Patents

Literature

189 results about "Flying probe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the testing of printed circuit boards, a flying probe test or fixtureless in-circuit test (FICT) system may be used for testing low to mid volume production, prototypes, and boards that present accessibility problems. A traditional "bed of nails" tester for testing a PCB requires a custom fixture to hold the PCBA and the Pogo pins which make contact with the PCBA. In contrast, FICT uses two or more flying probes, which may be moved based on software instruction. The flying probes are electro-mechanically controlled to access components on printed circuit assemblies (PCAs). The probes are moved around the board under test using an automatically operated two-axis system, and one or more test probes contact components of the board or test points on the printed circuit board.

Novel manufacturing method for back drilling of PCB (Printed Circuit Board)

InactiveCN101998768AImprove the problem of cloakingProtect from being etchedPrinted circuit manufactureBoring/drilling machinesEngineeringFlying probe

The invention discloses a novel manufacturing method for the back drilling of a PCB (Printed Circuit Board), which comprises the steps of: A) drilling the PCB substrate for the first time after the PCB substrate is subjected to cutting, bonding with a dry film, browning the inner layer and treating with a pressing board; B) carrying out the copper-deposition panel electroplating or added-panel electroplating; C) carrying out the back drilling on holes to be subjected to the back drilling; D) carrying out alkaline etching treatment on the board subjected to the back drilling; and E) carrying out solder stripping treatment on the PCB board, detecting the PCB board subjected to the solder stripping treatment through a flying probe tester and obtaining a finished product when the PCB is detected to be qualified. In the manufacturing method, the pattern tin electroplating is carried out after the external layer dry film on the PCB is made, then the back drilling is carried out on the hole to be subjected to the back drilling, and then etching is carried out so that the burr generated in the course of the drilling can be eliminated and the copper in a part of the hole with the copper can be protected from being etched at the same time.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Intelligent SMT production error-proof tracing method and process

InactiveCN108811365AImprove satisfaction rateGuaranteed traceabilityPrinted circuit assemblingElectrical componentsFunctional testingVisual inspection

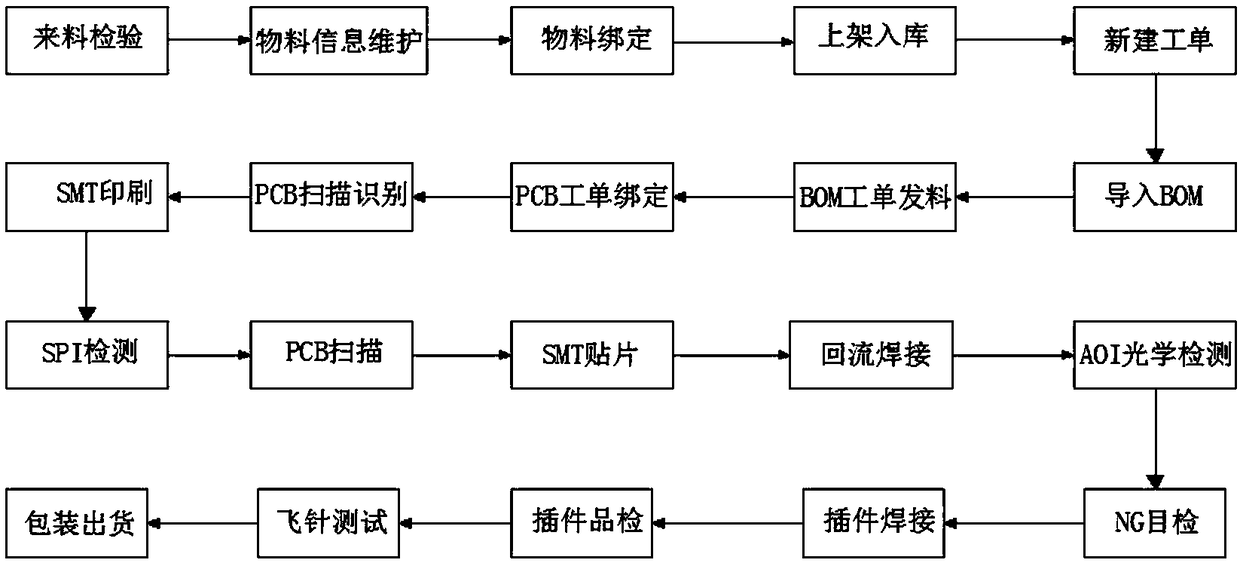

The invention discloses an intelligent SMT production error-proof tracing method and process, which comprises the following steps: incoming material inspection, material information maintenance, material binding, putaway and warehousing, work order filling, BOM introduction, material issuance according to BOM work order, PCB work order binding, PCB scanning identification, SMT printing, SPI detection, PCB scanning, SMT patching, reflow soldering, AOI optical inspection, NG visual inspection, insert welding, insert quality inspection, flying probe testing, packaging and shipping. The tracing method and process use the intelligent manufacturing production method on the basis of the conventional production process method to ensure the traceability of the product. After the production of the product, the flying probe test is added to perform the functional test to inspect the product reliability, so that the qualified rate is controlled from the source, the ex factory qualified rate is greatly improved, the customer satisfaction rate is improved, the repair rate is reduced correspondingly, and costs are reduced.

Owner:上海安理创科技有限公司

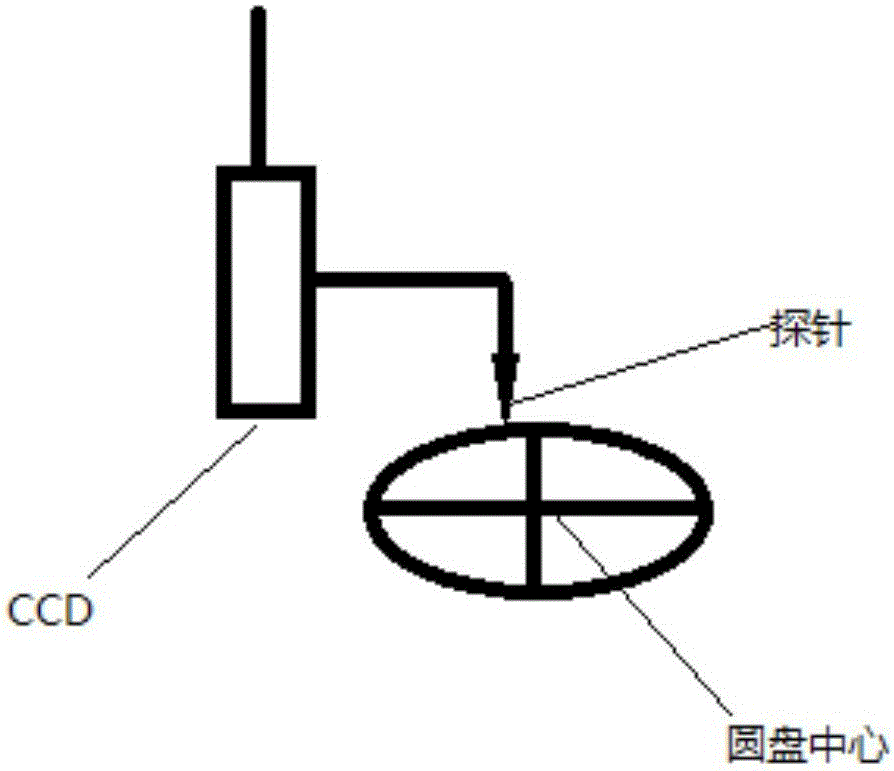

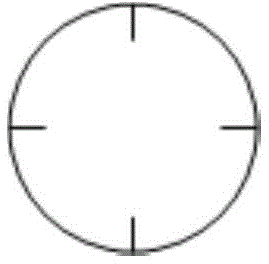

Error correction method of flying probe tester

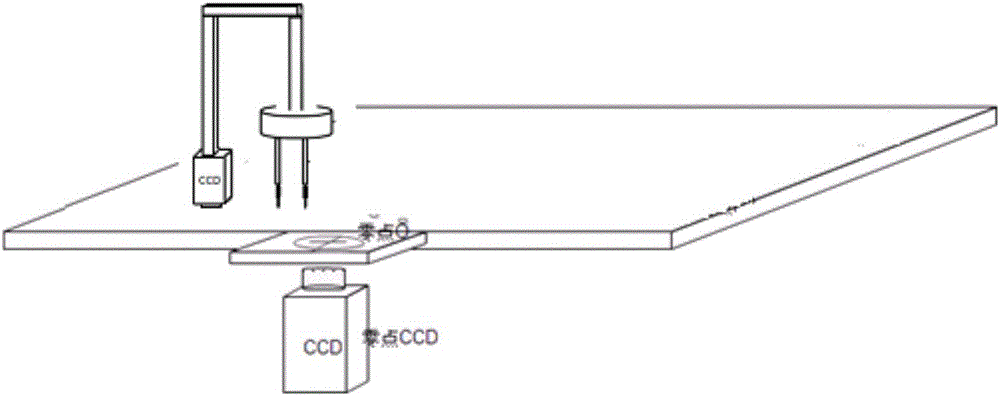

ActiveCN104914375AAvoid Problems That Affect Test AccuracyFast processElectronic circuit testingCamera imageControl system

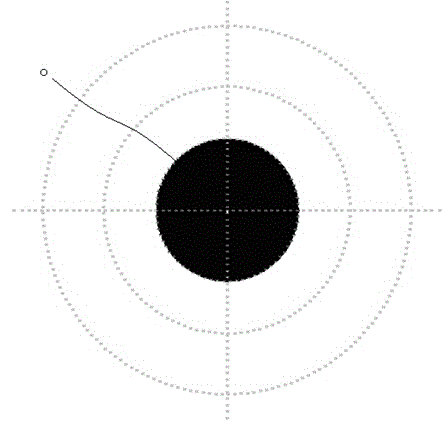

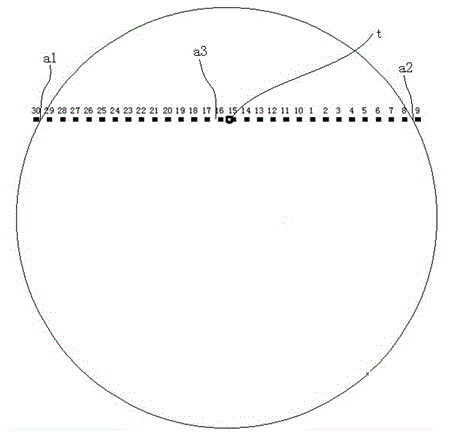

The invention discloses an error correction method of a flying probe tester. The method comprises the steps that the center of a cross target of a camera image is pointed to the center o of one test point of a PCB board to be calibrated; a probe is controlled to detect the PCB board to acquire a probe test point t; the probe test point t is taken as an initial point, and the probe is controlled to search an edge point a1 and an edge point a2 on both sides along X or Y direction; according to two detected edge points in X or Y direction, a center point a3 in X or Y direction is searched; the center point in X or Y direction is searched in the same manner, and the center point is the center o of the test point of the PCB board to be calibrated; the deviation between the probe initial point t and the center o of the test point is the actual offset of the probe to the camera center; and after a control system compensates the actual offset, a test is carried out. According to the error correction method, the actual offset of the probe to the camera center can be determined before the flying probe tester is used, and the test accuracy of the flying probe tester is ensured.

Owner:JOINT STARS TECH

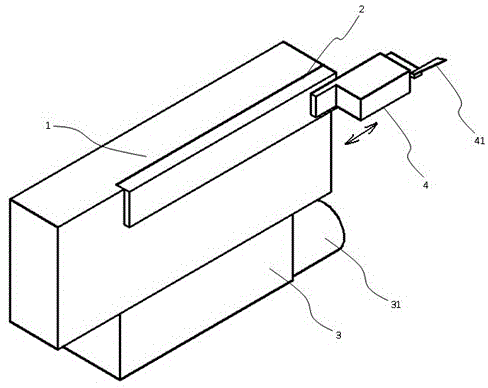

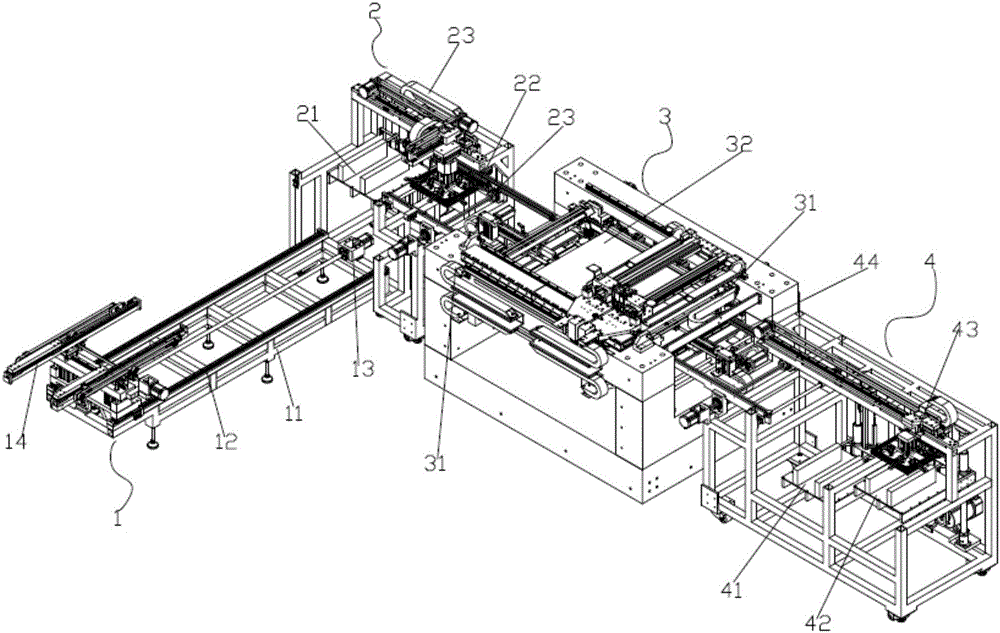

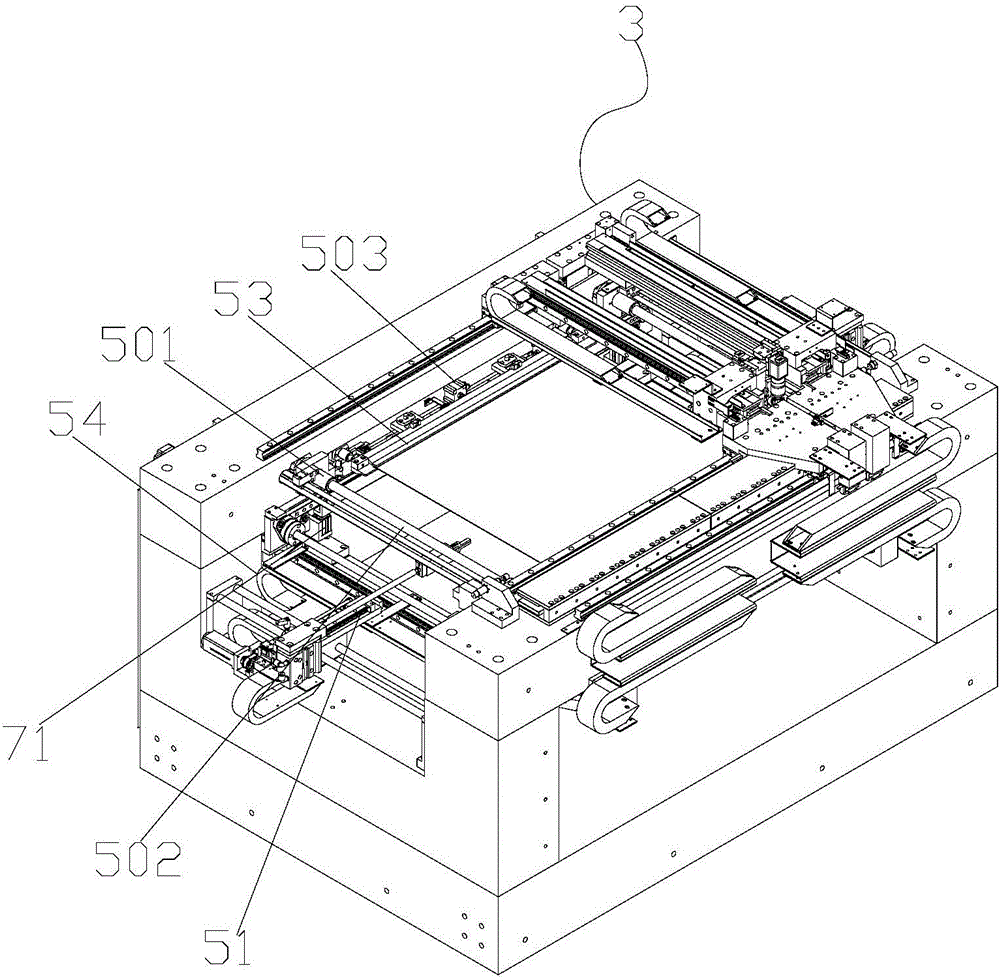

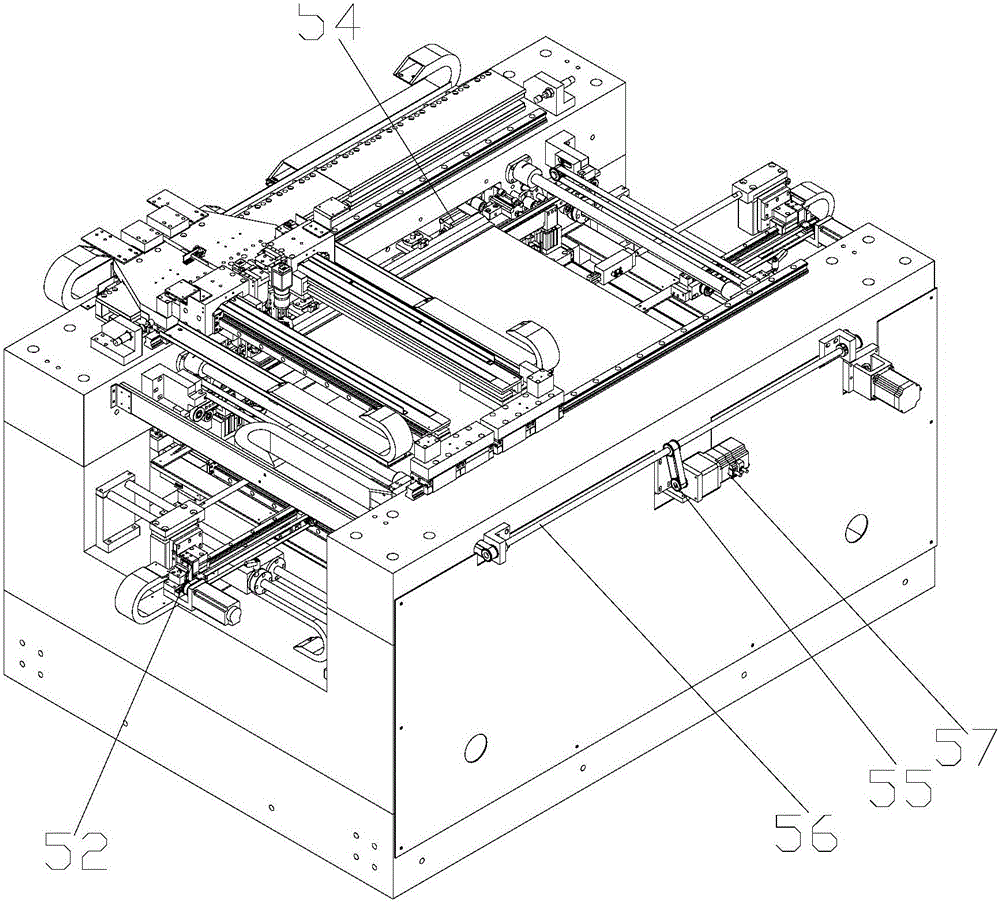

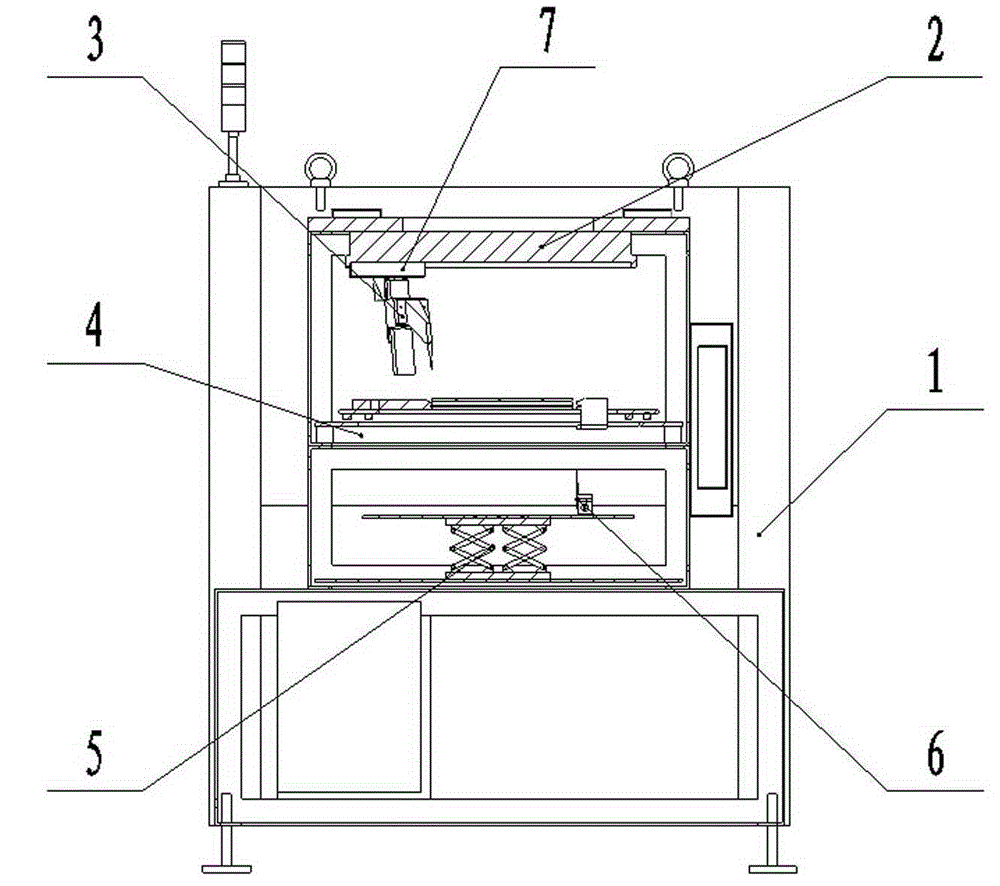

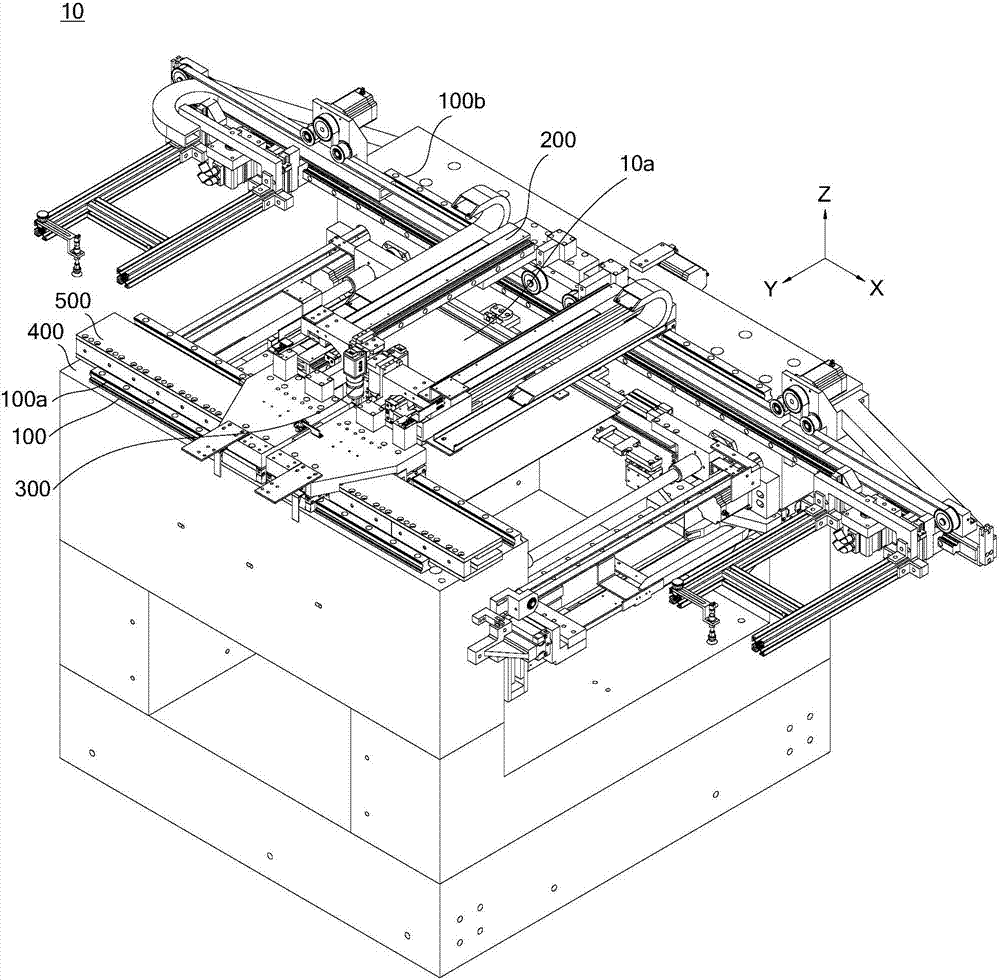

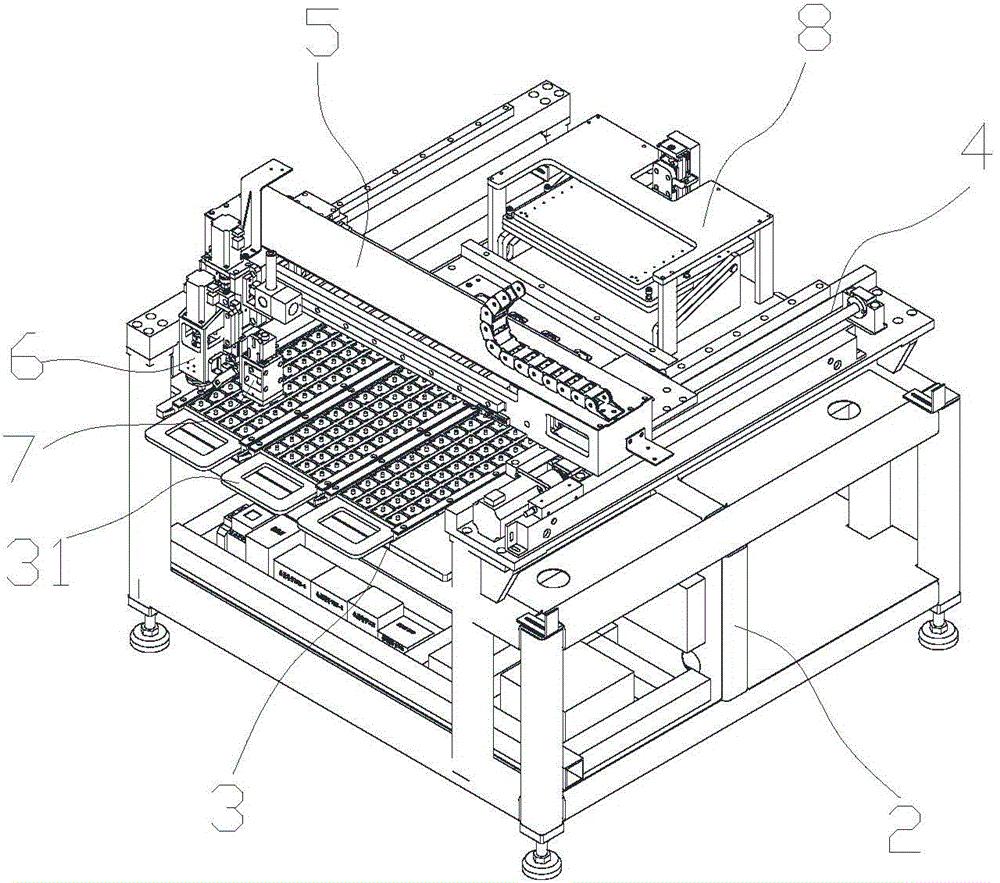

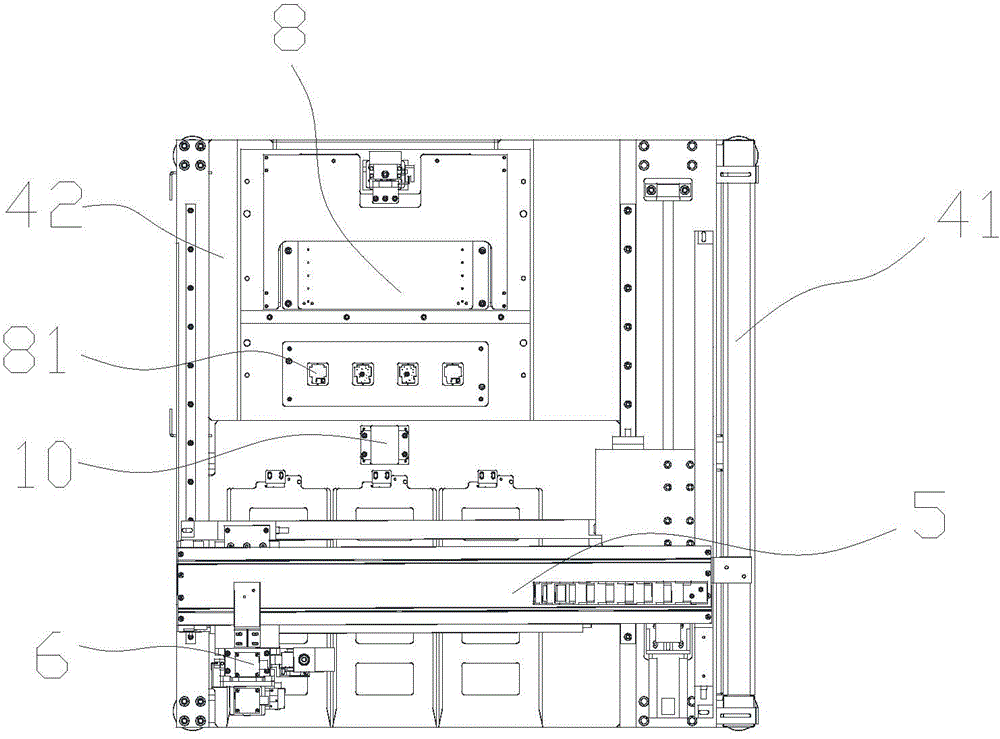

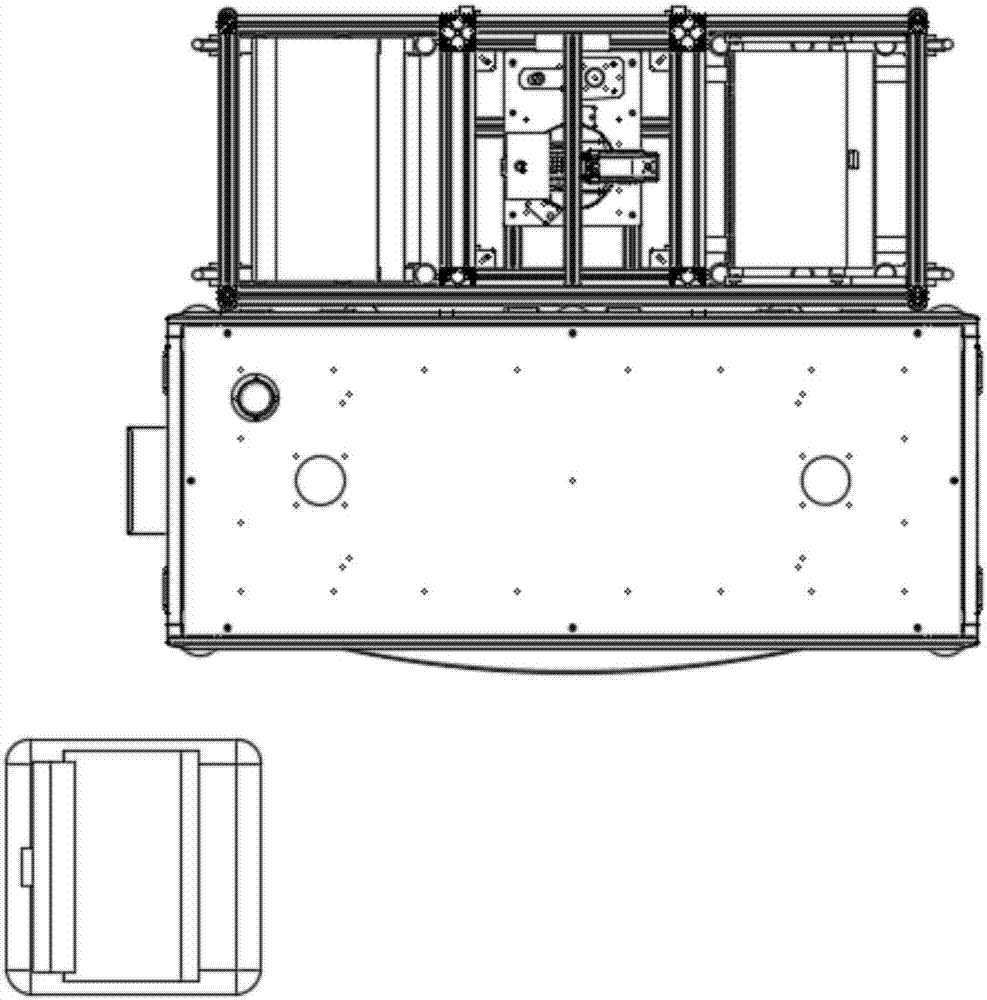

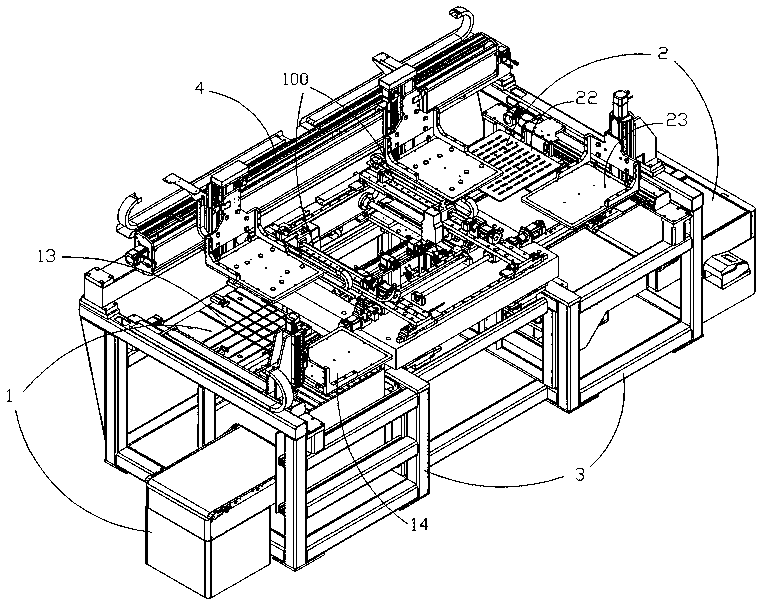

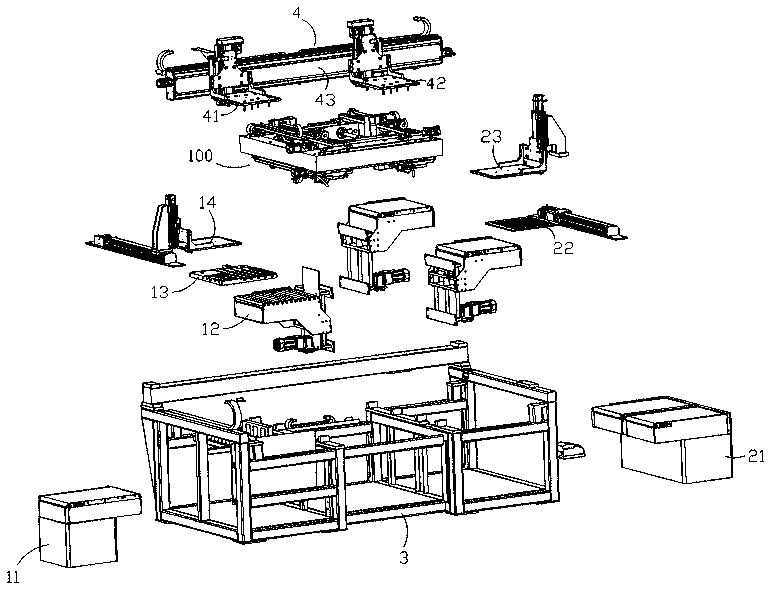

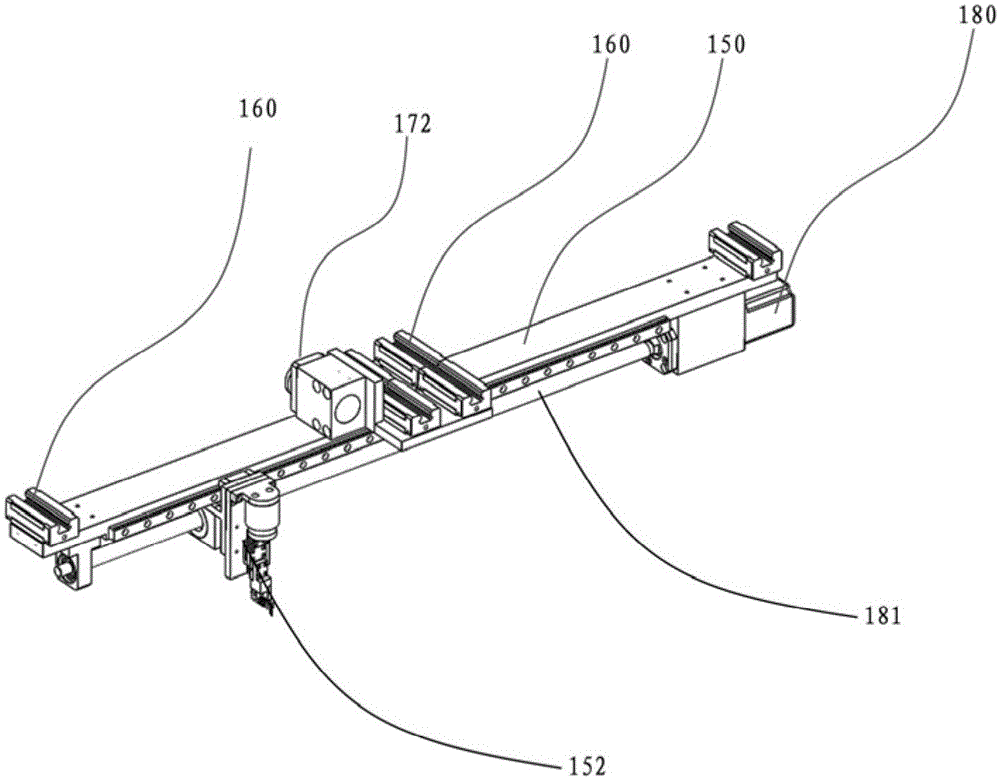

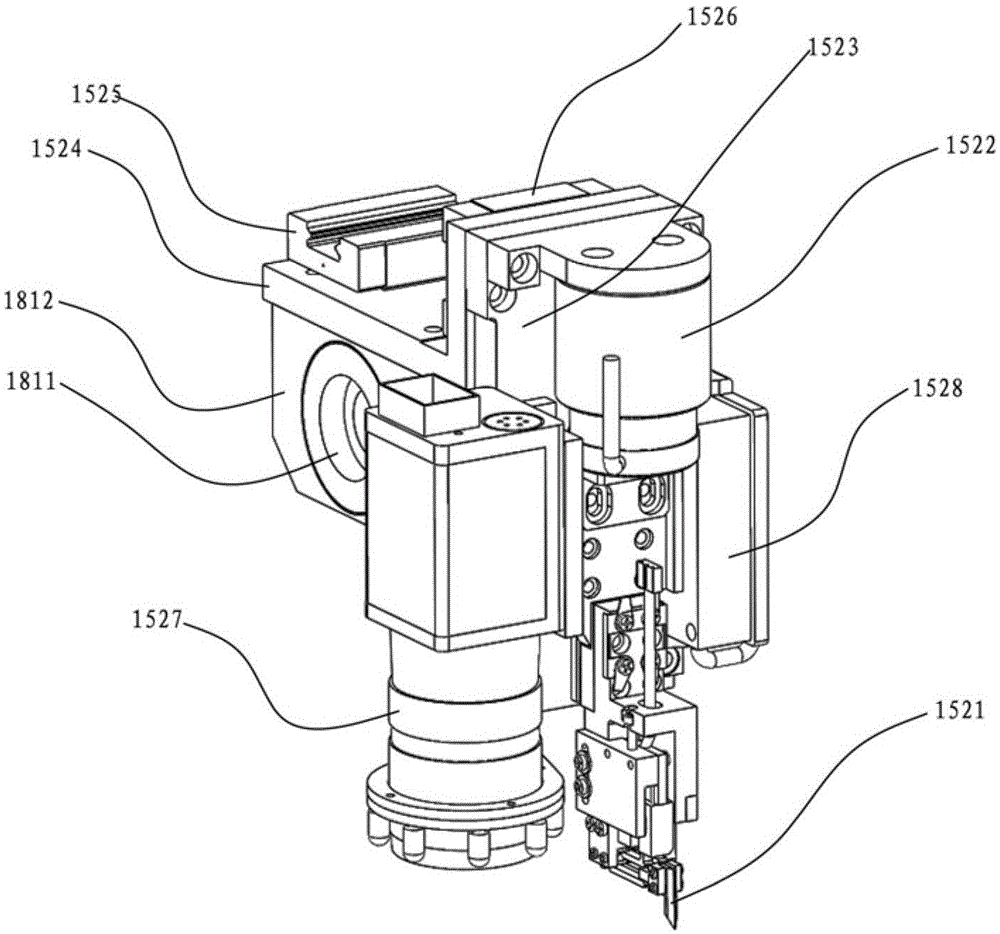

Planar flying probe tester and PCB transmission method

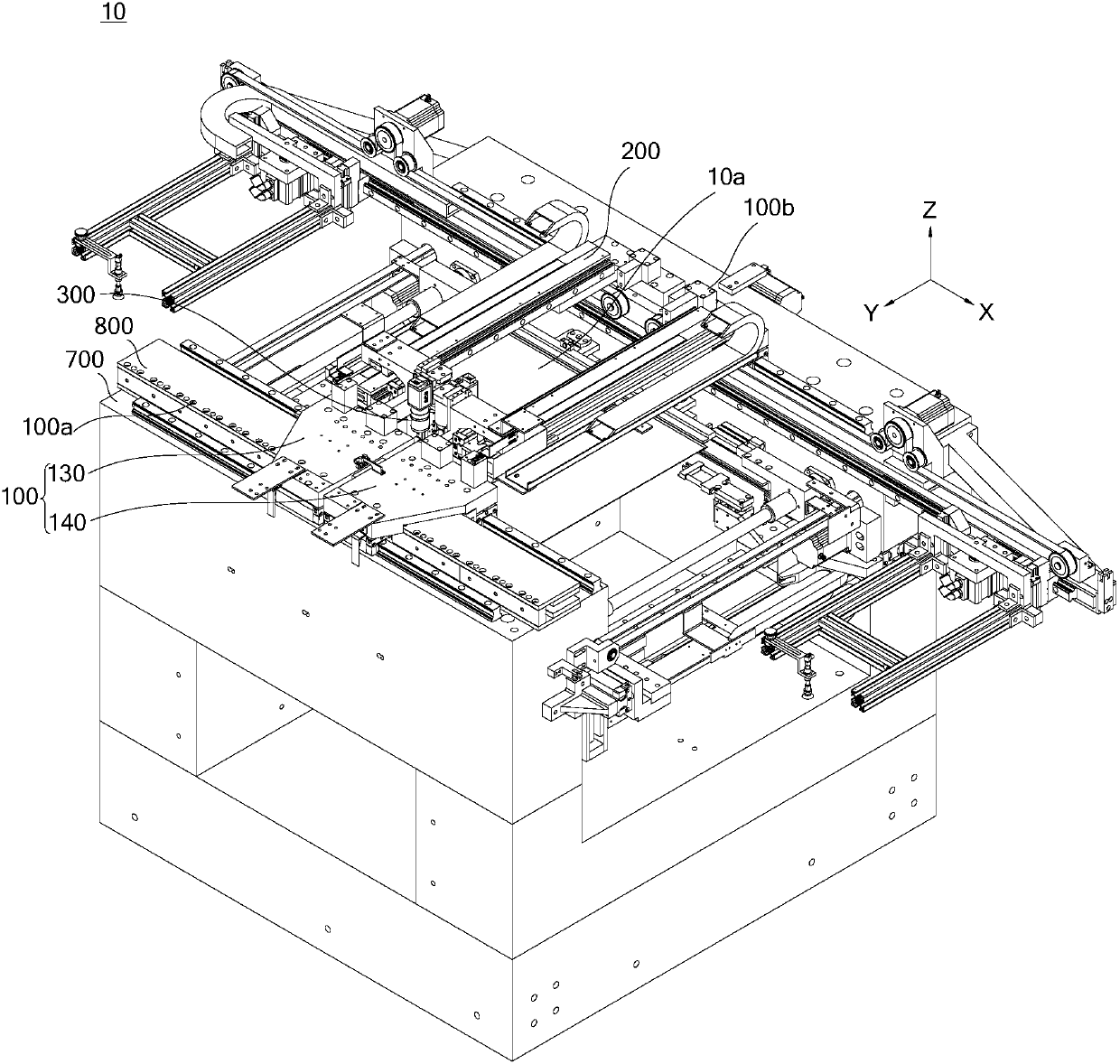

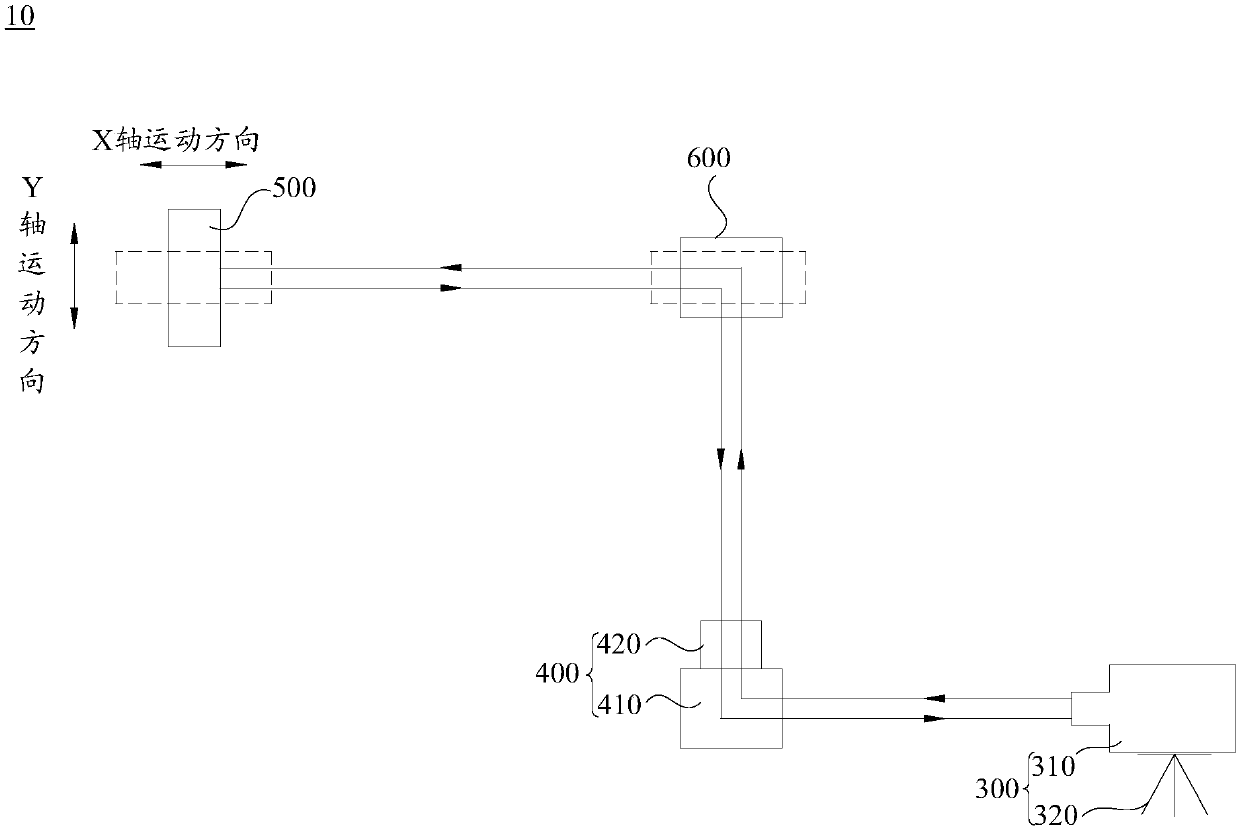

The invention provides a planar flying probe tester and a PCB transmission method. The planar flying probe tester includes a material receiving mechanism, consisting of a material take-out mechanism for taking qualified and unqualified PCBs under test out of a probe bed testing material table; a loading mechanism, consisting of a feeding table, a feeding mechanical arm and a feeding conveying device; a flying probe testing host, consisting of a test host conveying device and a test device; and a laying-off mechanism, consisting of a PASS material table, an NG material table, a laying-off mechanical arm and a laying-off motion device. The material receiving mechanism and a probe bed are connected in a seamless manner, the feeding mechanism conveys the PCBs under test to the flying probe testing host and tests the electrical properties thereof, then the laying-off mechanism places the qualified or unqualified PCBs onto the PASS material table or the NG material table, and the test is completed. The test stability and accuracy are high, the retest efficiency is greatly improved, and the scrap rate of the PCBs and the retest cost are also reduced.

Owner:HANS CNC SCI & TECH

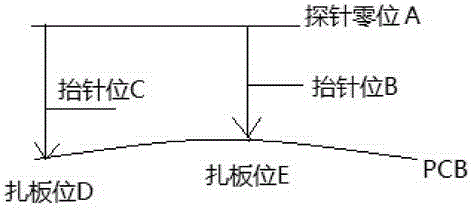

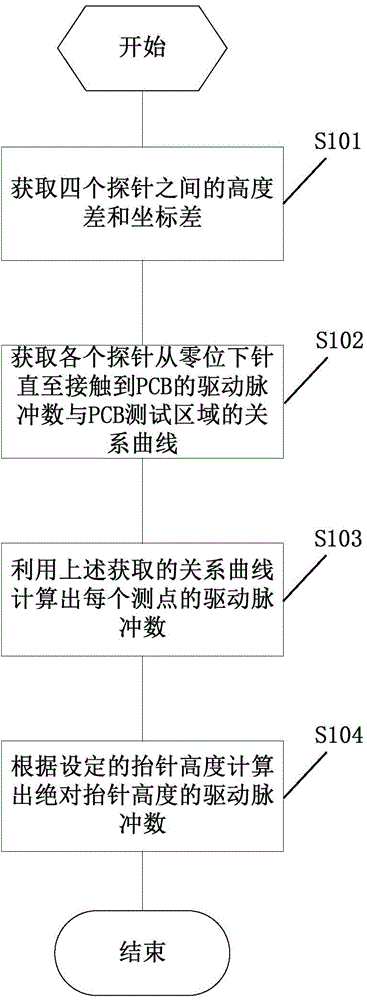

Computing method of probe lifting heights of test probes of flying-probe tester

ActiveCN104457539AGuaranteed test efficiencyReduce the probability of scrapersElectrical measurement instrument detailsElectrical testingMeasurement pointEngineering

The invention relates to a testing method of PCBs, in particular to a computing method of the probe lifting heights of test probes of a flying-probe tester. Each probe independently and rapidly moves under driving of a motor installed on the X-Y axis and makes contact with a corresponding welding point on a PCB to be tested under driving of a stepping motor in the Z direction for necessary electrical measurement. The computing method comprises the following steps that height differences and coordinate differences among the four probes are obtained; a relation curve between a PCB testing area and the number of drive pulses generated when each probe is fed from the zero position until the probe makes contact with the PCB is obtained; the number of drive pulses of each measurement point is worked out by utilization of the obtained relation curves; the number of drive pulses corresponding to the probe lifting height of each probe is worked out according to the set probe lifting height. The computing method can reduce the board scraping probability of the probes in the testing process under the condition of ensuring the testing efficiency.

Owner:HANS CNC SCI & TECH

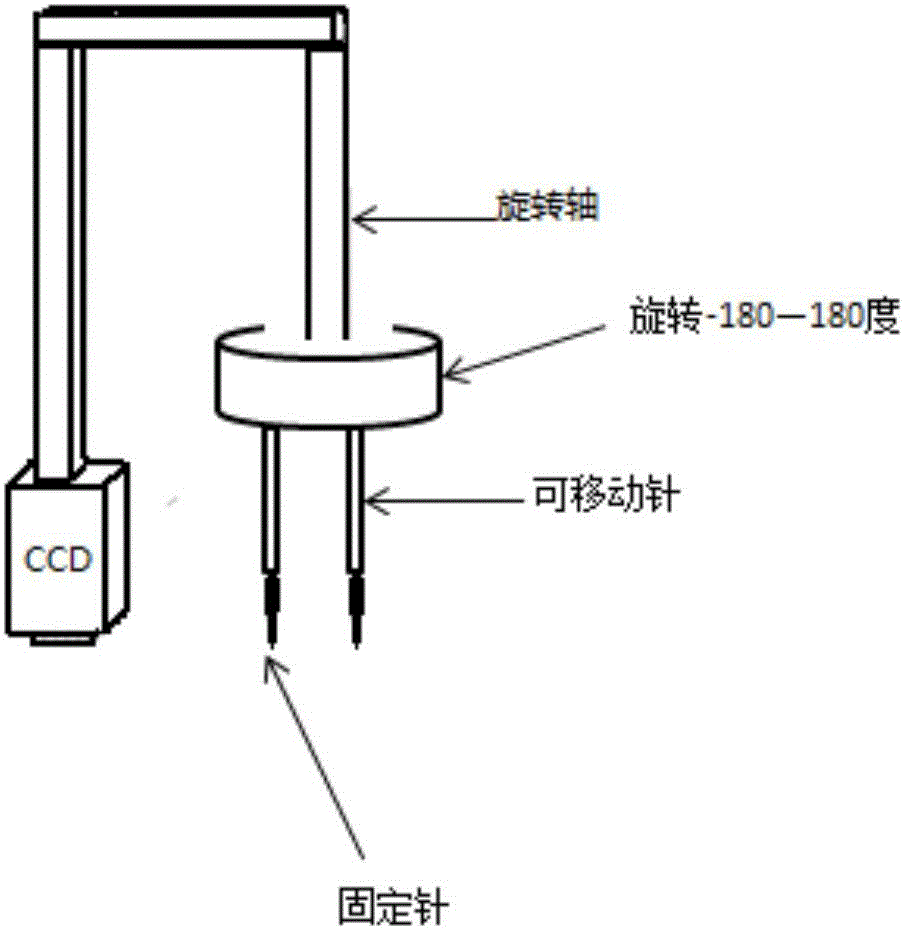

Calibration method of double-probe flying probe testing device

The invention discloses a calibration method of a double-probe flying probe testing device. The method comprises the steps of obtaining a first coordinate of a fixed probe when the probe rotates for 0 degree from an original point of a rotating shaft thereof, a second coordinate while rotating for 90 degrees, and a third coordinate while rotating for 180 degrees; obtaining a fourth coordinate of a mobile probe when its distance to the fixed probe is an initial distance, and a fifth coordinate when its distance to the fixed probe is a preset distance; obtaining coordinates of a camera unit; obtaining the distance from the fixed probe to the camera unit when the distance between the fixed probe and the mobile probe is a first distance and the included angle between the connection line of the fixed probe and the mobile probe and the X axis is a first angle according to the first coordinate, the second coordinate, the third coordinate, the fourth coordinate, the fifth coordinate and the coordinate of the camera unit; and calibrating the double-probe flying probe testing device according to the distance from the fixed probe to the camera unit. Therefore, calibration of positions of double probes is achieved, and the condition that the double probes can accurately stab corresponding points on a tested circuit board is ensured.

Owner:JOINT STARS TECH

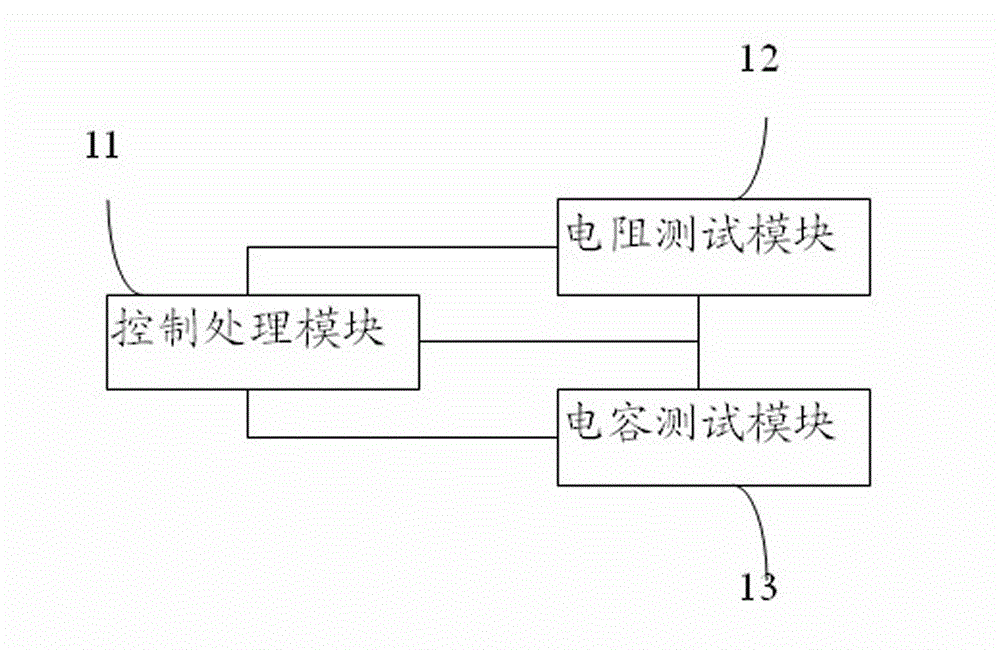

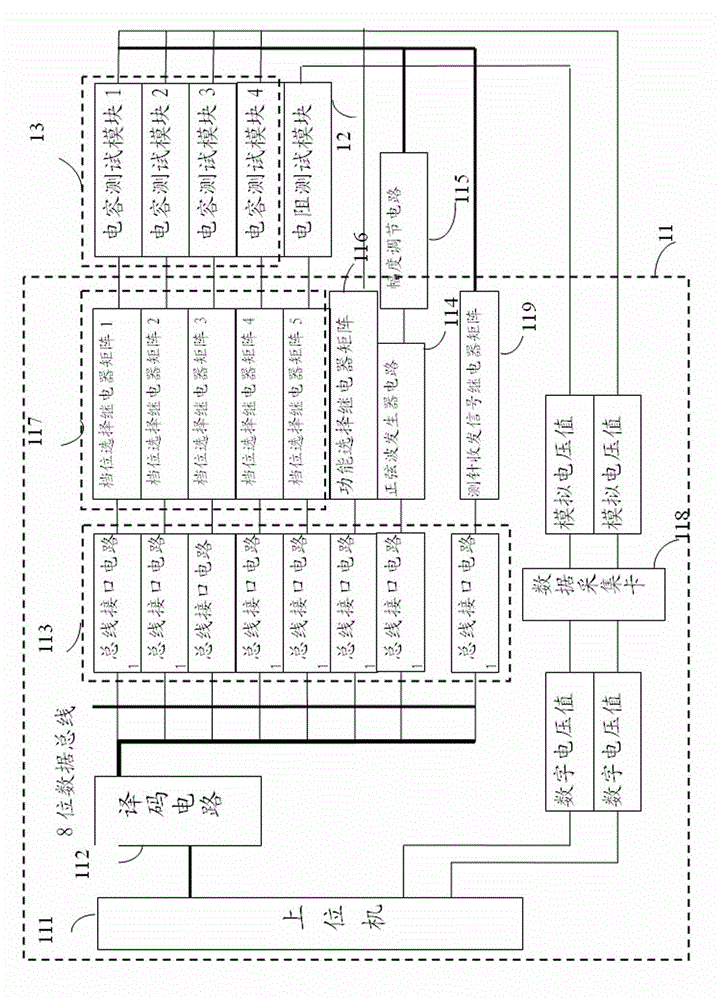

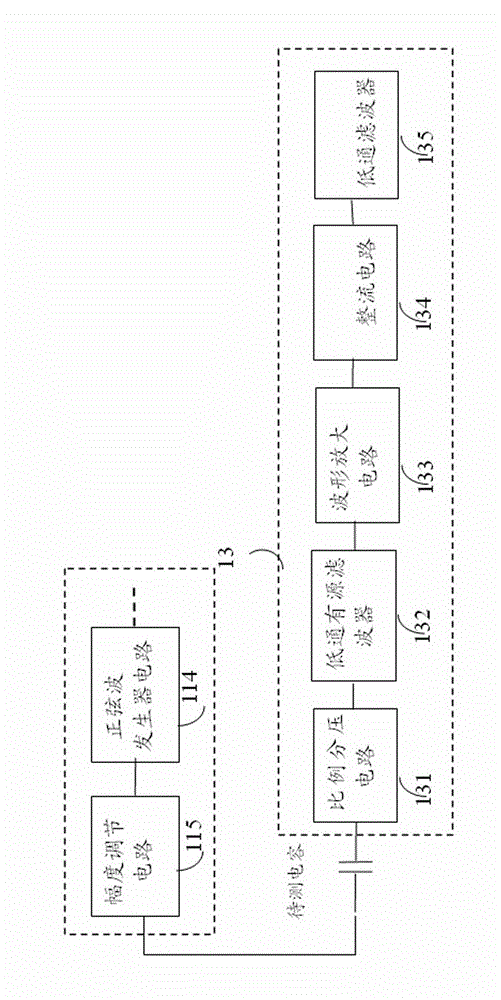

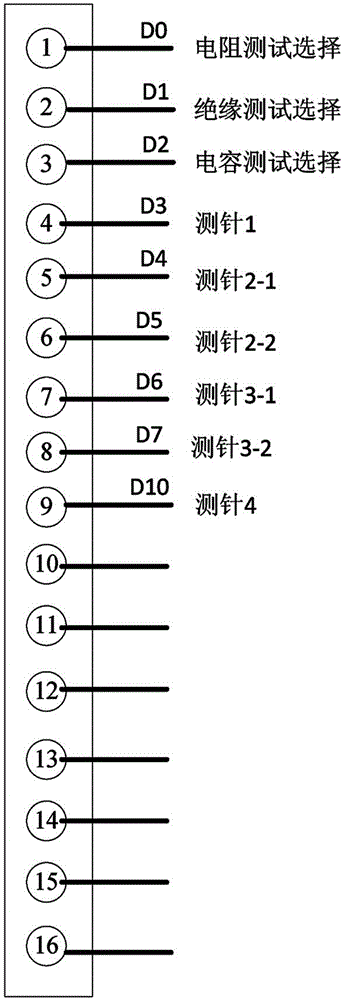

Resistor-capacitor measurement module applied to flying probe tests

InactiveCN103063922AMeet the process requirementsFast testResistance/reactance/impedenceElectrical testingCapacitanceElectrical resistance and conductance

The invention belongs to the technical field of flying probe tests, and particularly discloses a resistor-capacitor measurement module applied to the flying probe tests. The resistor-capacitor measurement module comprises a resistor test module, a capacitor test module and a control processing module. The resistor test module is used for testing a resistor value between same networks on a test substrate, and the capacitor test module is used for testing a capacitor value between different electric networks to the earth on the test substrate. The control processing module is respectively connected with the resistor test module and the capacitor test module, and is used for generating sine waves. The frequency and amplitude of the sine waves both are controllable, and the control processing module is used for controlling switching and electing between functions of the resistor test and the capacitor test, testing gear selection and probe assembly selection, receiving test data of the resistor test module and the capacitor test module for processing, and outputting test result data. The resistor-capacitor measurement module can be imbedded in a flying probe test device main system, realizes automatic probe selection test through software control, is quick in gear selection, accurate in test, and has the advantages of being high in test speed, and short in response time. The test accuracy can meet the technological requirements of the flying probe test.

Owner:THE 45TH RES INST OF CETC

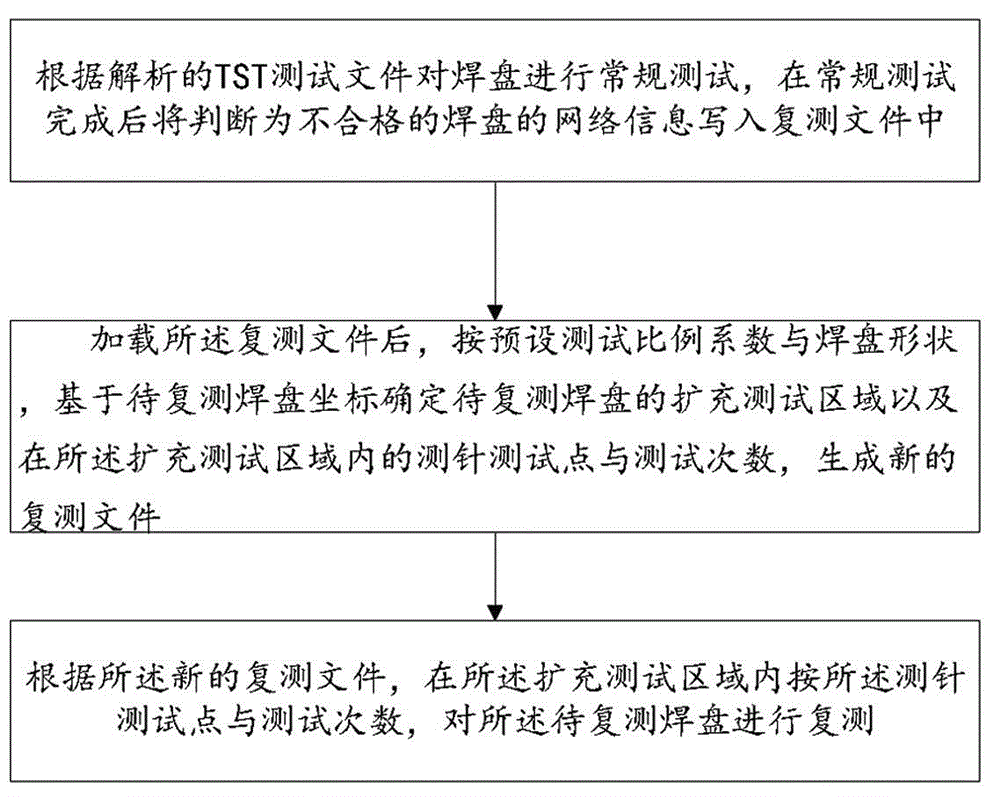

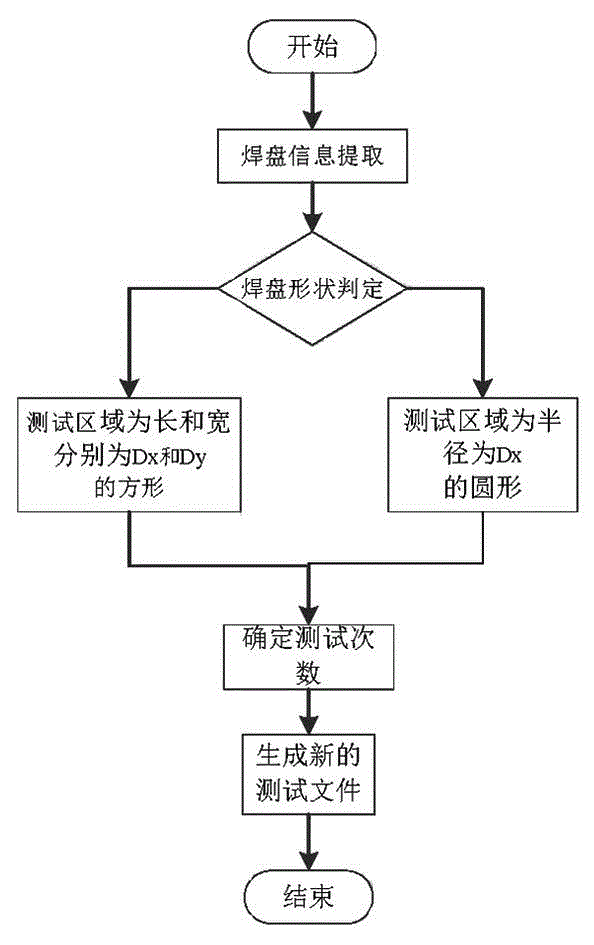

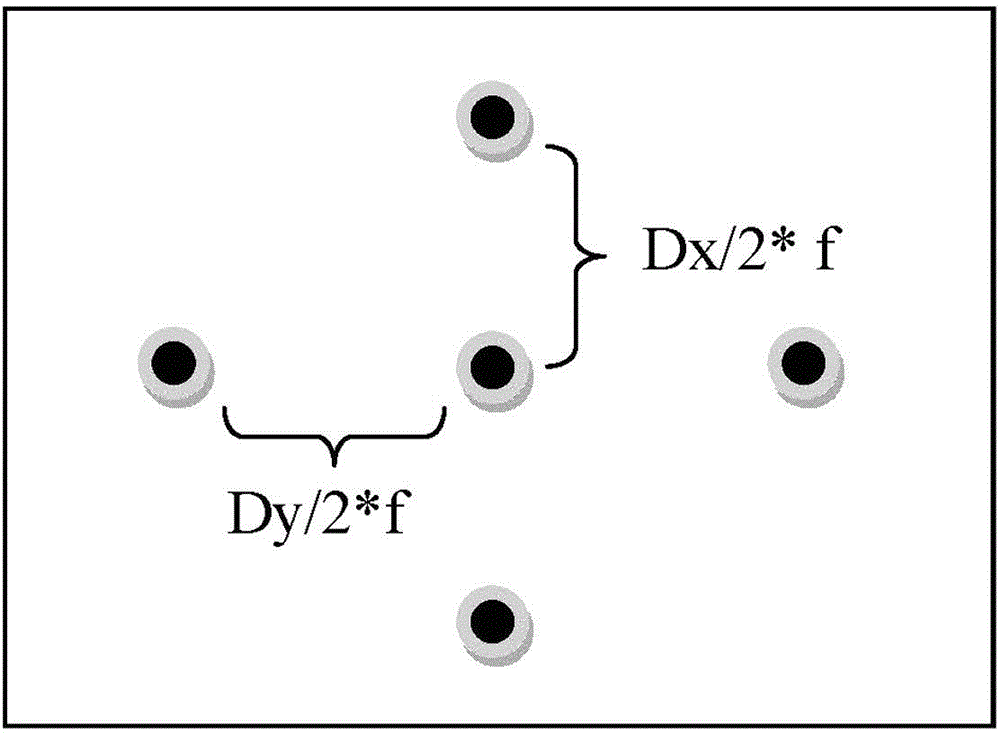

Retest method based on test of multiple points around coordinate position of test point

InactiveCN104977524ASolve misjudgmentReduce false positivesElectronic circuit testingSystem testingMultiple point

The invention relates to a retest method based on the test of multiple points around the coordinate position of a test point. The method comprises the steps that a routine test is carried out on a pad according to a parsed TST test file; after the routine test is completed, failed pad netlist information is written into a retest file; after the retest file is loaded, according to a preset test scale factor and the pad shape, the expanded test area of the pad to be retested is determined based on the coordinates of the pad, and based on stylus test points in the expanded test area and the number of times of tests, a new retest file is generated; and according to the new retest file, the pad to be retested is retested based on the stylus test points in the expanded test area and the number of times of tests. According to the invention, the retest method can automatically, efficiently and conveniently verify a test result of a flying probe test system; false tests are reduced; and the test reliability is improved.

Owner:THE 45TH RES INST OF CETC

Flying probe tester utilizing planar motor

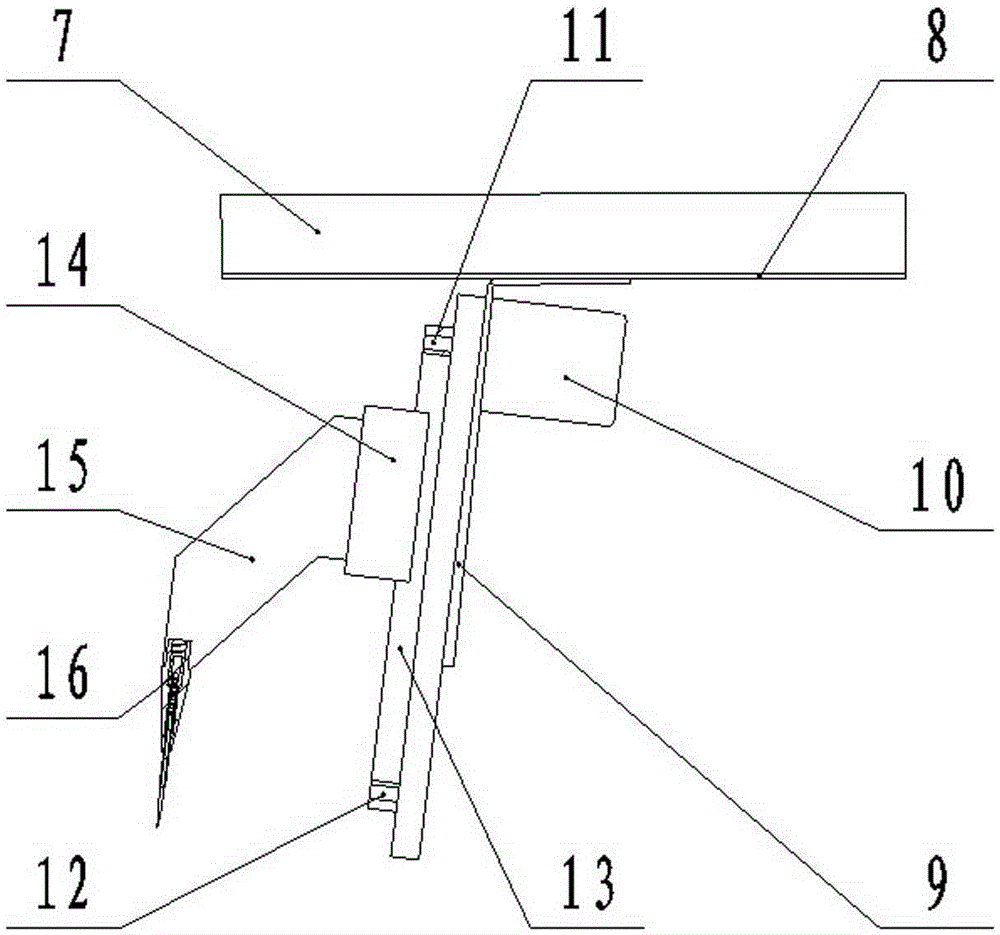

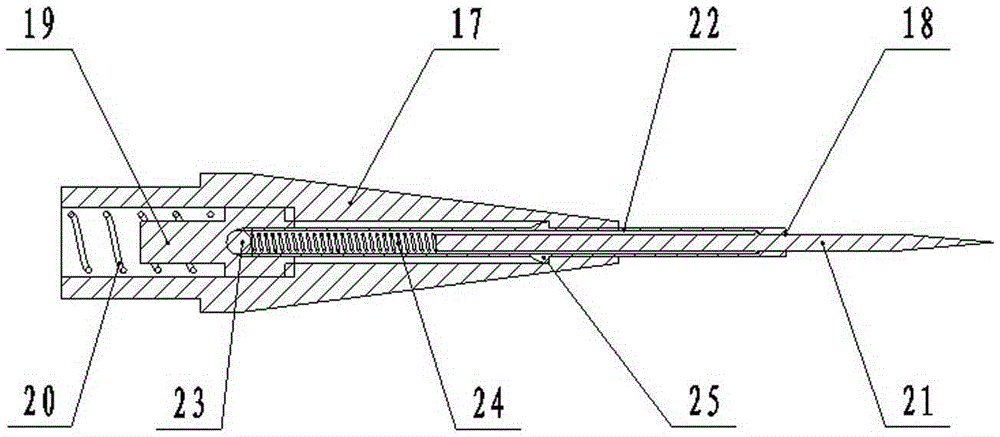

ActiveCN105353296AOvercome the problem of not being able to meet the test accuracyAchieve planeElectronic circuit testingTransmission beltEngineering

The invention specifically relates to a flying probe tester utilizing a planar motor and solves the problem of an existing flying probe tester that the testing precision cannot be satisfied due to an unreasonable structure. A machine frame is internally provided with a planar motor stator, a probe loading device, a circuit board positioning clamp and a lifting platform. The lifting platform is provided with a fixed probe. The probe loading device comprises a rotor body. The rotor body is provided with a support. A linear motor and a transmission belt are fixed at two sides of the support. The transmission belt is provided with an insulating block. A probe assembly is arranged on the lower end of the insulating block. The probe assembly comprises a sleeve. A probe penetrates through the sleeve. A buffering spring, in contact with the insulating block, sleeves the tail end of the probe. The probe is composed of a probe body and a probe sleeve, and a probe buffering spring is arranged between the probe sleeve and the probe body. According to the invention, the planar motor is adopted for realizing specific angle loading, an elastic contact circuit board, a programmable-control loading pressure, good conductivity, voltage resistance and insulation.

Owner:ZHONGBEI UNIV

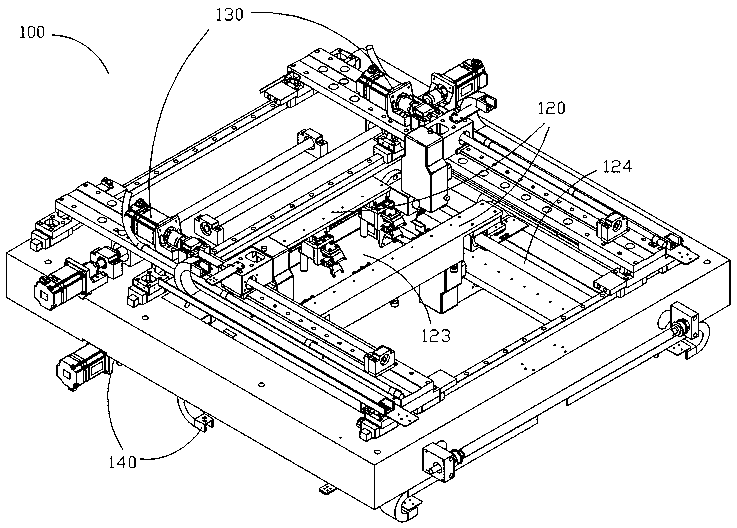

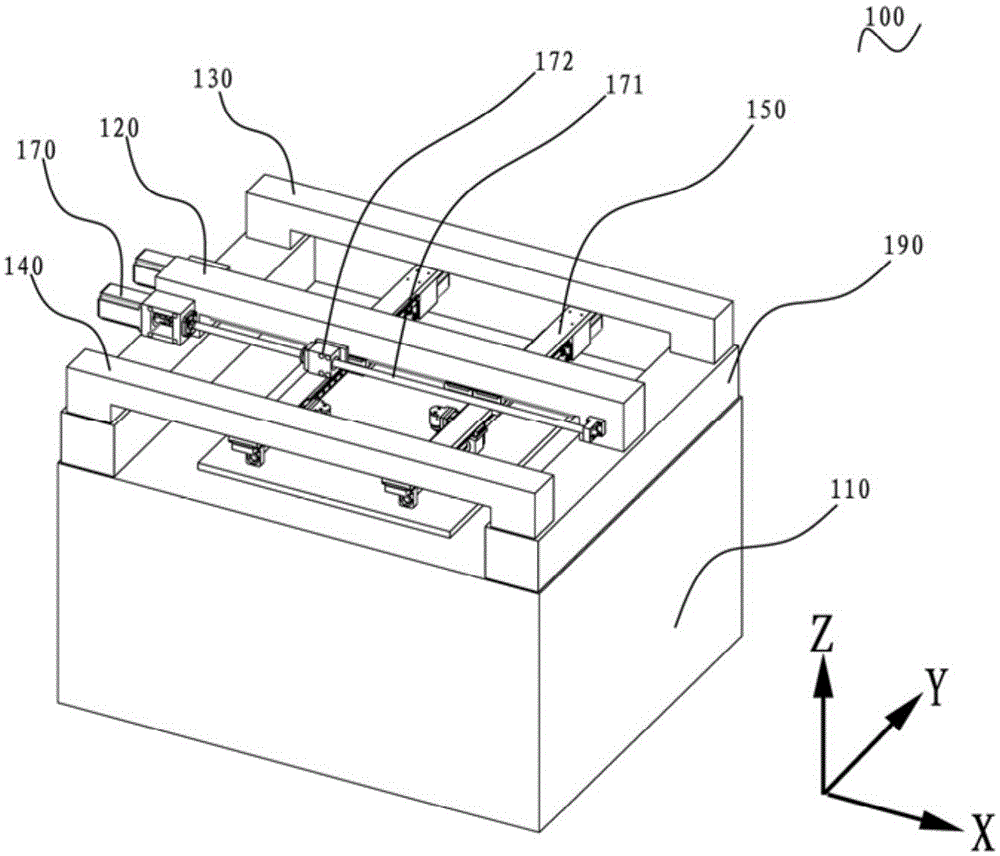

Flying probe tester

ActiveCN103176121AHigh movement precisionImprove driving precisionElectronic circuit testingDrive shaftEngineering

A flying probe tester comprises a substrate, two parallel X-axes, two Y-axes and two Z-axes. Each X-axis comprises a first guide rail, two first motors and two first screw, the two first screws are parallel with the first guide rail, the two first motors are located at one ends, which are relatively distant, of the two first screws, and a drive shaft of each first motor is coaxially connected with the corresponding first screw. Each Y-axis comprises a second guide rail, two connecting plates and two first slider, two ends of the second guide rail are fixedly connected with the two connecting plates respectively, the two first sliders are fixed on two surfaces, opposite to the second guide rail, of the two connecting plates respectively, the first sliders can slide along the first guide rail, and the first screws penetrate through the first sliders. The two Z-axes are disposed on the two Y-axes. One first slider, close to the corresponding first motor, of each Y-axis is provided with a screw hole connected with the corresponding screw in a threaded manner, and the other first slider is provided with a guide hole allowing for penetration of the corresponding screw. The flying probe tester is low in cost and high in motion precision.

Owner:HANS CNC SCI & TECH

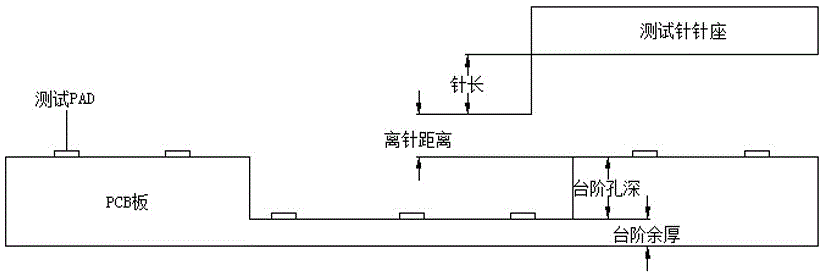

Detection method for monitoring open-short circuit functional defects of printed-circuit board step hole

ActiveCN106443299AImprove test efficiencyGuaranteed No Prick Test PADElectrical testingTest efficiencyInjection moulding

The invention discloses a detection method for monitoring open-short circuit functional defects of a printed-circuit board step hole. The method comprises the following steps that firstly, according to the depth of a step, a flying-probe testing machine with different needle lifting heights is selected, and a test file is made according to the parameter requirement of the flying-probe testing machine; secondly, a needle type needle head is selected to be fixed to the tail end of a needle bed, and a step testing needle of an integrated structure is made by injection molding of the needle type needle head and the elastic needle bed; thirdly, needle tip correction is conducted on the changed step testing needle by means of a correction plate, so that the front needle tip and the rear needle tip are precisely aligned; fourthly, measuring parameters of a step board are designed, and the design mainly comprises the steps of designing a needle lifting height and detecting the movement speed of the testing needle; fifthly, the flying-probe testing machine is started to detecting open-short circuit functional defects of the printed-circuit board step hole. The detection method for monitoring open-short circuit functional defects of the printed-circuit board step hole has the advantages that the testing needle does not crack up and puncture a testing PAD, the machine is made to achieve automatic and fast mass production, testing efficiency is effectively improved, and the loss of the open-short circuit functional defects of the stepped board is reduced.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

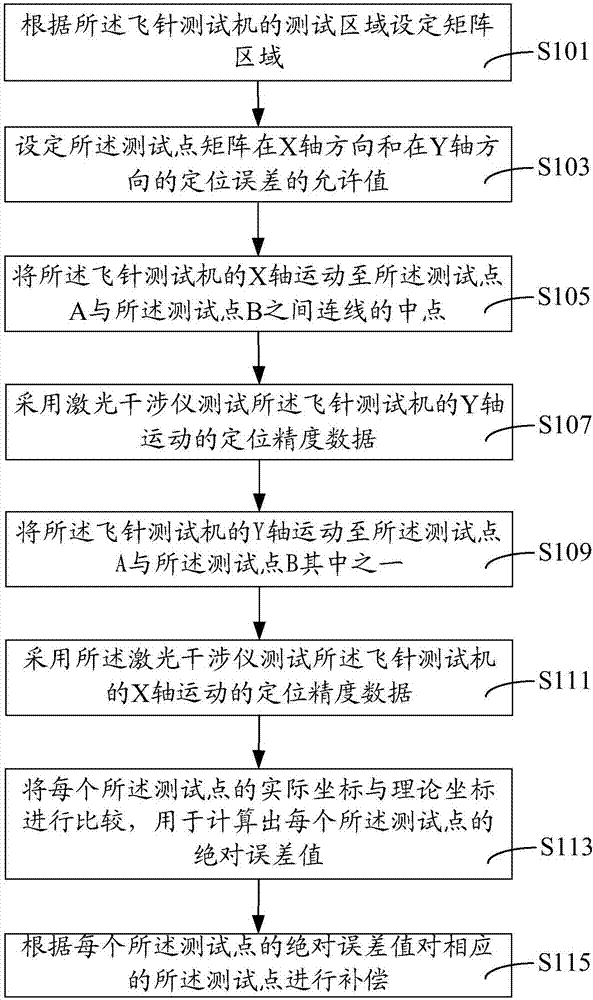

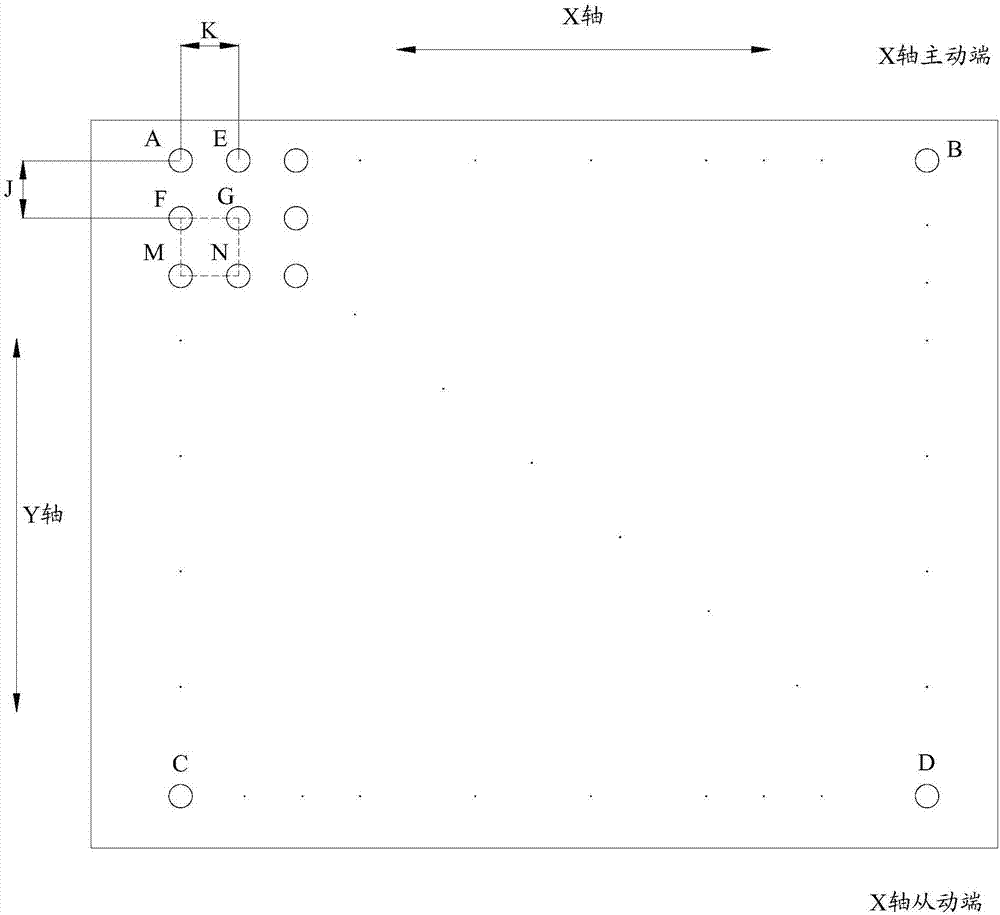

Control method of motion axis of flying probe testing machine and compensation method of positioning accuracy of motion shaft of flying probe testing machine

ActiveCN107462824AHigh positioning accuracySolve the problem of low test accuracyElectronic circuit testingEngineeringFlying probe

The invention relates to a control method of a motion axis of a flying probe testing machine and a compensation method of positioning accuracy of a motion axis of a flying probe testing machine. The compensation method of positioning accuracy comprises the following steps that: a matrix area is set according to a testing area of a flying probe testing machine; allowable values of positioning errors of a test point matrix in an X-axis direction and a Y-axis direction are set; the X axis of the flying probe testing machine is moved to a midpoint of a connecting line between a test point A and a test point B; a laser interferometer tests positioning accuracy data of Y-axis movement of the flying probe testing machine; and the Y axis of the flying probe testing machine is moved to the test point A or the test point B; and the laser interferometer tests positioning accuracy data of X-axis movement of the flying probe testing machine. With the compensation method, the X and Y axes of the flying probe testing machine are compensated within the whole plane in the testing area, so that the high testing precision of the flying probe testing machine is ensured and a problem of low testing precision of the flying probe testing machine is solved.

Owner:HANS CNC SCI & TECH

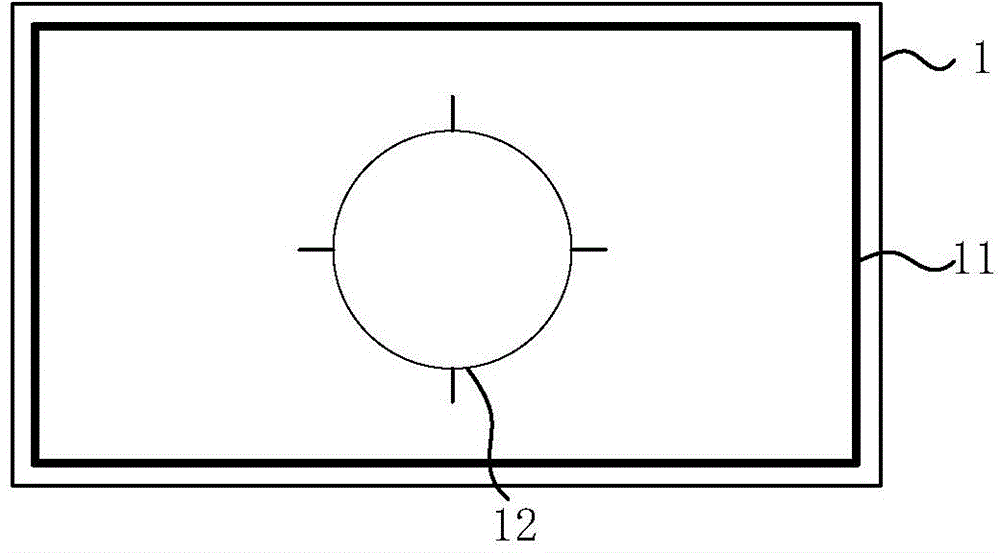

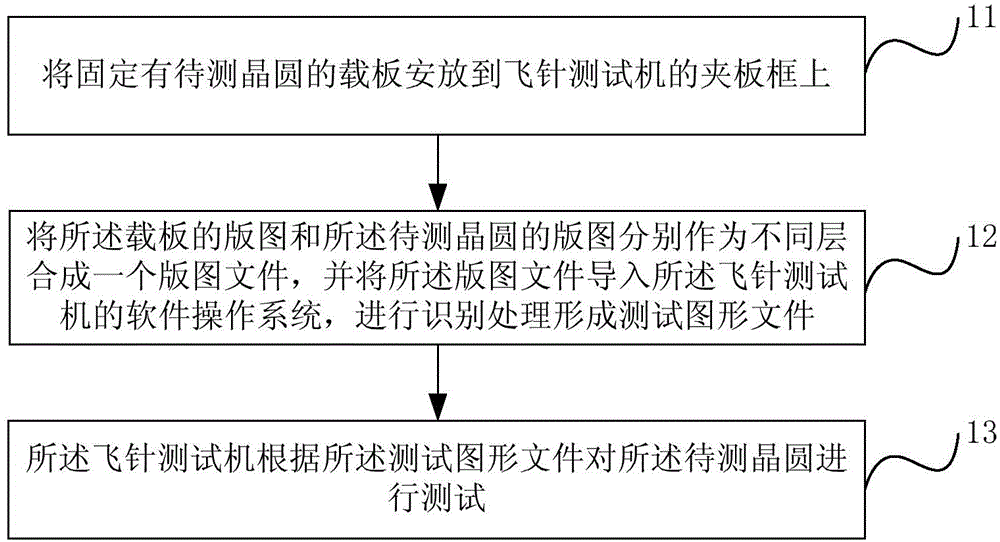

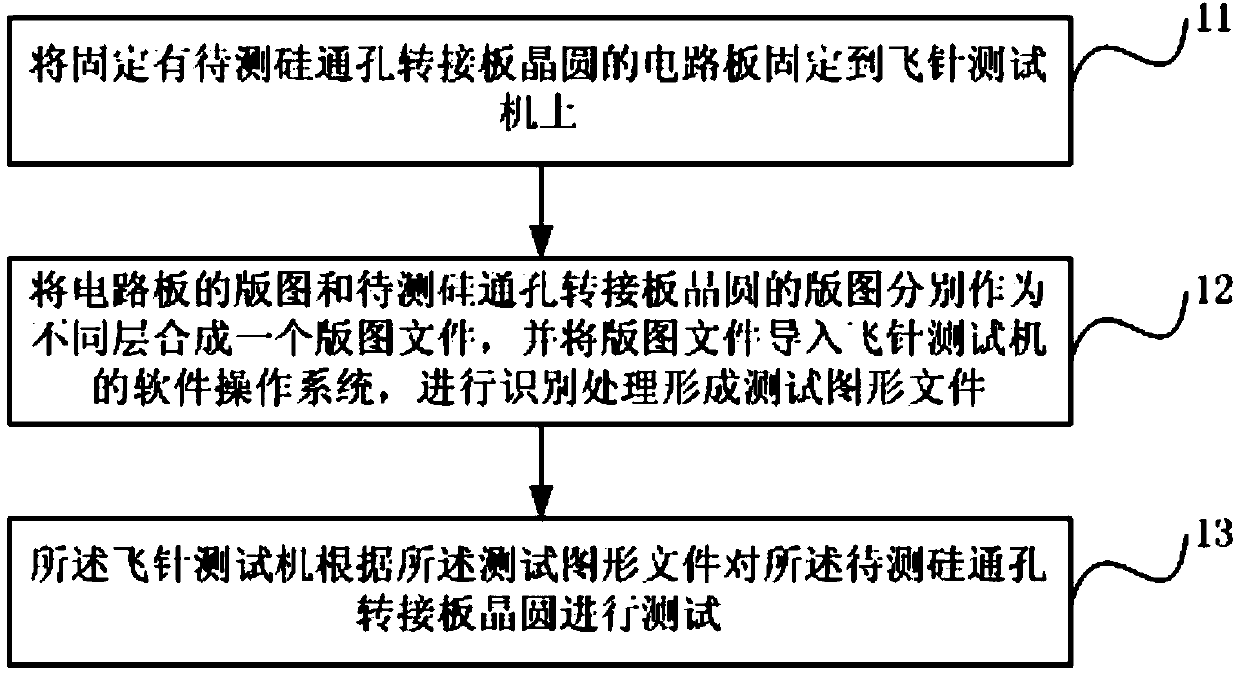

Wafer testing system and method

ActiveCN104459508AIncrease flexibilityImprove test efficiencyIndividual semiconductor device testingProbe cardEngineering

The invention discloses a wafer testing system and method. The system comprises a flying-probe tester and a carrier plate, the flying-probe tester is used for testing a wafer to be tested, the carrier plate is used for bearing the wafer to be tested on the flying-probe tester and providing an alignment mark corresponding to a clamping plate frame of the flying-probe tester and the domain of the carrier plate, the domain of the carrier plate and the domain of the wafer to be tested are matched to form a domain file to be tested, and after the domain file to be tested is led into a software operation system of the flying-probe tester, a testing figure file is formed. According to the wafer testing system and method, various pinboard wafers or wafers of passive integrated devices can be automatically tested through the flying-probe tester, an automatic probe table does not need to be bought for testing the wafer with different domains, corresponding expansive probe cards do not need to be customized according to the wafers to be tested with the different domains, the flexibility is improved, the cost is lowered, the period is shortened, and the industrialization process of the wafer pinboarrds such as TSV and TGV and an IPD technology is promoted.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

Electrical performance testing method for multi-material number spliced board

ActiveCN105137263AFew stepsImprove work efficiencyPrinted circuit assemblingPrinted circuit testingMulti materialElectricity

The invention discloses an electrical performance testing method for a multi-material number spliced board, comprising steps of splicing multiple single-material number boards on one production board, wherein the single-material number board has a plurality of network units, obtaining network unit position information of each single-material number board, and performing electric performance test on all network units according to the position information of all network units by a flying probe device, wherein electric performance test comprises the test to determine whether the network unit is an open circuit or a short circuit. As a result, the whole board can be put into the test device to test for one time instead of cutting the production board into multiple pieces and placing the multiple pieces into the flying probe testing device one-by-one to performthe electric performance test. The invention can greatly reduce the steps of the operation upper board and the lower board on the probe flying test device, greatly improves the working efficiency and greatly reduces the labor cost.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

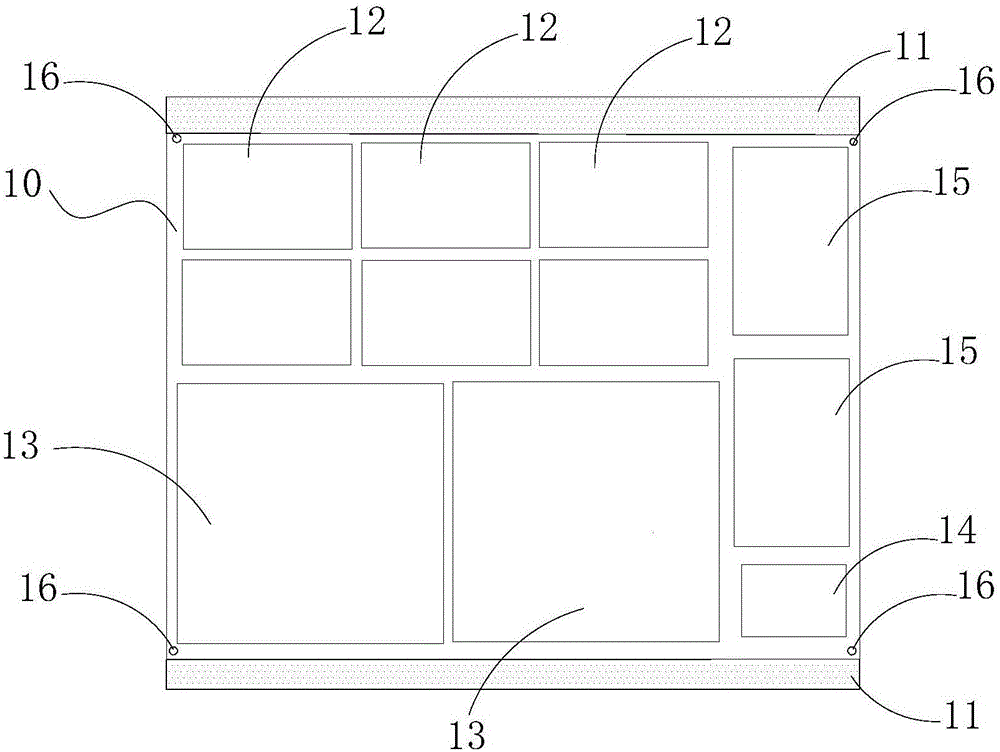

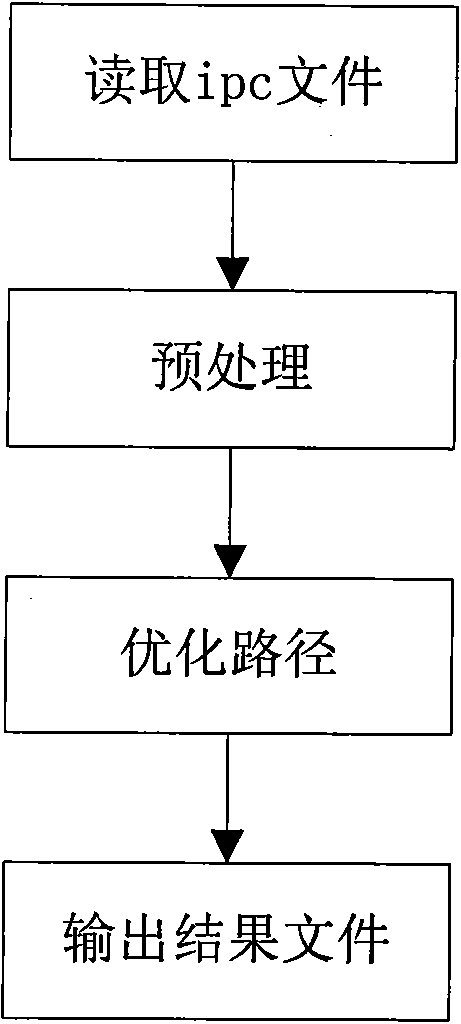

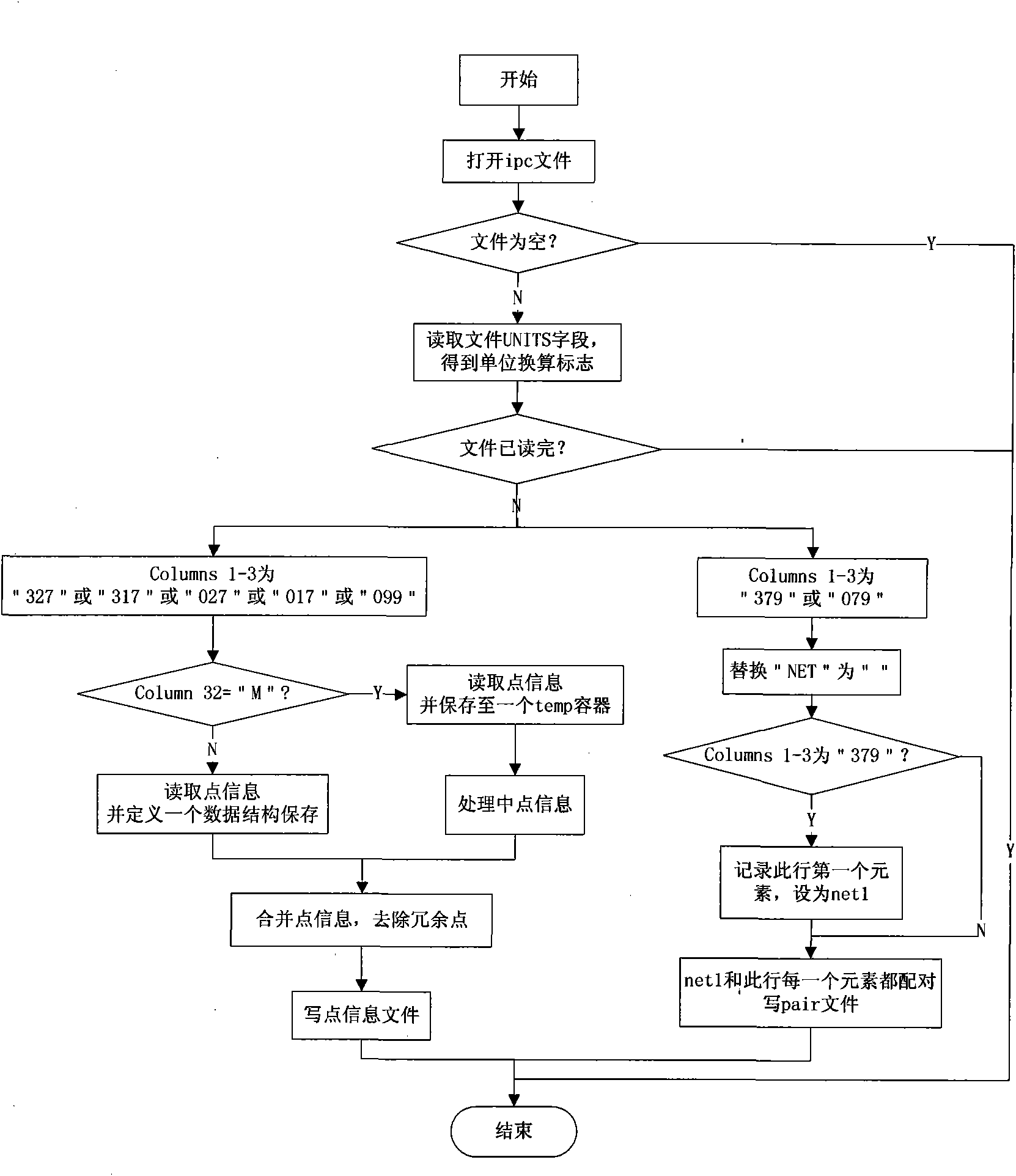

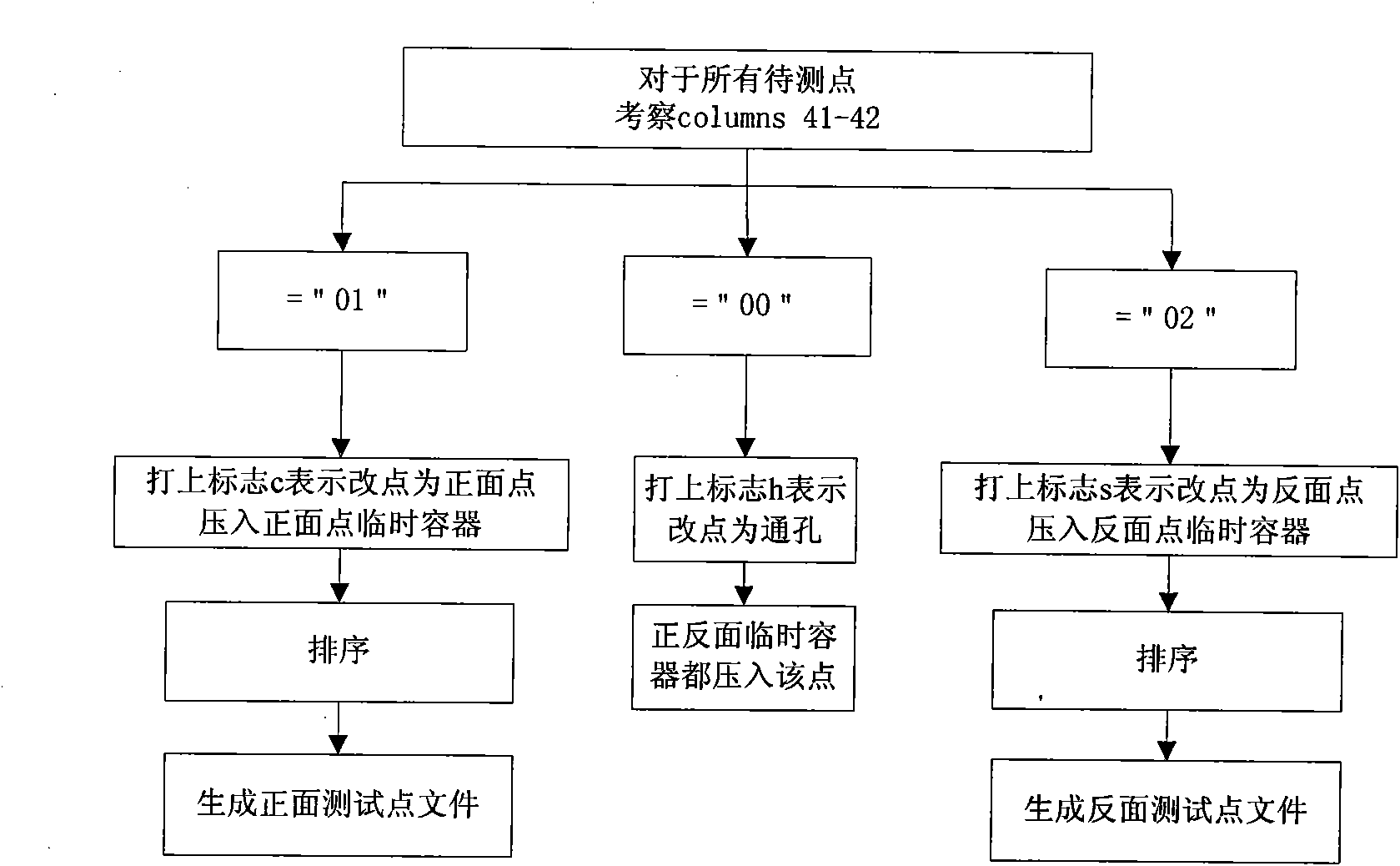

Optimization method of printed-circuit board test path

InactiveCN101667219AShort pathImproved test time efficiencySpecial data processing applicationsElectronic industryComputer science

The invention discloses an optimization method of a printed-circuit board test path, which is characterized in that the optimization method comprises the following steps: A. reading an ipc file to obtain the network number, and the information of front and back mark and coordinate of a point to be tested, and information of adjacent networks; B. preprocessing the information; C. optimizing the path and E and outputting a test file: after open circuit is optimized, a CONTI.LST file is generated according to the standard of the IPC file. The information of all points and adjacent networks of thecircuit board to be tested are read by the ipc file, all network numbers are recombined and rearranged according to the principle of four-probe test, and the path of probe running is optimized as faras possible in the premise of not missing any networks, thus leading the path of probe running of a flying probe tester to be shortest; and by practical application, the result shows that the efficiency on testing time is improved by 3 percent to 16 percent compared with the existing software, therefore, the optimization method can be widely used in the manufacturing industry of printed-circuit boards and the electronic industry.

Owner:CHONGQING UNIV

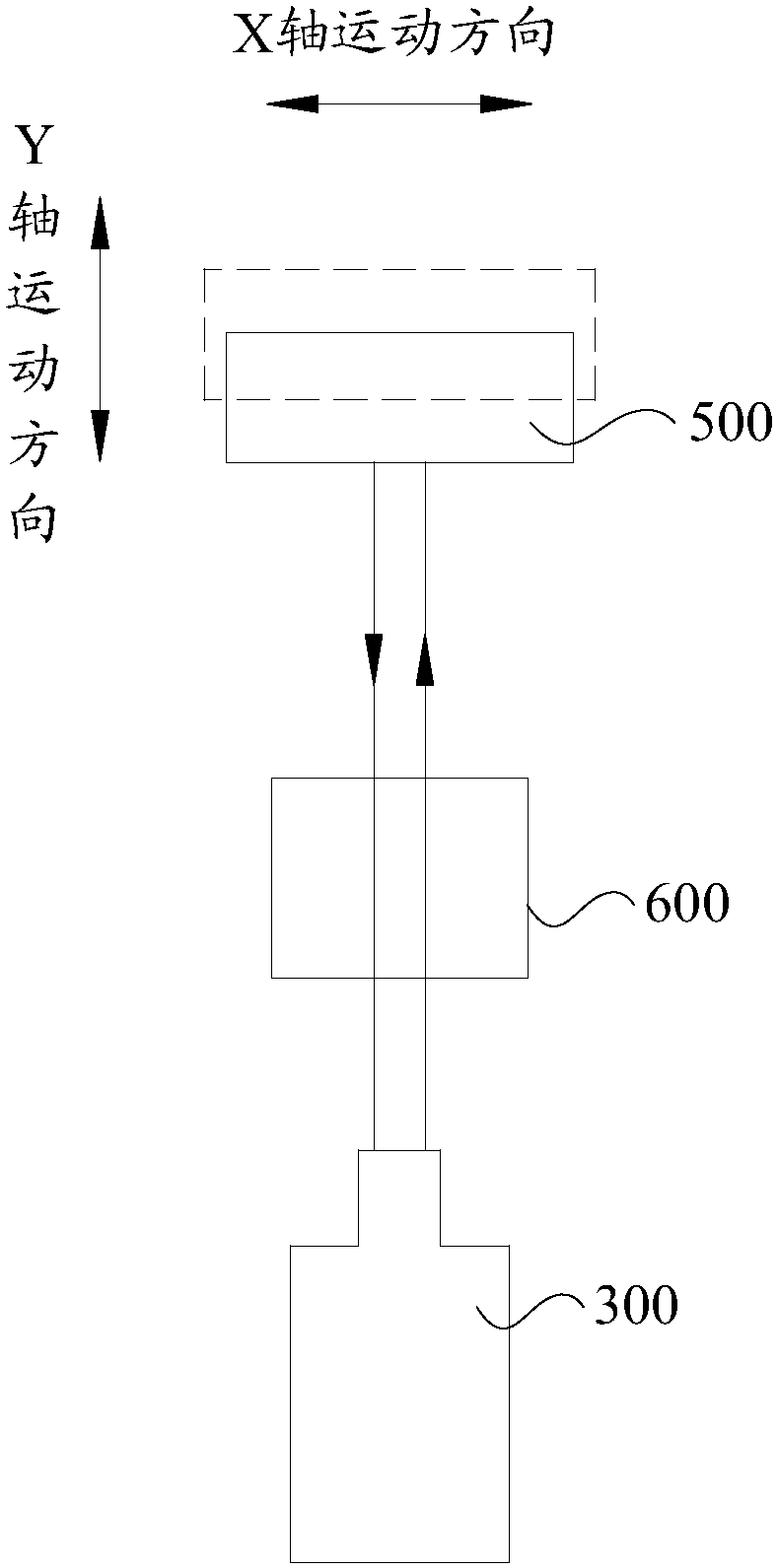

Device and method for automatically detecting PCB (printed circuit boards)

InactiveCN104793126AAchieve accuracyFully automatedElectronic circuit testingFlying probeEngineering

The invention discloses a device for automatically detecting PCB (printed circuit boards). The device comprises a support. A tray bearing table, an X-axis movement assembly, a Y-axis movement assembly, a detecting assembly and a second camera assembly are arranged on the support, a grabbing adjusting assembly is arranged on the X-axis movement assembly, a first camera assembly is arranged on the grabbing adjusting assembly, and the grabbing adjusting assembly comprises a vacuum sucker; the to-be-detected PCB are sucked by the vacuum sucker and then move along with the X-axis movement assembly and the Y-axis movement assembly to the detecting assembly, so that circuits can be detected. The device for automatically detecting the PCB has the advantages that the PCB can be automatically grabbed by the vacuum sucker, the device is provided with an automatic calibrating adjusting mechanism, and accordingly the surfaces of the PCB can be effectively protected from being damaged; flying probes can be accurately and automatically detected owing to the automatic detecting calibrating adjusting mechanism.

Owner:深圳德森精密设备有限公司

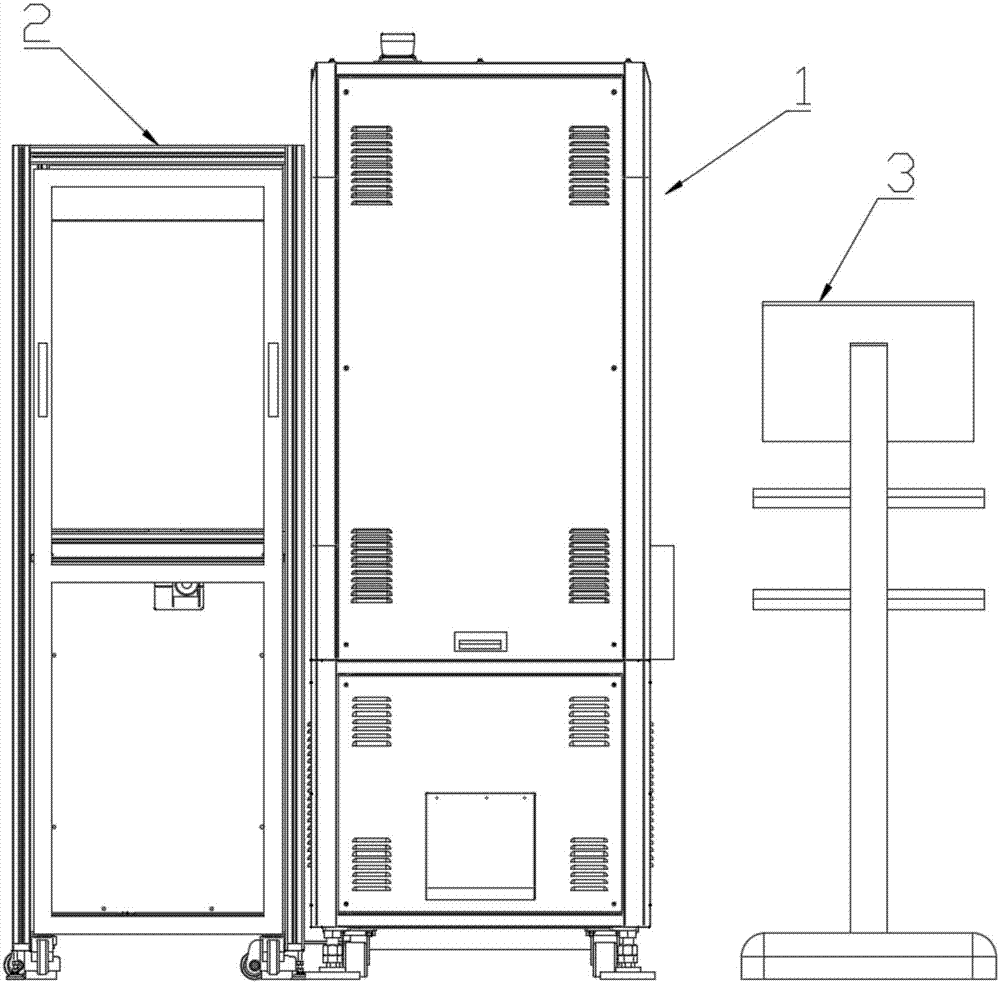

Flying probe testing system

PendingCN107121632AAvoid the influence of human factorsReduce vibrationPrinted circuit testingBarcodeEngineering

The invention discloses a flying probe testing system. The system comprises a flying probe testing machine as well as an automatic feeding and discharging mechanism and a control panel which are arranged on one side of the flying probe testing machine, wherein the flying machine testing machine comprises a base as well as a clamp and a testing shaft which are arranged on the base; the automatic feeding and discharging mechanism comprises a manipulator, a suction cup mounted on the manipulator and a code scanning device. Boards can be automatically supplied to or taken off from the clamp through the manipulator of the automatic feeding and discharging mechanism, and influences of artificial factors on flying probe testing results during manual board feeding and discharging are avoided effectively; the base is a mineral cast base, vibration caused during high-speed operation of the testing shaft can be reduced effectively, a mineral cast machine body formed by pouring mineral materials into a metal frame is adopted, interference of external electromagnetic fields can be reduced, and the testing precision is improved; bar codes or two-dimensional codes on PCBs are scanned and recognized through the code scanning device, time and mistakes made during artificial recognition of models of the PCBs are effectively reduced, and the work efficiency is improved.

Owner:SHENZHEN MICRONIC TECH

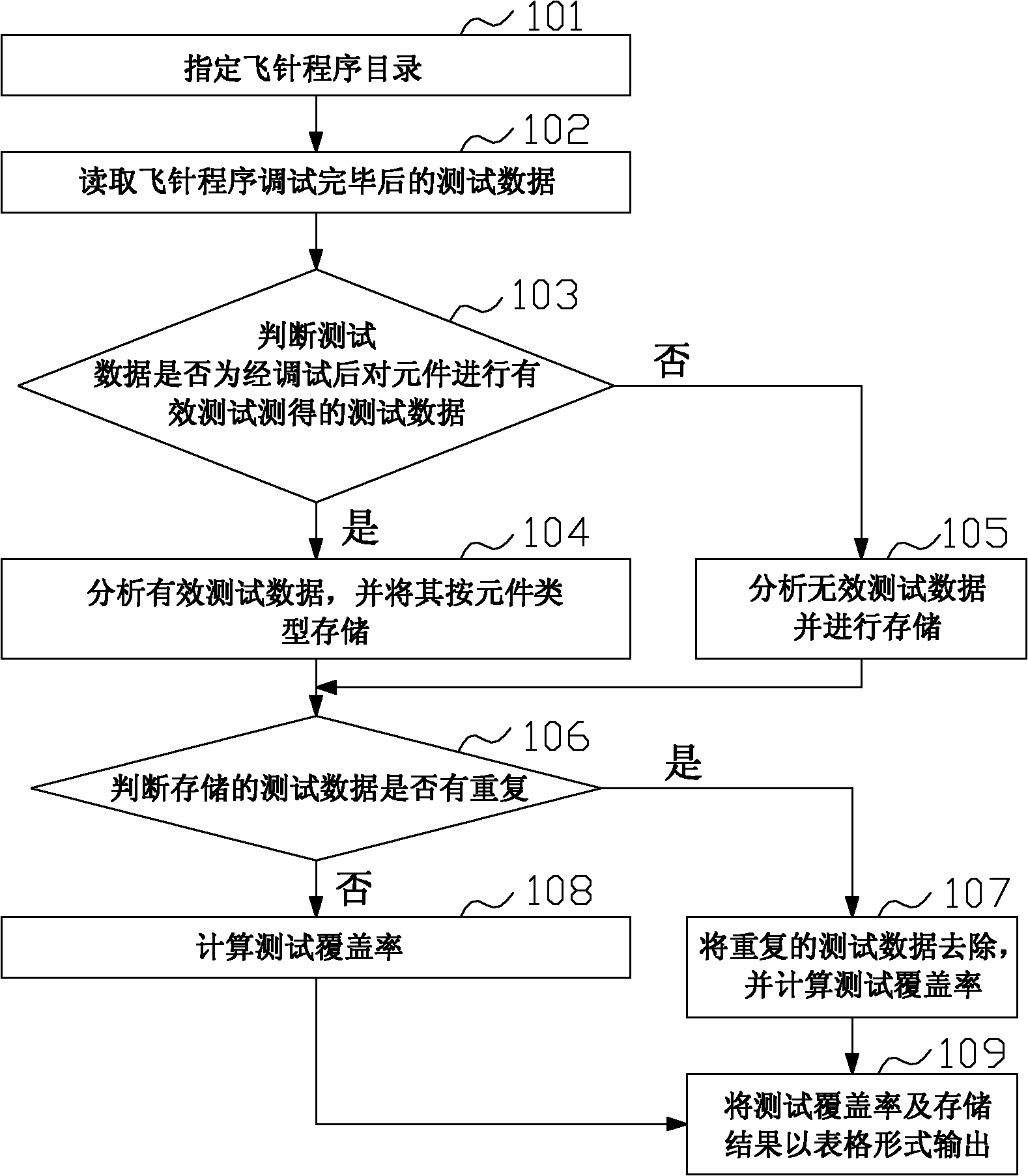

Method for automatically generating test coverage rate of flying probe test program

InactiveCN101989201AIntuitive acquisitionSpecific program execution arrangementsIndividual semiconductor device testingProgramming languageAutoanalysis

The invention provides a method for automatically generating test coverage rate of a flying probe test program, which comprises the following steps of: appointing a flying probe program menu; reading the test data after testing and debugging a flying probe; judging whether the debugged test data is valid to test an element, if so, determining the test data is valid, if not, determining the test data is invalid; analyzing and storing the valid test data according to type of the element and storing name of the element and corresponding valid test data; analyzing the invalid test data and storing the invalid test data in class; judging whether the stored test data is repeated or not, if so, removing repeated test data, and if not, calculating the test coverage rate; and outputting the test coverage rate and storage result. The invention analyzes automatically and stores the test results and collects test results in form of tables so that the test coverage rate or other information can be acquired intuitively.

Owner:MITAC COMP (SHUN DE) LTD

Manufacturing process of double-sided ultra-thick copper plate

InactiveCN109640529ARemove completelyReduce the impact of platingPrinted circuit aspectsConductive material chemical/electrolytical removalSolder maskFlying probe

A manufacturing process of the double-sided ultra-thick copper plate comprises the following steps: material distribution; performing first plate electroplating thick copper; drilling positioning holes in the side edges of the substrate; pressing a circuit dry film for the first time and performing acid etching for the first time; carrying out first resin printing, namely filling the resin in thearea with the copper layer etched in the last step, and keeping the resin layer and the copper layer flat after printing; carrying out primary copper deposition and secondary plate electroplating thick copper; pressing a circuit dry film for the second time and performing acid etching for the second time; Resin printing for the second time; repeating the steps 6-8 for n times, wherein n is greaterthan or equal to 0; drilling a via hole in the substrate; repeating the sixth step and the seventh step again; and finally, carrying out surface resistance welding, character printing, surface treatment, shaping, flying probe, FQC and packaging on the substrate to prepare the double-sided ultra-thick copper plate. Multiple times of etching are adopted, so that the bottom copper of the dry film can be completely removed in each time of etching; And meanwhile, resin is filled for multiple times, so that the poor solder mask printing phenomenon caused by too thick copper layers is reduced.

Owner:深圳万基隆电子科技有限公司

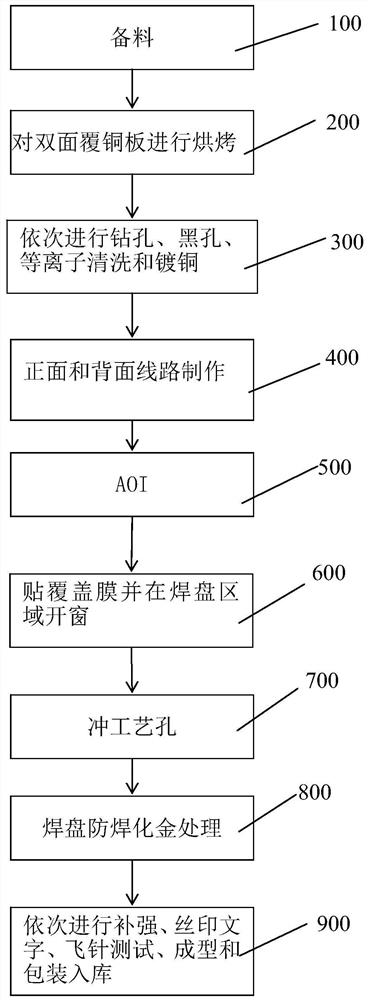

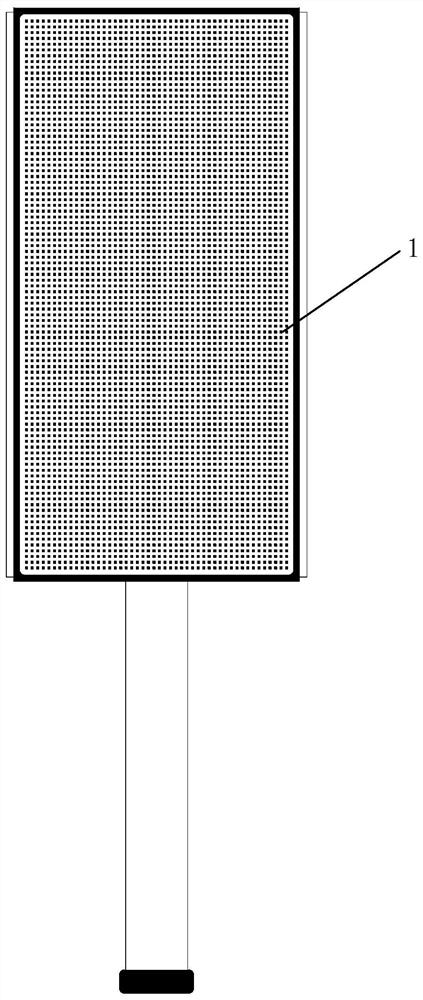

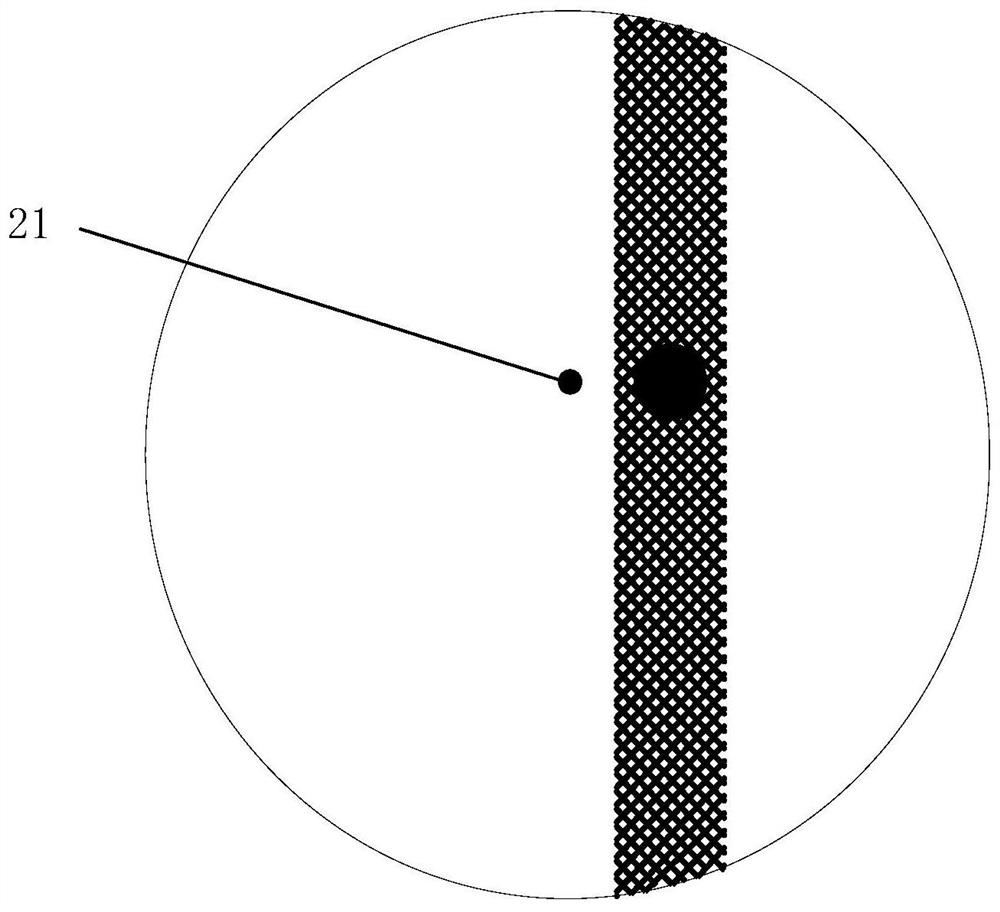

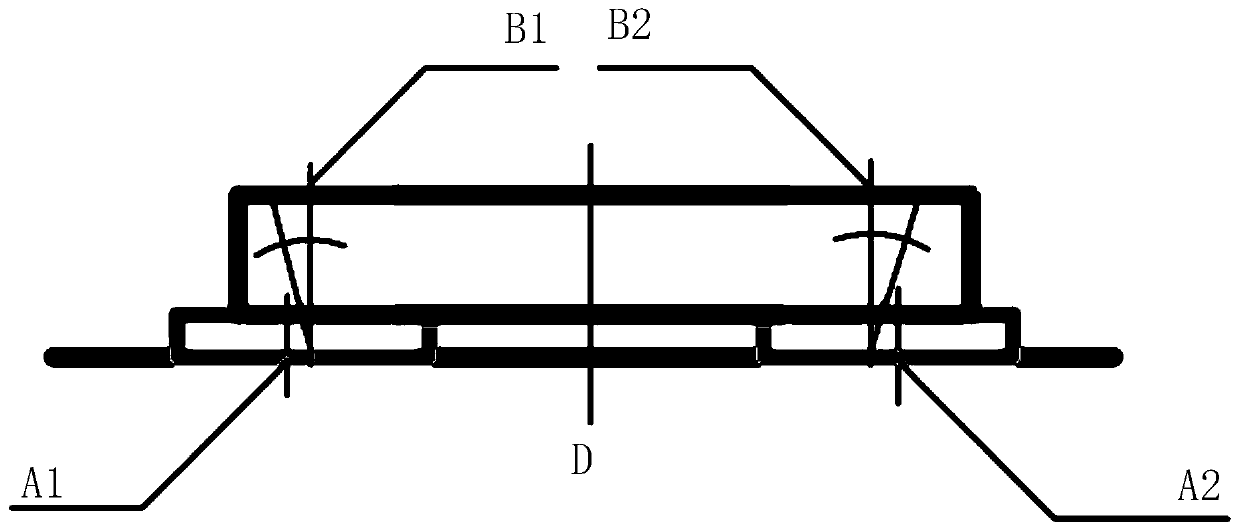

Manufacturing method of Micro LED flexible circuit board

ActiveCN111901968AEnsuring Exposed Offset AccuracyImprove bindingConductive material chemical/electrolytical removalNon-metallic protective coating applicationScreen printingSolder mask

The invention relates to a manufacturing method of a Micro LED flexible circuit board. The Micro LED flexible circuit board is a double-sided board and is provided with Micro LED bonding pads distributed in a matrix mode. The method comprises the following steps: preparing materials, cutting a double-sided copper-clad plate of a preset size, and a white glue layer being arranged between a copper layer and a base material of the double-sided copper-clad plate; baking the double-sided copper-clad plate; sequentially carrying out drilling, hole blackening, plasma cleaning and copper plating; manufacturing front and back circuits; aOI, controlling the gap of the wire to be within 10% of the wire width; wherein the Micro LED bonding pad surface needs to use a white covering film, the non-MicroLED bonding pad surface uses a yellow covering film, and the white covering film corresponding to the Micro LED bonding pad region needs to be windowed; conducting punching; carrying out solder mask gold melting treatment on the bonding pad, wherein the photosensitive ink is white; sequentially carrying out reinforcing, character silk-screen printing, flying probe testing, forming, packaging and warehousing. According to the invention, the exposure offset precision of the Micro LED bonding pad can be ensured, the light reflectivity and the binding force between the photosensitive ink and a circuit are improved, and the product quality is improved.

Owner:厦门爱谱生电子科技有限公司

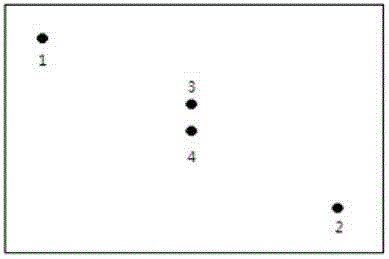

Target point calculation method for flying probe test

ActiveCN110333469AImprove accuracyHigh precisionElectrical measurementsUsing optical meansComputer scienceFlying probe

The invention discloses a target point calculation method for a flying probe test, comprising the steps of: S1: loading a light painting file, and obtaining design coordinates of a central point of aPCBA board bonding pad; S2: calculating a target test point and plane coordinates thereof according to the design coordinates of the central point of the PCBA board bonding pad, a pricking point typeand a device package type, and calculating a difference value between the plane coordinates of the target test point and the design coordinates of the central point of the PCBA board bonding pad; S3:calculating a deviation value of the target test point on height; S4: performing distance compensation in combination with the deviation distribution condition of the target test point; and S5: obtaining three-dimensional coordinates of the final target test point. By adopting the target point calculation method disclosed by the invention, by means of the technical means of compensating the difference value between the target test point and the central point of the bonding pad and compensating the height deviation to obtain the coordinates of the final target test point, the problem of inaccurate probe pricking point test in the prior art is overcome, and the purpose of improving the accuracy of electrodes of components and parts in the probe pricking point test is achieved.

Owner:深圳橙子自动化有限公司 +1

Flying probe tester movement shaft positioning precision test system and test method thereof

ActiveCN107621601AGuaranteed InterchangeGuaranteed operabilityElectronic circuit testingLaser beamsFlying probe

The invention relates to a flying probe tester movement shaft positioning precision test system and a test method thereof. The flying probe tester movement shaft positioning precision test system comprises a laser assembly, an angle turning lens group, a reflector group and a single light splitter group. The laser assembly is used for generating a laser beam; the angle turning lens group is used for propagating the laser beam; the reflector group is used for reflecting the laser beam to enable the laser beam to be reflected back into the laser assembly; and the single light splitter group is sued for propagating the laser beam. The flying probe tester movement shaft control method and positioning precision compensation method ensures that a flying probe tester has higher test precision, thereby solving the problem of low test precision of the flying probe tester. Besides, the flying probe tester movement shaft positioning precision compensation method is easy to operate and low in cost.

Owner:HANS CNC SCI & TECH

Manufacturing method of high-frequency mixed pressure printed circuit board

PendingCN110337200AReduce the amount of microetchImprove Hoz, the problem of piercing the bottom PAD of the blind holeMultilayer circuit manufacturePrinted element electric connection formationResistCopper plating

The invention provides a manufacturing method of a high-frequency mixed pressure printed circuit board. The method is characterized in that the method comprises the following steps: cutting-inner layer processing-etching-inspection-browning-pressing-copper reduction-laser drilling-gum residue removal-copper plating-porefilling-copper reduction-porefilling-copper reduction-drilling-degumming-boardplating-outer pattern transfer-etching-AOI detection-solder resist printing-text printing-moulding-flying probe test-silver plating- appearance inspection-packaging. The method solves the problem of not full hole filling of a high-frequency mixed pressure HDI board, optimizes hole filling and surface copper proportion hole filling parameters of the high-frequency mixed pressure HDI board, improvesthe quality problems of thick surface copper and poor uniformity in the prior art and reduces input of labor and material cost.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

Flying probe test machine fast alignment method

ActiveCN107271886ACapture fast and directImprove work efficiencyPrinted circuit testingEngineeringCcd camera

The invention discloses a flying probe test machine fast alignment method. A flying probe test machine comprises one or multiple test shafts, wherein at least one test shaft is provided with a test probe and a CCD camera. The coordinates of an alignment point in an X-axis direction can be fast located through the distance from the initial position of the CCD camera to the board side of a PCB and the distance from the board side to the alignment point. The CCD camera moves in the Z-axis direction of the X-axis coordinates of the alignment point so that the alignment point can be fast located and aligned, and then other alignment points can be aligned. The alignment point of the PCB can be fast searched with the board side of the PCB acting as the reference object so that the work efficiency can be effectively enhanced and the labor intensity of the employees can be reduced.

Owner:SHENZHEN MICRONIC TECH

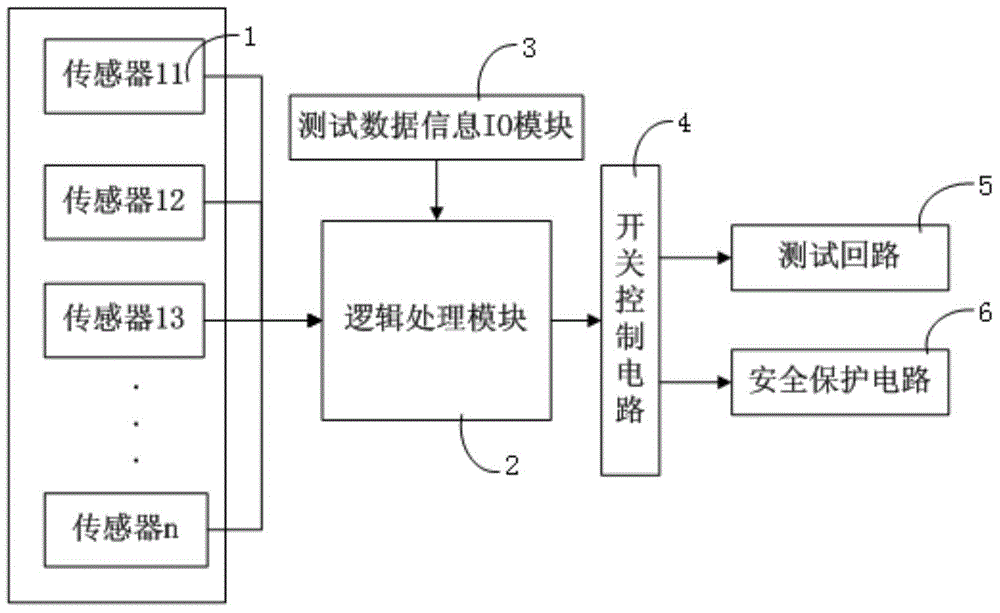

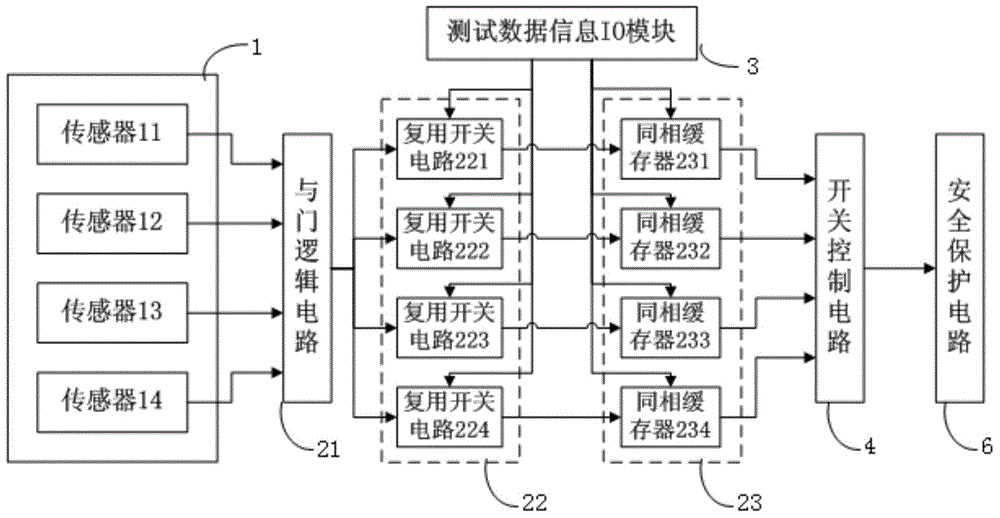

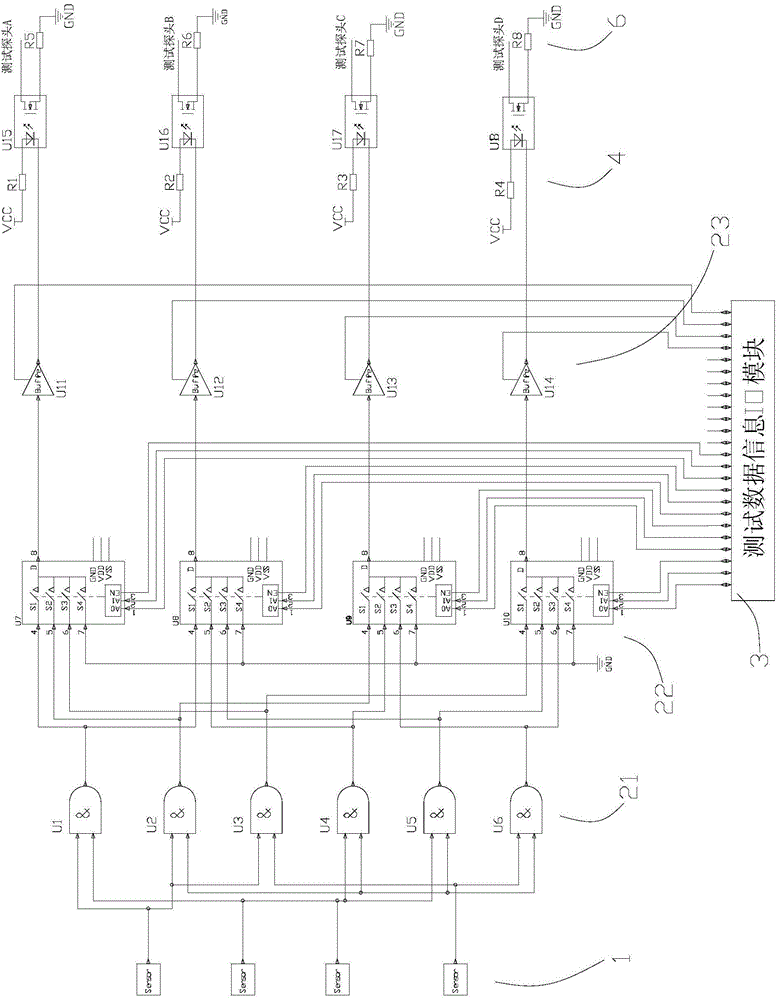

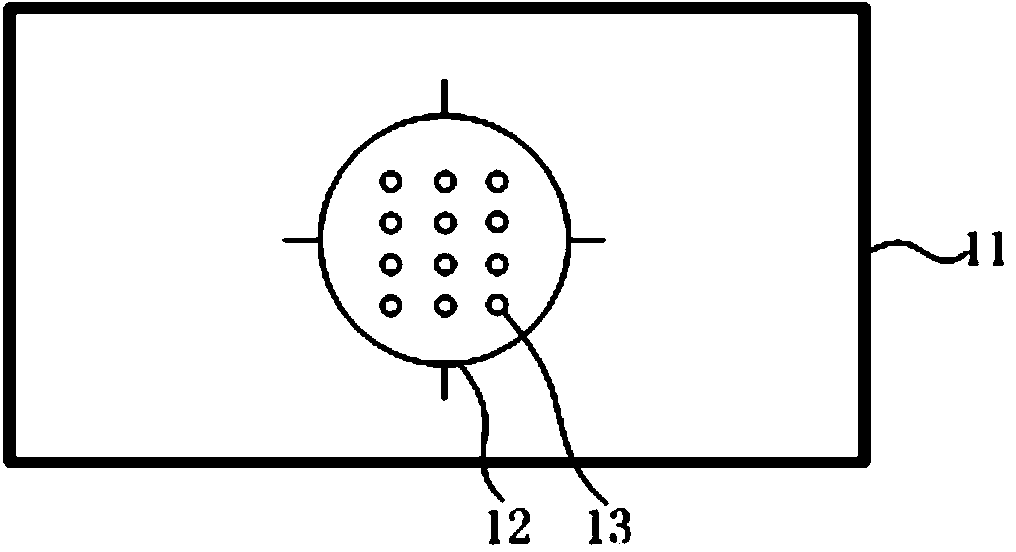

Insulation test control module

ActiveCN104898464AGuaranteed Insulation Test EfficiencyReduce the possibility of electric shockTesting dielectric strengthElectronic circuit testingTest efficiencyData information

The invention relates to the technical field of electronic measurement and discloses an insulation test control module. The insulation test control module comprises at least two contact detection sensors used for sensing whether a test probe of a flying-probe tester is stably contacted with a tested PCB and outputting level signals showing whether the test probe is stably contacted; a logic processing module connected with the contact detection sensors and used for receiving the level signals output by the contact detection sensors, carrying out AND logic processing on the level signals and outputting switch control signals; a test data information IO module connected with the logic processing module and used for providing insulation test control information; a switch control circuit connected with the logic processing module and used for receiving the switch control signals output by the logic processing module and controlling operation of the switch control circuit according to the switch control signals; and a safety protection circuit connected with the switch control circuit. The insulation test control module has the advantages of being high in test efficiency, and capable of eliminating the problem of sparking and improving personal safety.

Owner:HANS CNC SCI & TECH

Silicon through hole patch board wafer testing system and method

InactiveCN104181448AImprove test efficiencyElectrical measurement instrument detailsIndividual semiconductor device testingTest efficiencyProbe card

The invention discloses a silicon through hole patch board wafer testing system and method. The system comprises a fly-probe tester and a circuit board, wherein the fly-probe tester is used for testing a silicon through hole patch board wafer to be tested, the circuit board is used for fixing the silicon through hole patch board wafer to be tested to the fly-probe tester, and position alignment marks for alignment with a rack plate frame of the fly-probe tester are provided. According to the silicon through hole patch board wafer testing system and method, the silicon through hole patch board wafer can be automatically tested through the fly-probe tester, silicon through hole patch board wafers with different layouts can be tested, an automatic testing machine and an automatic probe table do not need to be purchased, corresponding expensive probe cards do not need to be customized according to the silicon through hole patch board wafers with different layouts, testing efficiency is improved, and a testing scheme with low cost is provided.

Owner:NAT CENT FOR ADVANCED PACKAGING

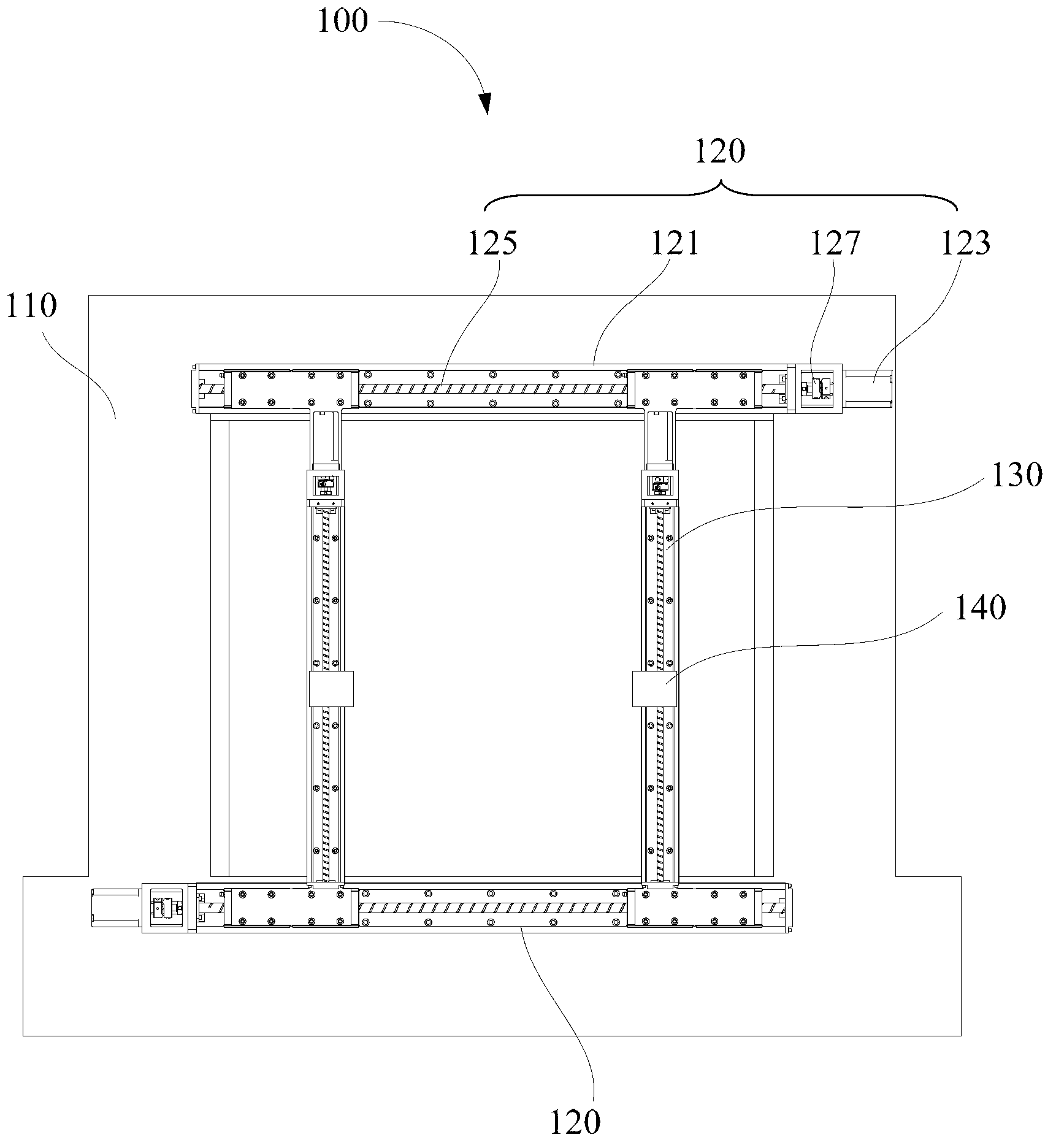

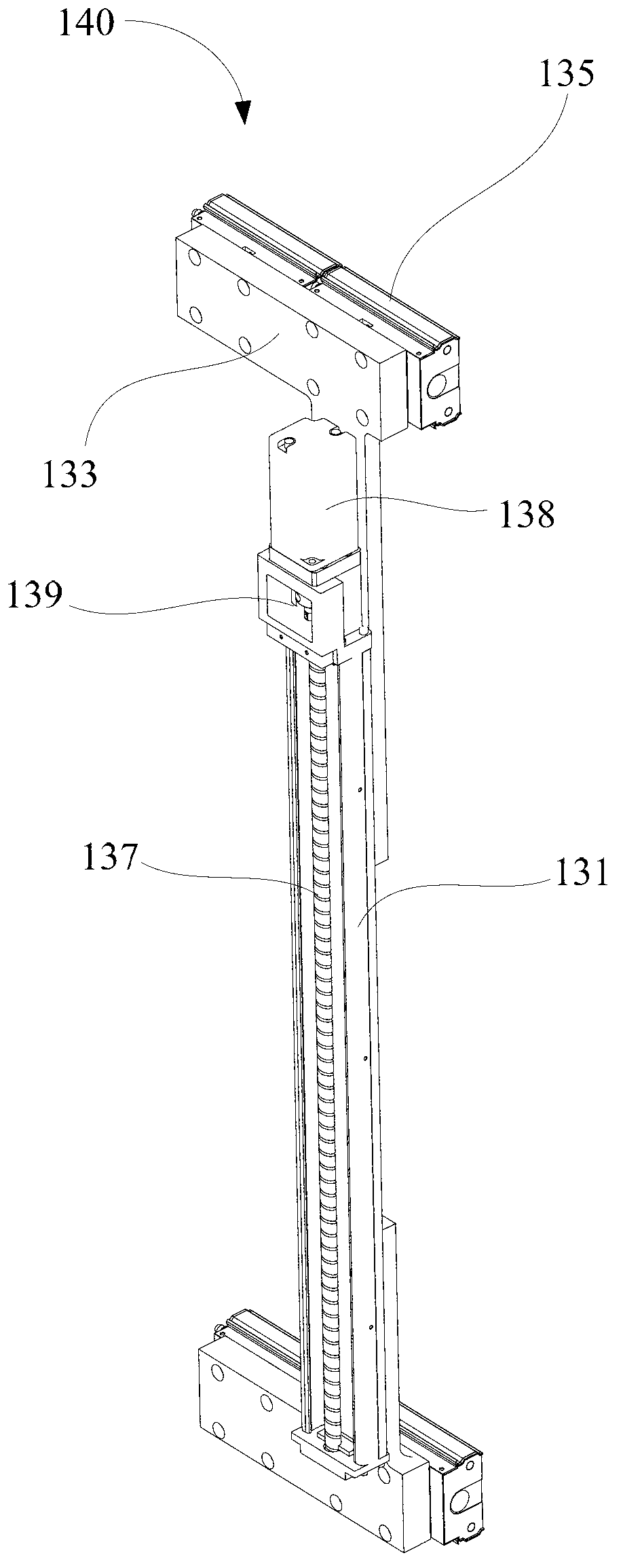

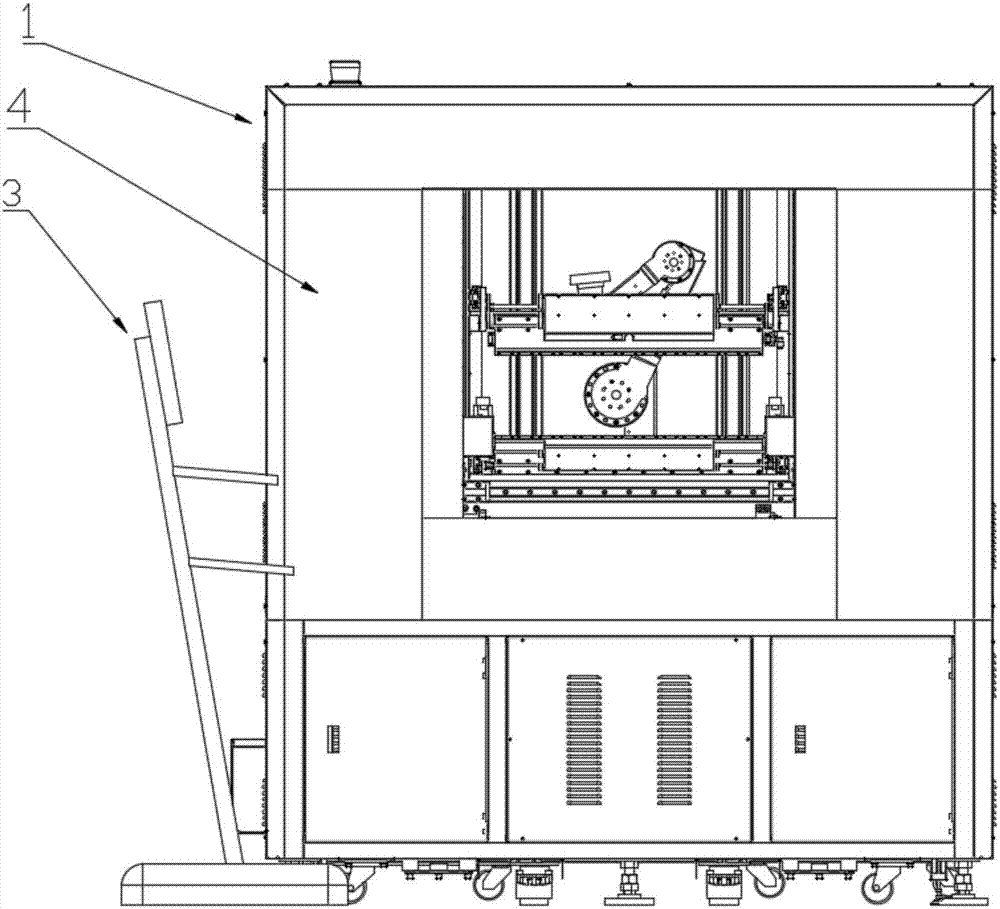

Fully automatic horizontal flying needle test system

The invention relates to a fully automatic horizontal flying needle test system. The system comprises a loading part, a horizontal flying needle test host and a discharging part, the loading part, thehorizontal flying needle test host and the discharging part are simultaneously arranged on a rack, the loading part and the discharging part are respectively disposed at two ends of the horizontal flying needle test host, an automatic feeding part is further disposed on the side of the horizontal flying needle test host, a to-be-detected circuit board is firstly placed on the loading part, the circuit board is grasped by the automatic feeding part to the horizontal flying needle test host for fixing and testing, the automatic feeding part grasps the circuit board detected onto the discharge part, and the classification of qualified products and non-conforming products is completed to complete the test work.

Owner:南通众博信智能科技有限公司

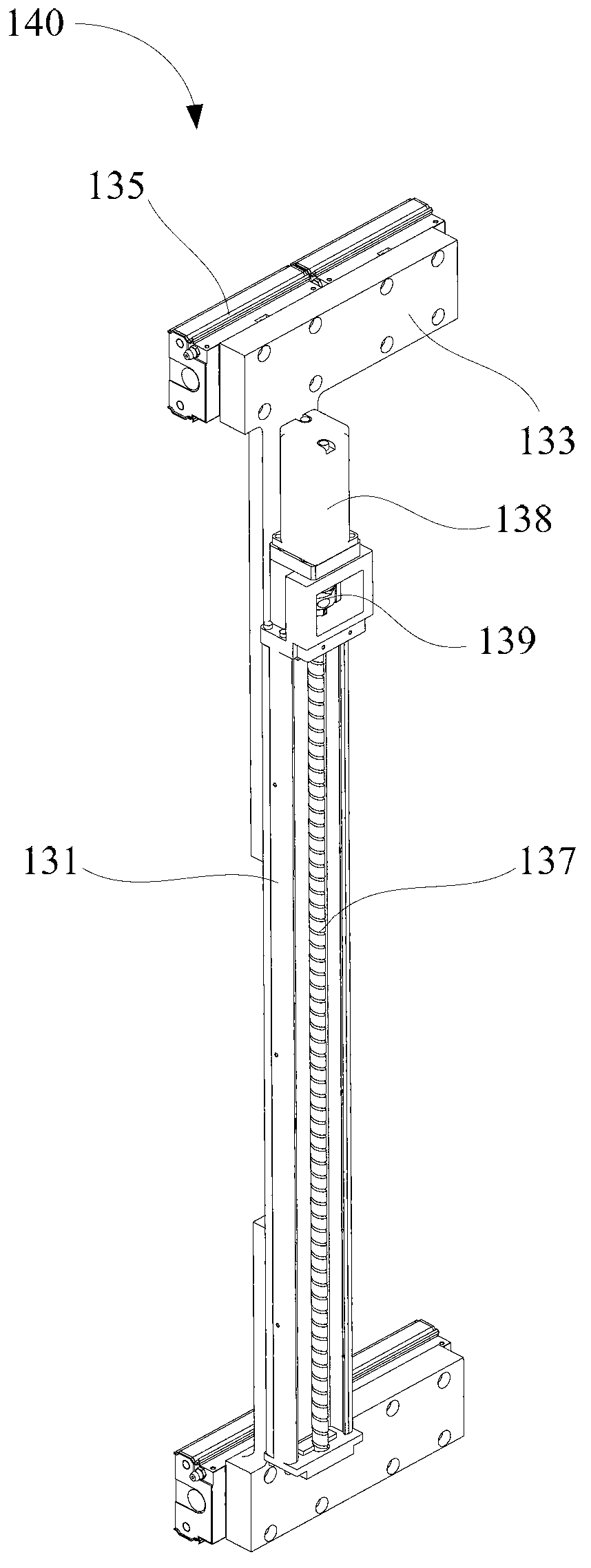

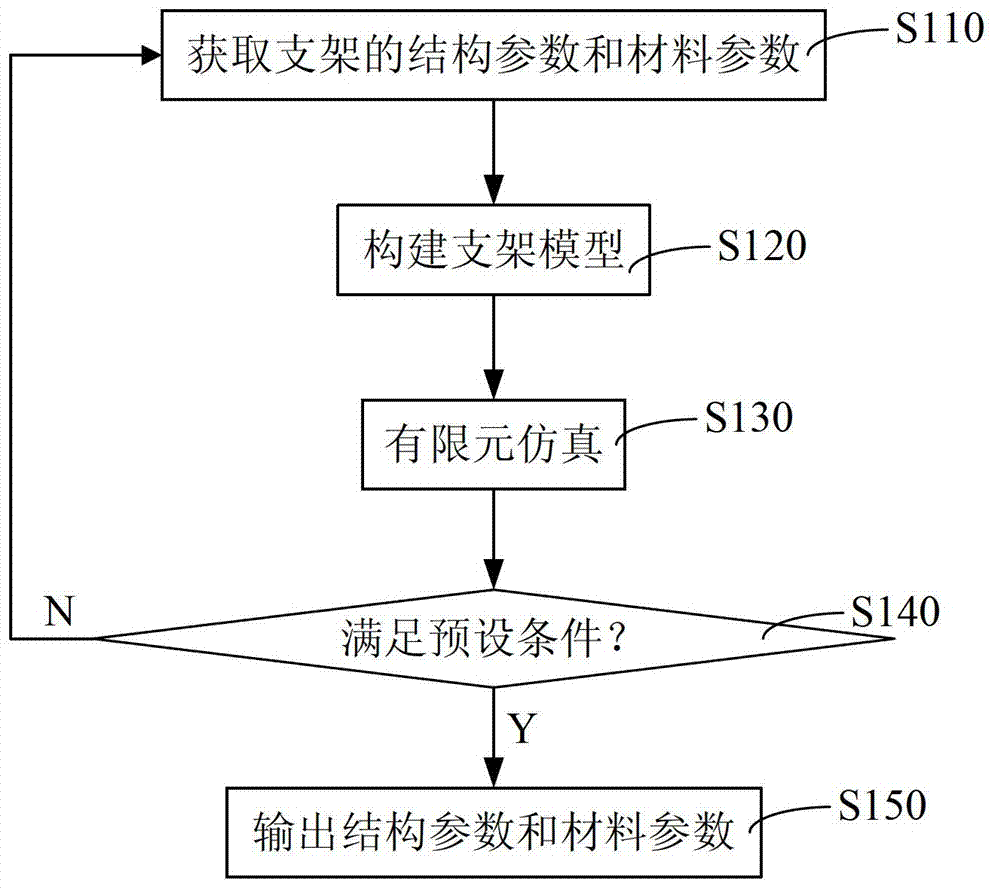

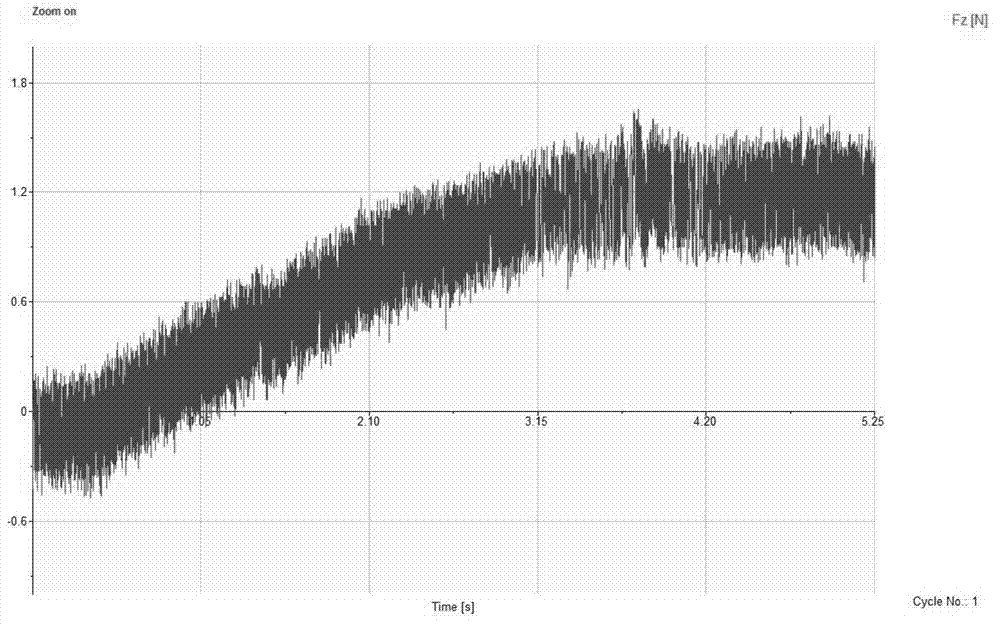

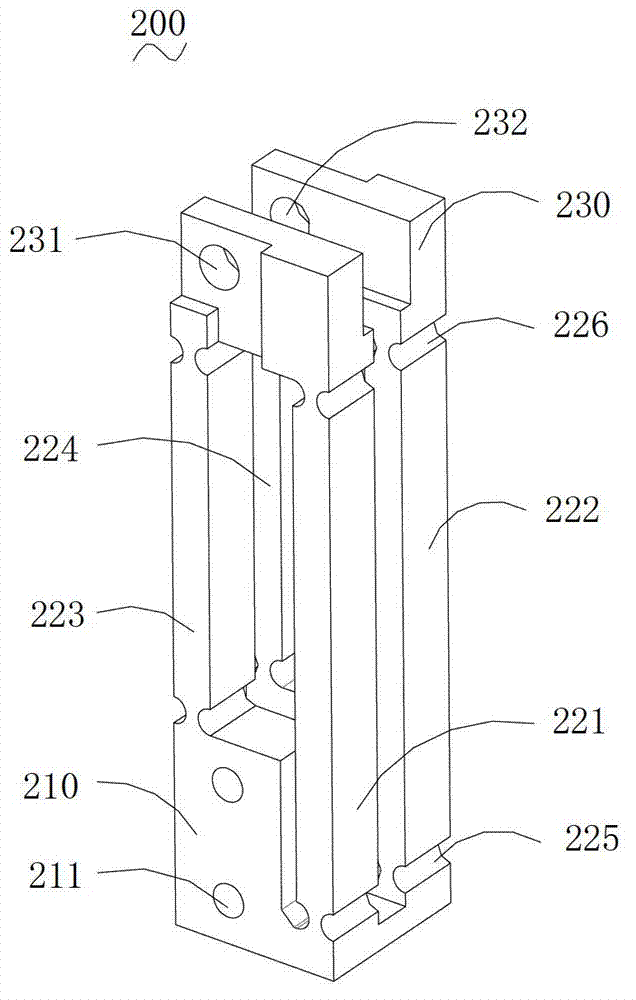

Bracket for measuring head of flying-probe tester and design method of bracket

ActiveCN102735884AModerate stiffnessShort development cycleElectronic circuit testingMeasurement instrument housingEngineeringFlying probe

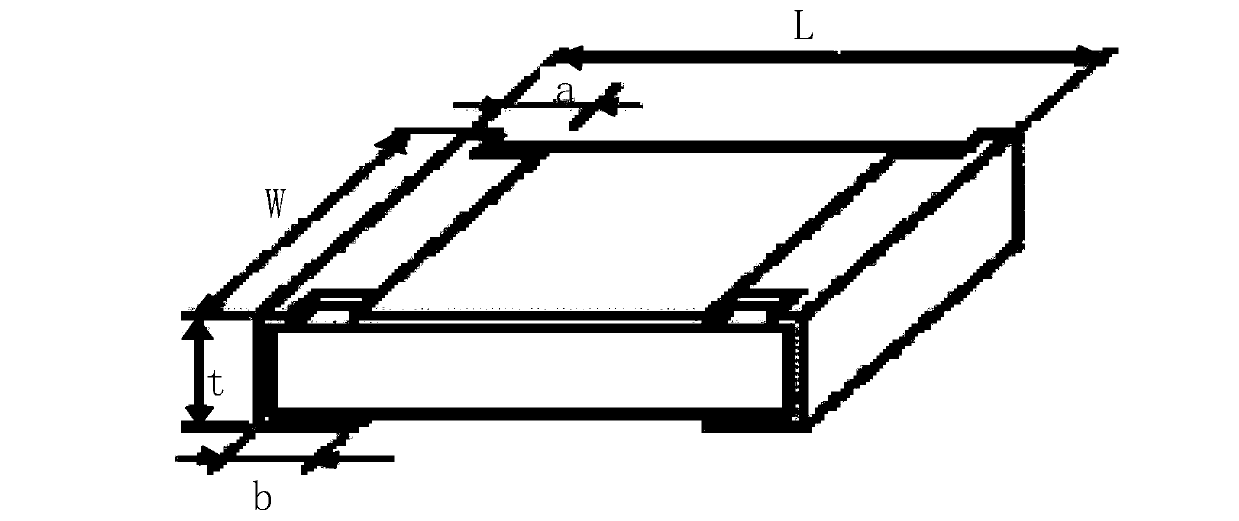

The invention relates to a design method of a bracket for a measuring head of a flying-probe tester. The design method comprises the following steps of: acquiring structural parameters and material parameters of the bracket; constructing a bracket model according to the structural parameters and the material parameters of the bracket; performing finite element simulation on the bracket model; and when a simulation result is in accordance with preset conditions, outputting the structural parameters and the material parameters of the bracket. The bracket which is designed according to the method meets material and structural requirements; and after a test probe is subjected to reverse thrust of a contact surface of a printed circuit board (PCB), the test probe and the contact surface can keep still relative to each other in the backward movement process, and a test probe head cannot be heavily deflected, so testing accuracy is ensured, and scratches can be avoided. Meanwhile, the bracket is moderate in rigidness, and the problems of recessing of the PCB caused by over-high rigidness, high deformation caused by over-low rigidness and over-short service life can be solved. Moreover, the invention also provides the bracket which is designed according to the method.

Owner:HANS CNC SCI & TECH

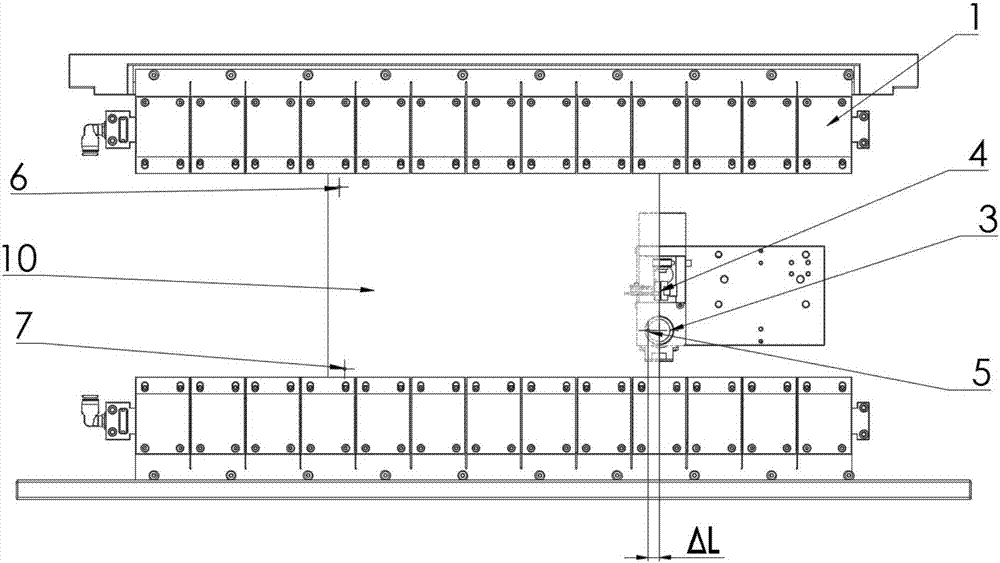

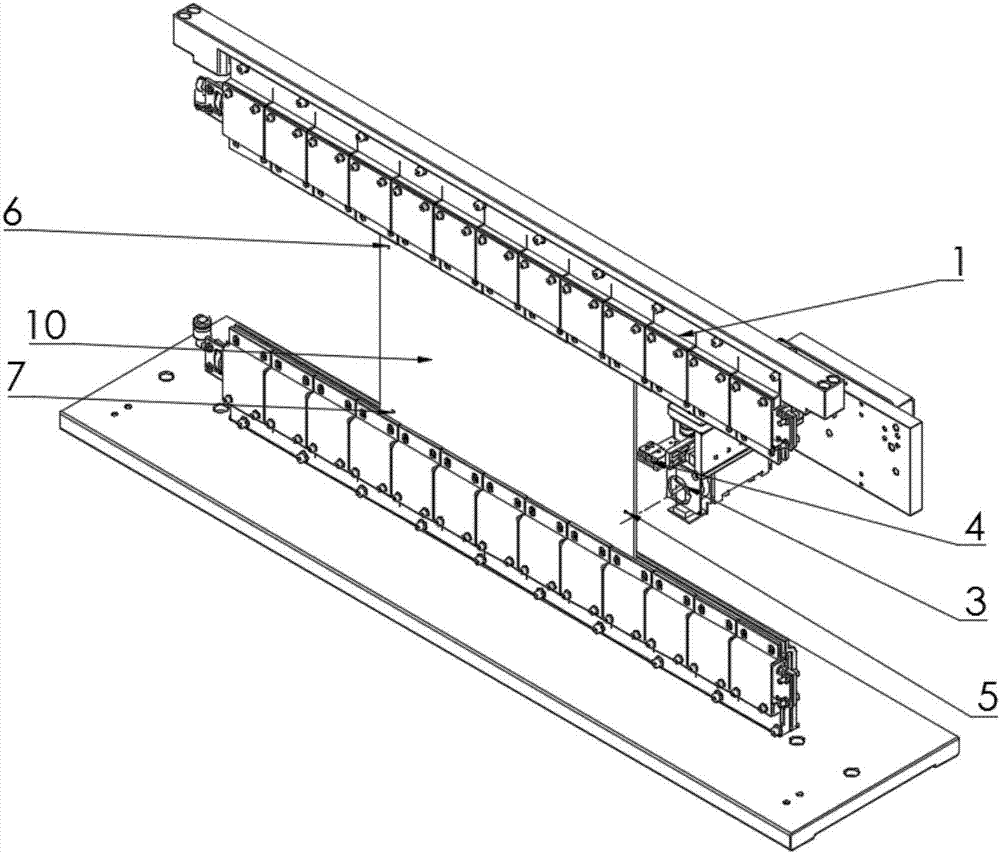

Design method of horizontal flying probe test machine

ActiveCN105067990AExpand the scope of testingShort spanElectronic circuit testingFlying probeDesign methods

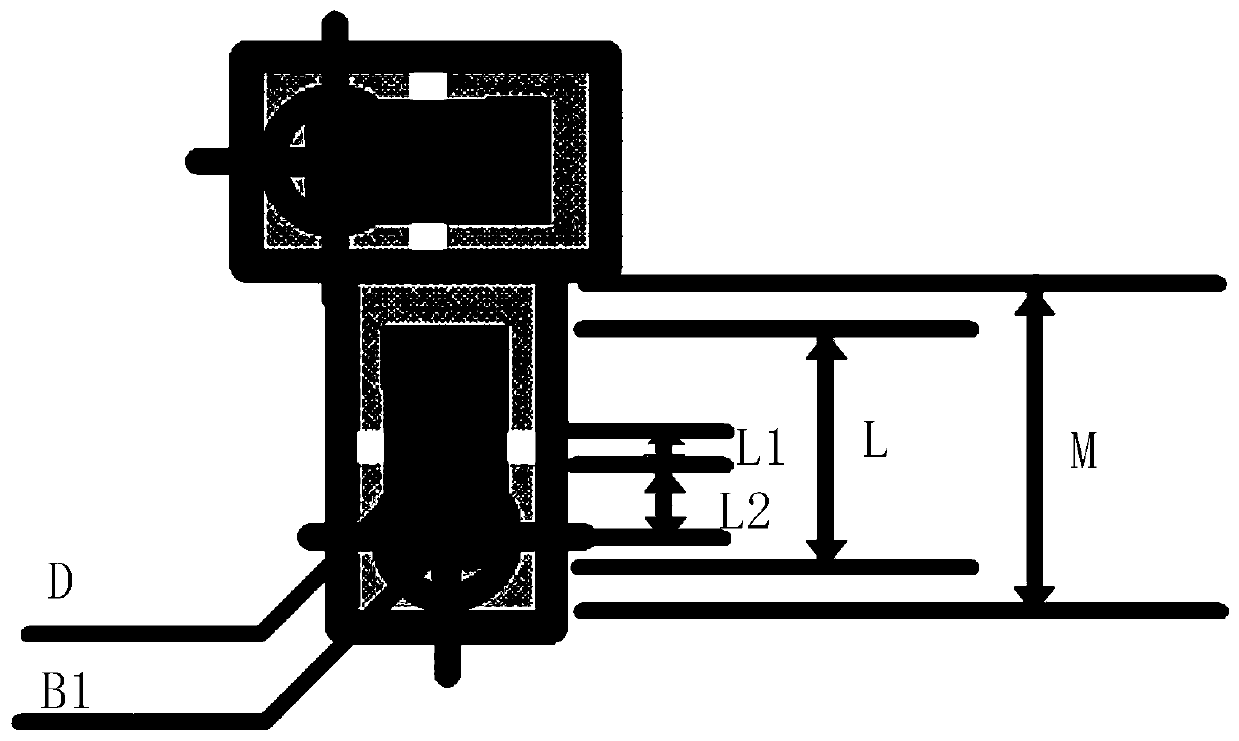

The invention is suitable for the field of flying probe test machine manufacturing, and provides a design method of a horizontal flying probe test machine. The horizontal flying probe test machine comprises a bed body, span beams which are arranged above the bed body, and test heads which are movably arranged on the span beams. The design method comprises the steps that a first cross beam, a second cross beam and a third cross beam are suspended above the bed body in the same direction; two span beams are suspended beneath first, second and third cross beams; two first drive devices which drive two span beams to move along the first cross beam are arranged on both sides of the end part of the first cross beam; the first cross beam is located in the middle of the bed body; and the second cross beam and the third cross beam are respectively located on both sides of the bed side. According to the invention, the first drive devices are arranged in the middle of the bed body to drive the middle position of the span beams; the horizontal flying probe test machine has the advantages of short overall span, large test range and high test precision; a single-drive mode is used to reduce the cost; and the precision consistency of the drive ends and the driven ends of the span beams is improved.

Owner:HANS CNC SCI & TECH

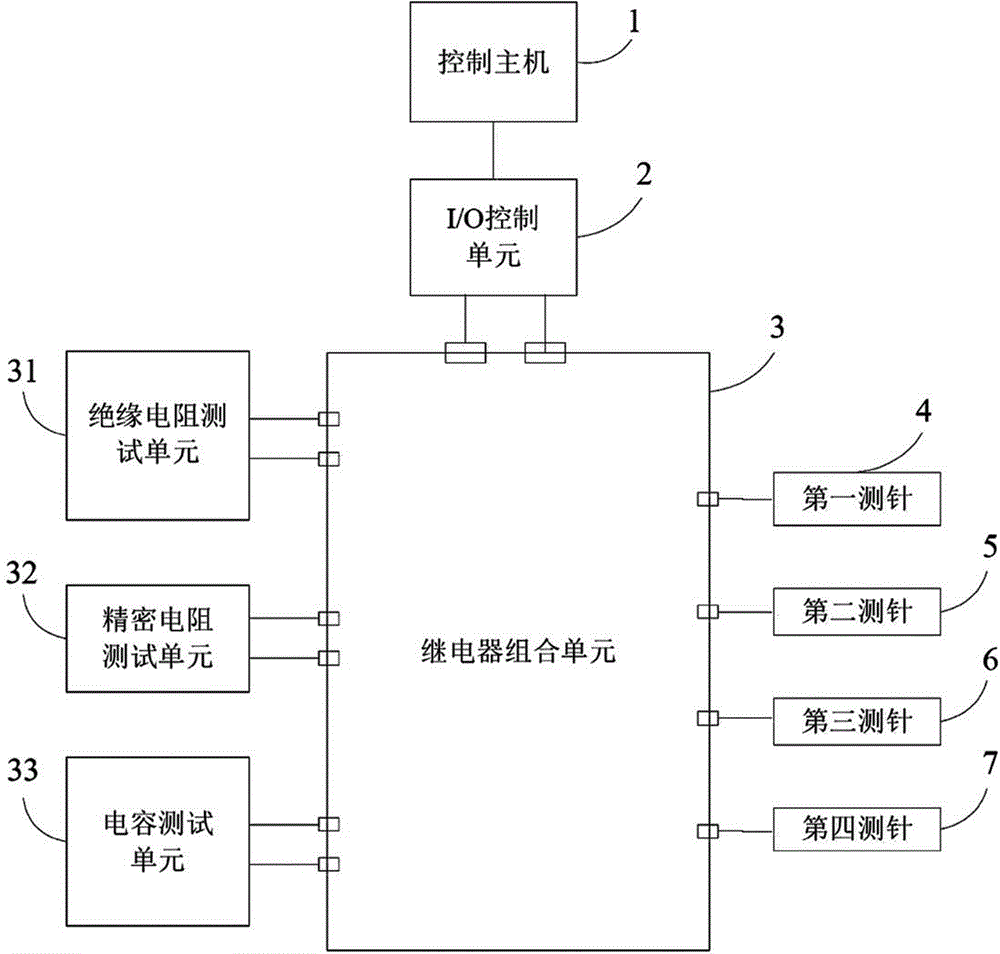

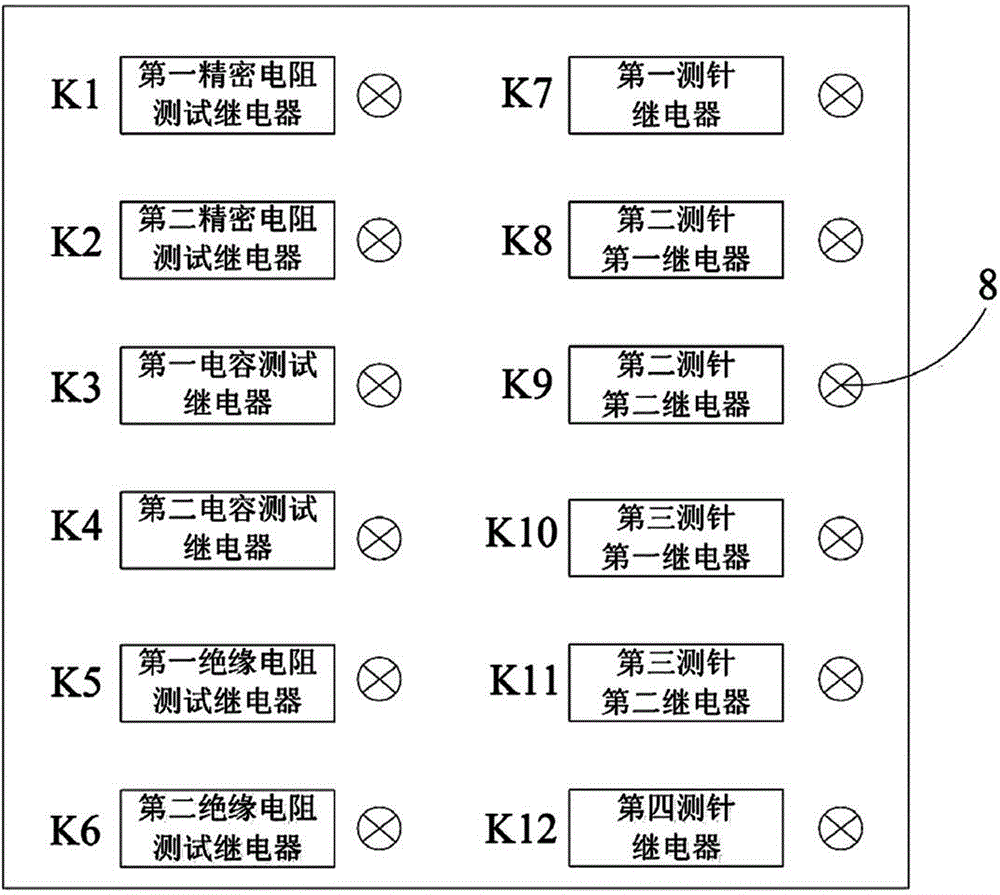

Probe switching control system for flying probe test and method thereof

InactiveCN104820177AReduce usageReduce design difficultyResistance/reactance/impedenceIndividual semiconductor device testingCapacitanceEngineering

The invention provides a probe switching control system for flying probe test and a method thereof. The probe switching control system comprises the components of a control host computer, an I / O control unit, a relay combination unit, an insulation resistance test unit, a precise resistance test unit and a capacitor test unit; wherein the insulation resistance test unit, the precise resistance test unit and the capacitor test unit are electrically connected with the relay combination unit. The relay control unit is furthermore connected with a first probe, a second probe, a third probe and a fourth probe electrically. The control host computer controls the on-and-off state of the combined relay in the relay combination unit through the I / O control unit, thereby realizing selection of a substrate test mode from insulation resistance test, precise resistance test and capacitance test, and switching a probe assembly in a corresponding substrate test mode. The probe switching control system for flying probe test and the method have functions of reducing number of used relays, reducing mounting dimension, reducing use cost and designing difficulty for an array switching control board, and improving test efficiency and reliability in control and operation of the whole system.

Owner:THE 45TH RES INST OF CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com