Machining technology of slide plate special for passengers

A processing technology, sliding bed plate technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problem of aggravating the dynamic action of the wheel and the tip rail, the tip rail and the backing plate, the longitudinal and lateral stiffness irregularities of the track structure rail, Welding deformation control is difficult and other problems, to achieve the effect of easy flow operation, simplifying the associated dimension chain, and obvious shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

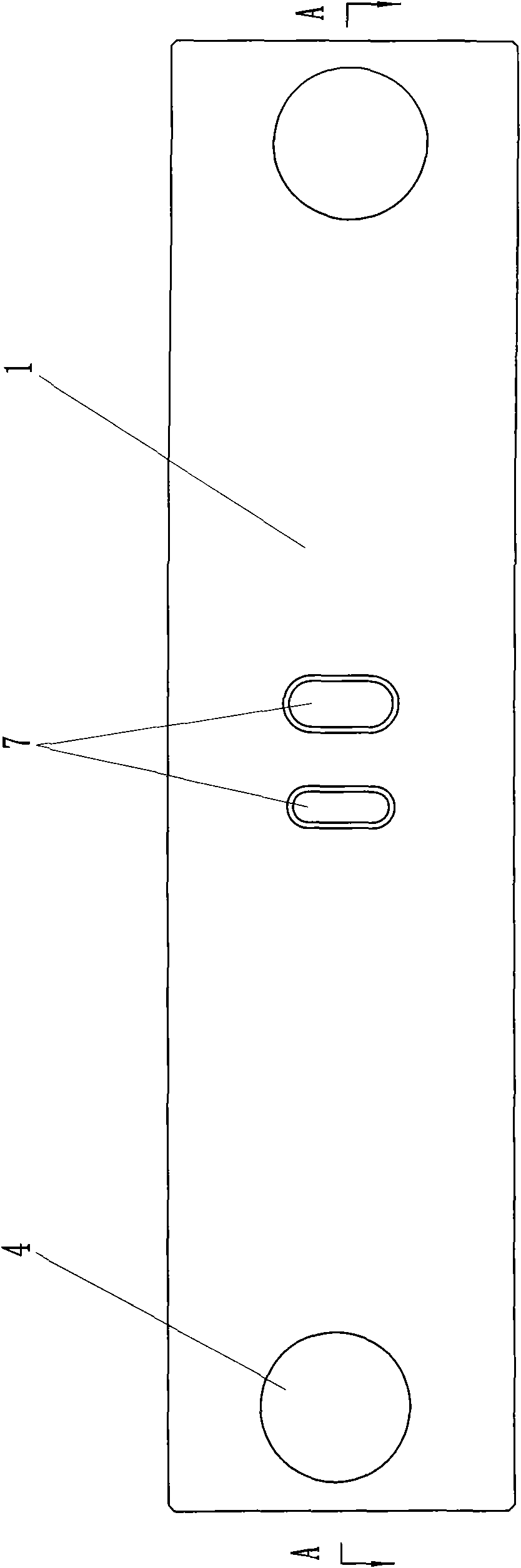

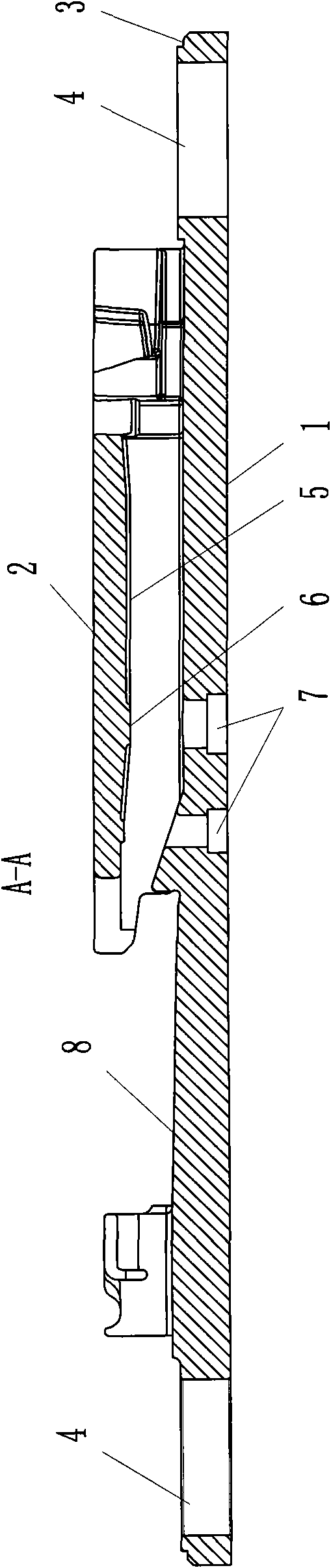

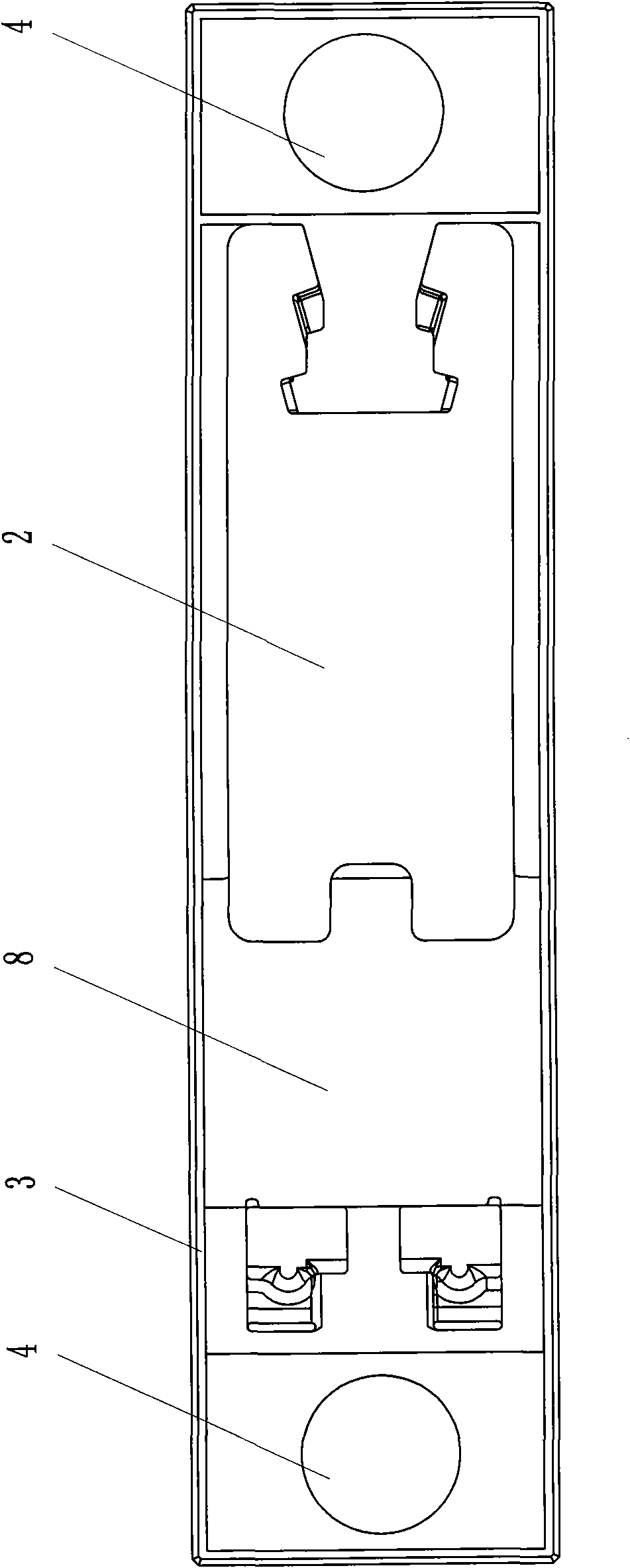

[0025] The present invention is a kind of customer special sliding bed plate processing technology, adopts the following steps:

[0026] a. Select the ductile iron grade QT400-18L, the tensile strength is above 400MP, the yield strength is above 250MP, the elongation exceeds 18%, and the impact toughness at room temperature reaches 14J / cm2, expressed in mass percentage, its composition For: carbon: 3.6-3.8%, phosphorus ≤0.06%, silicon: 1.8-2.1%, sulfur: ≤0.02%, manganese: ≤0.15%, titanium: ≤0.04%, and the rest is Fe;

[0027] b. Using the furan resin sand casting process, the backing plate is integrally cast, and a foam ceramic filter is placed at the bottom of the sprue. The riser adopts a thermal insulation riser, and the surface roughness is controlled within Ra50; because the whole cast ductile iron backing plate The size and surface requirements of the casting blank are relatively high, and the ordinary green sand casting process is difficult to guarantee the quality of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com