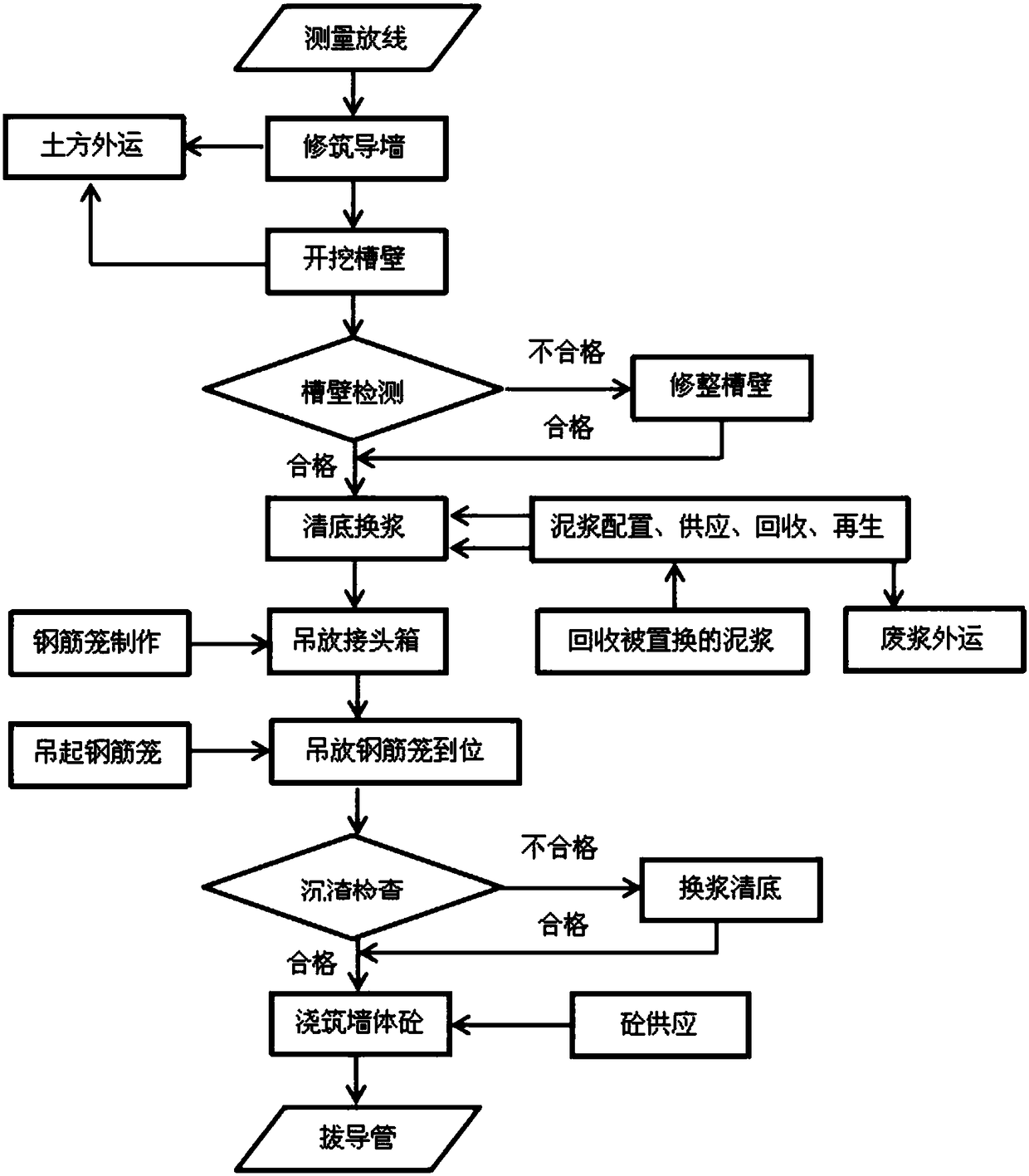

Prefabricated underground diaphragm wall capable of being integrally recycled, hanging tool and construction method

An underground continuous wall and integral technology, applied in sheet pile walls, infrastructure engineering, buildings, etc., can solve the problems of adjacent buildings and underground pipeline hazards, difficult to install detection devices, settlement and other problems, and achieve easy control of wall deformation and overall Good performance, tight connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing.

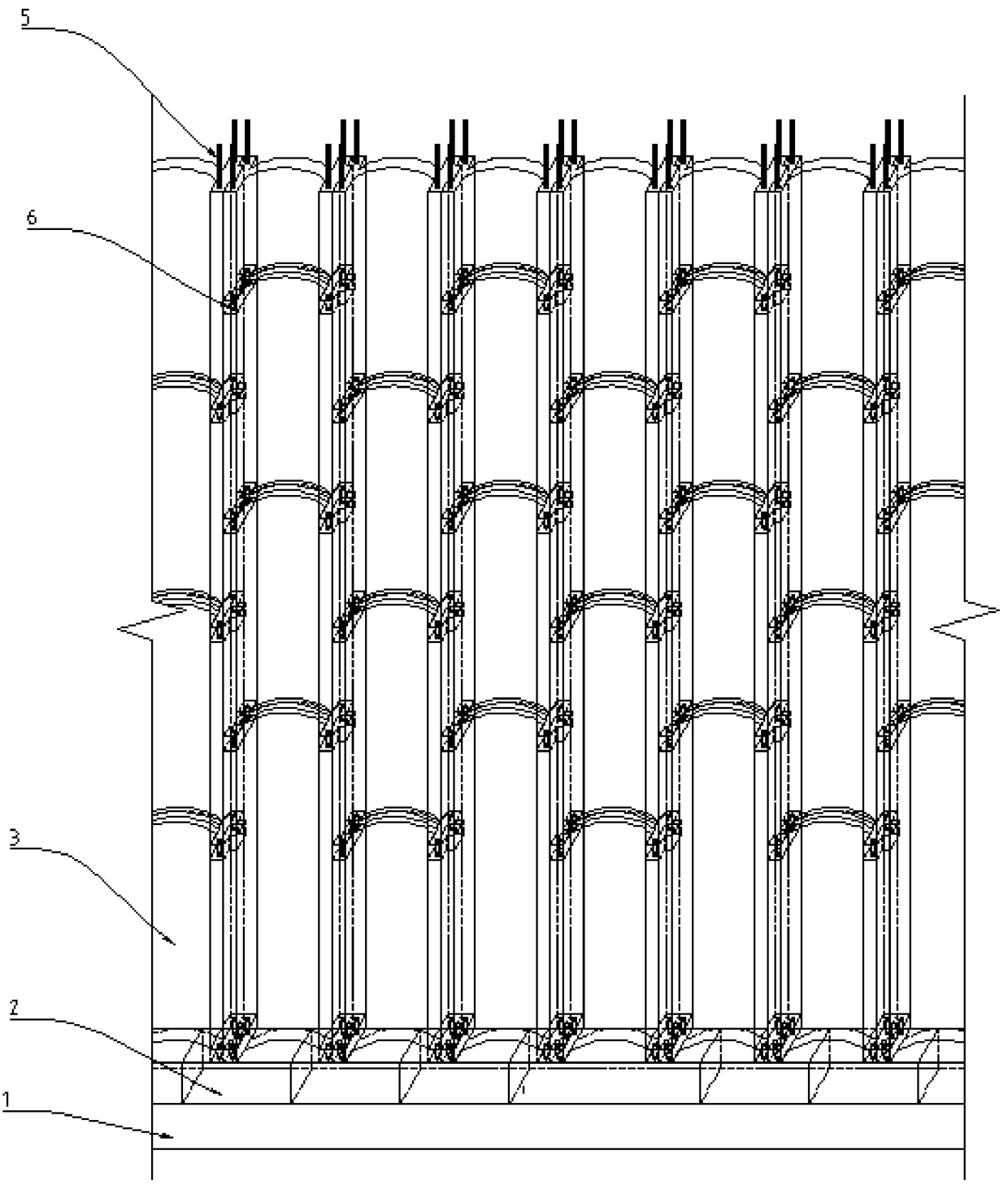

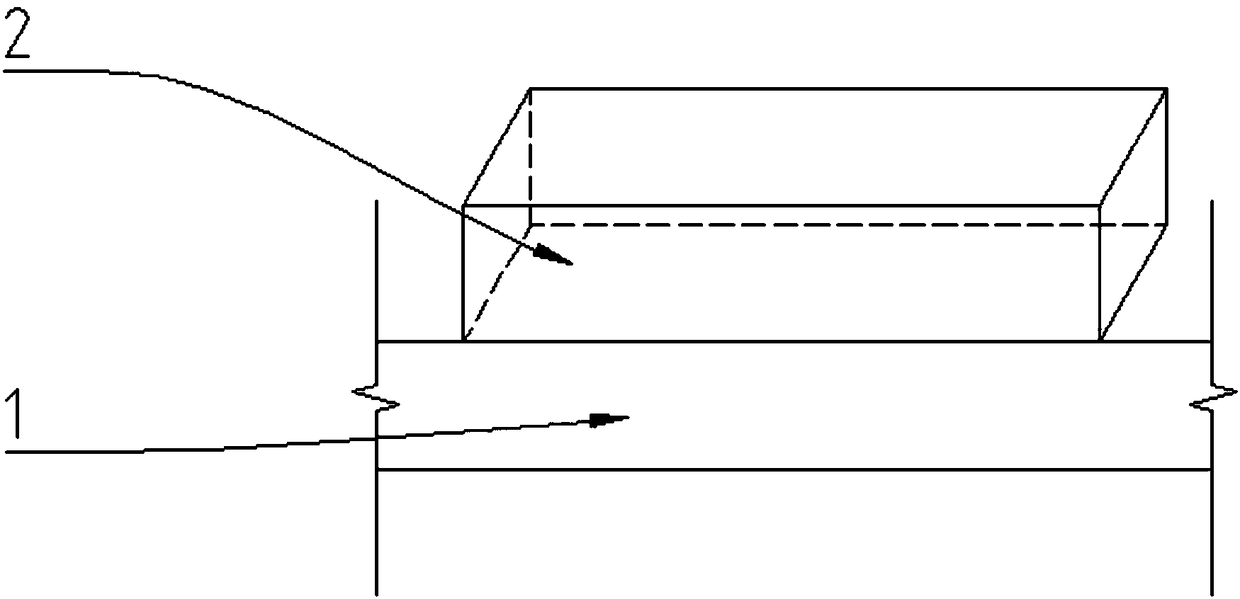

[0048] like Figure 2 to Figure 8 As shown, a prefabricated underground diaphragm wall that can be recycled as a whole includes a concrete cushion 1, an arch beam base 2 and an assembled diaphragm wall 3 arranged sequentially from bottom to top; wherein the assembled diaphragm wall 3 is composed of several arch beam members 4 , the long round steel 5 and the rubber steel plate base 6 are assembled;

[0049] Described arched plate beam member 4 comprises arched plate 41, left vertical beam 42 and right vertical beam 43, and the two ends of arched plate 41 are respectively connected in the middle of left vertical beam 42 and right vertical beam 43, on arched plate 41 The end faces protrude from the upper end faces of the left vertical beam 42 and the right vertical beam 43, and the lower end surface of the arched plate 41 is recessed into the lower end faces of the left vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com