On-line oil liquid monitoring sensor based on permittivity measurement and system thereof

A technology of oil monitoring and dielectric constant, applied in the direction of material capacitance, material inspection products, etc., can solve the problems of oil pollution and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

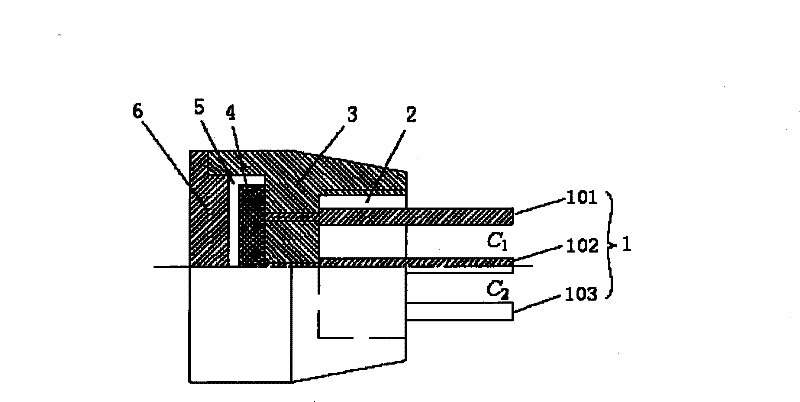

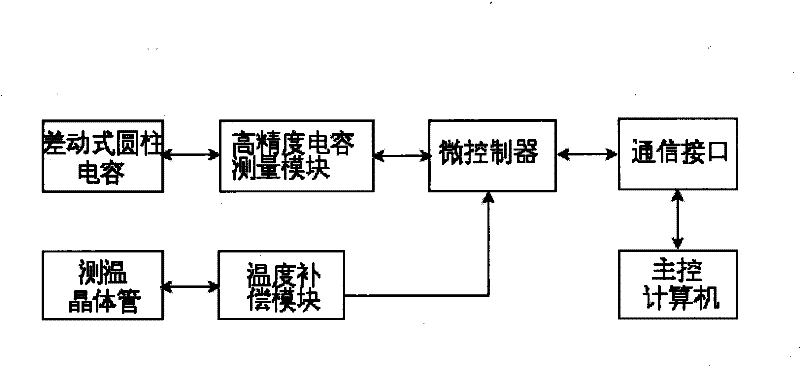

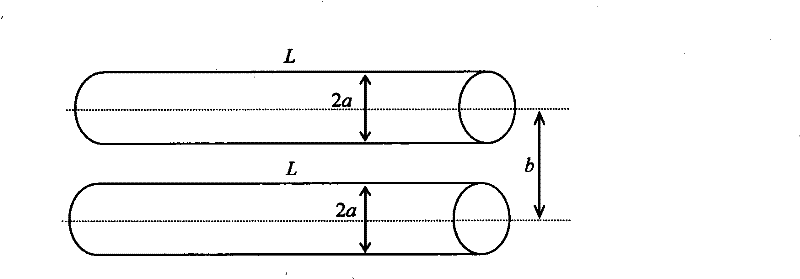

[0023] See figure 1 , an online oil monitoring sensor based on dielectric constant measurement, including a support 3, and three poles 1 are fixed with screw connections in the recess 4 at one end of the support 3, which are respectively a first pole 101, a second pole 102, The third pole 103 is fixed with a circuit board 4 with screws in the chamber 5 at the other end, and the circuit board 4 includes a high-precision capacitance measurement circuit module, a temperature measuring transistor, and a temperature compensation circuit. The cover 6 is closed; the first capacitor C is formed with the first pole 101 and the second pole 102 as two poles 1 , taking the third pole 103 and the second pole 102 as two poles to form the second capacitor C 2 , with the second pole 102 as the common pole, the above-mentioned first capacitor C 1 and a second capacitor C 2 Connected together in parallel to form a differential cylindrical capacitor (differential cylindrical capacitor sensor)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com