Method for manufacturing casting blank of die for inner containers of household appliances on basis of metal cavity with cold iron structure

A metal type and structure technology, applied in the field of aluminum alloy casting, can solve the problems of pinholes, shrinkage, difficulty in producing large castings, high mold manufacturing costs, etc., to improve quality and pass rate, overcome difficulty in trimming, and improve production quality. and the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

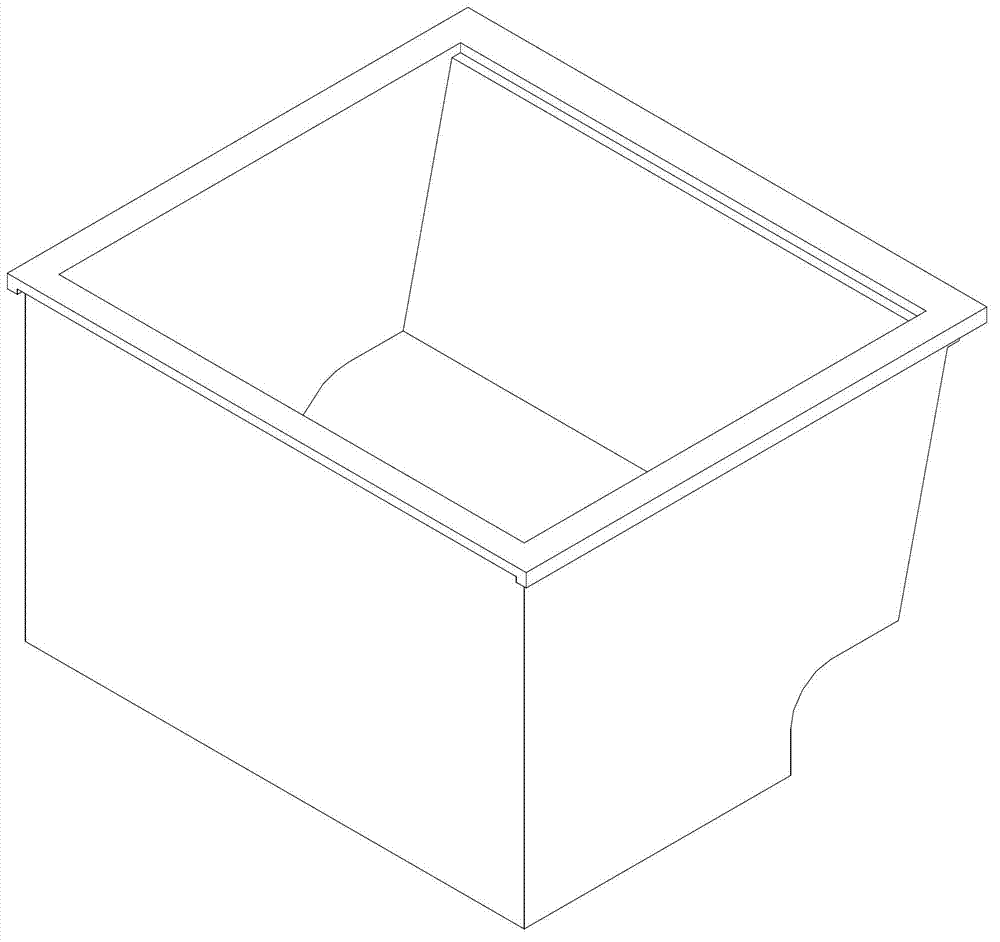

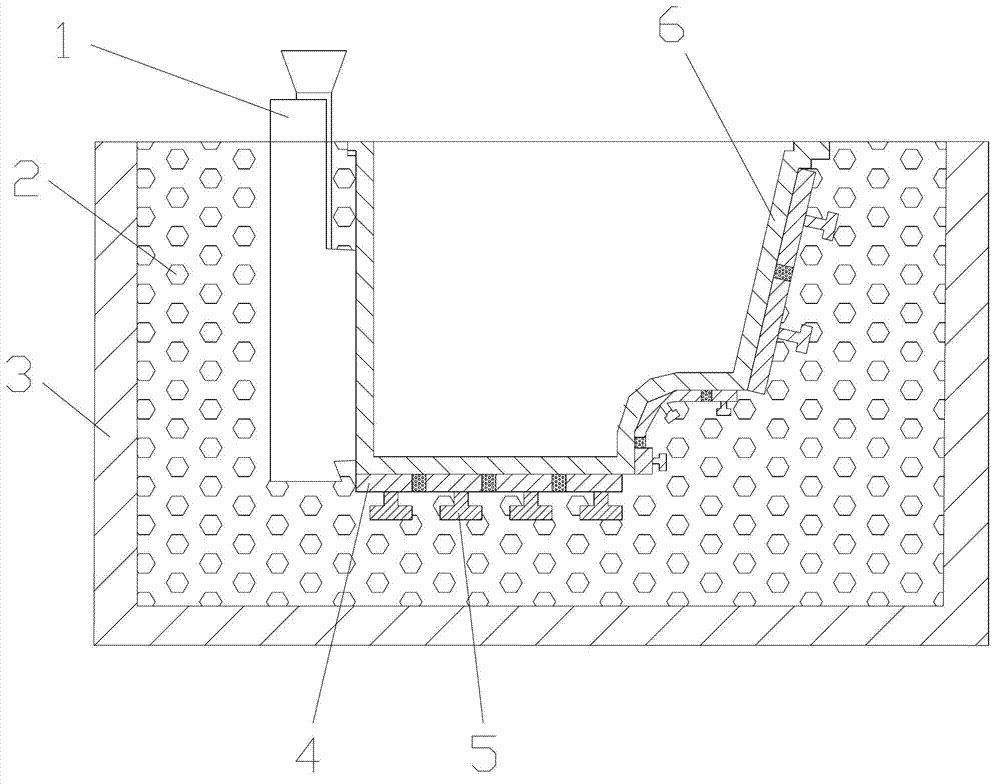

[0027] Such as figure 1 , figure 2 As shown, a large aluminum alloy type slab cast slab is manufactured by embedded stainless steel pipe technology, and the specific implementation method is as follows:

[0028] ①Complete the three-dimensional model design of the liner product based on the CAD modeling module of the computer-aided design software; use the offset surface command to offset and thicken the processing surface according to the two-dimensional drawing of the liner casting, and quickly and automatically add the machining allowance of the casting; To facilitate the removal of the wooden mold 6, the casting needs to be drafted. When drawing the mold, attention should be paid to: the size of the two ends of the draft part conforms to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com