Saline-soil light curing agent and method for treating saline soil with saline-soil light curing agent

A saline soil and curing agent technology, applied in the field of soil curing, can solve the problems of saline soil foundation and roadbed filling without effective and reasonable treatment methods, great damage to the upper structure, and uneven buildings, so as to reduce the quality and solve the problem. The effect of high cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Since the salt content of general coastal saline soil is mostly 1% to 3%, generally no more than 5%, there is currently no effective and reasonable treatment method for saline soil with high salt content, so this embodiment adopts a higher salt content 4% saline soil was tested.

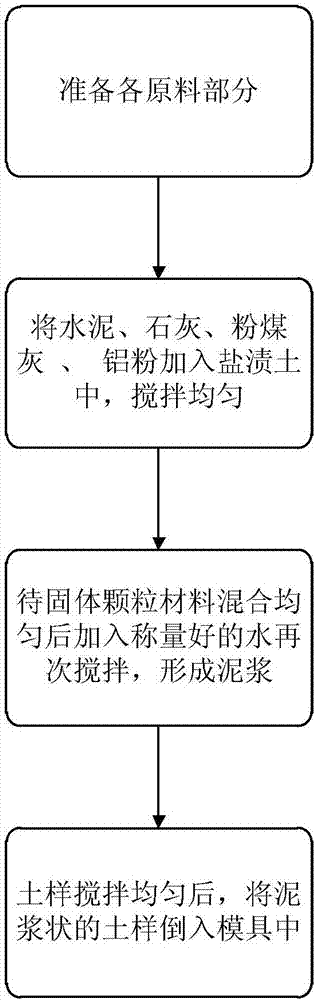

[0043] according to figure 1 As shown in the flow chart, the specific method for treating saline soil is as follows:

[0044] (1) Prepare each raw material component in the following manner:

[0045] A: Weigh the saline soil. In order to ensure the uniformity of the soil particles, pass the pulverized saline soil through a 1mm sieve, and weigh 55% water by weight based on the dry soil weight;

[0046] B: taking the weight sum of saline soil and water as a benchmark, weigh 14.23% curing agent (wherein 5.0% cement, 2.6% lime, 6.5% fly ash, 0.13% aluminum powder);

[0047] (2) Add cement, lime, fly ash, and aluminum powder into the saline soil, stir well, and the stirring time should not be le...

Embodiment 2

[0051] With embodiment 1, difference is only in the content of curing agent: take the weight sum of saline soil and water as a benchmark, weigh 17.86% curing agent (wherein 6.0% cement, 3.9% lime, 7.7% pulverized coal Ash, 0.26% aluminum powder).

Embodiment 3

[0053] With embodiment 1, difference is only in the content of curing agent: take the weight sum of saline soil and water as a benchmark, weigh 21.52% curing agent (wherein 7.0% cement, 5.2% lime, 9.0% pulverized coal Ash, 0.32% aluminum powder).

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com