Patents

Literature

61results about How to "Increased slab pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

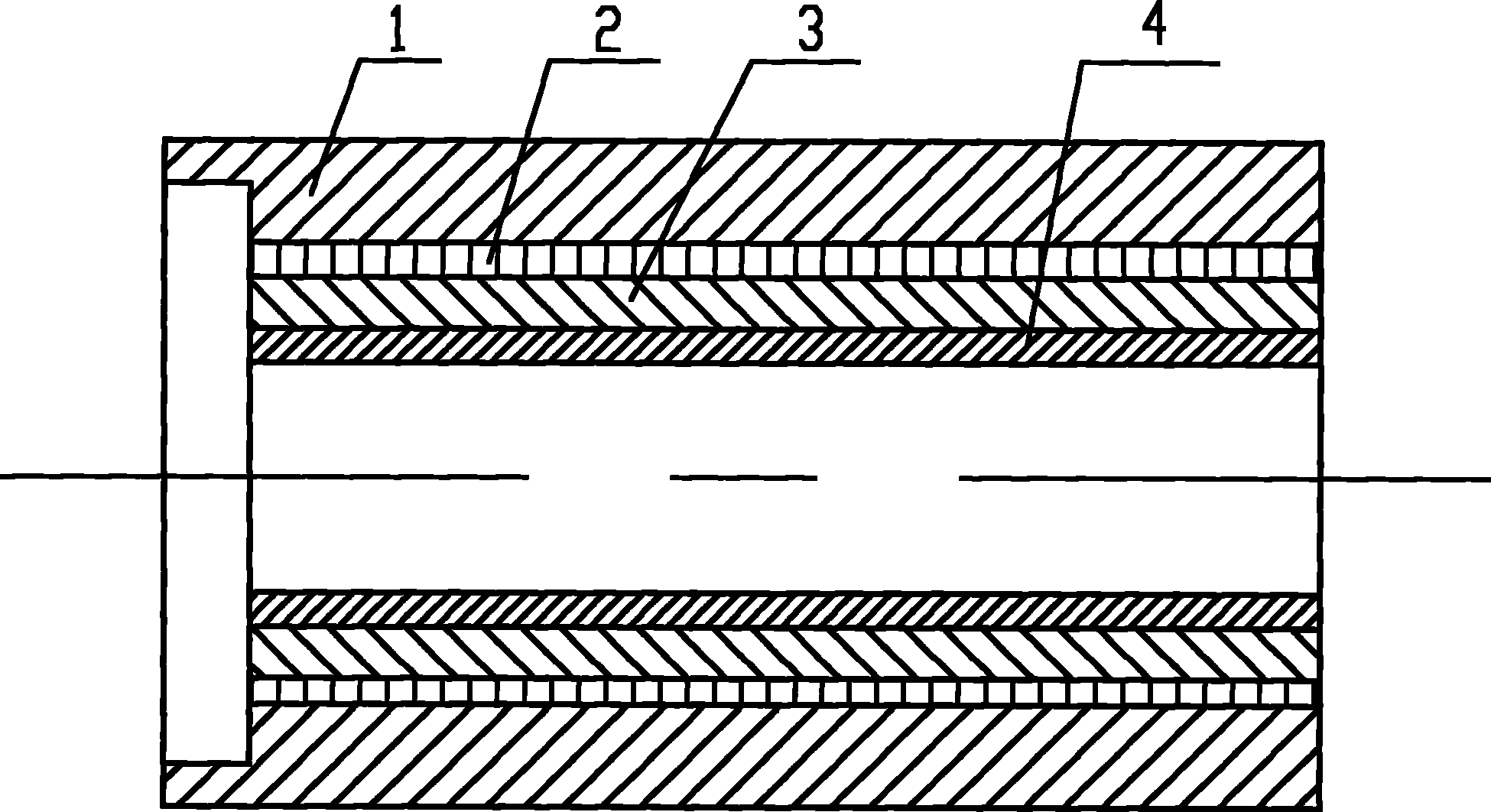

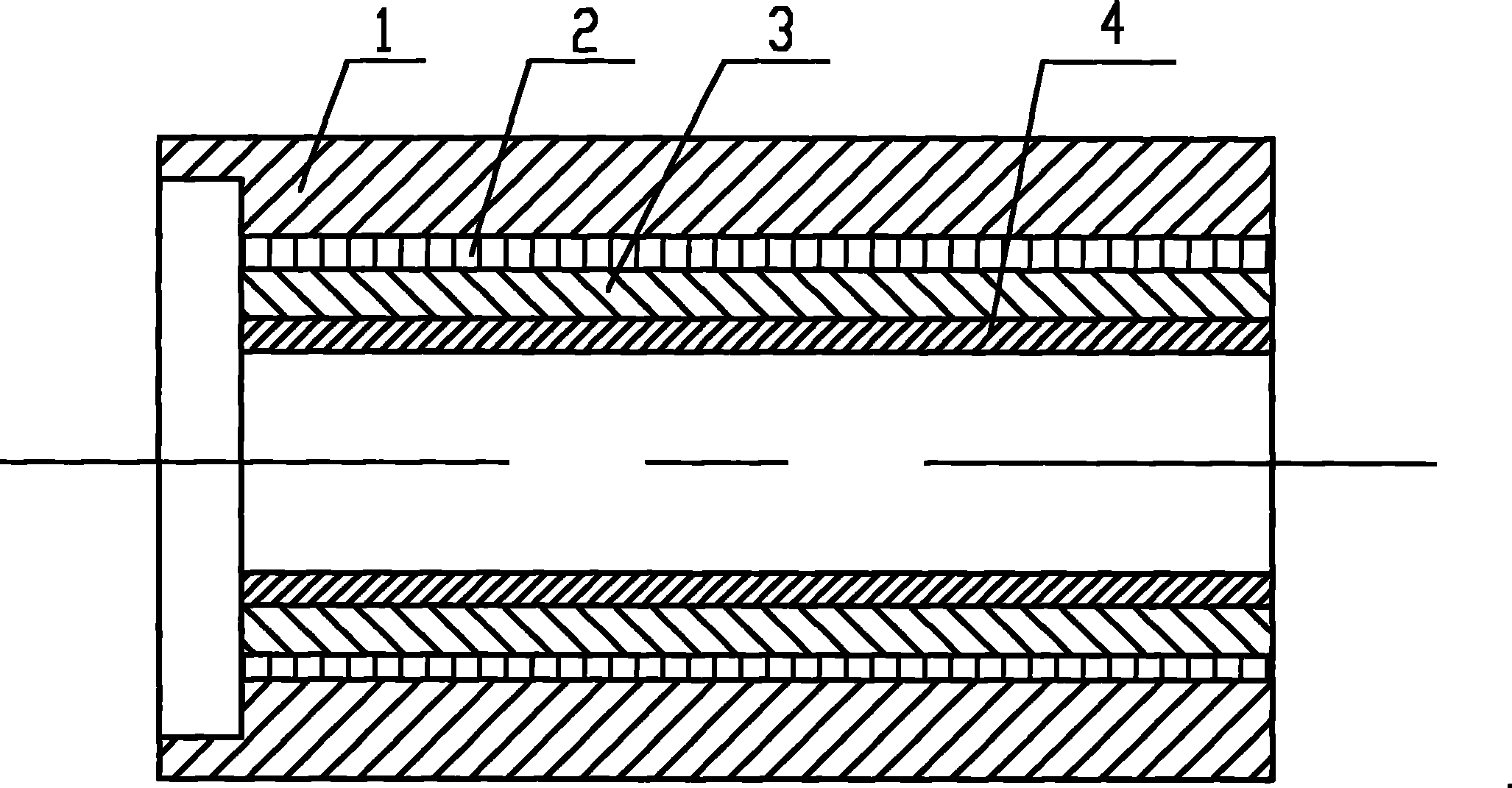

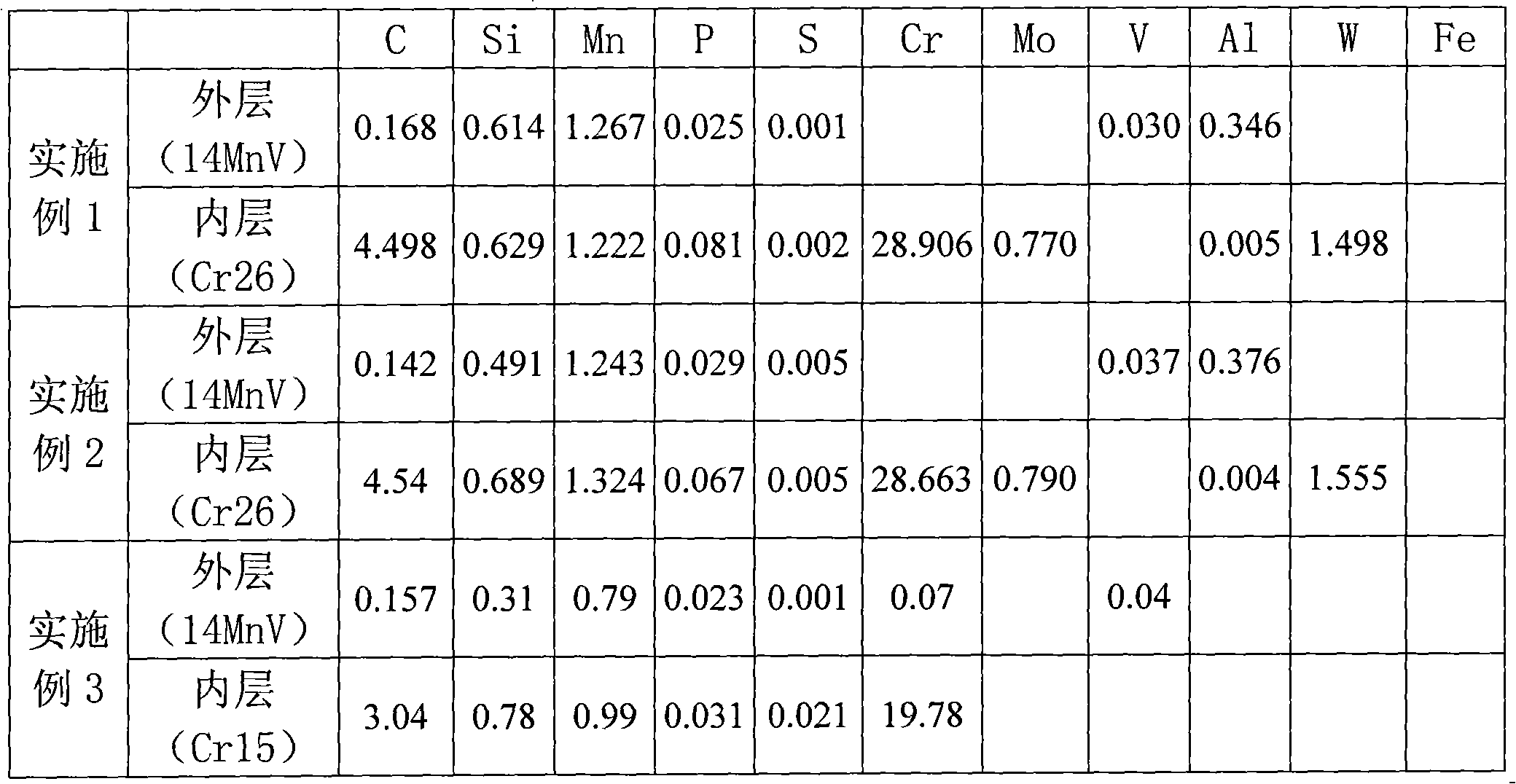

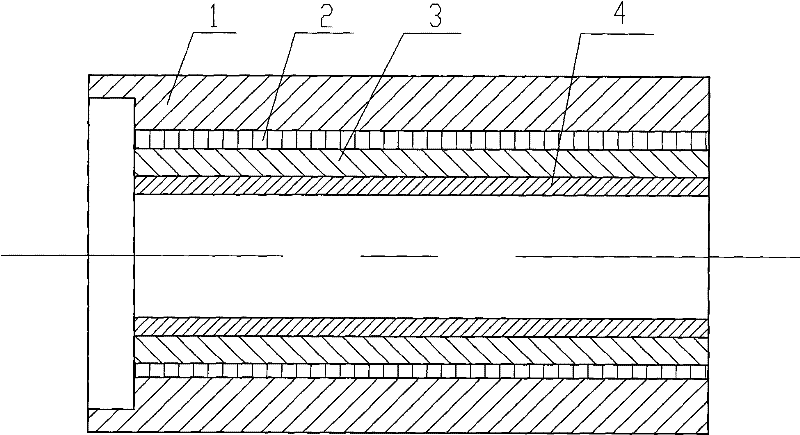

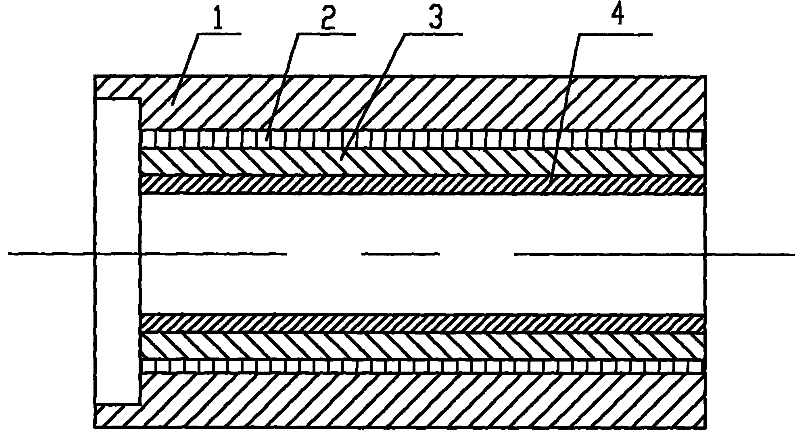

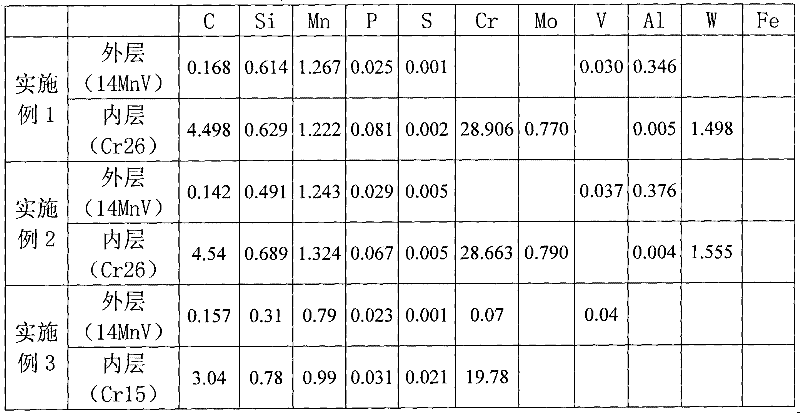

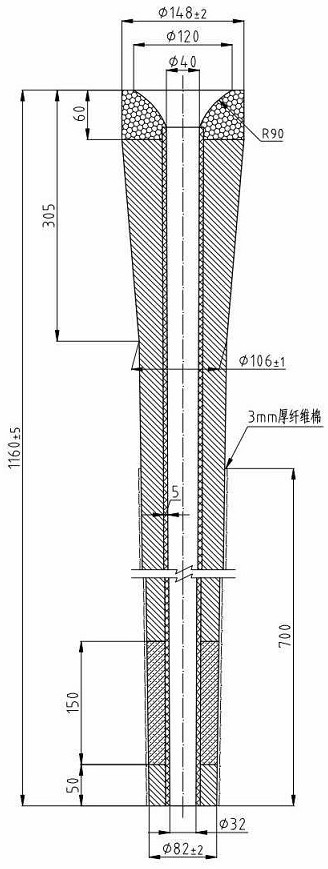

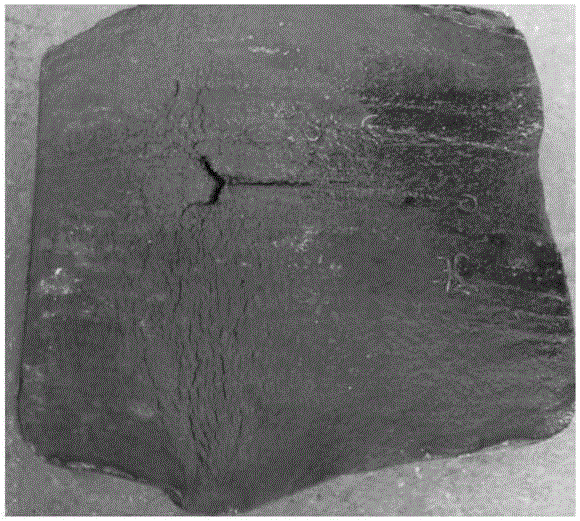

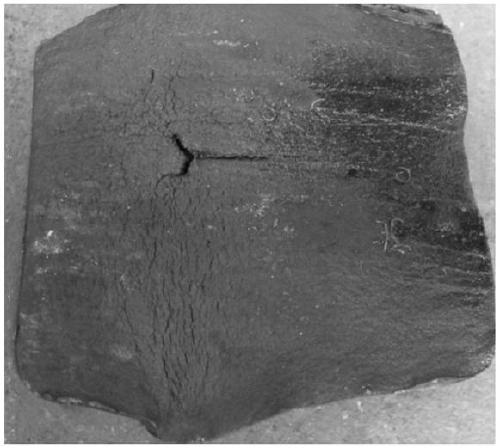

Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

The invention discloses a method for manufacturing a bimetallic metallurgical composite wear-resisting tube blank, which comprises the following steps: firstly, spraying a water-based zircon powder coating onto a metal tube die after being baked to between 200 and 300 DEG C, wherein the spraying thickness is 1.0 to 3.0mm; secondly, centrifugally casting external liquid metal on the metal tube die after being baked to between 200 and 350 DEG C, cooling the metal tube die after casting, beginning to cast internal liquid metal into the metal tube die when an internal surface temperature of the outer layer is cooled to a temperature lower than a solidus temperature of the external metal; and finally, pouring the internal liquid metal into the metal tube die for centrifugal casting, cooling the metal tube die after casting, and stopping cooling when the outer layer and the inner layer are completely solidified, then the outer layer and the inner layer are metallurgically fused completely, wherein the outer layer is made of a plain carbon steel material or a low-alloy high-strength steel material and the inner layer is made of a high-chromium white cast iron material. The invention also discloses the bimetallic metallurgical composite wear-resisting tube blank manufactured by the method. The outer-layer metal and the inner-layer metal of the tube blank manufactured by the method can be metallurgically fused completely; the qualification rate is improved; and the use safety is high.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

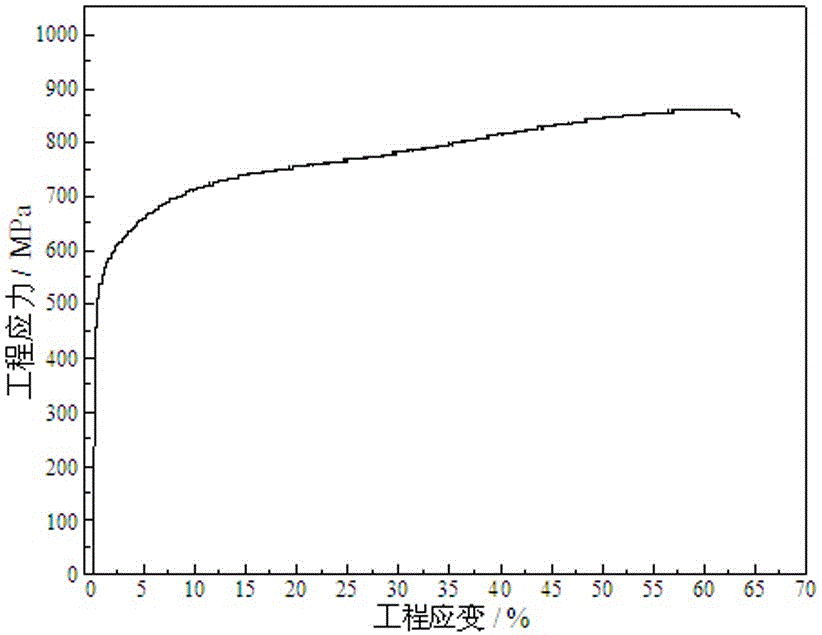

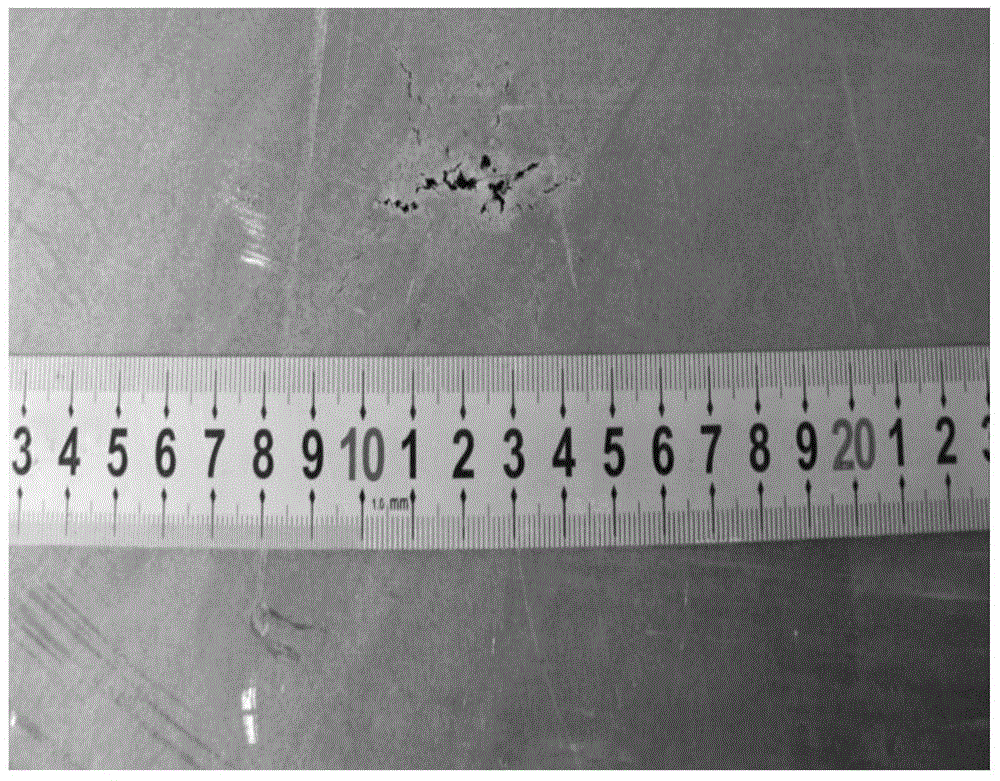

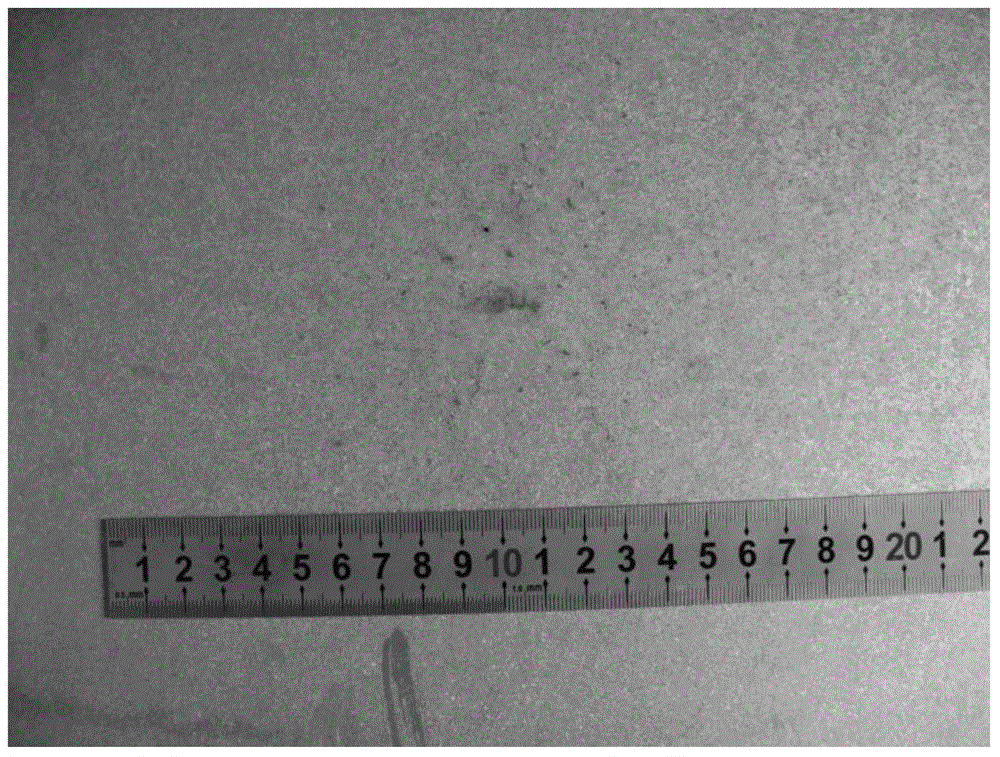

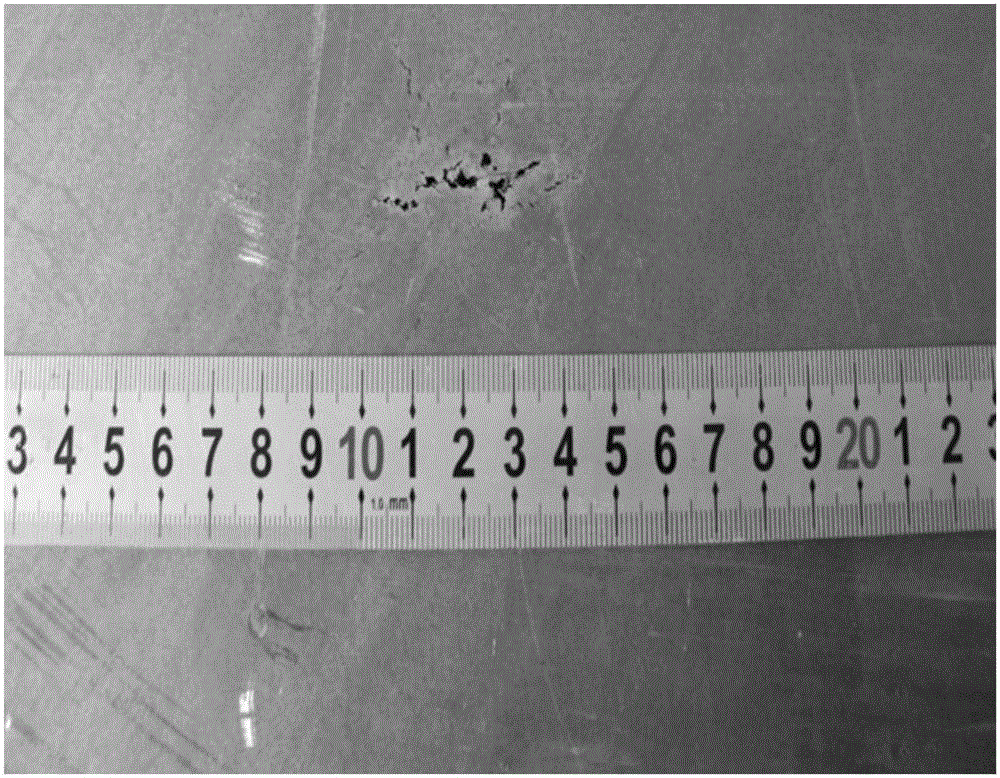

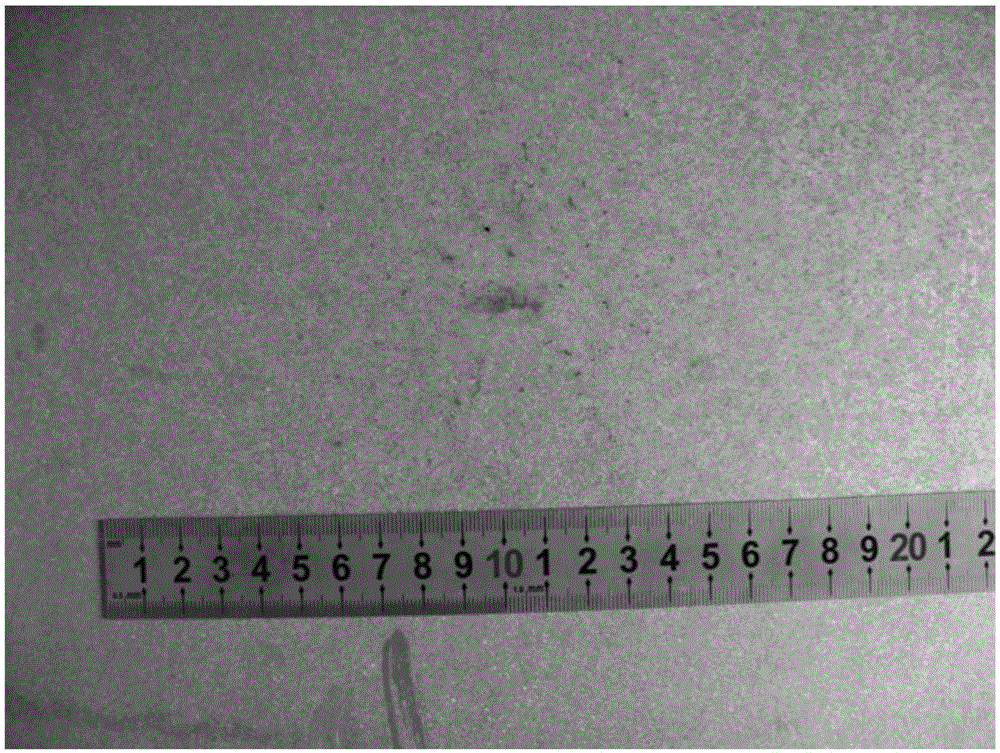

Economical duplex stainless steel sheet and preparation method thereof

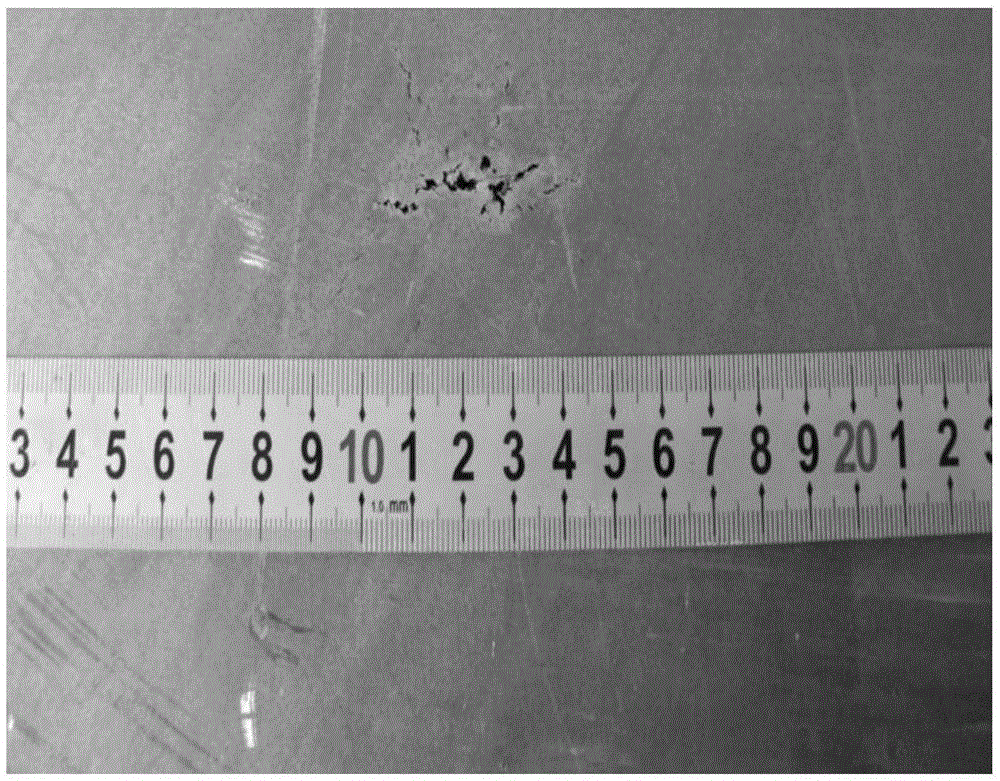

The invention discloses an economical duplex stainless steel sheet and a preparation method thereof. The stainless steel sheet comprises the following components in percentage by mass: 0.08 to 0.13 percent of C, 20 to 23 percent of Cr, 4 to 6 percent of Mn, 0.5 to 1.5 percent of Ni, 0.2 to 0.5 percent of Mo, 0.1 to 0.25 percent of N and the balance of iron and other inevitable impurities. The preparation method comprises the following steps: selecting and melting a raw material into molten steel according to the components; casting the molten steel into an ingot; performing hot rolling cogging and surface figuring on the ingot after a riser part is cut; performing hot rolling to obtain a hot-rolled plate with a thickness of 3 to 6mm; performing annealing, acid washing and cold rolling on the hot-rolled plate to obtain a sheet with a thickness of 1 to 1.5mm; performing solution annealing to obtain the economical duplex stainless steel sheet. According to the economical duplex stainless steel sheet and the preparation method thereof, by reasonable alloying design, the strength and the plasticity of the stainless steel sheet can be improved, hot rolling edge cracking can be eliminated, and the quality and the yield of the hot-rolled plate are greatly improved.

Owner:NORTHEASTERN UNIV

Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

The invention discloses a method for manufacturing a bimetallic metallurgical composite wear-resisting tube blank, which comprises the following steps: firstly, spraying a water-based zircon powder coating onto a metal tube die after being baked to between 200 and 300 DEG C, wherein the spraying thickness is 1.0 to 3.0mm; secondly, centrifugally casting external liquid metal on the metal tube dieafter being baked to between 200 and 350 DEG C, cooling the metal tube die after casting, beginning to cast internal liquid metal into the metal tube die when an internal surface temperature of the outer layer is cooled to a temperature lower than a solidus temperature of the external metal; and finally, pouring the internal liquid metal into the metal tube die for centrifugal casting, cooling the metal tube die after casting, and stopping cooling when the outer layer and the inner layer are completely solidified, then the outer layer and the inner layer are metallurgically fused completely, wherein the outer layer is made of a plain carbon steel material or a low-alloy high-strength steel material and the inner layer is made of a high-chromium white cast iron material. The invention alsodiscloses the bimetallic metallurgical composite wear-resisting tube blank manufactured by the method. The outer-layer metal and the inner-layer metal of the tube blank manufactured by the method canbe metallurgically fused completely; the qualification rate is improved; and the use safety is high.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

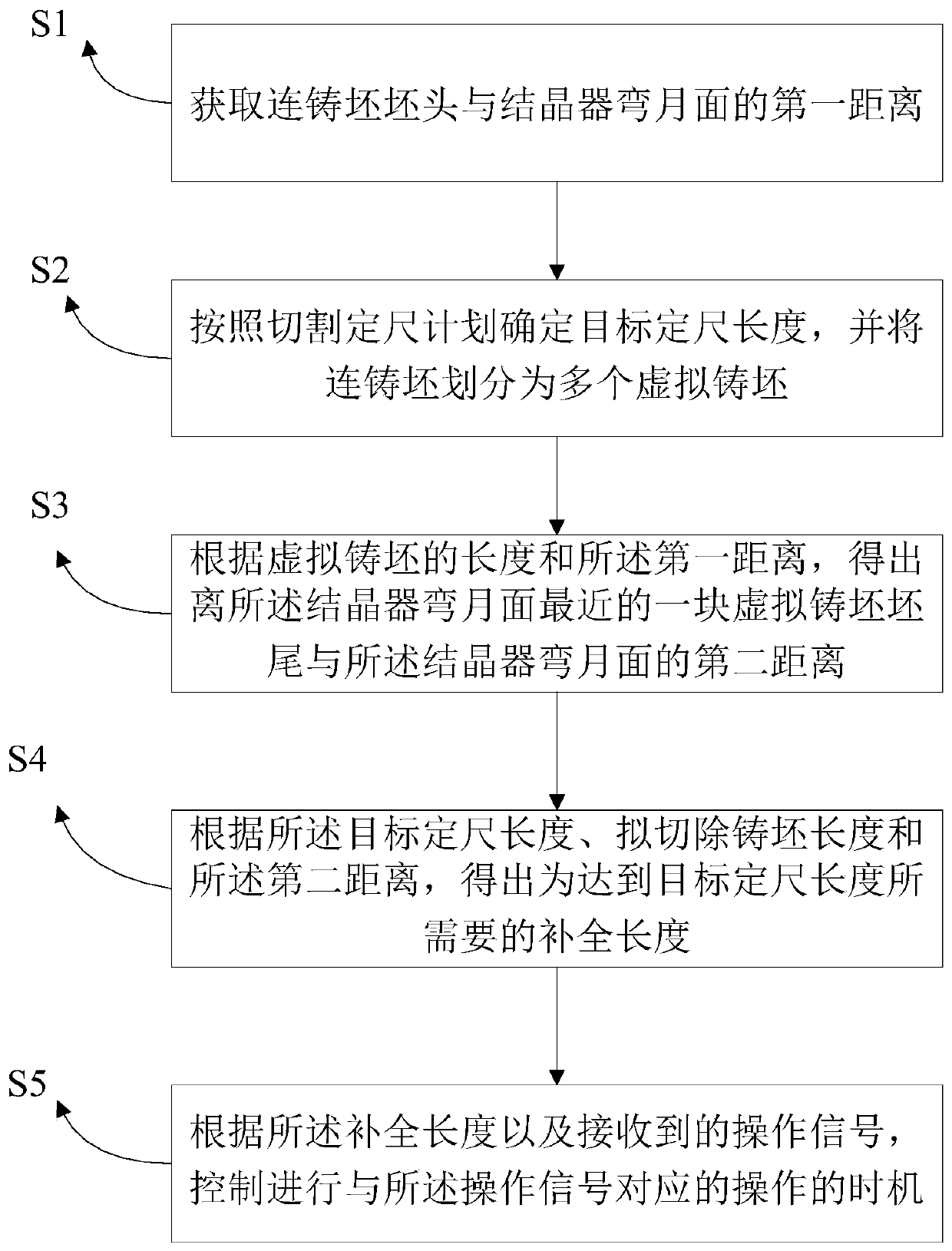

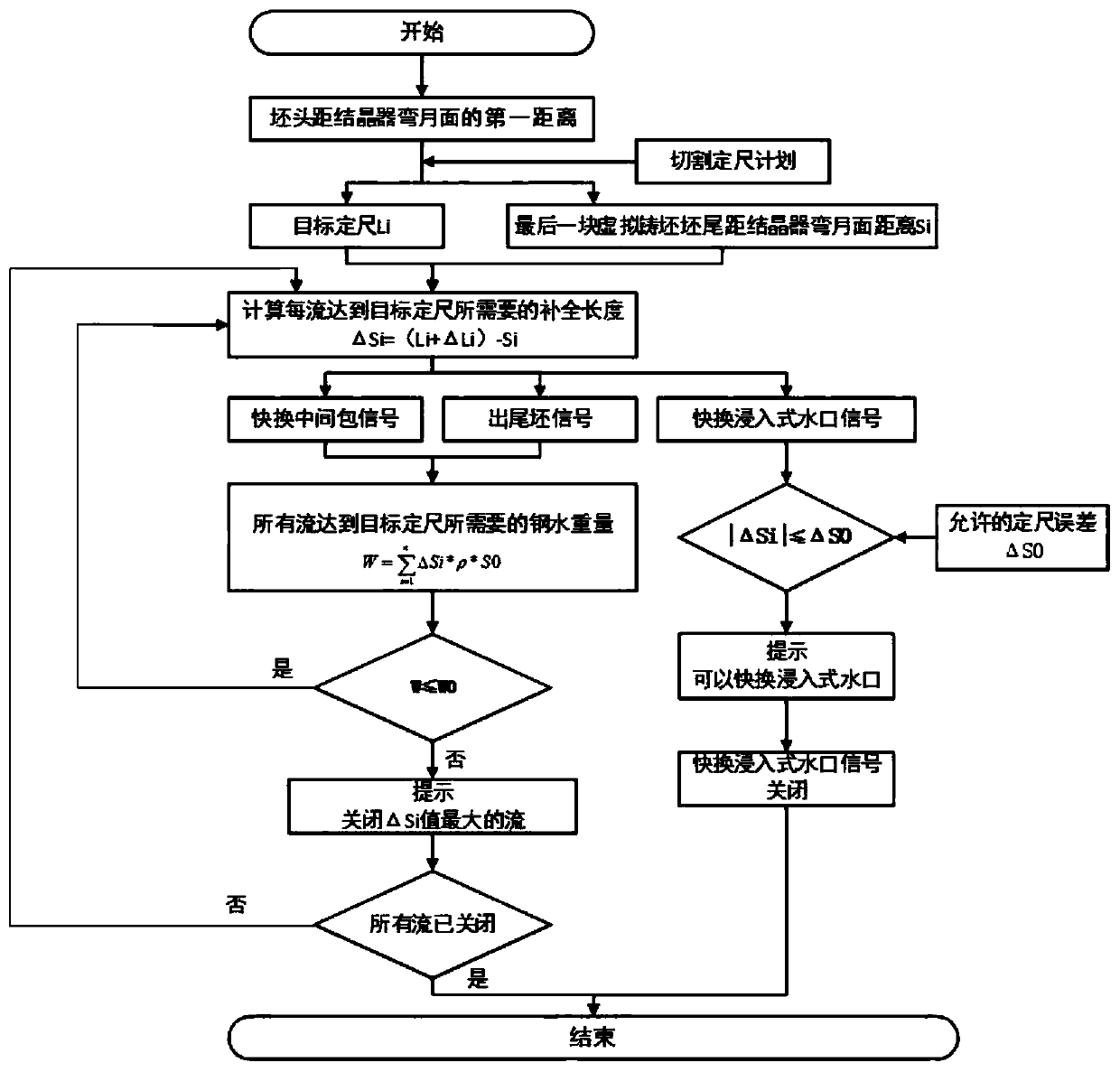

Fixed-length control method of continuous casting blank

ActiveCN110976804AEasy resectionReduce the amount of resectionMechanical engineeringIndustrial engineering

The invention discloses a fixed-length control method of a continuous casting blank. The method comprises the steps of obtaining a first distance between a continuous casting blank head and a crystallizer meniscus surface; according to a cutting fixed-length plan, determining a target fixed-length length, and dividing the continuous casting blank into multiple virtual casting blanks; according tothe length of the virtual casting blanks and the first distance, obtaining a second distance between one virtual casting blank tail closest to the crystallizer meniscus surface and the crystallizer meniscus surface; according to the tart fixed-length length, the planned-cutting casting blank length and the second distance, obtaining a complementing length needed for obtaining the target fixed-length length; and according to the complementing length and a received operation signal, controlling to carry out at the operation opportunity corresponding to the operation signal. The non-fixed-lengthcasting blank or waste blank caused by the casting blank quality during corresponding operation can be avoided, waste is avoided, and the casting blank yield can be improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Vanadium-titanium-nitrogen-containing atmospheric-corrosion-resistant molten steel, atmospheric-corrosion-resistant steel and production method of atmospheric-corrosion-resistant steel

The invention relates to the steel making field, and particularly provides atmospheric-corrosion-resistant molten steel. Based on the total weight of the molten steel, the molten steel comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 2.0-3.5% of Cr, 0.16-0.20% of V, 0.005-0.030% of Ti, 0.004-0.008% of N, less than or equal to 0.030% of P and less than or equal to 0.020% of S. The invention also provides atmospheric-corrosion-resistant steel and a production method thereof. When the molten steel is adopted for continuous casting, the center quality of casting blanks can be improved, center cracks and center line shrinkage are prevented, accordingly, the quality of the high strength and high atmospheric corrosion resistance steel casting blanks can be improved, and the qualification rate of the casting blanks can be improved to a great extent; and the finally obtained atmospheric-corrosion-resistant steel has good atmospheric corrosion resistance and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

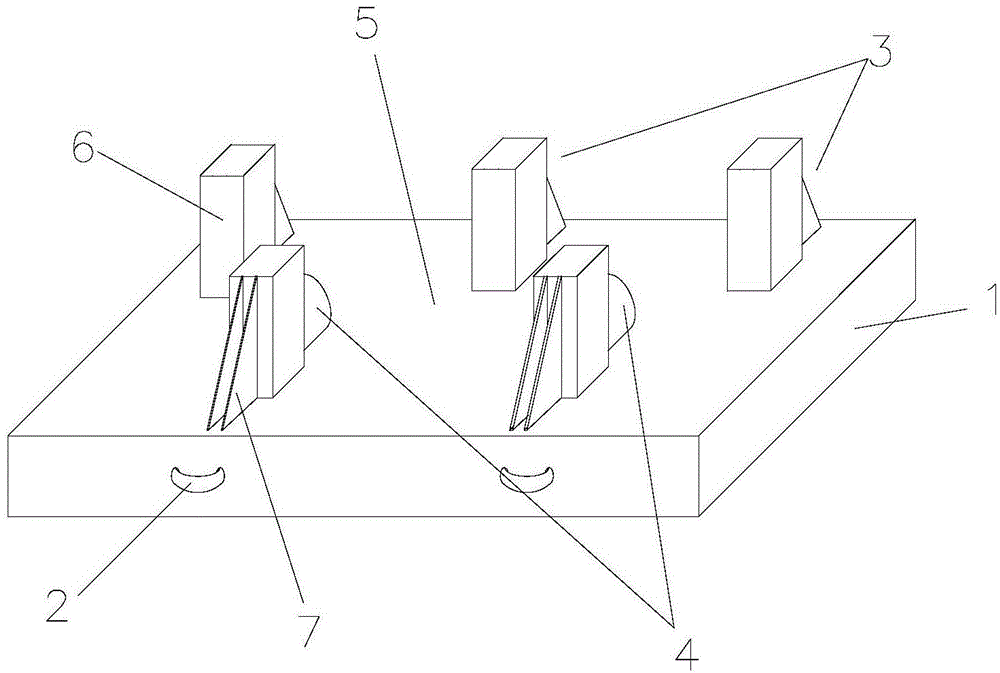

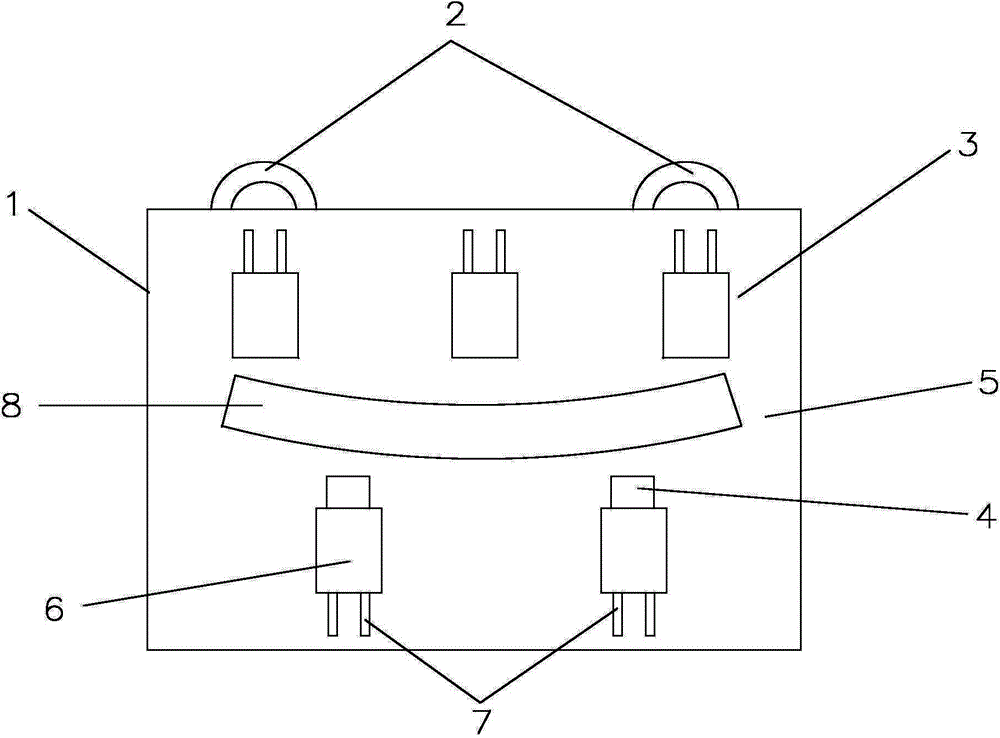

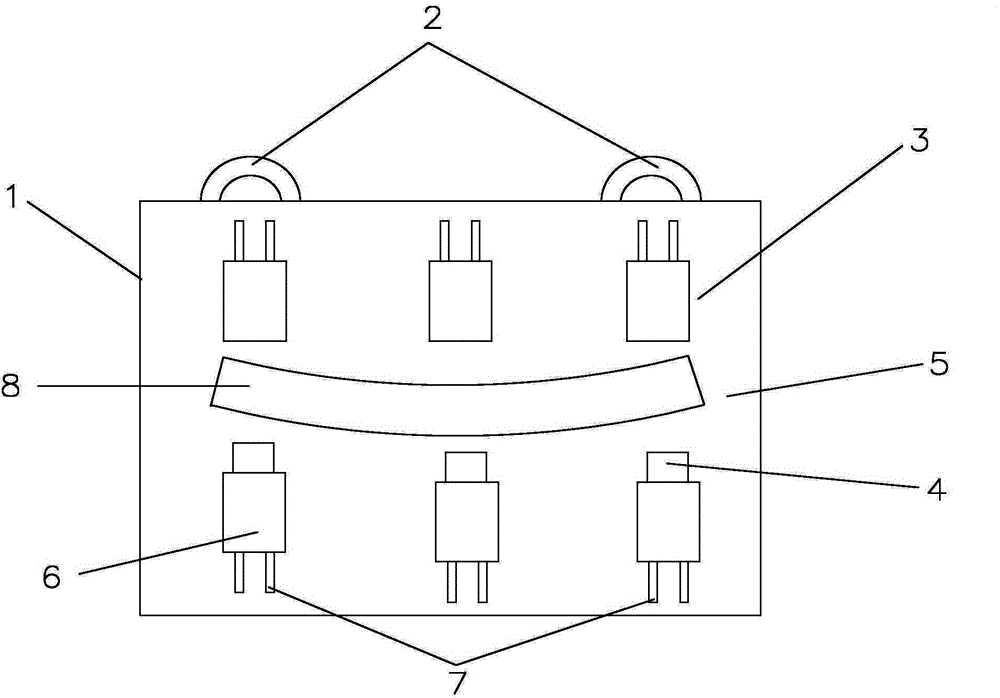

Device for straightening curved continuous casting billets

The invention provides a device for straightening curved continuous casting billets. The device comprises a frame and a continuous casting billet straightening structure arranged on the frame, wherein the continuous casting billet straightening structure comprises a supporting unit and a jack arranged on the supporting unit, and the supporting unit forms a first-row supporting unit and a second-row supporting unit; the first-row supporting unit and the second-row supporting unit are arranged on the frame side by side, and a space for containing the continuous casting billets is formed between the first-row supporting unit and the second-row supporting unit. By straightening the continuous casting billets being bent and deformed due to non-uniform cooling in the stacking process, the method can effectively make the original bent deformed continuous casting billets flat and straight, and the continuous casting billets enter the next procedure smoothly. Therefore, the percent of pass of casting billets is furthest increased, the rejection rate of casting billets is reduced, and the production cost is reduced. The device has the advantages of being simple in structure, low in manufacture cost and easy to operate and is suitable for popularization and application in the industry.

Owner:ZENITH STEEL GROUP CORP

Vanadium-nitrogen-containing atmospheric-corrosion-resistant molten steel, atmospheric-corrosion-resistant steel and production method of atmospheric-corrosion-resistant steel

The invention relates to the steel making field, and particularly provides atmospheric-corrosion-resistant molten steel. Based on the total weight of the molten steel, the molten steel comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 2.0-3.5% of Cr, 0.13-0.15% of V, 0.005-0.030% of Ti, 0.004-0.008% of N, less than or equal to 0.030% of P and less than or equal to 0.020% of S. The invention also provides atmospheric-corrosion-resistant steel and a production method thereof. When the molten steel is adopted for continuous casting, the center quality of casting blanks can be improved, center cracks and center line shrinkage are prevented, accordingly, the quality of the high strength and high atmospheric corrosion resistance steel casting blanks can be improved, and the qualification rate of the casting blanks can be improved to a great extent; and the finally obtained atmospheric-corrosion-resistant steel has good atmospheric corrosion resistance and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for increasing number of continuous drawing furnaces of sulfur-containing gear steel

InactiveCN113718081ASmooth pouringEasy to solveManufacturing convertersProcess efficiency improvementCarbide siliconSlag

The invention discloses a method for increasing the number of continuous drawing furnaces of sulfur-containing gear steel. The method comprises the working procedures of converter smelting, LF refining, RH refining and continuous casting. The method comprises the following steps of (1) at a converter smelting end point, C is not less than 0.06%, P is not more than 0.015%, and the tapping temperature is 1640 + / -10 degrees Celsius, during tapping, aluminum blocks and synthetic slag are added into molten steel, and the oxygen content in the steel is smaller than or equal to 50 ppm; (2) LF refining target slag comprises the following components of less than or equal to 0.6% of TFe, 54%-56% of CaO, 13%-15% of SiO2, 21%-23% of Al2O3 and 6%-8% of MgO, after slag is formed, white slag is kept by adopting a method of supplementing lime and silicon carbide, and adding a calcium line before outbound; (3) RH refining, after vacuum treatment is completed, adding a sulfur line, after soft argon blowing is carried out for more than or equal to 15 minutes, and discharging the molten steel; and (4) continuous casting, adopting a submersed nozzle. According to the method provided, the average continuous casting furnace number reaches 15, and the low-power grade of the produced gear steel reaches 2.0 grade.

Owner:HANDAN IRON & STEEL GROUP +1

Niobium-nitrogen-containing atmospheric corrosion-resistant molten structural steel, atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.021%-0.030% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-chromium-nitrogen-containing atmospheric corrosion-resistant molten structural steel, atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant steel and a production methodthereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel casting blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmosphericcorrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of atmospheric corrosion-resistant molten steel and vanadium-niobium-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.13%-0.15% by weight of V, 0.01%-0.015% by weight of Nb, 0.015%-0.020% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmosphere corrosion resisting structural steel liquid containing chrome, vanadium and nitride, atmosphere corrosion resisting structural steel and production method of atmosphere corrosion resisting structural steel

The invention relates to the field of steel making, and particularly provides atmosphere corrosion resisting structural steel liquid. Based on the total weight of the steel liquid, the steel liquid contains 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.16%-0.20% of V, 0.004%-0.008% of N, 0.030% or less of P and 0.020% or less of S. The invention provides atmosphere corrosion resisting structural steel and a production method of the atmosphere corrosion resisting structural steel. The center quality of a casting blank can be improved by adopting the steel liquid for continuous casting, center burst and center line shrinkage are avoided, accordingly, the quality of the high-strength atmosphere corrosion resisting structural steel casting blank can be improved, and the qualification rate of the casting blank can be greatly improved; and meanwhile the finally-obtained atmosphere corrosion resisting structural steel is good in atmosphere corrosion resistance and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-containing titanium-containing atmospheric corrosion-resistant molten steel, atmospheric corrosion-resistant steel and production method thereof

The invention relates to the steel-making field, and concretely provides an atmospheric corrosion resistant structural steel liquid, which contains the following components by adopting the total weight of the steel liquid as the baseline: 0.01 percent to 0.09 percent of C, 0.15 percent to 0.35 percent of Si, 0.30 percent to 0.60 percent of Mn, 0.30 percent to 0.40 percent of Cu, 0.20 percent to 0.30 percent of Ni, 2.0 percent to 3.5 percent of Cr, 0.06 percent to 0.12 percent of V, 0.005 percent to 0.030 percent of Ti, 0.008 percent to 0.014 percent of M, less than or equal to 0.030 percent of P, and less than or equal to 0.020 percent of S. The invention provides atmospheric corrosion resistant structural steel, and a production method thereof. By adopting the steel liquid provided by the invention for continuous casting, the central quality of a casting blank can be improved, and the occurrence of center burst and center line shrinkage is avoided, so that the quality of a high atmospheric corrosion resistant structural steel casting blank with high strength can be improved, and the yield of the casting blank can be greatly improved; and in addition, the finally obtained atmospheric corrosion resistant structural steel has good atmospheric corrosion resistance and a higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel containing vanadium and niobium resistant atmospheric corrosion steel, atmospheric corrosion resistant steel and production method thereof

The invention relates to the field of steelmaking and particularly provides molten steel of an atmosphere-corrosion-resistant structural steel. The total weight of the molten steel serves as the datum, and the molten steel comprises 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.13%-0.15% of V, 0.005%-0.030% of Ti, 0.01%-0.015% of Nb, 0.015%-0.020% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides the atmosphere-corrosion-resistant structural steel and a production method thereof. By means of continuous casting of the molten steel, center quality of a casting blank can be improved, center cracks and center shrinkage cavities are avoided, therefore quality of the casting blank of the structural steel high in strength and atmosphere-corrosion resistance can be improved, and the qualification rate of the casting blank can be remarkably increased; and in addition, the atmosphere-corrosion-resistant structural steel which is finally obtained is good in atmosphere-corrosion resistance and higher in strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-nitrogen-containing atmospheric corrosion-resistant molten structural steel, atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.13%-0.15% by weight of V, 0.01%-0.015% by weight of Nb, 0.005%-0.030% by weight of Ti, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant molten structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Chromium-vanadium-containing atmospheric corrosion-resistant steel molten steel, atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steelmaking, and particularly provides atmosphere corrosion resistant section steel molten steel. Taking the total weight of the molten steel as a standard, the molten steel comprises 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.06%-0.12% of V, 0.004%-0.008% of N, not larger than 0.030% of P and not larger than 0.020% of S. The invention provides atmosphere corrosion resistant section steel and a production method of the atmosphere corrosion resistant section steel. Through continuous casting of the molten steel in the invention, the center quality of a casting blank can be improved, center cracks and center line shrinkage can be avoided, and therefore the quality of the high-intensity high-atmosphere-corrosion-resistant section steel casting blank can be improved, and the yield of the casting blank can be greatly improved; and in addition, the finally-obtained atmosphere corrosion resistant section steel is good atmosphere corrosion resistance and has the high intensity performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel containing niobium nitrogen resistant atmospheric corrosion section steel and atmospheric corrosion resistant section steel and production method thereof

The invention relates to the field of steelmaking and particularly provides atmosphere corrosion resisting profile steel liquid. On the criterion of the total weight of the steel liquid, the steel liquid comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 2.0-3.5% of Cr, 0.16-0.20% of V, 0.005-0.030% of Ti, 0.01-0.015% of Nb, 0.021-0.030% of N, no more than 0.030% of P and no more than 0.020% of S. The invention provides atmosphere corrosion resisting profile steel and a production method thereof. When the steel liquid is adopted for continuous casting, the center quality of cast blanks can be improved, center cracking and center line shrinkage are avoided, and thus the quality of profile steel cast blanks with high strength and high atmosphere corrosion resistance can be improved, and the qualification rate of cast blanks can be greatly increased. In addition, the finally obtained atmosphere corrosion resisting profile steel has good atmosphere corrosion resistance and higher strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Chromium-vanadium-titanium-containing atmospheric corrosion-resistant molten steel and atmospheric corrosion-resistant steel and production method thereof

The invention relates to the steel-making field, and specifically provides molten steel of atmospheric corrosion resistant steel. Based on total weight of the molten steel, the molten steel comprises the following components in percentage by weight: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30-0.60% of Mn, 0.30%-0.40% of Cu, 0.20-0.30% of Ni, 2.0%-3.5% of Cr, 0.16%-0.20% of V, 0.005%-0.030% of Ti, 0.021%-0.030% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides atmospheric corrosion resistant steel and a production method thereof. The molten steel can be continuously cast to improve central quality of casting blank, and central cracks and central hole shrinkage are avoided, so that quality of high-strength steel casting blank with high atmospheric corrosion resistance can be improved, and the qualification rate of the casting blank can be greatly increased; and moreover, the finally obtained atmospheric corrosion resistant steel is good in atmospheric corrosion resistance, and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant molten structural steel, niobium-nitrogen-containing atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.021%-0.030% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel of atmospheric corrosion resistant steel and chromium-nitrogen containing atmospheric corrosion resistant steel and production method thereof

ActiveCN106676413AImprove center qualityHigh strengthManufacturing convertersSteelmakingMolten steel

The invention relates to the field of steel making, and specifically provides molten steel of atmospheric corrosion resistant steel. Based on total weight of the molten steel, the molten steel comprises the following components in percentage by weight: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3.5%-5.0% of Cr, 0.13%-0.15% of V, 0.004%-0.008% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides atmospheric corrosion resistant steel and a production method thereof. The molten steel can be continuously cast to improve central quality of casting blank, and central cracks and central pore shrinkage are avoided, so that quality of high-strength atmospheric corrosion resistant steel casting blank can be improved, and the qualification rate of casting blank can be greatly increased; and moreover, the finally obtained atmospheric corrosion resistant steel is good in atmospheric corrosion resistance, and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant steel molten steel and chromium-nitrogen-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making, and specifically provides molten steel of atmospheric corrosion resistant steel. Based on total weight of the molten steel, the molten steel comprises the following components in percentage by weight: 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3.5%-5.0% of Cr, 0.13%-0.15% of V, 0.004%-0.008% of N, not greater than 0.030% of P and not greater than 0.020% of S. The invention provides atmospheric corrosion resistant steel and a production method thereof. The molten steel can be continuously cast to improve central quality of casting blank, and central cracks and central pore shrinkage are avoided, so that quality of high-strength atmospheric corrosion resistant steel casting blank can be improved, and the qualification rate of casting blank can be greatly increased; and moreover, the finally obtained atmospheric corrosion resistant steel is good in atmospheric corrosion resistance, and has higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant molten structural steel, vanadium-titanium-containing atmospheric corrosion-resistant structural steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.005%-0.030% by weight of Ti, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Molten steel of atmospheric corrosion-resistant section steel, chromium-niobium-containing atmospheric corrosion-resistant section steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.06%-0.12% by weight of V, 0.01%-0.015% by weight of Nb, 0.008%-0.014% by weight of N, less than or equal to 0.030% by weight of P, less than or equal to 0.020% by weight of S and the balance of unavoidable impurities and Fe. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of atmospheric corrosion-resistant steel molten steel and chromium-nitrogen-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 3.5%-5.0% by weight of Cr, 0.13%-0.15% by weight of V, 0.01%-0.015% by weight of Nb, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant structural steel and a production method thereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the highstrength and high atmospheric corrosion resistant structural steel blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmospheric corrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion-resistant steel molten steel and chromium-vanadium-nitrogen-containing atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steelmaking, and particularly provides atmosphere corrosion resistant section steel molten steel. Taking the total weight of the molten steel as a standard, the molten steel comprises 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3. 5%-5.0% of Cr, 0.16%-0.20% of V, 0.004%-0.008% of N, not larger than 0.030% of P and not larger than 0.020% of S. The invention provides atmosphere corrosion resistant section steel and a production method of the atmosphere corrosion resistant section steel. Through continuous casting of the molten steel in the invention, the center quality of a casting blank can be improved, center cracks and center line shrinkage can be avoided, and therefore the quality of the high-intensity high-atmosphere-corrosion-resistant section steel casting blank can be improved, and the yield of the casting blank can be greatly improved; and in addition, the finally-obtained atmosphere corrosion resistant section steel is good atmosphere corrosion resistance and has the high intensity performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of chromium-vanadium-nitrogen-containing atmospheric corrosion-resistant molten steel and atmospheric corrosion-resistant steel and production method thereof

The invention relates to the field of steel making and provides atmospheric corrosion-resistant molten structural steel. The molten structural steel is composed of 0.01%-0.09% by weight of C, 0.15%-0.35% by weight of Si, 0.30%-0.60% by weight of Mn, 0.30%-0.40% by weight of Cu, 0.20%-0.30% by weight of Ni, 2.0%-3.5% by weight of Cr, 0.16%-0.20% by weight of V, 0.01%-0.015% by weight of Nb, 0.004%-0.008% by weight of N, less than or equal to 0.030% by weight of P and less than or equal to 0.020% by weight of S. The invention provides atmospheric corrosion-resistant steel and a production methodthereof. The molten steel continuous casting process improves the central quality of a casting blank, prevents central cracks and central shrinkage holes, improves the quality of the high strength and high atmospheric corrosion resistant structural steel casting blank and greatly improves a casting blank qualification rate. The atmospheric corrosion-resistant structural steel has good atmosphericcorrosion resistance and high strength properties.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric-corrosion-resistant molten steel, chromium-vanadium-titanium-containing atmospheric-corrosion-resistant steel and production method of atmospheric-corrosion-resistant steel

The invention relates to the steel making field, and particularly provides atmospheric-corrosion-resistant molten steel. Based on the total weight of the molten steel, the molten steel comprises 0.01-0.09% of C, 0.15-0.35% of Si, 0.30-0.60% of Mn, 0.30-0.40% of Cu, 0.20-0.30% of Ni, 3.5-5.0% of Cr, 0.16-0.20% of V, 0.005-0.030% of Ti, 0.021-0.030% of N, less than or equal to 0.030% of P and less than or equal to 0.020% of S. The invention also provides atmospheric-corrosion-resistant steel and a production method thereof. When the molten steel is adopted for continuous casting, the center quality of casting blanks can be improved, center cracks and center line shrinkage are prevented, accordingly, the quality of the high strength and high atmospheric corrosion resistance steel casting blanks can be improved, and the qualification rate of the casting blanks can be improved to a great extent; and the finally obtained atmospheric-corrosion-resistant steel has good atmospheric corrosion resistance and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of chromium-vanadium-containing atmospheric corrosion-resistant molten steel and atmospheric corrosion-resistant steel and production method thereof

Relating to the steelmaking field, the invention especially provides an atmospheric corrosion resistant molten steel. Based on a total weight, the molten steel contains: 0.01%-0.09% of C, 0.15%-0.35%of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 2.0%-3.5% of Cr, 0.06%-0.12% of V, 0.01%-0.015% of Nb, 0.004%-0.008% of N, and not more than 0.030% of P and not more than 0.020% of S.The invention provides an atmospheric corrosion resistant steel and a production method thereof. Continuous casting of the molten steel provided by the invention can improve the central quality of a casting blank, avoids central crack and central shrinkage cavity, thereby improving the quality of the high strength and high atmospheric corrosion resistant steel casting blank and greatly enhancing the casting blank qualification rate. Also, the finally obtained atmospheric corrosion resistant steel has good atmospheric corrosion resistant ability and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric corrosion resistant type liquid steel and niobium-nitrogen contained atmospheric corrosion resistant type steel and manufacturing method thereof

The invention relates to the field of steel making, in particular to atmospheric corrosion resistant type liquid steel. On the basis of the total weight of the liquid steel, the liquid steel comprises 0.01%-0.09% of C, 0.15%-0.35% of Si, 0.30%-0.60% of Mn, 0.30%-0.40% of Cu, 0.20%-0.30% of Ni, 3.5%-5.0% of Cr, 0.16%-0.20% of V, 0.005%-0.030% of Ti, 0.01%-0.015% of Nb, 0.021%-0.030% of N, no more than 0.030% of P and no more than 0.020% of S. The invention provides atmospheric corrosion resistant type steel and a manufacturing method thereof. By adopting continuous casting of the liquid steel, the center quality of a casting blank can be improved, and center cracks and center shrinkage cavities are avoided, so that the quality of the high strength and high atmospheric corrosion resistant type steel casting blank can be improved, and the qualification rate of the casting blanks can be increased greatly; and finally, the obtained atmospheric corrosion resistant type steel has good atmospheric corrosion resistant capacity and higher strength performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of atmospheric corrosion-resistant molten steel and vanadium-titanium-nitrogen-containing atmospheric corrosion-resistant steel and production method thereof

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com