Patents

Literature

57 results about "Membrane probe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

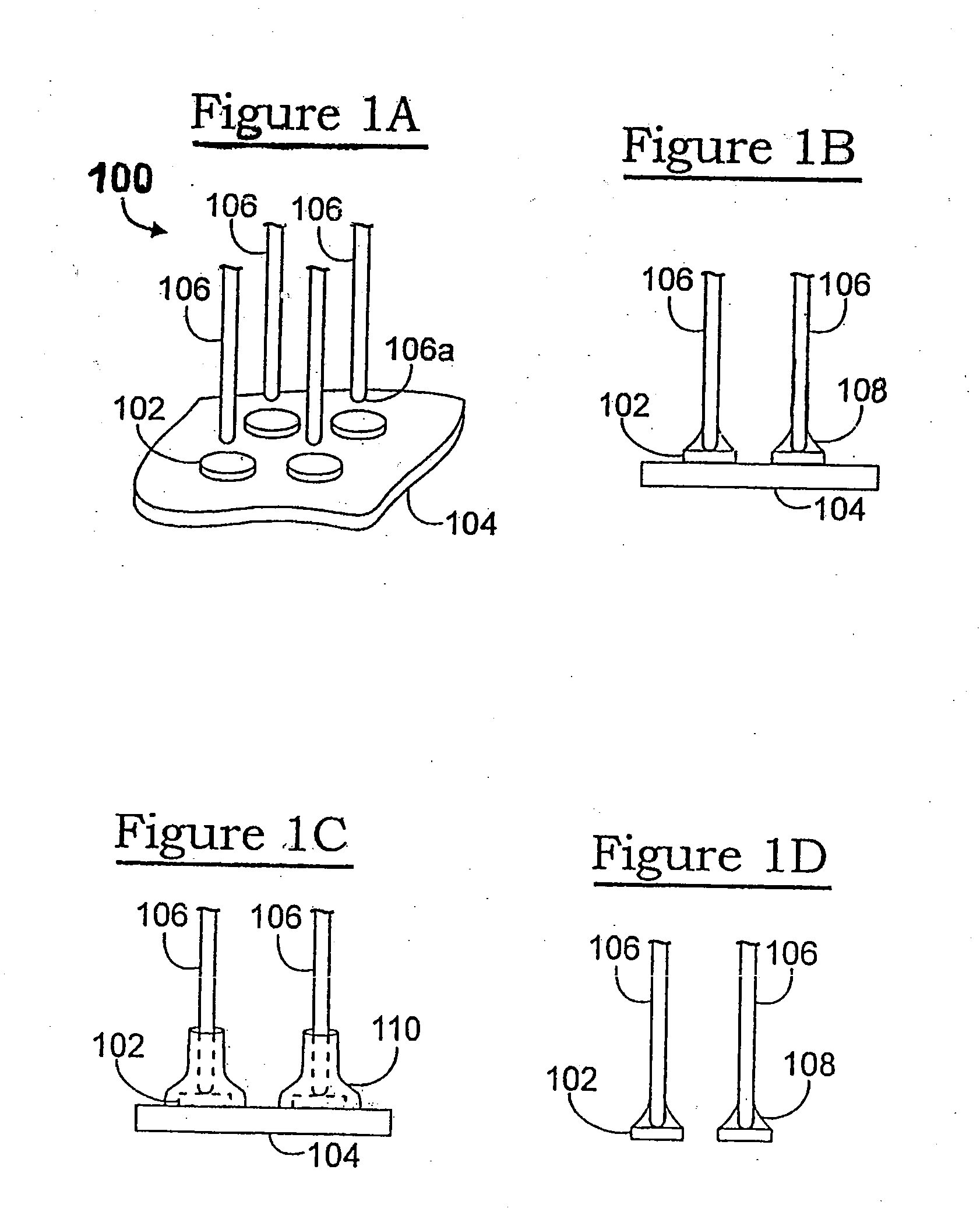

Flexible membrane probe and method of use thereof

InactiveUS6900652B2Reduce fluid pressureSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceEngineeringSemiconductor

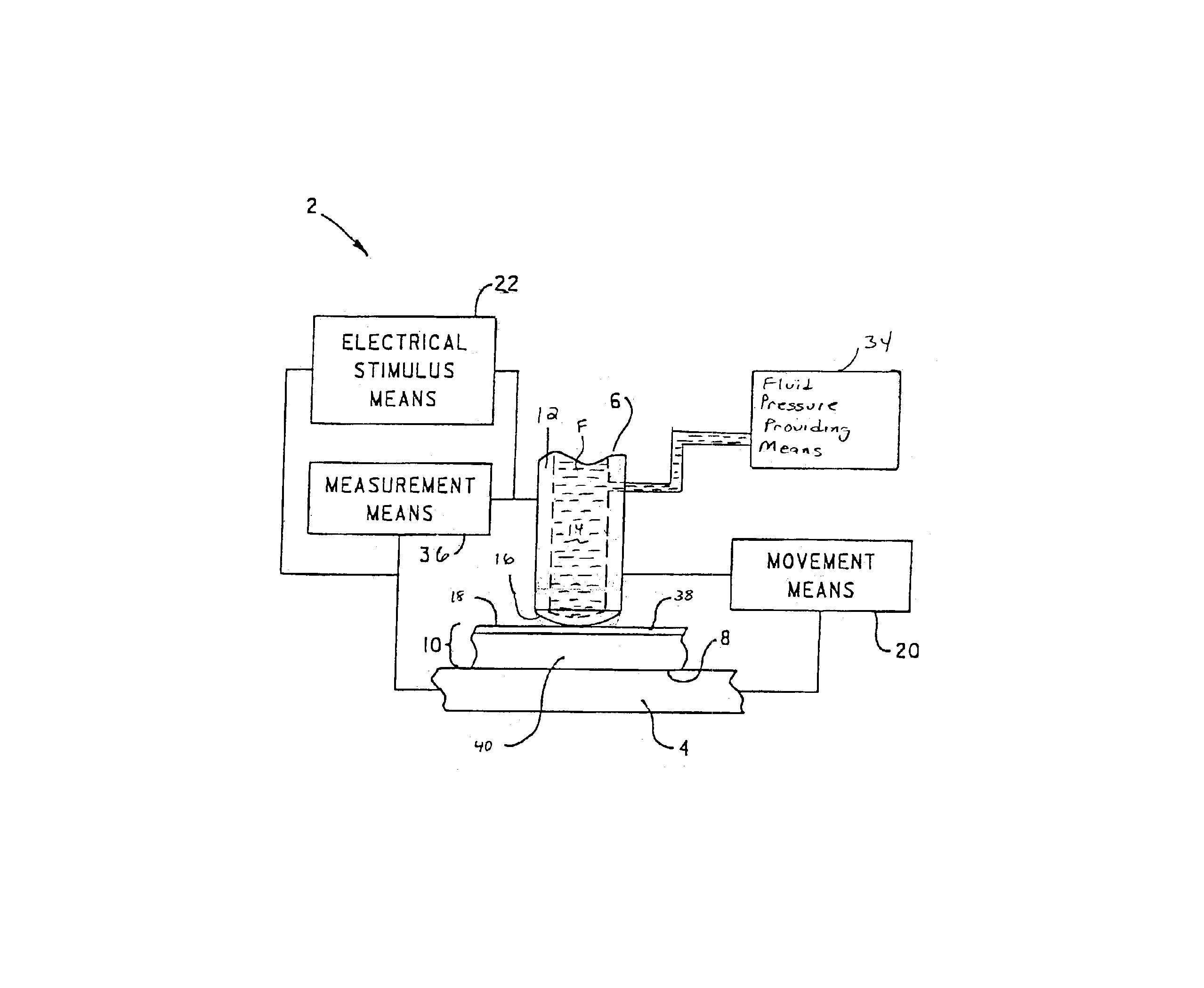

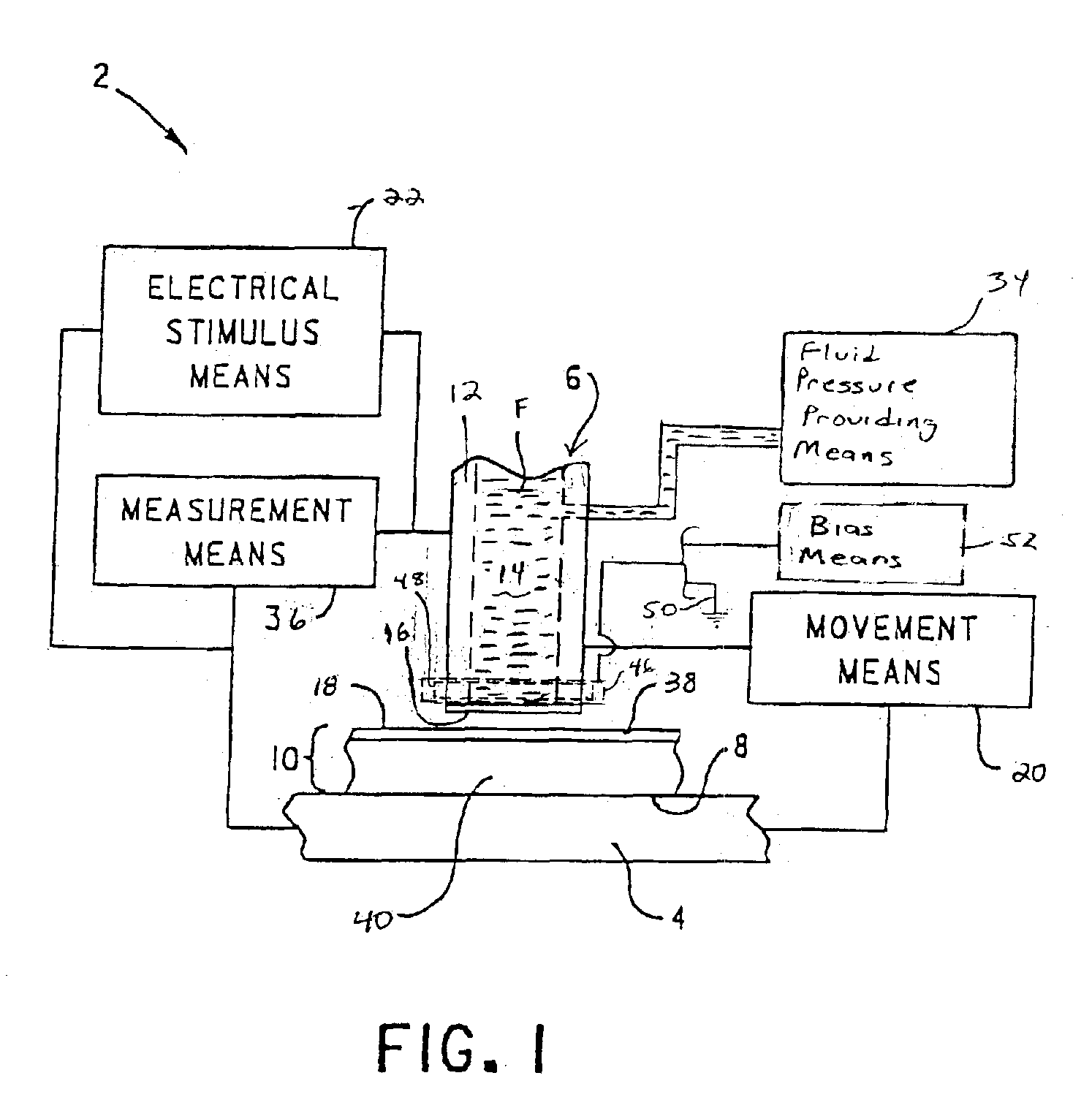

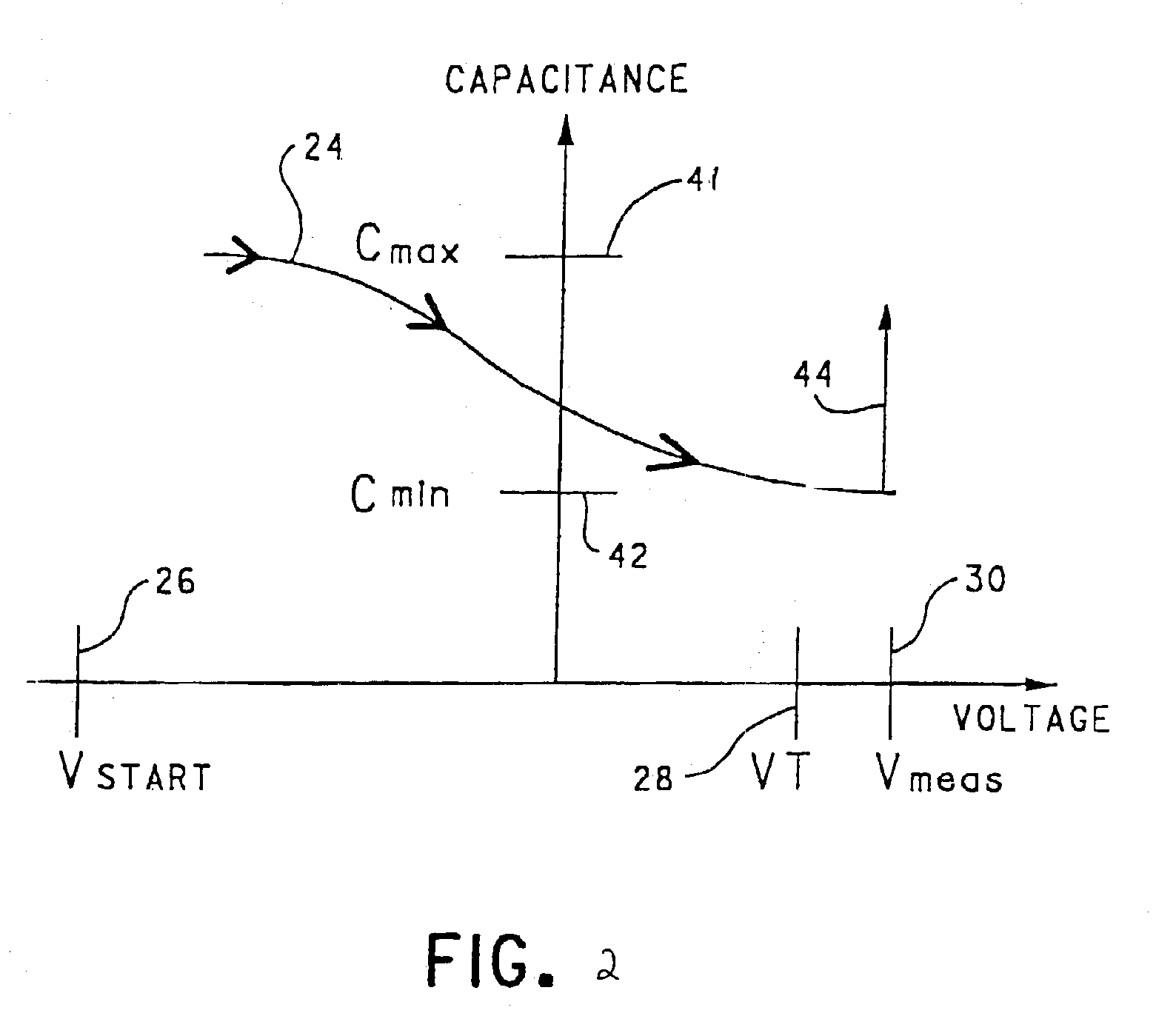

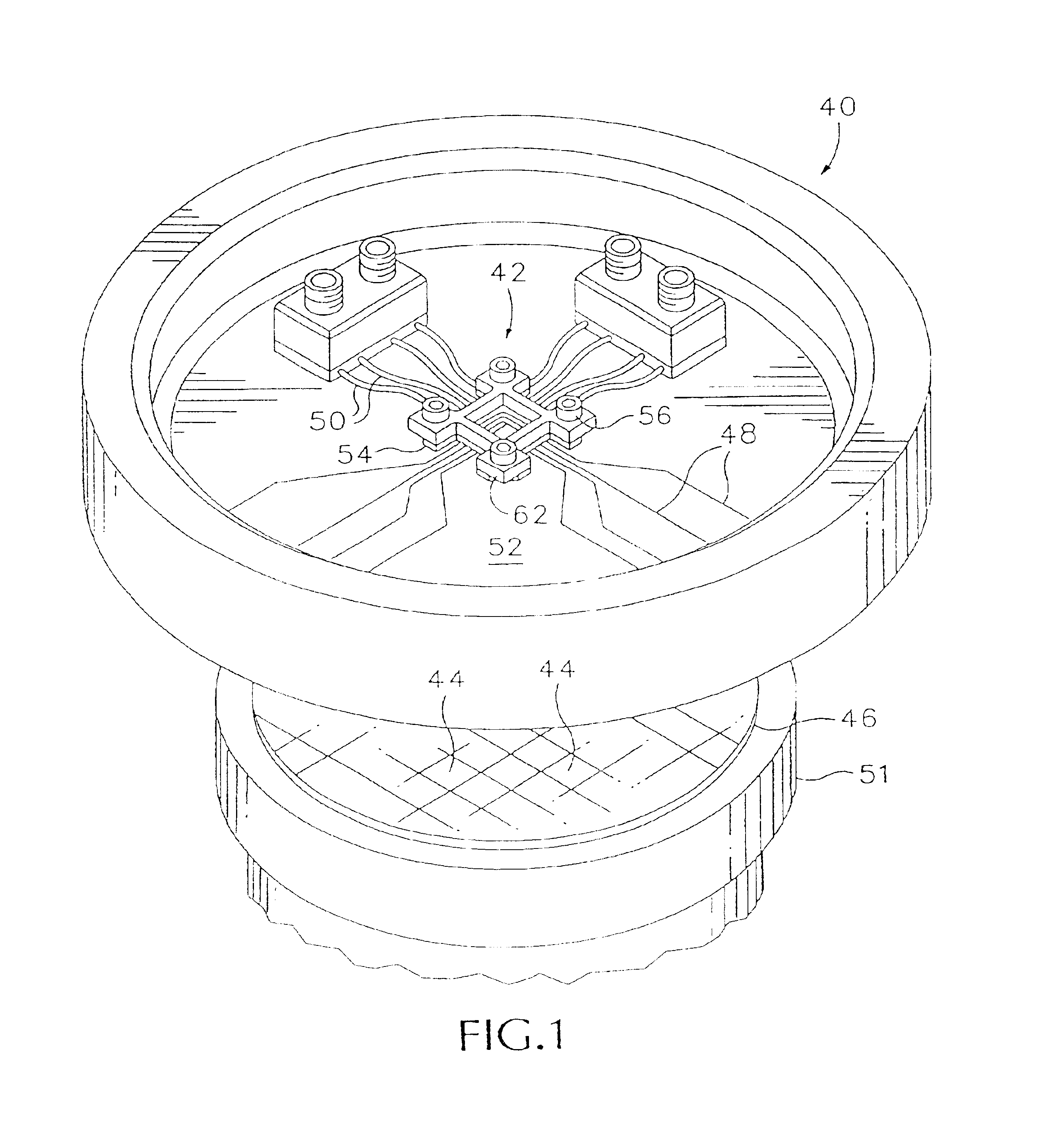

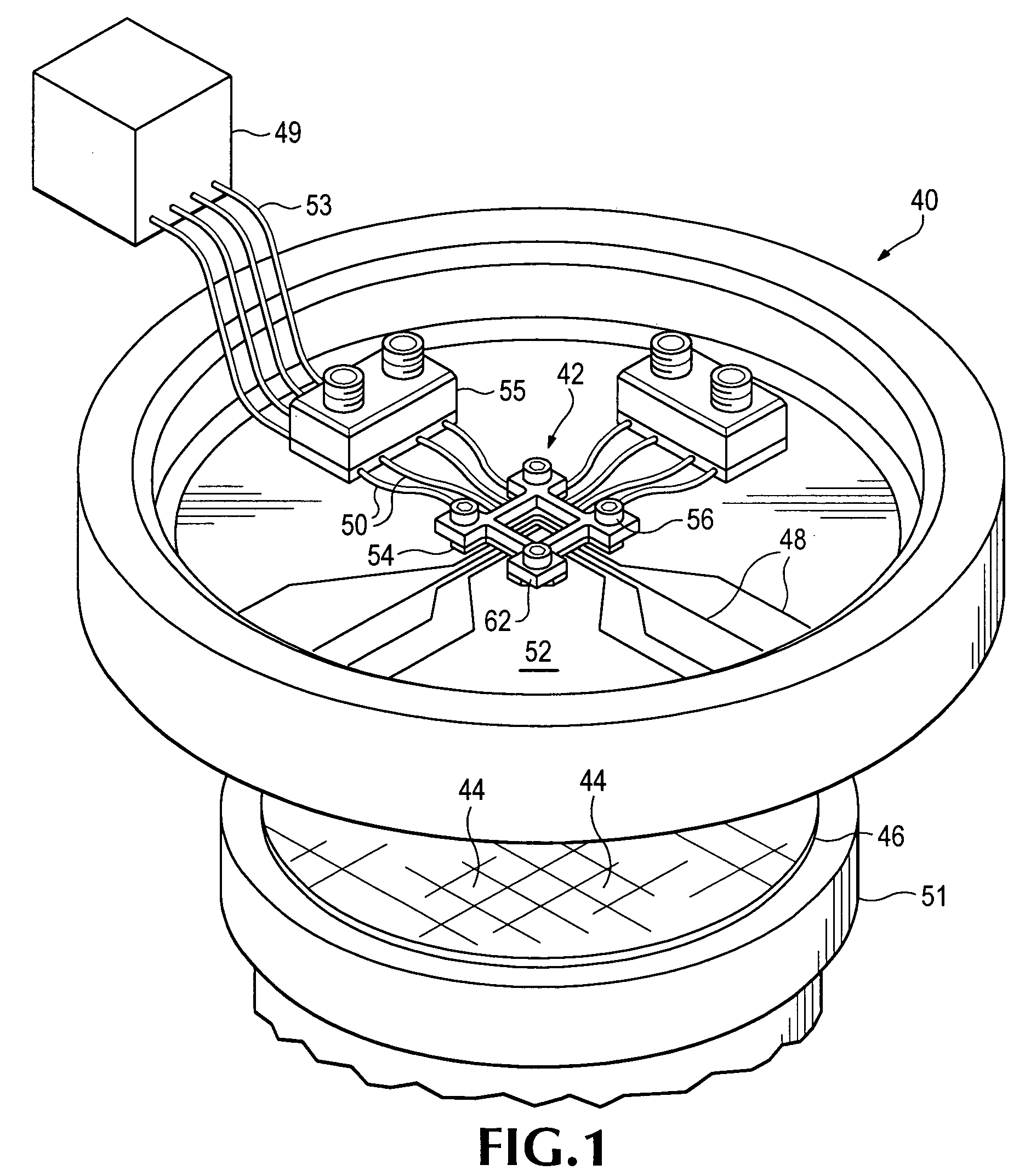

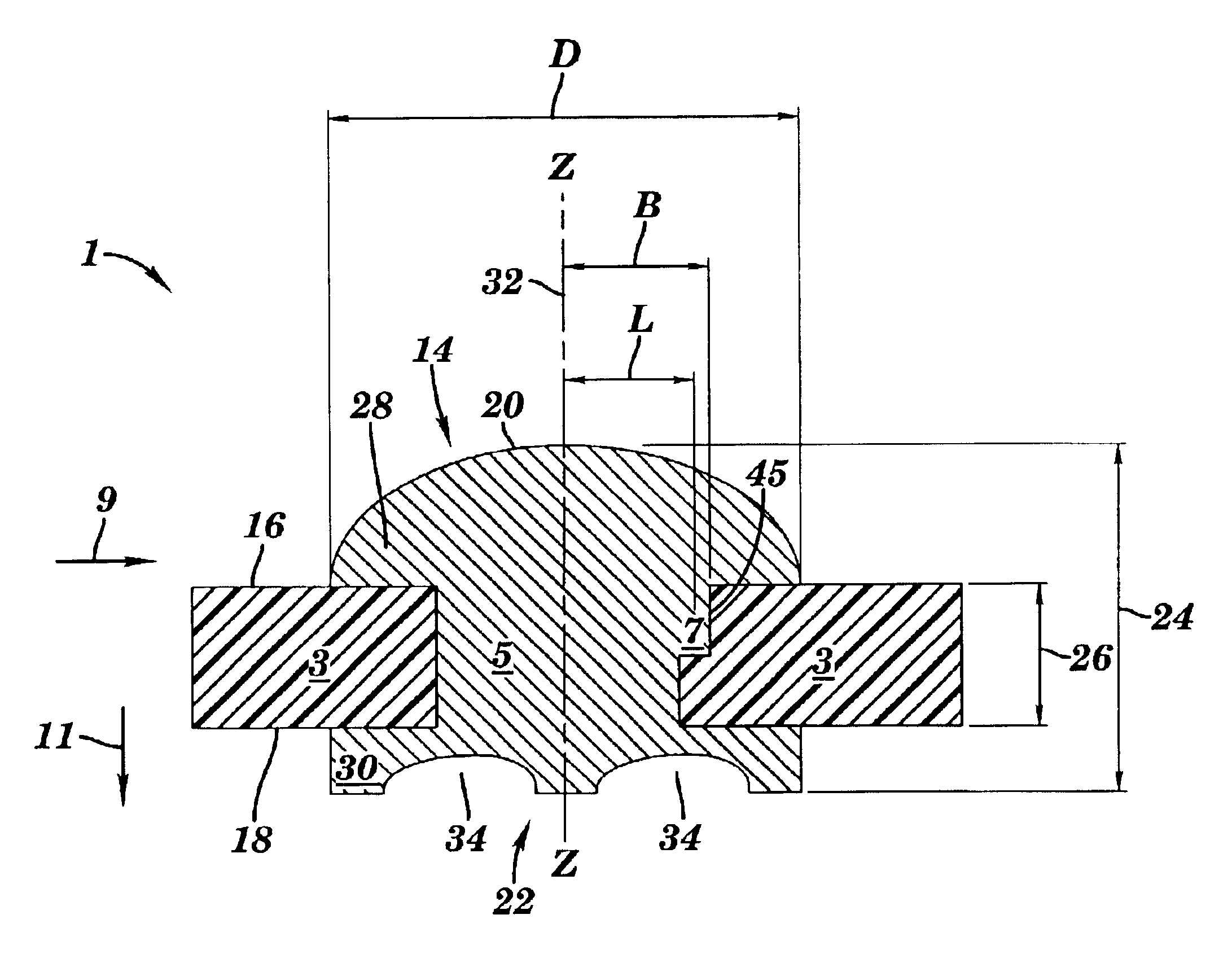

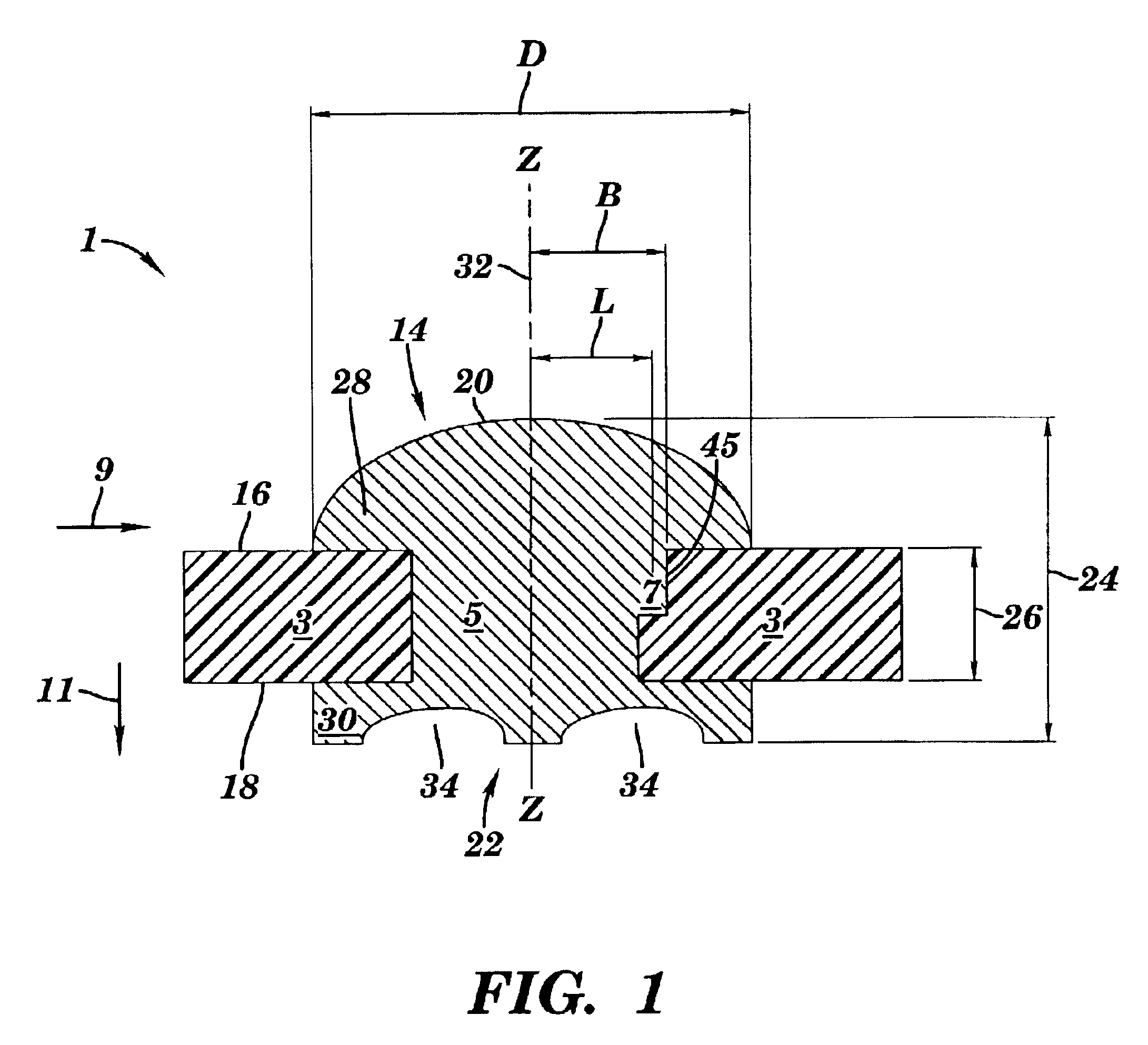

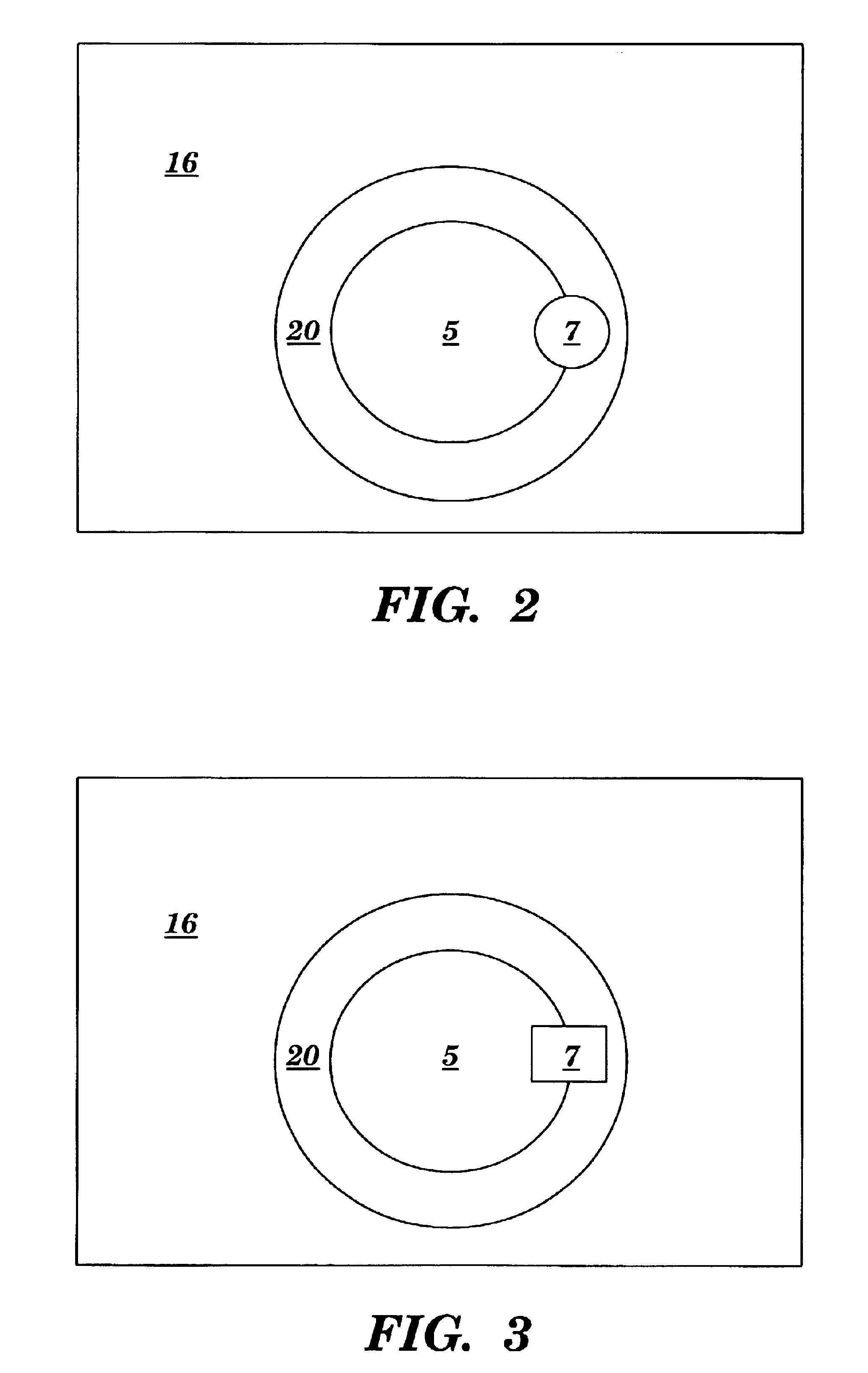

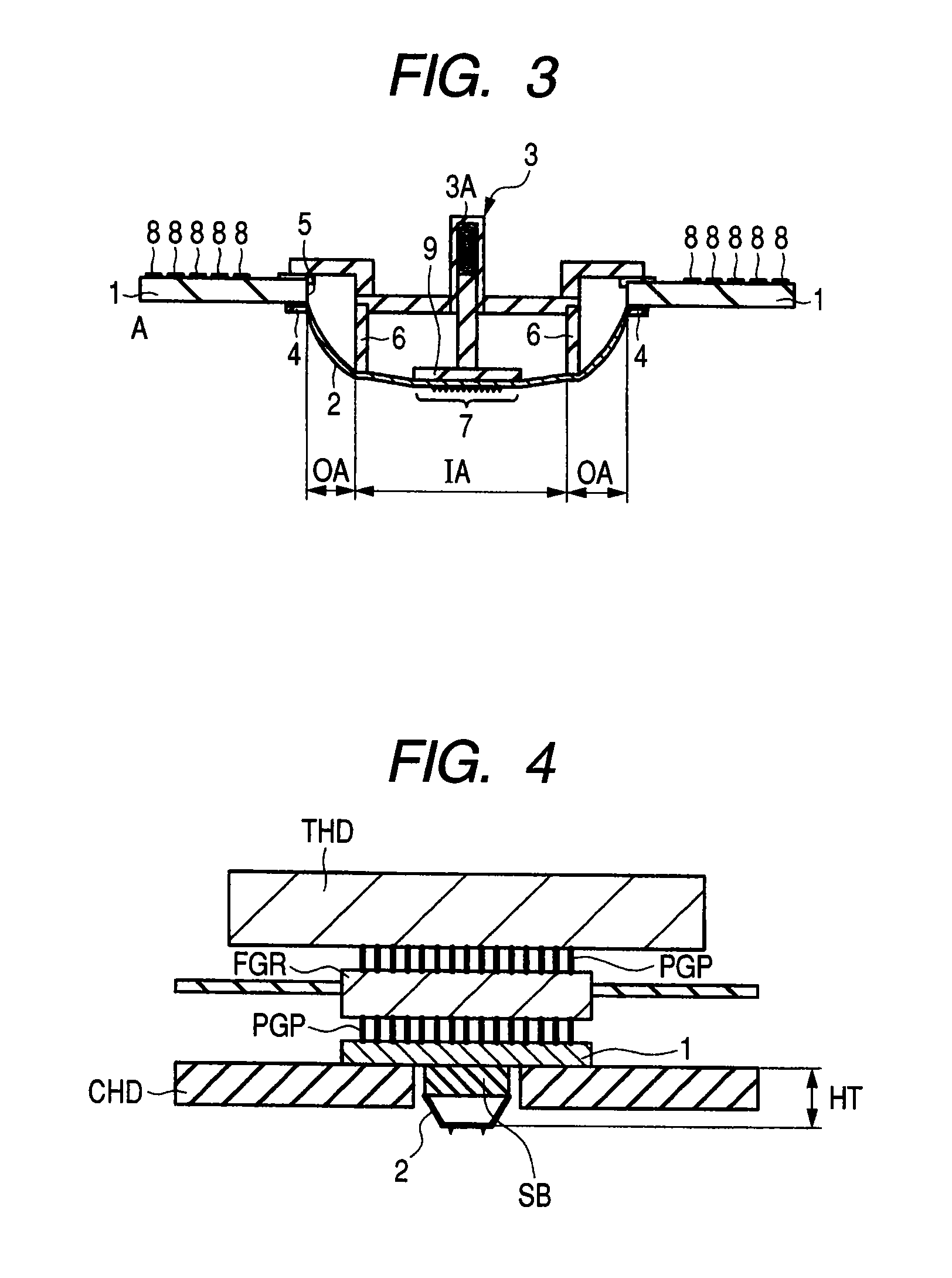

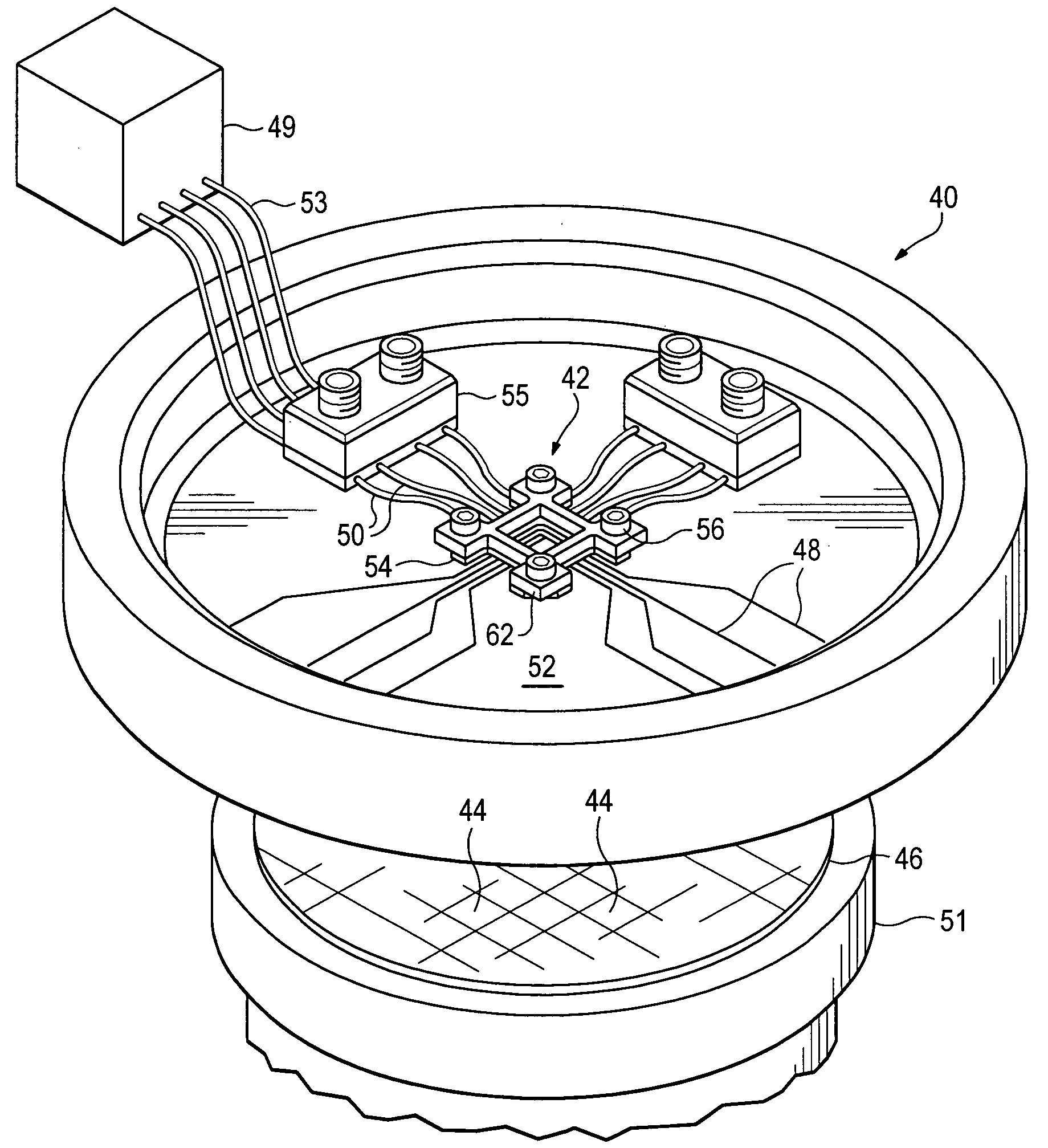

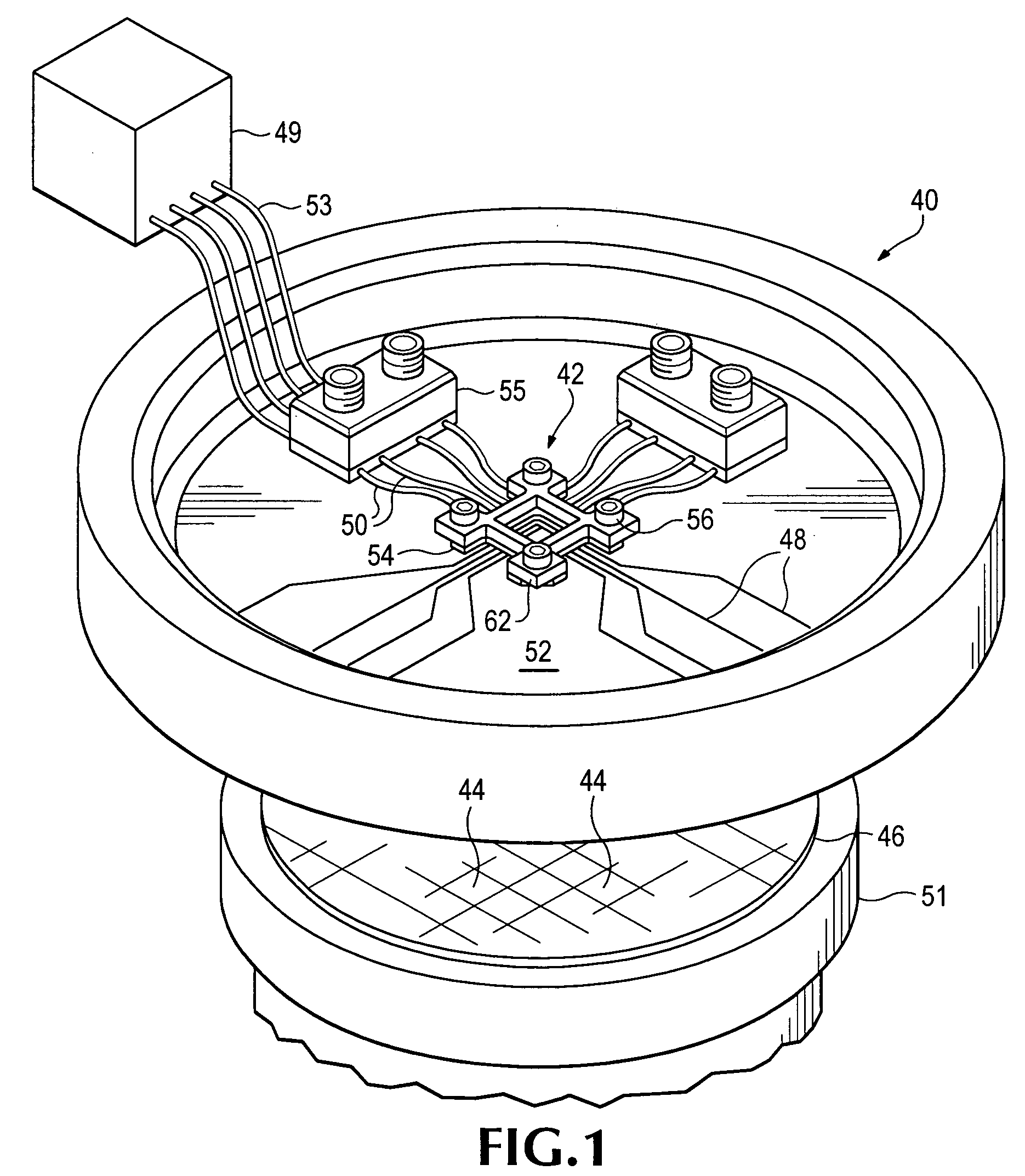

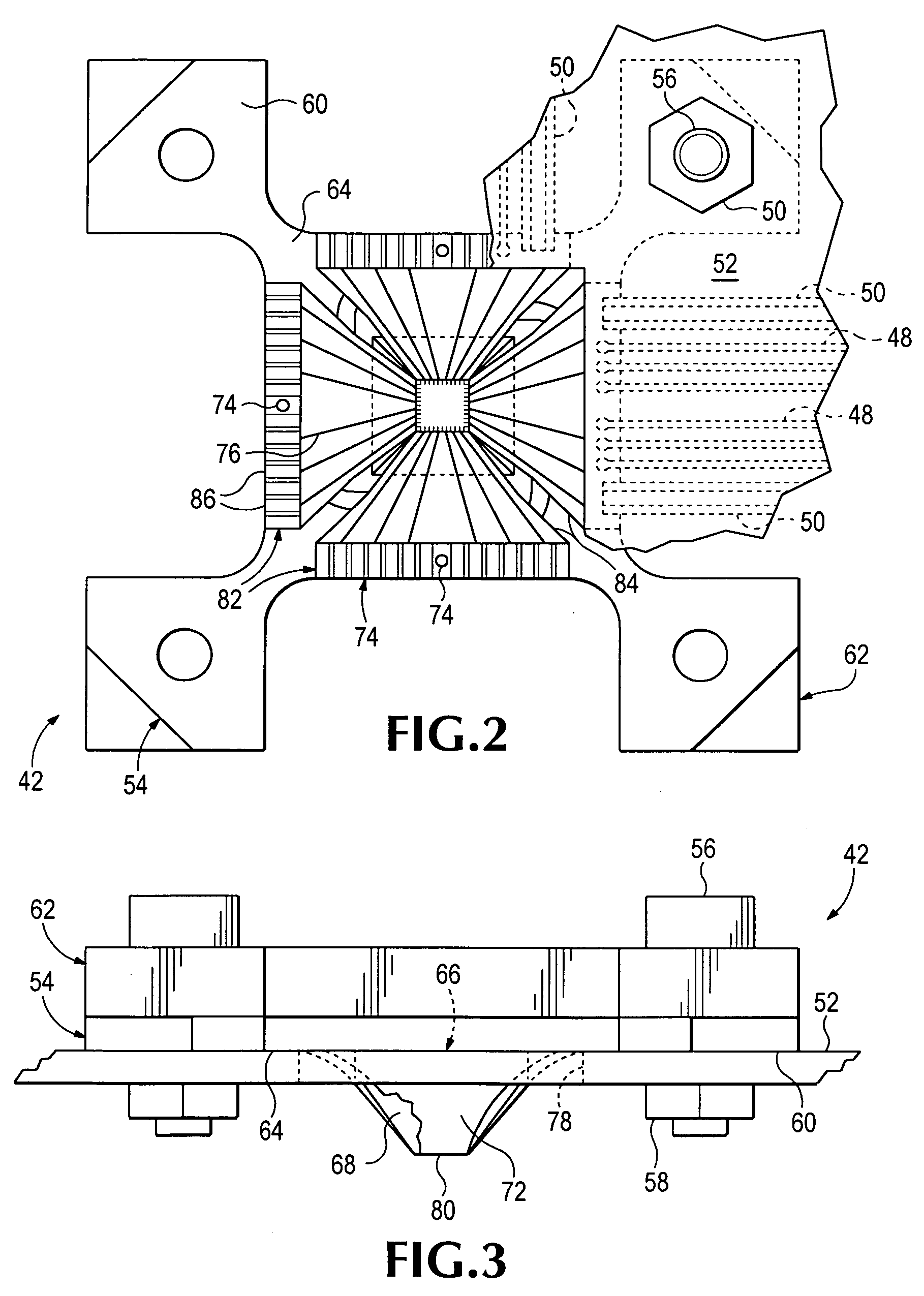

A measuring apparatus for measuring a semiconductor wafer, or a film or coating thereon, includes an electrically conductive wafer chuck and a probe having a probe body defining an internal cavity in fluid communication with an electrically conductive and elastic or resilient membrane. The membrane and a topside of the semiconductor wafer are moved into spaced relation when the semiconductor wafer is supported by the wafer chuck. A pressure of fluid supplied to the internal cavity of the probe body is selectively controlled whereupon the membrane expands into contact with the topside of the semiconductor wafer. A suitable test stimulus is applied to the membrane and the semiconductor wafer and the response of the semiconductor wafer to the test stimulus is measured.

Owner:SOLID STATE MEASUREMENTS

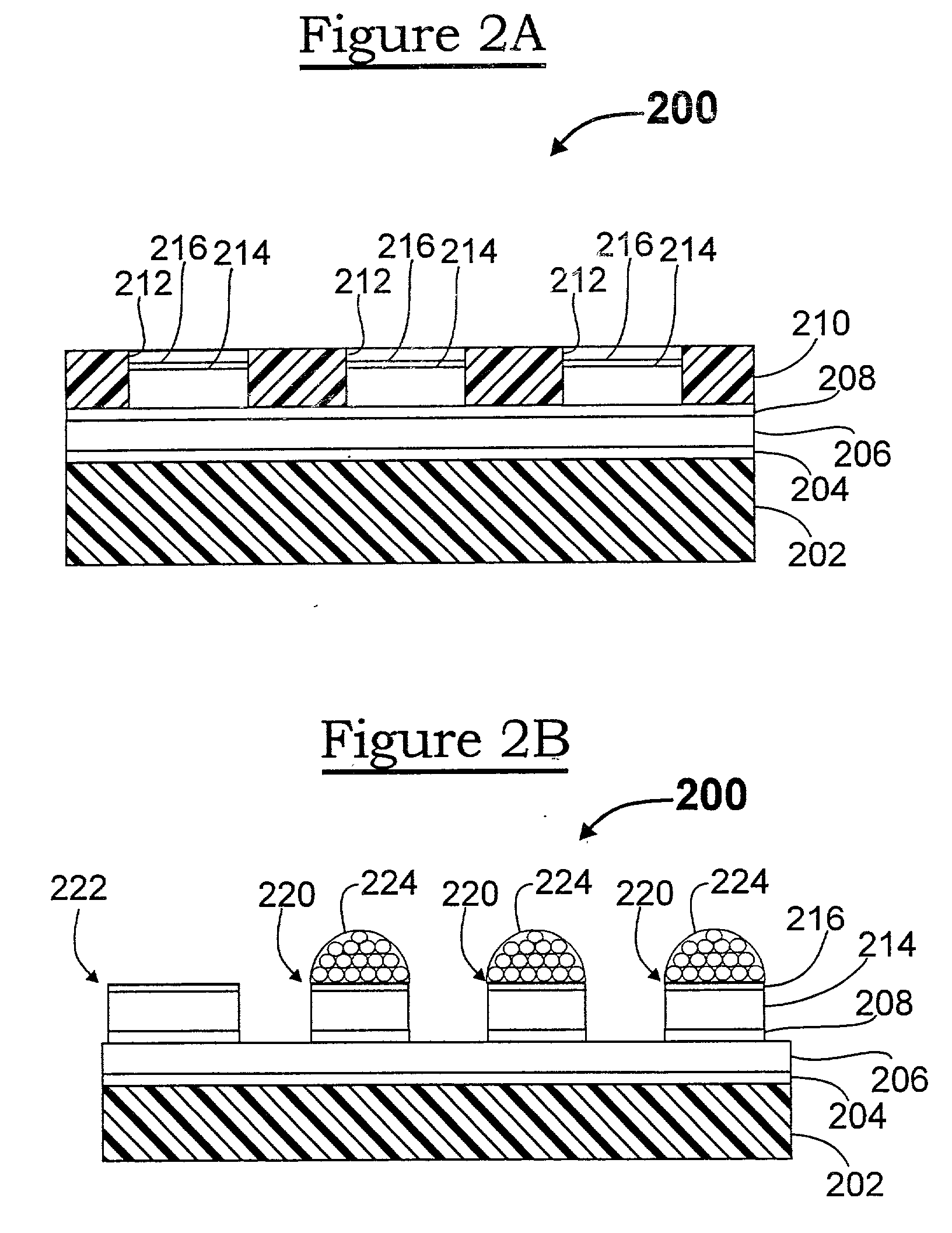

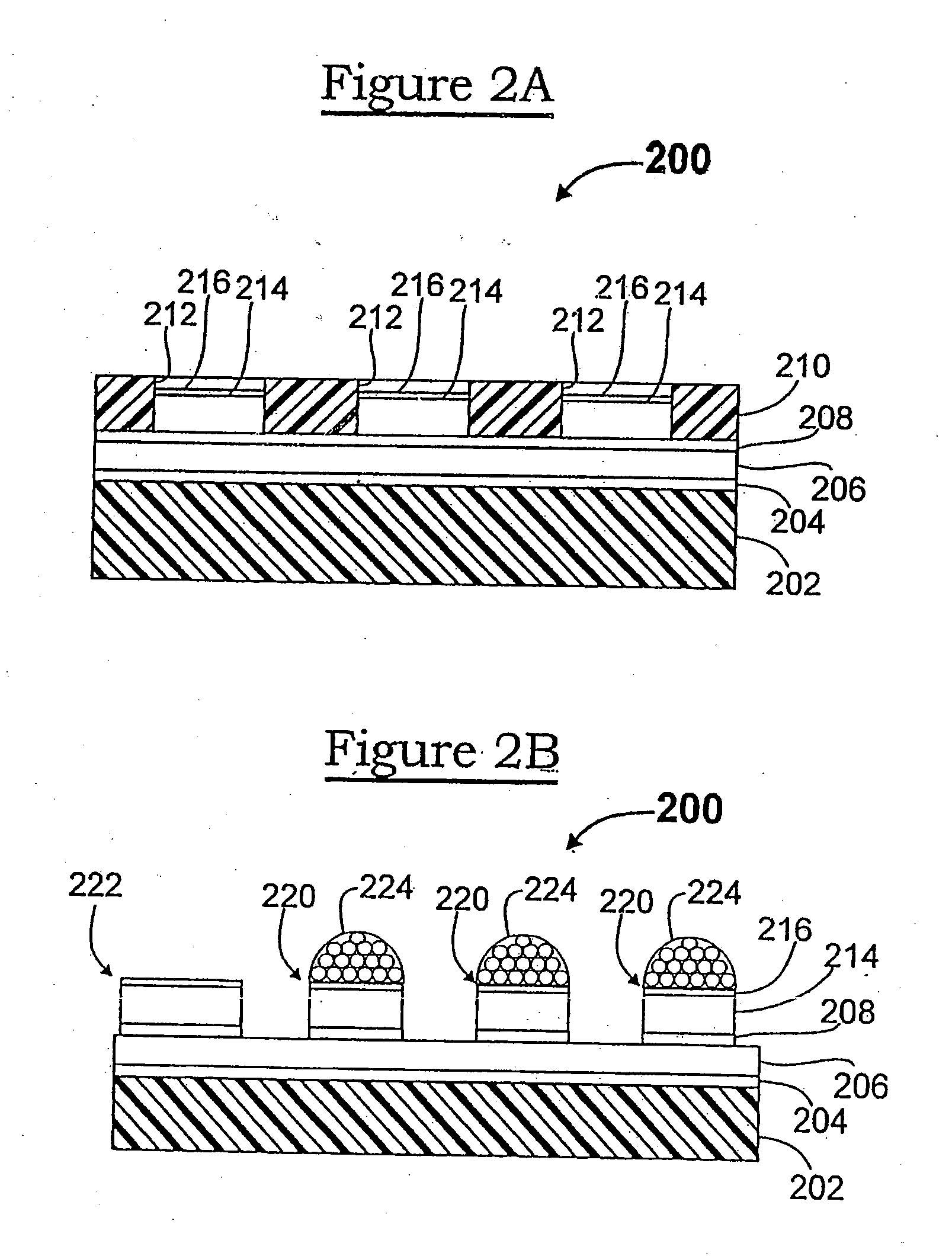

Contact tip structure for microelectronic interconnection elements and method of making same

InactiveUS20030199179A1Simple technologyElectrical measurement instrument detailsSolid-state devicesProbe cardInterconnection

Contact tip structures are fabricated on sacrificial substrates for subsequent joining to interconnection elements including composite interconnection elements, monolithic interconnection elements, tungsten needles of probe cards, contact bumps of membrane probes, and the like. The spatial relationship between the tip structures can lithographically be defined to very close tolerances. The metallurgy of the tip structures is independent of that of the interconnection element to which they are attached, by brazing, plating or the like. The contact tip structures are readily provided with topological (small, precise, projecting, non-planar) contact features, such as in the form of truncated pyramids, to optimize electrical pressure connections subsequently being made to terminals of electronic components. Elongate contact tip structures, adapted in use to function as spring contact elements without the necessity of being joined to resilient contact elements are described. Generally, the invention is directed to making (pre-fabricating) relatively 'perfect' contact tip structures ("tips") and joining them to relatively 'imperfect' interconnection elements to improve the overall capabilities of resulting "tipped" interconnection elements.

Owner:FORMFACTOR INC

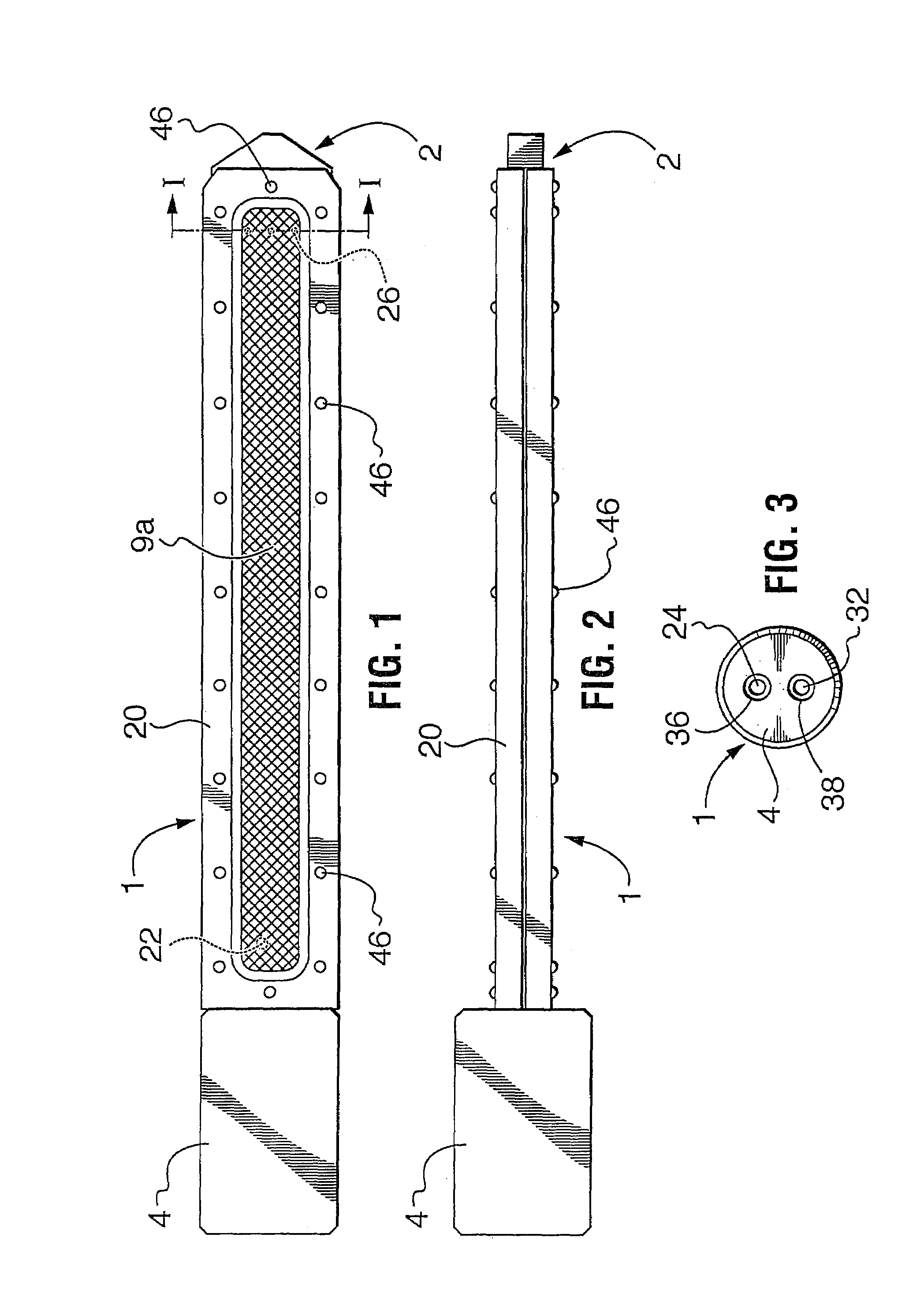

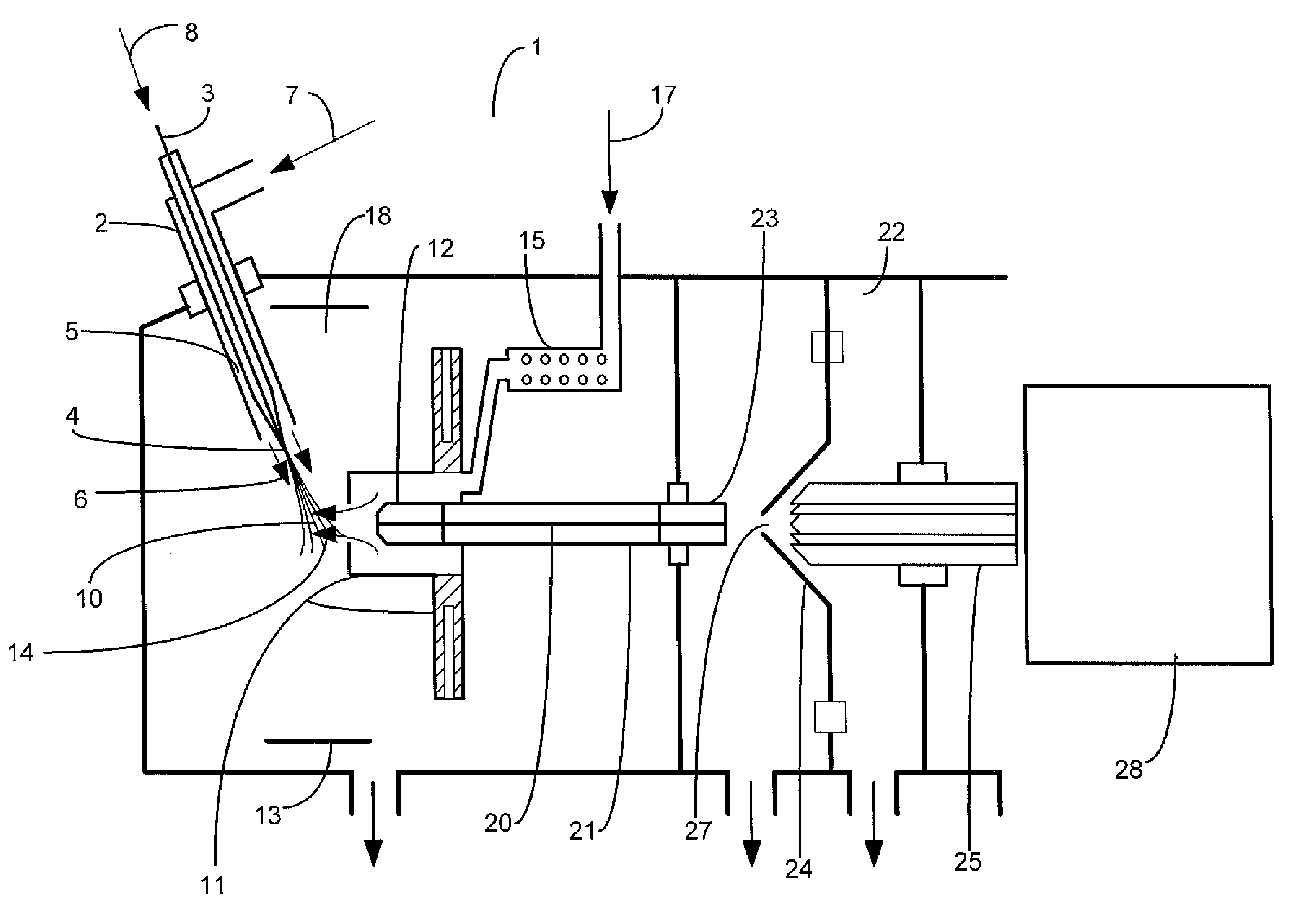

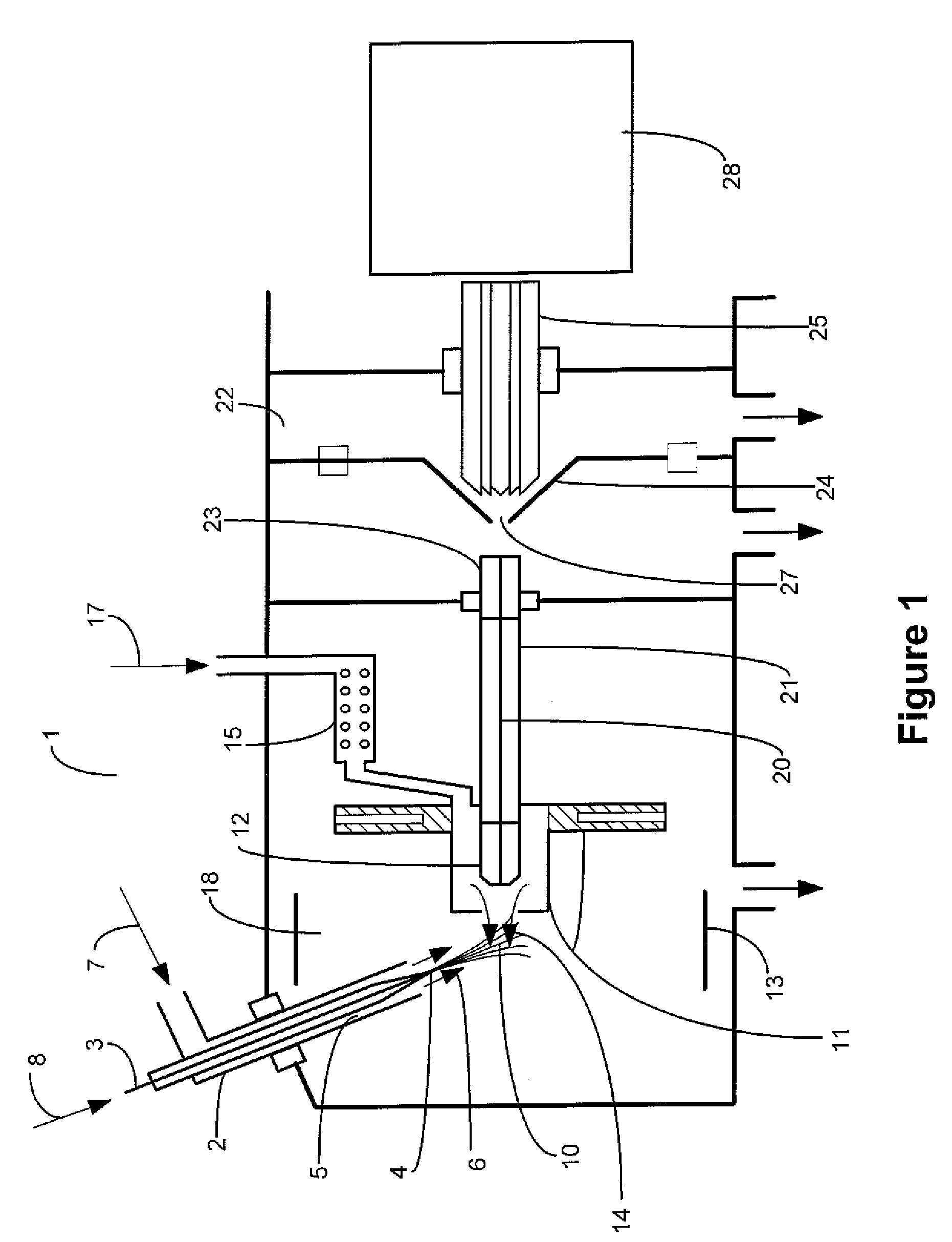

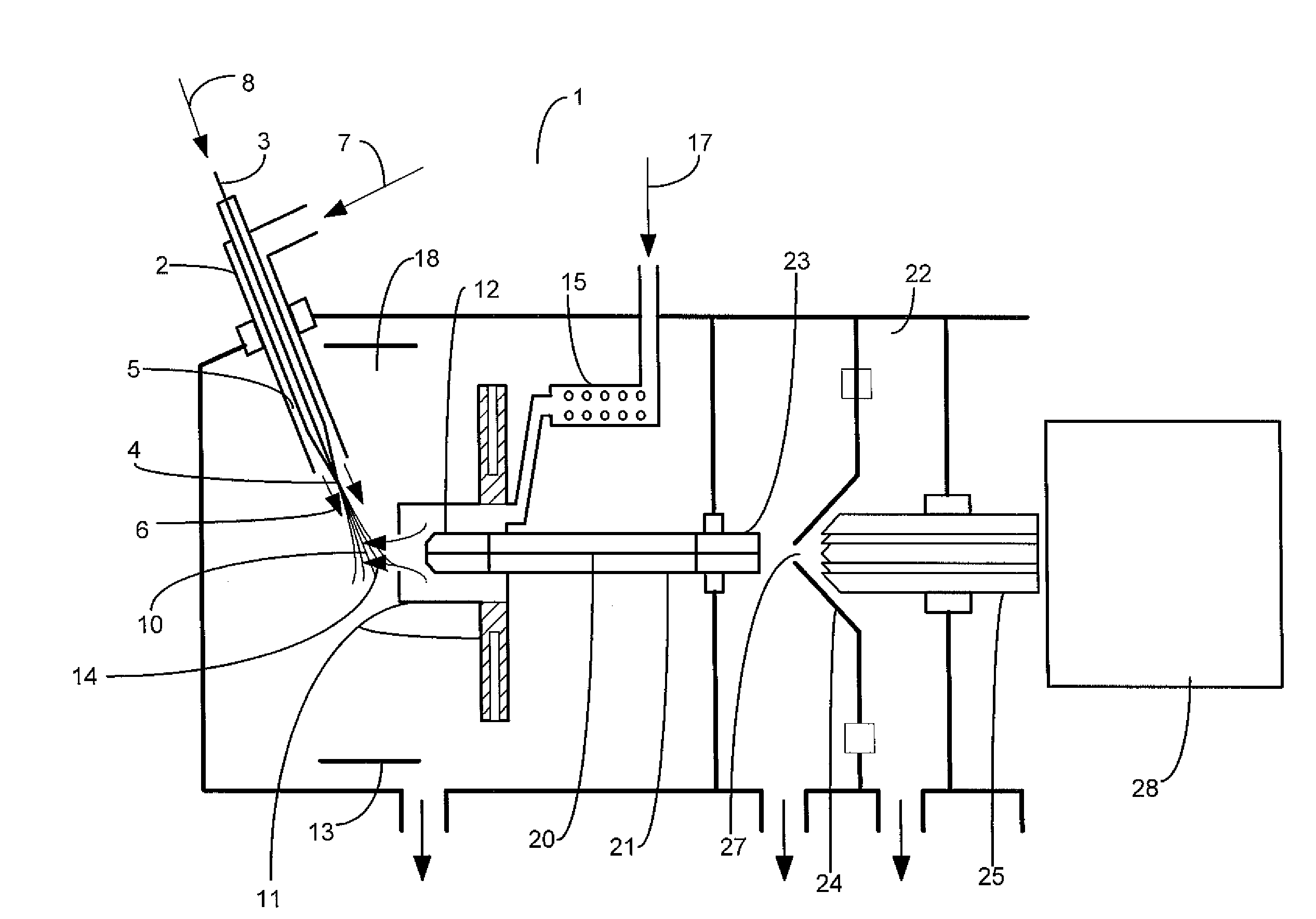

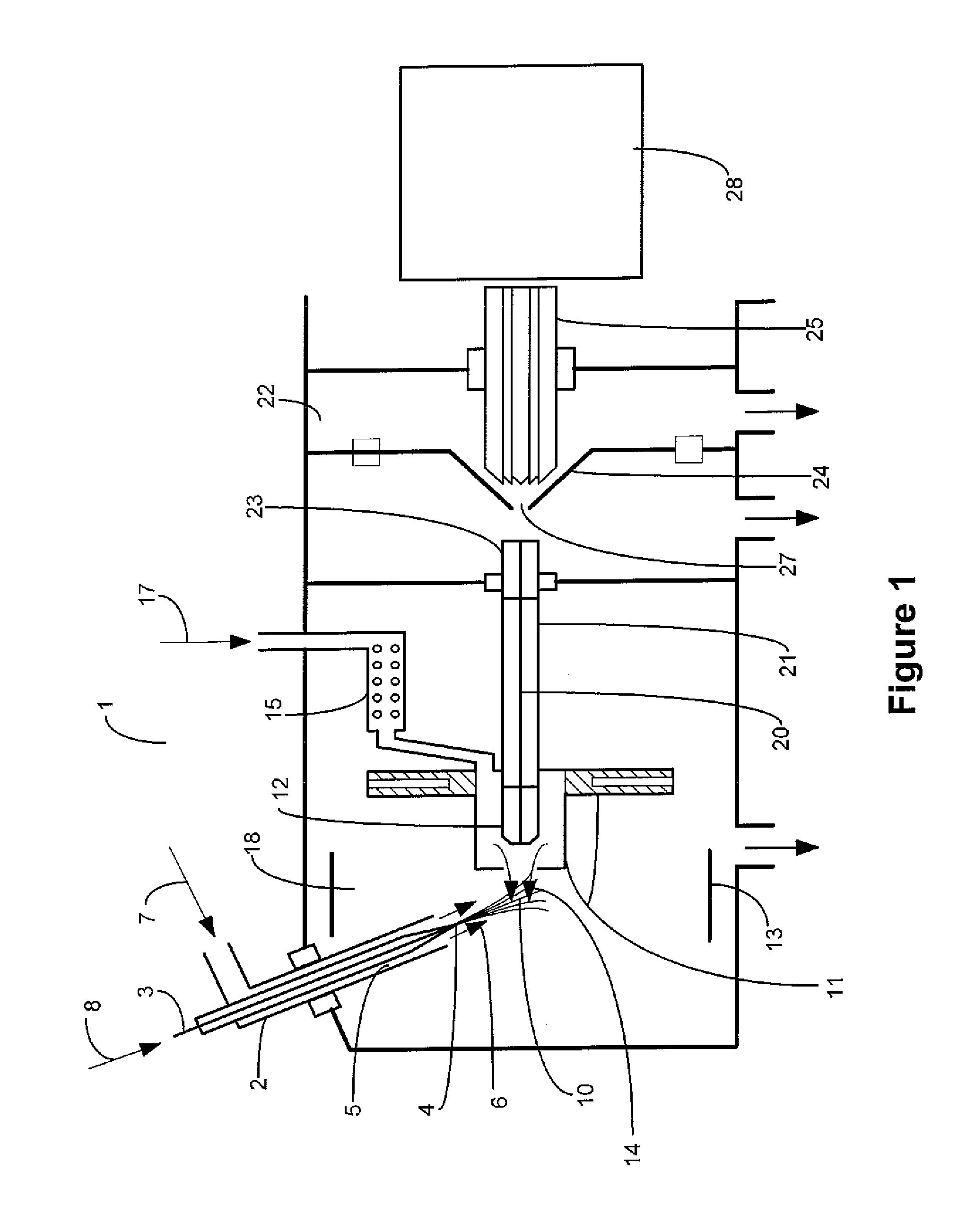

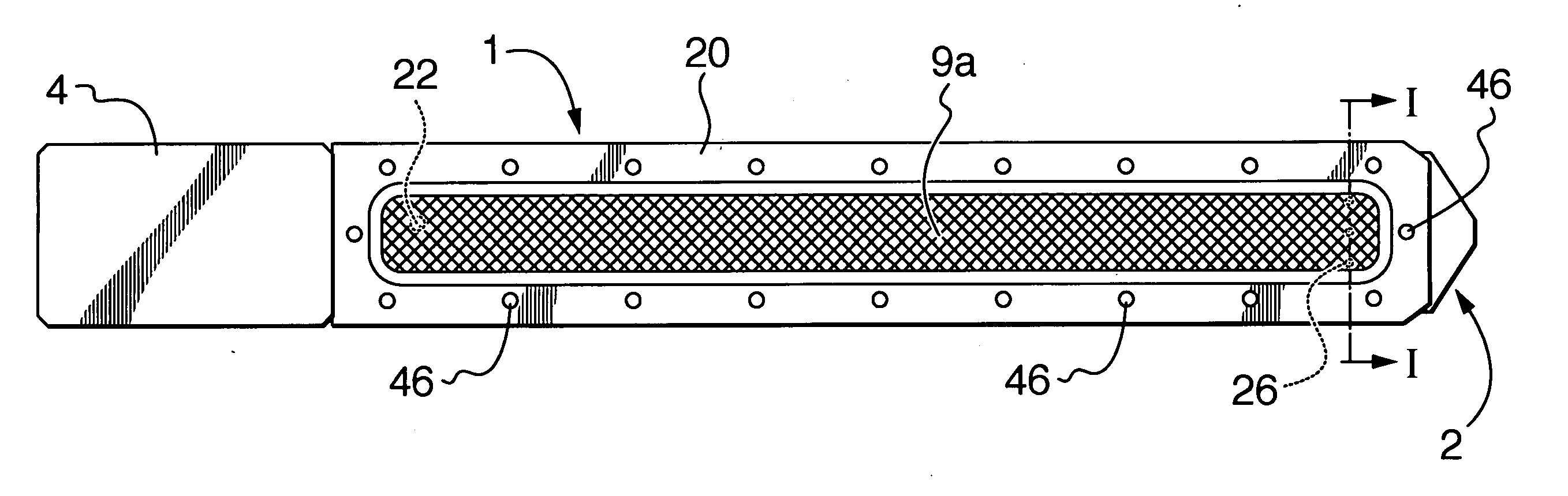

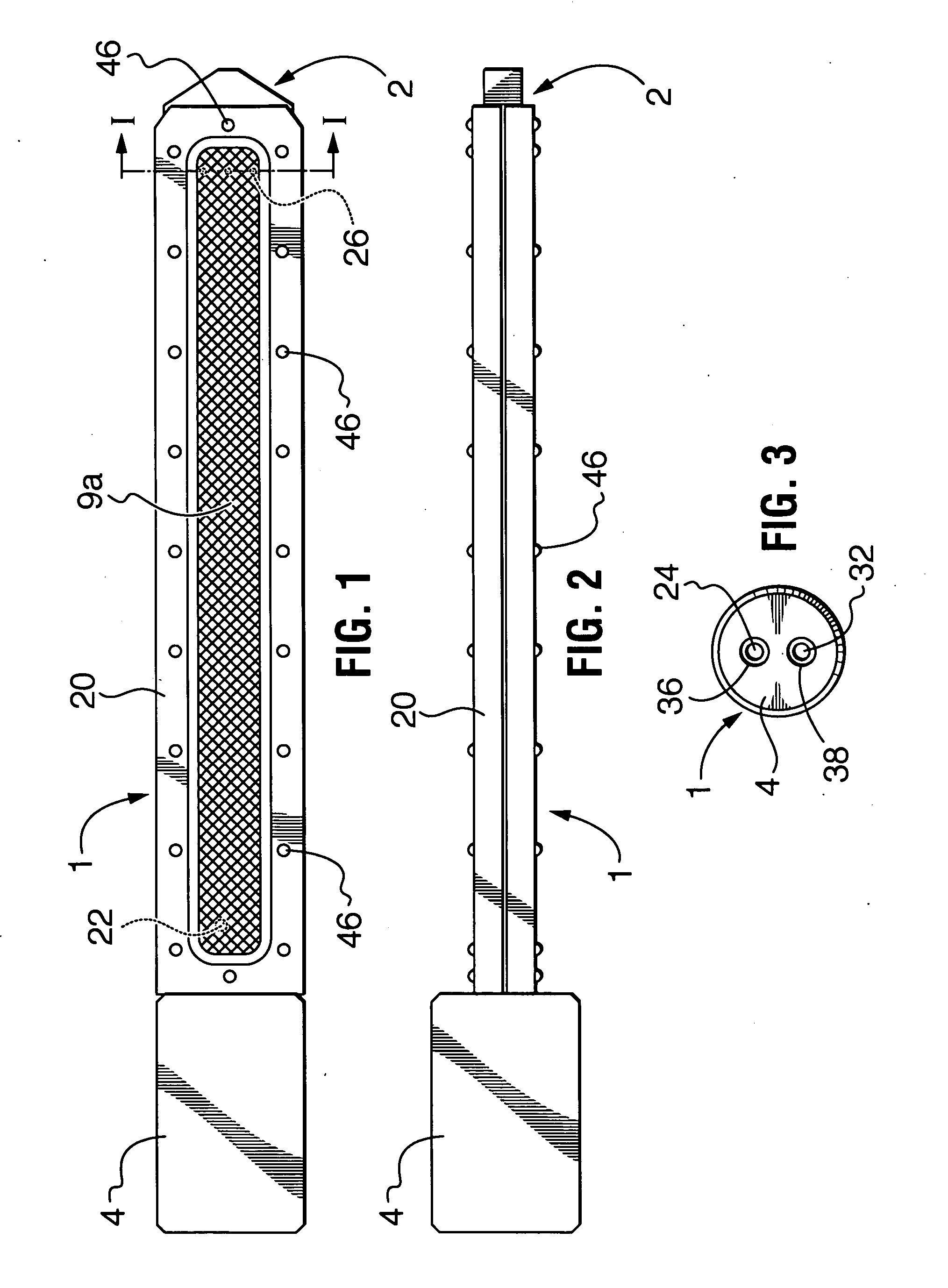

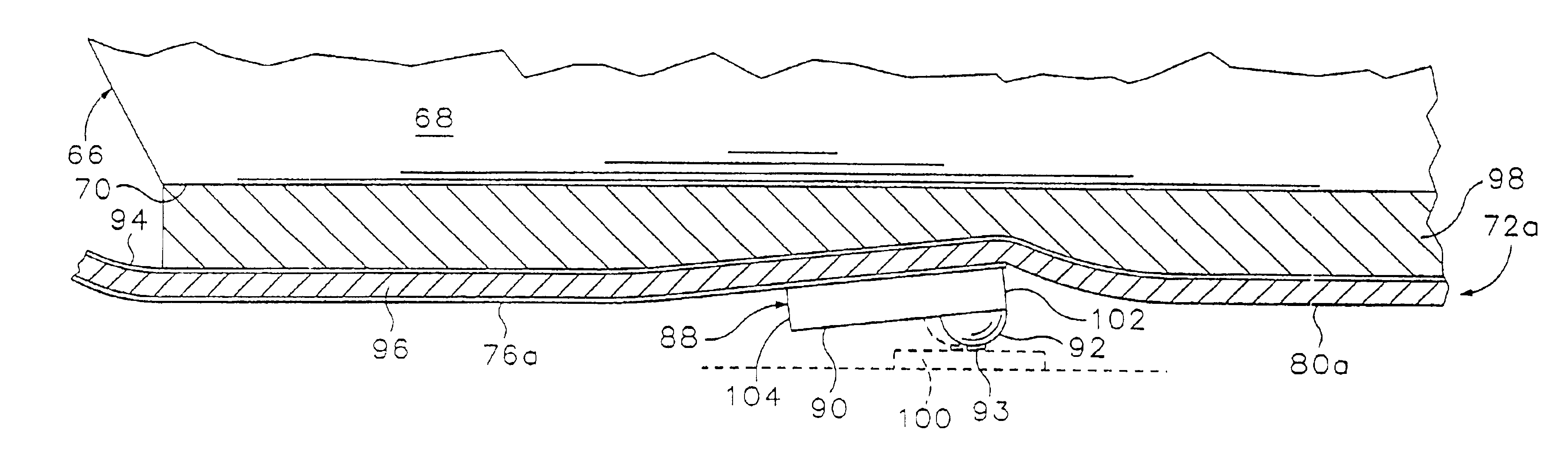

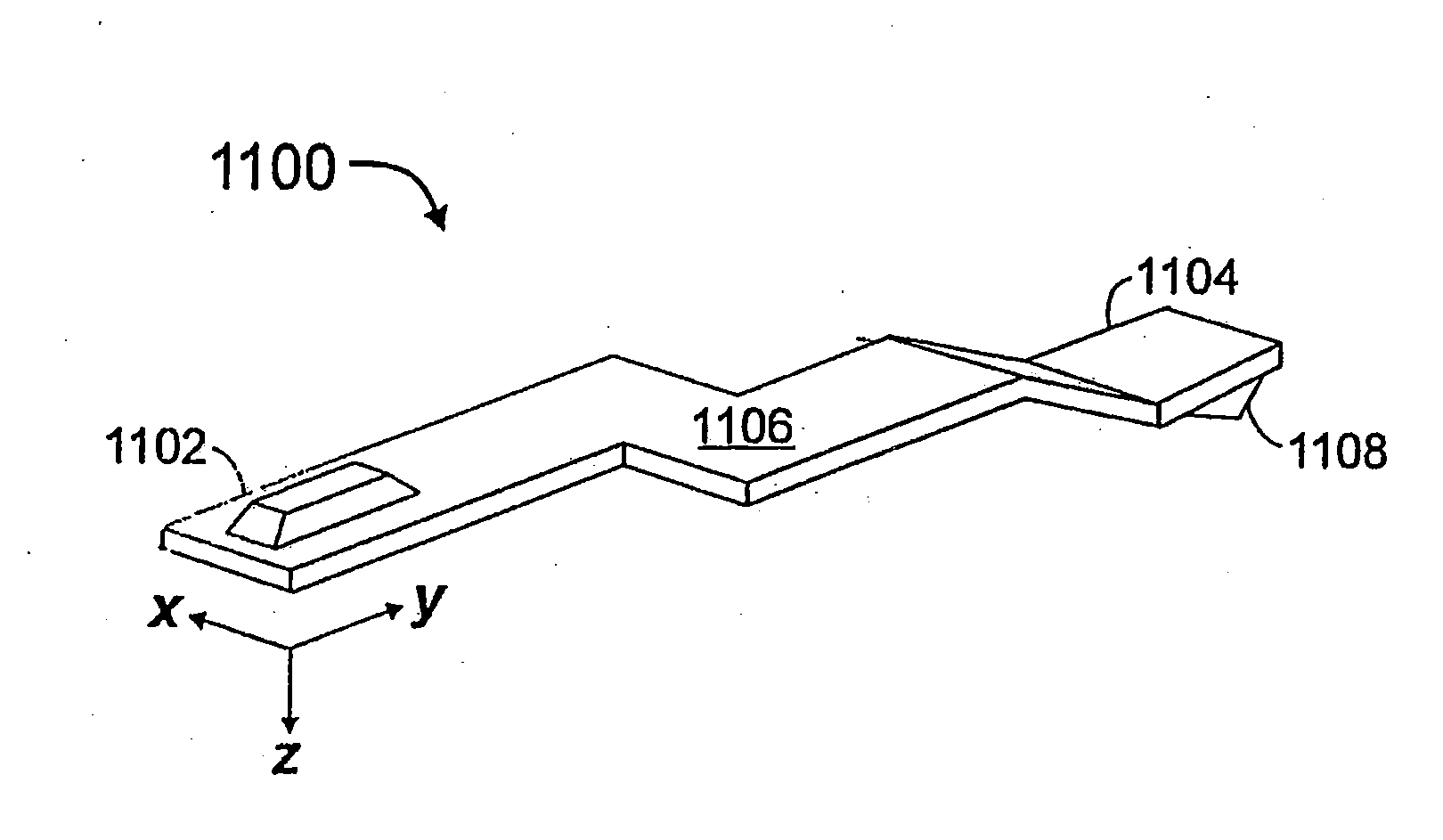

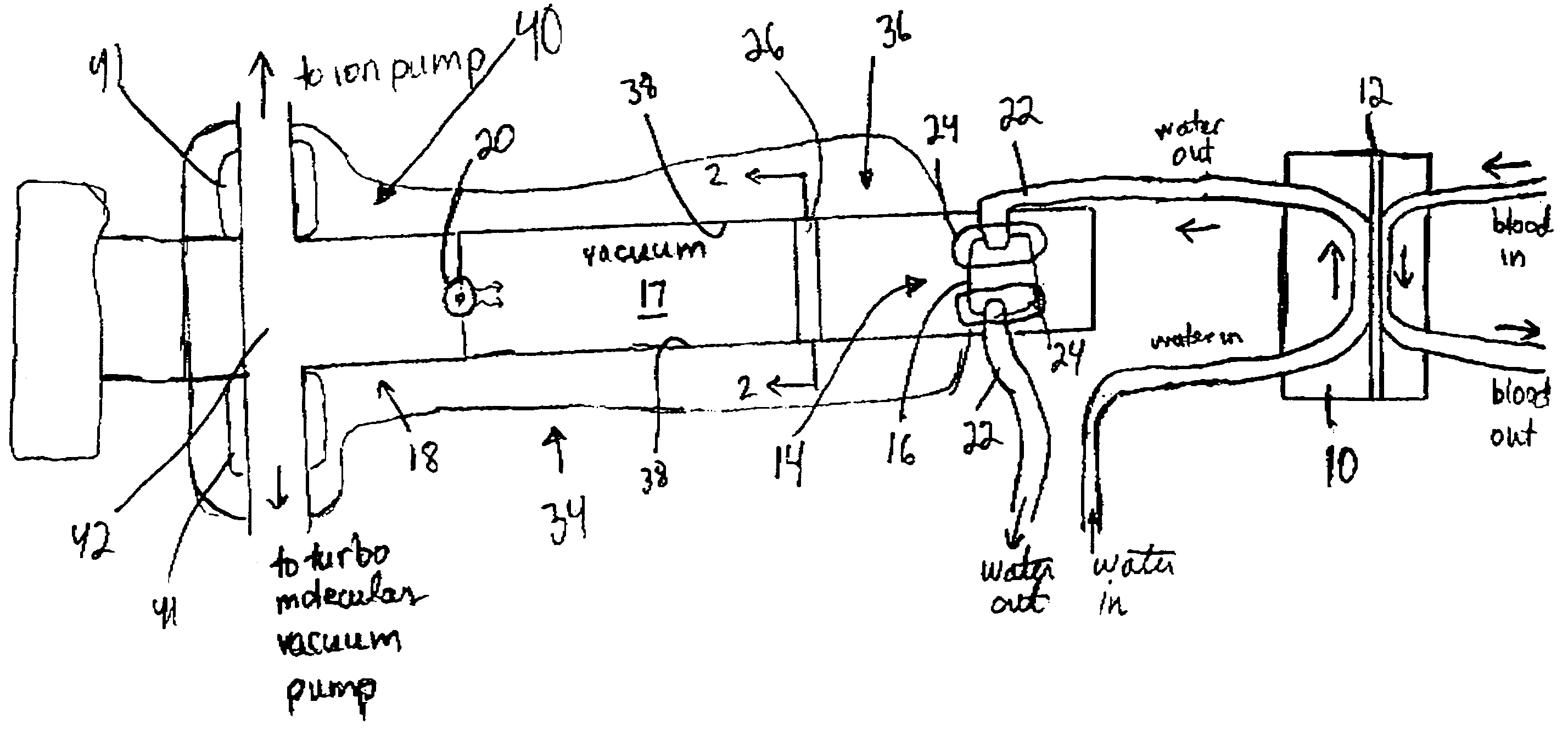

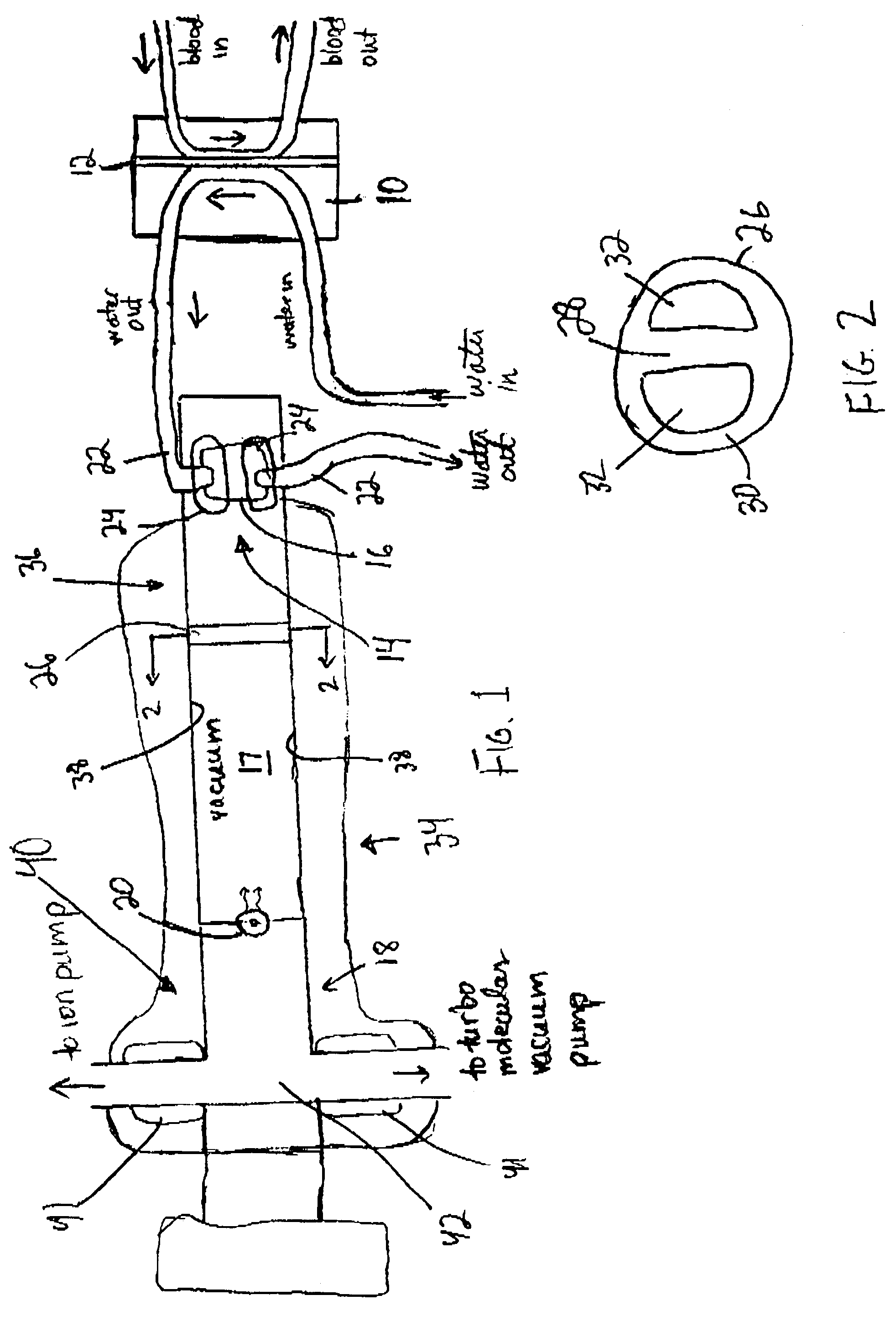

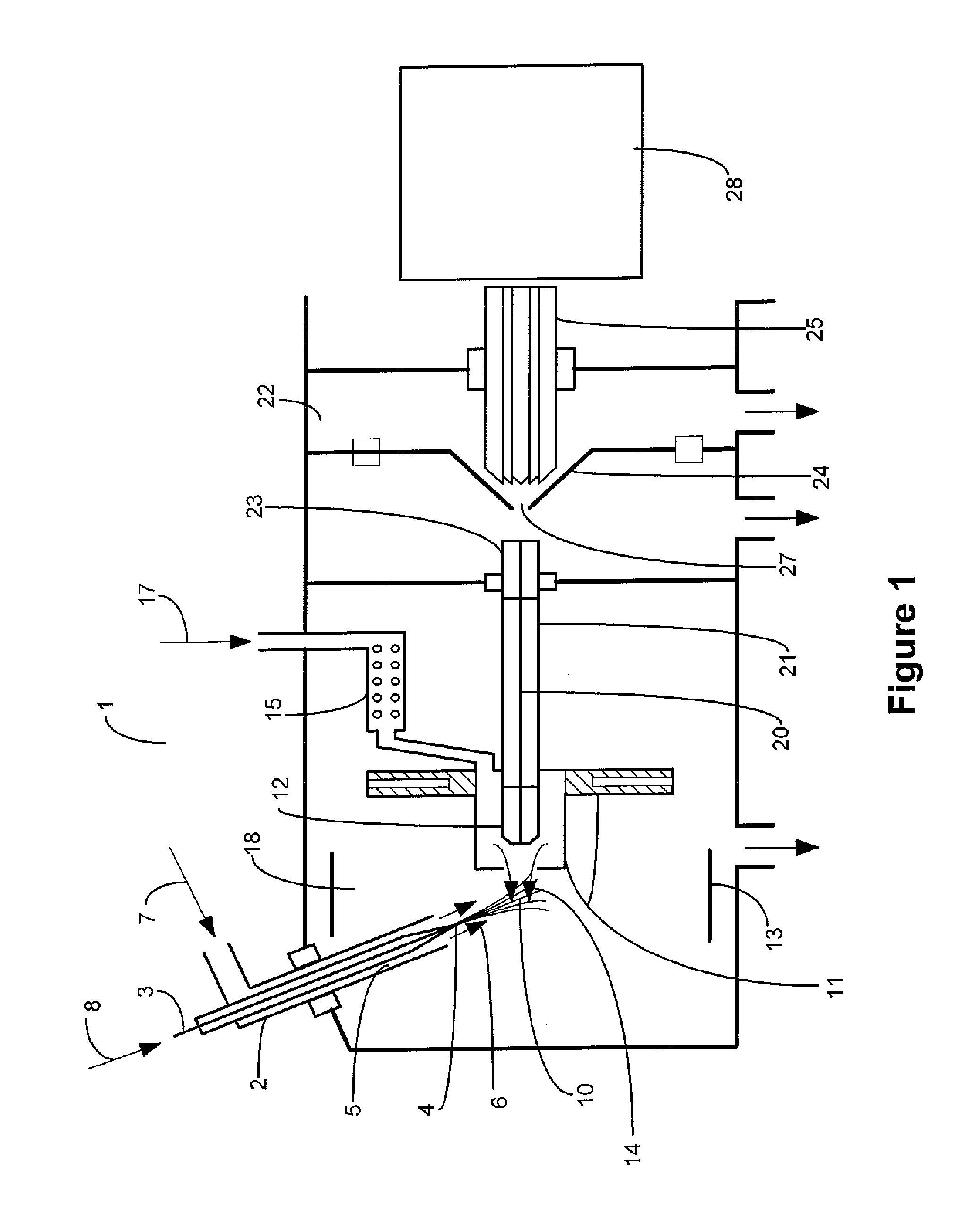

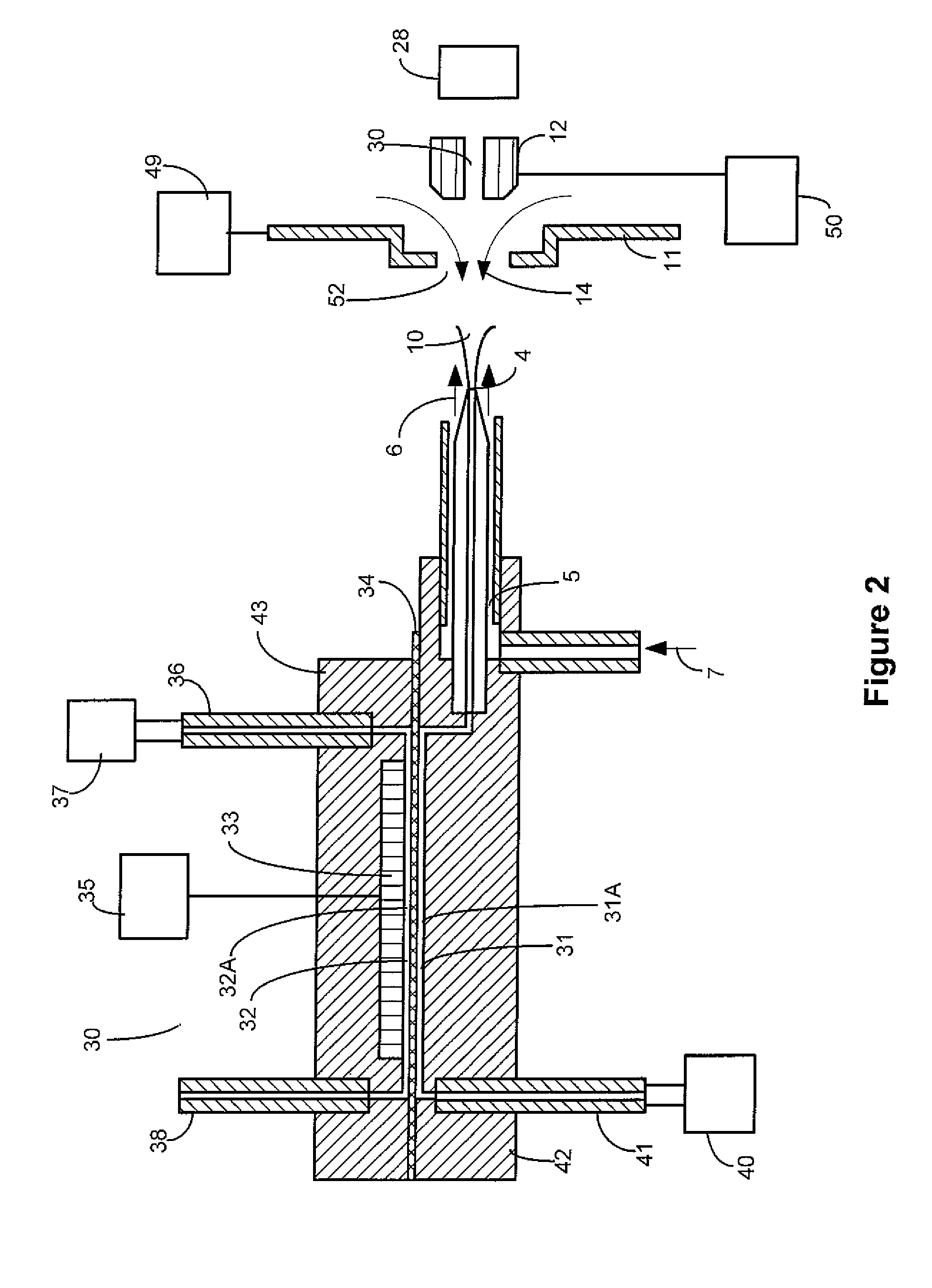

Sheet-form membrane sample probe, method and apparatus for fluid concentration analysis

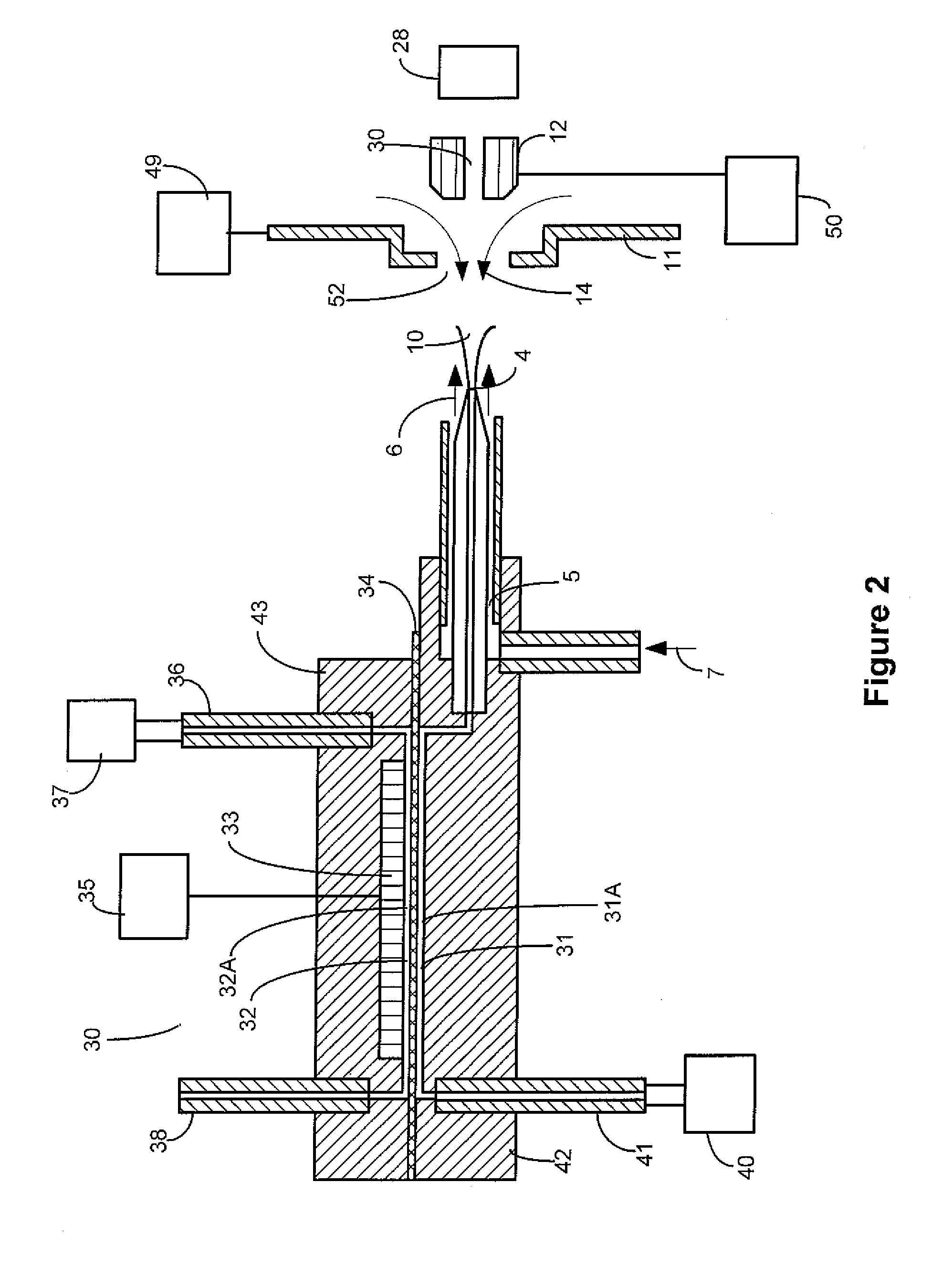

A sheet form membrane probe, an apparatus and method, wherein the probe includes a probe body, a sheet-form membrane secured to the probe body and including an open surface exposed to the exterior of the probe; a channel formed between the probe body and the membrane through which a collector fluid can flow; an inlet port opening to the channel to conduct collector fluid to the channel; and an outlet port spaced from the inlet port such that the collector fluid passes through the channel from the inlet port to the outlet port in a flow direction substantially parallel to the membrane. The channel may be formed to provide broad surface contact of the collector fluid with the membrane. The membrane open surface may include an active area open to a sample fluid and open on an opposite side for contact with collector fluid flow in the channel. The active area may be large relative to the total membrane area to provide for an effective use of the expensive membrane material. Another probe includes a fitting end and a membrane stem and secures membranes to at least two sides of the membrane stem such that permeation can occur along a channel passing from the fitting end along the membrane stem and returning to the fitting end from the membrane stem.

Owner:DATALOG ACQUISITION

Atmospheric pressure ion source performance enhancement

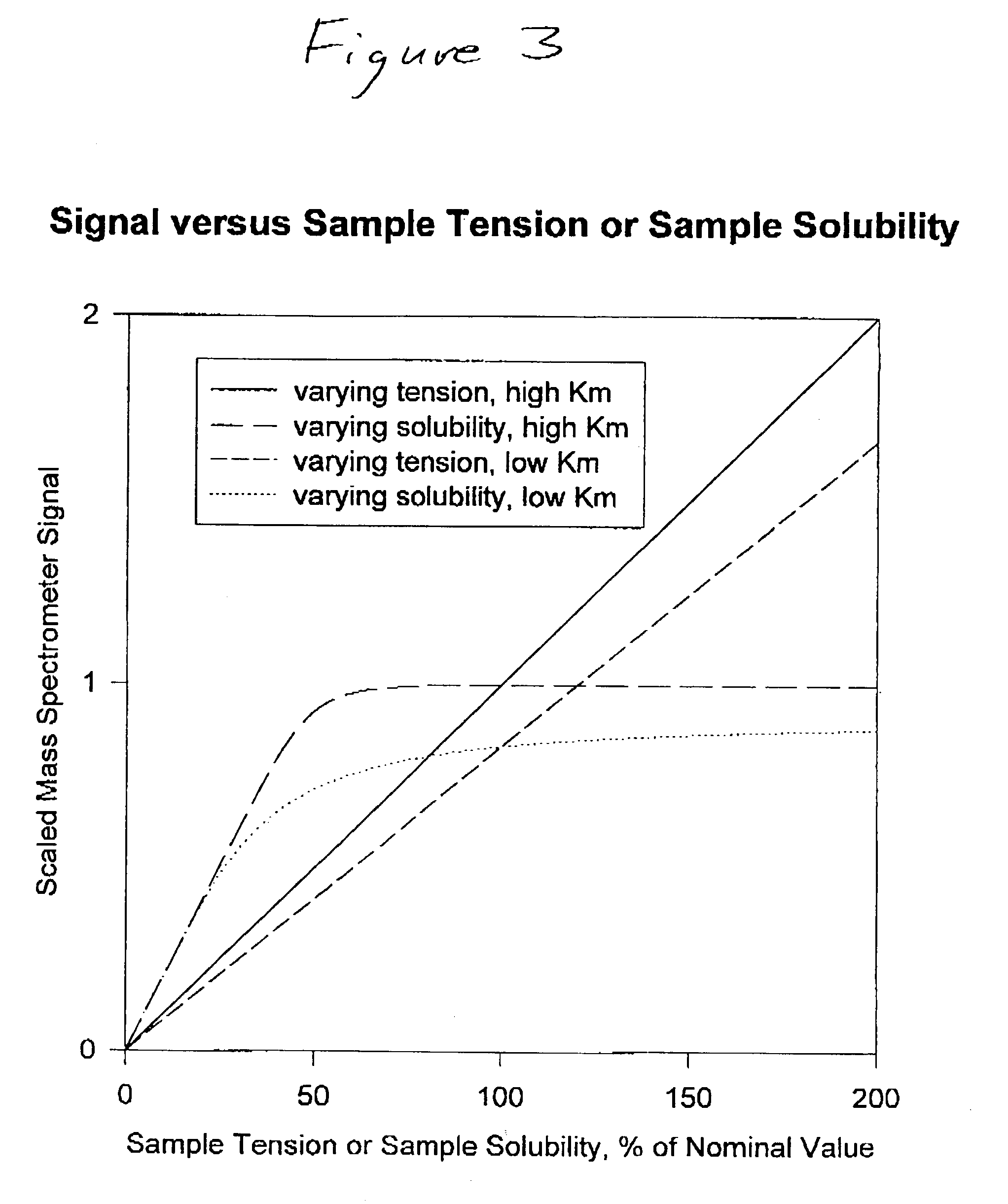

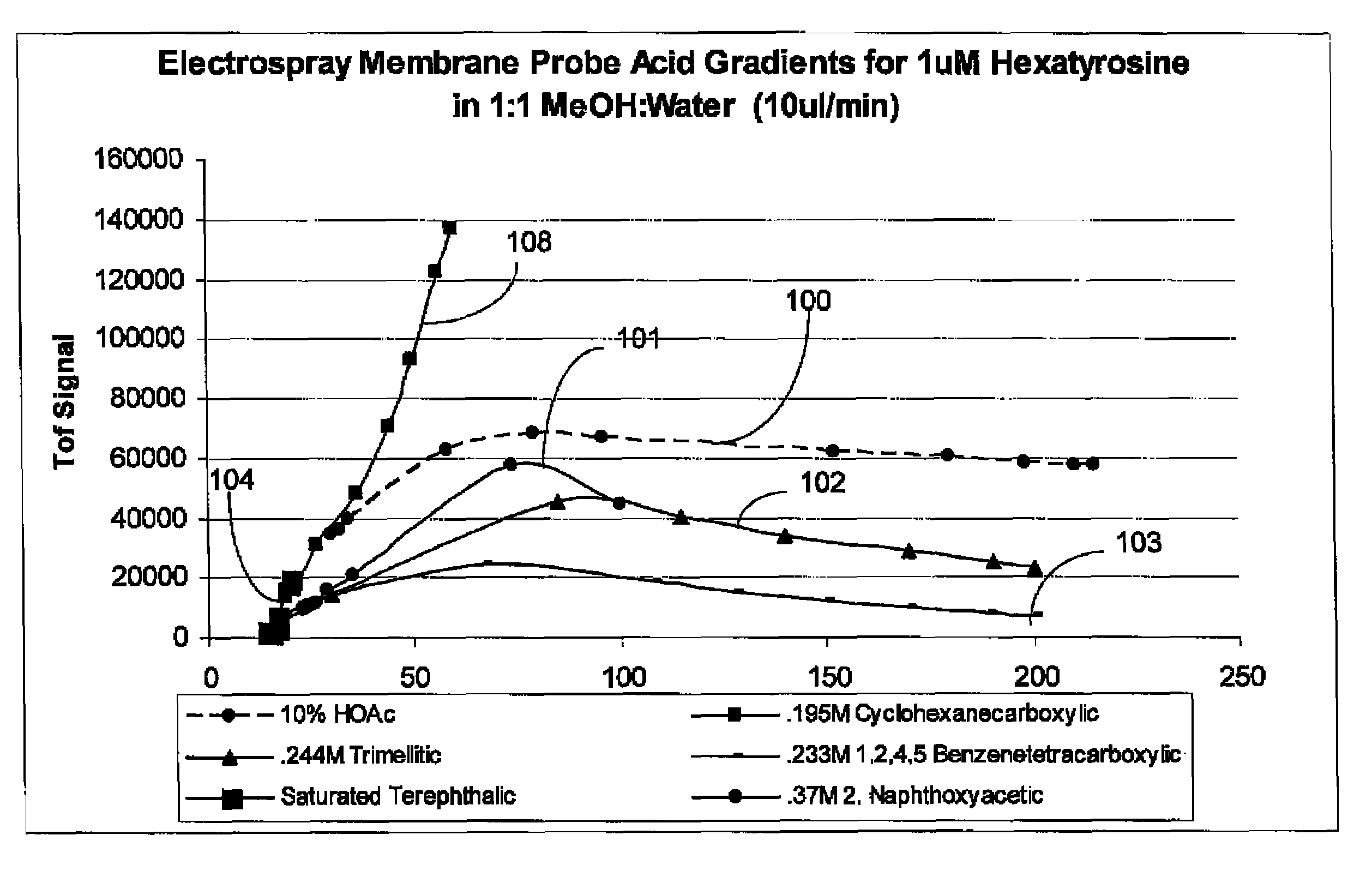

InactiveUS20090095899A1Increases Electrospray MS signalReduce signalingParticle spectrometer methodsIsotope separationPerformance enhancementGas phase

Electrospray ionization sources interfaced to mass spectrometers have become widely used tools in analytical applications. Processes occurring in Electrospray (ES) ionization generally include the addition or removal of a charged species such as H+ or other cation to effect ionization of a sample species. Electrospray includes ionization processes that occur in the liquid and gas phase and in both phases ionization processes require a source or sink for such charged species. Electrolyte species, that aid in oxidation or reduction reactions occurring in Electrospray ionization, are added to sample solutions in many analytical applications to increase the ion signal amplitude generated in Electrospray and detected by a mass spectrometer (MS) Electrolyte species that may be required to enhance an upstream sample preparation or separation process may be less compatible with the downstream ES processes and cause reduction in MS signal New Electrolytes have been found that increase positive and negative polarity analyte ion signal measured in ESMS analysis when compared with analyte ESMS signal achieved using more conventional electrolytes The new electrolyte species increase ES MS signal when added directly to a sample solution or when added to a second solution flow in an Electrospray membrane probe. It has also been found that running the ES membrane probe with specific Electrolytes in the second solution of the ES membrane probe have been found to enhance ESMS signal compared to using the same electrolytes directly in the sample solution being Electrosprayed The new electrolytes can be added to a reagent ion source configured in a combination Atmospheric pressure ion source to improve ionization efficiency.

Owner:WHITEHOUSE CRAIG M +2

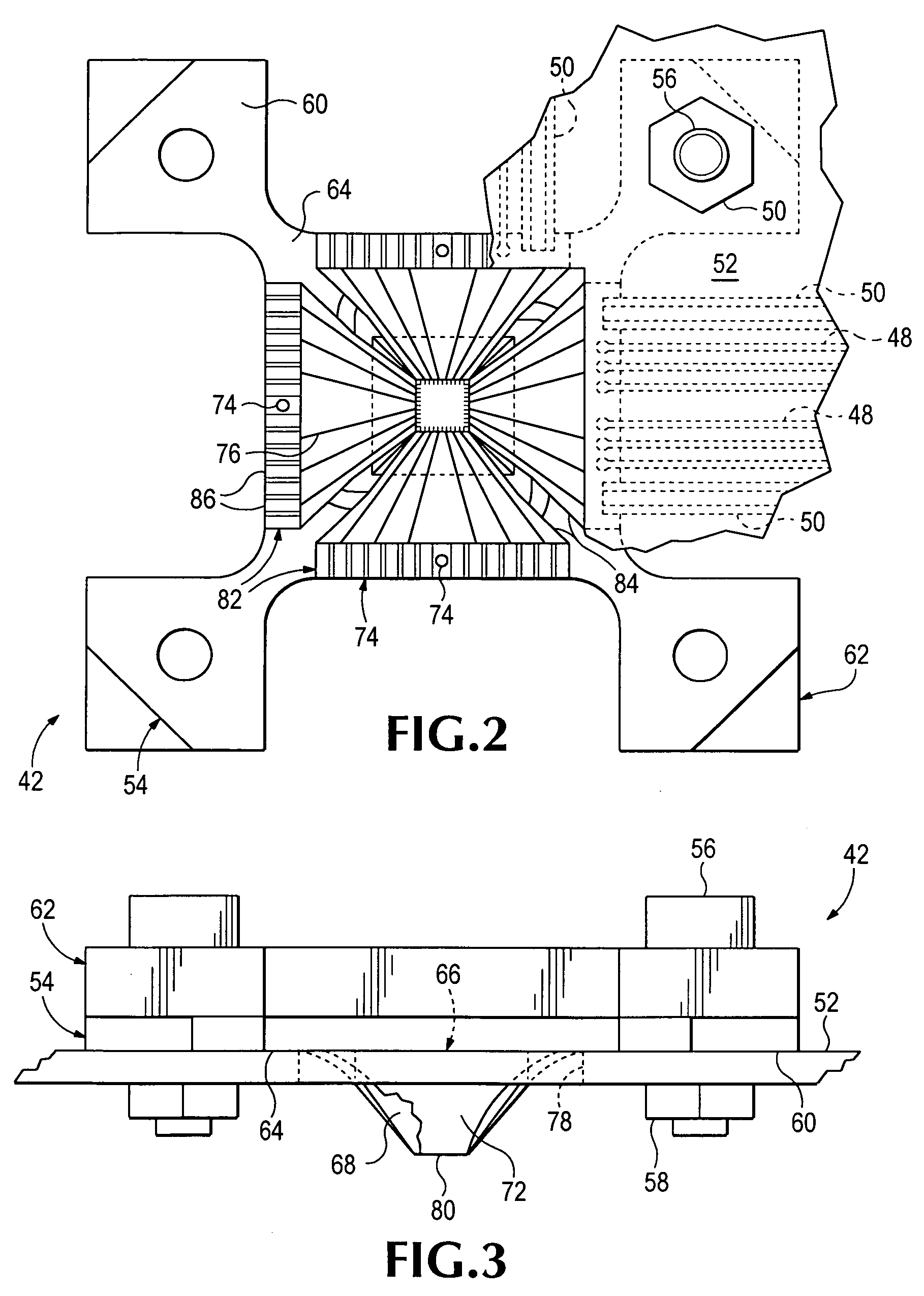

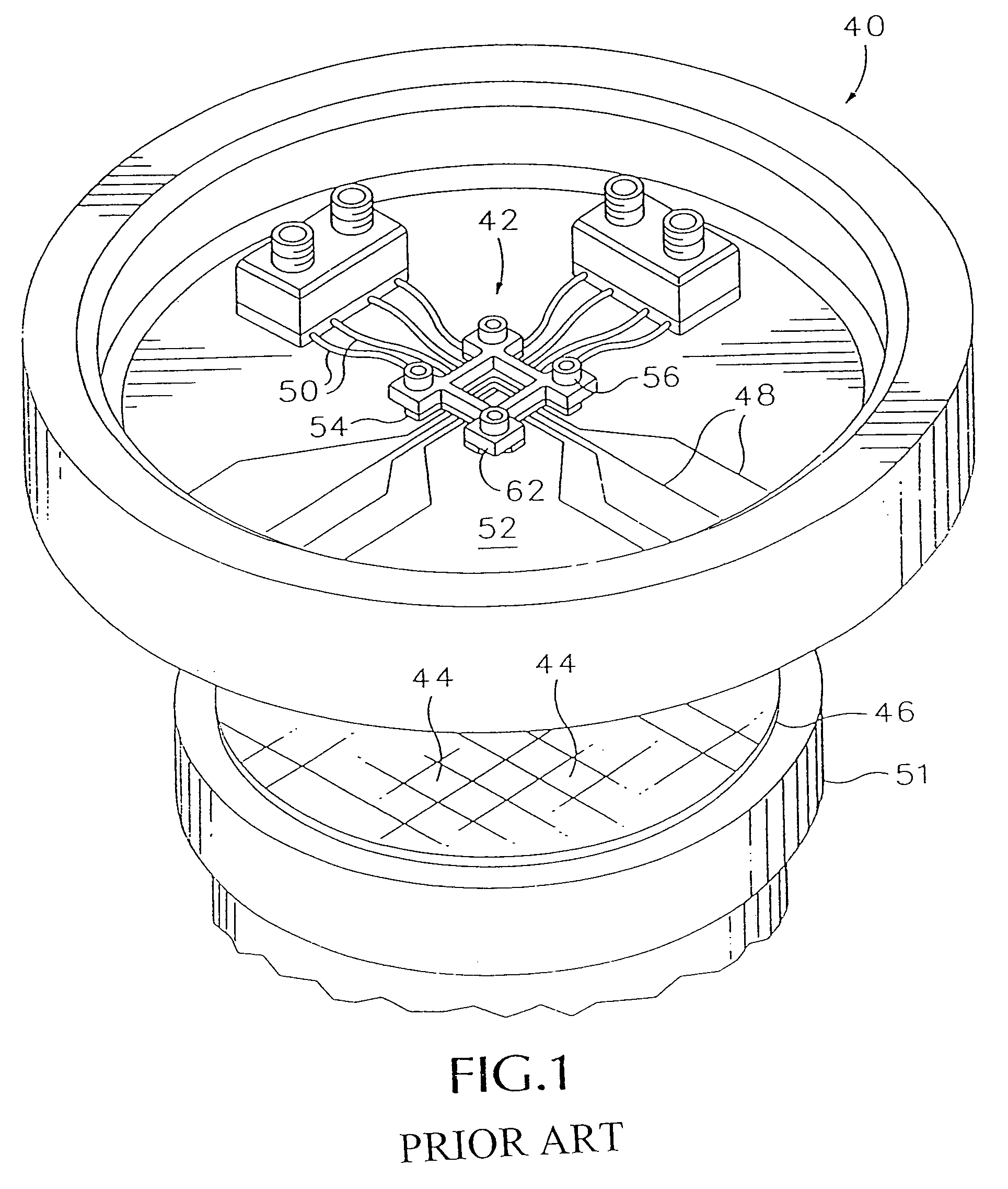

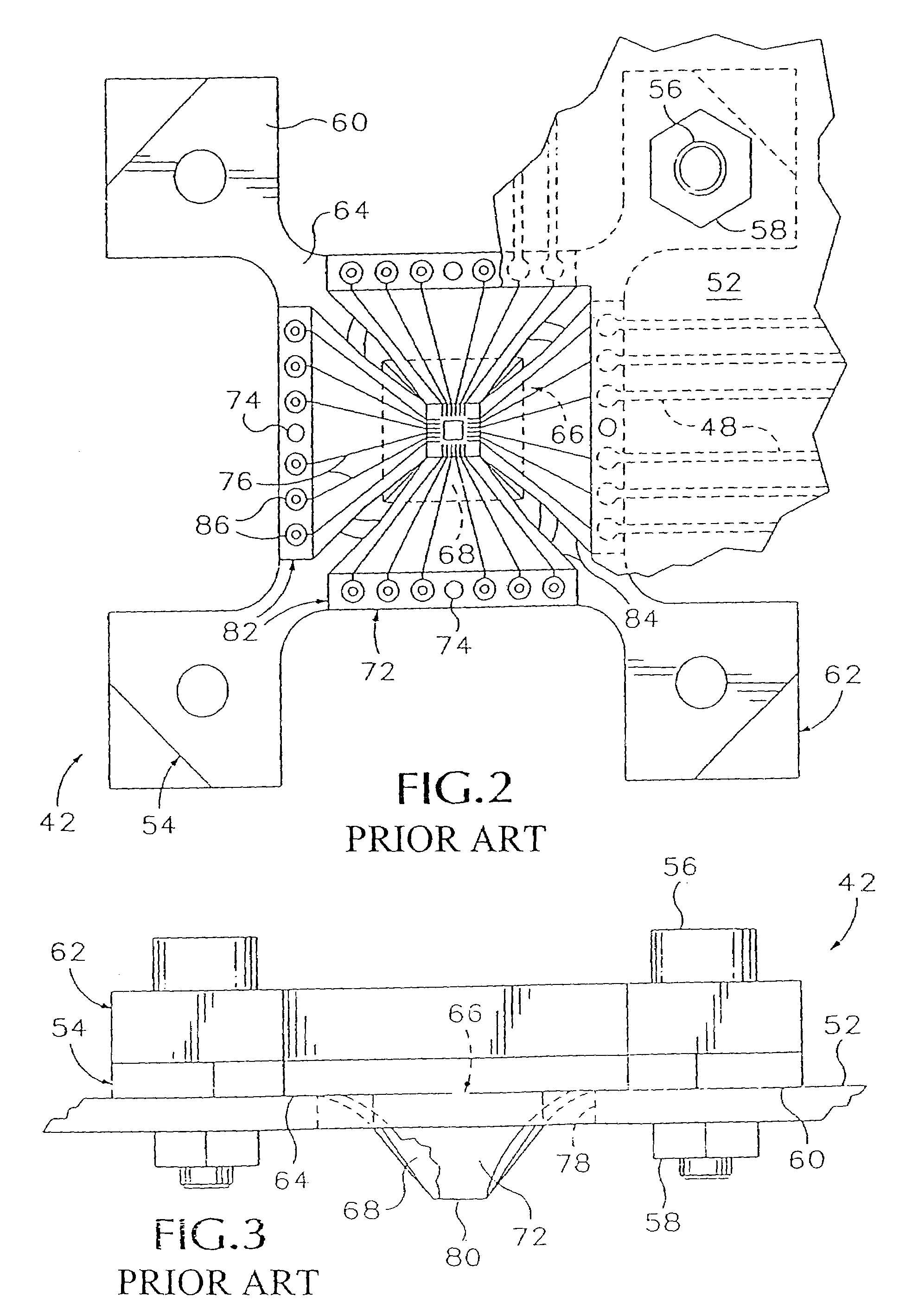

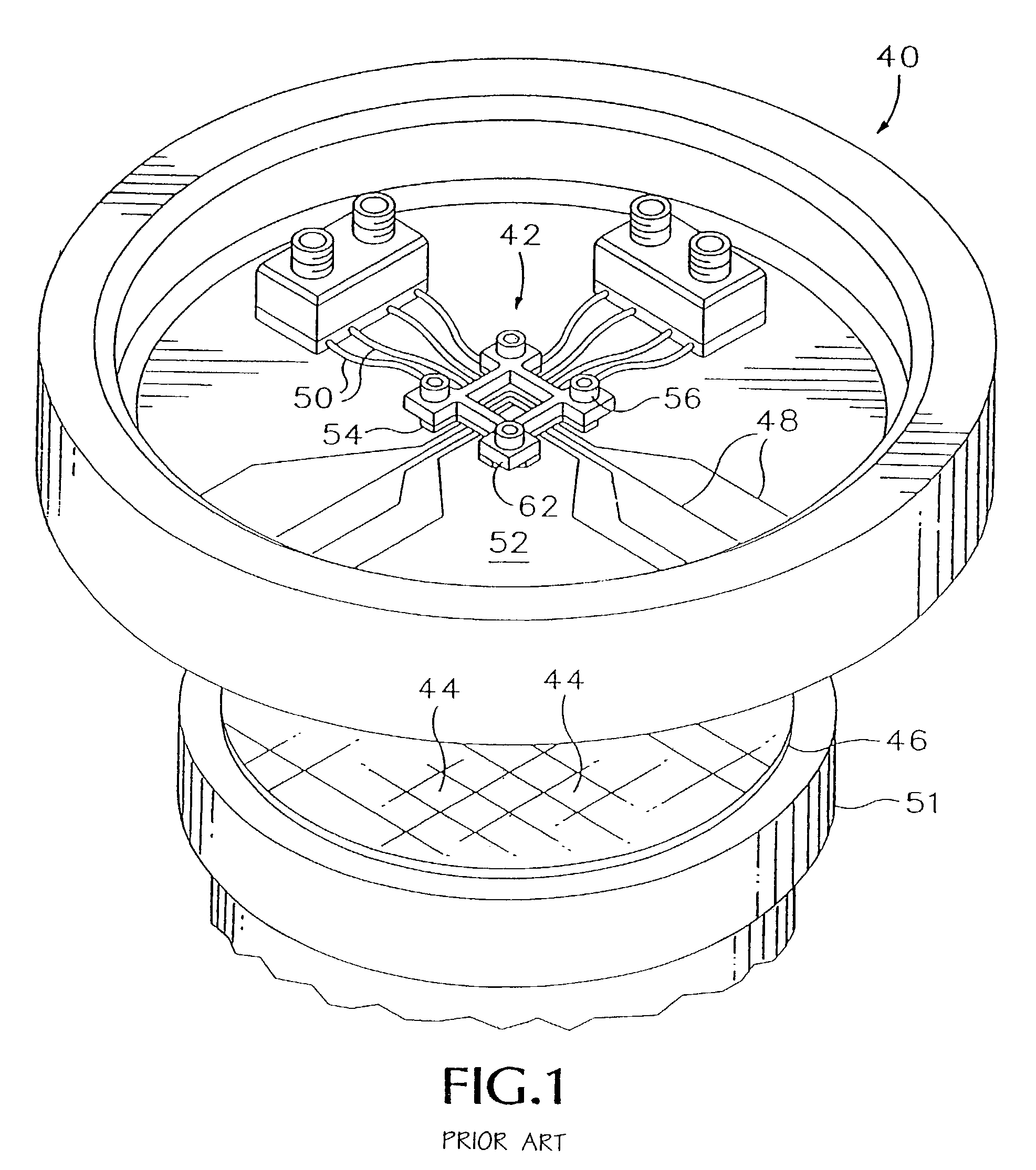

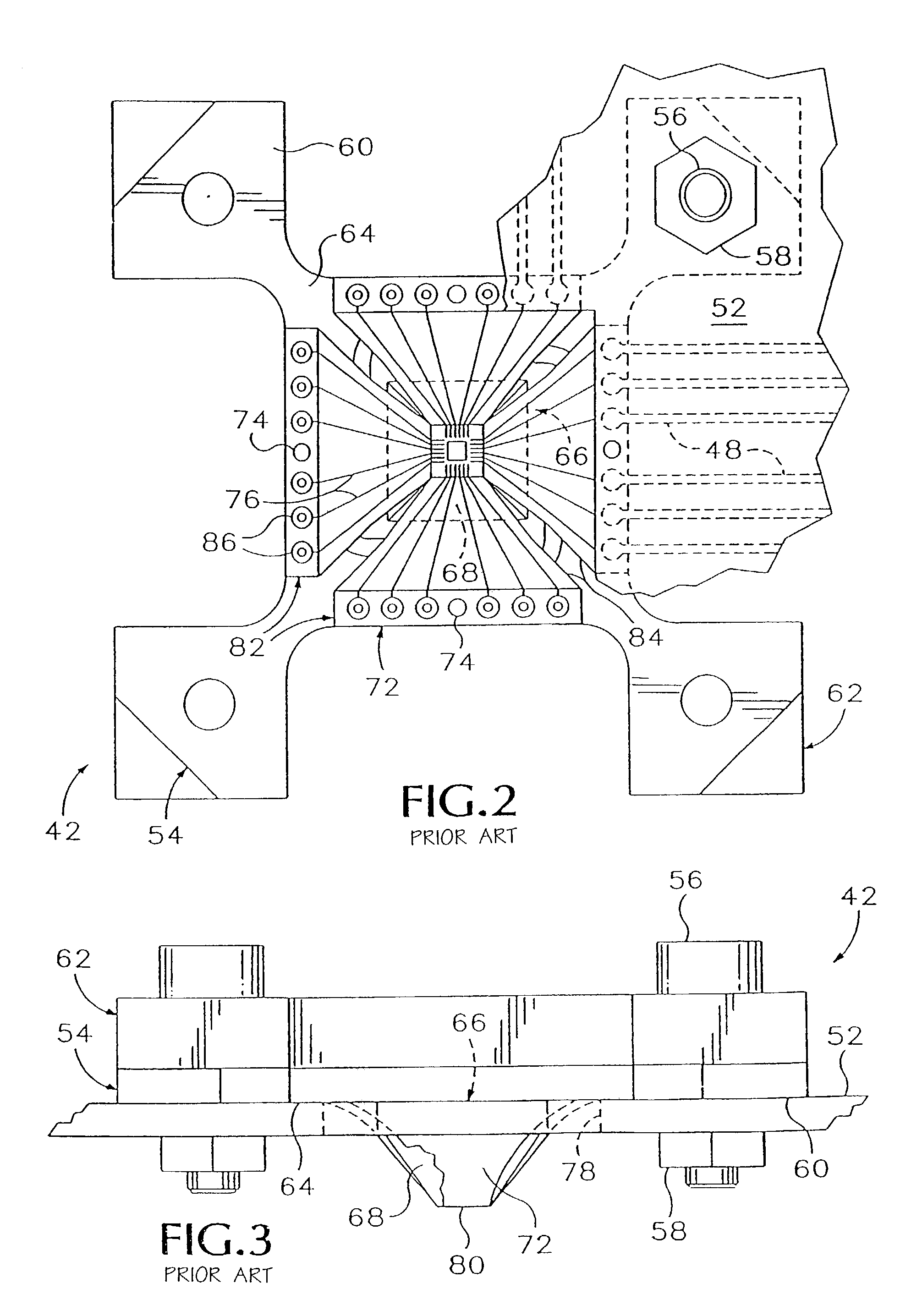

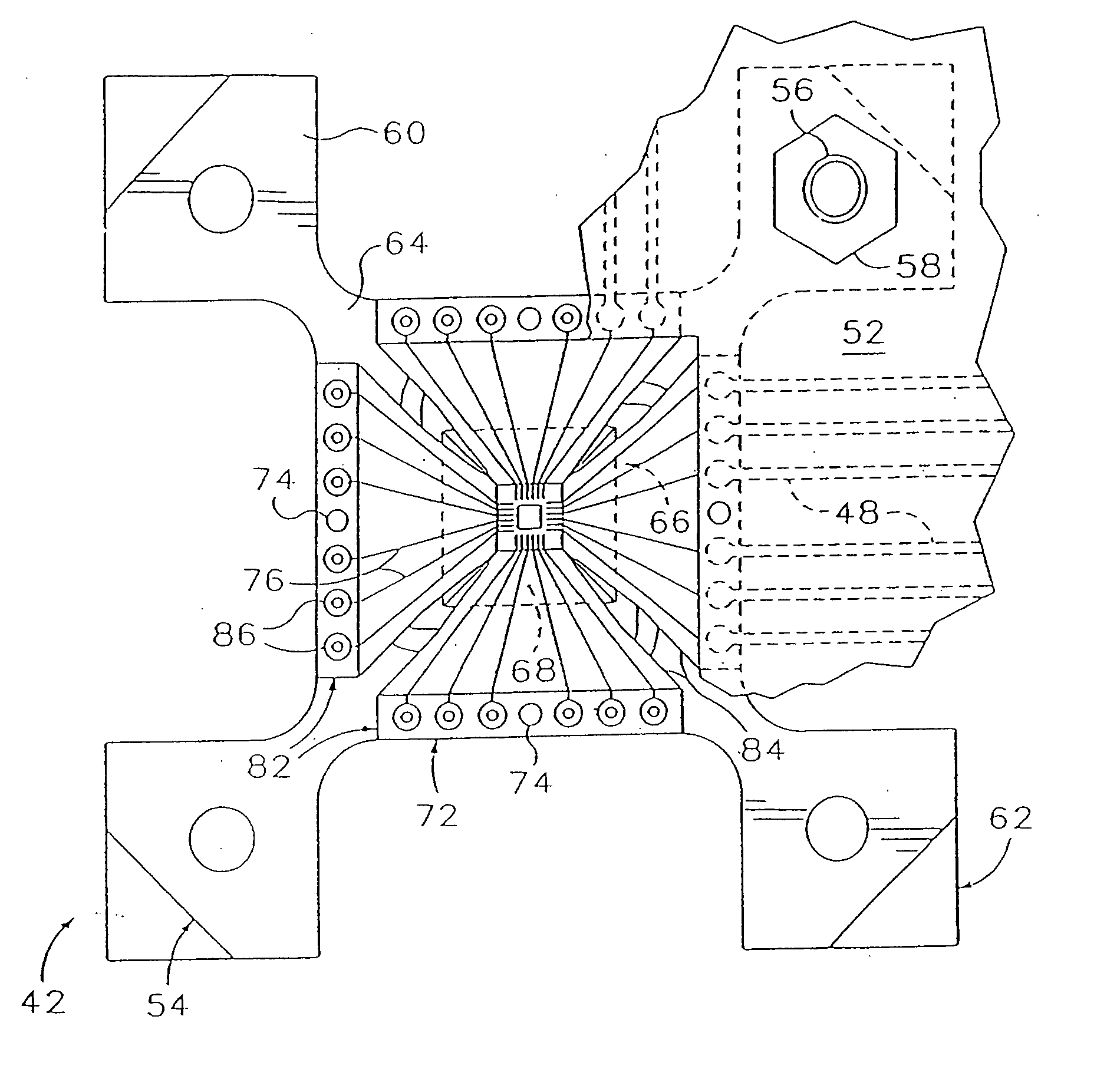

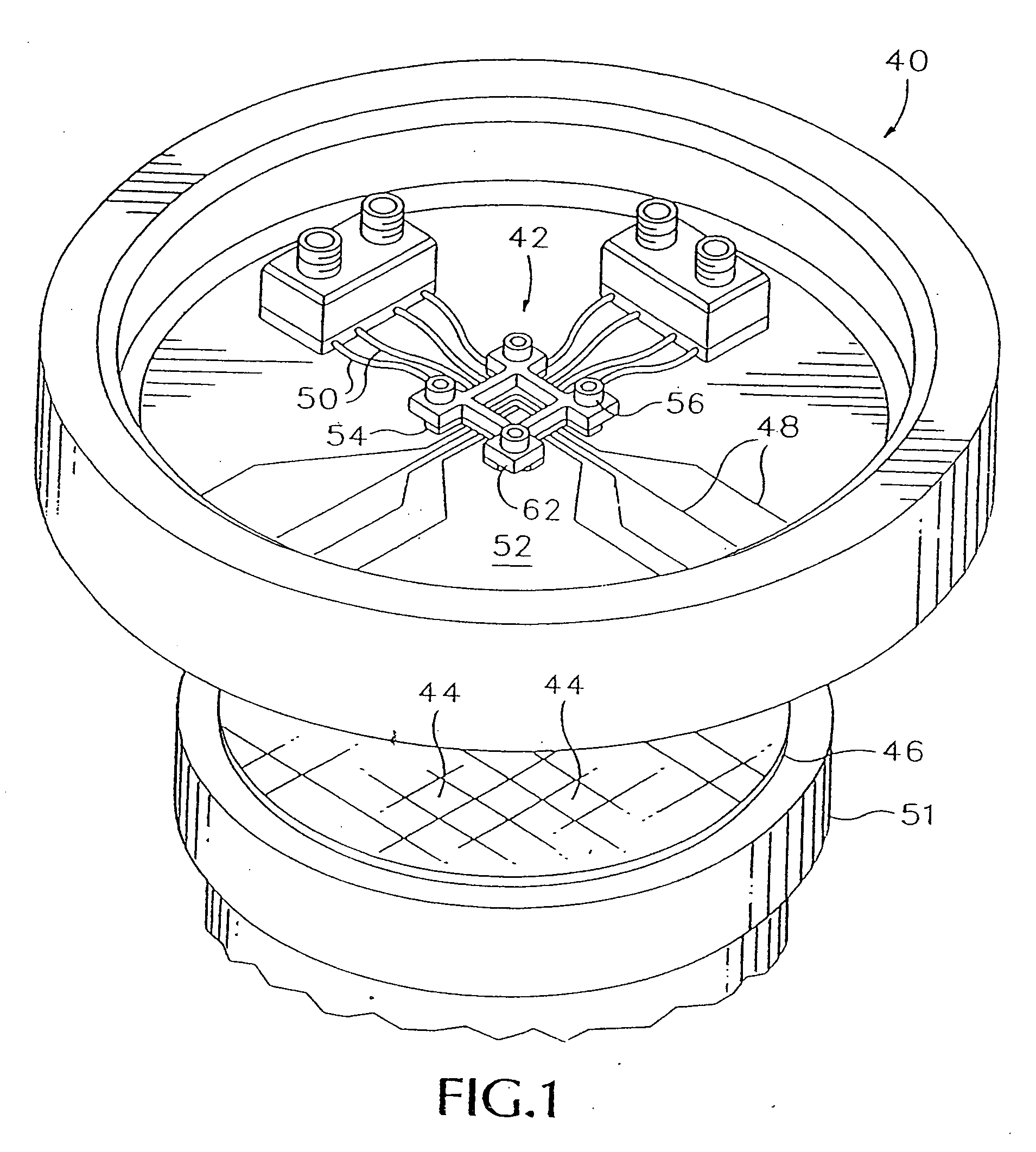

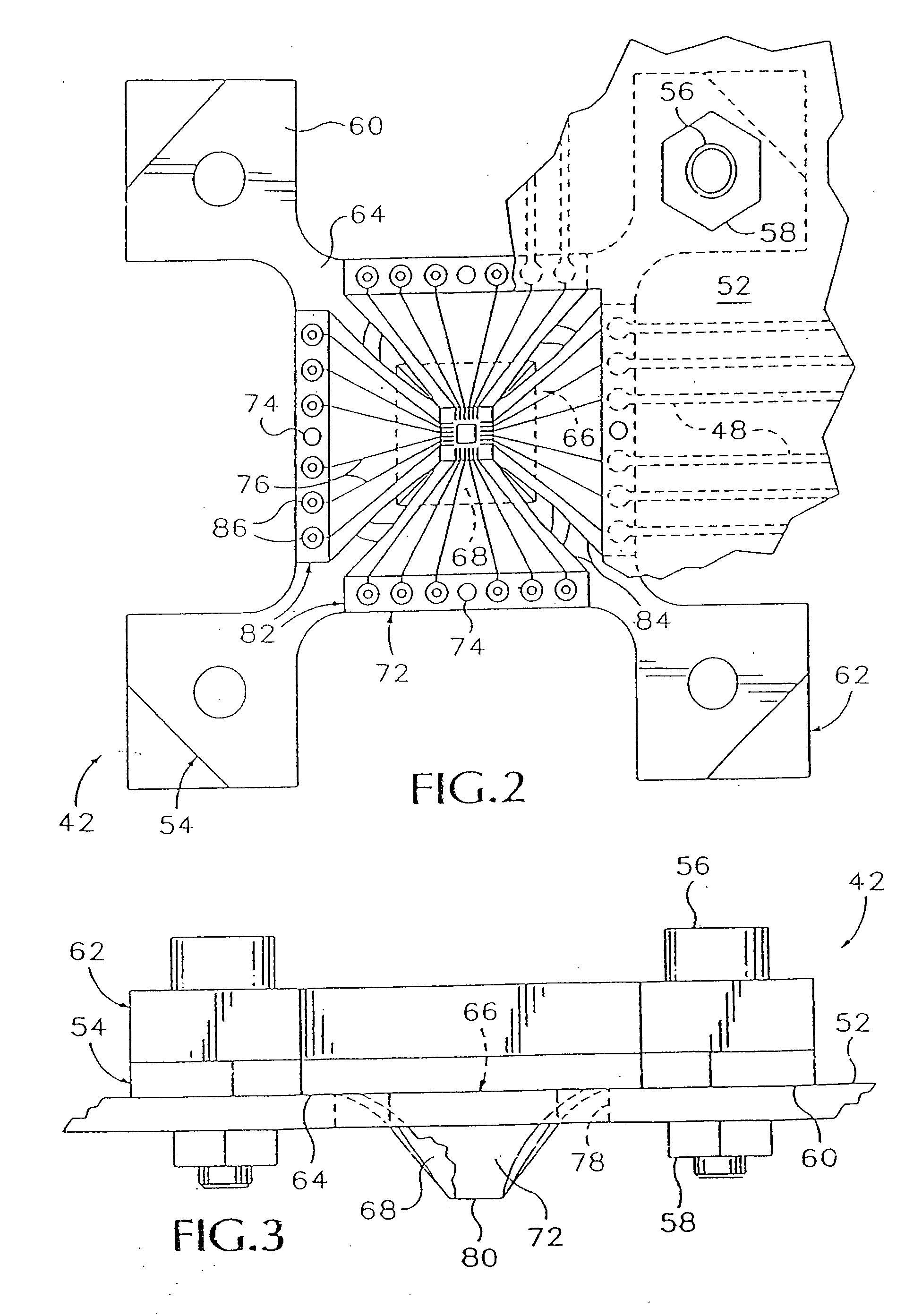

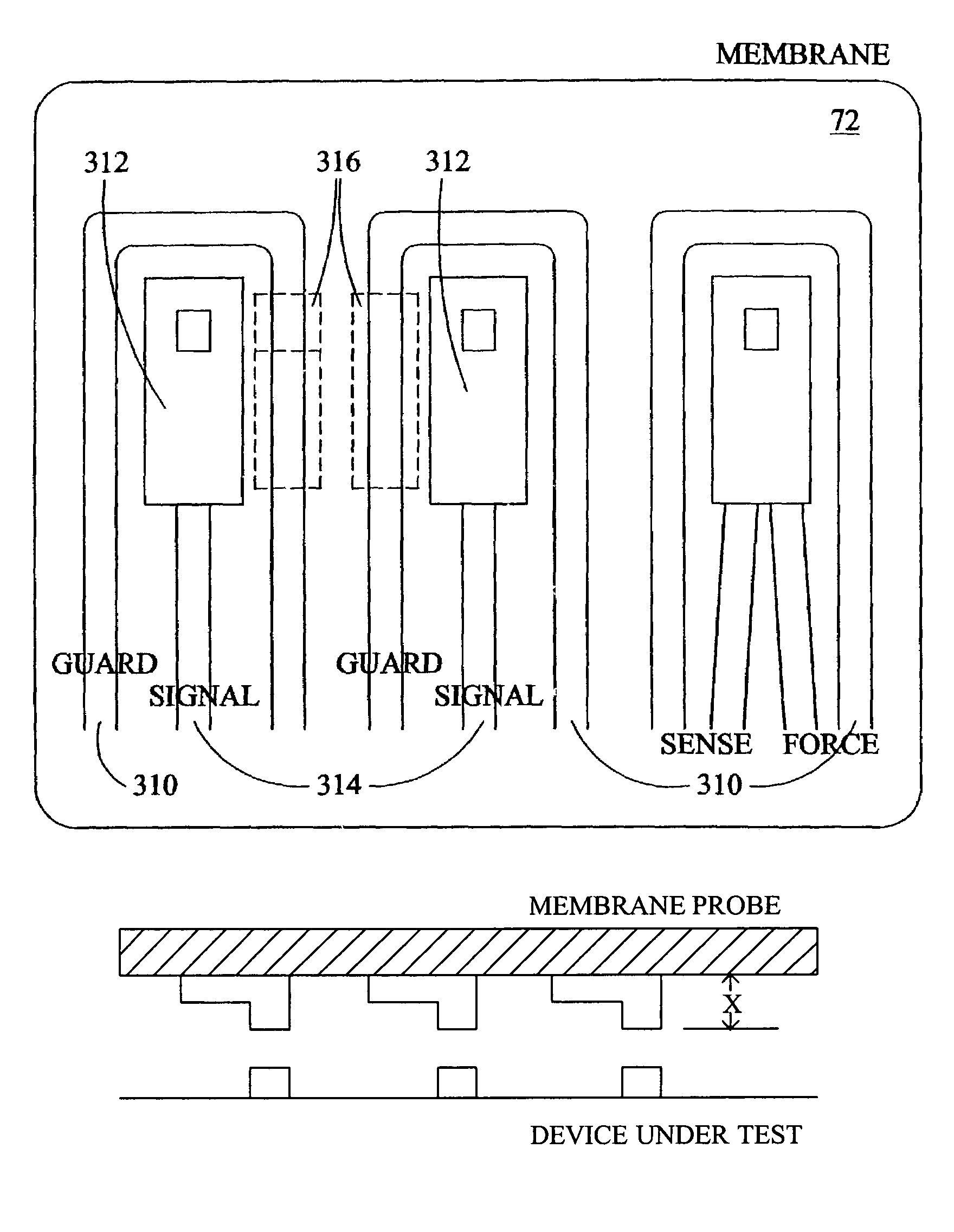

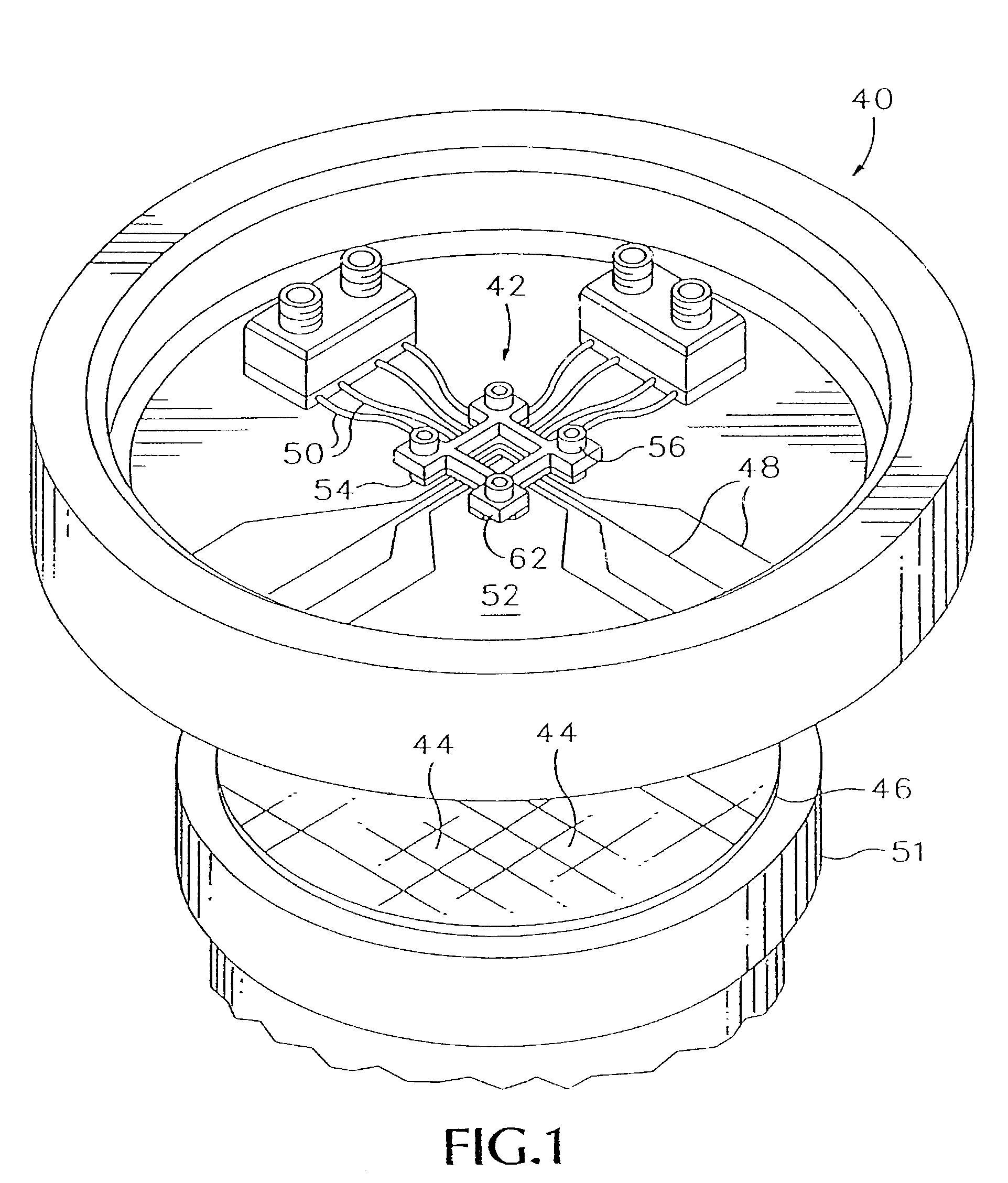

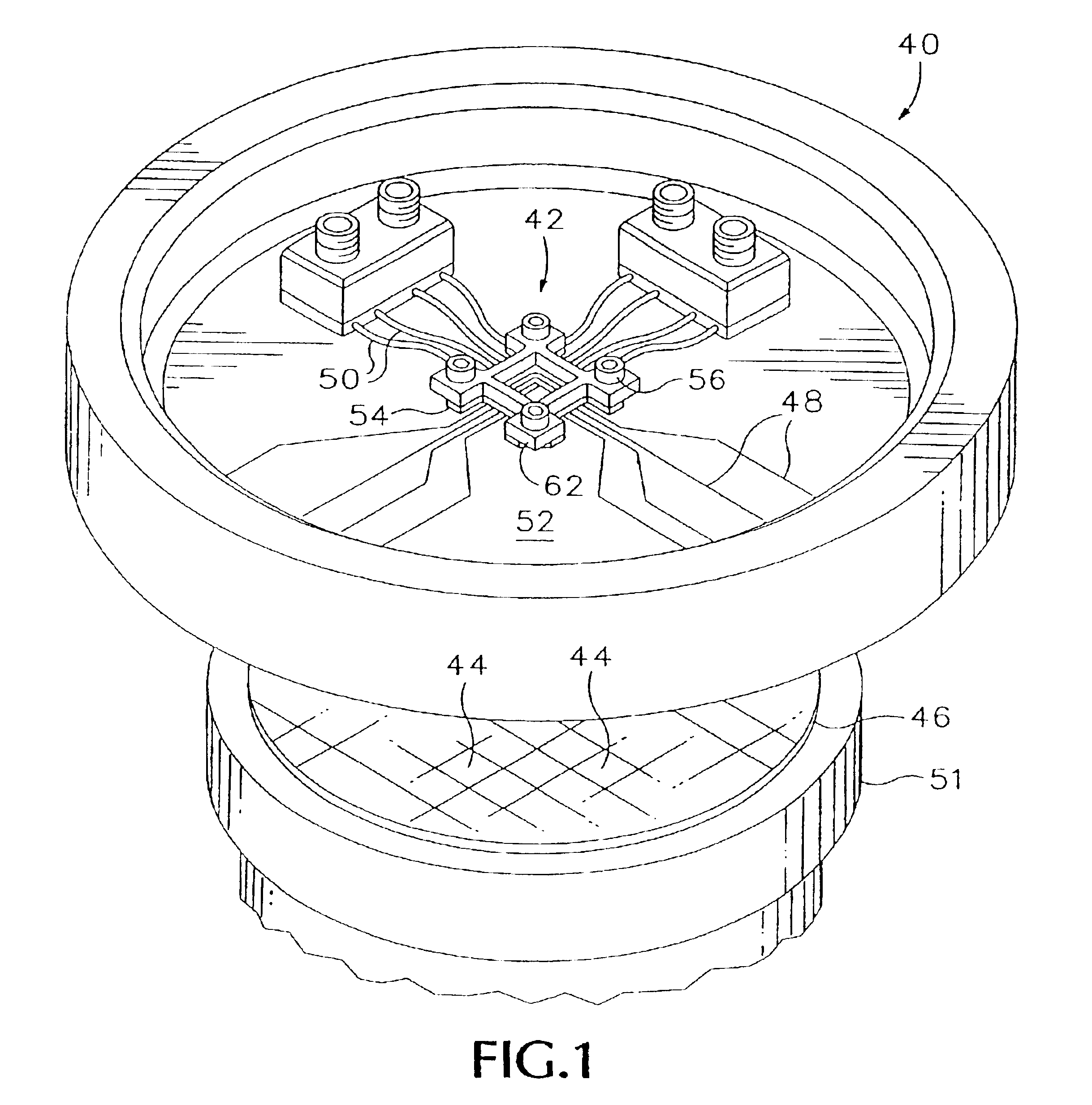

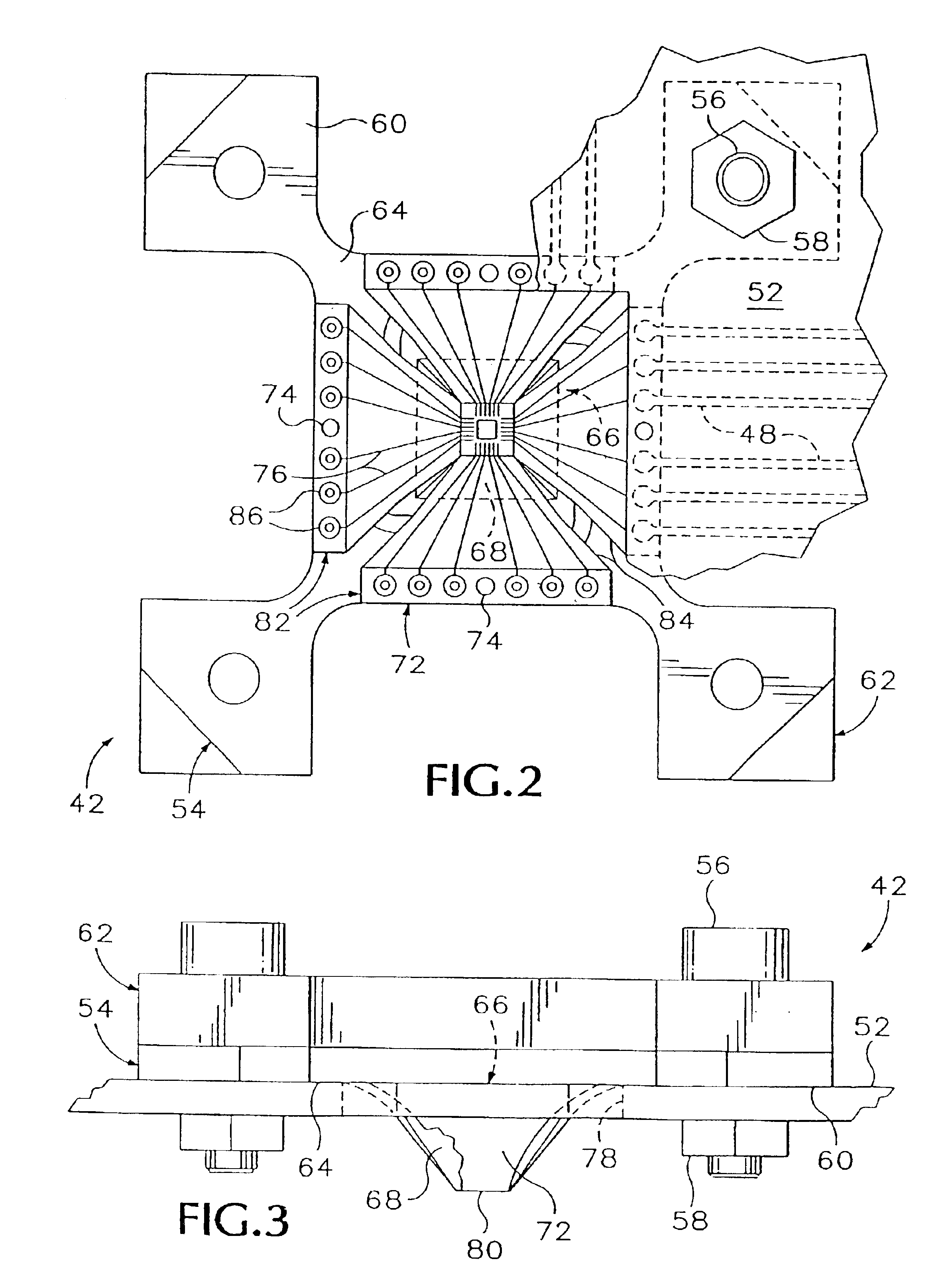

Membrane probing system

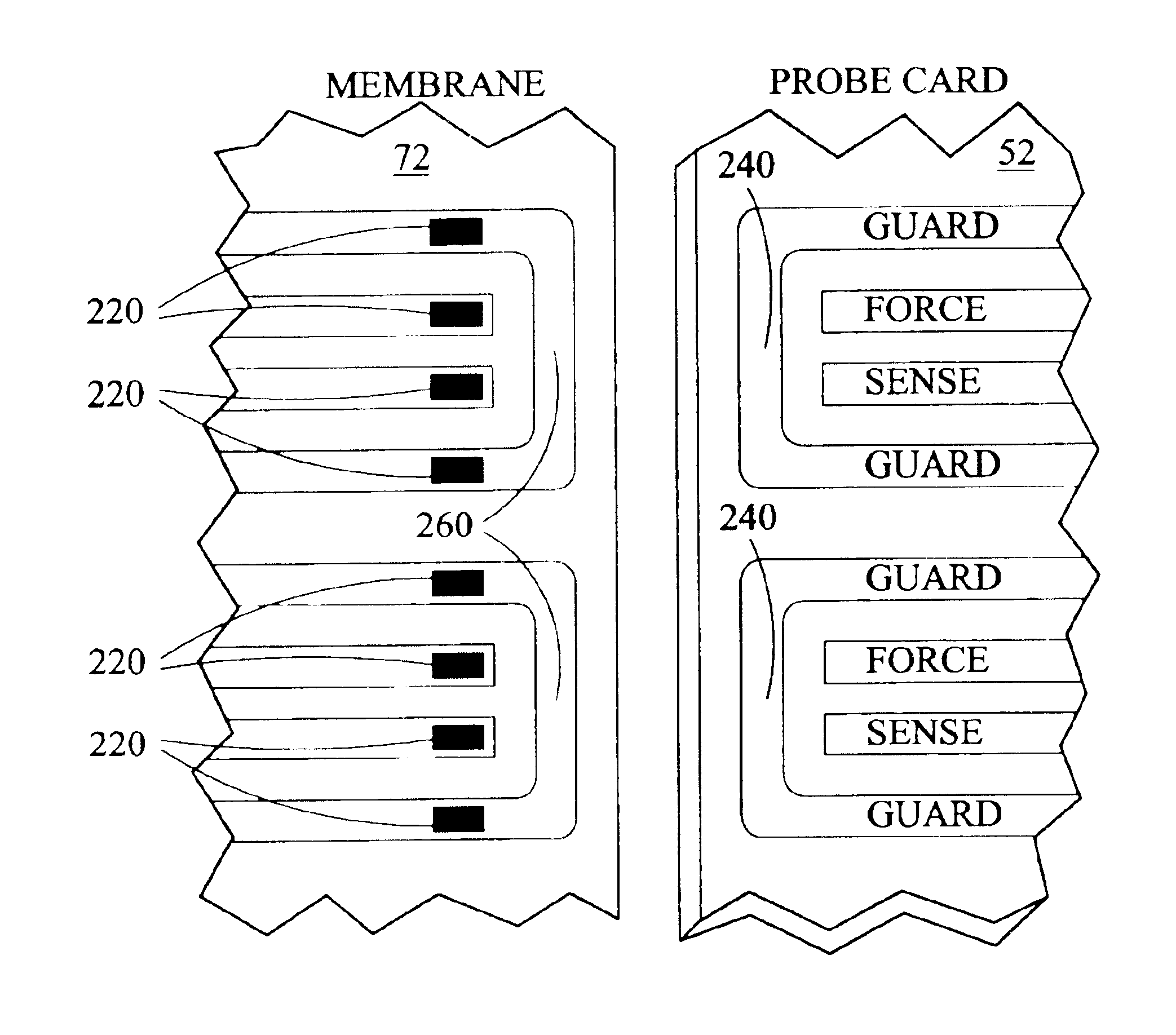

InactiveUS6838890B2Easy to understandElectronic circuit testingElectrical measurement instrument detailsProbe cardElectrical conductor

A membrane probing assembly includes a probe card with conductors supported thereon, wherein the conductors include at least a signal conductor located between a pair of spaced apart guard conductors. A membrane assembly includes a membrane with contacts thereon, and supporting at least a signal conductor located between a pair of spaced apart guard conductors. The guard conductors of the probe card are electrically interconnected proximate the interconnection between the probe card and the membrane assembly. The guard conductors of the membrane assembly are electrically interconnected proximate the interconnection between the probe card and the membrane assembly.

Owner:FORMFACTOR INC

Probing apparatus with impedance optimized interface

ActiveUS7888957B2Electrical measurement instrument detailsElectrical testingCoaxial cableCoplanar waveguide

In a membrane probing apparatus, the impedance of the interface between coaxial cables connected to the test instrumentation and the membrane supported co-planar waveguide that conductively connects to the probe's contacts is optimized by eliminating a ground plane in the interface board.

Owner:FORMFACTOR INC

Atmospheric pressure ion source performance enhancement

InactiveUS20090095900A1Increases Electrospray MS signalMaximize analyte signalParticle spectrometer methodsIsotope separationPerformance enhancementGas phase

Electrospray ionization sources interfaced to mass spectrometers have become widely used tools in analytical applications. Processes occurring in Electrospray (ES) ionization generally include the addition or removal of a charged species such as H+ or other cation to effect ionization of a sample species. Electrospray includes ionization processes that occur in the liquid and gas phase and in both phases ionization processes require a source or sink for such charged species. Electrolyte species, that aid in oxidation or reduction reactions occurring in Electrospray ionization, are added to sample solutions in many analytical applications to increase the ion signal amplitude generated in Electrospray and detected by a mass spectrometer (MS) Electrolyte species that may be required to enhance an upstream sample preparation or separation process may be less compatible with the downstream ES processes and cause reduction in MS signal. New Electrolytes have been found that increase positive and negative polarity analyte ion signal measured in ESMS analysis when compared with analyte ESMS signal achieved using more conventional electrolytes. The new electrolyte species increase ES MS signal when added directly to a sample solution or when added to a second solution flow in an Electrospray membrane probe. It has also been found that running the ES membrane probe with specific Electrolytes in the second solution of the ES membrane probe have been found to enhance ESMS signal compared to using the same electrolytes directly in the sample solution being Electrosprayed. The new electrolytes can be added to a reagent ion source configured in a combination Atmospheric pressure ion source to improve ionization efficiency.

Owner:PERKINELMER HEALTH SCIENCES INC

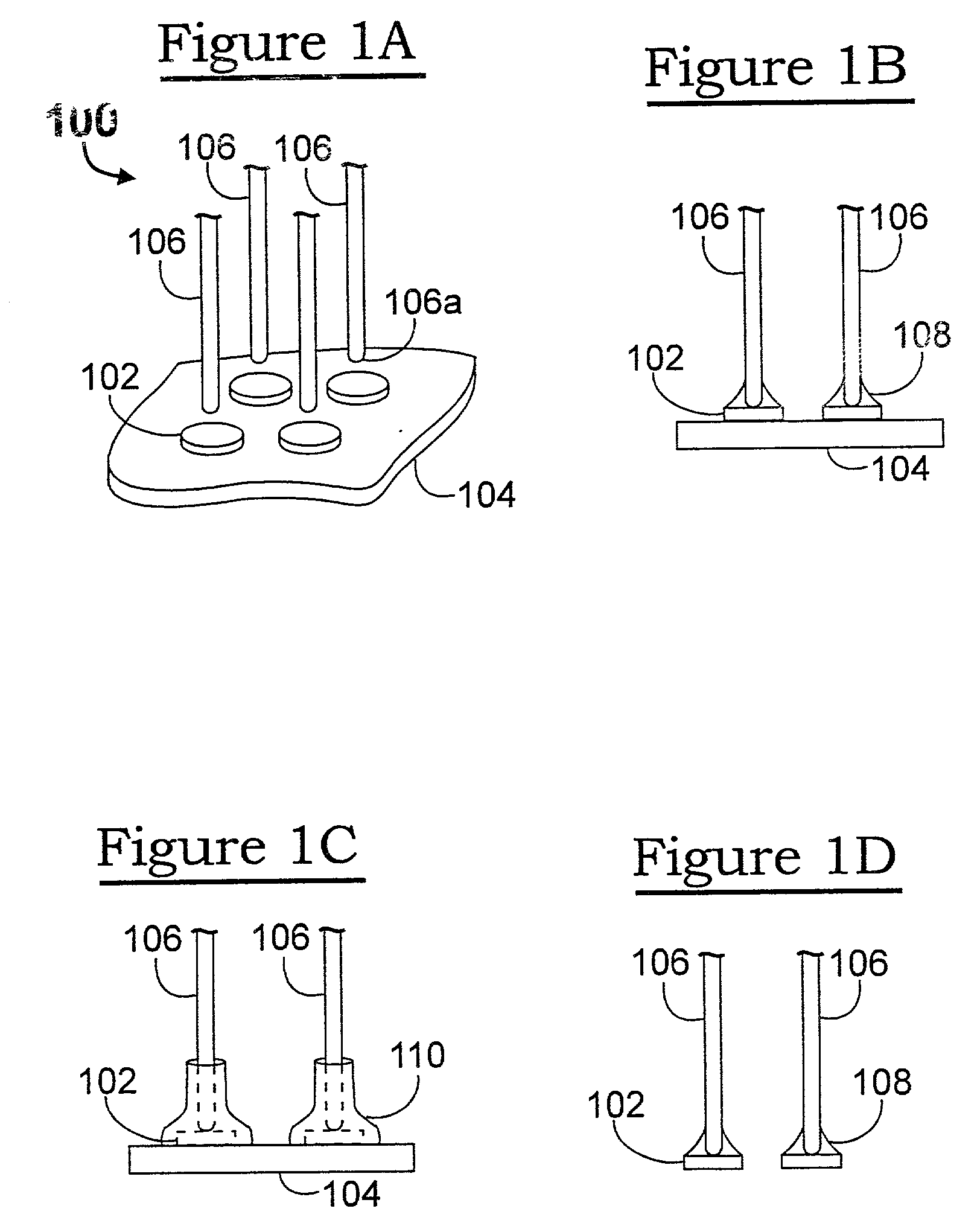

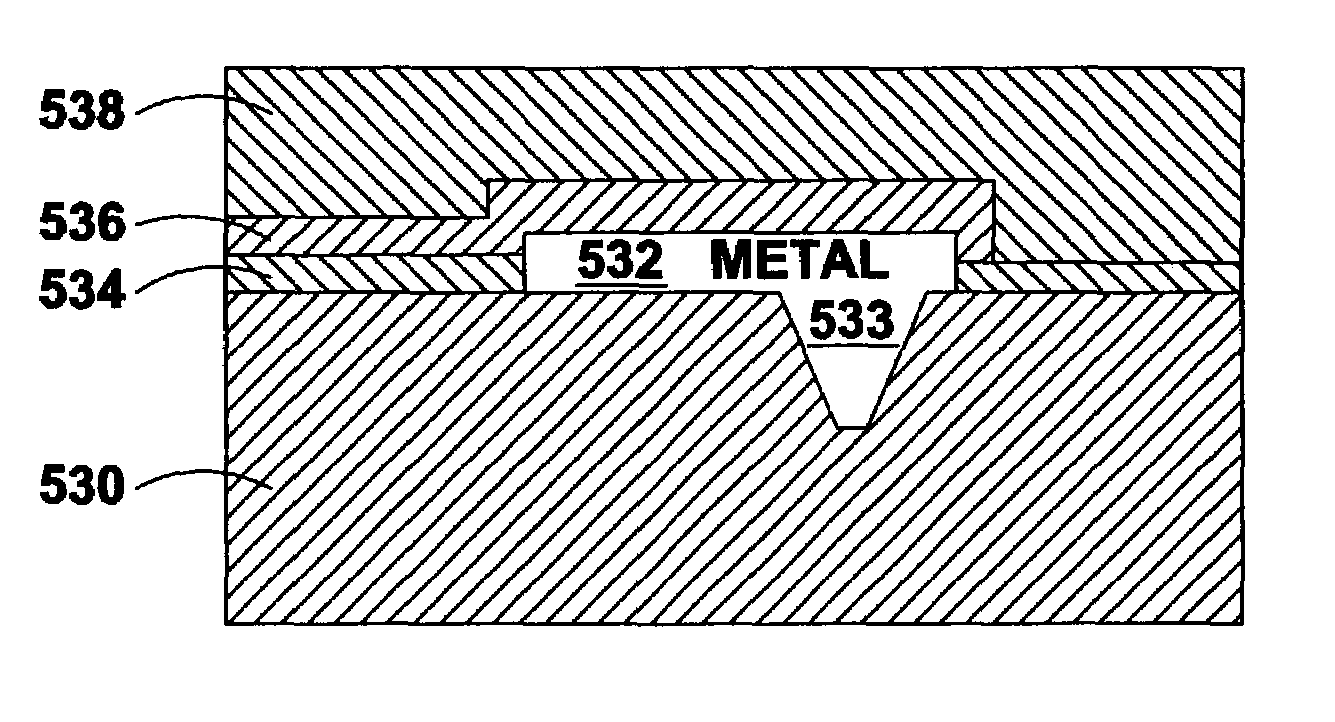

Membrane probe with anchored elements

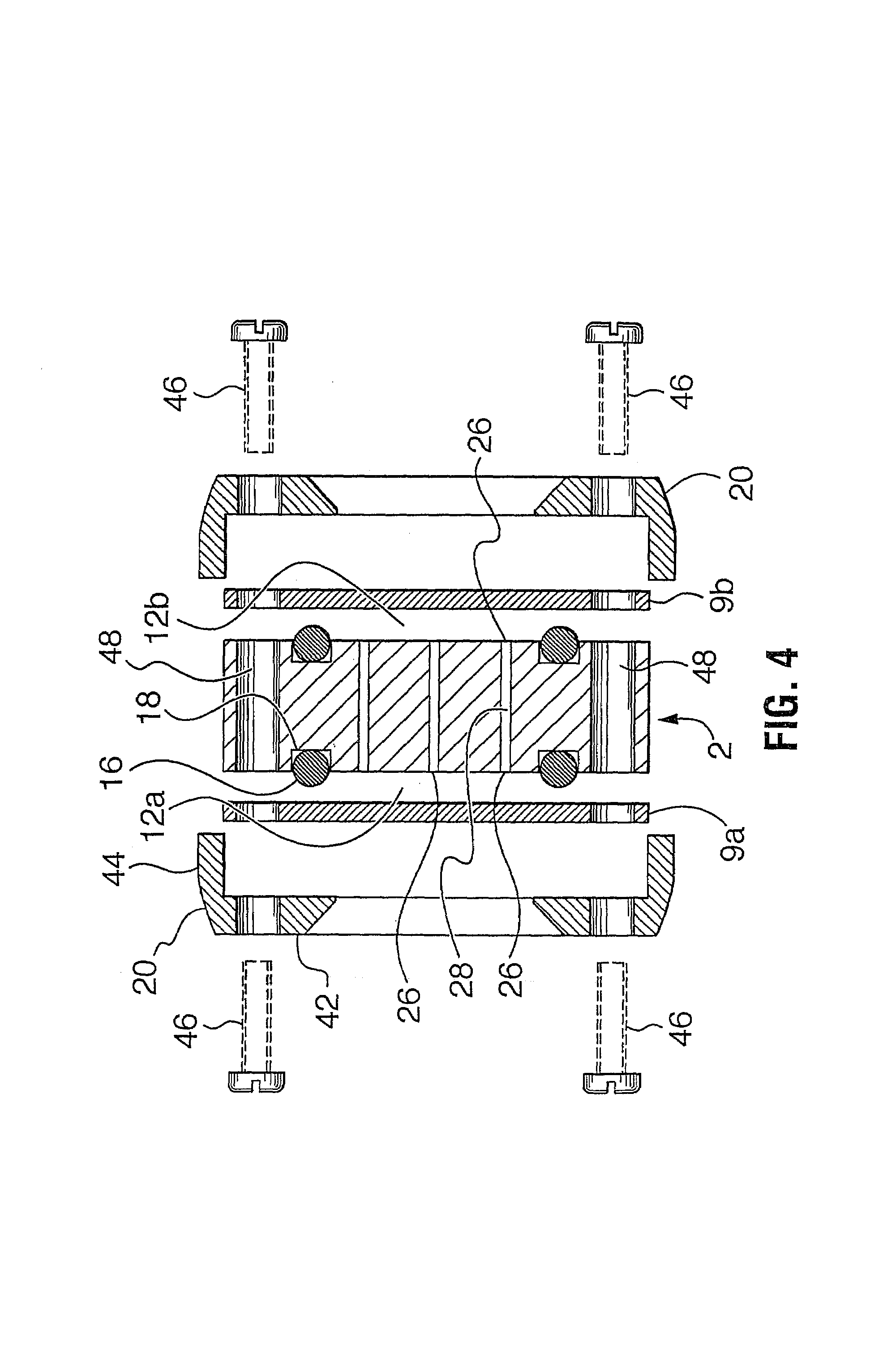

InactiveUS6881072B2Electrical measurement instrument detailsCoupling device detailsElectrical connectionEngineering

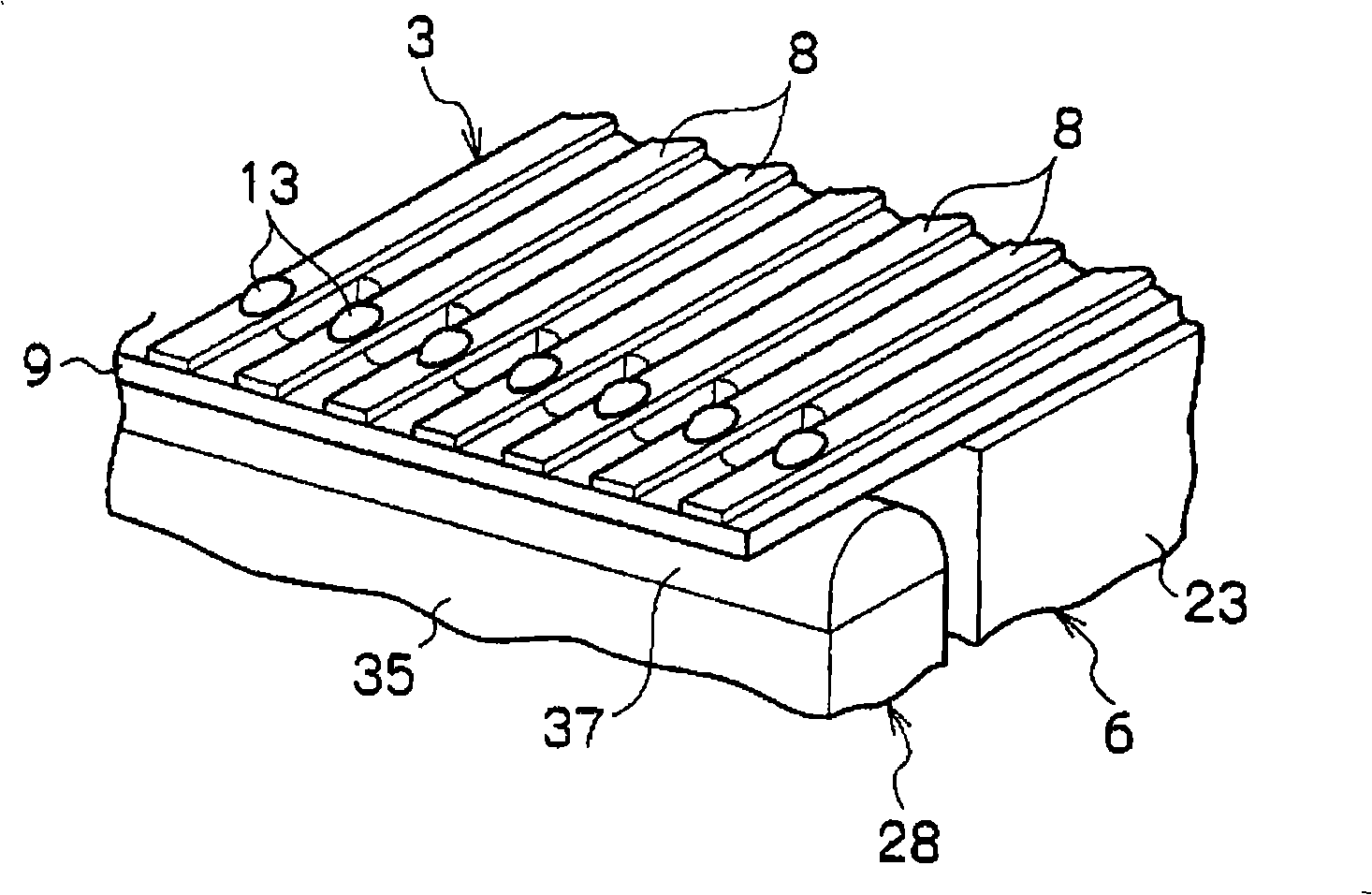

A structure and method to establish an electrical connection between a tester and an electrical component. A flexible dielectric layer has a first side and a second side. A through via extends through the first side and the second side of the dielectric layer. A blind via is placed in a position that is offset from the through via and extends laterally in a first direction from a section of the first through via to a section of the flexible dielectric layer. The blind via extends in a second direction from the first side of the flexible dielectric layer to a section of the flexible dielectric layer that is between the first side and the second side of the dielectric layer. An electrically conductive member extends through the through via and extends into the blind via, thereby filling the through via and the blind via. The electrically conductive member has a first surface and a second surface. Any distance between the first surface and the second surface is greater than a distance between the first side of the dielectric layer and the second side of the dielectric layer.

Owner:GLOBALFOUNDRIES INC

Membrane probing system

InactiveUS7266889B2Contact member manufacturingSemiconductor/solid-state device testing/measurementContact padEngineering

Owner:FORMFACTOR BEAVERTON INC

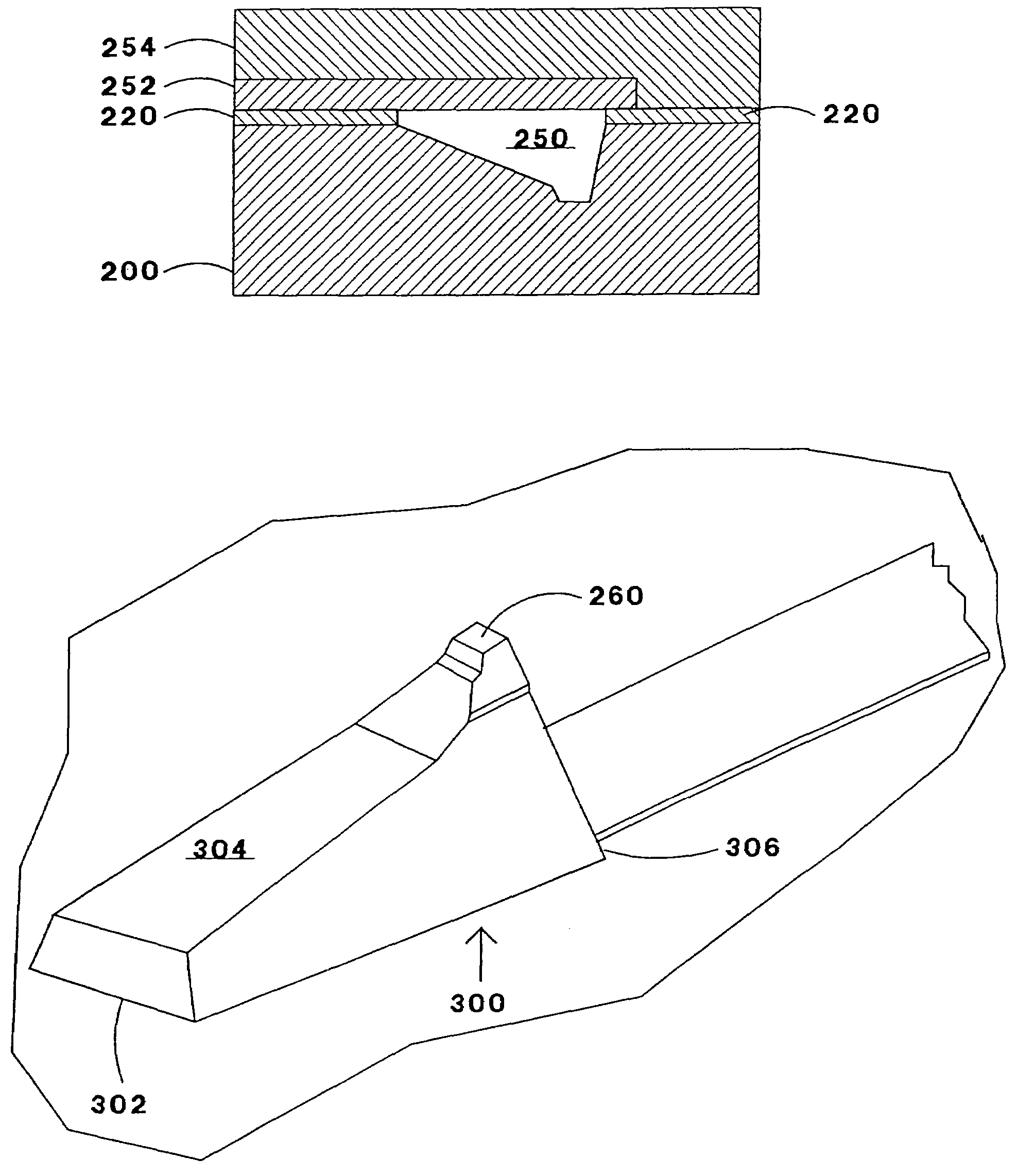

Method for constructing a membrane probe using a depression

InactiveUS7178236B2Overcomes drawbackSimple processPrinted circuit assemblingContact member manufacturingEngineeringConductive materials

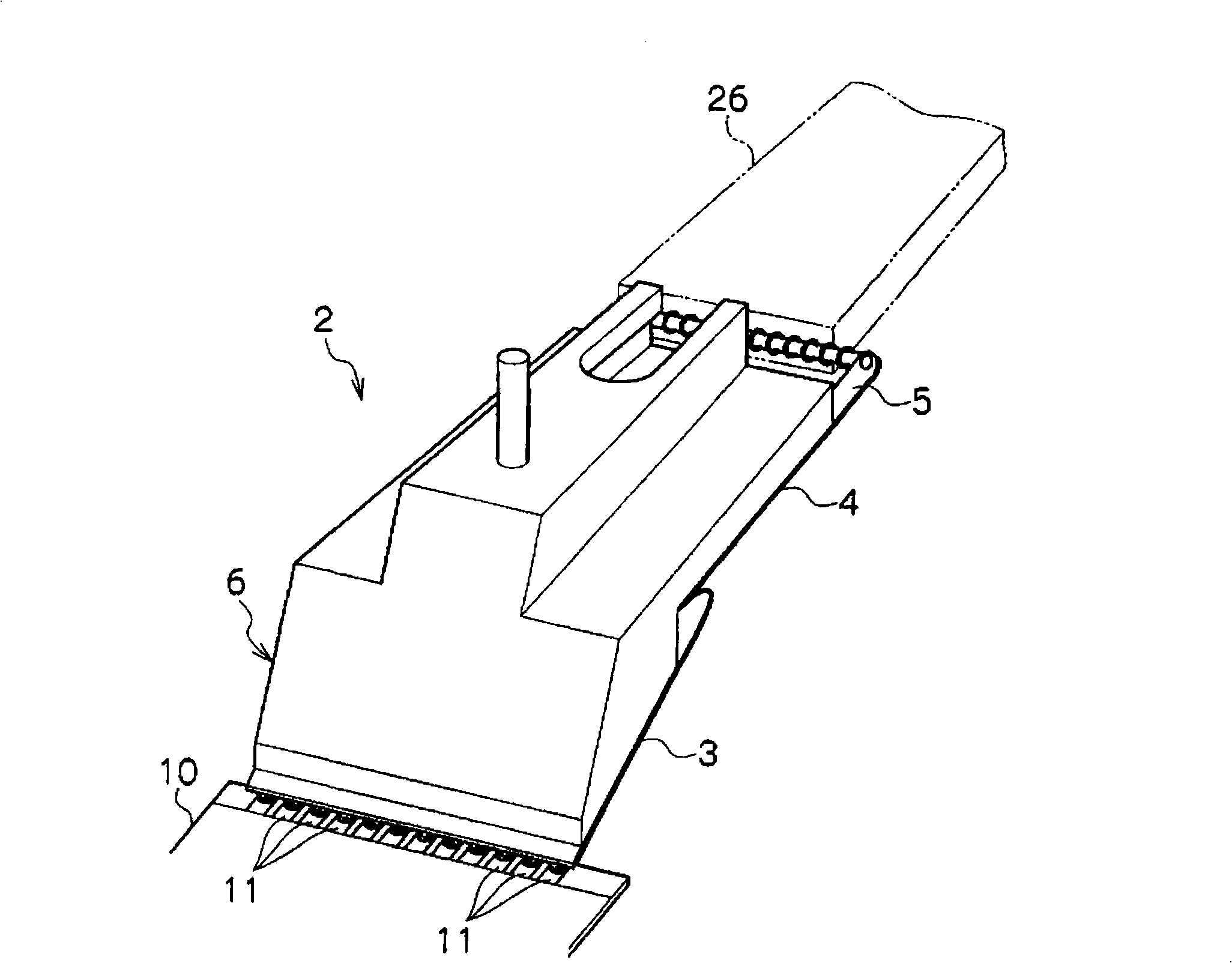

A method for constructing a membrane probe that includes providing a substrate, and creating a depression within the substrate. Conductive material is located within the depression and a conductive trace is connected to the conductive material. A membrane is applied to support the conductive material and the substrate is removed from the conductive material.

Owner:FORMFACTOR BEAVERTON INC

Sheet-form membrane sample probe, method and apparatus for fluid concentration analysis

A sheet form membrane probe, an apparatus and method, wherein the probe includes a probe body, a sheet-form membrane secured to the probe body and including an open surface exposed to the exterior of the probe; a channel formed between the probe body and the membrane through which a collector fluid can flow; an inlet port opening to the channel to conduct collector fluid to the channel; and an outlet port spaced from the inlet port such that the collector fluid passes through the channel from the inlet port to the outlet port in a flow direction substantially parallel to the membrane. The channel may be formed to provide broad surface contact of the collector fluid with the membrane. The membrane open surface may include an active area open to a sample fluid and open on an opposite side for contact with collector fluid flow in the channel. The active area may be large relative to the total membrane area to provide for an effective use of the expensive membrane material. Another probe includes a fitting end and a membrane stem and secures membranes to at least two sides of the membrane stem such that permeation can occur along a channel passing from the fitting end along the membrane stem and returning to the fitting end from the membrane stem.

Owner:DATALOG ACQUISITION

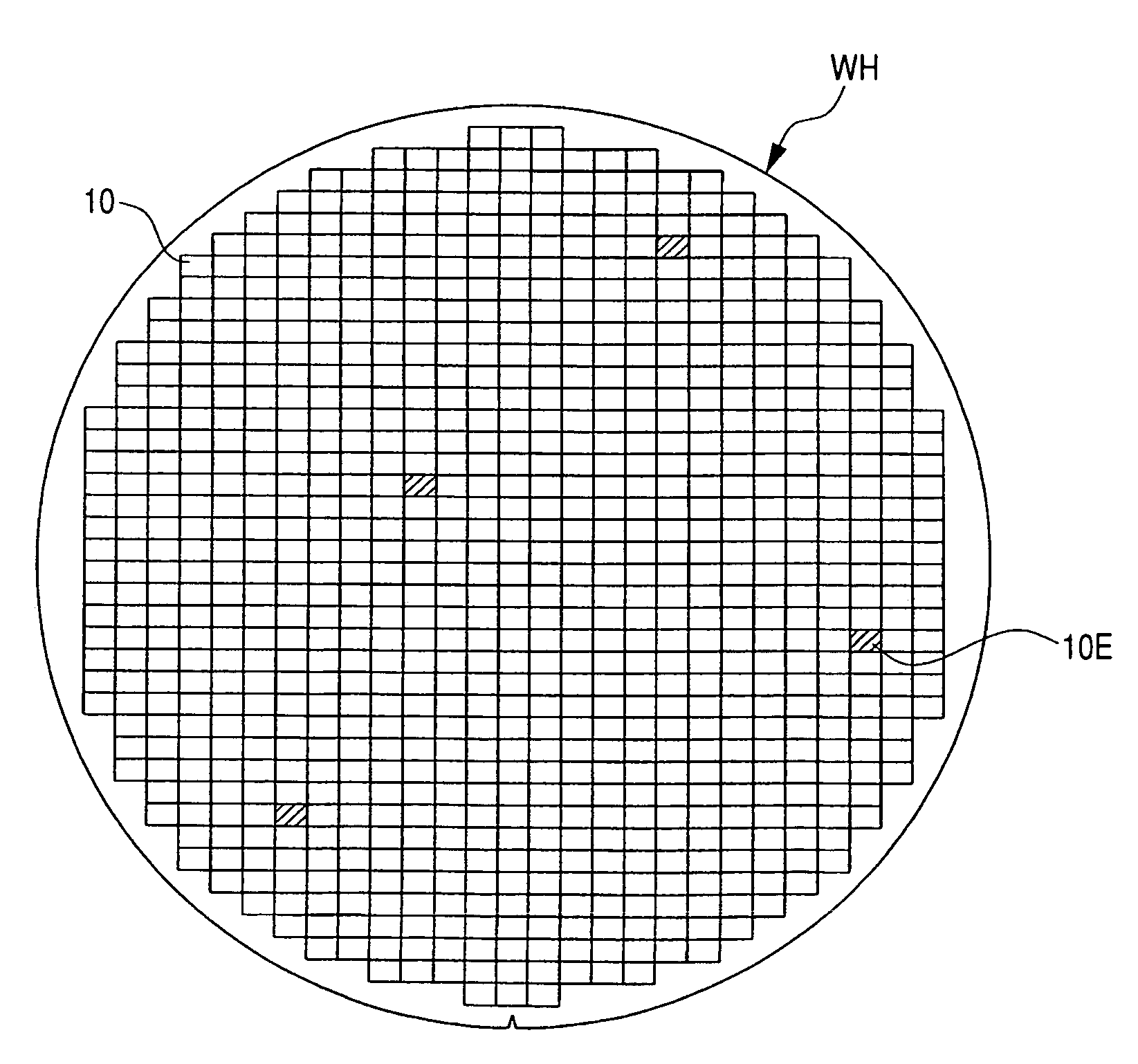

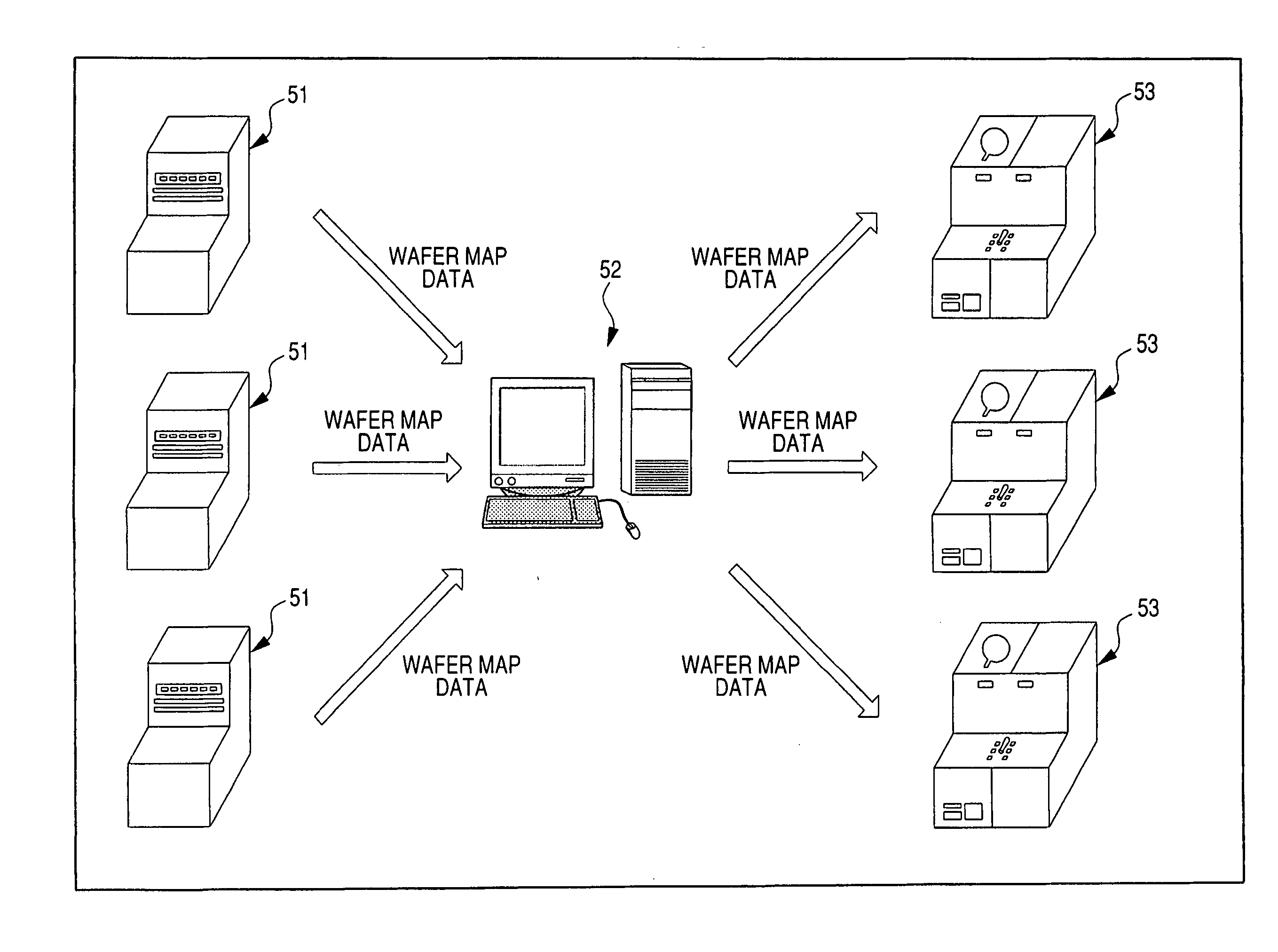

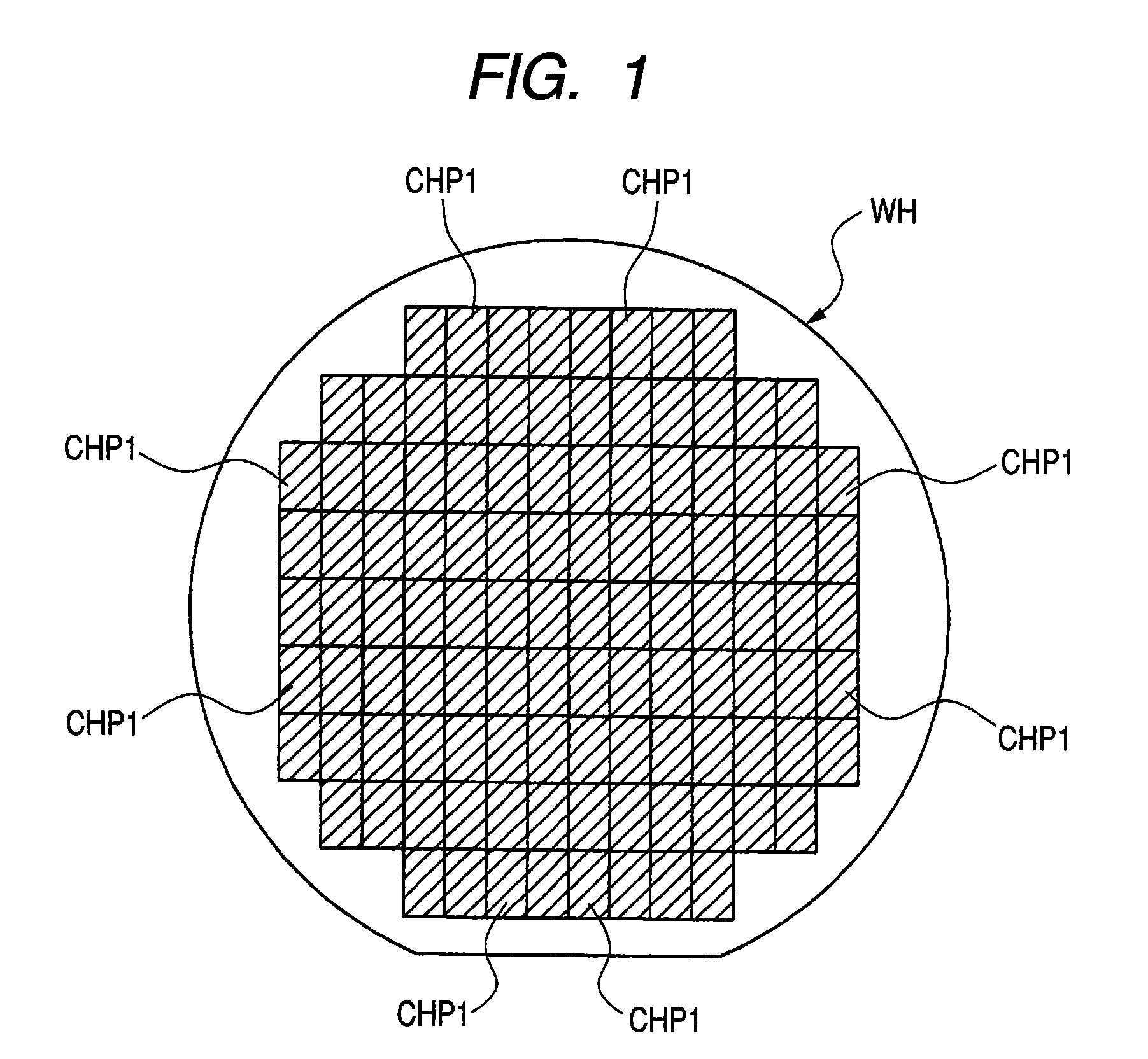

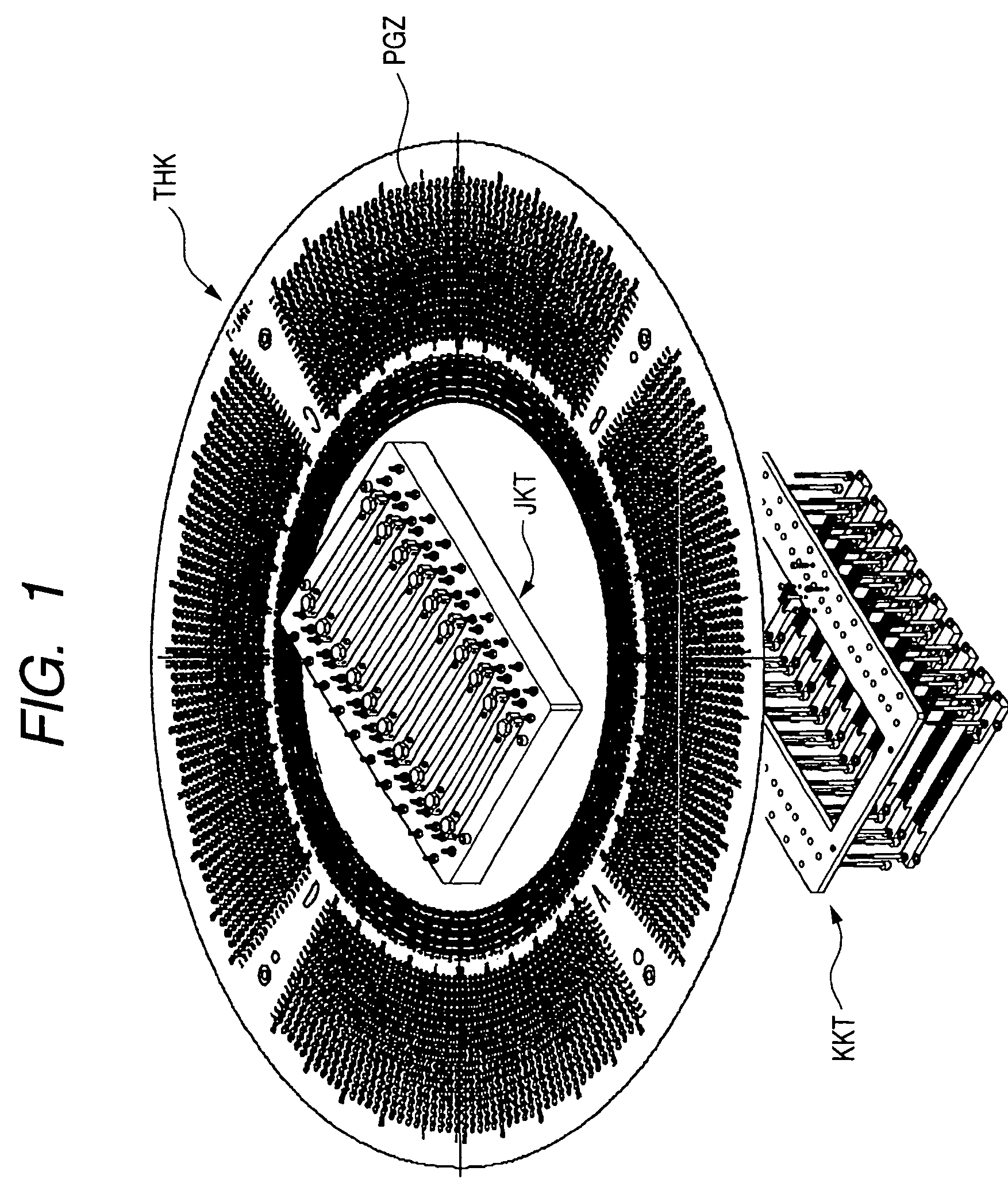

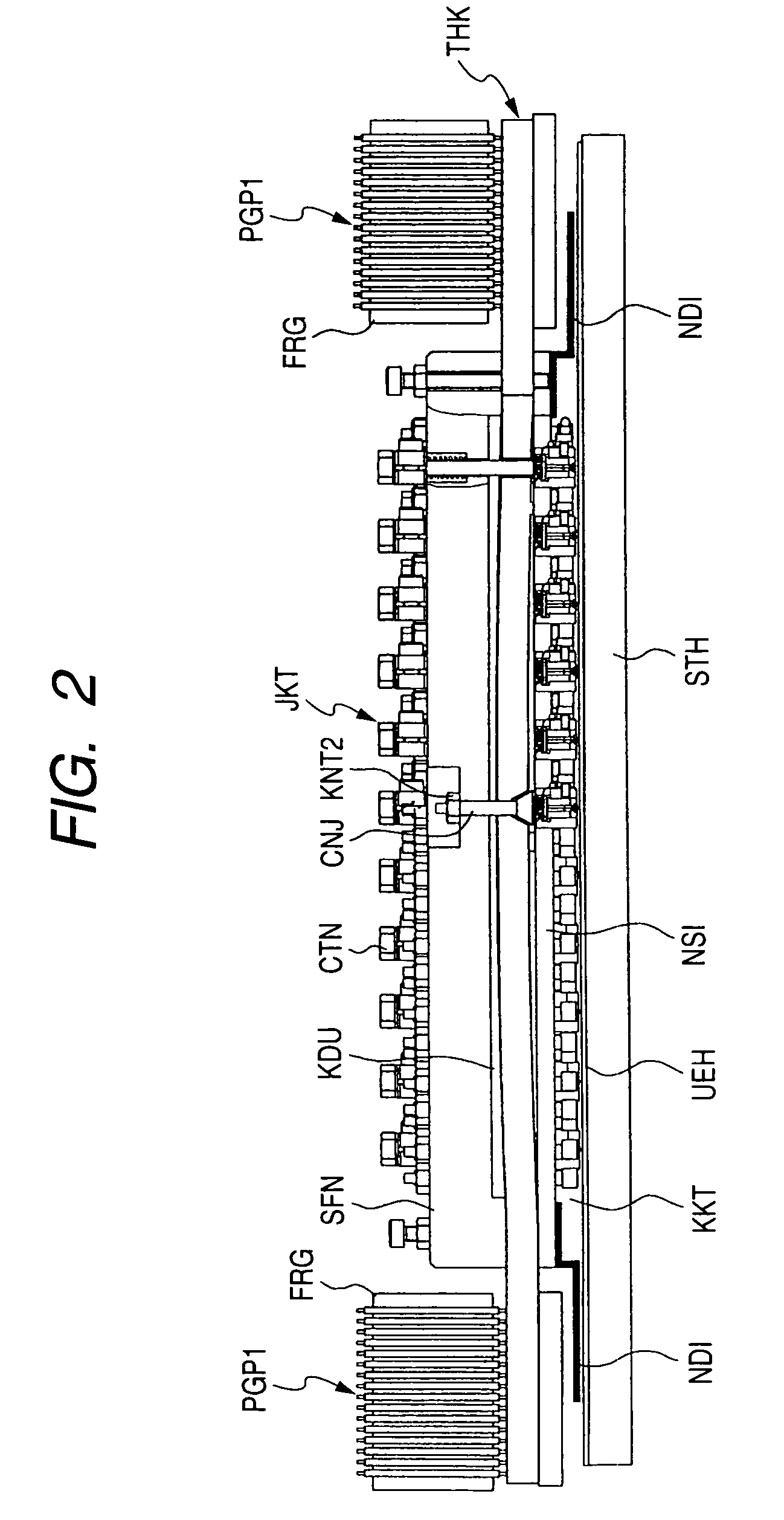

Fabrication method of semiconductor integrated circuit device

InactiveUS7544522B2Reduce manufacturing costIncrease the number ofSemiconductor/solid-state device testing/measurementElectronic circuit testingForeign matterProbe card

To prevent breakage of a membrane probe during a probe test using a probe card having the membrane probe, appearance of a main surface of a wafer as a test object is tested by an appearance tester 51, and results of bad appearance such as adhesion of a foreign substance to the main surface of the wafer and abnormality in shape of bump electrodes over the main surface of the wafer are collected as wafer map data according to arrangement of respective chips in a plane of the wafer, then the wafer map data are transmitted to a probe tester 53 via a server 52, and the probe tester 53 omits the probe test for chips in which bad appearance was detected, and concurrently performs the probe test to other chips in which bad appearance was not detected, based on the wafer map data.

Owner:RENESAS ELECTRONICS CORP

Membrane probing system

InactiveUS20080111571A1Electrical measurement instrument detailsElectrical testingElectrical conductorProbe card

A membrane probing assembly includes a probe card with conductors supported thereon, wherein the conductors include at least a signal conductor located between a pair of spaced apart guard conductors. A membrane assembly includes a membrane with contacts thereon, and supporting at least a signal conductor located between a pair of spaced apart guard conductors. The guard conductors of the probe card are electrically interconnected proximate the interconnection between the probe card and the membrane assembly. The guard conductors of the membrane assembly are electrically interconnected proximate the interconnection between the probe card and the membrane assembly.

Owner:FORMFACTOR BEAVERTON INC

Membrane probing system

InactiveUS7355420B2Electrical measurement instrument detailsIndividual semiconductor device testingElectrical conductorProbe card

A membrane probing assembly includes a probe card with conductors supported thereon, wherein the conductors include at least a signal conductor located between a pair of spaced apart guard conductors. A membrane assembly includes a membrane with contacts thereon, and supporting at least a signal conductor located between a pair of spaced apart guard conductors. The guard conductors of the probe card are electrically interconnected proximate the interconnection between the probe card and the membrane assembly. The guard conductors of the membrane assembly are electrically interconnected proximate the interconnection between the probe card and the membrane assembly.

Owner:FORMFACTOR BEAVERTON INC

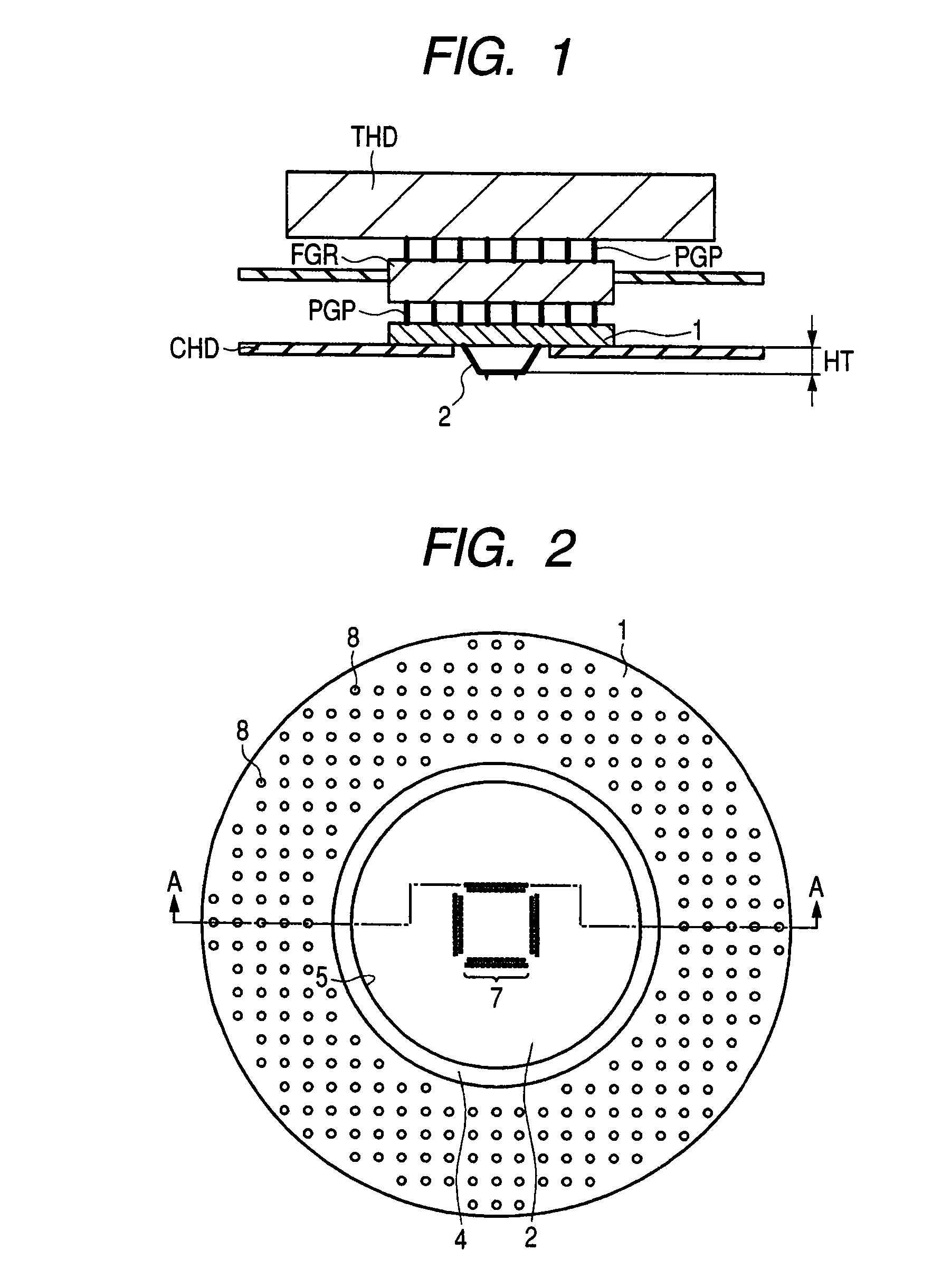

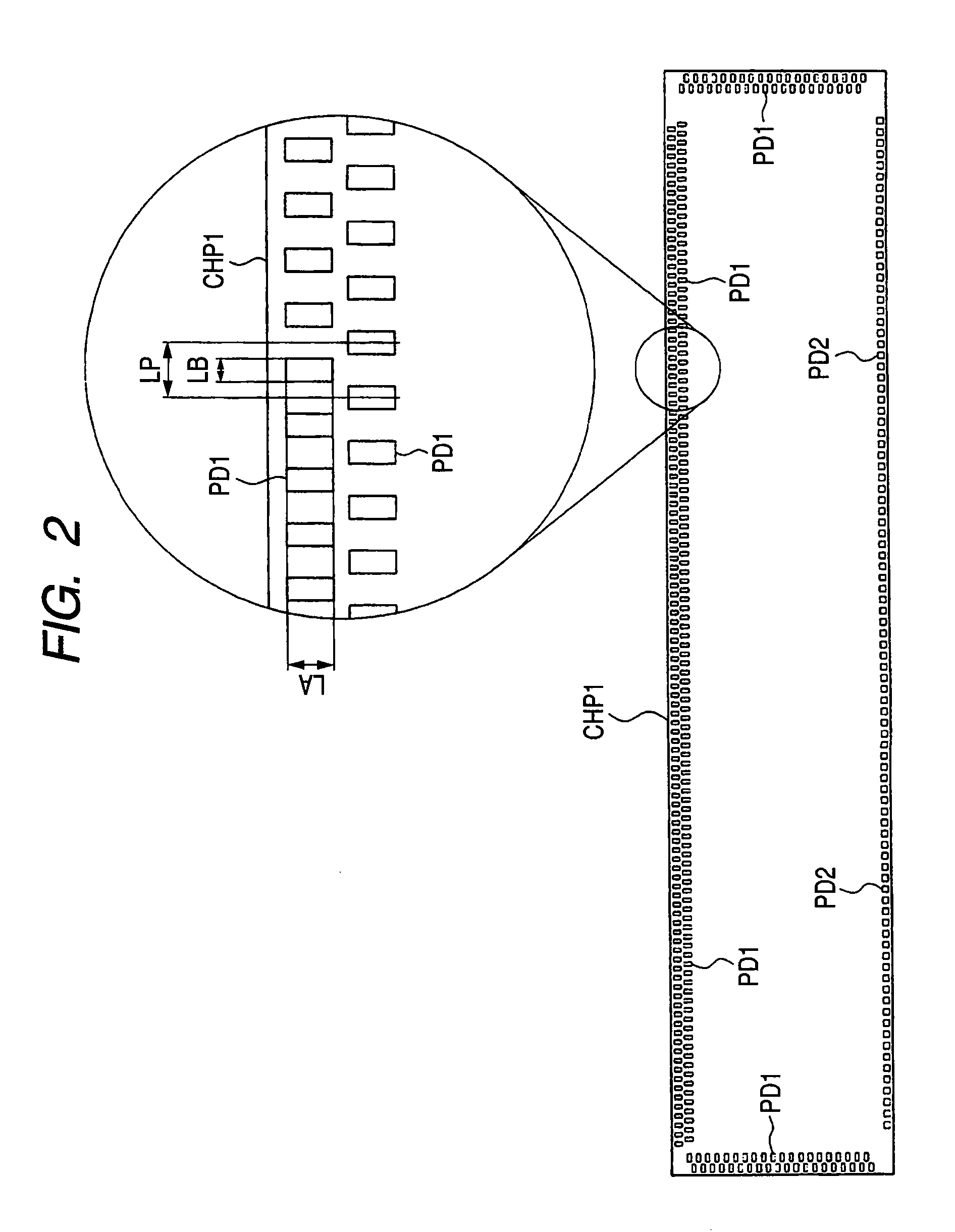

Method of manufacturing a semiconductor integrated circuit device

InactiveUS20080199980A1Improve manufacturing yieldAvoid breakingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsWaferingManufacturing technology

An object is to prevent a breakage of a membrane probe and a wafer to be tested in a probe testing using a membrane probe with styluses formed by a manufacturing technology for a semiconductor integrated circuit device.Measures are: obtaining an image of a region PCA within the surface of a wafer including a region OGA pressed by a pressing member, at the center of which a chip just after probe-tested is located, by an imaging means such as a camera; comparing an image of a normal chip obtained in advance and an image of all the chips within the region PCA; and judging thereby whether an abnormal shape is caused or not in all the chips within the region PCA.

Owner:RENESAS ELECTRONICS CORP

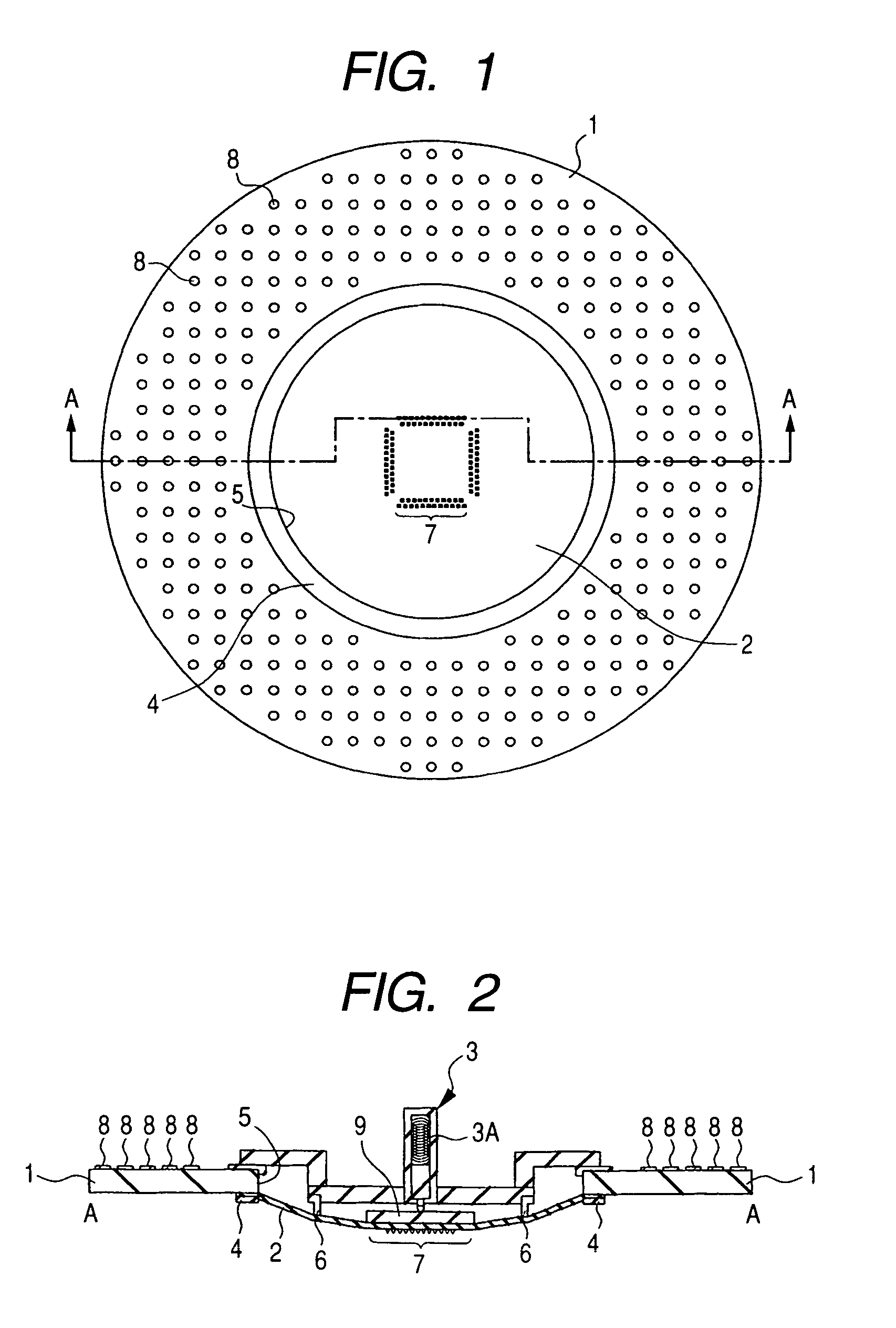

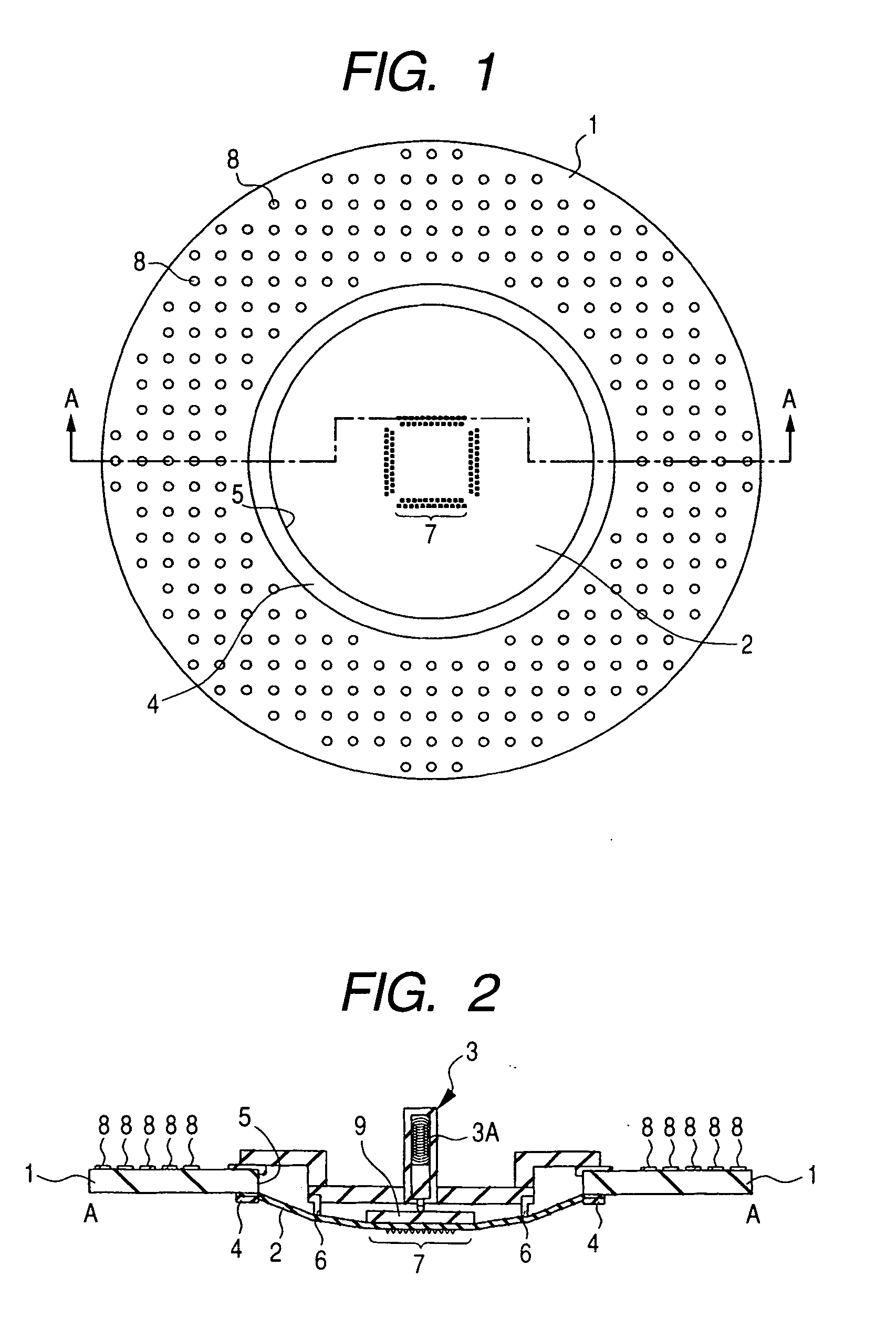

Probe apparatus and detection apparatus

InactiveCN101294984AElectronic circuit testingElectrical measurement instrument detailsElastomerBiomedical engineering

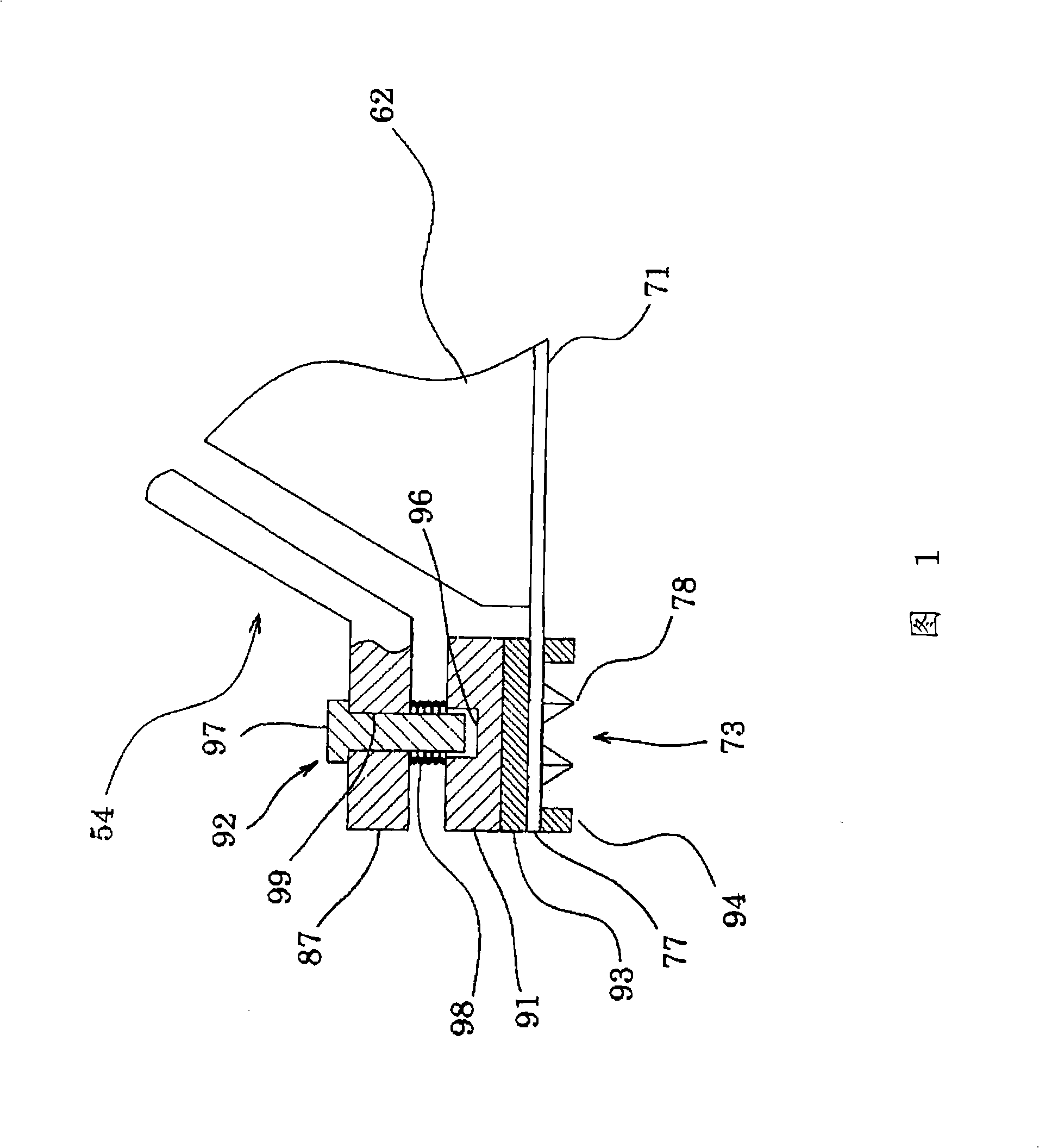

The invention provides a probe device and a detection device, to ensure each contact terminal of a membrane probe in contact with the electrode of the detected body accurately. The probe device includes: a probe base fixed at the body frame side, a probe block which bears the membrane probe and ensures the membrane probe in electrical contact with the electrode of the detected body, and a pressurizing mechanism which pressurizes the membrane probe by uniform pressure under the state that each contact terminal of the membrane probe is in contact with the electrode of the detected body. The pressurizing mechanism includes a top pressurizing part, which contacts with the membrane probe directly, and pressurizes the membrane probe under the state that each contact terminal of the membrane probe is in contact with the electrode of the detected body; the top pressurizing part is composed of a pressurizing plate for pressurizing the membrane probe, an elastic body which becomes uniform by using the pressure exerted by the pressurizing plate, and a bearing membrane which is arranged at one side of the contact terminal of the membrane probe and combines with the elastic body mutually to ensure that the pressure exerted on each contact terminal becomes uniform.

Owner:NIHON MICRONICS

Impedance optimized interface for membrane probe application

ActiveUS20100085069A1Electrical measurement instrument detailsElectrical testingCoaxial cableCoplanar waveguide

In a membrane probing apparatus, the impedance of the interface between coaxial cables connected to the test instrumentation and the membrane supported co-planar waveguide that conductively connects to the probe's contacts is optimized by eliminating a ground plane in the interface board.

Owner:FORMFACTOR INC

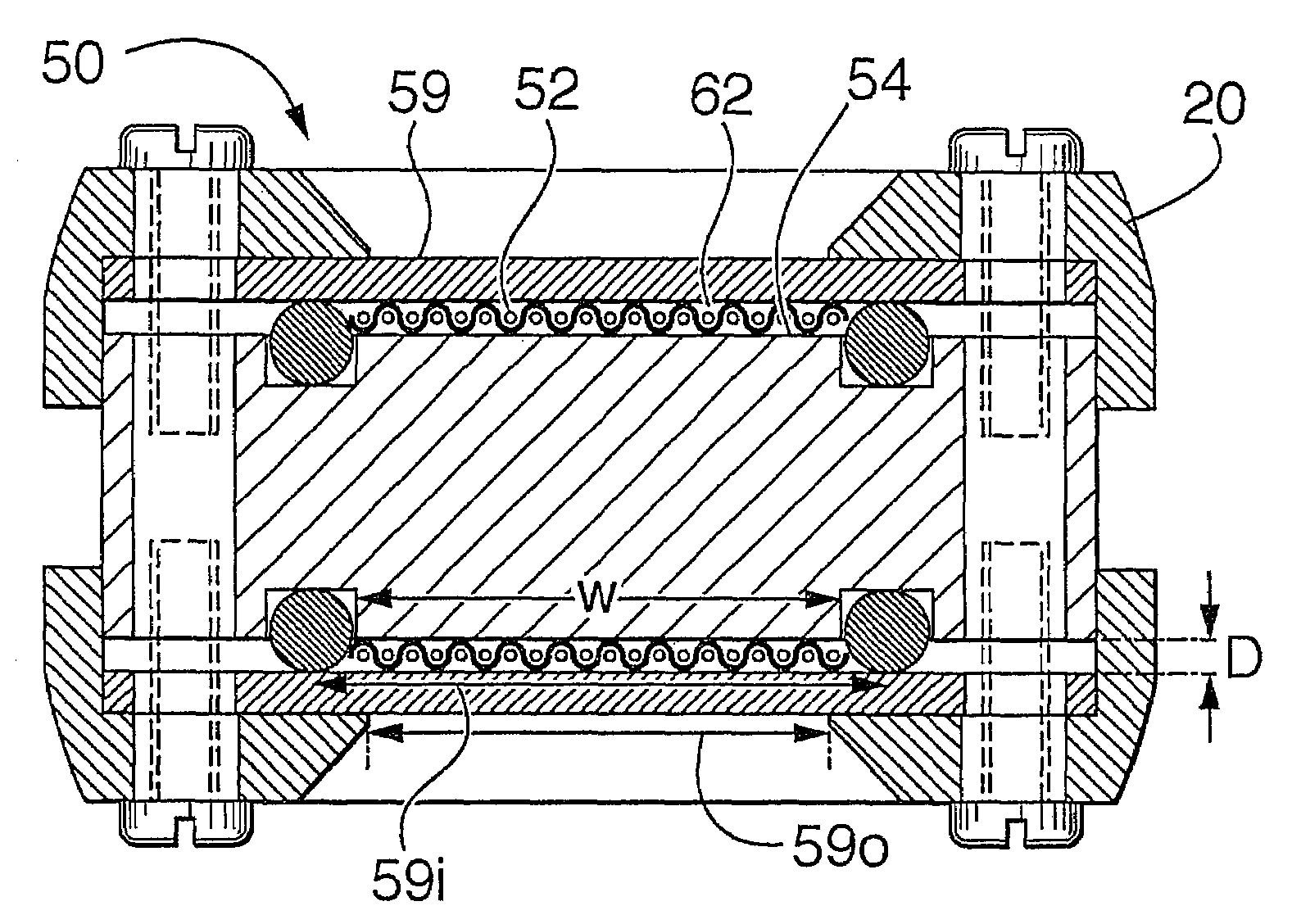

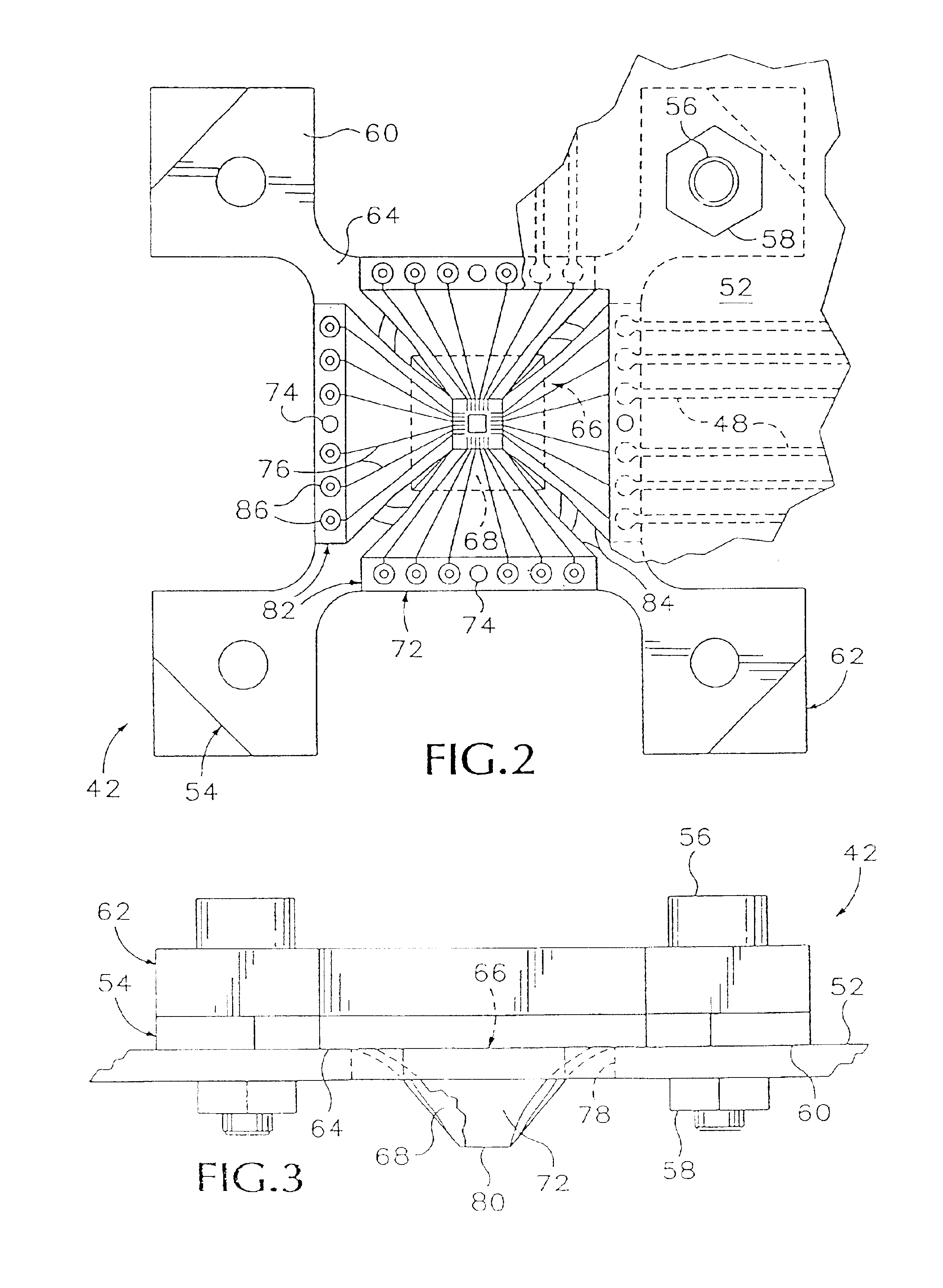

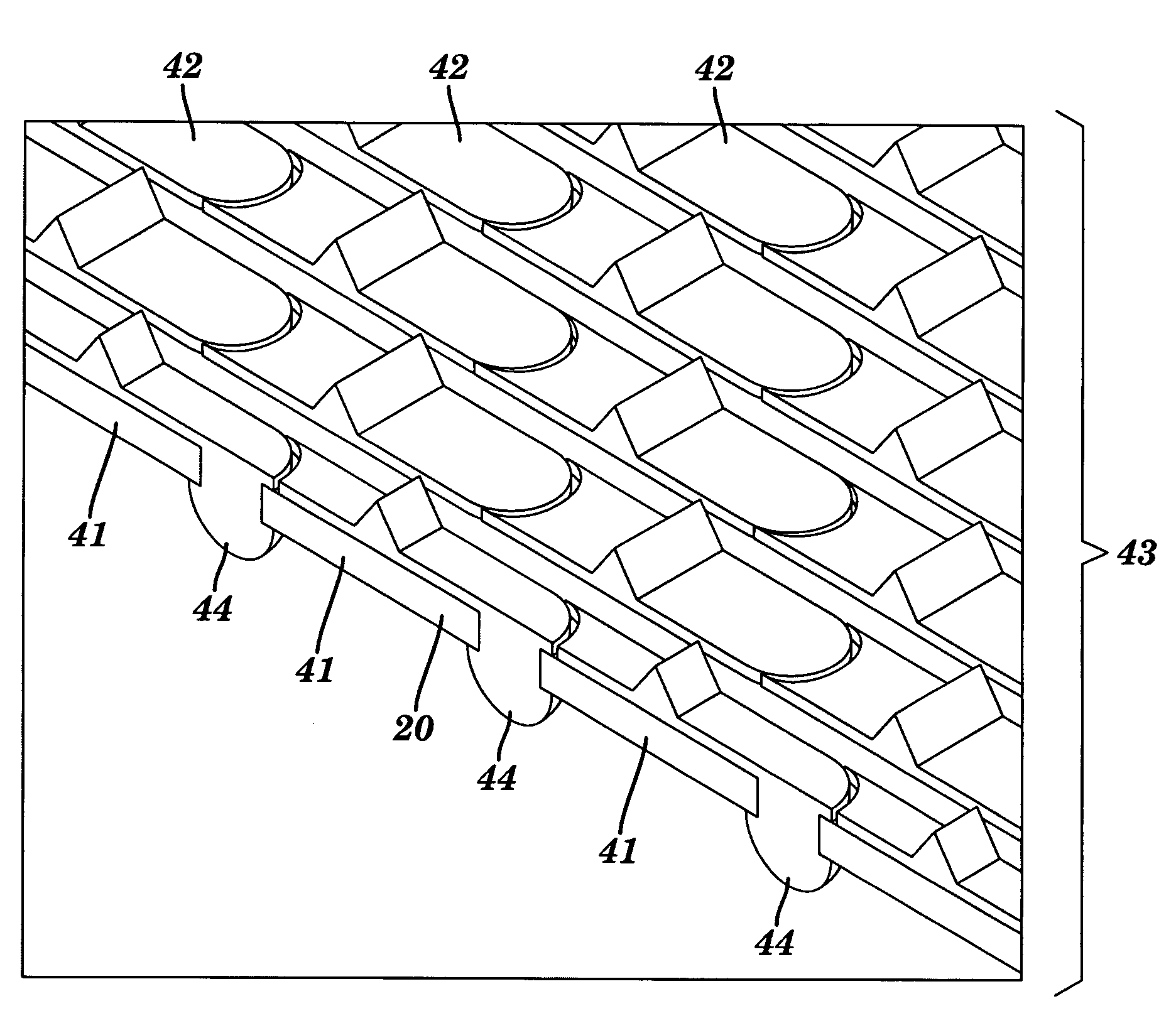

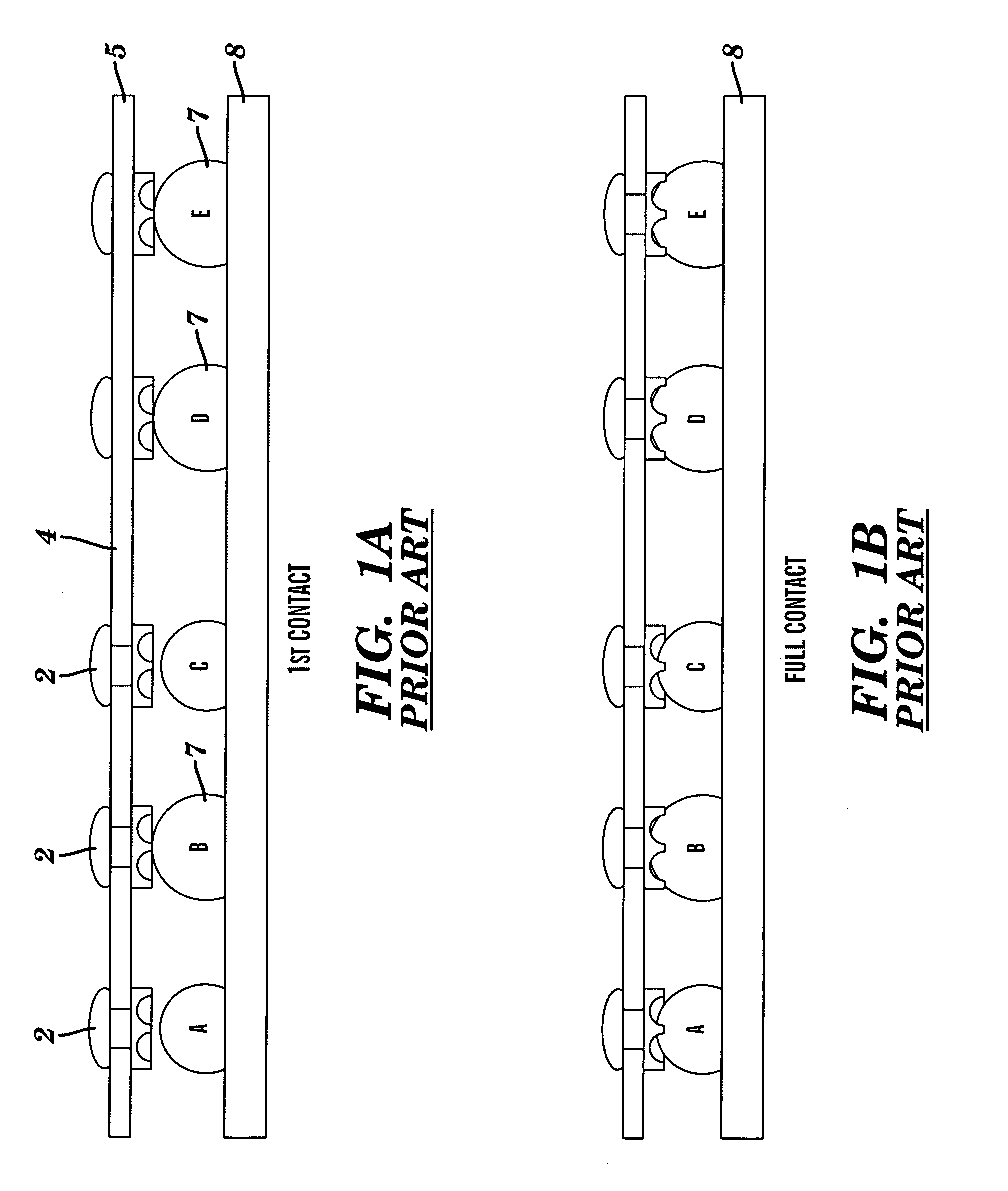

Membrane probing system with local contact scrub

InactiveUS6927585B2Avoid mechanical strainIneffective electrical performanceSemiconductor/solid-state device testing/measurementElectronic circuit testingMechanical engineeringMembrane probe

A membrane probing assembly includes a support element having an incompressible forward support tiltably coupled to a rearward base and a membrane assembly, formed of polyimide layers, with its central region interconnected to the support by an elastomeric layer. Flexible traces form data / signal lines to contacts on the central region. Each contact comprises a rigid beam and a bump located in off-centered location on the beam, which bump includes a contacting portion. After initial touchdown of these contacting portions, further over-travel of the pads causes each beam to independently tilt locally so that different portions of each beam move different distances relative to the support thus driving each contact into lateral scrubbing movement across the pad thereby clearing away oxide buildup. The elastomeric member backed by the incompressible support ensures sufficient scrub pressure and reliable tilt recovery of each contact without mechanical straining of the beam. In an alternative embodiment, the contacts comprise conductive beams each supported on a loose U-shaped flap formed in the membrane assembly where each flap and beam is tiltably supported in inclined position by an elastomeric hub interposed between the flap and support.

Owner:CASCADE MICROTECH

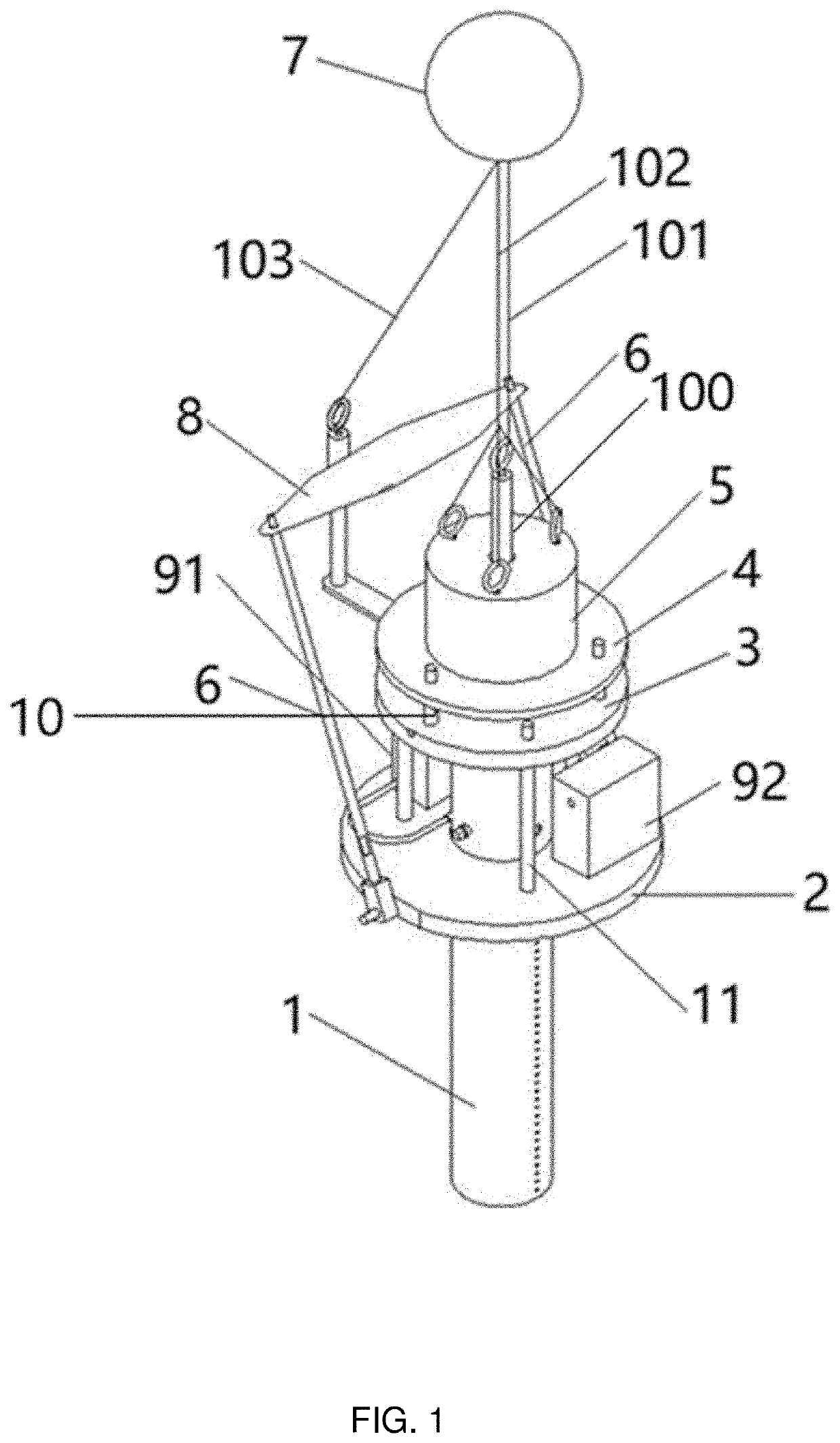

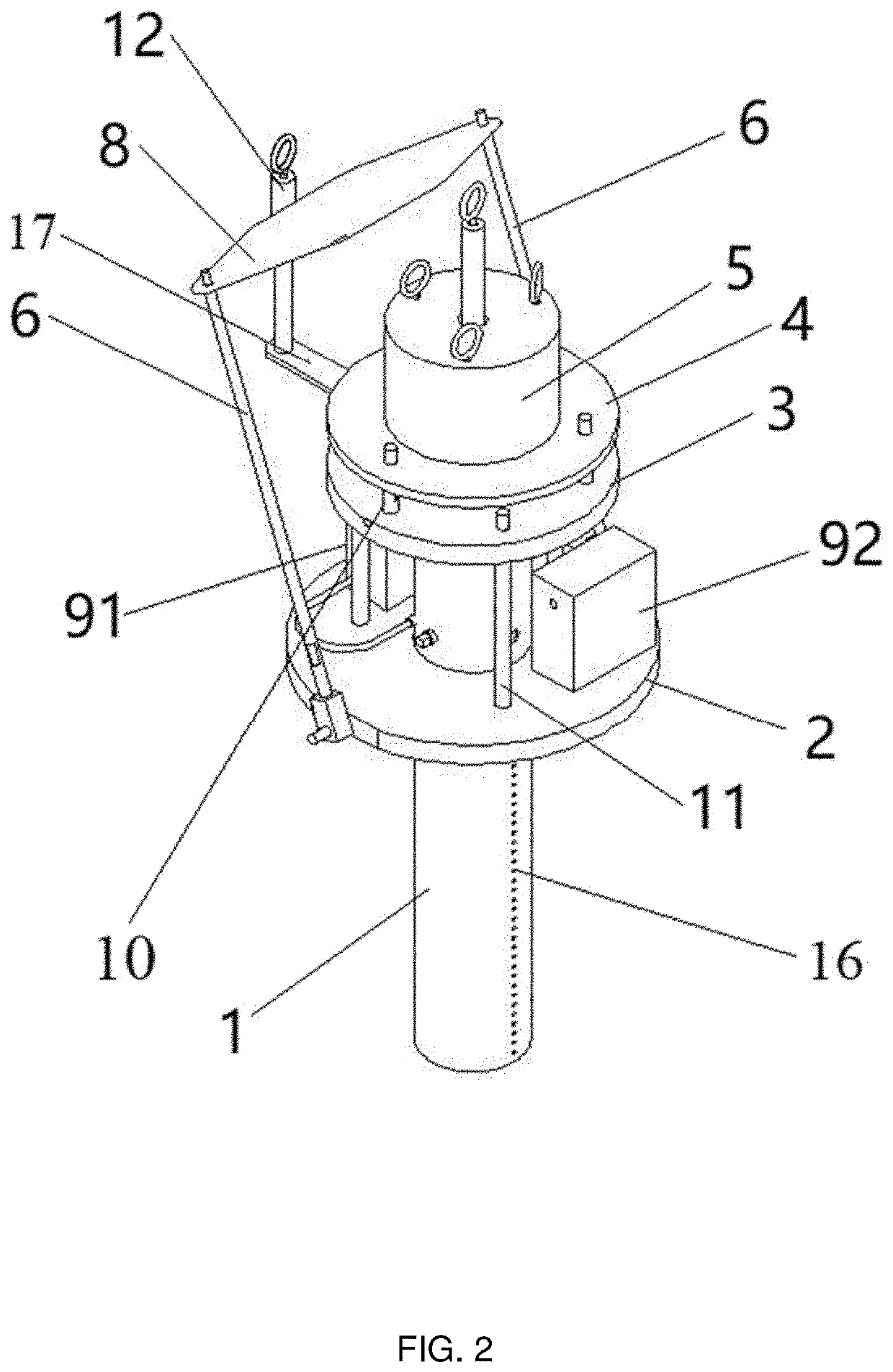

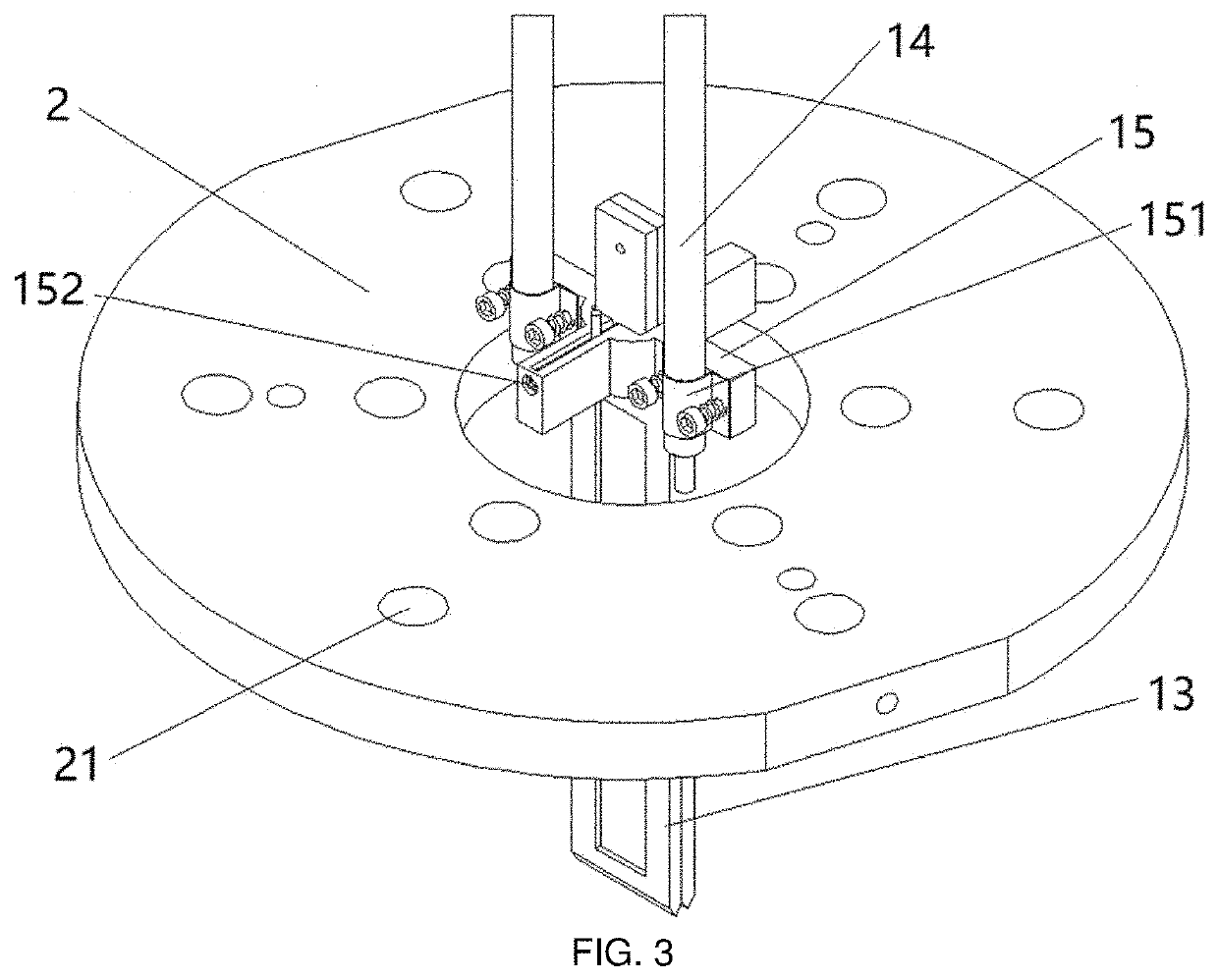

Diffusive gradients in thin films (DGT) probe test device for sediment core in lake and test method using the same

ActiveUS20210208031A1Facilitate subsequent collectionEasy to analyzeWithdrawing sample devicesMaterial electrochemical variablesThin membraneWater quality

The present disclosure provides a diffusive gradients in thin films (DGT) probe test device for a sediment core in a lake, including: a sampling tube, where, a settlement limit device is disposed on an outer wall of the sampling tube and a DGT probe and a multi-parameter water-quality detection electrode are installed within the sampling tube; a movable mudguard device comprising a connecting rod and a mudguard, where, the connecting rod rotates around a rotating shaft to drive the mudguard to move from a position where an opening at the lower end of the sampling tube is sealed to a side of the sampling tube; a position-limit mechanism removably installed outside the sampling tube; a hammering device located above the sampling tube and fixedly connected to the sampling tube; and a floating ball located above the hammering device and connected to the hammering device via a first pull rope.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

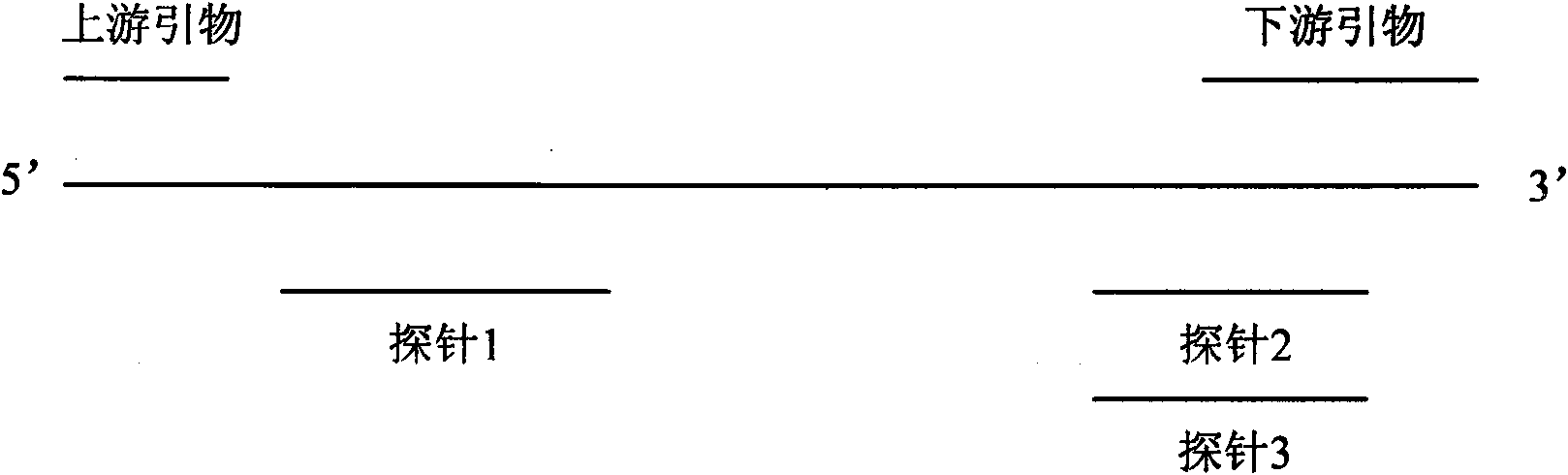

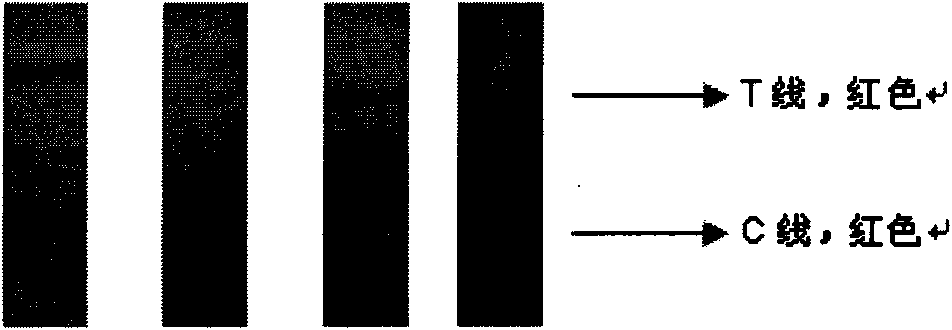

Nucleic acid nano-gold biosensor for detecting influenza A viruses and influenza A (H1N1) viruses

InactiveCN101942387AEasy to manufactureQuick checkBioreactor/fermenter combinationsBiological substance pretreatmentsNucleotideOligonucleotide

The invention relates to a nucleic acid nano-gold biosensor for detecting influenza A viruses and influenza A (H1N1) viruses. The nucleic acid nano-gold biosensor comprises a sample pad, glass fiber, a nitrocellulose membrane and absorbent paper fixed on a rubber plate in turn from left to right; the glass fiber is coated with nano-gold marked oligonucleotide probes which have a nucleotide sequence shown by SEQ ID No.2 or 7; two kinds of oligonucleotide probes are immobilized on the nitrocellulose membrane; the nitrocellulose membrane probes immobilized close to one end of the absorbent paper form a quality control line and have a nucleotide sequence shown by SEQ ID No.3 or 8; and the nitrocellulose membrane probes immobilized close to one end of the glass fiber form a detection line and have a nucleotide sequence shown by SEQ ID No.1 or 6. The nucleic acid nano-gold biosensor has the advantages of simple manufacturing and fast detection without needing professional technicians and expensive instrument and equipment.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI

Contact tip structure for microelectronic interconnection elements and methods of making same

InactiveUS20080116927A1Simple technologyEasy constructionElectrical measurement instrument detailsSolid-state devicesProbe cardInterconnection

Owner:FORMFACTOR INC

Compliant membrane probe

InactiveUS20090189620A1High densityLine/current collector detailsElectric discharge heatingHigh densityMembrane configuration

A probe test head for a high density pin count integrated circuit, includes: a flexible membrane; an array of conductive structures, each one of the structures including a mechanically compliant probe tip affixed to the membrane, such that an attachment point enables mechanical actuation of the probe tip through a conductive member parallel to the membrane. A method for fabrication and measurement apparatus are provided.

Owner:IBM CORP

Fabrication Method of Semiconductor Integrated Circuit Device

InactiveUS20070231936A1Reduce manufacturing costIncrease the number ofSemiconductor/solid-state device testing/measurementElectronic circuit testingForeign matterProbe card

To prevent breakage of a membrane probe during a probe test using a probe card having the membrane probe, appearance of a main surface of a wafer as a test object is tested by an appearance tester 51, and results of bad appearance such as adhesion of a foreign substance to the main surface of the wafer and abnormality in shape of bump electrodes over the main surface of the wafer are collected as wafer map data according to arrangement of respective chips in a plane of the wafer, then the wafer map data are transmitted to a probe tester 53 via a server 52, and the probe tester 53 omits the probe test for chips in which bad appearance was detected, and concurrently performs the probe test to other chips in which bad appearance was not detected, based on the wafer map data.

Owner:RENESAS ELECTRONICS CORP

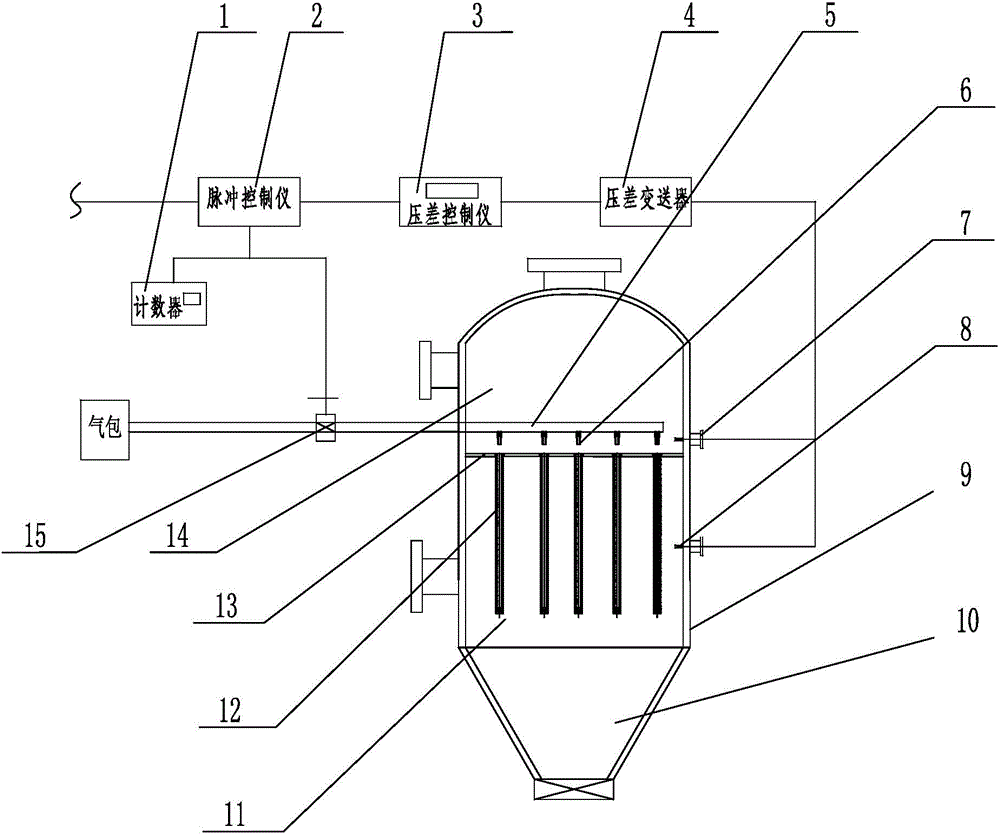

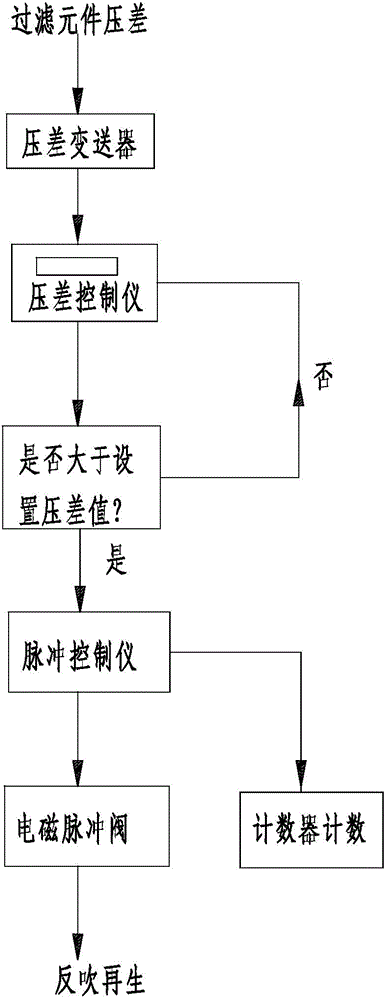

Backblowing regenerative soot cleaning time counting device and method for dust remover filter element

ActiveCN104156763ASimple structureRealize automatic countingDispersed particle filtrationCounting mechanisms/objectsElectromagnetic pulsePressure difference

The invention relates to an auxiliary test device for a dust remover filter element, in particular to a backblowing regenerative soot cleaning time counting device and method for the dust remover filter element, and belongs to the field of backblowing dust removing electric control counting of a dust remover. The backblowing regenerative soot cleaning time counting device comprises a filter; the filter comprises a clean gas chamber and a dusty gas chamber which are connected with two pressure-sensitive membrane probes of a pressure difference transmitter respectively; the pressure difference transmitter is connected with a pressure difference control instrument; the pressure difference control instrument is connected with an impulse control instrument; the impulse control instrument is connected with a counter and an electromagnetic pulse valve; the electromagnetic pulse valve is mounted on a backblowing pipeline of the filter. The device and method are reasonable in design, and accurate and full-automatic in backblowing time counting; through the adoption of the backblowing regenerative soot cleaning time counting device, the impact of backblowing times on the filter element and other parts of equipment can be observed effectively, so that the application and popularization values are very high.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

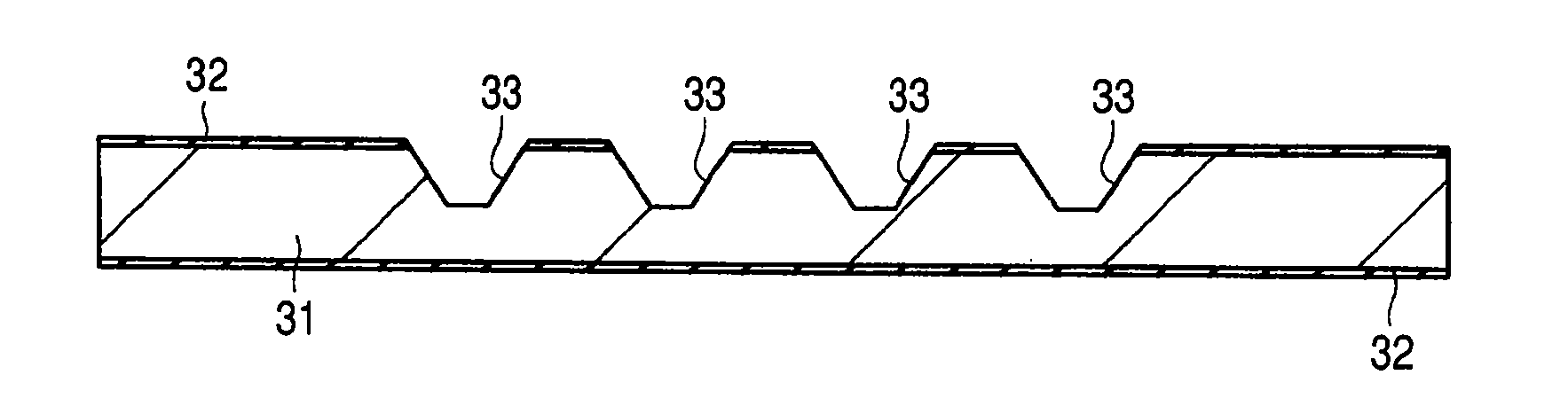

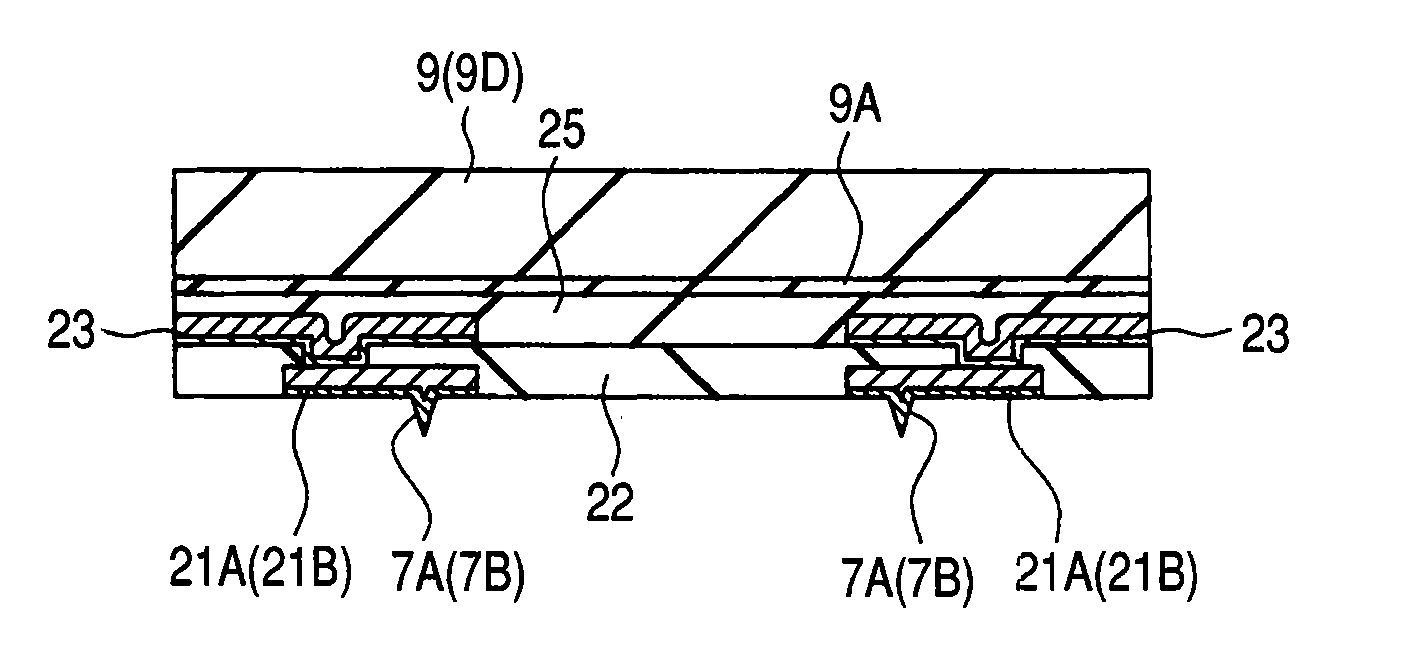

Method of manufacturing a semiconductor integrated circuit device

ActiveUS20080096295A1Reduce the possibilityIncrease productionSemiconductor/solid-state device testing/measurementSolid-state devicesForeign matterManufacturing technology

A technique of manufacturing a semiconductor integrated circuit device is provided for reducing the possibility of attachment of foreign matter to a membrane probe when performing probe inspection using the membrane probe formed by the manufacturing technique. A pressing member for pressing a membrane sheet includes a pressing pin receiving portion relatively disposed above for receiving the tip of a pressing pin of the plunger in a recess, and a membrane sheet pressing portion relatively disposed below. The membrane sheet pressing portion in contact with the membrane sheet has the minimum plane size to enable pressing of the entire surface of one chip of interest to be subjected to the probe inspection.

Owner:RENESAS ELECTRONICS CORP

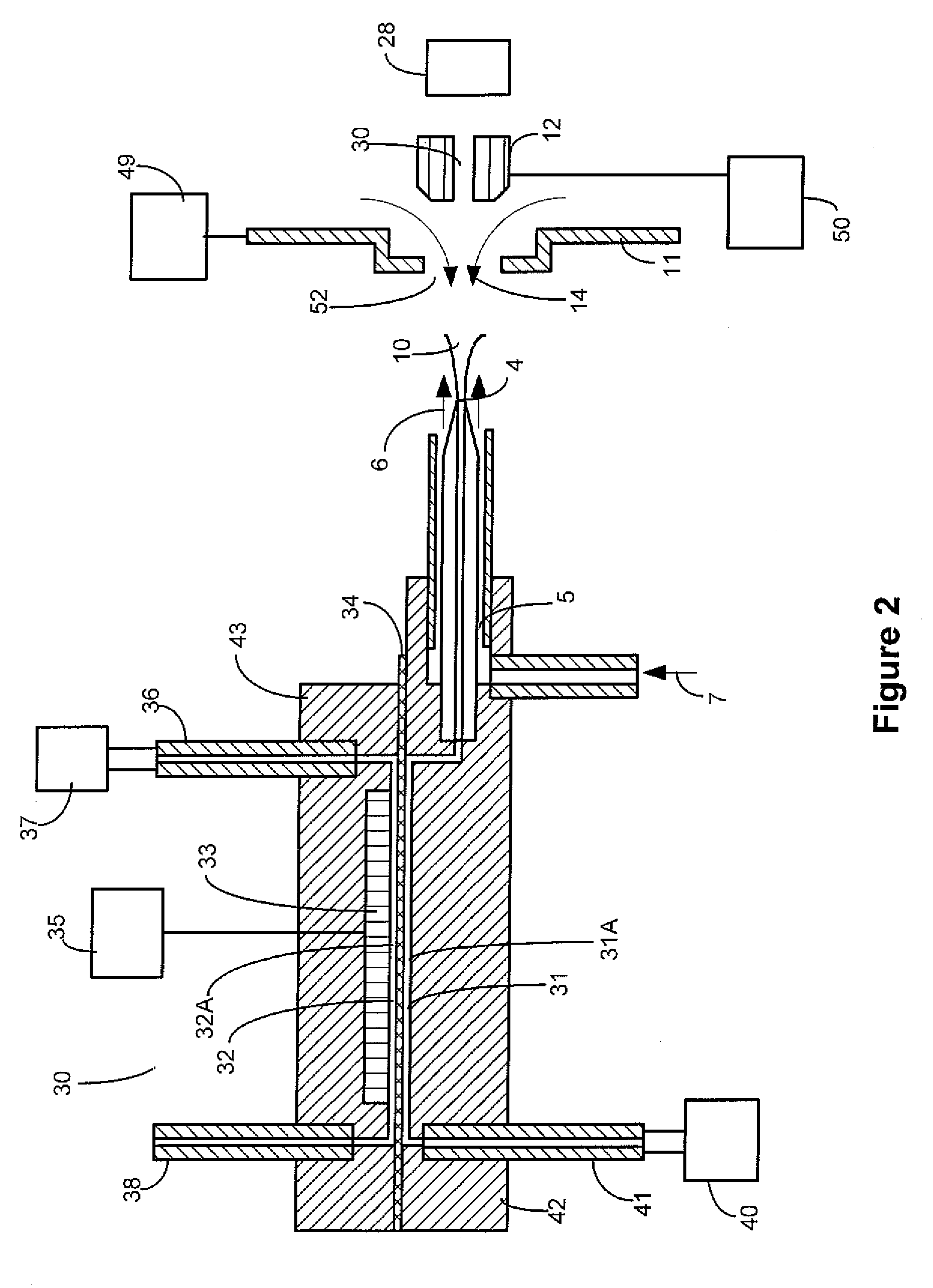

Membrane countercurrent exchanger and membrane inlet mass spectrometer for the analysis of gas partial pressure in liquid samples

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

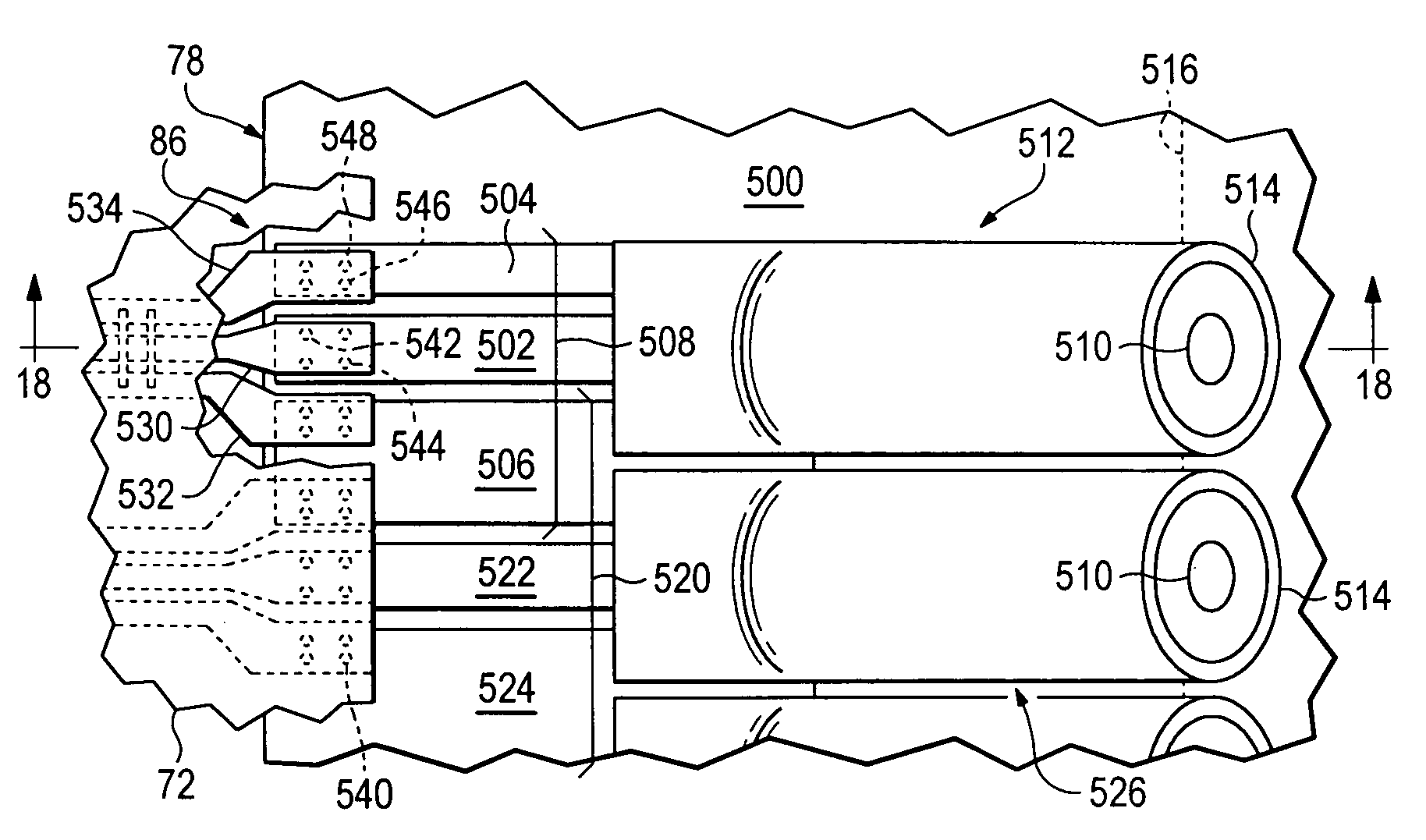

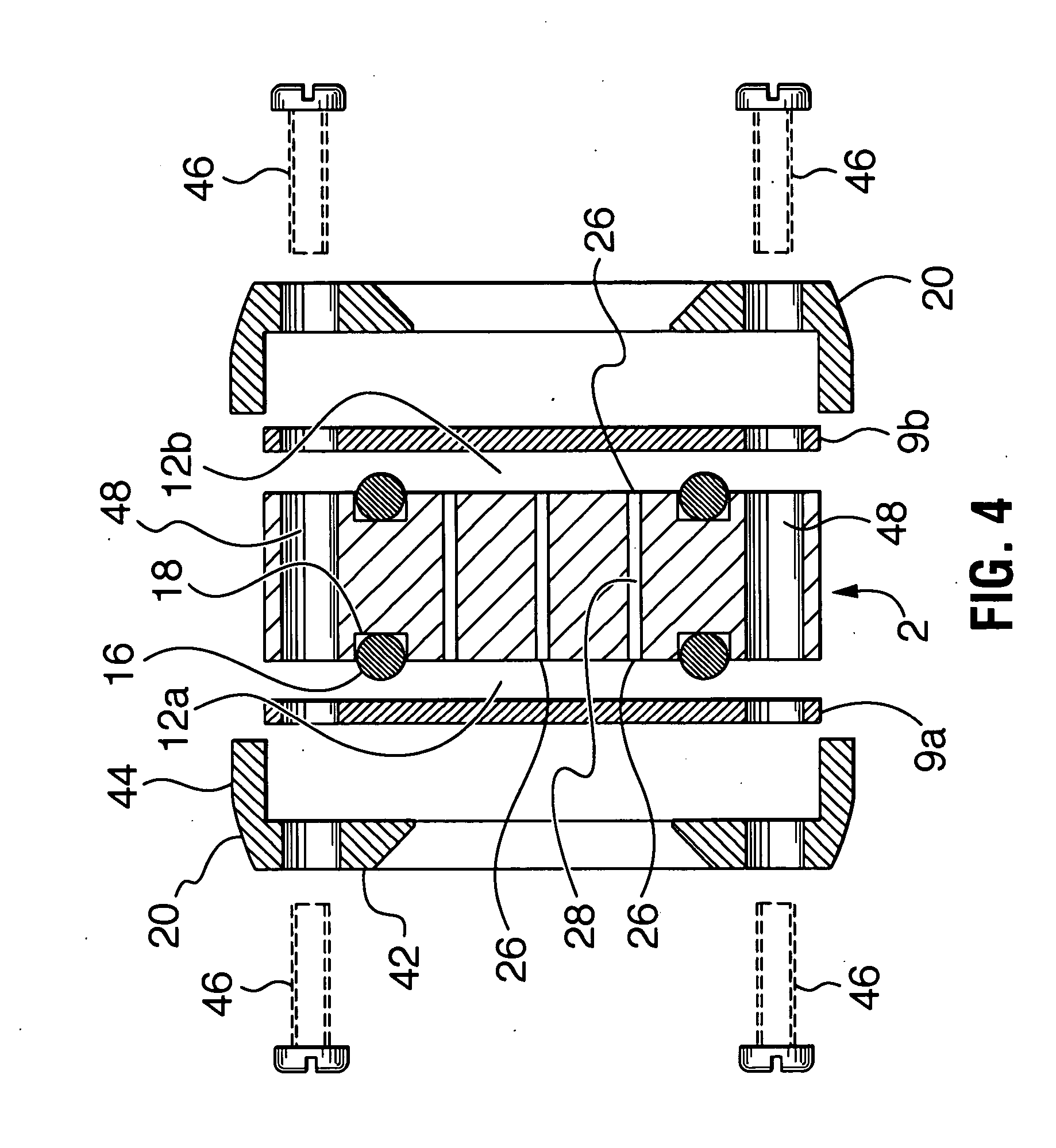

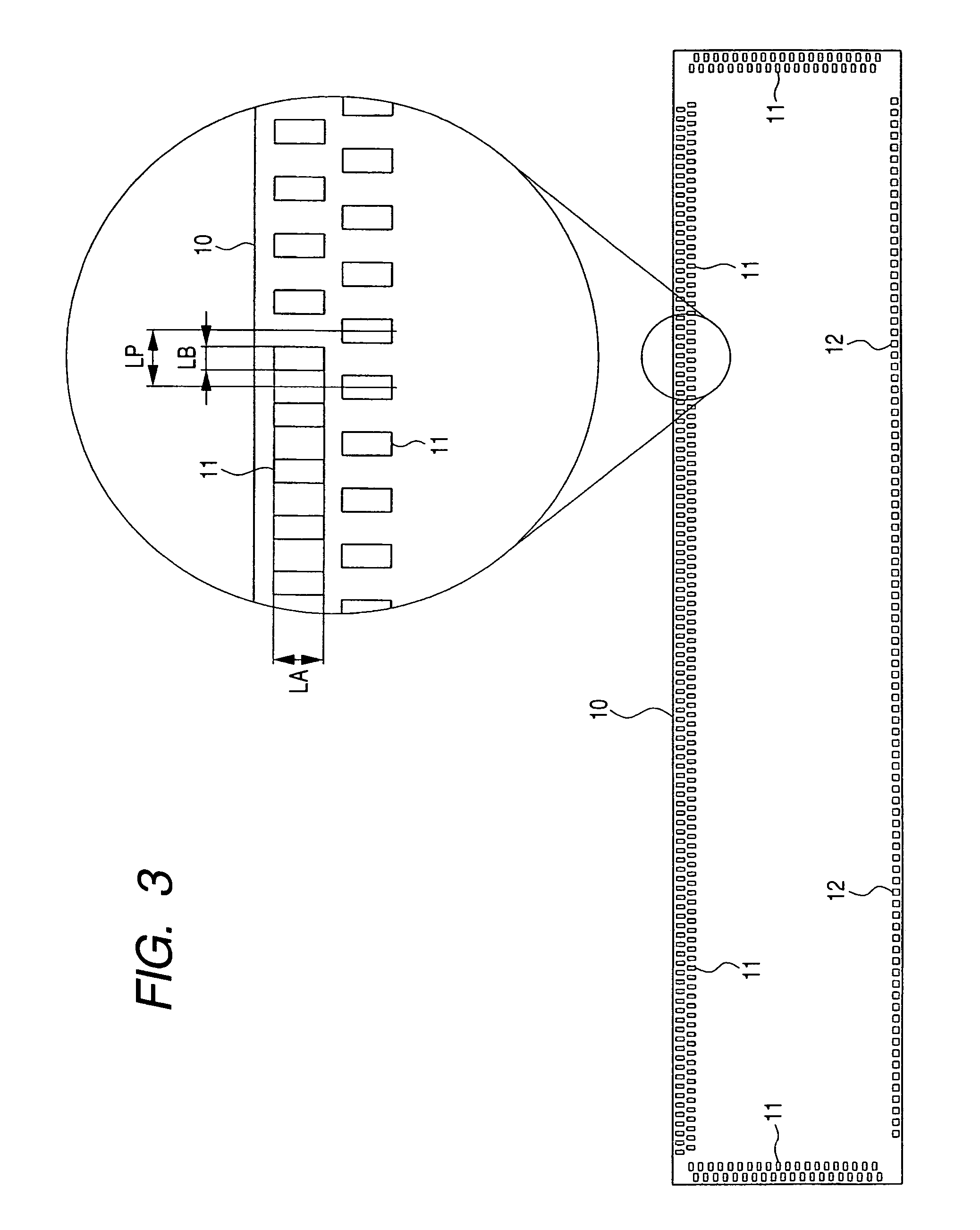

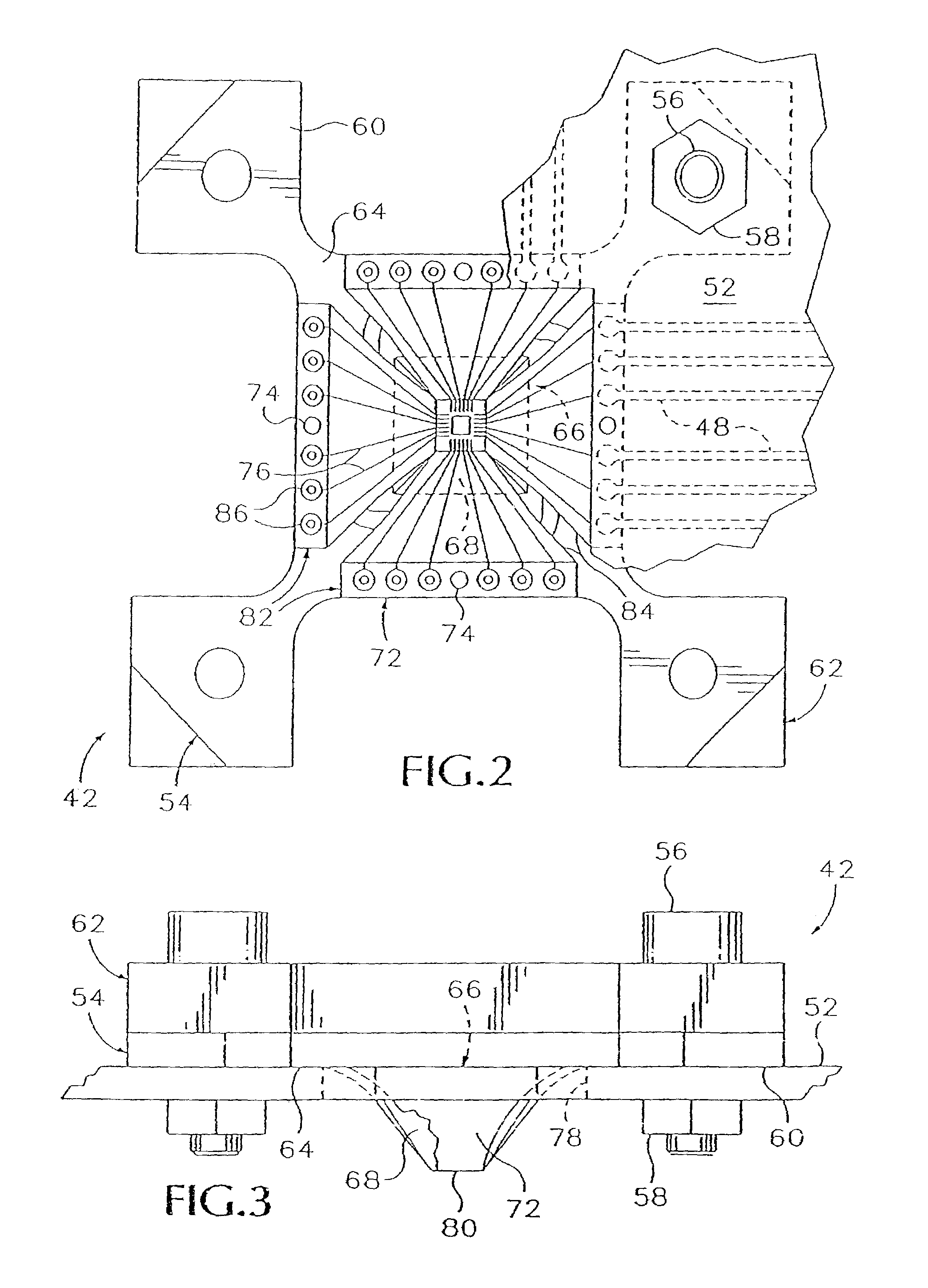

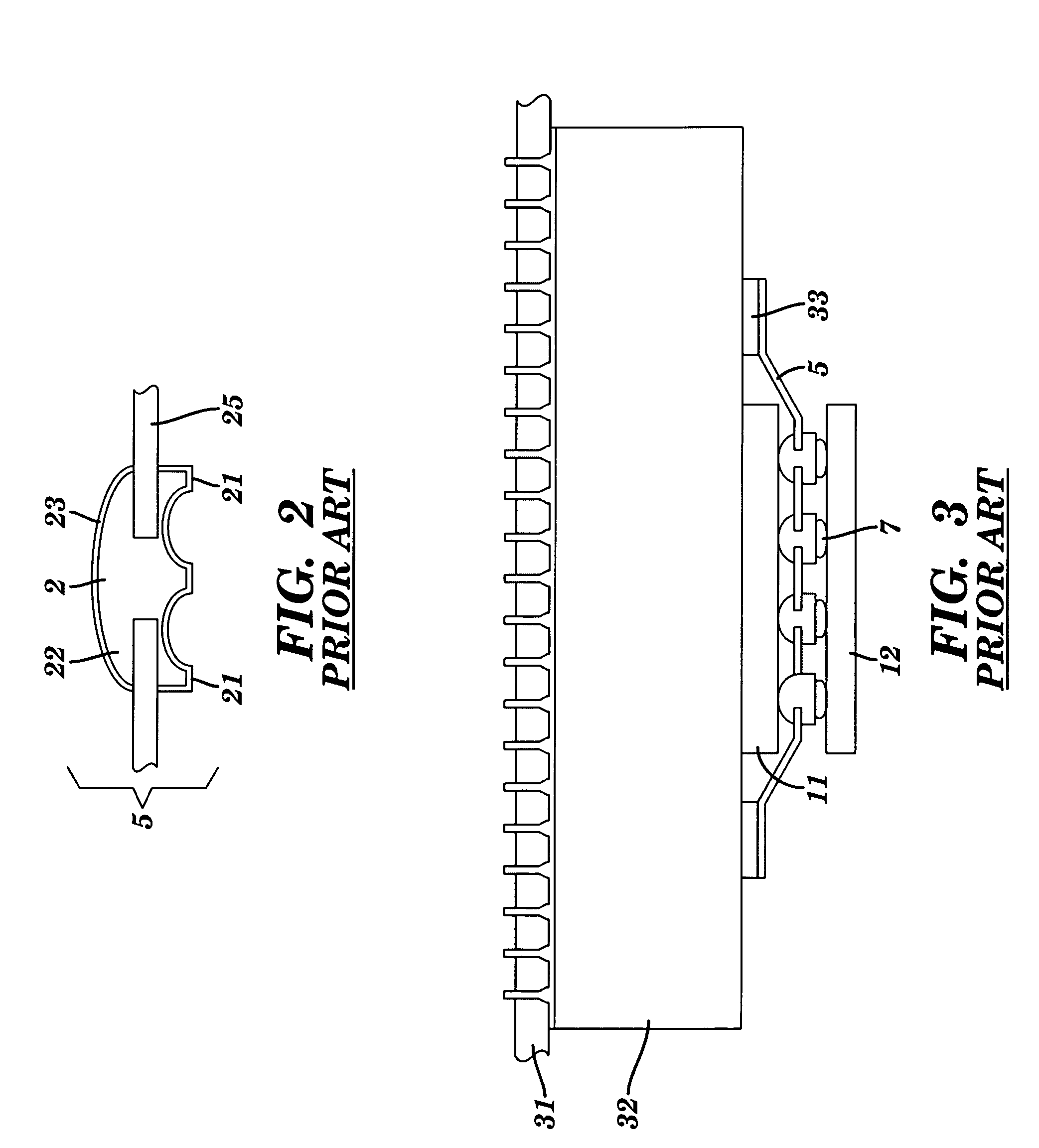

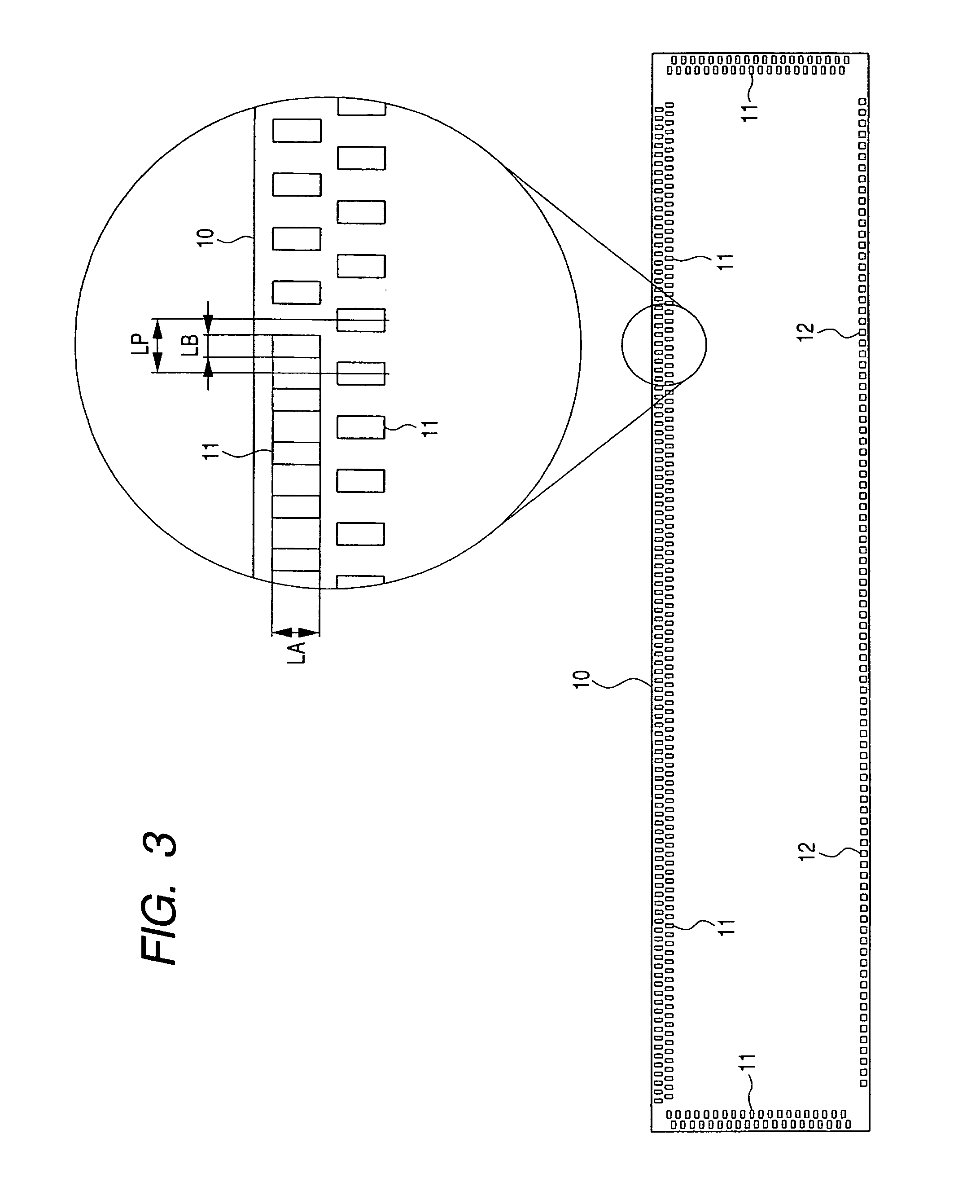

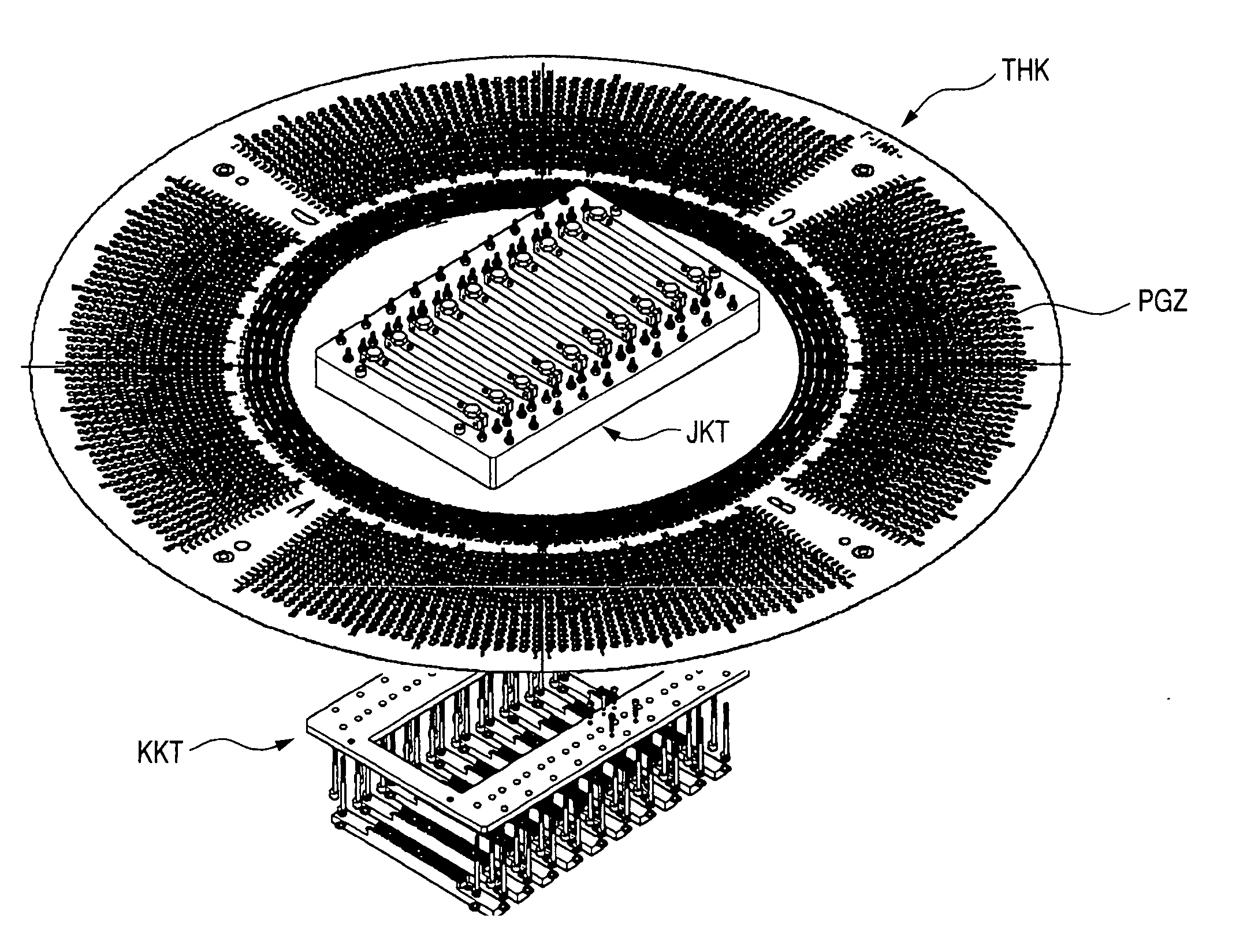

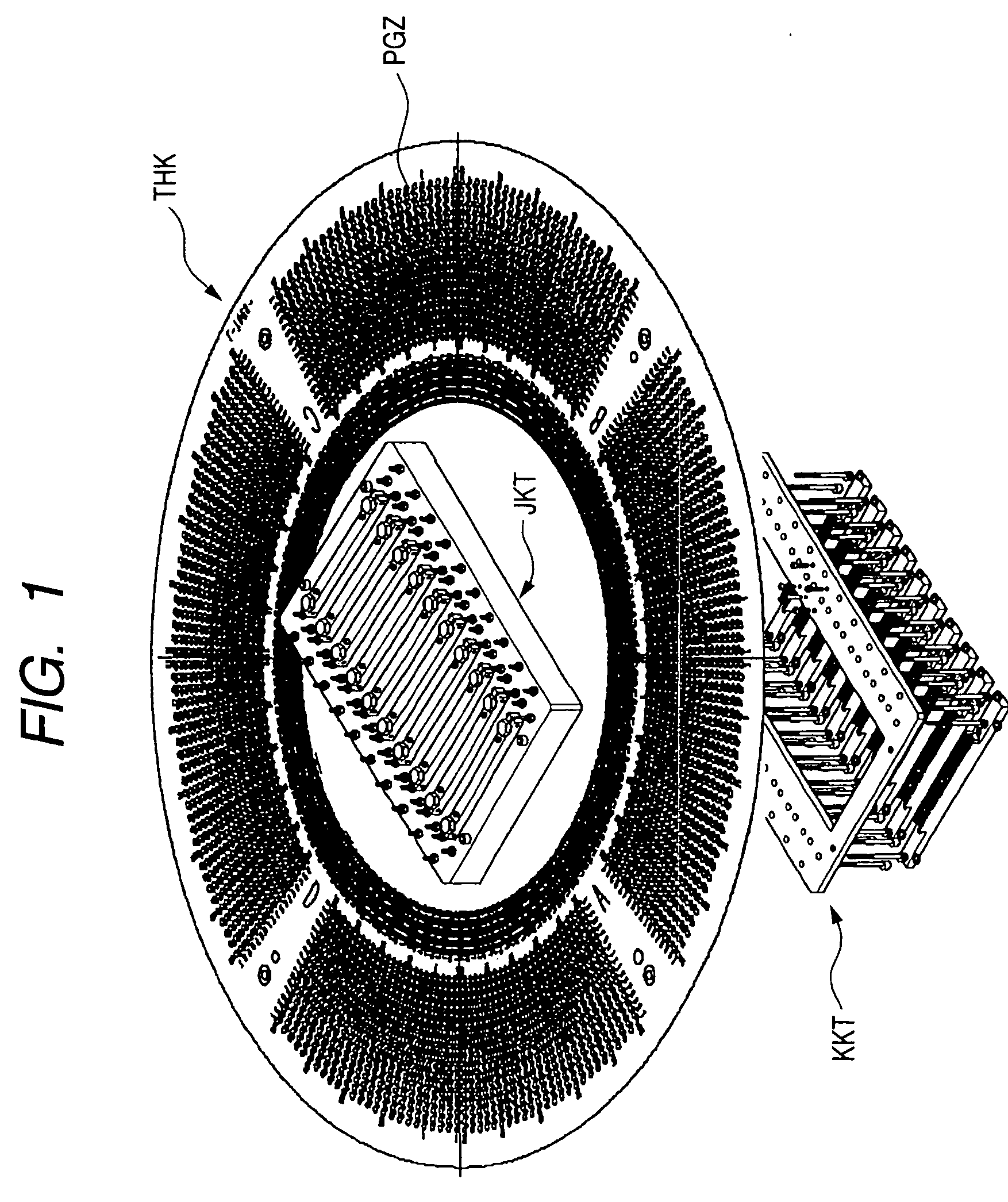

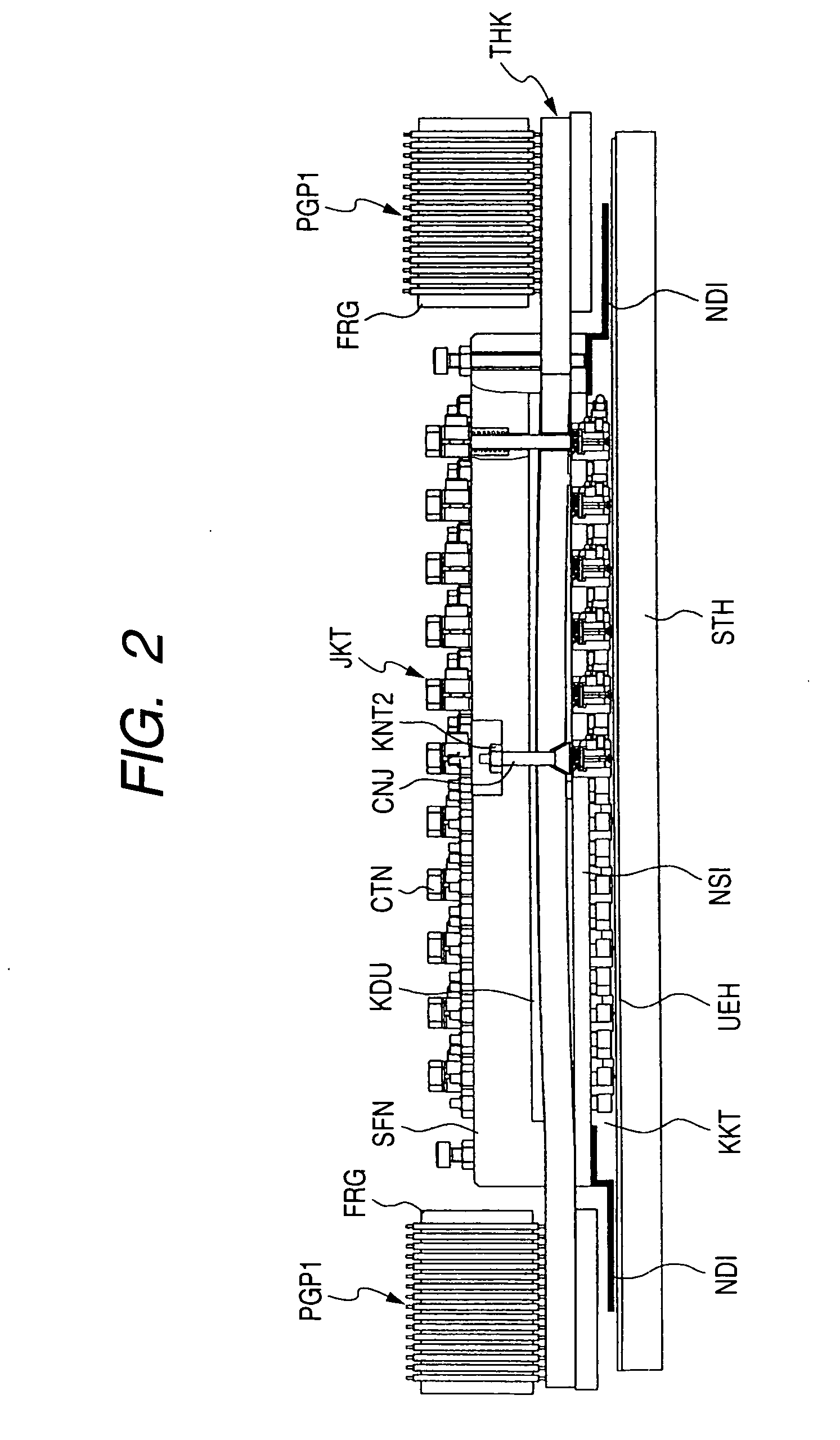

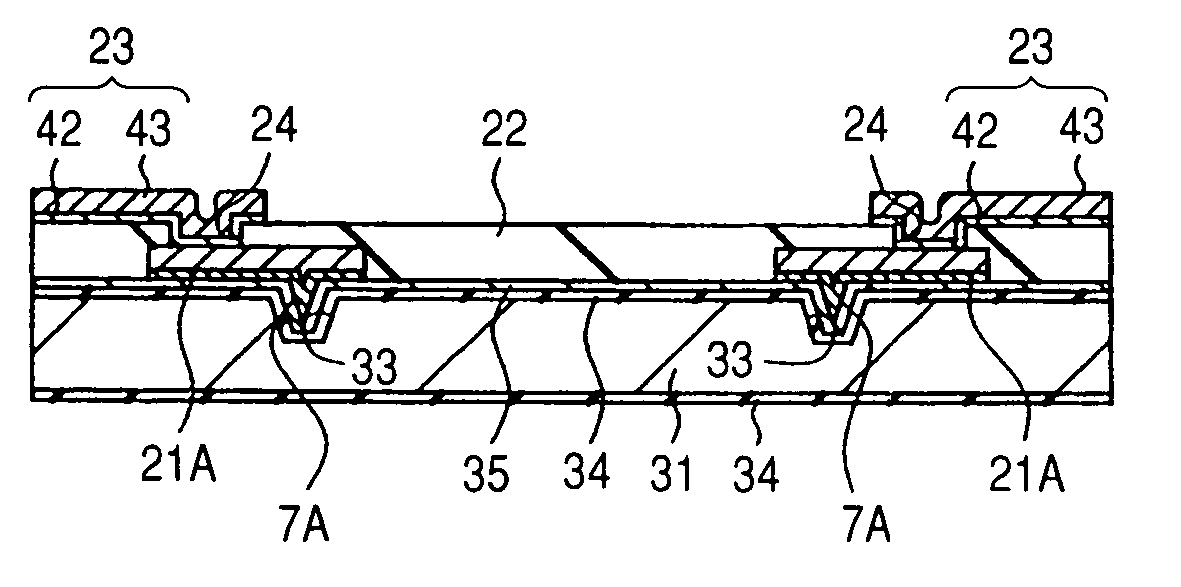

Manufacturing method of semiconductor integrated circuit device

InactiveUS20060281222A1Suppress manufacturing costReduce areaSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardEngineering

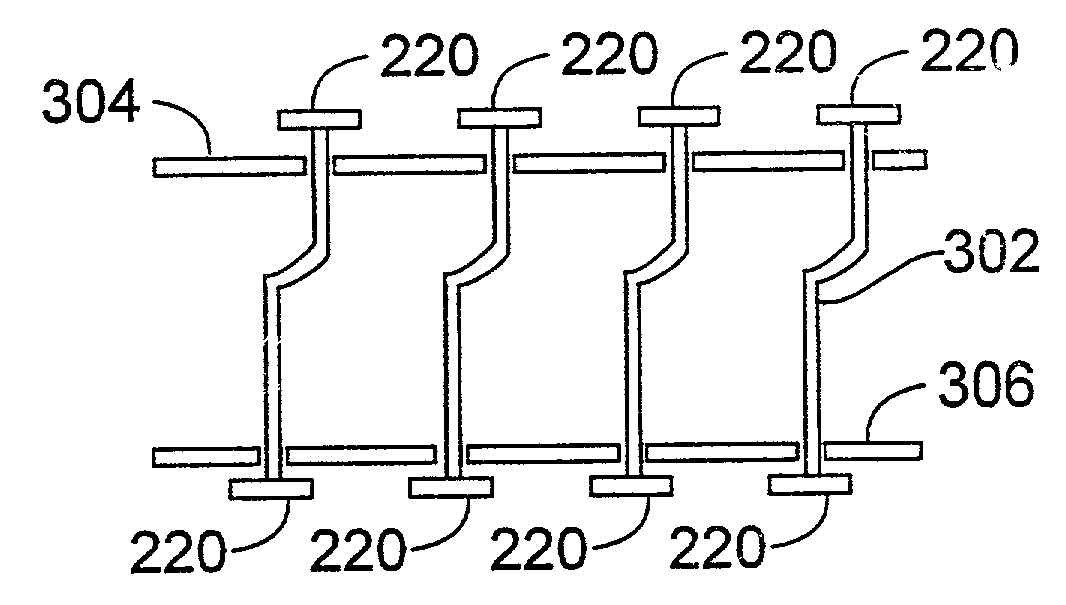

By using a membrane probe formed by using a manufacturing technique for semiconductor integrated circuit devices, the yield of probing collectively performed on a plurality of chips is to be enhanced. A probe card is formed by using a plurality of pushers, each pusher being formed of a POGO pin insulator, POGO pins, an FPC connector, a membrane probe HMS, an impact easing sheet, an impact easing plate, a chip condenser YRS and so on, wherein one or two POGO pins press a plurality of metal films arranged like islands. One or more cuts are made into what matches the chip to be tested in the area of the membrane probe in a direction substantially parallel to the extending direction of wiring electrically connected to probes formed in the membrane probe.

Owner:RENESAS ELECTRONICS CORP

Atmospheric pressure ion source performance enhancement

InactiveUS7919746B2Enhanced signalReduce signalingComponent separationSamples introduction/extractionPerformance enhancementAnalyte

The instant invention deals with species that may be required to enhance an upstream sample preparation or separation process may be less compatible with the downstream ES processes and cause reduction in MS signal. New electrolytes have been found that increase positive and negative polarity analyte ion signal measured in ESMS analysis when compared with analyte ESMS signal achieved using more conventional electrolytes. The new electrolyte species increase ES MS signal when added directly to a sample solution or when added to a second solution flow in an electrospray membrane probe, it has also been found that running the ES membrane probe with specific electrolytes in the second solution of the ES membrane probe have been found to enhance ESMS signal compared to using the same electrolytes directly in the sample solution being electrosprayed. The new electrolytes can be added to a reagent ion source configured in a combination atmospheric pressure ion source to improve ionization efficiency.

Owner:PERKINELMER HEALTH SCIENCES INC

Manufacturing method of semiconductor integrated circuit device

InactiveUS7534629B2Suppress manufacturing costReduce areaSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardManufacturing technology

By using a membrane probe formed by using a manufacturing technique for semiconductor integrated circuit devices, the yield of probing collectively performed on a plurality of chips is to be enhanced. A probe card is formed by using a plurality of pushers, each pusher being formed of a POGO pin insulator, POGO pins, an FPC connector, a membrane probe HMS, an impact easing sheet, an impact easing plate, a chip condenser YRS and so on, wherein one or two POGO pins press a plurality of metal films arranged like islands. One or more cuts are made into what matches the chip to be tested in the area of the membrane probe in a direction substantially parallel to the extending direction of wiring electrically connected to probes formed in the membrane probe.

Owner:RENESAS ELECTRONICS CORP

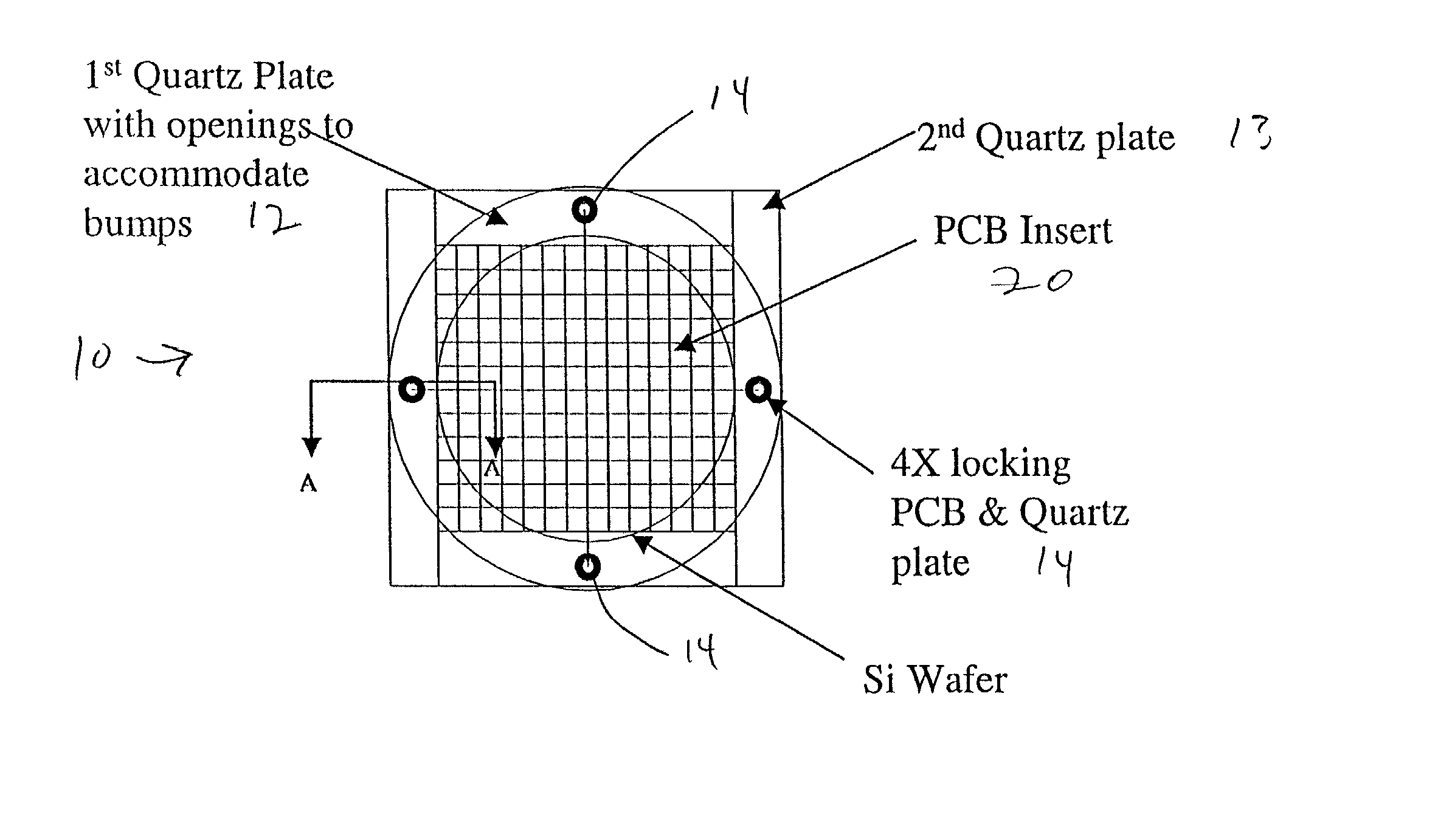

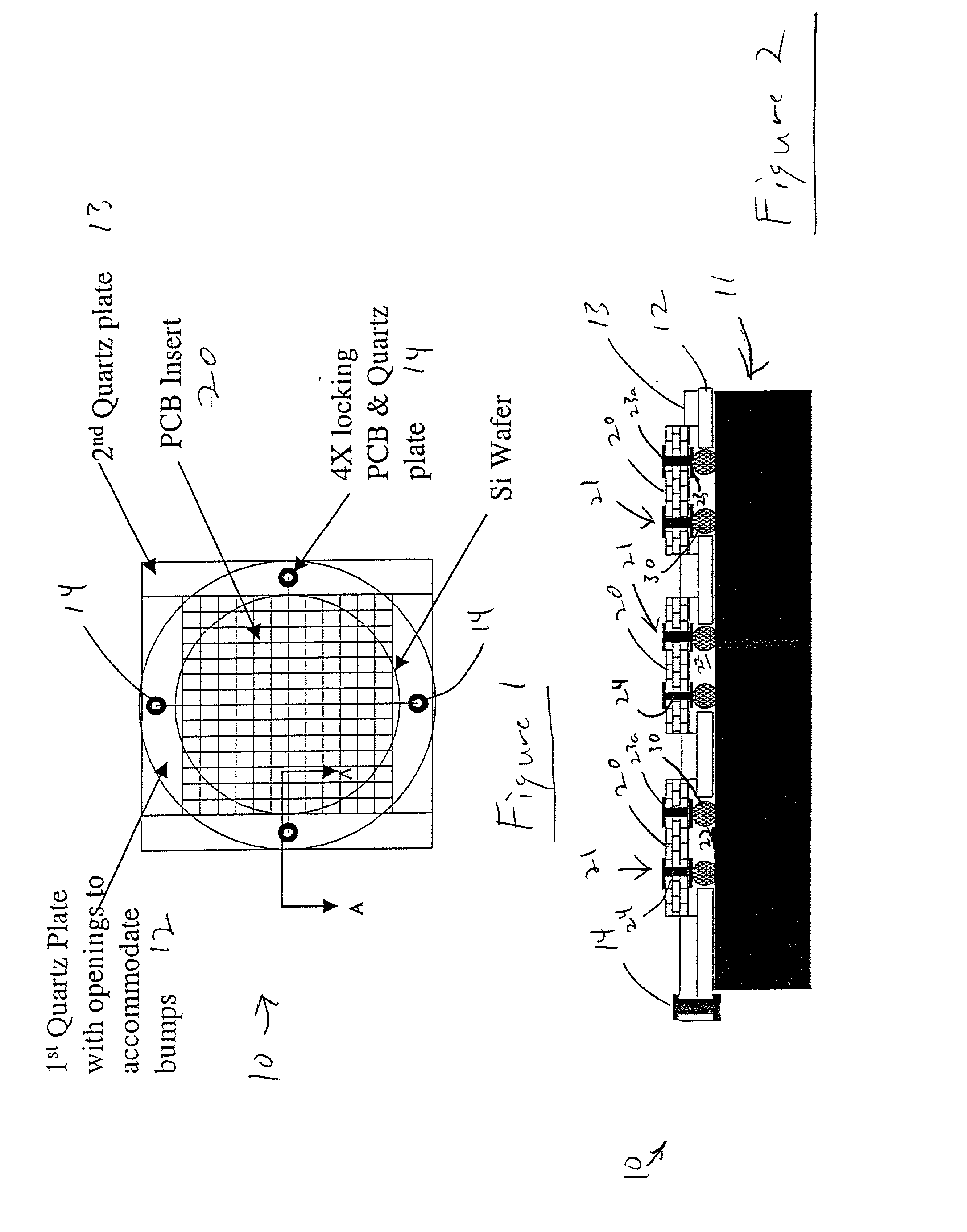

Systems and methods for testing bumped wafers

InactiveUS20020105351A1Individual semiconductor device testingContactless circuit testingPrinted circuit boardMembrane probe

A bumped wafer testing setup and associated method that eliminates the need for membrane probes. The test setup includes two plates coupled together, with the first plate including openings to accommodate solder bumps contained on the bumped wafer and the second plate including a test printed circuit board insert contained therein. The test printed circuit board insert includes solder bump contacts that contact the solder bumps within the openings.

Owner:SEMICON COMPONENTS IND LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com