Fixed-length control method of continuous casting blank

A control method and continuous casting billet technology, applied in the field of metallurgy, can solve the problem of narrow application range of the fixed-length control method, and achieve the effects of convenient cutting, avoiding waste, and improving the qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

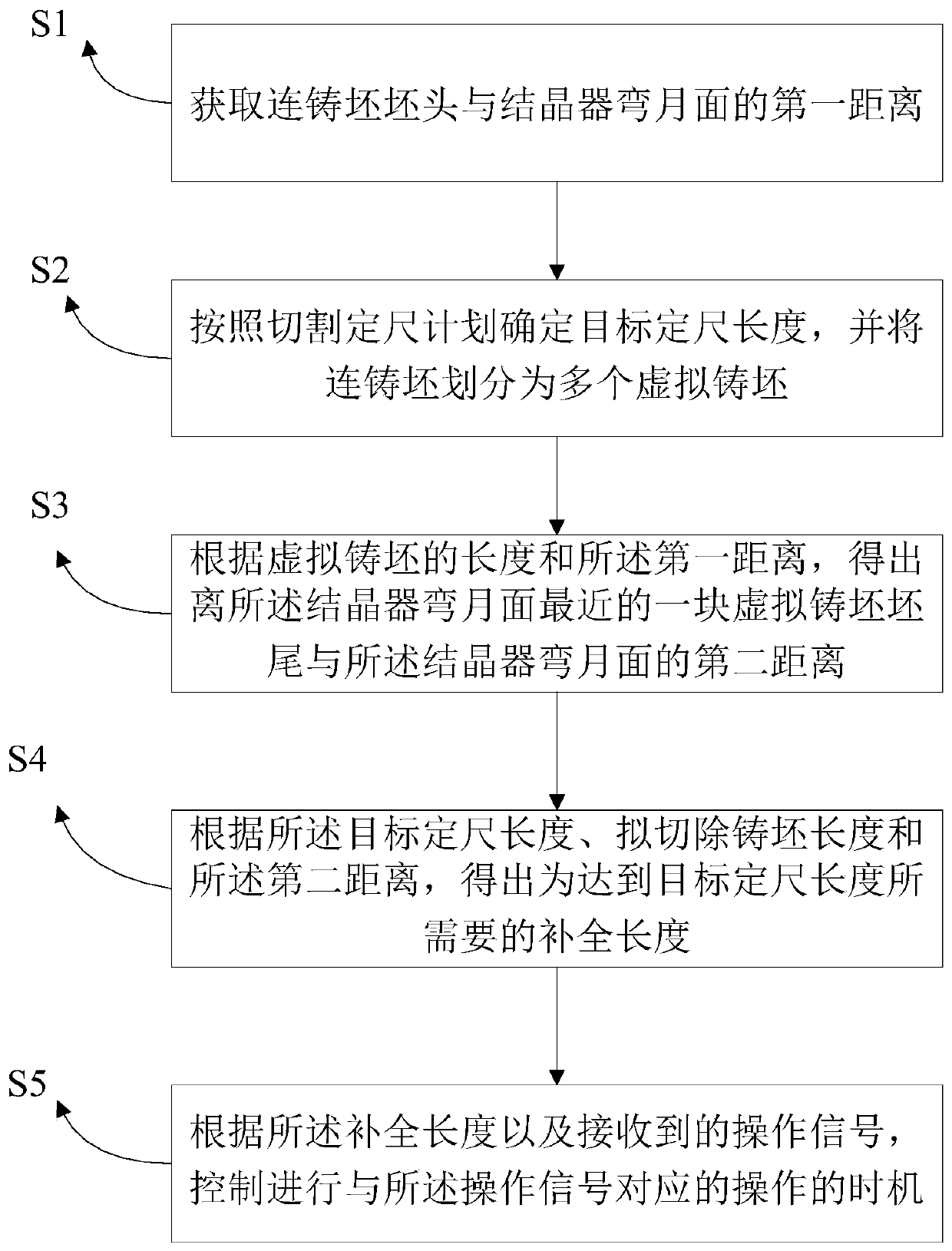

Method used

Image

Examples

Embodiment 1

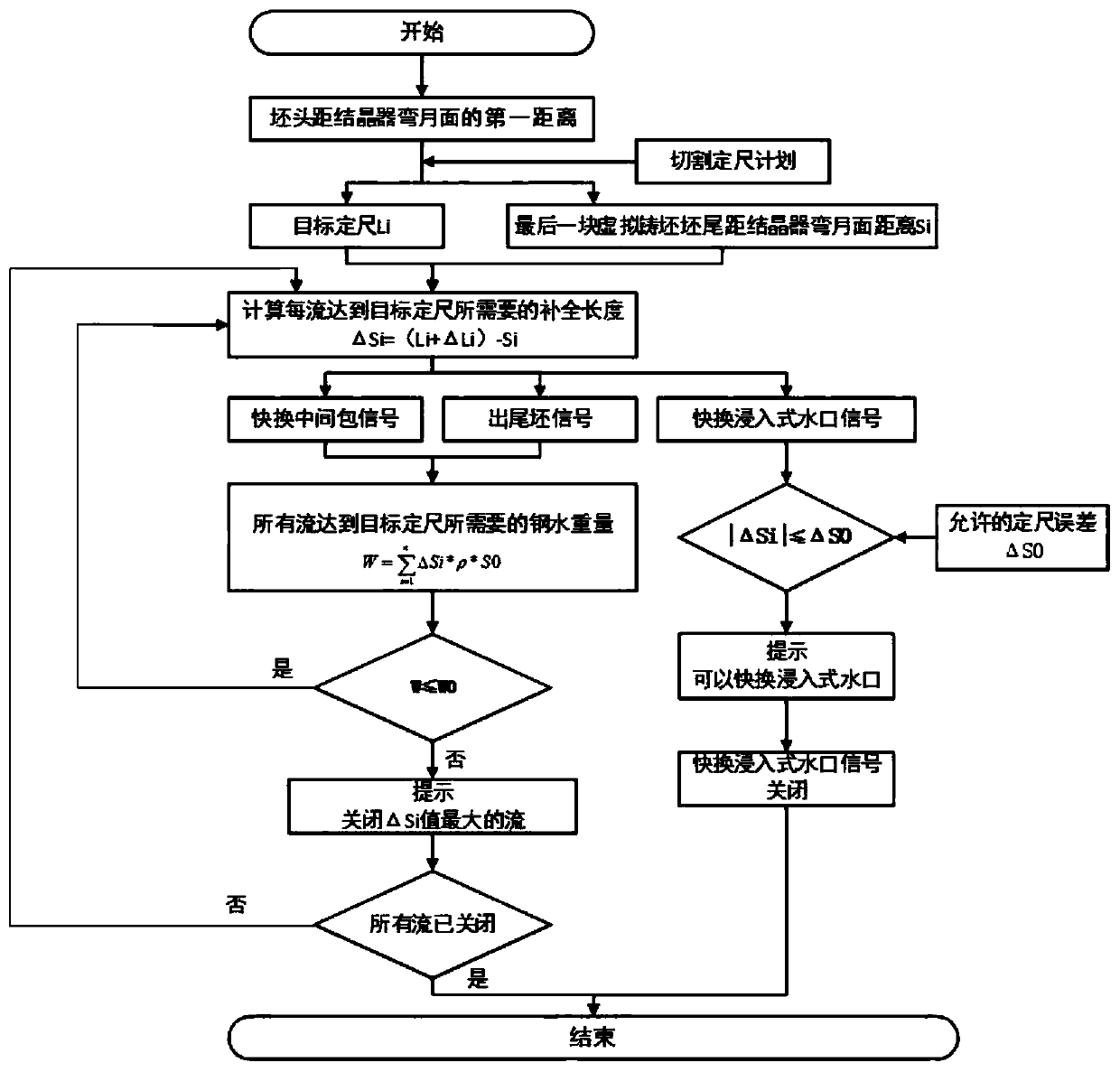

[0116] The continuous casting machine is a billet continuous casting machine with 6 machines and 6 strands. During the process of producing a cross-sectional size of 150mmX150mm, because the life of the tundish reaches the limit, it is necessary to change the tundish quickly. The operator triggers the signal of the quick change tundish. Flow drawing speed V (unit, m / min), the first distance Sd (unit, m) between the continuous casting slab head and the mold meniscus, and the virtual casting slab Pj formed according to the cutting and sizing plan (j is the virtual Billet count, j=1,2,...,m), target cut-to-length length L (unit, m), billet length or tail billet length ΔL (unit, m) in the connection area to be cut off, tundish steel Water weight W1 (unit, kg), weight of molten steel to be retained in the tundish W2 (unit, kg), cross-sectional area of continuous casting slab S0 (unit, m 2 ) and slab density ρ (unit: kg / m 3 ) are shown in Table 1 below:

[0117] Table 1

[0118...

Embodiment 2

[0145] The continuous casting machine is a 12-machine 12-strand billet continuous casting machine. During the actual process of producing a cross-sectional size of 165mmX165mm, the running speed of the billet is 3.0m / min. Due to the severe nodulation of the 5th submerged nozzle, which affects the flow of molten steel from the tundish into the mold, it is necessary to replace the submerged nozzle, and the operator triggers the signal of the 5th submerged nozzle for quick change. At this time, the first distance Sd=39.4m between the head of the continuous casting slab and the meniscus of the mold is 39.4m, and the virtual slab formed according to the cutting and sizing plan is P1=12m, P2=12m, P3=10m, and the target The ruler length L=10m, the slab length ΔL=1.5m in the connecting area to be cut off, and the allowable length error ΔS0=0.15m. Then the second distance between the tail of the last virtual slab and the meniscus of the mold is S=39.4-12-12-10=5.4m, and the complementa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com