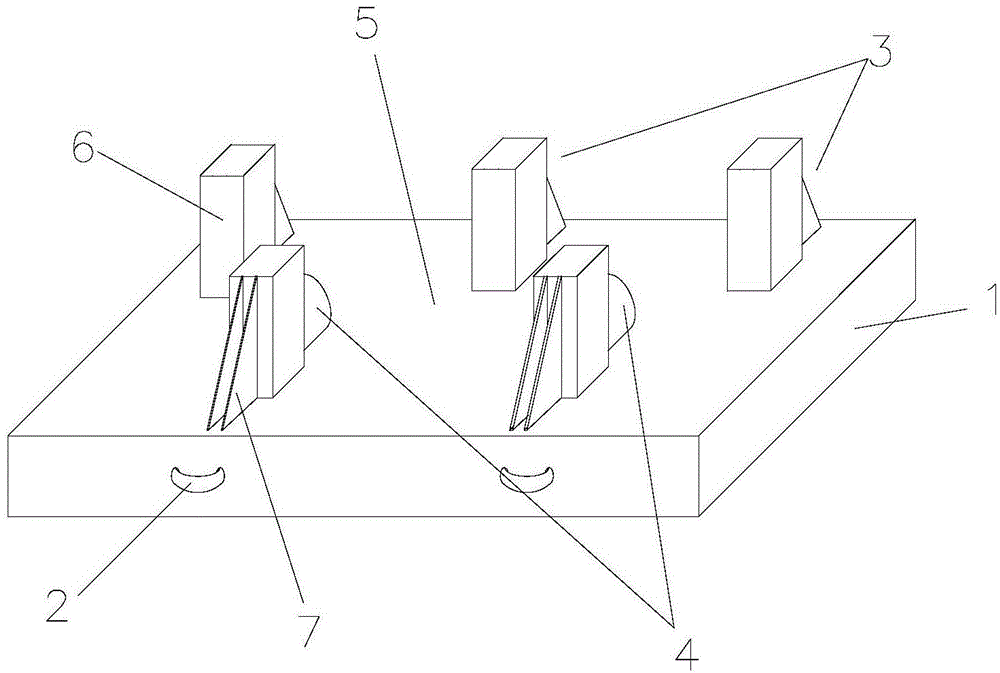

Device for straightening curved continuous casting billets

A continuous casting billet and straightening technology, applied in the field of steelmaking production, can solve the problems of low upper surface temperature, bending, waste of manpower and material resources, etc., and achieve the effects of low manufacturing cost, lowering production cost and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

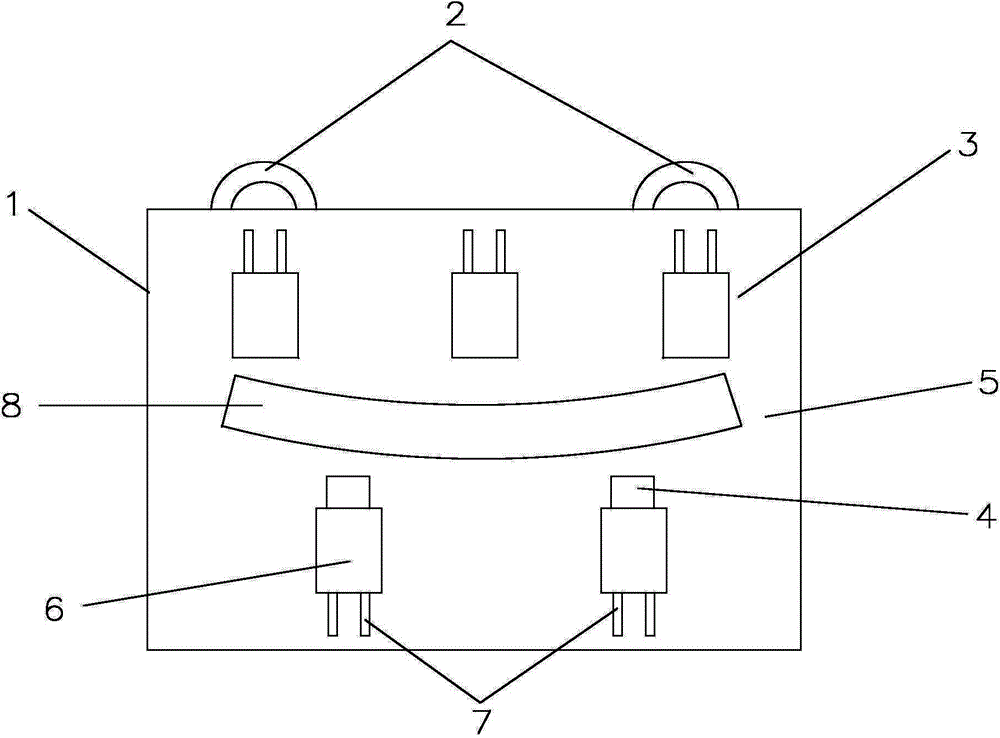

[0025] Embodiment one: if figure 2 As shown, the first row of support units includes two support units 3, and the distance between the two support units 3 is 1 / 4 to 1 / 2 of the length of the continuous casting slab 8; the second row of support units includes three support units, The three supporting units 3 are equally spaced, the distance between the supporting units 3 at both ends is greater than 1 / 2 of the length of the continuous casting slab 8 and less than or equal to the length of the continuous casting slab 8, and the two supporting units (3) in the first row Located on both sides of the support unit (3) in the middle of the second row. Embodiment 1 illustrates the minimum distribution quantity when the quantity of two rows of support units 3 distributed on the frame 1 is not equal, the quantity of two rows of support units 3 can be greater than the design quantity of the above-mentioned single row, but it must be ensured that the distribution in the length direction s...

Embodiment 2

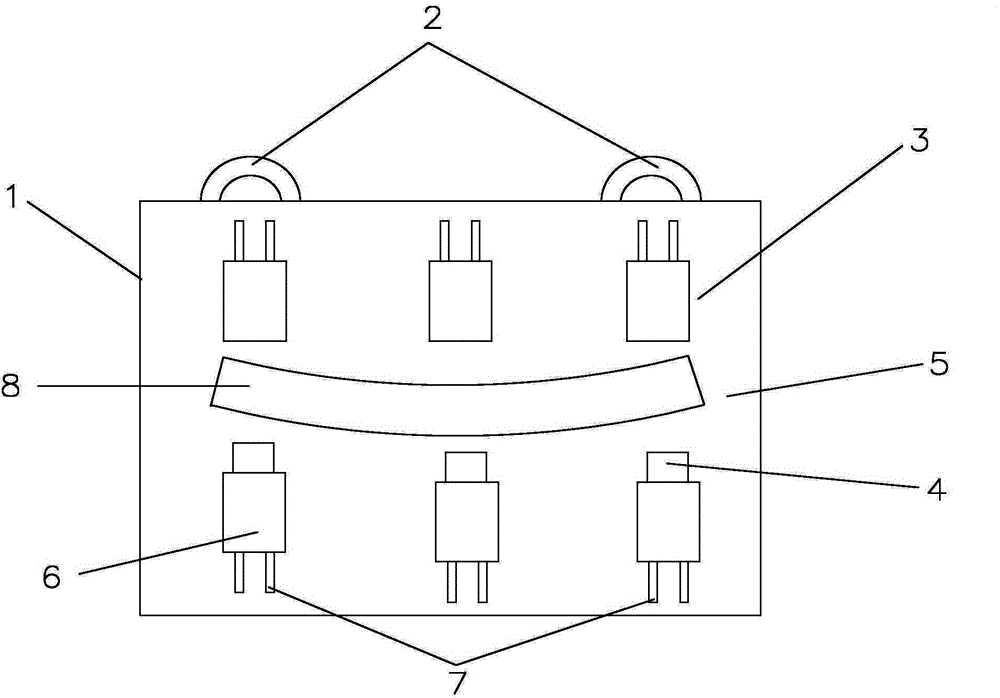

[0026] Embodiment two: if image 3 As shown, the support units 3 of the first row of support units and the second row of support units are symmetrically distributed, each row has at least three and the intervals are evenly distributed, and the distance between the support units 3 at both ends of each row is greater than 1 / 2 of the length of the continuous casting slab 8 And less than or equal to the length of the continuous casting slab 8 . Embodiment 2 illustrates the minimum distribution quantity when the number of supporting units distributed on both sides of the axis of the frame 1 is equal. This method has no requirements for the placement direction of the continuous casting slab 8, but it is also necessary to ensure that there are 3 supporting units at both ends of each row. The distance is greater than 1 / 2 of the length of the continuous casting slab 8 and less than or equal to the length of the continuous casting slab 8 . When the number of support units 3 in each row...

Embodiment 3

[0027] Embodiment three: as Figure 4 As mentioned above, when there are three support units in the first row and four support units in the second row, the distribution method in Embodiment 2 can also be adopted, the support units 3 in each row are evenly distributed, and the support units at both ends of each row are 3 The distance is greater than 1 / 2 of the length of the continuous casting slab 8 and less than or equal to the length of the continuous casting slab 8, but the two rows of support units 3 are not symmetrically distributed.

[0028] The hydraulic jack that jack 4 among the present invention adopts can also adopt mechanical jack.

[0029] When in use, place the lifting hook of the crane on the lifting lug 2, and move it to the side of the stack of curved continuous casting billets 8, hoist the curved continuous casting billets 8 to the center of the rectangular frame 1, and turn the bending direction away from the Hold the direction of the hydraulic jack 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com