Patents

Literature

73results about How to "Deformation controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

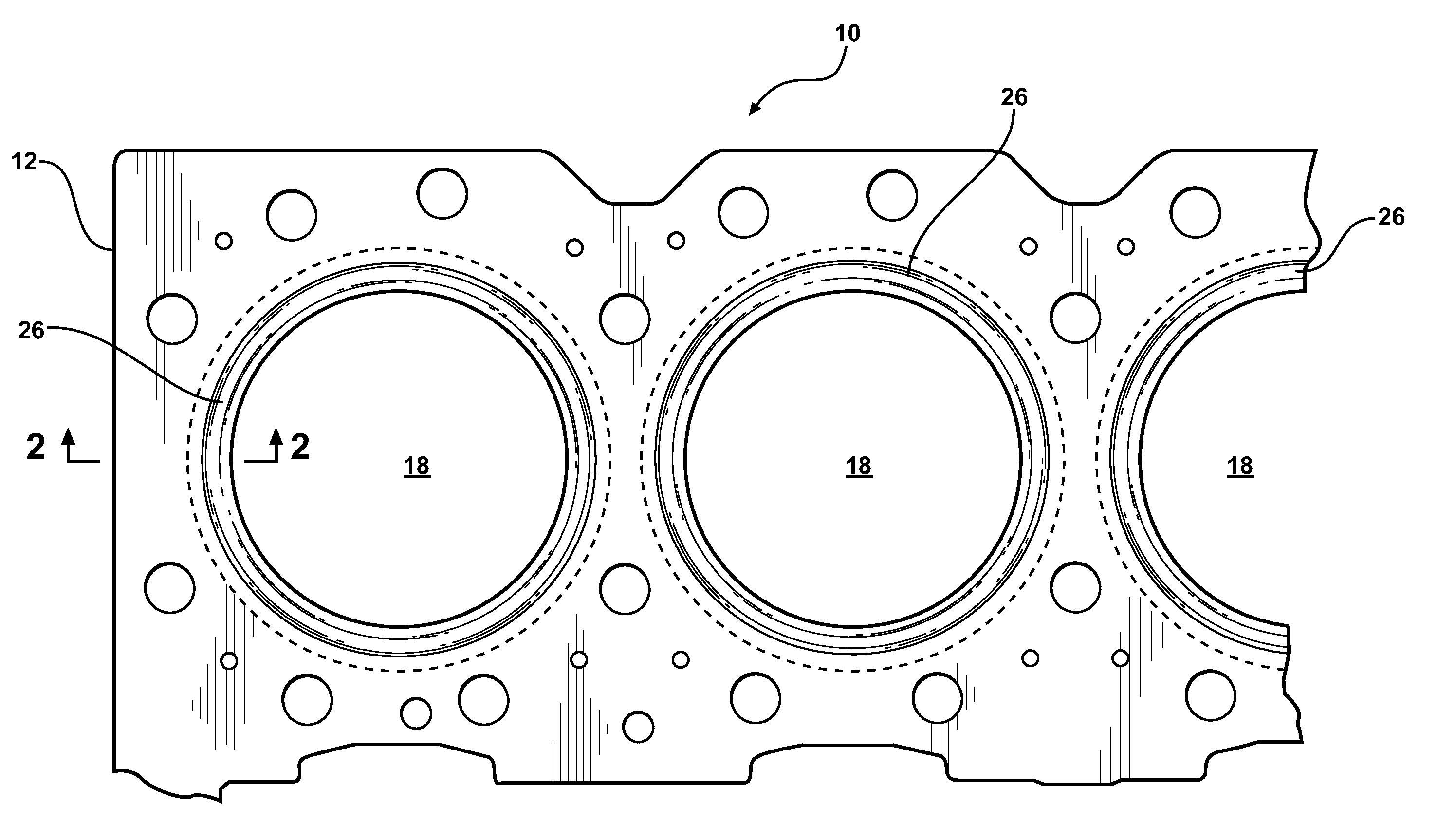

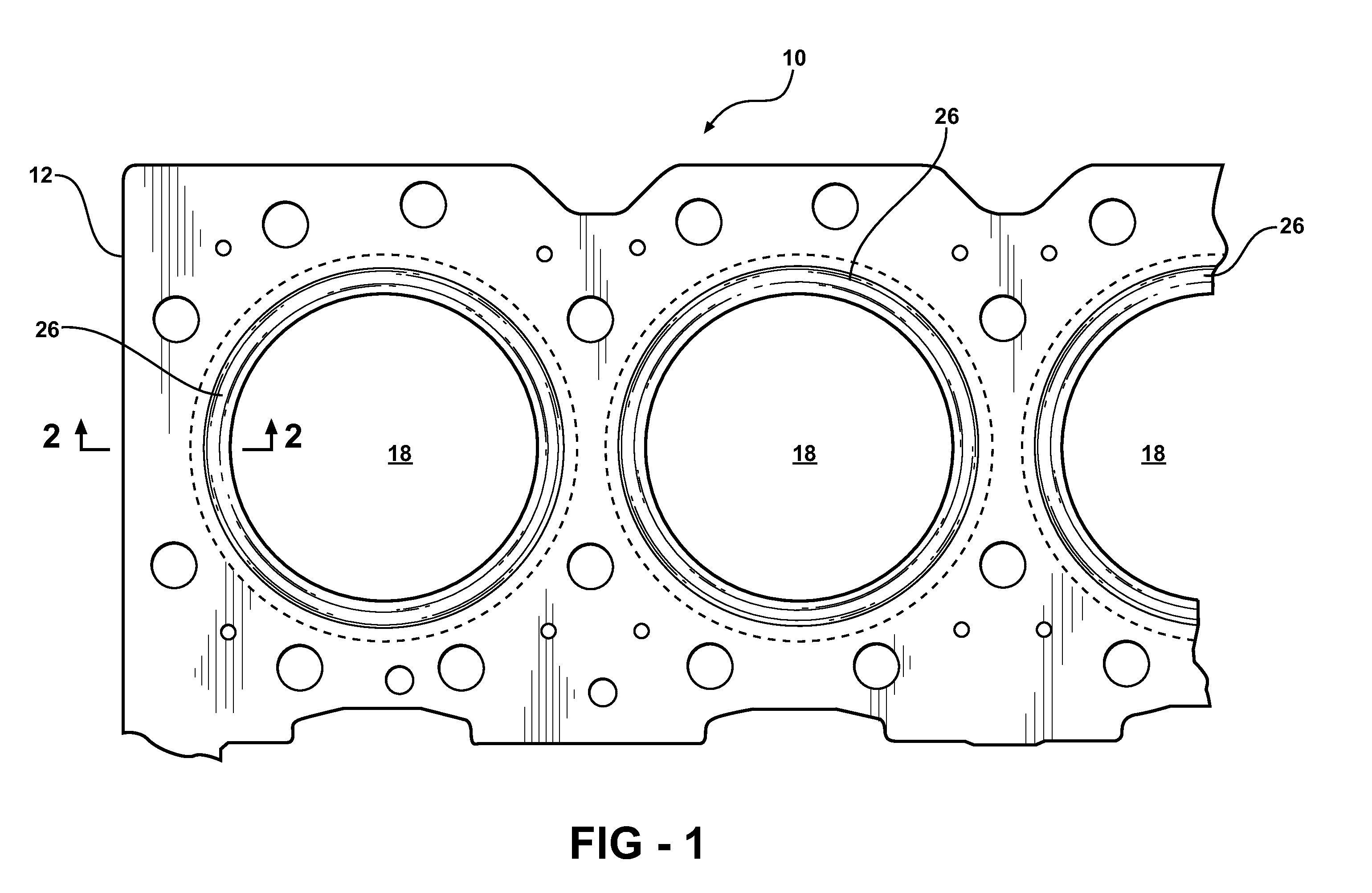

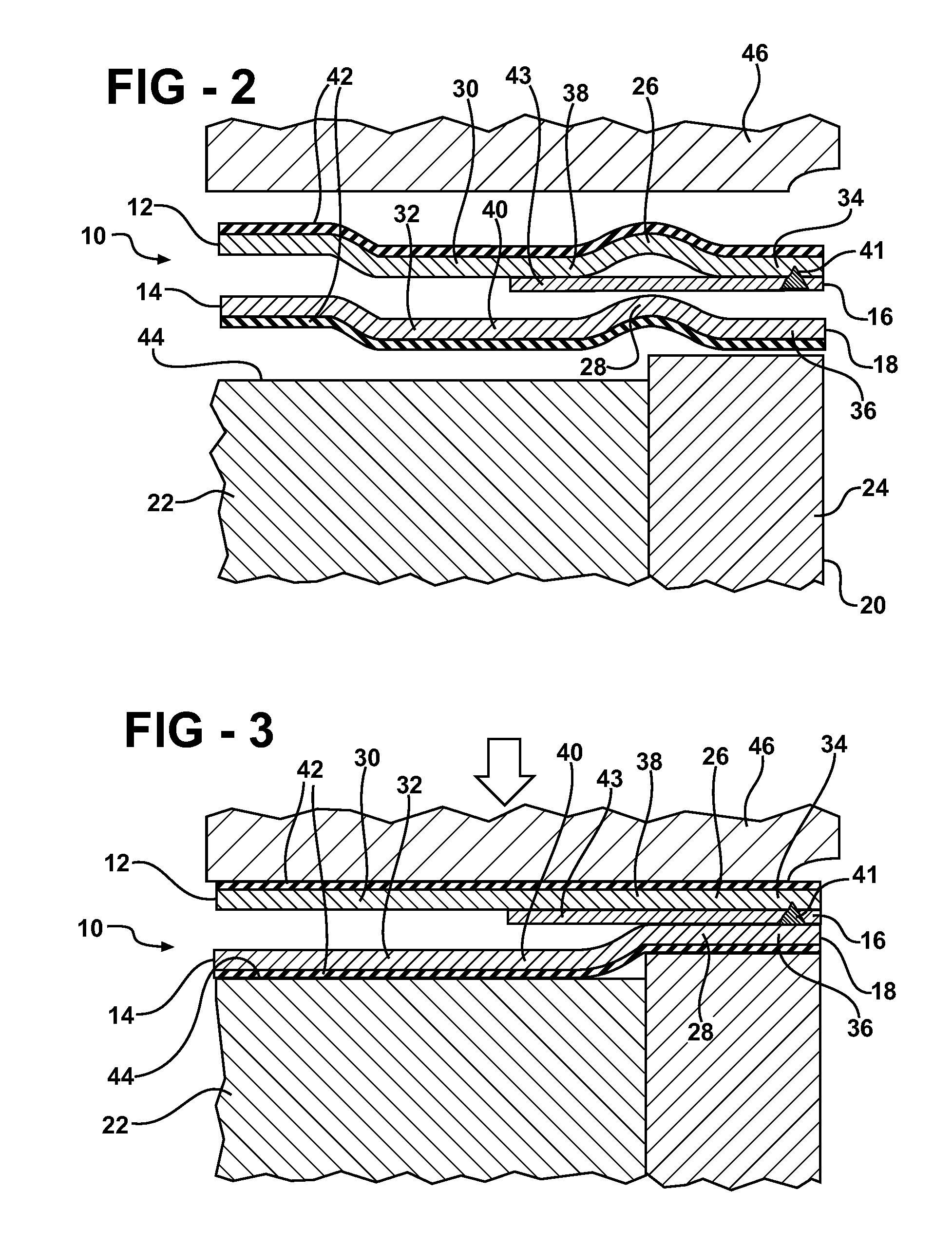

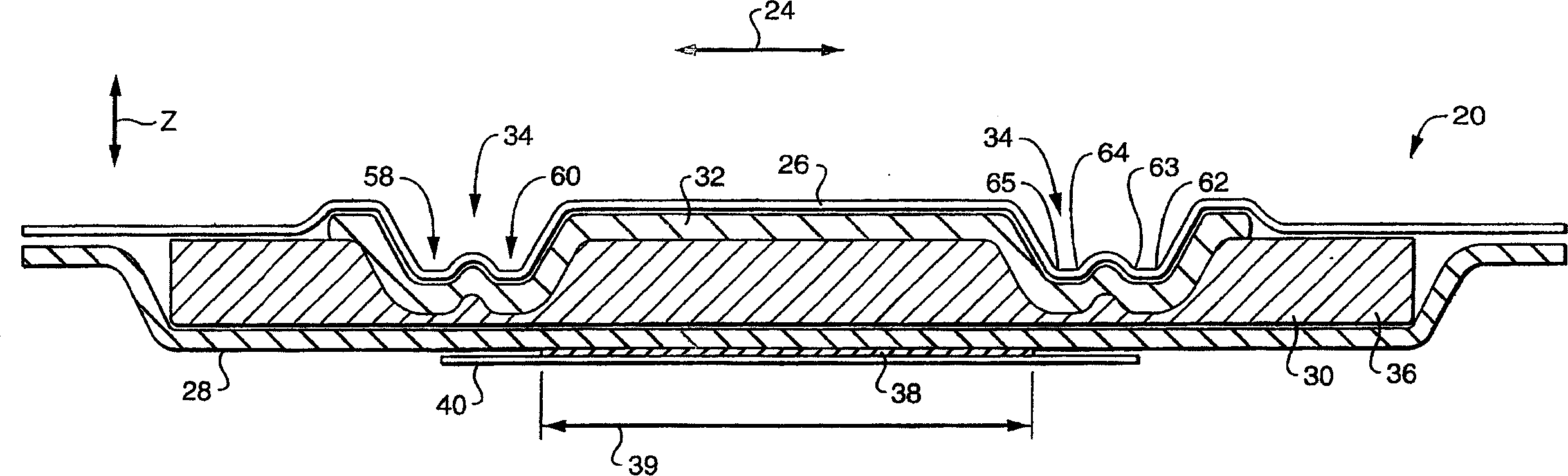

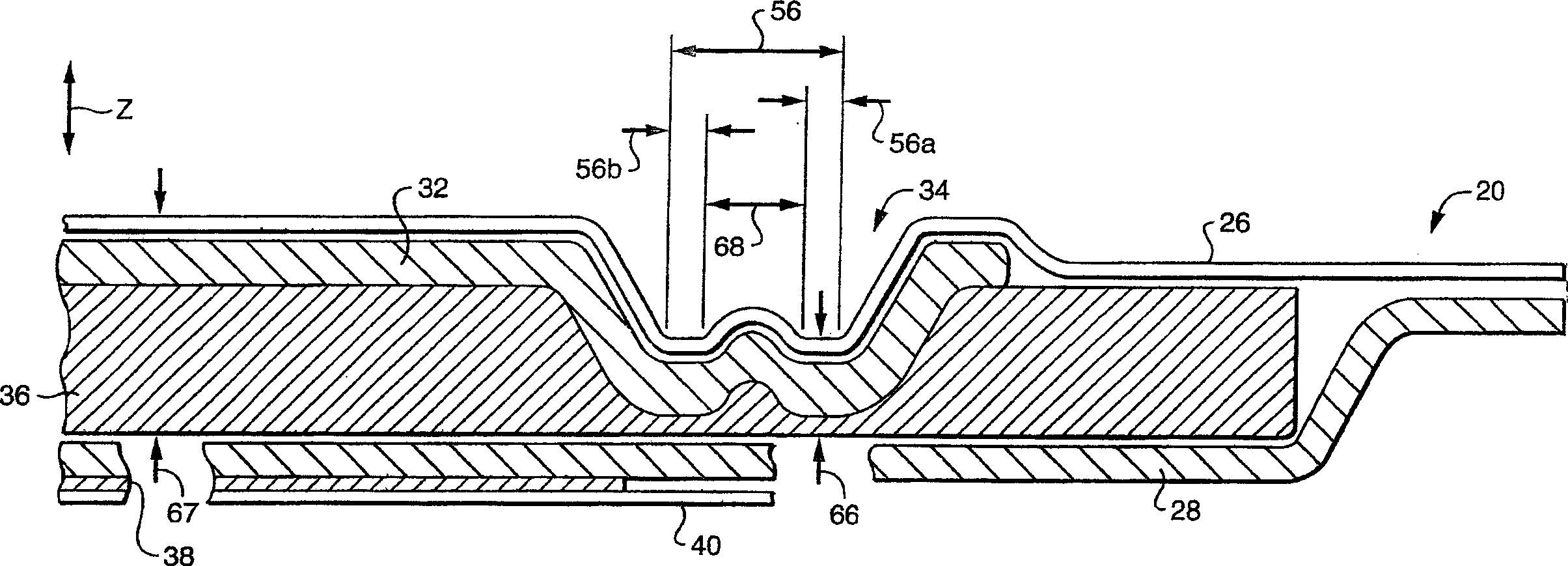

Metal gasket

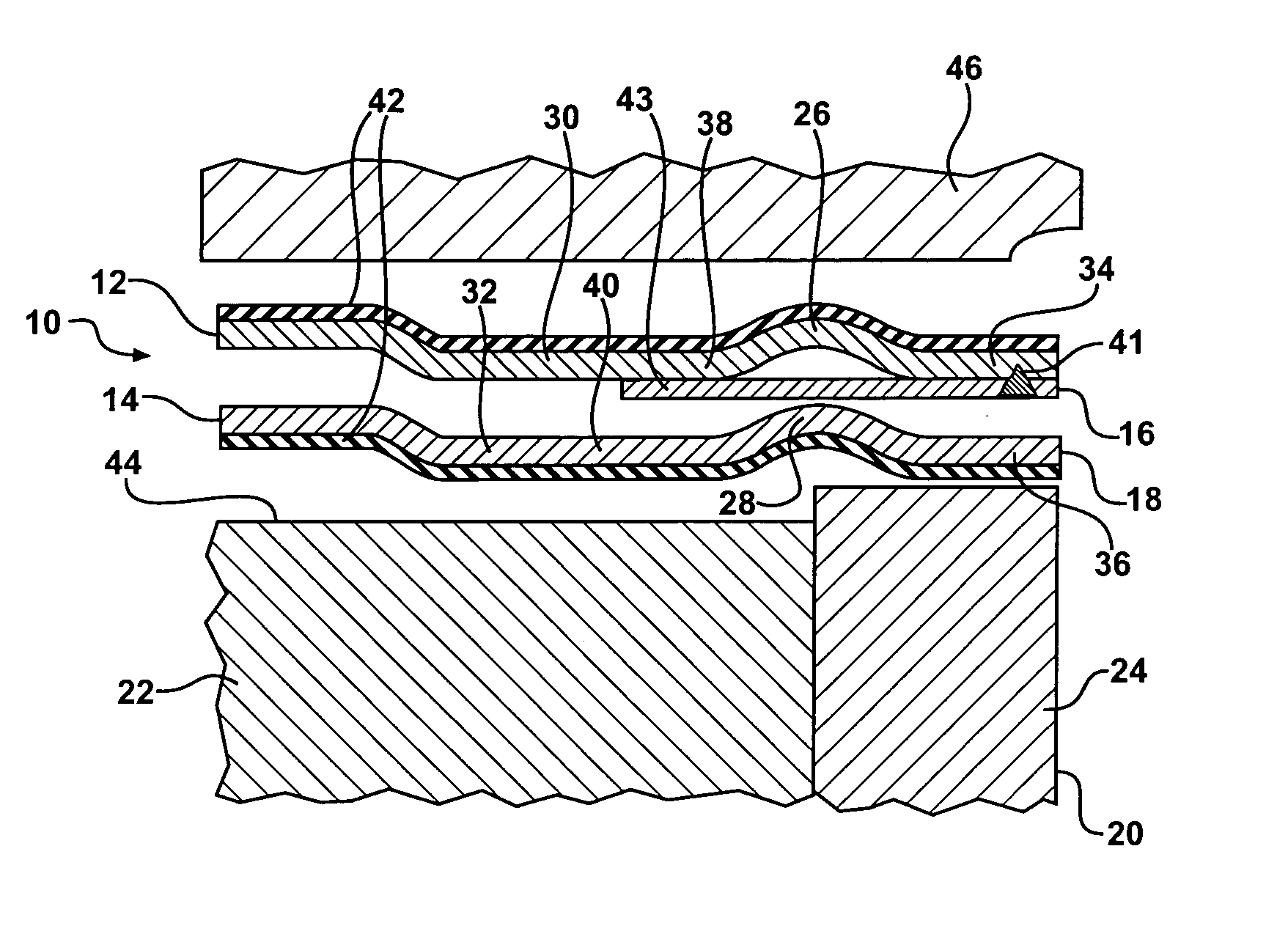

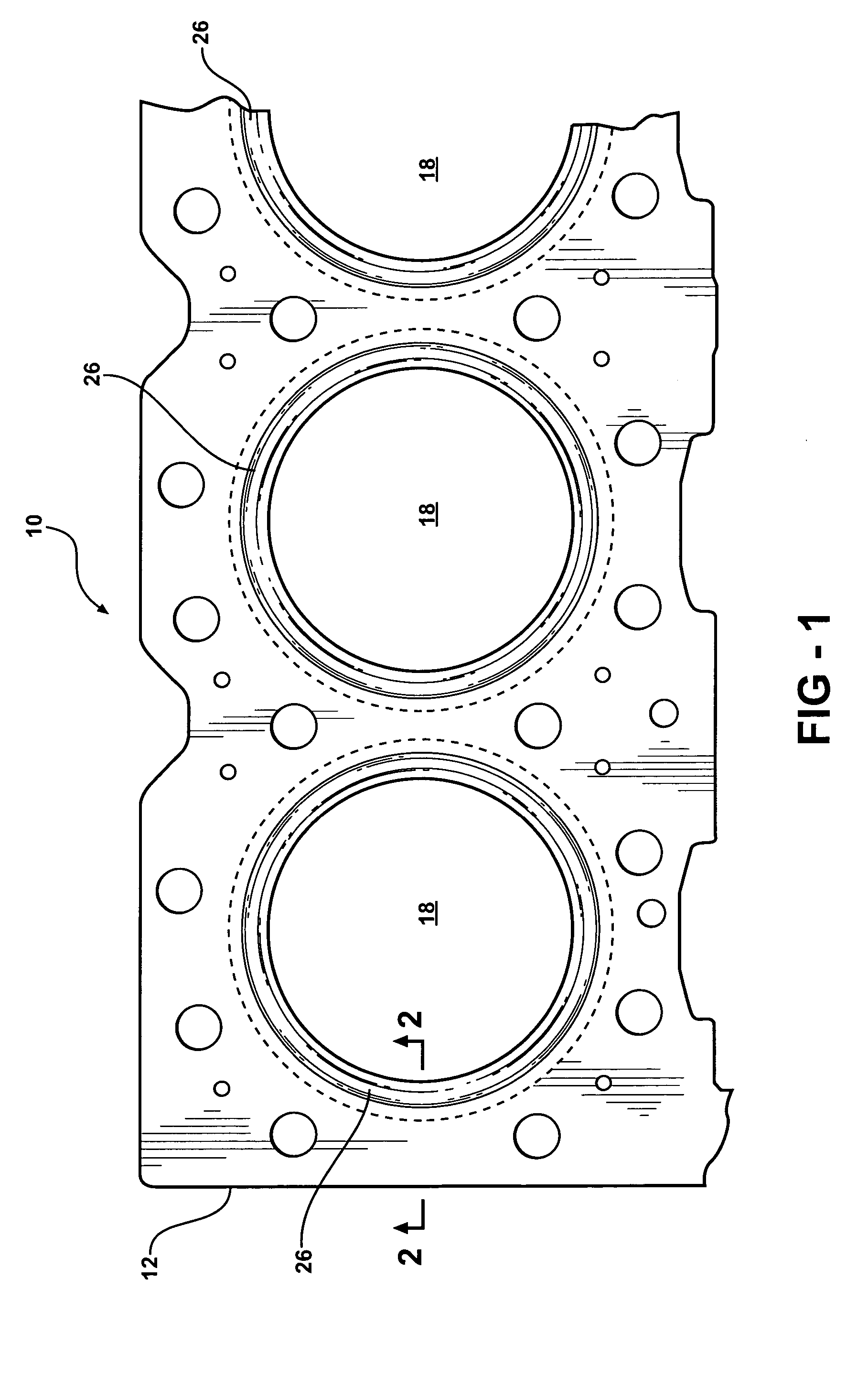

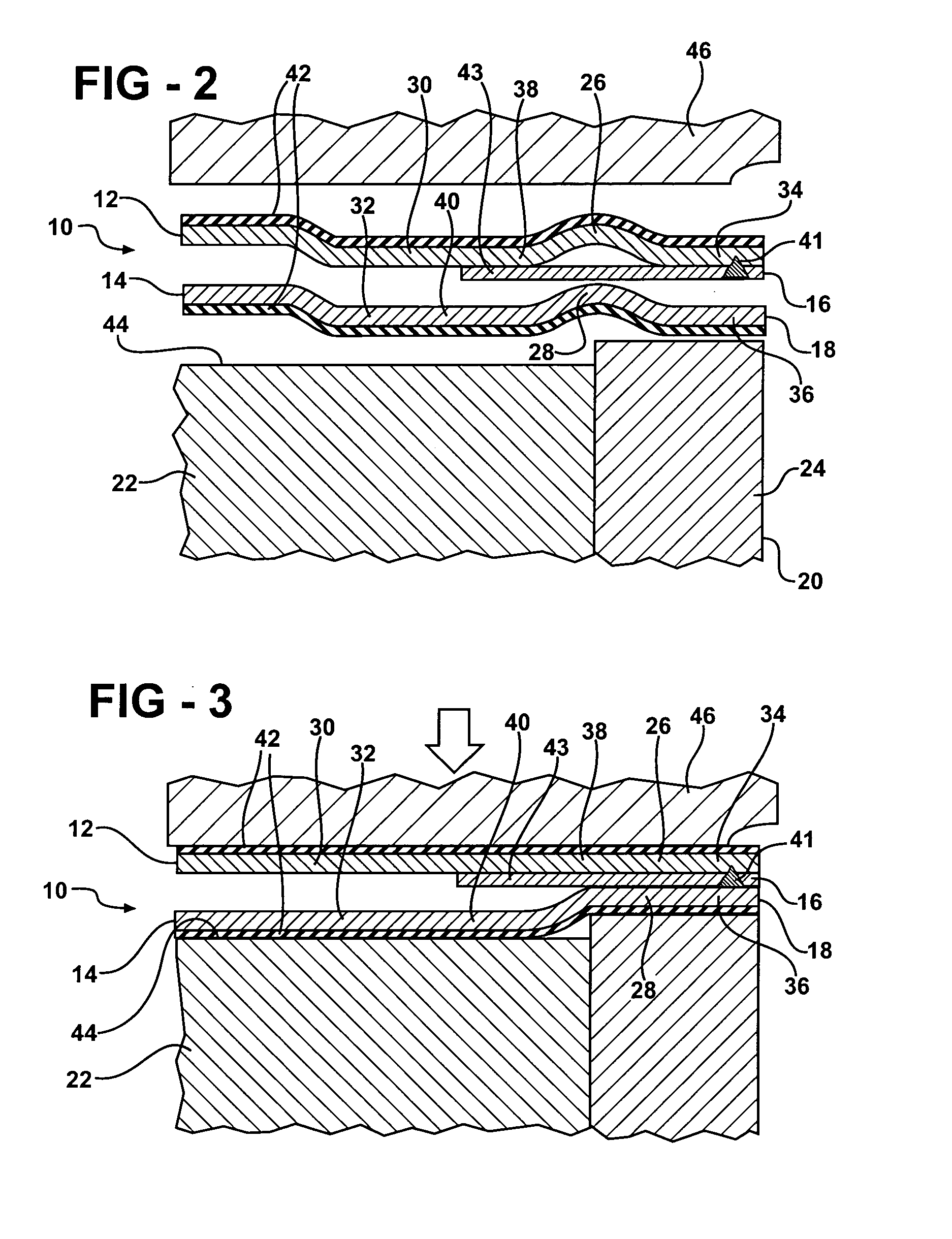

InactiveUS20050189724A1Minimal thicknessSoft compressibilityEngine sealsSealing arrangements for enginesEngineeringMetal

A multilayer metal gasket includes at least two metal gasket layers formed with an aligned opening and aligned opposing sealing beads surrounding the opening. A partial stopper layer is interposed between the gasket layers and is of lesser area than either of the gasket layers. The partial stopper layer extends from the opening outwardly beyond the sealing beads and is fixed to one of the layers on only one side of the sealing beads and is free on the opposite side.

Owner:FEDERAL MOGUL WORLD WIDE +1

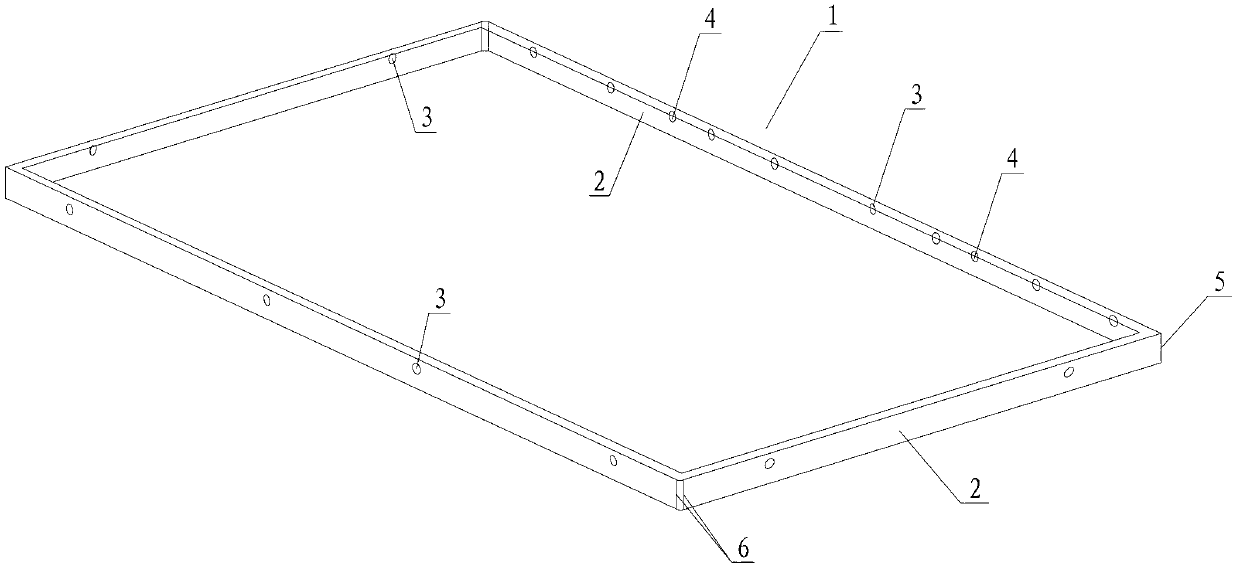

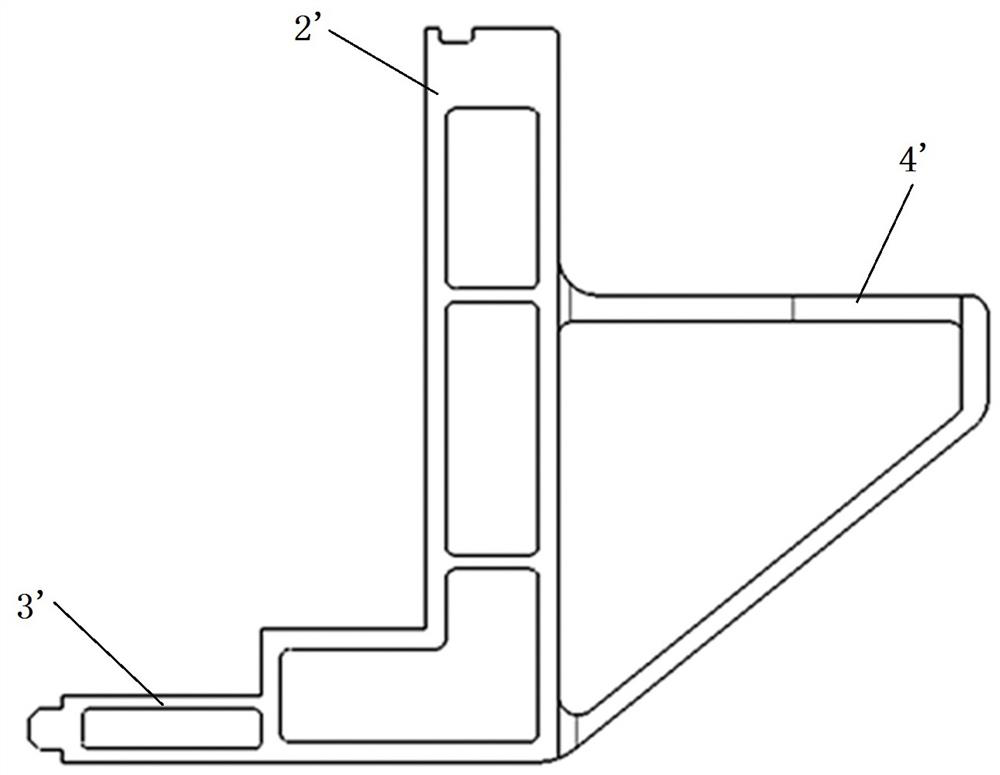

Integrated face frame used for panel television (TV) set and manufacturing method of integrated face frame

InactiveCN103139516ASimple structureReduce the amount of weldingTelevision system detailsColor television detailsEngineeringCable television

Owner:四川长虹技佳精工有限公司

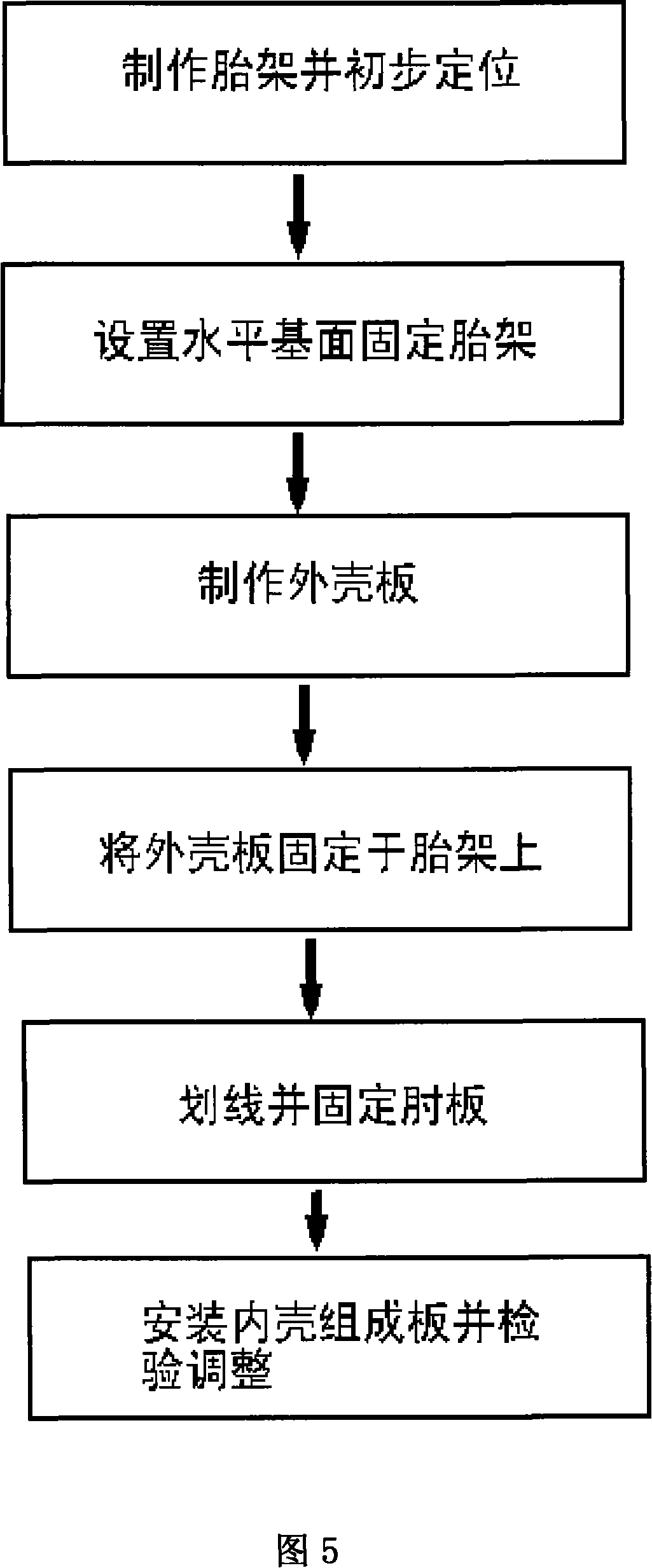

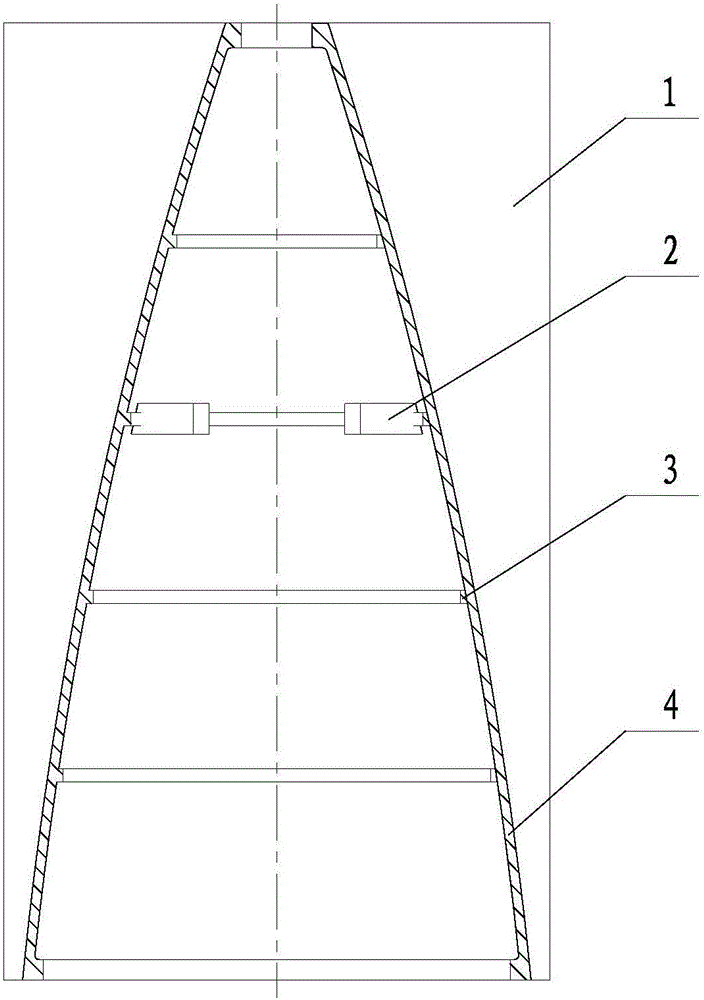

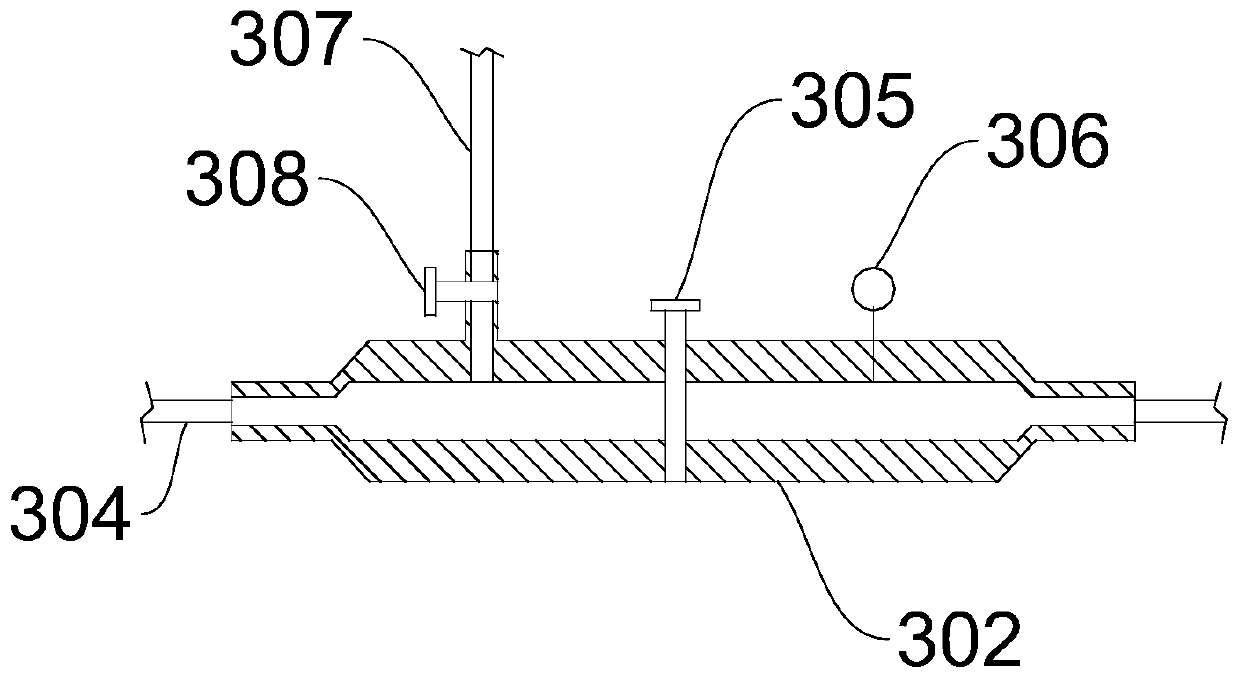

Method for manufacturing watercraft commutation tube

ActiveCN101108648AImprove shortcomingsDeformation controllableRotary propellersWelding apparatusSEMI-CIRCLEMarine engineering

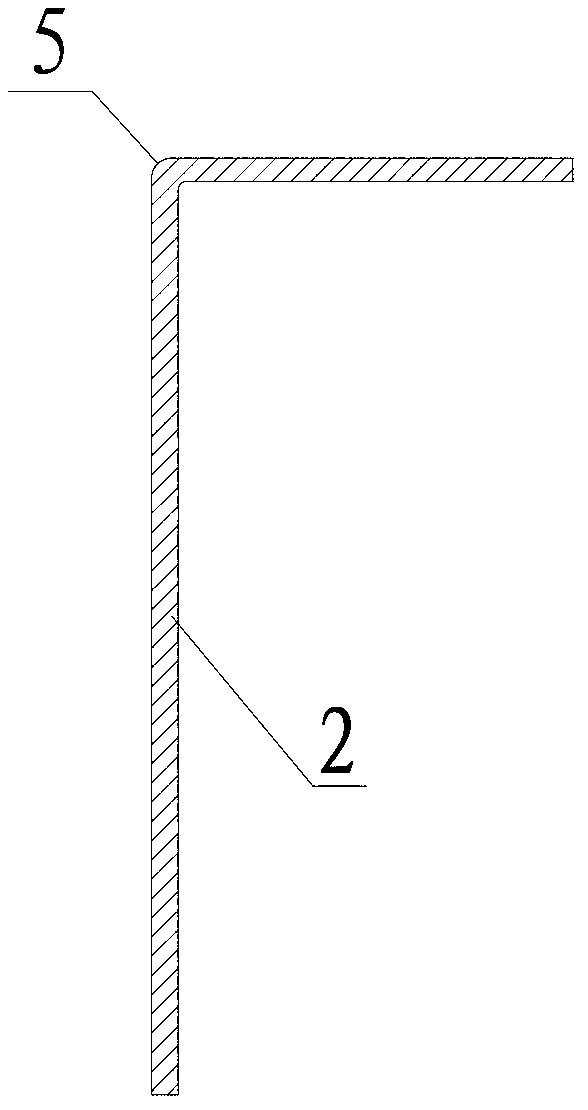

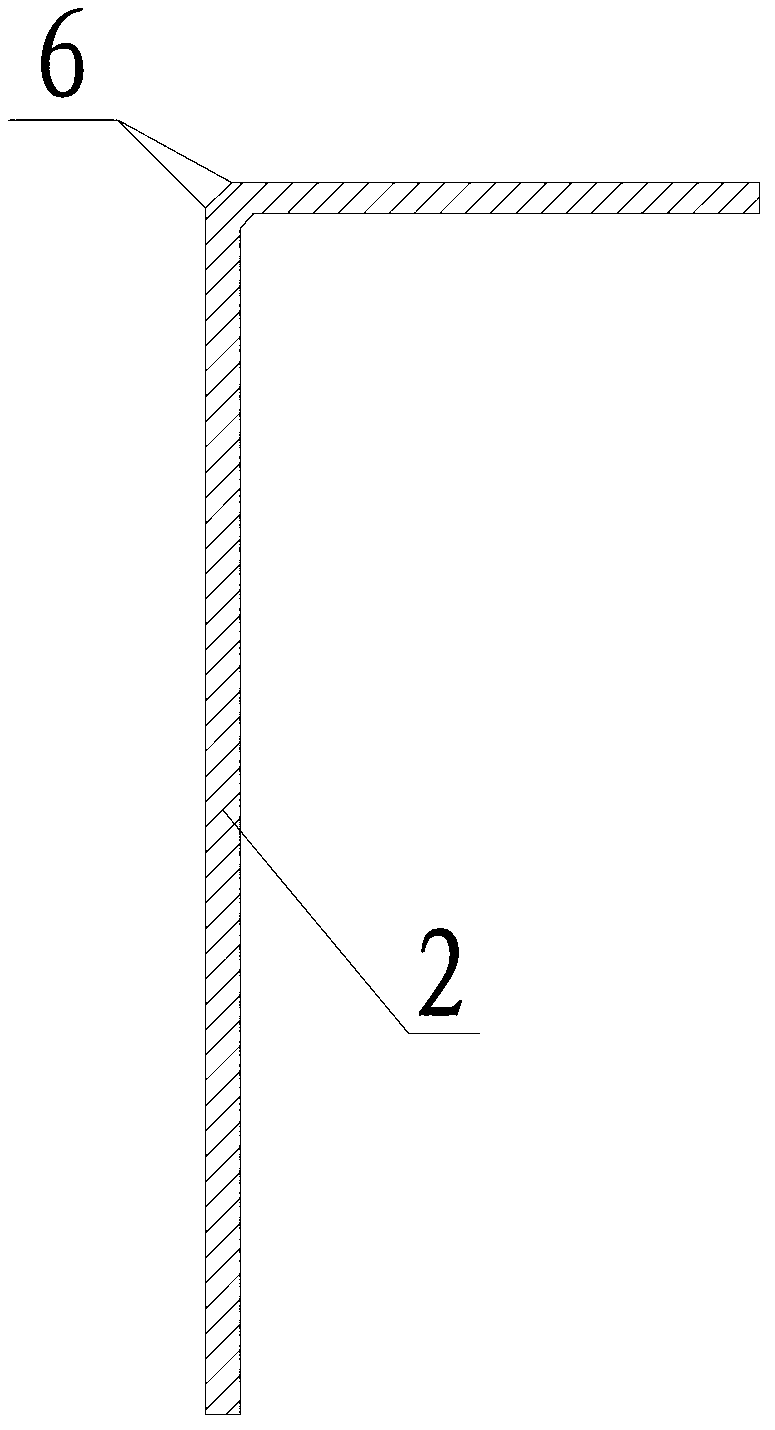

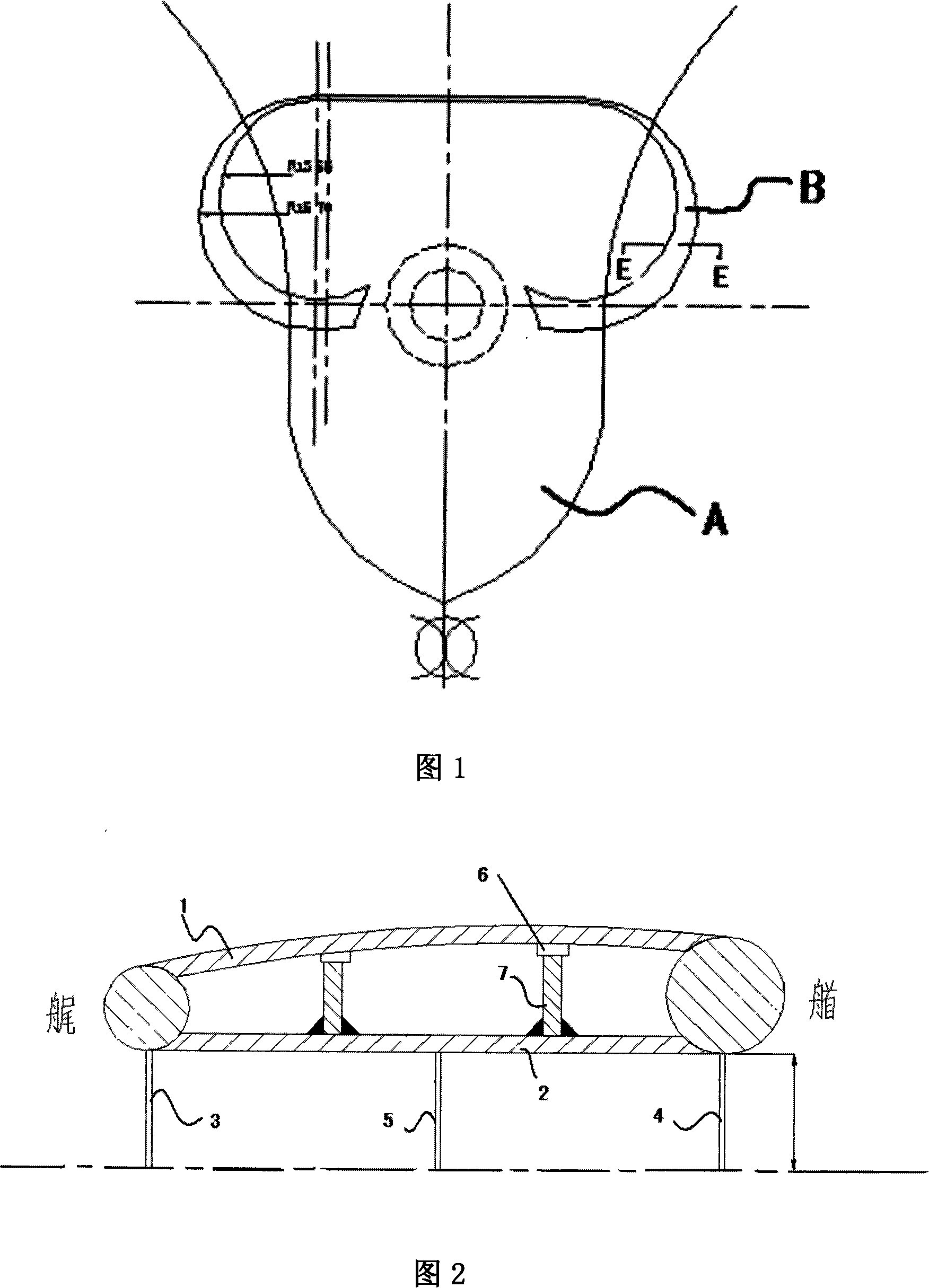

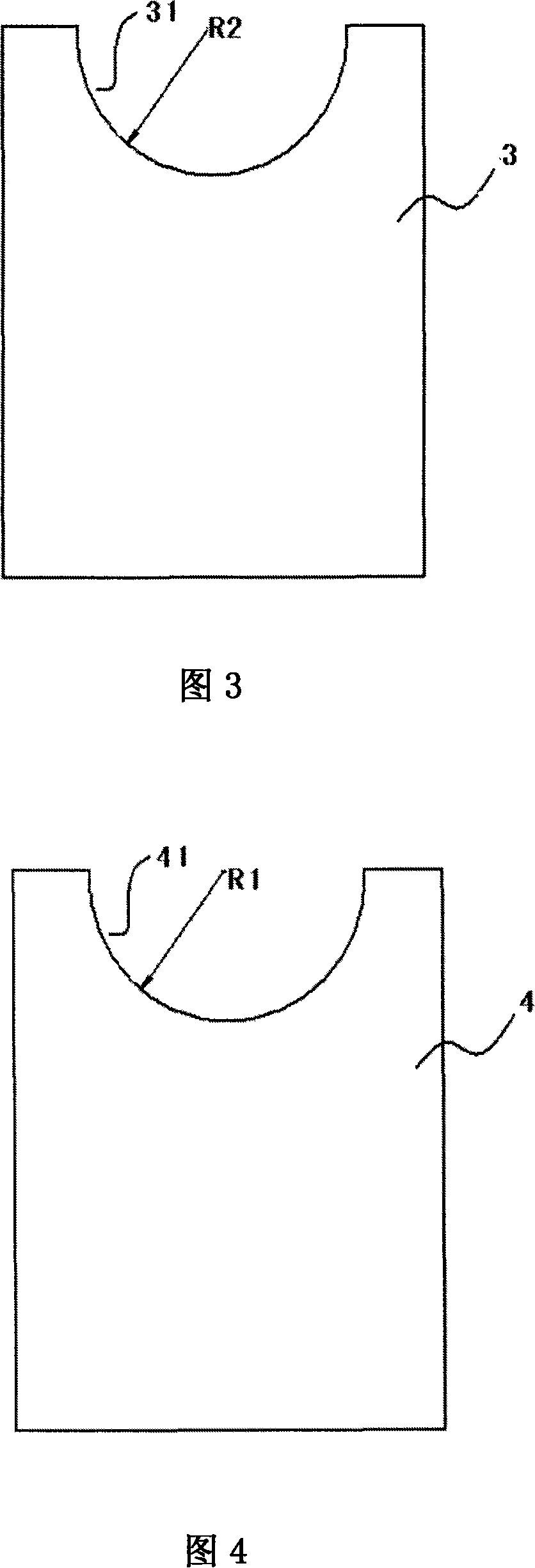

The invention relates to a manufacture method of a ship rectification duct, which comprises the following steps: (1) manufacturing a bow fetal board and processing a first breach and manufacturing a bow fetal board and processing a second breach which is located as a shaped grid; (2) arranging the base level of the shaped grid and fixing the lowest point and ensuring the level; (3) assembling an outside casing plate and rolling a semi-circled table for the outside casing plate; (4) providing the outside casing plates on the internal frames of the first breach and the second breach; (5) ruling in the outside casing plate and installing a knee plate distributed horizontally and vertically; (6) installing an inner casing composition plate on the knee plate and welding the composition plate into inner casing plate and completing the manufacture of the rectification duct after checking and adjusting. The manufacture method of the rectification duct of the invention can easily control the deformation of the whole manufacture method of the rectification duct, ensures the accuracy of inner and outer linearity of the rectification duct, improves the production efficiency, saves time and speeds up the construction of the whole ship.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Metal gasket

InactiveUS20110192369A1Minimal thicknessSoft compressibilityEngine sealsSealing arrangements for enginesEngineeringMechanical engineering

A multilayer metal gasket includes at least two metal gasket layers formed with an aligned opening and aligned opposing sealing beads surrounding the opening. A partial stopper layer is interposed between the gasket layers and is of lesser area than either of the gasket layers. The partial stopper layer extends from the opening outwardly beyond the sealing beads and is fixed to one of the layers on only one side of the sealing beads and is free on the opposite side.

Owner:FEDERAL MOGUL MOTORPARTS LLC

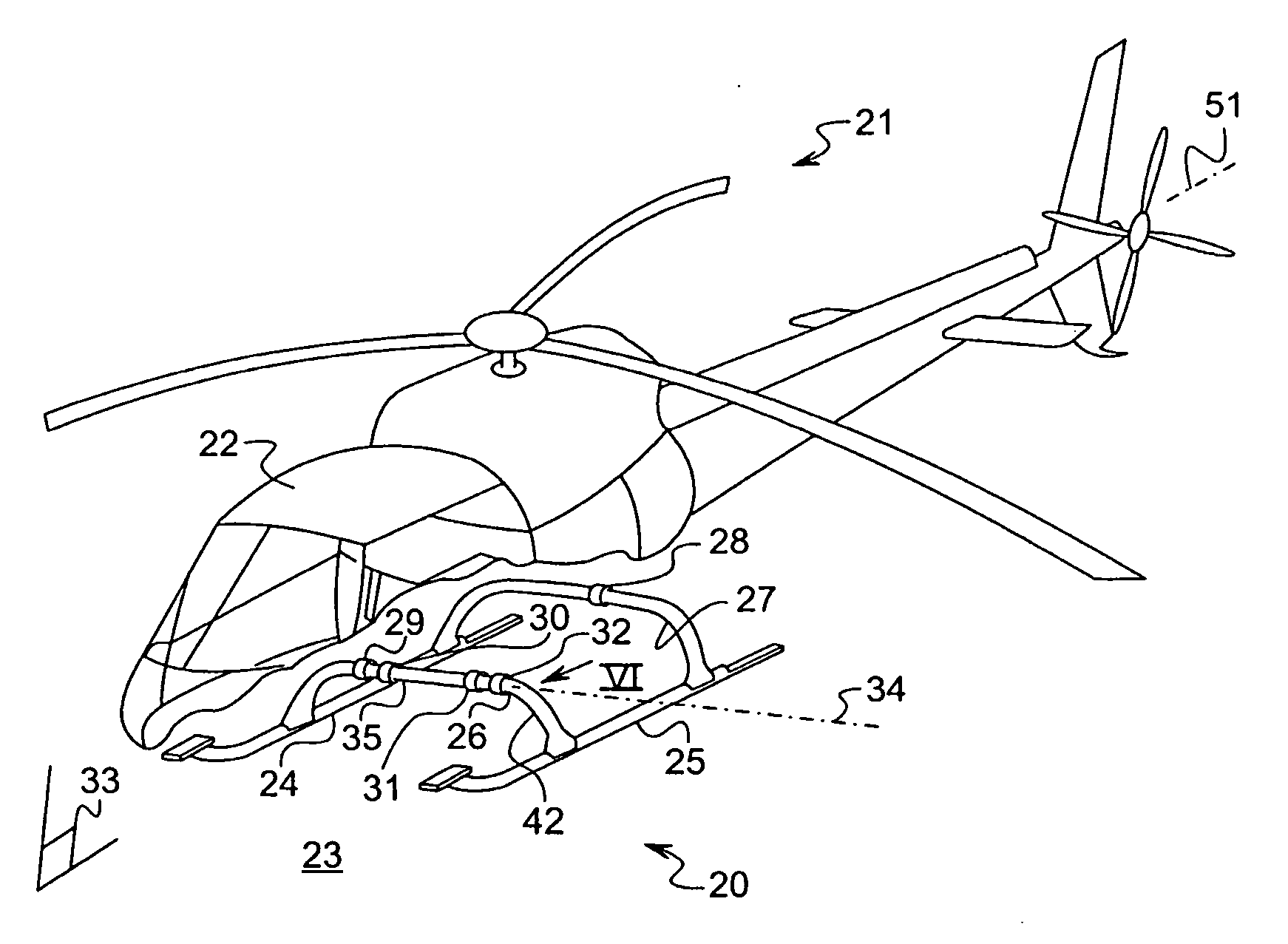

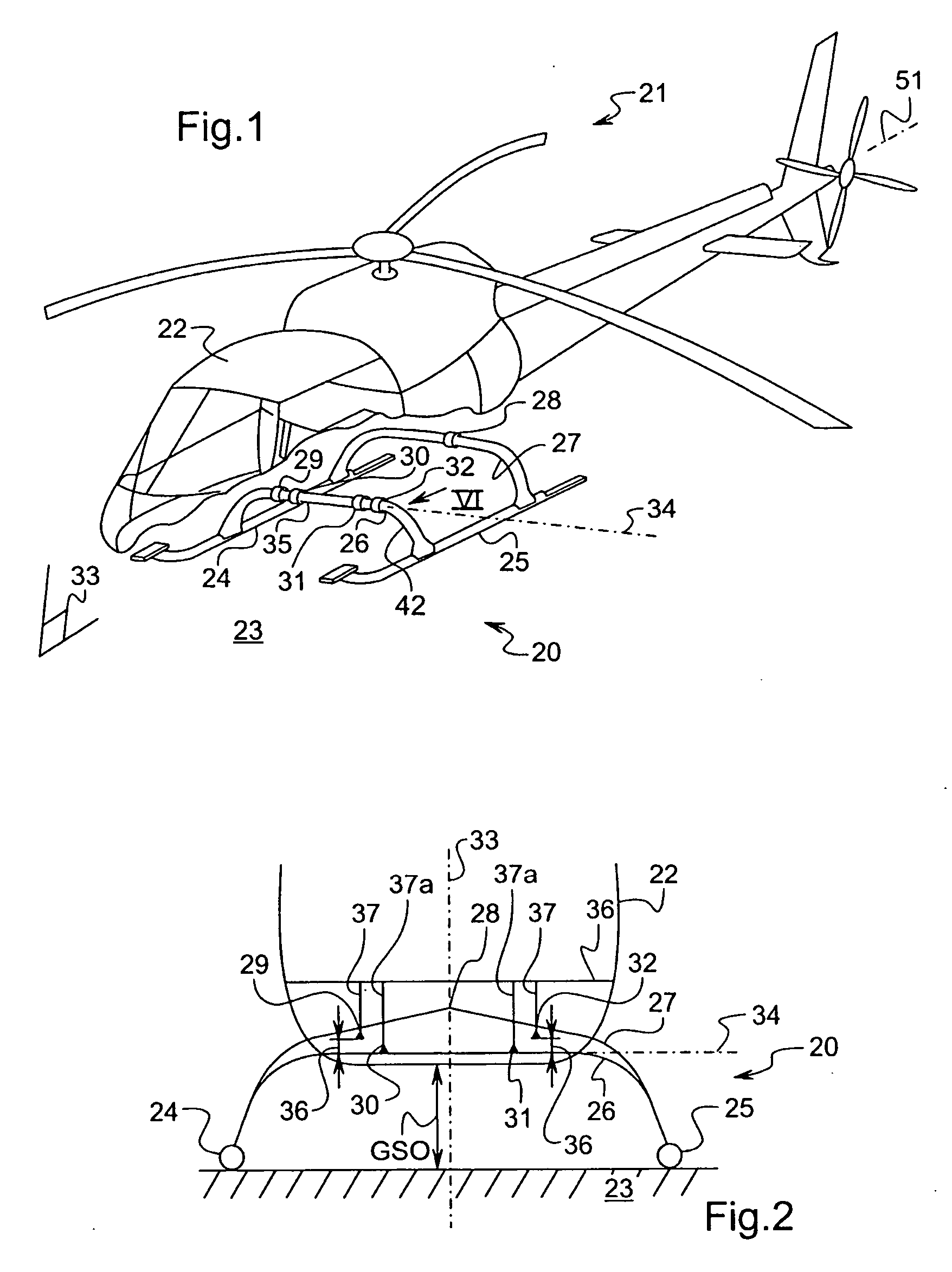

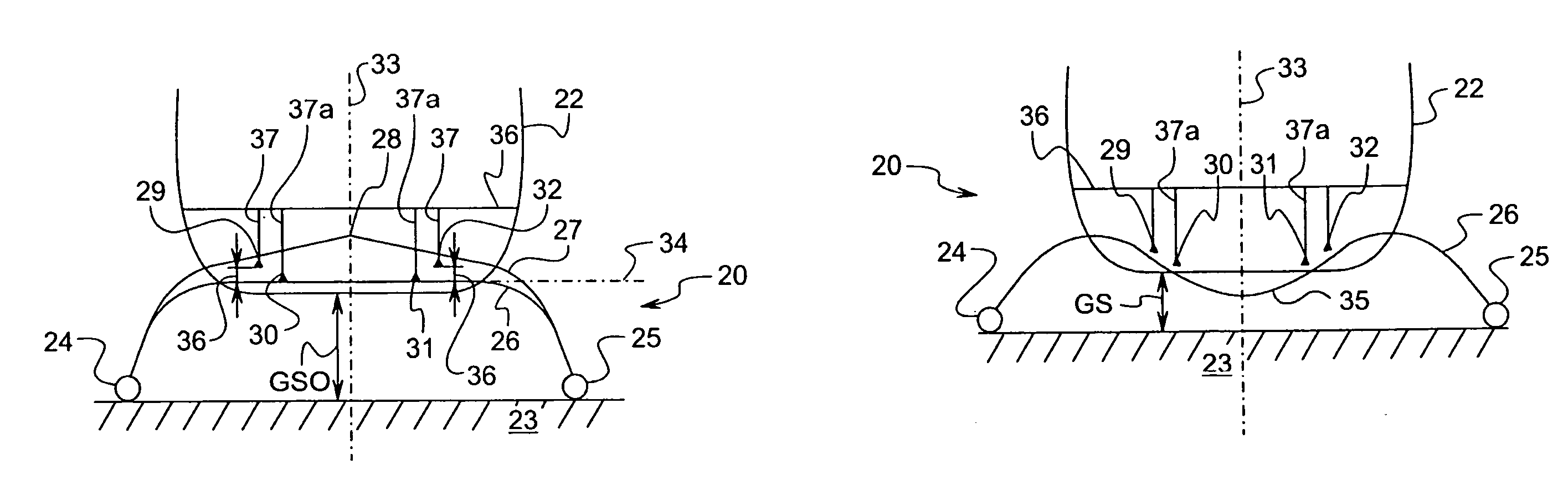

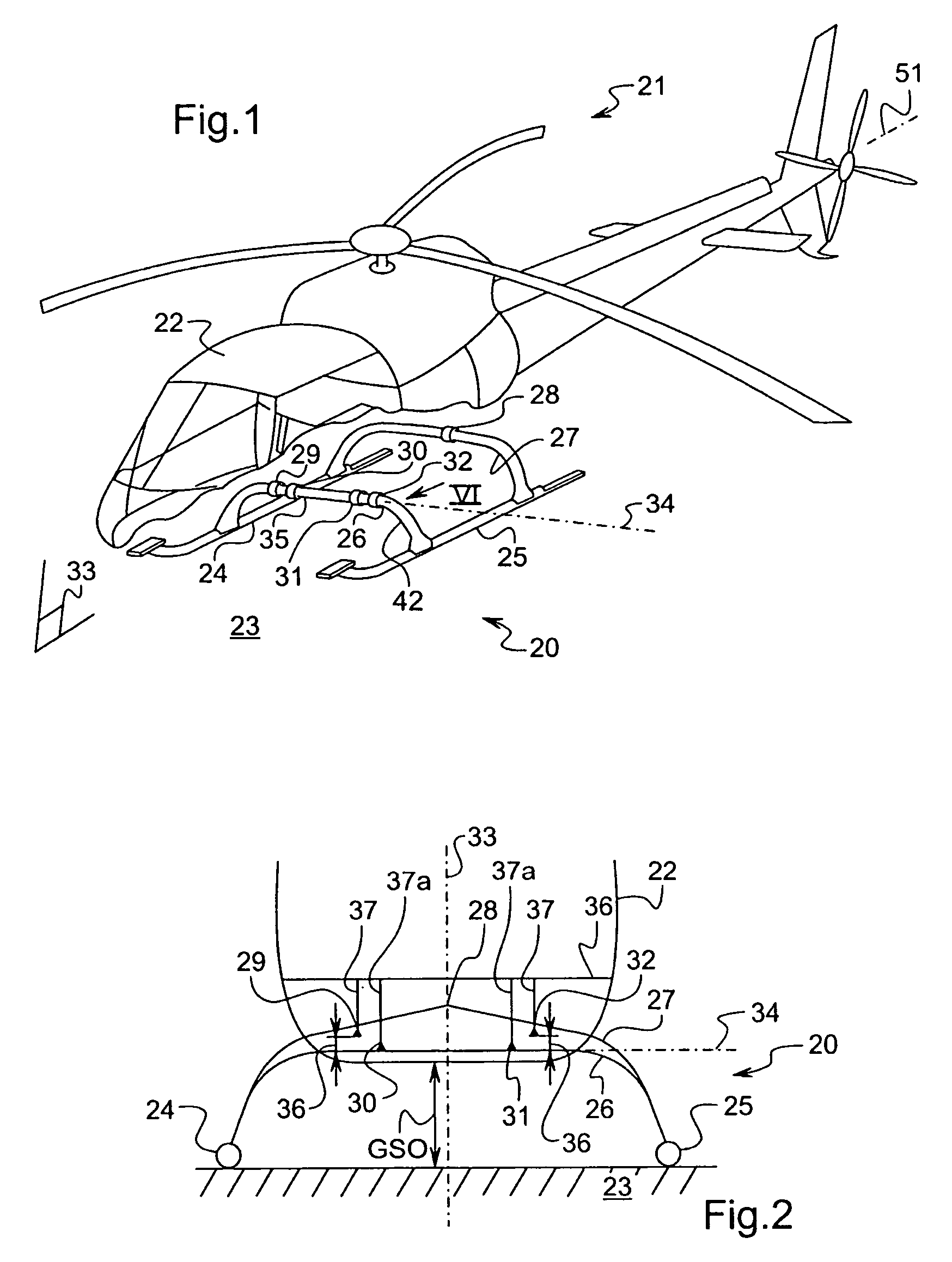

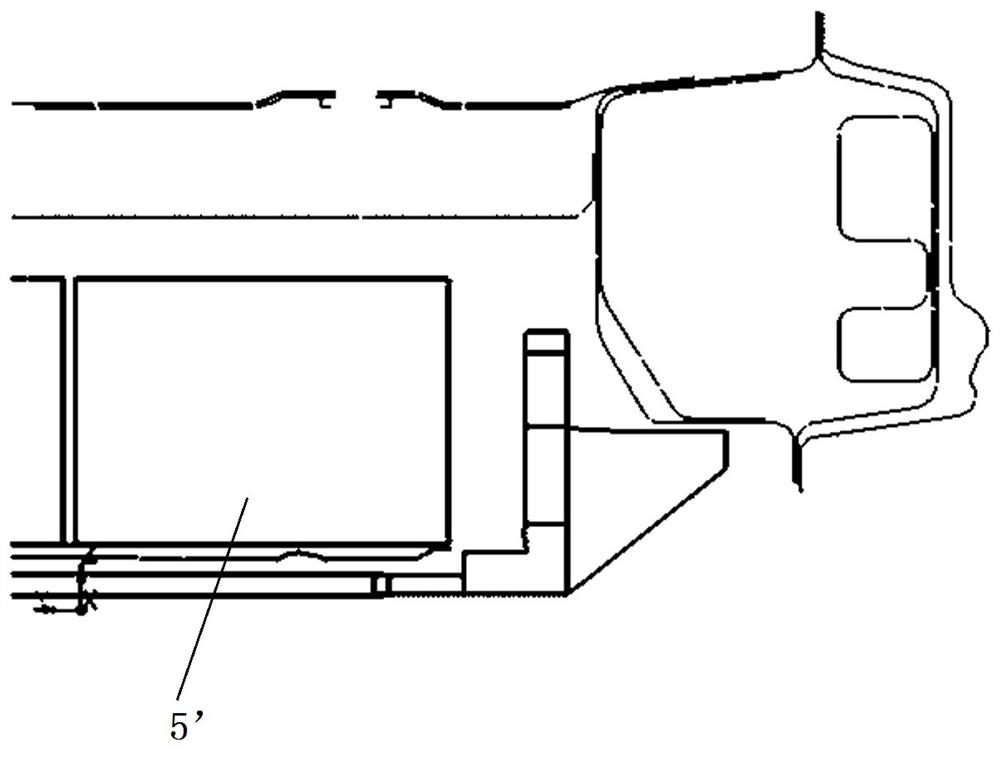

Rotorcraft skid undercarriage and a rotorcraft including such an undercarriage

InactiveUS20070181744A1Reduce stiffnessImprove deformationSkis/runnersRotocraftFlight vehicleEngineering

The invention relates to a rotorcraft (21) comprising a fuselage (22) and an undercarriage (20) having skids (24, 25) interconnected by at least one cross-member (26, 27), together with connection means for connecting the cross-member to the fuselage and presenting angular stiffness that varies with varying sinking (E) of the undercarriage as a result of contact with the ground (23).

Owner:EUROCOPTER

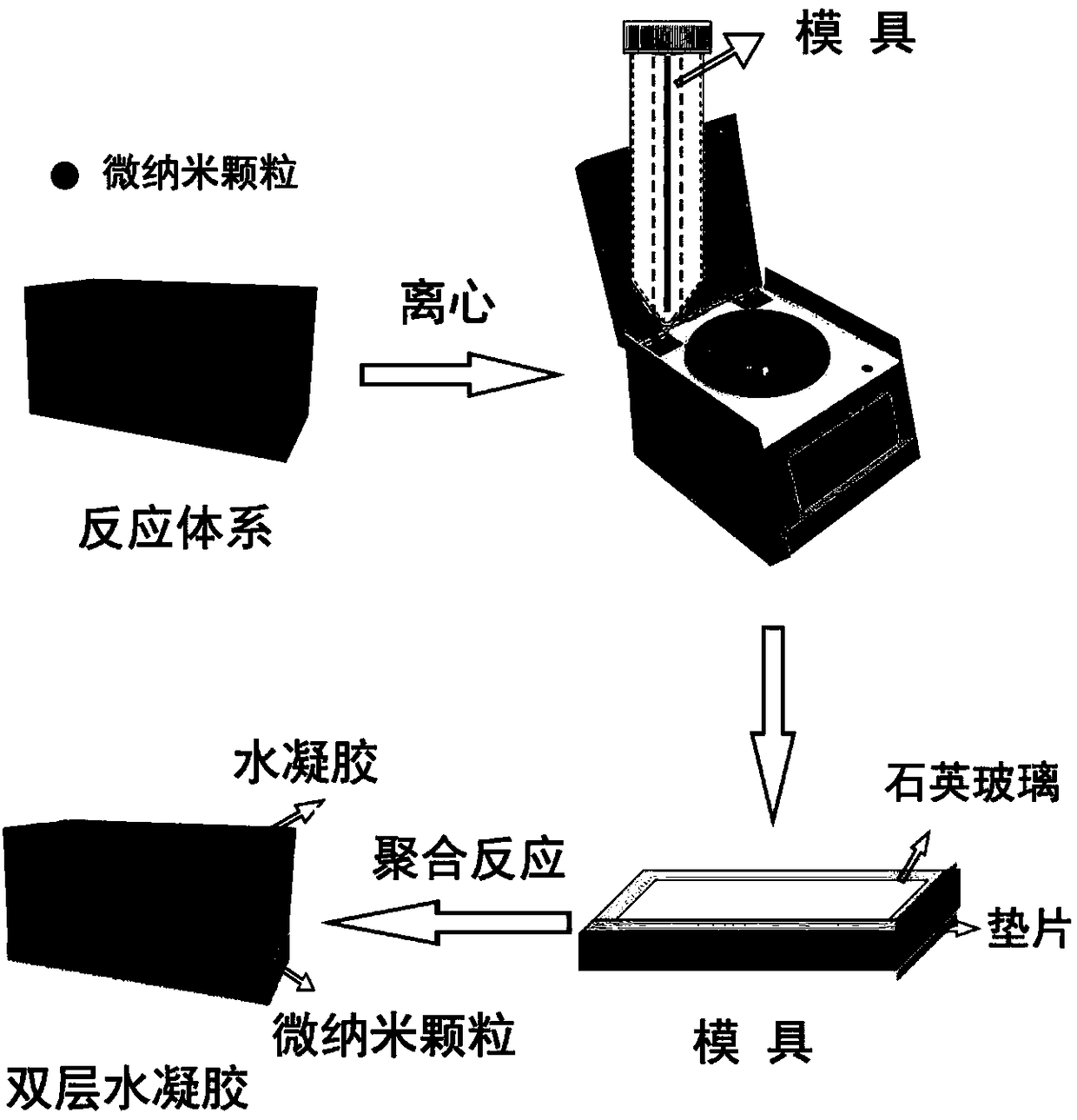

Method of preparing self-driving gradient-composition hydrogel through supergravity and application of the hydrogel

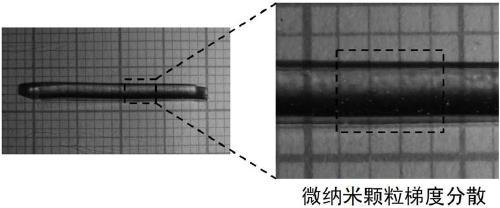

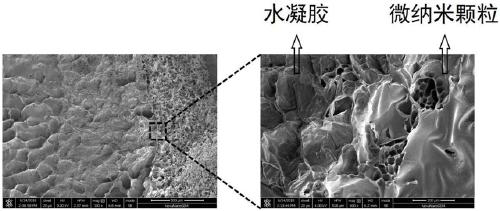

InactiveCN109280183ASimple methodLow costTissue regenerationProsthesisFunctional monomerMicro nanoparticles

The invention discloses a method of preparing self-driving gradient-composition hydrogel through supergravity and an application of the hydrogel. The method includes: mixing micron-nano particles witha gelatable functional monomer water solution with uniform dispersion, thus obtaining a mixed hydrogel system; centrifuging the mixed hydrogel system, centrifugal rotary speed being 1000-4000 rpm andcentrifugal time being 1-10 min, so that by accurately controlling the rotary speed and centrifugal time of a centrifuge, the micron-nano particles are separated and are gradient-dispersed; performing further gelation to prepare the self-driving gradient-composition hydrogel. The method is simple, low in cost and high in efficiency, has good universality and is green and environment-friendly. Theinvention also discloses the application of the self-driving gradient-composition hydrogel to tissue engineering and intelligent drivers.

Owner:ZHEJIANG UNIV OF TECH

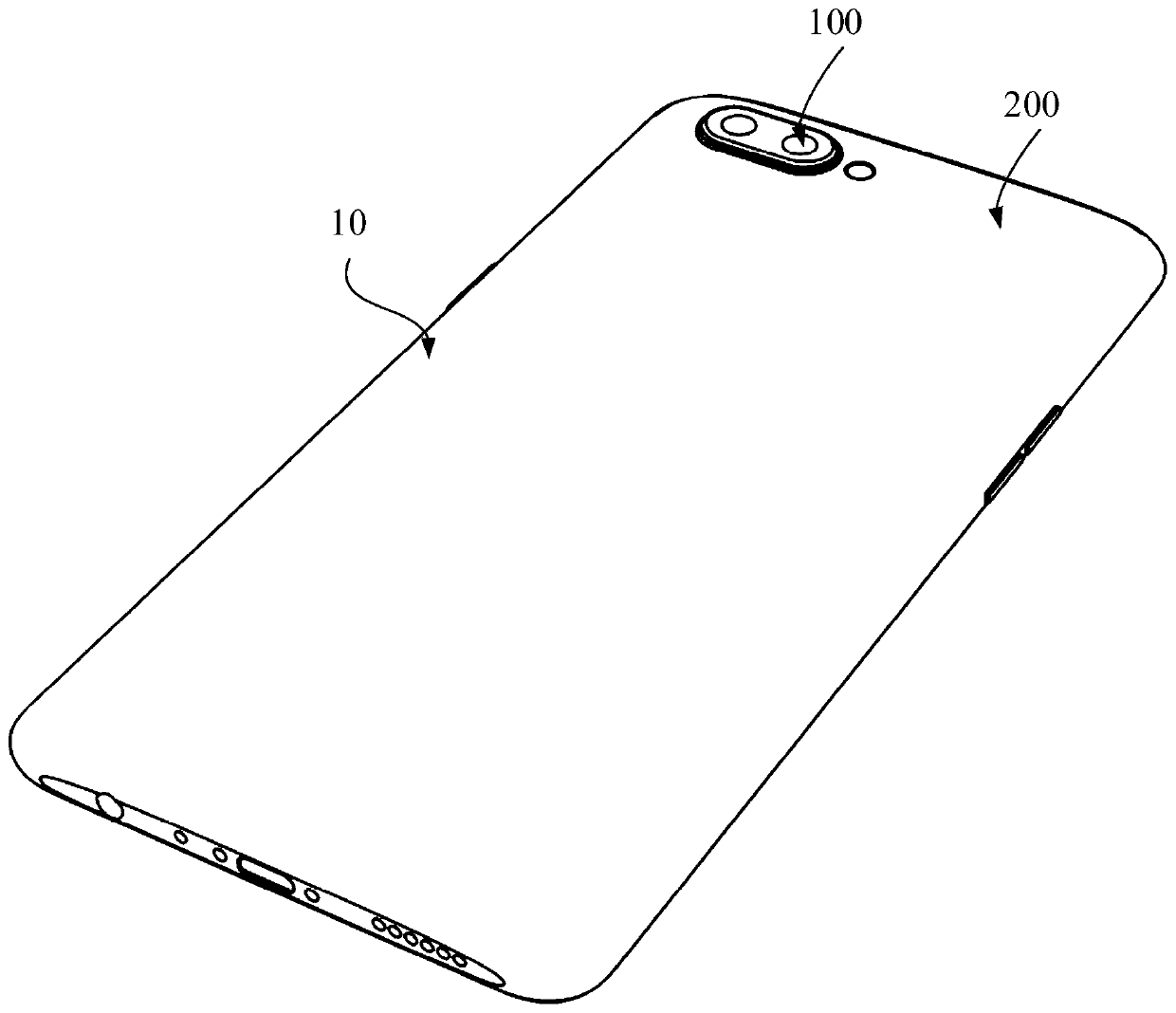

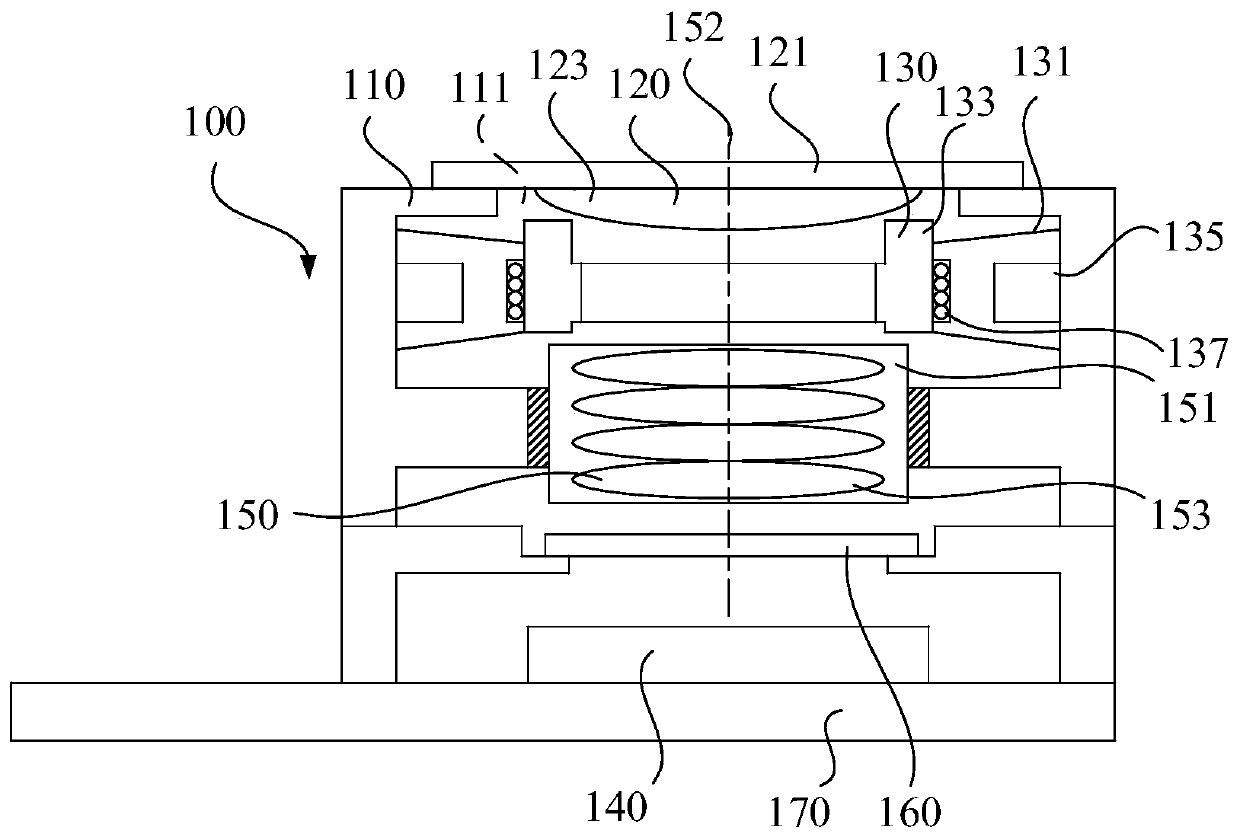

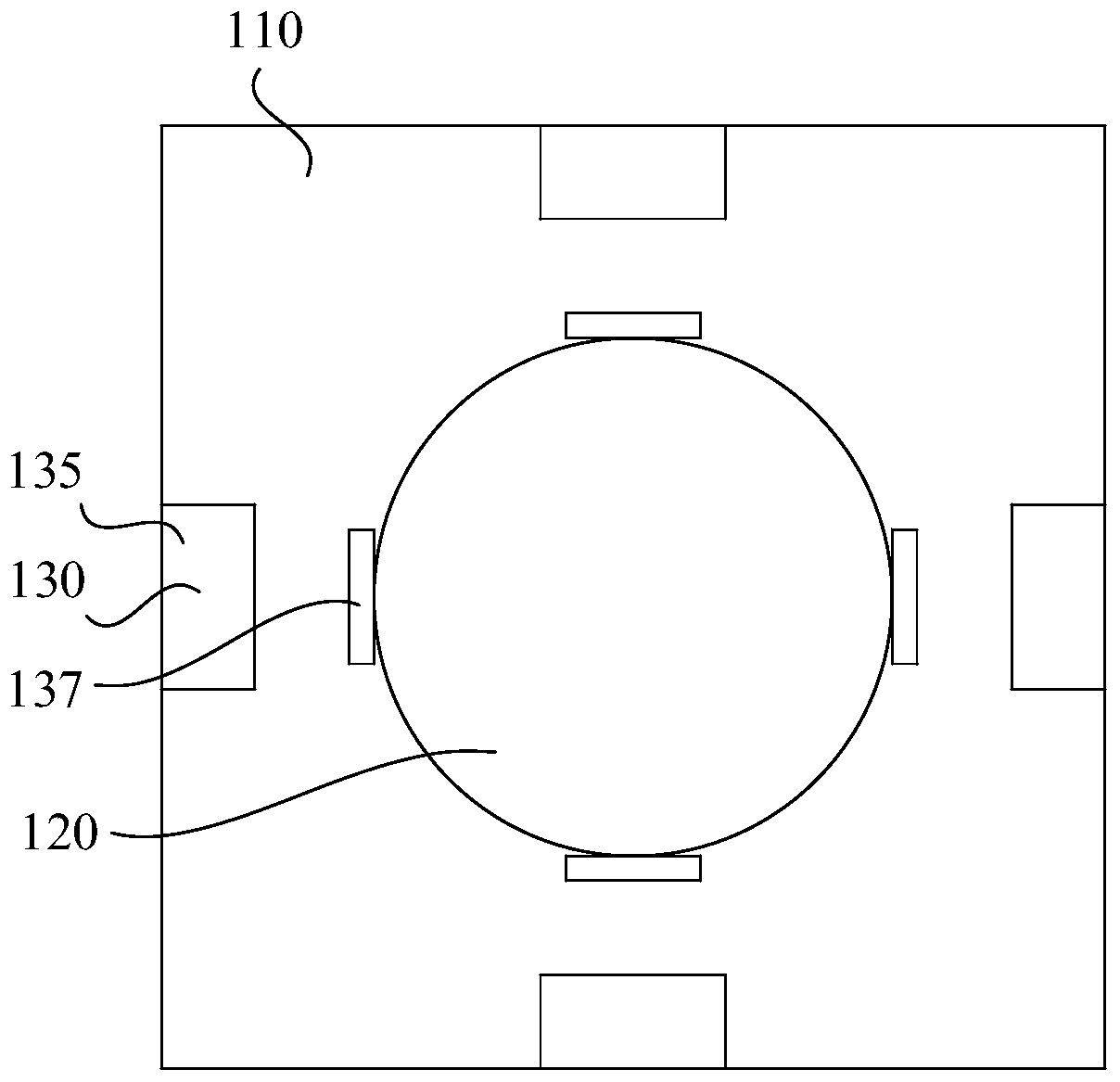

Camera module and terminal equipment

InactiveCN110661954ASimple structureReduce volumeTelevision system detailsProjector focusing arrangementTerminal equipmentMiniaturization

The invention relates to a camera module and terminal equipment. The camera module comprises a base body, a liquid lens, an extrusion structure, an image sensor and a lens group, wherein the base bodyis provided with a light inlet, the liquid lens is arranged at the light inlet and connected with the base body, the extrusion structure is connected with the base body and can extrude the liquid lens to deform the liquid lens, the image sensor is connected with the base body, and the lens group is connected with the base body and located between the liquid lens and the image sensor. Ambient light can enter from the light inlet, penetrates through the liquid lens and the lens group and then enters the image sensor. The camera module, the extrusion structure can extrude the liquid lens to deform the liquid lens; after the liquid lens is deformed, the radian of the surface of the liquid lens is also changed, so that the angle of the light passing through the liquid lens can be adjusted, thefocusing or anti-shake function can be realized, the focusing or anti-shake requirement of the high-pixel camera module can be met, and the miniaturization design of the camera module is facilitated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Combined manufacturing method of building exterior-wall thermal-insulation material

ActiveCN103570328AControllable sizeDeformation controllableClimate change adaptationPassive housesPumice dustThermal insulation

The invention relates to a building exterior-wall thermal-insulation material obtained by a combined manufacturing method and the combined manufacturing method. Raw materials of the building exterior-wall thermal-insulation material comprise an aggregate, a high-temperature binder and a low-temperature binder. The aggregate comprises expanded perlite, expanded vermiculite, pumice, expanded clay, expanded shale, expanded volcanic ash and expanded raw materials having a large amount of pores. The high-temperature binder comprises 45-60wt% of SiO2, 4-8wt% of Al2O3, 10-15wt% of CaO, 5-12wt% of B2O3, 1-8wt% of Na2O, 1-8wt% of K2O and 1-4wt% of ZnO. The low-temperature binder comprises water glass and bentonite. The combined manufacturing method has the characteristics that 1, in plate manufacture, the size and deformation can be controlled easily and the building exterior-wall thermal-insulation material is superior to foam light thermal-insulation materials; 2, compared with the foam thermal-insulation material manufacturing method utilizing a series of technological parameters such as a sintering temperature to control a heat conduction coefficient, the combined manufacturing method provided by the invention realizes heat conduction coefficient control only by raw material selection; 3, a sintering temperature is controlled in a range of 700-900 DEG C; and 4, in plate production, a roller kiln direct firing technology is utilized and kiln tools such as a base plate and a saggar are avoided so that a sintering heat utilization rate is high.

Owner:咸阳陶瓷研究设计院有限公司

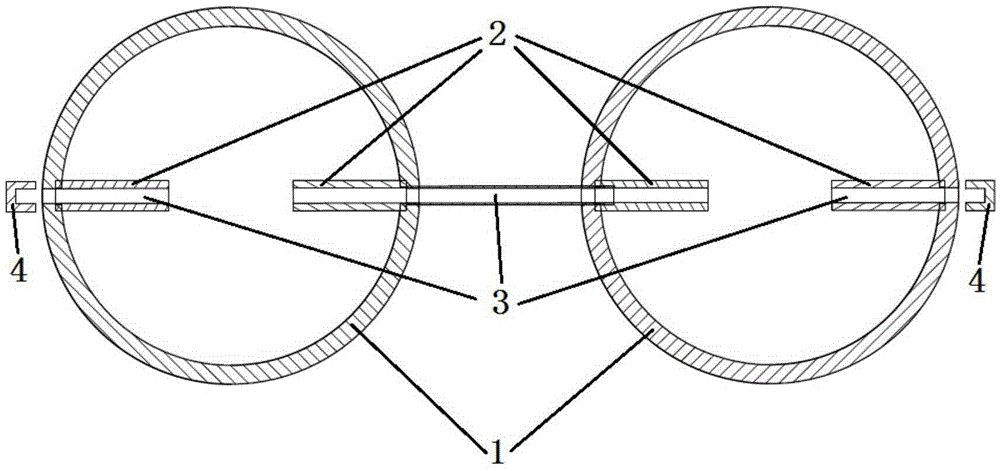

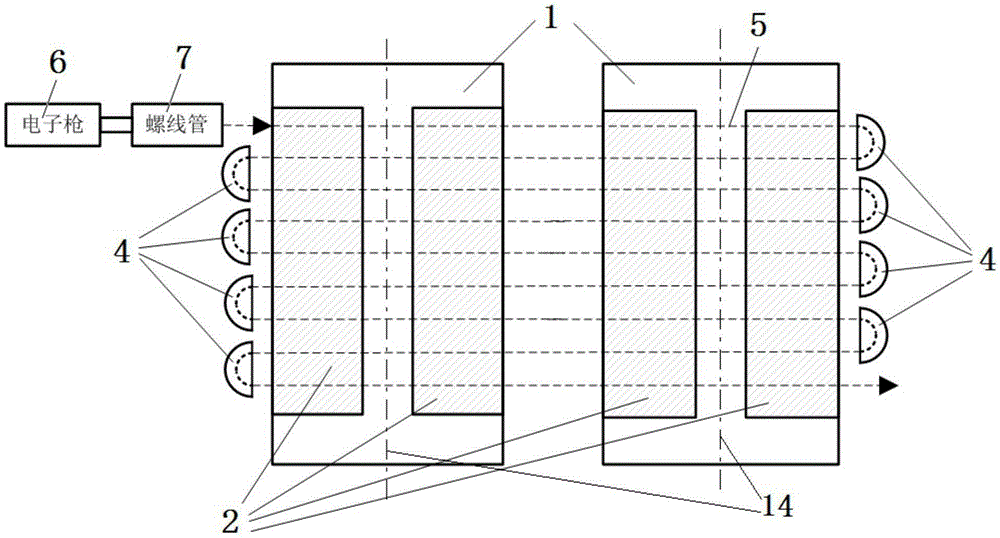

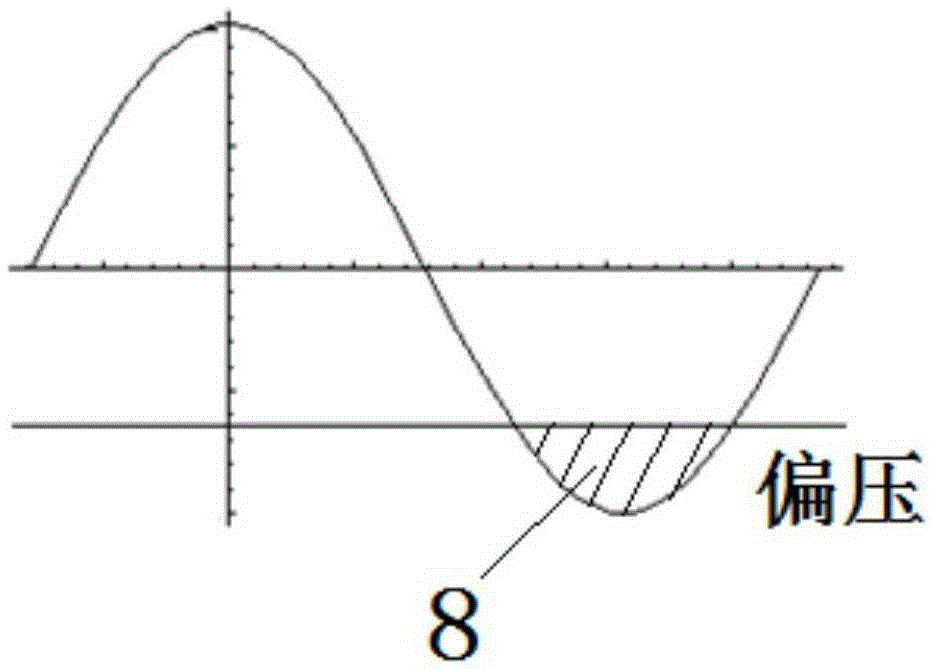

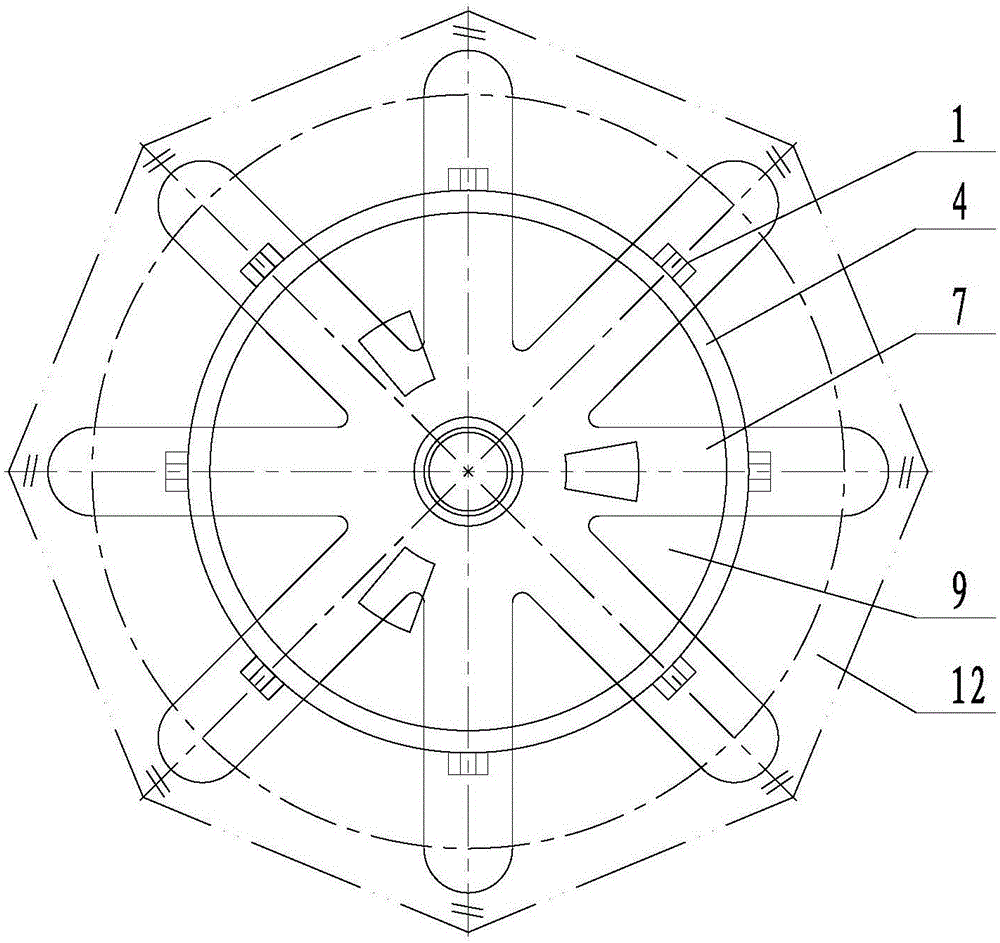

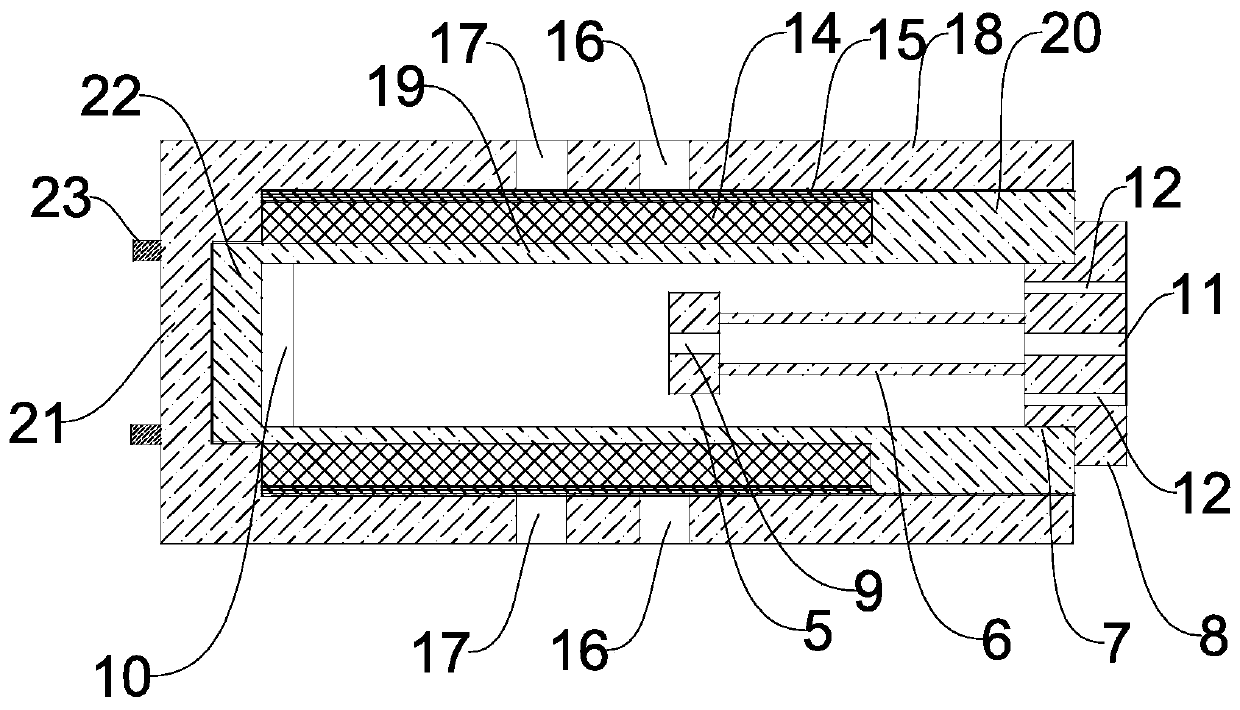

S-shaped-track-based multi-cavity electron accelerator

The invention, which belongs to the technology of the accelerator design, particularly relates to an S-shaped-track-based multi-cavity electron accelerator comprising an electron gun, a solenoid, and at least two resonance acceleration cavities arranged side by side. One pair of electrode plates not containing electrode heads is arranged inside each resonance acceleration cavity; the electrode plates are arranged on an S-shaped motion plane of an electron beam current, wherein the moving direction of the electron beam current is perpendicular to the cavity axis direction of the resonance acceleration cavity; and beam current hole channels where electron beam currents pass are arranged inside the electrode plates. A plurality of deflection magnets are arranged at positions, corresponding to the electrode plates, of the two sides of the resonance acceleration cavities arranged side by side and enable the electron beam currents to deflect at 180 degrees; and directions of adjacent two-times deflection the electron beam currents are opposite to each other to form an S-shaped motion track. The processing difficulty is low; the efficiency of conversion from a radio frequency power to a beam power is high; and a beam power over 100kW can be obtained easily.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Energy absorption method and uses thereof

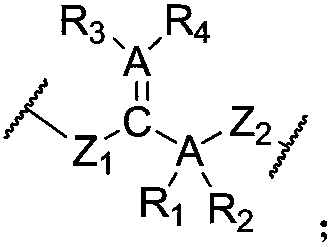

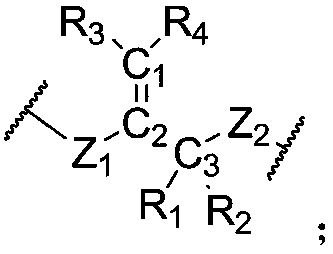

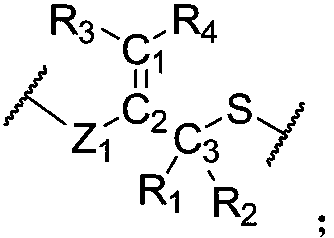

InactiveCN109666159ATake advantage and combineImproves tolerance and energy absorptionReversible addition−fragmentation chain-transfer polymerizationNoise reduction

The invention discloses an energy absorption method, which is characterized in that a dynamic polymer having dynamic covalent cross-linking and optional supramolecular hydrogen bond action is used asan energy absorbing material for energy absorption, wherein the dynamic covalent cross-linking is based on at least a reversible addition cleavage chain transfer dynamic covalent bond. According to the present invention, the dynamic polymer completely uses the characteristics of the dynamic covalent bond, such that the polymer has a certain strength and a certain stability; the dynamic covalent bond has strong dynamic reversibility under a certain condition, such that the dynamic polymer has characteristics of energy dissipating, dispersing and energy absorbing, can be used as the energy absorbing material so as to provide functions of good damping, good shock absorption, good sound insulation, good noise reduction, good impact resistance and the like, and can be especially used in body protection in sports and daily life and work, military and police body protection, explosion prevention, bullet prevention, airborne protection, airdrop protection, vehicle collision prevention, anti-impact protection of electronic and electrical products, and other fields.

Owner:翁秋梅

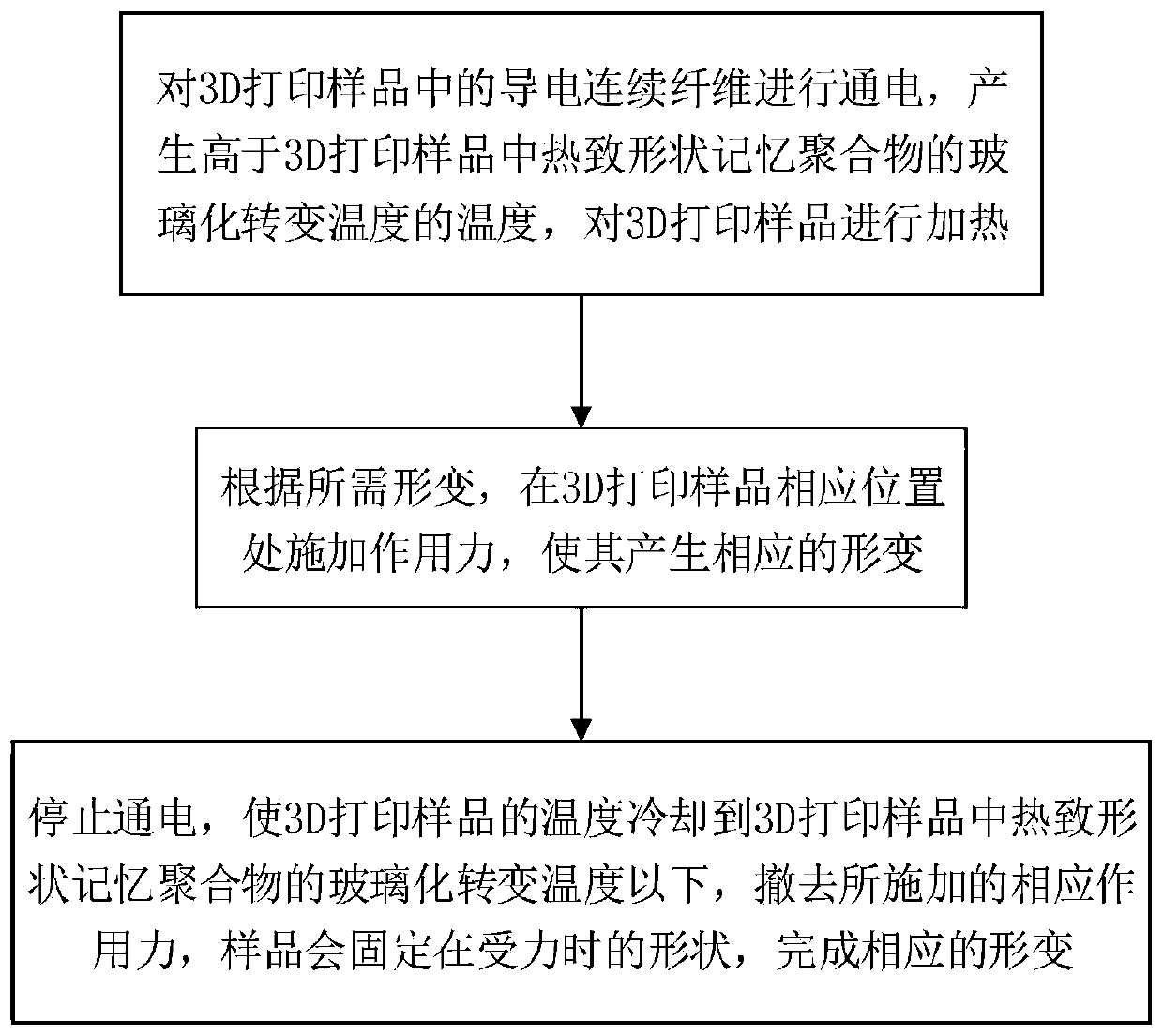

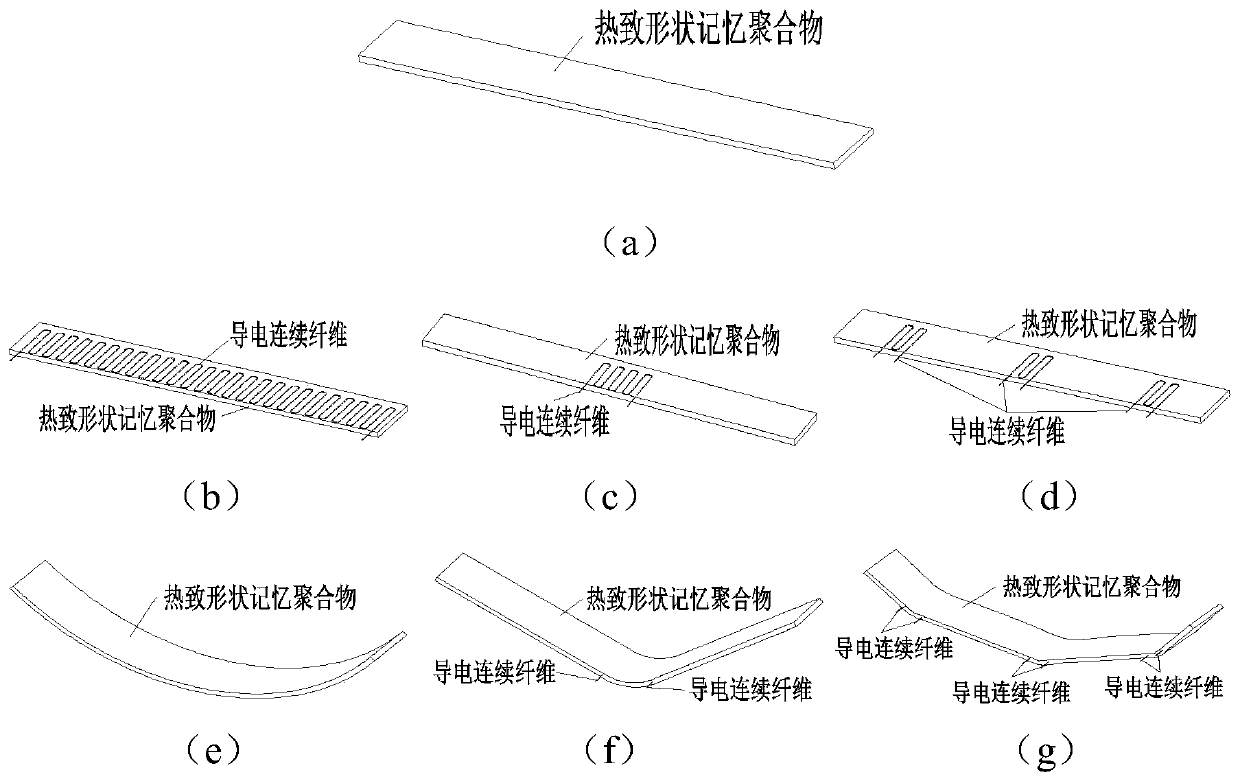

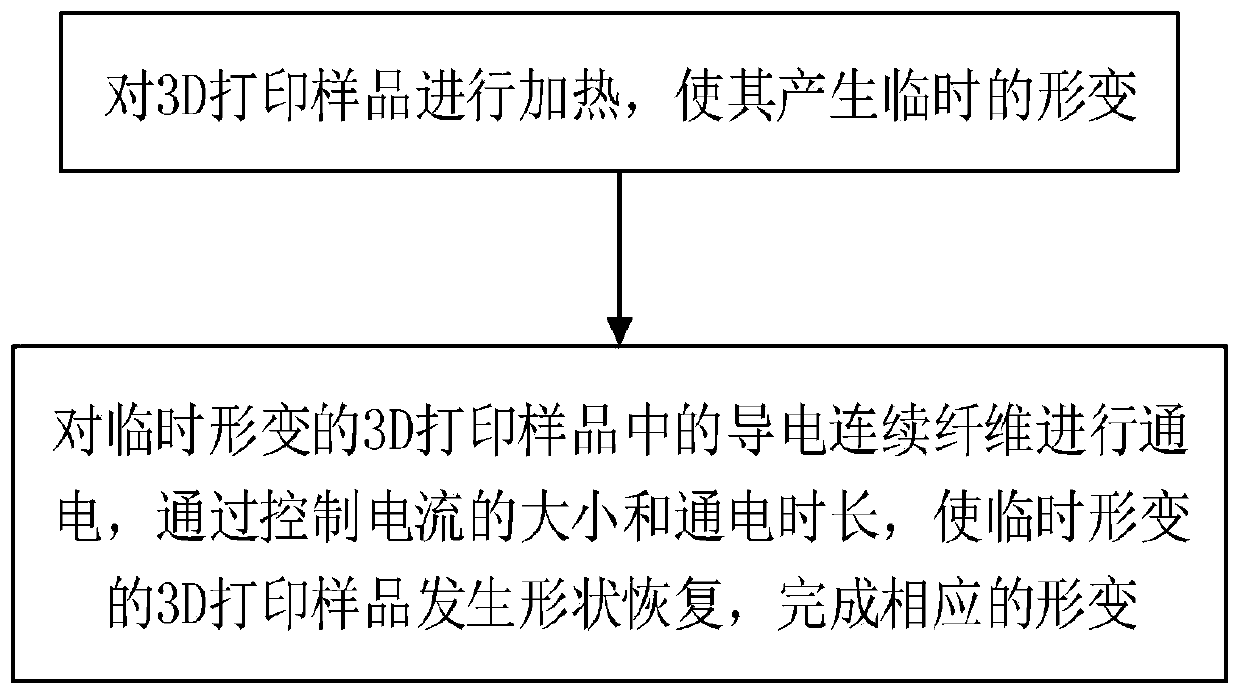

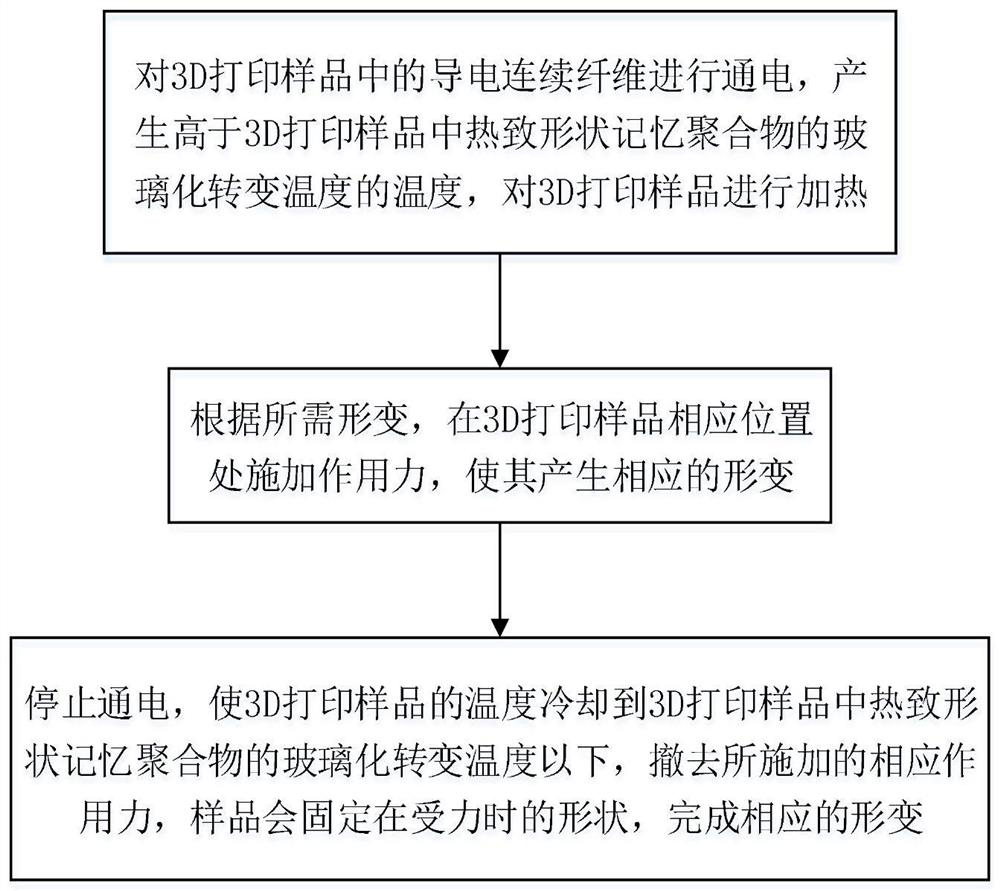

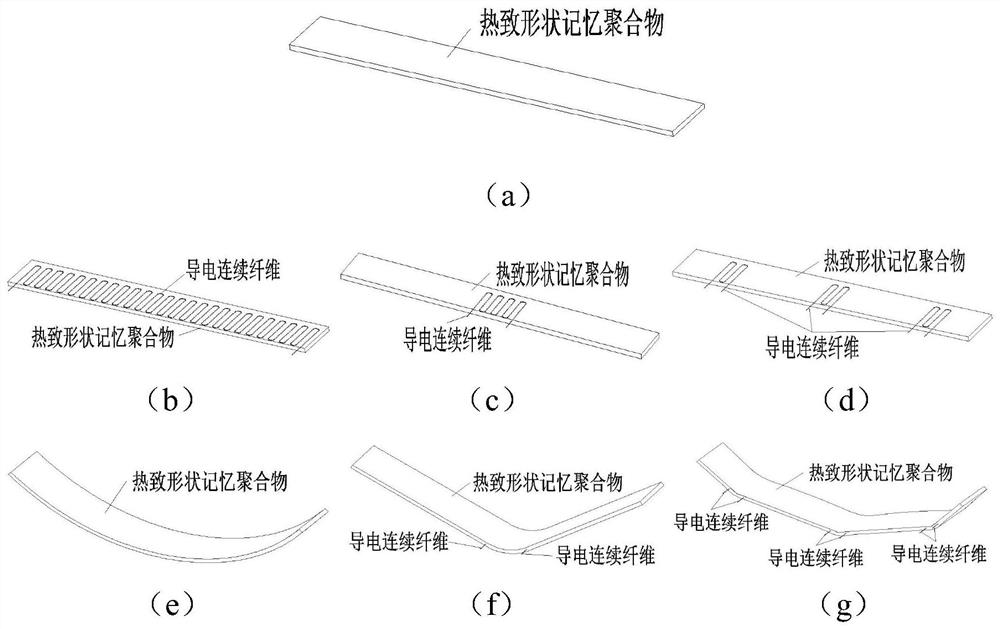

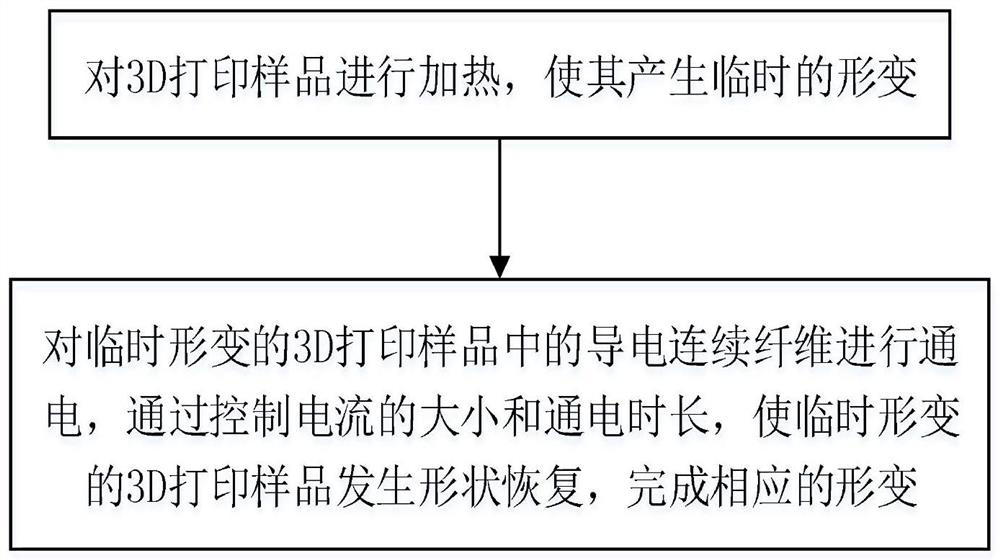

3D printing technology based sample deformation control method

ActiveCN111070689AControl the degree of shape recoveryControl recoveryAdditive manufacturing apparatus3D object support structuresDeformation controlMaterials science

The invention discloses a 3D printing technology based sample deformation control method. The 3D printing technology based sample deformation control method is characterized in that a heating source is generated based on electro-thermal effect of conductive continuous fibers for providing controllable temperature conditions for deformation to a 3D printing sample; corresponding force is applied ona corresponding position, so that the sample deforms; and the 3D printing sample is integrally or locally heated, so that deformation of different shapes is obtained; and in the whole process, a heating temperature, a force applying position and a force size are controllable, deformation types are various, ohmic heating can be performed on any spatial position, manual shape deformation control isconvenient, and controllability is better. The 3D printing technology based sample deformation control method disclosed by the invention electrifies the conductive continuous fibers in the 3D printing sample which is temporarily deformed, and enables the 3D printing sample which is temporarily deformed to generate shape restoration by controlling size and electrifying time of current, so that therestoration degree is controllable, the restoration effects are various, and controllability on a dynamic change process of deformation is better.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Processing method of integral-casting spherical iron base plate for high-speed railway

The invention relates to a processing method of an integral-casting spheroidal iron base plate for a high-speed railway, comprising the following steps of: a. selecting spheroidal graphite cast iron, wherein the tensile strength of the spheroidal graphite cast iron is greater than 400MP, the yield strength is greater than 250MP, the elongation exceeds 18%, and the impact toughness at room temperature reaches 14J / cm<2>; b. carrying out integral casting on the base plate by adopting a furan resin sand casting process and controlling the surface roughness within Ra50; c. placing a casting into a furnace to heat to 730-750 DEG C, keeping the temperature for 2-4 hours, then controlling the temperature in the furnace to be 580-610 DEG C, and then taking out the casting for naturally cooling; d. mechanically processing; and e. carrying out QPQ (Quench Polish Quench) salt bath composite processing on the surface of the casting. The integral-casting spheroidal iron base plate is formed by integrally casting the spheroidal graphite cast iron, has high integrity, more obvious shock-absorption effect, higher wearing resistance, corrosion resistance and fatigue resistance, easy control of deformation, small internal stress and better machinability, simplifies various associated dimension chains, and greatly reduces the mechanical processing amount, thereby having short production period, easily forming line production and being suitable for batch production.

Owner:JIANGSU XINKANGHUA MACHINERY

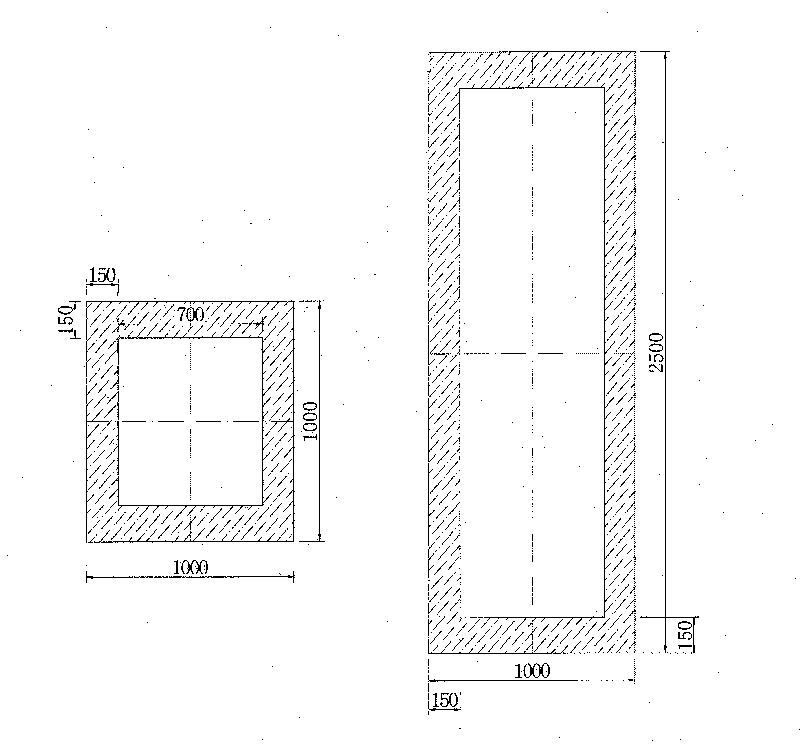

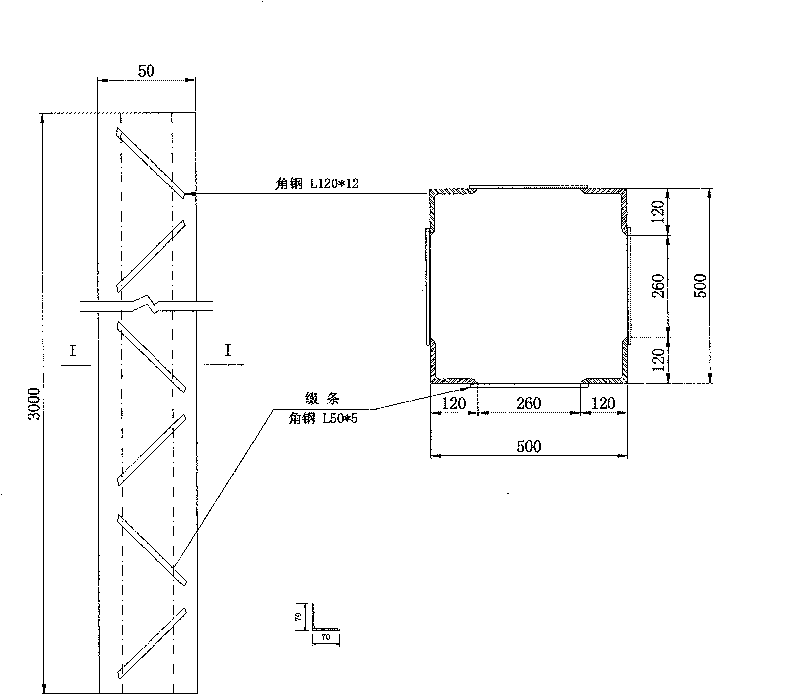

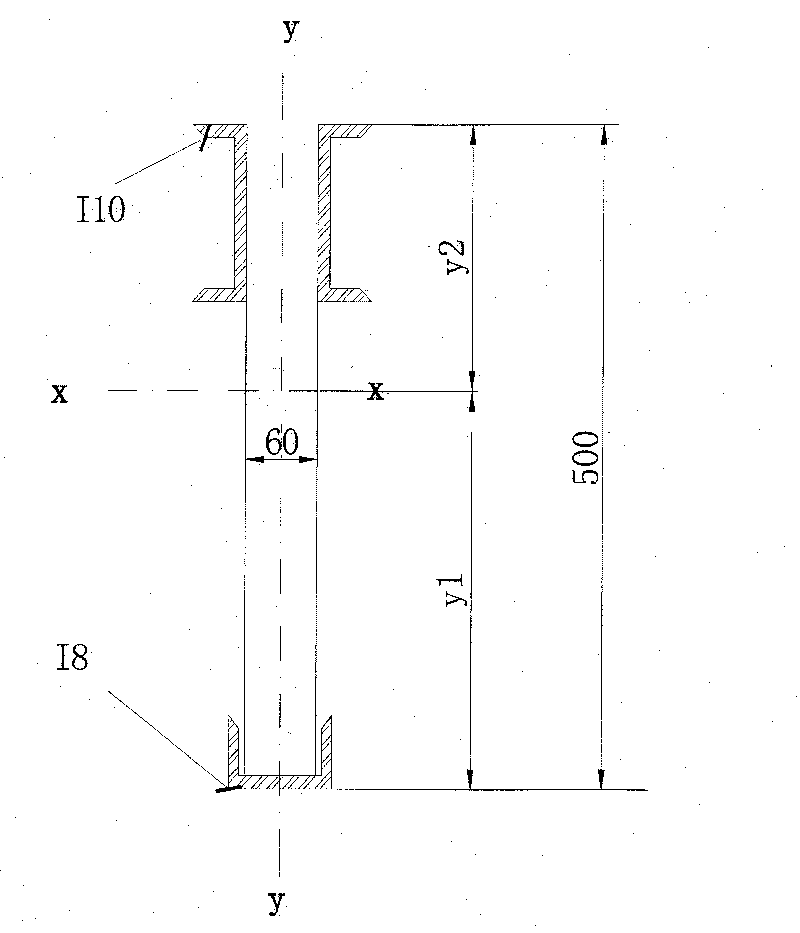

Construction process for casting large-tonnage box beam in site by support pier method

ActiveCN101736693ADeformation controllableSimple structureBridge erection/assemblyReinforced concreteOperability

The invention relates to a construction process for a cast-in-site beam, in particular to the construction process for casting a large-tonnage box beam under a condition that the height of a pier is less than 10m. The construction process is characterized in that: a support pier system formed by a reinforced concrete prefabricated hollow support pier, a steel lattice structured column, a connecting rod and the like bears the load; a height adjusting system formed by an I-shaped steel beam, a longitudinal trussed beam, an adjusting wedge, square stock wood pads arranged as required, a beam falling sand box and the like adjusts an elevation of a bottom mould, sets a camber and transfers the load; and a mould plate system ensures the casting and forming of the concrete, so that the construction process for quickly and safely casting the box beam well in site is formed. The construction process has simple structure and less connecting points, and the deformation of the support pier is easily controlled; the cross section area is big, which facilitates the foundation treatment; the operability is strong, the beam preparation period is short, and the beam is big in rigidity and reliable in stability; and the resources are saved, the cost is lowered, and the construction process is widely applied.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

Rotorcraft skid undercarriage and a rotorcraft including such an undercarriage

InactiveUS7770843B2Reduce stiffnessImprove deformationSkis/runnersRotocraftFlight vehicleEngineering

The invention relates to a rotorcraft (21) comprising a fuselage (22) and an undercarriage (20) having skids (24, 25) interconnected by at least one cross-member (26, 27), together with connection means for connecting the cross-member to the fuselage and presenting angular stiffness that varies with varying sinking (E) of the undercarriage as a result of contact with the ground (23).

Owner:EUROCOPTER

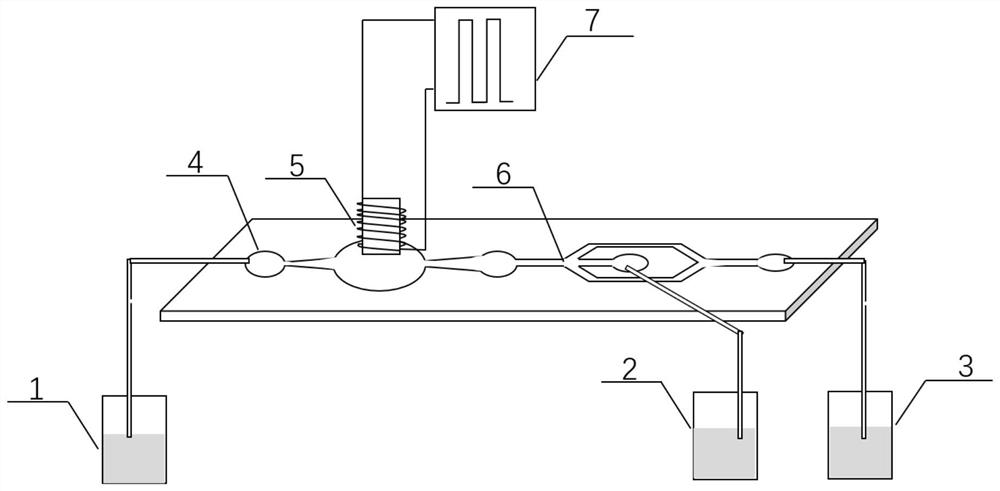

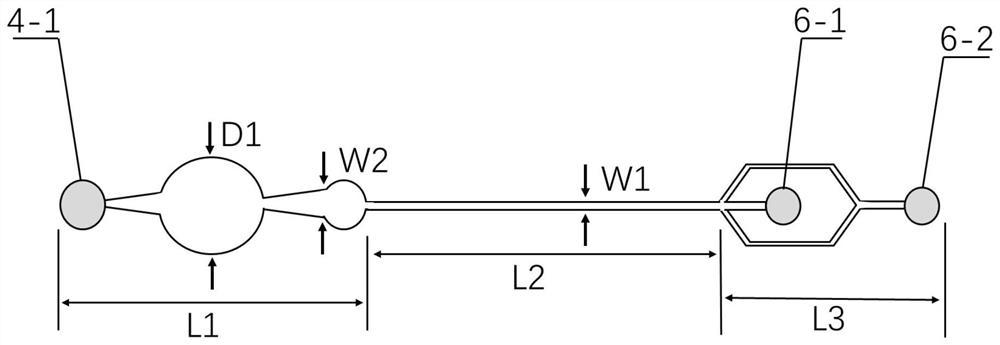

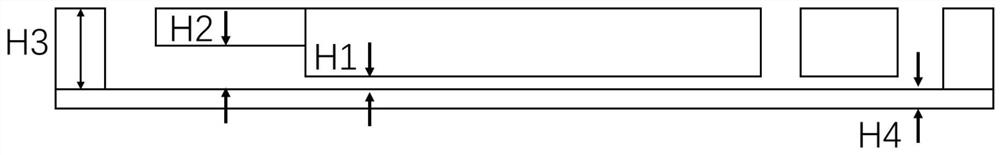

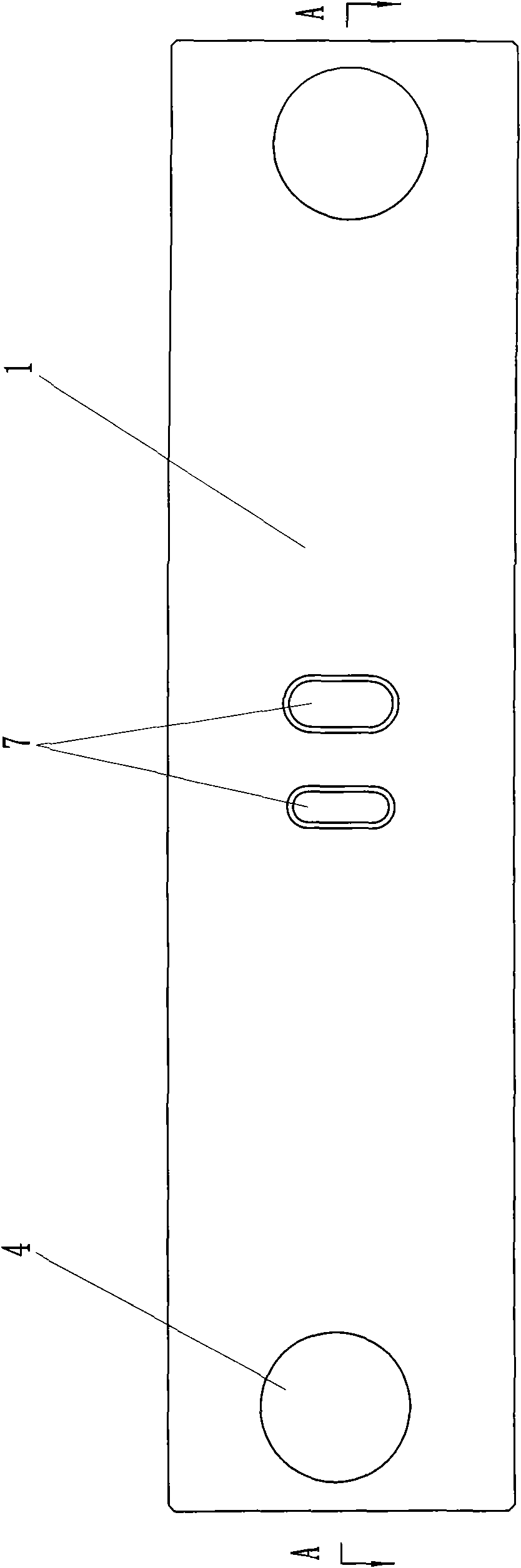

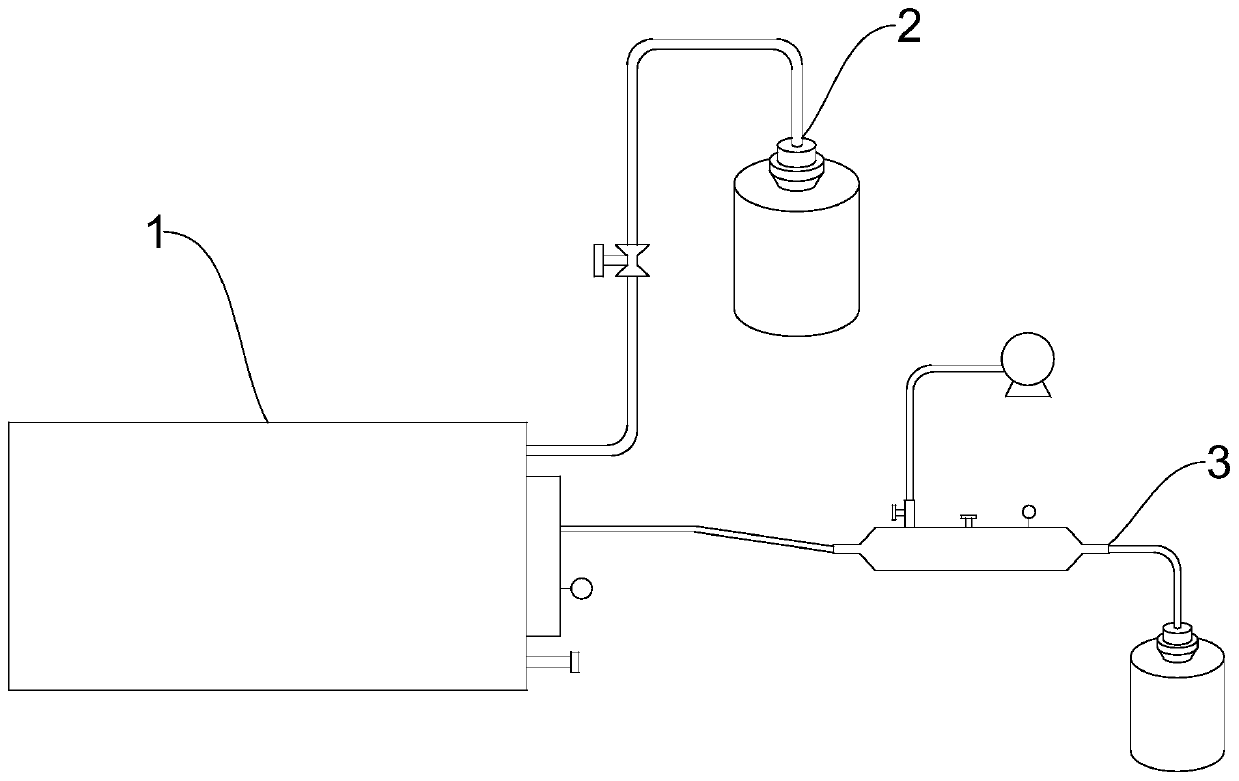

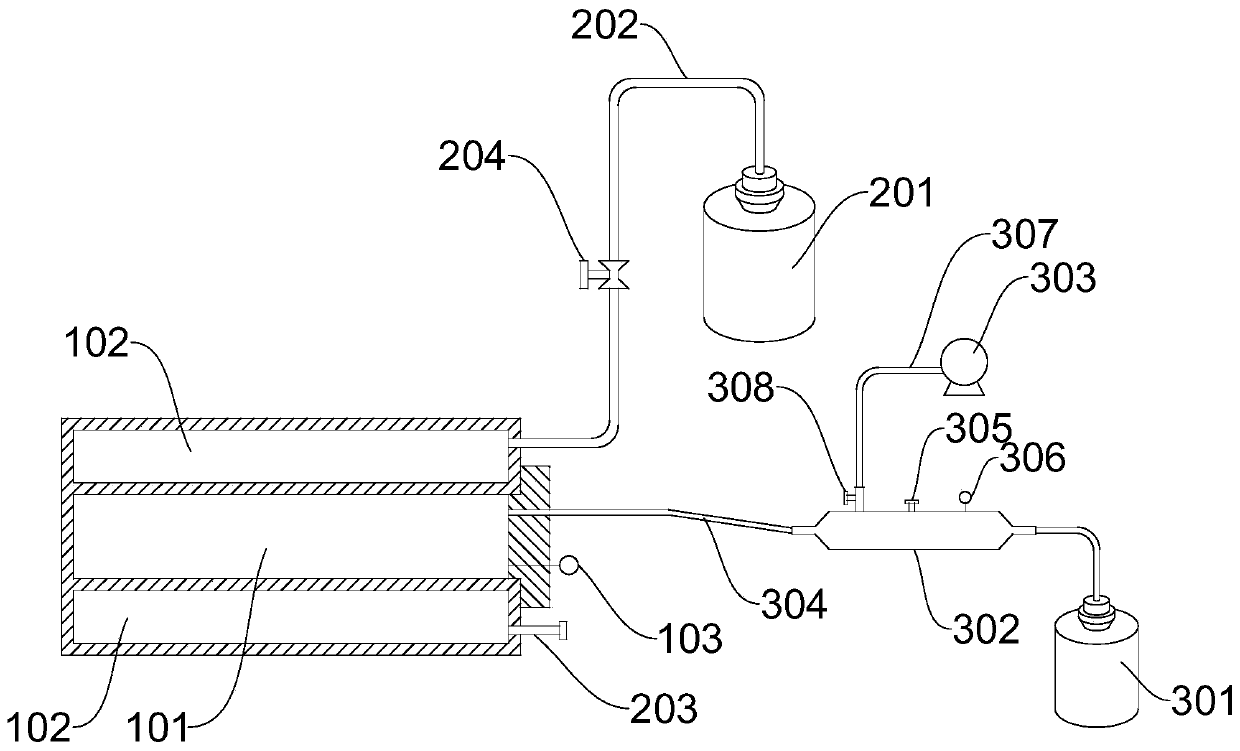

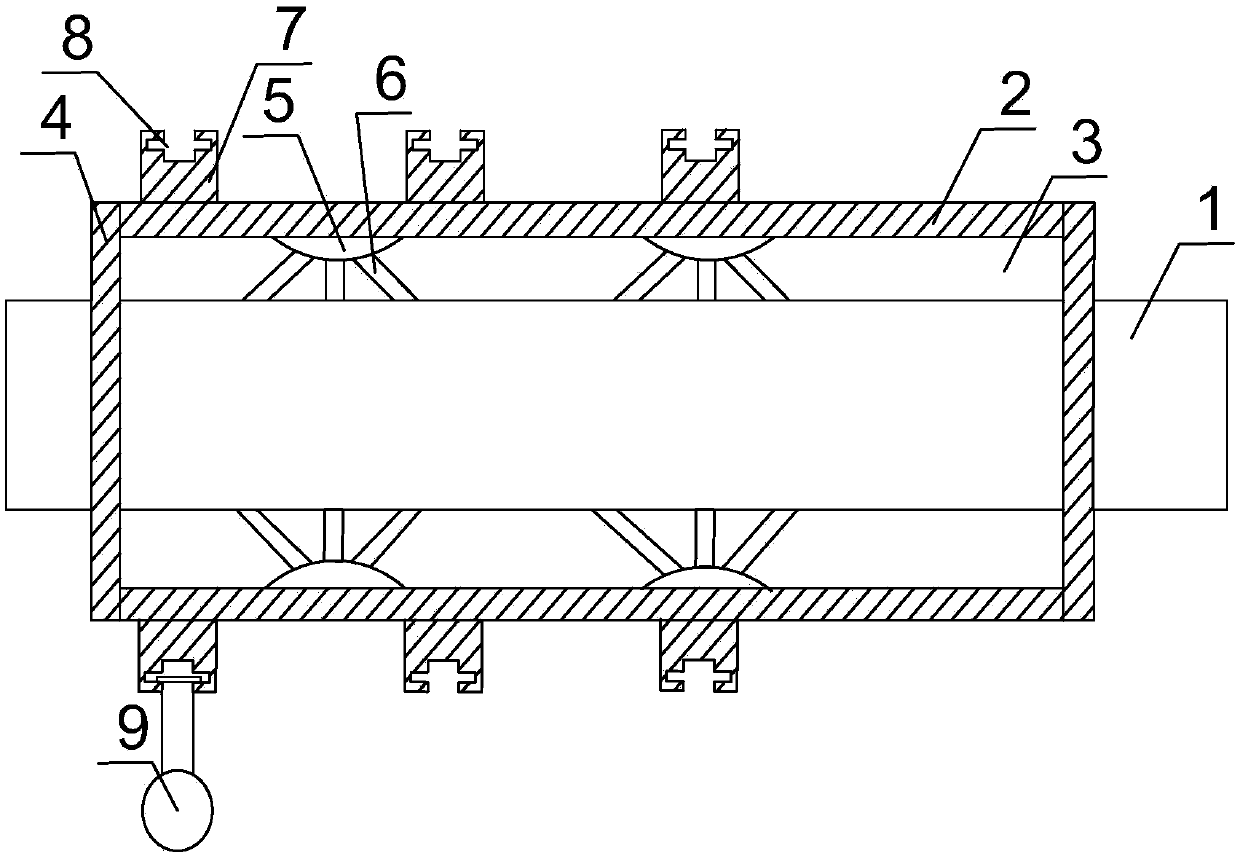

High-integration-level micro-nano particle convergence micro-fluidic device utilizing oscillatory flow

ActiveCN113333040AEfficient aggregationHighly integratedLaboratory glasswaresFluid controllersControl systemLiquid storage tank

The invention belongs to the technical field of micro-fluidic chips, and provides a high-integration micro-nano particle convergence micro-fluidic device utilizing oscillatory flow, which mainly comprises a micro-fluidic chip (comprising a valveless micropump and a convergence channel), a pump membrane control system (comprising an electromagnet and a singlechip), a liquid storage tank and a conduit. The device provided by the invention can realize efficient and convenient micro-nano particle convergence. The micro-fluidic device for converging the micro-nano particles, provided by the invention, is high in integration level, ingenious in design and simple to operate. Oscillatory flow design is utilized to realize 'infinite long channel' flow in a short channel, and a valveless micropump is utilized to drive fluid, so that integration and miniaturization of the device are realized; the elastic lift force and the inertial lift force are combined, convergence and enrichment of the micro-nano particles can be successfully achieved, and the device is used for research in the fields of biology, chemistry and environment.

Owner:DALIAN UNIV OF TECH

Machining technology of slide plate special for passengers

InactiveCN101823193AImprove integrityDeformation controllableHeat treatment process controlCushioningSurface roughness

The invention relates to a machining technology a slide plate special for passengers. The technology comprises the following steps of: a. selecting a spheroidal graphite cast iron with the ball iron card number of QT400-18L; b. wholly casting a cushioning plate with a furan resin sand casting technology, and controlling the surface roughness to be within Ra50; c. putting a casting part into a furnace to be heated at 730-750 DGE, keeping the temperature for 2-4h, controlling the temperature in the furnace at 580-610 DEG C, withdrawing the casting part, and naturally cooling; d. mechanically machining; and e. compositely treating the surface of the casting part by means of QPQ salt bath. The machining technology wholly molds the slide plate with the spheroidal graphite cast iron, has high integrity, is more obvious in shock absorption effect, has higher abrasive resistance, corrosion resistance and fatigue resistance, easily controls the deformation, has small internal stress and good cutting performance, simplifies various associated dimension chains by wholly casting, and greatly reduces the mechanic machining quantity, thereby having short production period, easily forming into line production, and being suitable for quantity production.

Owner:JIANGSU XINKANGHUA MACHINERY

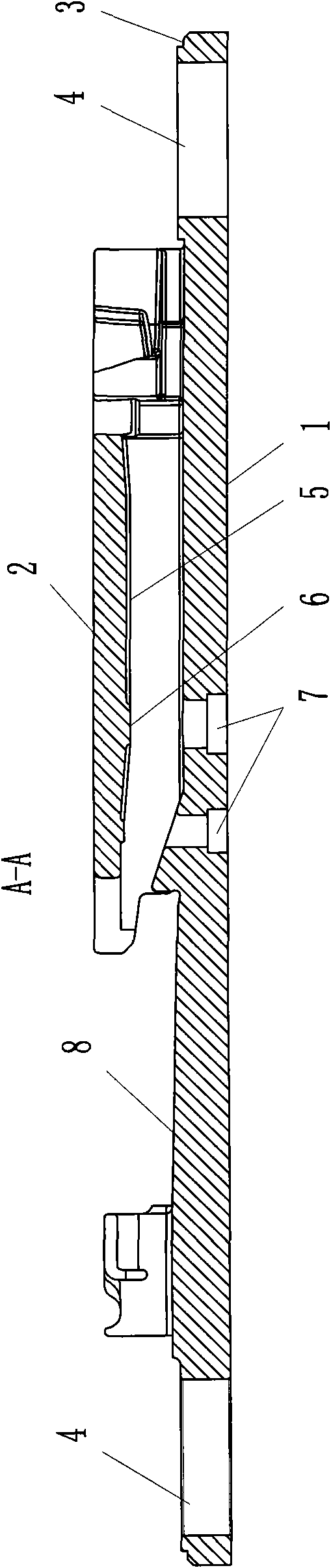

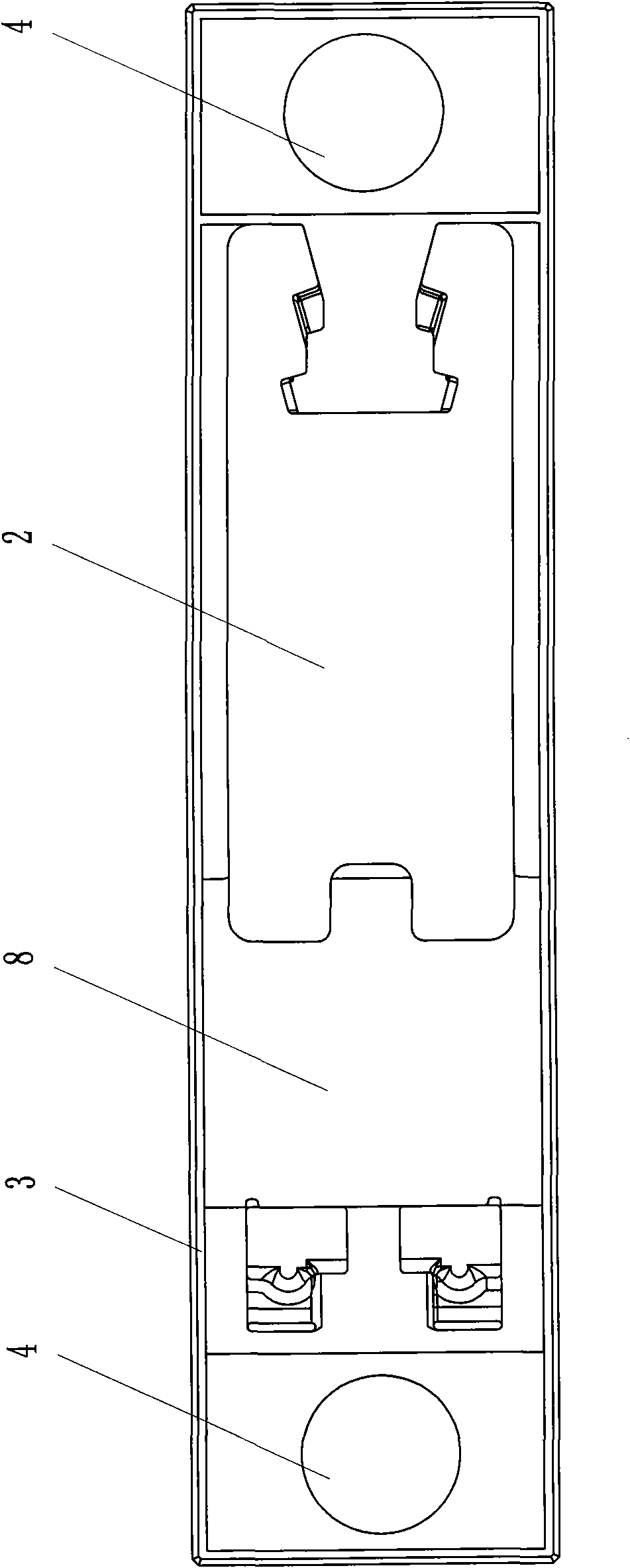

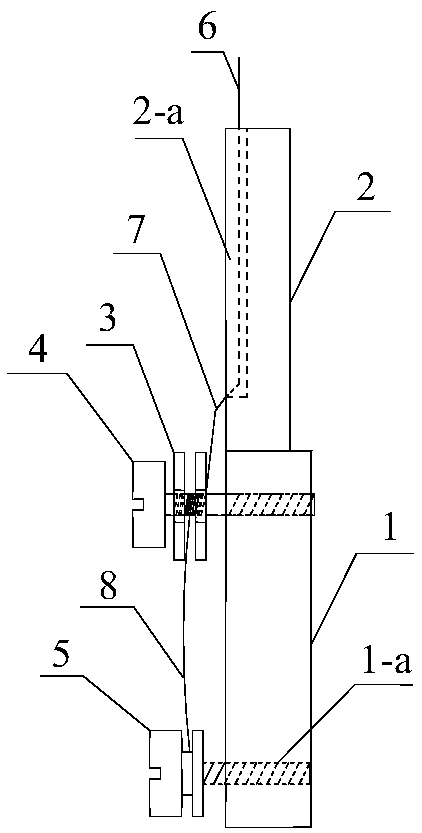

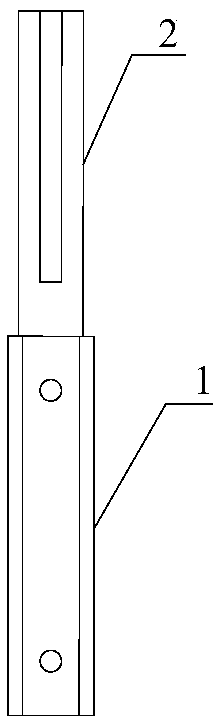

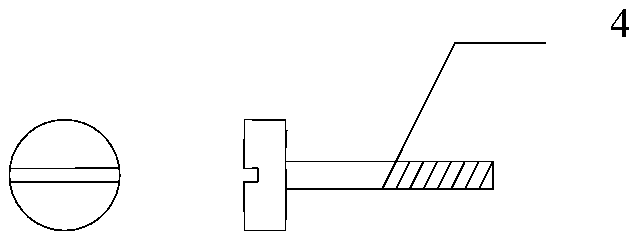

Adjustable electrochemical testing electrode clamp

The invention discloses an adjustable electrode clamp, and belongs to the field of material electrochemical performance testing devices. The adjustable electrode clamp comprises a clamp main body, a cylinder and a screw; the cylinder comprises two cylinder bodies which have the same center but different diameters and are connected vertically, the upper cylinder body is provided with a slot, a conductive bar can be placed in the slot, a slot surface is formed in the lower cylinder body, is parallel to the upper cylinder body and is a plane, and the lower cylinder body is provided with two threaded holes with the same diameter; a round hole of which the diameter is greater than that of the threaded holes is formed in the middle of a gasket, a long screw is fixed on the threaded hole of the upper end through two gaskets,, a threaded end can be wound with a wire through the round hole, a slot is formed in an A-A end of a short screw, and the short screw is fixed on the threaded hole at thelower end; a sample to be tested is fixed between the slot of the short screw and the gasket of the long screw; and the requirement for controllable deformation of the sample to be tested in piezoelectric test is solved, and moreover, all materials are polytetrafluoroethylene which resists corrosion of acid and alkali and is low in cost.

Owner:HAINAN UNIVERSITY

Manufacturing technology for carburizing steel gear

The invention discloses a manufacturing process of a 20CrMo carburizing steel gear, comprising the following steps: forging billet → normalizing → machining → incomplete annealing → machining → carburizing and quenching → tempering → shot blasting, wherein the incomplete annealing process Under the protection of the atmosphere, keep it warm for 2 hours at the temperature of Ac1+(30-50)°C, and cool it to 700-720°C with the furnace, then air-cool. The manufacturing process of the 20CrMo carburized steel gear of the present invention can not only eliminate the internal stress of the workpiece more thoroughly, but also improve the crystal phase structure of the workpiece, so that the matrix structure of the workpiece is more uniform, and the deformation in the subsequent carburizing and quenching process is smaller. Guarantee the processing accuracy of the workpiece.

Owner:赵敏

Tail wing pouring system and tail wing manufacturing method for aluminum alloy underwater launching tube

The invention discloses a tail wing pouring system for an aluminum alloy underwater launching tube. According to the tail wing pouring system, a horizontal runner and a vertical runner are located on the bottoms of vertical cylinders and communicate with each other, and the horizontal runner communicates with the bottoms of the vertical cylinders; a tail wing casting of the underwater launching tube is located inside the cylindrical area defined by the vertical cylinders and is spaced from the outer side wall of each vertical cylinder by a gap, the top of each vertical cylinder communicates with the corresponding gap, a cavity of the tail wing casting of the underwater launching tube is formed by an inner sand core, and an outline and wings of the tail wing casting of the underwater launching tube, the vertical cylinders and the gaps are formed by outer sand cores. According to the system, the tail wings high in overall strength, water tightness, stability, earthquake resistance, corrosion resistance and dimensional accuracy can be provided; the method has the advantages that the process is simple, the operation is convenient and the manufacturing cost is low.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

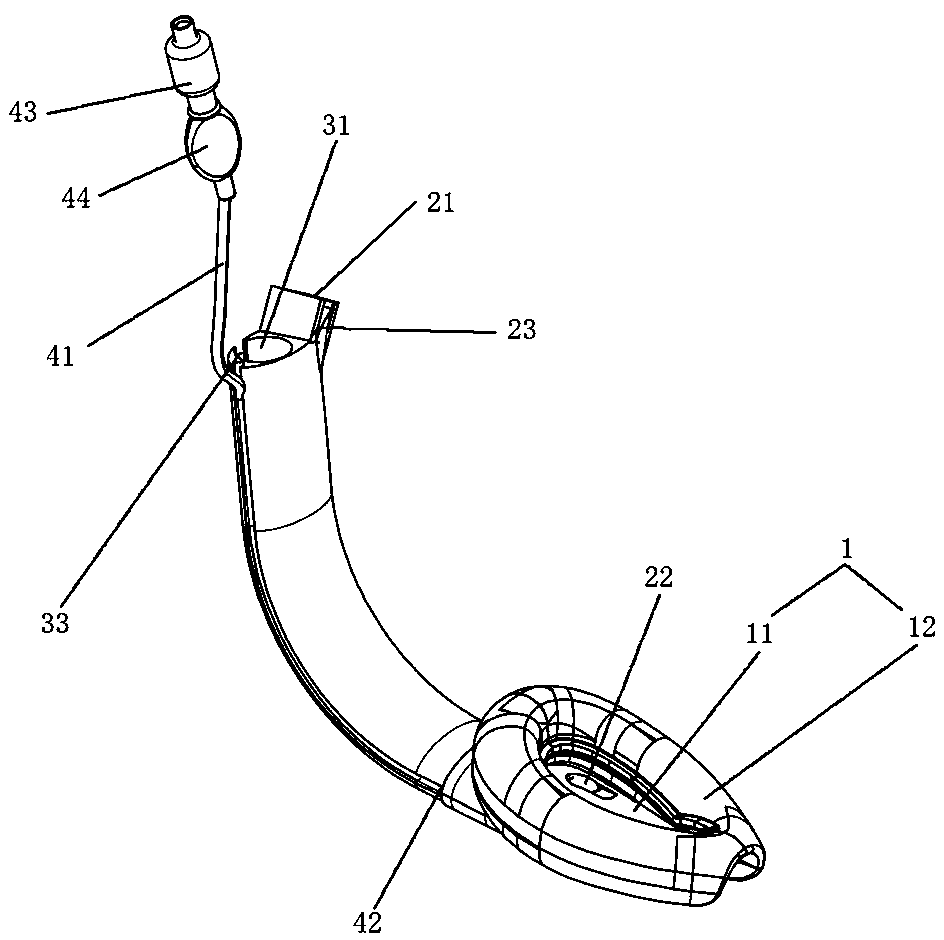

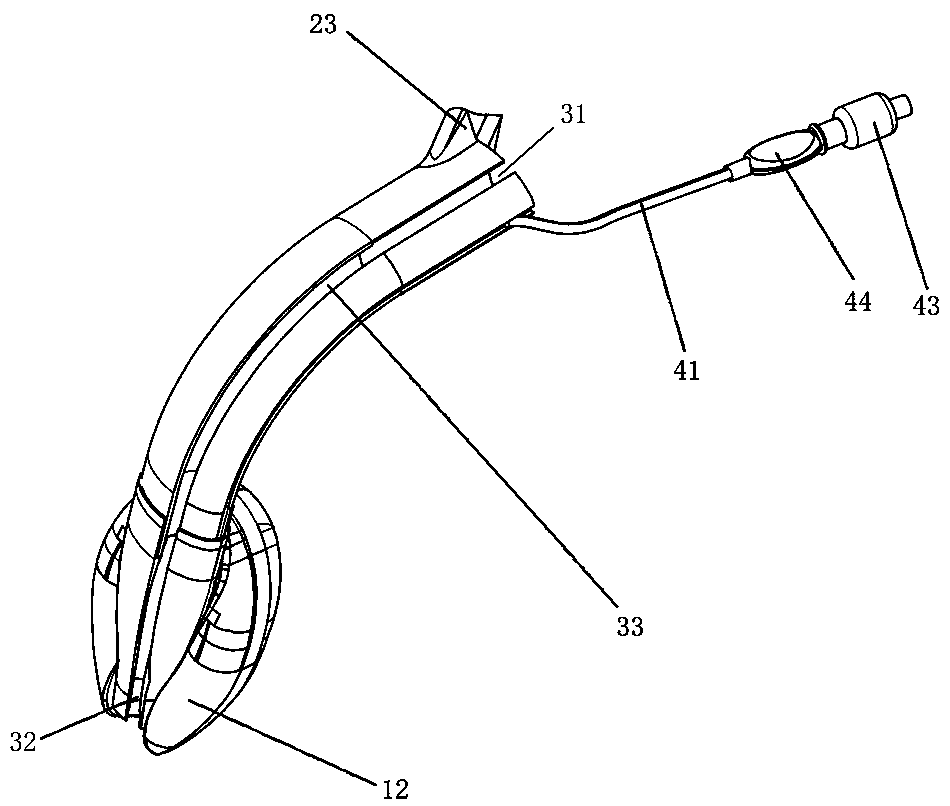

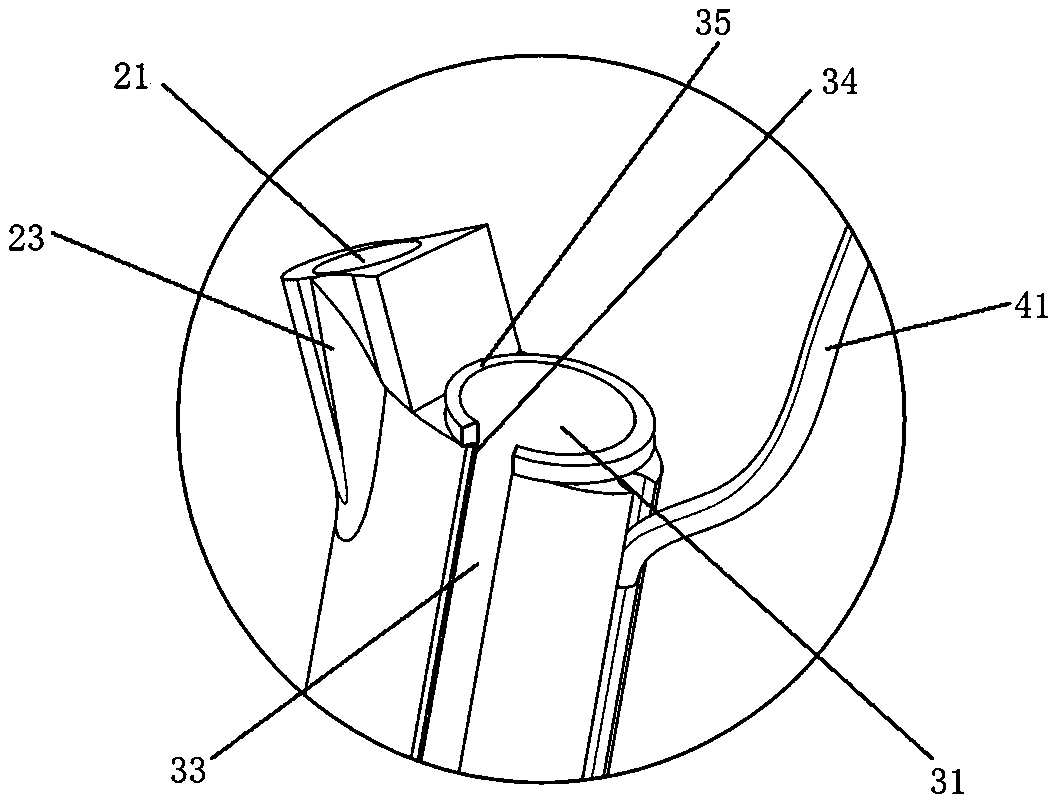

Laryngeal mask capable of dilating and used for endoscope diagnosis and treatment

PendingCN109621128ANo harm will happenDeformation controllableBronchoscopesTracheal tubesLaryngeal MasksCatheter

The invention discloses a laryngeal mask capable of dilating and used for endoscope diagnosis and treatment, and relates to the technical field of medical instruments. The laryngeal mask comprises a mask bag and an air passage catheter, the mask bag is fixedly connected to the air passage catheter, the air passage catheter comprises an aerating air passage, an endoscope channel and an air fillingtube channel, an aerating inlet, an endoscope inlet and an air filling tube inlet are located in the end, away from the mask bag, of the air passage catheter, the mask bag comprises a basic body and an air bag connected to the basic body, the air bag surrounds the edge of the basic body in an annular shape, the air filling tube inlet is connected to the air bag, the endoscope outlet is connected to the lower surface of the basic body and points to the front side of the basic body, a dilating opening which extends from the endoscope inlet to an endoscope outlet is formed in the back face of theendoscope channel, and the air bag becomes smaller easily and gradually from the rear side of the basic body to the front side. The laryngeal mask can effectively dilate and deform so that an endoscope can be inserted.

Owner:ANJI JENSTON MEDICAL TECH CO LTD

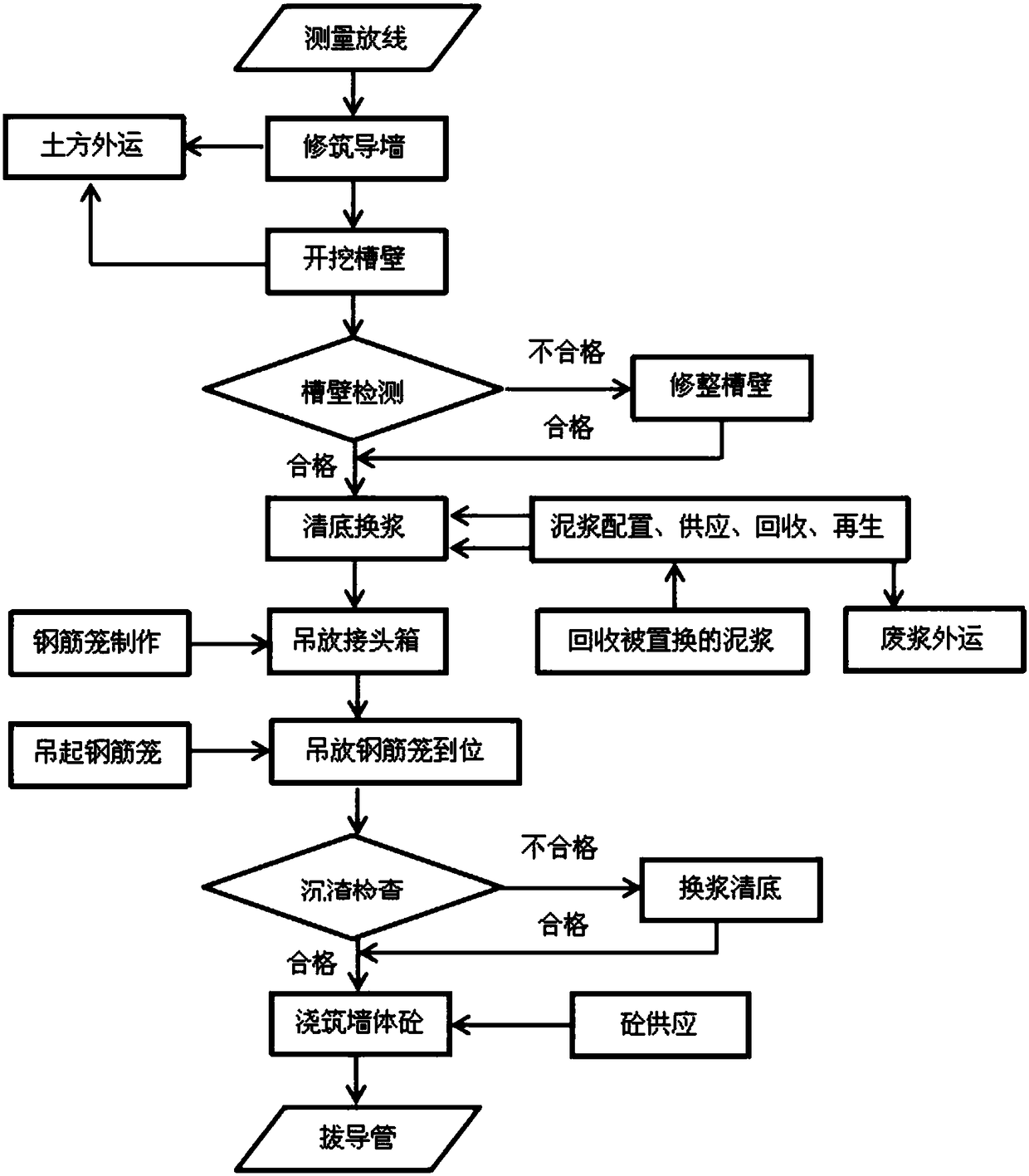

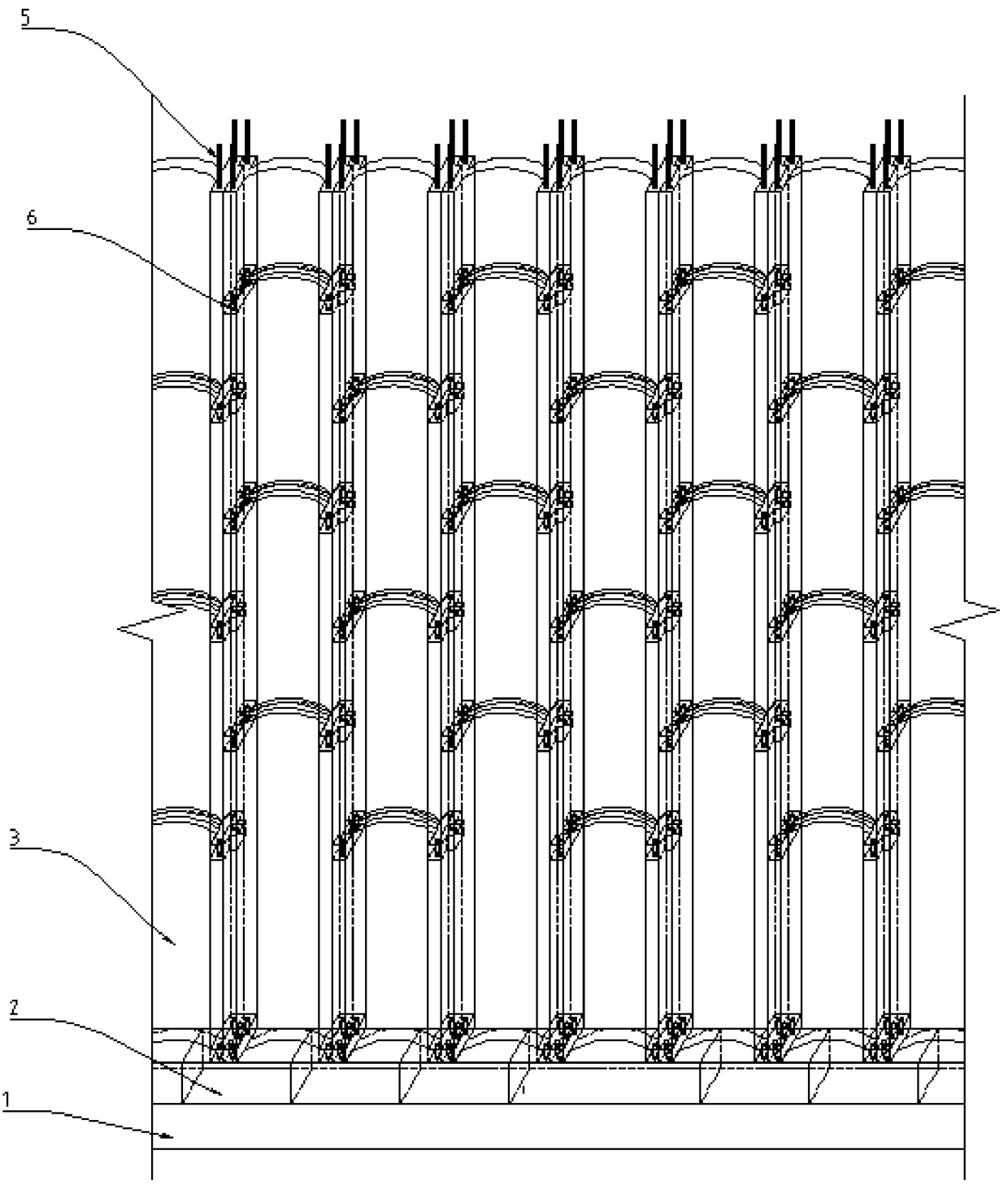

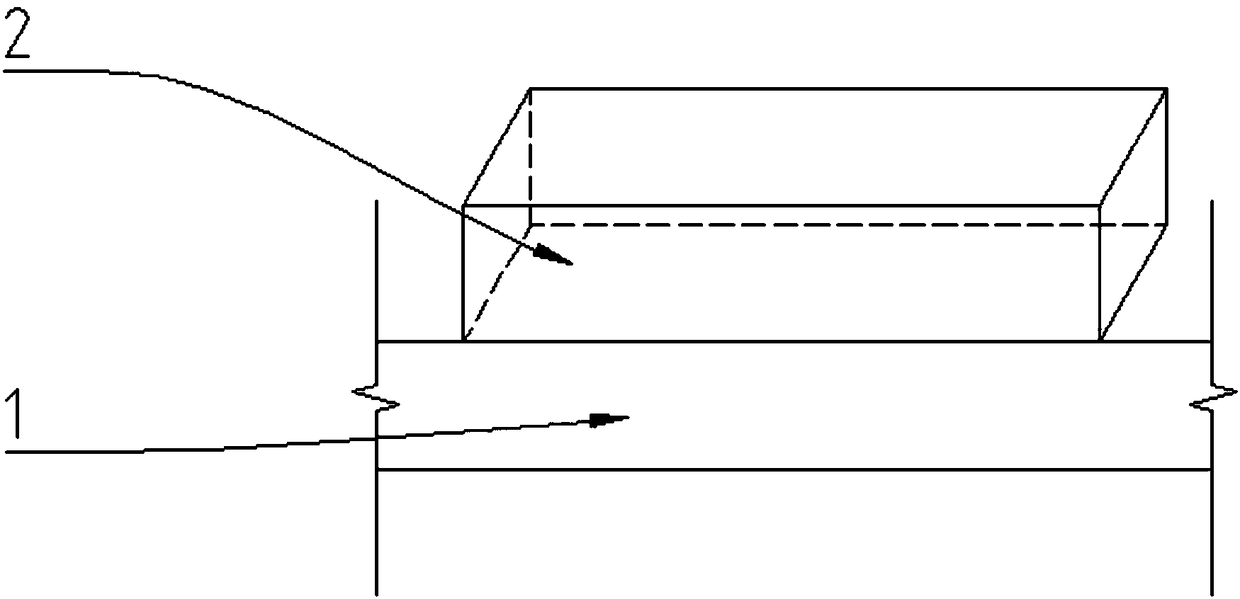

Prefabricated underground diaphragm wall capable of being integrally recycled, hanging tool and construction method

ActiveCN108221955ASolve the cost problemSolve the long construction periodBulkheads/pilesSlurry wallEngineering

The invention discloses a prefabricated underground diaphragm wall capable of being integrally recycled, a hanging tool and a construction method. The diaphragm wall comprises a concrete cushion, an arch bar beam base and a spliced diaphragm wall which are successively arranged from bottom to top, wherein the spliced diaphragm wall is formed by splicing a plurality of arch bar beam members, continuous round steel and a rubber steel plate base; the arch bar beam members have different length models, and long arch bar beam members and short arch bar beam member are arranged transversely and longitudinally in a staggered manner, and the upper and lower arch bar beam members in cutting depth are connected through an arc-shaped pipe piece bolts. The diaphragm wall is formed by means of the structure by splicing the arch bar members, so that the diaphragm wall is compact in connection, good in integral performance and easy to control deformation of wall. The diaphragm wall can be also hoisted out integrally in accordance with specific conditions, and is recycled repeatedly, so that the resources are saved and the diaphragm wall is economical and environment-friendly.

Owner:CHINA UNIV OF MINING & TECH

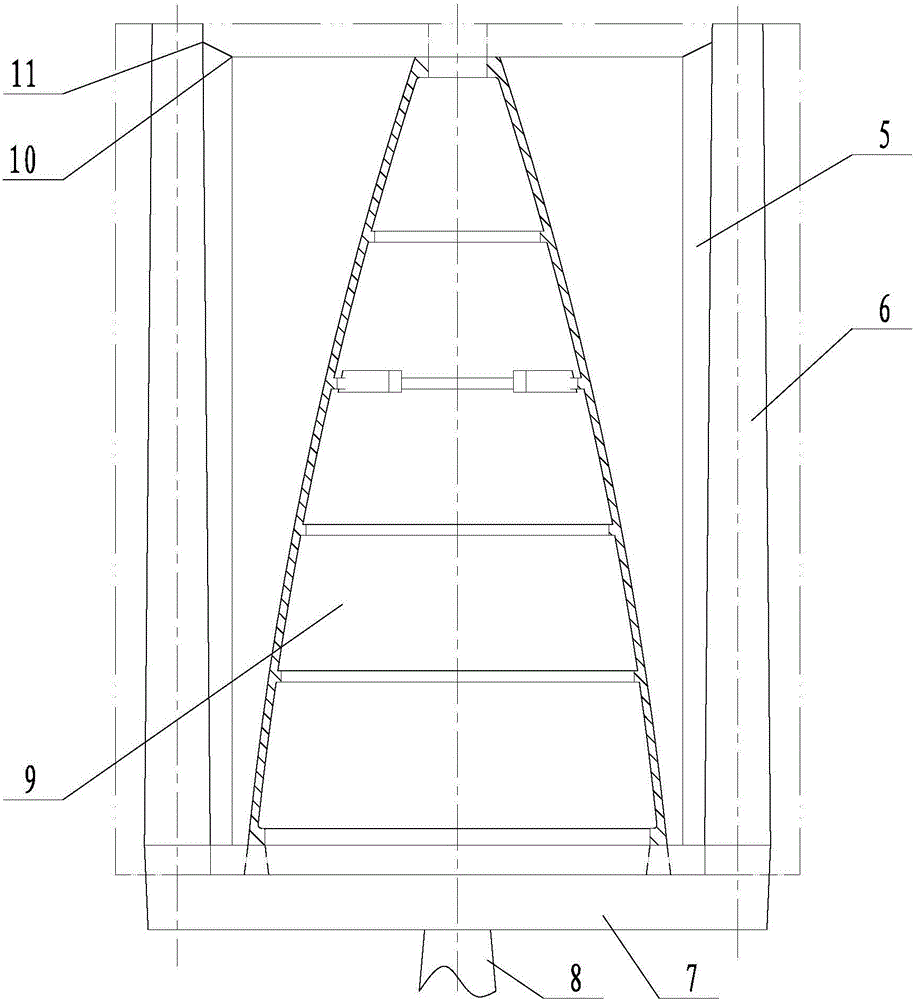

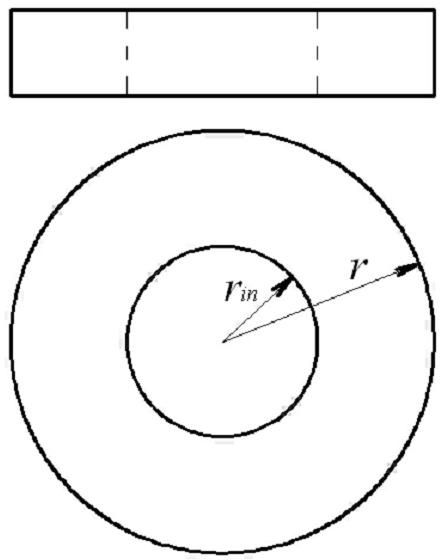

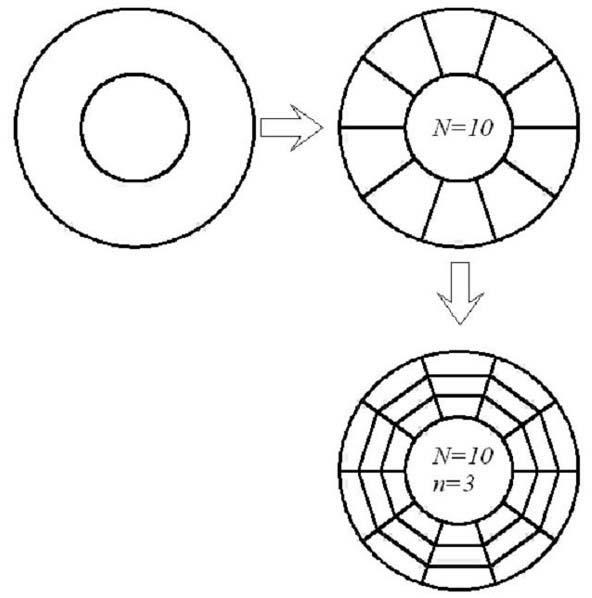

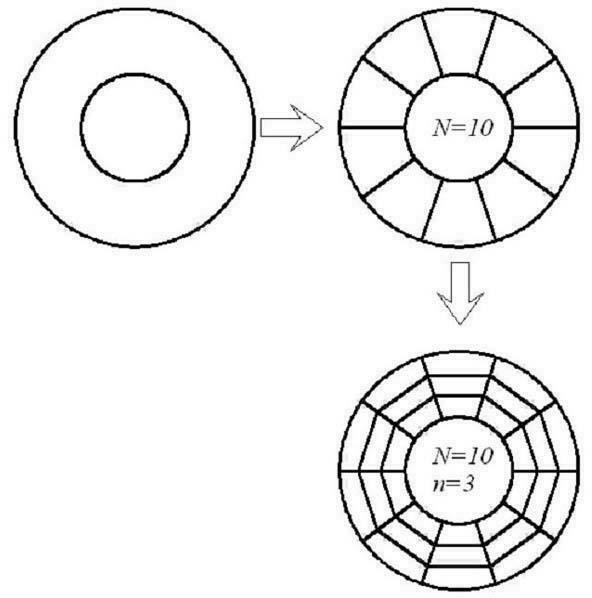

Segmentation dividing method of cylindrical deep sea drilling platform basement built based on semi-submersible barge

InactiveCN102673735AReduce the number of liftingImprove the efficiency of segmented constructionVessel partsFloating buildingsBasementGeomorphology

The invention relates to the field of marine engineering equipment, in particular to a segmentation dividing method of a cylindrical deep sea drilling oil storage platform basement built based on a semi-submersible barge. The method includes that: the cylindrical deep sea drilling oil storage platform basement is symmetrically and equally divided into N sector-shaped columns in the circumferential direction from top to bottom, and N is an integer; each sector-shaped column is divided into N quadrilateral columns from top to bottom in the direction of the radius of each sector-shaped column, N is an integer and the dividing standard is that top-to-bottom projection areas of the quadrilateral columns are identical; and each quadrilateral column is one segment of the cylindrical deep sea drilling oil storage platform basement. The segmentation dividing method enables the total number of segments of the basement to be the minimum, reduces segment hoisting times and improves the segment building efficiency of the cylindrical deep sea drilling oil storage platform basement. Straight-line welding joints are reserved between the segments, worker construction is fast, deformation of the welding joints can be controlled easily, and the segmentation dividing method improves economic benefit of plants compared with arc welding joints due to the fact that no special welding devices are needed.

Owner:JIANGSU UNIV

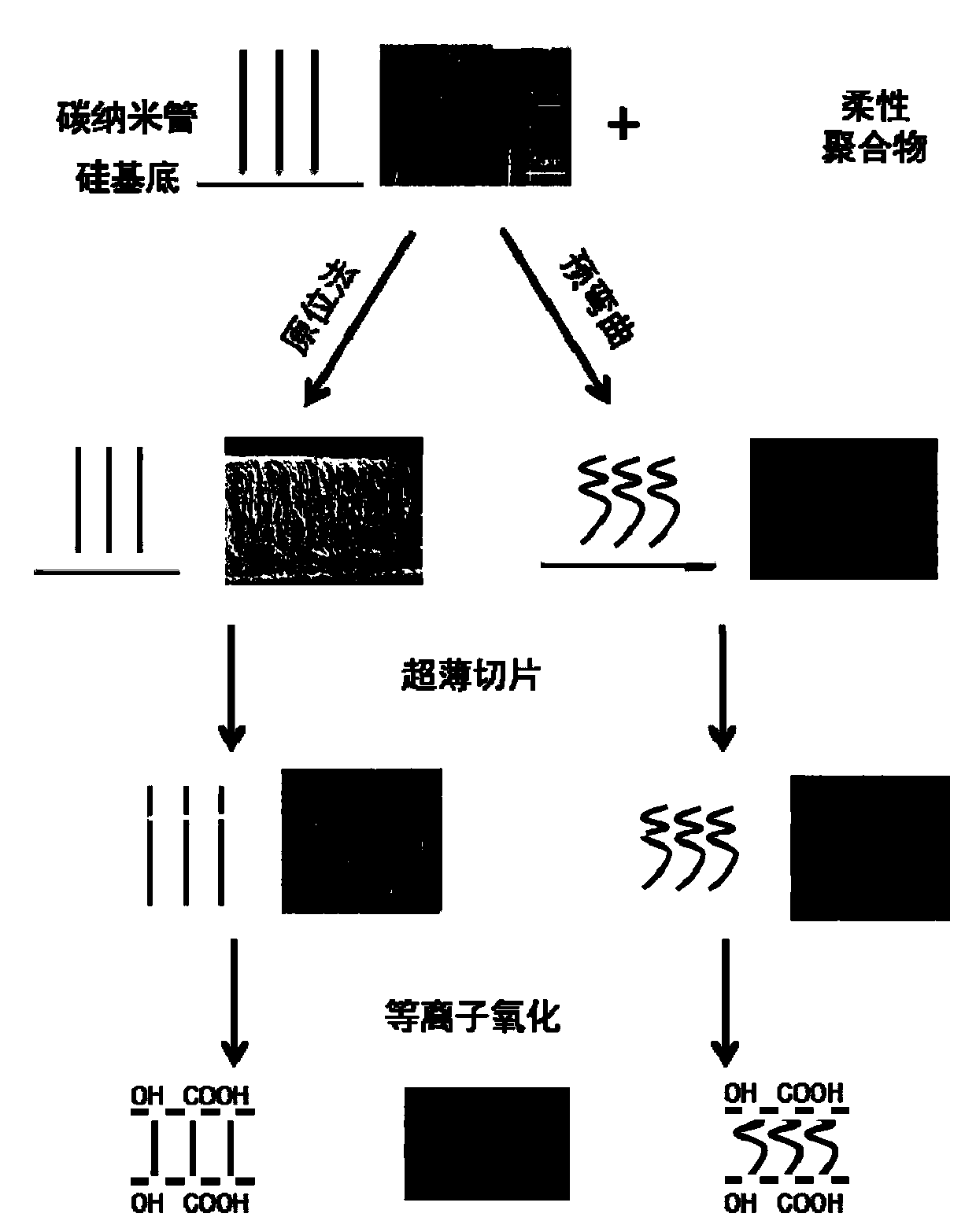

Dynamic nanochannel and preparing and testing methods thereof

ActiveCN110527296AGuaranteed testingRealize dynamic deformationMaterial analysis by electric/magnetic meansNanotechnologyIonNanometre

The invention relates to a dynamic nanochannel and preparing and testing methods thereof. A flexible nano hole channel capable of dynamically deformation is prepared from a carbon nanotube array and aflexible polymer which are composited, a corresponding device is designed to research the transport property of ions in the flexible nano hole channel, the conditions are controlled, thus the array is dynamically deformed at different degrees, and the property of ion transport during dynamic deformation is researched. By combining with special properties of an ion solution in the dynamic nano hole channel, the preparation method is a novel method for researching the dynamic nanochannel. Different from a traditional preparation method of the nano hole channel, the carbon nanotube array and thepolymer are composited, thus the flexible nano channel capable of dynamically deformation is prepared easily and conveniently, and meanwhile, the ion transport property of the nanochannel in the dynamic deformation process can be researched.

Owner:XIAMEN UNIV

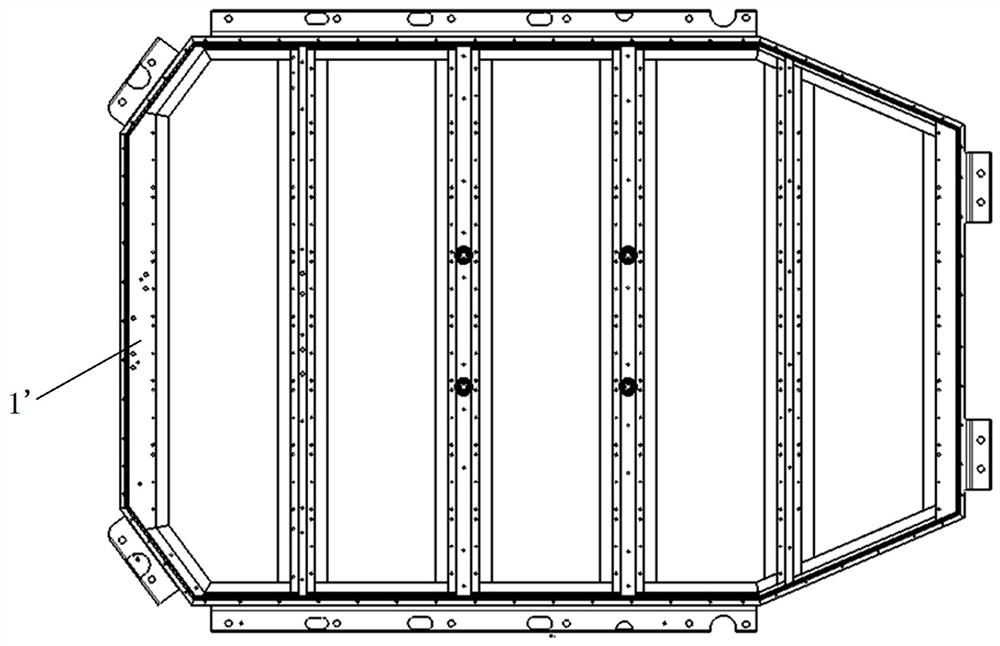

Anti-collision tray frame beam structure of power battery energy storage system and production method thereof

ActiveCN112599904AControllable deformationReduce internal damageCell component detailsPower batteryEnergy absorption

Owner:上海捷新动力电池系统有限公司

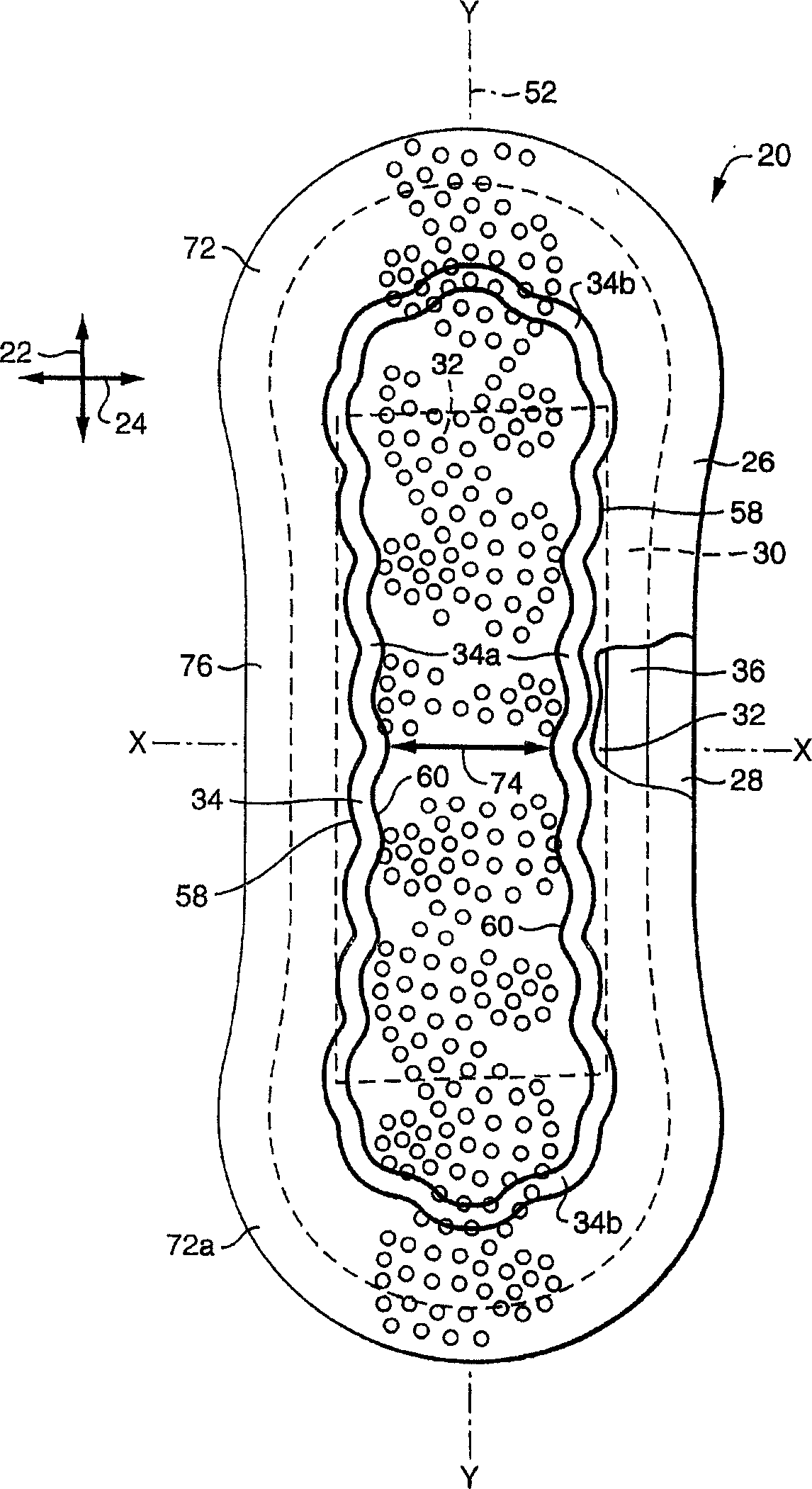

An absorbent article with an embossment along the perimeter

ActiveCN1750802ADeformation controllableEasy to guideSanitary towelsBaby linensMechanical engineeringEngineering

Owner:KIMBERLY CLARK (CHINA) CO LTD

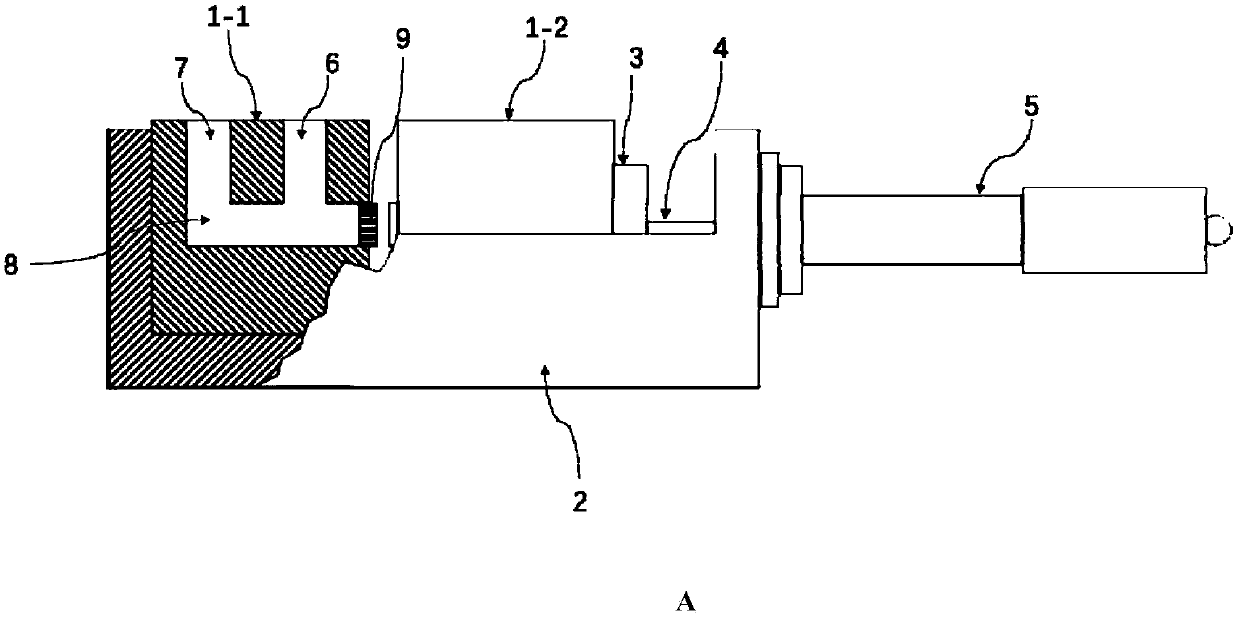

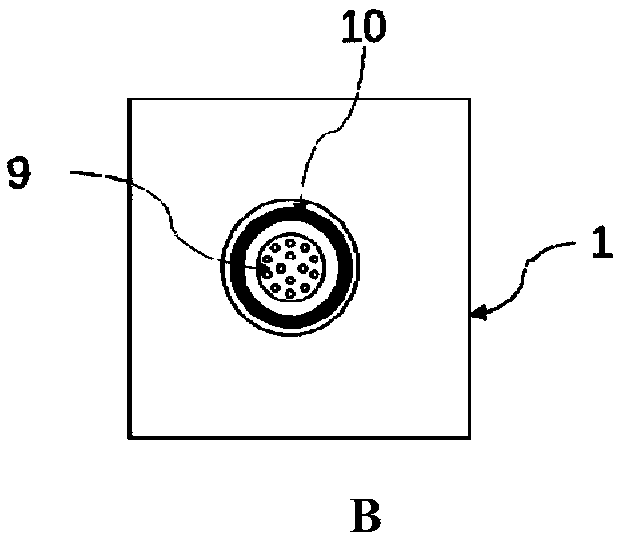

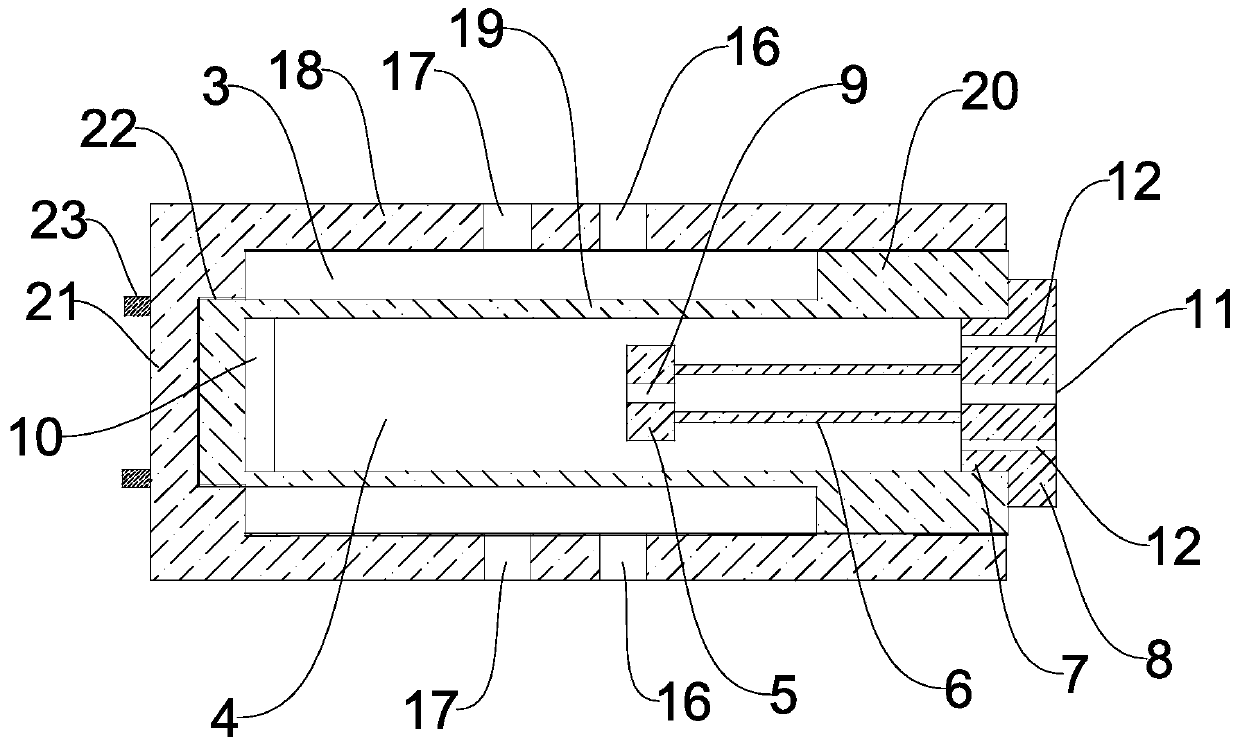

Preparation system for low-boiling-point light-gas gun loading test sample and use method

PendingCN111220447AImprove cooling effectRapid coolingLiquefactionPreparing sample for investigationPoint lightCooling chamber

The invention relates to the technical field of impact compression, and particularly relates to a preparation system of a low-boiling-point light-gas gun loading test sample and a use method thereof.The system comprises a target device, a cooling mechanism and a sample preparation mechanism, wherein the target device comprises a sample chamber and a cooling chamber. The sample chamber is arrangedin the cooling chamber or the cooling chamber is arranged around the sample chamber; a sensor unit is arranged on the side wall of the sample chamber, and the sensor unit is used for detecting the temperature and the pressure in the sample chamber; the cooling mechanism comprises a cooling liquid tank, a cooling liquid inlet pipe and a cooling liquid outlet pipe; and the sample preparation mechanism comprises a sample gas storage tank, a sample injection pipe, a vacuum pump and a connecting pipe. According to the invention, the temperature of the sample in the sample chamber of the target device can be reduced to hundreds of DEG C below zero in an extremely short time according to the temperature requirement of an experiment, pure and stable samples such as liquid nitrogen and liquid hydrogen can be rapidly prepared in a short time, and the system has important significance for promoting the high-pressure research of low-boiling-point samples such as liquid nitrogen and liquid hydrogen.

Owner:SOUTHWEST JIAOTONG UNIV

Unmanned underwater equipment capable of stably running underwater

ActiveCN107839835ASolve the problem of being hitPlay a shock absorbing roleUnderwater vesselsUnderwater equipmentMarine engineeringUnmanned underwater vehicle

The invention discloses unmanned underwater equipment capable of stably running underwater. The unmanned underwater equipment includes an unmanned underwater vehicle, the unmanned underwater vehicle is coated with a shell matched with the shape of the unmanned underwater vehicle, the head and tail of the unmanned underwater vehicle are both located outside the shell, a cavity is formed between theshell and the unmanned underwater vehicle, a plurality of dampers which connect the shell and the unmanned underwater vehicle are installed in the cavity, openings of the two end faces of the shell are provided with elastomers for plugging the openings, through holes for the unmanned underwater vehicle to penetrate through are formed in the elastomers, and the elastomers are fixedly connected with the unmanned underwater vehicle. According to the unmanned underwater equipment capable of stably running underwater, the design of the shell solves the problem that the unmanned underwater equipment is stricken.

Owner:四川嘉义索隐科技有限公司

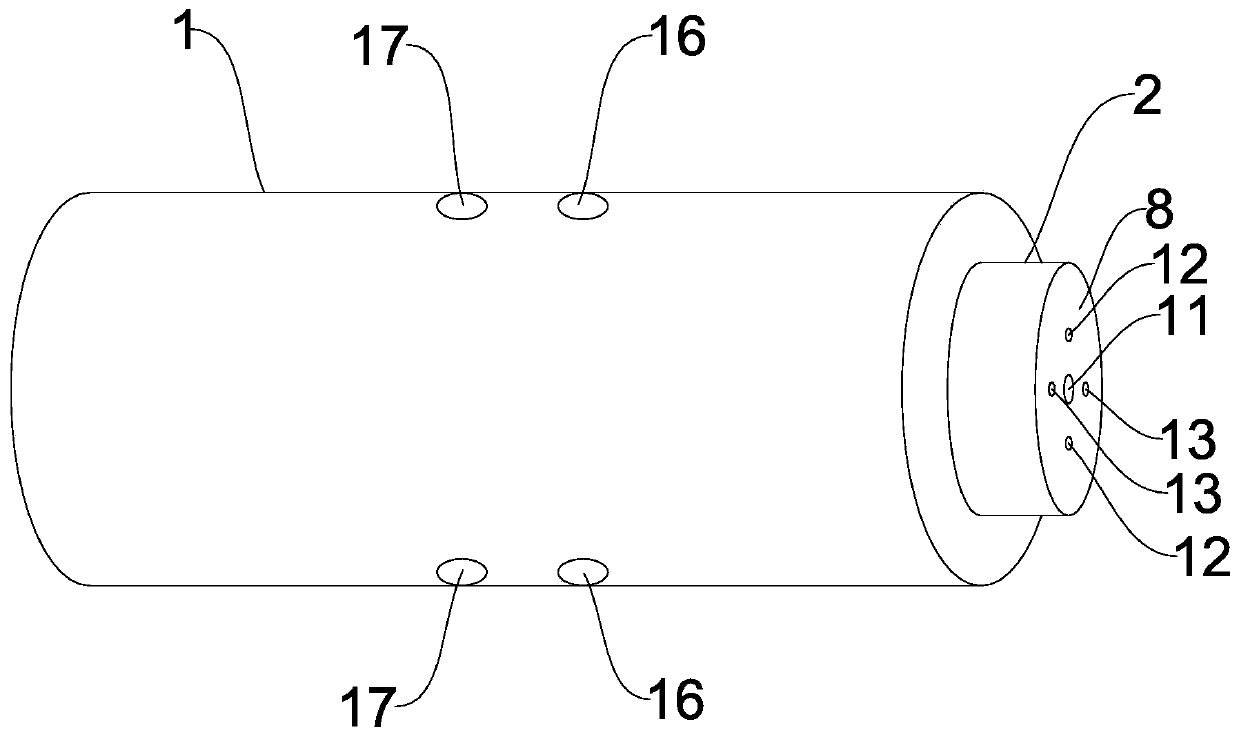

Heating target device for light-gas gun loading experiment and using method of heating target device

InactiveCN110927188AControllable deformationGuaranteed tightnessMaterial analysis using wave/particle radiationMechanical engineeringLight-gas gun

The invention relates to the technical field of impact compression, in particular to a heating target device for a light-gas gun loading experiment and a using method thereof. The device comprises a target outer body and a detection mechanism, wherein a sample bin and a heating chamber are arranged in the target outer body; an electric heating unit is arranged in the heating chamber; the detectionmechanism comprises a window, a detection tube and a fixing table which are sequentially arranged from left to right, wherein a temperature detection unit is arranged on the window and used for detecting the temperature in the sample bin, a base plate is arranged on the inner wall of the left end of the sample bin, and a temperature detection cable hole and a measurement cable hole are formed inthe fixing table. The heating target device provided by the invention meets the high-temperature experiment requirement of a light gas gun experiment; the main body structure of the target device is made of Q235 steel, so that the target device is ensured to be controllable in deformation at high temperature and under impact pressure of several megapascals, the sealing performance and the stability of the target device in the high-temperature experiment process are ensured, and the target device has important significance for research of a light-gas gun heating loading experiment.

Owner:SOUTHWEST JIAOTONG UNIV

Low-temperature welding process of high-pressure-resistant silicon carbide micro-reaction assembly

The invention discloses a high-pressure-resistant silicon carbide micro-reaction assembly and a low-temperature welding process. The process is characterized in that tetraethyl orthosilicate, dimethyldiethoxysilane and trimethyl borate are dissolved in ethanol, silicon carbide powder is added into a mixed solution to be coated on the welding surface of a silicon carbide micro-reaction plate, low-temperature welding is carried out in a hot-pressing furnace after slurry coating, cooling is performed to 500 DEG C or below, reheating is performed to 1600 DEG C, heat preservation is performed for 1hour, and secondary cooling is performed to obtain the silicon carbide micro-reaction assembly with the welding thickness. According to the invention, the welding temperature is low, the requirementfor a high-temperature welding furnace is lowered, and the welding cost is reduced; the silicon carbide ceramic is low in softening degree, deformation is easy to control, the depth is easy to control, the welding yield of the silicon carbide micro-reaction assembly is increased, and the welding cost is reduced; the silicon carbide micro-reaction assembly obtained by welding through the process ishigh in bonding strength, and the withstand voltage can reach 60 BAR or above; and the binding phase is silicon carbide ceramic which is resistant to strong acid and strong alkali corrosion and can be applied to various harsh reaction conditions.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Method for controlling sample deformation based on 3D printing technology

ActiveCN112248446AMany types of deformationImprove controllabilityAdditive manufacturing apparatus3D object support structures3d printMechanical engineering

Owner:HUAZHONG UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com