Patents

Literature

65 results about "MicroLED" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MicroLED, also known as micro-LED, mLED or µLED, is an emerging flat-panel display technology. microLED displays consist of arrays of microscopic LEDs forming the individual pixel elements. When compared with widespread LCD technology, microLED displays offer better contrast, response times, and energy efficiency.

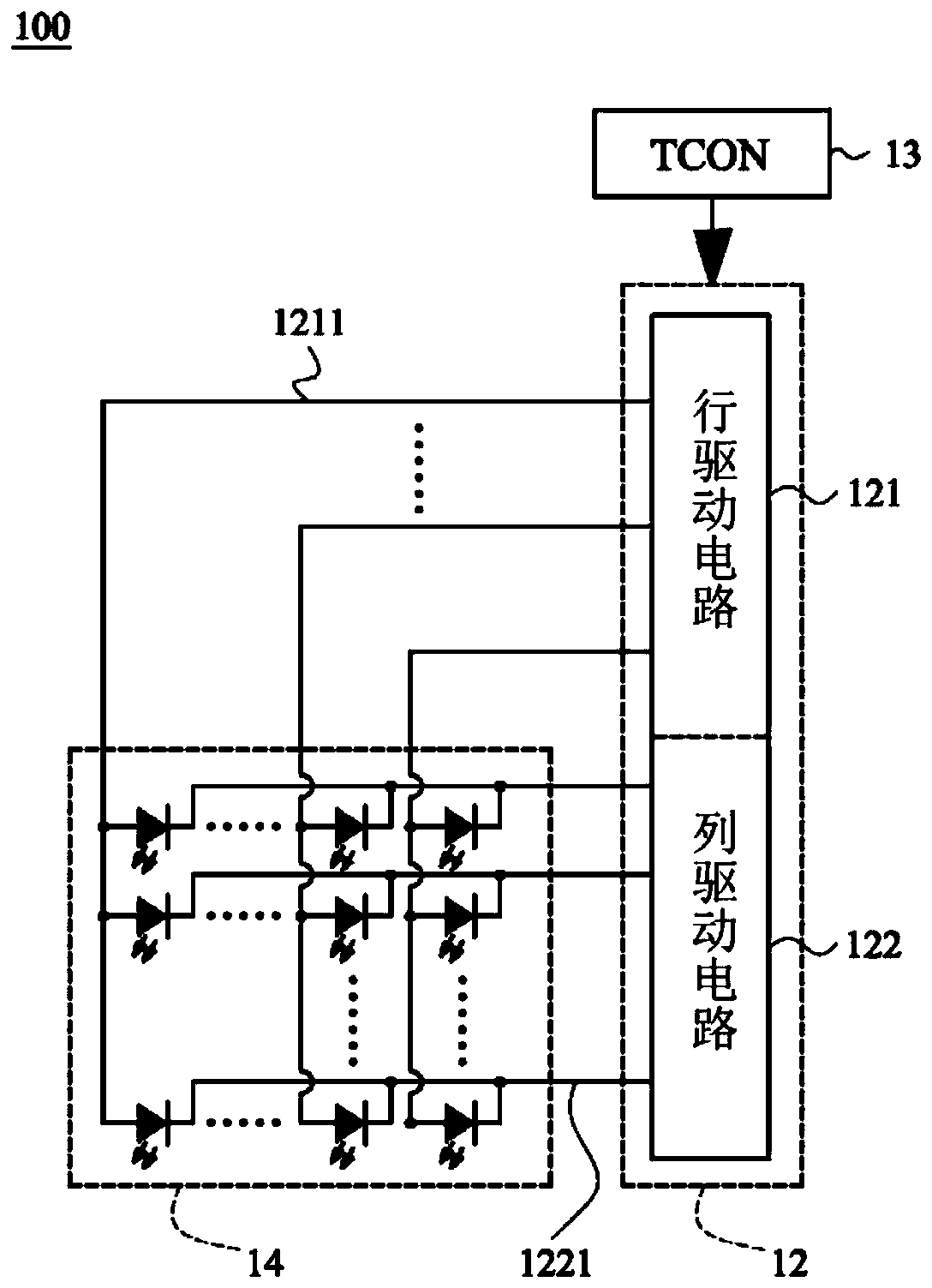

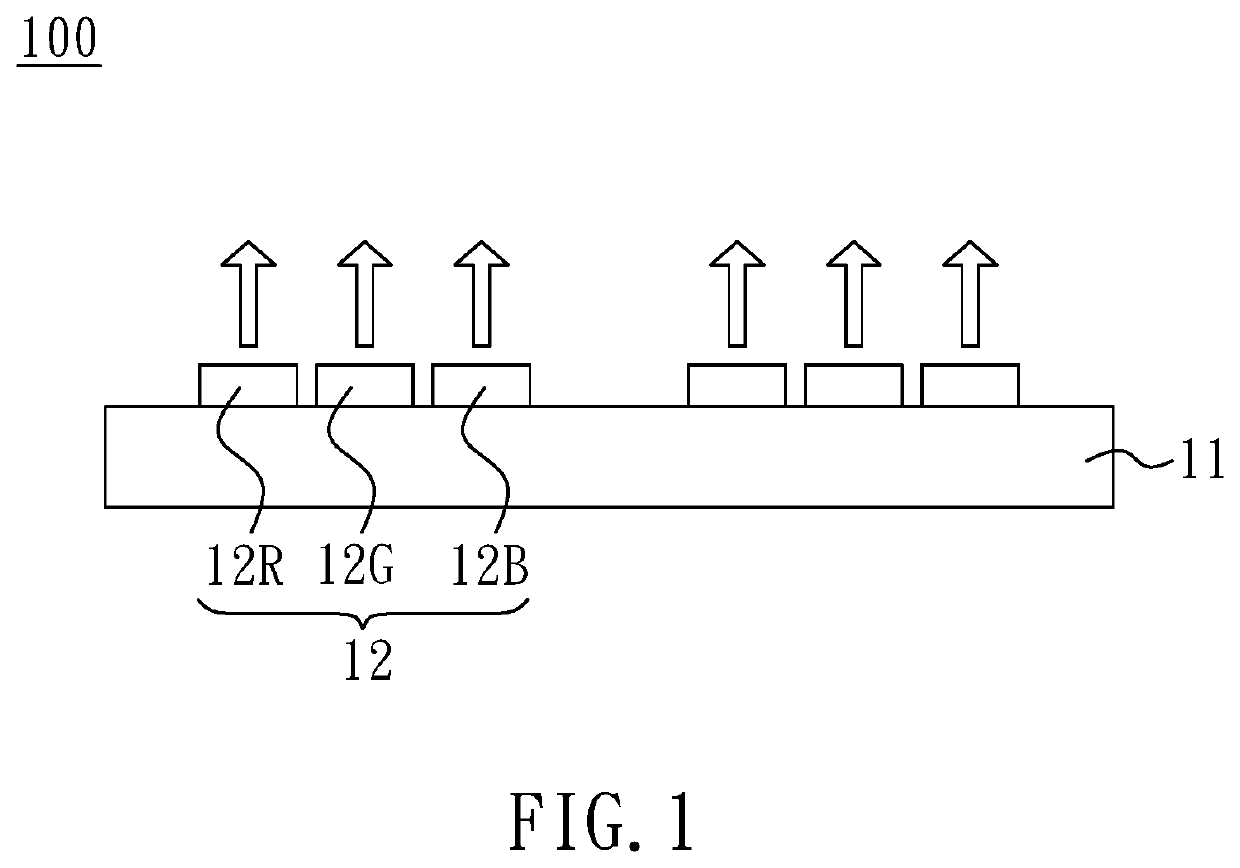

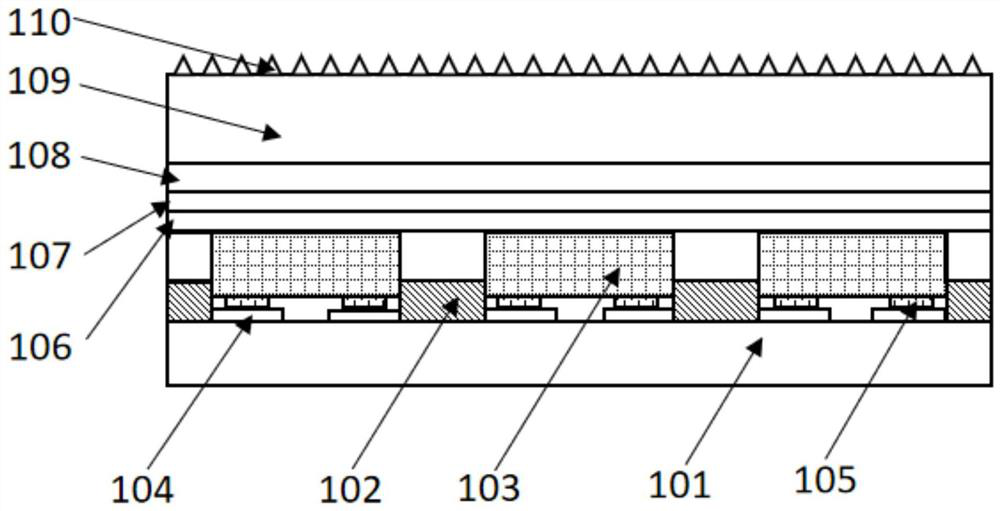

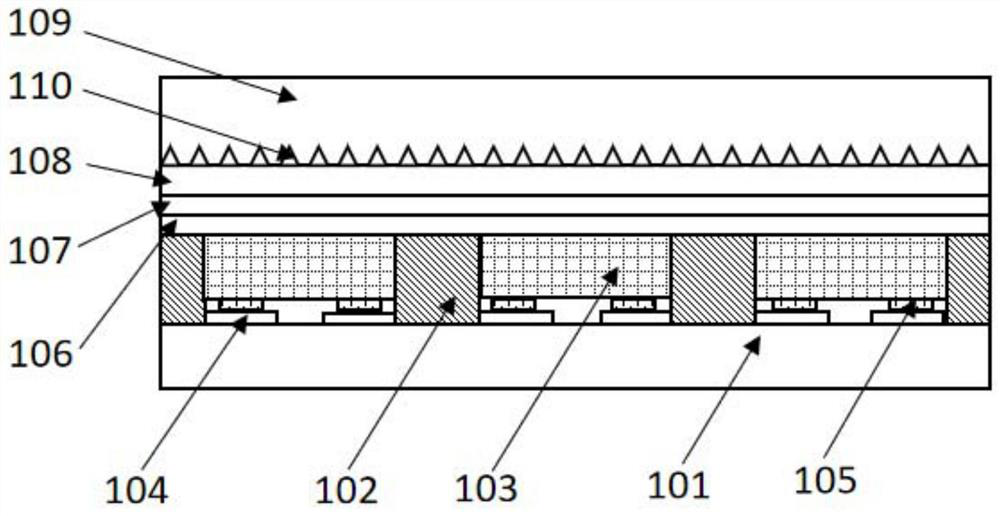

Micro light-emitting diode display device

InactiveCN106098720AReduce manufacturing difficultyHigh color purityElectroluminescent light sourcesSolid-state devicesPhotoluminescenceDisplay device

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

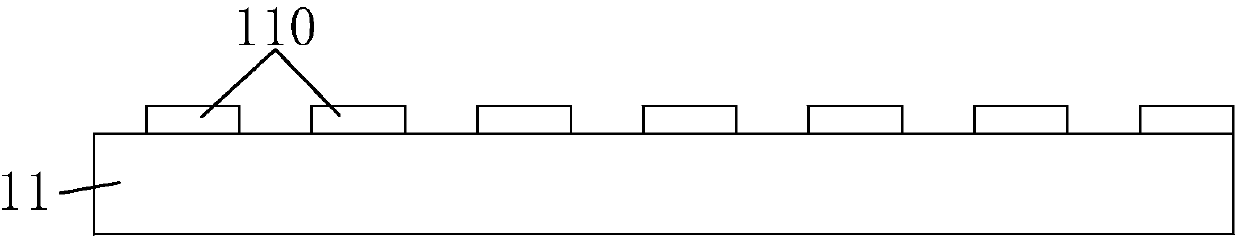

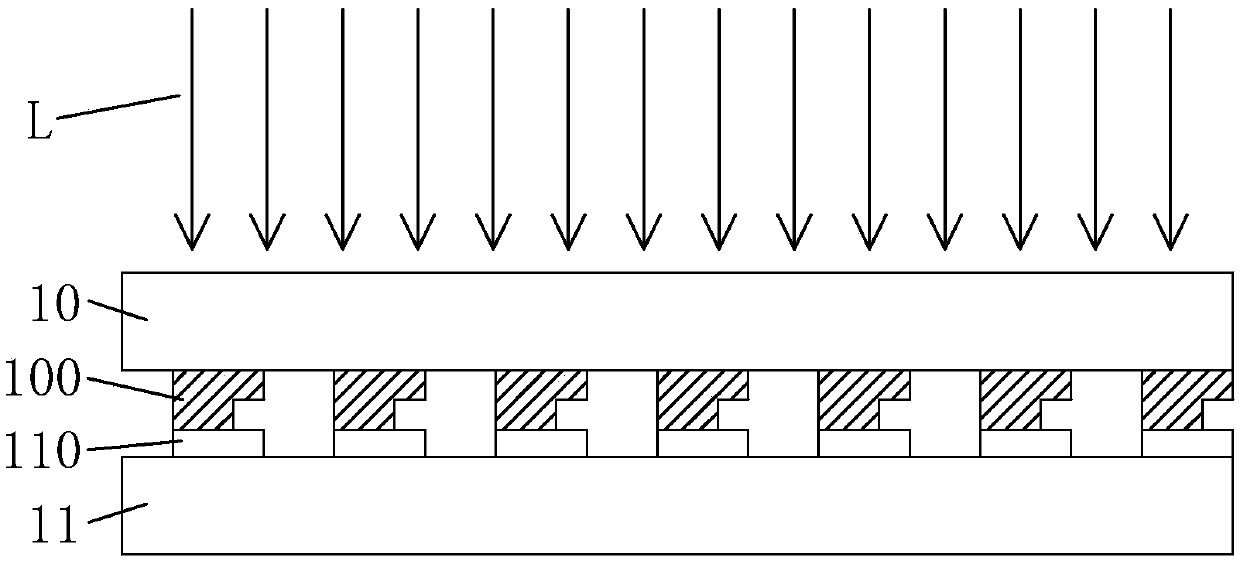

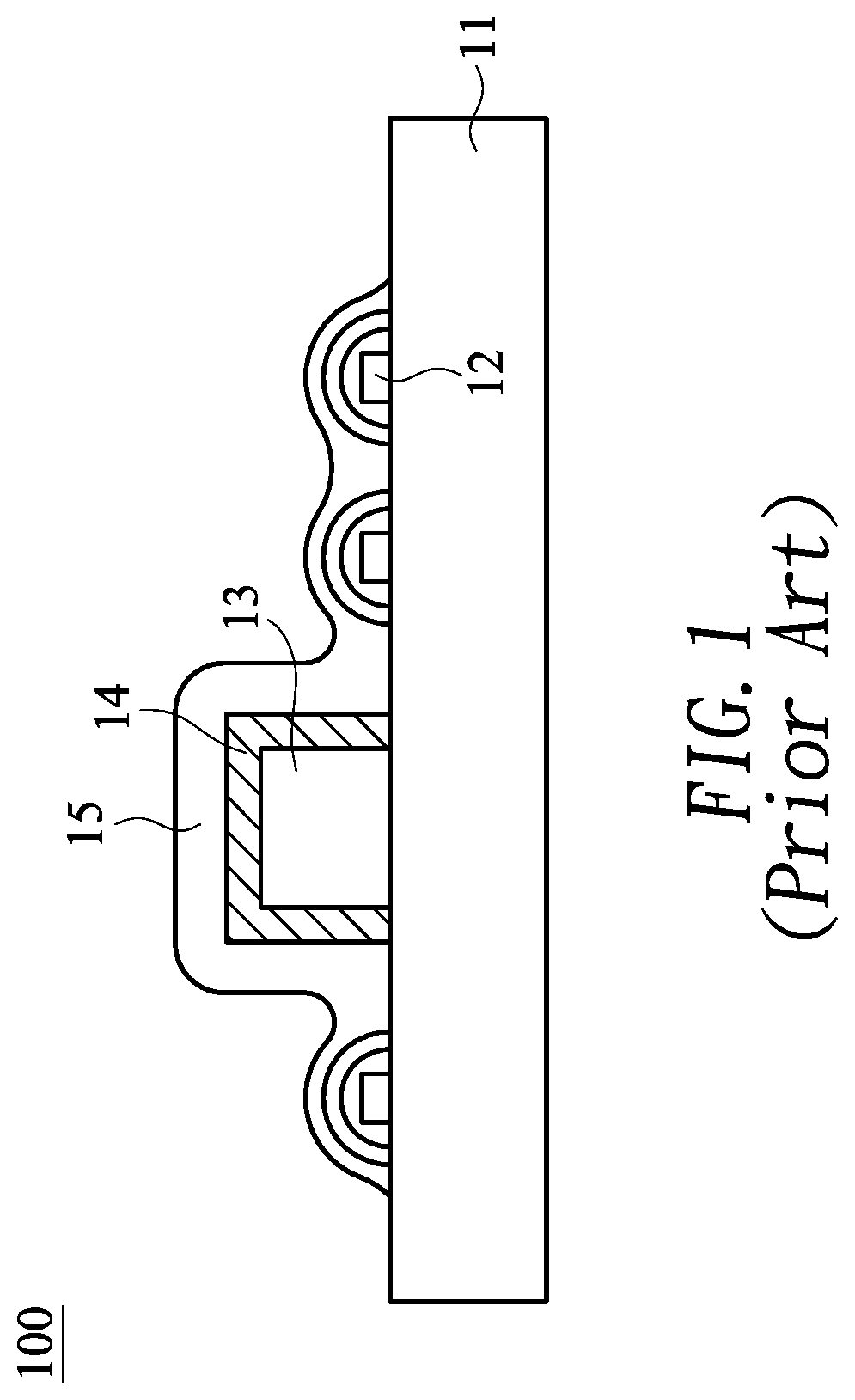

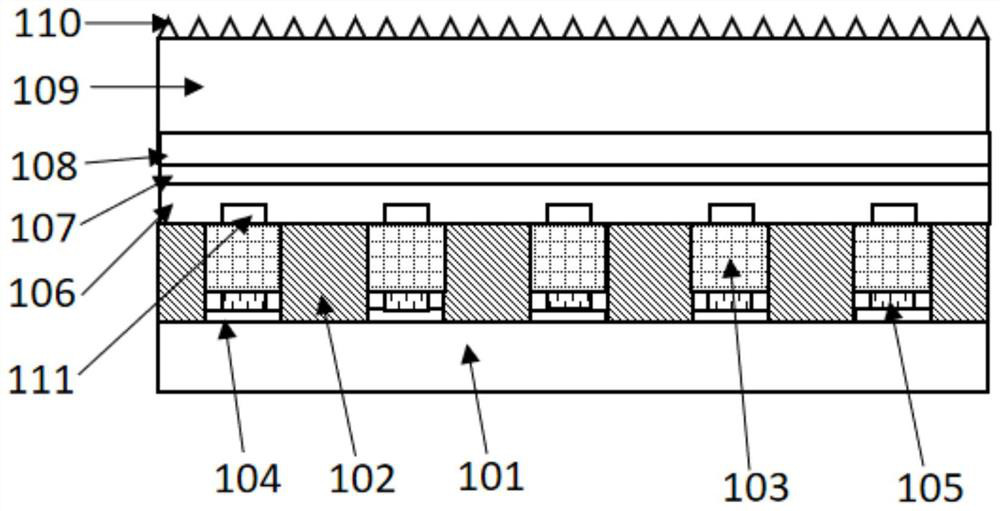

Displayer for micro-light-emitting diode and manufacturing method

ActiveCN107731864AReduce breakageReduce the chance of breaking offSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a displayer for a micro-light-emitting diode and a manufacturing method thereof. The manufacturing method comprises the following steps that firstly, a light-emitting diode chip is formed on a supply substrate. Then, a first substrate is provided, and a printing circuit is arranged on the first substrate. Then, the supply substrate is reversely arranged on and covers the first substrate, and the light-emitting diode chip is attached to the printing circuit in an alignment mode. Then, the light-emitting diode chip falls off from the supply substrate. Then, the supply substrate is removed. Then, sol-gel glass is formed on the first substrate, and gaps among the light-emitting diode chips are completely filled with the sol-gel glass. Then, the second substrate is attached to the first substrate. According to the displayer for the micro-light-emitting diode and the manufacturing method thereof, the yield and reliability can be improved.

Owner:KAISTAR LIGHTING (XIAMEN) CO LTD

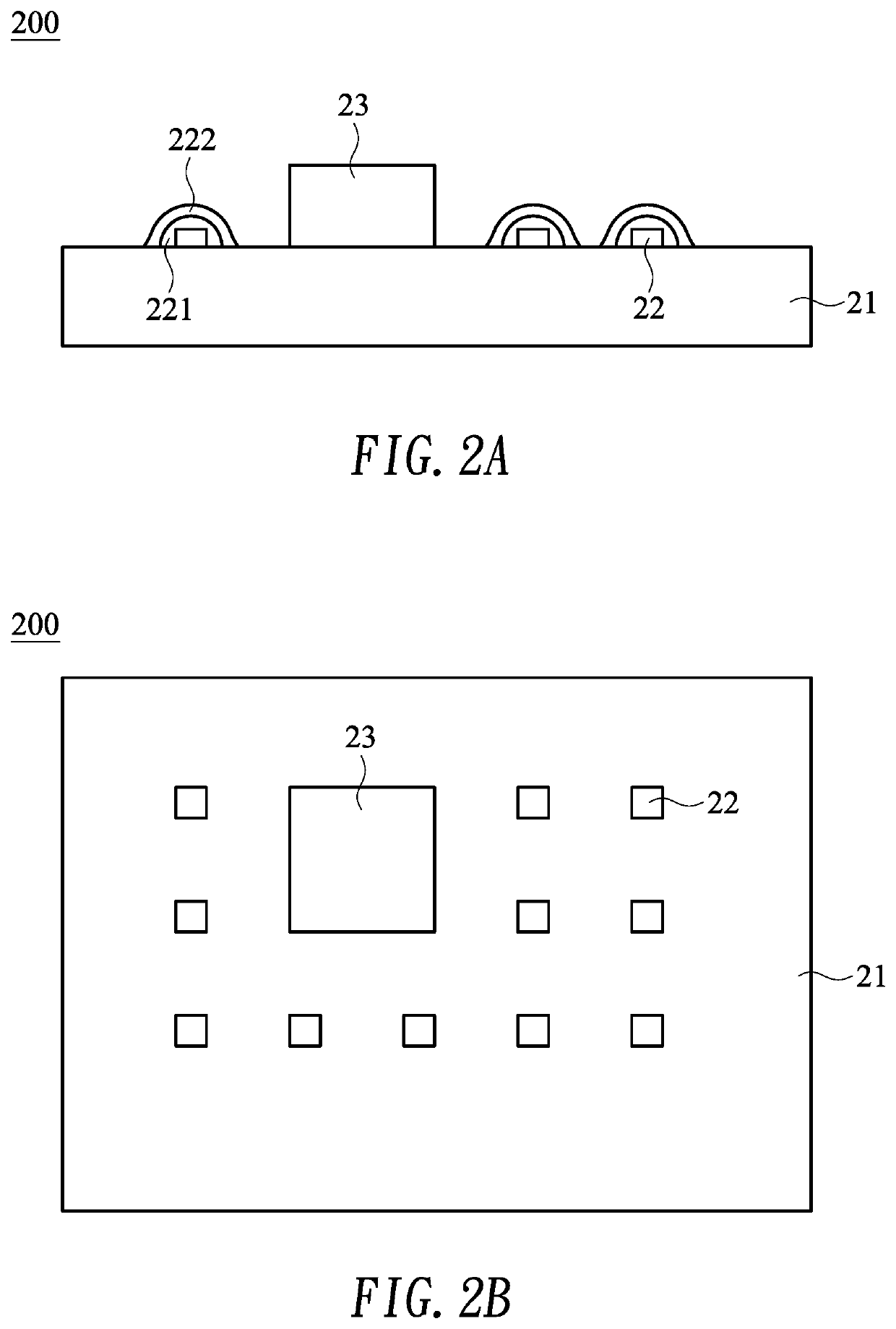

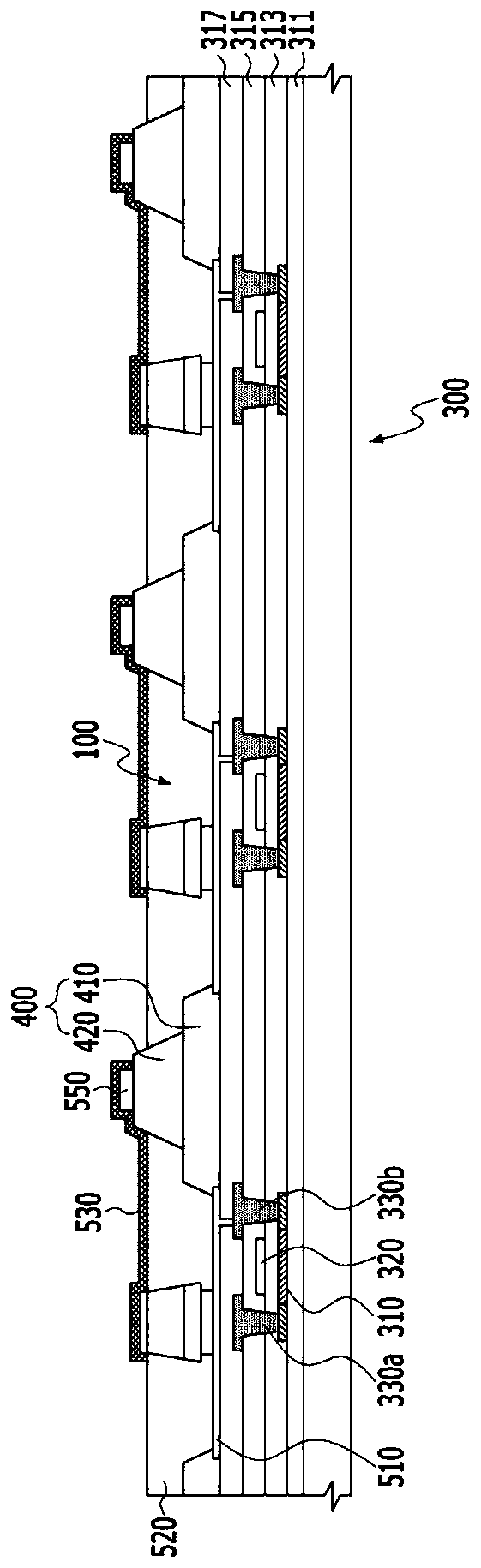

Microled display panel

ActiveUS20190013307A1Reduce loadStatic indicating devicesSemiconductor/solid-state device detailsChip on filmEngineering

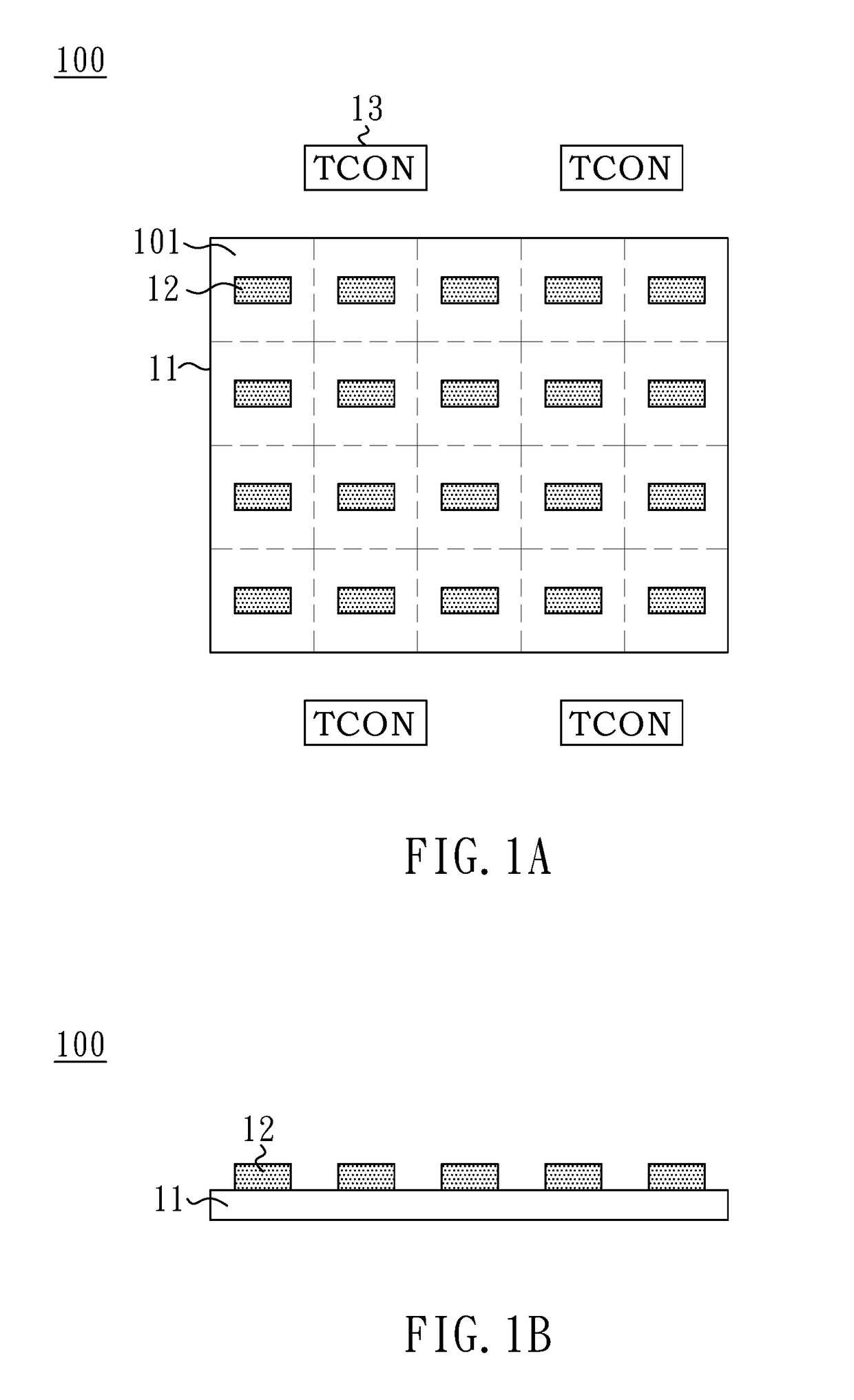

A micro light-emitting diode (microLED) display panel includes microLEDs; a substrate for supporting the microLEDs, the substrate being divided into a plurality of sub-regions; and a plurality of chip-on-film (COF) packages mounted on surfaces of the sub-regions respectively, a plurality of drivers being disposed on the COF packages respectively.

Owner:PRILIT OPTRONICS INC

Microled display panel

ActiveUS20180092173A1Reduce loadSimple processStatic indicating devicesElectroluminescent light sourcesMicroLEDDriving circuit

A microLED display panel includes a substrate being divided into a plurality of sub-regions for supporting microLEDs, and a plurality of drivers being correspondingly disposed on surfaces of the sub-regions respectively. The driver includes a low-dropout (LDO) regulator and a drive circuit. The LDO regulator receives a system power, according to which a regulated power is generated and provided for the drive circuit.

Owner:PRILIT OPTRONICS INC

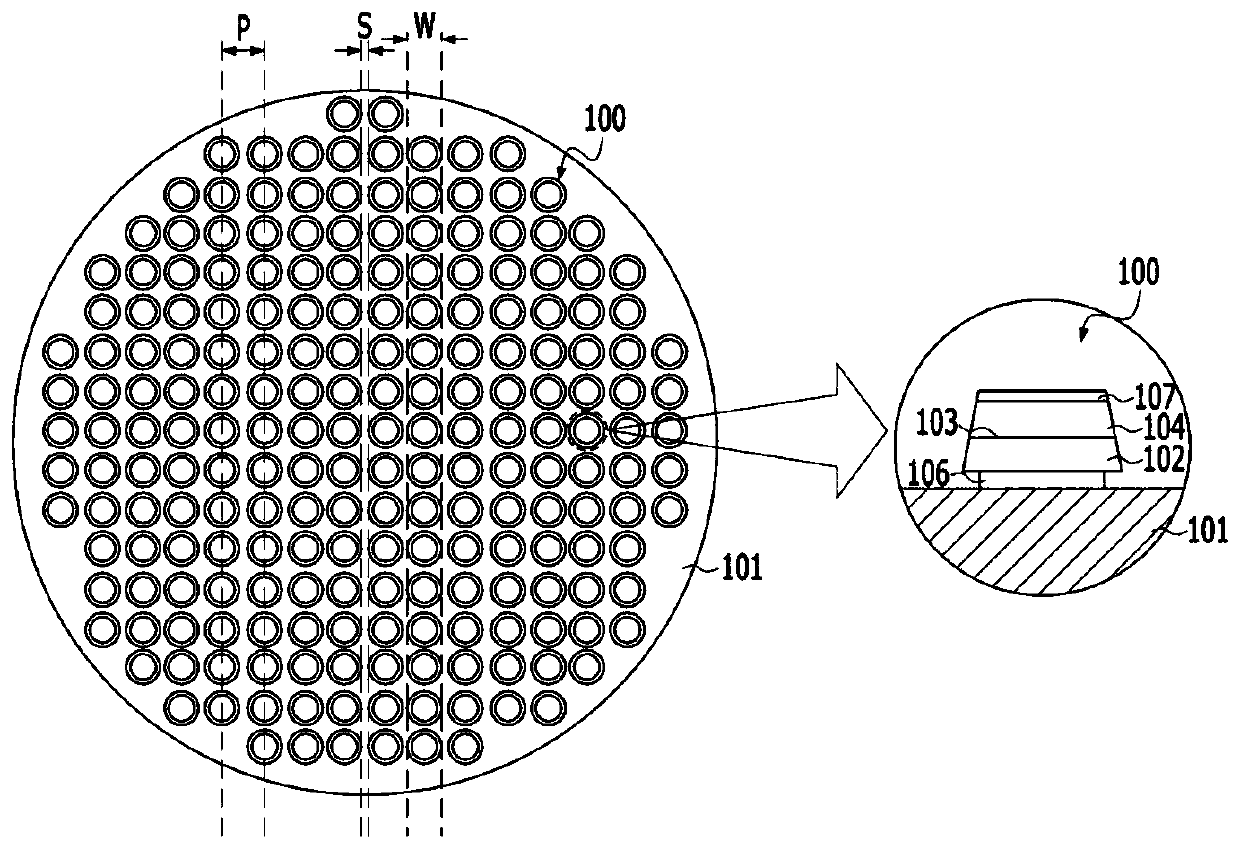

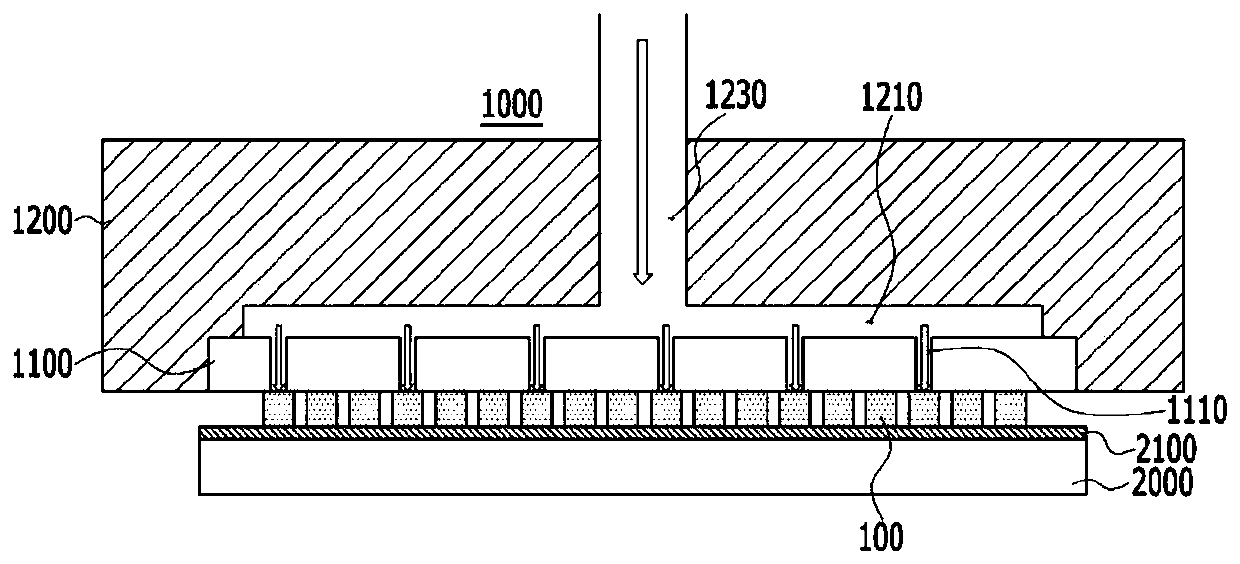

Fluidic Assembly Enabled Mass Transfer for MicroLED Displays

PendingUS20210091052A1Permit useSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingDisplay device

A microLED mass transfer stamping system includes a stamp substrate with an array of trap sites, each configured with a columnar-shaped recess to temporarily secure a keel extended from a bottom surface of a microLED. In the case of surface mount microLEDs, the keel is electrically nonconductive. In the case of vertical microLEDs, the keel is an electrically conductive second electrode. The stamping system also includes a fluidic assembly carrier substrate with an array of wells having a pitch separating adjacent wells that matches the pitch separating the stamp substrate trap sites. A display substrate includes an array of microLED pads with the same pitch as the trap sites. The stamp substrate top surface is pressed against the display substrate, with each trap site interfacing a corresponding microLED site, and the microLEDs are transferred. Fluidic assembly stamp substrates are also presented for use with microLEDs having keels or axial leads.

Owner:ELUX INC

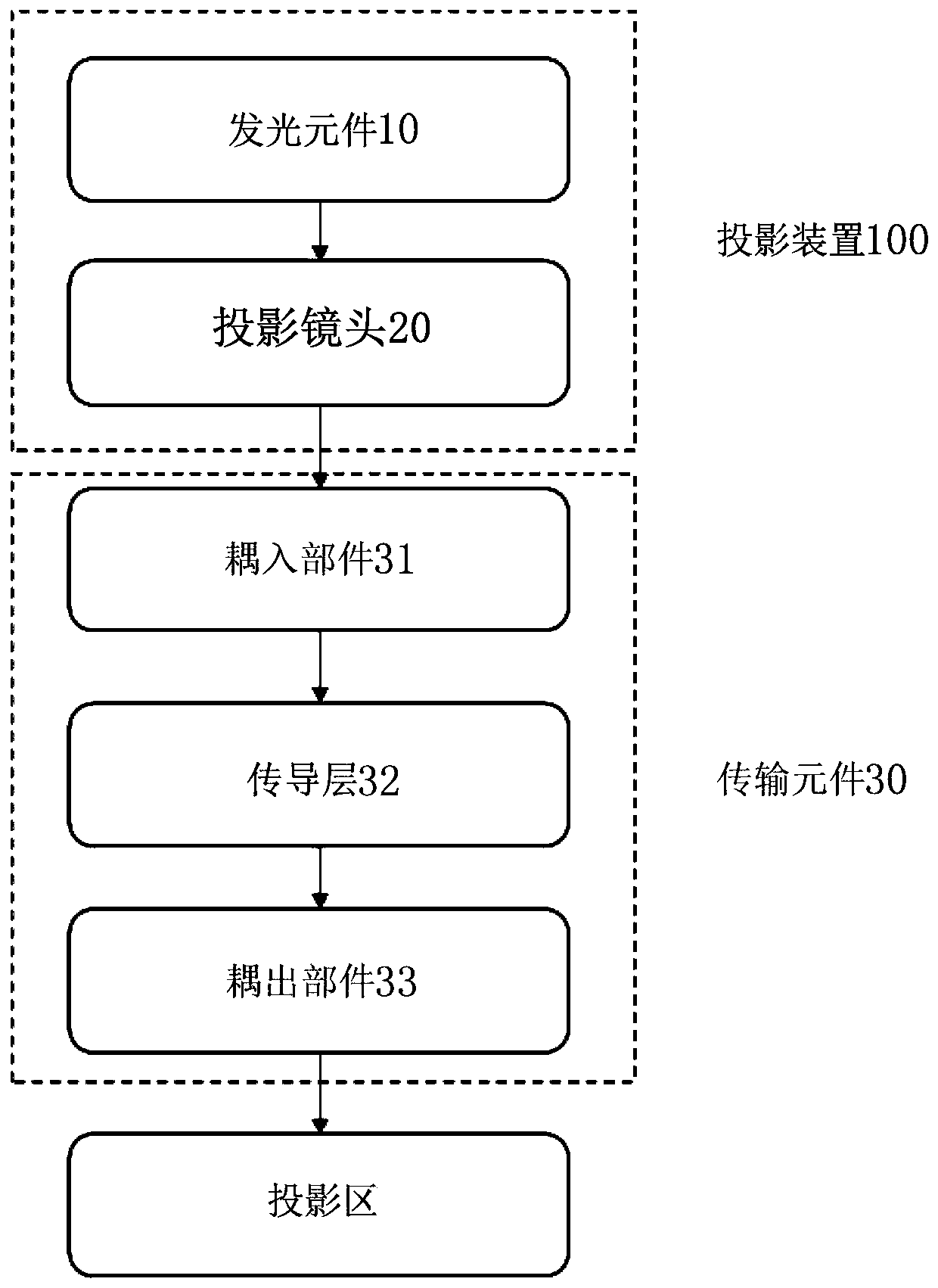

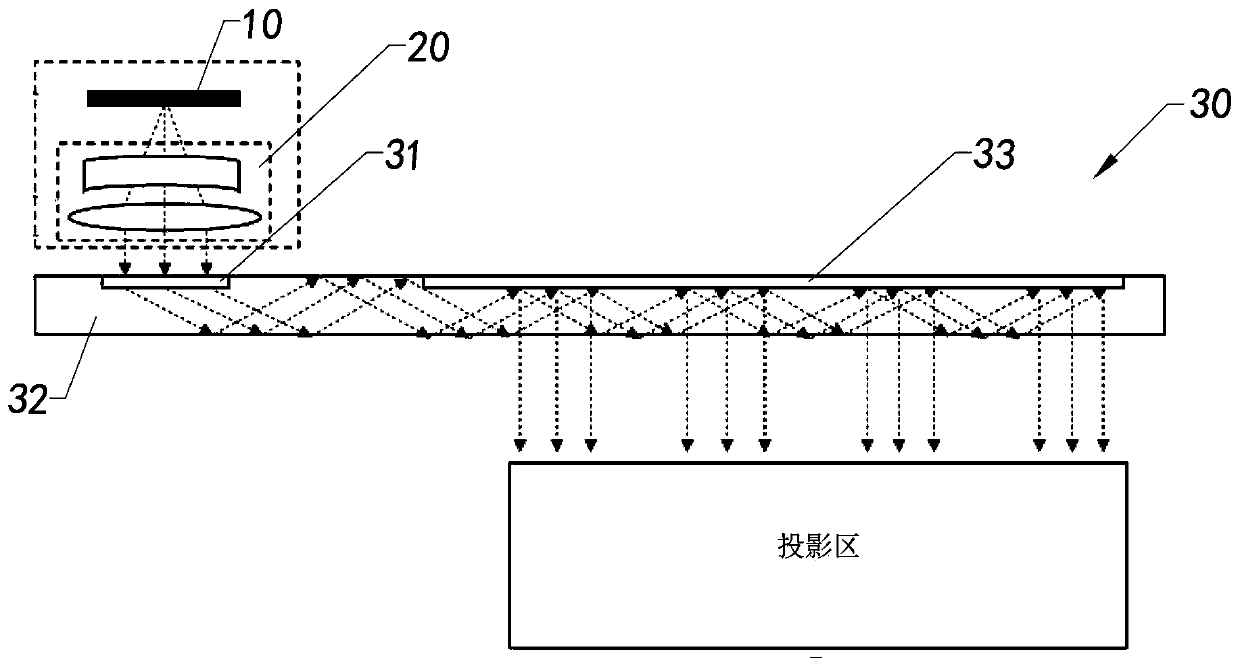

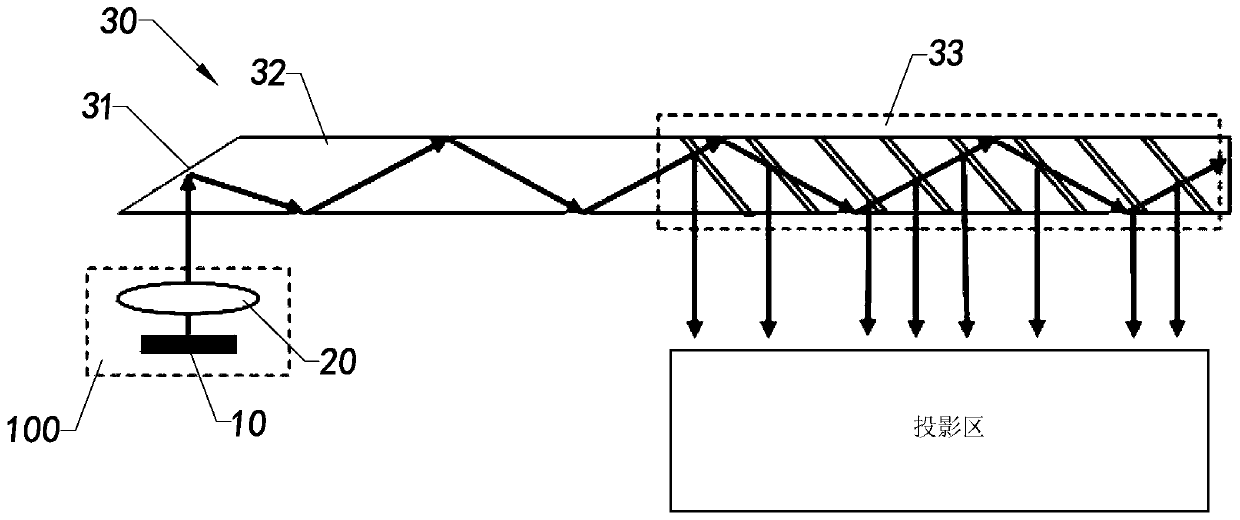

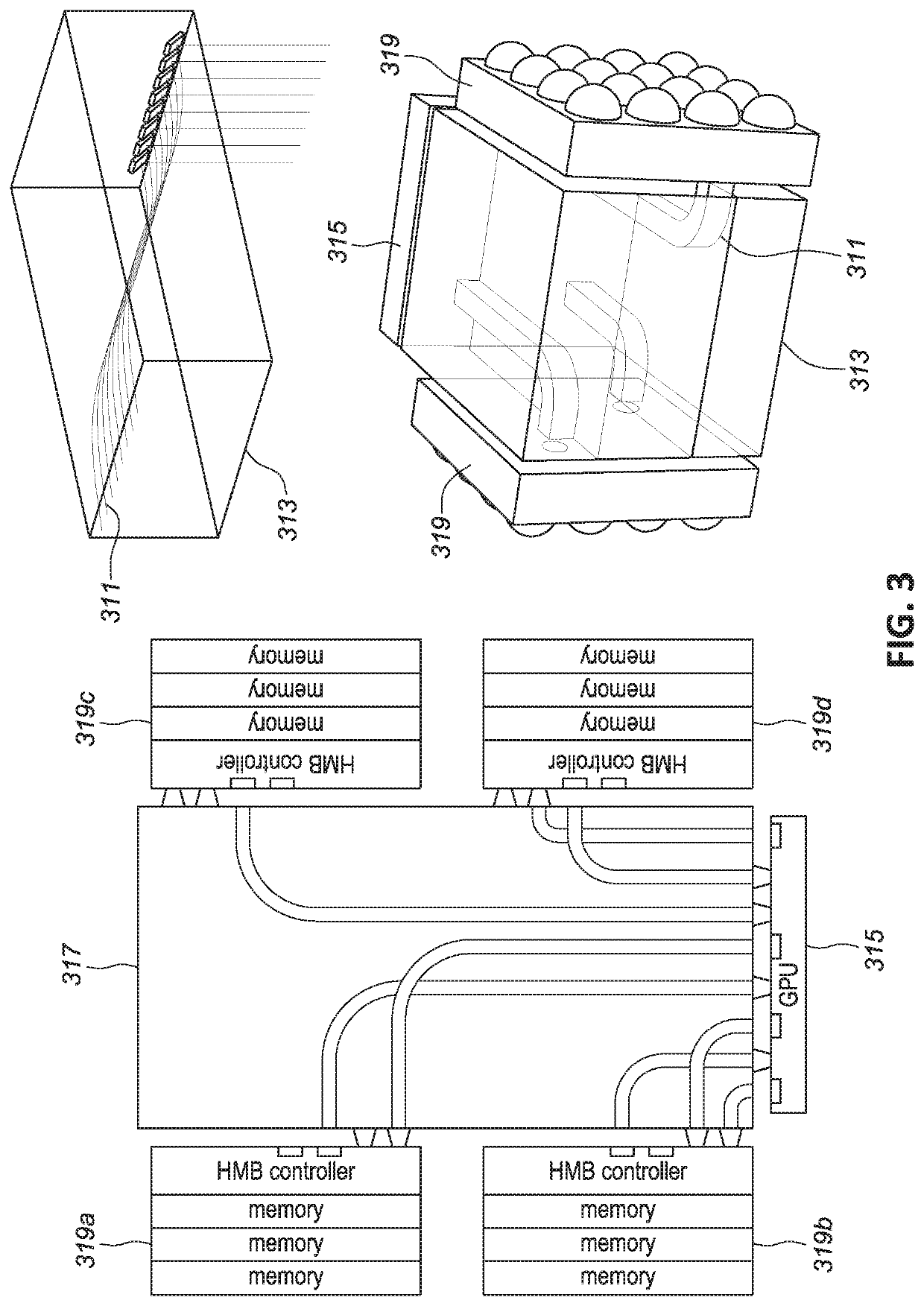

MicroLED-based display device and display method thereof

InactiveCN110850669AImprove final display qualityEfficiently provideProjectorsOptical elementsDisplay deviceComputer science

According to the present invention, a MicroLED-based display device for sending an image to a projection area includes a projection device and a transmission element. The projection device emits imagelight based on a MicroLED. The transmission element includes a coupling-in component, a conveying layer and a coupling-out member. The projection device is arranged on the coupling-in component of the transmission element in a manner to align the image light. The coupling-in component receives and guides the image light transmission. The coupling-out component expands and outputs the image lightoutward. The image that enters the conveying layer from the coupling-in component is totally reflected to a light output component, and then is conveyed to the projection area. In addition, the present invention provides a MicroLED-based projection device and a display method thereof. The display device balances on image generation and image transmission to improve the final display quality.

Owner:SHANGHAI NORTH OCEAN PHOTONICS CO LTD

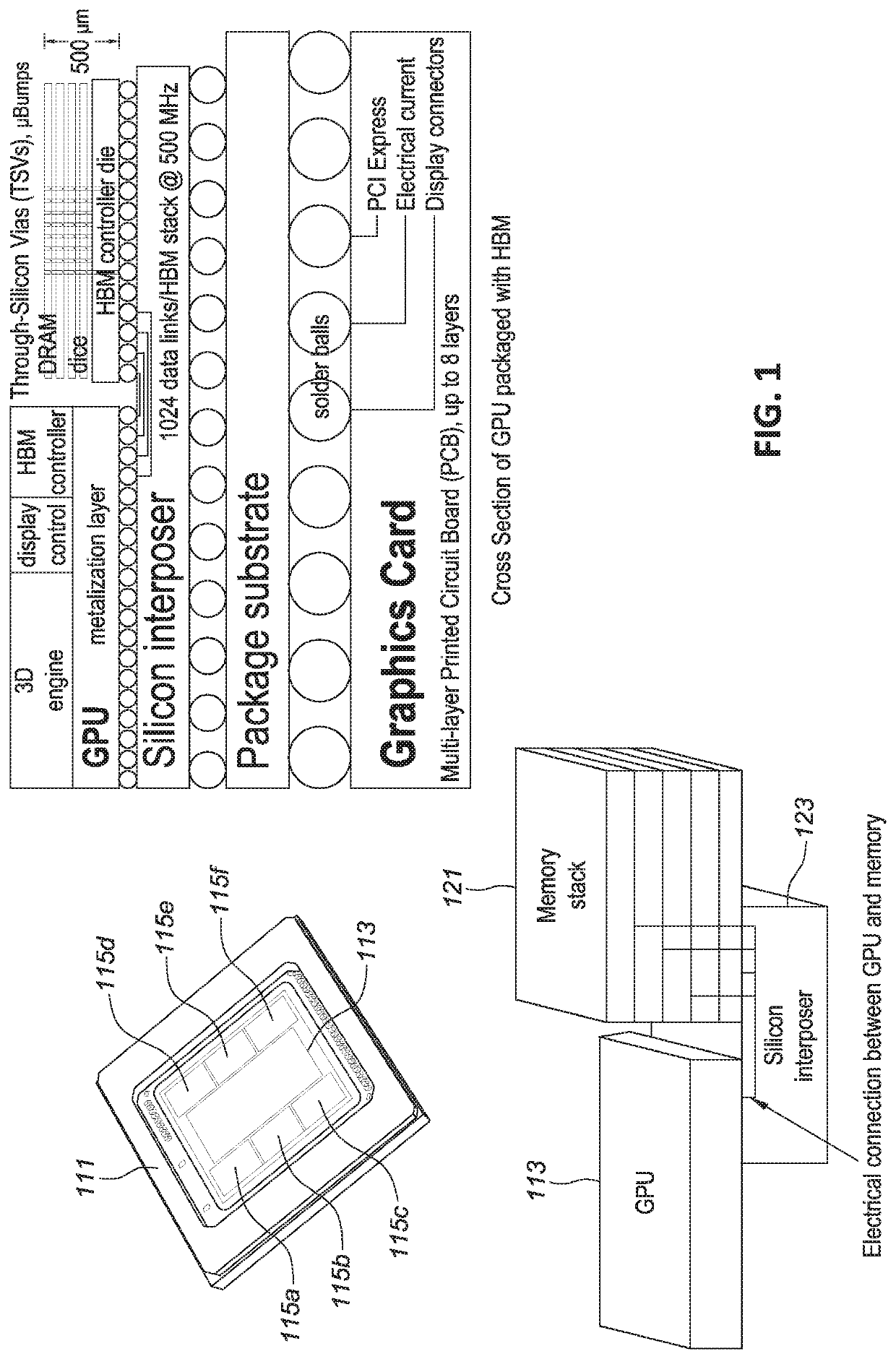

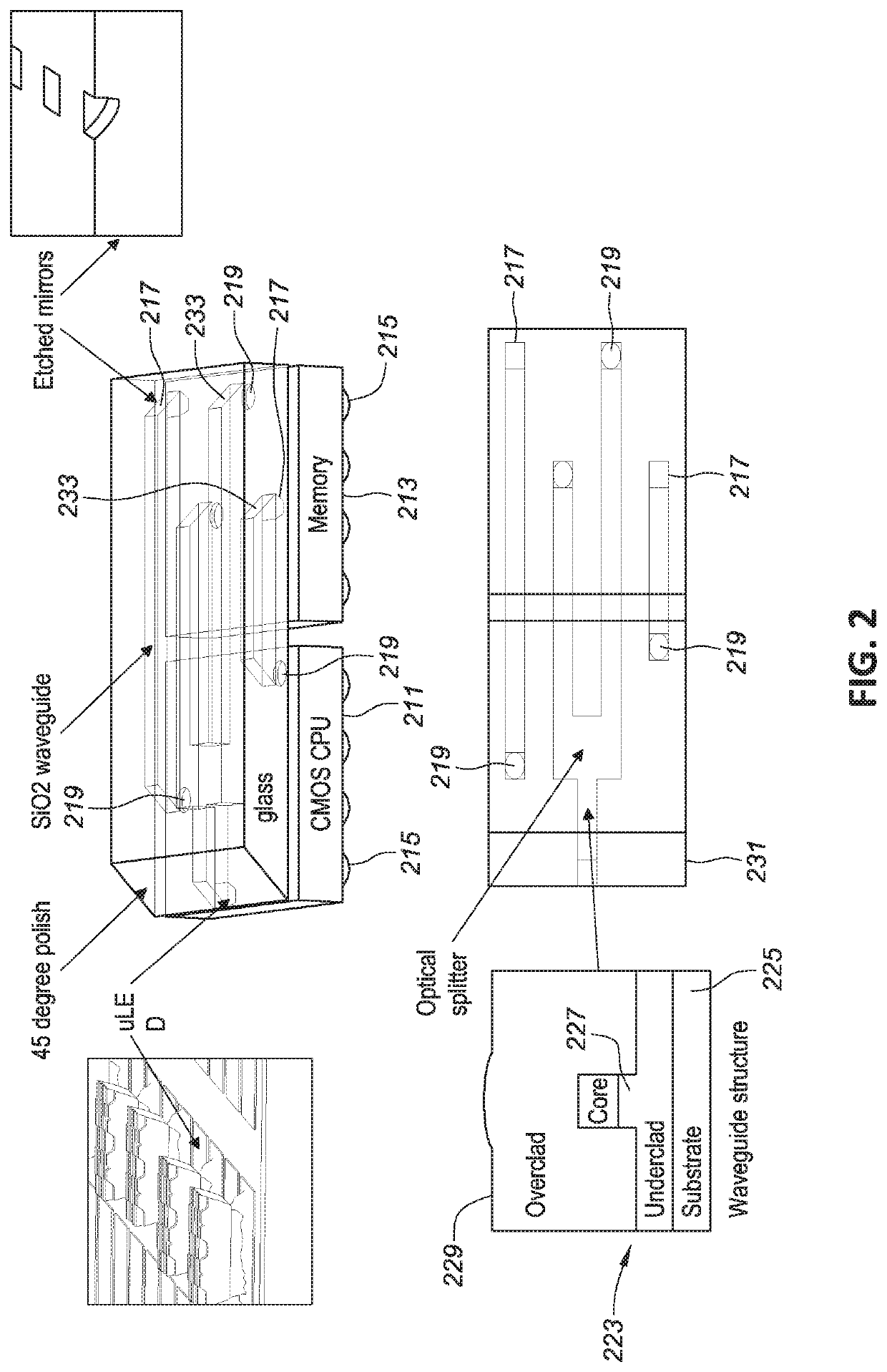

Chip-scale optical interconnect using microleds

ActiveUS20200411587A1Low powerLow costSolid-state devicesCoupling light guidesTransceiverPhotodetector

In package intra-chip and / or inter-chip optical communications are provided using microLEDs and photodetectors mounted to integrated circuit (IC) chips and / or to transceiver dies associated with the IC chips. Light from the LEDs may pass through waveguides on or in a substrate to which the IC chips are mounted or which couple the IC chips.

Owner:AVICENATECH CORP

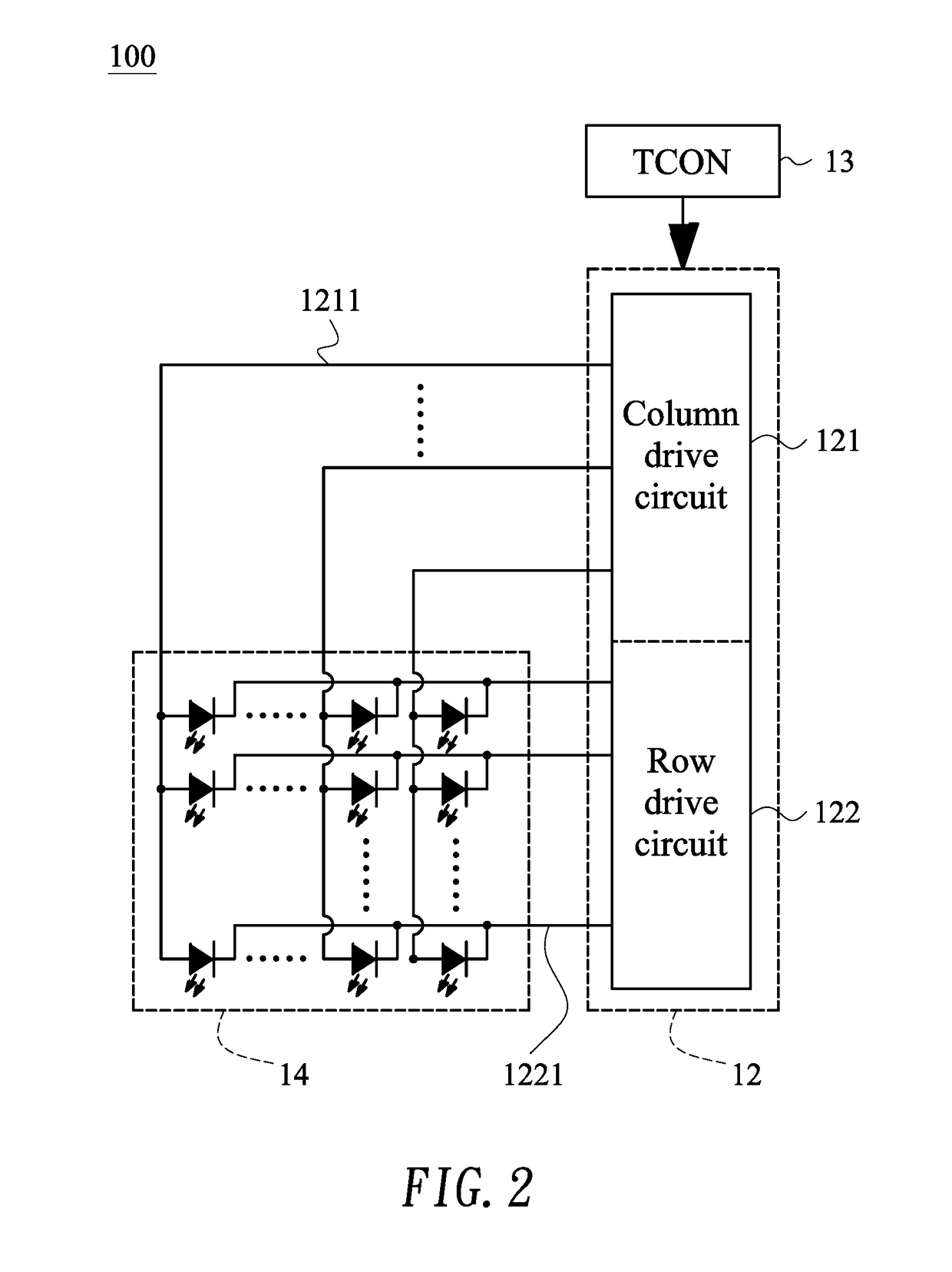

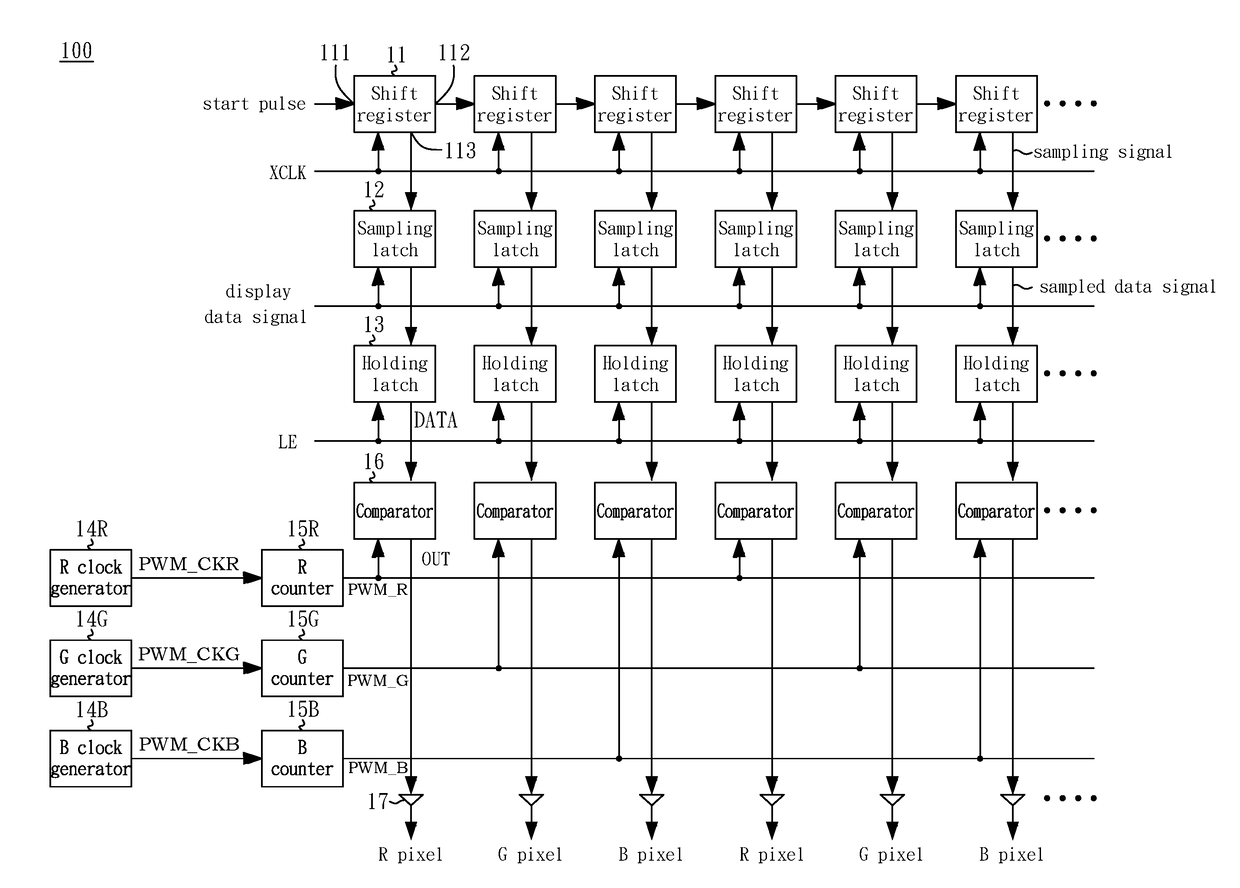

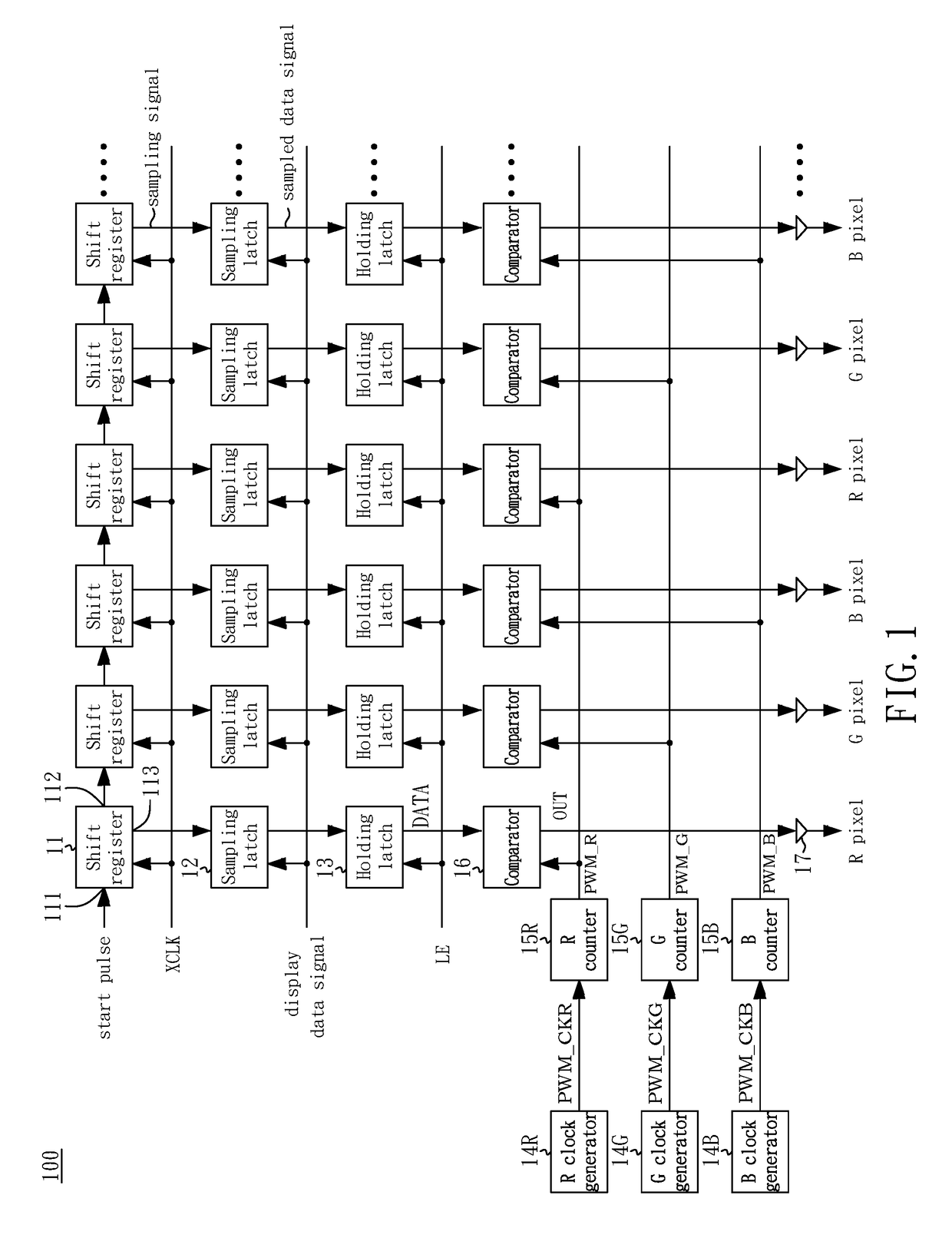

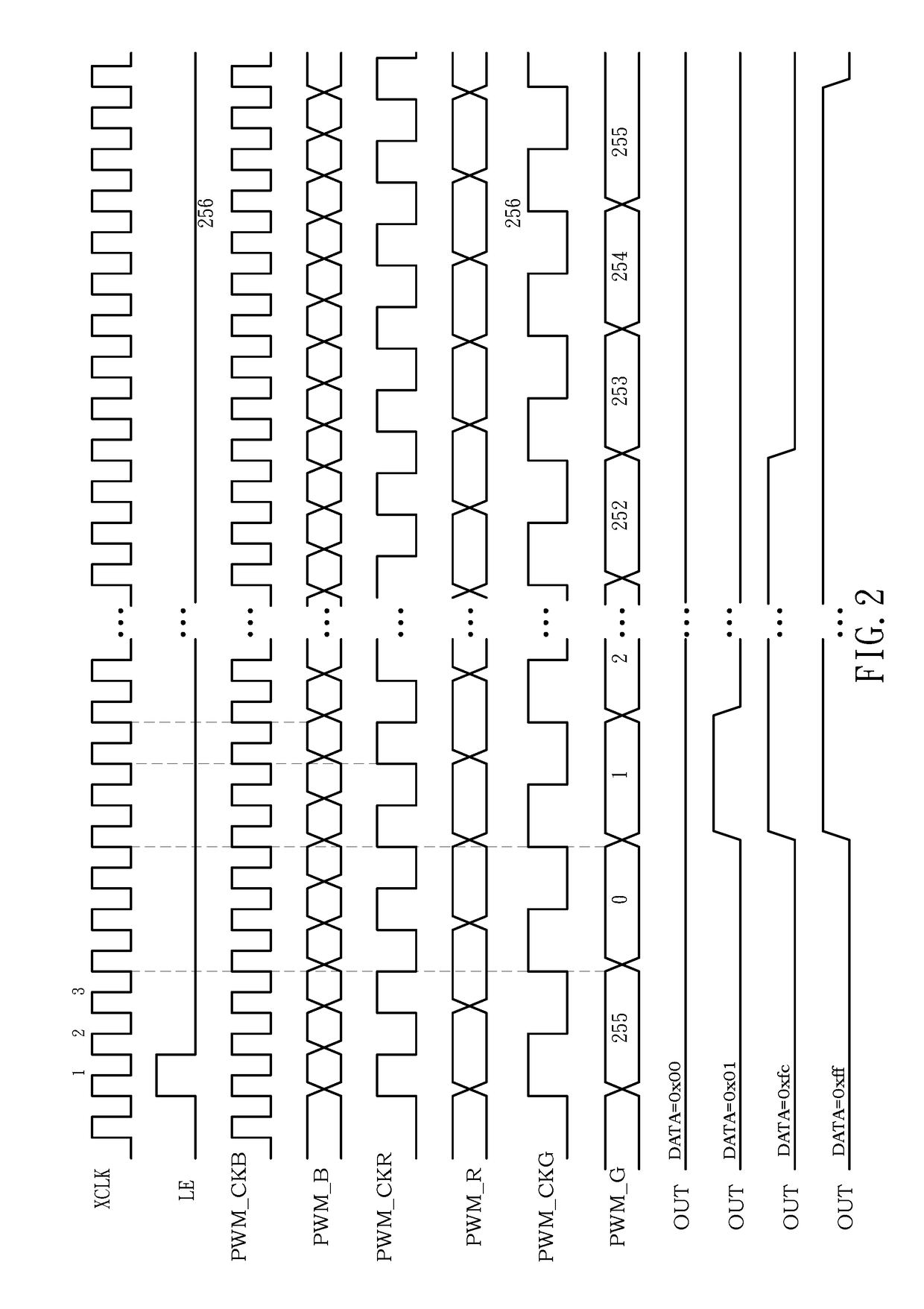

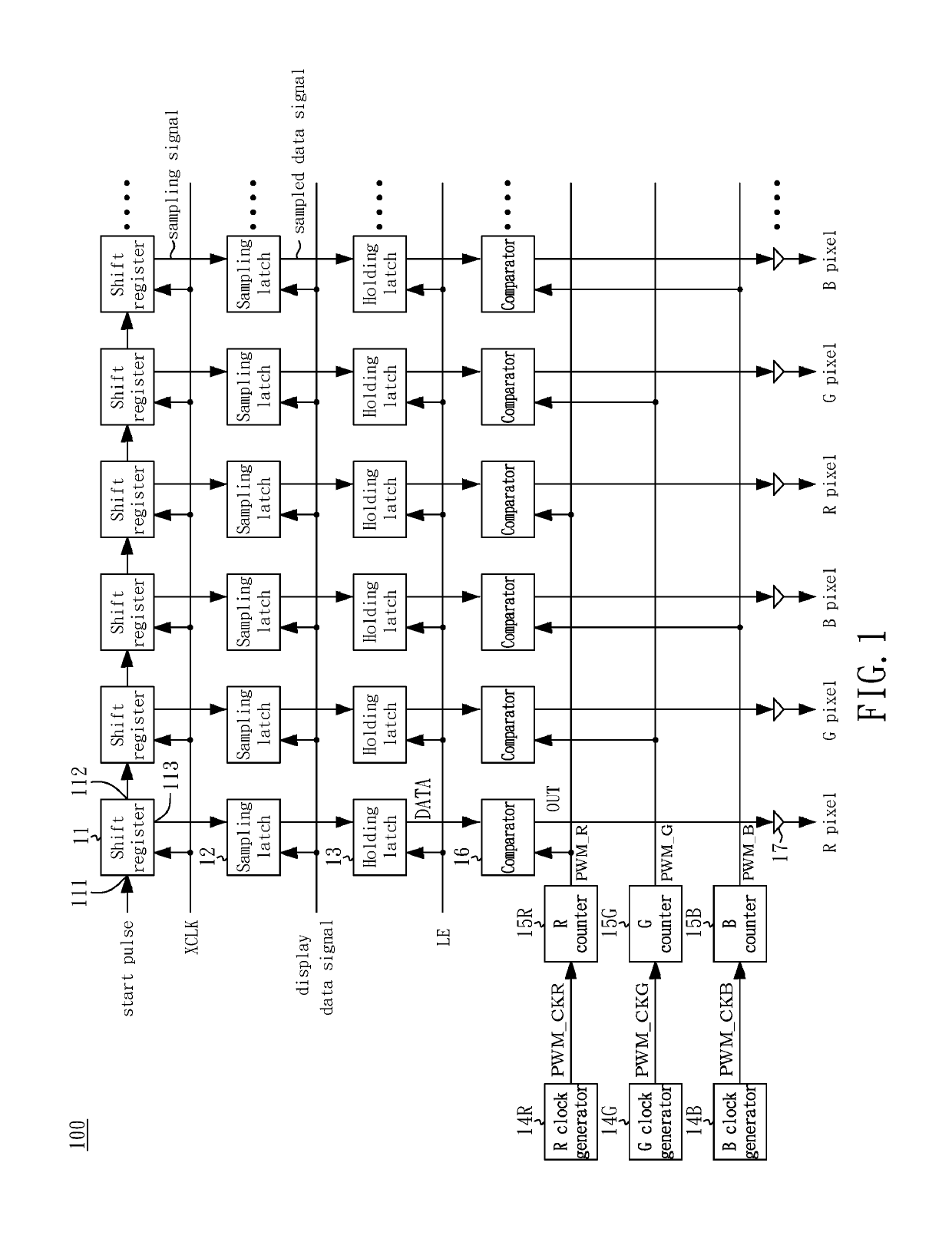

Data driver of a microled display

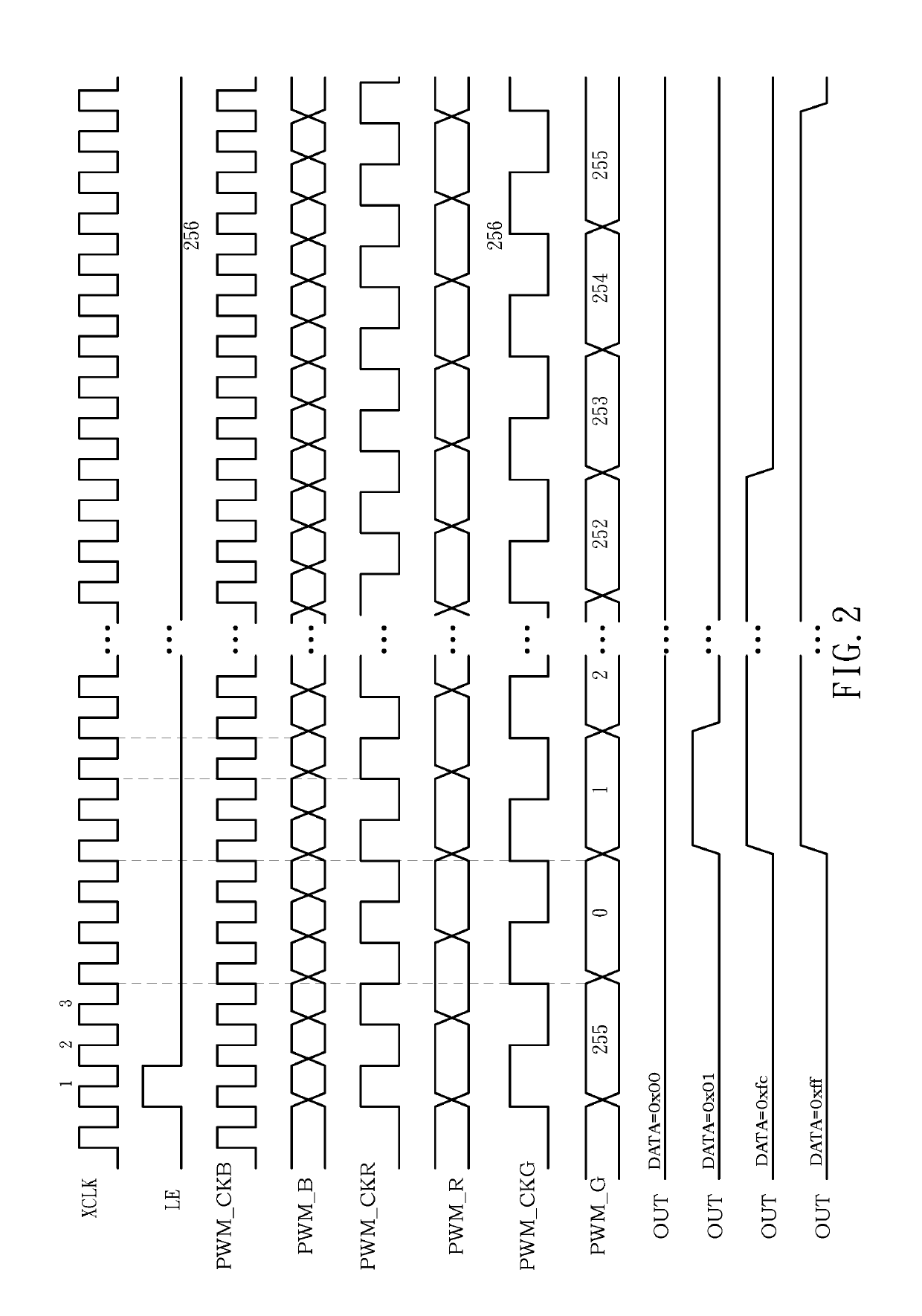

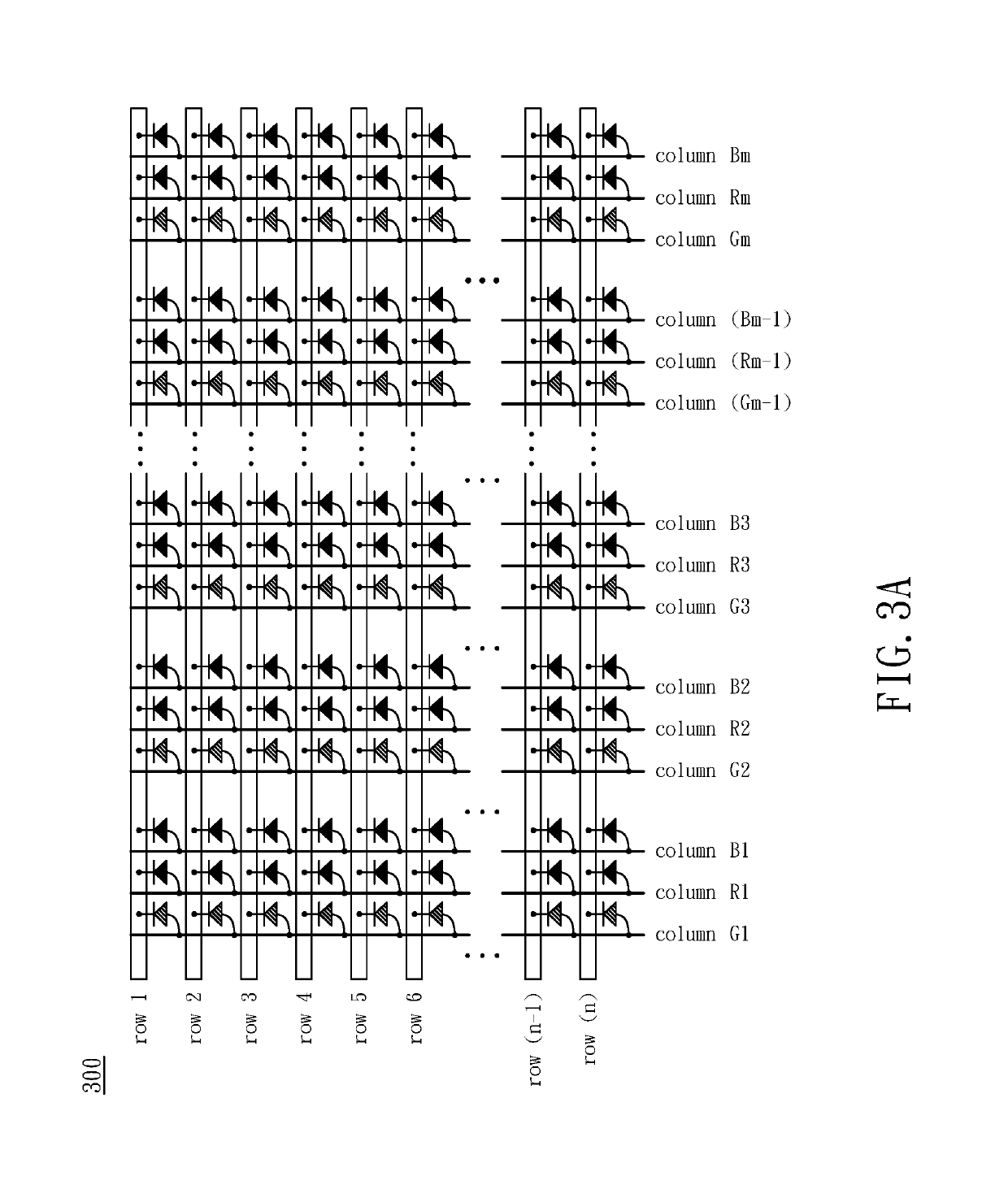

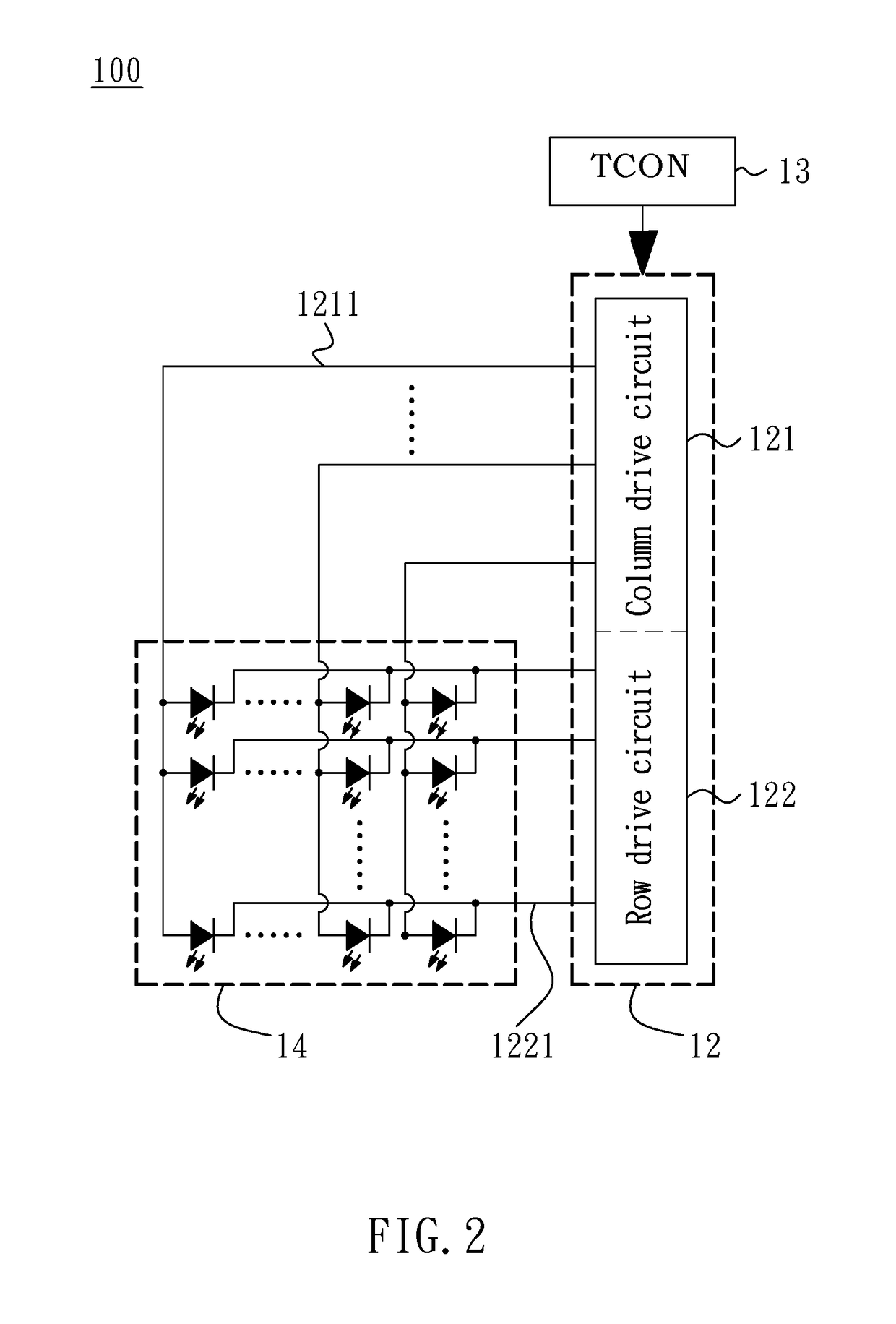

ActiveUS20180122286A1Efficient implementationCathode-ray tube indicatorsAudio power amplifierDisplay device

A data driver of a microLED display includes clock generators that generate pulse width modulation (PWM) clocks of corresponding primary colors respectively; counters that receive the PWM clocks of corresponding primary colors respectively and accordingly generate corresponding PWM signals; and comparators associated with corresponding data channels respectively for comparing a held data signal with the corresponding PWM signal, thereby generating a comparison result signal. In one embodiment, the data driver further includes switches configured to electrically short output nodes of channel amplifiers of corresponding primary colors respectively for testing uniformity of microLEDs of one color.

Owner:PRILIT OPTRONICS INC

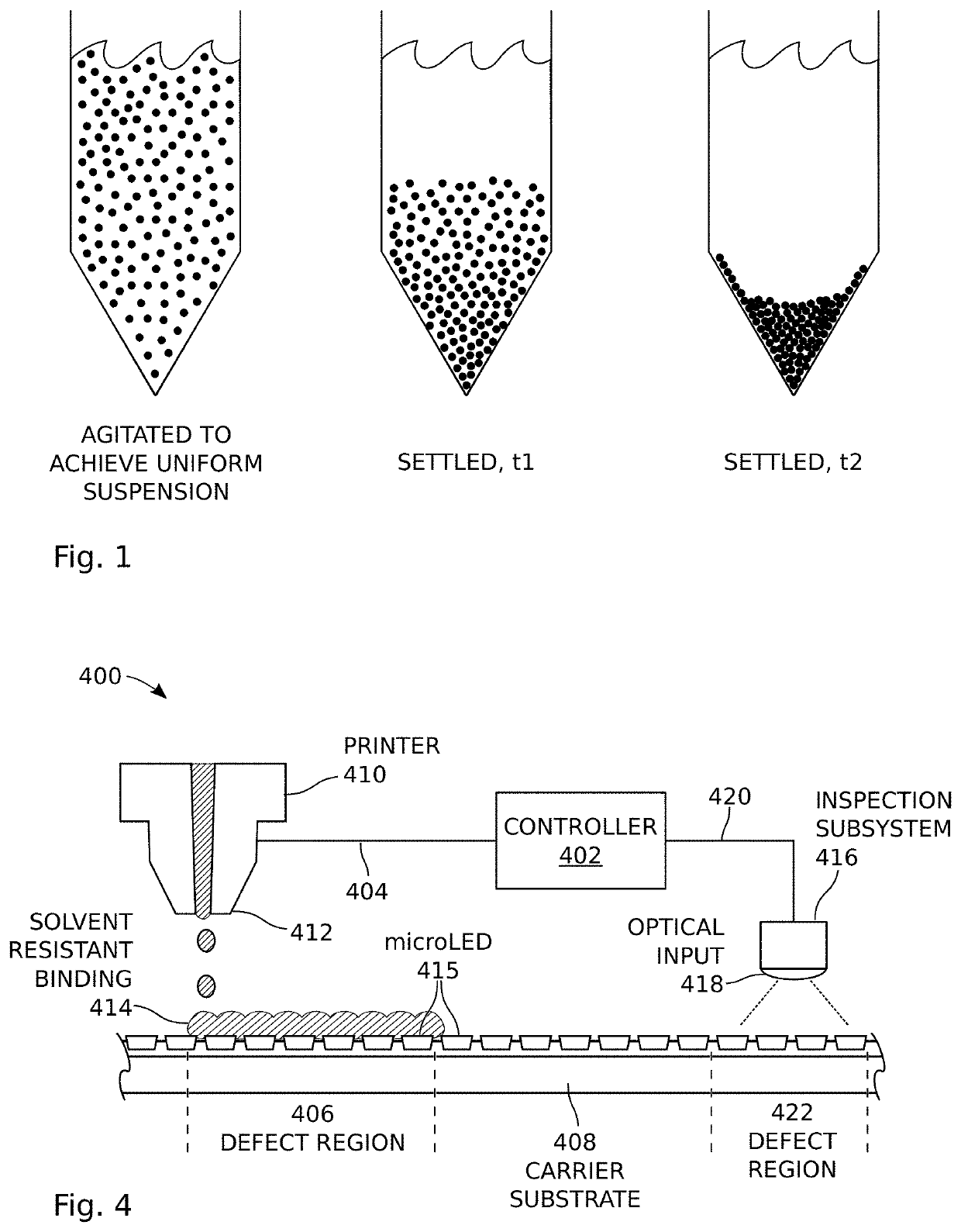

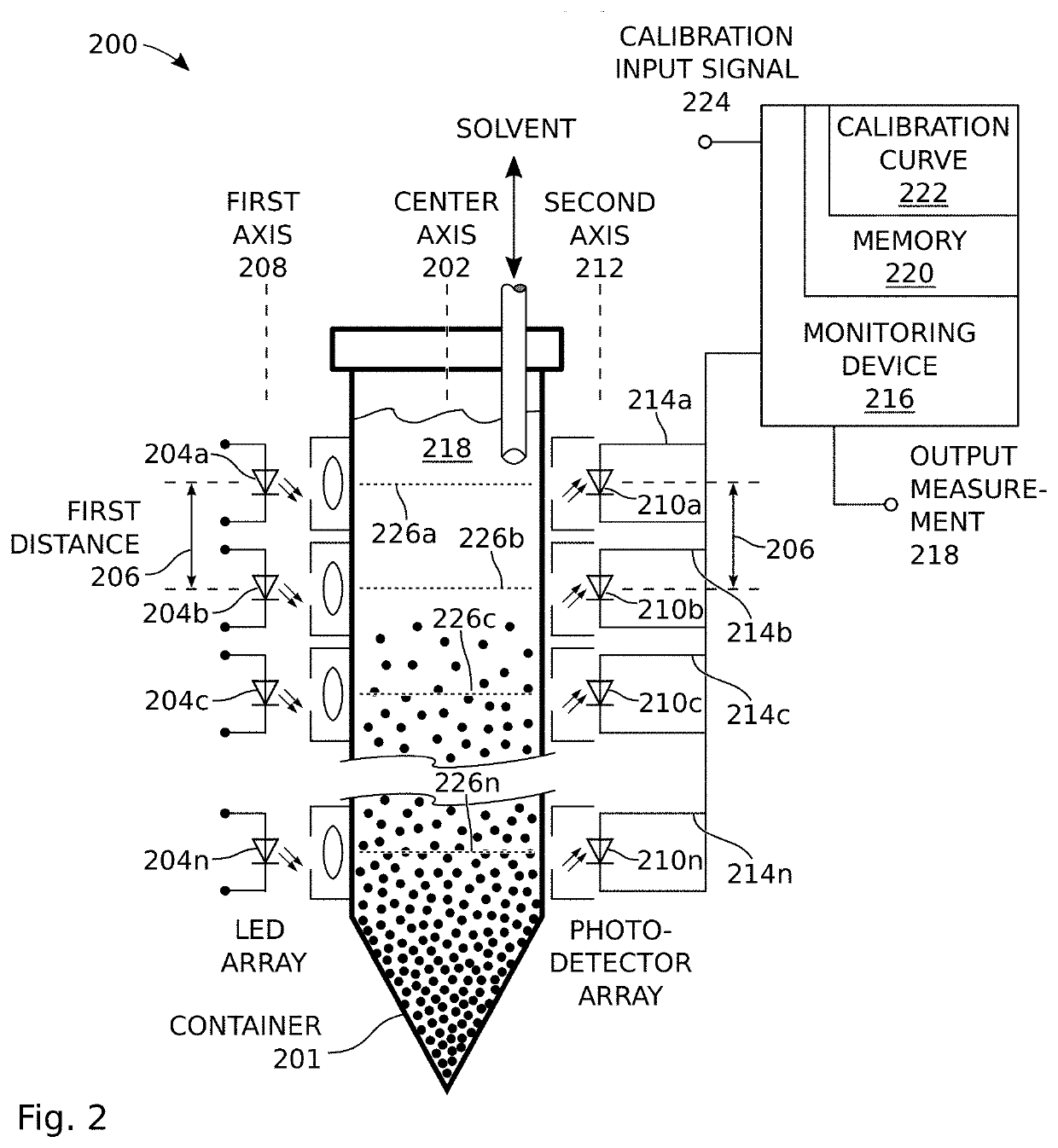

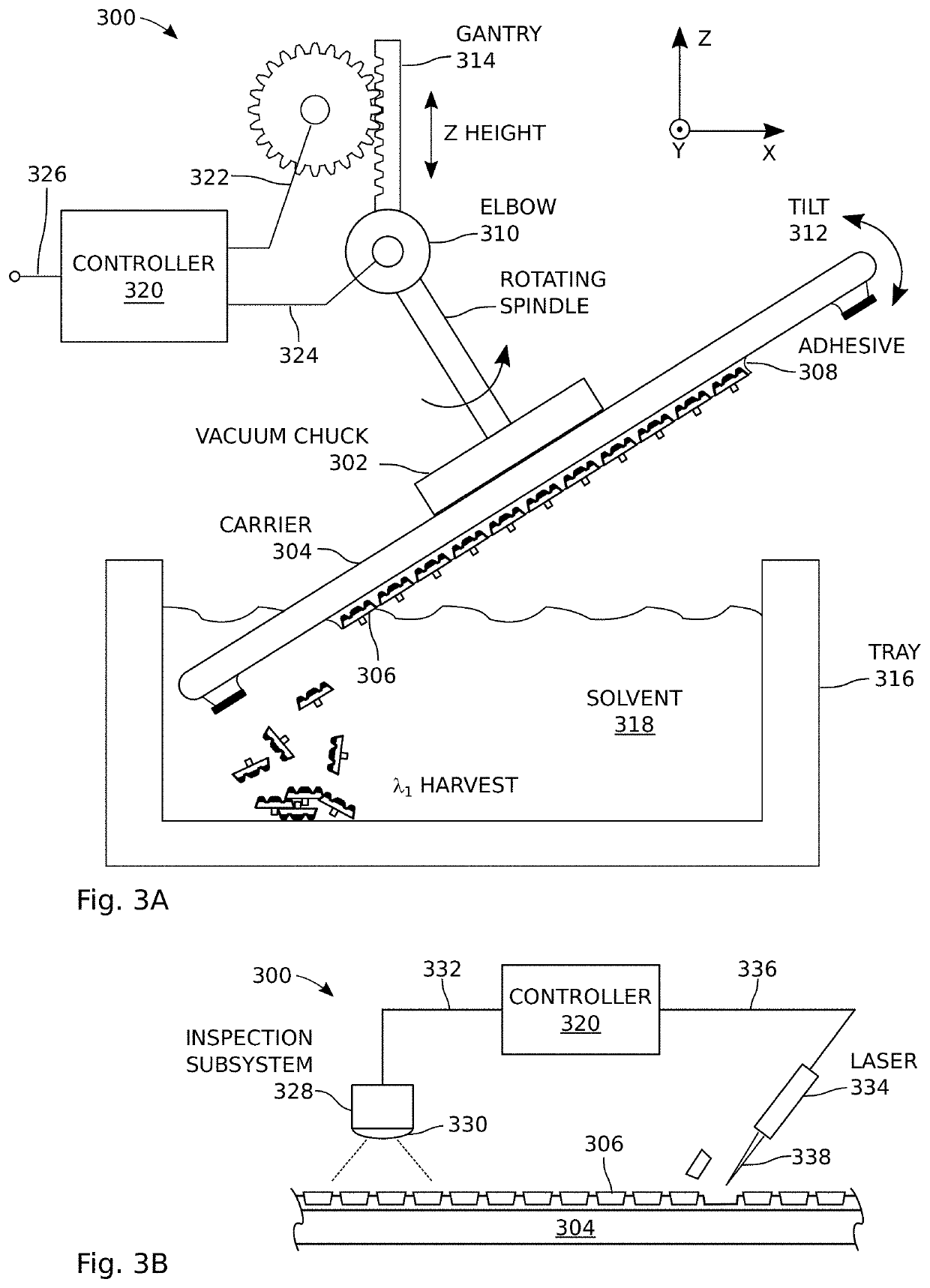

System and Method for the Selective Harvest of Emissive Elements

ActiveUS20200279835A1Minimize damageMinimize total lossSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsAdhesiveStructural engineering

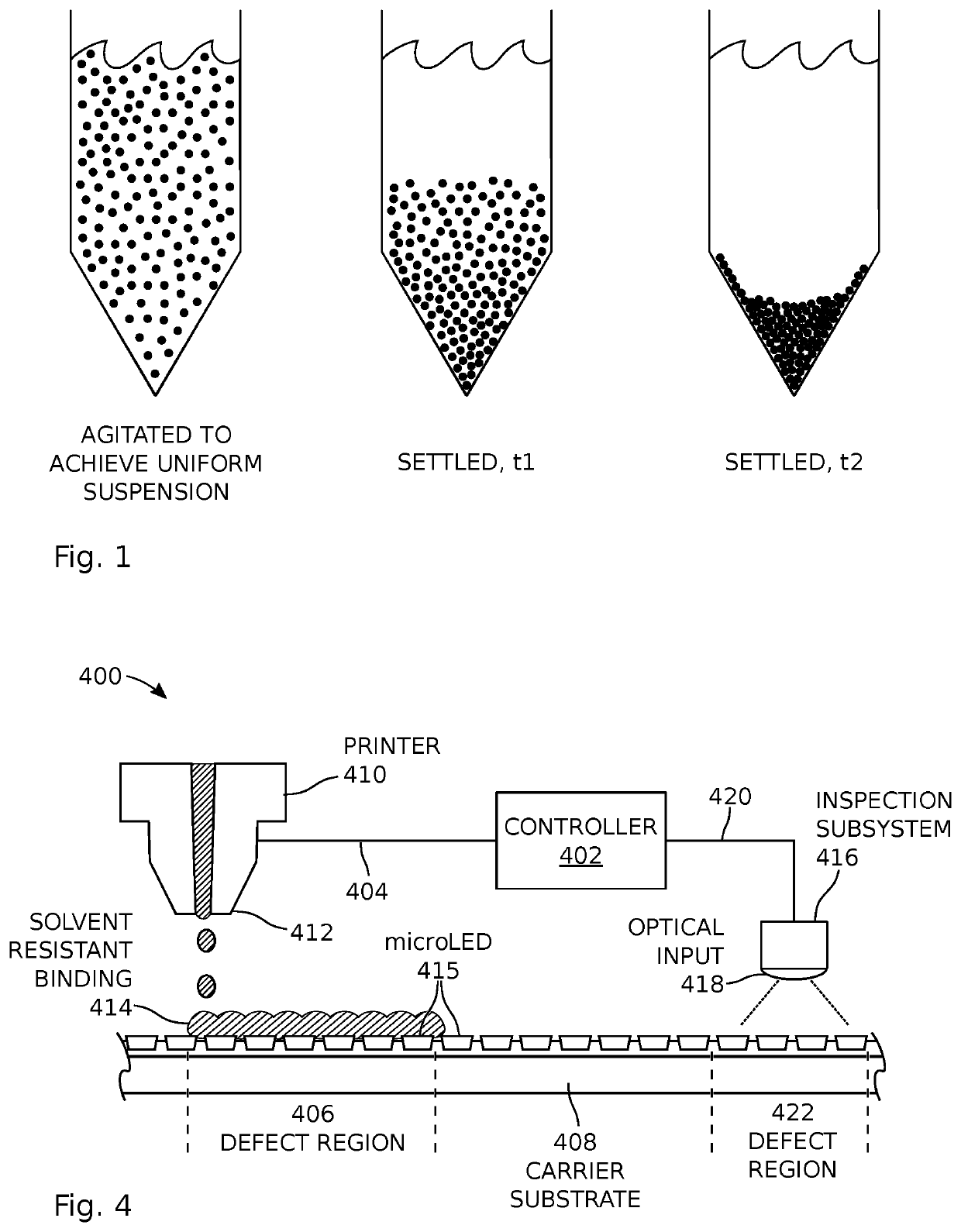

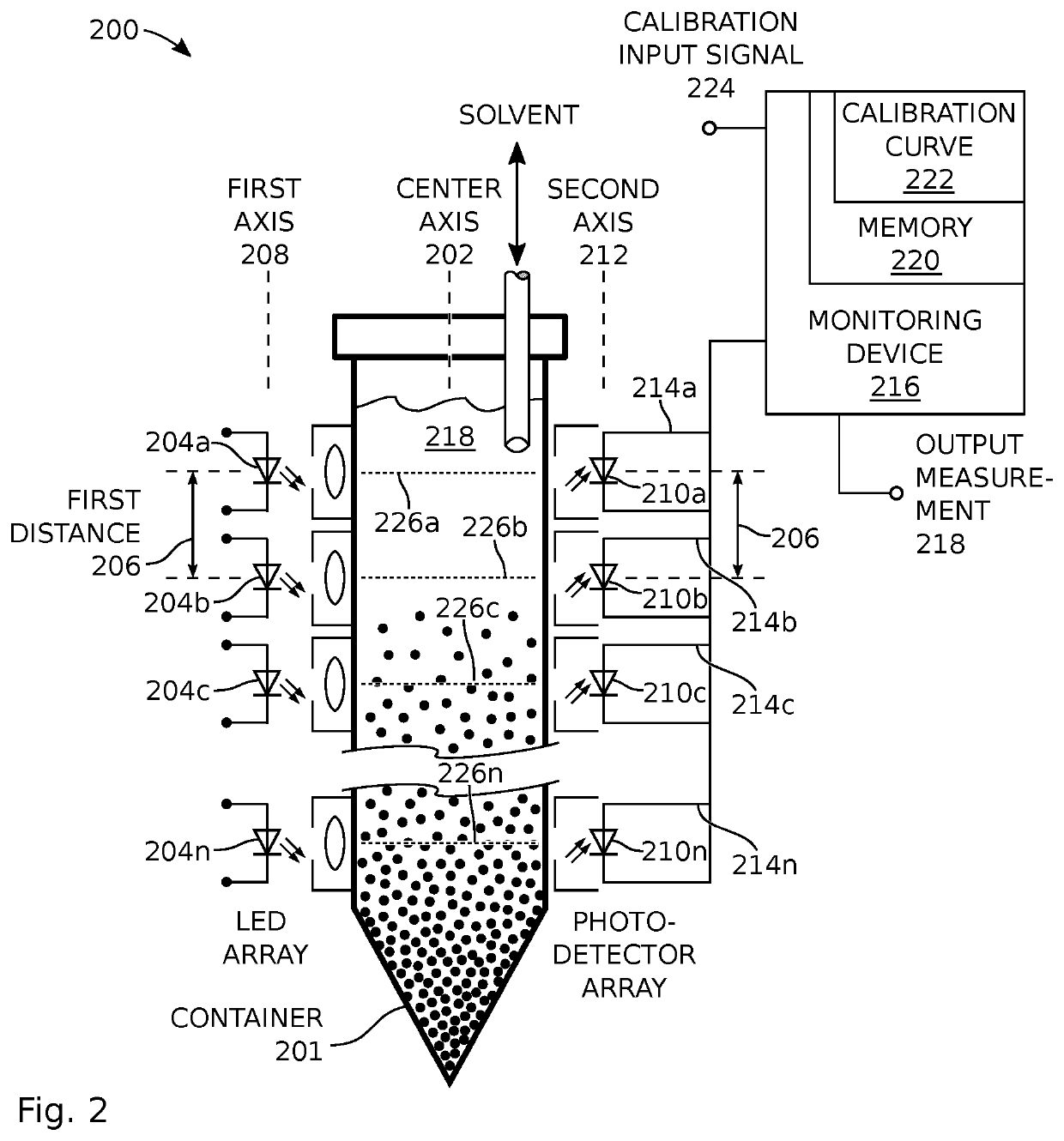

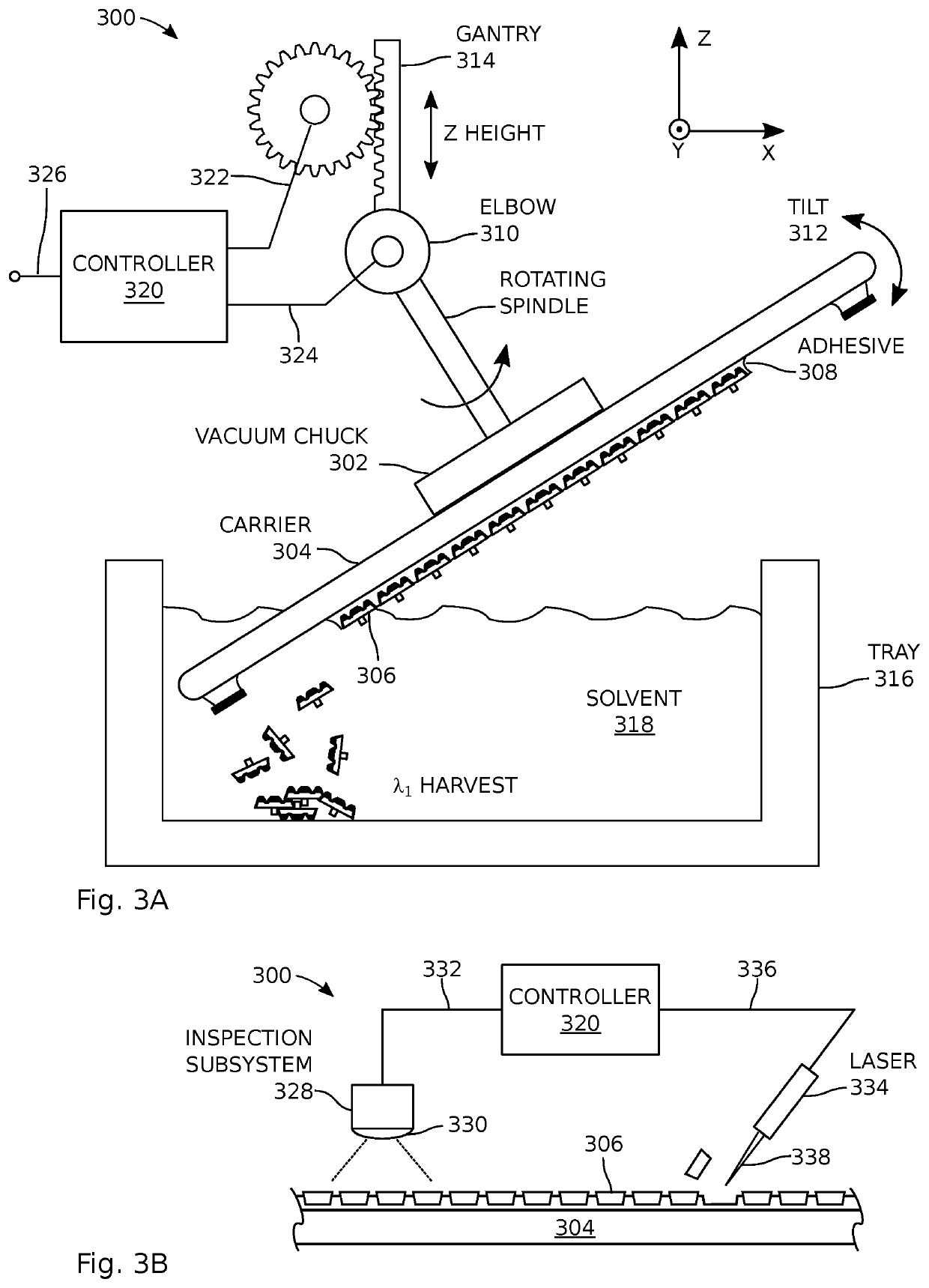

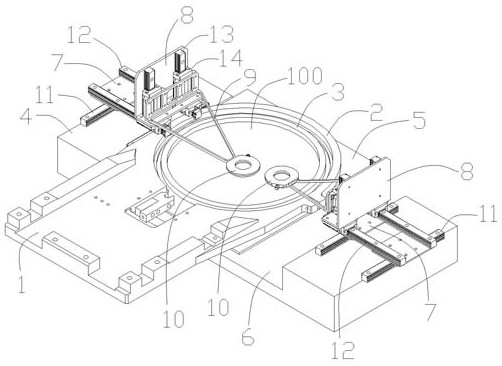

A method is provided for the selective harvest of microLED devices from a carrier substrate. Defect regions are predetermined that include a plurality of adjacent defective microLED devices on a carrier substrate. A solvent-resistant binding material is formed overlying the predetermined defect regions and exposed adhesive is dissolved with an adhesive dissolving solvent. Non-defective microLED devices located outside the predetermined defect regions are separated from the carrier substrate while adhesive attachment is maintained between the microLED devices inside the predetermined defect regions and the carrier substrate. Methods are also provided for the dispersal of microLED devices on an emissive display panel by initially optically measuring a suspension of microLEDs to determine suspension homogeneity and calculate the number of microLEDs per unit volume. If the number of harvested microLED devices in the suspension is known, a calculation can be made of the number of microLED devices per unit of suspension volume.

Owner:ELUX INC

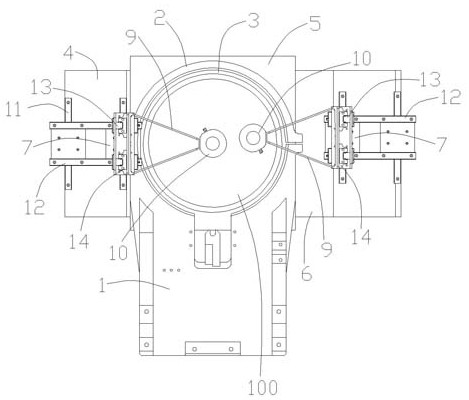

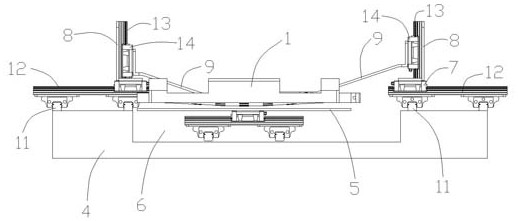

Micro LED mass transfer mechanism

ActiveCN113035766AExact alignmentAccurate needling actionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMicroLED

The invention provides a MicroLED mass transfer mechanism. The mass transfer mechanism comprises a source disc assembly, a target disc assembly, a top suction assembly and a thorn head assembly; and the source disc assembly is located above the target disc assembly, the top suction assembly is installed on the target disc assembly, and the thorn head assembly is located above the source disc assembly. The top suction assembly comprises a moving plate, a mounting plate mounted on the moving plate, a support mounted on the mounting plate and an annular top suction cup mounted on the support, the interior of the annular top suction cup is a working area, and the annular top suction cup is located above the transfer film. According to the MicroLED mass transfer mechanism, the MicroLED transfer precision is effectively improved, the product yield is improved, and high-precision mass transfer of MicroLEDs is achieved.

Owner:广东阿达智能装备有限公司

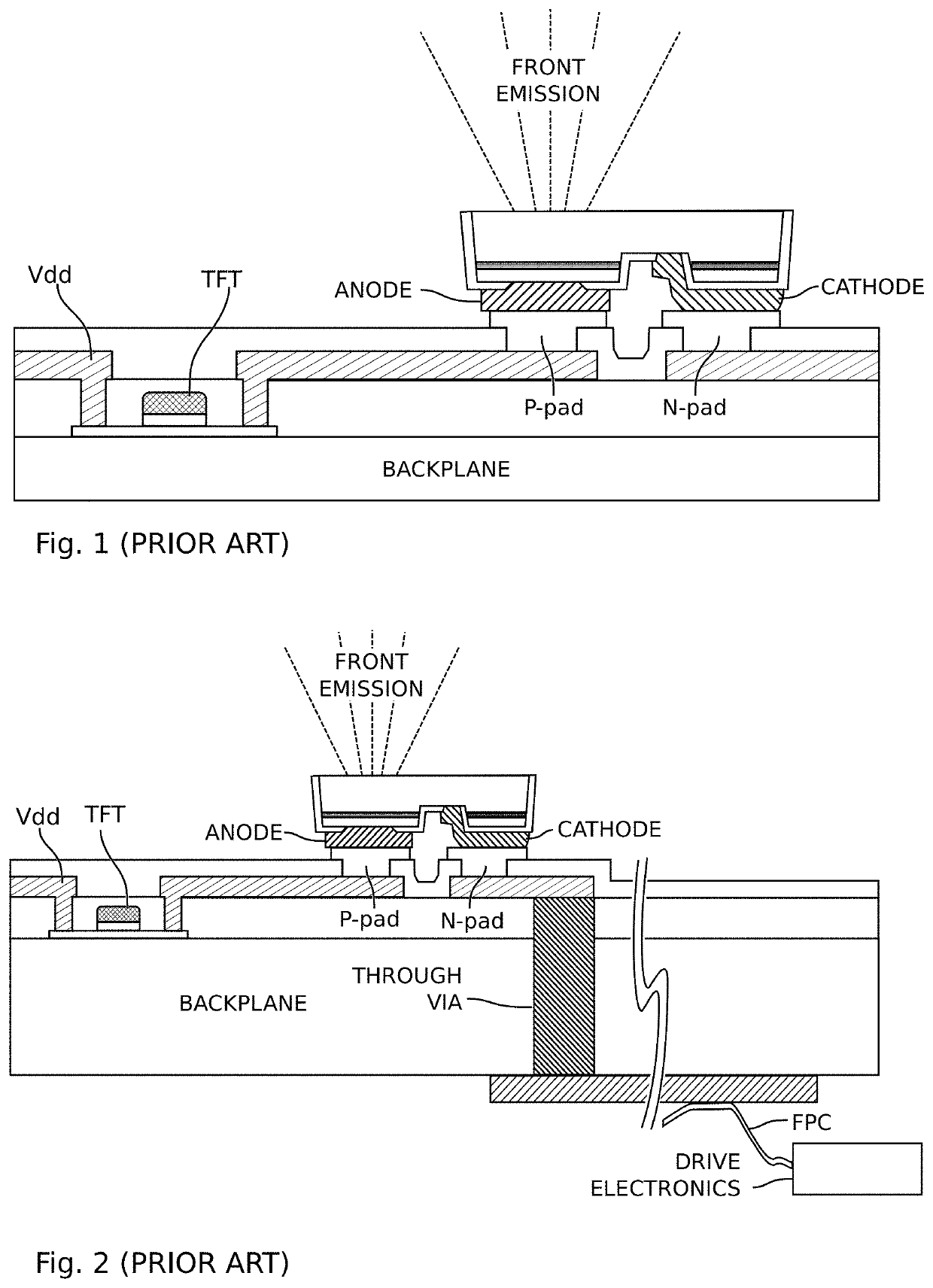

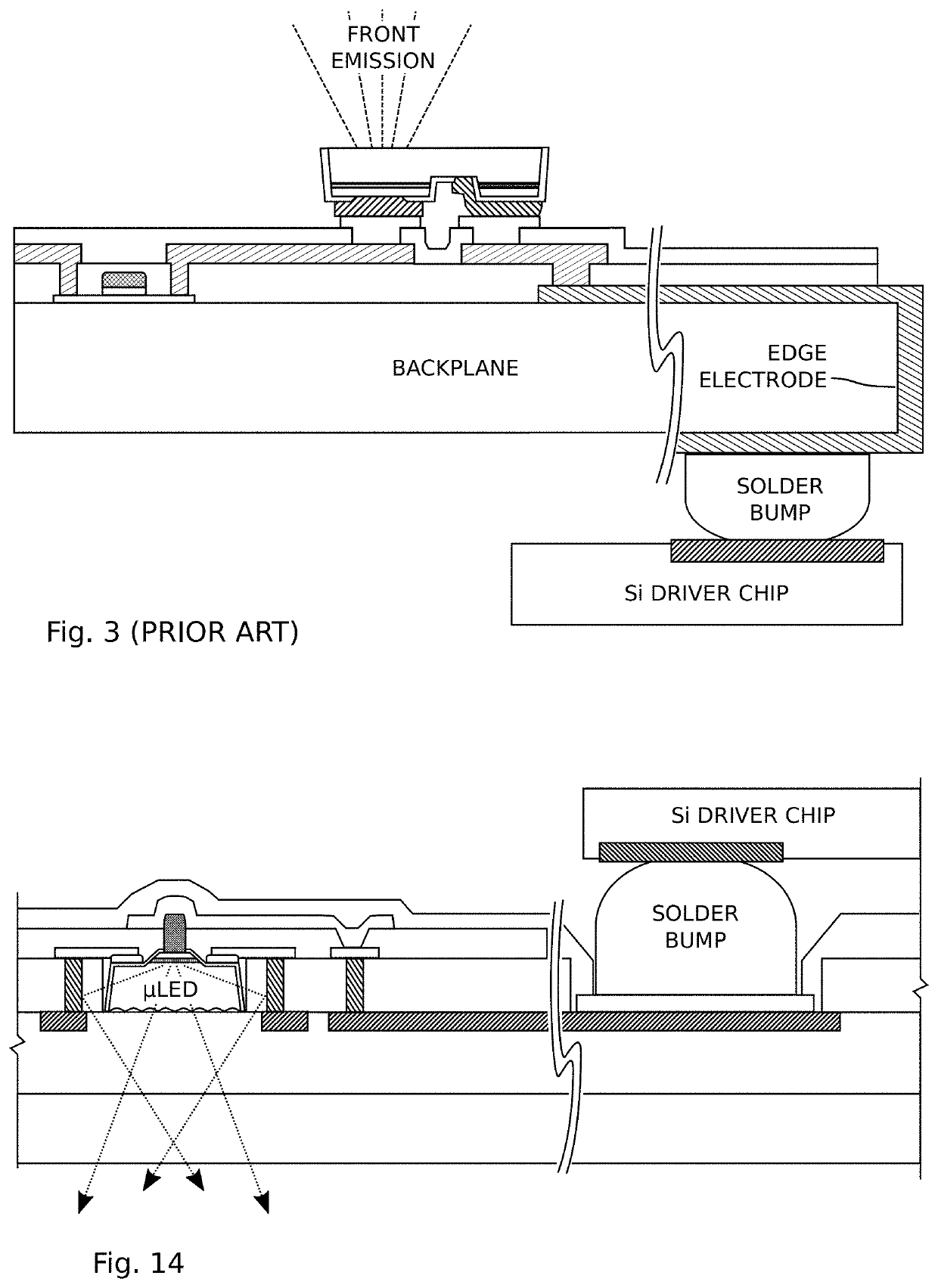

Back Emission Display

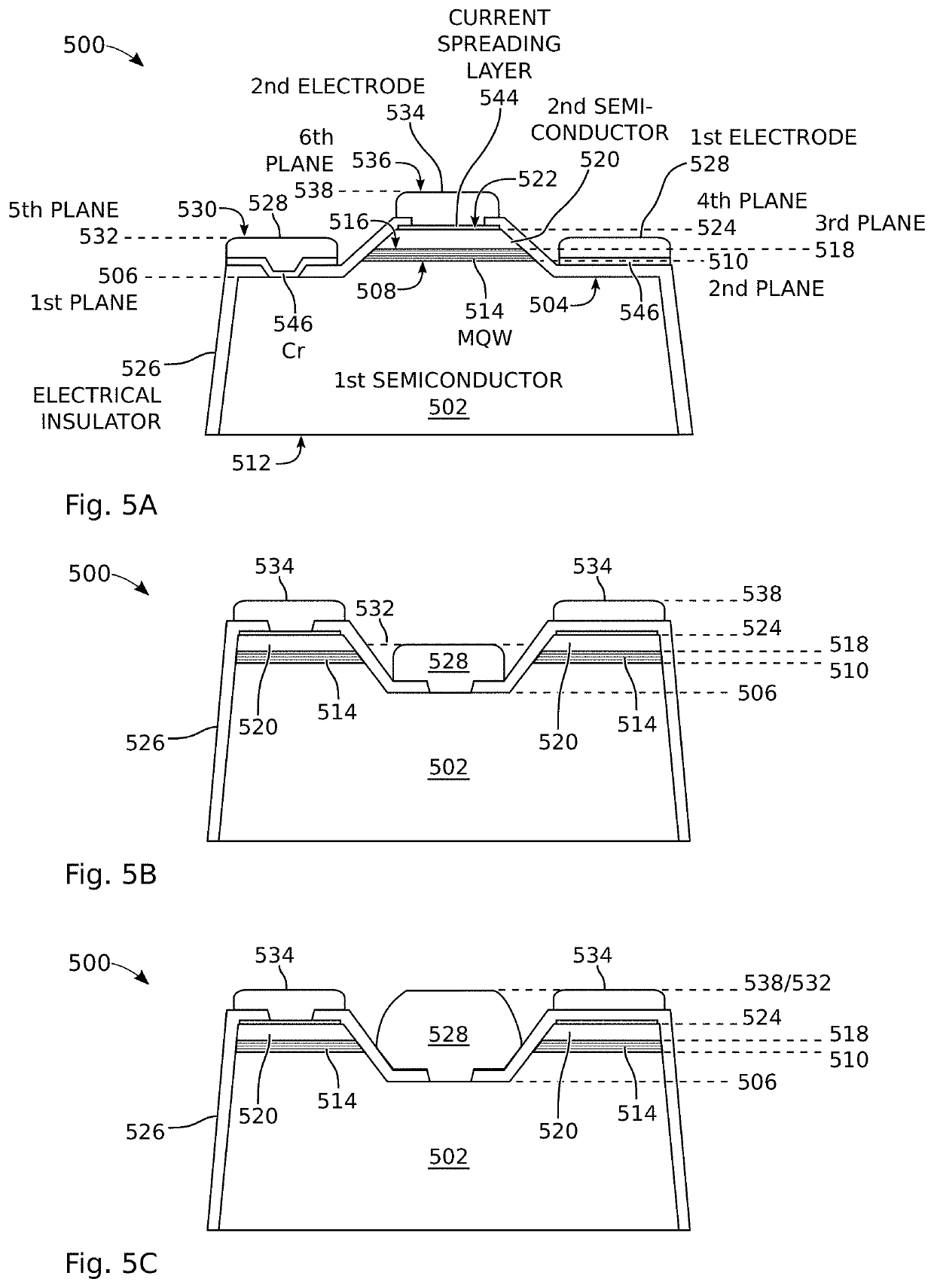

PendingUS20220149254A1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMicroLED

Disclosed herein is a micro light emitting diode (microLED) display structure with emission from the back side of a transparent substrate, which can be manufactured by fluidic assembly. The architecture allows microLED displays or display tiles to be fabricated simply, with processing and interconnection only on one side of the backplane. The structure may incorporate reflectors in the fluidic assembly structures to direct substantially all of the emitted light toward the viewer. Also disclosed are microLEDs and emission backplanes designed to support a back emission display.

Owner:ELUX INC

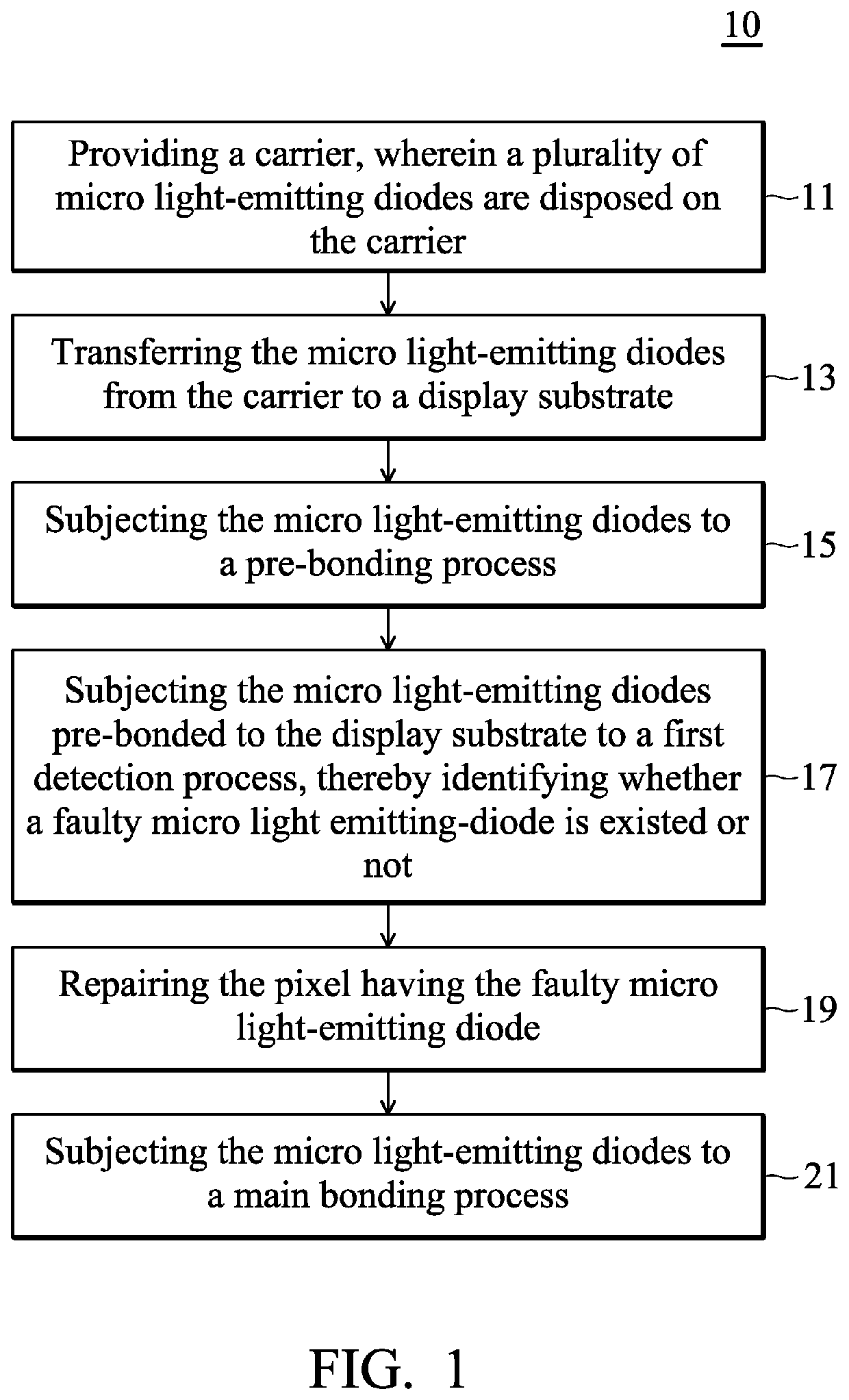

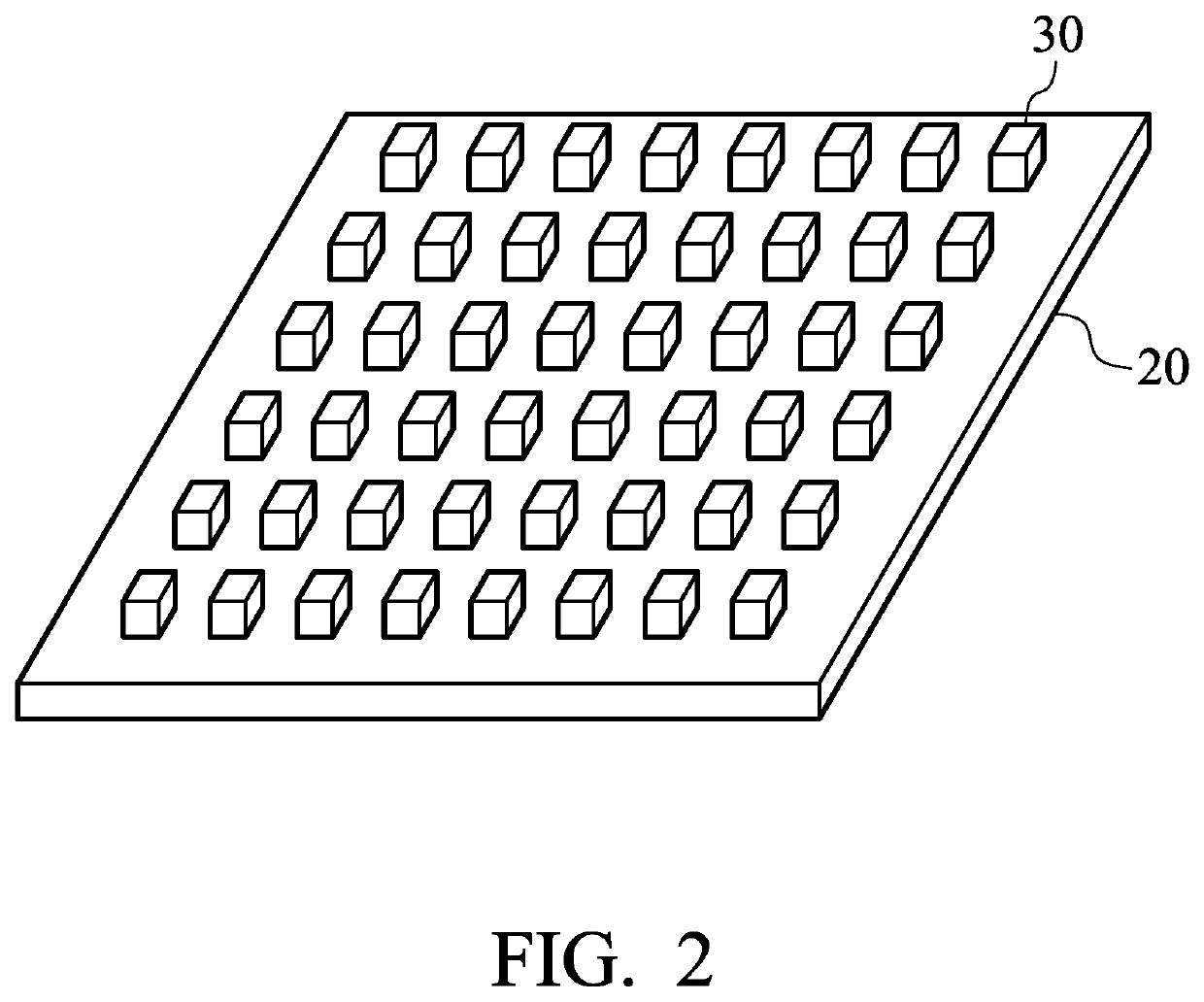

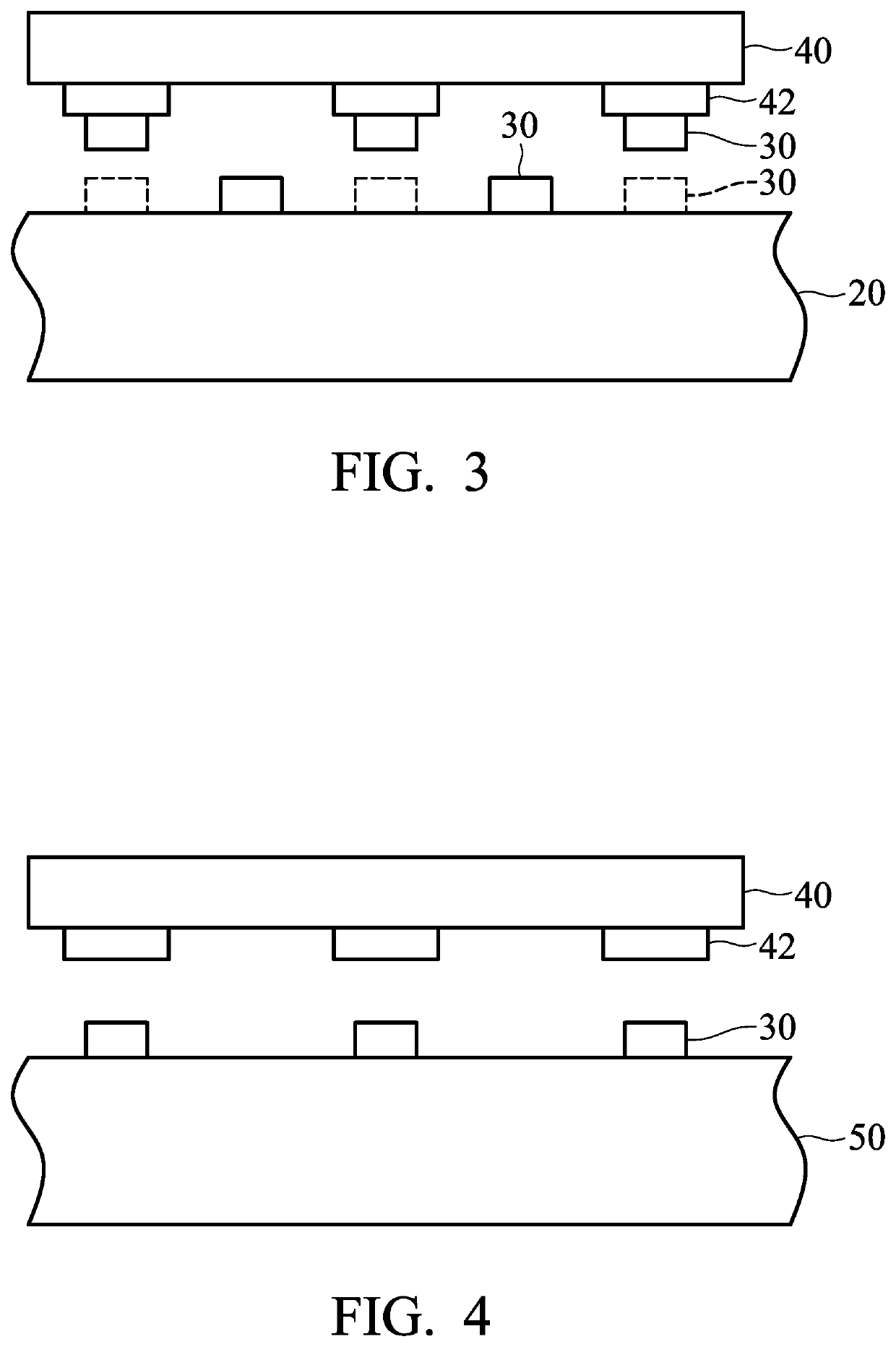

Method for fabricating micro light-emitting diode display

ActiveUS20200388736A1High bonding strengthSemiconductor/solid-state device testing/measurementSolid-state devicesLED displayDisplay device

A method for fabricating a micro light-emitting diode display is provided. The method includes disposing a plurality of micro light-emitting diodes on a carrier; transferring the micro light-emitting diodes from the carrier to a display substrate and disposing the micro light-emitting diodes in a plurality of pixels of the display substrate; subjecting the micro light-emitting diodes to a pre-bonding process to electrically connect the micro light-emitting diodes to the display substrate; subjecting the micro light-emitting diodes pre-bonded to the display substrate to a first detection process, thereby identifying whether a faulty micro light-emitting diode is present or not; and, subjecting the micro light-emitting diodes to the main bonding process after the first detection process.

Owner:PLAYNITRIDE DISPLAY CO LTD

Interconnect networks using microled-based optical links

Integrated circuit chips may be optically interconnected using microLEDs. Some interconnections may be vertically-launched parallel optical links. Some interconnections may be planar-launched parallel optical links.

Owner:AVICENATECH CORP

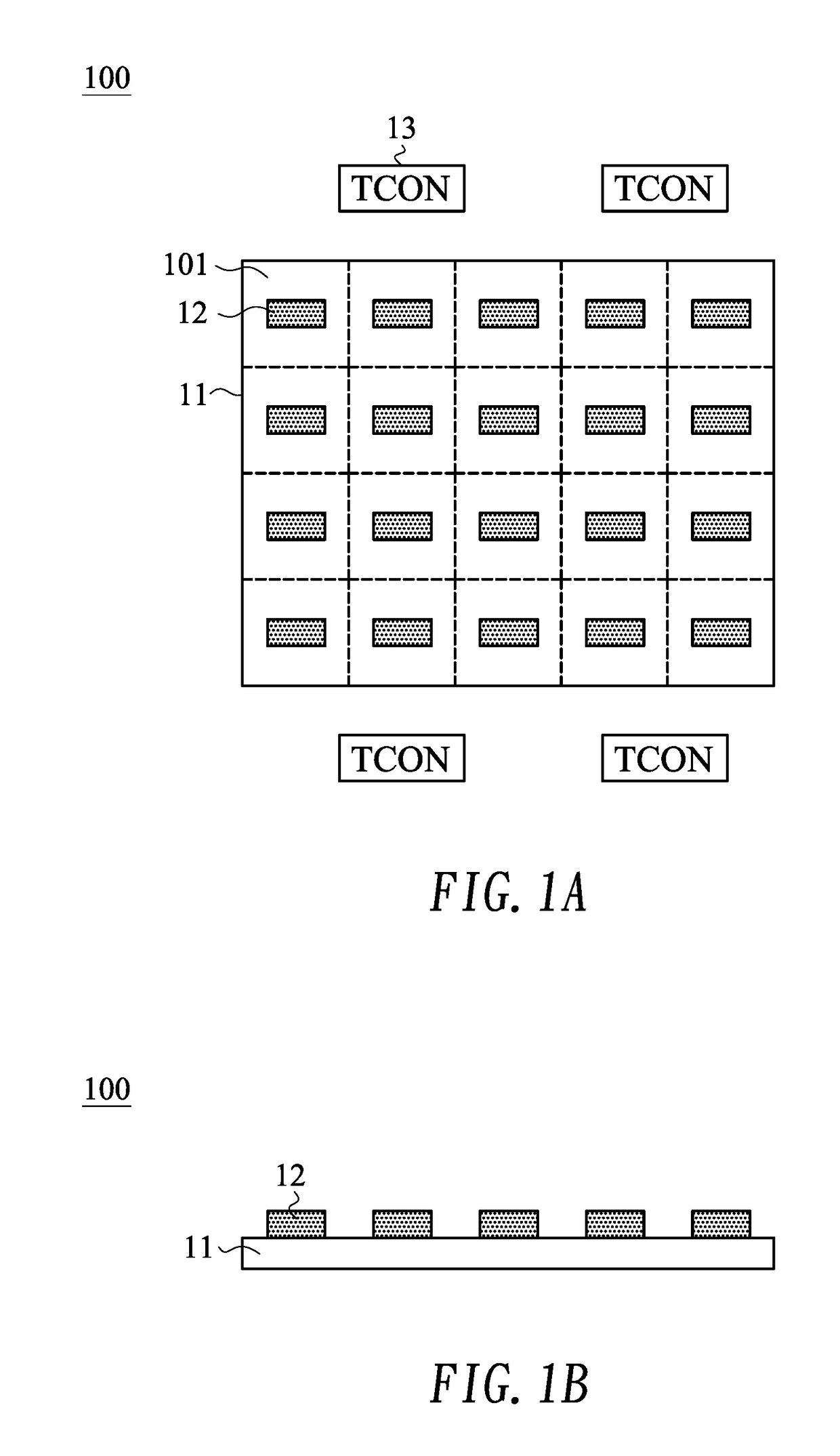

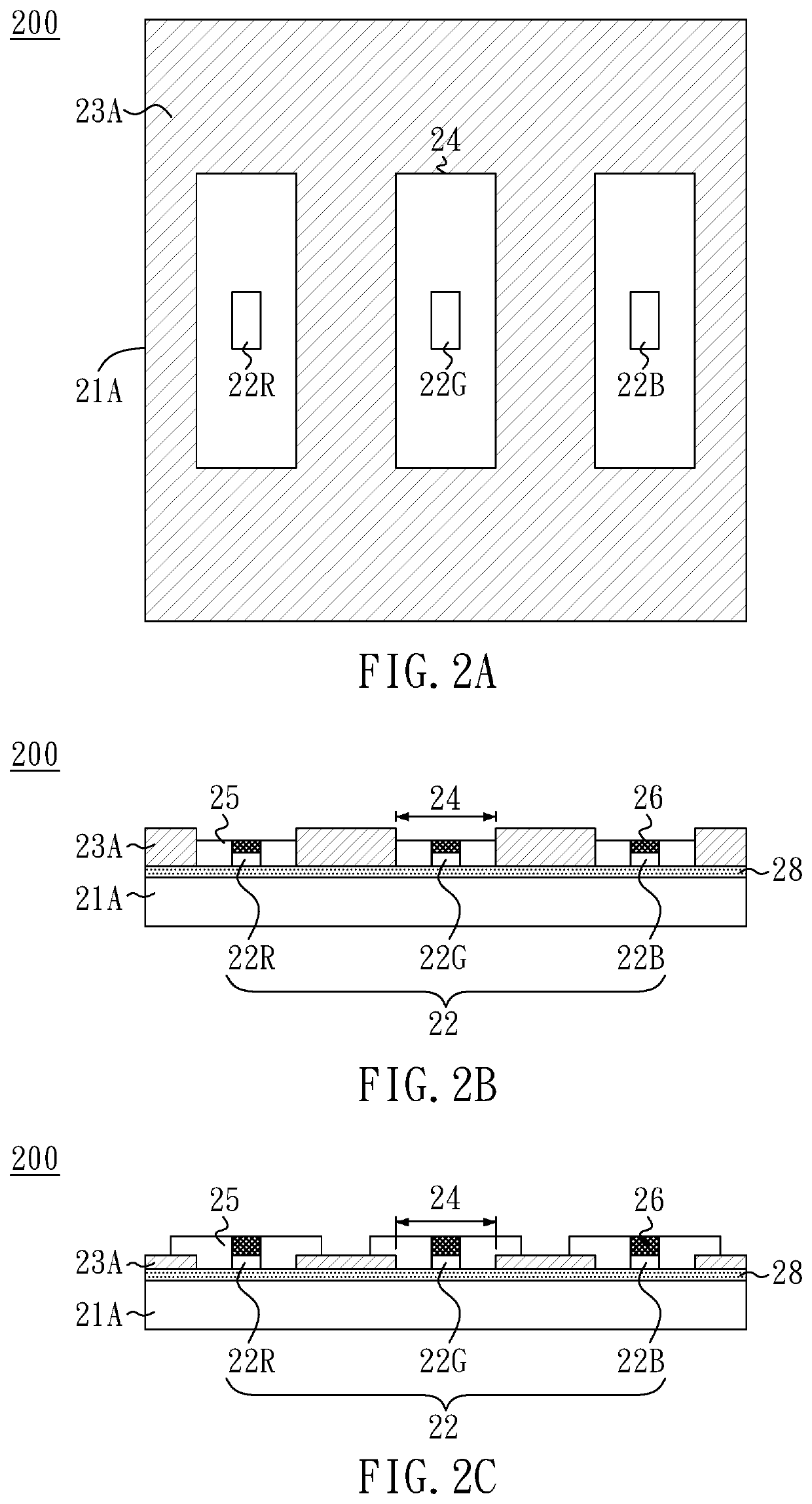

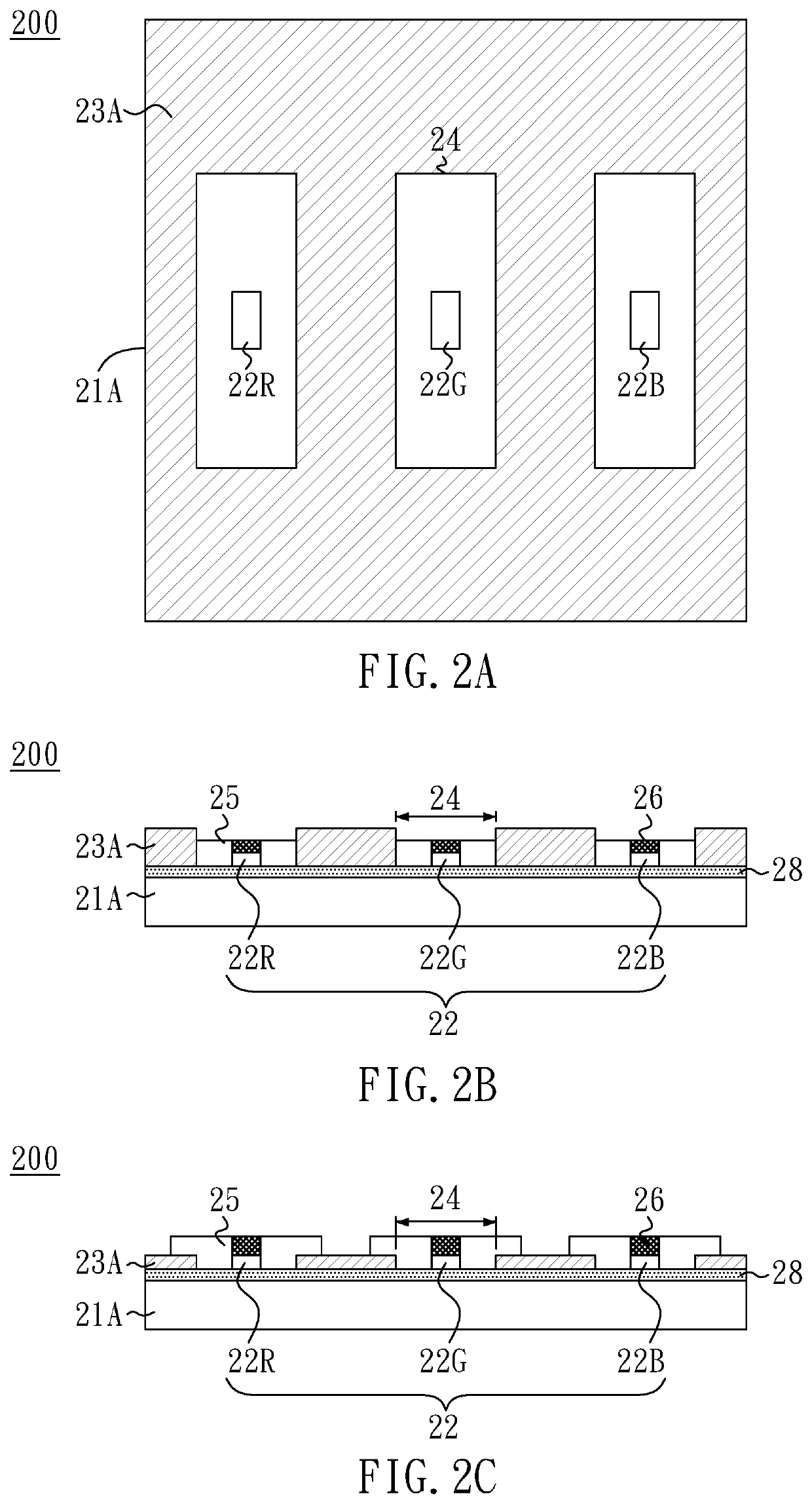

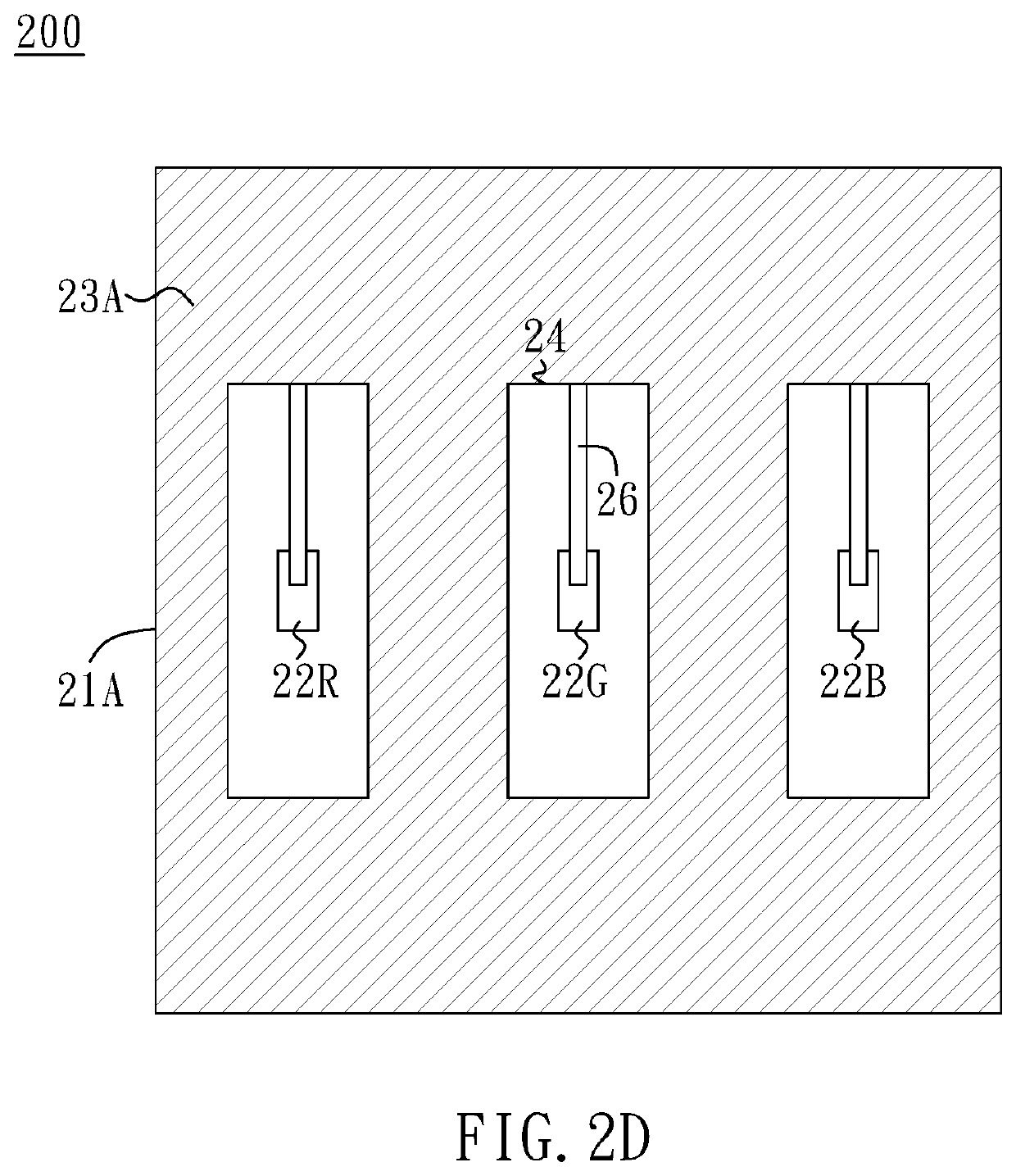

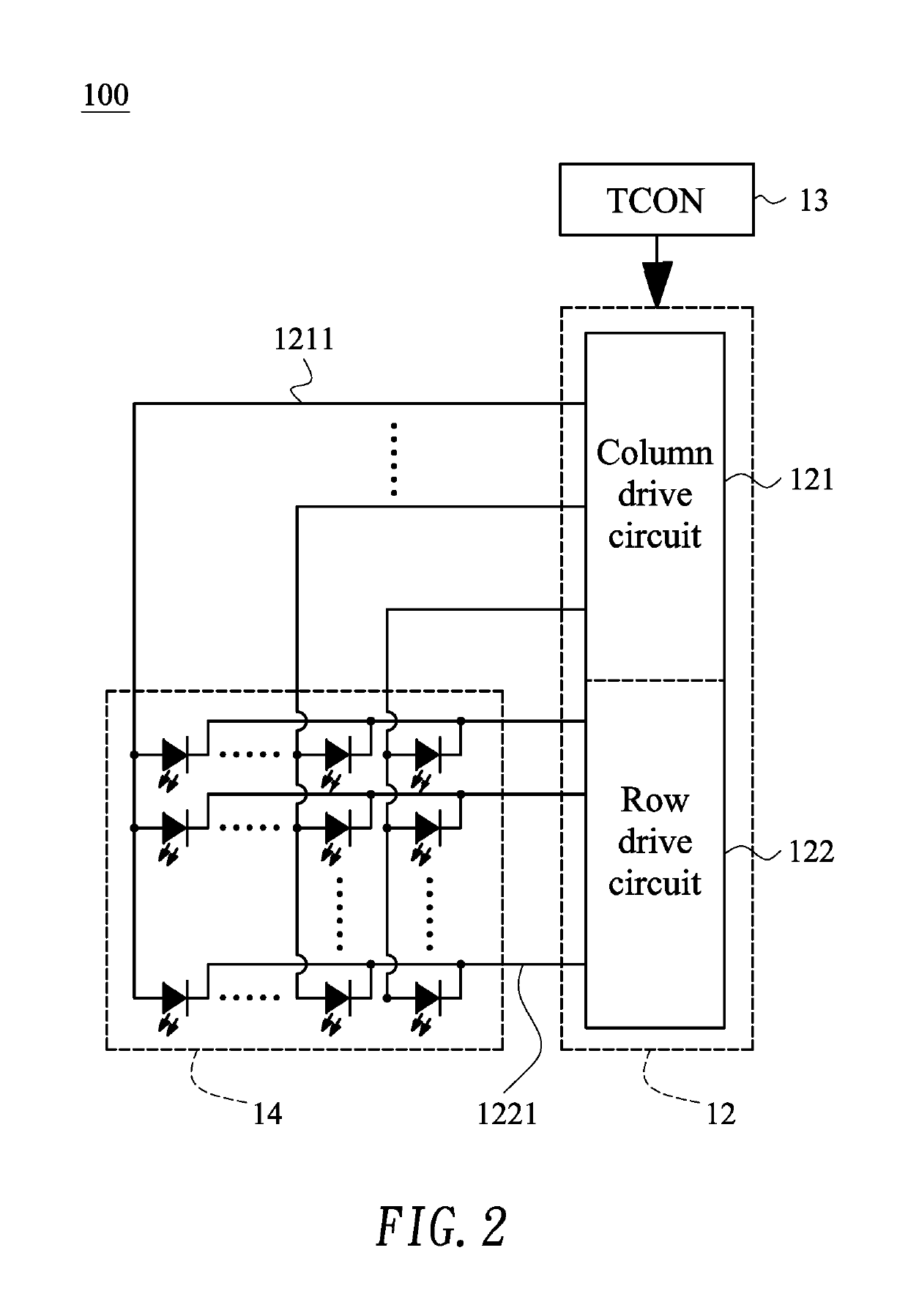

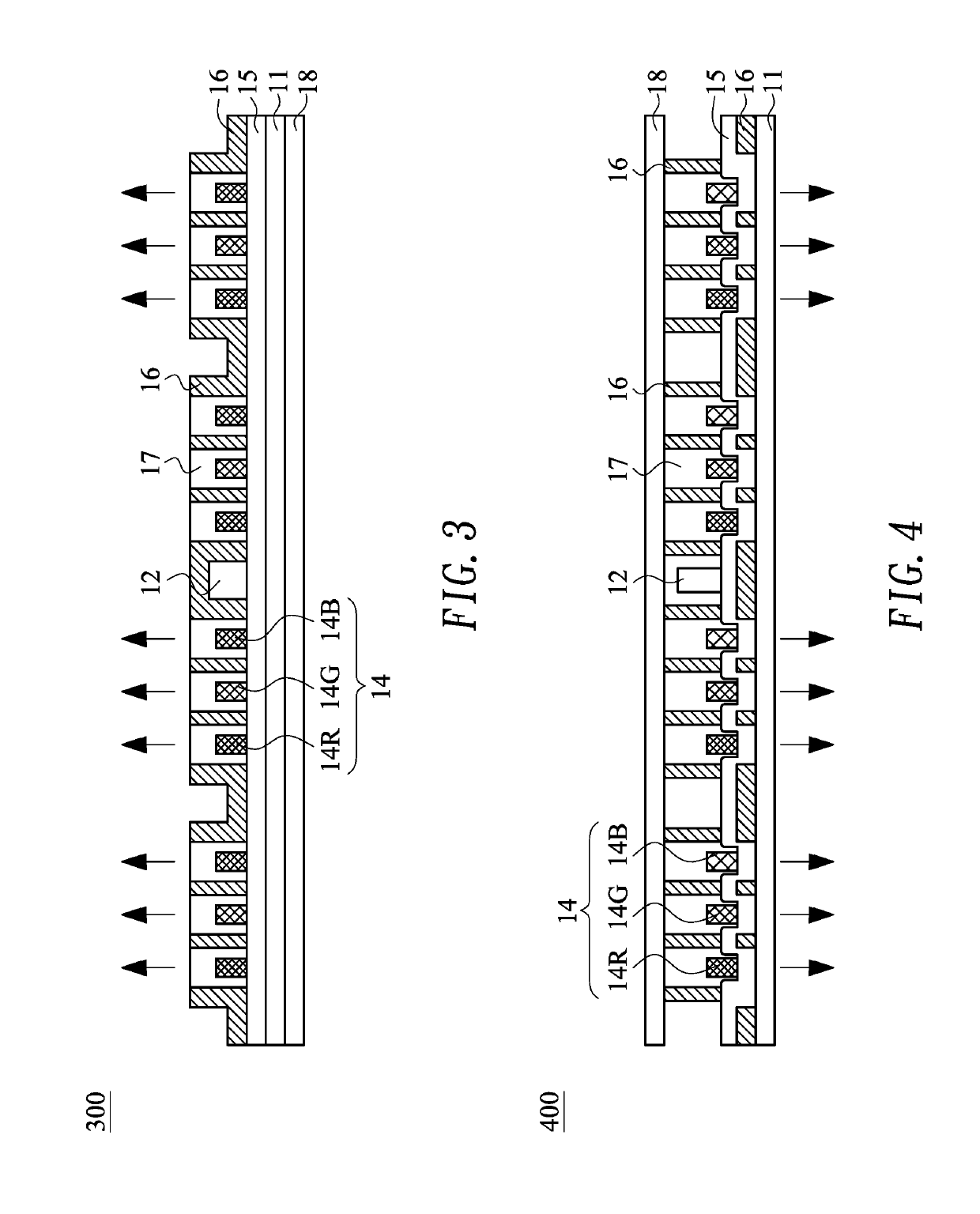

Top emission microled display and bottom emission microled display and a method of forming the same

InactiveUS20200083280A1Avoid interferenceAvoid color mixingStatic indicating devicesSolid-state devicesLight guideDisplay device

A microLED display includes a first main substrate, micrLEDs disposed above the first main substrate, a first light blocking layer disposed above the first main substrate to define emission areas, a light guiding layer disposed in the emission areas, and a plurality of connecting structures disposed in the emission areas respectively and electrically connected with the microLEDs.

Owner:PRILIT OPTRONICS INC

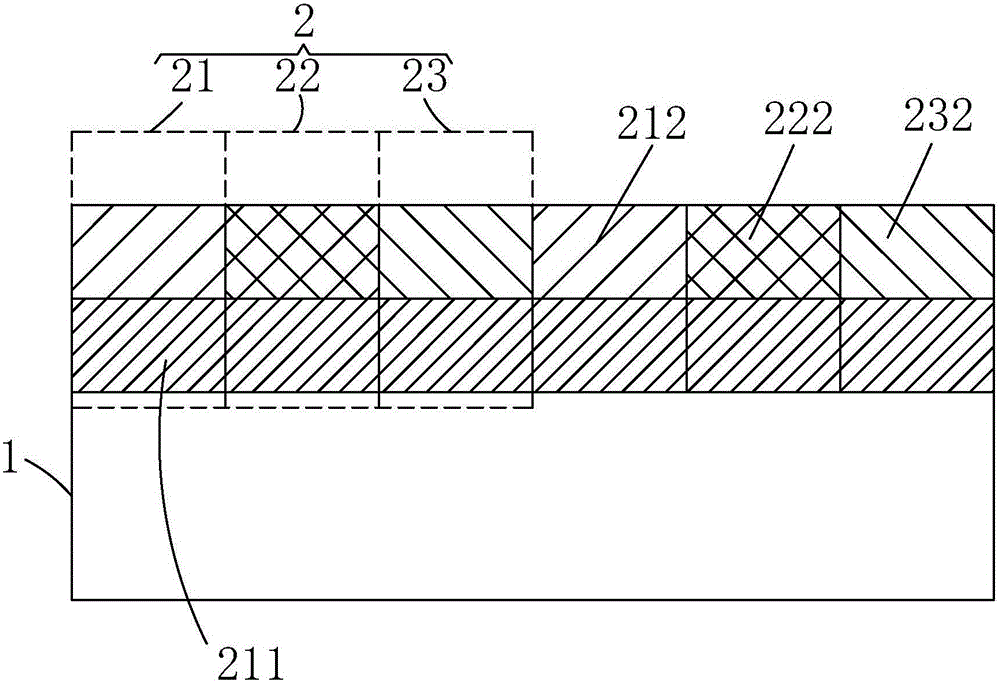

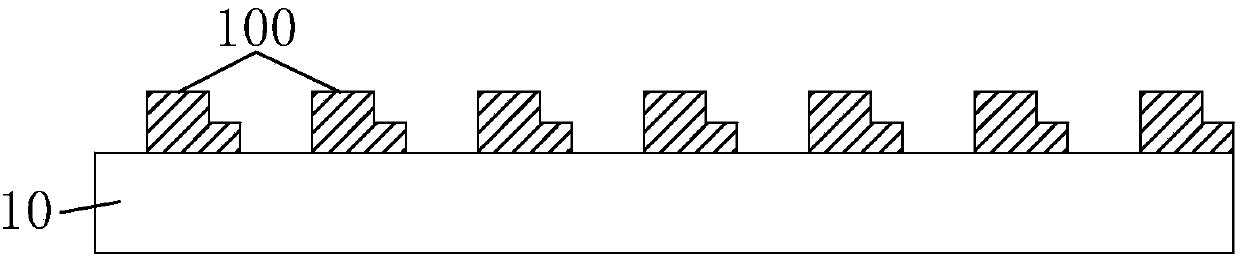

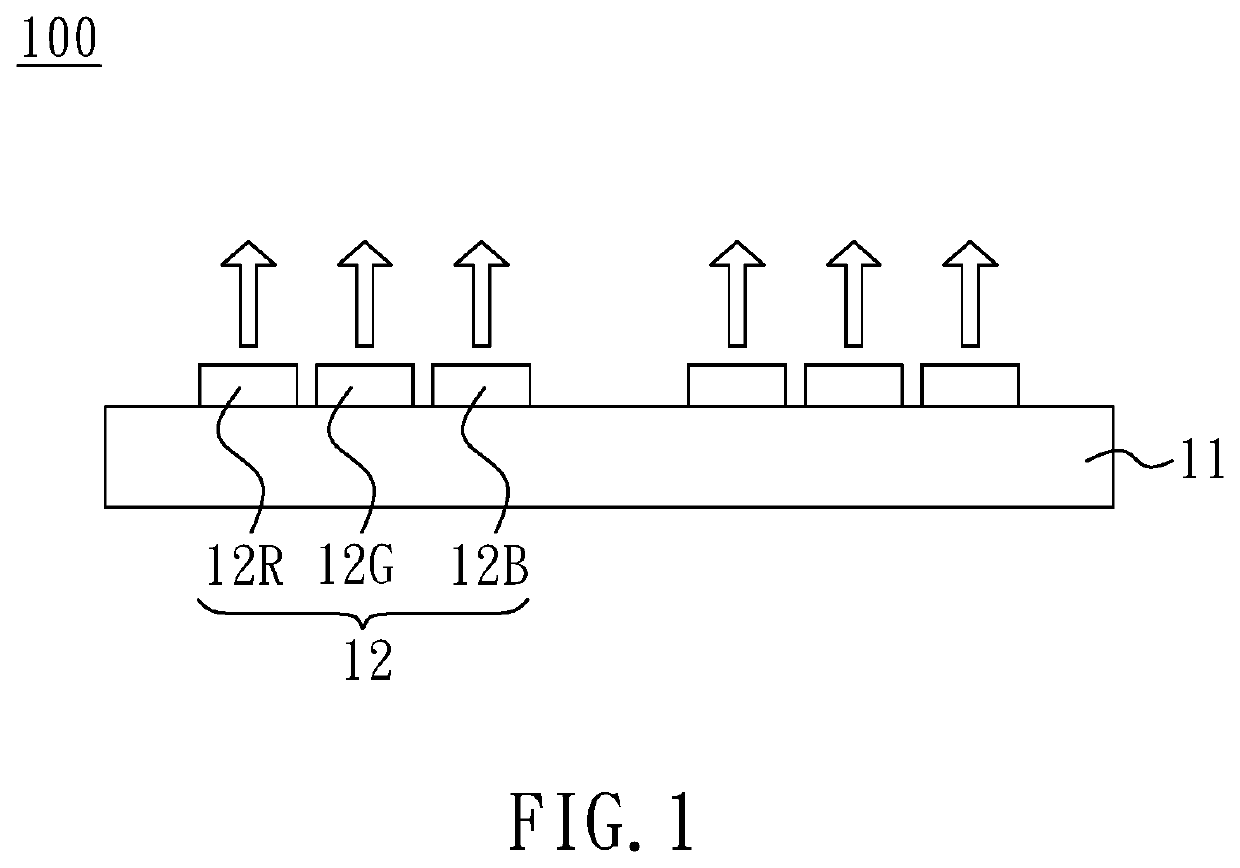

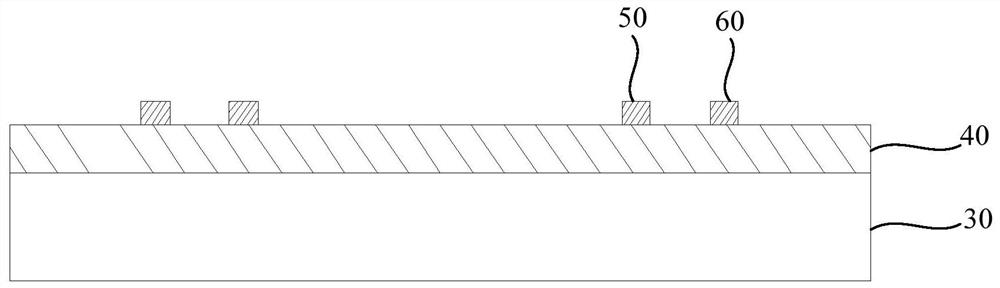

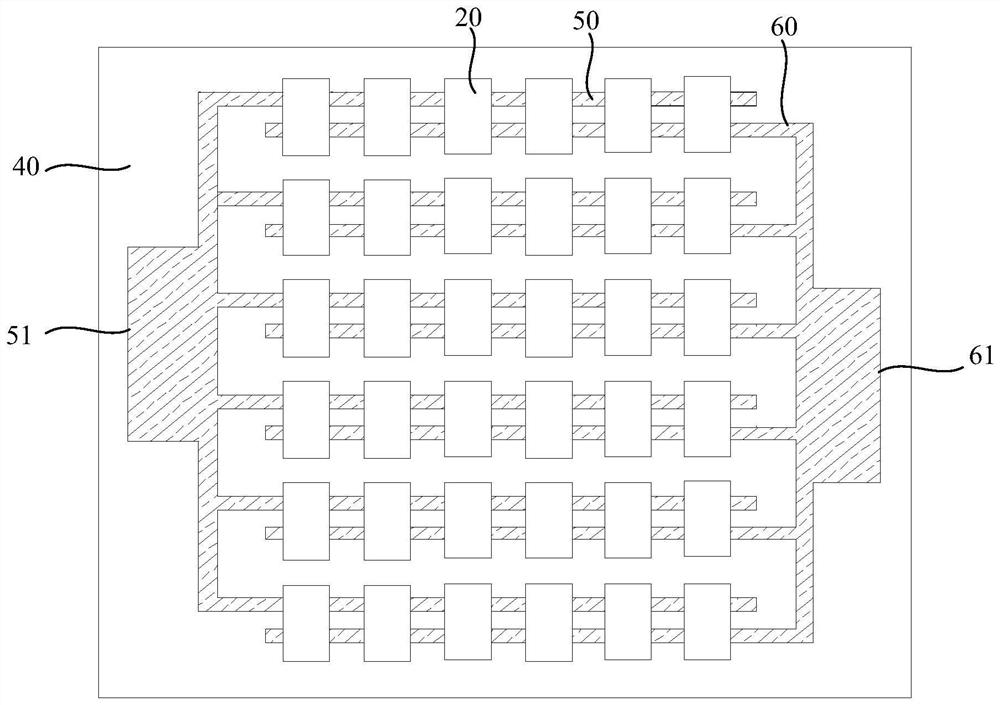

Luminous unit coplanar structure of micro light emitting diode display

PendingCN110391262AImprove uniformity of light emissionSolid-state devicesSemiconductor devicesDisplay deviceHeight difference

The invention discloses a luminous unit coplanar structure of a micro light emitting diode display. The micro light emitting diode display is formed through an array which is formed by arranging multiple luminous units on a substrate; the luminous units are formed by arranging red, green and blue LED chips on a support plate; the height of at least one LED chip in the red, green and blue LED chipsincluded by the luminous units is relatively greater than that of other LED chips so that height difference can be formed; the first surface of the support plate is provided with at least one groovefor accommodating the LED chip with relatively large height; and each groove has a depth which is approximately equal to the height difference. Thus, the red, green and blue LED chips can form a coplanar state on the support plate so as to enhance the luminous uniformity of the micro light emitting diode display at different visual angles.

Owner:晶旺半导体(厦门)有限公司

Micro light emitting diode detection device and method

ActiveCN112649711AAvoid diversionReduce the difficulty of repairDiode testingPhotometryDisplay deviceHemt circuits

The invention provides a micro light emitting diode detection device and method, and belongs to the technical field of display. The micro light emitting diode detection device is used for detecting a micro light emitting diode which arranged on an original substrate; the bottom part, far away from the original substrate, of the micro light emitting diode comprises an electrode region and a non-electrode region; and the electrode region is provided with a first contact and a second contact. The detection device comprises a detection substrate and a detection circuit, wherein a bonding layer is arranged on the detection substrate, and the bonding layer is used for being bonded with an original substrate during testing; and the detection circuit comprises an electrode set arranged on the bonding layer, the electrode set comprises a first electrode and a second electrode, the first electrode is used for making contact with a first contact of the micro-light-emitting diode during testing, and the second electrode is used for making contact with a second contact of the micro-light-emitting diode during testing. According to the micro light emitting diode detection device and the method provided by the invention, the repair difficulty of a micro light emitting diode display can be reduced.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Micro light-emitting diode display production detection method and display thereof

PendingCN113450681AIncrease productivityReduce complexityStatic indicating devicesLED displayDisplay device

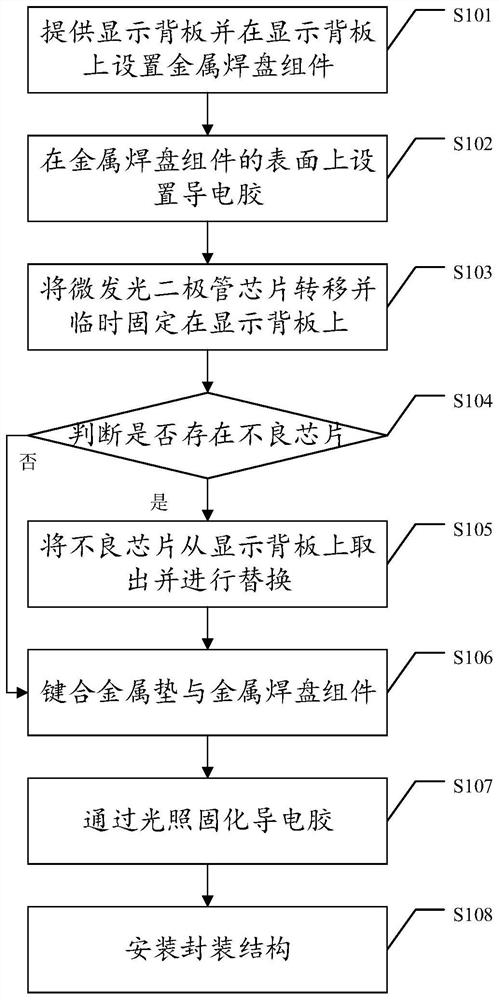

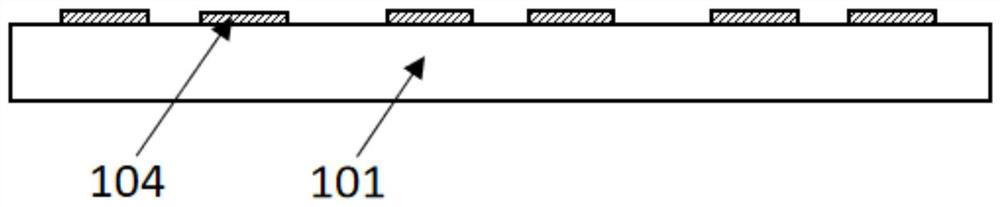

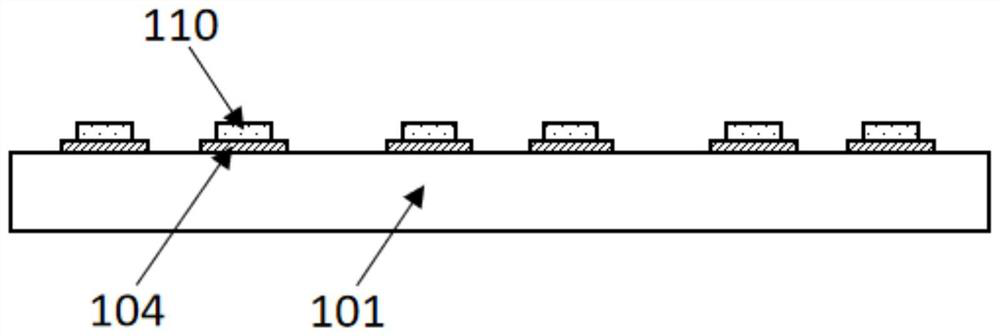

The invention relates to the technical field of semiconductors, in particular to a micro light-emitting diode display production detection method and a display thereof, and the method comprises the steps: providing a display backboard, and arranging a metal bonding pad assembly on the display backboard; arranging a conductive adhesive on the surface of the metal bonding pad assembly; transferring a micro light-emitting diode chip to a position above the metal bonding pad assembly, and fixing a metal pad at the lower end of the micro light-emitting diode chip temporarily with the surface of the metal bonding pad assembly through the conductive adhesive; carrying out electrical measurement on the micro light-emitting diode chip, and determining whether a bad chip exists or not; if the bad chip exists, taking out the bad chip from the display backboard and replacing the bad chip. According to the micro light-emitting diode display production detection method, the complexity of replacing the micro light-emitting diode chip is greatly reduced, the production efficiency of the display is greatly improved, and a guarantee is brought to rapid mass production of display screens.

Owner:CHONGQING KONKA PHOTOELECTRIC TECH RES INST CO LTD

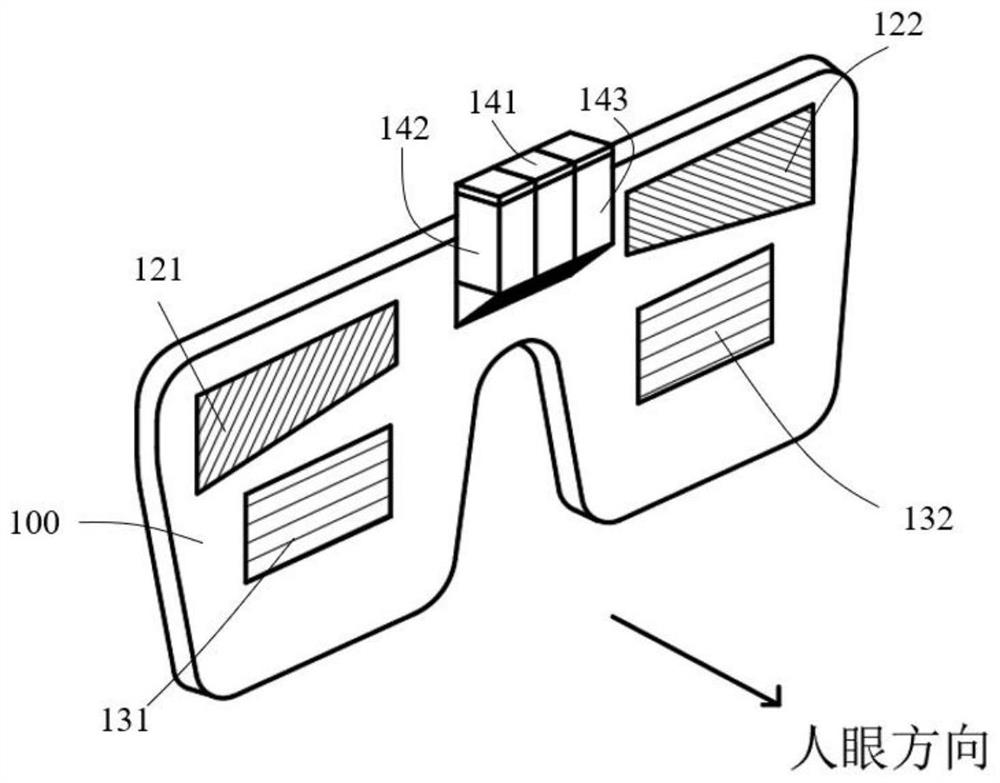

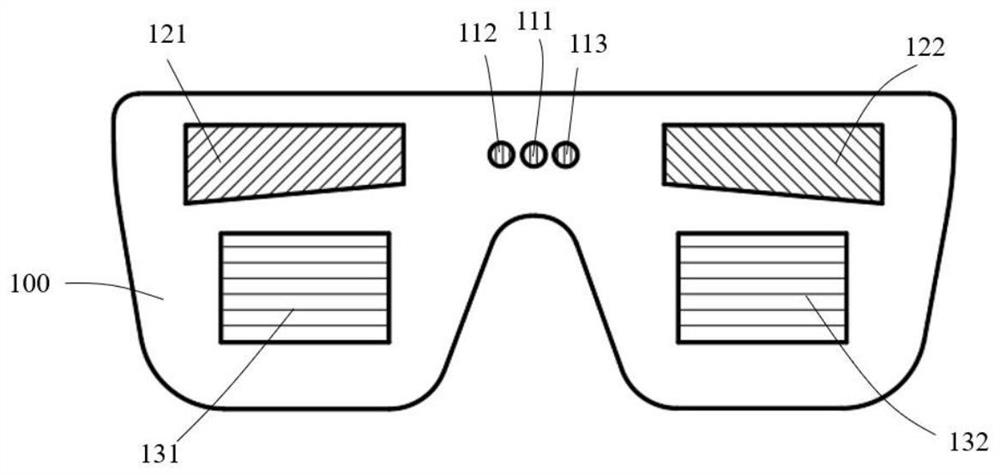

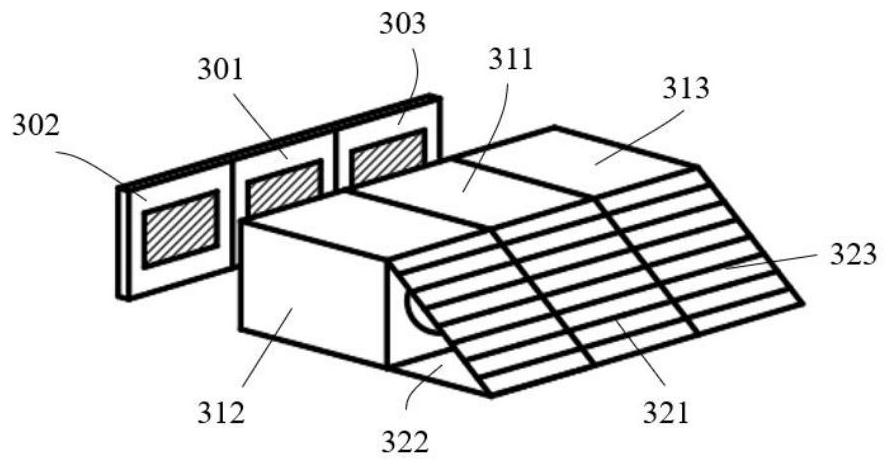

Colorful AR glasses

The invention discloses a pair of colored AR glasses, which comprises a waveguide sheet template, and is characterized in that the waveguide sheet template is provided with a first entrance pupil area, a second entrance pupil area and a third entrance pupil area, and the first entrance pupil area, the second entrance pupil area and the third entrance pupil area are uniformly distributed on the central axis of the waveguide sheet template and are located above a nose bridge of the waveguide sheet template; a first pupil dilation area and a second pupil dilation area are symmetrically arranged on the left side and the right side of the pupil entrance area; a first exit pupil area and a second exit pupil area are respectively positioned below the first pupil dilation area and the second pupil dilation area; and a first projection light machine, a second projection light machine and a third projection light machine are respectively configured with the first entrance pupil area, the second entrance pupil area and the third entrance pupil area, and the first projection light machine, the second projection light machine and the third projection light machine respectively project one color light in RGB three colors. According to the invention, the projection light machines of the MicroLEDs with three wavelengths are arranged, so that a color image is successfully displayed on the AR glasses, the brightness of emitted light is ensured, and the color is richer and fuller.

Owner:SHENZHEN OPTIARK SEMICON TECH LTD

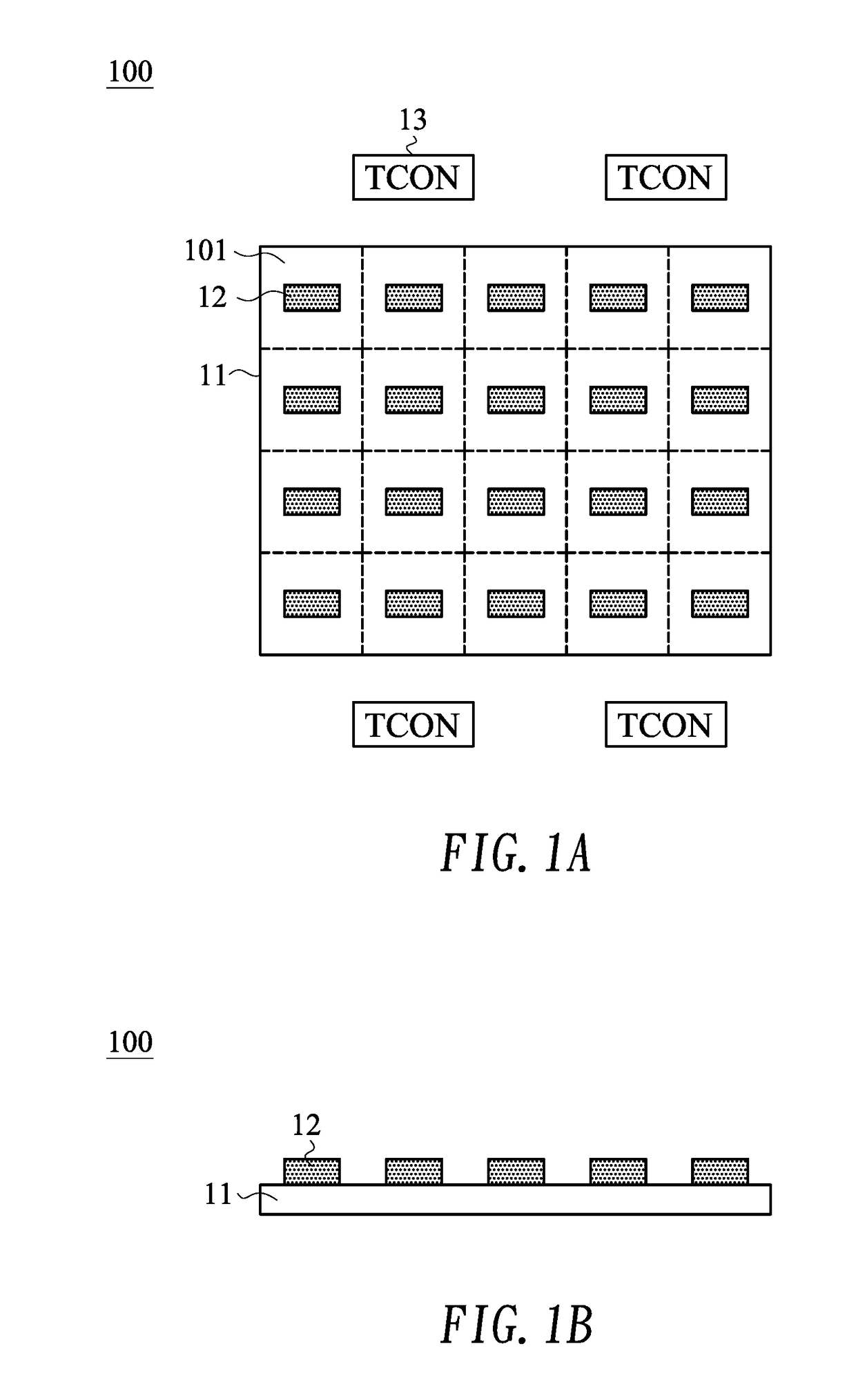

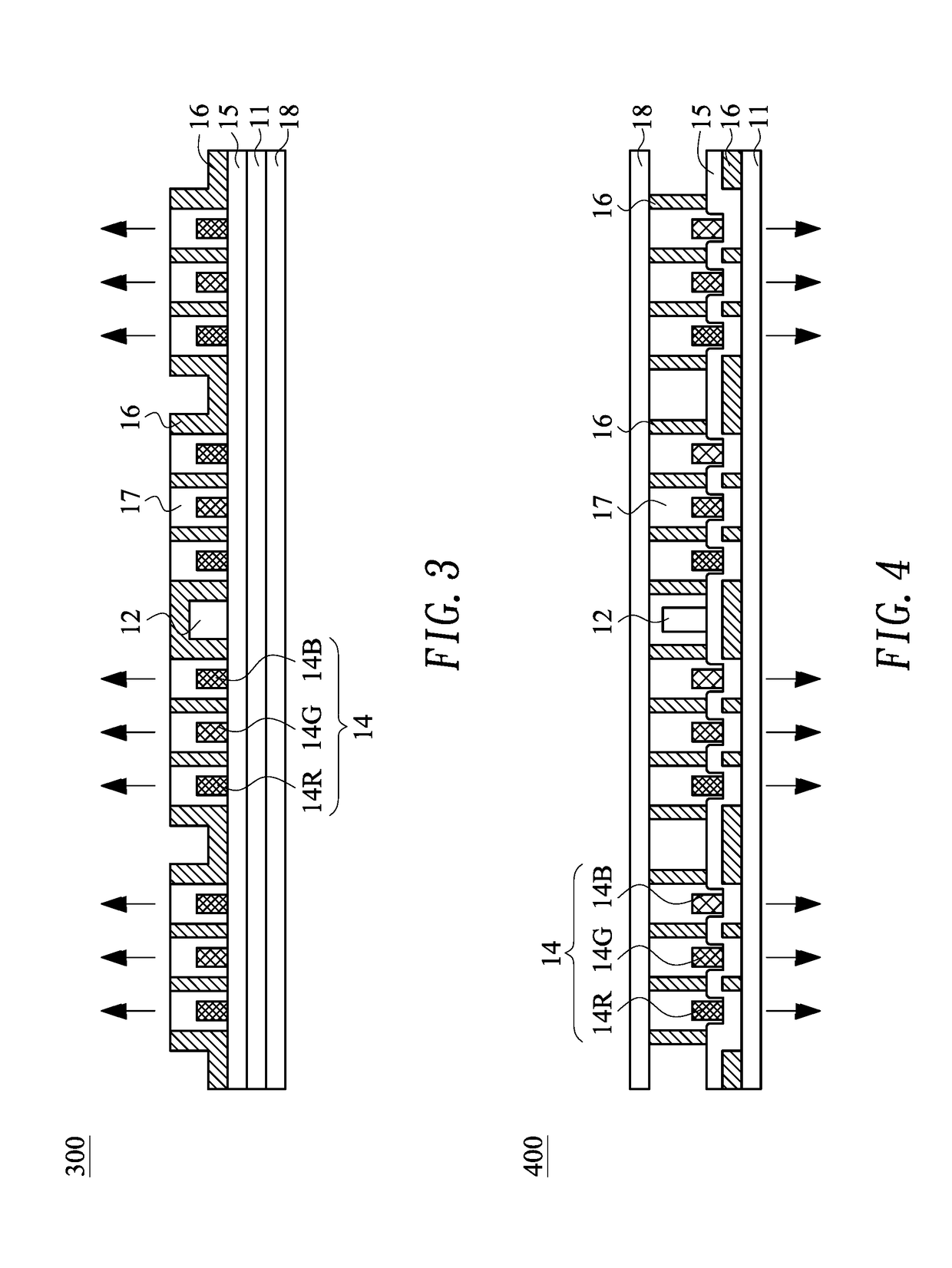

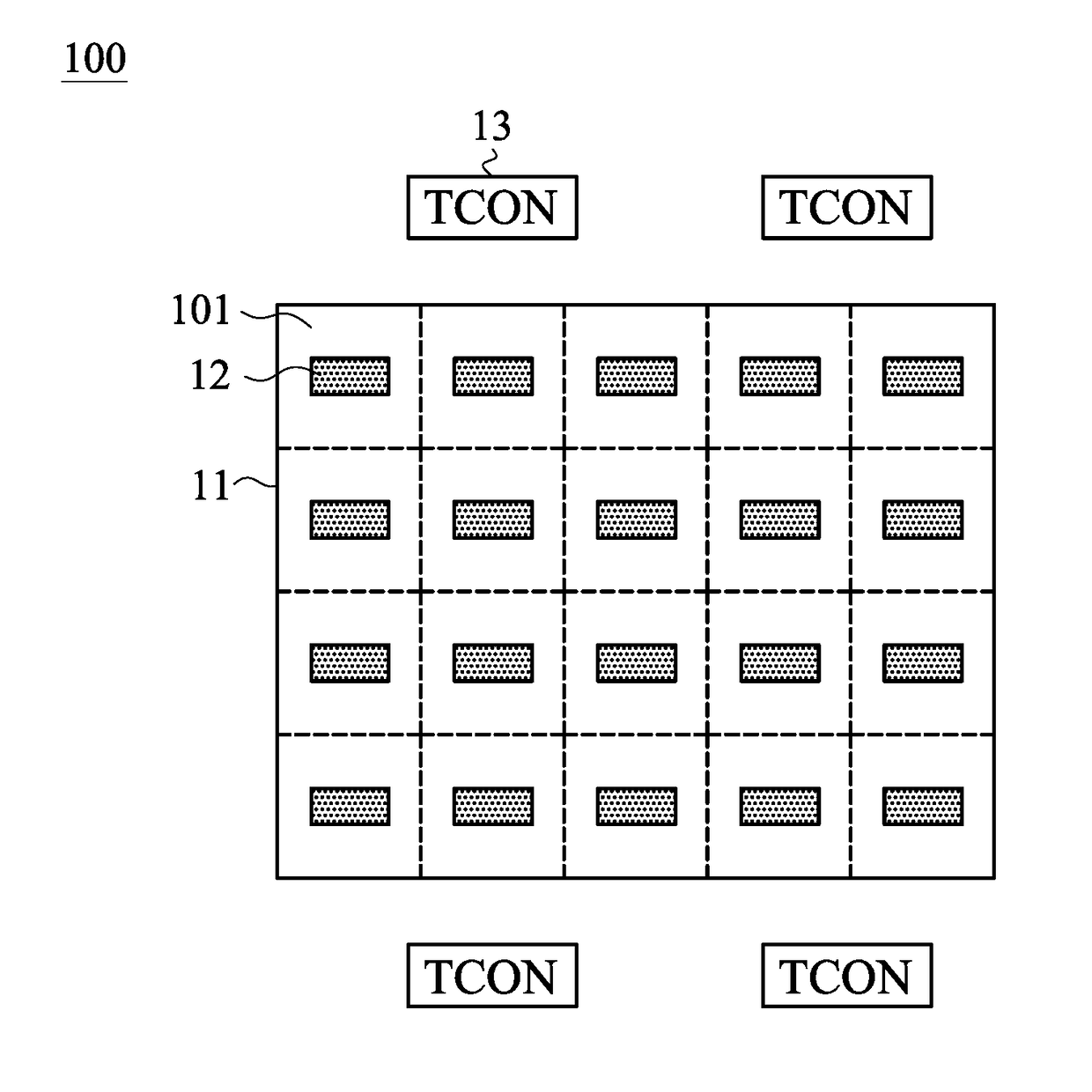

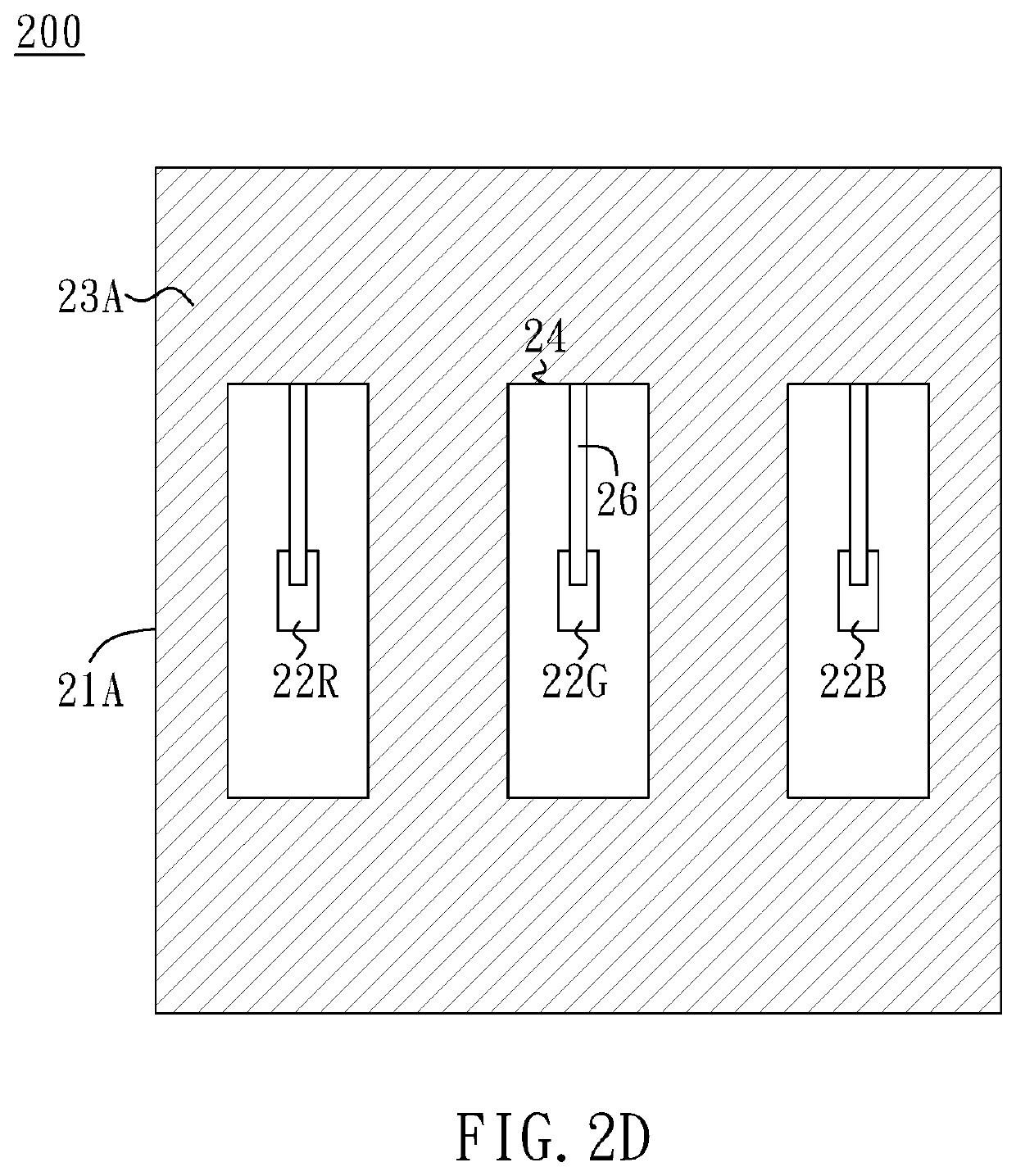

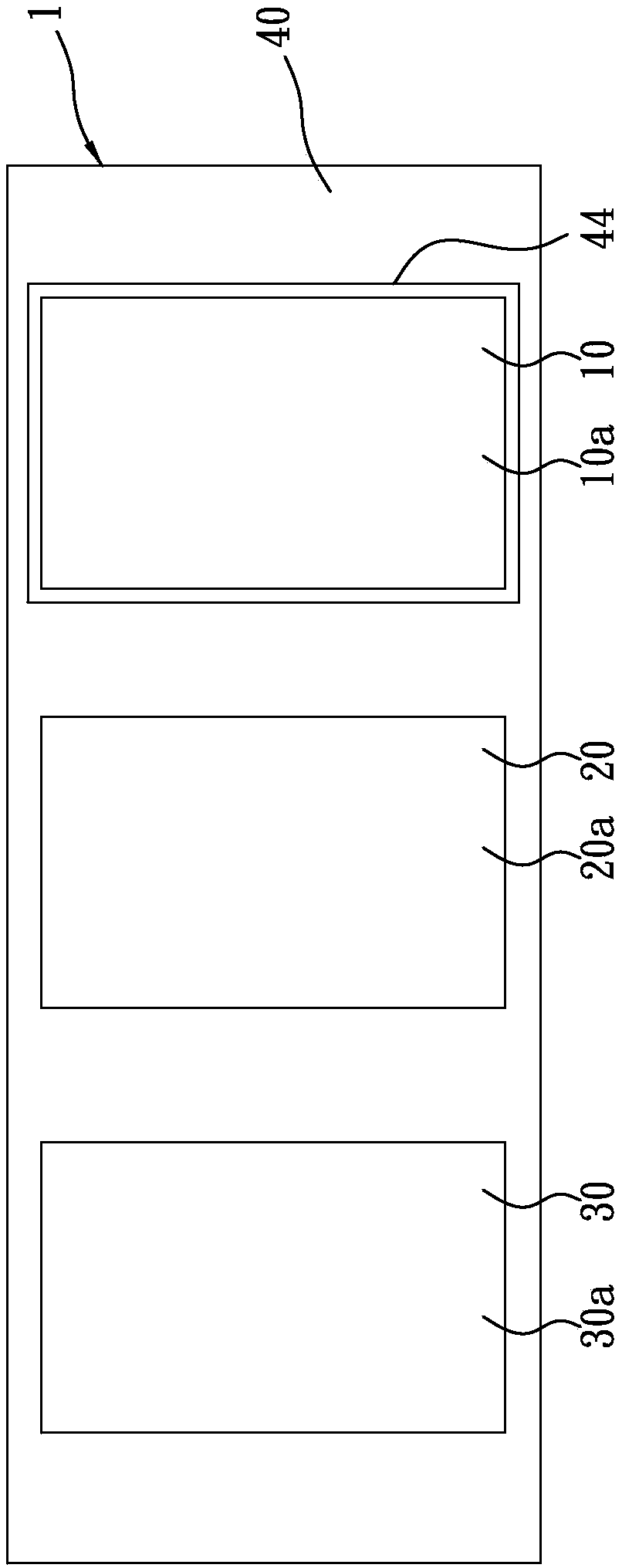

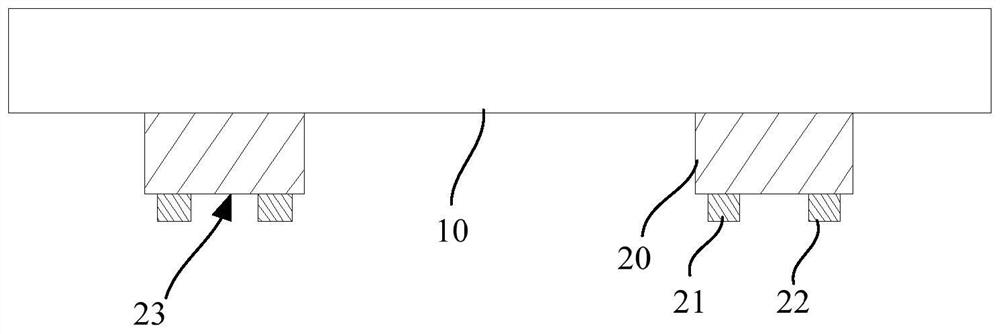

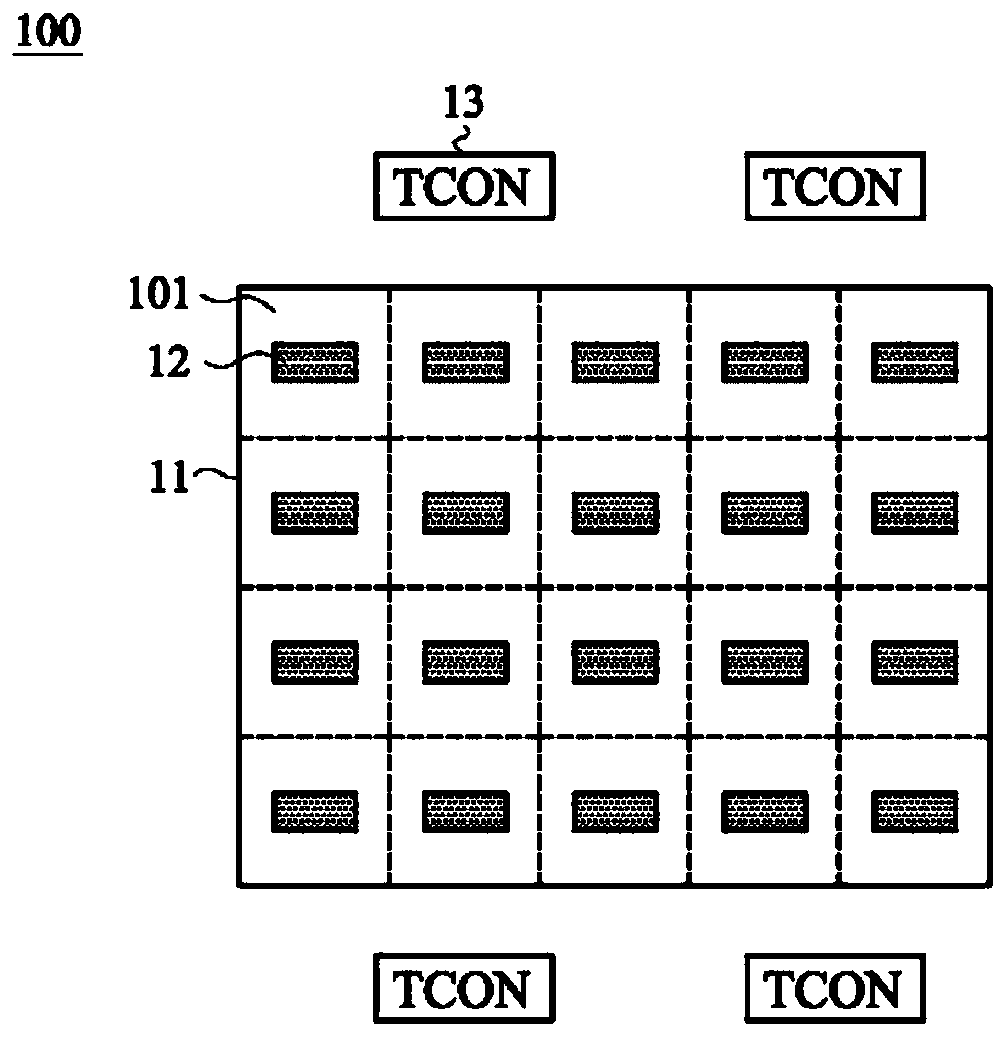

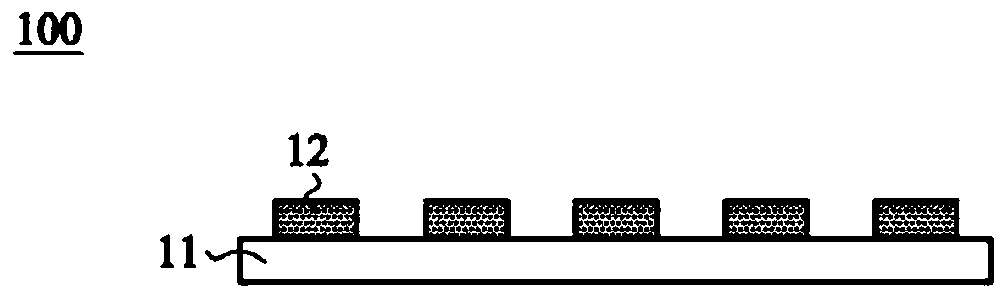

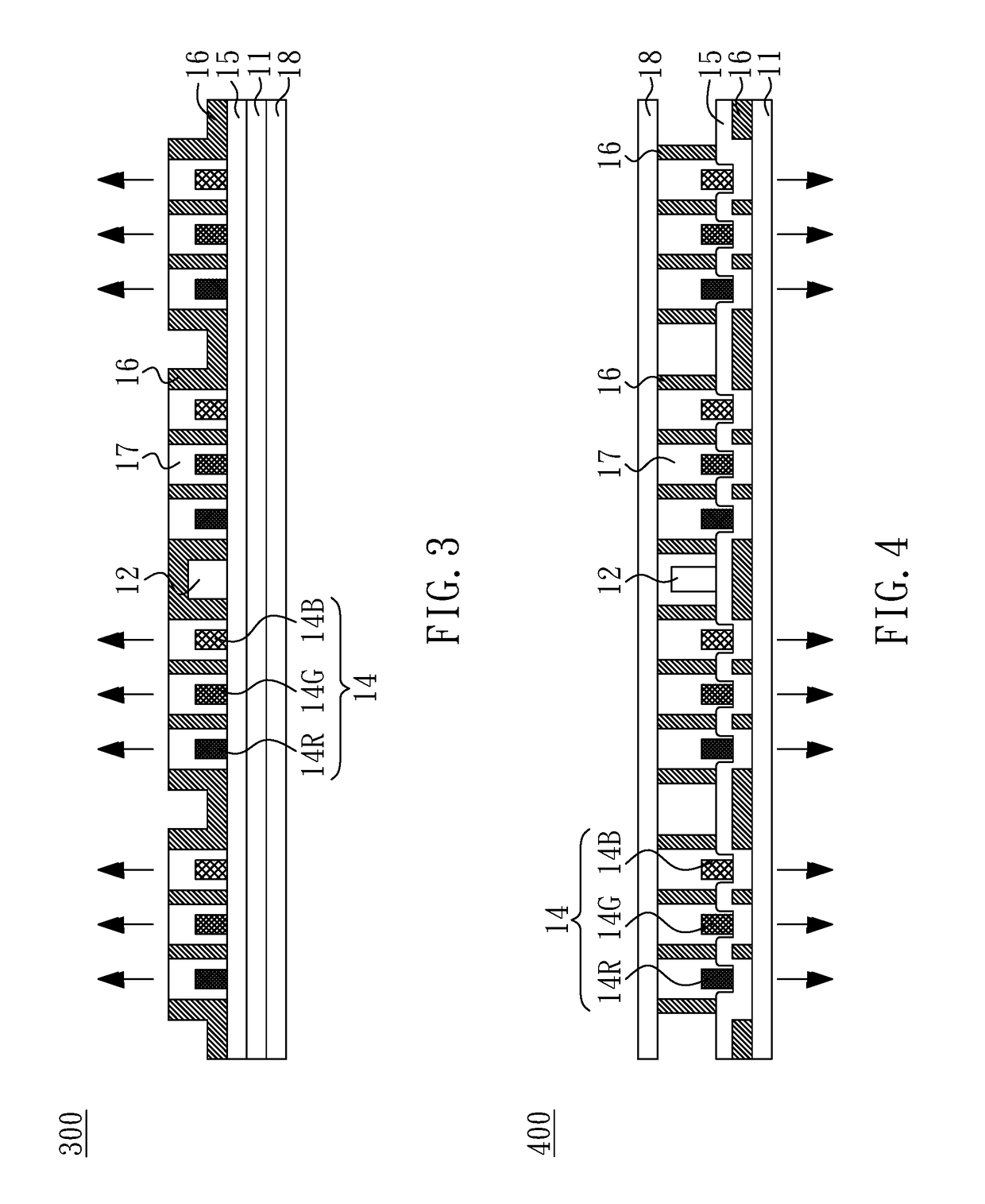

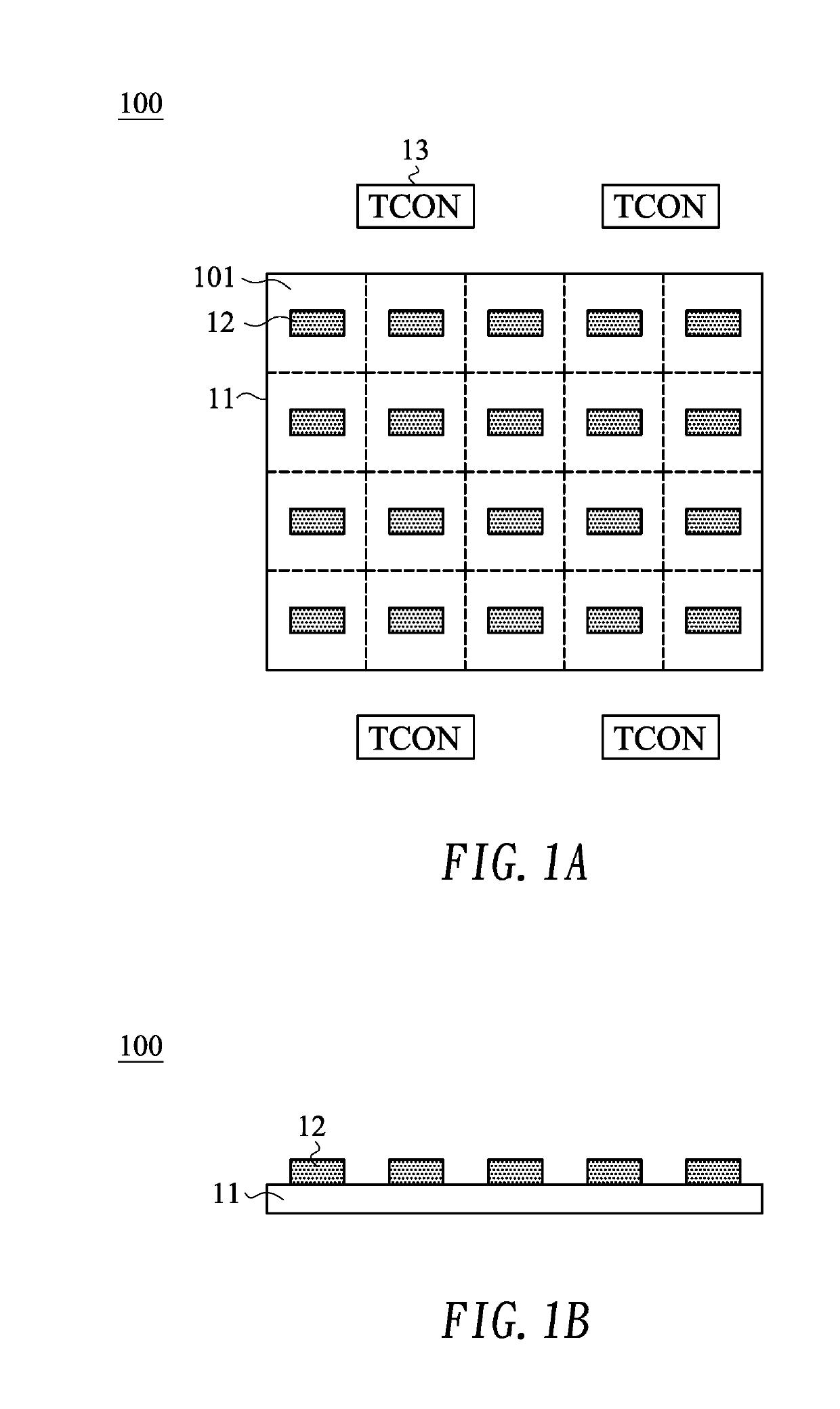

Microled display panel

InactiveCN110890393AImprove shortcomingsReduce loadSolid-state devicesSemiconductor devicesEngineeringMicroLED

A micro light-emitting diode (microLED) display panel includes a plurality of microLEDs; a substrate for supporting the microLEDs, the substrate being divided into a plurality of sub-regions; and a plurality of chip-on-film (COF) packages mounted on surfaces of the sub-regions respectively, a plurality of drivers being disposed on the COF packages respectively. Through the technical scheme, the load of the drivers can be effectively reduced to achieve the single large-size high-resolution microLED display panel.

Owner:PRILIT OPTRONICS INC

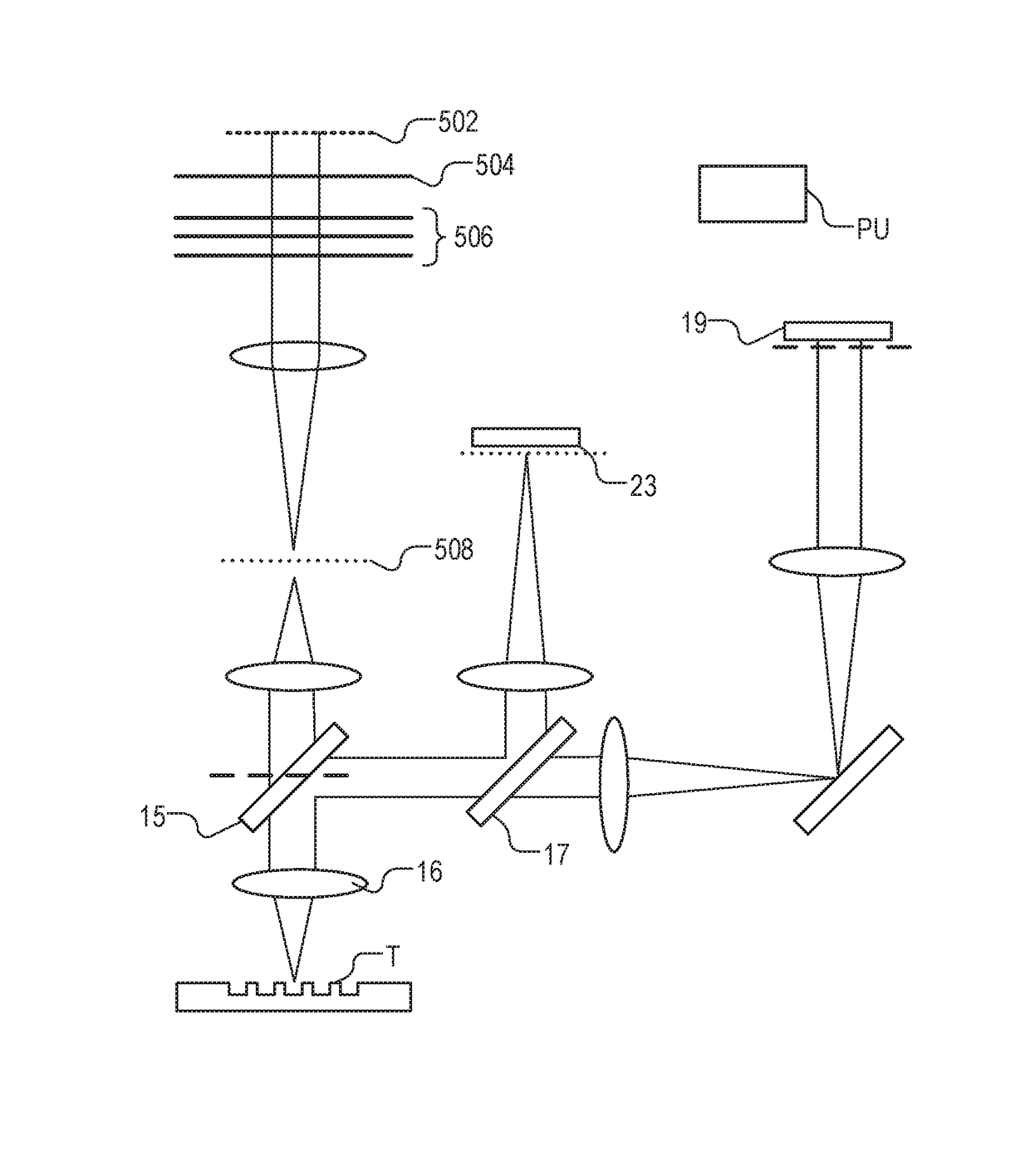

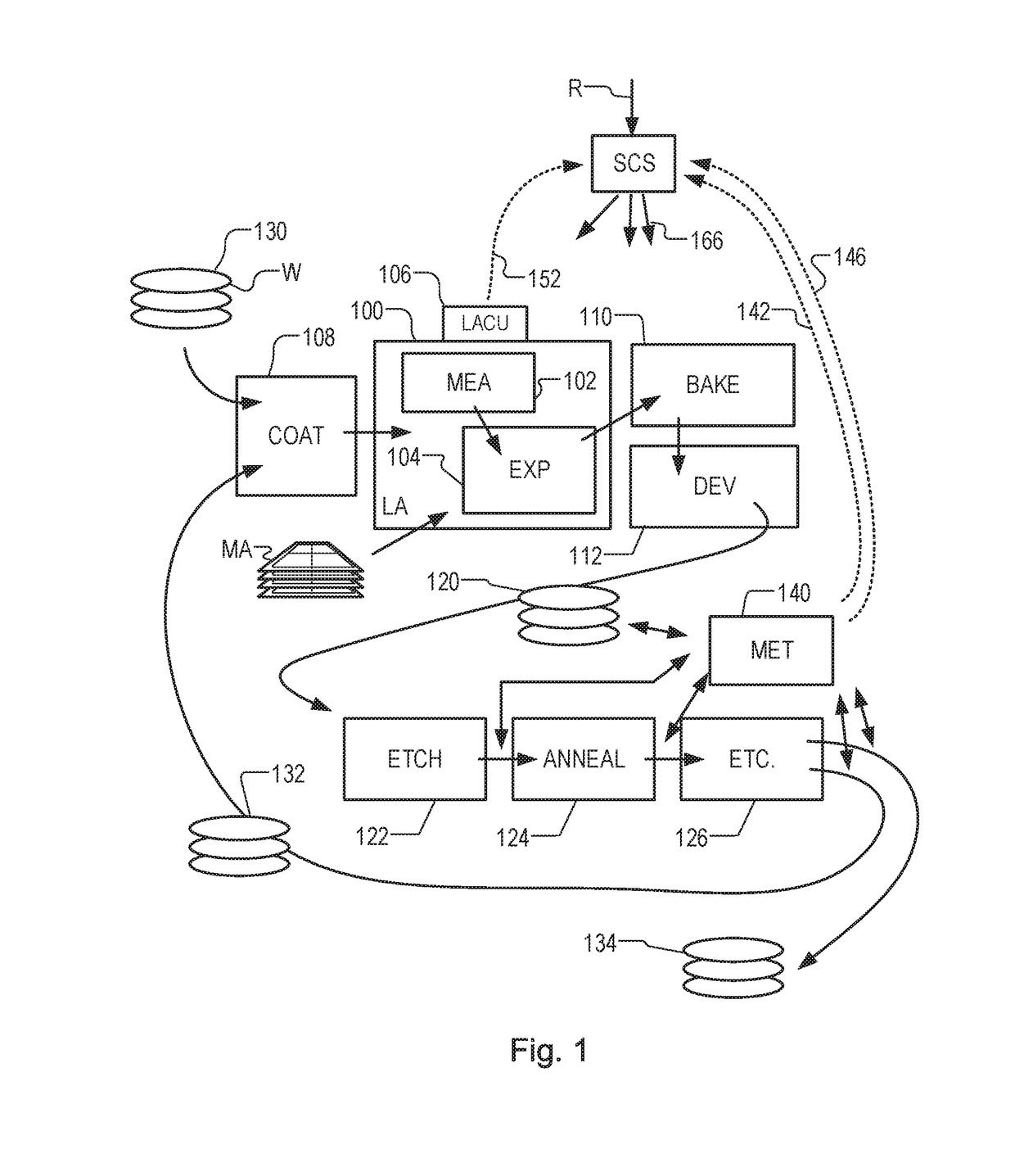

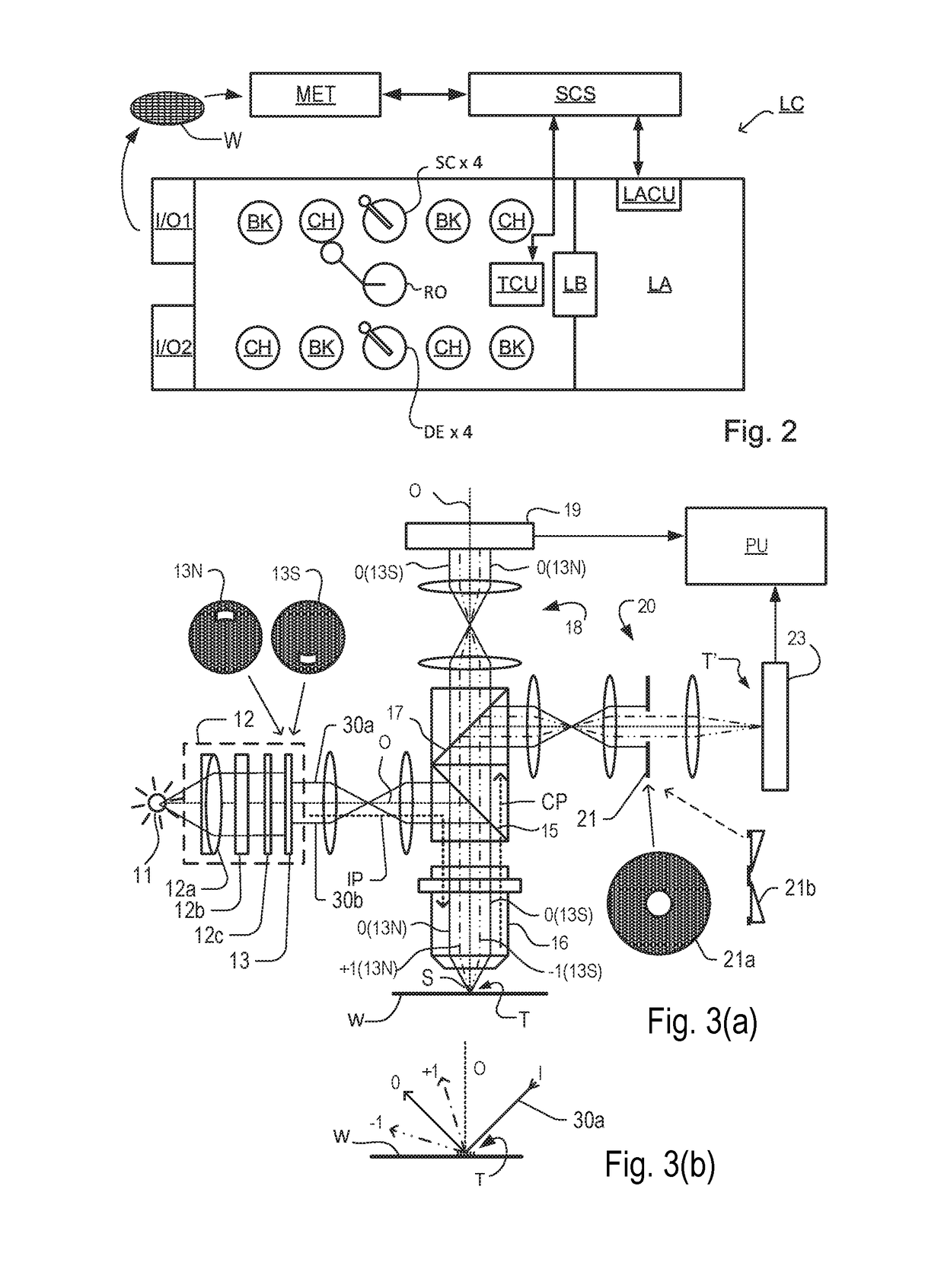

Illumination System for a Lithographic or Inspection Apparatus

InactiveUS20180004095A1Photomechanical exposure apparatusMicrolithography exposure apparatusPhotoluminescenceBiological activation

An illumination system has a microLED array 502. The microLED array 502 is imaged or placed very close to a phosphor coated glass disc 504 which upconverts the light from the microLED array into a narrow band emission. The plate has at least two different photoluminescent materials arranged to be illuminated by the microLED array and to thereby emit output light. The different photoluminescent materials have different emission spectral properties of the output light, e.g. different center wavelength and optionally different bandwidth. Illumination of different photoluminescent materials by the illumination sources is selectable, by selective activation of the microLEDs or by movement of the photoluminescent materials relative to the illumination sources, to provide different illumination of the different photoluminescent materials. This provides tunable spectral properties of the output light. Selectively configurable filters 506 are arranged to filter the output light in accordance with the selected illumination of the different photoluminescent materials.

Owner:ASML NETHERLANDS BV

Top emission microled display and bottom emission microled display and a method of forming the same

InactiveUS20200083281A1Avoid interferenceAvoid color mixingStatic indicating devicesSolid-state devicesLight guideDisplay device

A microLED display includes a first main substrate, microLEDs disposed above the first main substrate, a first light blocking layer disposed above the first main substrate to define emission areas, a light guiding layer disposed in the emission areas, and a plurality of connecting structures disposed in the emission areas respectively and electrically connected with the microLEDs.

Owner:PRILIT OPTRONICS INC

Data driver of a microLED display

ActiveUS10290255B2Efficient implementationCathode-ray tube indicatorsAudio power amplifierData signal

A data driver of a microLED display includes clock generators that generate pulse width modulation (PWM) clocks of corresponding primary colors respectively; counters that receive the PWM clocks of corresponding primary colors respectively and accordingly generate corresponding PWM signals; and comparators associated with corresponding data channels respectively for comparing a held data signal with the corresponding PWM signal, thereby generating a comparison result signal. In one embodiment, the data driver further includes switches configured to electrically short output nodes of channel amplifiers of corresponding primary colors respectively for testing uniformity of microLEDs of one color.

Owner:PRILIT OPTRONICS INC

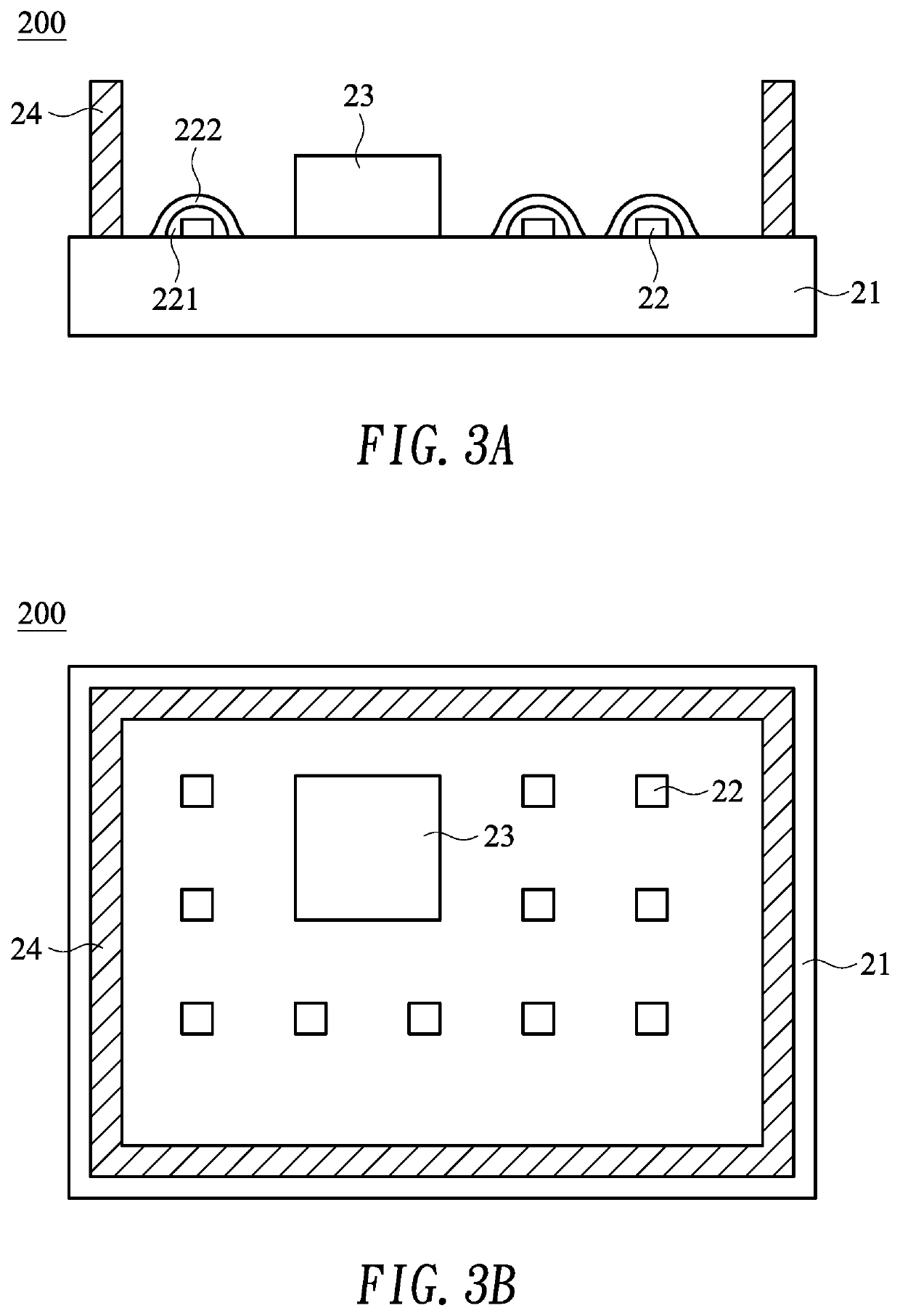

MicroLED display panel

ActiveUS10199362B1Reduce loadSimple processSolid-state devicesSemiconductor devicesEngineeringMicroLED

A microLED display panel includes a substrate being divided into a plurality of sub-regions for supporting microLEDs, and a plurality of drivers being correspondingly disposed on surfaces of the sub-regions respectively. In one embodiment, a top surface of the substrate has a recess for accommodating the driver.

Owner:PRILIT OPTRONICS INC

MicroLED display panel

ActiveUS10356858B2Reduce loadSimple processStatic indicating devicesElectroluminescent light sourcesEngineeringMicroLED

A microLED display panel includes a substrate being divided into a plurality of sub-regions for supporting microLEDs, and a plurality of drivers being correspondingly disposed on surfaces of the sub-regions respectively. The driver includes a low-dropout (LDO) regulator and a drive circuit. The LDO regulator receives a system power, according to which a regulated power is generated and provided for the drive circuit.

Owner:PRILIT OPTRONICS INC

Microled display and a method of forming the same

A method of forming a micro light-emitting diode (microLED) display includes providing a substrate with a plurality of microLEDs and at least one integrated circuit disposed thereon; and forming a planarization layer to cover the microLEDs and the at least one integrated circuit. The planarization layer acts as both a light blocking layer and a corrosion-resistant layer.

Owner:PRILIT OPTRONICS INC

Hot air supplying head for transferring micro LED and micro LED transferring system

PendingCN110797281AEfficient transferSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMicroLED

The present invention relates to provide a hot air supplying head for transferring a micro LED and a micro LED transfer system using the same, the hot air supplying head effectively transferring microLEDs.

Owner:POINT ENG

System and Method for the Characterization and Dispersal of Emissive Elements

ActiveUS20200286870A1Minimizes damage and lossEvenly distributedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsAdhesiveStructural engineering

A method is provided for the selective harvest of microLED devices from a carrier substrate. Defect regions are predetermined that include a plurality of adjacent defective microLED devices on a carrier substrate. A solvent-resistant binding material is formed overlying the predetermined defect regions and exposed adhesive is dissolved with an adhesive dissolving solvent. Non-defective microLED devices located outside the predetermined defect regions are separated from the carrier substrate while adhesive attachment is maintained between the microLED devices inside the predetermined defect regions and the carrier substrate. Methods are also provided for the dispersal of microLED devices on an emissive display panel by initially optically measuring a suspension of microLEDs to determine suspension homogeneity and calculate the number of microLEDs per unit volume. If the number of harvested microLED devices in the suspension is known, a calculation can be made of the number of microLED devices per unit of suspension volume.

Owner:ELUX INC

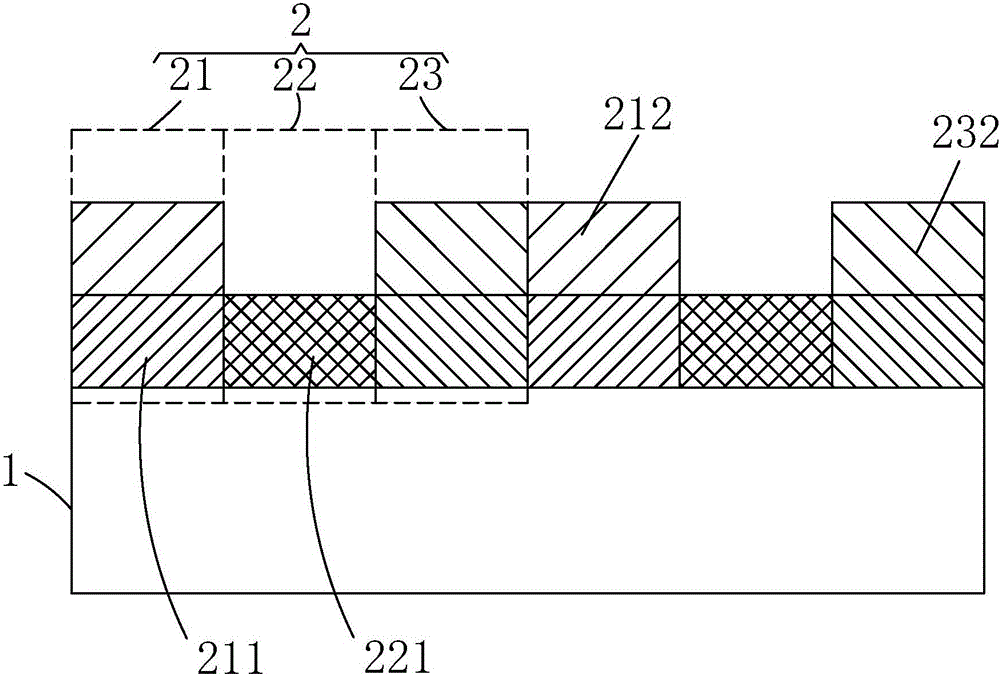

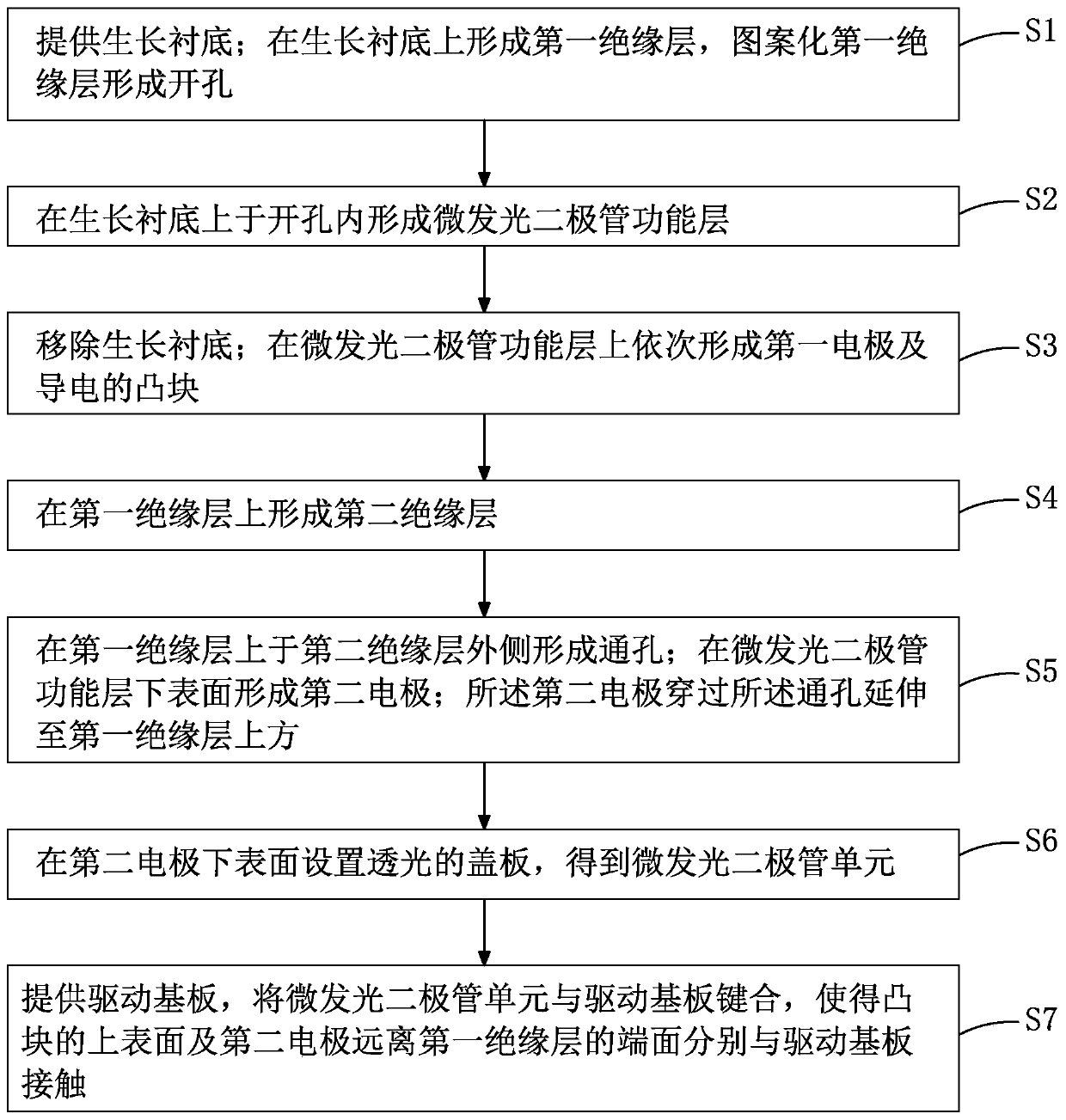

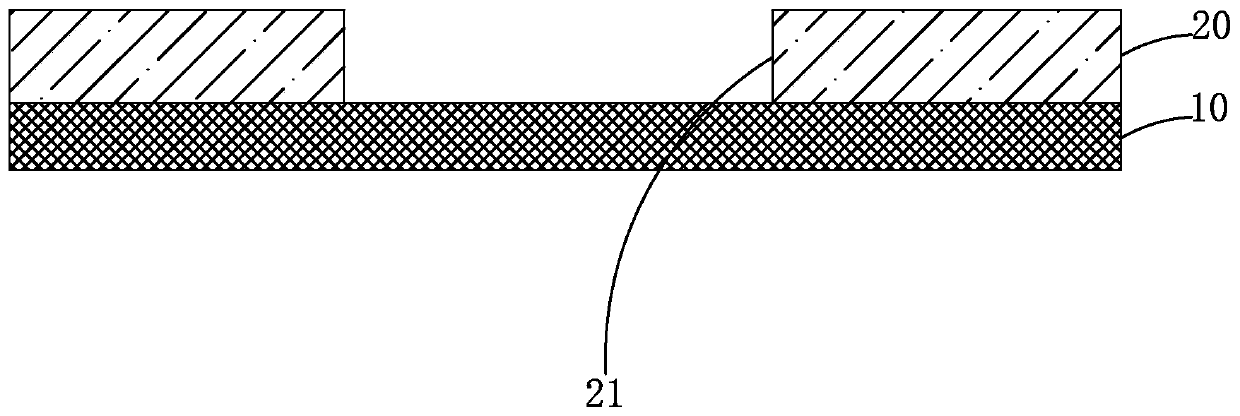

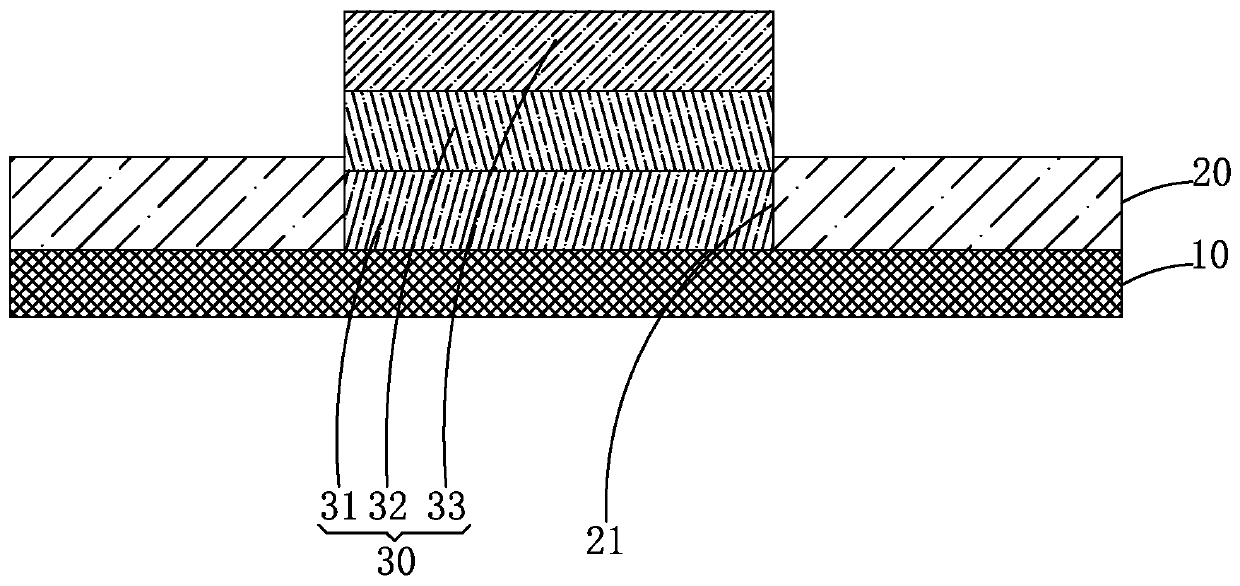

Micro-light emitting diode display and manufacturing method thereof

PendingCN110600589ASimple structureSimple processSolid-state devicesSemiconductor devicesLED displayDisplay device

The invention provides a micro-light emitting diode display and a manufacturing method thereof. The manufacturing method of the micro-light emitting diode display comprises the steps of forming a first insulating layer with an opening on a growth substrate and forming a micro-light emitting diode function layer in the opening on the growth substrate; removing the growth substrate and sequentiallyforming a first electrode and a conductive bump on the micro-light emitting diode function layer; forming a second insulating layer on the first insulating layer to cover the part, which protrudes onthe upper surface of the first insulating layer, of the micro-light emitting diode function layer, the first electrode and side walls of the bump; forming a second electrode on the lower surface of the micro-light emitting diode function layer and making the second electrode extend to the upper part of the first insulating layer through the first insulating layer; and arranging a transparent coverplate on the lower surface of the second electrode, obtaining a micro-light emitting diode unit and bonding the micro-light emitting diode unit with a driving substrate to form the micro-light emitting diode display. The process is simple, and reduction of the cost of a product and improvement of the quality of the product are facilitated.

Owner:SHENZHEN KECHUANG DIGITAL DISPLAY TECH

Coupling microleds to optical communication channels

PendingUS20210318503A1Reduce drive powerHigh densitySolid-state devicesDiodeEngineeringOptical communication

Owner:AVICENATECH CORP

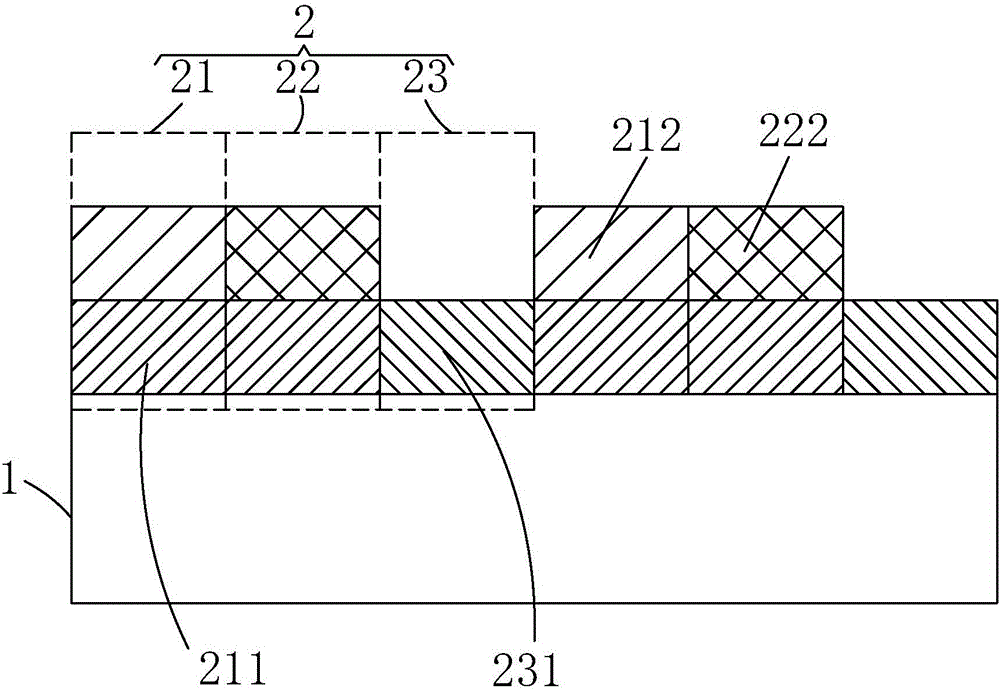

Micro light-emitting diode display and manufacturing method thereof

PendingCN113380847AAvoid driftingImprove bonding abilitySolid-state devicesIdentification meansLED displayDisplay device

The invention relates to the technical field of light-emitting diodes, in particular to a micro light-emitting diode display and a manufacturing method thereof. The micro light-emitting diode display comprises a display backboard, the display backboard is provided with more than three mutually-separated limiting assemblies, every two adjacent limiting assemblies form an installation position used for limiting a diode chip, the installation position is matched with the side wall of the diode chip, the bottom of each installation position is provided with a group of metal bonding pad assemblies, the metal bonding pad assemblies are fixedly arranged on the display backboard, metal contacts are bonded on the metal bonding pad assemblies and are connected with the lower end of the diode chip, the diode chip is are mounted in the instalaltion positions, and a packaging structure and a surface micro-processing layer are covered above all the diode chips and the limiting assemblies. The display is provided with the limiting assembly, so that the position of the micro light-emitting diode chip on the display backboard can be effectively limited, and the bonding effect is effectively improved; and the manufacturing steps are simplified, so that mass production of products is easy to realize.

Owner:CHONGQING KONKA PHOTOELECTRIC TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com