Backblowing regenerative soot cleaning time counting device and method for dust remover filter element

A filter element and counting device technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problem of shortened service life, inability to accurately judge the relationship between the service life of filter elements, and inability to accurately judge backflushing Influence of the number of times, etc., to achieve the effect of equipment cost economy, good use and promotion value, and good equipment use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

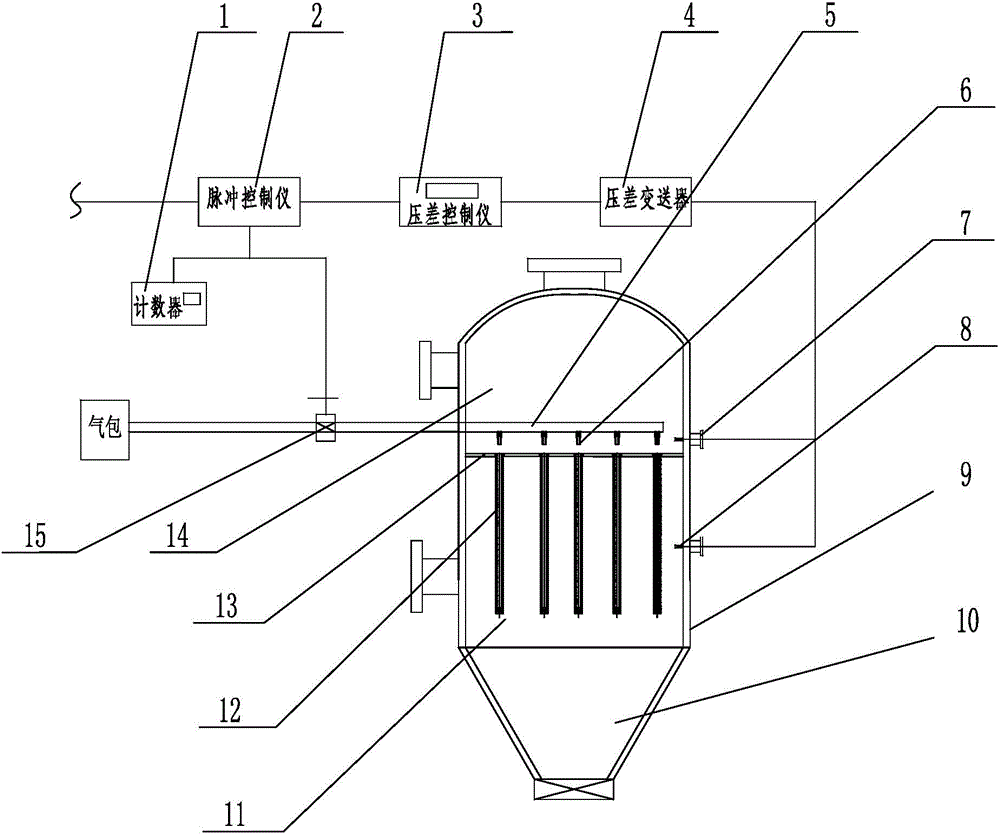

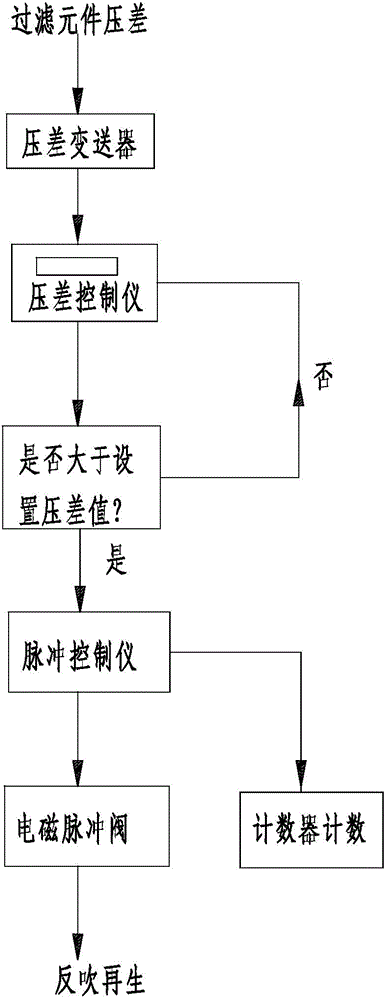

[0025] Such as figure 1 As shown, the device for counting the number of times of back-blowing and regenerating dust removal of dust collector filter elements according to the present invention includes a filter 10, and the filter 10 includes a housing 9, and the inside of the housing 9 fixes the filter element 12 through the tube plate 13, and the filter element The top of 12 is correspondingly provided with the blowback nozzle 6, the blowback nozzle 6 is connected with the blowback pipeline 5, the inside of the filter 10 is divided into a clean gas chamber 14 and a dusty gas chamber 11 by a tube plate 13 and a filter element 12, and the clean gas chamber 14- The clean gas outlet is provided on one side of the dust-containing gas chamber 11, and the dust-containing gas inlet is provided on one side of the dust-containing gas chamber 11. The two pressure-sensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com