Patents

Literature

74results about How to "Improve center quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

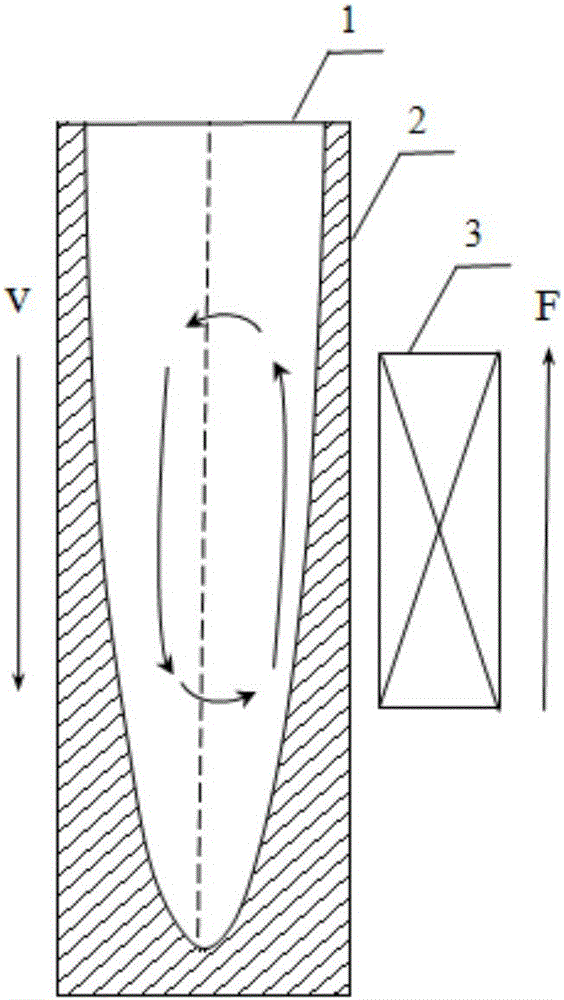

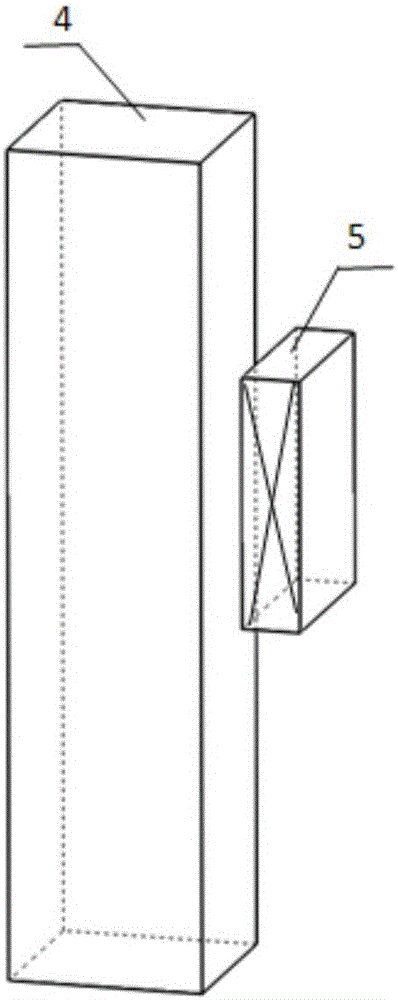

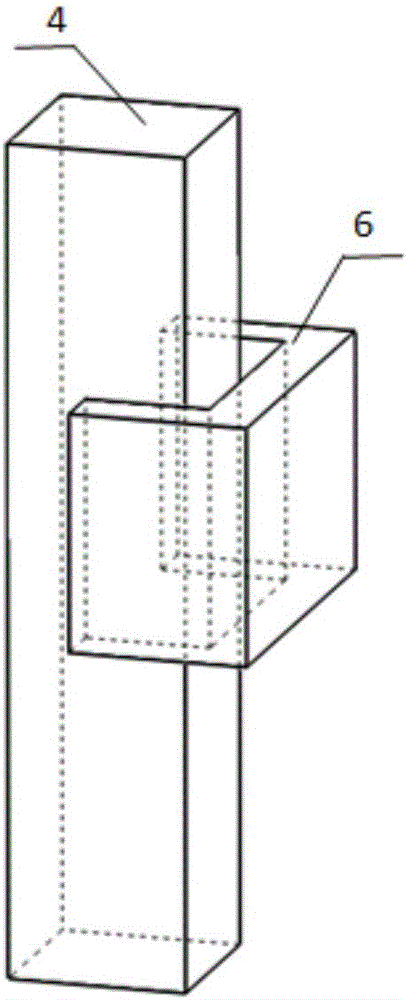

Vertical electromagnetic stirring method for controlling casting blank center quality

The invention belongs to the technical field of continuous casting electromagnetic stirring, and particularly relates to a vertical electromagnetic stirring method for controlling casting blank center quality. In the continuous casting production process, a traveling wave magnetic field type stirrer is arranged on the side face of a casting blank, and the overall direction of electromagnetic force generated by the traveling wave magnetic field stirrer in the casting blank is parallel to the direction of the center line of the casting blank. Traveling wave magnetic field stirrers in different shapes can be selected according to different cross-section shapes and sizes of casting blanks. The supply frequency of the vertical electromagnetic stirrer is 0.5-50 Hz, and the current of the vertical electromagnetic stirrer is 50-3000 A. By means of the method, melt in the casting blank center area can generate upward or downward forced convection movement along the center line of the casting bank, the effective action area of electromagnetic stirring in the length direction of the casting blank is enlarged, mixing of an upper high-temperature melt area and a lower low-temperature melt area of the casting blank center area is intensified, the feeding capability of upper melt of the casting blank center area to lower melt in solidification is improved, and uniformization of temperature and solute distribution in the casting blank is promoted.

Owner:NORTHEASTERN UNIV

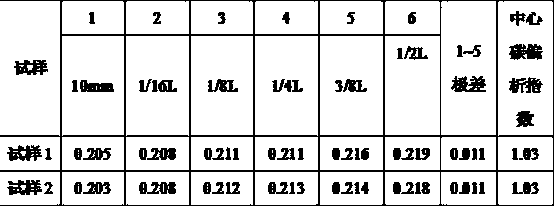

Method for reducing segregation during casting process of continuous-casting square billet for gear

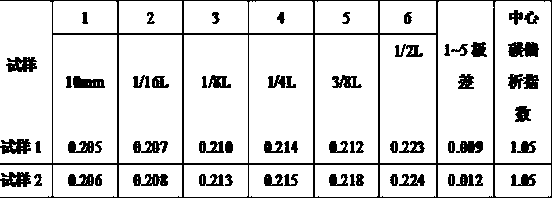

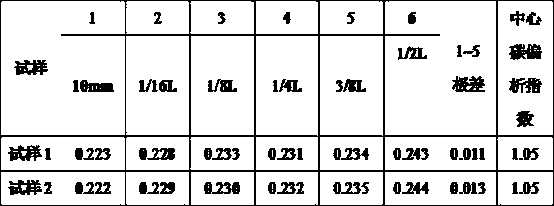

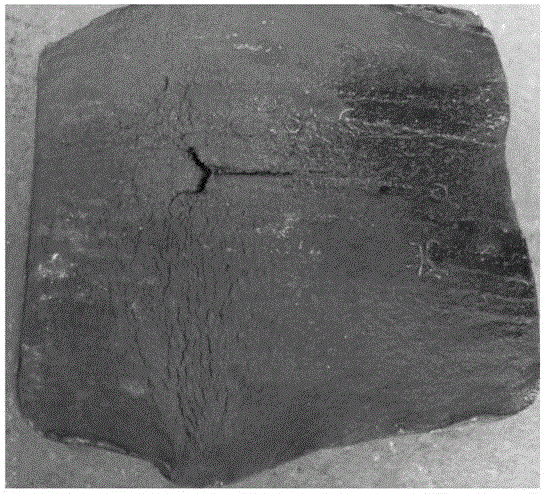

The invention discloses a method for reducing segregation during a casting process of a continuous-casting square billet for a gear. The method comprises the following steps: before the end of LF refining, the temperature of molten steel is increased to the continuous-casting molten steel overheating degree of 20-30 DEG C; a relatively large amount of water is utilized for primary cooling and secondary cooling of the continuous-casting square billet of 150x150 mm; the proportion of the water volume of a foot roller section reaches 40%; the electromagnetic stirring function of a crystallizer isdisabled; the electromagnetic stirring at the tail end is performed at a relatively low electric current; and the casting is performed at a withdrawing speed of 2.00 m / min. According to the method, the electromagnetic stirring function of the crystallizer is disabled, and thus the circumstance that the molten steel purity is influenced when entrapped slag is generated due to excessive stirring inthe crystallizer during the molten steel casting process can be avoided; the cooling water volume can be increased, the cooling strength can be improved, the withdrawing speed can be reduced, and thecasting billet can be sufficiently cooled, the effects that the growth of columnar crystals is promoted and the central equiaxed crystal ratio is reduced can be achieved, the aggregation of solute elements towards the space among the crystals and the center can be avoided, and then the segregation of elements in the casting billet can be reduced; the carbon range from the surface to 3 / 8 of a diagonal of the continuous-casting square billet for the gear can be controlled to be within 0.015%; the central carbon segregation index can be within 1.05; and the steel performance stability can be improved.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Atmospheric corrosion-resistant molten structural steel, chromium-titanium-containing atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.06%-0.12% by weight of V, 0.01%-0.015% by weight of Nb, 0.005%-0.030% by weight of Ti, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-titanium-nitrogen-containing atmospheric-corrosion-resistant molten steel, atmospheric-corrosion-resistant steel and production method of atmospheric-corrosion-resistant steel

The invention relates to the steel making field, and particularly provides atmospheric-corrosion-resistant molten steel. Based on the total weight of the molten steel, the molten steel comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 2.0-3.5% of Cr, 0.16-0.20% of V, 0.005-0.030% of Ti, 0.004-0.008% of N, less than or equal to 0.030% of P and less than or equal to 0.020% of S. The invention also provides atmospheric-corrosion-resistant steel and a production method thereof. When the molten steel is adopted for continuous casting, the center quality of casting blanks can be improved, center cracks and center line shrinkage are prevented, accordingly, the quality of the high strength and high atmospheric corrosion resistance steel casting blanks can be improved, and the qualification rate of the casting blanks can be improved to a great extent; and the finally obtained atmospheric-corrosion-resistant steel has good atmospheric corrosion resistance and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-nitrogen-containing atmospheric-corrosion-resistant molten steel, atmospheric-corrosion-resistant steel and production method of atmospheric-corrosion-resistant steel

The invention relates to the steel making field, and particularly provides atmospheric-corrosion-resistant molten steel. Based on the total weight of the molten steel, the molten steel comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 2.0-3.5% of Cr, 0.13-0.15% of V, 0.005-0.030% of Ti, 0.004-0.008% of N, less than or equal to 0.030% of P and less than or equal to 0.020% of S. The invention also provides atmospheric-corrosion-resistant steel and a production method thereof. When the molten steel is adopted for continuous casting, the center quality of casting blanks can be improved, center cracks and center line shrinkage are prevented, accordingly, the quality of the high strength and high atmospheric corrosion resistance steel casting blanks can be improved, and the qualification rate of the casting blanks can be improved to a great extent; and the finally obtained atmospheric-corrosion-resistant steel has good atmospheric corrosion resistance and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmosphere corrosion resisting molten profile steel, atmosphere corrosion resisting vanadium-titanium-nitrogen-containing profile steel and production method of atmosphere corrosion resisting vanadium-titanium-nitrogen-containing profile steel

The invention relates to the field of steelmaking and particularly provides atmosphere corrosion resisting molten profile steel. Based on the total weight, the molten profile steel contains 0.01% to 0.09% of C, 0.15% to 0.35% of Si, 0.30% to 0.60% of Mn, 0.30% to 0.40% of Cu, 0.20% to 0.30% of Ni, 3.5% to 5% of Cr, 0.16% to 0.20% of V, 0.005% to 0.030% of Ti, 0.004% to 0.008% of N, not larger than 0.030% of P and not larger than 0.020% of S. The invention provides atmosphere corrosion resisting profile steel and a production method thereof. By adopting the molten profile steel provided by the invention for continuous casting, the center quality of an ingot can be improved, and generation of center cracks and center line shrinkage can be avoided, so the quality of high-strength high-atmosphere-corrosion-resistance type profile steel ingot can be improved, the percent of pass of the ingot can be greatly increased, and moreover the finally-obtained atmosphere corrosion resisting profile steel is good in atmosphere corrosion resistance and higher in strength property.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Niobium-nitrogen-containing atmospheric corrosion-resistant molten structural steel, atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.021%-0.030% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-chromium-nitrogen-containing atmospheric corrosion-resistant molten structural steel, atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant steel and a production methodthereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel casting blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmosphericcorrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of atmospheric corrosion-resistant molten steel and vanadium-niobium-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.13%-0.15% by weight of V, 0.01%-0.015% by weight of Nb, 0.015%-0.020% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmosphere corrosion resisting structural steel liquid containing chrome, vanadium and nitride, atmosphere corrosion resisting structural steel and production method of atmosphere corrosion resisting structural steel

The invention relates to the field of steel making, and particularly provides atmosphere corrosion resisting structural steel liquid. Based on the total weight of the steel liquid, the steel liquid contains 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.16%-0.20% of V, 0.004%-0.008% of N, 0.030% or less of P and 0.020% or less of S. The invention provides atmosphere corrosion resisting structural steel and a production method of the atmosphere corrosion resisting structural steel. The center quality of a casting blank can be improved by adopting the steel liquid for continuous casting, center burst and center line shrinkage are avoided, accordingly, the quality of the high-strength atmosphere corrosion resisting structural steel casting blank can be improved, and the qualification rate of the casting blank can be greatly improved; and meanwhile the finally-obtained atmosphere corrosion resisting structural steel is good in atmosphere corrosion resistance and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-containing titanium-containing atmospheric corrosion-resistant molten steel, atmospheric corrosion-resistant steel and production method thereof

The invention relates to the steel-making field, and concretely provides an atmospheric corrosion resistant structural steel liquid, which contains the following components by adopting the total weight of the steel liquid as the baseline: 0.01 percent to 0.09 percent of C, 0.15 percent to 0.35 percent of Si, 0.30 percent to 0.60 percent of Mn, 0.30 percent to 0.40 percent of Cu, 0.20 percent to 0.30 percent of Ni, 2.0 percent to 3.5 percent of Cr, 0.06 percent to 0.12 percent of V, 0.005 percent to 0.030 percent of Ti, 0.008 percent to 0.014 percent of M, less than or equal to 0.030 percent of P, and less than or equal to 0.020 percent of S. The invention provides atmospheric corrosion resistant structural steel, and a production method thereof. By adopting the steel liquid provided by the invention for continuous casting, the central quality of a casting blank can be improved, and the occurrence of center burst and center line shrinkage is avoided, so that the quality of a high atmospheric corrosion resistant structural steel casting blank with high strength can be improved, and the yield of the casting blank can be greatly improved; and in addition, the finally obtained atmospheric corrosion resistant structural steel has good atmospheric corrosion resistance and a higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel containing vanadium and niobium resistant atmospheric corrosion steel, atmospheric corrosion resistant steel and production method thereof

The invention relates to the field of steelmaking and particularly provides molten steel of an atmosphere-corrosion-resistant structural steel. The total weight of the molten steel serves as the datum, and the molten steel comprises 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.13%-0.15% of V, 0.005%-0.030% of Ti, 0.01%-0.015% of Nb, 0.015%-0.020% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides the atmosphere-corrosion-resistant structural steel and a production method thereof. By means of continuous casting of the molten steel, center quality of a casting blank can be improved, center cracks and center shrinkage cavities are avoided, therefore quality of the casting blank of the structural steel high in strength and atmosphere-corrosion resistance can be improved, and the qualification rate of the casting blank can be remarkably increased; and in addition, the atmosphere-corrosion-resistant structural steel which is finally obtained is good in atmosphere-corrosion resistance and higher in strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-nitrogen-containing atmospheric corrosion-resistant molten structural steel, atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.13%-0.15% by weight of V, 0.01%-0.015% by weight of Nb, 0.005%-0.030% by weight of Ti, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant molten structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Chromium-vanadium-containing atmospheric corrosion-resistant steel molten steel, atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steelmaking, and particularly provides atmosphere corrosion resistant section steel molten steel. Taking the total weight of the molten steel as a standard, the molten steel comprises 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.06%-0.12% of V, 0.004%-0.008% of N, not larger than 0.030% of P and not larger than 0.020% of S. The invention provides atmosphere corrosion resistant section steel and a production method of the atmosphere corrosion resistant section steel. Through continuous casting of the molten steel in the invention, the center quality of a casting blank can be improved, center cracks and center line shrinkage can be avoided, and therefore the quality of the high-intensity high-atmosphere-corrosion-resistant section steel casting blank can be improved, and the yield of the casting blank can be greatly improved; and in addition, the finally-obtained atmosphere corrosion resistant section steel is good atmosphere corrosion resistance and has the high intensity performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel containing niobium nitrogen resistant atmospheric corrosion section steel and atmospheric corrosion resistant section steel and production method thereof

The invention relates to the field of steelmaking and particularly provides atmosphere corrosion resisting profile steel liquid. On the criterion of the total weight of the steel liquid, the steel liquid comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 2.0-3.5% of Cr, 0.16-0.20% of V, 0.005-0.030% of Ti, 0.01-0.015% of Nb, 0.021-0.030% of N, no more than 0.030% of P and no more than 0.020% of S. The invention provides atmosphere corrosion resisting profile steel and a production method thereof. When the steel liquid is adopted for continuous casting, the center quality of cast blanks can be improved, center cracking and center line shrinkage are avoided, and thus the quality of profile steel cast blanks with high strength and high atmosphere corrosion resistance can be improved, and the qualification rate of cast blanks can be greatly increased. In addition, the finally obtained atmosphere corrosion resisting profile steel has good atmosphere corrosion resistance and higher strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

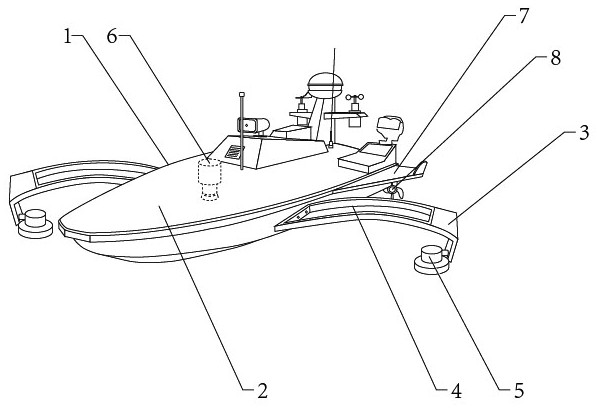

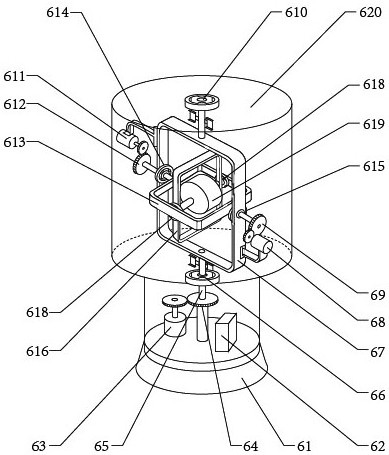

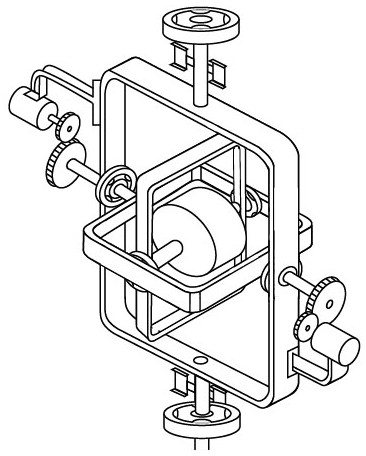

Unmanned ship structure suitable for severe sea conditions

InactiveCN111776150AReduce volumeReduce weightUnmanned surface vesselsVessel movement reduction by foilsMicrocomputerGear wheel

The invention discloses an unmanned ship structure suitable for a severe sea condition environment. The unmanned ship structure comprises an unmanned ship body, a ship body, a balance wing, a hollow groove, a stable heavy hammer, an automatic adjusting stabilizer, a holder, a microcomputer controller, a first servo motor, a first gear, a connecting shaft, an outer ring angle sensor, an outer ring,a second servo motor, a second gear, an outer ring torquer, a third servo motor, a third gear, a middle ring, a middle ring torquer, an inner ring, an inner ring angle sensor, an inner ring torquer,a rotor, a shell, a tail balance wing and a propeller; the ship body is installed on the unmanned ship body, the hollow groove is formed in the balance wing, the stable heavy hammer is installed at the tail end of the balance wing, the automatic adjusting stabilizer is installed in the middle of the ship body, and the holder is installed on the automatic adjusting stabilizer. The unmanned ship structure has the advantages that the appearance is novel, the internal automatic adjusting stabilizer is small in size, light in weight, simple in structure and good in reliability, the running state ofan unmanned ship can be intelligently detected, automatic adjustment is achieved, and the stability of the unmanned ship in the course is kept.

Owner:ZHEJIANG OCEAN UNIV

Chromium-vanadium-titanium-containing atmospheric corrosion-resistant molten steel and atmospheric corrosion-resistant steel and production method thereof

The invention relates to the steel-making field, and specifically provides molten steel of atmospheric corrosion resistant steel. Based on total weight of the molten steel, the molten steel comprises the following components in percentage by weight: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30-0.60% of Mn, 0.30%-0.40% of Cu, 0.20-0.30% of Ni, 2.0%-3.5% of Cr, 0.16%-0.20% of V, 0.005%-0.030% of Ti, 0.021%-0.030% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides atmospheric corrosion resistant steel and a production method thereof. The molten steel can be continuously cast to improve central quality of casting blank, and central cracks and central hole shrinkage are avoided, so that quality of high-strength steel casting blank with high atmospheric corrosion resistance can be improved, and the qualification rate of the casting blank can be greatly increased; and moreover, the finally obtained atmospheric corrosion resistant steel is good in atmospheric corrosion resistance, and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant molten structural steel, niobium-nitrogen-containing atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.021%-0.030% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel of atmospheric corrosion resistant steel and chromium-nitrogen containing atmospheric corrosion resistant steel and production method thereof

ActiveCN106676413AImprove center qualityHigh strengthManufacturing convertersSteelmakingMolten steel

The invention relates to the field of steel making, and specifically provides molten steel of atmospheric corrosion resistant steel. Based on total weight of the molten steel, the molten steel comprises the following components in percentage by weight: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3.5%-5.0% of Cr, 0.13%-0.15% of V, 0.004%-0.008% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides atmospheric corrosion resistant steel and a production method thereof. The molten steel can be continuously cast to improve central quality of casting blank, and central cracks and central pore shrinkage are avoided, so that quality of high-strength atmospheric corrosion resistant steel casting blank can be improved, and the qualification rate of casting blank can be greatly increased; and moreover, the finally obtained atmospheric corrosion resistant steel is good in atmospheric corrosion resistance, and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant steel molten steel and chromium-nitrogen-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making, and specifically provides molten steel of atmospheric corrosion resistant steel. Based on total weight of the molten steel, the molten steel comprises the following components in percentage by weight: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3.5%-5.0% of Cr, 0.13%-0.15% of V, 0.004%-0.008% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides atmospheric corrosion resistant steel and a production method thereof. The molten steel can be continuously cast to improve central quality of casting blank, and central cracks and central pore shrinkage are avoided, so that quality of high-strength atmospheric corrosion resistant steel casting blank can be improved, and the qualification rate of casting blank can be greatly increased; and moreover, the finally obtained atmospheric corrosion resistant steel is good in atmospheric corrosion resistance, and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant molten structural steel, vanadium-titanium-containing atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.005%-0.030% by weight of Ti, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel of atmospheric corrosion-resistant section steel, chromium-niobium-containing atmospheric corrosion-resistant section steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.06%-0.12% by weight of V, 0.01%-0.015% by weight of Nb, 0.008%-0.014% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of atmospheric corrosion-resistant steel molten steel and chromium-nitrogen-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.13%-0.15% by weight of V, 0.01%-0.015% by weight of Nb, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the highstrength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of vanadium-containing atmospheric corrosion-resistant molten steel and atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.06%-0.12% by weight of V, 0.008%-0.014% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant steel molten steel and chromium-vanadium-nitrogen-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steelmaking, and particularly provides atmosphere corrosion resistant section steel molten steel. Taking the total weight of the molten steel as a standard, the molten steel comprises 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3. 5%-5.0% of Cr, 0.16%-0.20% of V, 0.004%-0.008% of N, not larger than 0.030% of P and not larger than 0.020% of S. The invention provides atmosphere corrosion resistant section steel and a production method of the atmosphere corrosion resistant section steel. Through continuous casting of the molten steel in the invention, the center quality of a casting blank can be improved, center cracks and center line shrinkage can be avoided, and therefore the quality of the high-intensity high-atmosphere-corrosion-resistant section steel casting blank can be improved, and the yield of the casting blank can be greatly improved; and in addition, the finally-obtained atmosphere corrosion resistant section steel is good atmosphere corrosion resistance and has the high intensity performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of chromium-vanadium-nitrogen-containing atmospheric corrosion-resistant molten steel and atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant steel and a production methodthereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel casting blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmosphericcorrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant molten structural steel and chromium-vanadium-containing atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.16%-0.20% by weight of V, 0.021%-0.030% by weight of N, less than or equal to 0.030% of P, less than or equal to 0.020% of S and the balance of inescapable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a productionmethod thereof. Through continuous casting of molten steel, the central quality of a casting blank is improved, central cracks and central shrinkage cavity are avoided, the quality of the high strength and high atmospheric corrosion resistant structural steel blank is improved, a casting blank qualification rate is greatly improved and good atmospheric corrosion resistance and high strength of the atmospheric corrosion-resistant structural steel are obtained.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel of atmospheric corrosion resistant steel and titanium-nitrogen containing atmospheric corrosion resistant steel and production method thereof

The invention relates to the steel-making field, and specifically provides molten steel of atmospheric corrosion resistant steel. Based on total weight of the molten steel, the molten steel comprises the following components in percentage by weight: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3.5%-5.0% of Cr, 0.13%-0.15% of V, 0.005%-0.030% of Ti, 0.015%-0.020% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides atmospheric corrosion resistant steel and a production method thereof. The molten steel can be continuously cast to improve central quality of casting blank, and central cracks and central pore shrinkage are avoided, so that quality of high-strength atmospheric corrosion resistant steel casting blank can be improved, and the qualification rate of casting blank can be greatly increased; and moreover, the finally obtained atmospheric corrosion resistant steel is good in atmospheric corrosion resistance, and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric-corrosion-resistant molten steel, chromium-vanadium-titanium-containing atmospheric-corrosion-resistant steel and production method of atmospheric-corrosion-resistant steel

The invention relates to the steel making field, and particularly provides atmospheric-corrosion-resistant molten steel. Based on the total weight of the molten steel, the molten steel comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 3.5-5.0% of Cr, 0.16-0.20% of V, 0.005-0.030% of Ti, 0.021-0.030% of N, less than or equal to 0.030% of P and less than or equal to 0.020% of S. The invention also provides atmospheric-corrosion-resistant steel and a production method thereof. When the molten steel is adopted for continuous casting, the center quality of casting blanks can be improved, center cracks and center line shrinkage are prevented, accordingly, the quality of the high strength and high atmospheric corrosion resistance steel casting blanks can be improved, and the qualification rate of the casting blanks can be improved to a great extent; and the finally obtained atmospheric-corrosion-resistant steel has good atmospheric corrosion resistance and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of chromium-vanadium-containing atmospheric corrosion-resistant molten steel and atmospheric corrosion-resistant steel and production method thereof

Relating to the steelmaking field, the invention especially provides an atmospheric corrosion resistant molten steel. Based on a total weight, the molten steel contains: 0.01%-0.09% of C, 0.15%-0.35%of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.06%-0.12% of V, 0.01%-0.015% of Nb, 0.004%-0.008% of N, and not more than 0.030% of P and not more than 0.020% of S.The invention provides an atmospheric corrosion resistant steel and a production method thereof. Continuous casting of the molten steel provided by the invention can improve the central quality of a casting blank, avoids central crack and central shrinkage cavity, thereby improving the quality of the high strength and high atmospheric corrosion resistant steel casting blank and greatly enhancing the casting blank qualification rate. Also, the finally obtained atmospheric corrosion resistant steel has good atmospheric corrosion resistant ability and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com