Detection method for monitoring open-short circuit functional defects of printed-circuit board step hole

A printed circuit board and detection method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of easily crashing the test knife, slow detection speed, introduction of conventional products, etc., to ensure no leakage of quality, The overall performance is stable and the test efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

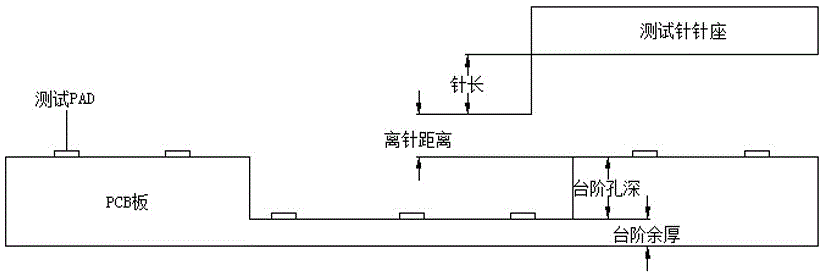

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

[0023] A detection method for detecting open and short-circuit functional defects of stepped holes of a printed circuit board, characterized in that it includes the following steps:

[0024] The first step is to make the test file. Firstly, select the flying probe tester with different needle lifting height according to the depth of the steps, and then make the test file according to the parameters of the flying probe tester. The completed test file will be marked on the operation process card , for step slabs with multi-level step holes or the height difference between steps exceeds 0.5mm, test files for steps at all levels should be made separately according to the above operations.

[0025] The second step is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com