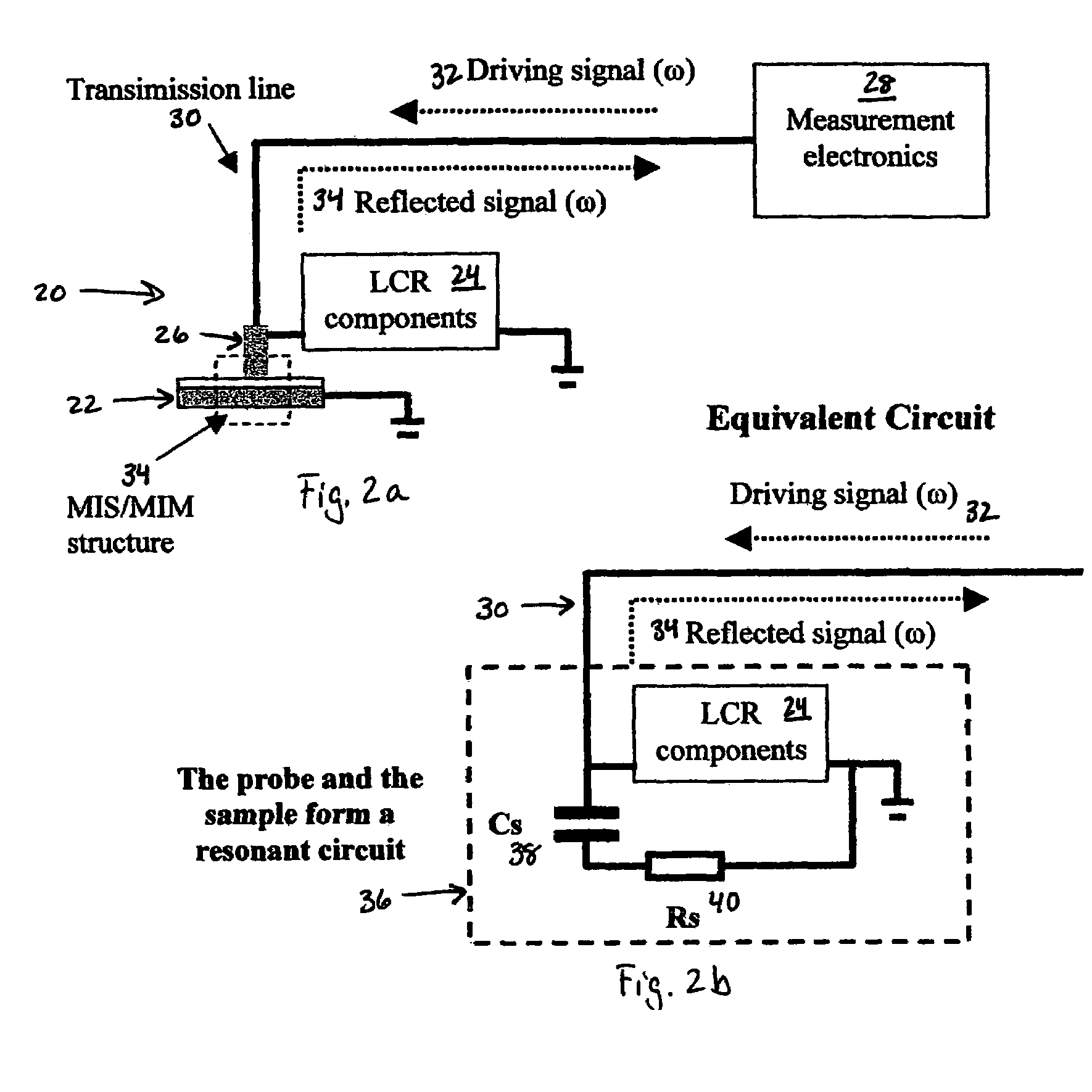

A capacitance probe for thin dielectric film characterization provides a highly sensitive capacitance measurement method and reduces the contact area needed to obtain such a measurement. Preferably, the capacitance probe is connected to a measurement system by a transmission line and comprises a center conductive tip and RLC components between the center conductor and the ground of the transmission line. When the probe tip is in contact with a sample, an MIS or MIM structure is formed, with the RLC components and the capacitance of the MIS or MIM structure forming a resonant circuit. By sending a driving signal to the probe and measuring the reflected signal from the probe through the transmission line, the resonant characteristic of the resonant circuit can be obtained. The capacitance of the MIS or MIM structure is obtainable from the resonant characteristics and the dielectric film thickness or other dielectric properties are also extractable.

Owner:VEECO METROLOGY

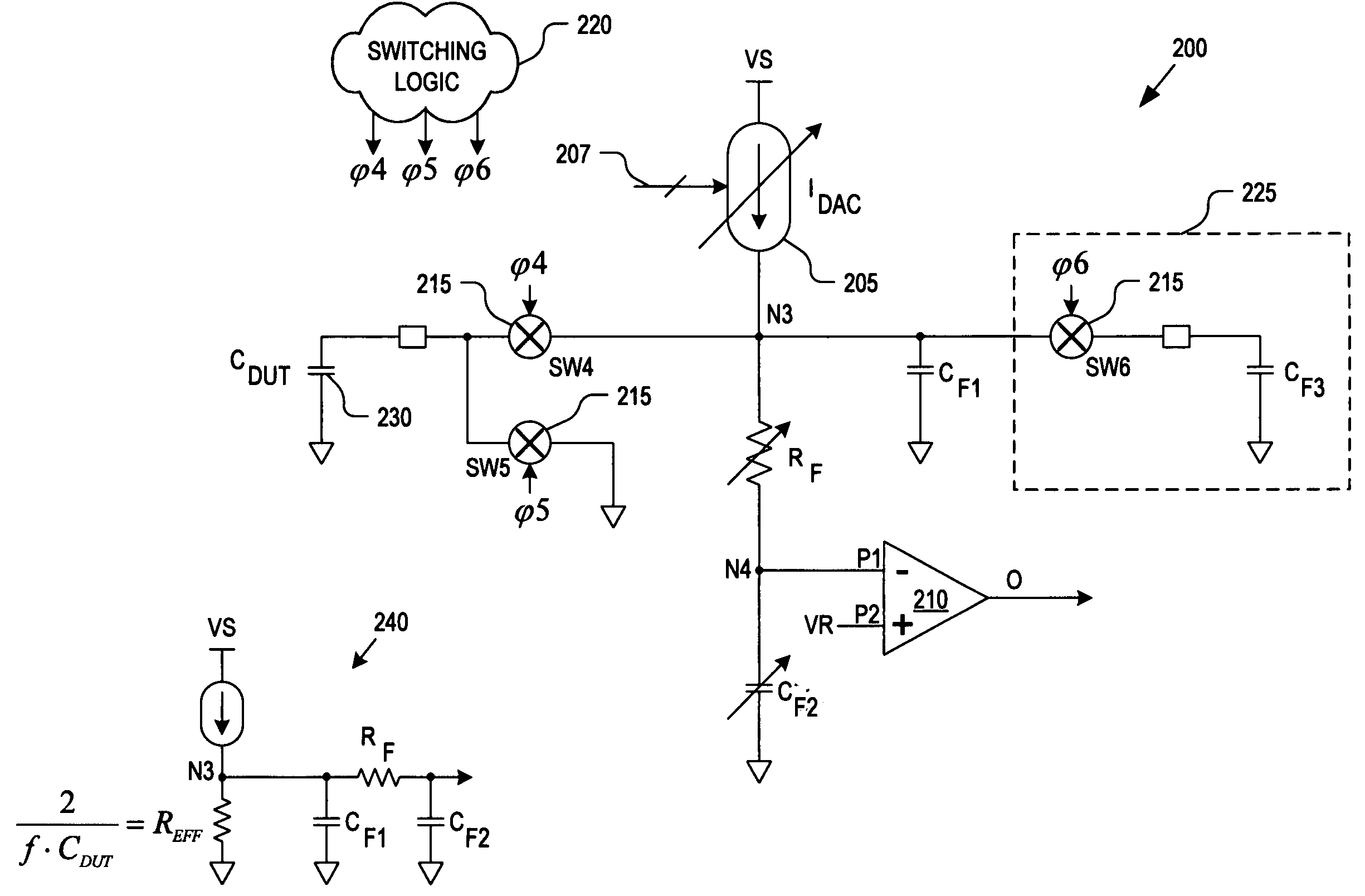

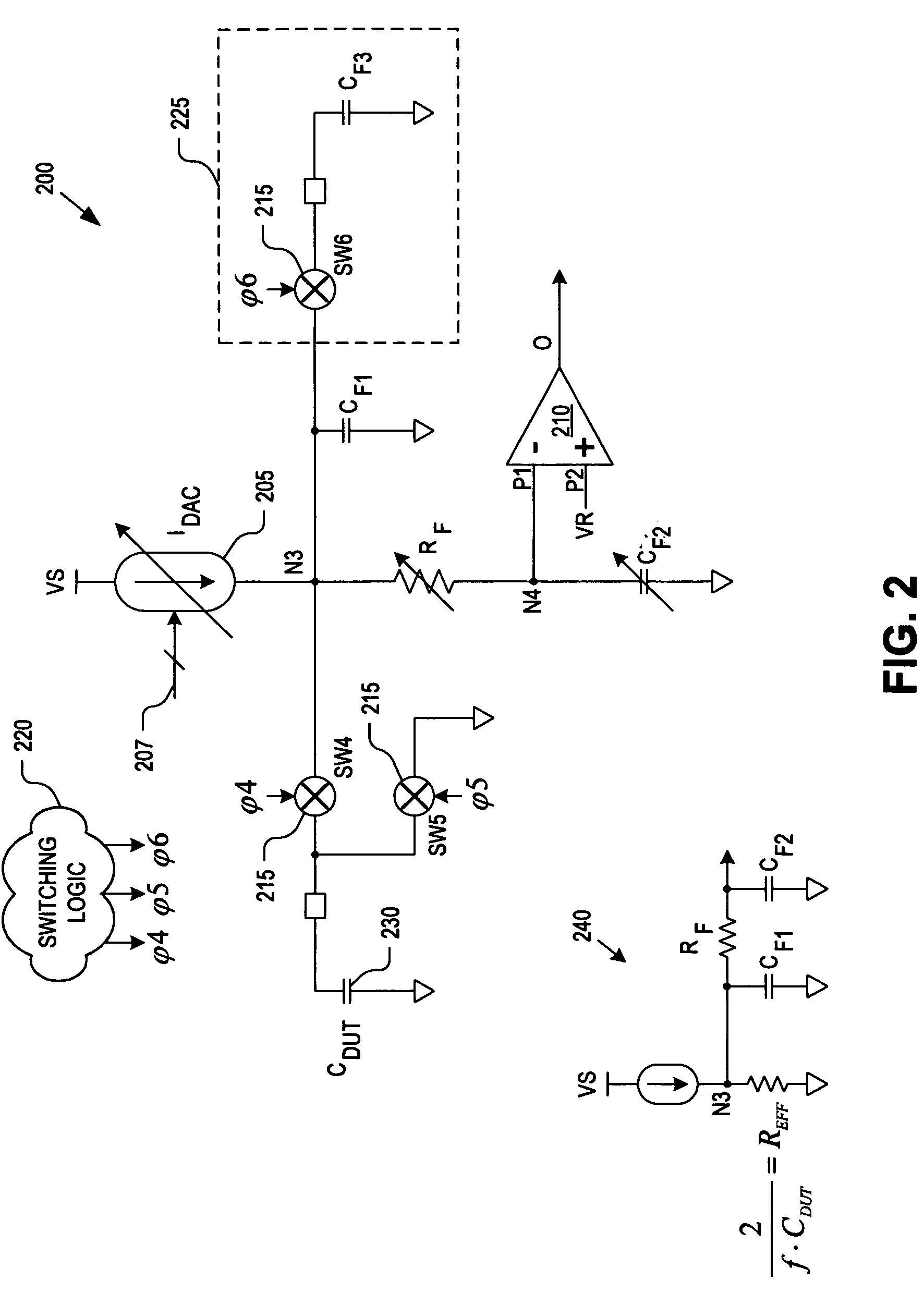

Successive approximate capacitance measurement circuit

Owner:MONTEREY RES LLC

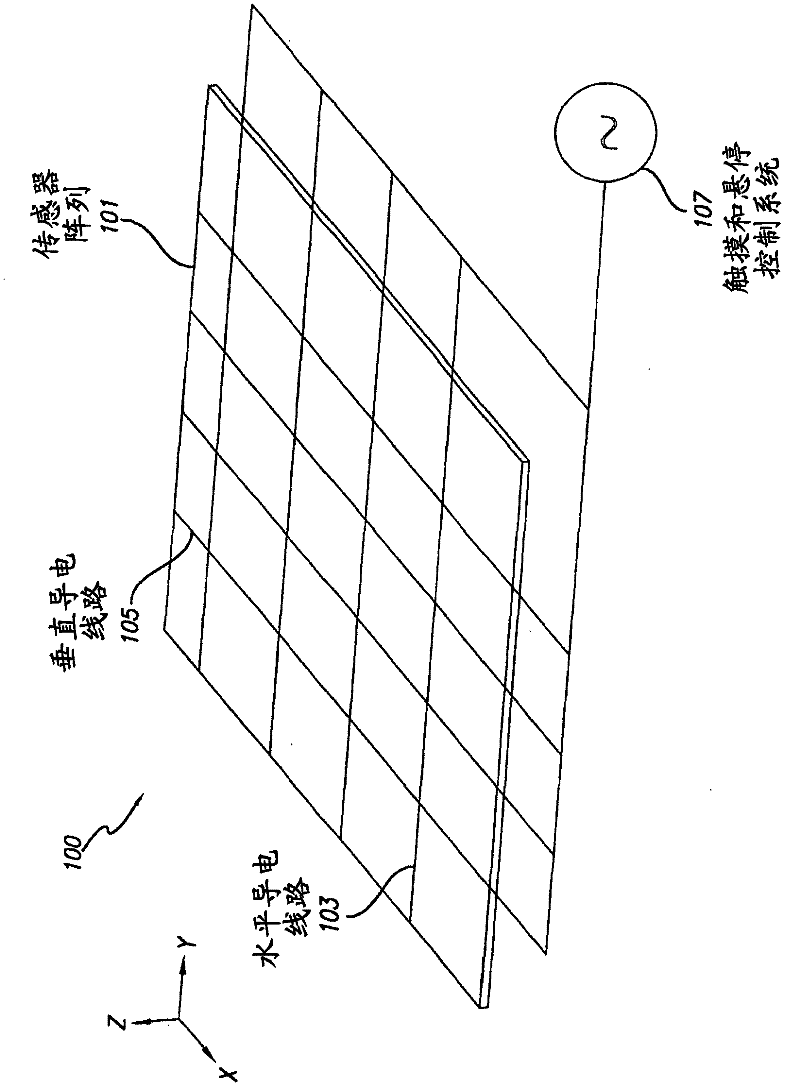

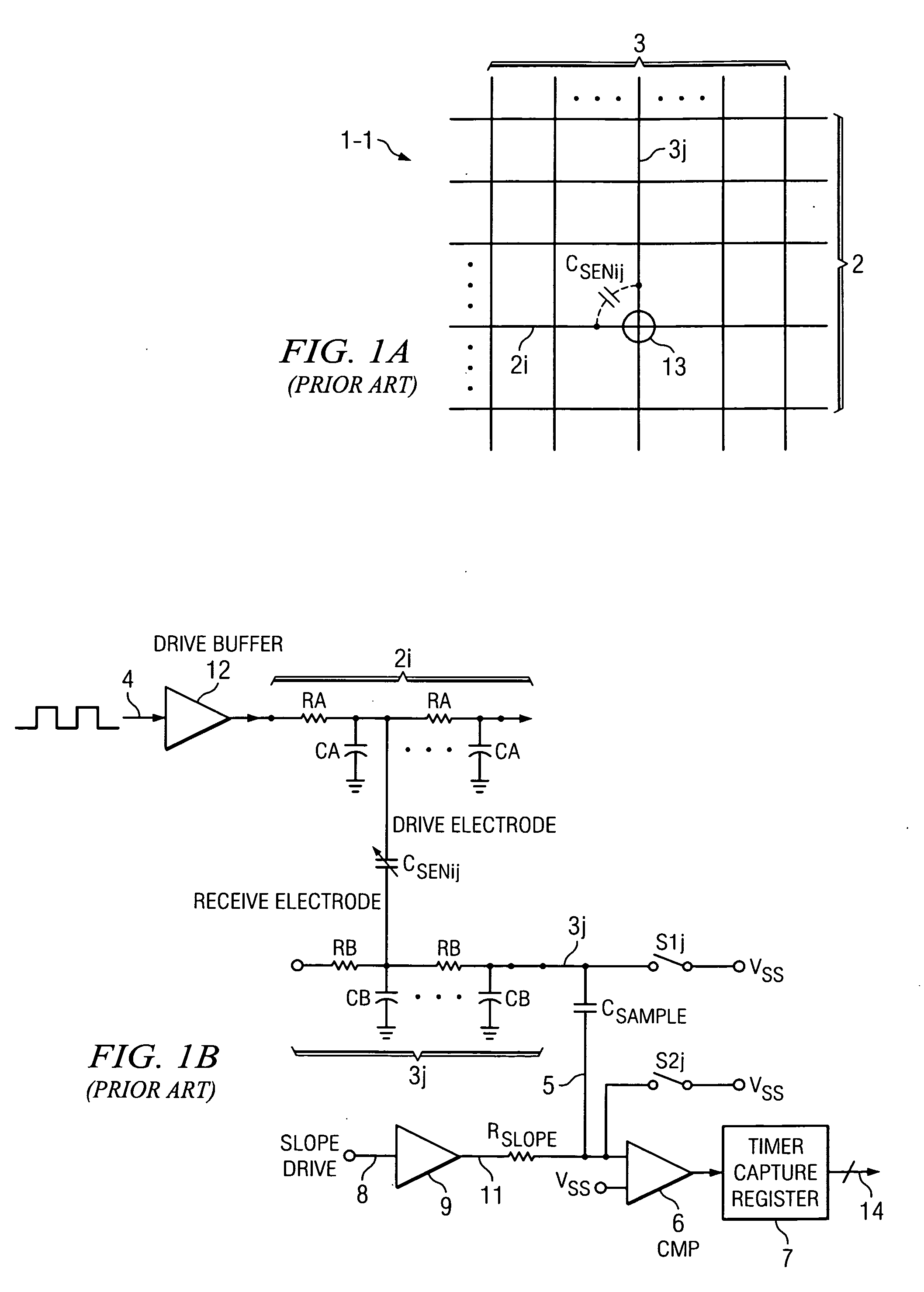

Capacitive two dimensional sensor

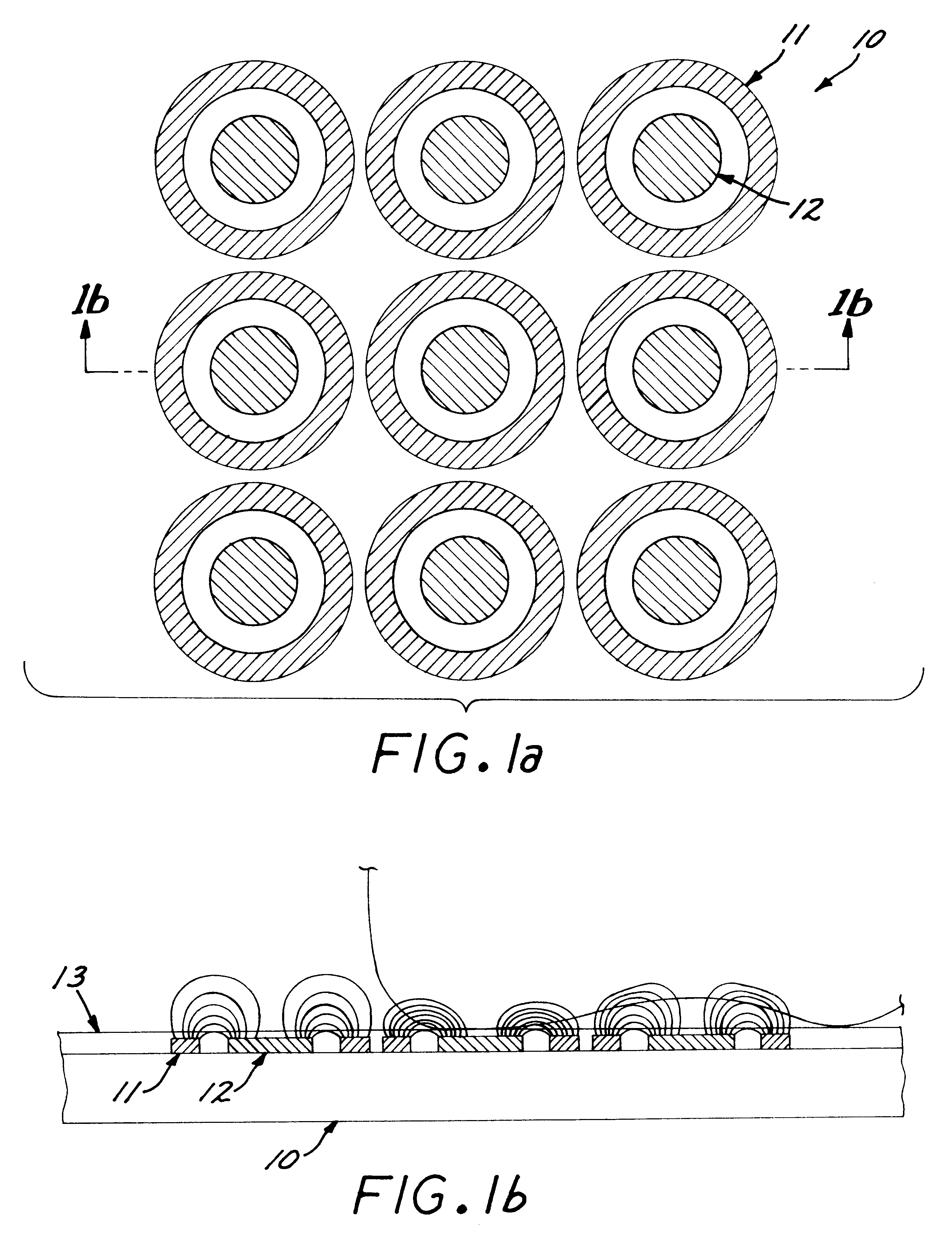

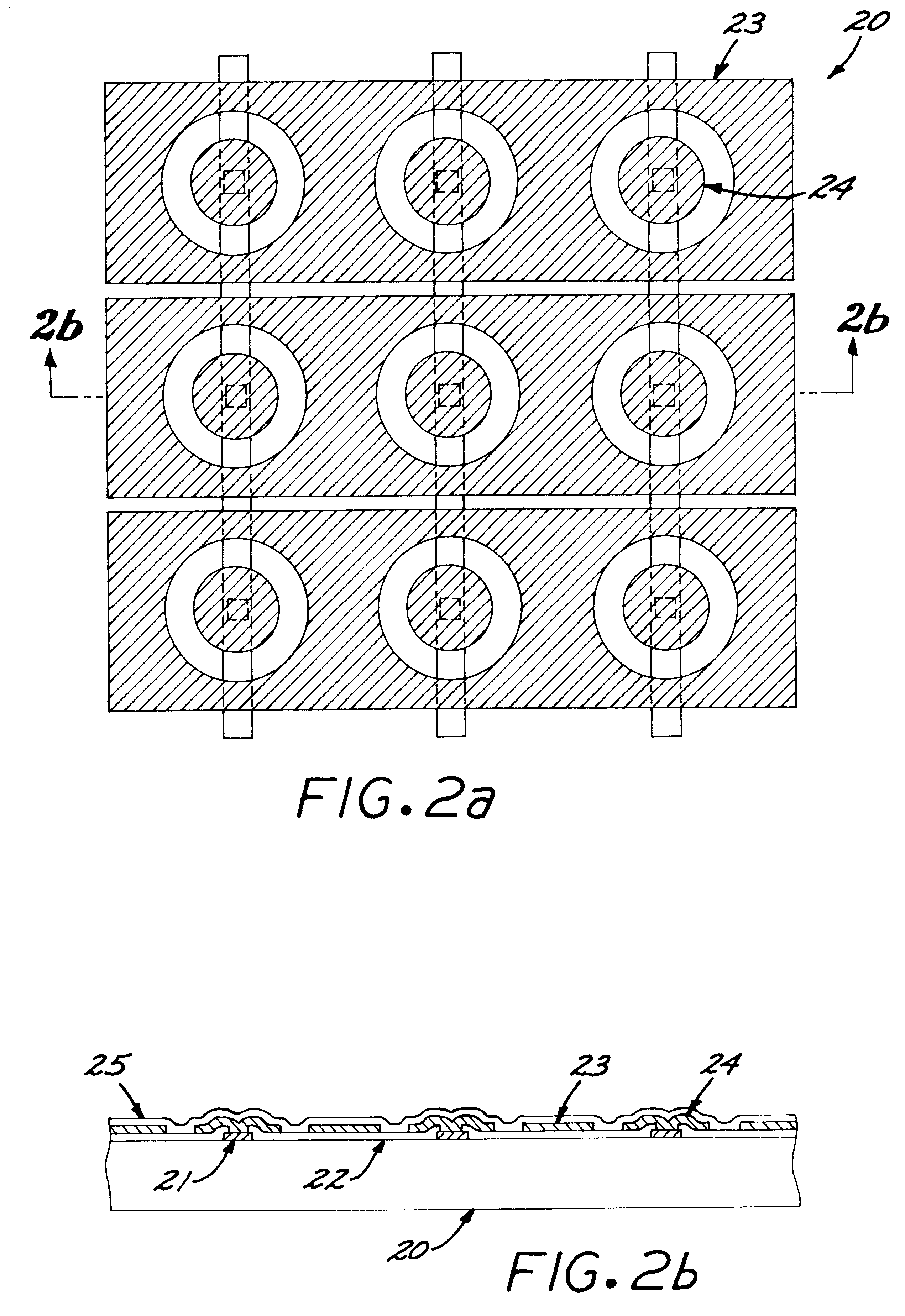

InactiveUS6525547B2Resistance/reactance/impedenceMeasurement arrangements for variableSemiconductorCapacitive measurement

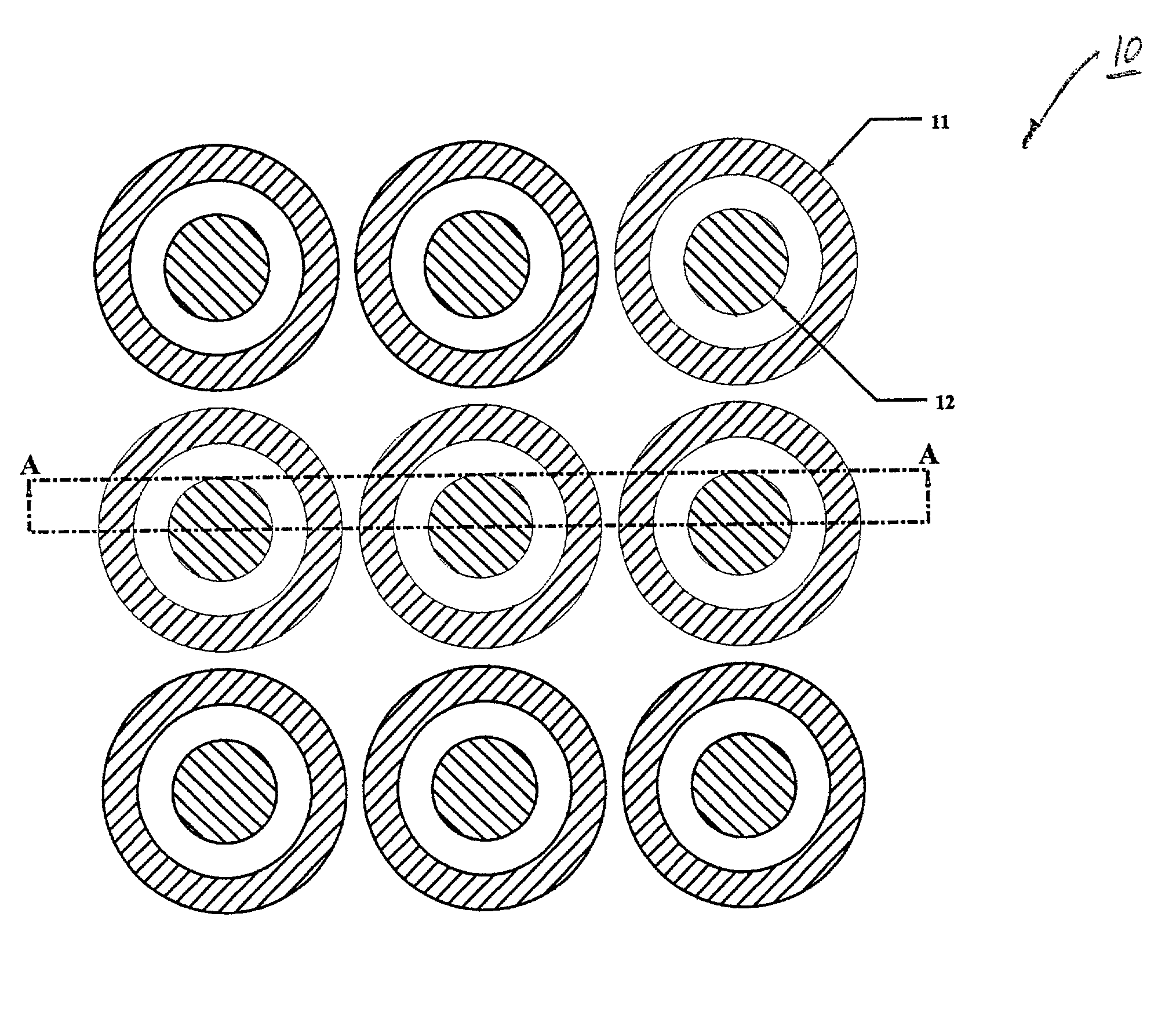

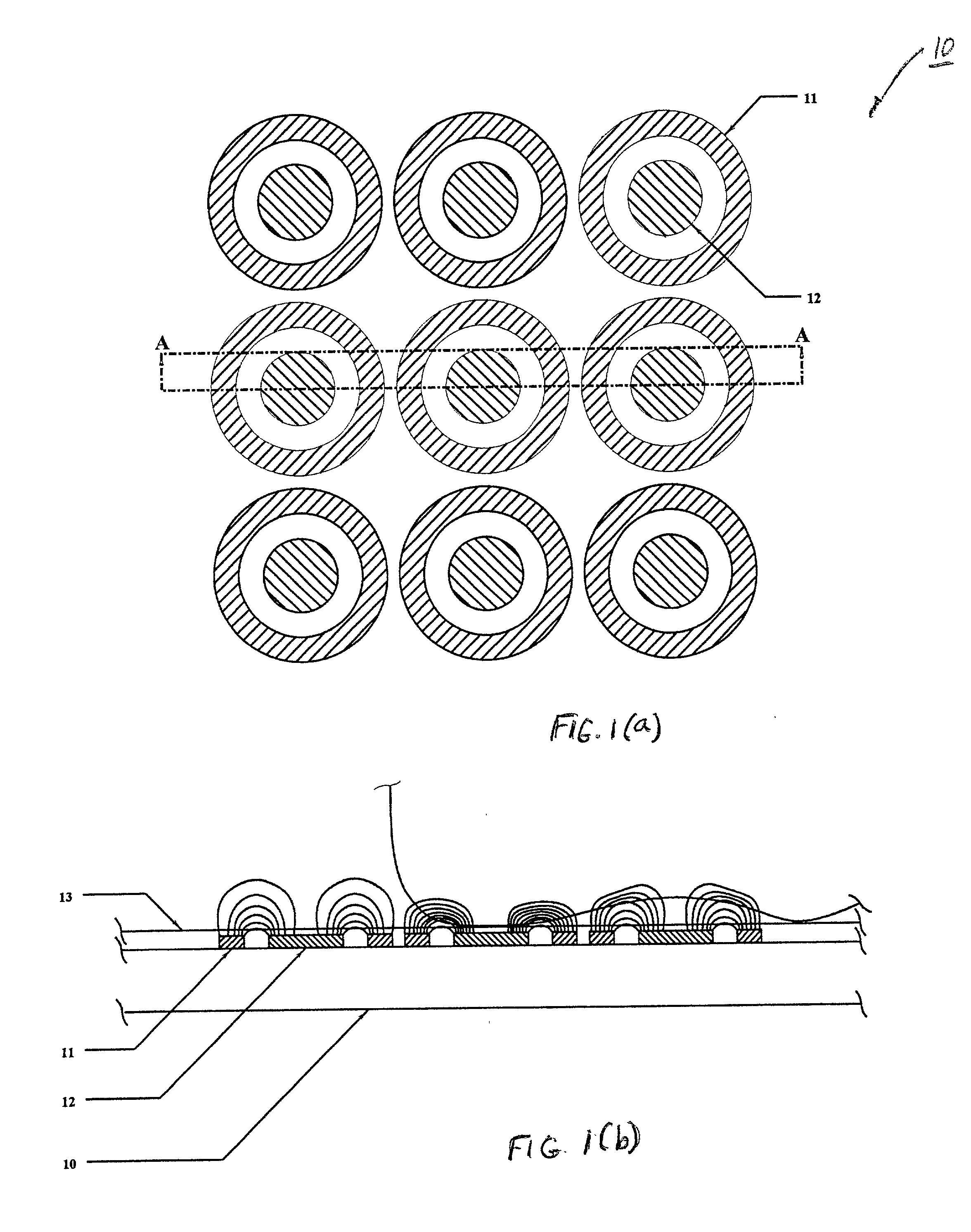

A two dimensional array of electrods for sensing the presence or absence of the ridges in a fingerprint through capacitive measurements. Exciting signals are supplied from outside the array which allows the array to be fabricated from metal and insulator layers on non-semiconductor substrates such as glass or plastic using normal deposition and patterning techniques. A top protective layer consisting of hard, rigid material may be provided. The required electronic circuits are preferably located around the periphery of the array.

Owner:SENTRONICS CORP

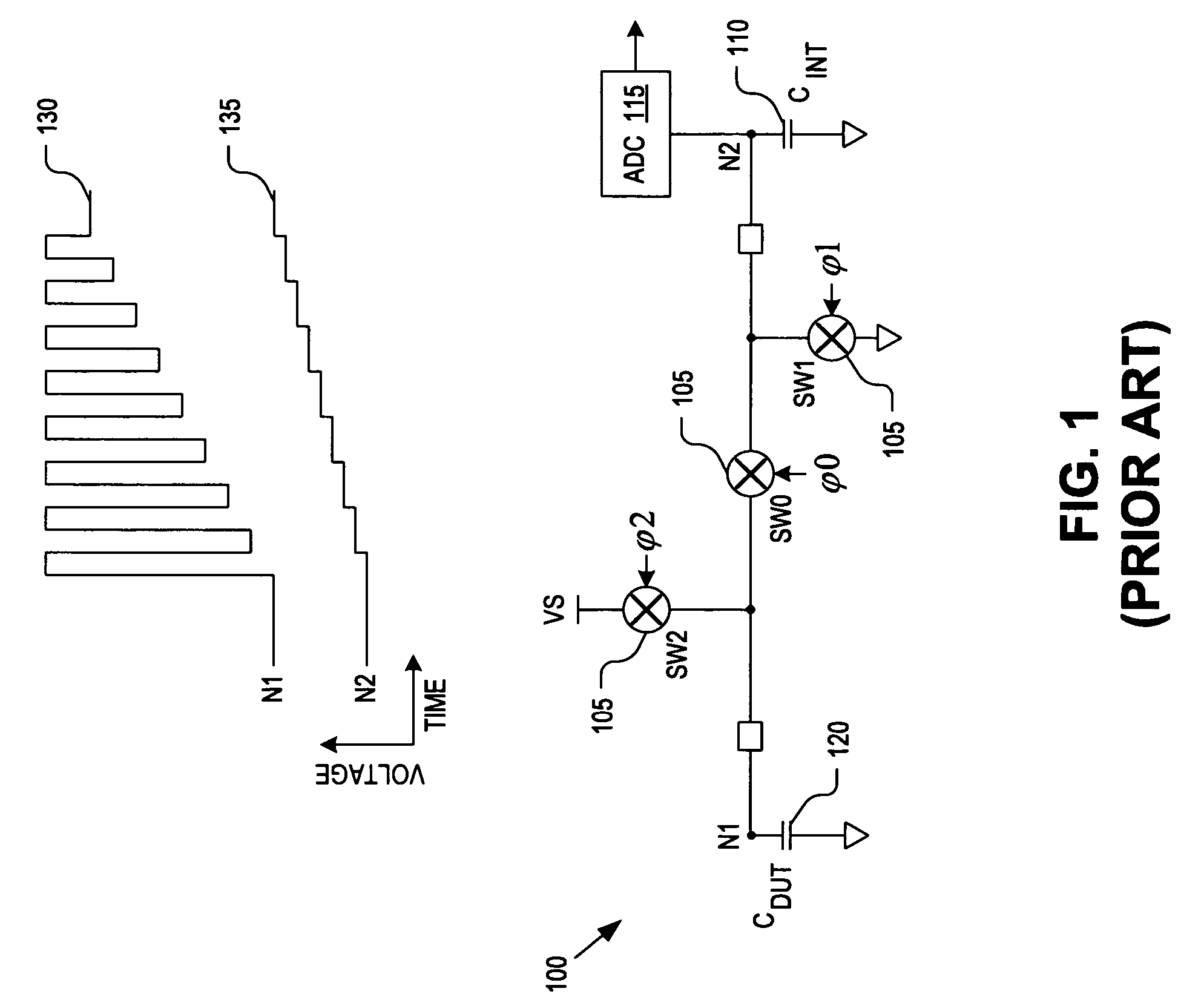

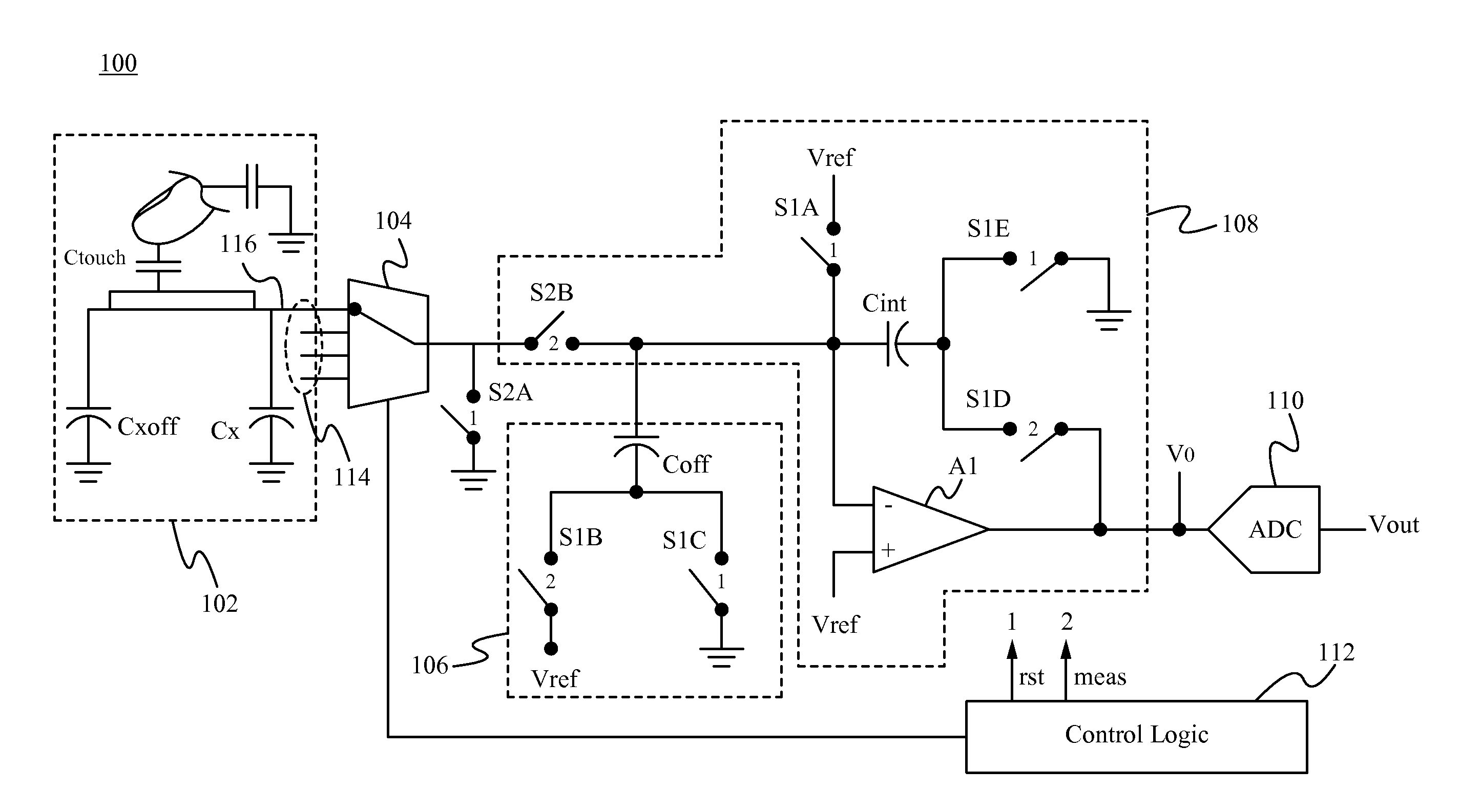

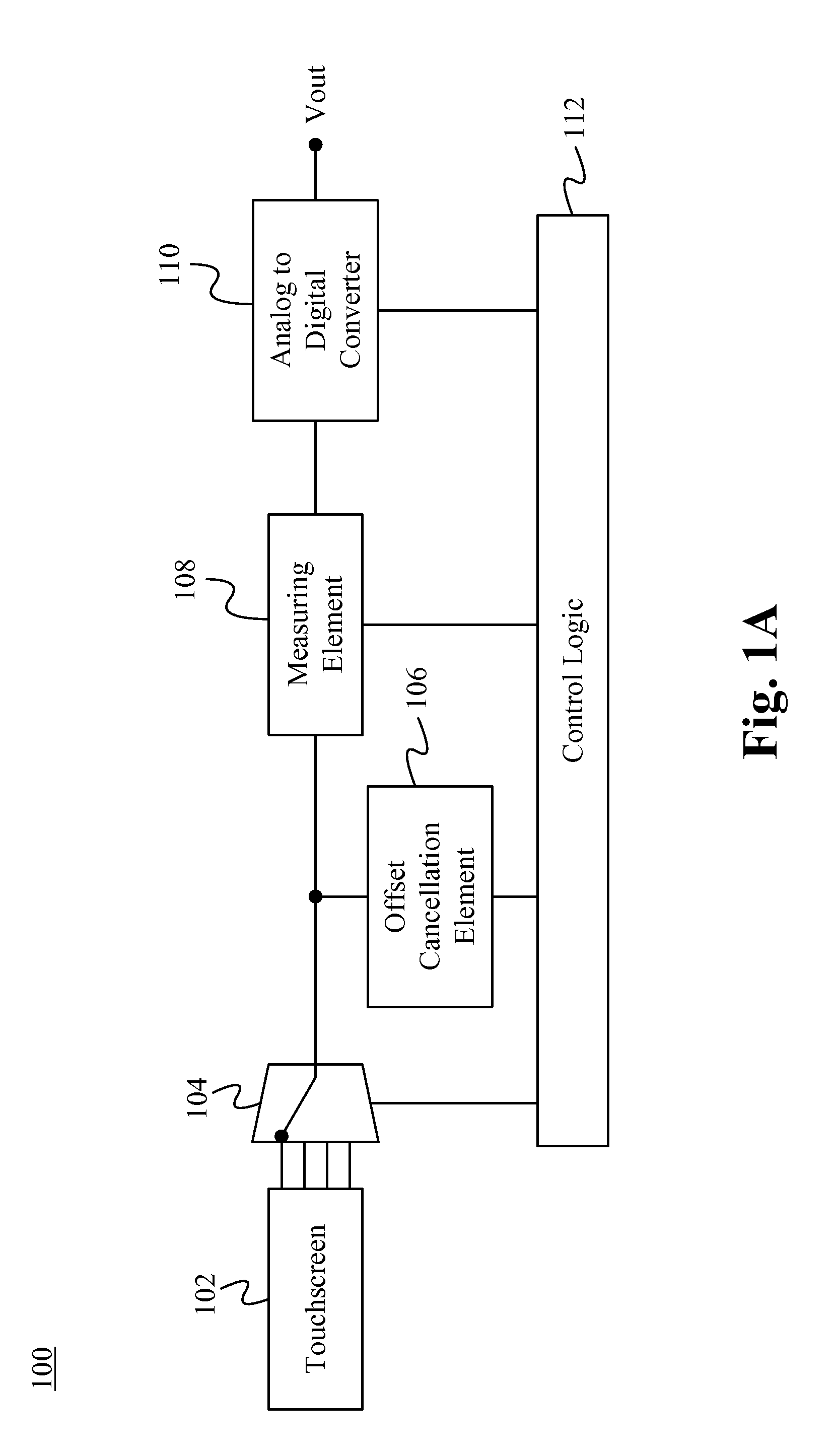

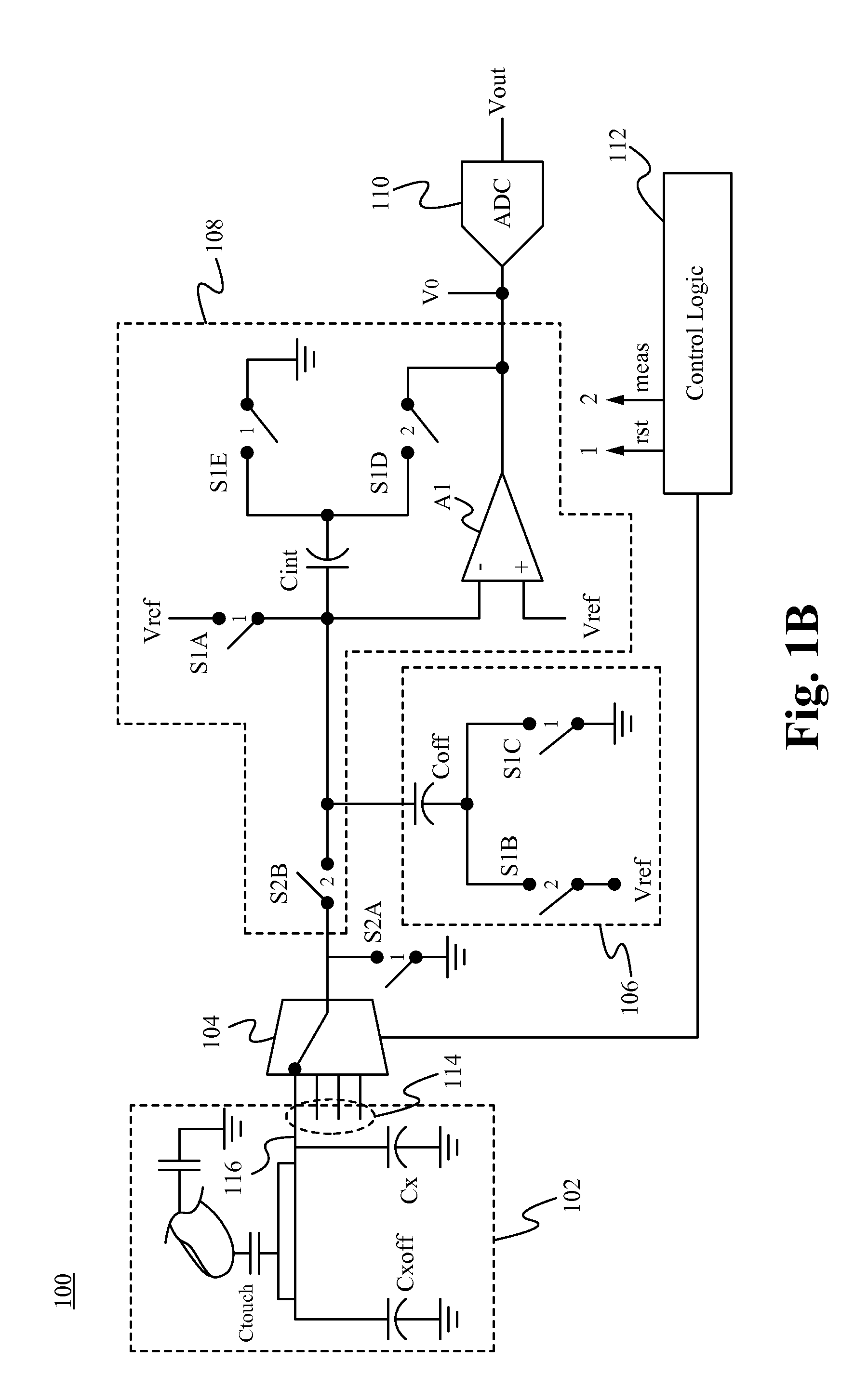

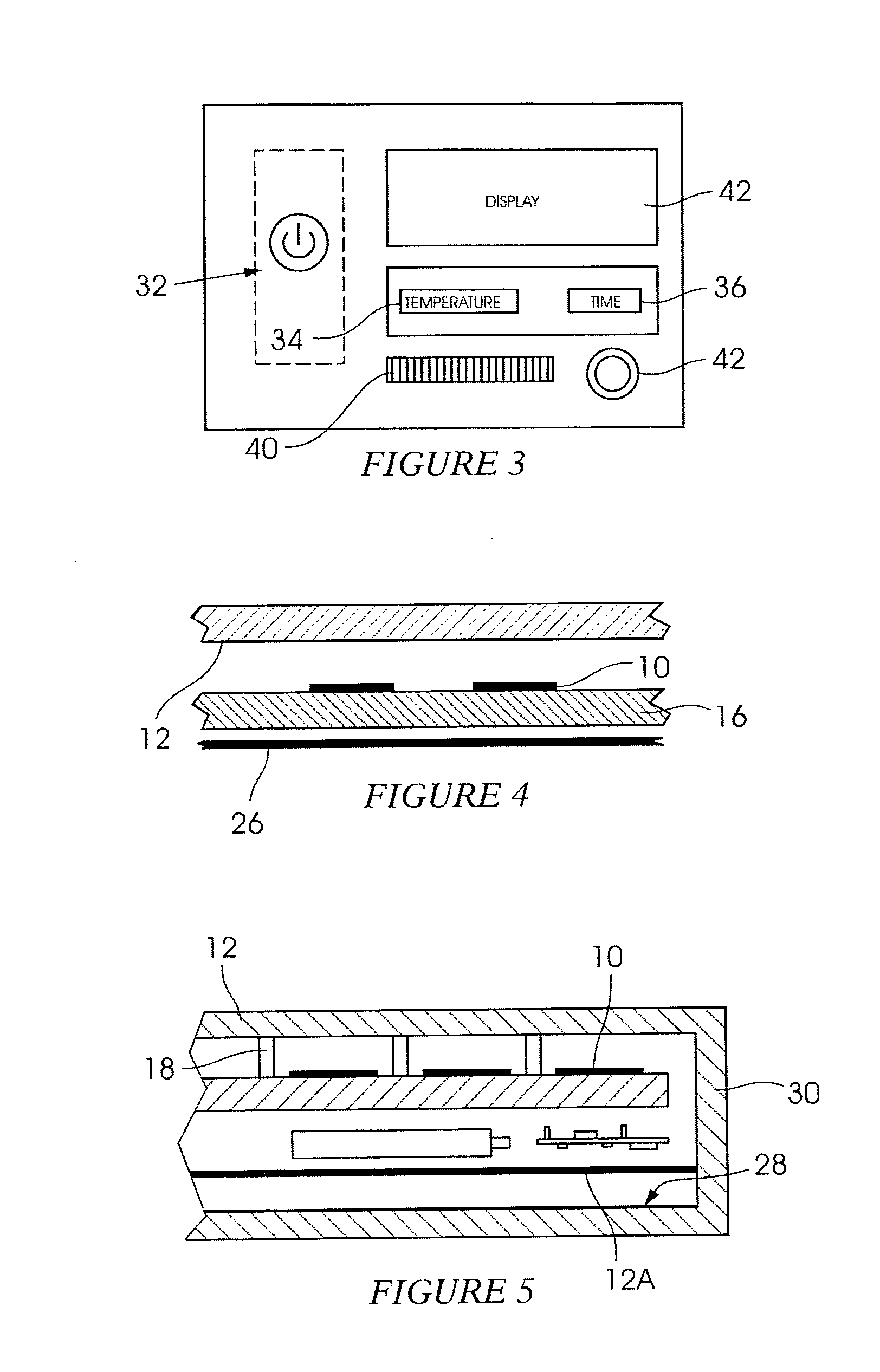

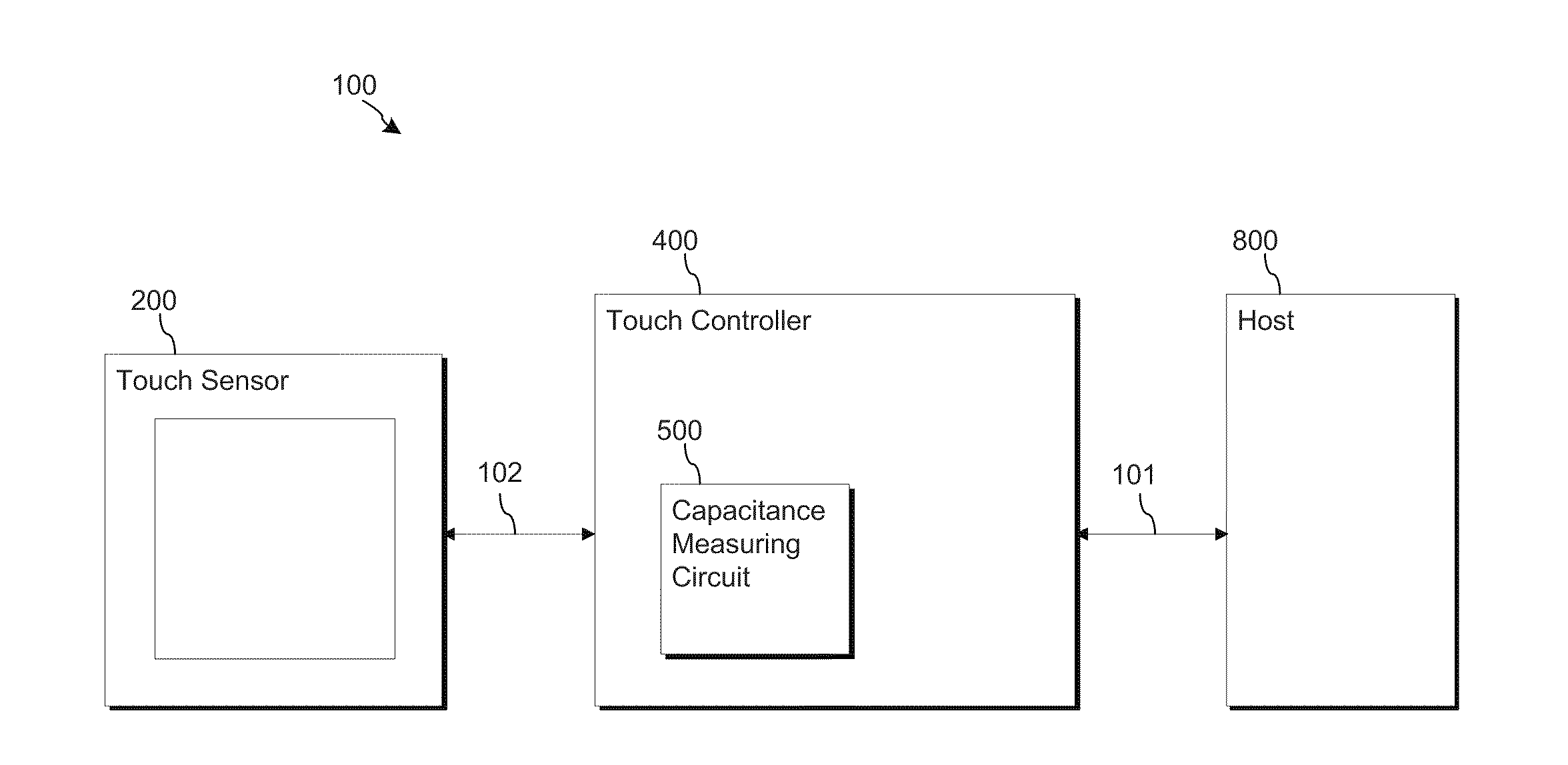

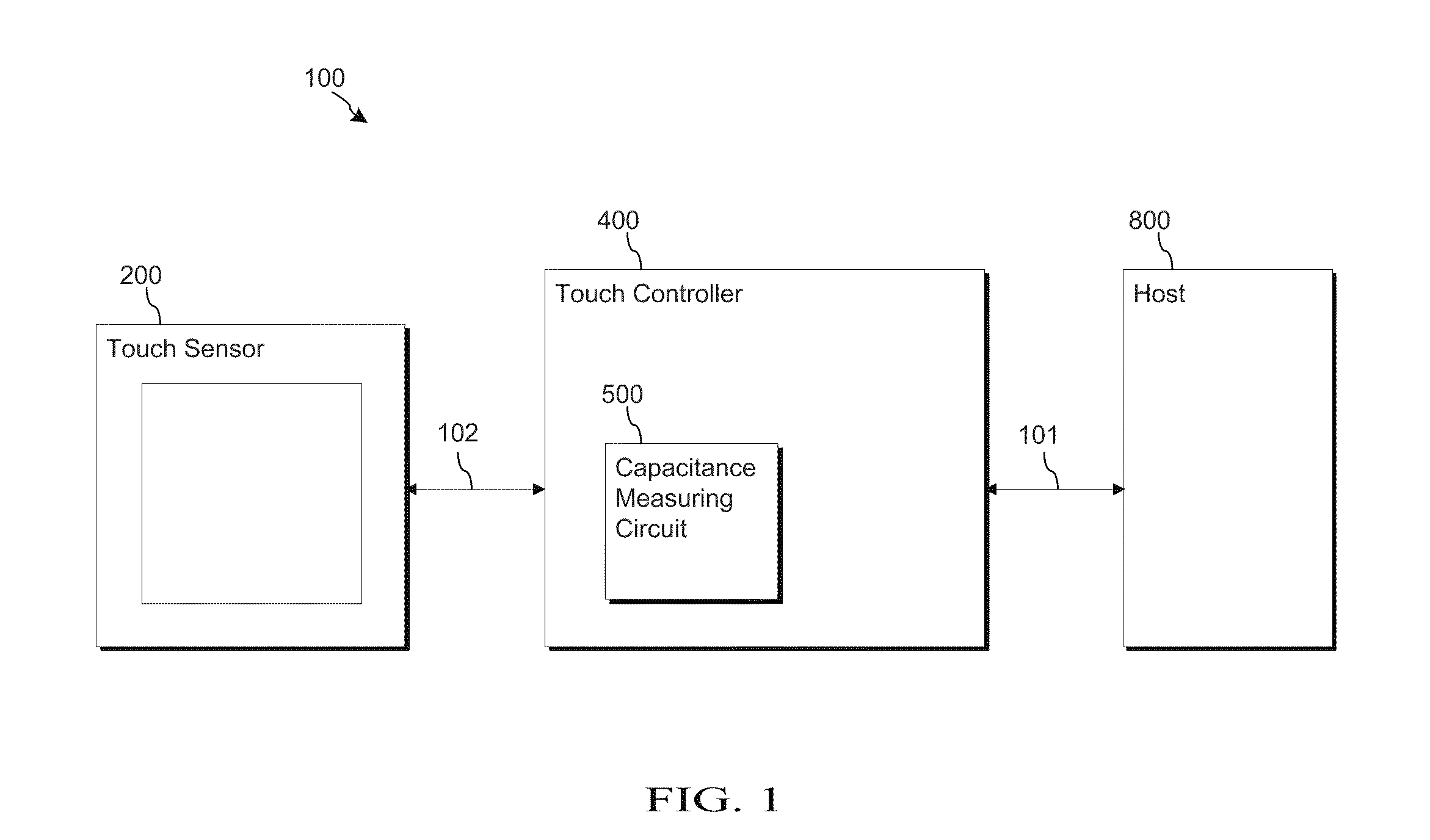

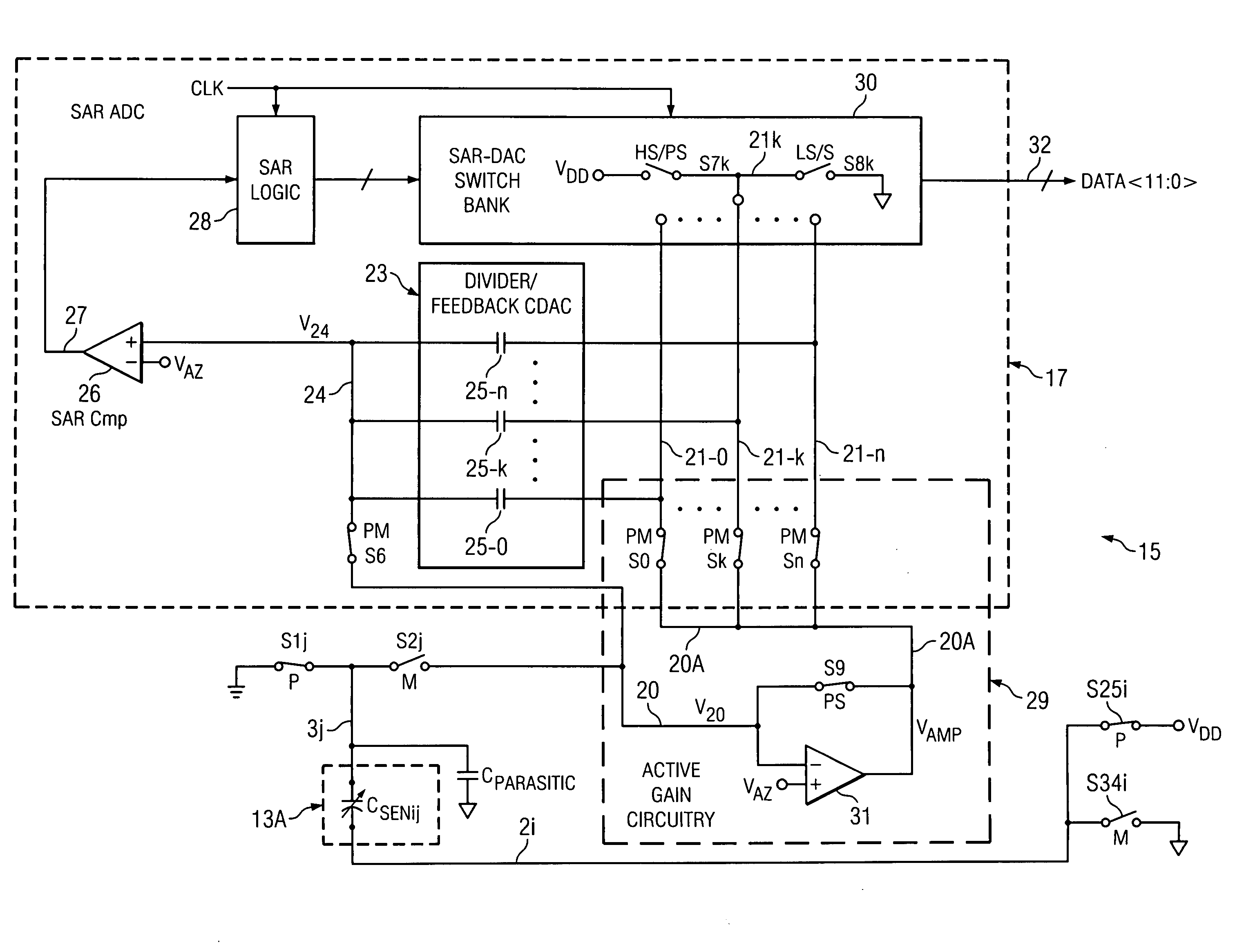

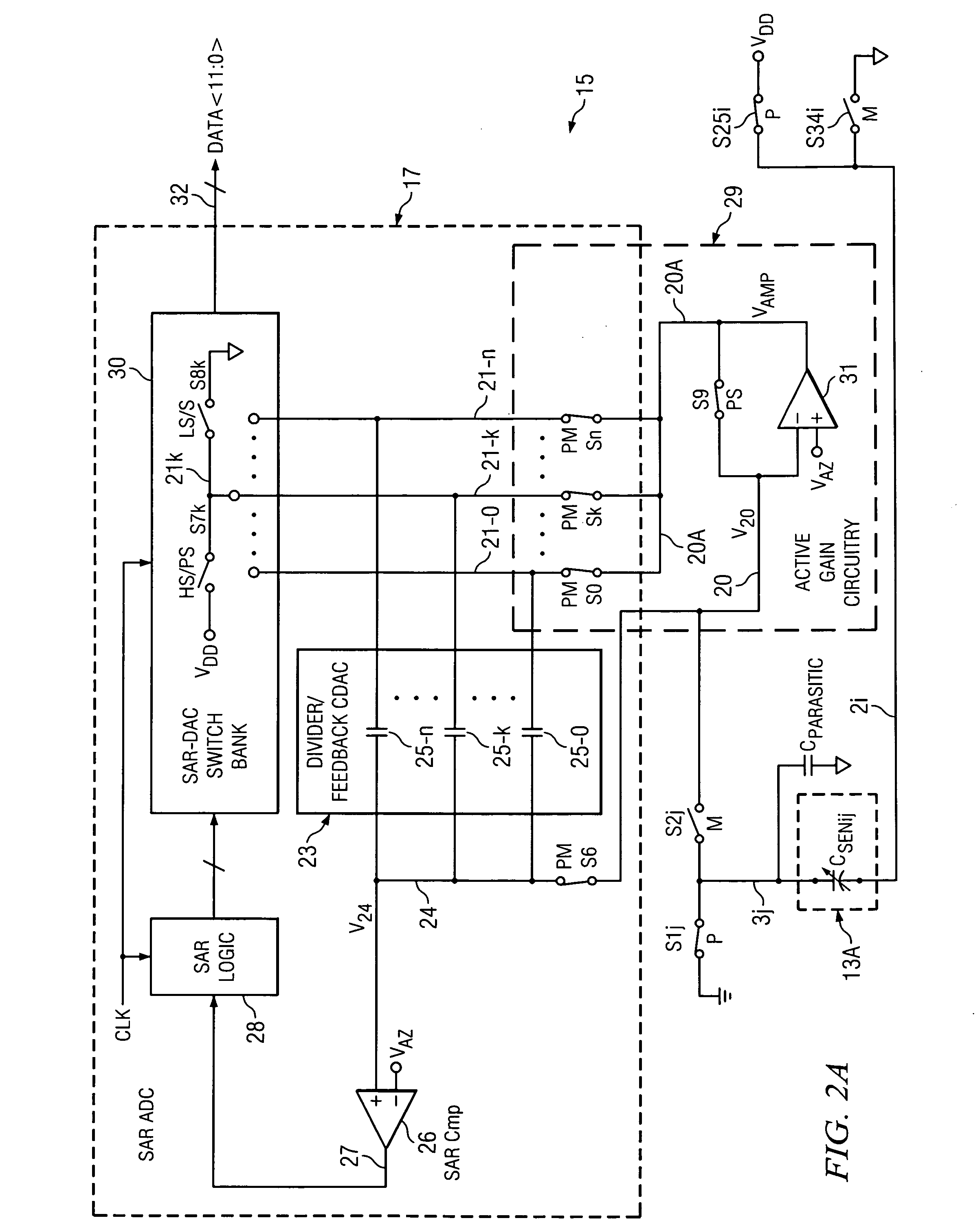

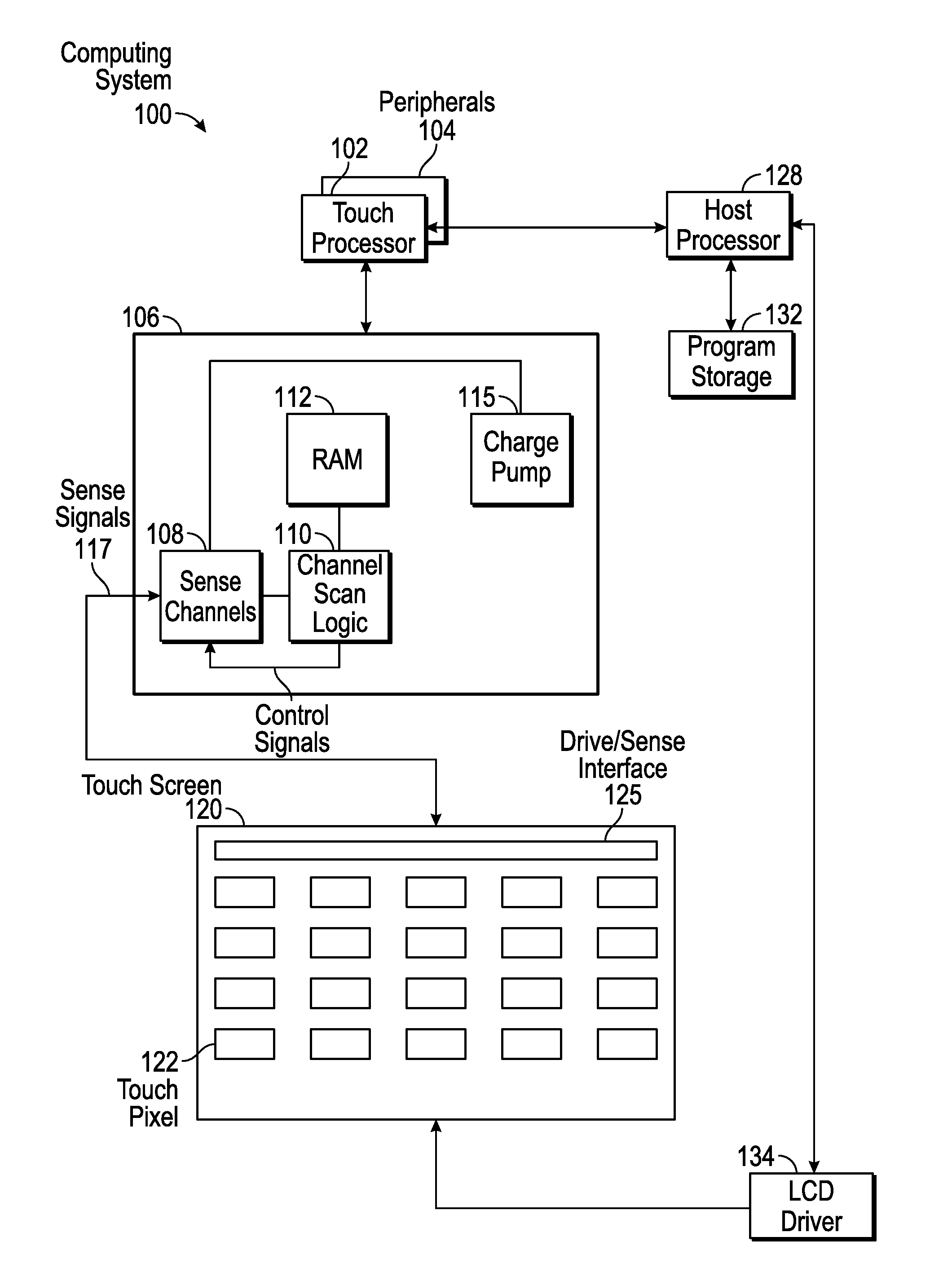

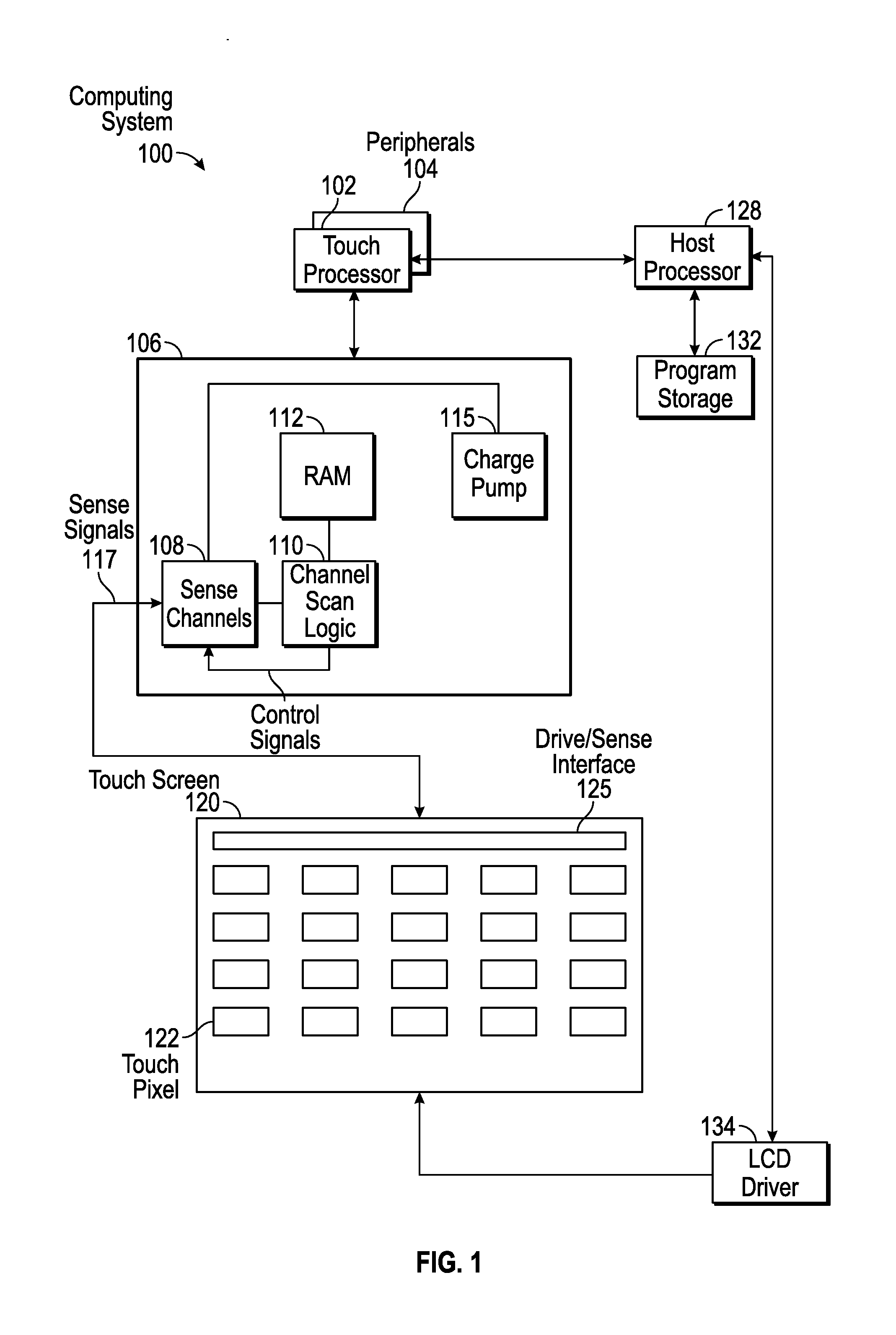

Method and apparatus for improving dynamic range of a touchscreen controller

ActiveUS20110261005A1Improve dynamic rangeLow costElectronic switchingInput/output processes for data processingOffset cancellationEngineering

A touchscreen system for increasing the dynamic range of the system comprising a touchscreen coupled to an offset cancellation element and a capacitance measuring element. The offset cancellation element is configured to be dynamically changed in capacitance such that it offsets parasitic and sensor capacitances of the touchscreen sensors thereby leaving only touch event capacitance to be measured by the measuring element. The offset cancellation element is able to adjust to the initial unwanted capacitances of each sensor as well as dynamically adjust to changes in the unwanted capacitance due to the environment. In some embodiments, the offset cancellation element is a capacitance digital-to-analog converter that is controlled by a controller for offsetting the unwanted capacitance. As a result, the touchscreen system is able to utilize a small integrating capacitor thereby lowering cost and improving the dynamic range of the system.

Owner:QUALCOMM INC

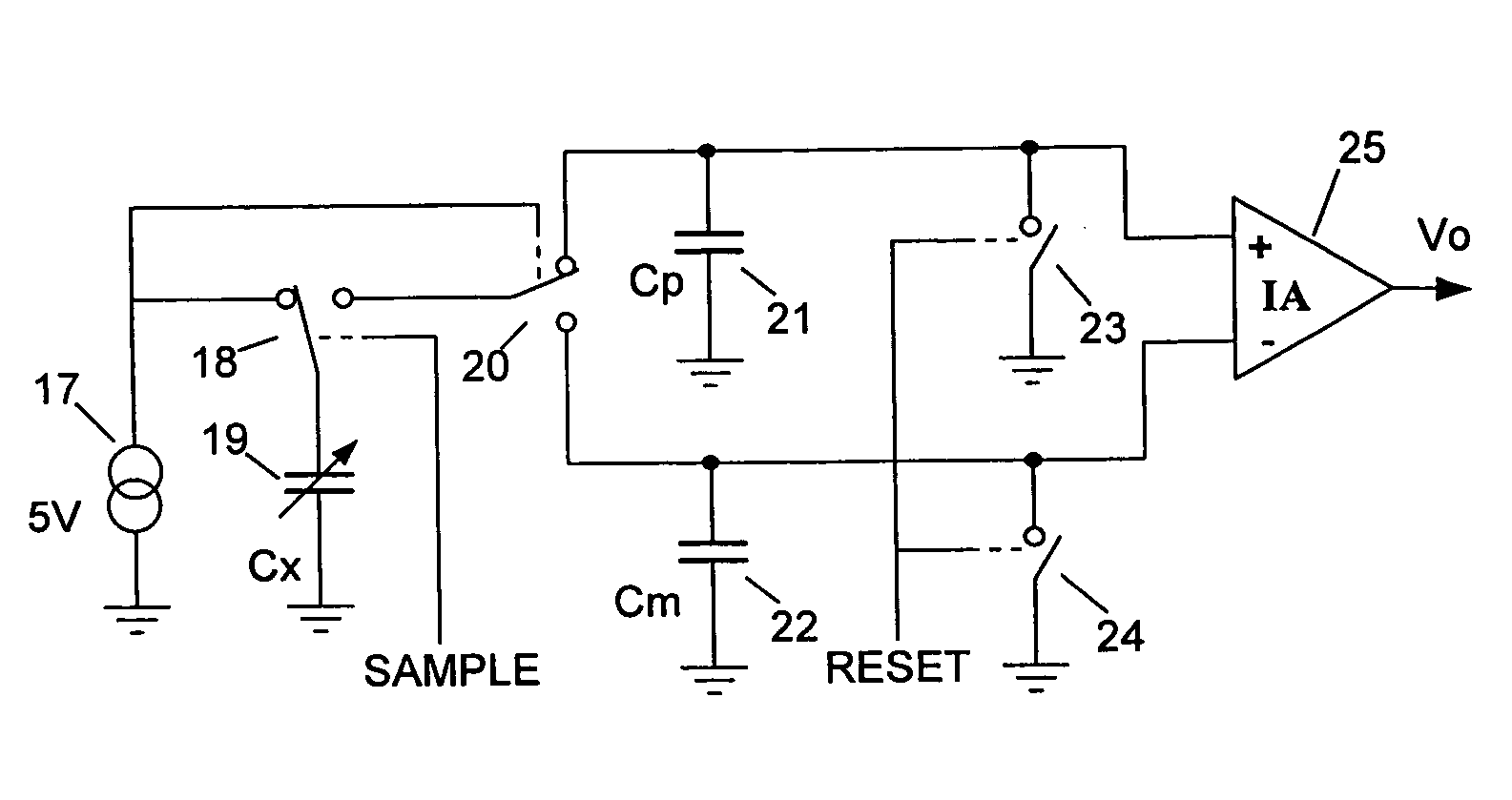

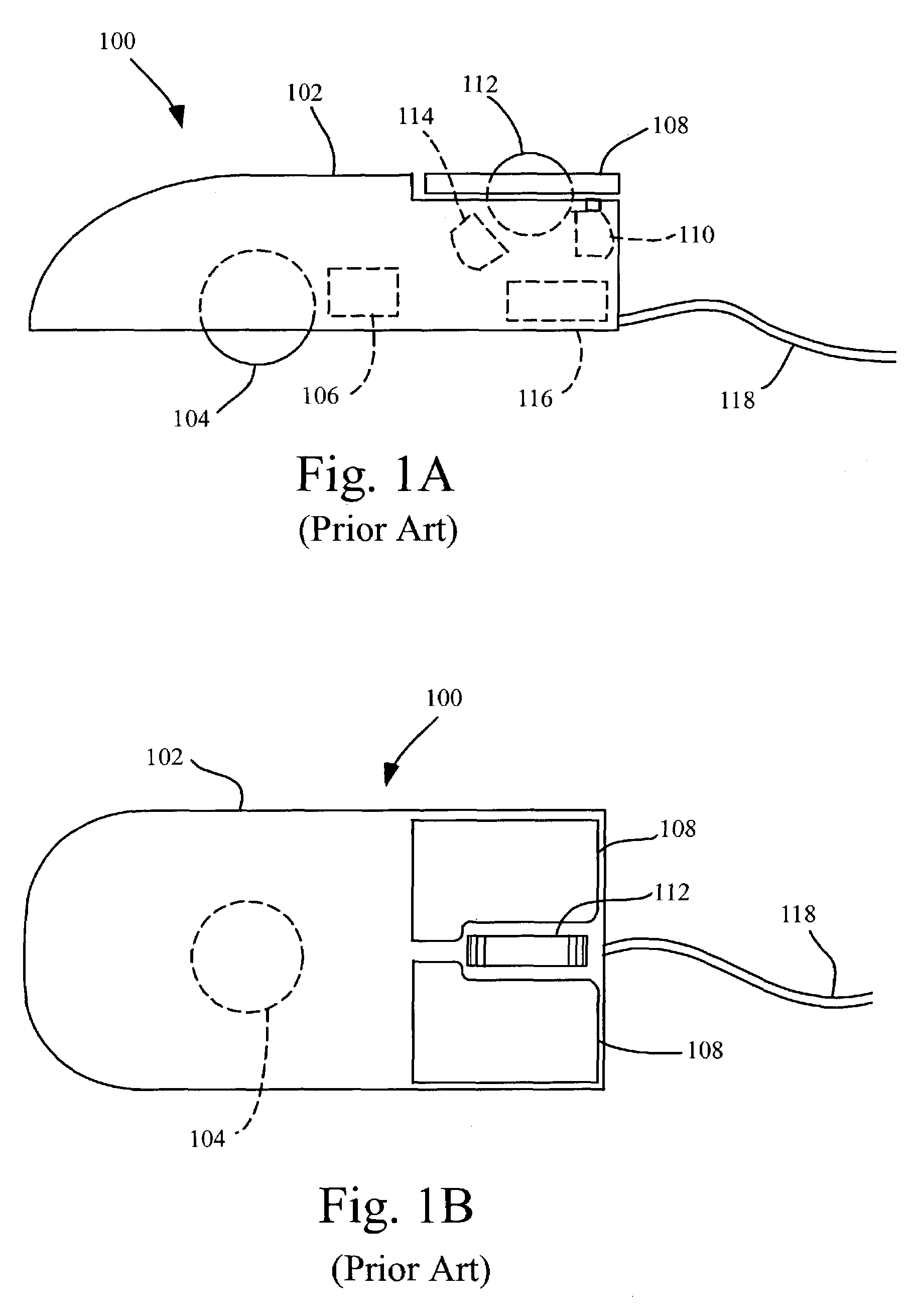

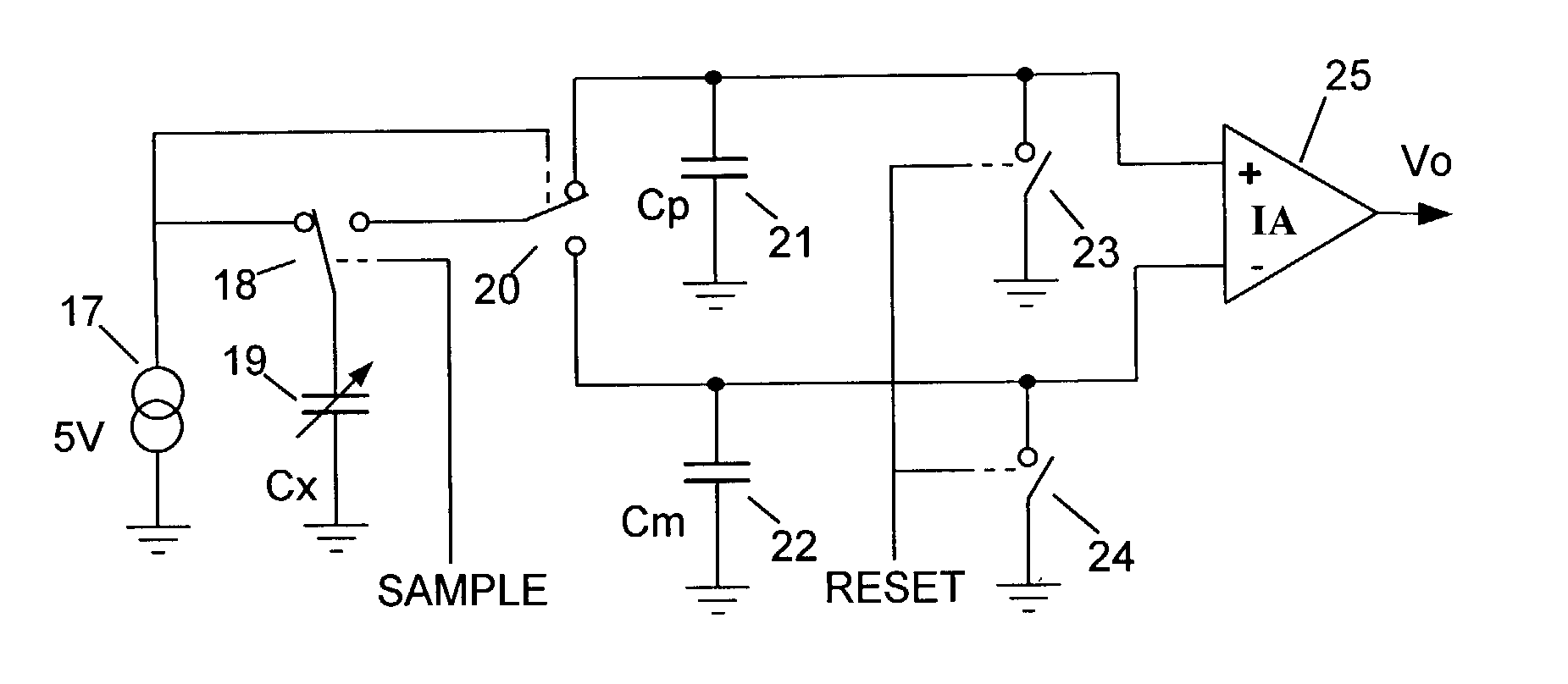

Capacitive measurement system

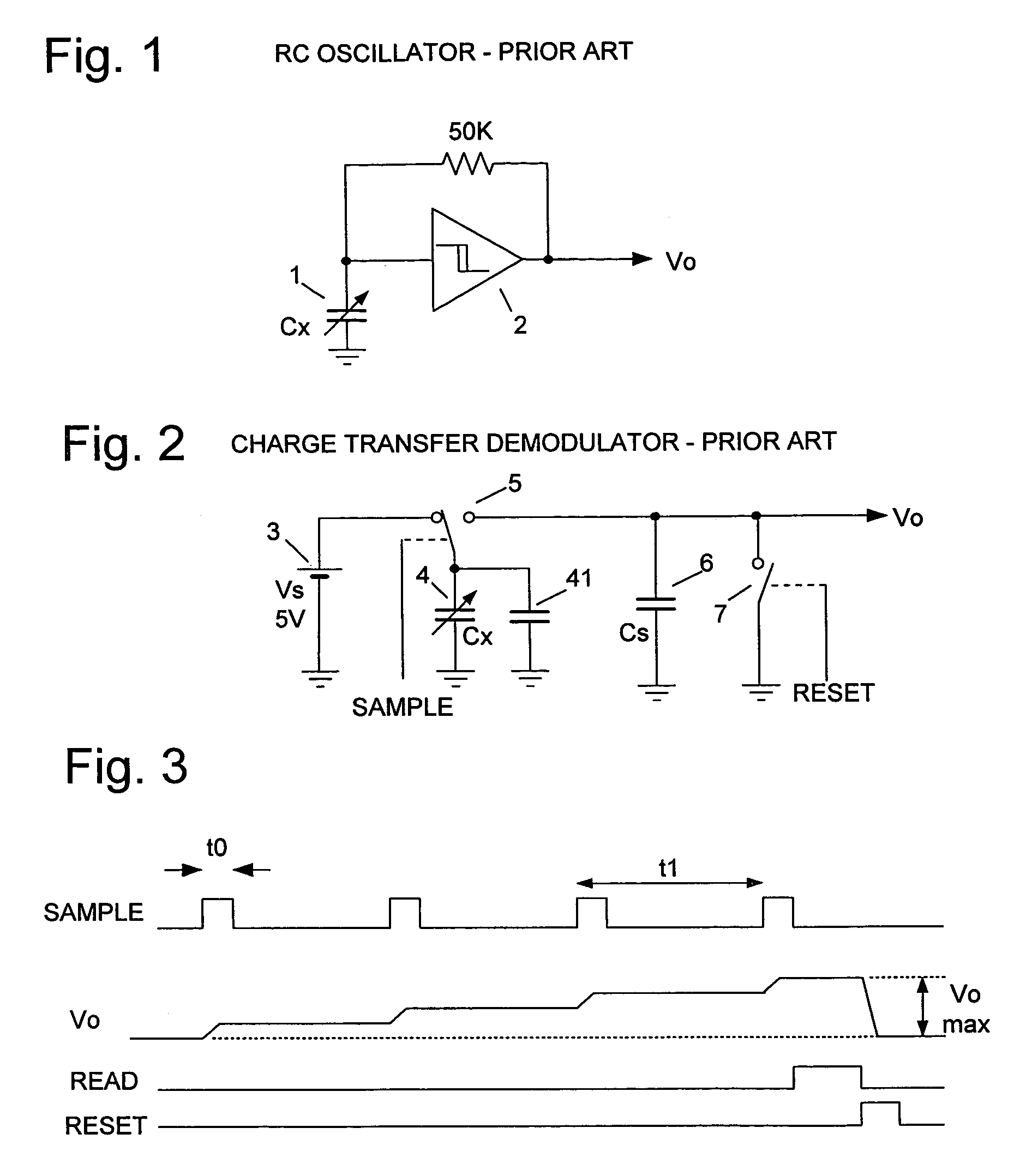

InactiveUS7129714B2Reduce and eliminate effectResistance/reactance/impedenceConverting sensor output electrically/magneticallyEngineeringCapacitor

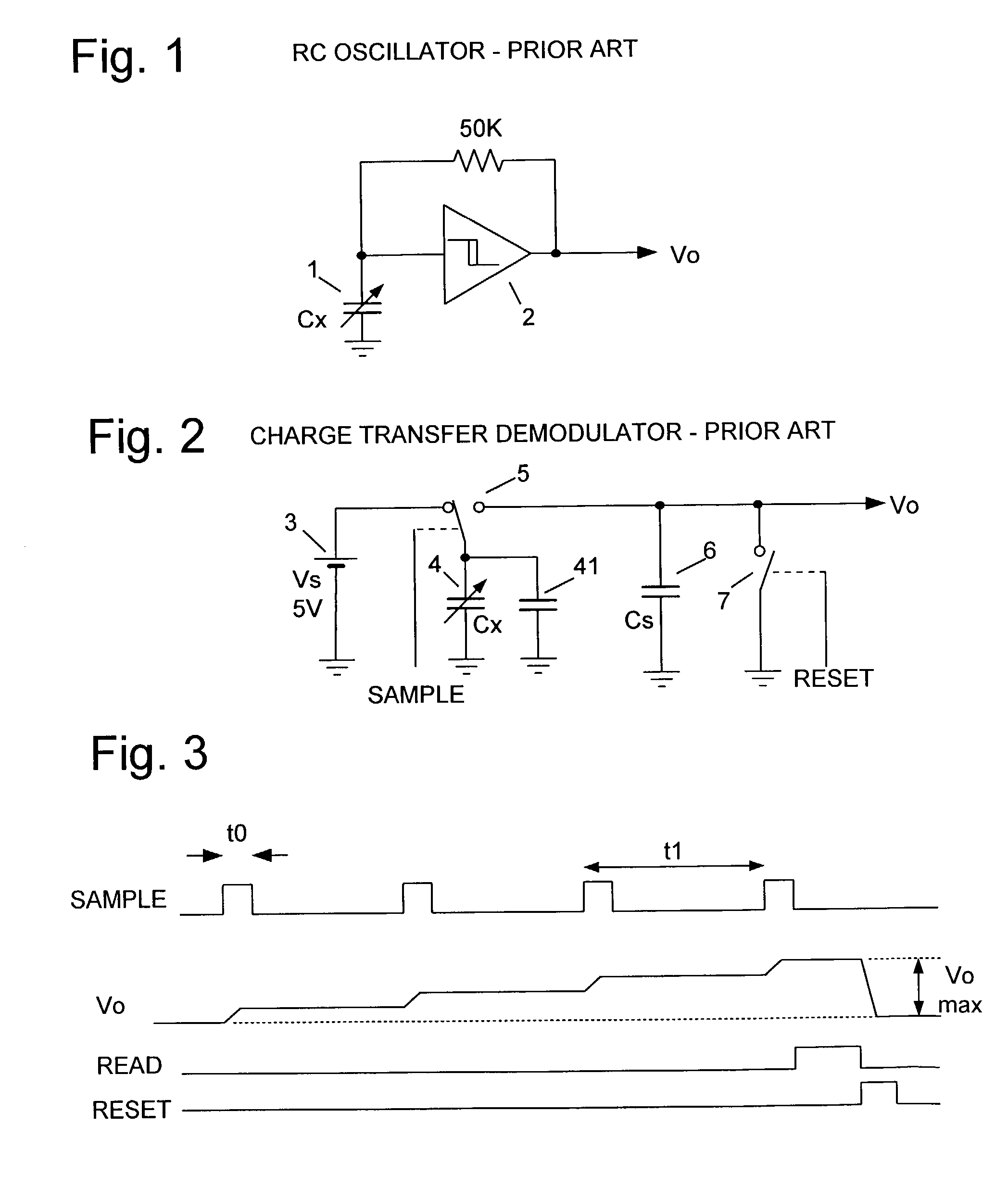

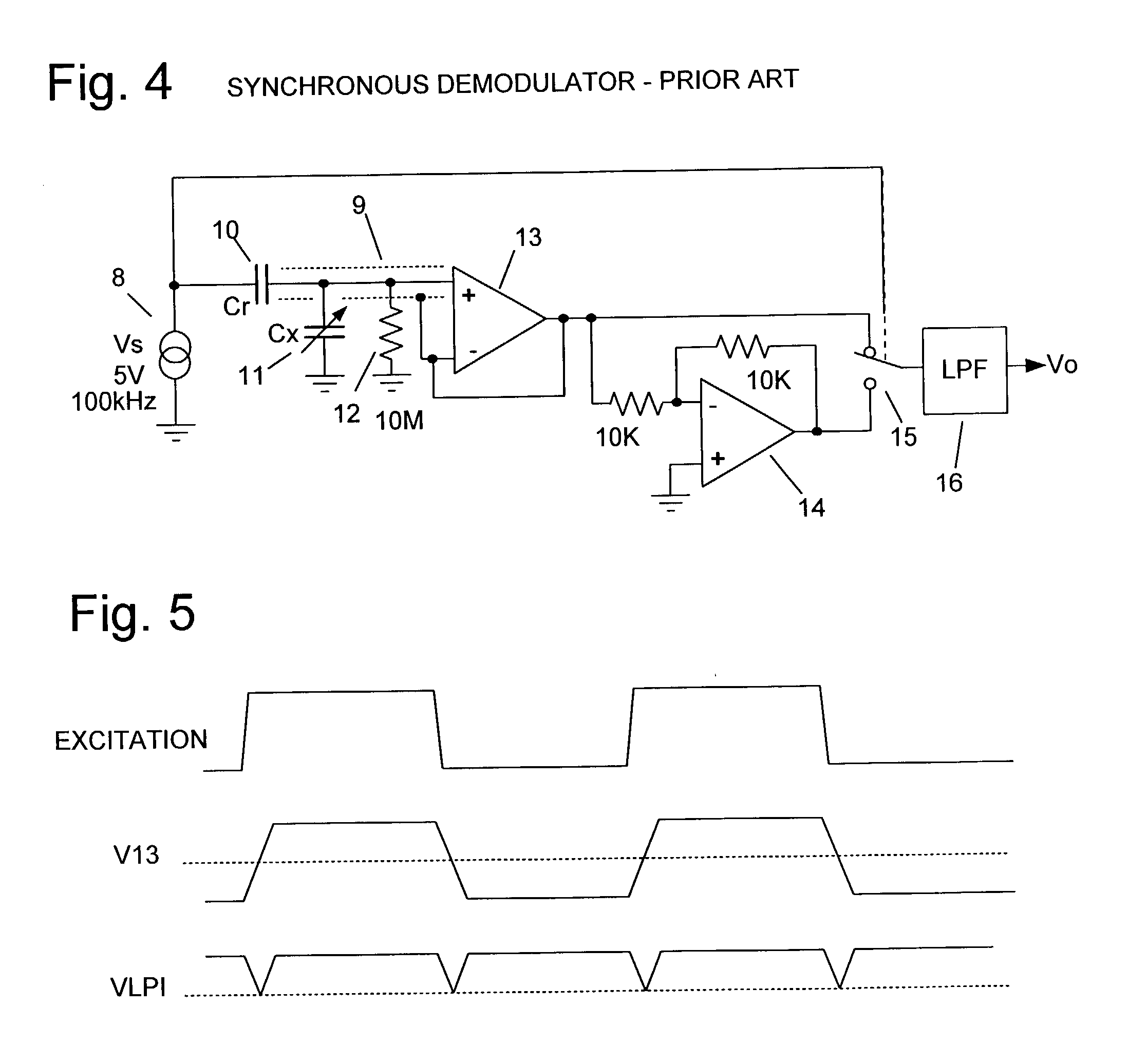

Sensor circuits for the measurement of small variations in the value of a sensing capacitor. An alternating voltage excites the sensing capacitor a predetermined frequency whereby the voltage on the sensing capacitor reverses polarity. This voltage on the sensing capacitor is sampled each time the voltage reverses polarity. An accumulator accumulates the sampled charges from the sensing capacitor. An output signal that represents the charge in the charge accumulating means indicates the measured capacitance.

Owner:BAXTER LARRY K

Capacitive mouse

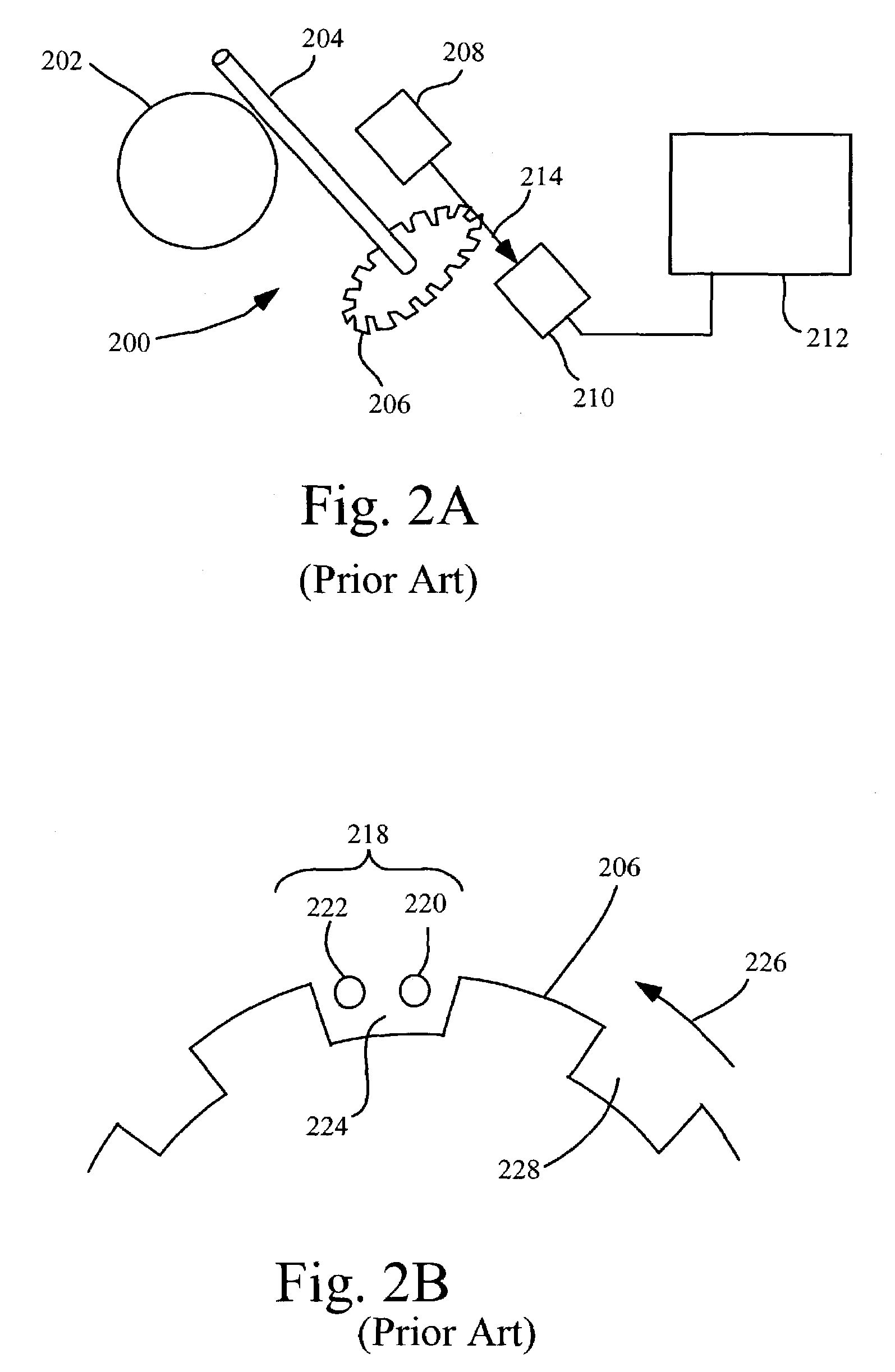

InactiveUS7212189B2Cathode-ray tube indicatorsInput/output processes for data processingKey pressingMotion detector

A pointing device some or all of whose elements are made from capacitive sensors. Such elements may include a rotary motion detector which includes a rotating member and a plurality of fixed capacitive detecting members; a rolling ball with patterned conductive surface and a plurality of fixed capacitive detecting members; capacitive touch sensors or capacitive switches to serve as mouse buttons; and a scrolling wheel, knob, or touch surface built from capacitive sensors. The pointing device further includes a capacitance measuring circuit and processor to measure variations of capacitance on the various capacitive elements and to determine the movement of and other activations of the mouse.

Owner:SYNAPTICS INC

Methods and apparatus for capacitive sensing

ActiveUS20110043227A1Resistance/reactance/impedenceElectronic switchingParasitic capacitanceEngineering

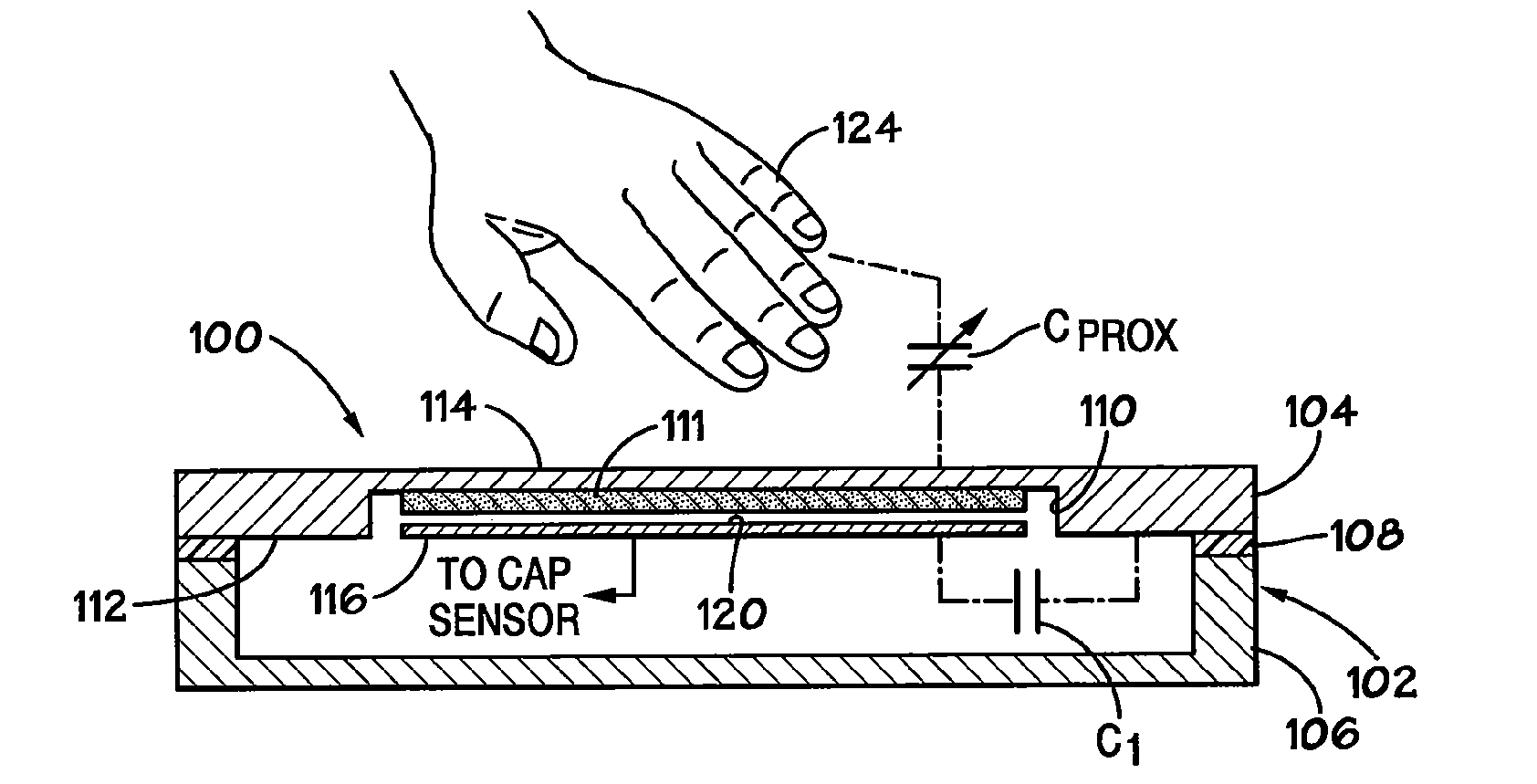

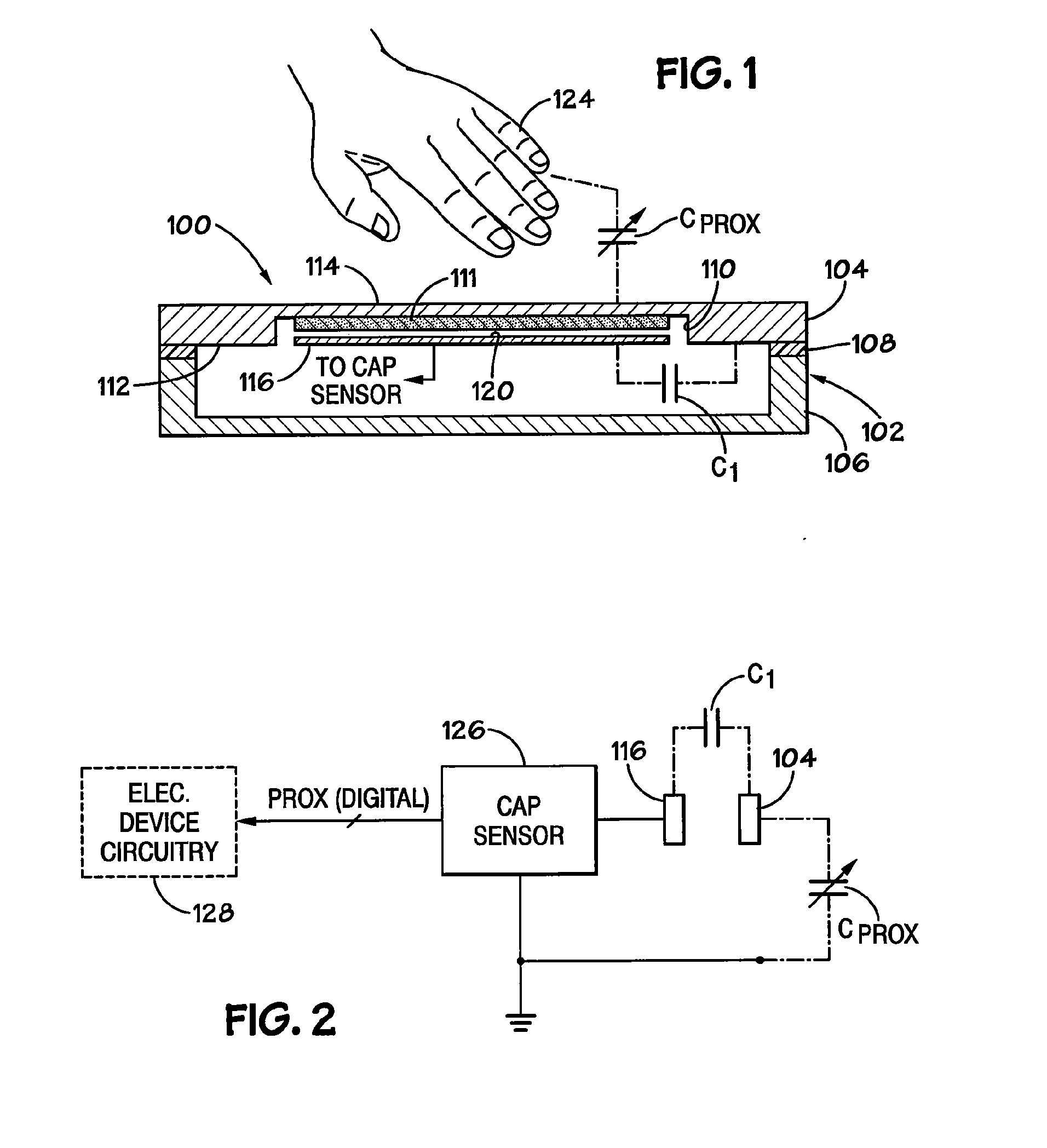

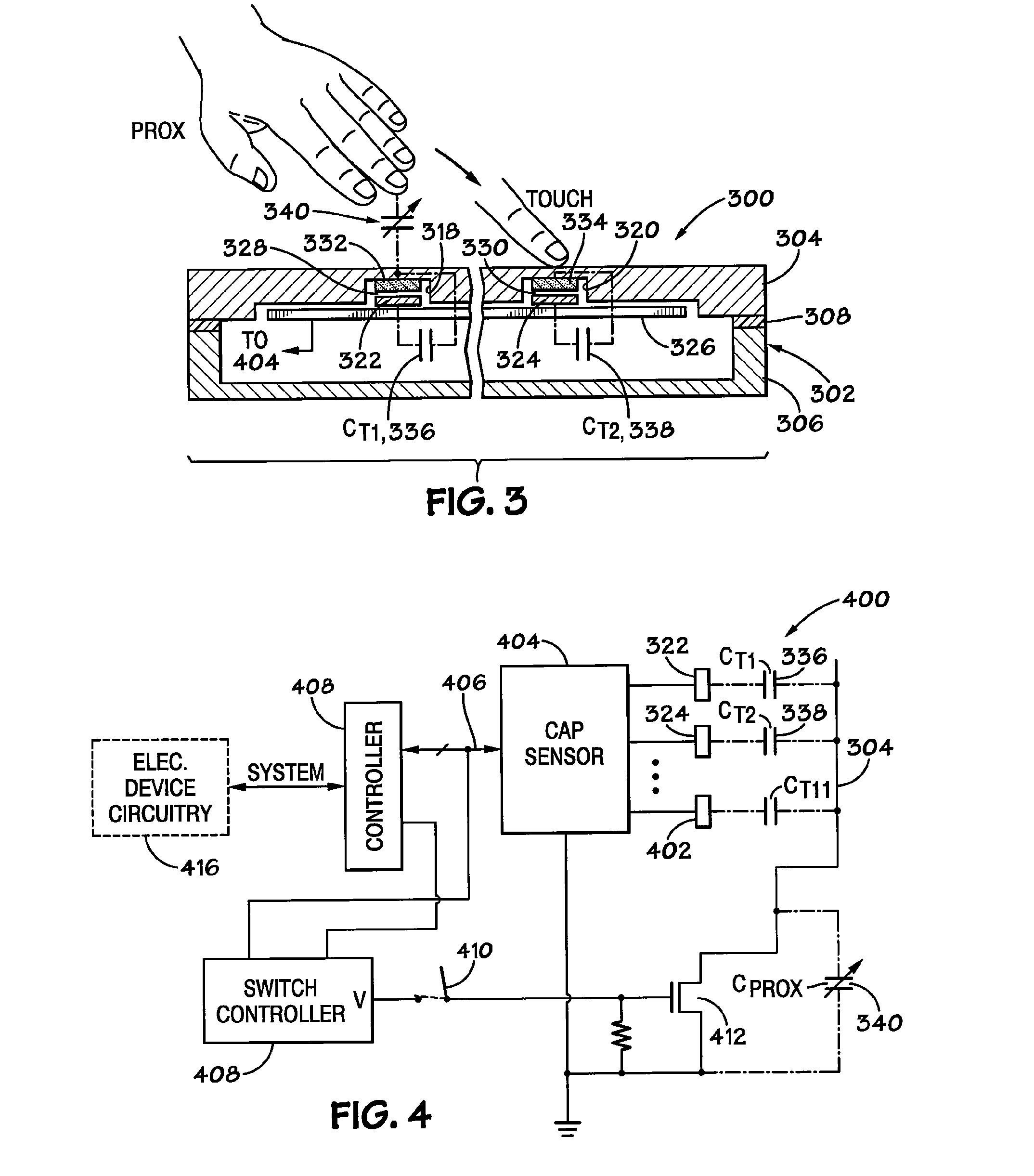

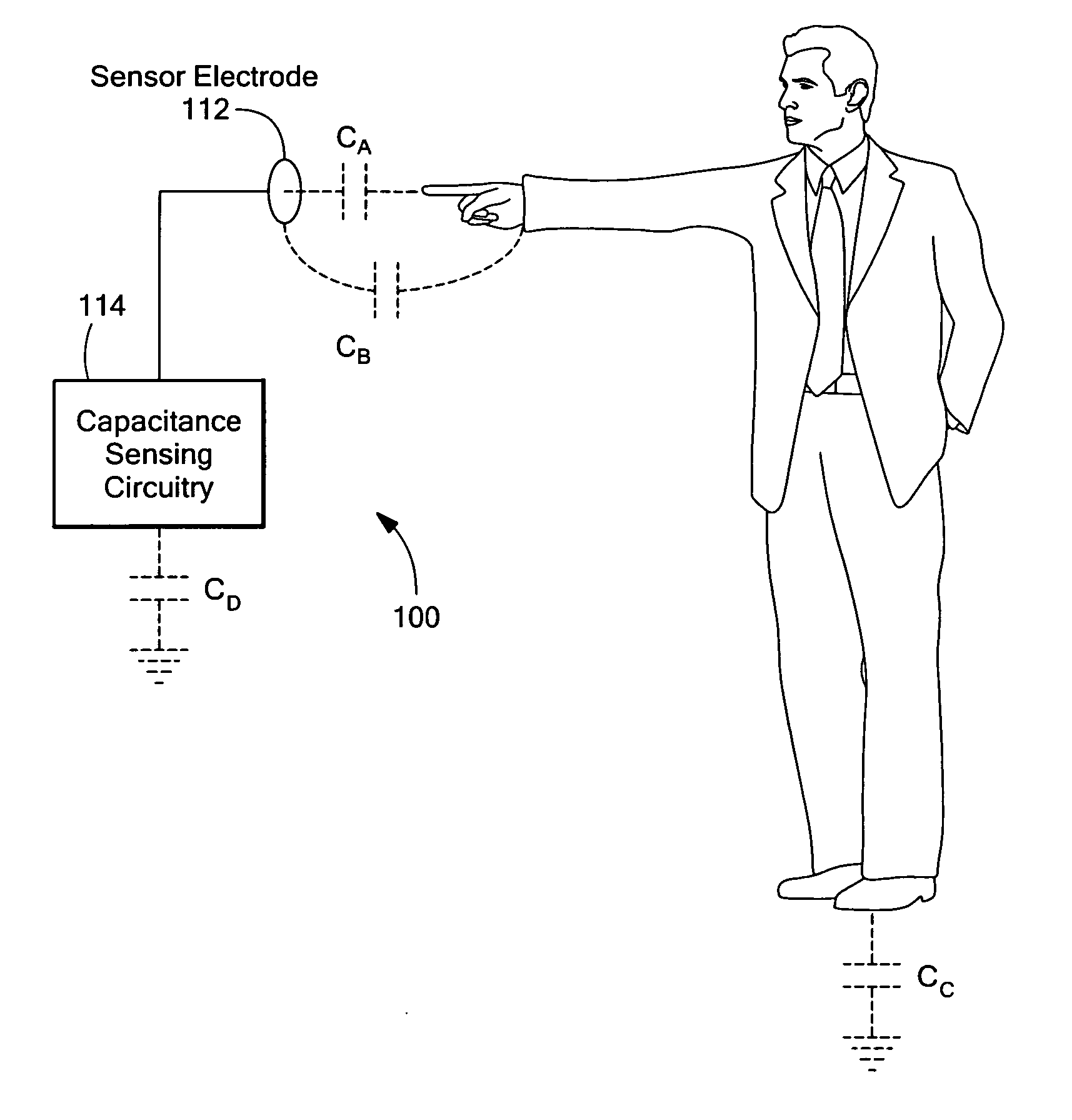

The present disclosure addresses methods and apparatus facilitating capacitive sensing using a conductive surface, and facilitating the sensing of proximity to the conductive surface. The sensed proximity will often be that of a user, but can be another source of a reference voltage potential. In some examples, the described systems are capable of sensing capacitance (including parasitic capacitance) in a circuit that includes the outer conductive surface, and where that outer conductive surface is at a floating electrical potential. In some systems, the systems can be switched between two operating modes, a first mode in which the system will sense proximity to the conductive surface, and a second mode in which the system will use a capacitance measurement to sense contact with the conductive surface.

Owner:APPLE INC

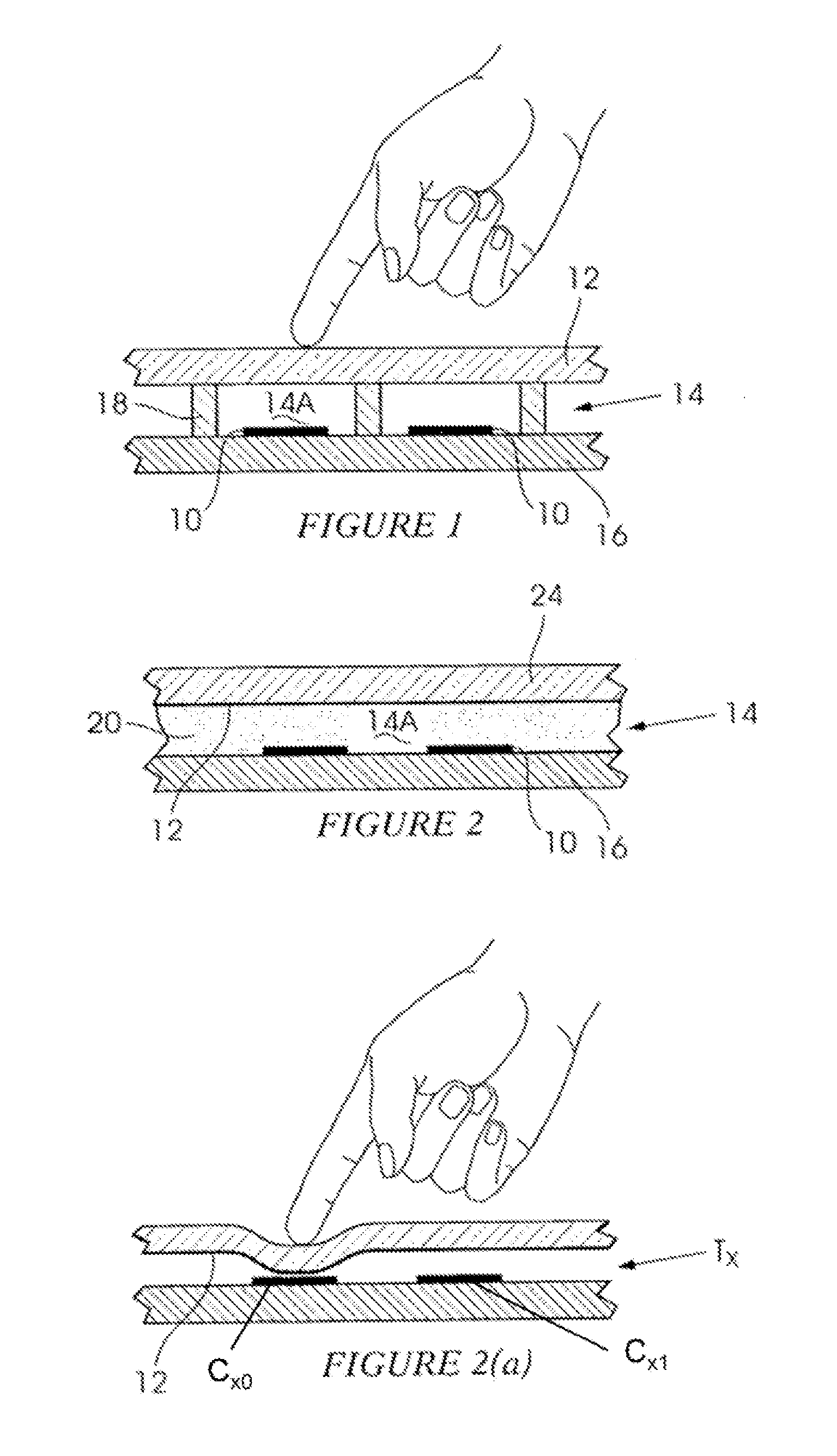

Pressure dependent capacitive sensing circuit switch construction

ActiveUS20130093500A1Easy constructionElectronic switchingInput/output processes for data processingEvent typeEngineering

A user interface which includes a capacitive measurement circuit with a sense plate covered by an electrically conductive cover member, and wherein said circuit may sense two types of events, said types distinguished by an inverse change in measured capacitance, and wherein user proximity and touches with less than a minimum required force constitute one event type, and touches with more than said minimum force constitute the other event type.

Owner:AZOTEQ HLDG LTD

Capacitive sensor circuit with good noise rejection

InactiveUS20040004488A1Improved noise suppressionResistance/reactance/impedenceConverting sensor output electrically/magneticallyNoise suppressionImpedance sensor

This invention describes the deficiencies of current art for sensitive impedance sensors, particularly capacitive sensors, and describes several circuits that improve measurement of small value capacitances, especially in the presence of noise. It also shows various circuit architectures optimized for different capacitive sensing tasks. The circuits also describe a novel method to linearize a conventional charge-transfer capacitive sense circuit and a novel method to eliminate the effect of stray capacitance in charge-transfer capacitive sensors.

Owner:BAXTER LARRY K

Capacitive two dimensional sensor

InactiveUS20020152048A1Resistance/reactance/impedenceMeasurement arrangements for variableEngineeringElectrode array

A two dimensional array of electrodes for sensing the presence or absence of the ridges in a fingerprint through capacitive measurements. Exciting signals are supplied from outside the array which allows the array to be fabricated from metal and insulator layers on non-semiconductor substrates such as glass or plastic using normal deposition and patterning techniques. A top protective layer consisting of hard, rigid material may be provided. The required electronic circuits are preferably located around the periphery of the array.

Owner:SENTRONICS CORP

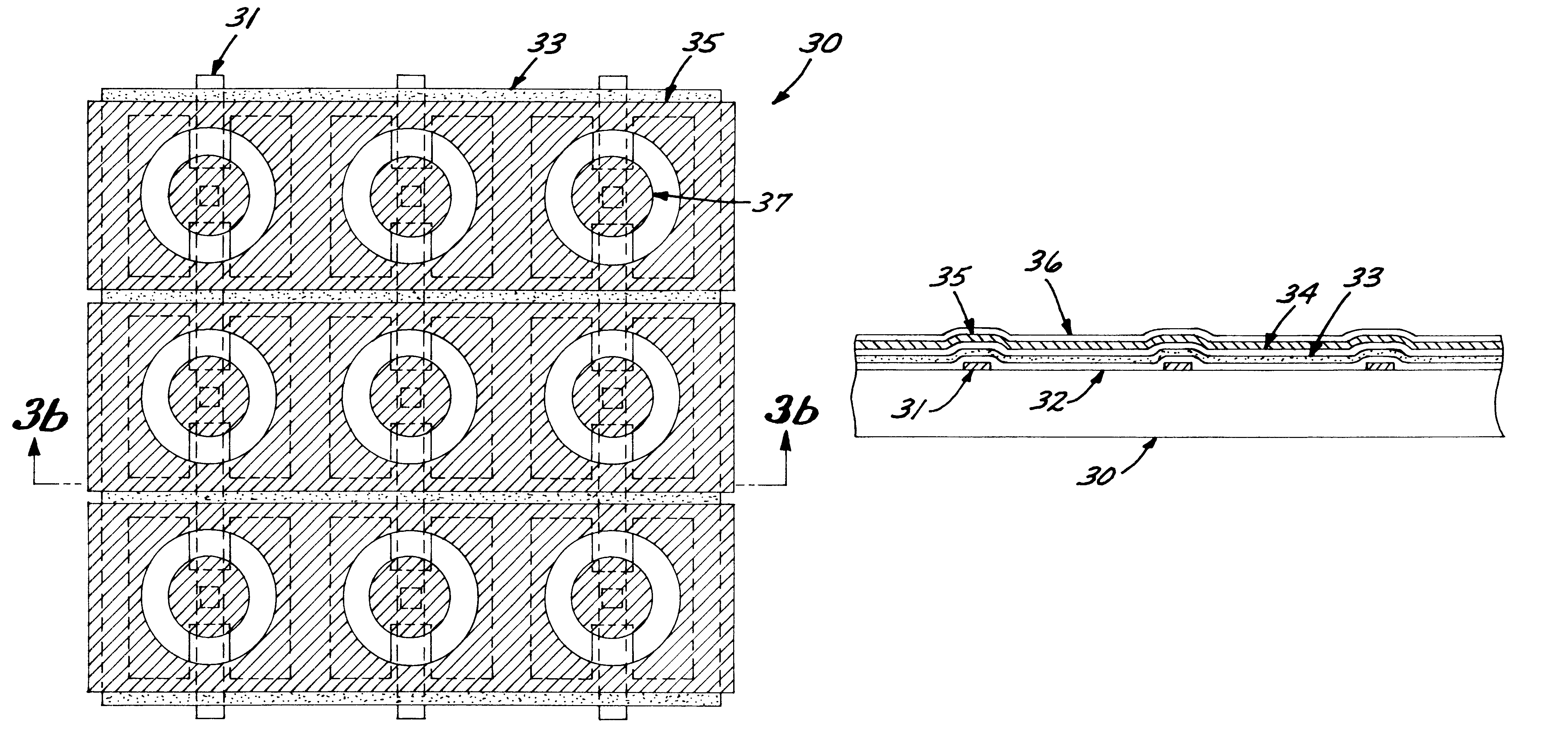

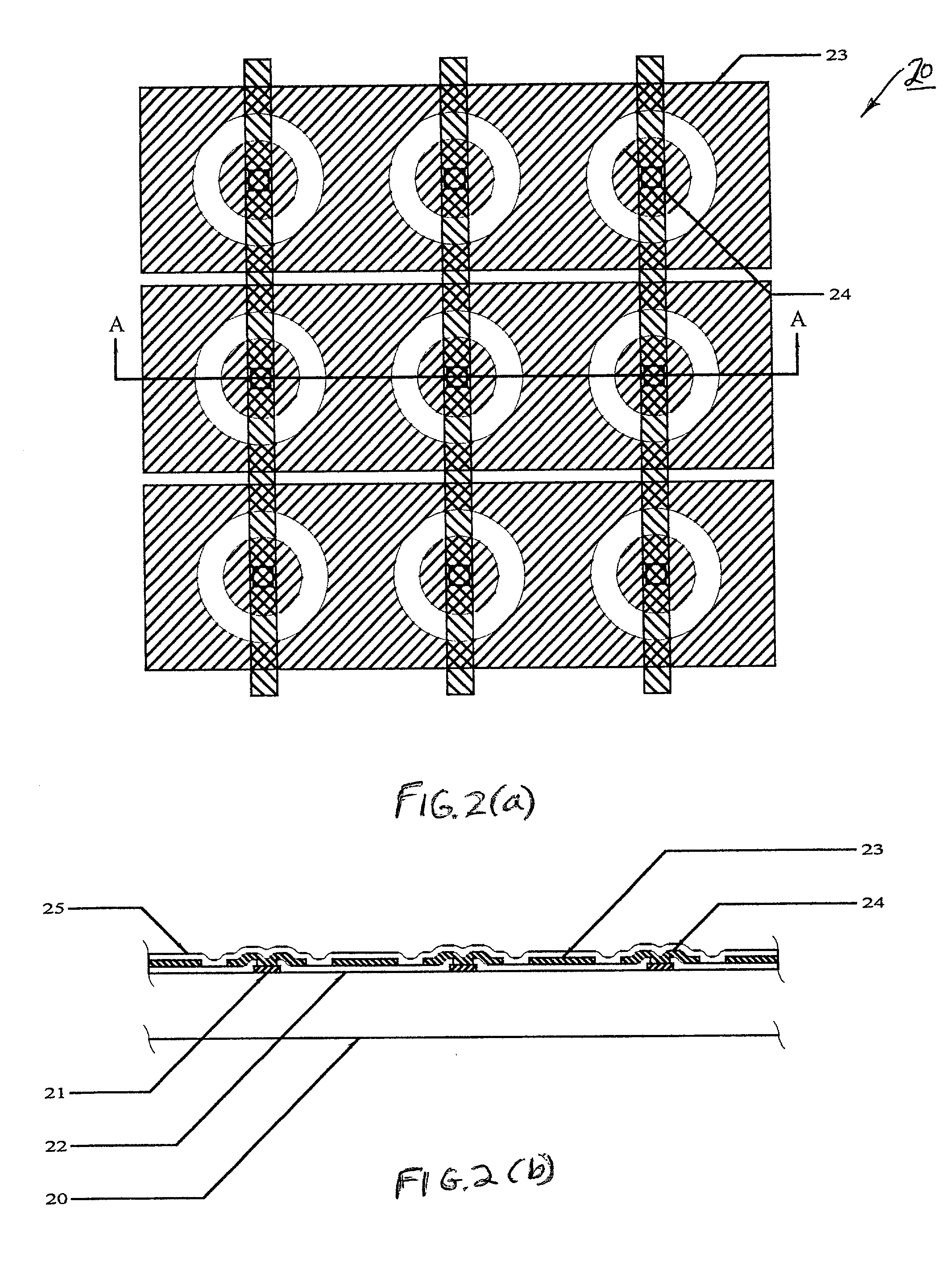

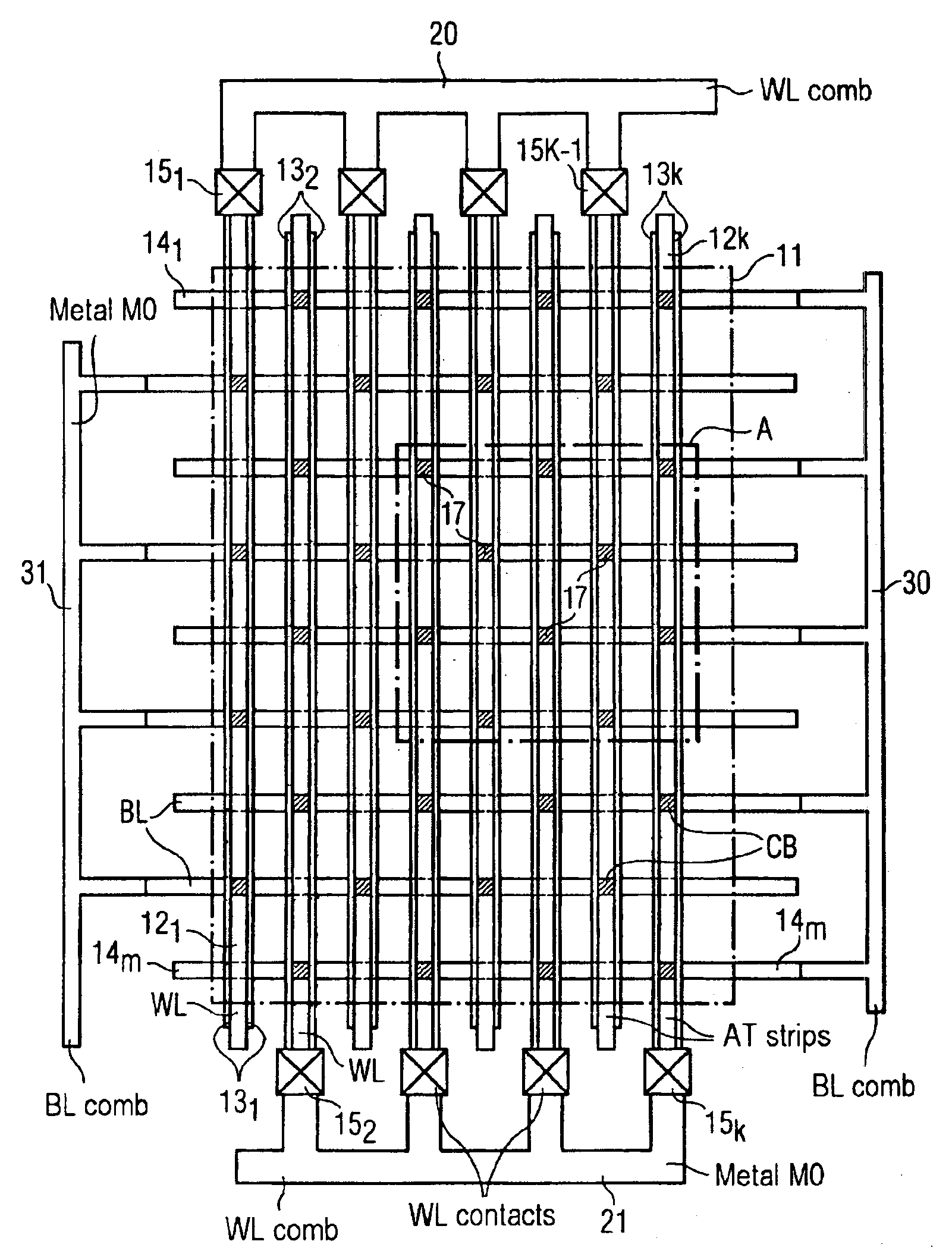

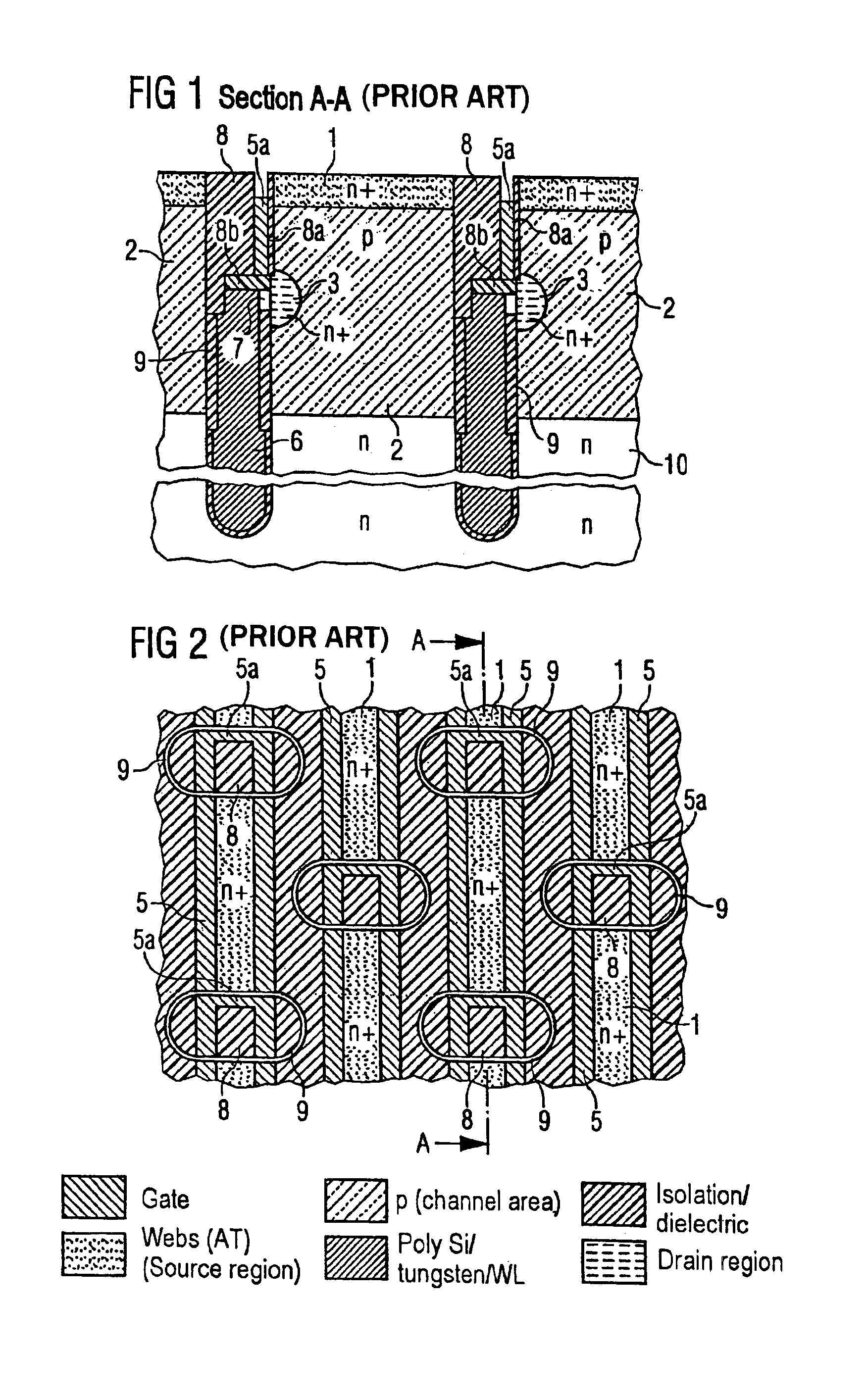

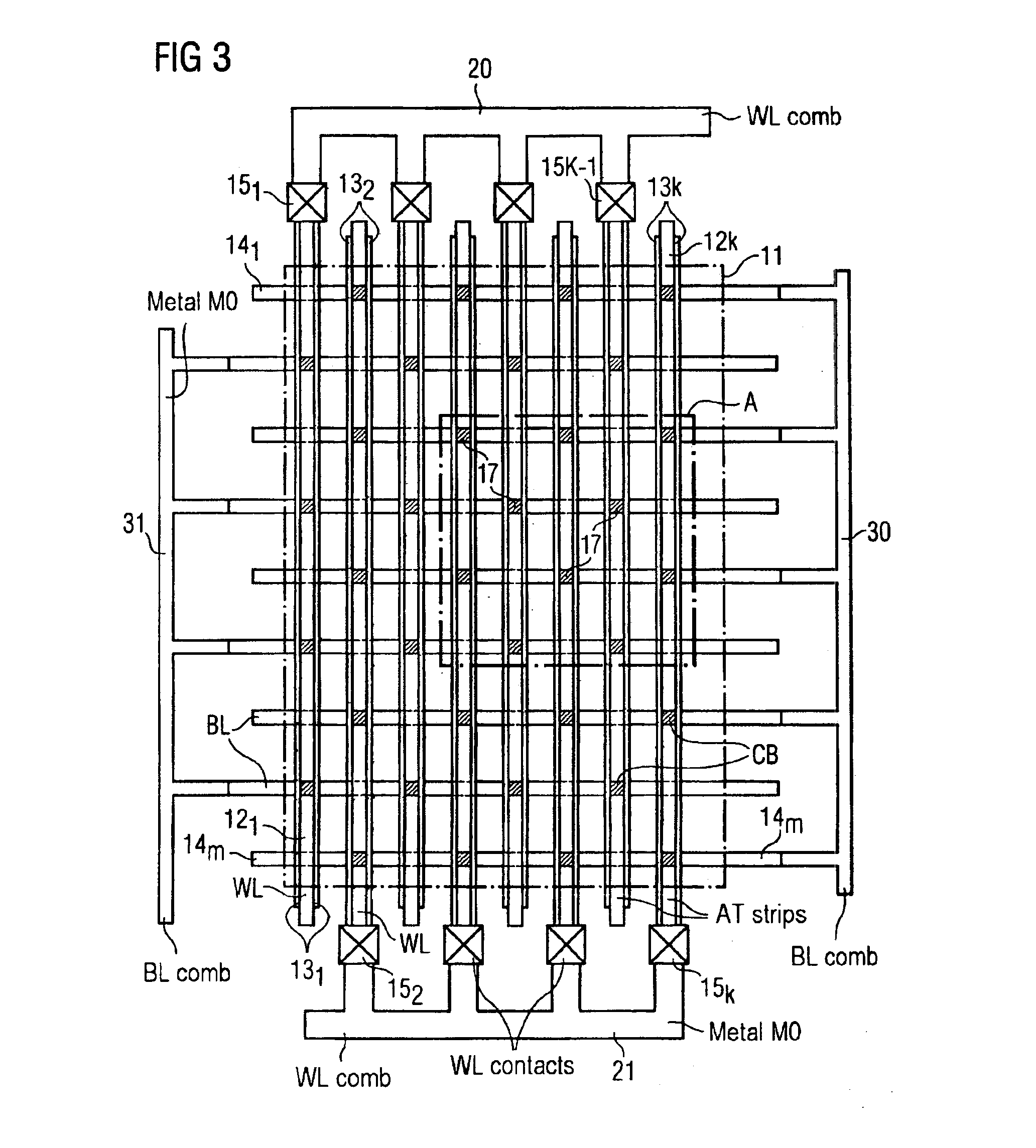

Device architecture and process for improved vertical memory arrays

InactiveUS6930324B2TransistorSemiconductor/solid-state device testing/measurementTransistor arrayDielectric

An array process diagnosis test structure for an integrated circuit including a transistor array composed of vertical FET memory cell access transistors, which are formed into the depth of a substrate in the form of active webs which run parallel in the lateral direction of the circuit is disclosed. Memory cell storage capacitors in the array test structure are formed in deep trenches on the end faces of those sections of the active webs which form the vertical FET transistors. Word lines are arranged along the webs and along parallel intersecting bit lines of the array, outside of which, and on two mutually opposite edges, are located a first and second word line comb. The wordline combs are offset and connected alternately to different word lines. In addition, a first and a second bit line comb are formed on the two other opposing edges of the transistor array mutually offset and each connected to different bit lines. The test structure provides a convenient means to carry out reliability investigations on the gate oxide of the vertical FET transistors and on the capacitor dielectric in the deep trenches, capacitance measurements between the word lines, and between the word lines and other circuit layers, as well as capacitance measurements between the bit lines and between the bit lines and other circuit layers, and thus facilitates diagnosis of possible fault sources arising during the production process.

Owner:POLARIS INNOVATIONS

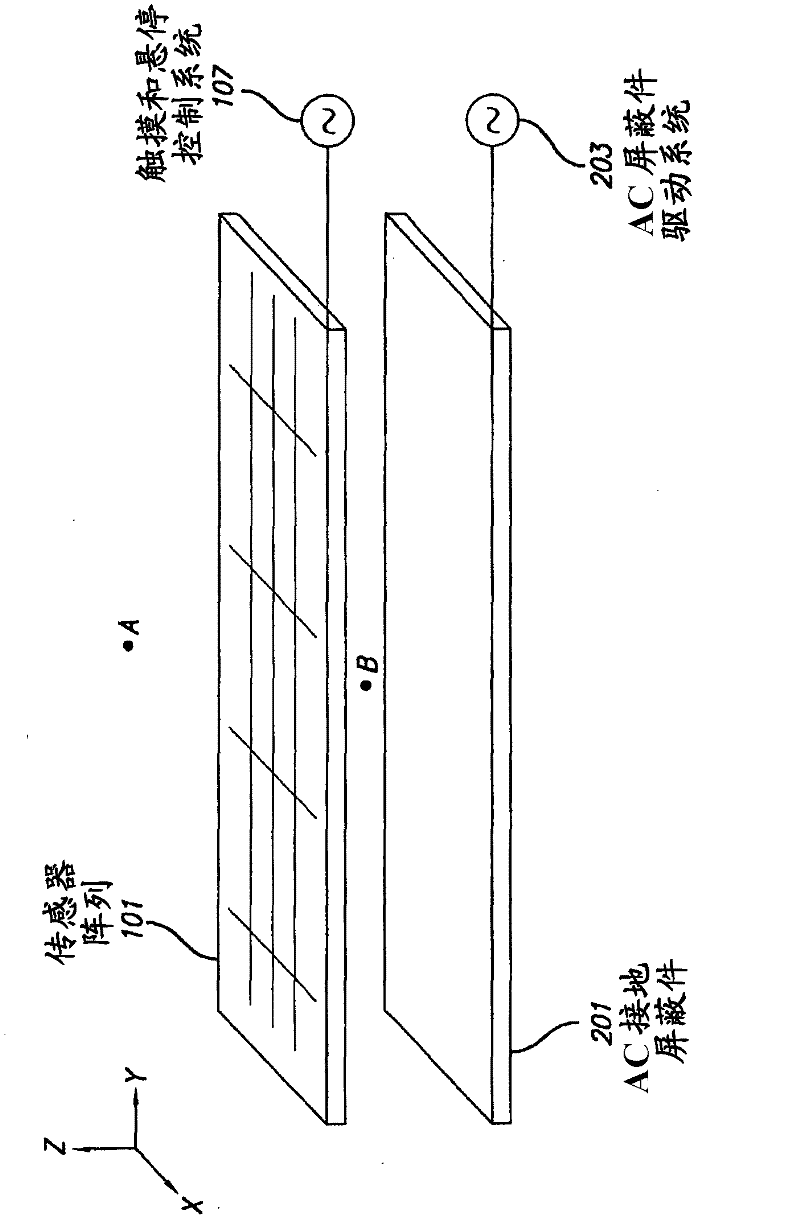

Touch and hover sensing

Improved capacitive touch and hover sensing with a sensor array is provided. An AC ground shield positioned behind the sensor array and stimulated with signals of the same waveform as the signals driving the sensor array may concentrate the electric field extending from the sensor array and enhance hover sensing capability. The hover position and / or height of an object that is nearby, but not directly above, a touch surface of the sensor array, e.g., in the border area at the end of a touch screen, may be determined using capacitive measurements of sensors near the end of the sensor array by fitting the measurements to a model. Other improvements relate to the joint operation of touch and hover sensing, such as determining when and how to perform touch sensing, hover sensing, both touch and hover sensing, or neither.

Owner:APPLE INC

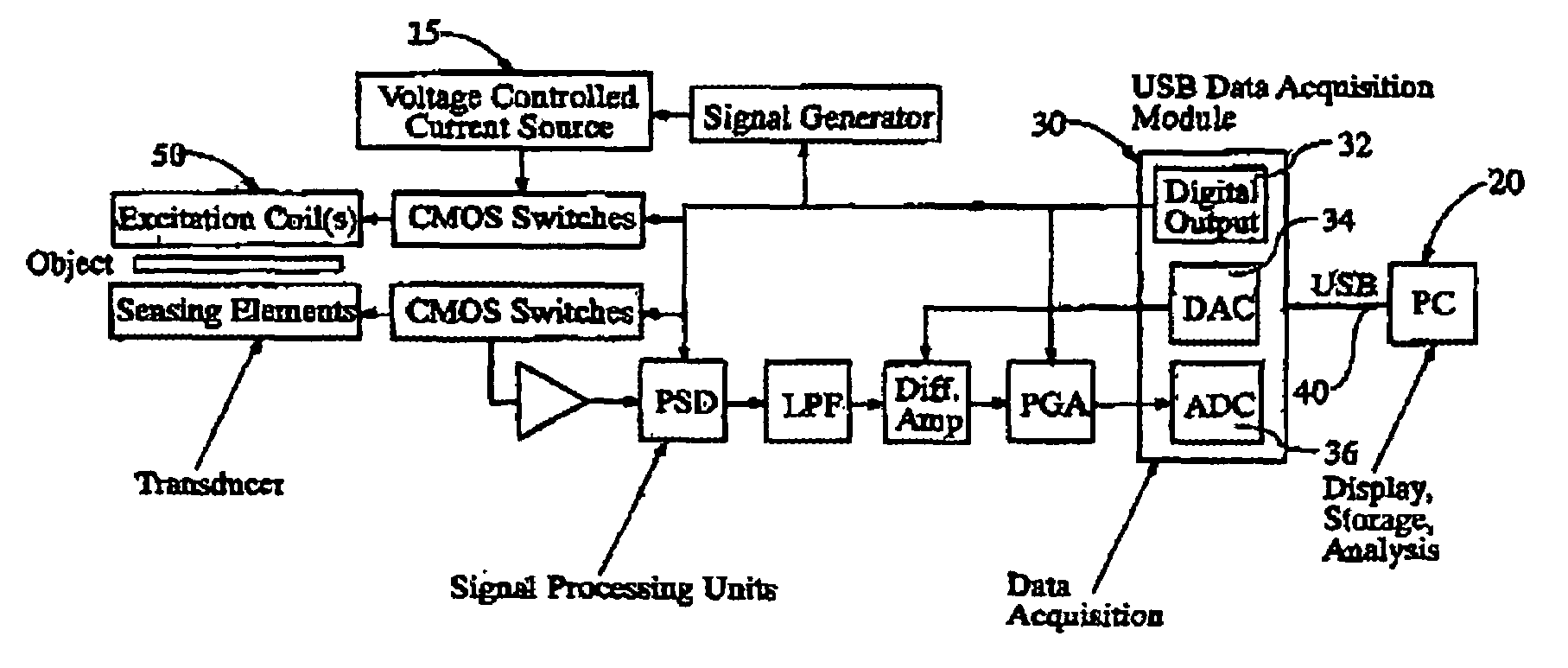

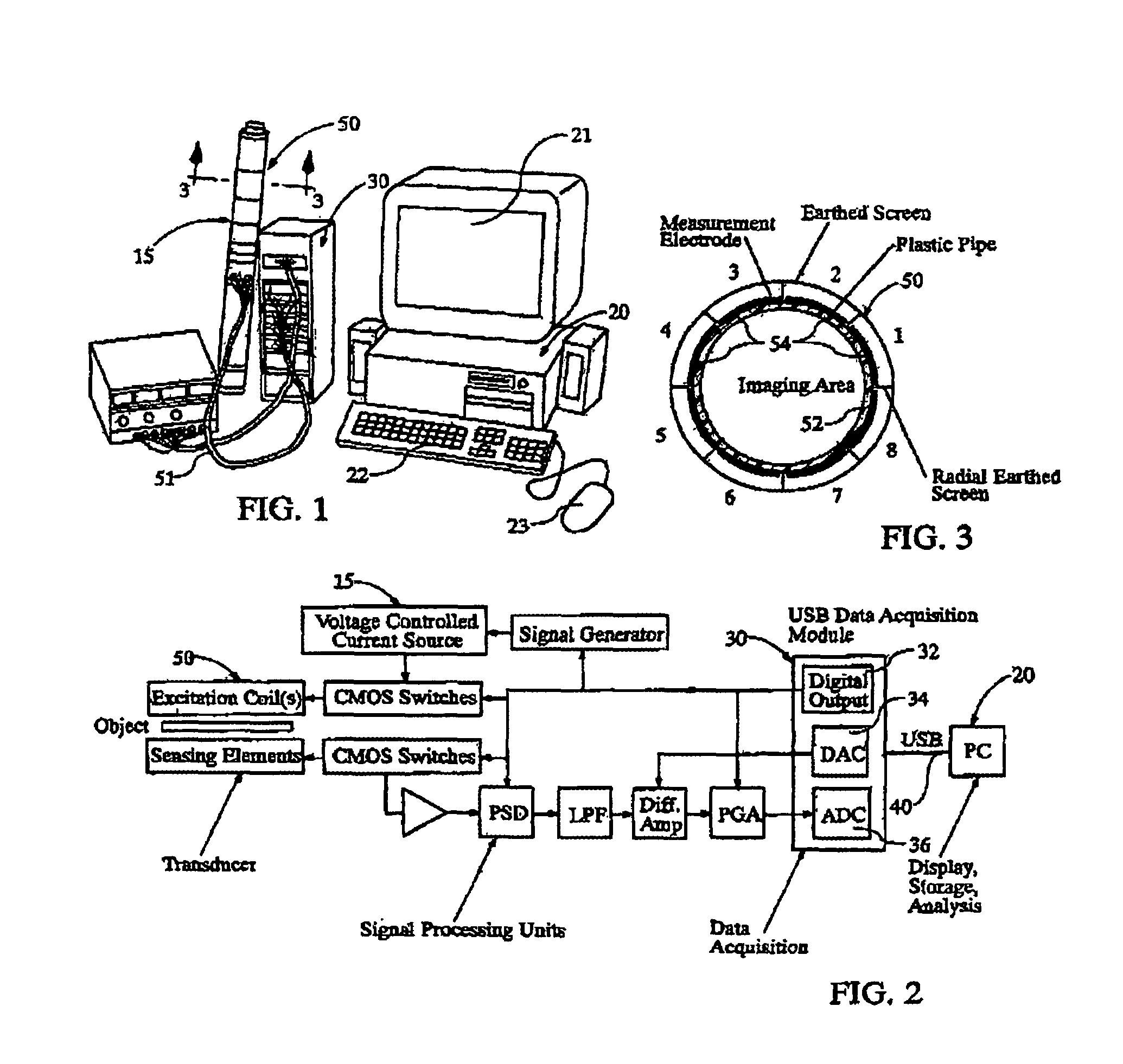

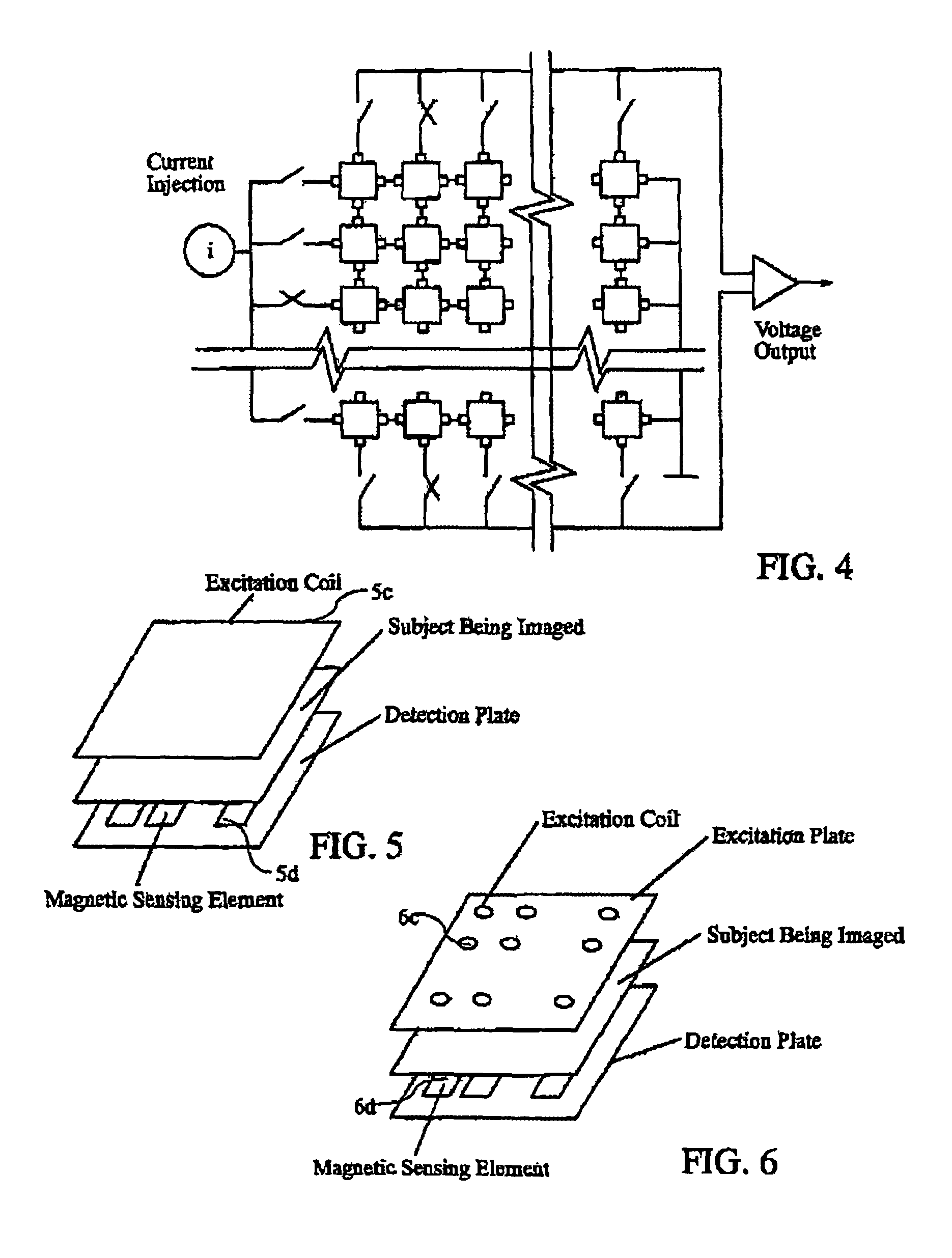

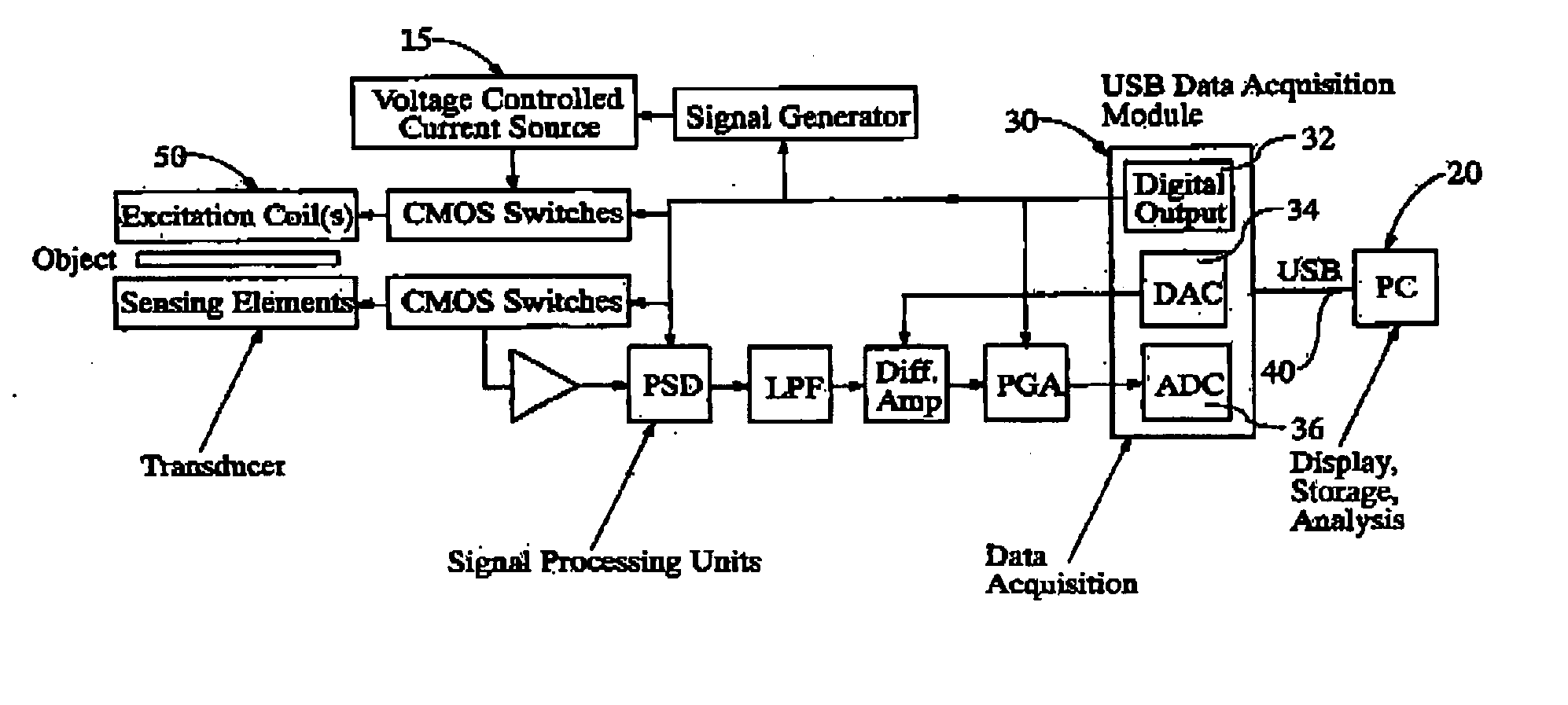

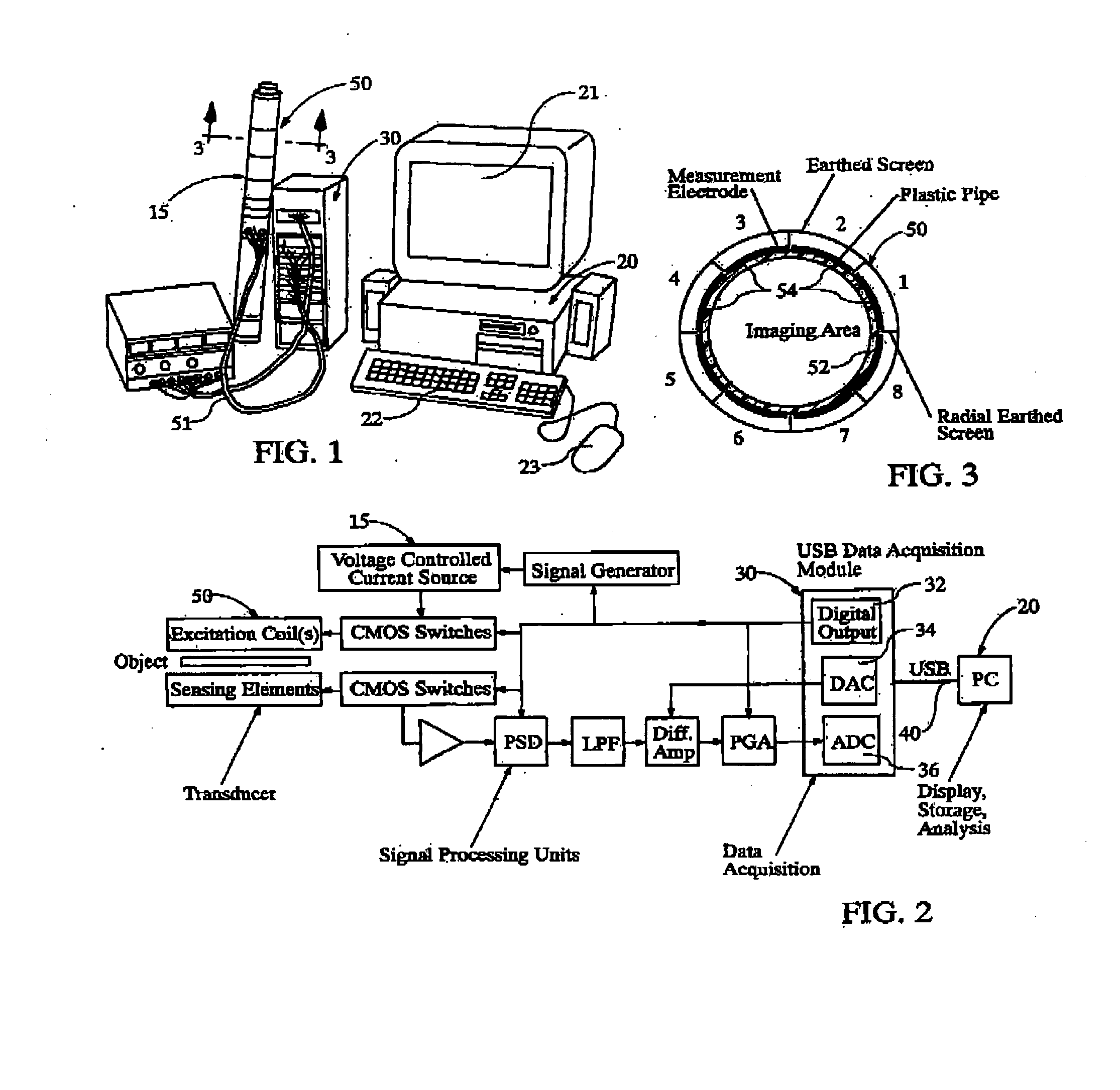

Security scanners with capacitance and magnetic sensor arrays

InactiveUS7119553B2Facilitate creating imageImprove performanceResistance/reactance/impedenceMaterial analysis by electric/magnetic meansSensor arrayMultiple sensor

Security scanning devices based on electrical tomography, including tomography systems based on the measurement of capacitance (ECT) and electromagnetic tomography (EMT), in combination with knowledge-based image analysis and understanding. Each device includes a sensing head or transducer, sensing electronics, image reconstruction and image analysis microprocessor, a display unit and accompanying software for identifying dangerous materials and items. The security scanning devices are employed for obtaining multiple independent measurements and enable implementation of data fusion to combine the complementary sensitivity of ECT and EMT to different material properties, while providing architecture to implement image knowledge bases, which characterize objects, whose image attributes are acquired from multiple sensors.

Owner:KONSULTEURO LIMITED LIMITED UK

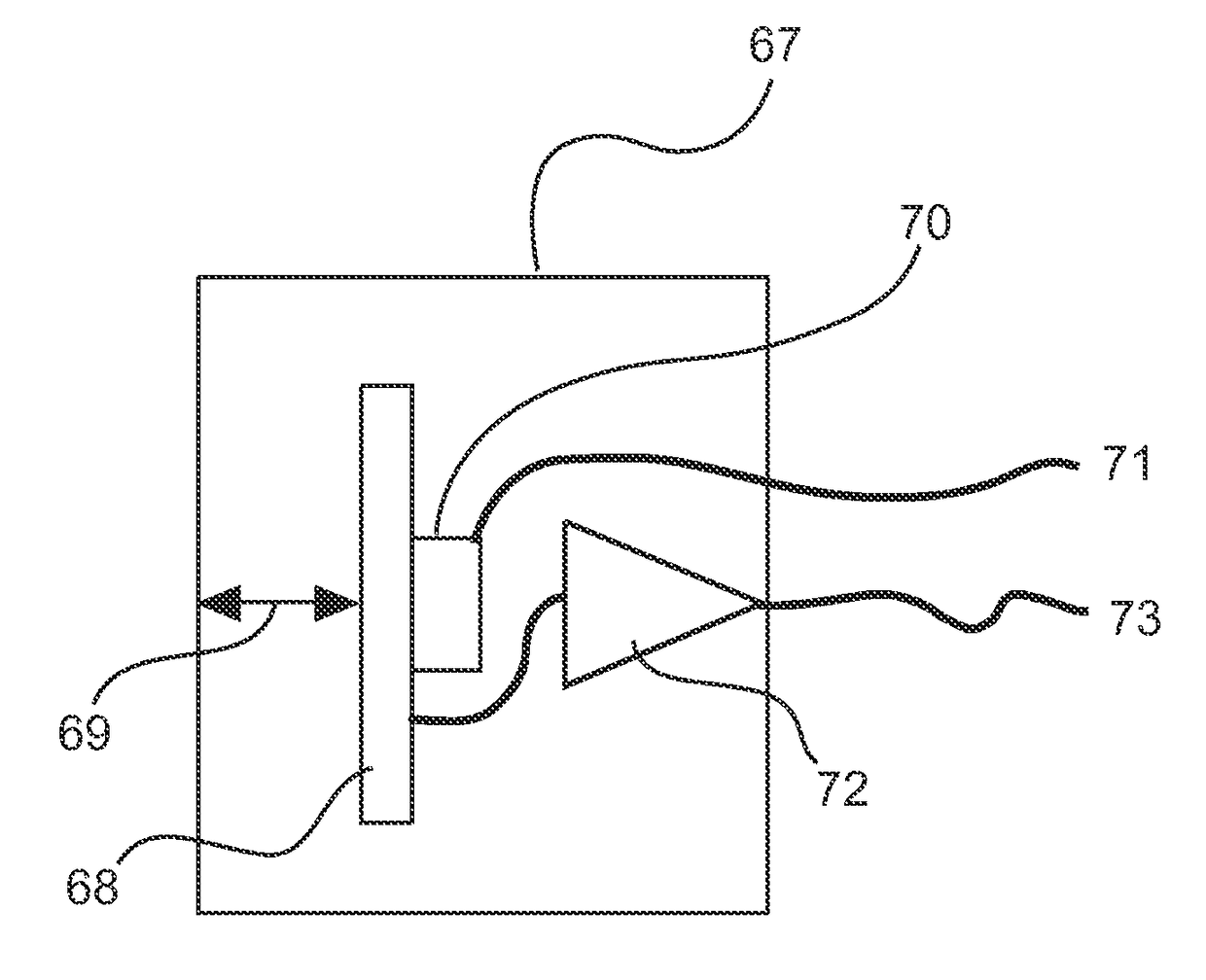

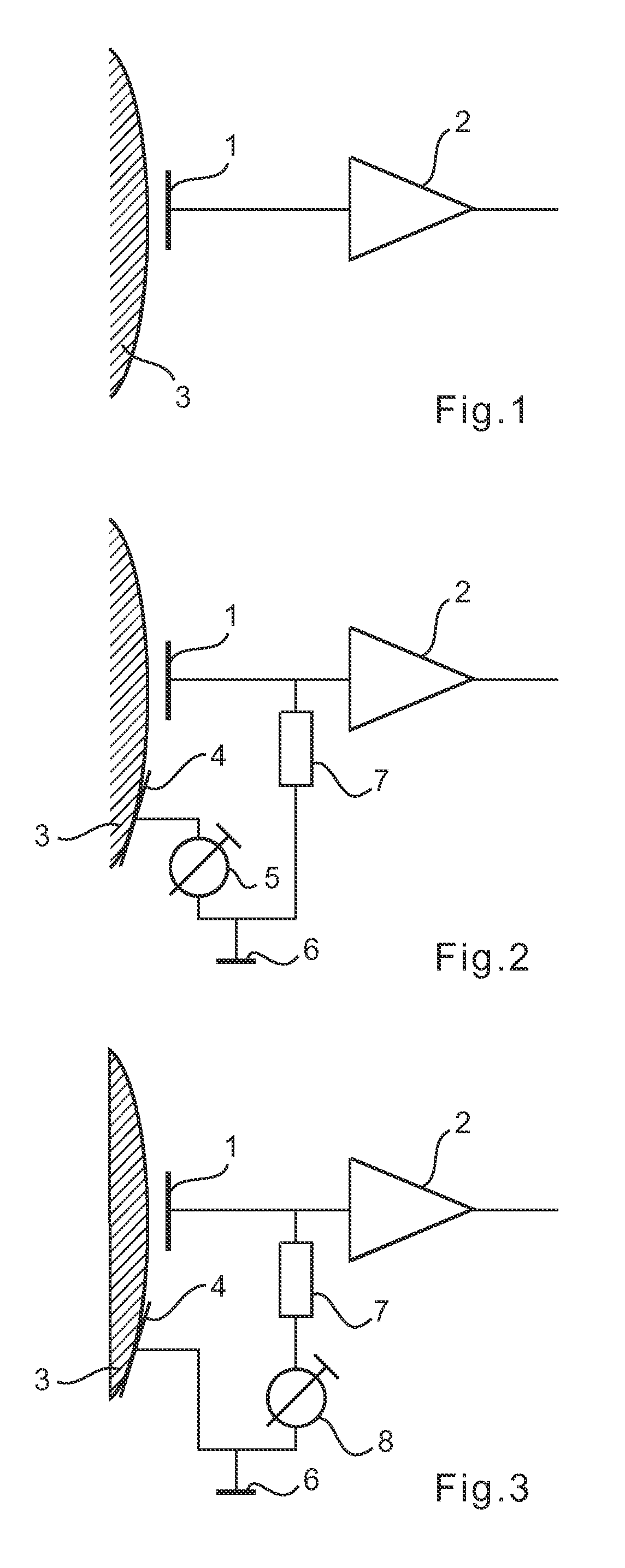

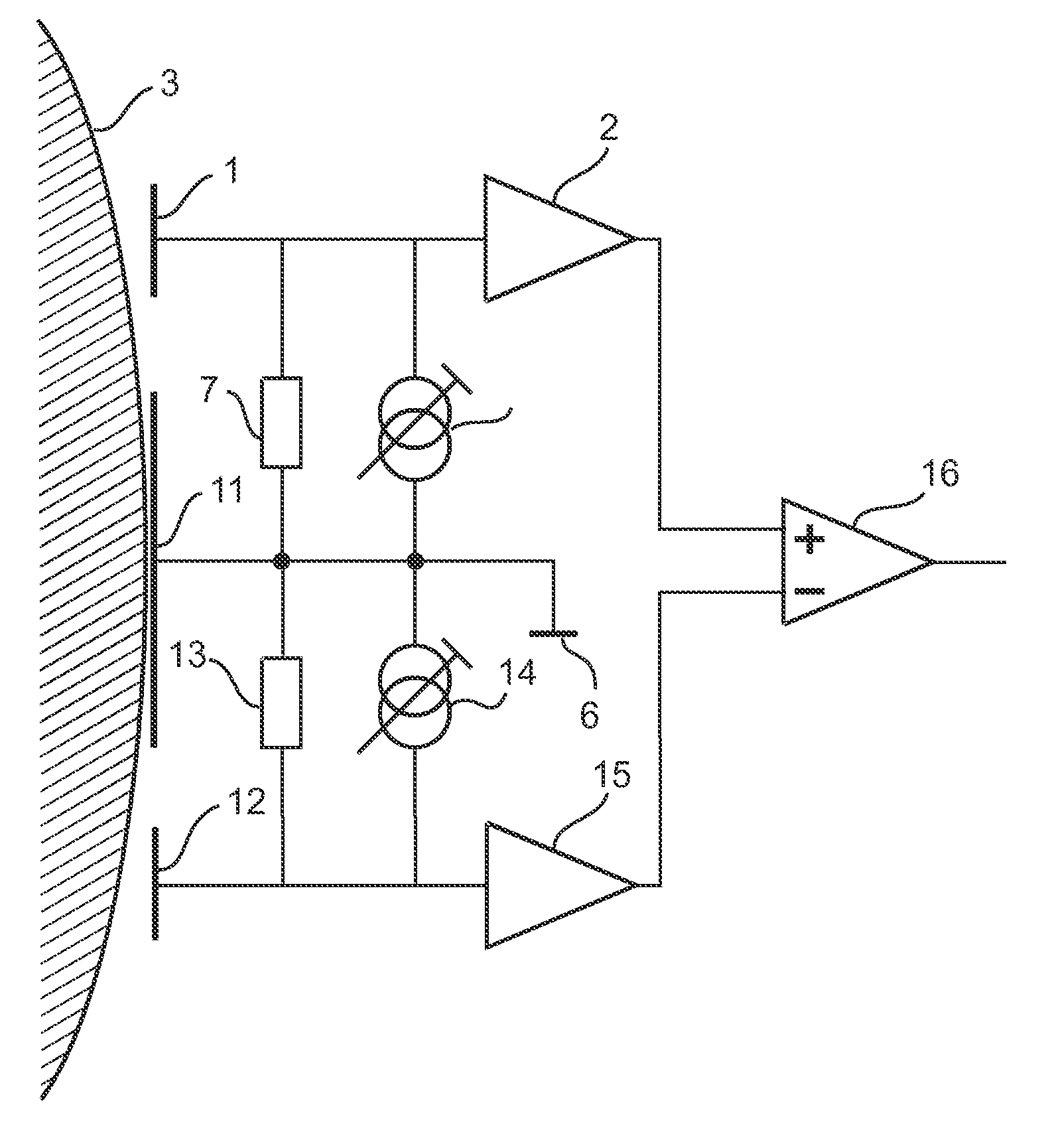

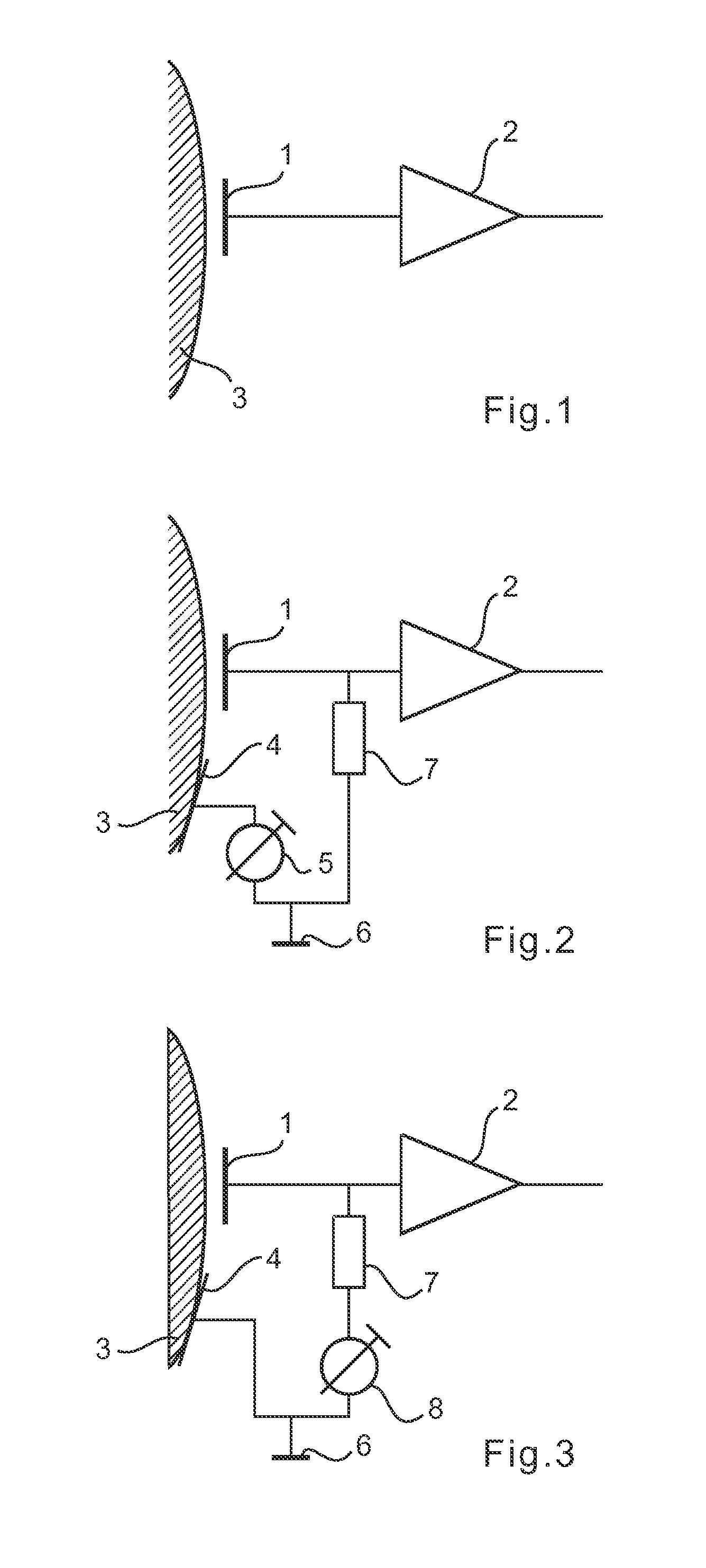

Electro-physiological measurement with reduced motion artifacts

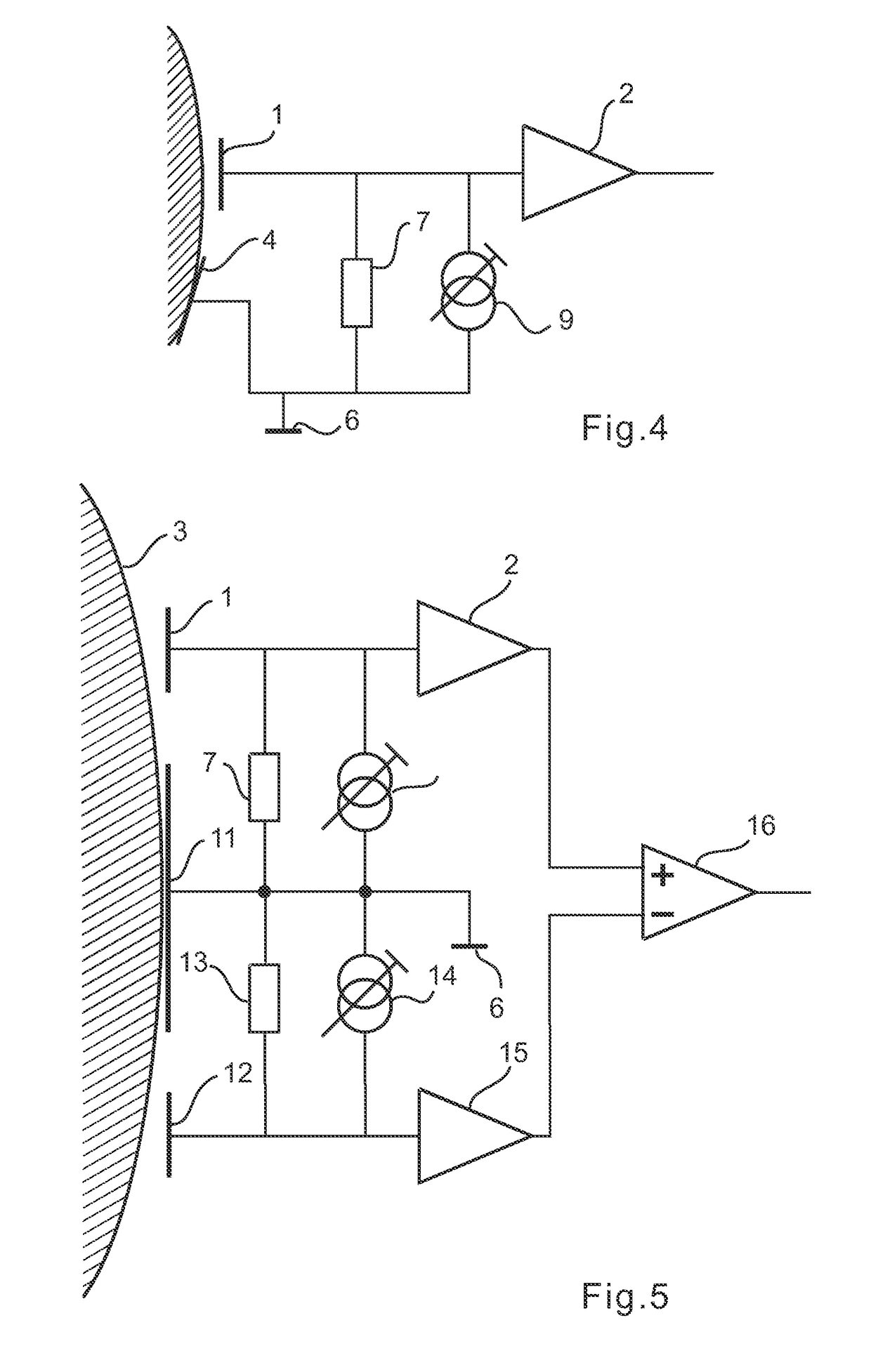

ActiveUS9603542B2Reducing or minimizing motion-induced signalsAccurate measurementElectrocardiographySensorsEngineeringCapacitance transducer

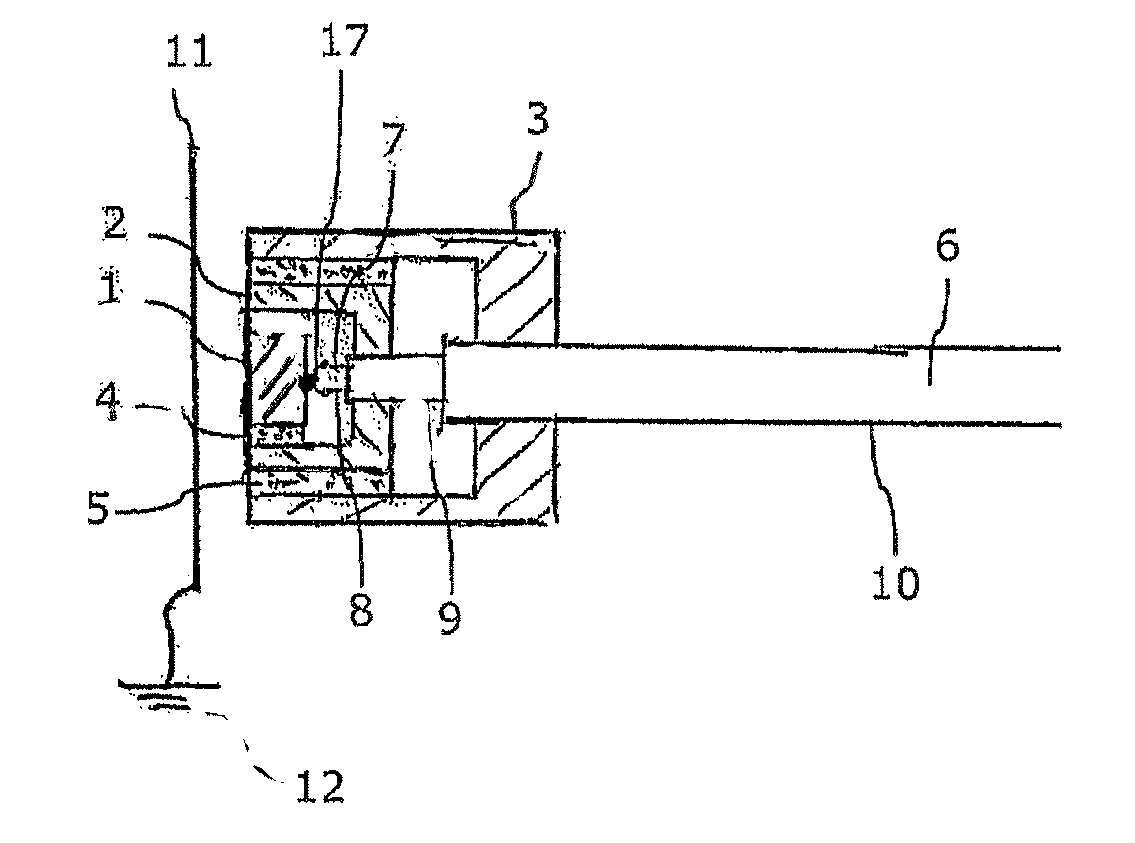

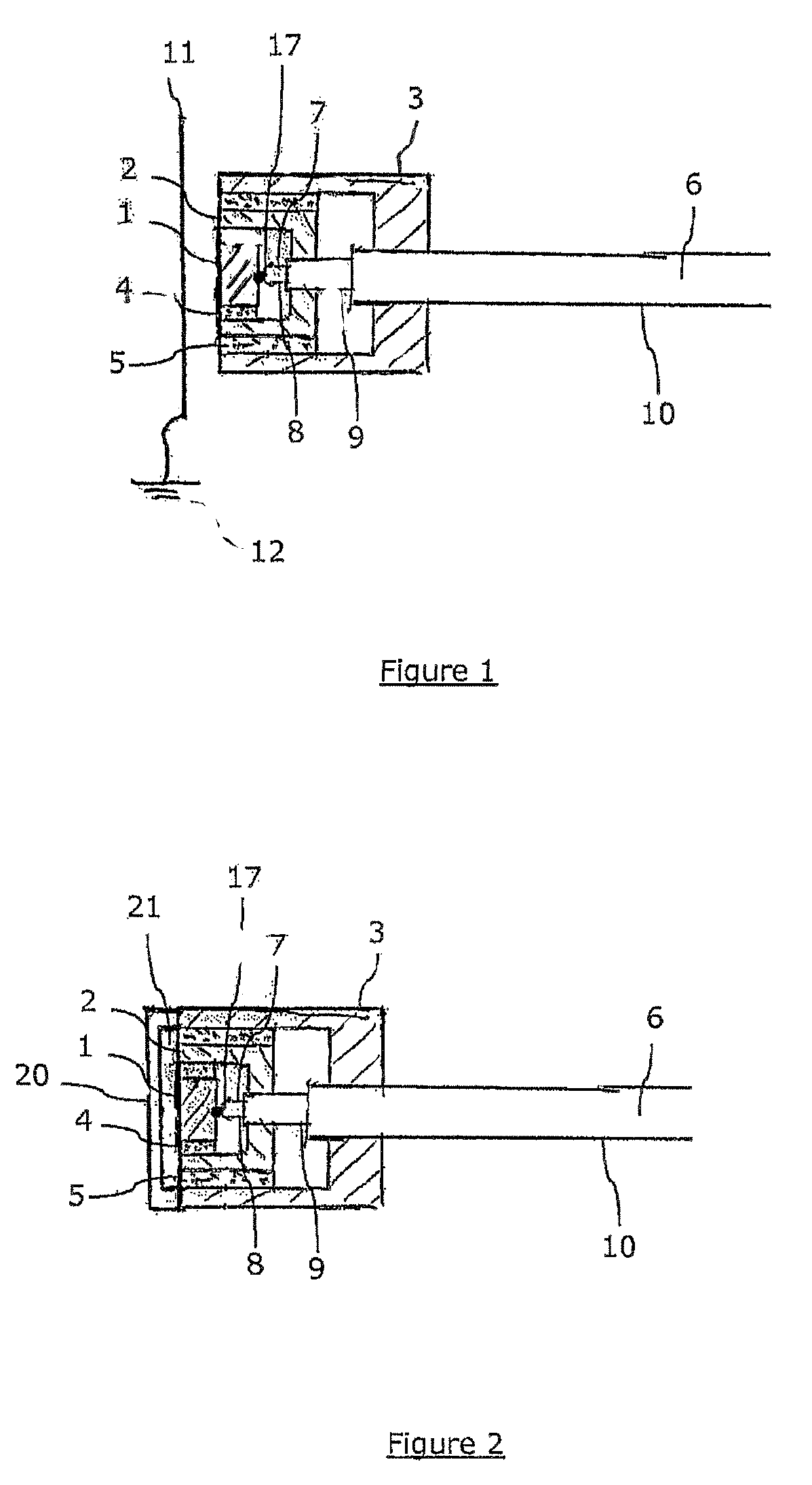

An apparatus and method (4,5,6,7,2) for capacitive measurement of electrophysiological signals (1) suppresses or reduces motion artifacts by providing a feedback mechanism. An average voltage between a capacitive sensor electrode (1) and the body (3) is controlled so as to reduce or minimize motion-induced signals.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Security scanners with capacitance and magnetic sensor arrays

InactiveUS20060176062A1Facilitate creating imageImprove performanceResistance/reactance/impedenceMaterial analysis by electric/magnetic meansSensor arrayMultiple sensor

Security scanning devices based on electrical tomography, including tomography systems based on the measurement of capacitance (ECT) and electromagnetic tomography (EMT), in combination with knowledge-based image analysis and understanding. Each device includes a sensing head or transducer, sensing electronics, image reconstruction and image analysis microprocessor, a display unit and accompanying software for identifying dangerous materials and items. The security scanning devices are employed for obtaining multiple independent measurements and enable implementation of data fusion to combine the complementary sensitivity of ECT and EMT to different material properties, while providing architecture to implement image knowledge bases, which characterize objects, whose image attributes are acquired from multiple sensors.

Owner:KONSULTEURO LIMITED LIMITED UK

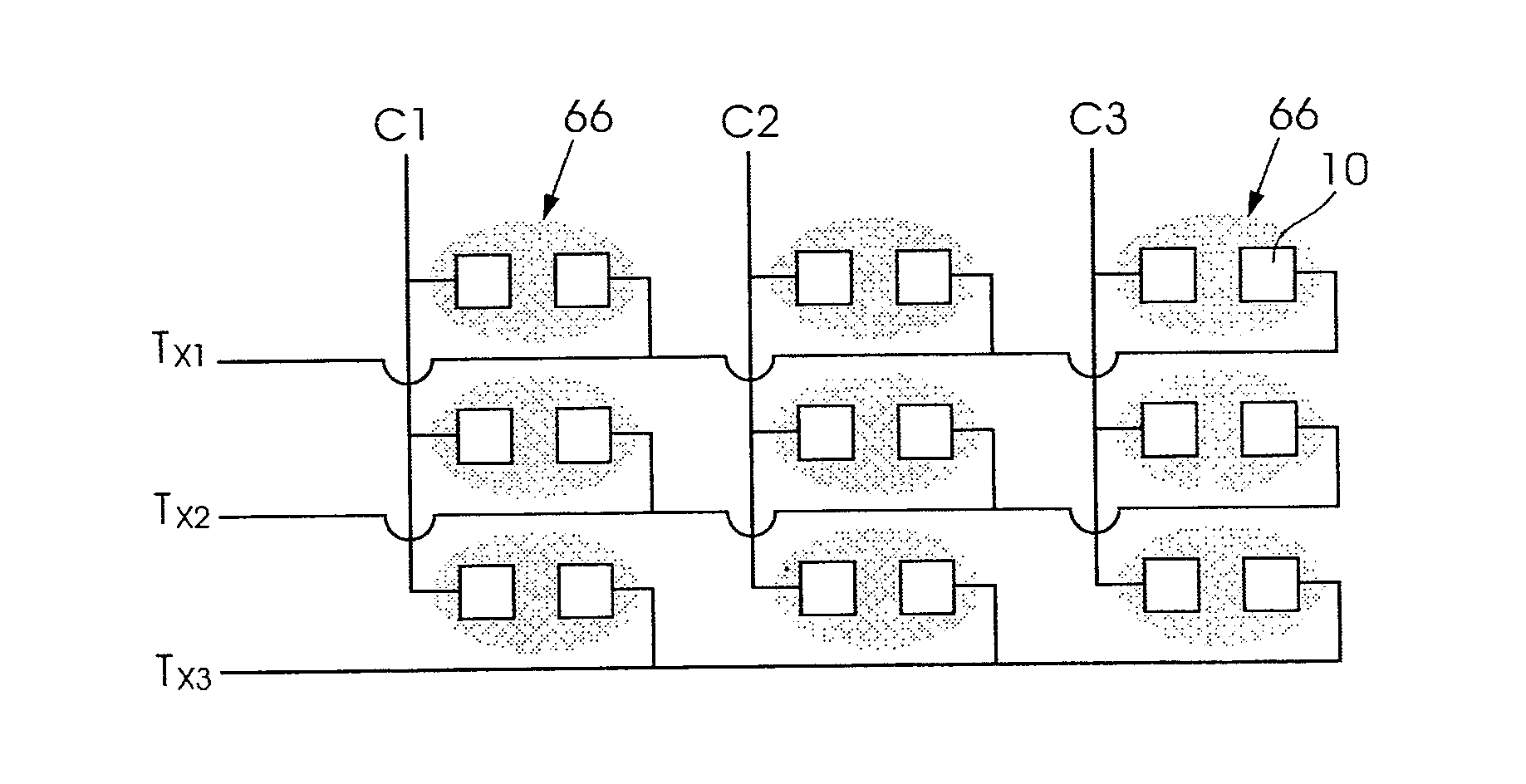

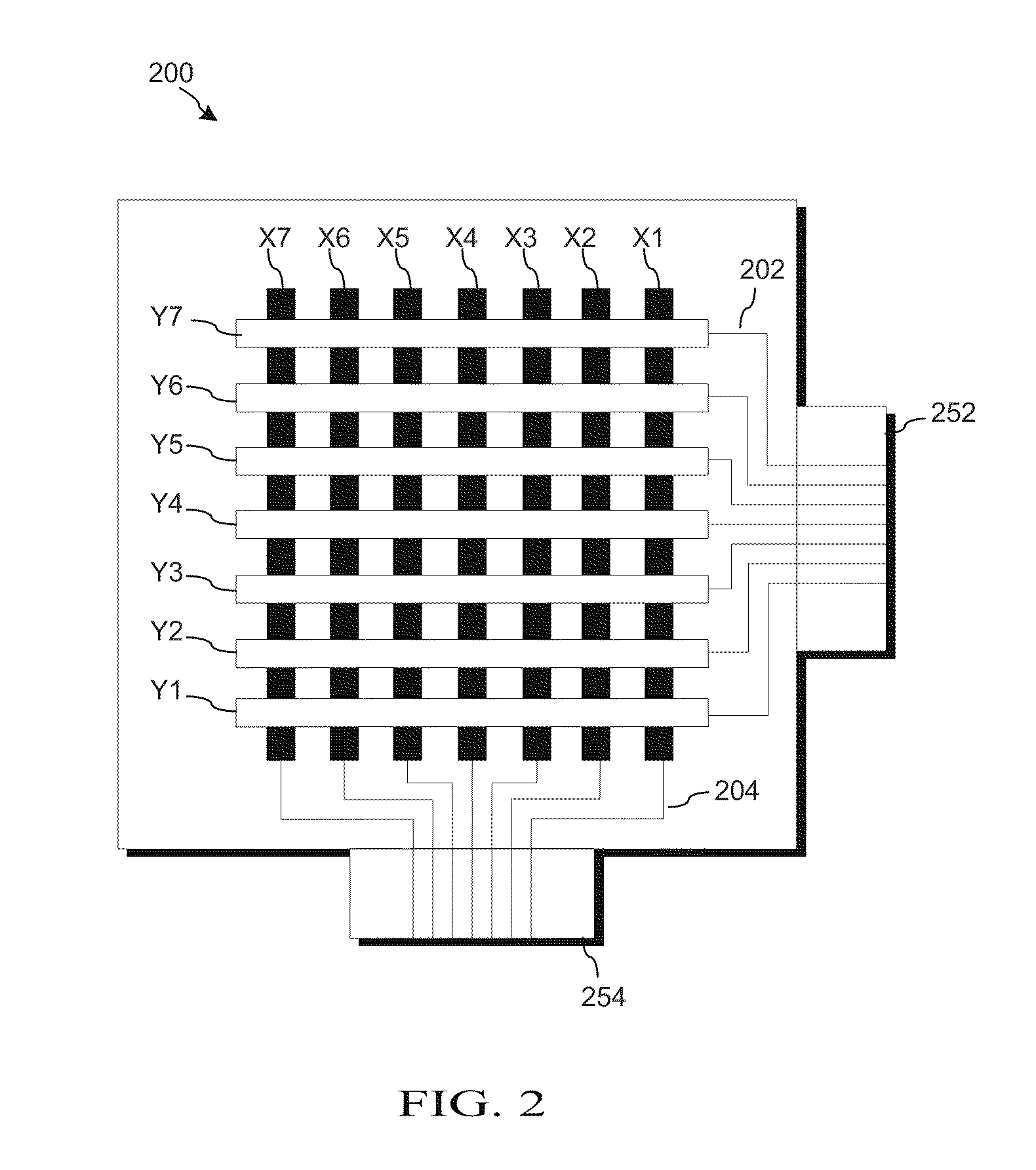

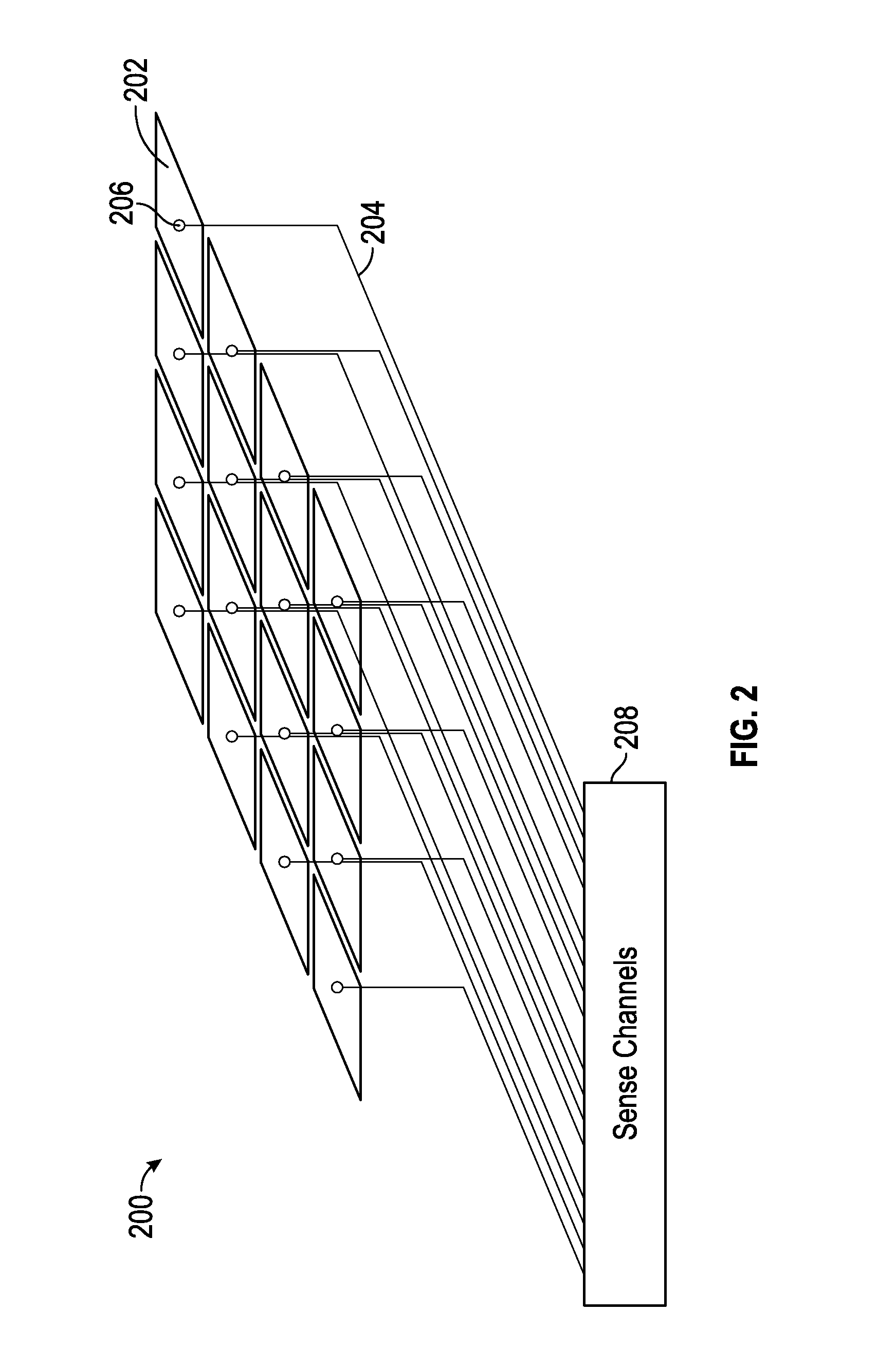

Mutual capacitance measurement in a multi-touch input device

Systems and methods for determining multiple touch events in a multi-touch sensor system are provided. The system may include a capacitance measurement unit, a pulse drive unit, and a touch sensor having a plurality of nodes and a plurality of electrodes comprising at least two sets of electrodes. The method may include connecting a first electrode in a first set to the capacitance measurement unit, the pulse drive unit driving a voltage or current pulse onto a second electrode in a second set of electrodes. The method may further include the capacitance measurement unit measuring the mutual capacitance at a node corresponding to the first and second electrodes. The method may include comparing the measured mutual capacitance at the node with a previously measured mutual capacitance for the node, and reporting that the node has been touched if there has been a deviation from the previously measured mutual capacitance.

Owner:NEODRON LTD

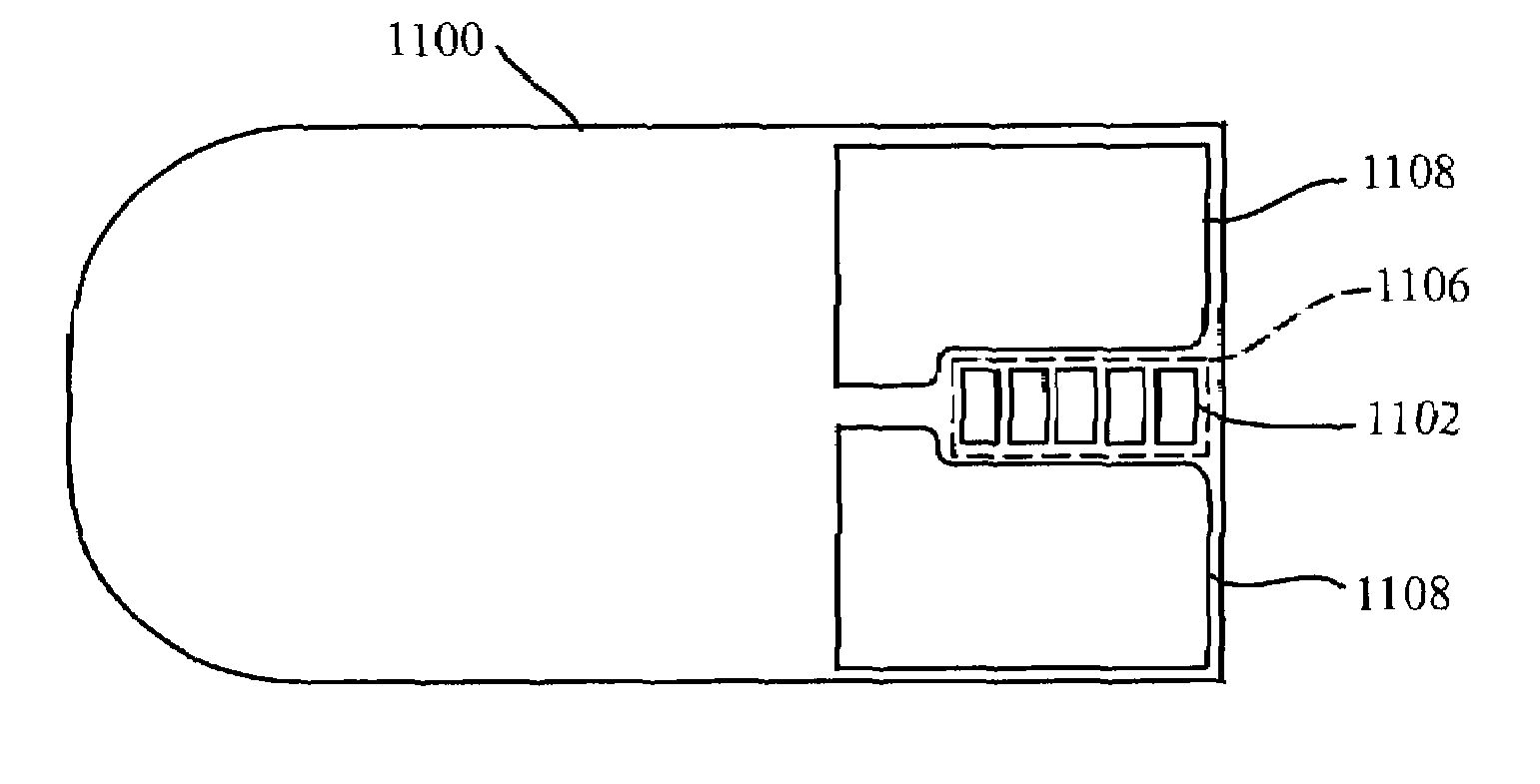

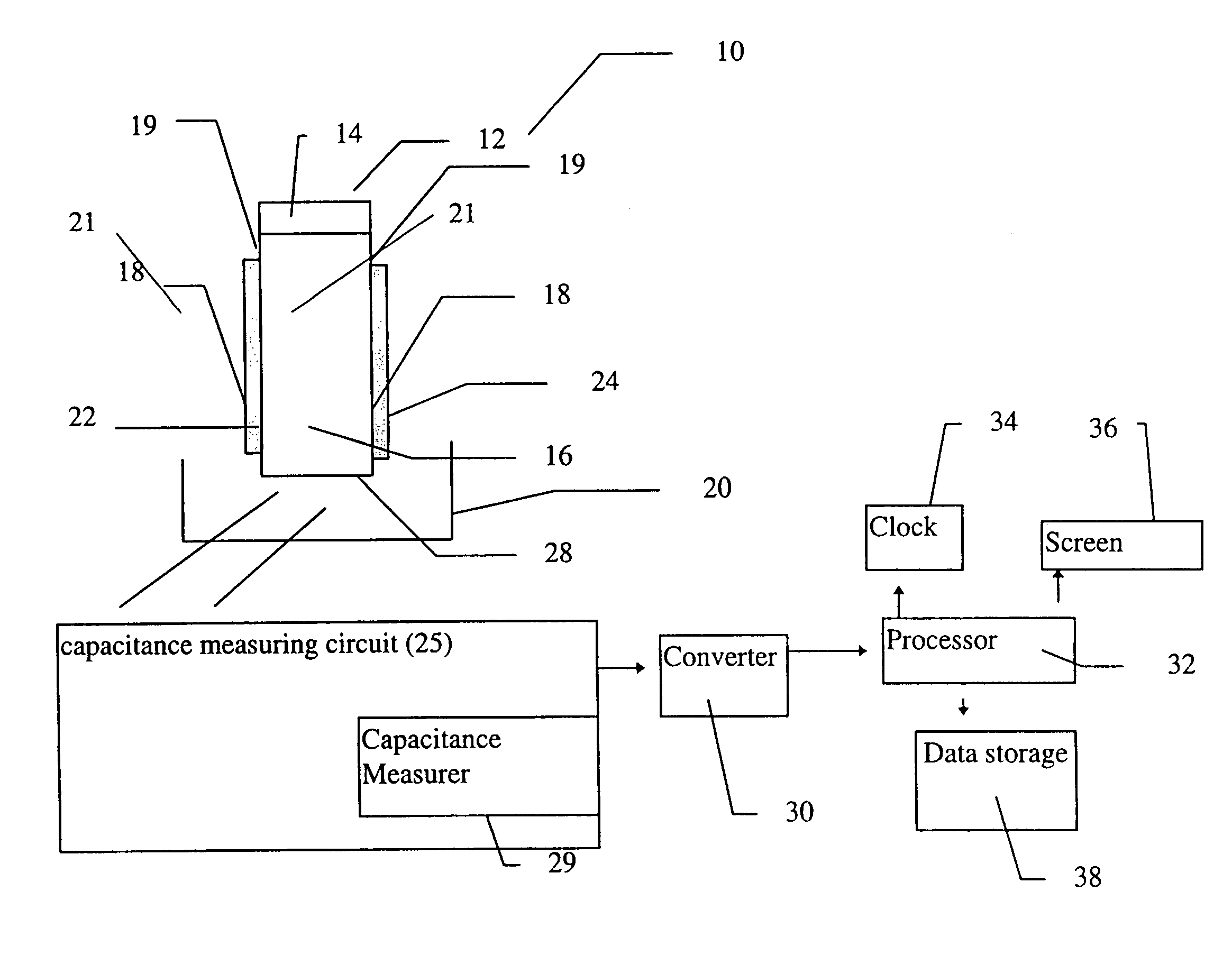

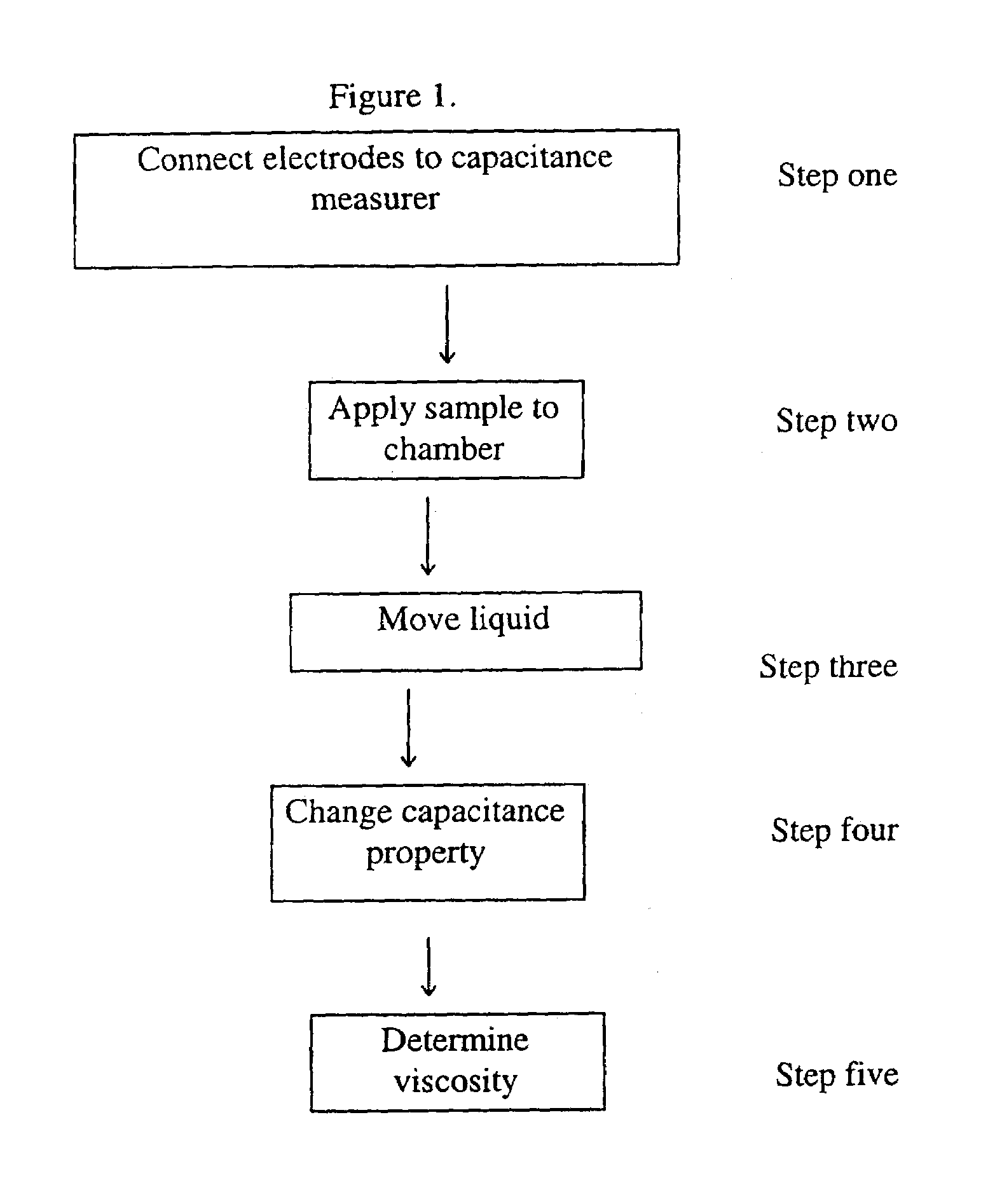

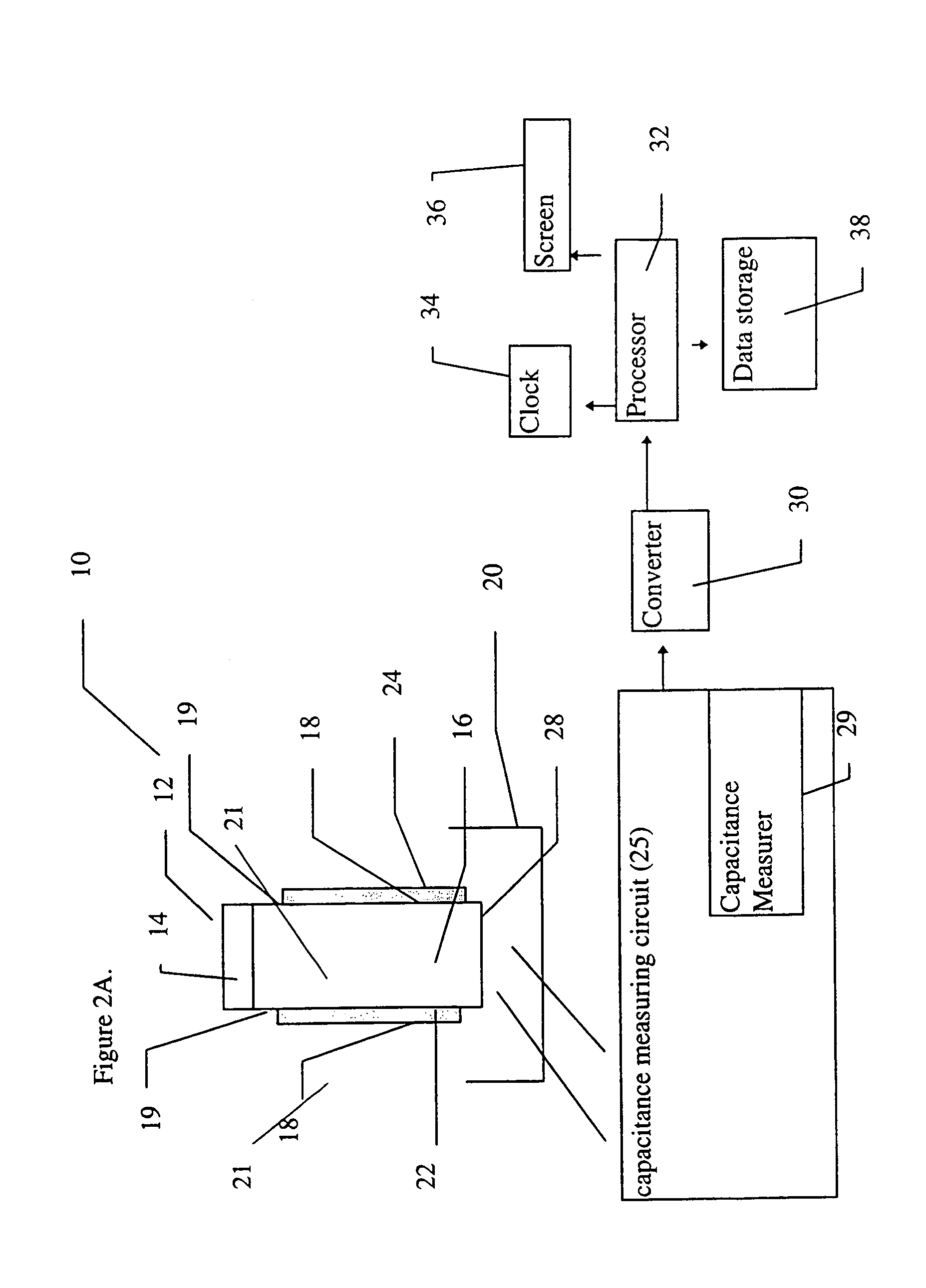

Device for the determination of blood clotting by capacitance or resistance

InactiveUS7021122B1Machines/enginesLubrication indication devicesElectrical resistance and conductanceViscosity

A sensor device (10) and a method for measuring a viscosity of a sample of a liquid. The sensor features a chamber (12) for receiving the sample of the liquid, two electrodes (18) disposed either on the surfaces of the chamber, but possibly isolated from contacting the sample, or electrodes located externally to the chamber, and a capacitance measuring circuit (25). The sensor is used by connecting to a measurer for determining a capacitance on the electrodes, such that the capacitance directly reflects a volume occupied by the sample of the liquid. Preferably, the liquid is blood and the capacitance is used to determine the clotting time of the blood. Also preferably, a cover for the chamber is provided with at least one aperture, which more preferably is a mesh. Alternatively, an electrical property such as the amplitude of current passed through the sample is used to determine clotting time. Also preferably, the time period required for the maximum capacitance to be reached could be measured. Alternatively, the capacitance could be measured after a fixed time period (34) had elapsed. Also alternatively, the time period required for the maximum current to be reached could be measured, or the amount of current could be measured after a fixed time period had elapsed. In preferred embodiments of the present invention, a kit for measuring the clotting time of blood is provided. In other preferred embodiments of the present invention, methods are provided for using the kit and device of the present invention.

Owner:ORGENICS BOISENSORS

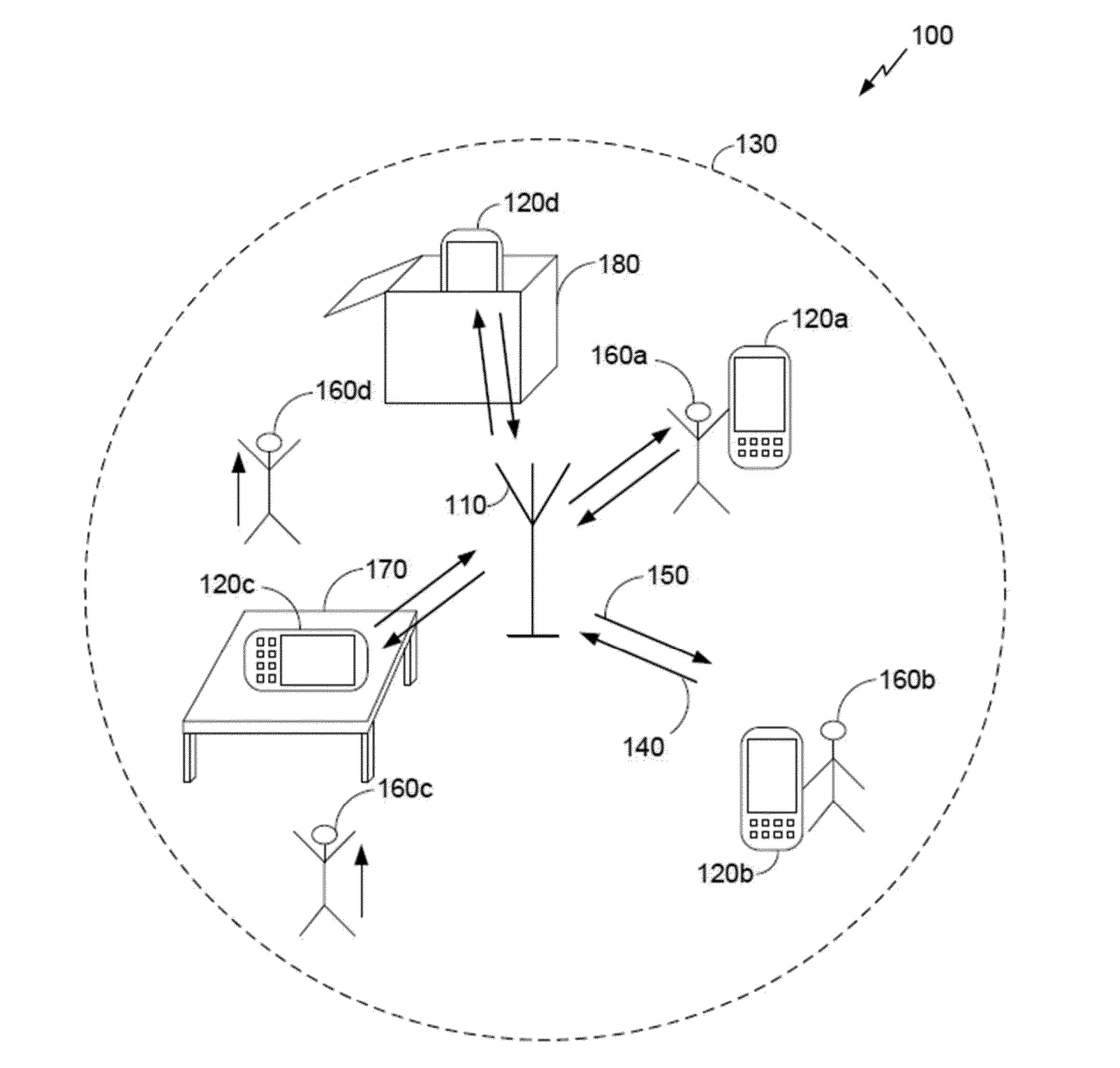

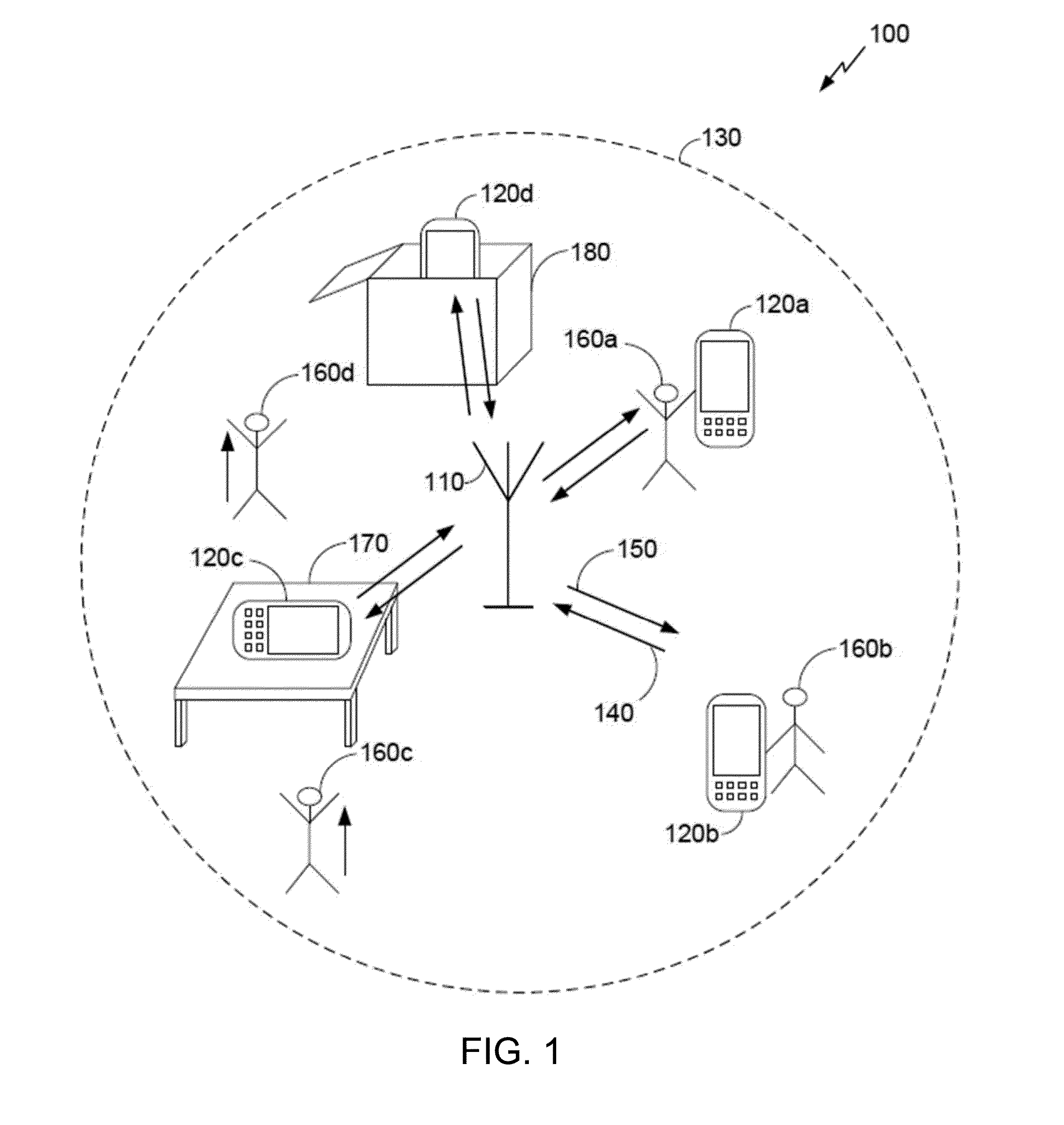

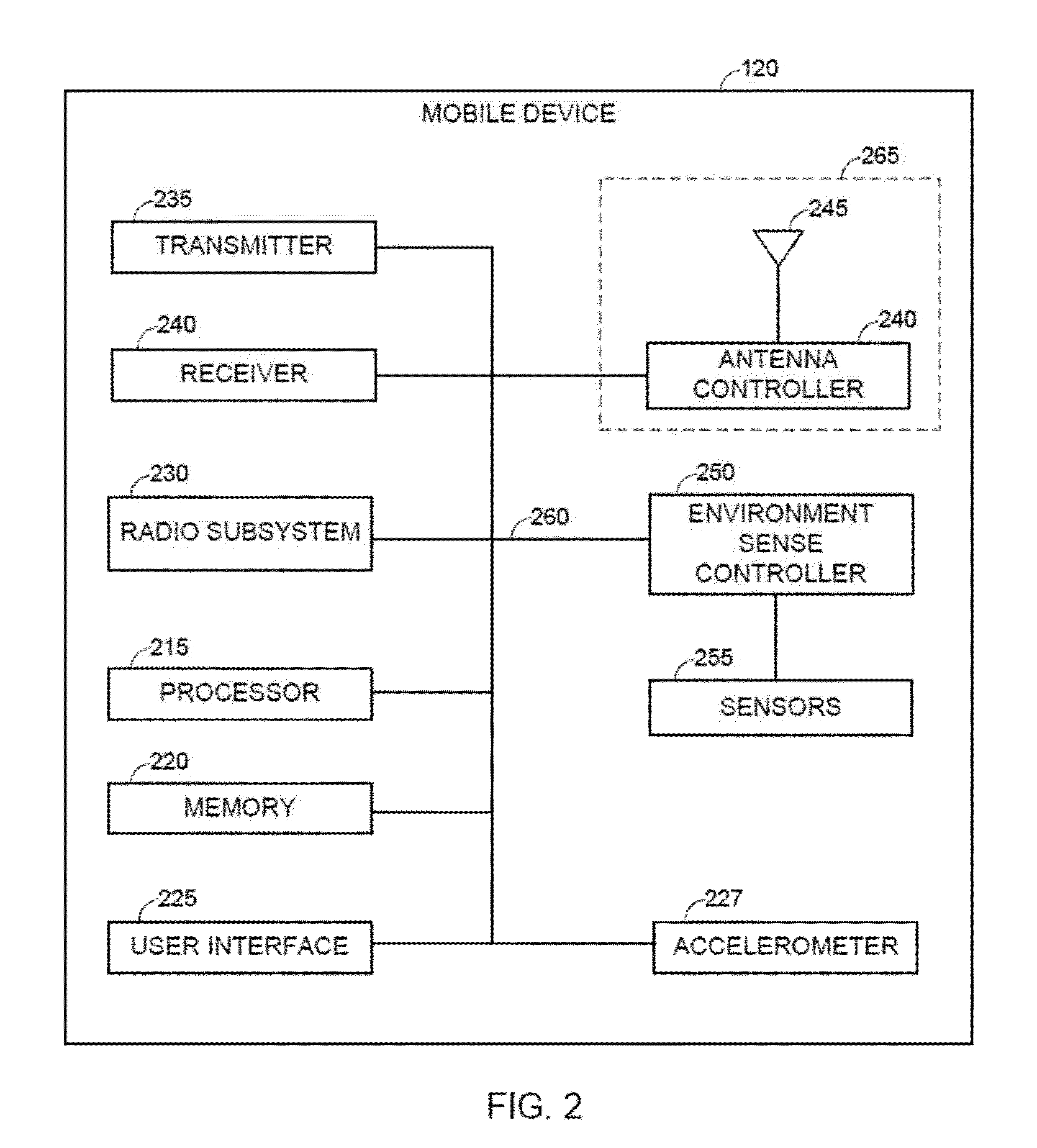

Grip detection and capacitive gesture system for mobile devices

ActiveUS20150237183A1Easy to implementSave powerDevices with sensorTelephone set constructionsMobile deviceCapacitance transducer

Apparatus and methods are disclosed related to managing characteristics of a mobile device based upon capacitive detection of materials proximate the mobile device, a capacitive gesture system that can allow the same gestures be used in arbitrary locations within range of a mobile device. One such method includes receiving a first capacitive sensor measurement with a first capacitive sensor of the mobile device. The method further includes determining a value indicative of a material adjacent to the mobile device based on a correspondence between the first capacitive sensor measurement and stored values corresponding to different materials. The method further includes sending instructions to adjust a characteristic of the mobile device based on the determined value indicative of the material adjacent to the mobile device. In certain examples, gesture sensing can be performed using capacitive measurements from the capacitive sensors.

Owner:ANALOG DEVICES INC

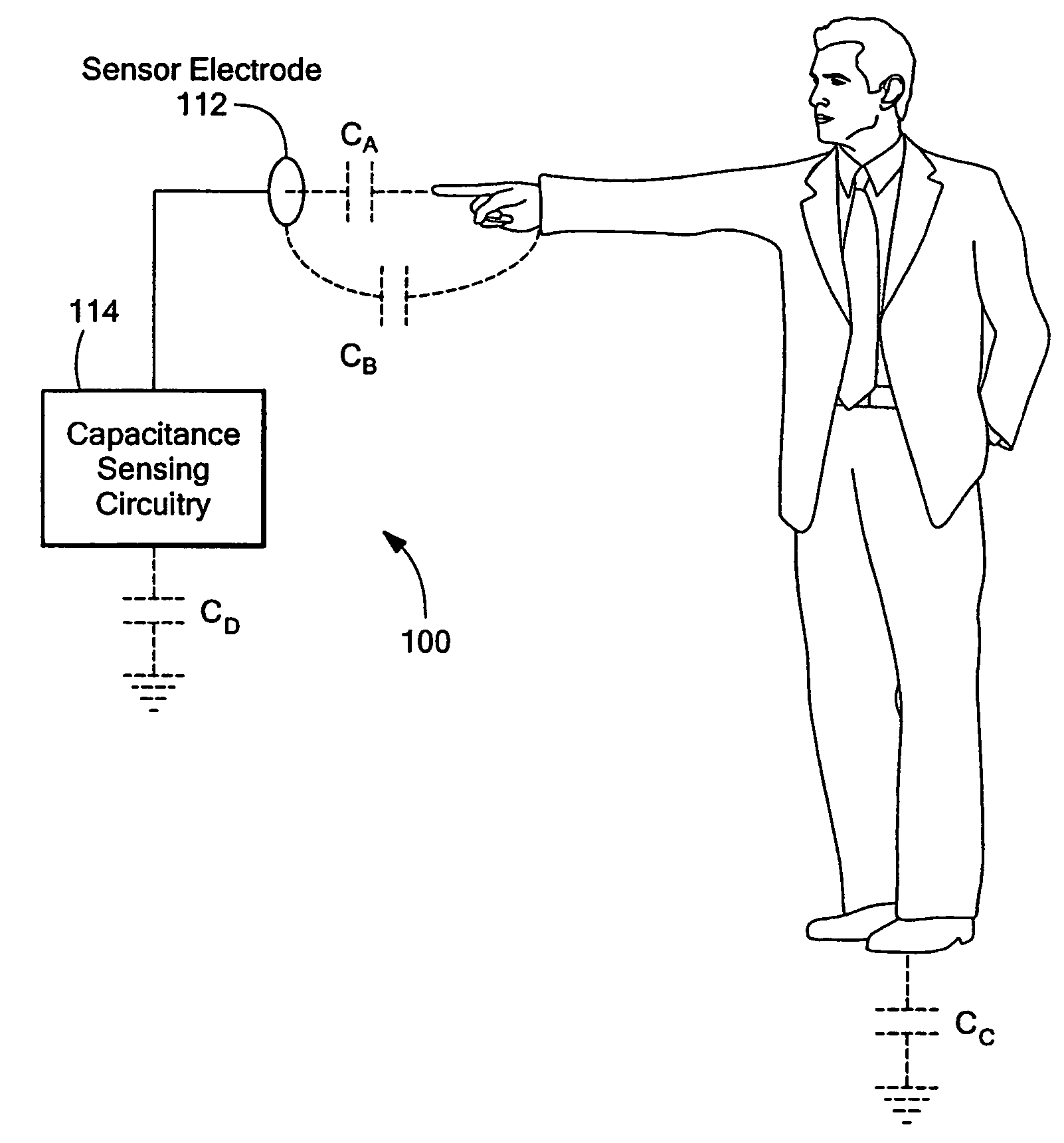

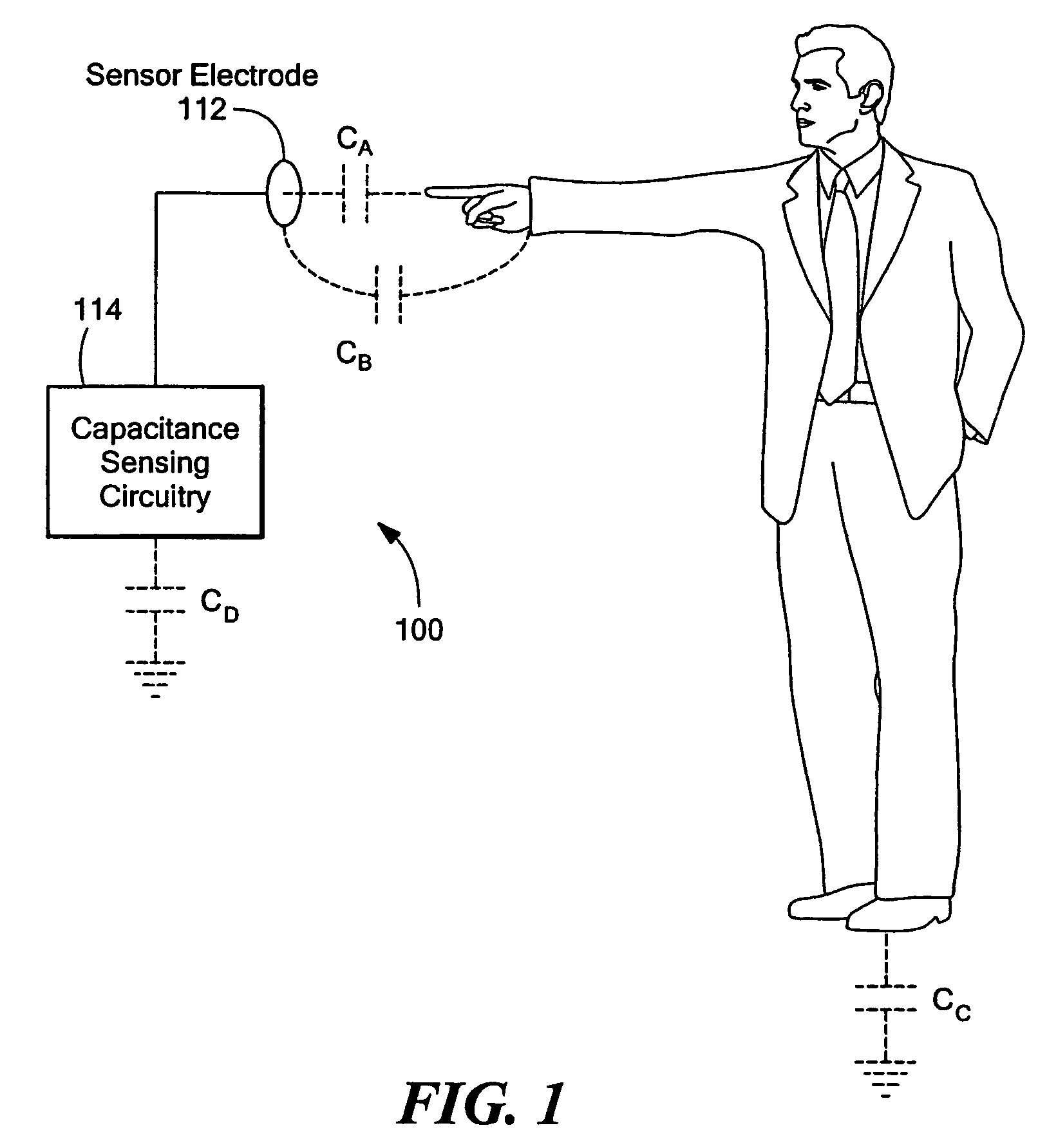

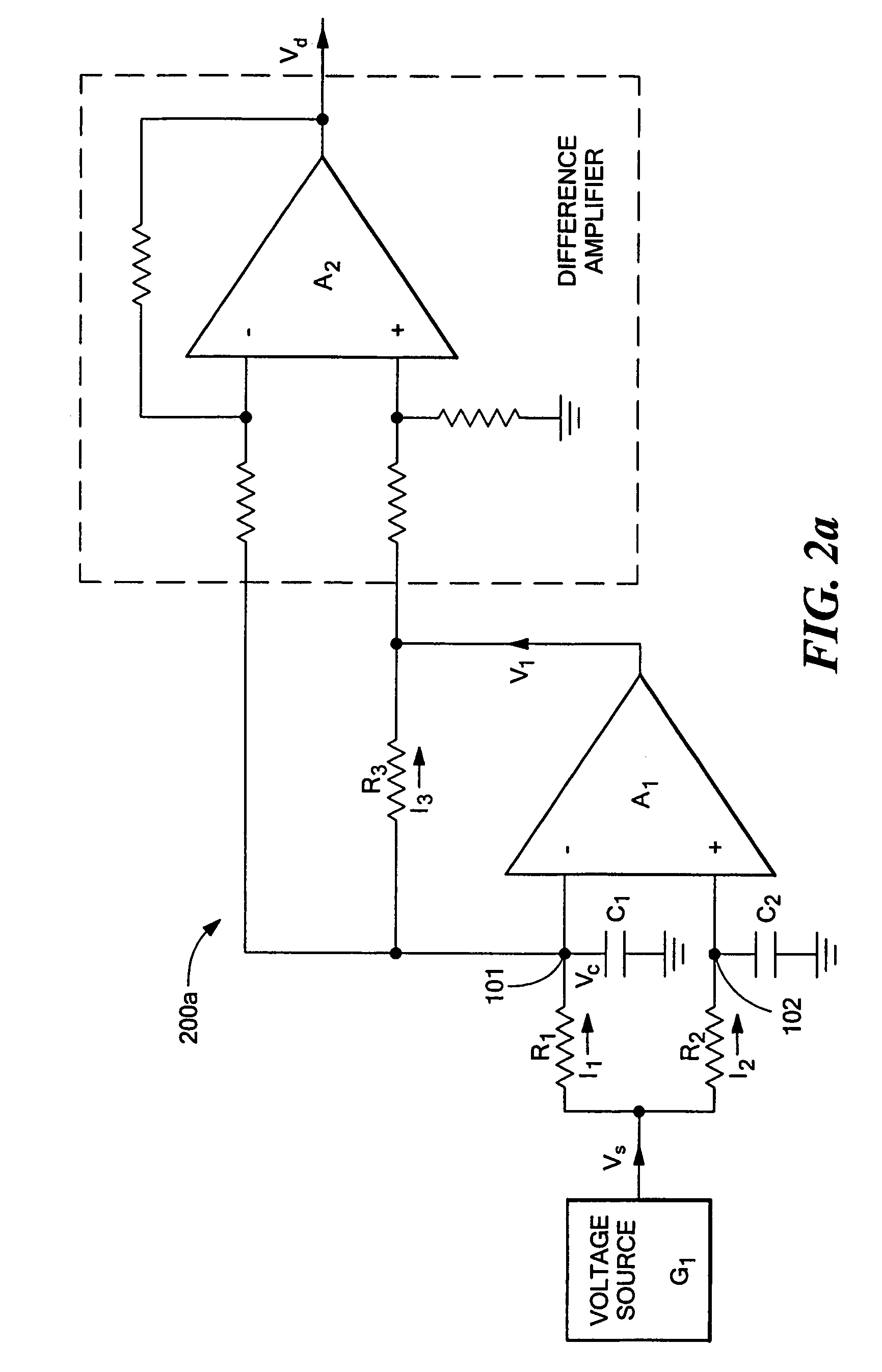

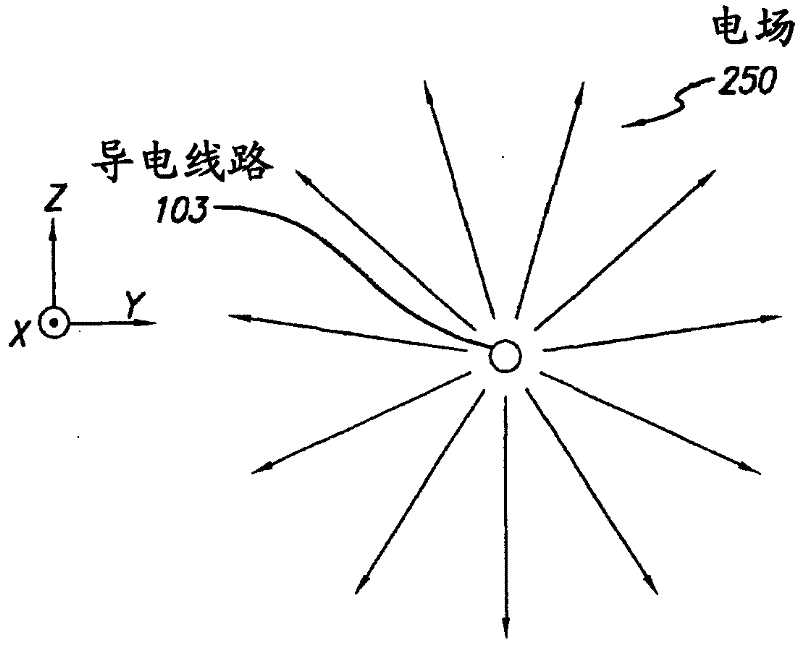

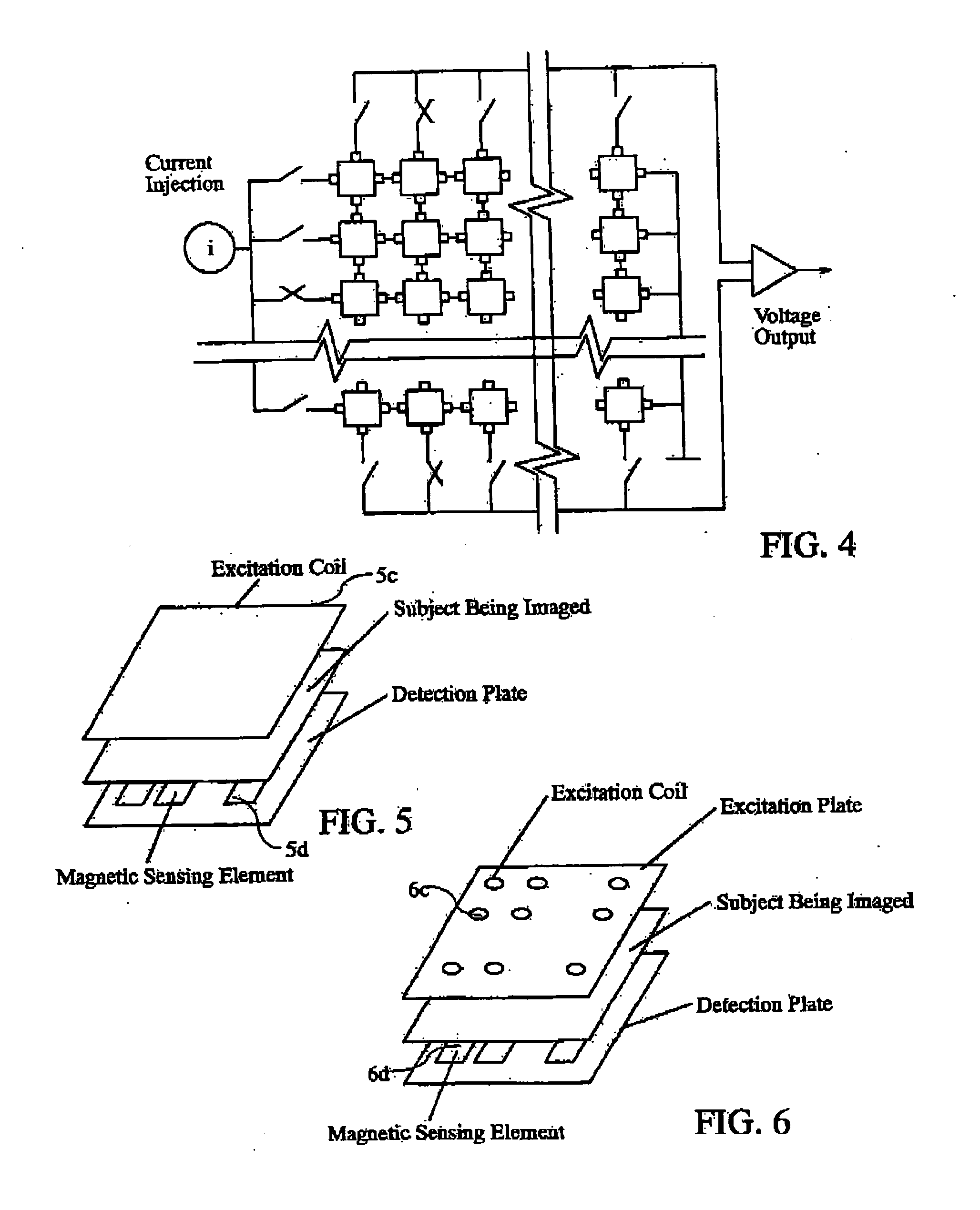

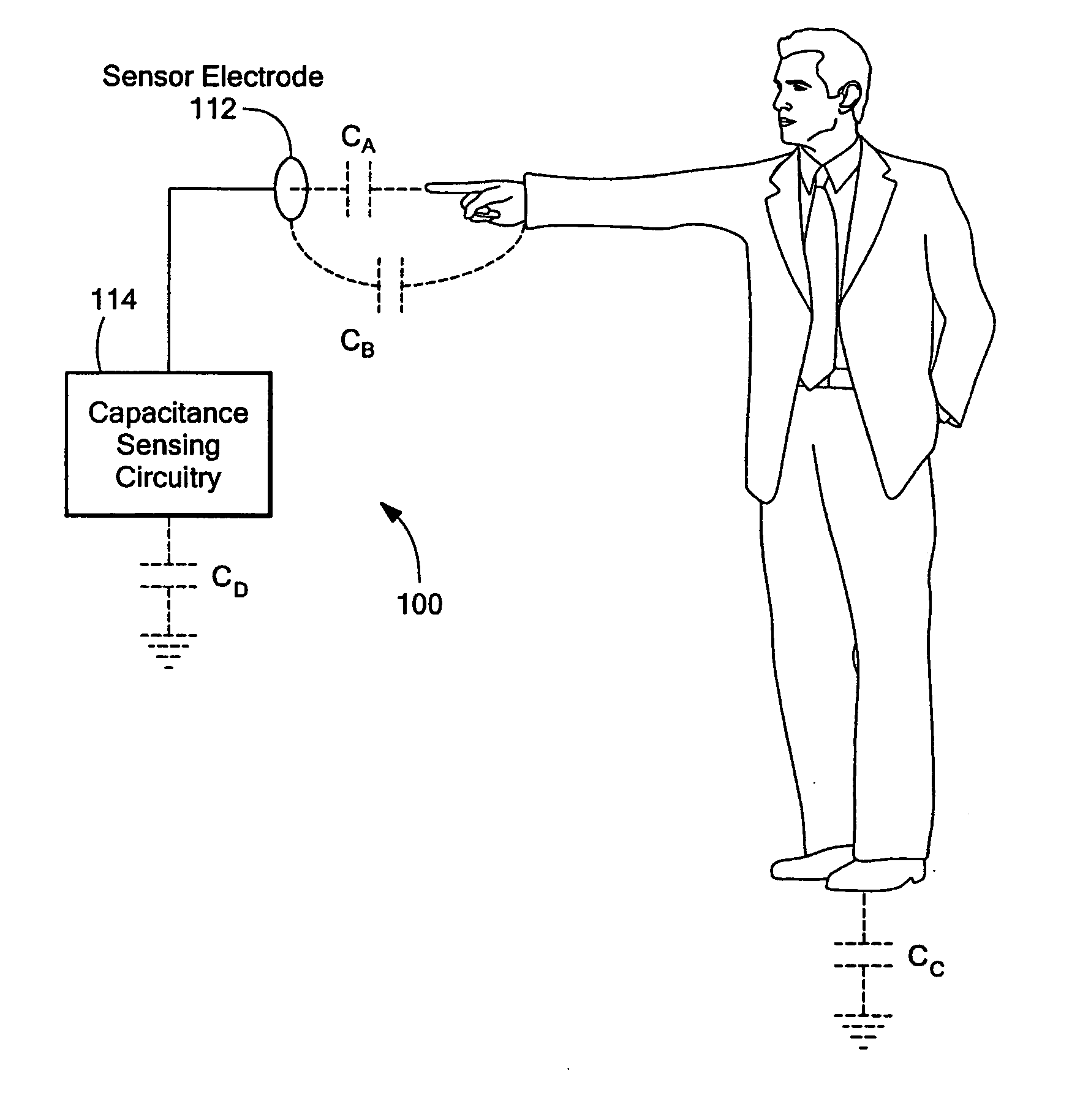

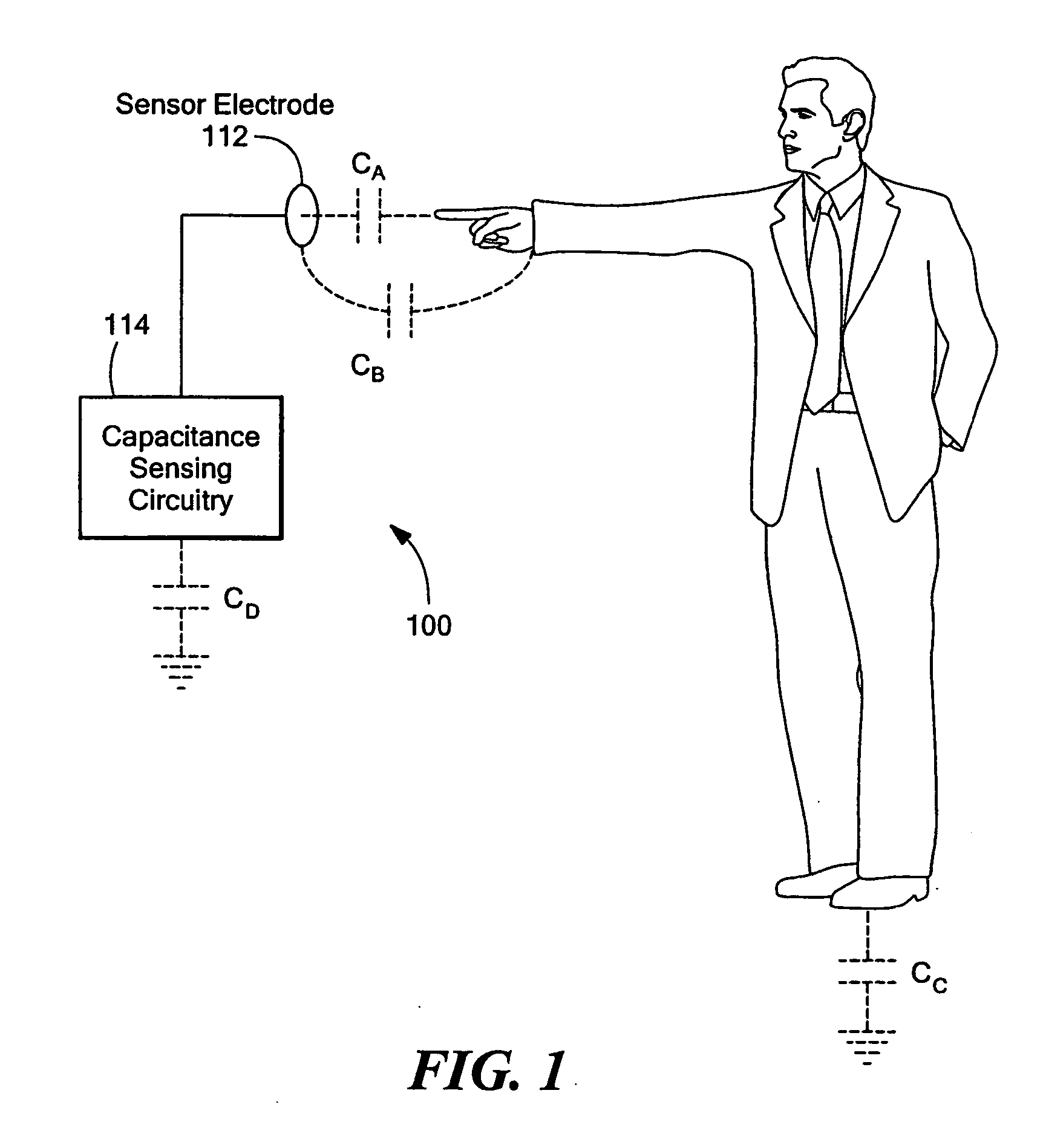

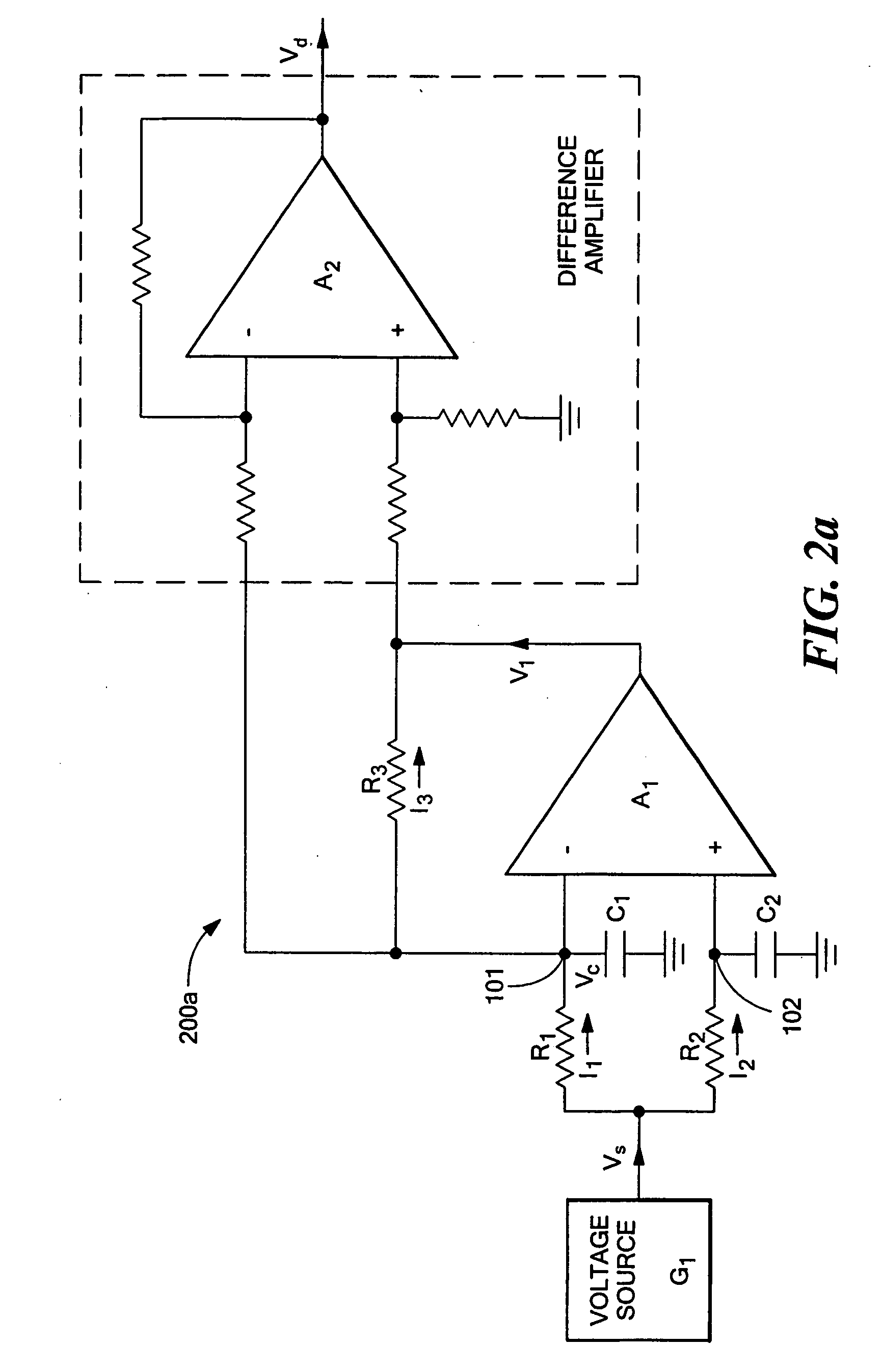

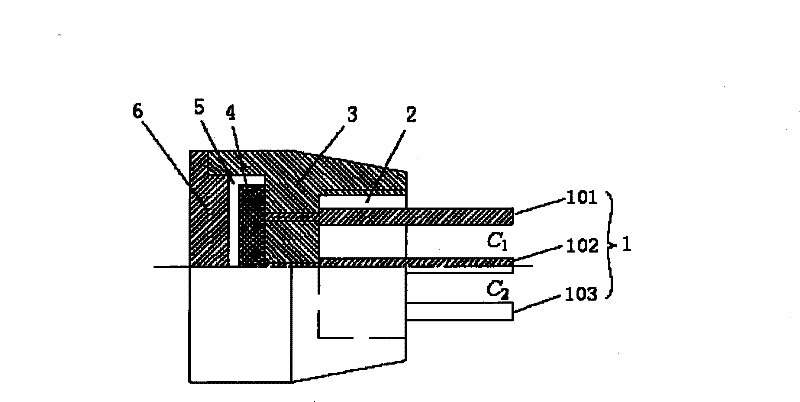

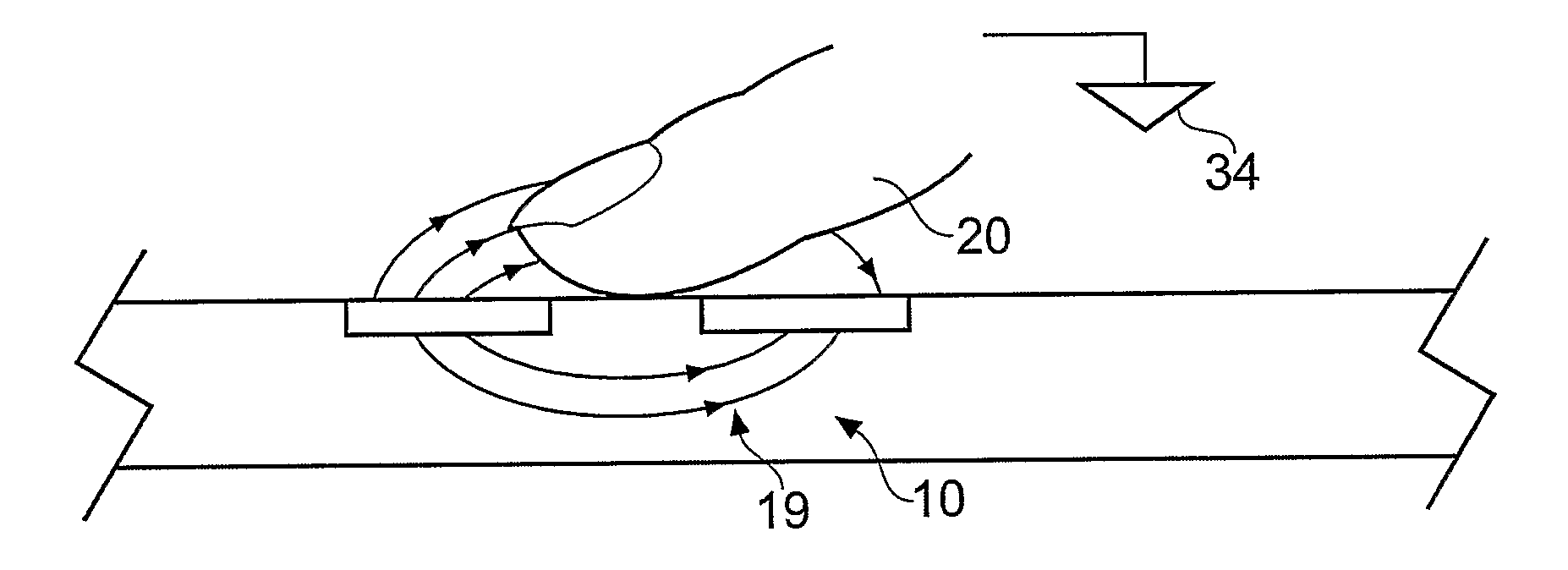

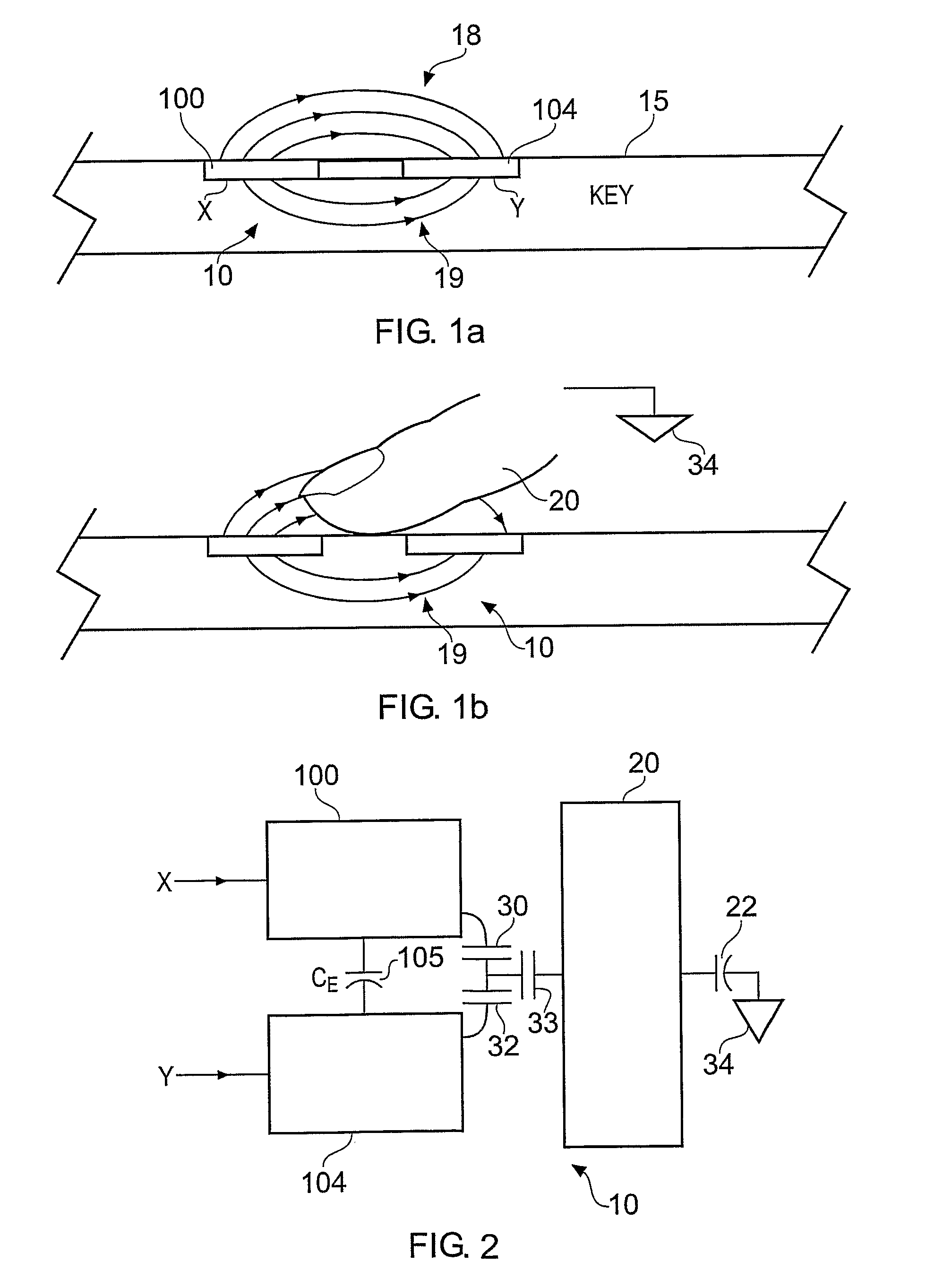

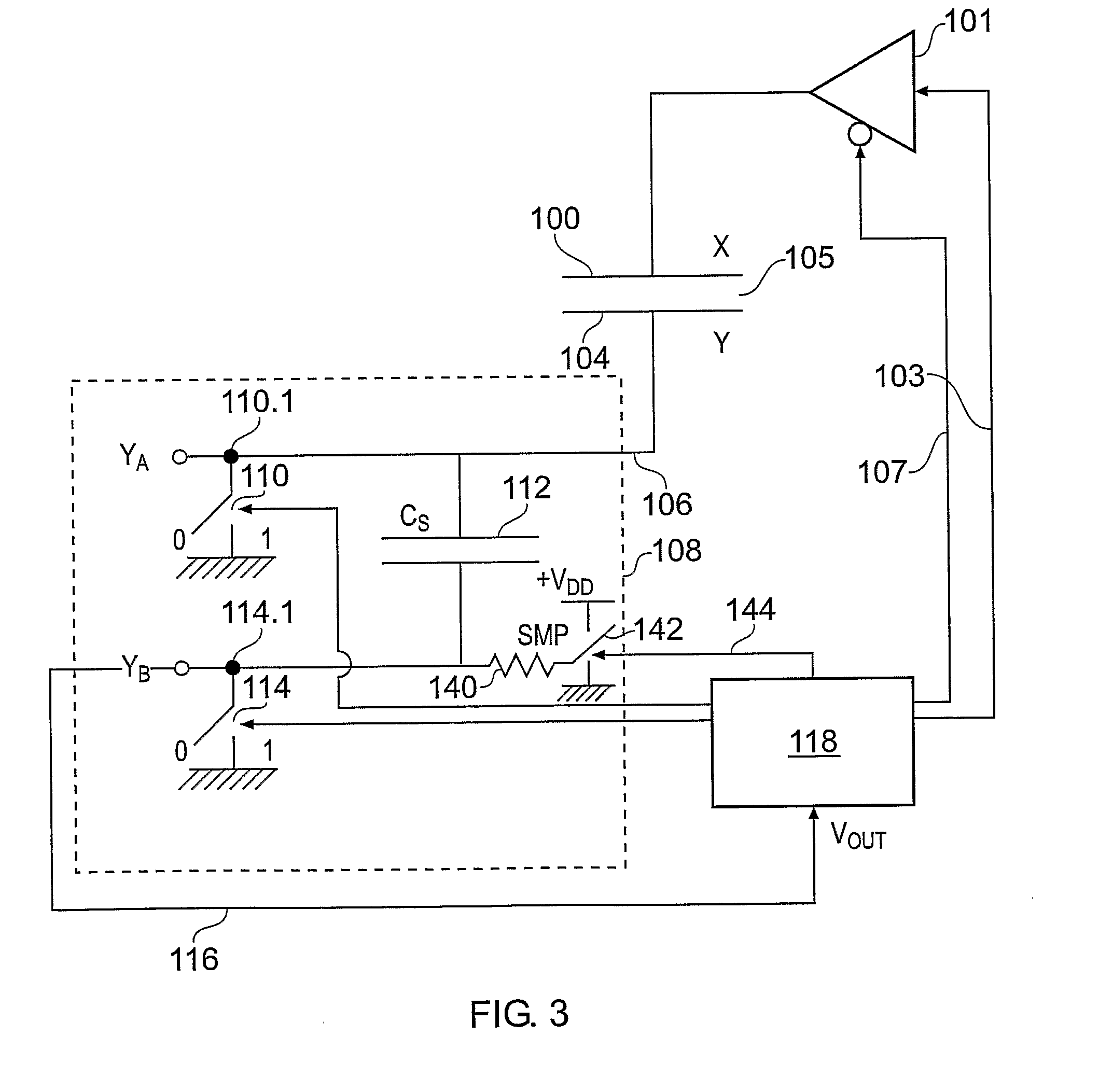

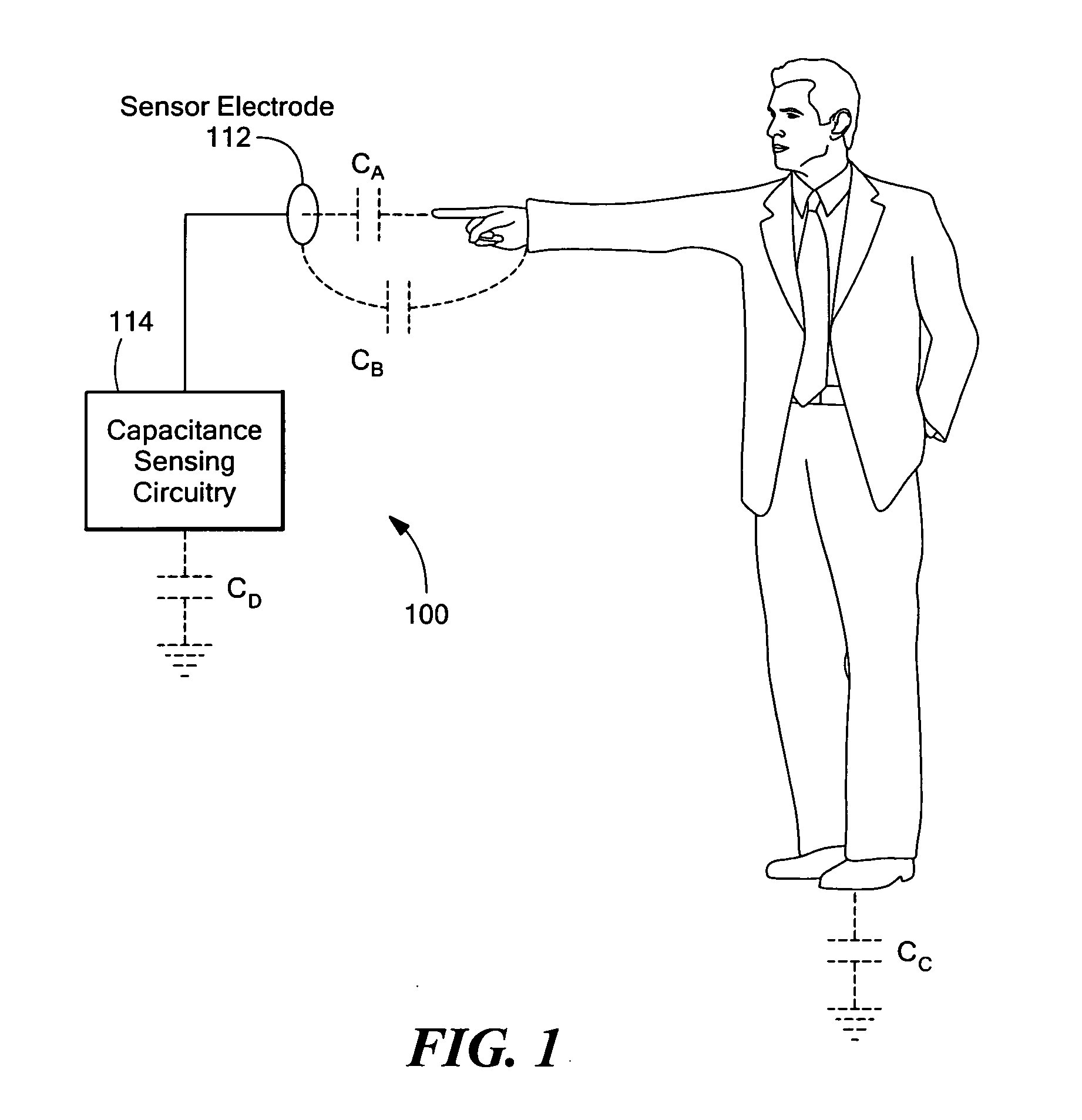

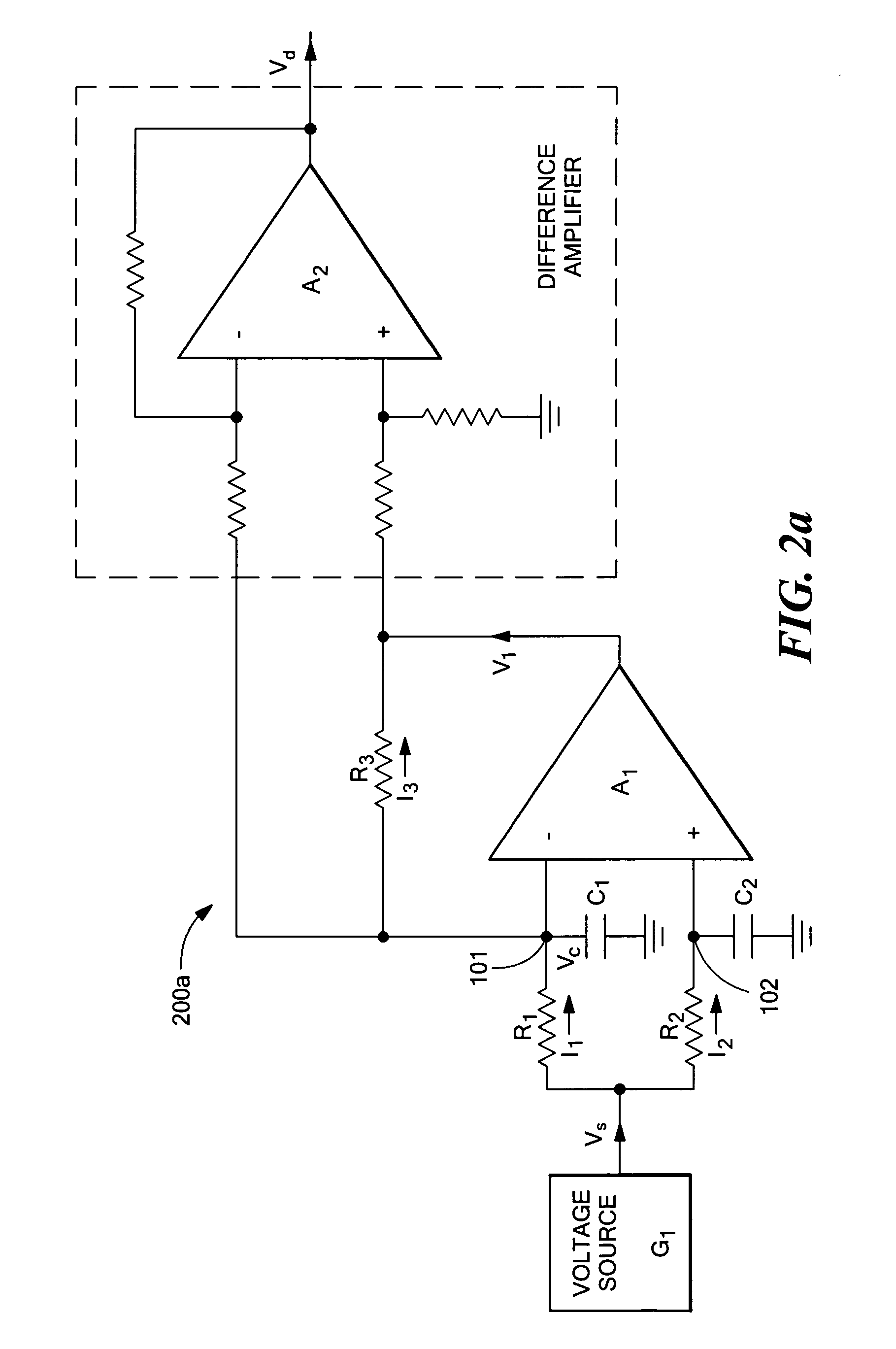

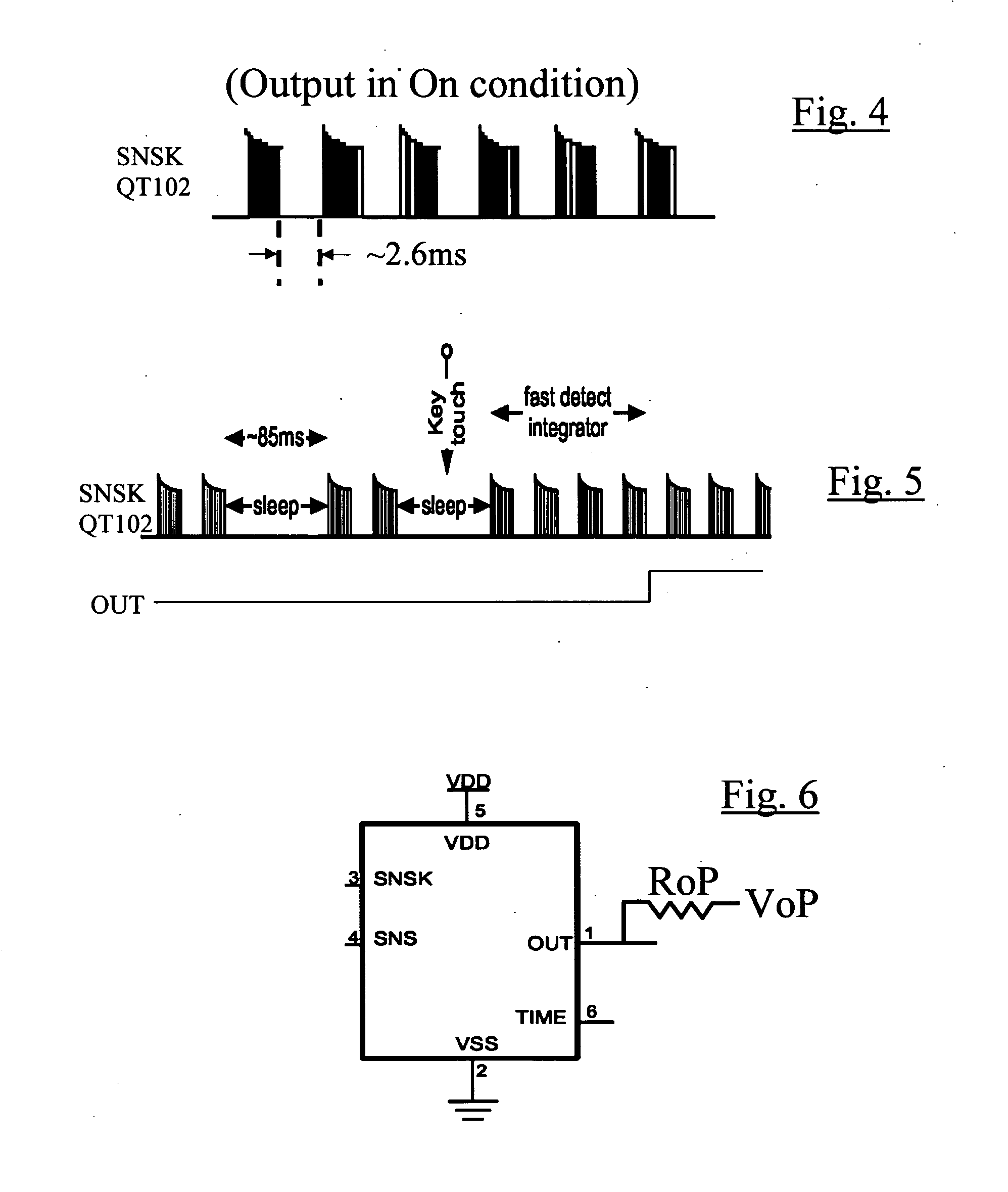

Linear capacitance measurement and touchless switch

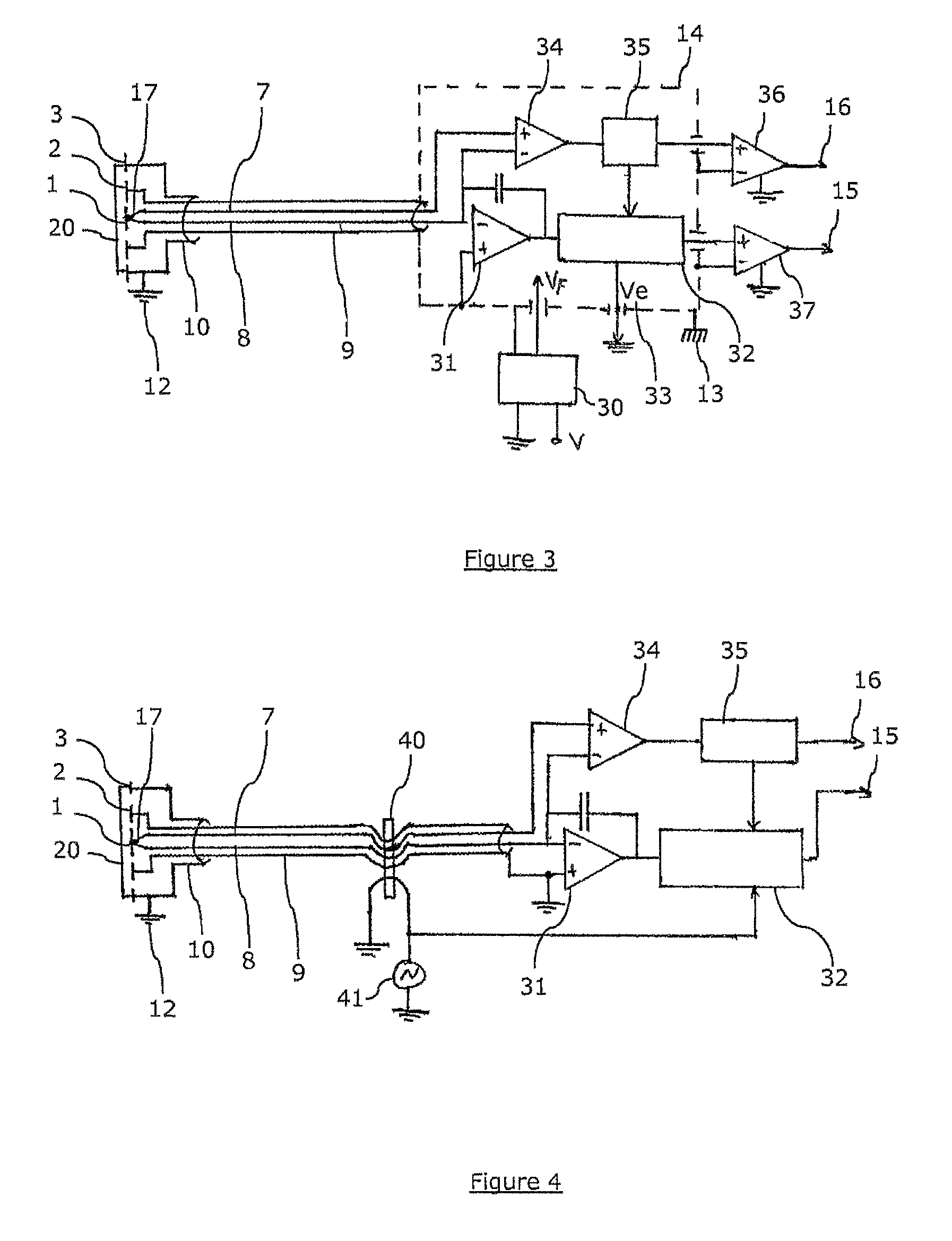

InactiveUS20070164756A1Improve accuracyHigh sensitivityResistance/reactance/impedenceElectronic switchingProximity sensorLinear relationship

Capacitance measurement apparatus that enhances the sensitivity and accuracy of capacitive transducers, proximity sensors, and touchless switches. Each of two capacitors (C1, C2) under measurement has one end connected to ground and is kept at substantially the same voltage potential by operational amplifier (A1) or amplifiers (A0, A1) using negative feedback. The apparatus is driven by a periodic e.g. sinusoidal signal source (G1) or sources (G1, G2) and includes a difference amplifier (A2) operative to produce an electrical signal having a linear relationship with a specified arithmetic function of the capacitances of the two capacitors (C1, C2). A touchless switch is implemented using the capacitance measurement apparatus. The touchless switch includes two sensor electrodes (E1, E2) that correspond to the two capacitors (C1, C2) under measurement and in one embodiment has a front surface in the form of a container.

Owner:LEE YING LAU

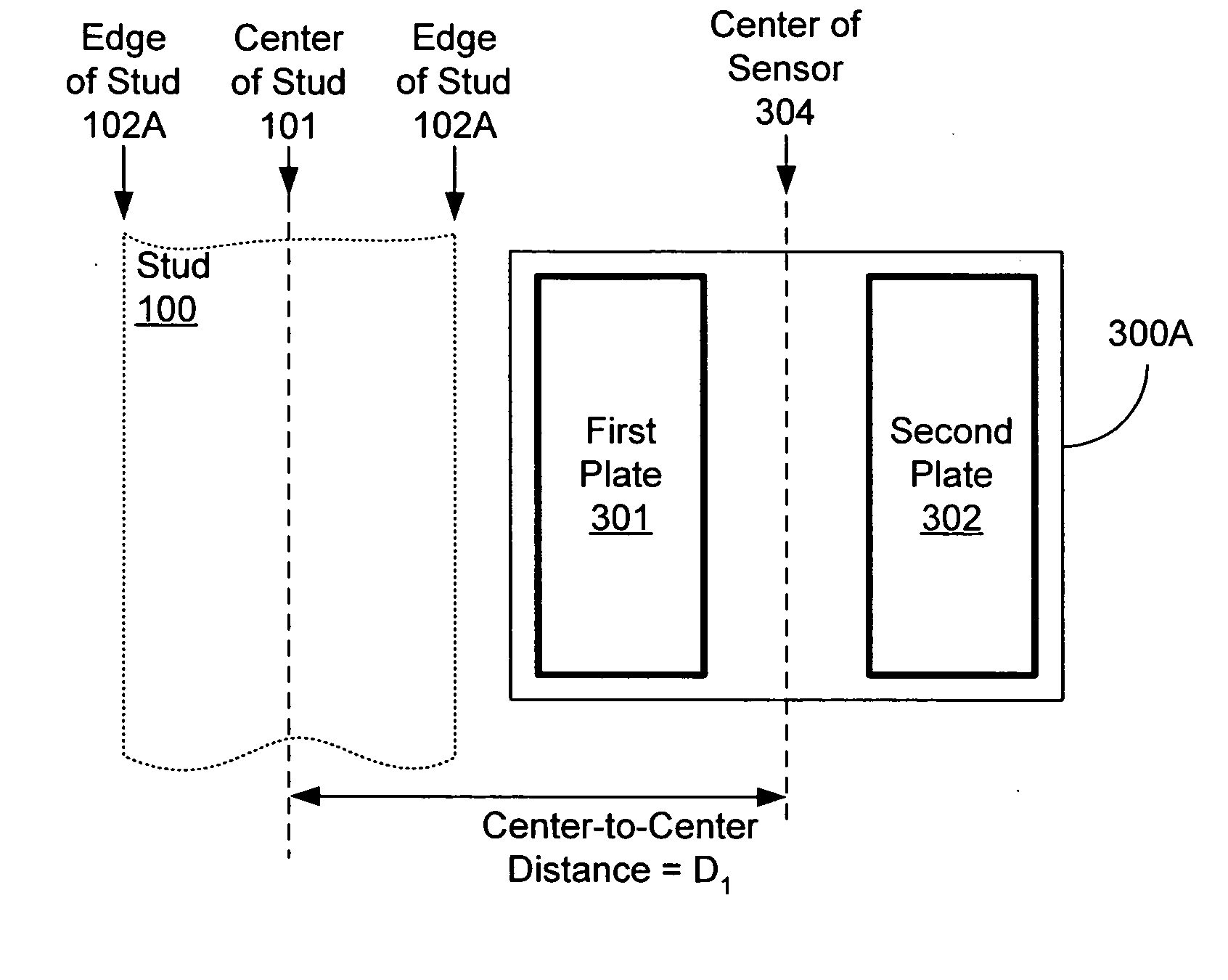

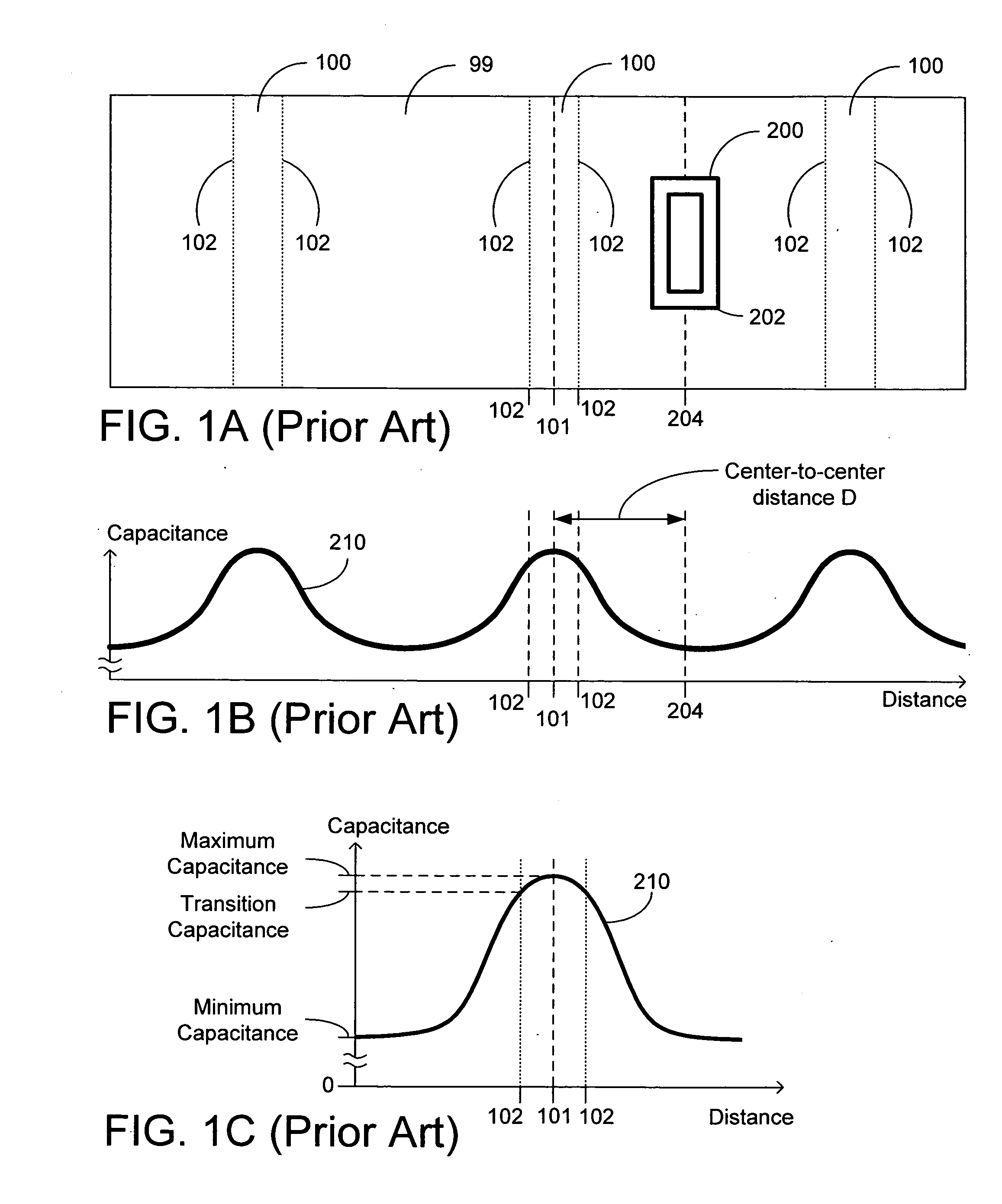

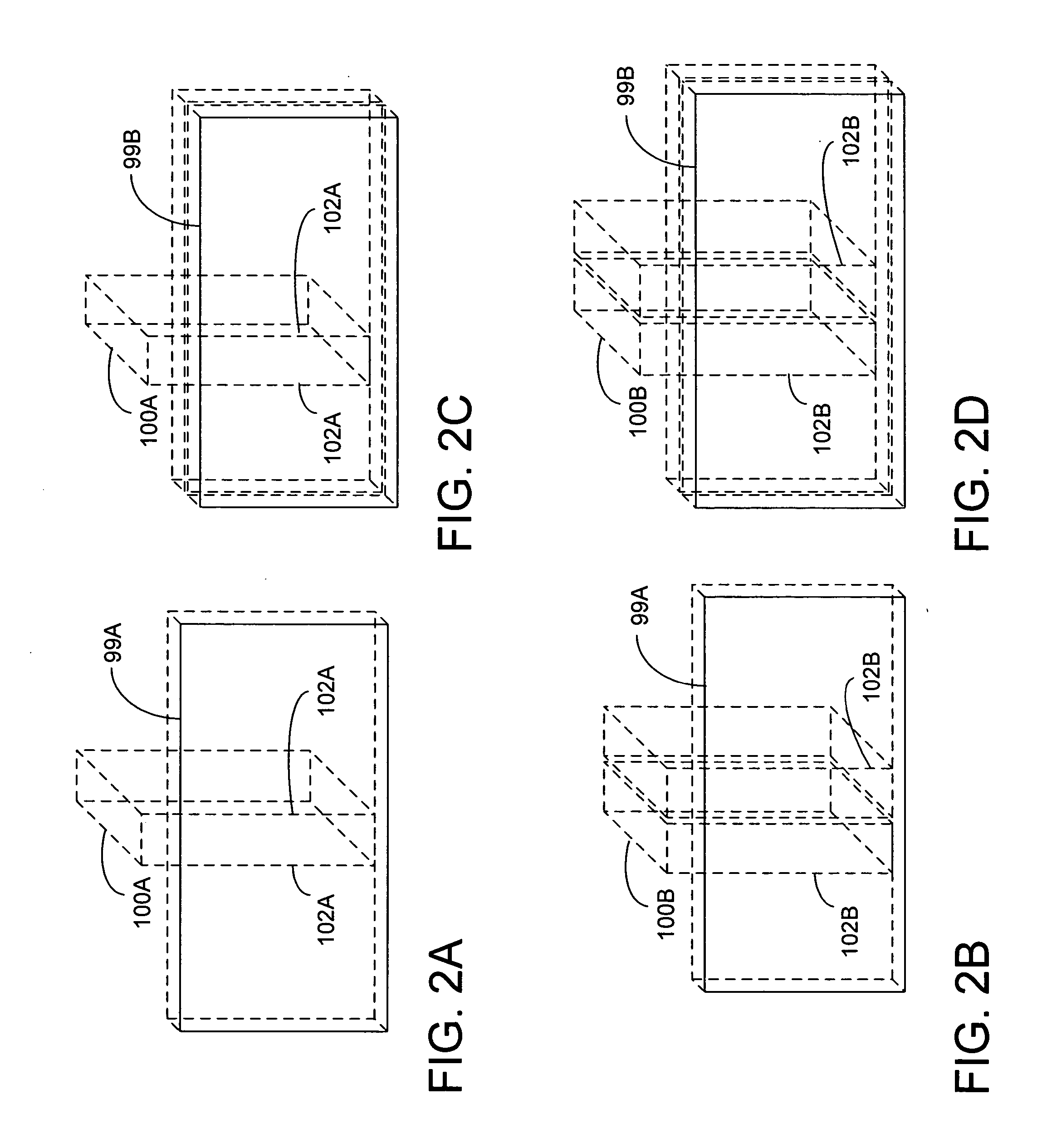

Ratiometric stud sensing

ActiveUS20050194959A1Reduce the impactEffective capacitanceResistance/reactance/impedenceCurrent/voltage measurementDielectricElectrical conductor

A stud or joist sensor device and associated sensing method using a ratio of capacitance measurements from a plurality of capacitive sensing elements. The device locates a feature of an object or discontinuity behind a surface or wall, such as an edge and / or a center of a stud behind the surface, a joist under a floorboard, a gap behind sheetrock, a metal conductor behind a surface or the like. The device may be moved over a surface, thereby detecting changes in capacitance. The change in capacitance is due to the effective dielectric constant caused by the passage over an object such as a stud. When two capacitive sensing elements provide equivalent capacitance measures, the device is over a centerline of the stud. When a ratio of the capacitance measurements equals a transition ratio, the device is over an edge of the stud.

Owner:ZIRCON

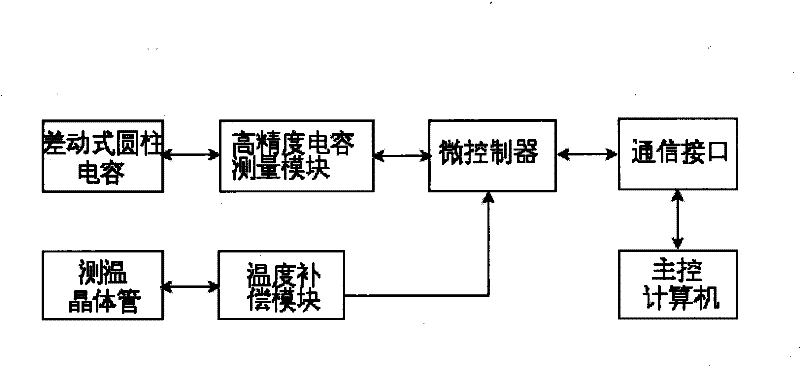

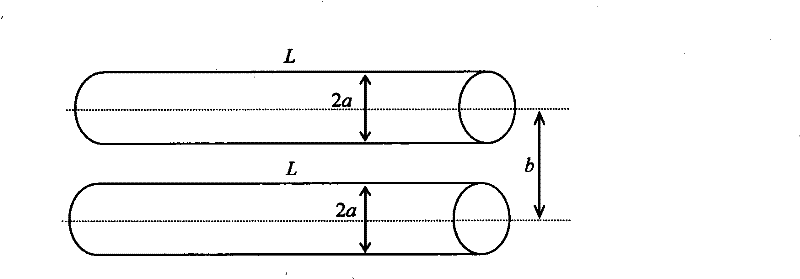

On-line oil liquid monitoring sensor based on permittivity measurement and system thereof

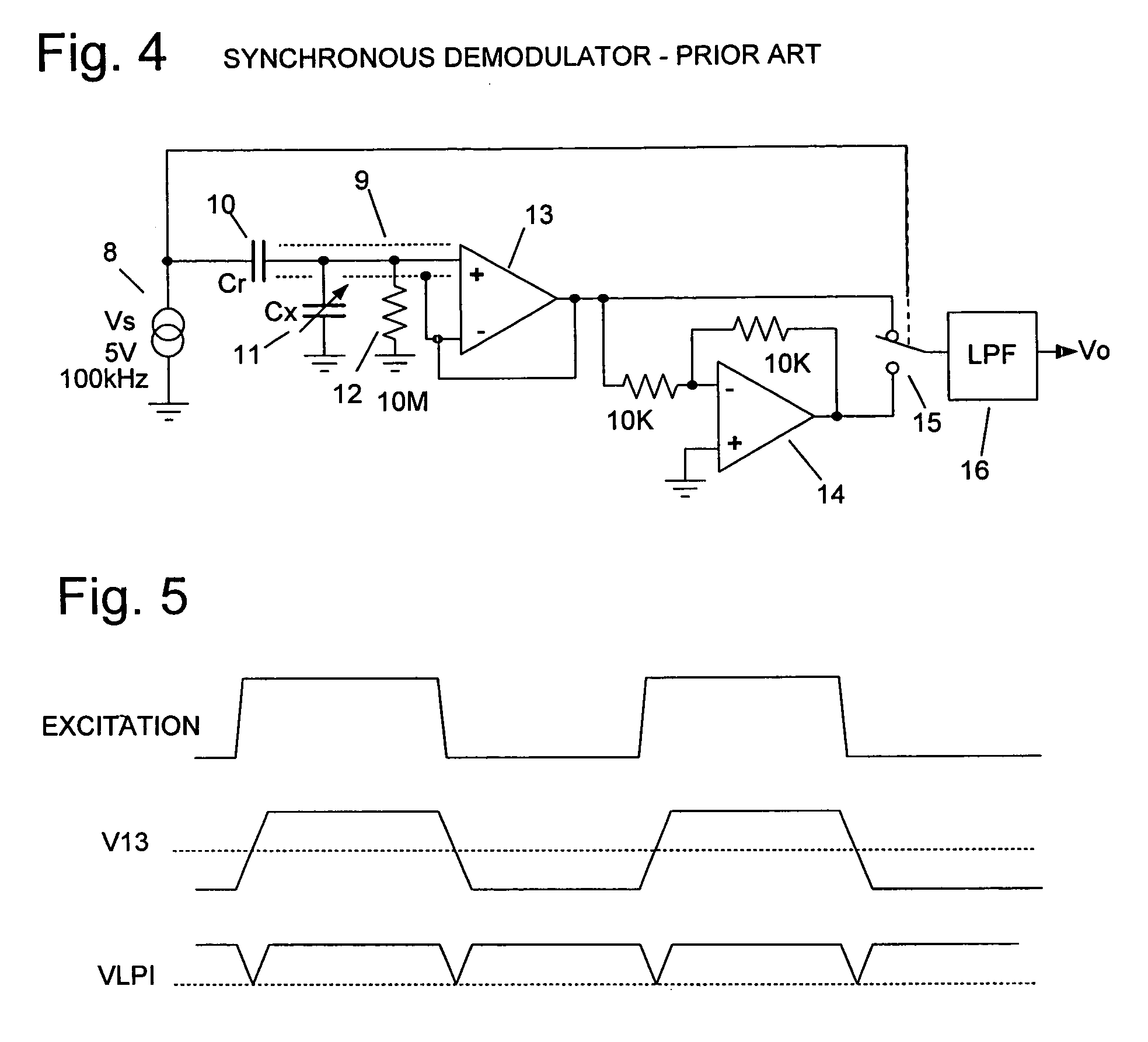

InactiveCN101435788BReal-time monitoring of pollution degreeImprove stabilityMaterial testing goodsMaterial capacitanceMonitoring systemComputer module

The invention discloses an on-line oil monitoring sensor based on permittivity measurement and a system thereof. The sensor comprises a supporting base, three polar posts are fixed in a concave part at one end of the supporting base, a circuit board is arranged in a cavity at the other end of the supporting base, and the cavity is closed by a rear cover; the first polar post and the second polar post are taken as two poles to form a first capacitor, the third polar post and the second polar post are taken as two poles to form a second capacitor, the second polar post is taken a public pole, and the first capacitor and the second capacitor are connected in parallel to form a differential cylindrical capacitor; and the differential cylindrical capacitor is connected with a wiring terminal of a high-precision capacitance measurement module in the circuit board through a shielded conducting wire. The adoption of a monitoring system of the sensor can detect the small change of a capacitance value of a capacity transducer, thereby reversely educing the small change of the permittivity of oil fluid further to perform real-time monitoring to the pollution degree of the oil fluid.

Owner:NAT UNIV OF DEFENSE TECH

Electro-physiological measurement with reduced motion artifacts

ActiveUS20120116198A1Reduce and minimize motion-induced signalReducing or minimizing motion-induced signalsElectrocardiographySensorsEngineeringCapacitance transducer

The present invention relates to an apparatus and method (4,5,6,7,2) for capacitive measurement of electrophysiological signals (1) wherein motion artifacts are suppressed or reduced by providing a feedback mechanism. An average voltage between a capacitive sensor electrode (1) and the body (3) is controlled so as to reduce or minimize motion-induced signals.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Deconvolution-based capacitive touch detection circuit and method

InactiveUS20100244859A1Increase capacitanceFacilitates simultaneous drivingResistance/reactance/impedenceInput/output processes for data processingDriver circuitElectrical conductor

A capacitance measuring system includes analog-digital circuitry (15) coupled to row conductors (2i) and column conductors (3i) of a touch screen panel (13A) for producing a first digital signal (DATA) representative of cross-coupling capacitances (CSENij). Row drive circuitry (45) superimposes charge transfers from cross-coupling capacitances of the row conductors to a first column conductor to cause the first digital signal to be a convoluted signal. Calibration circuitry (39,40) subtracts base line data from the first digital signal to produce a second digital signal (ΔDATA) representing touch-induced capacitance change values (ΔCSENIJ). A deconvolution circuit (44) deconvolutes the second digital signal to produce a digital output (58) representing a magnitude map of the touch-induced capacitance change values.

Owner:INTEL CORP

Sensor and method of sensing

ActiveUS20100214259A1Reduce impactEliminate the effects ofStatic indicating devicesInput/output processes for data processingEngineeringControl circuit

A sensor is arranged to determine the presence of an object from a change in a capacitance of a sensing element. The sensor includes a capacitance measurement circuit operable to perform measurement cycles to measure a capacitance of the sensing element, and a controller circuit. The control circuit is operable to detect a periodic noise signal induced on the sensing element, to determine a first part, of a repeating pattern of the periodic noise signal, which causes a change in an amount of charge present on the sensing element, which affects the measurement of the capacitance of the sensing element by the capacitance measurement circuit, to determine a second part of the repeating pattern of the periodic noise signal, which does not cause a change in the amount of charge present on the sensing element, and to control the measurement cycles of the capacitance measurement circuit to perform the measurement cycles during the second part of the periodic noise signal and not to perform the measurement cycles during the first part of the periodic noise signal.

Owner:NEODRON LTD

Linear capacitance measurement and touchless switch

InactiveUS20060033508A1Improve accuracyHigh sensitivityNegative-feedback-circuit arrangementsCapacitance measurementsNegative feedbackProximity sensor

Owner:LEE YING LAU

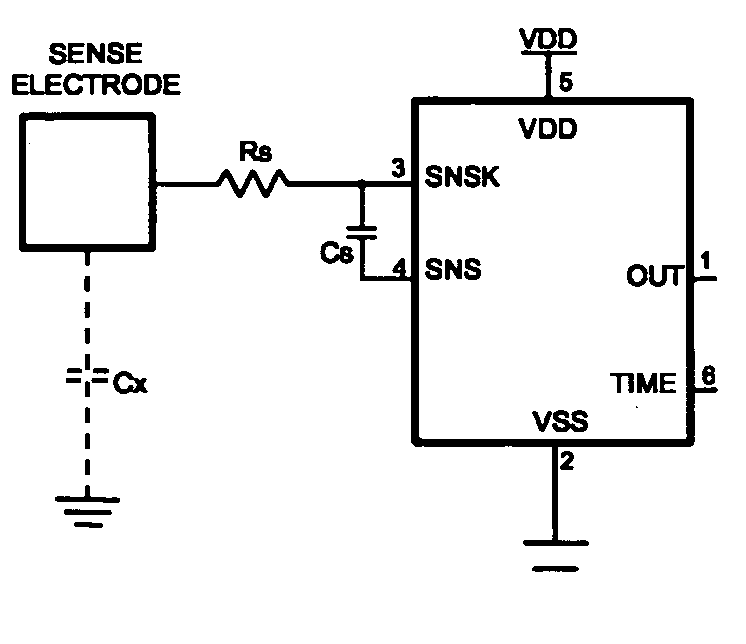

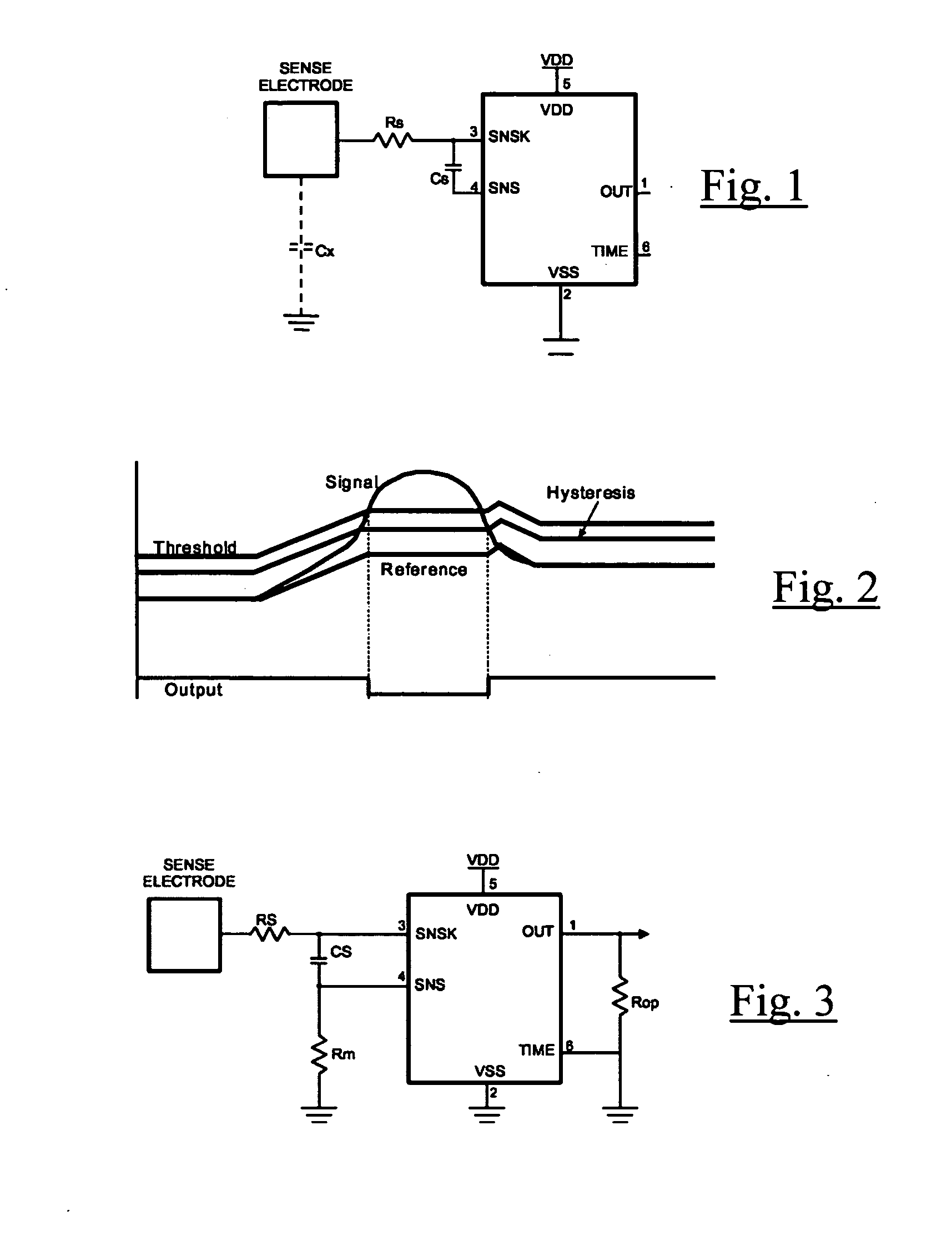

Proximity Sensor

InactiveUS20090027068A1Burglar alarm by openingResistance/reactance/impedenceProximity sensorControl circuit

A capacitive touch sensor providing an automatic switch-off function for an apparatus in which the sensor is incorporated is provided. The sensor comprises a sensing element coupled to a capacitance measurement circuit for measuring the capacitance of the sensing element. A control circuit is operable to determine from the capacitance measurement whether an object is in proximity with the sensor. The determined presence of an object may be used to toggle a function of the apparatus. Furthermore, when it is determined that an object has not been in proximity with the sensor for a predetermined time duration, an output signal for switching off the apparatus is provided. The predetermined time duration may be selected from a number of predefined time durations, or may be programmed using an resistor-capacitor network. Pulses may be applied to the control circuit to override features of the automatic switch-off functionality.

Owner:NEODRON LTD

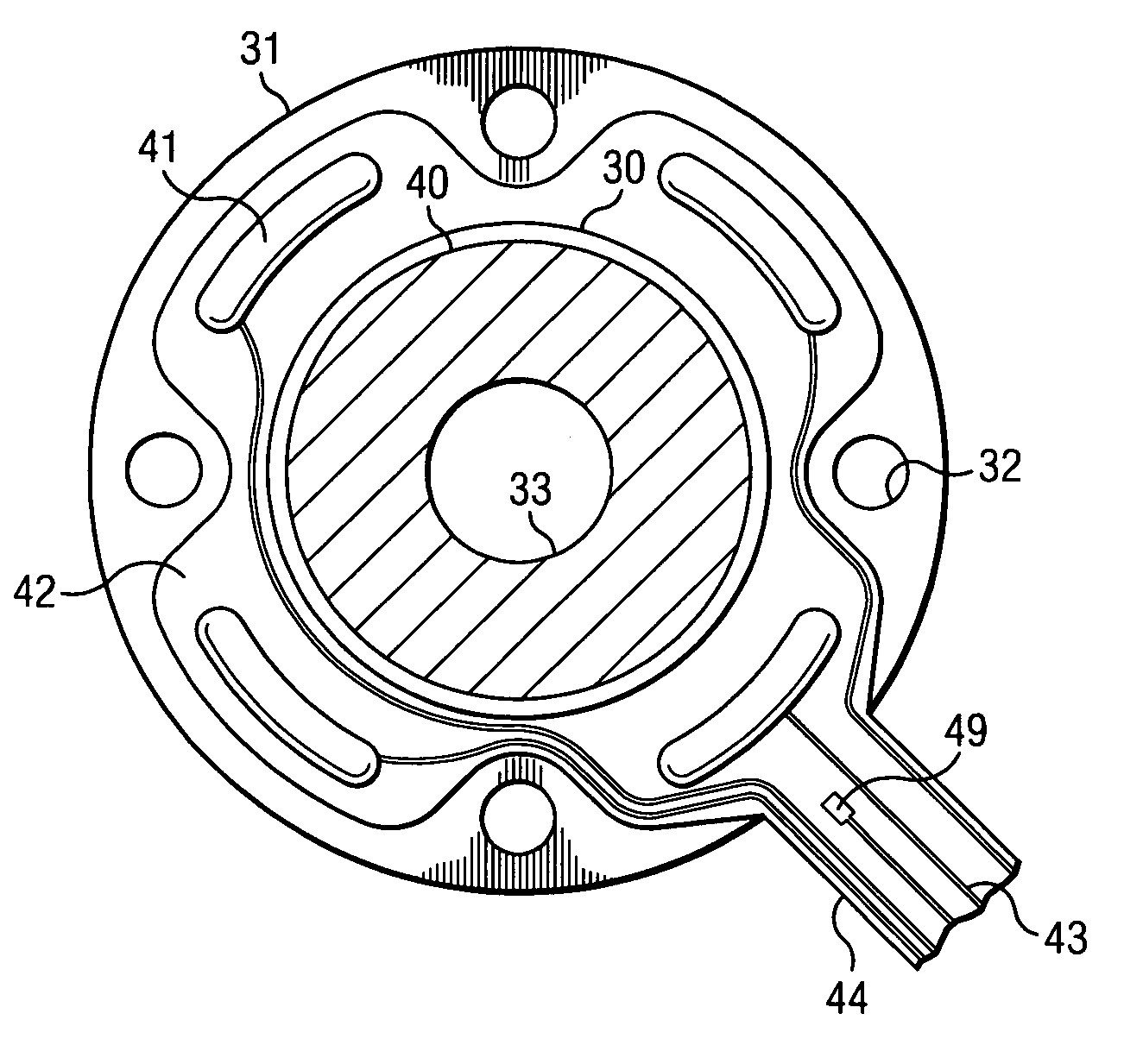

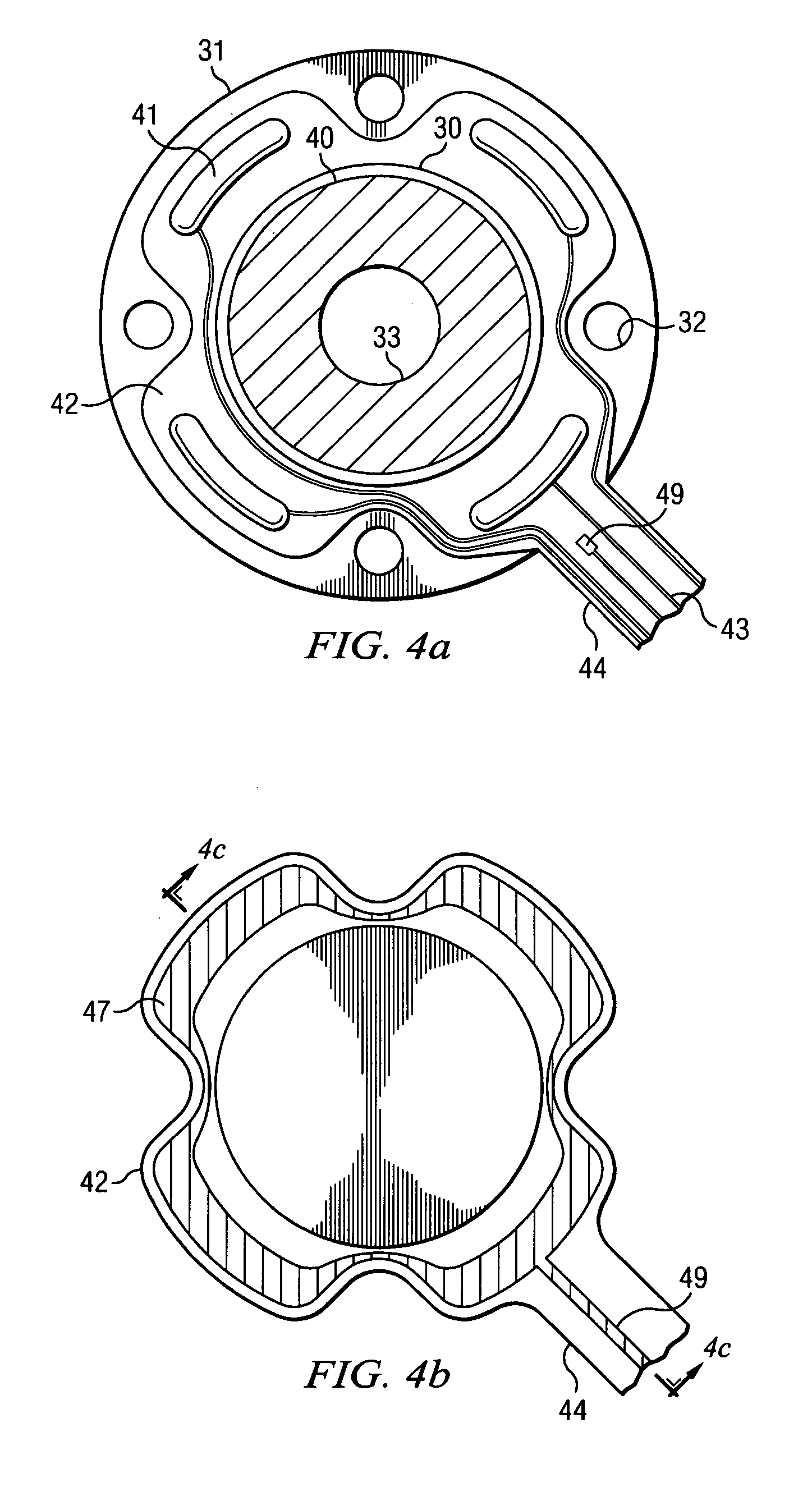

Compressive load sensor by capacitive measurement

InactiveUS20070193361A1Effectively measure parameterMaintain measurement accuracyForce measurementMachine sealing rings testingContinuous measurementElectricity

A thin, flat capacitive load sensor, such as of layered sandwich construction, having a variety of shapes, so as to provide a seal between two or more opposing surfaces. The load sensor includes a thin first and second insulating outer layer between which an inner layer is secured. The inner layer can be formed of dielectric material of a known dielectric constant, with at least one thin electrical conductor to accommodate load sensing disposed against a first face, and another thin electrical conductor to accommodate load sensing disposed against a second face. Electrical conductors connect the thin conductive areas on the first and second faces to the distal end of a tab extending beyond the load or connection measurement area. The distal end of the tab accommodates a connection with electrical measurement apparatus. As the inner layer is compressed, the spacing between the electrically conductive areas on the opposing faces is decreased such that compressive forces can be measured as a function of the changes in capacitance of the sensor. In this manner, proper compression can be achieved by monitoring capacitance during installation. Follow-up sampling or continuous measurement of sensor compression provides early detection prior to failure to allow corrective action.

Owner:DAVIE COFFEY TECH L L C

Capactive pressure sensor incorporating a temperature measurement and compatible with hot environments

ActiveUS8770033B2Improve accuracyPrevent capacitanceConverting sensor output electrically/magneticallyFluid pressure measurement using capacitance variationCapacitive pressure sensorMeasurement device

A capacitive measurement device including first measurement device designed to carry out a first measurement function in relation to a nearby object, the first measurement device including a body and, a capacity electrode, both of a substantially conductive material, and a guard electrode placed between the body and the capacitive electrode and insulated from the body on the one hand and from the capacitive electrode on the other hand by dielectric elements; an excitation apparatus which maintains the capacitive electrode and the guard electrode to a desired AC electrical potential; a first electronic apparatus, connected to the capacitive and guard electrodes, for measuring the capacitance between the capacitive electrode and the object; and a second measurement device designed to carry out a second measurement function, which are located in the vicinity of either the capacitive or guard electrode, and maintained by the excitation apparatus to a desired AC electrical potential.

Owner:FOGALE NANOTECH SA

Coded integration of a self-capacitance array

ActiveUS20150338952A1Increased signal noiseEasy to measureInput/output processes for data processingSignal-to-noise ratio (imaging)Integrator

Coded integration of a self-capacitance array to improve signal-to-noise ratio (SNR) of self-capacitance measurements is disclosed. A composite measurement of the self-capacitance of a plurality of electrodes can be measured for a plurality of integration periods. The composite measurements can include weighted contributions of charge from the plurality of electrodes, the weighting corresponding to a code. In some examples, the weighted contribution can include positive contributions integrated by a first integrator circuit and negative contributions integrated by a second integrator circuit. The composite measurements of the self-capacitance for the plurality of integration periods can be decoded to extract the self-capacitance measurement for the electrodes. The SNR for the self-capacitance measurements can therefore be improved by increasing the number of samples during the total integration period without requiring dedicated sensing circuitry for the electrodes.

Owner:APPLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com