Vertical electromagnetic stirring method for controlling casting blank center quality

An electromagnetic stirring and electromagnetic stirring technology, which is applied in the field of continuous casting electromagnetic stirring, can solve the problems that the upper and lower melt temperature and solute distribution are not sufficient, the feeding capacity of the solidification end of the casting billet is insufficient, and the structure of the magnet device is complex, etc. problems, to improve the effective area, reduce and center shrinkage, and promote the effect of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

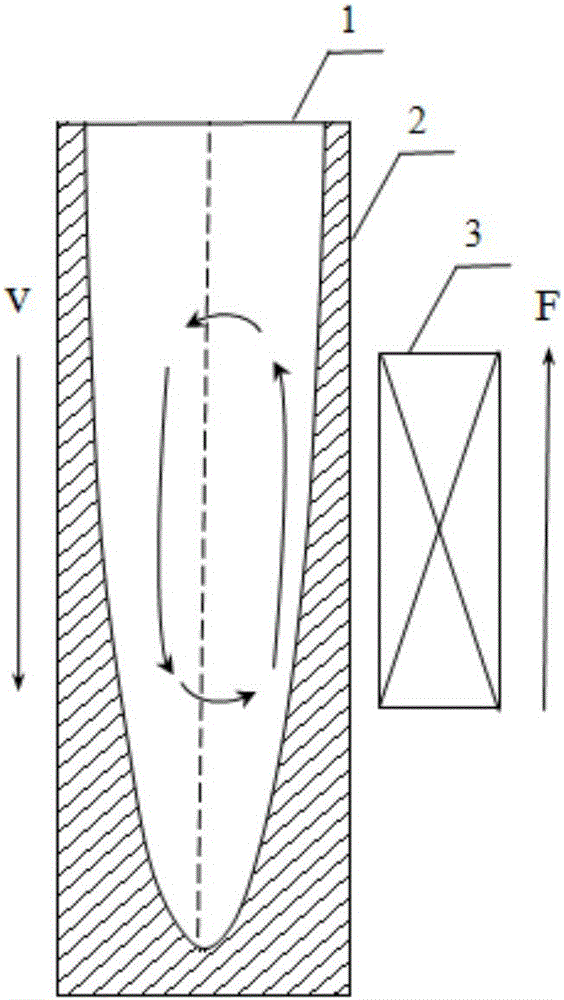

[0041] The vertical electromagnetic stirring method of the control slab center quality of the present embodiment is carried out according to the following steps:

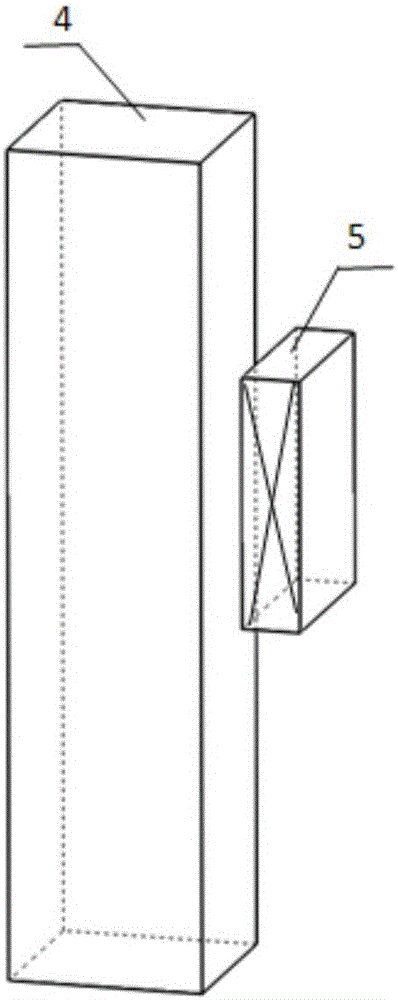

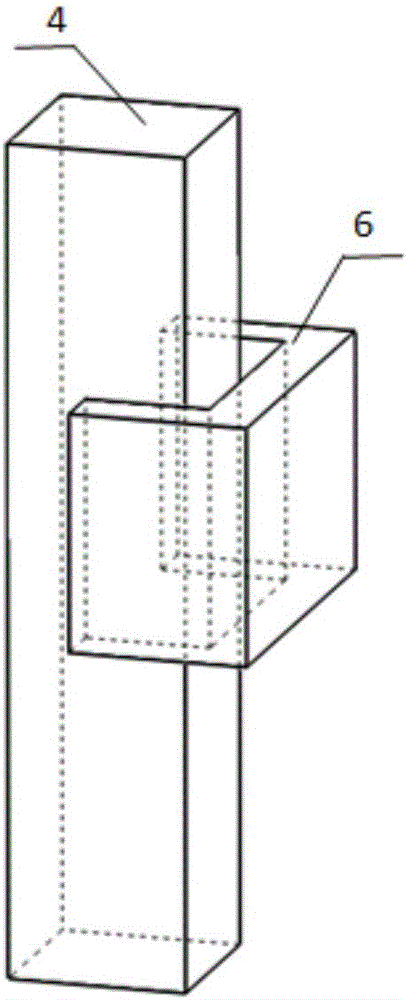

[0042] (1) Before continuous casting of 1Cr13 martensitic stainless steel, a rectangular traveling wave magnetic field type vertical electromagnetic stirrer is vertically erected on the side of the billet, 20mm away from the surface of the billet, and its steel composition w(%) 0.12 C, 0.60 Si, 0.60 Mn, 0.035 P, 0.03 S, 13 Cr, and the balance Fe; the distance between the upper end of the rectangular vertical electromagnetic stirrer and the lower end of the crystallizer is 600mm, the height of the stirrer is 450mm, and the magnetic pole The number is 3;

[0043] (2) During the continuous casting process, the power frequency of the traveling wave magnetic field type vertical electromagnetic stirrer is 12Hz, and the stirring current is selected as 350A; when the continuous casting starts, the vertical electromagnetic s...

Embodiment 2

[0046] The vertical electromagnetic stirring method of the control slab center quality of the present embodiment is carried out according to the following steps:

[0047] (1) Before continuous casting of high-carbon GCr15 bearing steel, a rectangular traveling wave magnetic field type vertical electromagnetic stirrer is vertically placed on the side of the billet, 30mm away from the surface of the billet, and its steel composition is w(%) 0.98 C, 0.20 Si, 0.30 Mn, 0.035 P, 0.002 S, 1.48 Cr, 0.03Ni, 0.05Cu, balance Fe; the distance between the upper end of the rectangular vertical electromagnetic stirrer and the lower end of the crystallizer is 550mm, and the stirrer The height is 450mm, and the number of magnetic poles is 3;

[0048] (2) During the continuous casting process, the power frequency of the traveling wave magnetic field type vertical electromagnetic stirrer is 12Hz, the stirring current is 320A, and the vertical electromagnetic stirring is carried out at the beginn...

Embodiment 3

[0051] The vertical electromagnetic stirring method of the control slab center quality of the present embodiment is carried out according to the following steps:

[0052] (1) Before the continuous casting of peritectic steel Q235 steel with a carbon content of 0.13, a rectangular traveling wave magnetic field type vertical electromagnetic stirrer is vertically placed on the side of the casting slab, and the distance from the surface of the slab is 25mm. The component w (%) is 0.13 C, 0.30 Si, 0.40 Mn, 0.045 P, 0.035 S, and the balance is Fe; the distance between the upper end of the rectangular vertical electromagnetic stirrer and the lower end of the crystallizer is 580 mm, and the height of the stirrer is 450mm, the number of magnetic poles is 3;

[0053] (2) During the continuous casting process, the power frequency of the traveling wave magnetic field type vertical electromagnetic stirrer is 12Hz, and the stirring current is selected as 300A. The continuous casting starts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com