Patents

Literature

300results about How to "Improve feeding capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

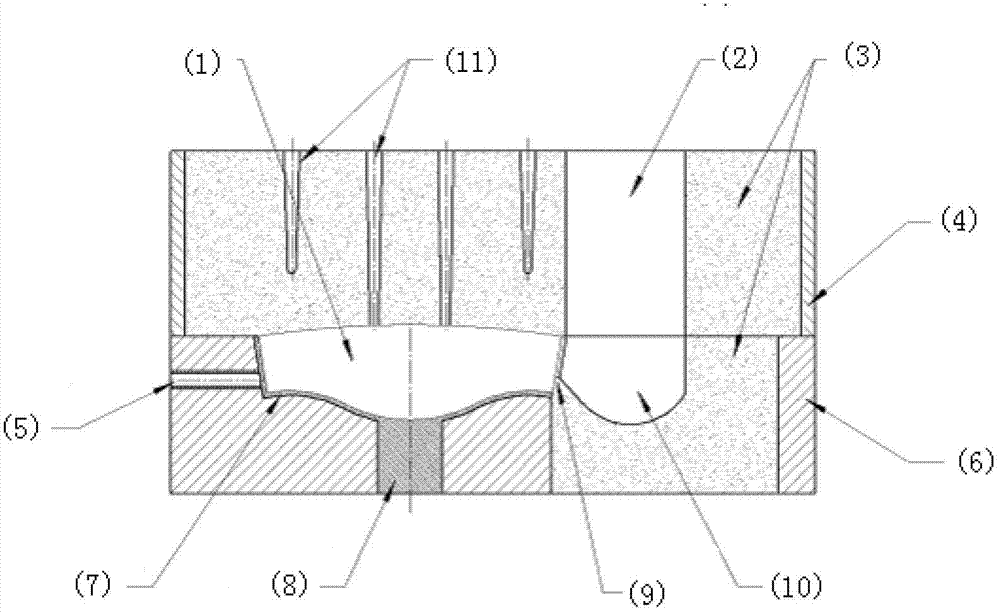

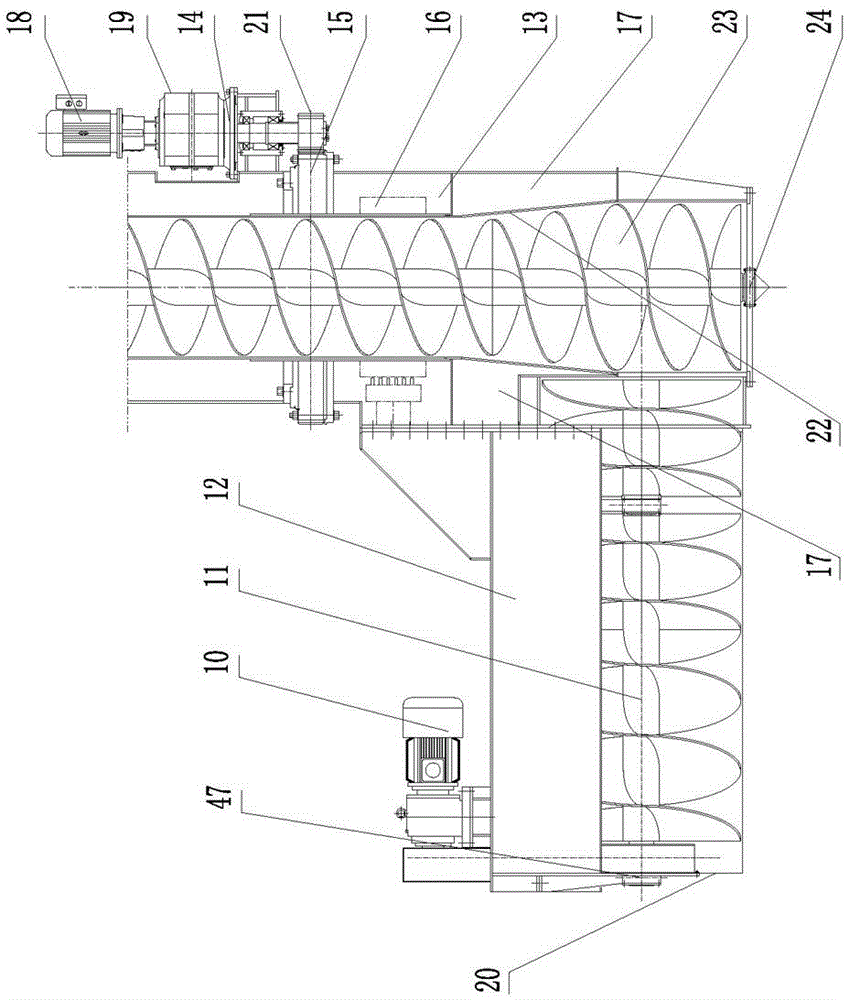

Vacuum low-pressure casting forming device for titanium alloy component

InactiveCN104028729AImprove feeding capacitySuppresses the tendency to segregate chemical componentsActuatorPressure difference

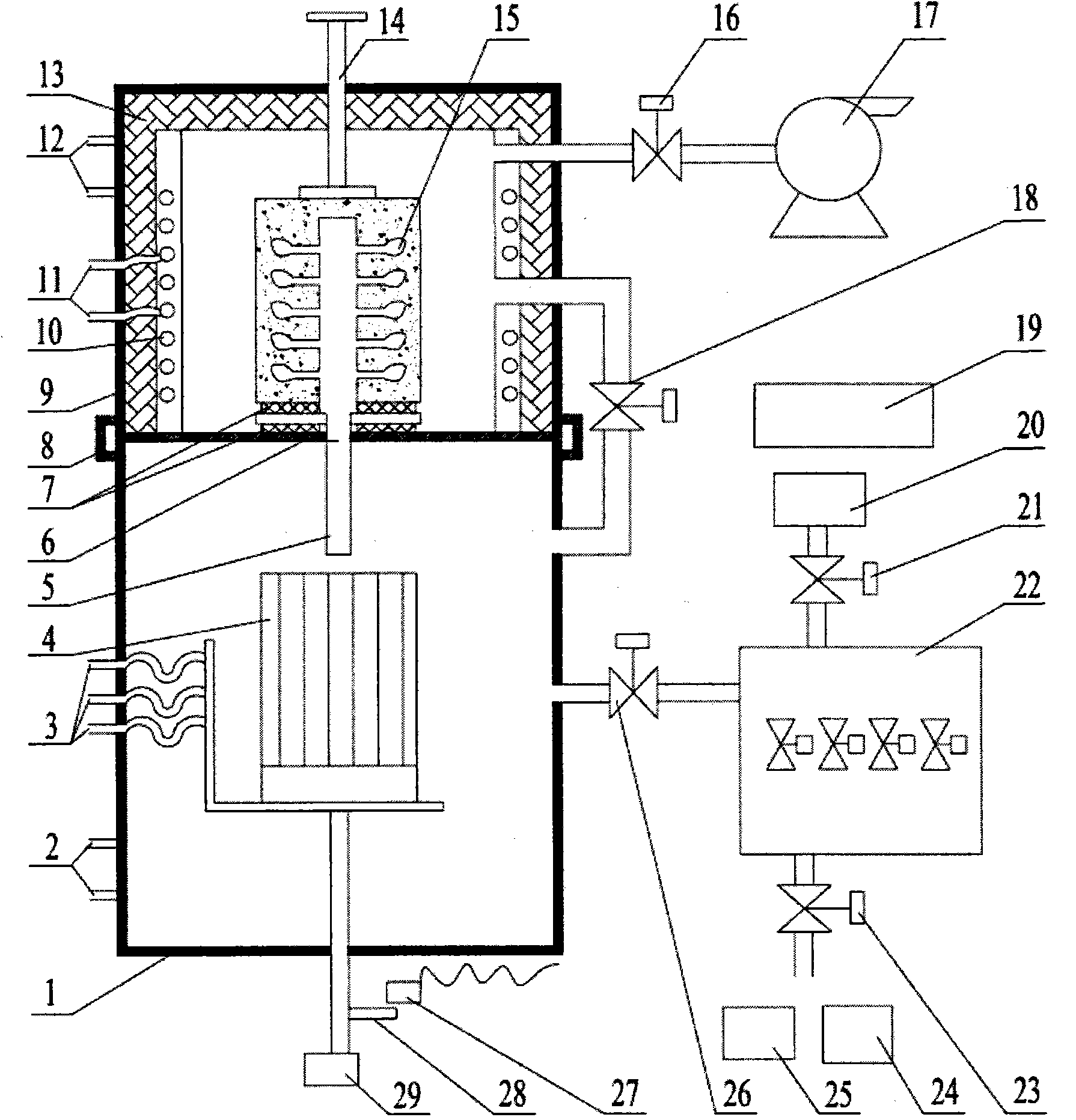

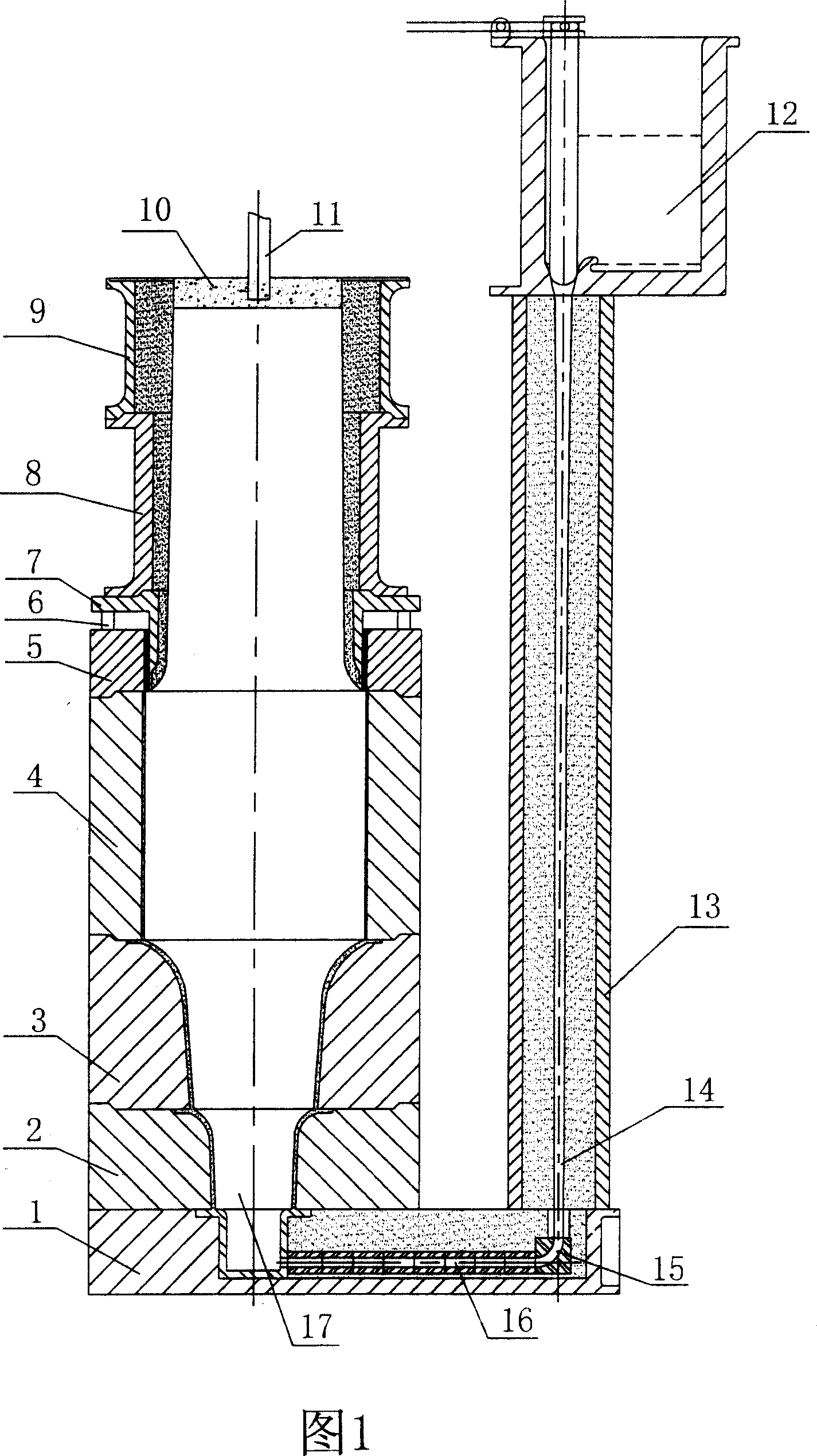

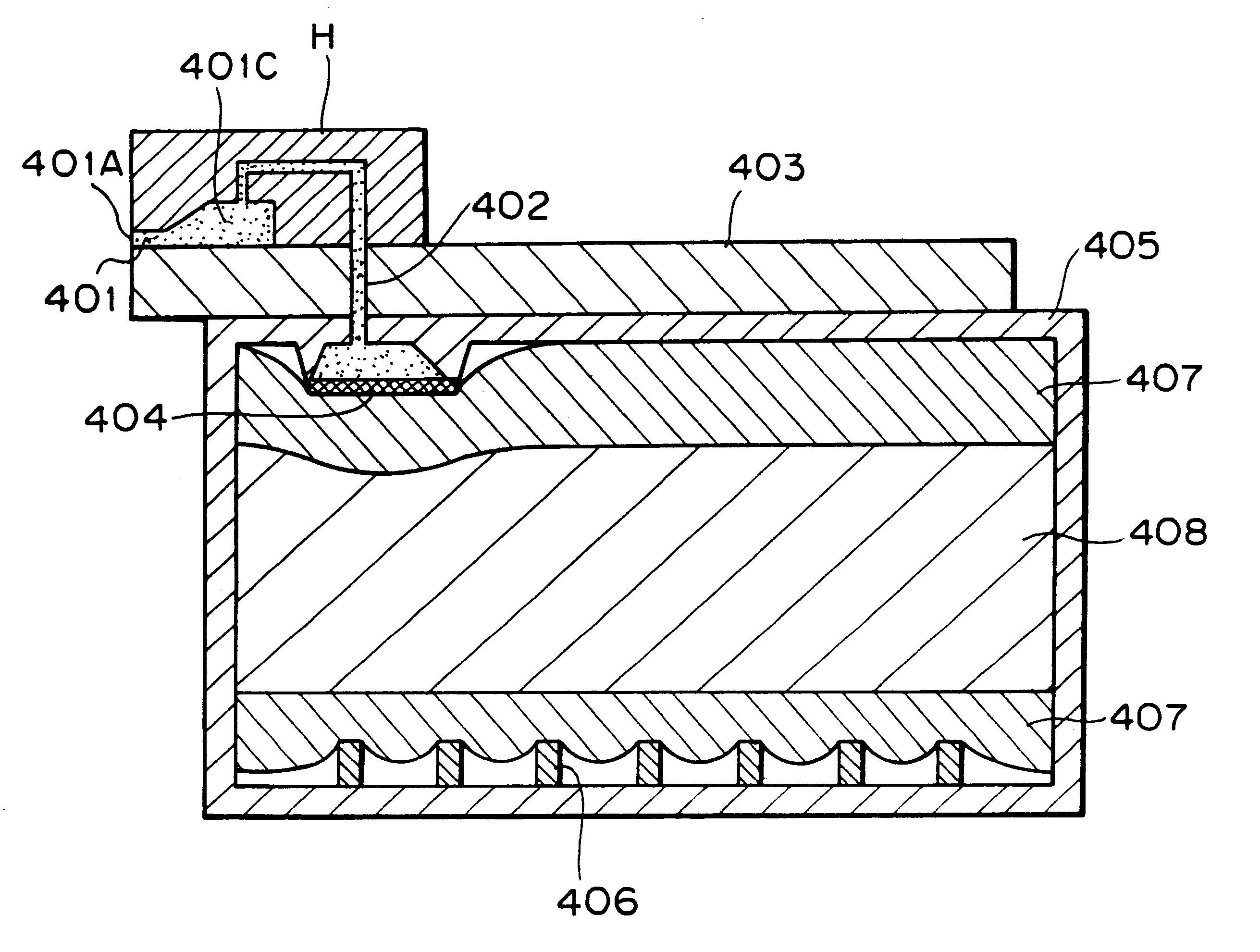

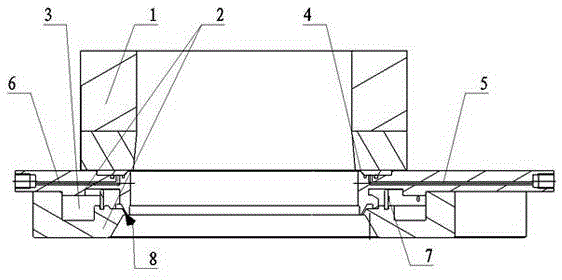

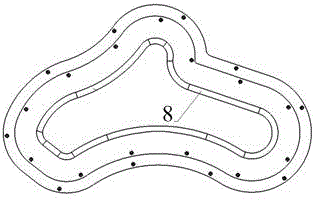

The invention provides a vacuum low-pressure casting forming device for a titanium alloy component. The vacuum low-pressure casting forming device for the titanium alloy component comprises a device body, a vacuum low-pressure casting pneumatic control system and an electronic control system. An upper chamber and lower chamber type structure is adopted by the device body, a water-cooled copper crucible is arranged in a lower chamber, a casting mold is arranged in an upper chamber, an intermediate separation plate is arranged between the upper chamber and the lower chamber, and a liquid lifting pipe is arranged on the intermediate separation plate. The vacuum low-pressure casting pneumatic control system is connected with the device body, a vacuum system and a protective gas source system, and digital combination valves are adopted as flow regulation actuators. The electronic control system is composed of an industrial control computer and a PLC. After the smelting process of titanium alloy is completed in a smelting chamber, the water-cooled copper crucible is lifted to a casting position through a lifting device, an upper chamber and lower chamber intercommunication valve is closed, the flow of protective gas fed into the lower chamber is controlled through the computer, the pressure difference between the upper chamber and the lower chamber is established, the liquid alloy is filled in the casting mold through the liquid lifting pipe under the action of the pressure difference, and the casting process is completed. Compared with traditional centrifugal casting and bottom leakage type suction casting, the mold-filling capacity and solidification feeding capacity of the titanium alloy can be improved, castings with better casting quality and thinner wall thicknesses can be obtained, and a new means is provided for batch production of minitype titanium alloy components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

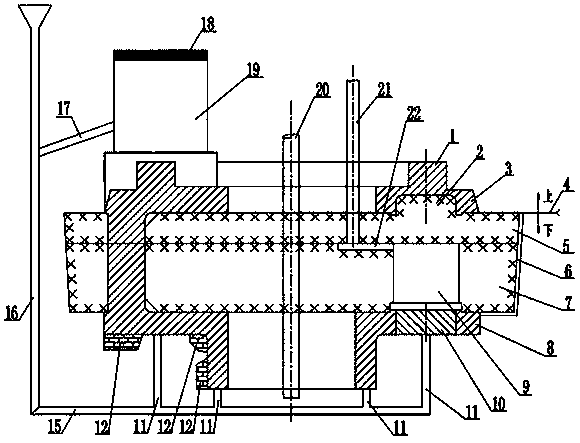

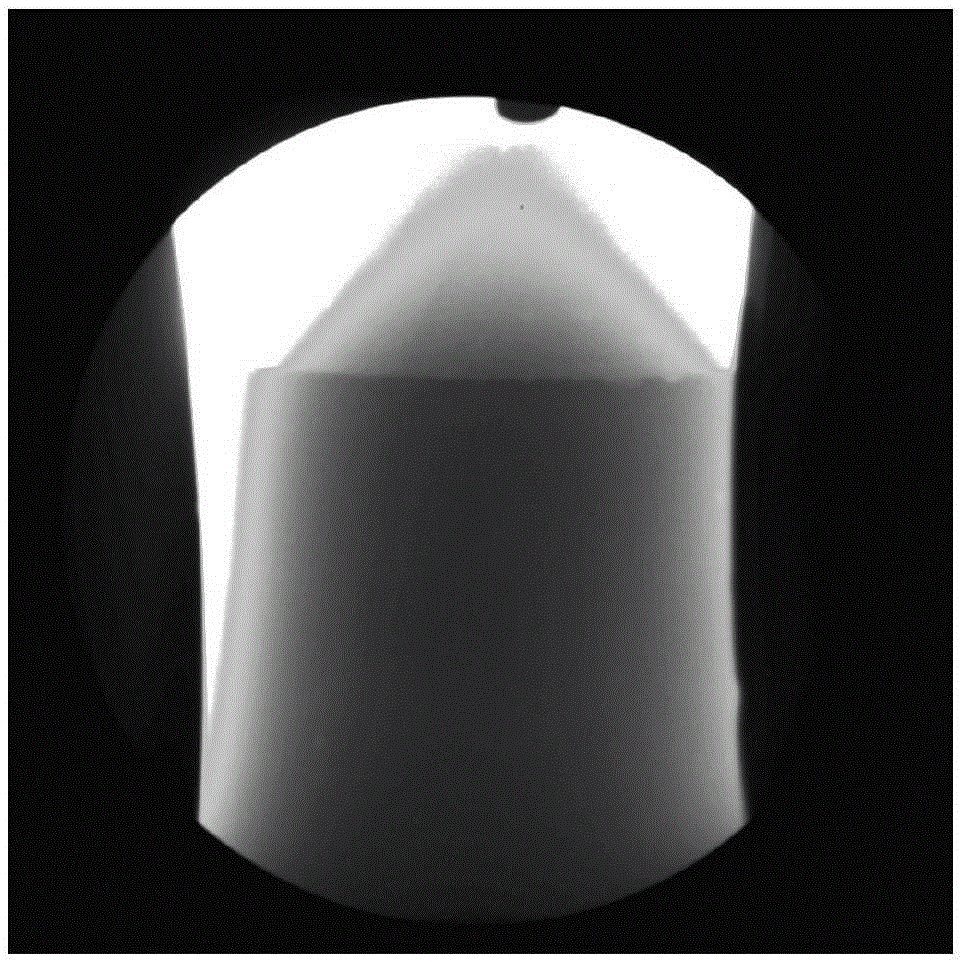

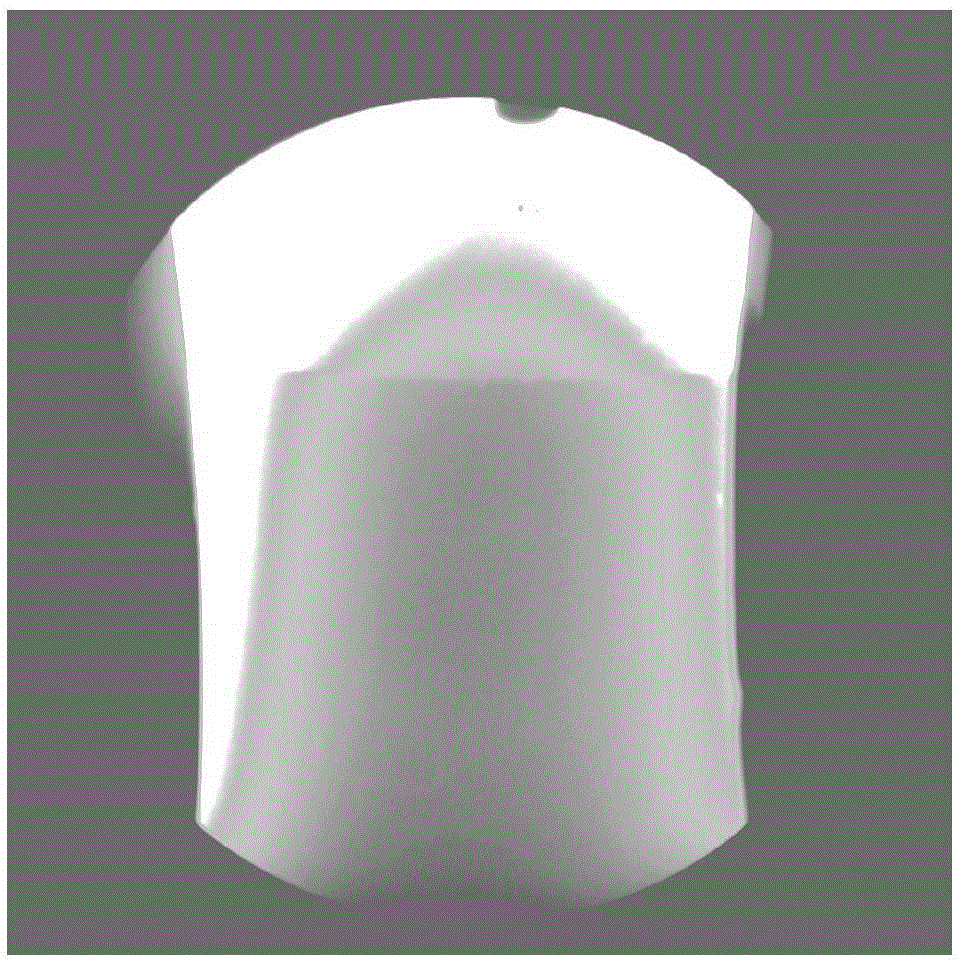

Pressurizing casting device and method for automobile hub

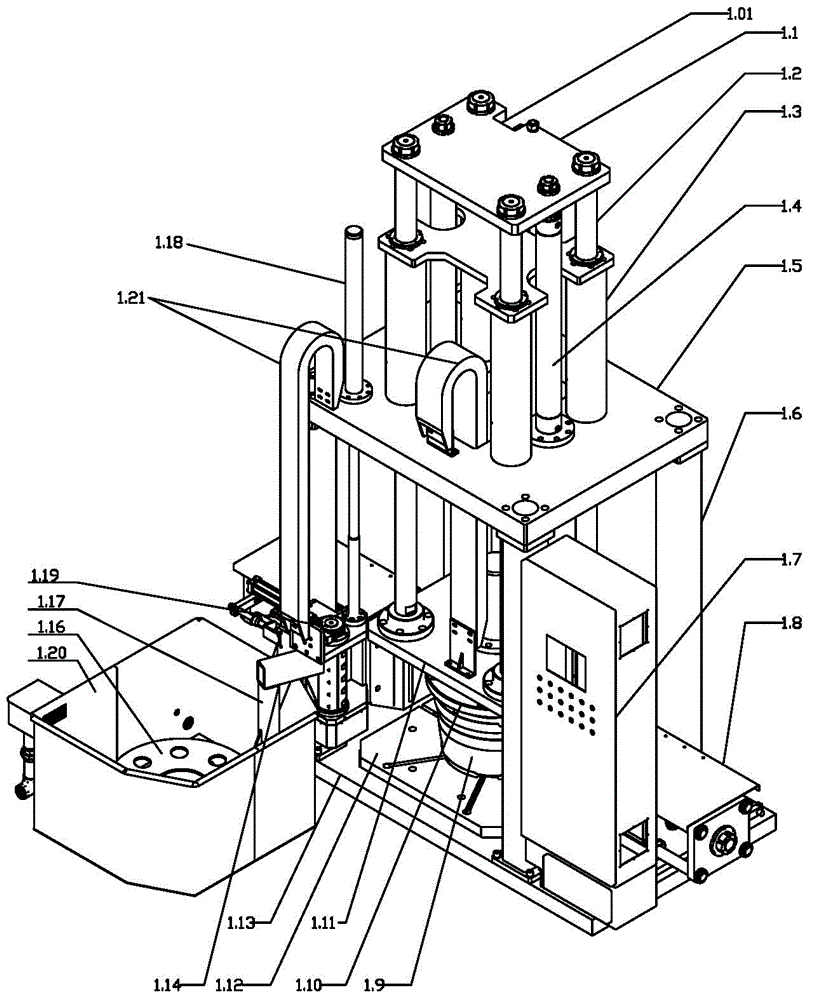

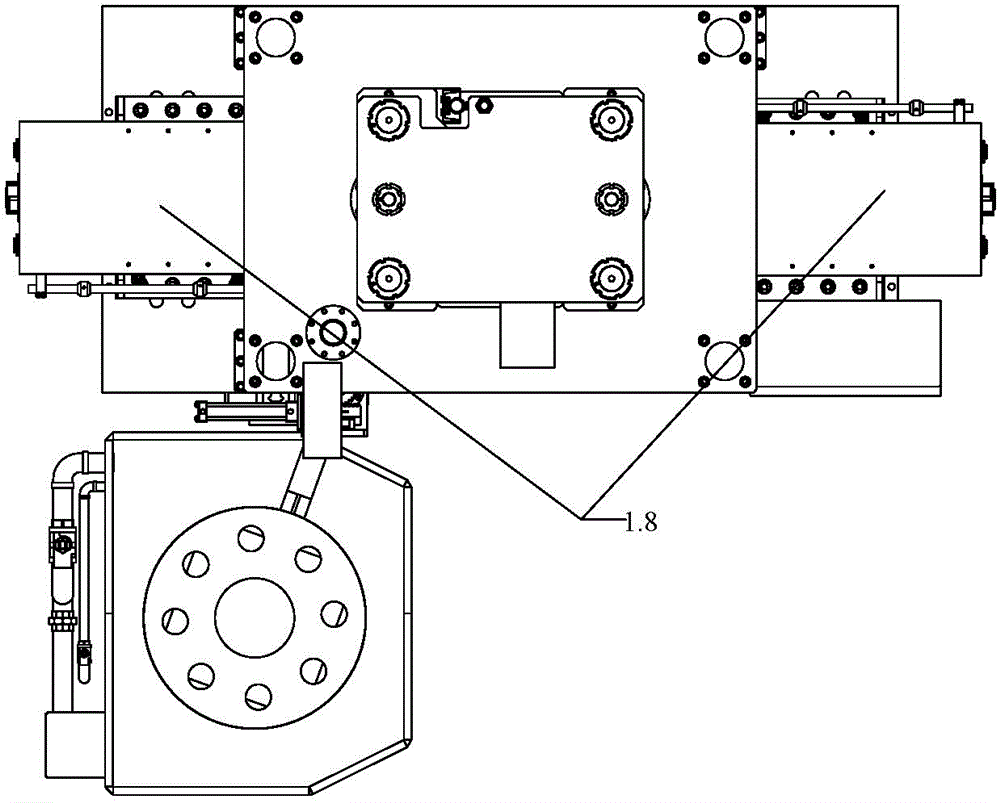

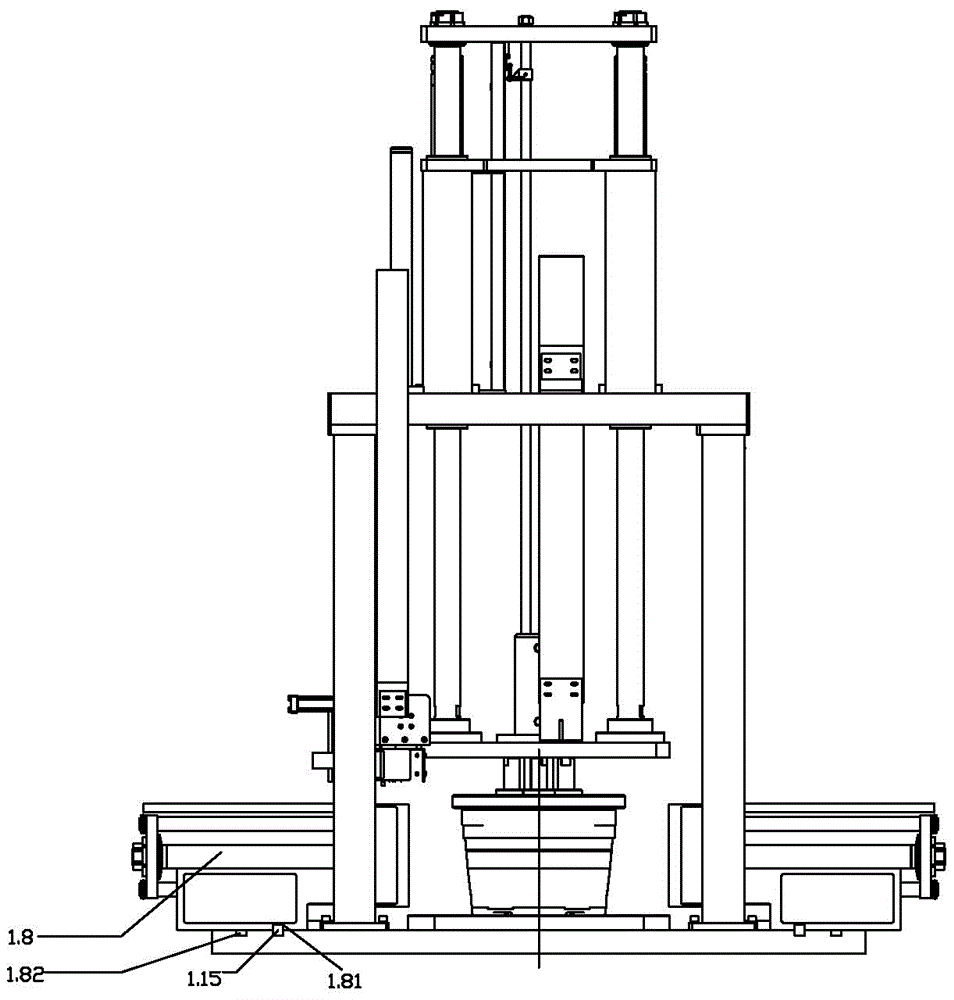

The invention discloses pressurizing casting device and method for an automobile hub. The device comprises a device body, a casting die, a movable sliding table, a die closing oil cylinder, a pressurizing mechanism, a side die closing mechanism, a quenching device and a control cabinet. The device has the advantages that 1, the pressurizing mechanism is additionally arranged on the basis of the existing gravity device and process; the pressurizing mechanism drives a pressurizing ring above the die to pressurize molten aluminum alloy in a die cavity; 2, a center riser is removed, and an exhaust plug is provided for exhausting; 3, a cooling system is improved, the multi-point multi-form cooling manner is carried out, and therefore, the cooling effect is improved, and the sequential solidifying process of a product can be effectively controlled; 4, a feeding opening forced cooling system is additionally arranged, so that the molten aluminum at a feeding opening can be solidified firstly, and as a result, the molten aluminum in the die cavity can be avoided reflowing. The invention also discloses a casting method of the gravity pressurizing casting device for the automobile hub. With the adoption of the device and method, the yield of castings is more than 99%; the percentage of pass of air tightness of finished product is up to 99.3%, and the elongation is up to 9.5%.

Owner:SUMEC WHEELS CO LTD

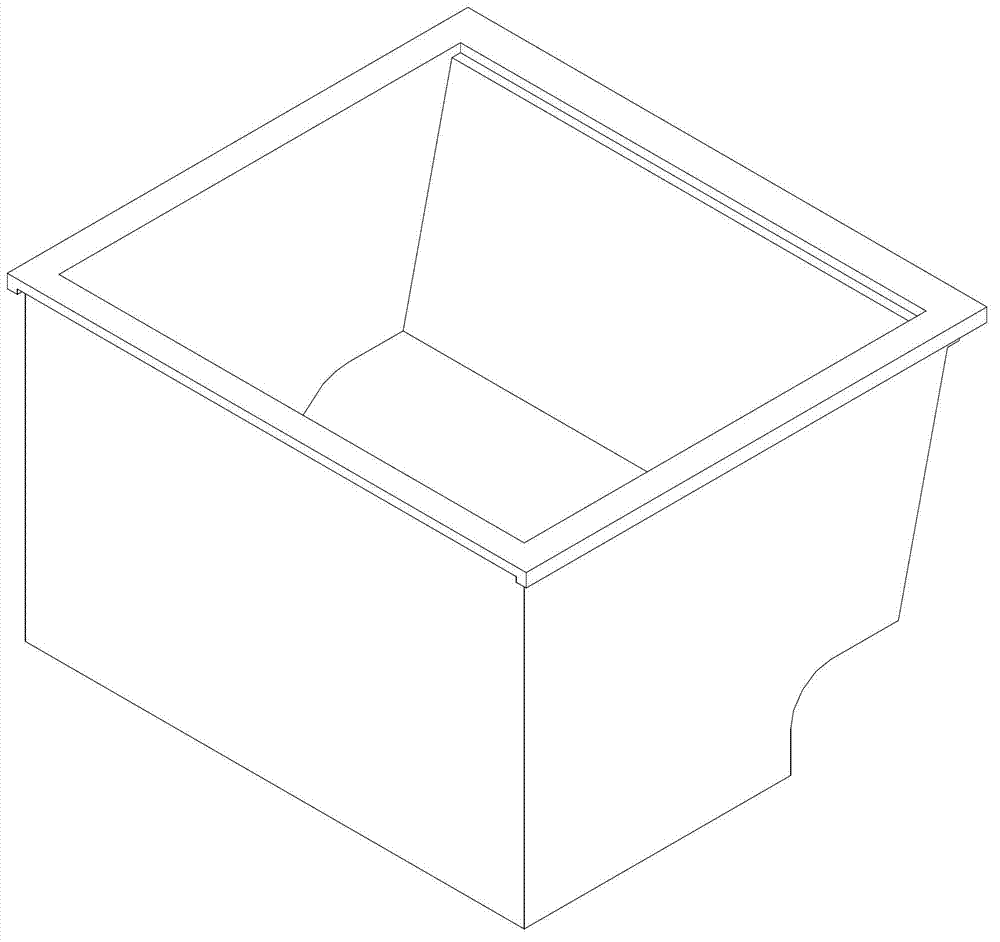

Method for manufacturing casting blank of die for inner containers of household appliances on basis of metal cavity with cold iron structure

InactiveCN102773409AQuality improvementImprove pass rateFoundry mouldsFoundry coresSurface finishFree cooling

The invention discloses a method for manufacturing a casting blank of a die for inner containers of household appliances on the basis of a metal cavity with a cold iron structure, and relates to the technical field of aluminum alloy casting. The method includes particular steps of constructing an outer cavity by cold iron blocks on the periphery of a manufactured wood mold in a form following manner; filling gaps among the cold iron blocks by clay sand, tightly filling the corresponding cold iron blocks by clay sand after each local structure is completed, and compacting a sand mould to prevent the cold iron blocks from moving; constructing a sand core of an inner cavity by the same method after the outer cavity is constructed; opening a case to take out the wood mould after the sand core of the inner cavity is manufactured so that a cavity of a casting is formed; drying the cavity of the casting and the sand core consisting of clay sand; preheating the cavity of the casting at the preheating temperature of 200 DEG C before pouring of the cavity of the casting; casting melted aluminum alloy into the cavity of the casting; and opening the case to take out the casting after the cavity of the casting is cooled naturally. The method is mainly used for casting the die for the inner containers of the household appliances, the surface of a casting product produced by the process is high in smoothness and does not have sand holes or pin holes after the surface of the casting product is treated in a follow-up machining process, and accordingly yield of molded inner container products is greatly increased.

Owner:CHUZHOU JINNUO INDAL

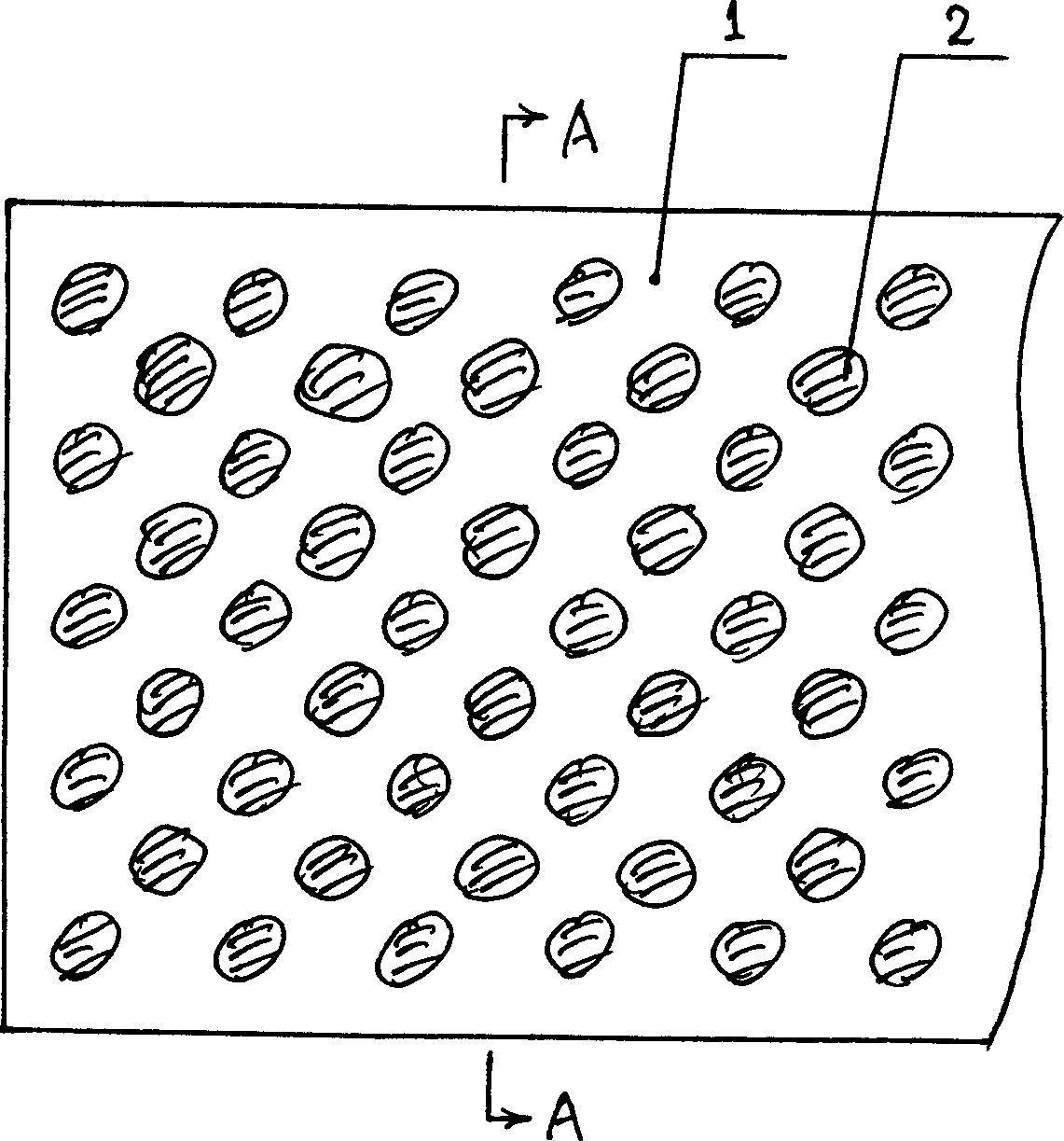

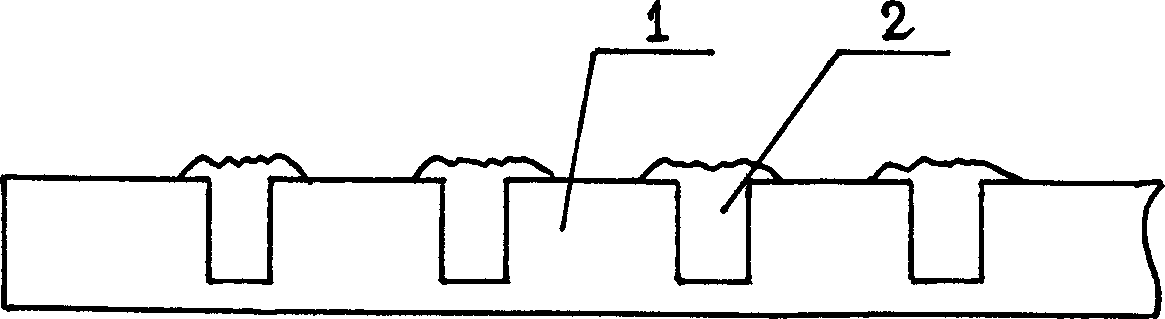

Sticking adiabatic cotton and method of making the same

ActiveCN1654876ASimple processReduce energy consumptionThermal insulationPipe protection by thermal insulationFiberRoom temperature

This invention relates to adhesive heat isolation cotton and its process method, which is applied in forging with constant temperature of alloy with firm shape. The invention is characterized by the following: it comprises the isolation cotton, double adhesive agent, wherein, the isolation cotton is of ceramics fire wearing fiber in sale and its rectangle plate is distributed with parallel and crossed holes with distance between as 50mm and with depth less than the cotton thickness; the double adhesive agent is made by mixture of adhesive agent with room temperature and one with high temperature with their proportion as three to seven. The double adhesive agent in the cotton holes is above the surface of the cotton distributed discontinuously and finally for drying.

Owner:宝武特种冶金有限公司

Casting method of metal substrate cooling wall

InactiveCN1513622AEnhanced feedingImprove feeding capacityFoundry mouldsCooling devicesIron powderChemical reaction

A technology for casting the steel-based cooling wall features that the cooling medium which is the mixture of corundum powder, iron powder and electrode powder is filled in its cooling pipeline. Said cooling medium features strong cooling action, low thermal expansibility, not adhering to pipe wall, and easy removing it.

Owner:MAANSHAN IRON & STEEL CO LTD

Process for preparing large cast steel support roller

The process of making cast steel supported roller is suitable for integral casting of cast steel supported roller of 5-100 ton weight. The present invention has adopts computer simulation, coating iron mold with sand, rotary cavity filling, heat insulating casting head technology, electrically casting head heating technology and sliding roller neck technology; and designs pouring system and casting mold design by means of new design principle and successive solidification principle. Adopting sliding roller neck technology and electrically casting head heating technology can avoid cracking in the cast steel supported roller.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

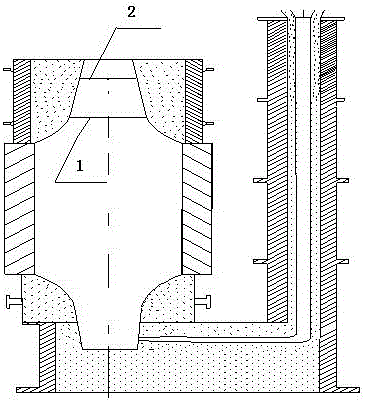

Device and process for manufacturing large-scale complex thin-wall aluminum alloy casting through vacuum pressurization casting

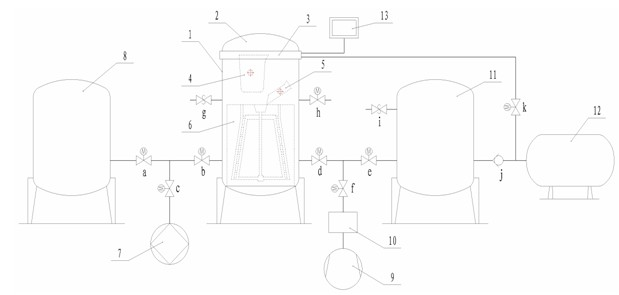

The invention relates to a device for manufacturing a large-scale complex thin-wall aluminum alloy casting through pouring and mold filling under vacuum and crystallization and solidification under pressure. The device comprises a vacuum pressurization casting chamber, a vacuum pumping system, an air pressurization system and an intelligent control system. The vacuum pressurization casting chamber is a high-pressure air-tight seal tank and adopts the vertical arrangement; a turnover seal cover driven by a cylinder and a locking ring for performing rotary seal are arranged at the upper part of the high-pressure air-tight seal tank; a pressure and vacuum detector is arranged on the seal cover; a ladle, a overturn casting drive device, a metal liquid diversion trench, a turnover temperature measuring device and the like are internally arranged in the chamber; a manual casting mechanism is arranged at the outer part of the chamber; the vacuum pumping system is composed of a vacuum pump, a vacuum storage cabin and a pipeline system; the air pressurization system is composed of an air compressor, a refrigeration drier, a pressure storage cabin, a circuit and a pipeline system; and the intelligent control system consists of a PLC (Programmable Logic Controller), an air bottle, a security caution light and an affiliated pipeline system, wherein the PLC is connected with the air bottle, the security caution light and the affiliated pipeline system, which collects and displays data of vacuum, pressure, temperature and the like to realize the intelligent control for the devices, so that the stages in the vacuum pressurization casting can be ensured to be performed sequentially, continuously and smoothly.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

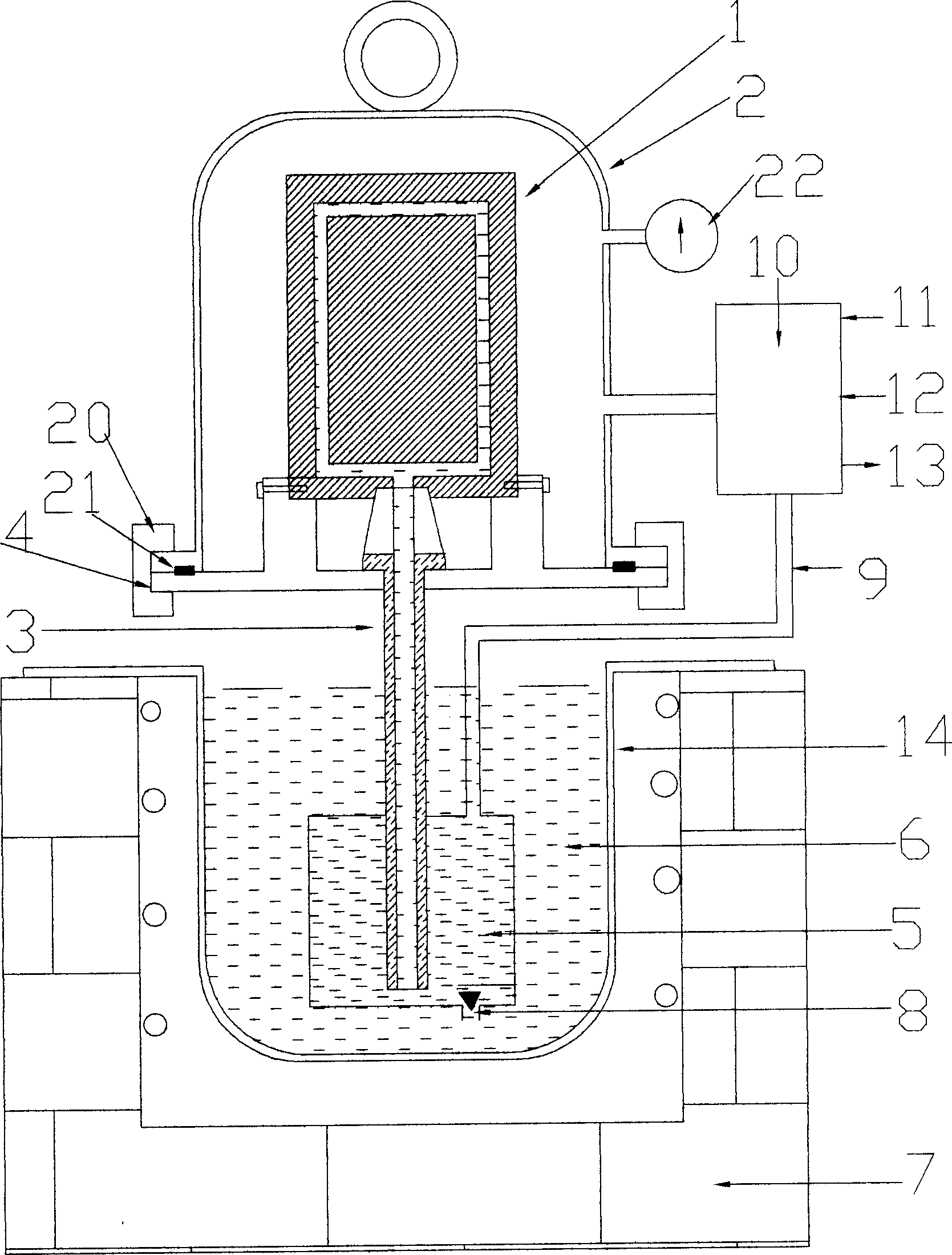

Vacuum pressure casting machine for magnesium alloy

The invention belongs to metal casting device. The magnesium alloy cast is complex, and the performance is bad. The invention is a magnesium alloy casting device which fills shape in vacuum state and solidifies them in various pressure state. It can realize the optimized casting process condition, it can be applied to produce each kind of large, complex, thin magnesium alloy casting piece with precise size and high thickness.

Owner:李书伟 +2

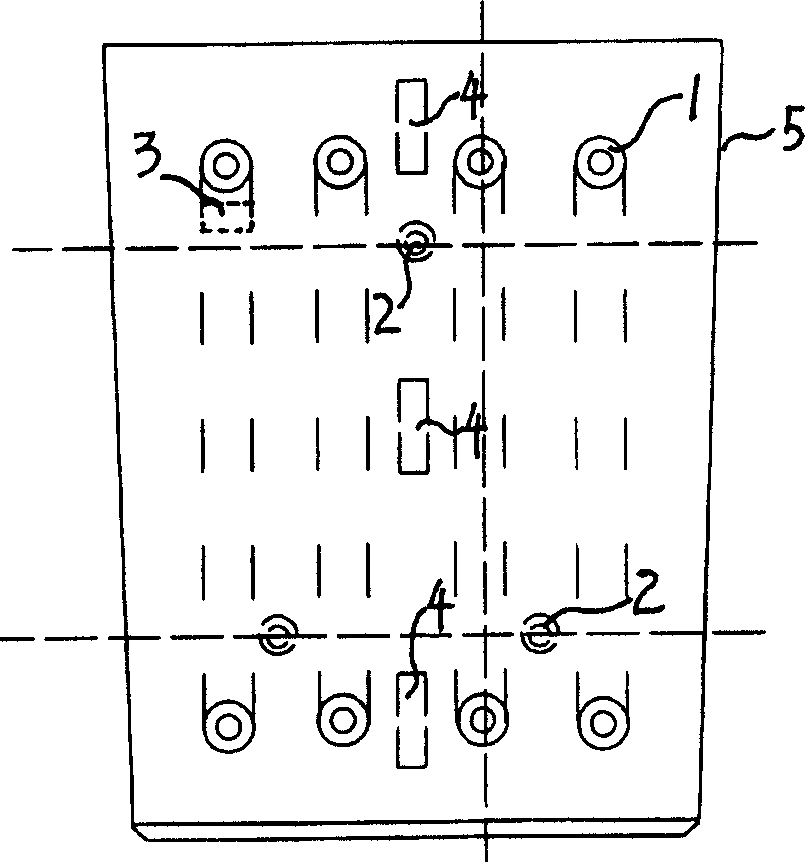

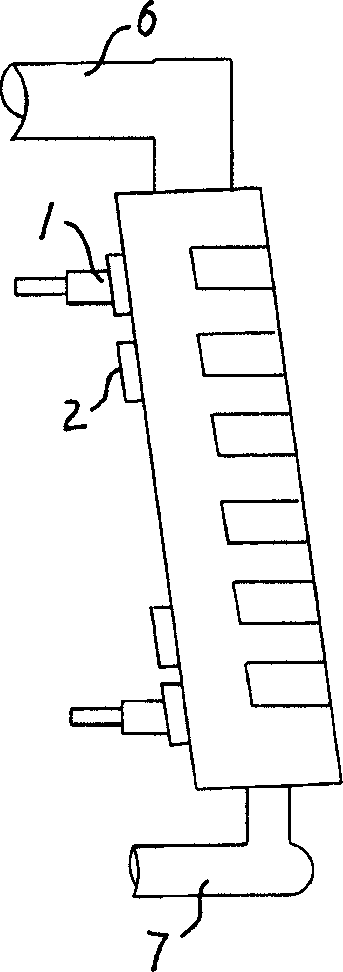

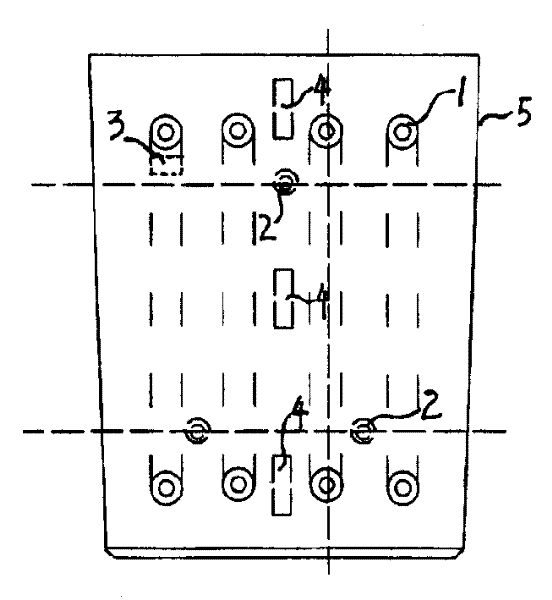

Ink tank, head cartridge and ink jet printing apparatus

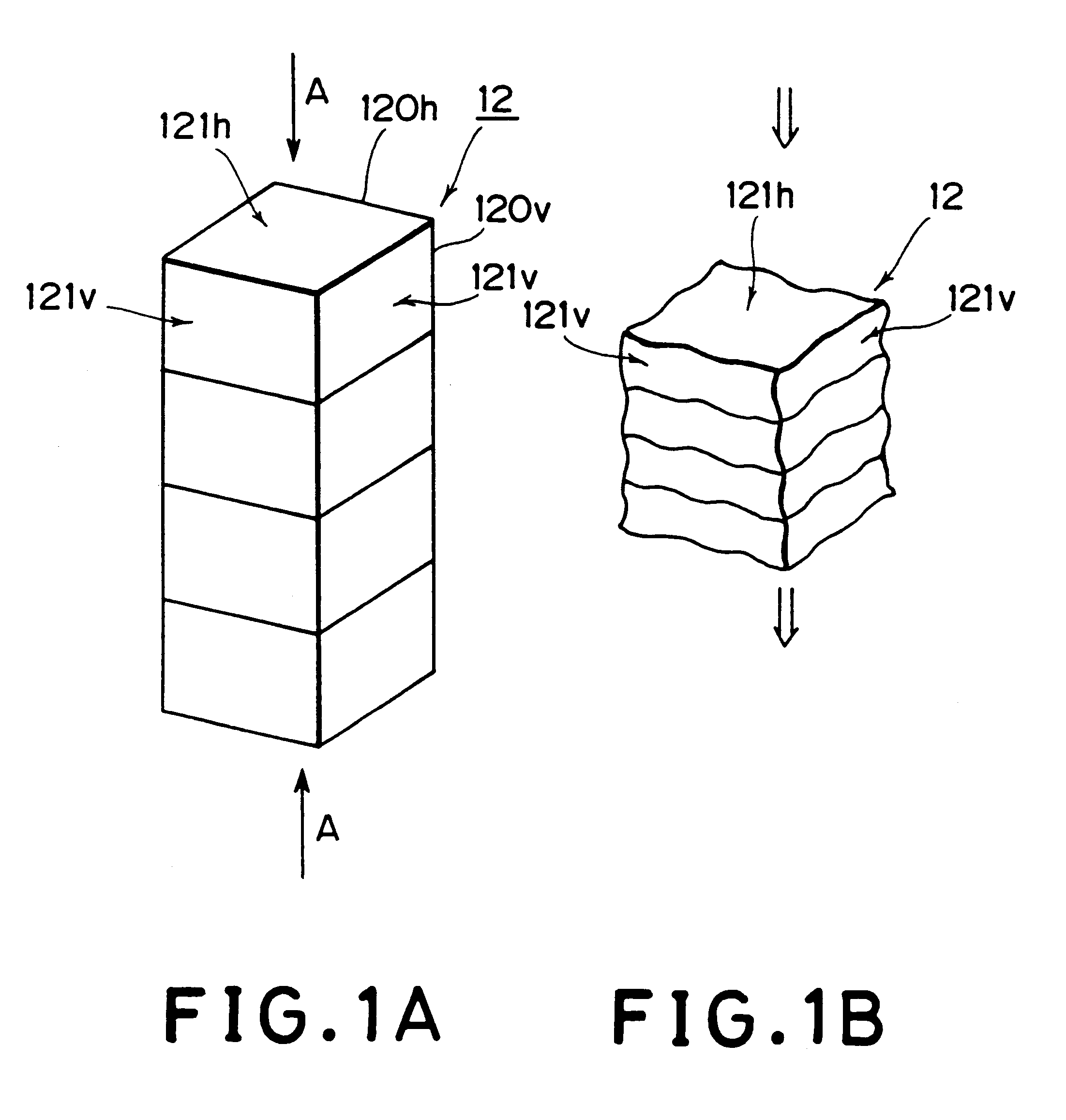

A length of a melamine foamed block to be accommodated in an ink tank housing as measured in the longitudinal direction is dimensioned to be larger than a length of the ink tank housing as measured in the longitudinal direction. Thus, while the foamed block is accommodated in the ink tank housing, it is compressed in the direction orienting toward an ink feeding port from which ink is fed to a printing head, i.e., in the ink feeding direction. Consequently, the ink retaining force induced by the capillary force is not intensified in the compressing direction of the melamine foamed block, resulting in an ink feeding capability of the printing head being improved. On the contrary, the ink retaining force effective at a right angle relative to the compressing direction of the melamine foamed block is intensified.

Owner:CANON KK

Coating for metal mold casting of aluminum alloy thin-walled piece and preparation method and coating method thereof

InactiveCN102145372AImprove filling abilityImprove feeding capacityFoundry mouldsFoundry coresAdhesivePhosphate

The invention provides a metal mold casting coating for an aluminum alloy thin-walled piece. The coating is prepared from refractory aggregate, adhesive and carrier liquid, wherein the refractory aggregate contains kieselguhr, corundum powder, titanium dioxide and asbestos powder; the adhesive is silica sol or anhydrous phosphate; the carrier liquid is industrial alcohol; and the coating comprises the following components in part by weight: 0.5 to 1 part of kieselguhr, 0.5 to 1 part of corundum powder, 1.5 to 3.5 parts of titanium dioxide, 3 to 7 parts of asbestos powder, 0.6 to 1 part of silica sol or anhydrous phosphate, and 20 to 60 parts of industrial alcohol. The invention also provides a preparation method for the coating; the method comprises the following steps of: putting the refractory aggregate and the adhesive into a container with proper size, stirring the refractory aggregate and the adhesive uniformly through manpower or a machine, pouring the industrial alcohol into the container, and stirring uniformly for later use. The invention finally relates to a coating method of the coating. When the coating is used, the temperature of a die is between 180 and 400 DEG C, and a coating with the thickness of 0.1 to 0.5 millimeter is coated on the surface of the die.

Owner:SHANGHAI AIERSI LIGHT ALLOY

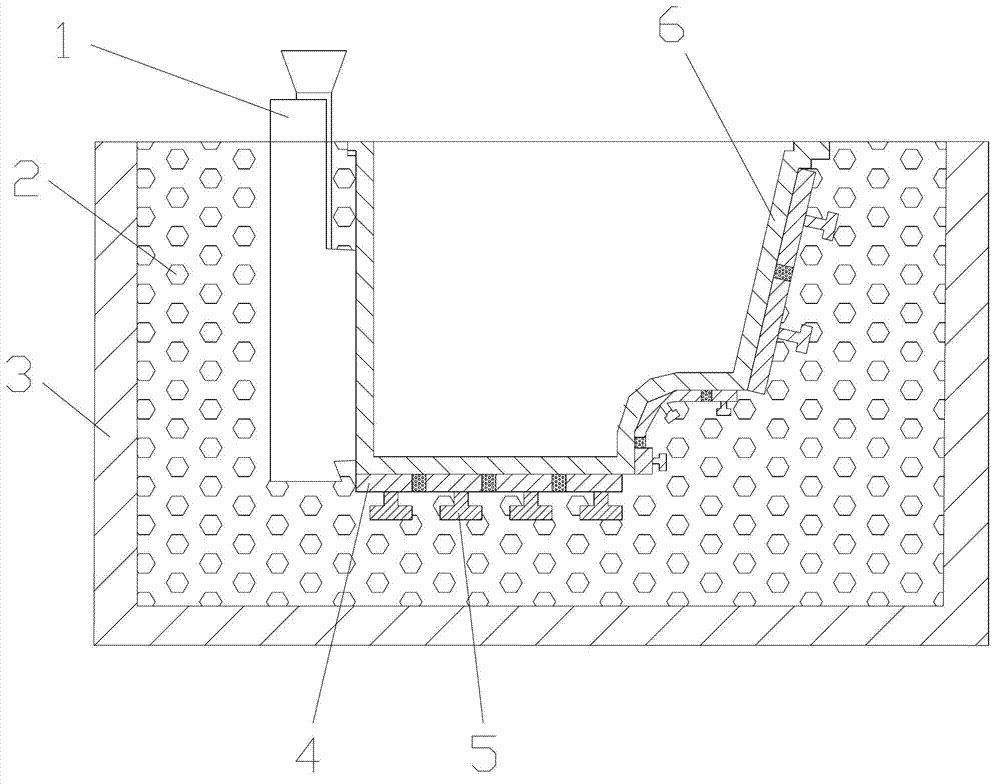

Sand-lined metal mold casting technology for high-manganese steel liner plate

ActiveCN103157768AImprove feeding capacityGrain refinementFoundry mouldsFoundry coresManganeseMolten steel

The invention discloses a sand-lined metal mold casting technology for a high-manganese steel liner plate. The sand-lined metal mold casting technology comprises design and processing of a metal mold, coating of sand on the metal mold, metal mold pre-heating, smelting casting, cooling and aftertreatment. The sand-lined metal mold casting technology realizes effective combination of a gating system and a feeding system, and effectively improves a feeding capacity of a feed head. Through utilization of a fast cooling capacity of a metal mold, fast molten steel solidification is realized so that high-manganese steel liner plate grains are refined; a good internal shrinkage degree is obtained; shrinkage cavity defects are reduced; surface smoothness and a dimensional precision are greatly improved; product quality is effectively improved; a production cost is reduced; and a service life of the high-manganese steel liner plate is improved. The sand-lined metal mold casting technology effectively solves the problem that the existing metal mold casting technology has a short mold service life and produces liner plate appearance casting defects and problems in production.

Owner:NINGGUO DONGDU CASTING

Garrupa extruded feed and processing method thereof

InactiveCN102726635APromote rapid growthImprove feeding capacityAnimal feeding stuffBiotechnologyAnimal science

The invention discloses a garrupa extruded feed and a processing method thereof. The garrupa extruded feed comprises the following raw materials in percent by mass: 41-48% of steam fish meal, 10-14% of bean pulp, 5-10% of extruded bean powder, 5-8% of corn protein, 1-2.8% of beer yeast, 1-2% of squid liver paste, 1-2% of fish oil, 1-2% of grain raw powder, 11-15% of high protein flour, 1-2% of calcium dihydrogenphosphate, 3-4% of lecithin, 0.4-0.6% of compound vitamin, 0.5-1% of compound mineral substance, 0.6-1% of choline chloride and 0.5-0.8% of seaweed meal. In the invention, according to the digestion physiological characteristics of garrupa, feed raw materials with high bioavailability are selected, thus garrupa can be promoted to grow quickly, and ingestion effect of the garrupa is improved; and curing degree of feed granules is 85%, thus digestibility of the garrupa is improved.

Owner:XIAMEN HAILIN BIOTECH CO LTD

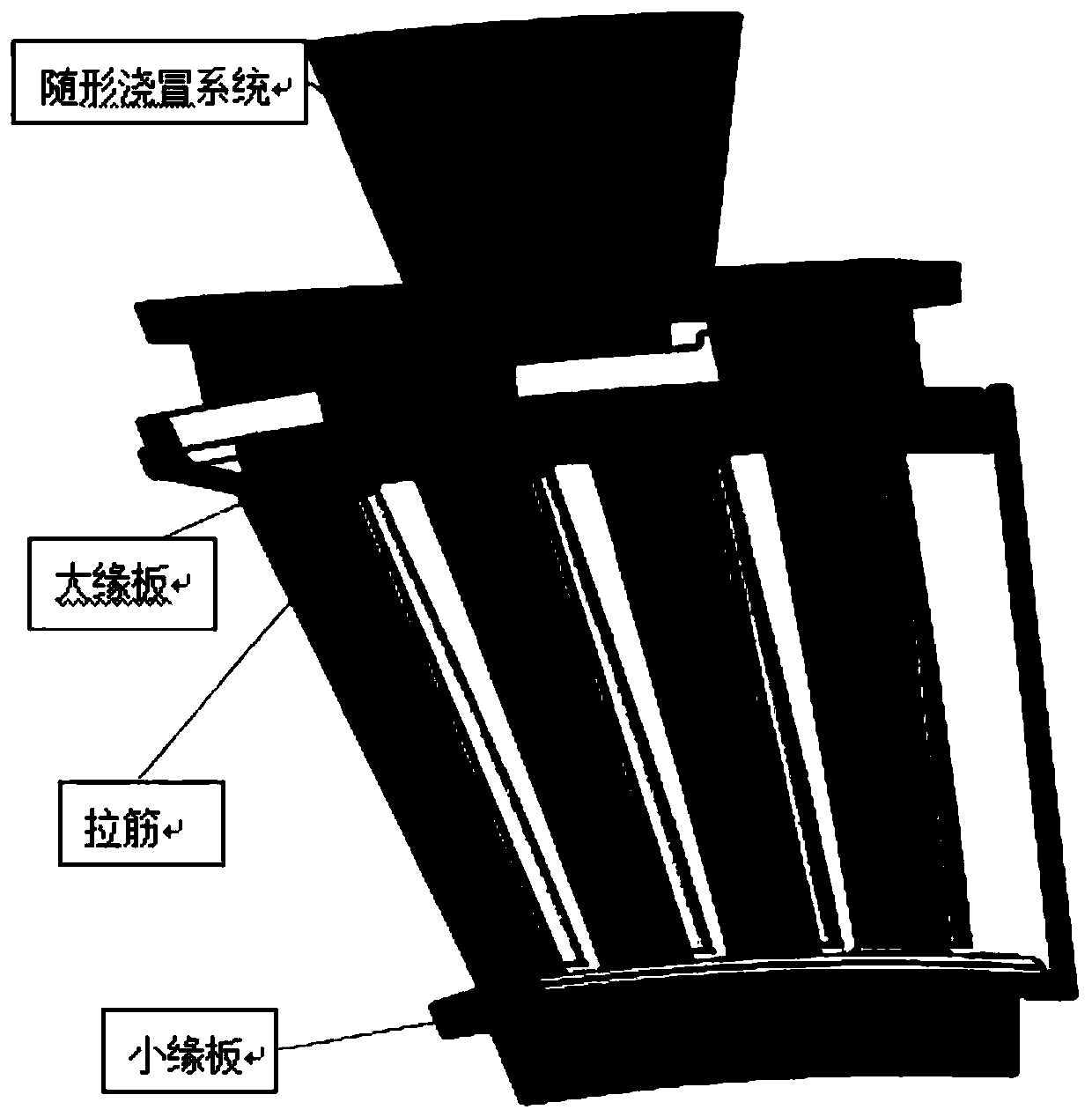

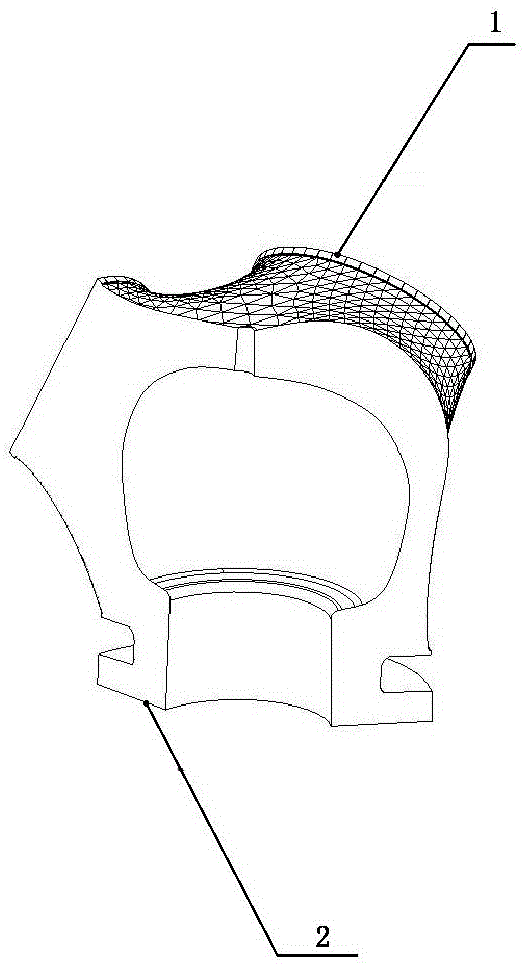

Casting forming process of complex high temperature alloy multi-union guide vane casting

The invention discloses a casting forming process of a complex high temperature alloy multi-union guide vane casting, and belongs to the technical field of precision casting. The process is characterized in that a casting body wax mold is prepared, and the casting body wax mold and a rigging system are assembled into a module; the module is coated with refractory coating layer by layer, is sent into a dewaxing kettle for dewaxing, and is sent into a baking furnace for high temperature pre-baking; the exterior of a shell is wrapped in a step type and is tied with refractory insulation cotton; ahigh temperature alloy rod is remelted and smelted to obtain high temperature alloy metal liquid; before pouring, the shell is sent into the baking furnace again, and then is sent into a vacuum induction casting furnace, and the high temperature alloy metal liquid is poured into the shell; and after pouring is completed, heat preservation is carried out, and shell removal, cutting, sand blastingand polishing are carried out after furnace exiting. The casting forming process effectively reduces or eliminates casting defects such as looseness and cracking easily generated at the connecting positions of hot joint vanes and small edge plates, the yield is improved to 75% to 80%, and the process is suitable for complex high temperature alloy multi-union guide vane casting.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

Casting technique of supporting frame for building

InactiveCN106363129AGuarantee the pouring qualityReduce sticky sandFoundry mouldsFoundry coresModel sampleChiller

The invention relates to the technical field of casting, in particular to a casting technique of a supporting frame for building. The casting technique comprises the following processes that an outer cavity real sample model is adopted to be combined with an inner cavity sand core to form a cavity of a casting; the outer cavity real sample comprises a casting model sample and a supporting bed mould wholly covering the upper side of the supporting end of the casting model sample, and the top plane of the supporting bed mould serves as a model parting surface; the inner cavity sand core comprises a first sand core body for forming an inner cavity and a second sand core body for forming a small top hole, the second sand core body is inserted into the first sand core in a matched manner, and the bottom of the first sand core extends to the lower side of a flange hole and is fixed to a lower sand mould through an arbor; an open riser is arranged at the supporting end of the casting, a riser neck is arranged between the open riser and the end face of the supporting end, and a blind riser is arranged in the flange hole of the casting; the inner cavity of the casting, the normal direction of the end face of the flange end and the periphery of the flange end are each provided with a direct cooling chiller; and an open type gating system is adopted, a flow gate of an ingate is located below the blind riser of the inner cavity and is directly communicated with the blind riser, and a filter is arranged at the tail end of the flow gate.

Owner:KOCEL STEEL

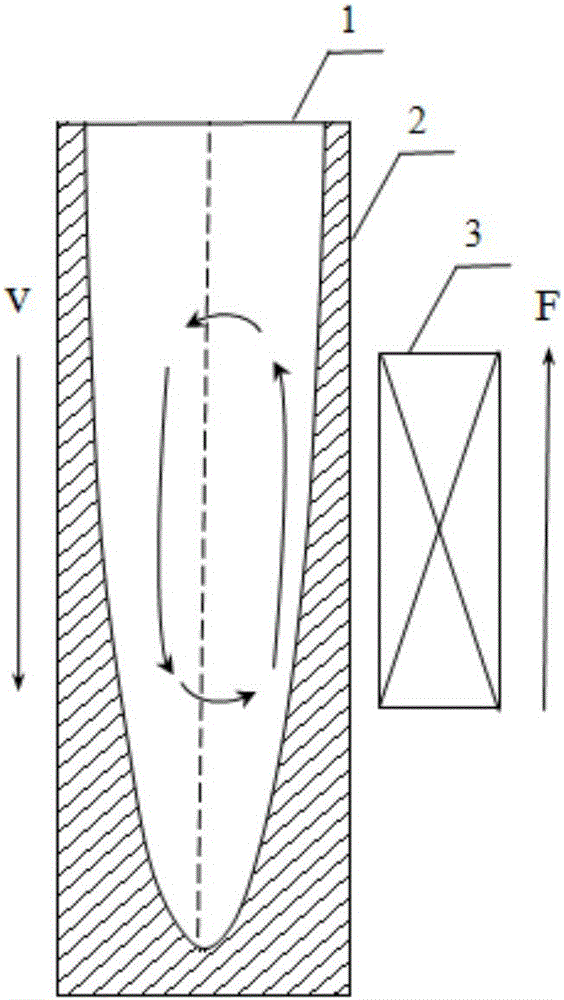

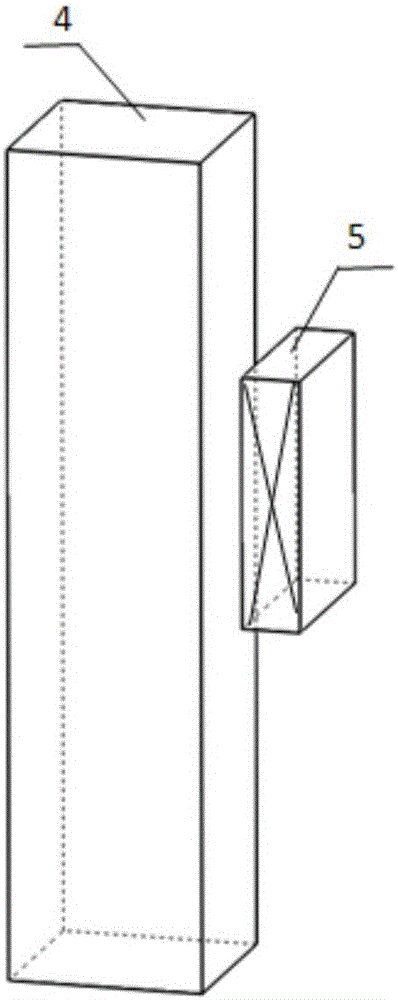

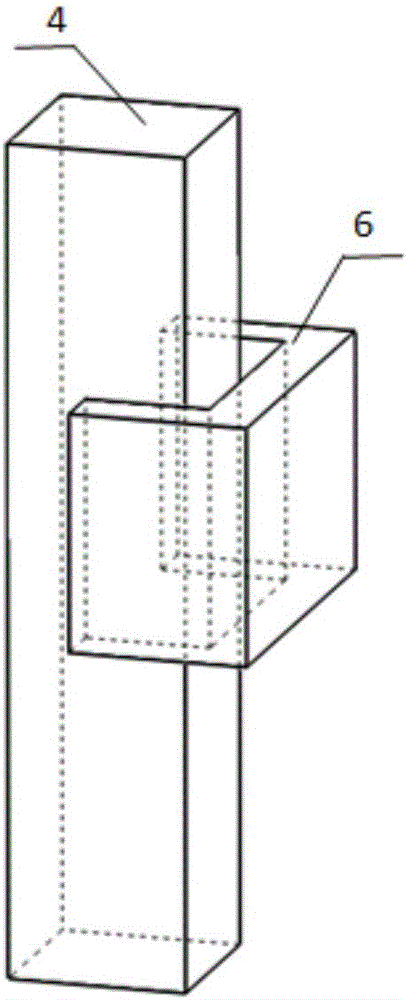

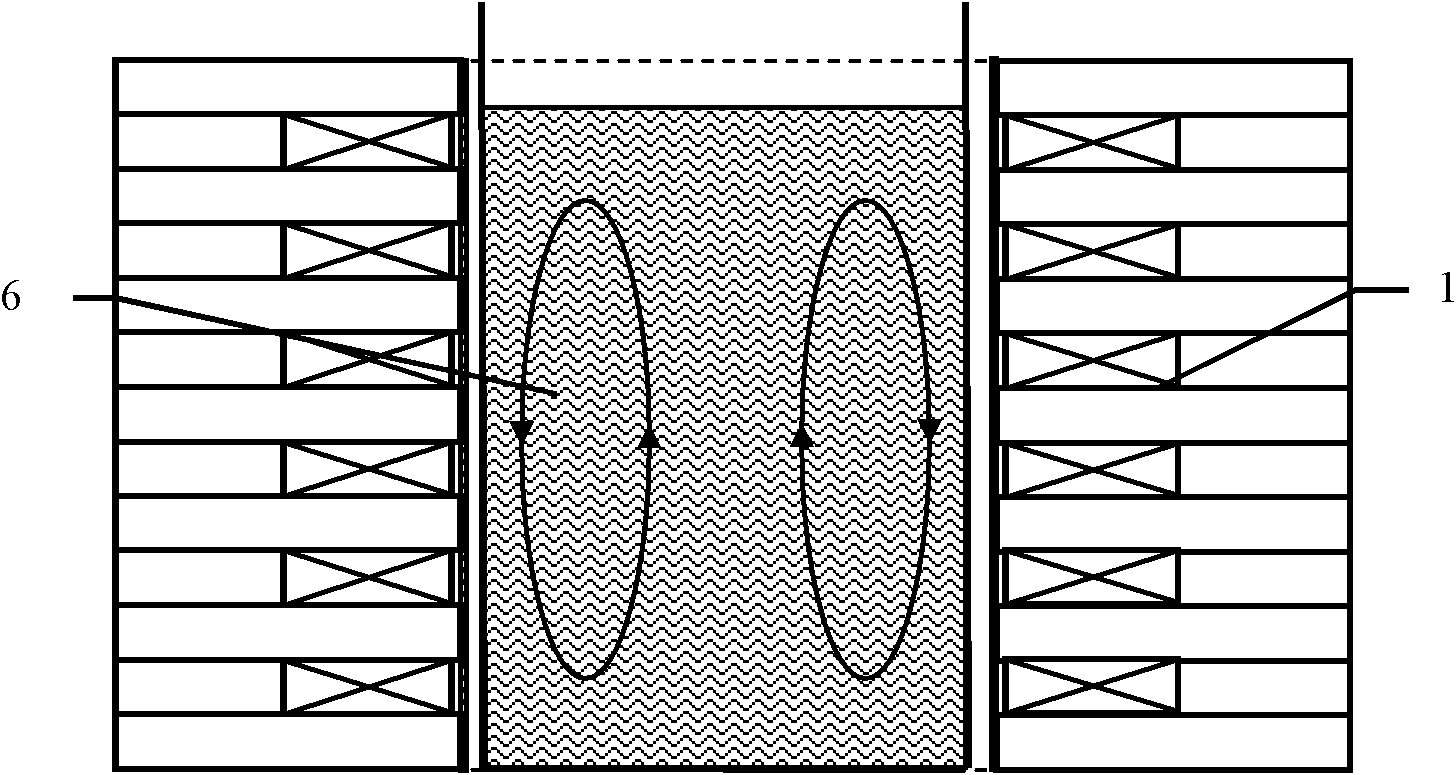

Vertical electromagnetic stirring method for controlling casting blank center quality

The invention belongs to the technical field of continuous casting electromagnetic stirring, and particularly relates to a vertical electromagnetic stirring method for controlling casting blank center quality. In the continuous casting production process, a traveling wave magnetic field type stirrer is arranged on the side face of a casting blank, and the overall direction of electromagnetic force generated by the traveling wave magnetic field stirrer in the casting blank is parallel to the direction of the center line of the casting blank. Traveling wave magnetic field stirrers in different shapes can be selected according to different cross-section shapes and sizes of casting blanks. The supply frequency of the vertical electromagnetic stirrer is 0.5-50 Hz, and the current of the vertical electromagnetic stirrer is 50-3000 A. By means of the method, melt in the casting blank center area can generate upward or downward forced convection movement along the center line of the casting bank, the effective action area of electromagnetic stirring in the length direction of the casting blank is enlarged, mixing of an upper high-temperature melt area and a lower low-temperature melt area of the casting blank center area is intensified, the feeding capability of upper melt of the casting blank center area to lower melt in solidification is improved, and uniformization of temperature and solute distribution in the casting blank is promoted.

Owner:NORTHEASTERN UNIV

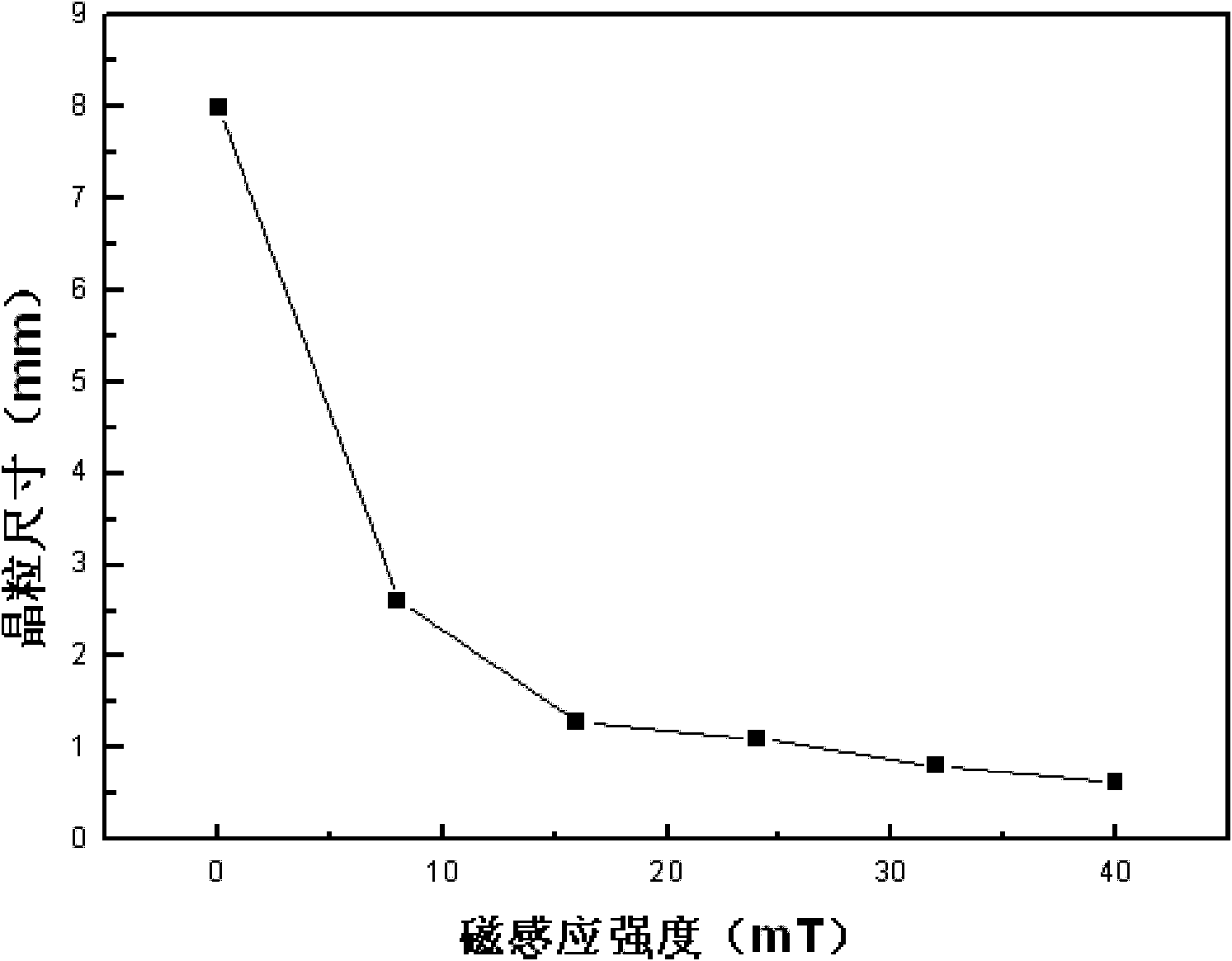

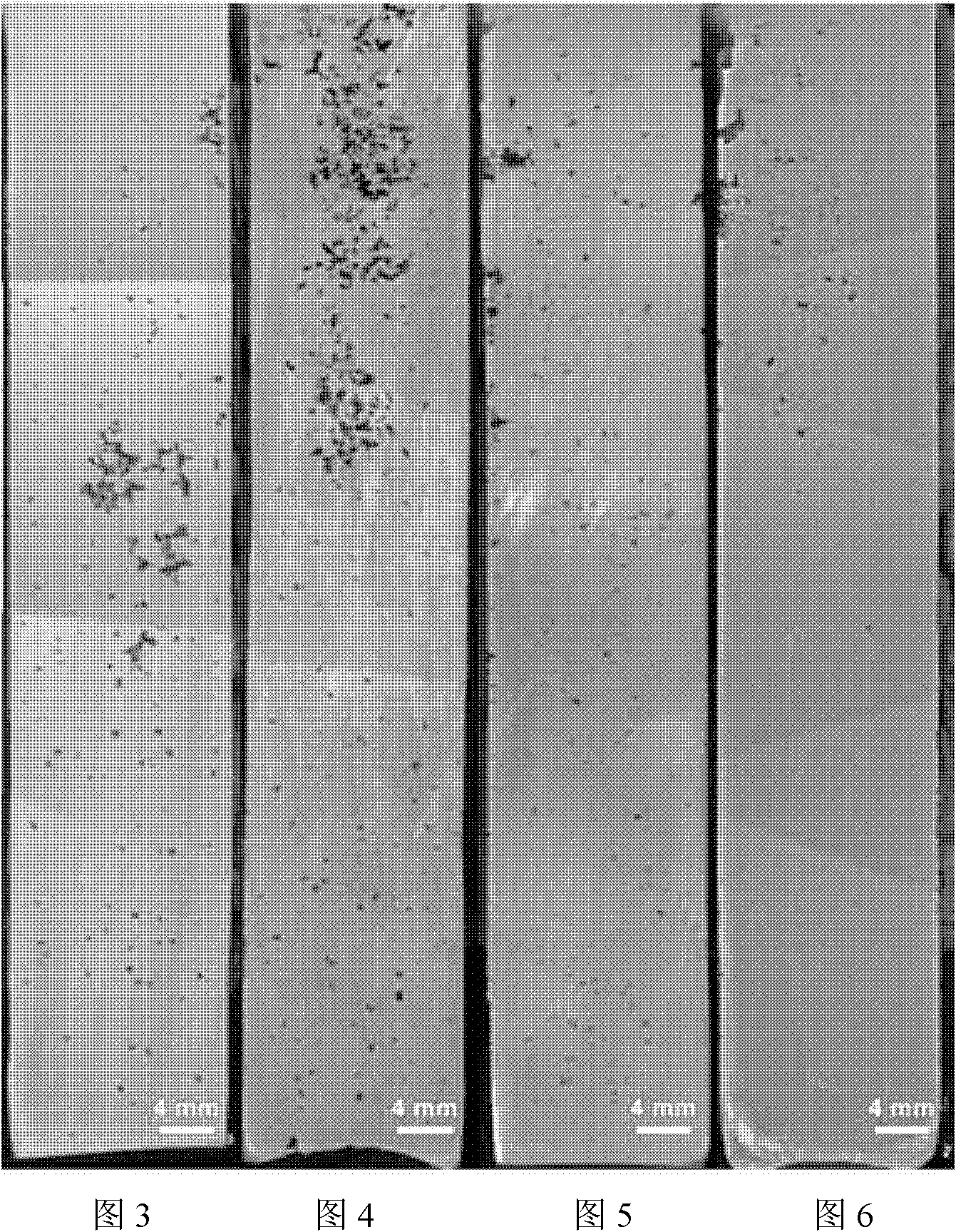

Precision casting method for refining aluminum alloy by using adjustable traveling wave magnetic field

The invention relates to a precision casting method for refining aluminum alloy by using an adjustable traveling wave magnetic field, belonging to the technical field of casting. The invention aims to solve the technical problems of high cost and difficulty in control in the process of grain refining and compacting for changing the properties of aluminum alloy in the prior art. The method provided by the invention comprises the following steps: 1. heating to melt aluminum alloy, and carrying out heat preservation,, thus obtaining an aluminum alloy molten mass; and 2. putting a casting mold, which is made of a non-magnetic material, in a traveling wave magnetic field inductor, turning on the traveling wave magnetic field inductor, adjusting the magnetic field intensity of the traveling wave magnetic field inductor, injecting the aluminum alloy molten mass obtained in the step 1 into the casting mold, and applying a traveling wave magnetic field, of which the magnetic field direction is vertically downward and the magnetic induction intensity is 32-500mT, onto the aluminum alloy molten mass to solidify the aluminum alloy under the traveling wave magnetic field, thereby completing the precision casting of the aluminum alloy. The method provided by the invention is easy to control and low in cost; and by utilizing the method provided by the invention, the obtained alloy crystal grains are fine, bubbles and voids can be effectively reduced, and the metal feeding capacity in the solidification process can be enhanced.

Owner:HARBIN INST OF TECH

Loose control method for fine and long thin-wall crowned isometric crystal cast turbine blade

ActiveCN108176817AIncrease the number of piecesIncrease productivityFoundry mouldsFoundry coresWaxThin walled

The invention relates to the technical field of investment pattern precision casting, in particular to a loose control method for a fine and long thin-wall crowned isometric crystal cast turbine blade. According to the provided loose control method for the fine and long thin-wall crowned isometric crystal cast turbine blade, a blade body inner pouring gate does not need to be additionally arrangedduring wax pattern combination, the opening design is made on a prepared shell when the 1 / 3 section of the middle portion of a blade body is wrapped by heat preservation cotton, the temperature at the blade body cotton wrapping opening position of the shell is low, solidification is fast, and the 1 / 3 section of the middle portion of the blade body can be promoted to be preferably solidified; goodfeeding can be provided for the preferably-solidified 1 / 3 section of the middle portion of the blade body through the non-solidified or slowly-solidified tenon end blade body 1 / 3 section and the blade crown end blade body 1 / 3 section, good feeding can be provided for the tenon end blade body 1 / 3 section and the blade crown end blade body 1 / 3 section through a blade crown inner pouring gate, a tenon inner pouring gate and a transverse sprue, accordingly, the sequential solidification mode that the 1 / 3 section of the middle portion of the blade body is preferably solidified can be achieved, andthe loose degree of the fine and long thin-wall crowned isometric crystal cast turbine blade can be effectively reduced.

Owner:GUIYANG AVIC POWER PRECISION CASTING

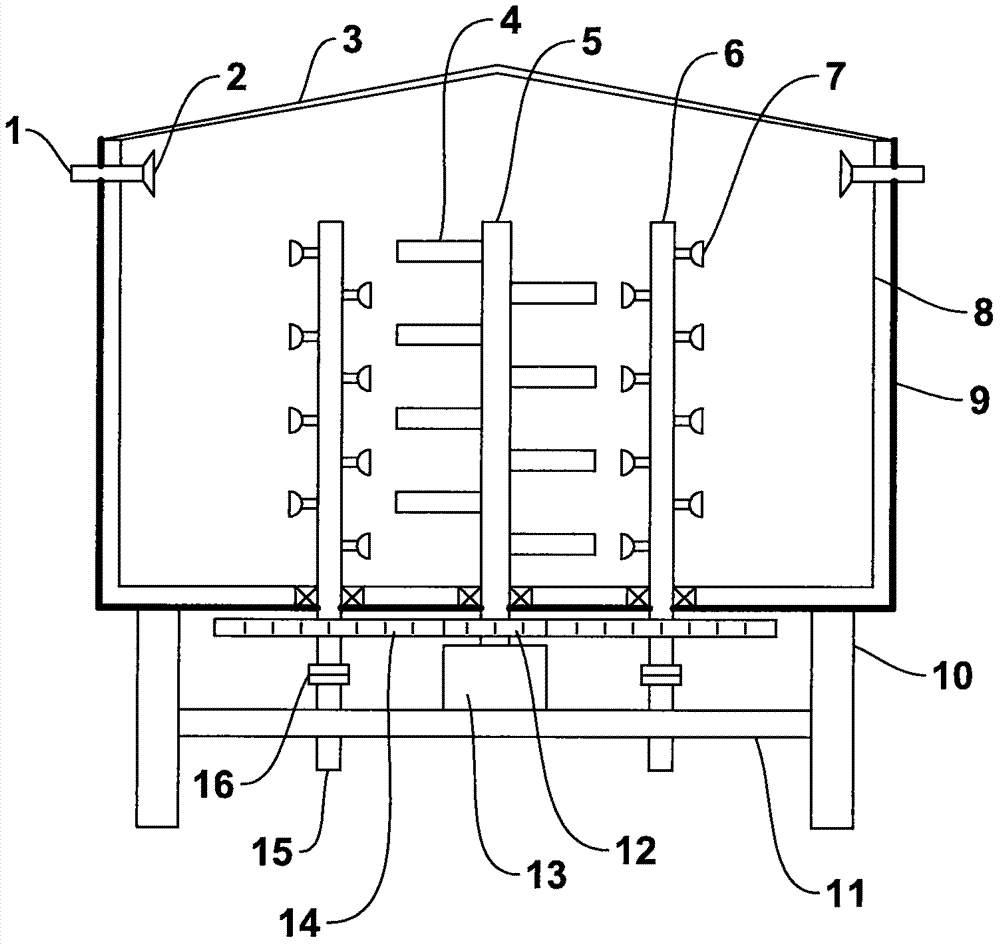

Mixed aeration type organic fertilizer fermenting equipment

InactiveCN106927877AIncreased fermentation activityFully fermentedBio-organic fraction processingIrradiation based treatmentOrganic manurePulp and paper industry

The invention discloses mixed aeration type organic fertilizer fermenting equipment, which comprises a fermenting tank. A sun shed is fixedly installed at the top of the fermenting tank. The upper part of the sidewall of the fermenting tank is provided with multiple water supplement pipes. Water spray heads are arranged at the ends of the water supplement pipes at the inner side of the fermenting tank. A mixer shaft is arranged in the middle of the inner side of the fermenting tank, and aerator pipes are arranged at left and right sides of the mixer shaft. Multiple stirring paddles are arranged on the mixer shaft at the inner side of the fermenting tank. Multiple jet heads are arranged on the aerator pipes at the inner side of the fermenting tank. A driving gear is arranged on the mixer shaft at the lower side of the fermenting tank. The lower end of the mixer shaft is provided with a motor. A driven gear is arranged on each aerator pipe at the lower side of the fermenting tank. The lower end of each aerator pipe is connected to an oxygen pipe through a rotating joint. By the use of the equipment, organic fertilizers can be enshrined, fermentation activity is enhanced, fermentation period is shortened, and fermentation quality is guaranteed.

Owner:刘海明

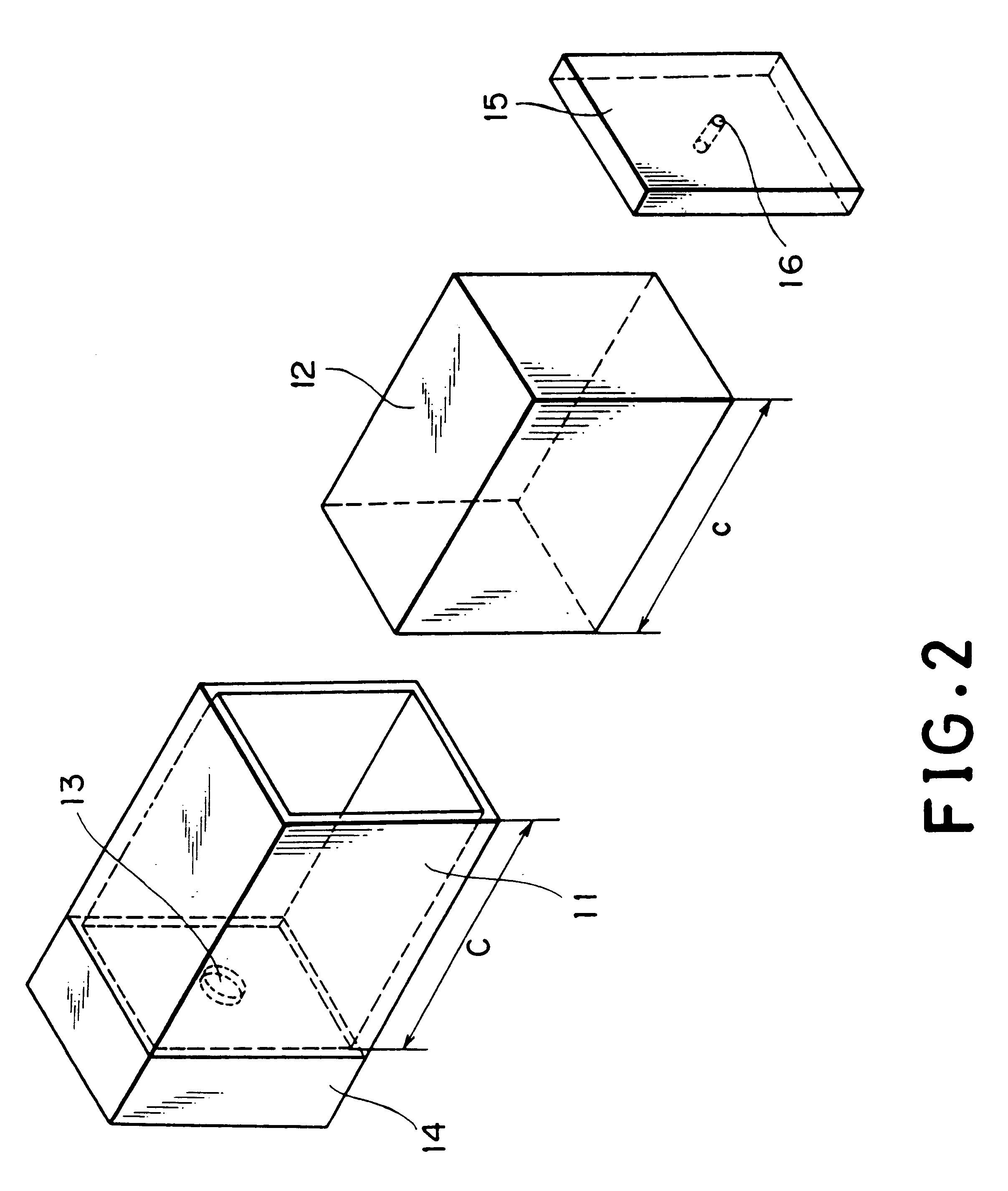

Ink tank, head cartridge and ink jet printing apparatus

A printing system having an ink tank for storing ink, the ink tank having a housing having an ink feeding port formed through a first surface for feeding ink therethrough, and a second surface opposite the first. An ink absorbing member is accommodated in the housing, is a porous member having a three-dimensional net-shaped structure molded of a composition comprising a condensate of (i) a compound having an amino group and (ii) formaldehyde, and has a first surface facing the ink feeding port. An alleviating member having more resilience than the ink absorbing member is disposed between the ink absorbing member and an ink outflow portion formed through the ink feeding port and alleviates pressure applied by the ink outflow portion against the ink absorbing member. Both the alleviating member and the ink absorbing member are deformed by compression against the ink outflow portion. A compensating member having more resilience than the ink absorbing member is disposed between the ink absorbing member and the ink outflow portion and applies a functional force to the ink absorbing member corresponding to deterioration of properties of the ink absorbing member. Another ink absorbing member having more resilience than the ink absorbing member is disposed between the ink absorbing member and the ink outflow portion.

Owner:CANON KK

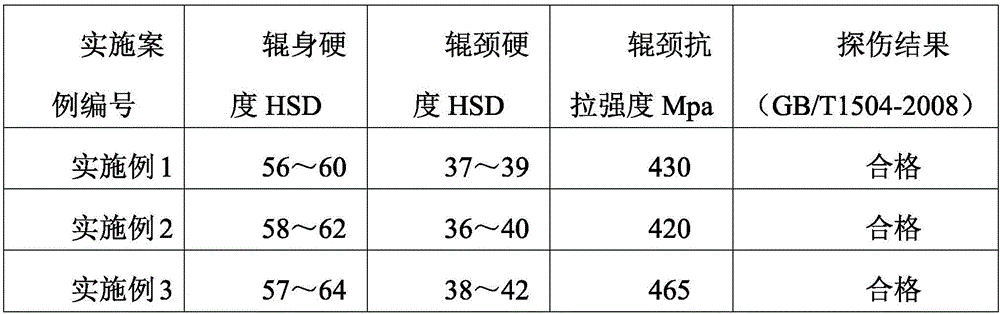

Nodular cast iron edging roll suitable for universal rolling mill and manufacturing method thereof

ActiveCN106367671AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesDuctile ironWear resistance

The invention discloses a nodular cast iron edging roll suitable for a universal rolling mill and a manufacturing method thereof. The nodular cast iron edging roll suitable for the universal rolling mill comprises a roll body, an upper roll neck and a lower roll neck, wherein the chemical components of the roll body and the lower roll neck are consistent, and the roll body includes, by weight percentage, 2.8-3.6% of C, 0.6-2.0% of Si, 0.3-0.6% of Mn, 0.3-1.0% of Cr, 1.0-3.0% of Ni, 0.2-0.7% of Mo, 0.05-0.1% of Re, 0.04% or more of Mg, 0.04% or less of P, 0.04% or less of S and the balance Fe. The manufacturing method includes the steps of molding, smelting, casting, box opening and heat treatment. Nodular cast iron replaces traditional universal rolling mill edging roll materials, a specific manufacturing process is adopted, the problems that an existing roll is long in production period and high in production cost are solved, and the abrasion resistance of the roll is improved.

Owner:邢台轧辊线棒辊有限责任公司

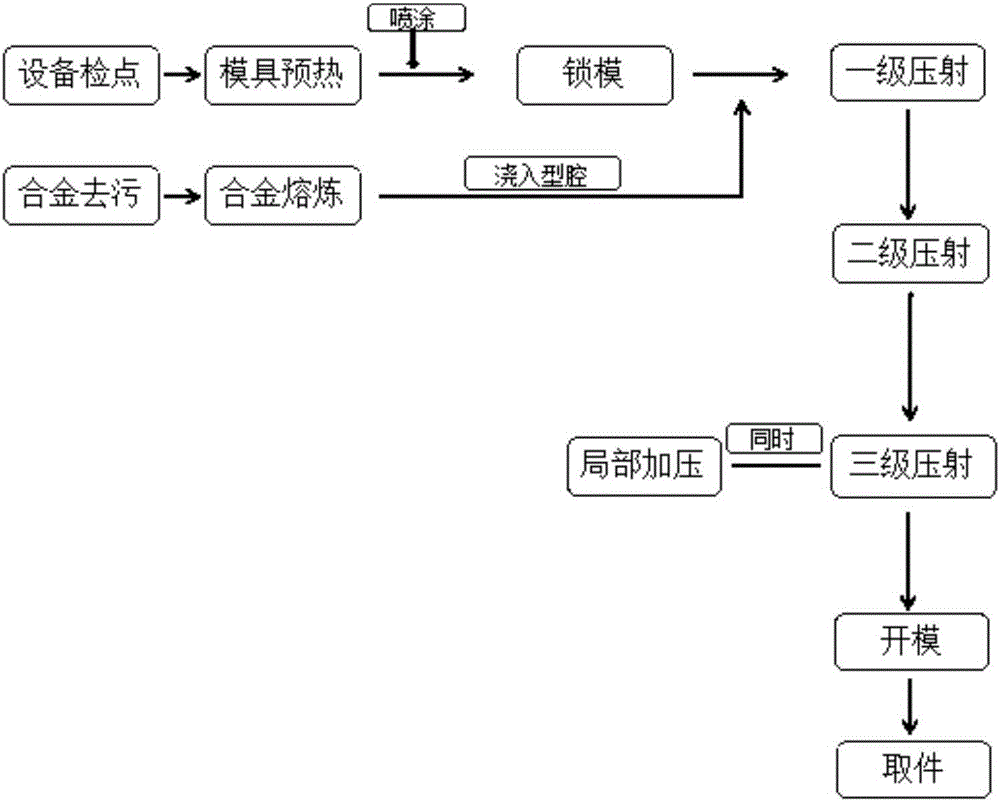

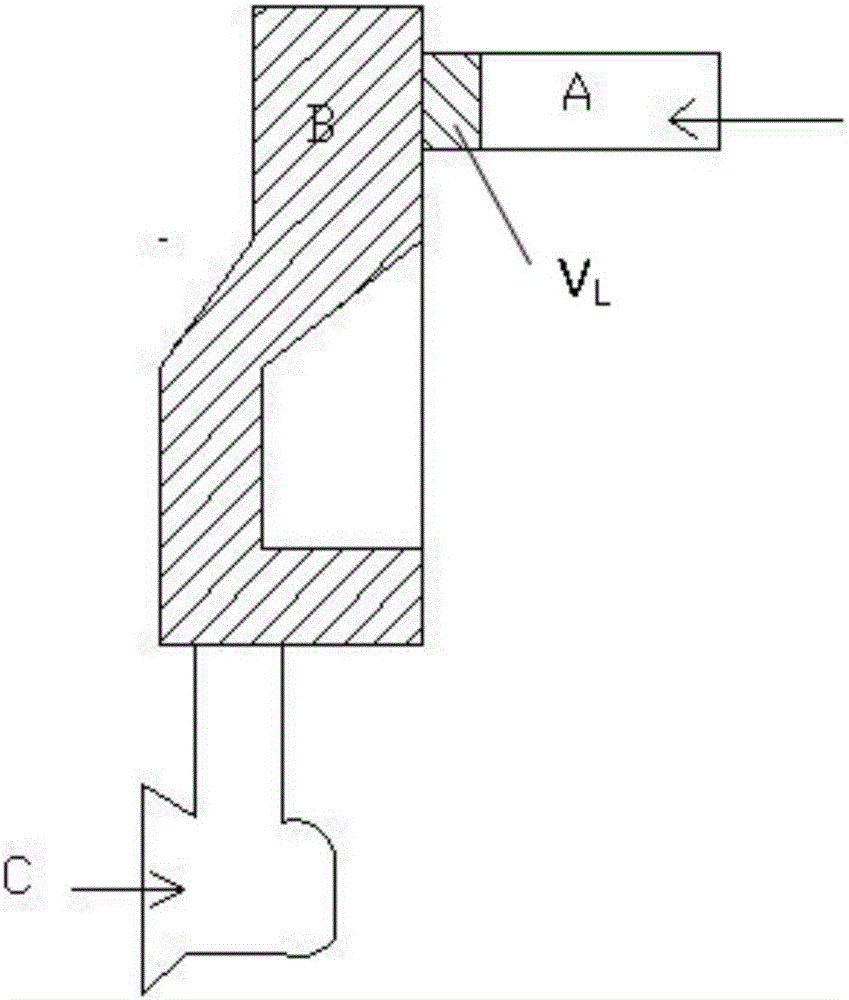

Die-casting forming method free from shrinkage cavity and shrinkage porosity defects for thick wall die-casting fitting

InactiveCN106270441ASolve the shrinkage porosity that is easy to appearSolve defects such as poresMold fillingDie casting

The invention discloses a die-casting forming method free from shrinkage cavity and shrinkage porosity defects for a thick wall die-casting fitting. By the adoption of the method, the problems of shrinkage cavity, shrinkage porosity and air hole defects which are likely to happen to a thick wall aluminum alloy die-casting fitting frequently can be solved effectively. The die-casting forming method includes the main contents that a specific pouring method with the low superheat degree is adopted, large fullness pouring with the pressure chamber fullness being 60%-70% is used, the high-pressure mold filling die-casting technique is utilized, and the internal compactness zero-defect performance of the die-casting fitting is achieved. The local pressurization structure is added in mold design, and pressurization feeding at the thick wall position far away from the position of an inner casting gate is realized. By the adoption of the method, the casting defects of the thick wall die-casting fitting can be reduced, the rejection rate of products is lowered, material wasting is avoided, cost is reduced and benefits are increased.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD +1

Method for coating alloy metal mould casting die

The invention relates to a method for coating an alloy metal mould casting die, wherein coatings for the die in the method disclosed by the invention are DAG395 heat-insulating coating and PRODAG release agent. A coating process for a heat-insulating layer comprises the following steps of: firstly, thoroughly eliminating foreign matters on the surface of the die; secondly, preheating the die to 150-230 DEG C, and eliminating oxides on the surface of the die by a steel wire brush; and finally, spraying the diluted DAG395 heat-insulating coating with a thickness of 0.3-0.5 mm at a die surface temperature of 150-230 DEG C, wherein the die surface temperature is greater than 95 DEG C during the coating of the release agent, and the spraying mode is a mist-spraying method, so that the thicknesses of the coated surface film are balanced and consistent. With the adoption of the method disclosed by the invention, protection for the alloy metal mould casting die and the heat-insulating effect of preventing alloy solution from being rapidly condensed are realized; the casting defects of loosening, heat-cracking, oxidization slag inclusion and the like are not easy to generate; and a compact organization and a high-quality casting are obtained.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

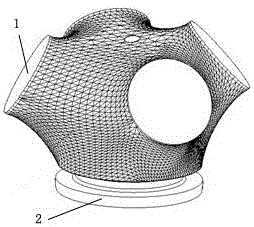

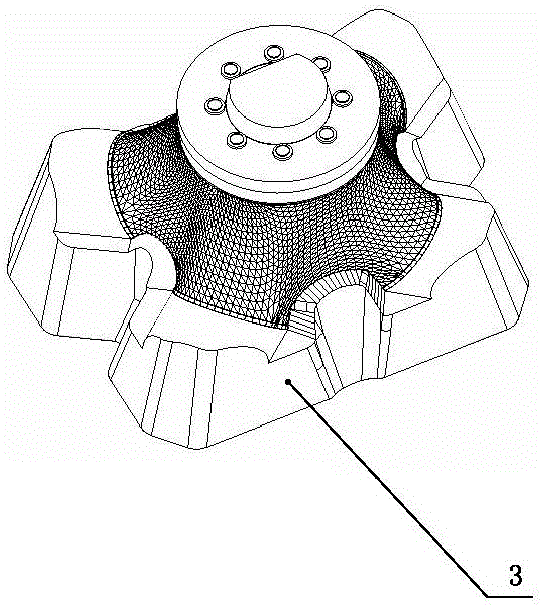

Casting forming process for large wind power planetary carrier

ActiveCN107790641ASmall size deviationEasy to operateFoundry mouldsFoundry coresElectricityEconomic benefits

The invention discloses a casting forming process for a large wind power planetary carrier casting. The planetary carrier casting comprises an upper annular plate and a lower annular plate which are vertically connected with triangular vertical columns, and a parting face of the planetary carrier casting is arranged on the interfaces of the upper annular plate and the triangular vertical columns;a first sand core and a second sand core are arranged between the upper annular plate and the lower annular plate, a triangular air outlet channel is formed in the outer sides of the sand cores, and vertical air outlet channels are formed in the centers of the sand cores; open risers are arranged right above the intersections of the upper annular plate and the triangular vertical columns, blinderrisers are arranged on the lower annular plate, and external chills are arranged under the lower annular plate. Pouring is carried out by adopting combined pouring mode of bottom-back pouring gates and stepped pouring gates. The planetary carrier produced by the method is good in forming and qualified in size, the matric structure of the casting is compact, joint parts of the triangular verticalcolumns and the upper annular plate and the lower annular plate has no crack defect, the other parts only need to undergo modification repair welding, the production cost of the casting is reduced, and higher economic benefits are achieved.

Owner:兰州兰石铸锻有限责任公司

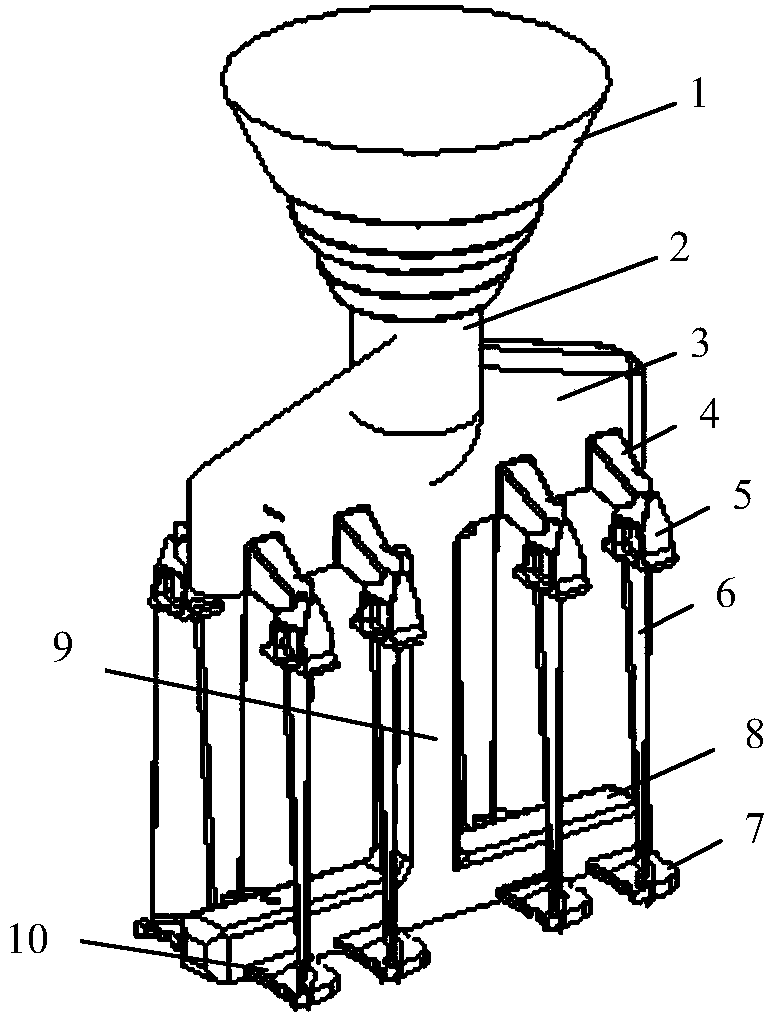

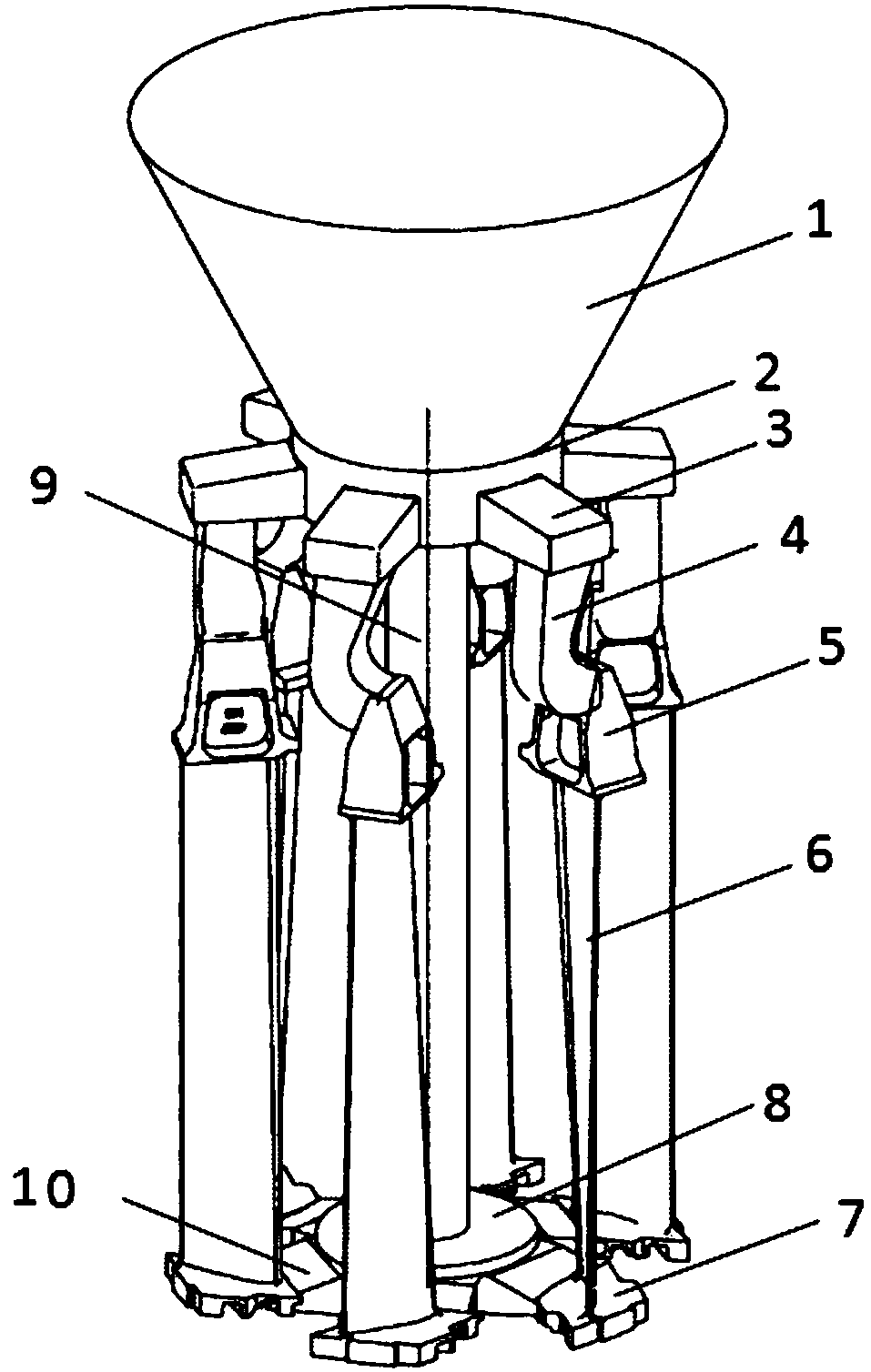

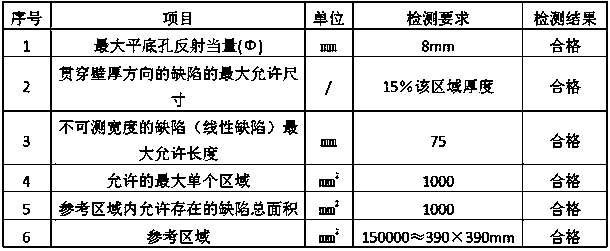

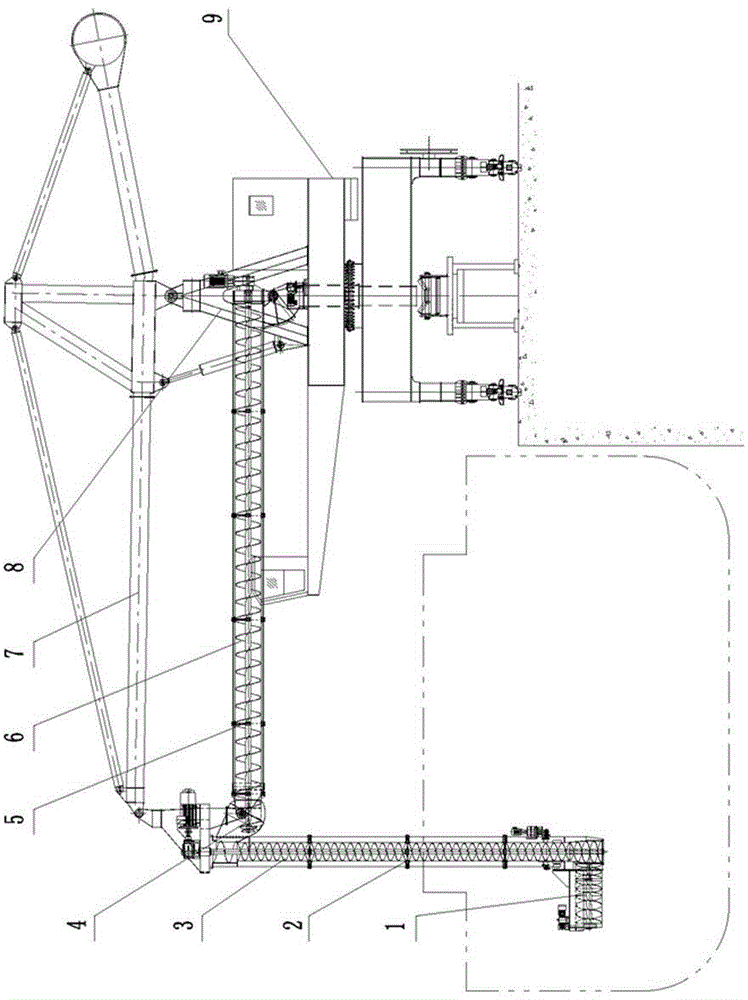

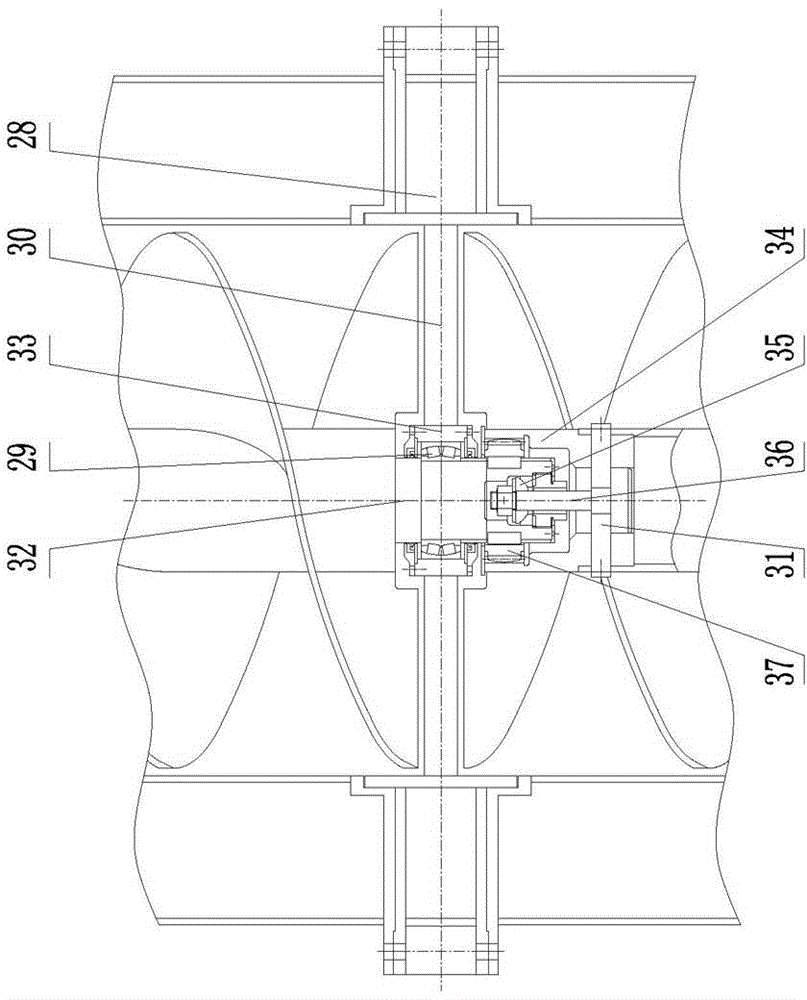

L-shaped screw ship unloader

ActiveCN104627700AImprove feeding capacityImprove unloading capacityLoading/unloadingLoad carryingScrew conveyor

The invention discloses an L-shaped screw ship unloader which can improve material taking capacity and efficiency, improve ship unloading capacity, increase the utilization rate, improve the material flow smoothness of a conveying system, improve the load-carrying capacity of a supporting structure, lower ship clearing quantity, lower the energy consumption of the ship unloader and lower the requirement for the manufacturing and mounting accuracy of a vertical screw shaft. The L-shaped screw ship unloader comprises a vertical milling type screw material taking device, a reverse screw spoke middle supporting device, a vertical screw conveyor, a coaxial annular material groove material transferring device, a horizontal screw conveyor, a balance beam, a Y-shaped frame and a supporting frame. The vertical screw conveyor, the horizontal screw conveyor, the balance beam and the Y-shaped frame form a parallel four-connecting-rod mechanism. By means of the scheme, the L-shaped screw ship unloader achieves the purposes of improving the material taking capacity and efficiency, improving the ship unloading capacity, increasing the utilization rate, improving the material flow smoothness of the conveying system, improving the load-carrying capacity of the supporting structure, lowering the ship clearing quantity, lowering the energy consumption of the ship unloader and lowering the requirement for the manufacturing and mounting accuracy of the vertical screw shaft.

Owner:WUHAN UNIV OF TECH +1

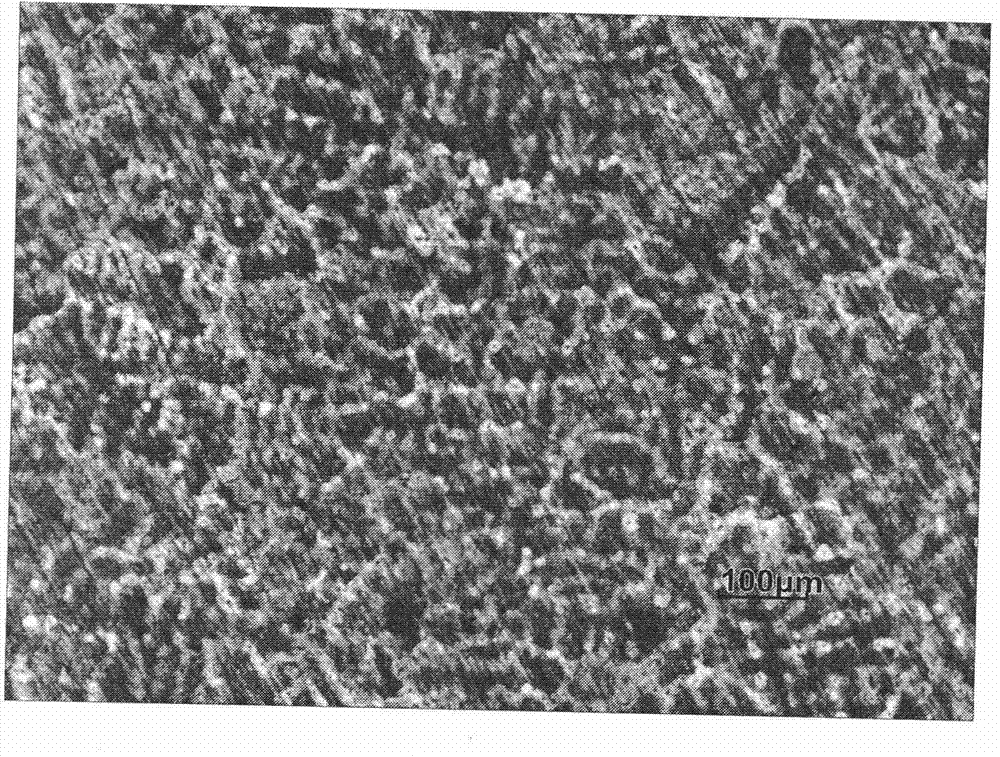

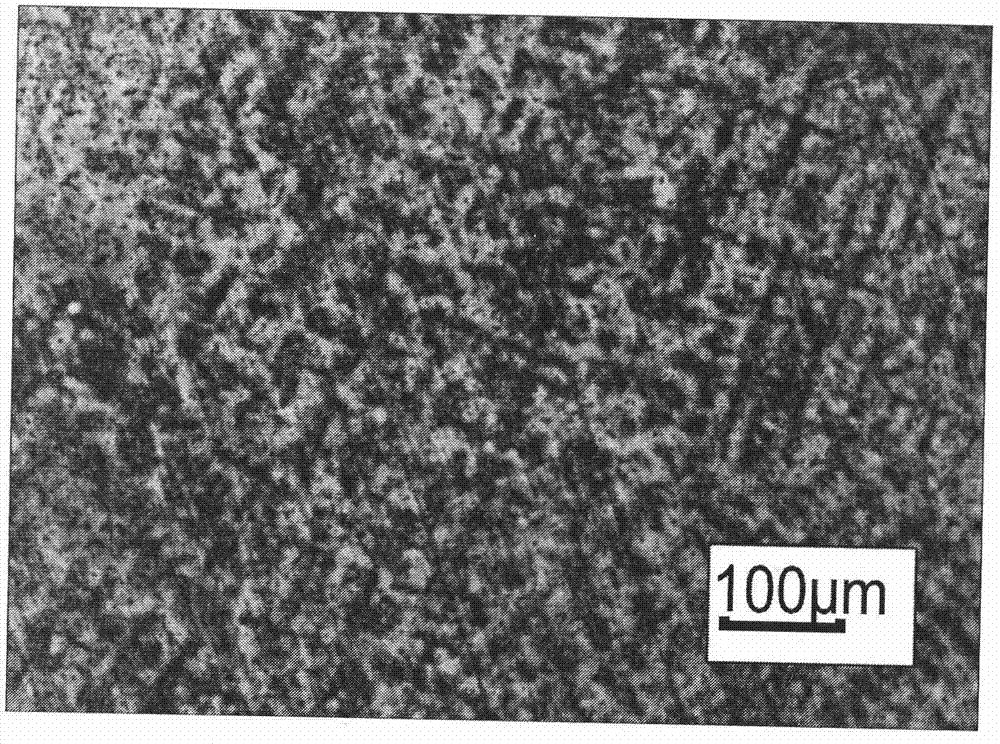

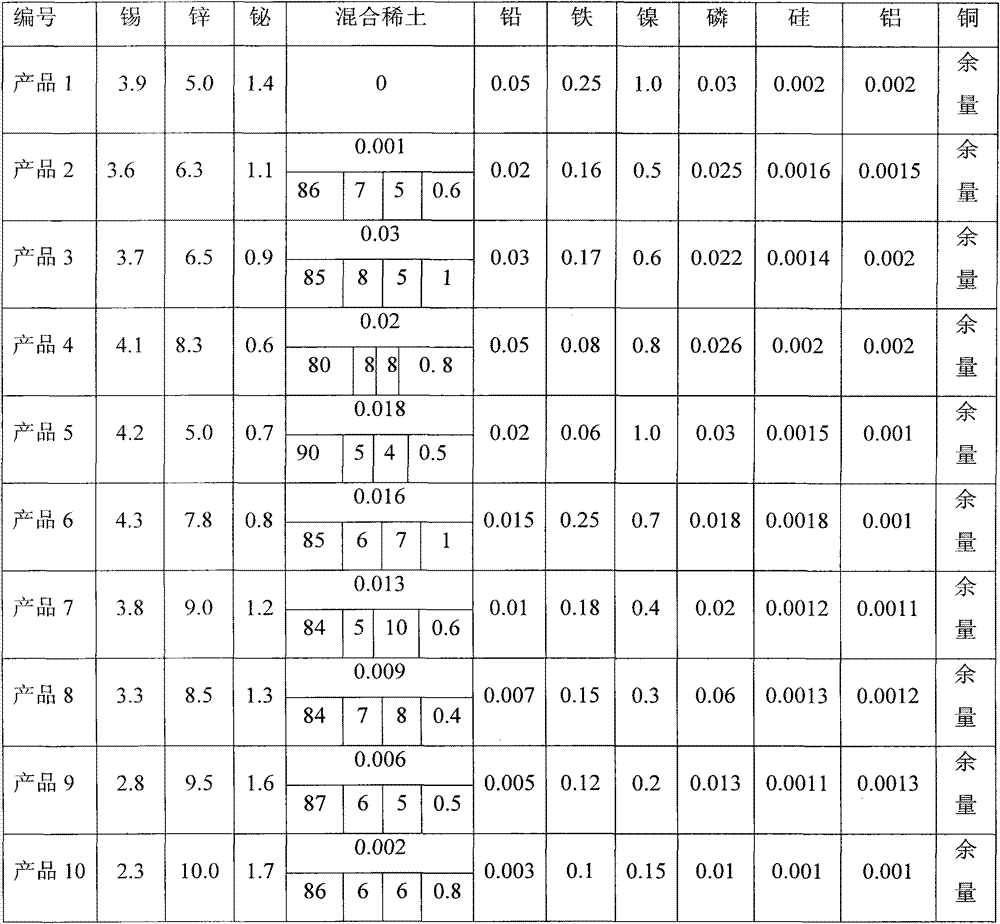

Lead-free bronze alloy and application thereof

The invention discloses a lead-free bronze alloy and an application thereof. The lead-free bronze alloy comprises the following chemical components by mass percent: 2.3-4.3 percent of stannum, 5.0-10.0 percent of zinc, 0.6-1.7 percent of bismuth, 0.002-0.02 percent of misch metal, equal to or less than 0.05 percent of lead, equal to or less than 0.25 percent of iron, equal to or less than 1.0 percent of nickel, equal to or less than 0.03 percent of phosphor, equal to or less than 0.002 percent of silicon, equal to or less than 0.002 percent of aluminum and the balance of copper, wherein the misch metal contains 80-90 percent of lanthanum, 5-8 percent of cerium, 4-10 percent of praseodymium and equal to or less than 1.0 percent of neodymium by mass percent. The alloy basically contains no lead, is harmless to human bodies and environments, is easily cut and suitable for low pressure casting and gravity casting, and has good erosion resistance; and the bronze alloy is suitable for casts of a drinking water system.

Owner:安新县华昌合金厂

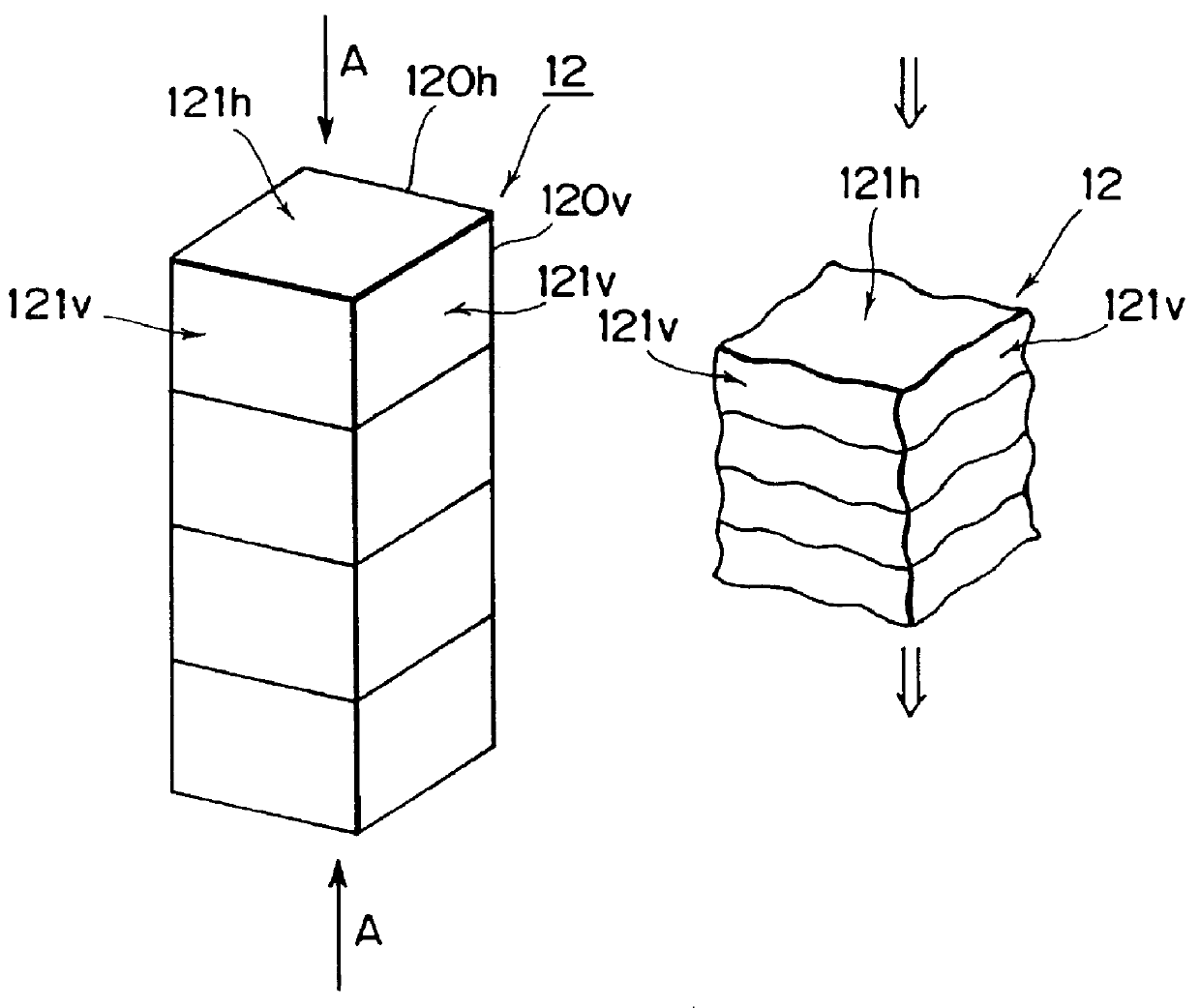

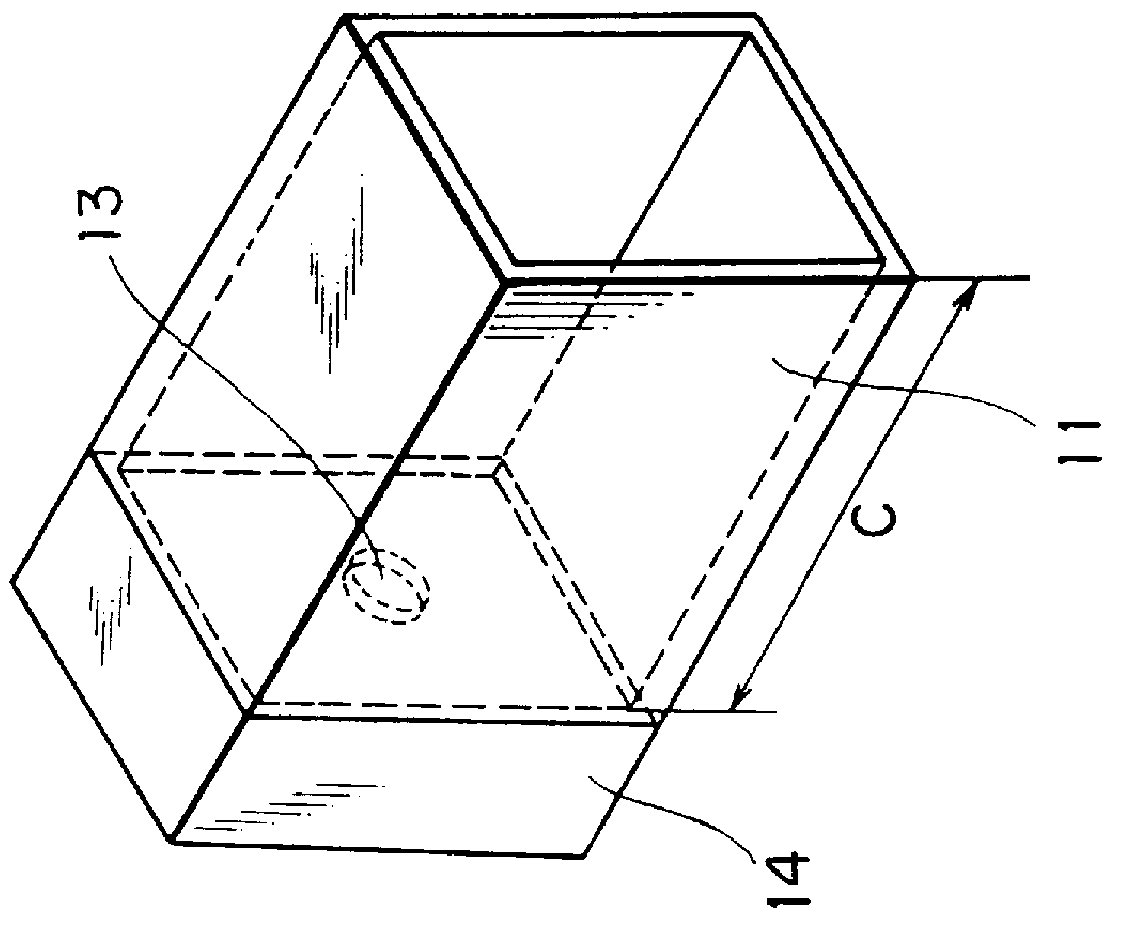

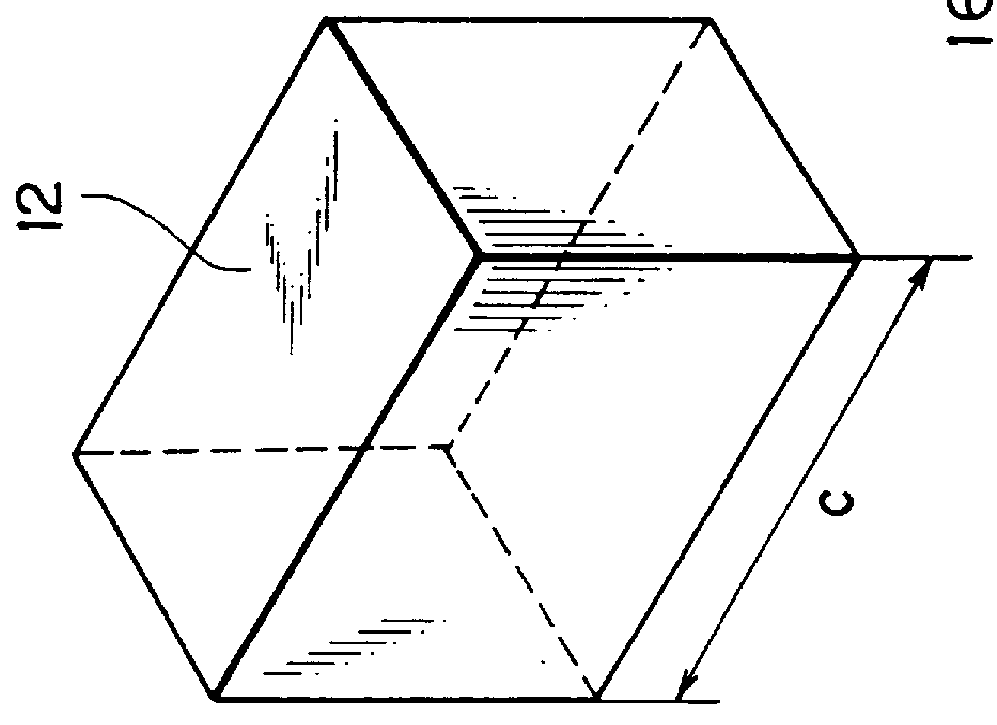

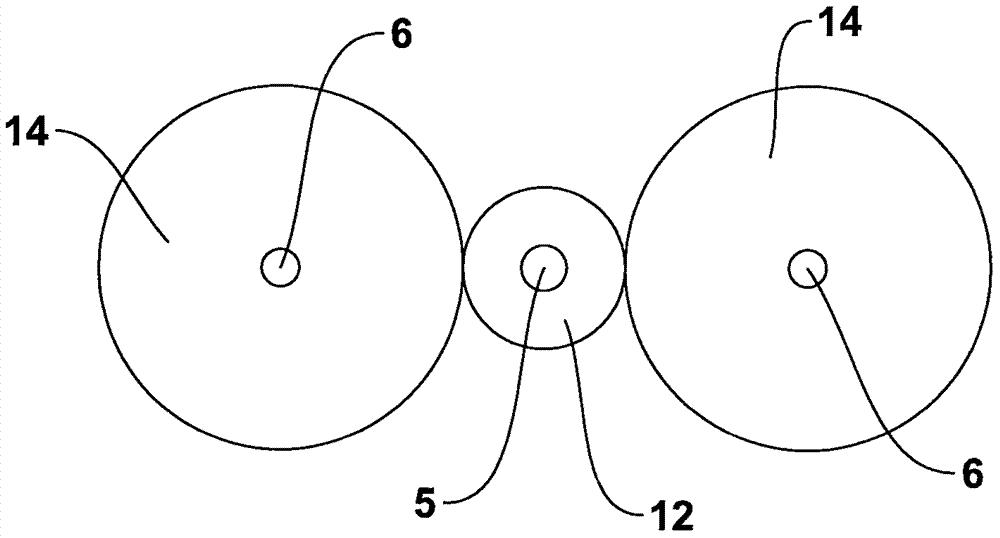

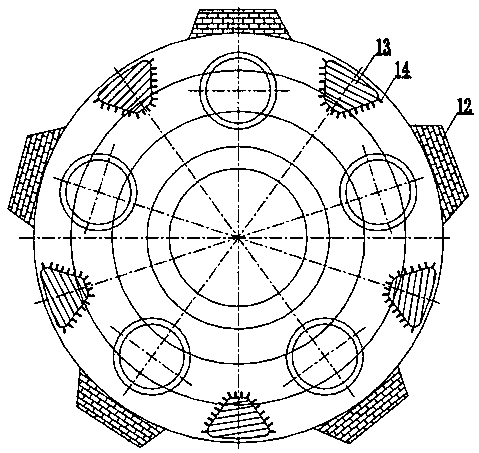

Semi-continuous casting crystallizer for aluminum alloy near net shape cast ingot

The invention relates to a semi-continuous casting crystallizer for an aluminum alloy near net shape cast ingot. The semi-continuous casting crystallizer comprises a crystallizer body and a thermal insulation hot top, wherein the thermal insulation hot top is arranged on the crystallizer body, an oil-gas distribution ring is arranged between the thermal insulation hot top and the crystallizer, gas injection holes and oil injection holes are uniformly distributed in the oil-gas distribution ring along the circumferential direction, the crystallizer body comprises a cooling water cavity and water spray structures communicated with the water cavity, the water spray structures are water seam structures with unequal widths, so that the cooling water flow in the circumferential direction of the crystallizer is a non-equivalent value. According to the crystallizer, liquid metal can be restrained, so that the liquid metal is condensed to a required shape of the cast ingot, and the cast ingot has a smooth surface and consistent quality to meet the dimensional requirements on subsequent thermal forming of the cast ingot. The cast ingot has stable forming condition, smooth surface and no defects, such as a drawing stamp and a gap.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Method for applying fluctuating pressure in low-pressure casting process

The invention relates to the technical field of special formation of non-ferrous alloy, particularly relates to a method for applying fluctuating pressure in a low-pressure casting process and aims at solving the problem that the existing large aluminum copper alloy casting forms shrinkage cavity and porosity defects in the low-pressure solidification process. The method comprises the steps of applying the fluctuating pressure to carry out a pressure maintaining stage after an alloy casting finishes a liquid lifting stage, a mold filling stage and a pressurizing stage when the alloy casting is subjected to low-pressure casting, and unloading the fluctuating pressure after the casting is completely solidified to finish low-pressure casting, wherein the time of the pressure maintaining stage is t, and the pressure maintaining time t ranges from pressure maintaining starting to complete casting solidification. The method is used for low-pressure casting.

Owner:HARBIN INST OF TECH

Method for regenerating and utilizing discarded silicasol case

InactiveCN101011720AImproved thermal shock stabilityStrong crack resistanceFoundry mouldsFoundry coresManufacturing cost reductionCasting mold

The invention relates to a reproduction and utilization of wasted silicasol skin. It crushes and sorts out the wasted silicasol skin to get material with the size 14-18, further screening it to get those 58-62, grinding those selected from 180-270180-270, replacing those ground quartz and so on to make sodium silicate shell. It can improve the feature of the cast mold shell with reduced manufacturing cost for the benefit of the environment.

Owner:关伟 +1

Feed for lobsters and preparation method of feed

InactiveCN105942023AReasonable ingredientsReduce mortalityFood processingClimate change adaptationChitin formationFish meal

The invention relates to the technical field of feed production and processing, in particular to feed for lobsters and a preparation method of the feed. The feed for the lobsters is prepared from components in parts by weight as follows: 15-25 parts of fish meal, 10-20 parts of soybean meal, 3-6 parts of distillers' grains, 3-6 parts of fish oil, 3-6 parts of lard, 8-12 parts of locust powder, 8-12 parts of chicken intestine powder, 3-6 parts of glycine betaine, 5-10 parts of chitin, 3-6 parts of corn stigmas, 5-10 parts of rice roots, 3-6 parts of dried bean milk cream in tight rolls, 1-3 parts of garlic, 1-2 parts of vitamin C, 3-6 parts of shaddock peels, 3-5 parts of isatis roots, 1-3 parts of ginger, 1-3 parts of poria cocos, 1-3 parts of dodder seeds, 1-3 parts of kudzuvine roots and 3-5 parts of hawthorn fruits. The formula is reasonable, the feed can meet requirements of the lobsters in rapid growth and development for nutrition, the death rate of the lobsters is reduced, and the feeding ability of the lobsters is enhanced.

Owner:HEZE HAINUO INTPROP SERVICES

Casting method for directional solidification column crystal and single-crystal blade

ActiveCN106734907ASolve the problem of loose defectsImprove feeding capacityFoundry mouldsFrom frozen solutionsWaxPorosity

The invention discloses a casting method for a directional solidification column crystal and a single-crystal blade. During finishing combination of a blade wax mold, one end of a technology feeding rib is stuck to an inner gate of the upper end of the blade, and the other end of the technology feeding rib is stuck to the position of the farthest corner, away from a blade body, of an edge plate. The technology feeding rib is parallel to the blade body so that molten metal can reach the position of the thin corner of a casting during pouring, the feeding capability of the casting is improved, and the problem of the porosity defect caused by the fact that cooling is conducted too fast and feeding cannot be conducted in time in the solidification process of the thin and large blade edge plate with a suddenly-changed section is solved.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com