Additive for improving utilization ratio of silicon crystal line cutting mortar as well as preparation method and application method of addictive

A technology of wire cutting and additives, applied in the petroleum industry, lubricating compositions, etc., can solve the problems affecting the cutting and cleaning of silicon wafers, the increase of metal ion content, and the inability to use the third cutting, so as to facilitate cleaning and subsequent processing, Improve overall performance and address the effect of chip and pelletized powder redeposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

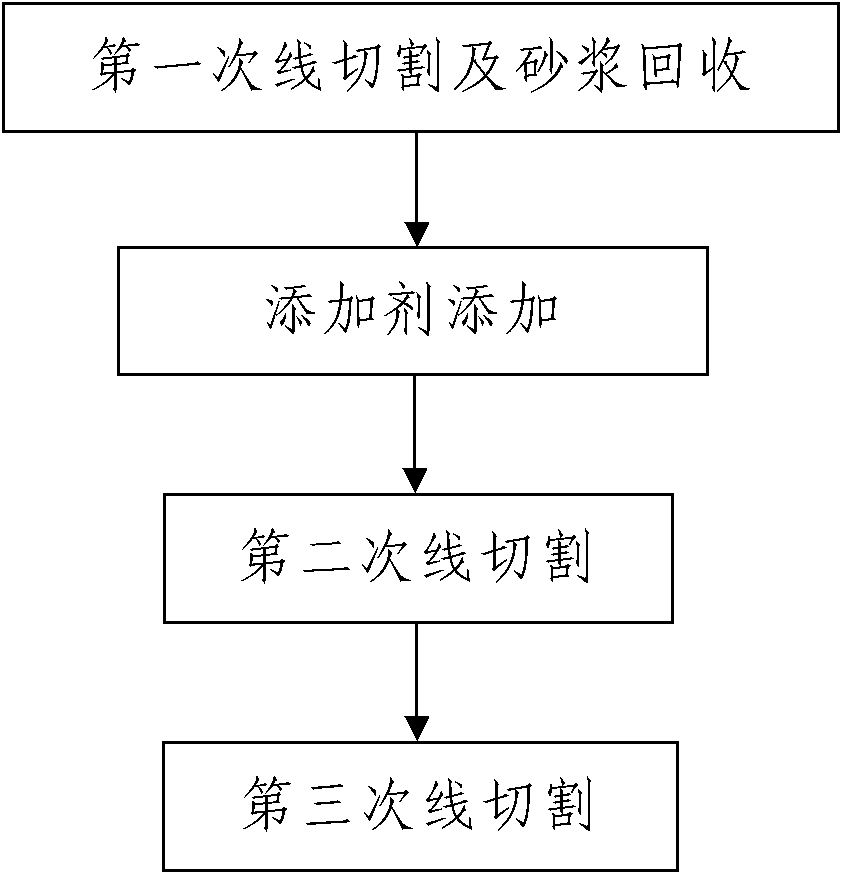

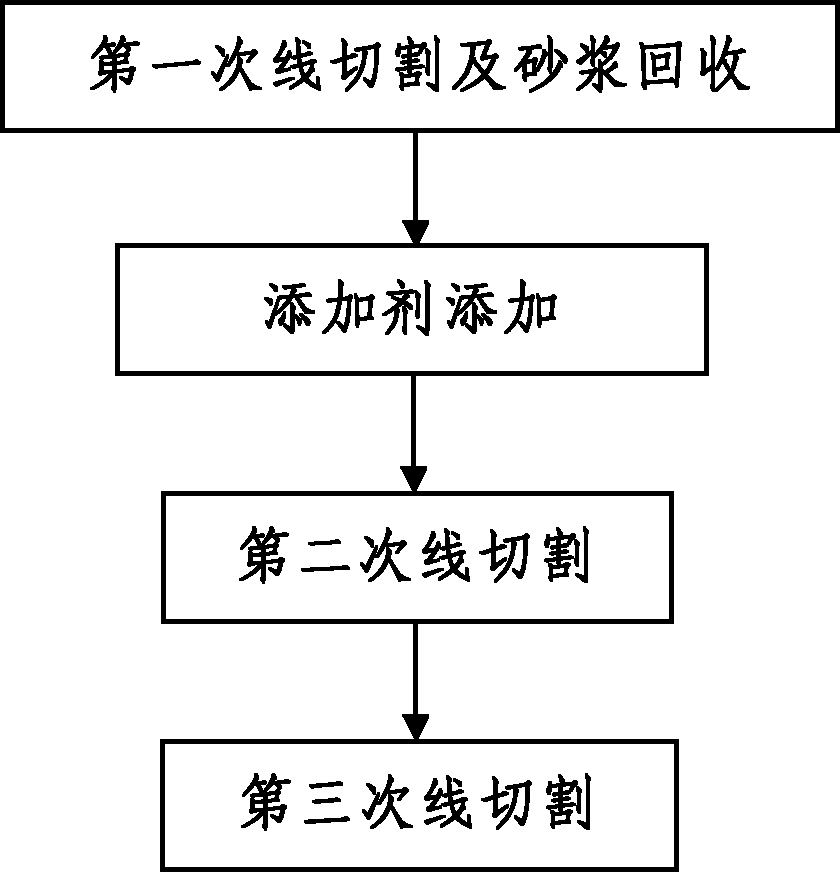

Image

Examples

preparation example Construction

[0035]When preparing the additive for improving the utilization rate of silicon crystal wire cutting mortar, the preparation method includes the following steps:

[0036] Step 1, each component is weighed: According to the ratio of 50%~96.5% by weight: 1%~10%: 1%~20%: 0.5%~10%: 1%~10%, to polyethylene glycol , penetrant, ether alcohol surfactant, anti-extreme pressure chelating agent and builder are weighed respectively.

[0037] Step 2, mixing preparation: under the temperature condition of 35°C to 120°C, mix the polyethylene glycol, penetrant, ether alcohol surfactant, anti-extreme pressure chelating agent and builder weighed in step 1 and After fully stirring for 5 minutes to 10 minutes, the additive is prepared.

[0038] During the actual operation, when the polyethylene glycol, penetrant, ether alcohol surfactant, anti-extreme pressure chelating agent and builder weighed in step 1 are uniformly mixed under the temperature condition of 35℃~120℃ Firstly, the polyethylene ...

Embodiment 1

[0046] In this embodiment, when preparing the additive: weigh 9.65 kg of polyethylene glycol (PEG200) with a molecular weight of 200D (200 Daltons), the penetrating agent is 0.1 kg of polyoxyethylene secondary alkyl alcohol ether (JFC), ether The alcohol activator is 0.1kg of AEO-7 nonionic surfactant, the anti-extreme pressure chelating agent is 0.05kg of fatty alcohol sulfate monoethanolamine salt (ASEA), and the builder is 0.1kg of polyvinylpyrrolidone (PVP-k25); Then add the penetrating agent, ether alcohol active agent, anti-extreme pressure chelating agent and builder in the above amounts into polyethylene glycol (PEG200) at 35° C. and stir for 5 minutes until uniform to obtain 10 kg of additive.

[0047] When preparing the additive, first select polyethylene glycol with an appropriate molecular weight as a solvent. First of all, the wire cutting fluid itself is mainly composed of polyethylene glycol, and secondly, all other components have good solubility in polyethylen...

Embodiment 2

[0055] In this example, when preparing additives: first weigh 9.2 kg of polyethylene glycol (PEG) with a molecular weight of 400D, the penetrant is 0.1 kg of polyoxyethylene secondary alkyl alcohol ether (JFC), and the ether alcohol active agent is AEO -12 nonionic surfactant 0.5kg, anti-extreme pressure chelating agent is alcohol ether phosphate monoester ethanolamine salt 0.1kg, builder is polyvinylpyrrolidone (PVP-k25) 0.1kg; The ether alcohol active agent, the anti-extreme pressure chelating agent and the builder were sequentially added to polyethylene glycol (PEG) at 65° C., stirred for 5 minutes until uniform, and 10 kg of the additive was obtained.

[0056] In this embodiment, when the prepared additive is used, its usage method is different from that of Example 1 in that: in step II, when the mixed and prepared additive is added to the first wire-cutting mortar recovered in step I , the stirring time was 90 minutes, and all the other using methods and steps were the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com