Vanadium-containing titanium-containing atmospheric corrosion-resistant molten steel, atmospheric corrosion-resistant steel and production method thereof

A technology of atmospheric corrosion resistance and section steel, which is applied in the field of atmospheric corrosion resistance section steel, can solve the problems such as the lack of strength index of section steel, and achieve the effects of improving quality, raising the pass rate of billets, and improving the quality of the center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

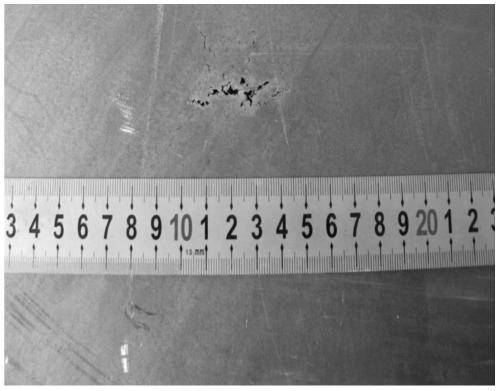

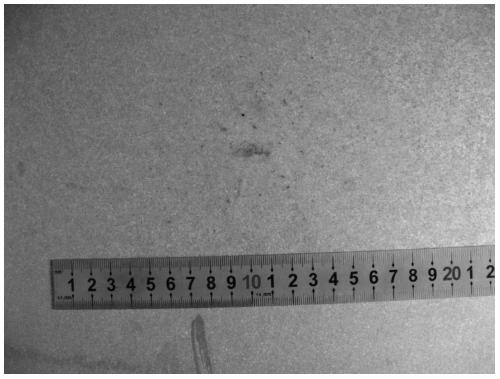

[0026] As mentioned above, the present invention provides a kind of atmospheric corrosion-resistant molten steel, based on the total weight of molten steel, molten steel contains: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% Cu, 0.20%-0.30% Ni, 2.0%-3.5% Cr, 0.06%-0.12% V, 0.005%-0.030% Ti, 0.008%-0.014% N, Not more than 0.030% of P and not more than 0.020% of S. The central quality of the slab (also called continuous casting slab) obtained by continuous casting of molten steel with the aforementioned composition is improved, and the center of the cross section of the continuous casting slab (after acid etching) basically has no central cracks and holes.

[0027] According to the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com