Probe apparatus and detection apparatus

A technology for inspection devices and probes, which is applied in the directions of measuring devices, electronic circuit testing, instruments, etc., can solve the problems of deflection of thin-film probes 41, fewer contacts 43, and non-existence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

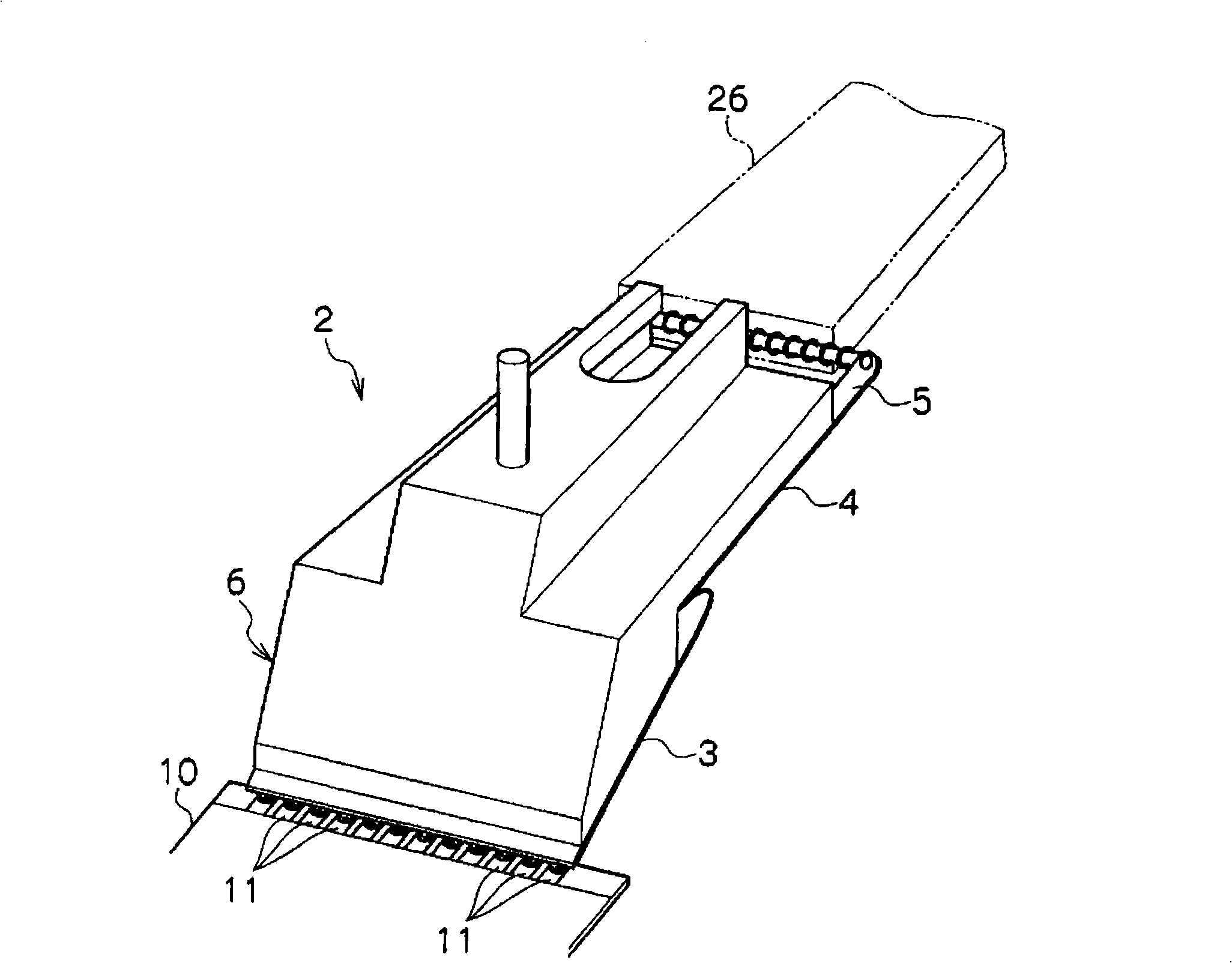

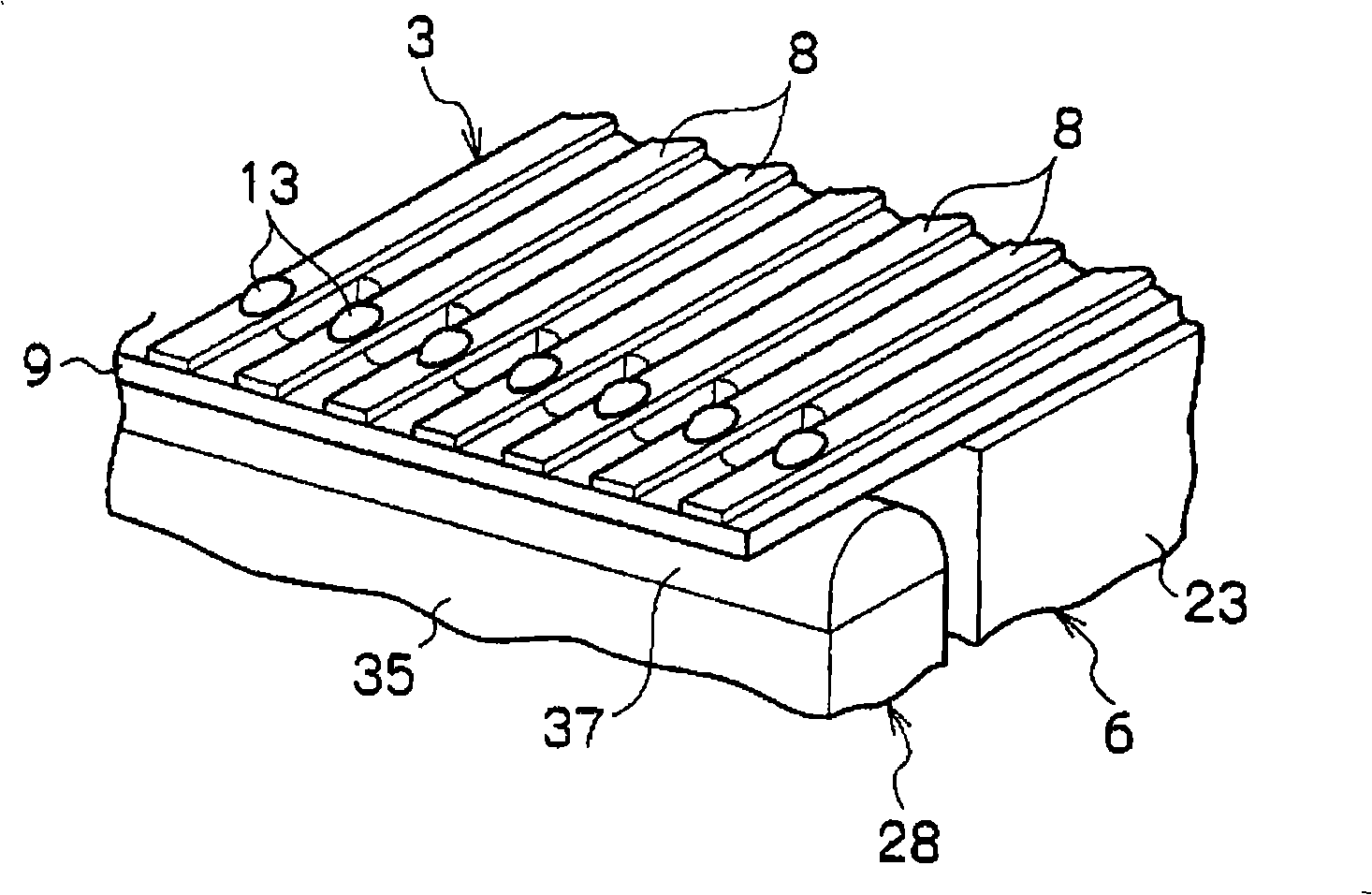

[0047] Next, a probe device and an inspection device according to an embodiment of the present invention will be described with reference to the drawings. The inspection device according to the present embodiment is substantially the same as the above-mentioned conventional inspection device, and therefore, the probe device will be mainly described here. In addition, it can be applied to all devices that can use the probe device of this embodiment as an inspection device.

[0048] The probe apparatus 1 of this embodiment is an apparatus used for the inspection apparatus of a liquid crystal panel. The liquid crystal panel has a rectangular shape, and a plurality of electrodes (not shown) are formed at predetermined pitches on edges corresponding to two adjacent sides of the rectangle.

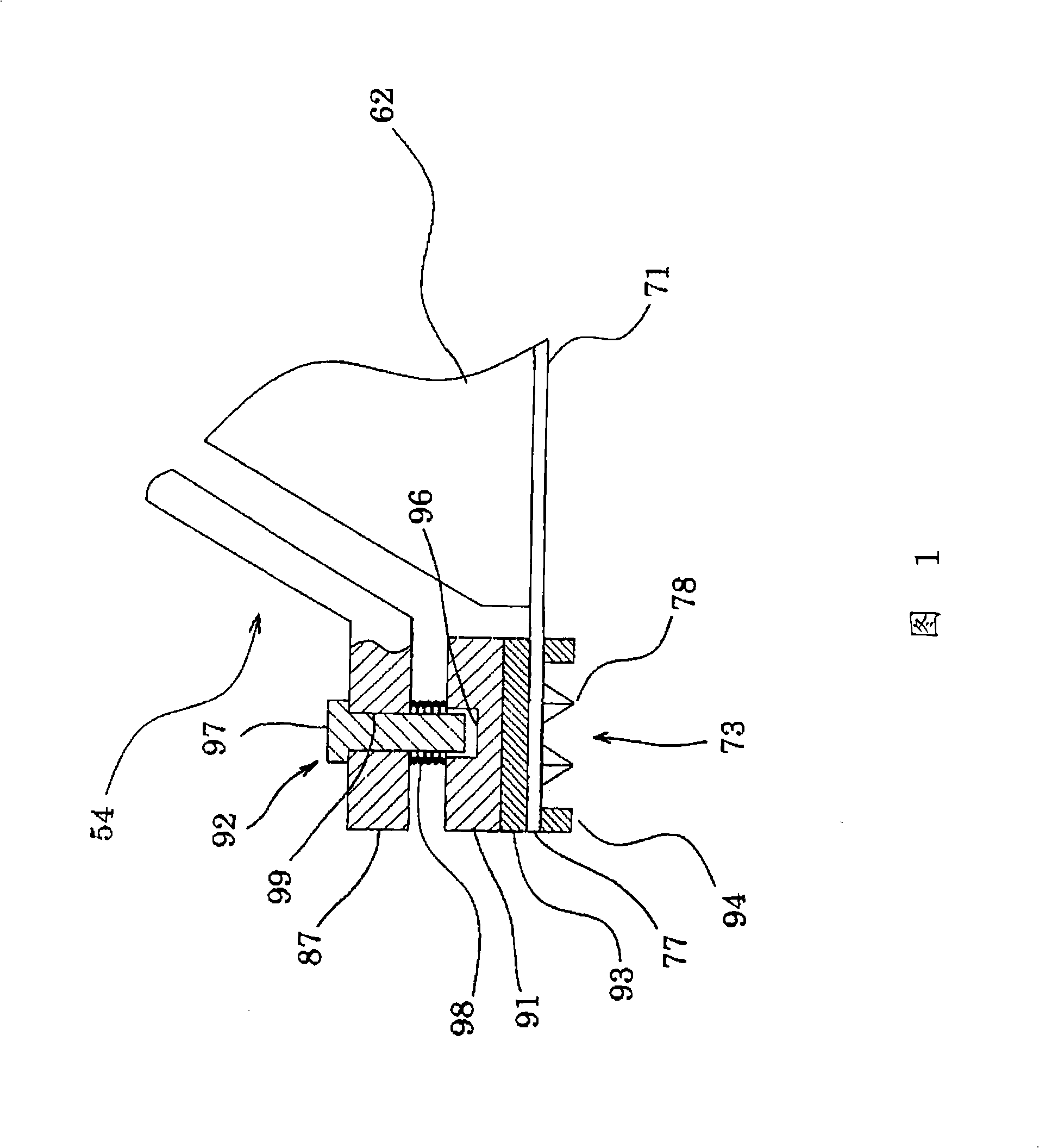

[0049] As shown in FIGS. 12 to 14 , the probe device 51 is configured to include a probe base 52 , a probe block 53 , and a pressurizing mechanism 54 .

[0050] The probe base 52 is a member f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com