Microled display panel

A technology of micro-light-emitting diodes and display panels, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., and can solve the problems of large output load of the driver, failure of the display panel to be driven normally, and inability to apply the micro-light-emitting diode display panel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

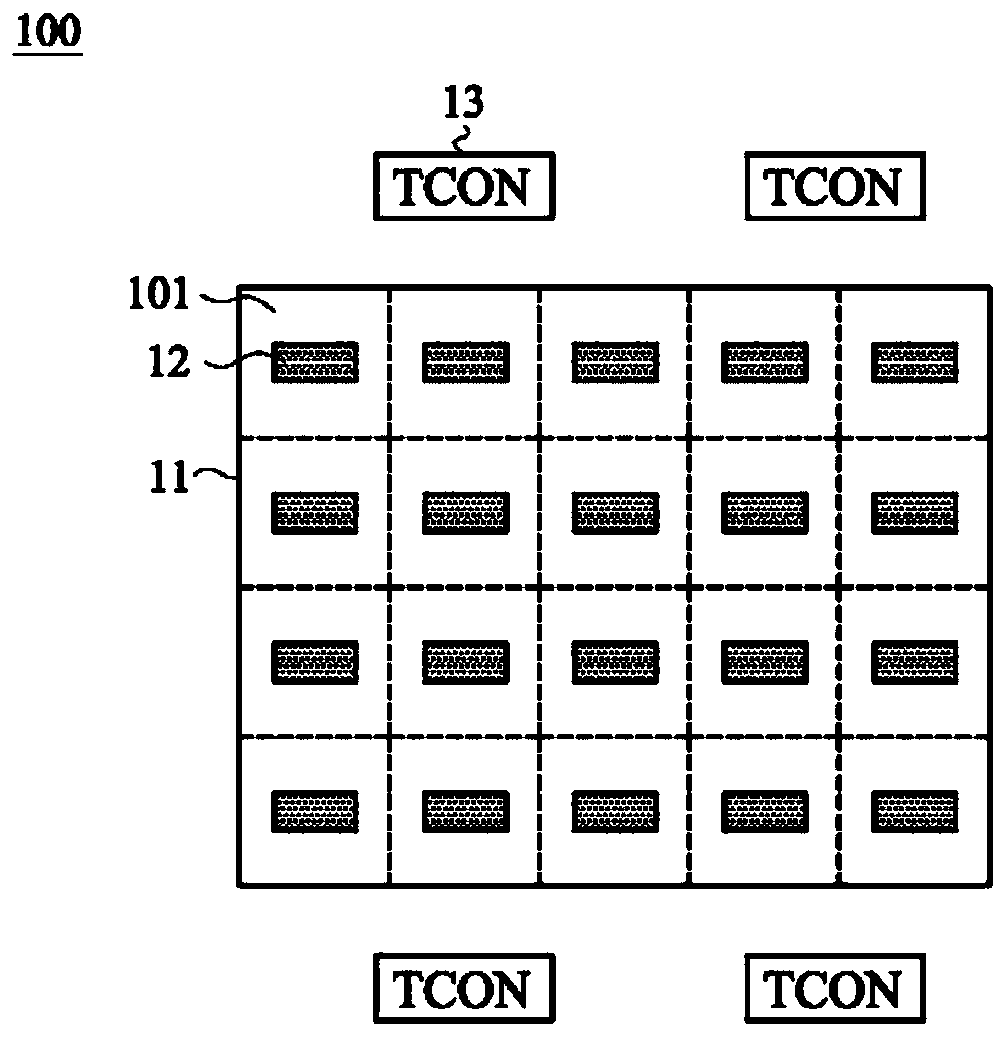

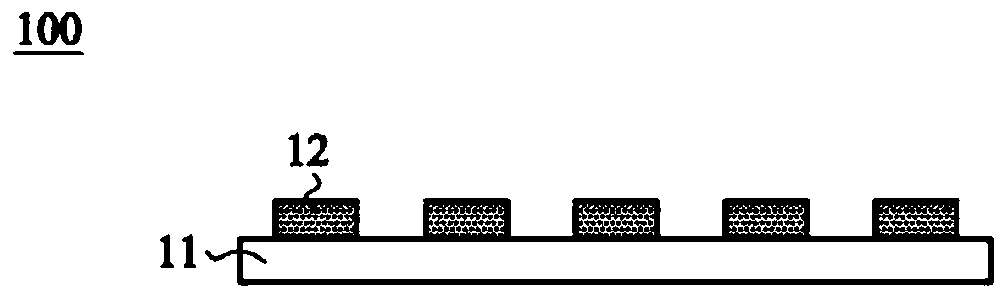

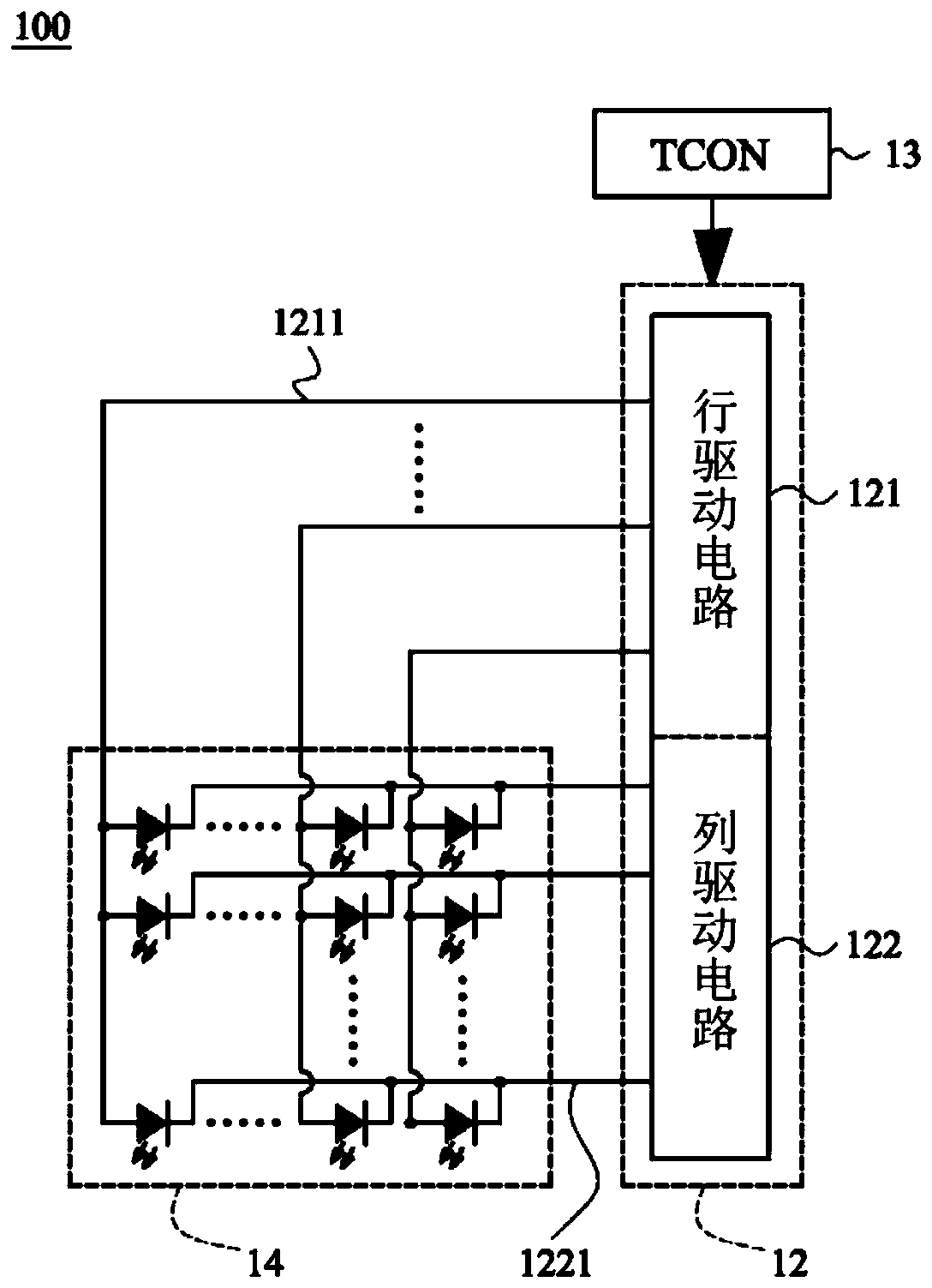

[0080] Figure 1A A top view showing a micro light emitting diode (microLED) display panel 100 according to an embodiment of the present invention, Figure 1B show Figure 1A A side view of the micro light emitting diode display panel 100 . The structure of the micro-LED display panel 100 of this embodiment is preferably suitable for a large-size high-resolution display panel, such as a display panel with a resolution of 3840RGBx2160. In this specification, the size class of the micro light-emitting diodes is 1-10 microns. However, it will be smaller due to the application field of the product or the development of future technology. In this specification, a "large-size" display panel is defined as a display panel larger than 10 inches according to current industry practice. However, the definition of a "large-size" display panel may change due to product application fields or future technological developments. In this specification, a "high-resolution" display panel is def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com