Patents

Literature

40results about How to "Reduce the number of inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

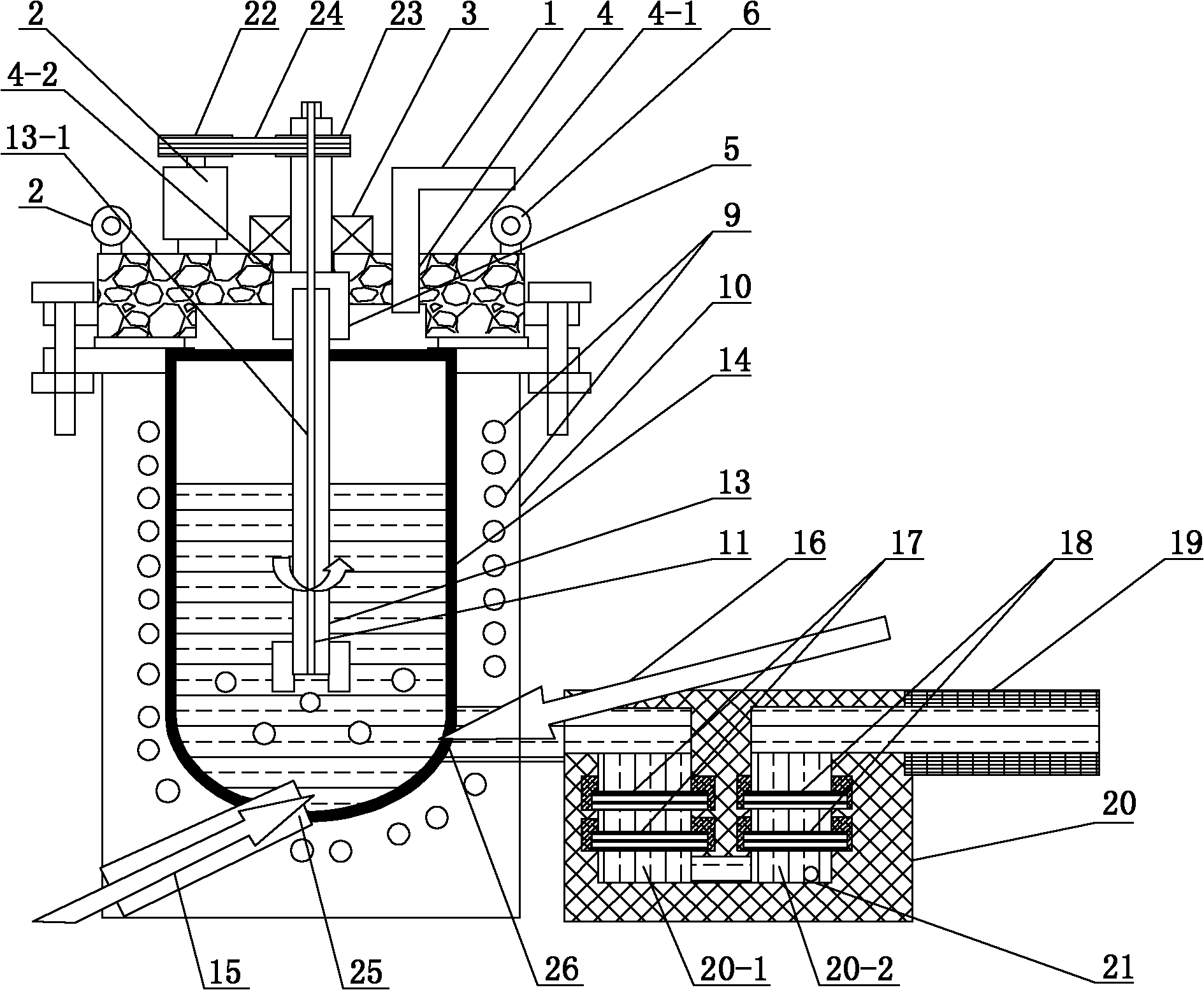

Aluminum alloy smelting-purifying device and smelting-purifying method

The invention discloses an aluminum alloy smelting-purifying device and a smelting-purifying method, relates to a smelting device and a smelting method and aims at solving the problems that the existing aluminum alloy smelting-purifying device is complex in structure, big in volume and low in smelting purity; and the existing aluminum alloy smelting-purifying method causes the aluminum alloy to generate cracks easily and the crack parts are easy to corrode. The upper end of a graphite rotator penetrates through a stepped hole and is installed on a furnace cover by a bearing; an argon tube is arranged in the central through hole of the graphite rotator in a penetration way; a crucible is communicated with the inlet of a filter box through a liquid metal filter outlet; and the filter box is internally provided with a first filter cavity and a second filter cavity. The smelting-purifying method includes the steps as follows: firstly, cleaning the inner surface of the crucible; secondly, spraying zinc oxide aqueous solution; thirdly, adding primary aluminum and a master alloy and adding alloying elements; fourthly, introducing argon; fifthly, slagging; sixthly, standing; seventhly, vacuumizing; eight, entering the filter box for filtration; ninth, discharging melt out of the filtering box; and tenth, discharging solid blocky metal compound impurities out of the crucible. The aluminum alloy smelting-purifying device and the smelting-purifying method are used for the smelting and purification of the aluminum alloy.

Owner:HARBIN ZHONGFEI NEW TECH CO LTD

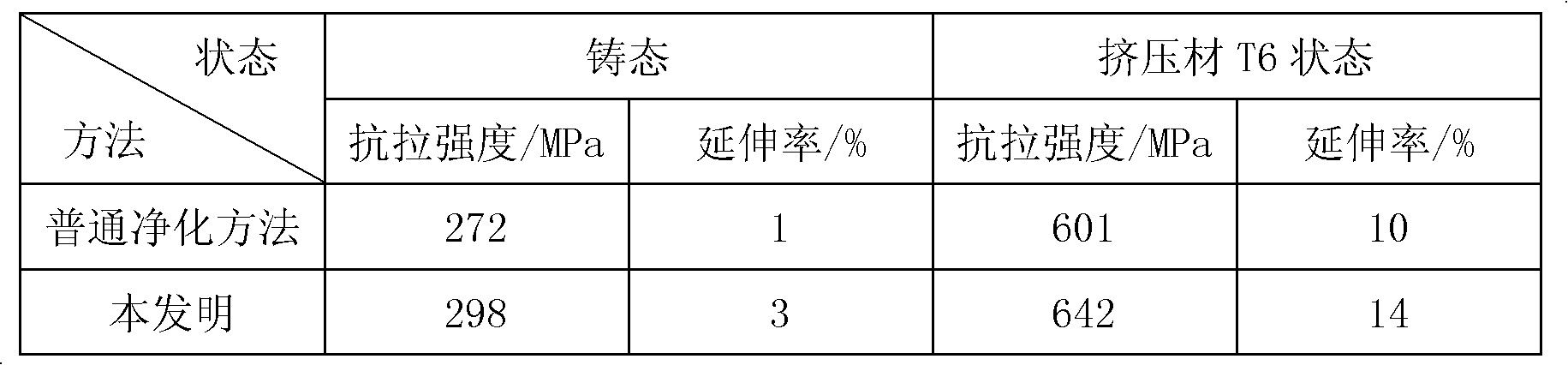

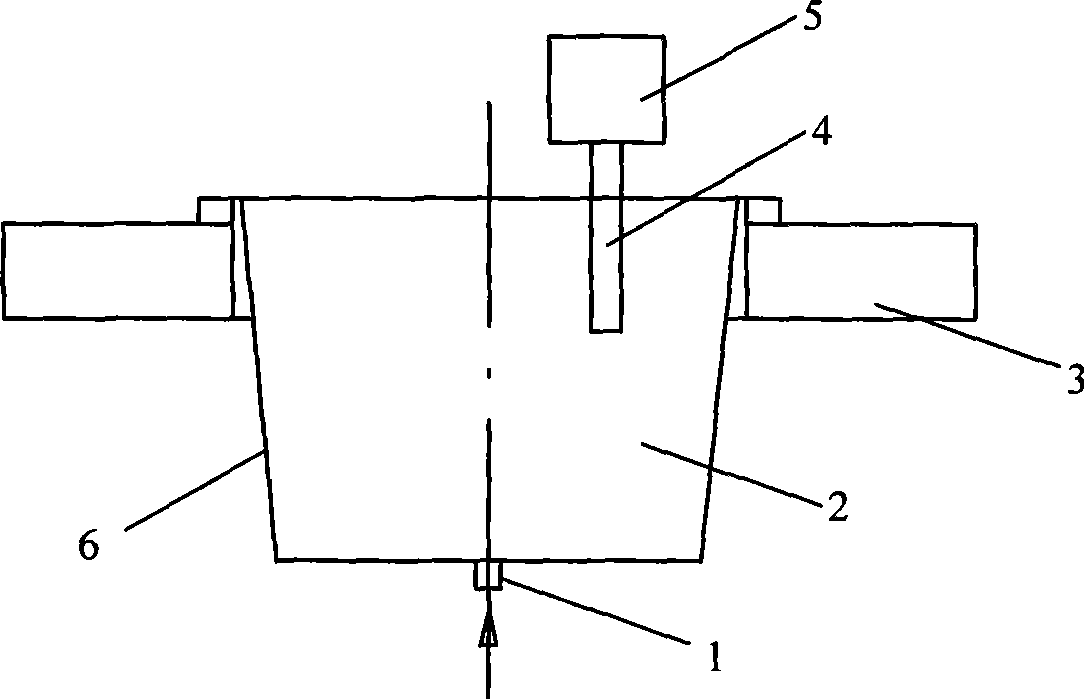

Gold base alloy casting blank melting and casting integrated device and utilization method thereof

ActiveCN103691912AReduce the number of oxide inclusionsEliminate severe oxidationIntegrated devicesCrucible

The invention discloses a gold base alloy casting blank melting and casting integrated device and a utilization method thereof. The gold base alloy casting blank melting and casting integrated device comprises a melting pot, a fireproof material cylinder, a cooling base, an outer cylinder, a heating induction coil and a magnetic stirring device. The utilization method of the gold base alloy casting blank melting and casting integrated device comprises putting gold into the melting pot and inserting the melting pot into the fireproof material cylinder; piping inert gas or reducing gas into the outer cylinder; heating the metal inside the melting pot to be melted through magnetic fields, adding other metal or alloy and performing alloying; enabling the melting pot with the fusant to descend to an annual boss of the cooling base and cooling the fusant to cast the fusant which is gradually solidified from bottom to upper during the cooling process. The gold base alloy casting blank melting and casting integrated device has the advantages of being simple in structure, convenient to operate and low in integral cost and enabling prepared gold base alloy to be uniform in ingredient and less in internal defect. The gold base alloy casting blank melting and casting integrated device and the utilization method thereof have good application prospects.

Owner:NORTHEASTERN UNIV

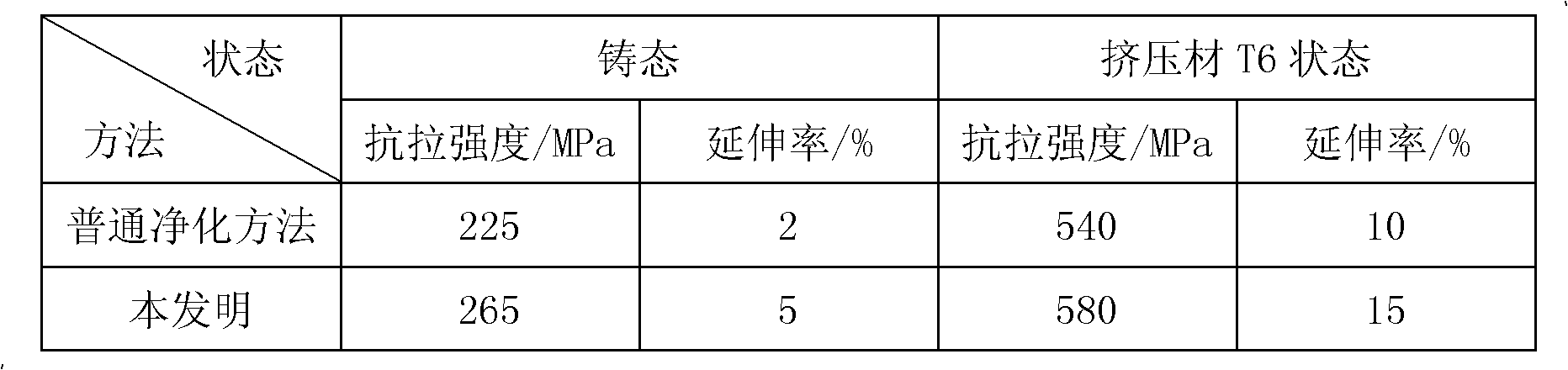

Aluminum alloy welding wire for high speed train and preparation method of aluminum alloy welding wire for high speed train

InactiveCN105772981AHigh tensile strengthImprove plasticityWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

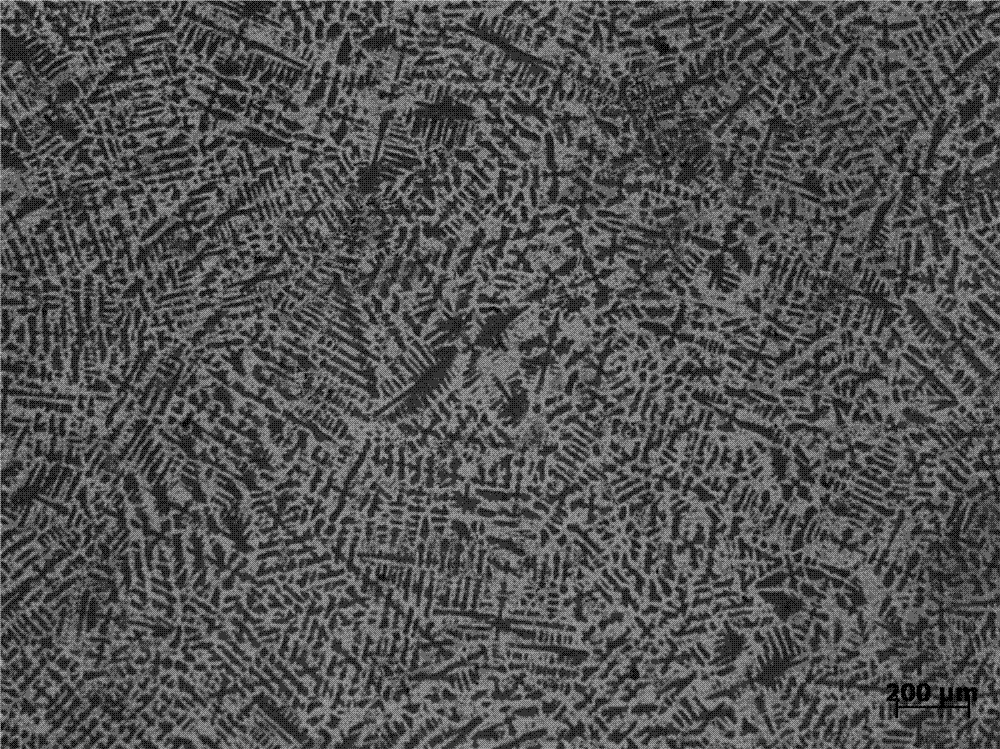

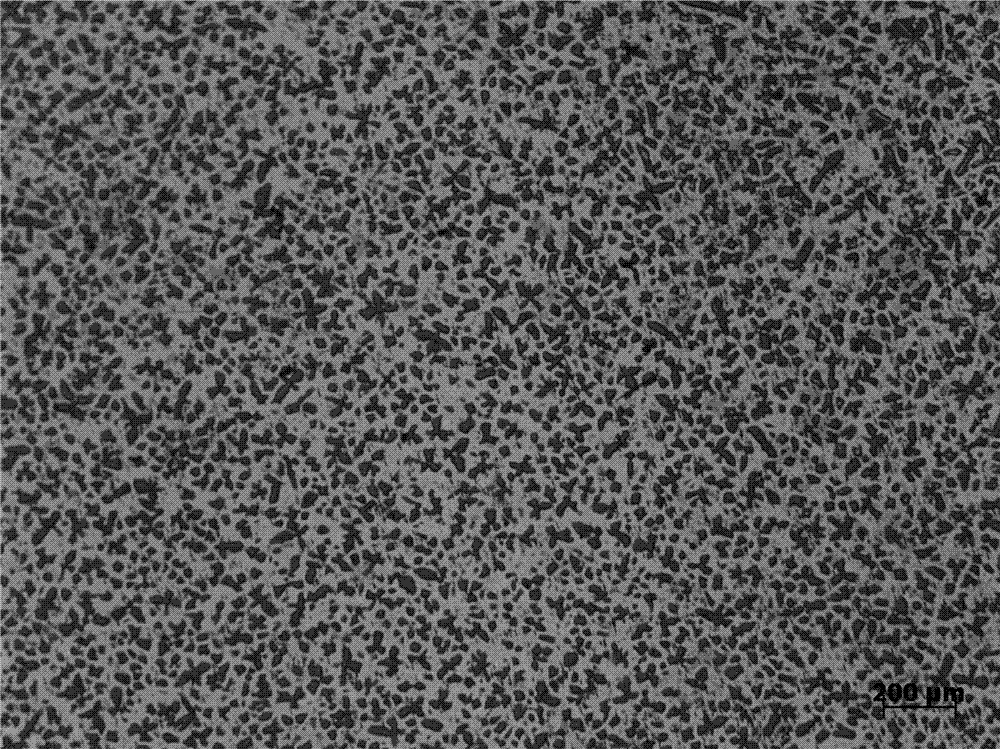

The invention relates to an aluminum alloy welding wire for a high speed train and a preparation method of the aluminum alloy welding wire for the high speed train. The aluminum alloy welding wire for the high speed train is characterized by comprising the following chemical components in percentages by mass: 4.0-6.5% of Mg, 0.06-0.2% of Ti, 0.1-0.3% of Cr, 0.05-0.2% of Mn, 0.05-0.2% of La, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for the high speed train comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for the high speed train provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common ER5356 and ER5183 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

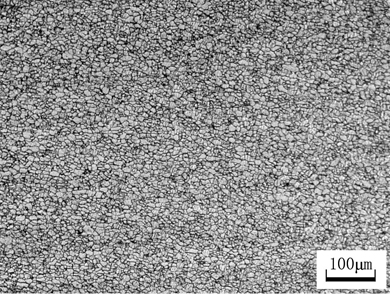

Coating-free weathering resistant steel with few welding seam inclusions and preparation method thereof

ActiveCN108642389AReduce the number of inclusionsSmall sizeProcess efficiency improvementMechanical properties of carbon nanotubesChemical composition

The invention provides a coating-free weathering resistant steel with few welding seam inclusions and a preparation method thereof, and belongs to the technical field of weathering resistant steels. According to the technical scheme, the coating-free weathering resistant steel with the few welding seam inclusion is characterized in that the content and mixing ratio of chemical components are optimized; the contents of Si, Mn, Ni, Cr, Cu, Mo and Ca in the weathering resistant steel are optimized, and the mixing ratio of the elements meets that J ranges from 1.2 to 1.7, and J is the ratio of (Si+Mn+50Ca) to (Cr+Ni+Cu+Mo). The coating-free weathering resistant steel with the few welding seam inclusions has the beneficial effects that the quantity of inclusions of various welding seams is obviously decreased, and the size of the inclusions decreases during the welding of the weathering resistant steel, thus the welding seam crack tendency caused by big inclusion obviously decreases, and the welding metallurgical quality is greatly improved, and as a result, the nondestructive inspection qualification rate is increased; the weathering resistant steel is resistant to atmosphere corrosionand remains outstanding mechanical performance and is applicable to board and section production with general industrial processes; and moreover, the cost is low.

Owner:YANSHAN UNIV

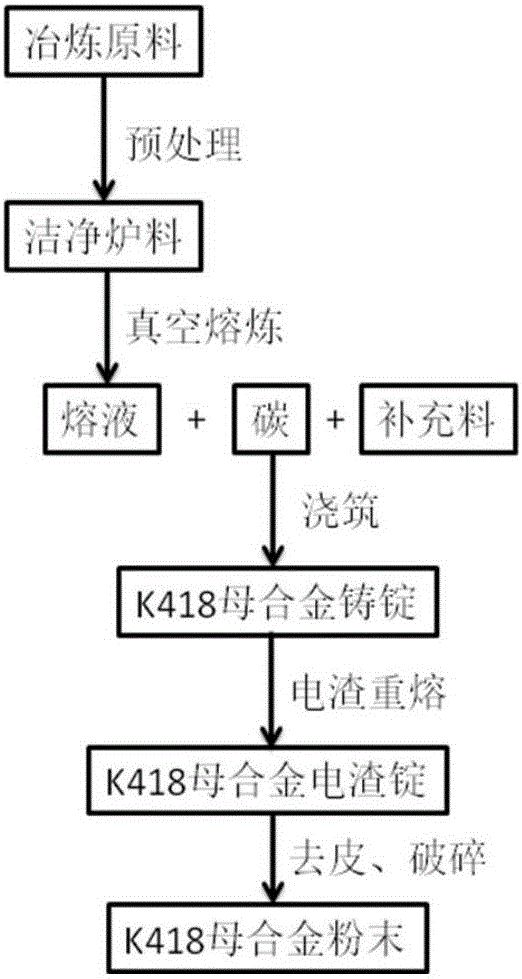

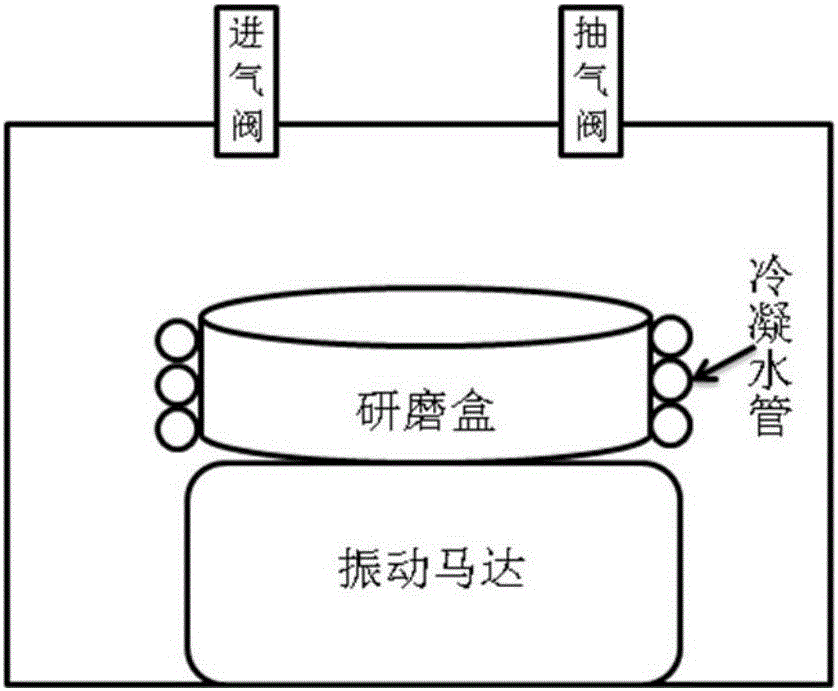

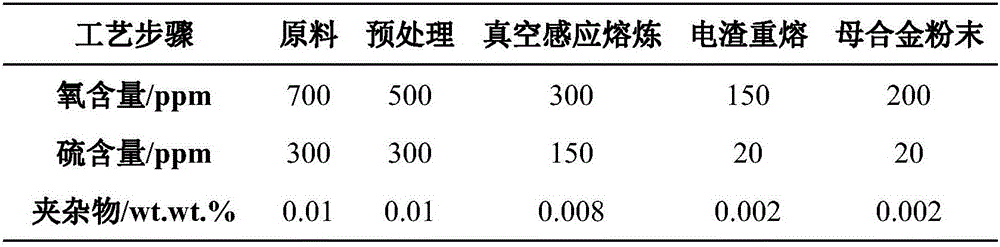

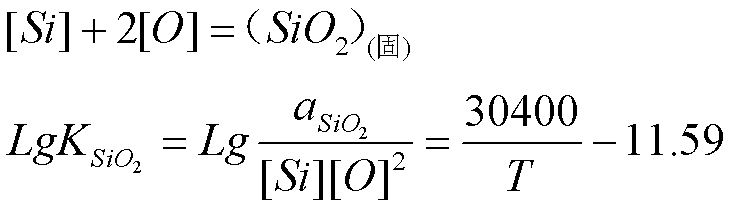

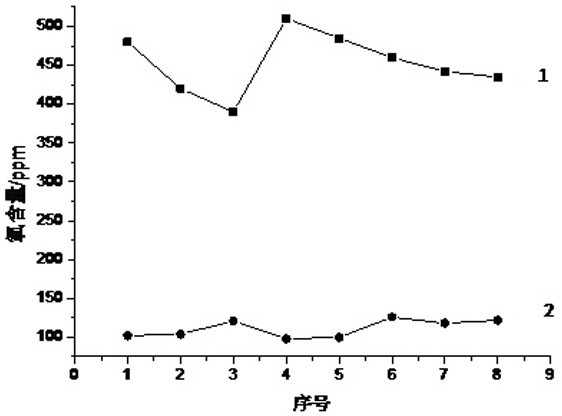

Preparation method for low oxygen content and high alloying nickel-based mother alloy and powder

The invention discloses a preparation method for a low oxygen content and high alloying nickel-based mother alloy and powder and belongs to the field of powder metallurgy. The technological process of the preparation method includes the steps that firstly, a pure mother alloy ingot is prepared by means of duplex processes of vacuum smelting and electroslag remelting. In the process of vacuum smelting, a calcium oxide crucible is adopted, raw materials are pre-treated, carbon blocks are added in a refining stage for deoxidization, elements prone to the burning loss are supplemented at the end stage of smelting, and the mother alloy ingot in designed components is obtained. In the process of the electroslag smelting, by adjusting the shape, the depth, the viscosity and other parameters of a slag pond, the float-up condition of the nonmetallic inclusion is created, and the mother alloy is further purified. After the mother alloy ingot subjected to electroslag remelting is subjected to scaling, the mother alloy ingot is subjected to high-speed disk grinding breakage under the protective atmosphere, and the ultra-thin mother alloy powder is obtained. The particle size of the K418 mother alloy powder prepared through the method is smaller than 20 microns, the oxygen content is lower than 200 ppm, the sulfur content is lower than 20 ppm, after the alloy podwer is mixed with carbonyl nickel powder, sintering compacting at low temperature can be achieved, and the production cost and the process energy consumption of a high temperature alloy of the powder are greatly reduced.

Owner:UNIV OF SCI & TECH BEIJING

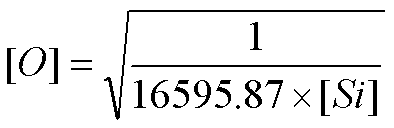

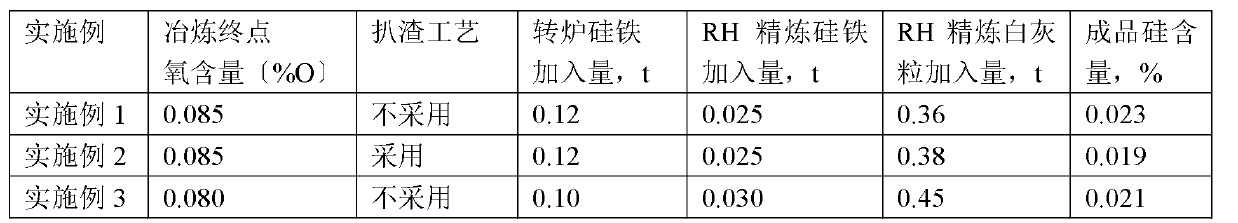

Deoxidation method of low-silicon steel by utilization of silicon alloys

The invention relates to the technical field of steel-making, especially to a deoxidation method of low-silicon steel by the utilization of silicon alloys. In the production process route of converter-RH vacuum refining-slab continuous casting, silicon alloys are respectively added as a deoxidizer during the converter tapping process and RH treatment process so as to remove excess oxygen in ultra-low carbon steel in the converter area and excess oxygen left after RH decarburization. The method provided by the invention specifically comprises the following steps: 1) boiling and tapping during the converter process, and carrying out deoxidation by adding ferrosilicon during the tapping process; 2) carrying out pre-deoxidation by the use of ferrosilicon during the RH treatment process; and 3) adding aluminium for final deoxidation after RH decarburization, calculating critical oxygen content according to 0.045%, and carrying out ingredient adjustment. In comparison with the prior art, the invention has the following beneficial effects: by the use of silicon alloys (ferrosilicon) to remove excess oxygen, the content of silicon in molten steel can be controlled below 0.030%; and in the case of realizing the same deoxidation effect, inclusion quantity of Al2O3 in a casting blank is minimized, and deoxidation alloy cost is reduced.

Owner:ANGANG STEEL CO LTD

Refining method for reducing inclusions in steel for steel cord

InactiveCN103320571AAbsorb SiO

<sub>2</sub>

ability to improveReduced activitySilicon alloyManganese

The invention provides a refining method for reducing inclusions in steel for steel cord. The refining method provided by the invention is characterized in that converter or electric furnace smelting tapping control elements comprise: by weight, 0.20-0.50% of carbon content, less than 0.01% of phosphorus content, less than 0.02% of sulfur content and less than 0.005% of titanium; during the tapping process, pre-deoxidation and alloying are carried out by the use of manganese and silicon alloys, powdered carbon is used as a carburant, a steel ladle slag reducing agent and premelting top slag are added in steel ladle, calcium carbide or silicon carbide are used as the steel ladle slag reducing agent, and the premelting slag is formed by premelting lime-boron oxide; deep deoxidation and desulphurization are carried out by the use of silico-calcium or silico-calcium-barium alloy during the LF refining process, the content of Al2O3 is controlled to be less than 5%, and from tapping in the smelting furnace to LF outbound, argon blowing is carried out on molten steel in ladle in the whole course to promote inclusions to float. By the adoption of the refining method provided by the invention, it is beneficial to remove oxide inclusions, sulfide inclusions, titanium inclusions and the like in steel for steel cord and raise performance of steel cord, cost is reduced, and resources are saved.

Owner:JIANGSU UNIV

Homogeneous free machining steel and production process thereof

The invention discloses a homogeneous easy-cutting steel and a method for producing the same. The homogeneous easy-cutting steel comprises the following compositions (in percentage by weight): less than or equal to 0.12 percent of C, less than or equal to 0.07 percent of Si, 0.803 to 1.31 percent of Mn, less than or equal to 0.07 percent of P, 0.23 to 0.37 percent of S, less than or equal to 0.001 percent of Al and the balance being Fe and residual elements. The homogeneous easy-cutting steel has the advantages of heat processing, good cutting performance, etc. In the homogeneous easy-cutting steel produced by adopting the method, elements are uniformly distributed; sulfide impurities are uniformly distributed in a cambiform or an elongated cambiform, thereby removing adverse influence of the heat processing of FeS impurities and obviously improving the heat processing and easy-cutting performances of the produced homogeneous easy-cutting steel; and the part surface after being cut has better smoothness.

Owner:LIAONING KAIRUI SPECIAL STEEL

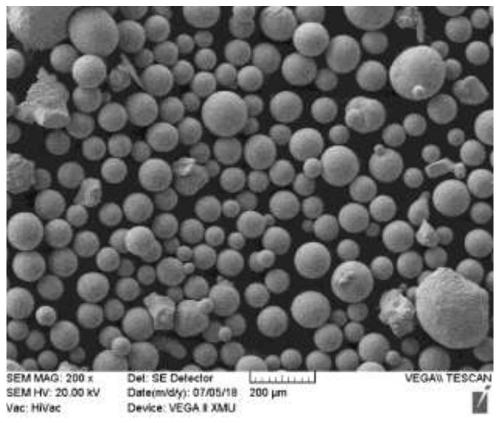

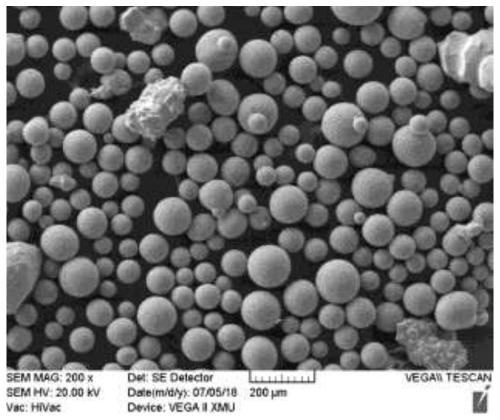

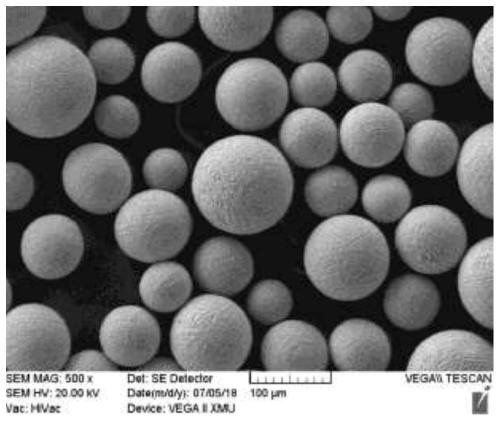

Preparation method of low-cost medium carbon steel spherical powder for 3D printing

PendingCN111570814AHigh sphericityGood surface morphologyTransportation and packagingMetal-working apparatusCarbon steelVacuum induction melting

The invention discloses a preparation method of low-cost medium carbon steel spherical powder for 3D printing. The preparation method comprises the following steps: proportioning medium carbon steel from the following components: 0.43% of C, 0.58% of Mn, 0.18% of Si, 0.25% of Cr, 0.24% of Ni and the balance of Fe, adopting vacuum induction melting to prepare a carbon steel bar, removing the oxidescale on the surface of the alloy bar through machining to process an electrode bar size meeting the requirement of a plasma rotating electrode atomization powder manufacturing apparatus, placing theelectrode bar in a flour mill, adopting a plasma gun to melt the end part of the electrode bar to obtain spherical powder under the action of the centrifugal force, and later, adopting supersonic vibration to screen the collected powder according to different particle sizes. According to the preparation method, plasma rotating electrode atomization is adopted to prepare medium carbon steel spherical metal powder, and the prepared powder has the characteristics of being high in degree of sphericity, less in satellite powder, high in powder density and low in impurity content, can meet the demand of metal powder for 3D printing and is suitable for wide popularization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for deoxidization for nickel-based high-temperature alloy

InactiveCN111118318AReduce the number of inclusionsImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a method for deoxidization for a nickel-based high-temperature alloy. The method comprises the following steps: smelting raw materials are selected; an Inconel690 alloy cast ingot is smelted through a ZG-0.025 type vacuum induction smelting furnace, and the process parameters are as follows: vacuumizing is carried out to reach 0.01Pa, and smelting is carried out for 10-20min under 10-15kW, and carried out under 20-25kW until the Inconel690 alloy cast ingot is melted; the vacuum degree is not greater than 0.1Pa, refining is carried out for 10min, and electromagnetic stirring is carried out; the power is reduced to 5kw under a vacuum, freezing deflation is carried out, then heating is carried out, and the process is repeated for 2-3 times; high-purity argon is chargedunder a high vacuum, a temperature is adjusted, deoxidization elements rare-earth lanthanum and magnesium are added, electromagnetic stirring is carried out, then microalloying elements silicon, aluminum, titanium, niobium and molybdenum, and volatile element manganese are added, and the electromagnetic stirring is carried out; and the power is reduced, pouring and cooling are carried out, then the cast ingot is taken out, and a riser is cut off. The cast ingot obtained by the method is compact in internal structure, uniform in chemical component, and free from shrinkage and porosity, and hasan oxygen content of not greater than 10ppm.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

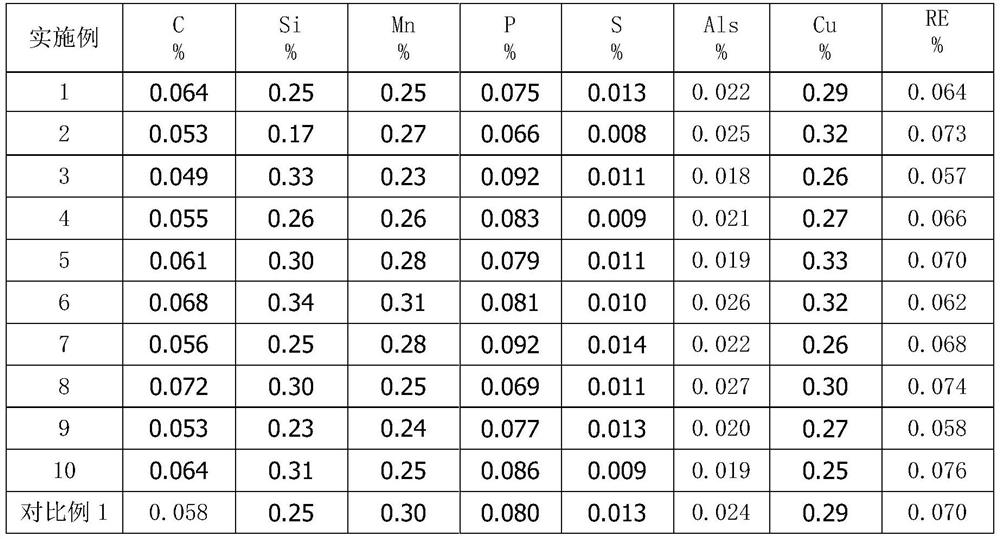

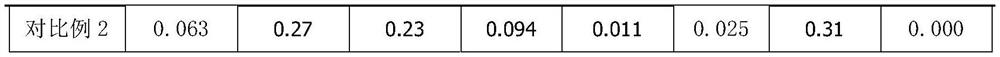

Rare-earth-containing cold-rolled weathering steel with yield strength of 310 MPa for automobiles and production method of rare-earth-containing cold-rolled weathering steel

PendingCN113637903AReduce manufacturing costImprove stamping formabilityWeather resistanceContinuous annealing

The invention relates to rare-earth-containing cold-rolled weathering steel with yield strength of 310 MPa for automobiles. The rare-earth-containing cold-rolled weathering steel comprises the following chemical components in percentage by weight: less than or equal to 0.09% of C, 0.10-0.40% of Si, 0.15-0.35% of Mn, 0.05-0.11% of P, less than or equal to 0.015% of S, 0.010-0.030% of Als, 0.2-0.35% of Cu and 0.04-0.09% of RE. A production method comprises the following steps of: conducting desulfurizing; heating a casting blank; scouring the surface of the casting blank with high-pressure water; conducting rough rolling; conducting finish rolling; conducting coiling; conducting cold rolling after pickling; conducting continuous annealing; and conducting leveling according to different cold-rolled finished product thicknesses. Under the condition that the yield strength is 310-380 MPa and the tensile strength is 400-480 MPa, the elongation A can be improved to be larger than or equal to 38%. The rare-earth-containing cold-rolled weathering steel has good atmospheric corrosion resistance and weather resistance, is simple in element and is particularly suitable for structural parts which cannot be coated in the automobiles and are large in stamping deformation.

Owner:武汉钢铁有限公司

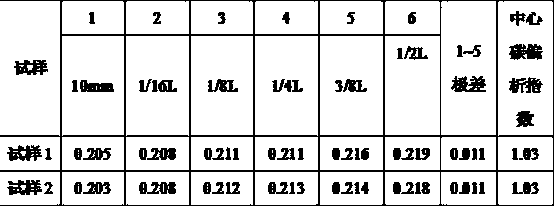

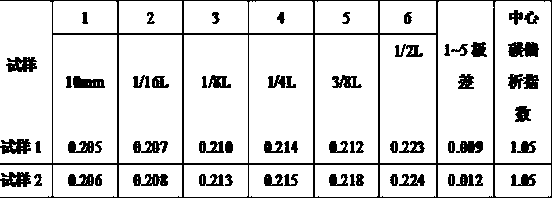

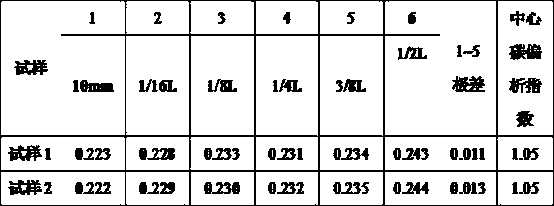

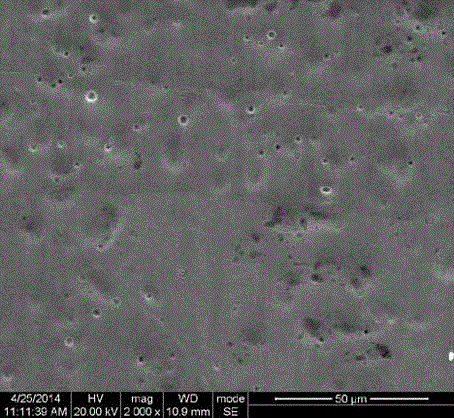

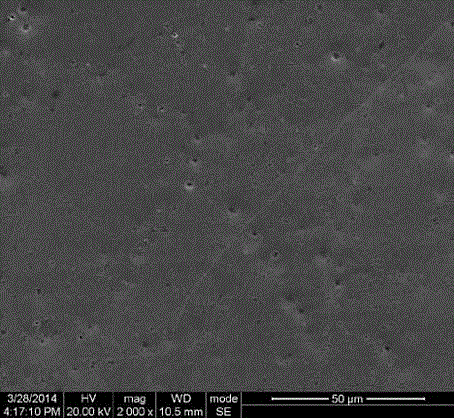

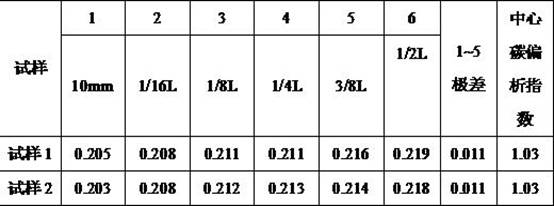

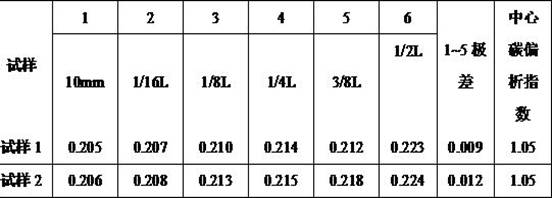

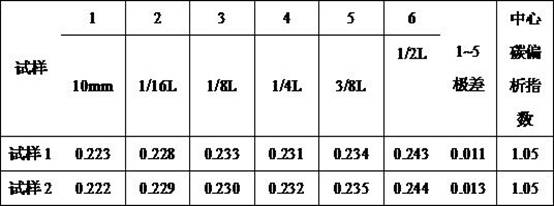

Method for reducing segregation during casting process of continuous-casting square billet for gear

The invention discloses a method for reducing segregation during a casting process of a continuous-casting square billet for a gear. The method comprises the following steps: before the end of LF refining, the temperature of molten steel is increased to the continuous-casting molten steel overheating degree of 20-30 DEG C; a relatively large amount of water is utilized for primary cooling and secondary cooling of the continuous-casting square billet of 150x150 mm; the proportion of the water volume of a foot roller section reaches 40%; the electromagnetic stirring function of a crystallizer isdisabled; the electromagnetic stirring at the tail end is performed at a relatively low electric current; and the casting is performed at a withdrawing speed of 2.00 m / min. According to the method, the electromagnetic stirring function of the crystallizer is disabled, and thus the circumstance that the molten steel purity is influenced when entrapped slag is generated due to excessive stirring inthe crystallizer during the molten steel casting process can be avoided; the cooling water volume can be increased, the cooling strength can be improved, the withdrawing speed can be reduced, and thecasting billet can be sufficiently cooled, the effects that the growth of columnar crystals is promoted and the central equiaxed crystal ratio is reduced can be achieved, the aggregation of solute elements towards the space among the crystals and the center can be avoided, and then the segregation of elements in the casting billet can be reduced; the carbon range from the surface to 3 / 8 of a diagonal of the continuous-casting square billet for the gear can be controlled to be within 0.015%; the central carbon segregation index can be within 1.05; and the steel performance stability can be improved.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

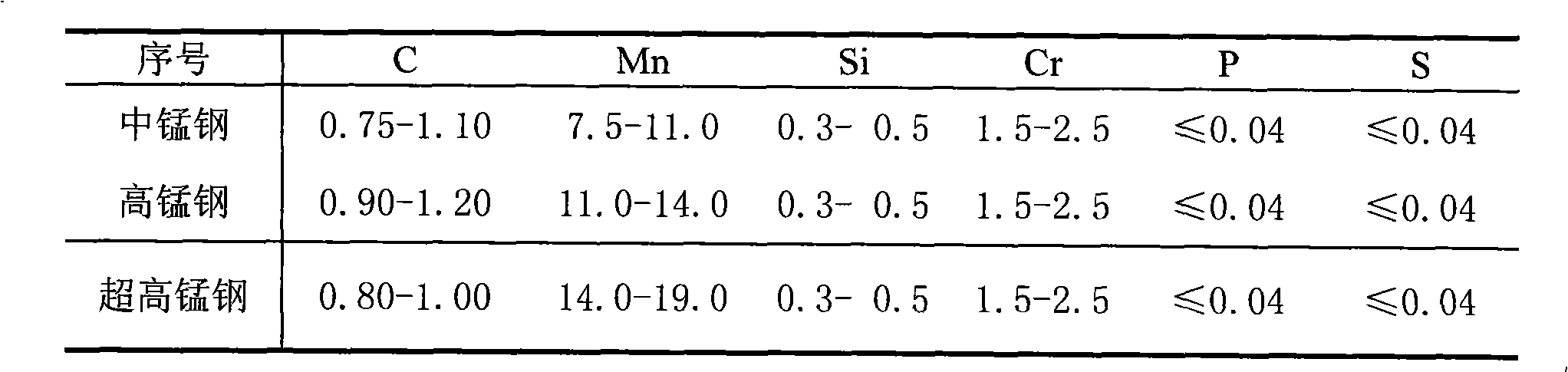

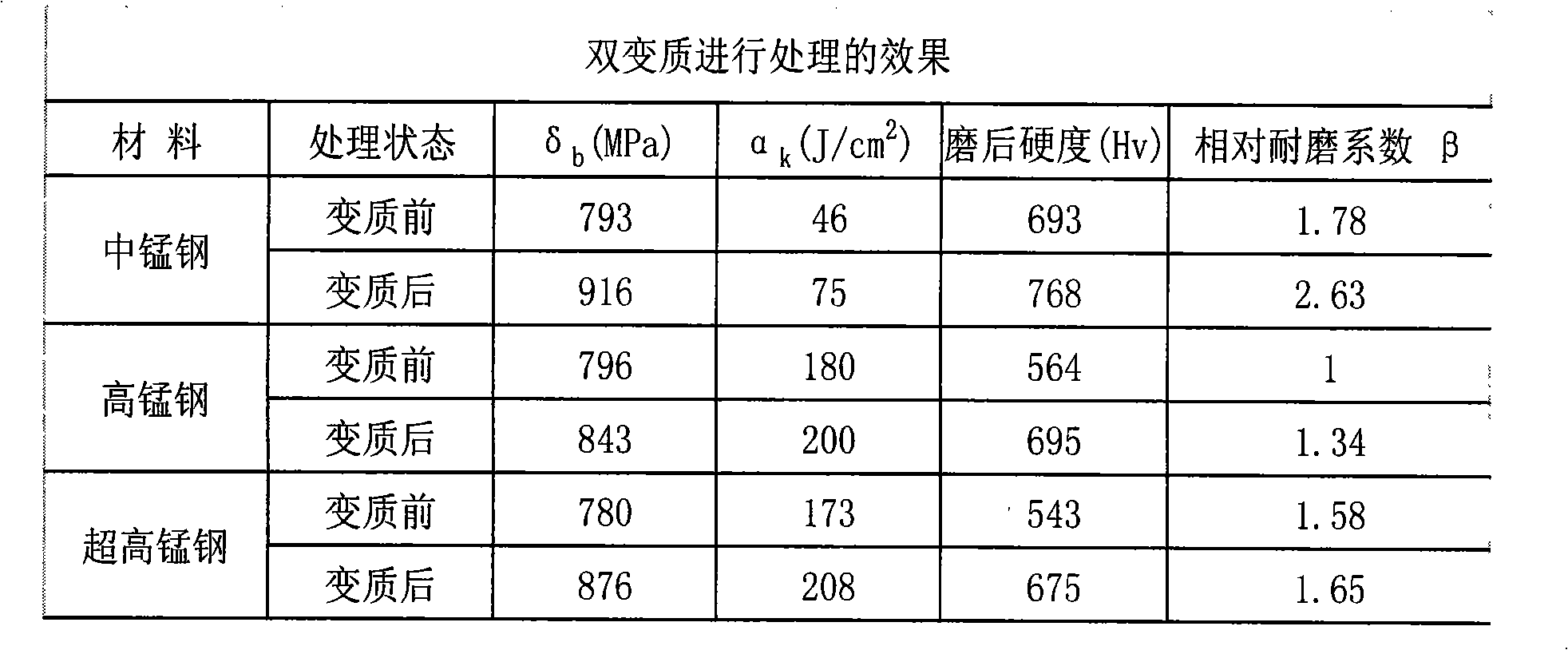

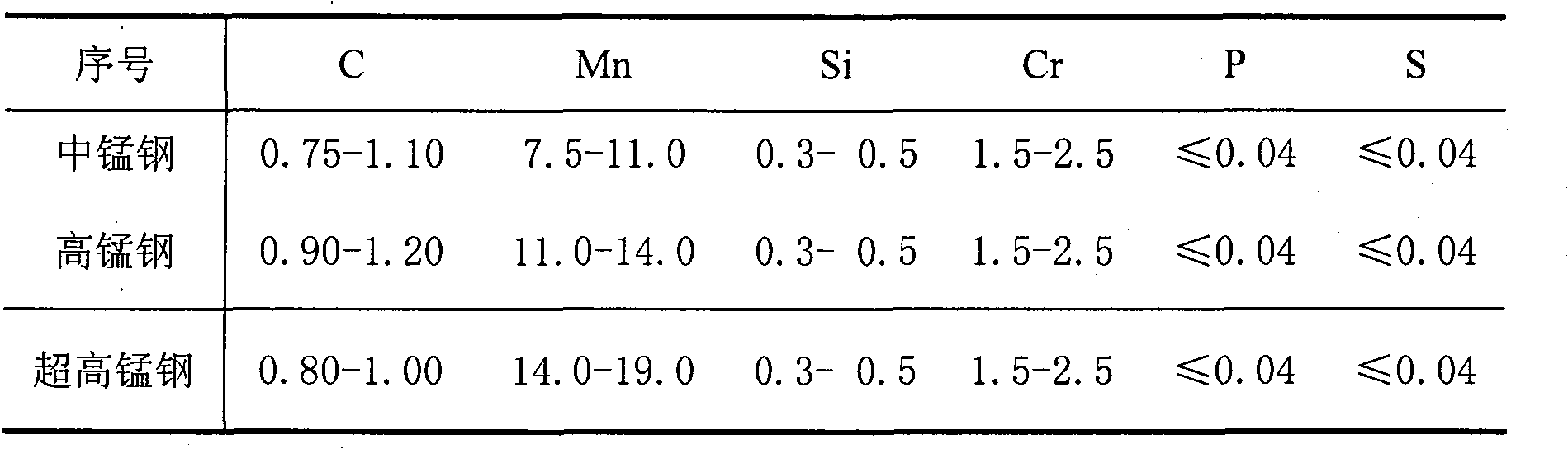

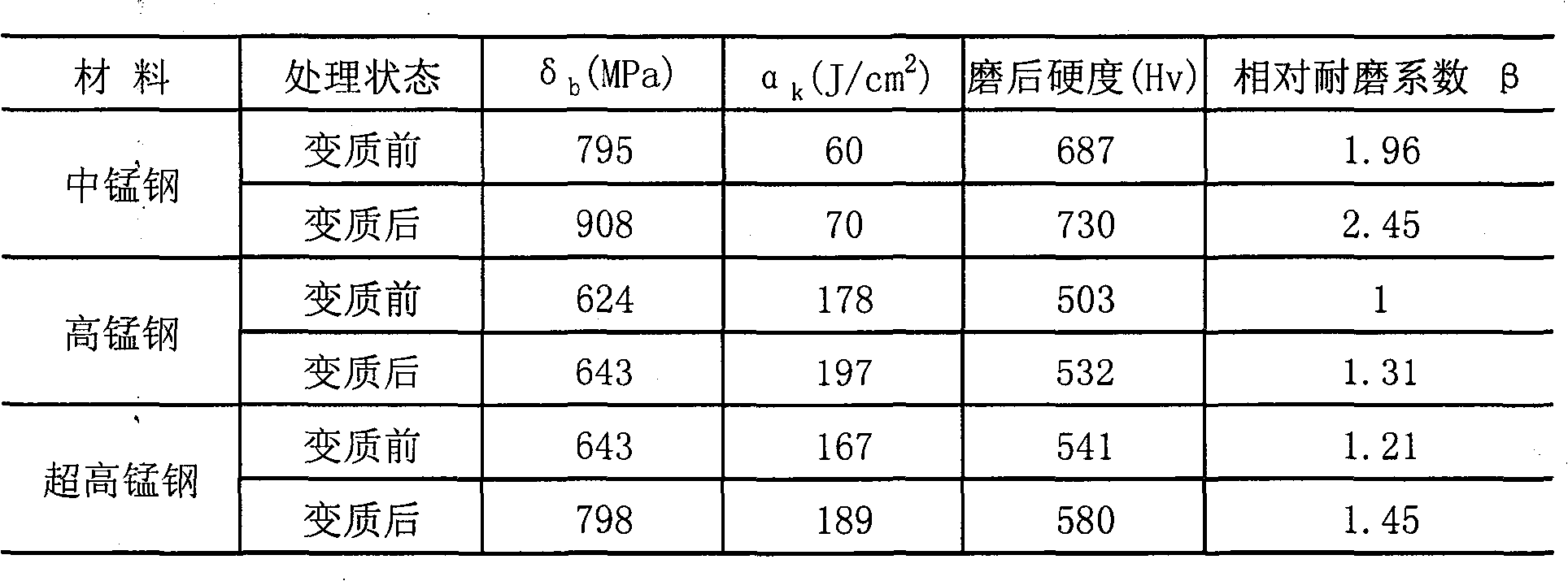

Double- modification method for advanced austenitic manganese steel

The invention discloses an advanced double-modification method for austenitic manganese steel. The method comprises the following steps that: after ferromanganese is added to molten steel for the fine adjustment of manganese content, Re-containing rare earth alloy accounting for 0.067-0.081 percent of the weight of the molten steel and vanadium slag accounting for 2.0-2.5 percent of the weight of the molten steel are orderly added to a molten pool; aluminum accounting for 0.15-0.20 percent of the weight of the molten steel is added in before the tapping of the molten steel; calcium silicon accounting for 0.04-0.06 percent of the weight of the molten steel, Re-containing rare earth alloy accounting for 0.133-0.169 percent of the weight of the molten steel, ferrotitanium accounting for 0.02-0.03 percent of the weight of the molten steel, as well as zinc accounting for 0.006-0.008 percent of the weight of the molten steel are added to a steel ladle outside a furnace. The comprehensive mechanical property and wear resistance of austenitic manganese steel are improved through double modification.

Owner:铜陵市大明玛钢有限责任公司

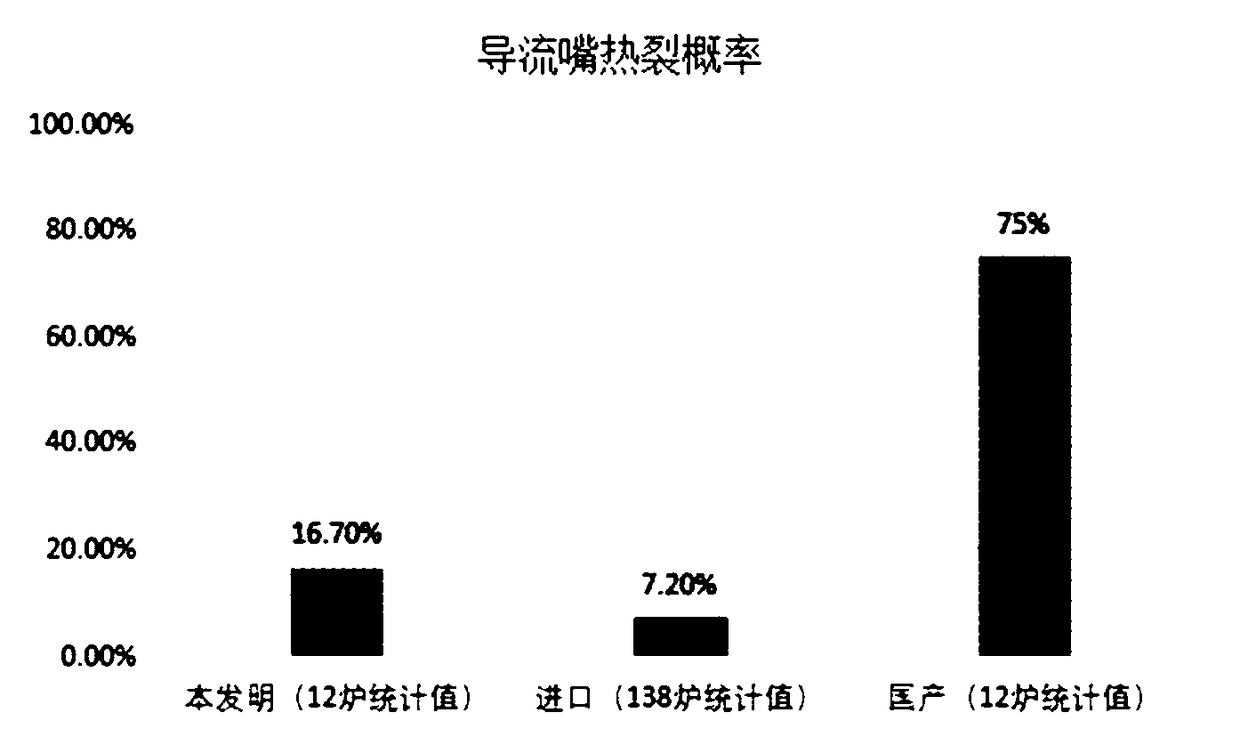

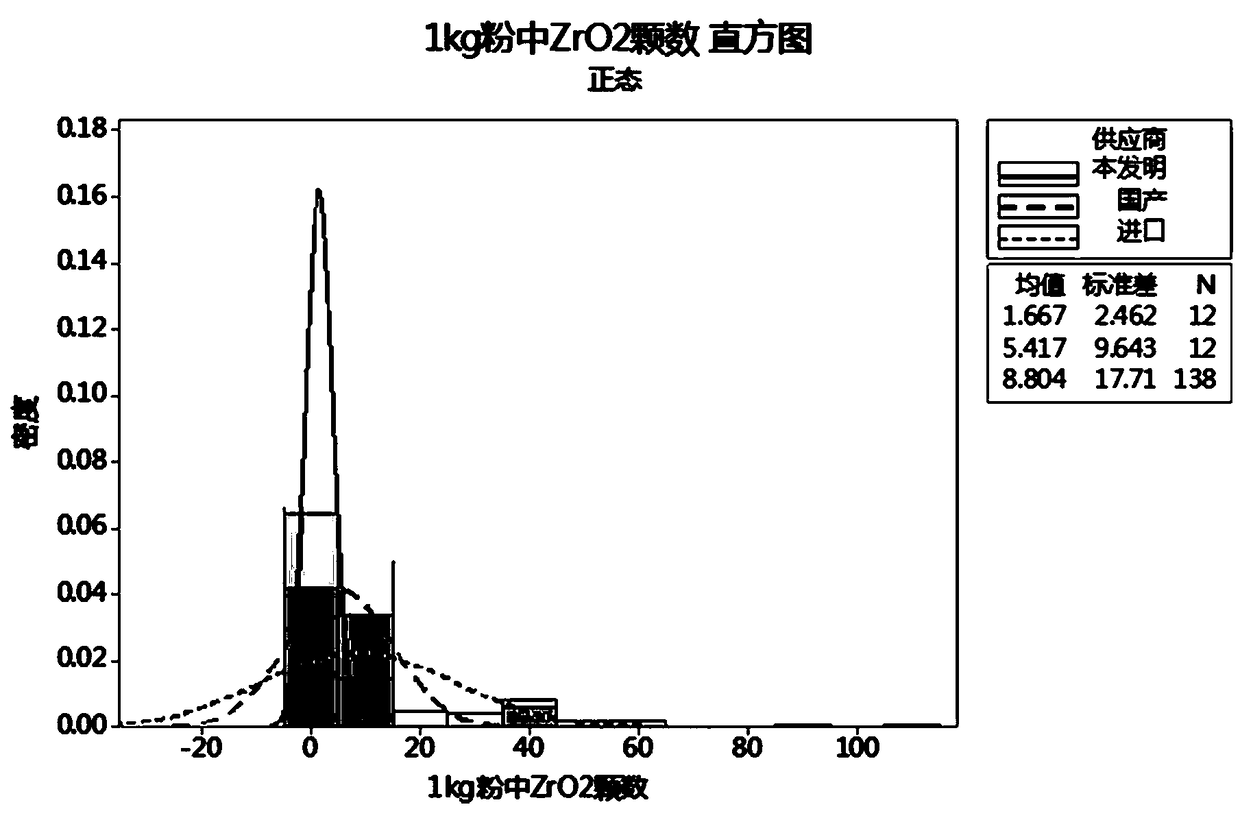

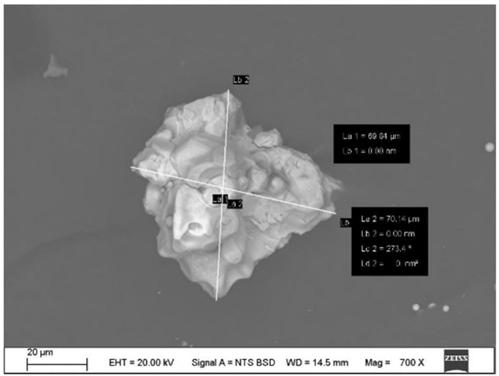

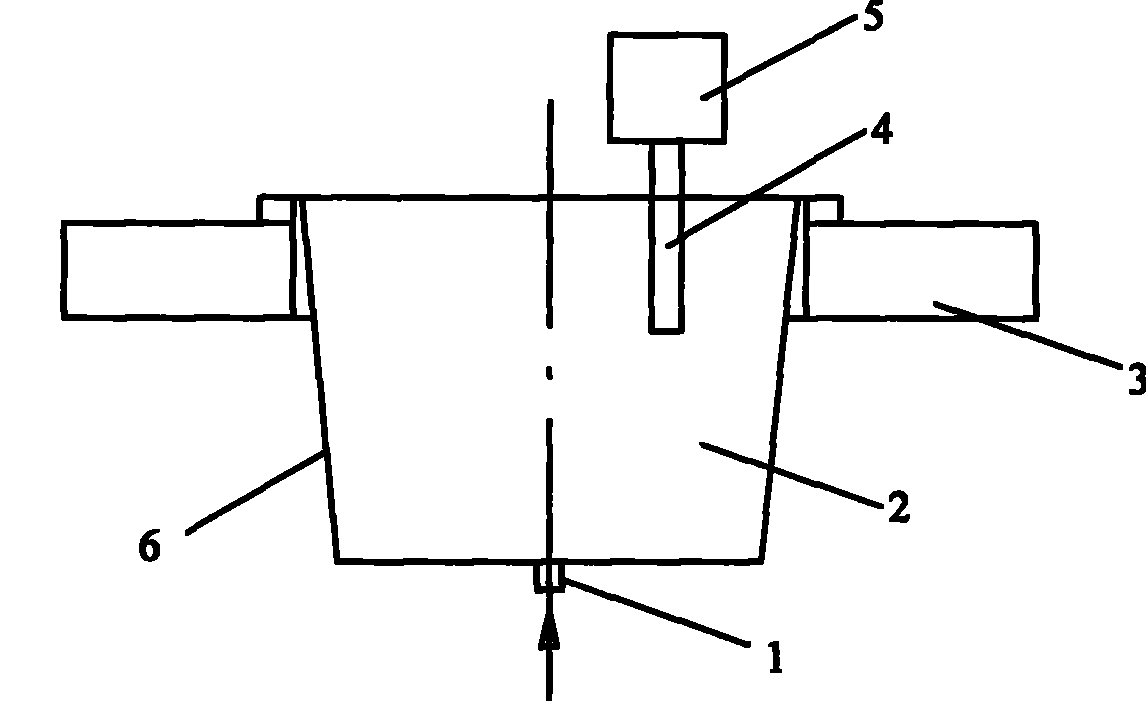

Composite ceramic powder, flow guide nozzle and preparation method of composite ceramic powder

The invention discloses composite ceramic powder, a flow guide nozzle, a preparation method of the composite ceramic powder. The method comprises the following steps: S1, preparing composite ceramic powder by taking ZrO2+HfO2 as a substrate, wherein the composite ceramic powder is prepared from the following components in percentage by weight: 92 to 96 percent of ZrO2+HfO2, 2 to 6 percent of Y2O3+CeO2, and 1 to 3 percent of SiO2+TiO2+Fe2O3+Al2O3+CaO+MgO; S2, mixing the composite ceramic powder, deionized water and a dispersing agent in a mass ratio of 1 to (1 to 2) to (0.001 to 0.002), and performing ball milling to obtain a sizing agent; S3, adding a bonding agent into the sizing agent, and performing ball milling continually; S4, performing spray granulation on the sizing agent preparedin step S3 to obtain composite ceramic finished powder. By adopting the prepared flow guide nozzle in a gas atomization powder preparing test, the zirconia-like matter content of the finished powder is lowered by up to 80 percent compared with the domestic products of the same kind.

Owner:深圳市万泽中南研究院有限公司 +1

Control method of steel inclusions for railway bogie

InactiveCN111455257AReduce inclusion contentImprove quality stabilityManufacturing convertersBogieSmelting process

The invention discloses a control method of steel inclusions for a railway bogie. According to the method, through pretreatment of molten iron, the content of slag in the molten iron and the low sulfur content are effectively reduced, the heat source of a converter is guaranteed, and the smelting pressure of the converter is relieved; through smelting of the converter, the original oxygen contentof the molten iron is effectively reduced, oxide inclusions generated after the molten iron reaches a steel ladle are greatly reduced, and the number of the inclusions generated in the molten iron ina smelting process is reduced; through a refining treatment mode, the inclusions are denatured, and solid inclusions mainly containing CaO-CaS are generated; and a high overheating degree and weak cooling mode is adopted for continuous casting, it is guaranteed that the molten iron effectively floats and is adsorbed at a ladle, a tundish, a cleaner and a solidification tail end in a casting process, a quite small amount of inclusions are gathered in the center of a casting blank, the purity of the molten iron is effectively improved, and the anti-fatigue characteristic of a product is improved.

Owner:NANJING IRON & STEEL CO LTD

Method for controlling inclusion in ultra-low carbon steel based on straight cylinder type vacuum refining device

The invention discloses a method for controlling inclusion in ultra-low carbon steel based on a straight cylinder type vacuum refining device. The method comprises the following steps that a steel ladle is conveyed to a straight cylinder type vacuum refining station and jacked; a dipping pipe is inserted below the liquid level of molten steel by 50 mm, an argon blowing nozzle, on the same side asa steel ladle eccentric bottom blowing nozzle, of the semi-circumference of the wall of the dipping pipe is adjusted to blow argon strongly, and an argon blowing nozzle on the different size is adjusted to blow argon weakly; the dipping pipe is inserted below the liquid level of the molten steel by 200 mm, and the steel ladle is opened for eccentric bottom argon blowing; the dipping pipe is inserted below the liquid level of the molten steel by 400-500 mm, and rapidly pumped to the limit vacuum degree; the argon blowing flow is adjusted slightly until top slag is pushed to the weak blowing side of the wall of the dipping pipe to the minimum area; after decarbonization treatment is carried out, a molten steel sample is taken for oxygen fixation, then molten steel deoxidization treatment iscarried out, and CaO / Al2O3 in a top slag system is controlled to be equal to 1.2-2.0; and after air breaking, the steel ladle is opened. According to the method, Al2O3 inclusion generated by deep deoxidization is transformed into calcium aluminate low-melting-point inclusion, the amount of the Al2O3 inclusion in the continuous casting molten steel is reduced, thus the adhesion amount of the Al2O3inclusion on the wall of a water opening in the process of the molten steel poured into a crystallizer by passing through a tundish water opening is reduced, and occurrence of flow accumulation of thewater opening is avoided.

Owner:MAANSHAN IRON & STEEL CO LTD

Nickel-based high-temperature alloy denitrification method

InactiveCN111187929ASubstantial denitrificationReduce the number of inclusionsWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a nickel-based high-temperature alloy denitrification method. The method comprises the following steps that smelting raw materials are carefully selected, an Inconel690 alloy ingot is smelted by adopting a ZG-0.025 type vacuum induction smelting furnace according to the following technological parameters that vacuumizing is performed to reach 0.01Pa, 10-15kW is kept for 10-20min, and 20-25kW is kept until the ingot is molten; the vacuum degree is less than or equal to 0.05Pa, refining is performed for 10min, and electromagnetic stirring is performed; under vacuum, the power is reduced for freezing and deflating, heating is performed again, and repeating for 2-3 times is performed; high-purity argon is introduced in high vacuum, the temperature is adjusted, deoxidizing elements, namely silicon and aluminum and a volatile element, namely manganese are added, microalloying elements, namely niobium, titanium and molybdenum are added after electromagnetic stirring, and electromagnetic stirring is performed; and the power is reduced, pouring is performed, cooling is performed, an ingot is taken out, and a riser is cut off. According to the method, the technological process is easy to achieve, safety, stability and reliability are achieved, and the nitrogen content of the ingot capable of being obtained is less than or equal to 10ppm.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Process for removing nonmetal inclusion in molten steel

InactiveCN101307374BReduce the number of inclusionsInclusion size is smallProcess efficiency improvementNon-metallic inclusionsMolten steel

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of preparation method of high-performance high-alumina silicon steel

ActiveCN112176240BGuaranteed purityReduce the number of inclusionsTransportation and packagingMetal-working apparatusAl powderIron powder

The invention discloses a method for preparing high-performance high-alumina silicon steel, which belongs to the technical field of powder metallurgy. The invention uses gas-atomized ferrosilicon powder, aluminum powder and ferrophosphorus powder as raw materials, obtains Fe-Si-Al-P mixed powder after full ball milling and mixing, and forms a green thin plate by powder rolling after vacuum annealing , through high-temperature sintering to make it metallurgically bonded, multi-pass hot-rolled to a certain thickness, then cold-rolled 2‑5 times, and finally high-temperature annealed to obtain high-alumina silicon steel sheets with excellent properties. The present invention introduces Al and P elements into the Fe-Si system, which can effectively improve the soft magnetic performance parameters of the material, and use the Al powder with good ductility to improve the formability of the system, ensure powder rolling forming, and have the advantages of operation Simple, high production efficiency, high product precision, no pollution and inclusions, excellent performance and other advantages.

Owner:UNIV OF SCI & TECH BEIJING

Novel composite modifier for austenitic manganese steel

InactiveCN101289723BControl crystallizationEnhance the ability to resist "recession"Melting tankRare earth

The invention discloses a novel composite modifier for austenitic manganese steel, comprising rare earth alloy, ferrotitanium, calcium silicon and aluminum, wherein the dosage of the Re-containing rare earth alloy accounts for 0.20-0.25 percent of the weight of molten steel; the dosage of the ferrotitanium accounts for 0.02-0.03 percent of the weight of the molten steel; the dosage of the calciumsilicon accounts for 0.20-0.25 percent of the weight of the molten steel; and the dosage of the aluminum accounts for 0.15-0.20 percent of the weight of the molten steel. Treatment inside a furnace is carried out in the alloying adjustment stage for the composition of the molten steel after ferromanganese is added for the fine adjustment of the manganese content of the molten steel; one third of the rare earth alloy is added to a molten pool, and the aluminum is added before the tapping of the molten steel. Treatment outside the furnace is to add the calcium silicon, two thirds of the rare earth alloy and the ferrotitanium to a steel ladle. The adoption of the Re-Ca-Ti-Al multi-element composite modifier prolongs the effective time of the modification process of the molten steel and guarantees good modification effect.

Owner:铜陵市大明玛钢有限责任公司

Heating process before rolling to control the size of titanium inclusions in hypereutectoid cord steel wire rod

InactiveCN103320604BSmall sizeReduce the number of inclusionsFurnace typesHeat treatment furnacesWire rodAerosol Mist

The invention relates to a rolling preheating process for controlling the sizes of titanium inclusions in a hypereutectoid tire cord steel wire rod. The technical scheme of the rolling preheating process is characterized by comprising the following steps of: heating a hypereutectoid tire cord steel continuous casting blank to 1150-1250 DEG C in a steel rolling heating furnace, wherein the heating time is 2-6 hours, the titanium inclusion (TiN or Ti(C,N)) in the casting blank is decomposed (namely solid dissolving) in the heating process, small inclusions disappear, and the sizes of the larger-size titanium inclusions are reduced; cooling the high-temperature-heated hypereutectoid tire cord steel continuous casting blank to the normal rolling temperature of hypereutectoid tire cord steel in a water mist cooling or air mist cooling manner; and carrying out rolling by utilizing a high-speed rolling mill. According to the rolling preheating process for controlling the sizes of the titanium inclusions in the hypereutectoid tire cord steel wire rod, the titanium inclusions in the super-strength hypereutectoid tire cord steel wire rod are diffused and distributed, and the number and the sizes of the titanium inclusions in casting blank are effectively controlled. The rolling preheating process has the characteristics that the titanium inclusions are small in number and sizes and are diffused and distributed, and the process is reliable; and according to the rolling preheating process, the penalty point rate of the titanium inclusions of the hypereutectoid tire cord steel wire rod can be effectively reduced.

Owner:WUHAN UNIV OF SCI & TECH

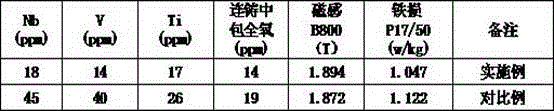

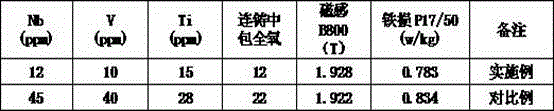

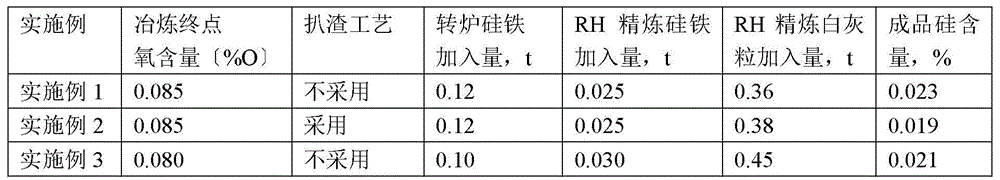

Smelting method of grain oriented silicon steel alloyed in rh furnace

The invention provides a method for smelting alloyed oriented silicon steel in a RH furnace. The method includes the steps that converter smelting and tapping are conducted, slag is blocked when converter tapping is finished, and RH refining is conducted; after circulating decarburization is conducted for 3 minutes to 5 minutes, aluminum balls and bauxite are added for deoxidization and slag formation, and when the aluminum balls and the bauxite stop being added, circulation is further conducted for 2 minutes to 3 minutes, and alloying is conducted; and casting is conducted, blanks are formed, and later working procedures are conducted. According to the method, on the one hand, due to the fact that RH refining is conducted, alloying is conducted after residual carbon in molten steel is deoxidized, the number of generated oxide inclusions can be reduced, the total oxygen content in the steel is kept below 15 ppm, the alloy oxidation loss is reduced as well, and the contents of harmful elements such as Nb, V and Ti remaining in the steel are all kept below 20 ppm, and magnetic performance is excellent. Furthermore, due to the fact that decarburization can be conducted in the RH furnace, no converter low-carbon high-oxygen tapping is needed, and corrosion to a converter lining caused by oxygen blast can be relieved remarkably.

Owner:武汉钢铁有限公司

A method for controlling inclusions in ultra-low carbon steel based on a straight cylinder vacuum refining device

The invention discloses a method for controlling inclusion in ultra-low carbon steel based on a straight cylinder type vacuum refining device. The method comprises the following steps that a steel ladle is conveyed to a straight cylinder type vacuum refining station and jacked; a dipping pipe is inserted below the liquid level of molten steel by 50 mm, an argon blowing nozzle, on the same side asa steel ladle eccentric bottom blowing nozzle, of the semi-circumference of the wall of the dipping pipe is adjusted to blow argon strongly, and an argon blowing nozzle on the different size is adjusted to blow argon weakly; the dipping pipe is inserted below the liquid level of the molten steel by 200 mm, and the steel ladle is opened for eccentric bottom argon blowing; the dipping pipe is inserted below the liquid level of the molten steel by 400-500 mm, and rapidly pumped to the limit vacuum degree; the argon blowing flow is adjusted slightly until top slag is pushed to the weak blowing side of the wall of the dipping pipe to the minimum area; after decarbonization treatment is carried out, a molten steel sample is taken for oxygen fixation, then molten steel deoxidization treatment iscarried out, and CaO / Al2O3 in a top slag system is controlled to be equal to 1.2-2.0; and after air breaking, the steel ladle is opened. According to the method, Al2O3 inclusion generated by deep deoxidization is transformed into calcium aluminate low-melting-point inclusion, the amount of the Al2O3 inclusion in the continuous casting molten steel is reduced, thus the adhesion amount of the Al2O3inclusion on the wall of a water opening in the process of the molten steel poured into a crystallizer by passing through a tundish water opening is reduced, and occurrence of flow accumulation of thewater opening is avoided.

Owner:MAANSHAN IRON & STEEL CO LTD

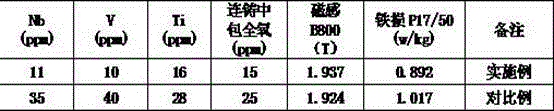

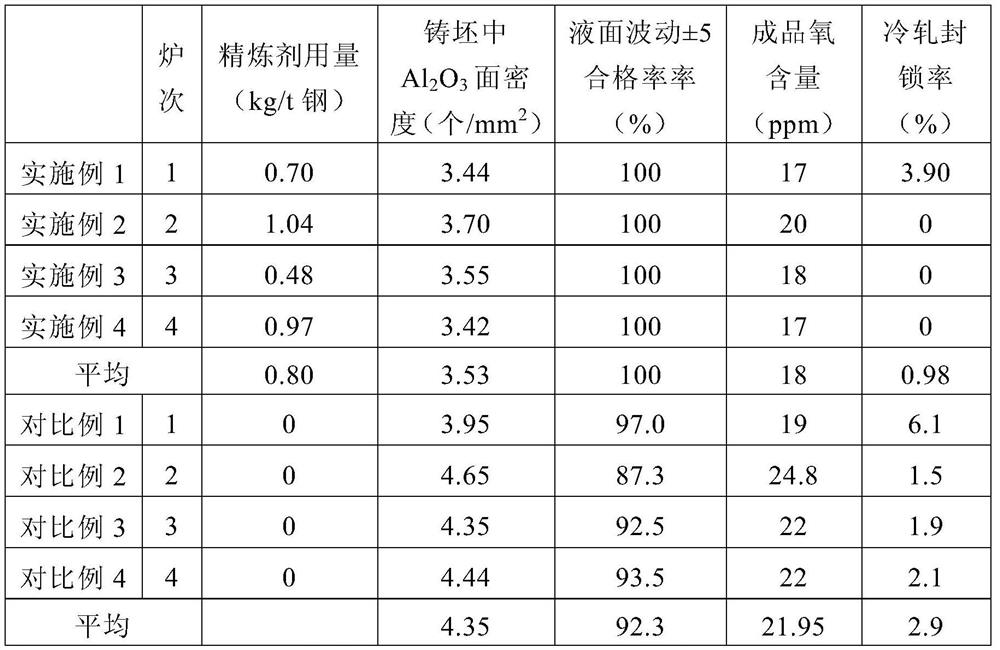

A control method for oxide inclusions in ultra-low carbon steel produced by ld-rh process

ActiveCN109554605BReduce the number of inclusionsImprove product qualityManufacturing convertersProcess efficiency improvementMolten steelCarbon steel

A method for controlling oxide inclusions in ultra-low carbon steel produced by LD-RH process, which includes adding lime 2.0-3.5kg / t steel in the early tapping stage of LD converter, and adding 0.5-1.2kg / t Al-based modifier at the end of tapping Steel; then enter the RH furnace for vacuum decarburization; decarburization is completed, deoxidation, adding refining agent 0.3-2kg / t steel, the composition of the refining agent is: CaO: 50-60wt%, Al 2 o 3 : 30~40wt%, MgO: 2~6wt%, SiO 2 ≤3wt%, TiO 2 <0.08wt%, FeO≤1wt%, H 2 O≤0.5wt%; alloying; circulation of molten steel for 3‑12 minutes, and the vacuum refining process ends. The method greatly reduces the amount of oxide inclusions in the slab and the oxygen content of the finished product, reduces the blocking rate of cold rolling, and significantly improves the quality of ultra-low carbon steel products.

Owner:BAOSHAN IRON & STEEL CO LTD

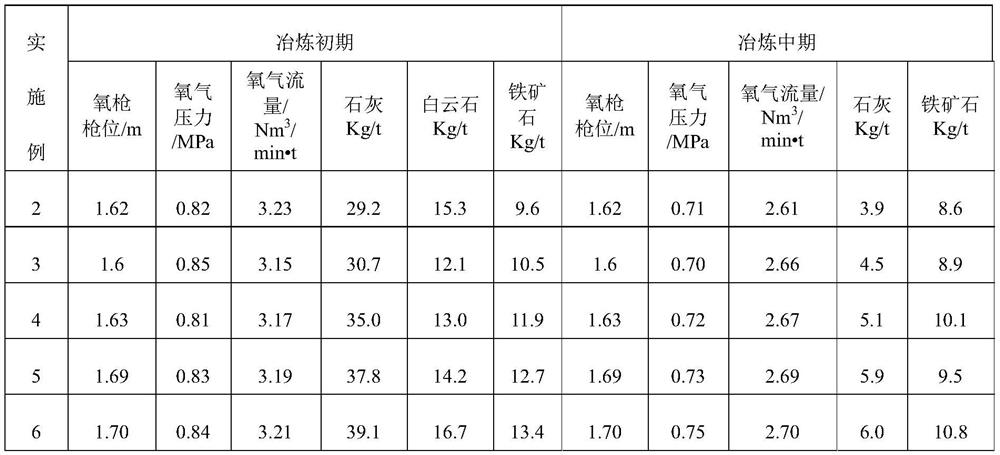

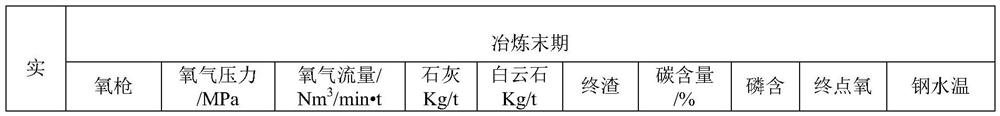

A heavy rail steel converter smelting method capable of reducing oxygen content during tapping

ActiveCN110468249BReduce usageReduce the number of inclusionsManufacturing convertersThermodynamicsEngineering

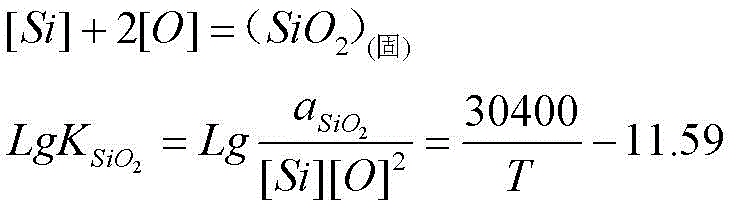

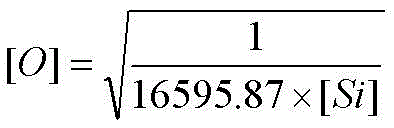

A heavy rail steel converter smelting method that can reduce the oxygen content during tapping: the first 350s of converter smelting is the initial smelting period. Two batches are added; from the end of the initial period to 750s is the mid-smelting period, during which the oxygen lance position is still kept at 1.6-1.7m for continuous oxygen blowing, and lime and iron ore are added in sequence when the smelting reaches 450s; The end of the mid-term to 900s is the final stage of smelting. During this period, the position of the oxygen lance is still kept at 1.6-1.7m for continuous oxygen blowing, and lime and lightly burned dolomite are added in sequence. The present invention solves the unstable factors caused by the dynamic control of the lance position and empirical operation by keeping the oxygen lance position fixed; while ensuring effective dephosphorization, the oxygen content at the end of the converter blowing can be kept below 120PPm, thereby enabling Reduce the amount of carburizer by 40% to 60%, and reduce the amount of deoxidized alloy by 10% to 20%, thereby reducing the inclusion of endogenous oxides in the steel and improving the service life and safety of the rail.

Owner:武汉钢铁有限公司

A method for deoxidizing low-silicon steel using silicon alloys

The invention relates to the technical field of steelmaking, in particular to a method for deoxidizing low-silicon steel using silicon alloys. In the production process route of converter-RH vacuum refining-slab continuous casting, add Silicon alloy is used as a deoxidizer to remove the excess oxygen in the ultra-low carbon steel in the converter area and the excess oxygen after RH decarburization. The specific implementation steps are as follows: 1) The converter process requires boiling tapping, and ferrosilicon is added during the tapping process for deoxidation; 2) During RH treatment, ferrosilicon is used for pre-deoxidation; 3) After RH decarburization, aluminum is added for final deoxidation. The critical oxygen content can be calculated as 0.045%, and the composition is adjusted. Compared with the prior art, the beneficial effect of the present invention is that the silicon alloy (ferrosilicon) is used to remove excess oxygen, the silicon content of molten steel can be controlled below 0.030%, and the Al in the slab can be reduced while achieving the same deoxidation effect. 2 o 3 Increase the number of inclusions while reducing the cost of deoxidized alloys.

Owner:ANGANG STEEL CO LTD

Aluminum alloy welding wire for high-speed train and preparation method thereof

InactiveCN105772981BHigh tensile strengthImprove plasticityWelding/cutting media/materialsSoldering mediaCrack resistanceToughness

The invention relates to an aluminum alloy welding wire for a high speed train and a preparation method of the aluminum alloy welding wire for the high speed train. The aluminum alloy welding wire for the high speed train is characterized by comprising the following chemical components in percentages by mass: 4.0-6.5% of Mg, 0.06-0.2% of Ti, 0.1-0.3% of Cr, 0.05-0.2% of Mn, 0.05-0.2% of La, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for the high speed train comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for the high speed train provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common ER5356 and ER5183 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

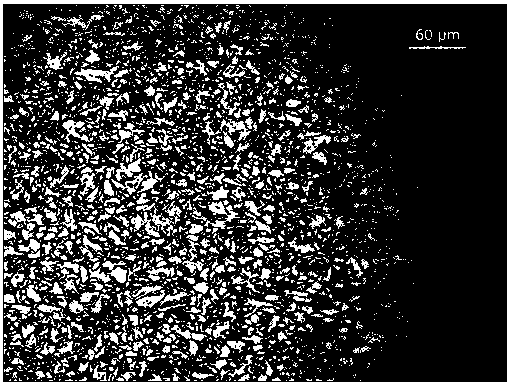

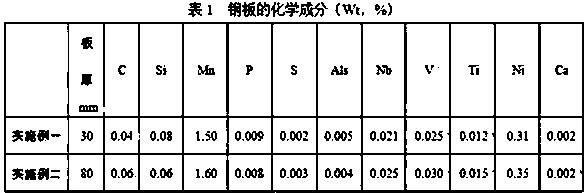

A steel plate for ocean engineering that can be welded with large heat input and its manufacturing method

The invention belongs to the technical field of structural steel for ships and ocean engineering, and in particular, relates to a high-energy-input welded steel plate for ocean engineering and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.04-0.10% of C, 0.05-0.10% of Si, 1.40-1.70% of Mn, P not more than 0.010%, S not more than 0.005%, Als not more than 0.010%, 0.020-0.030% of Nb, 0.020-0.040% of V, 0.008-0.016% of Ti, 0.30-0.50% of Ni, 0.001-0.003% of Ca, and the balance of Fe and inevitable impurities. The steel plate has the following advantages: the deoxidation process in the smelting procedure is simple; the ferrosilicon and metal manganese deoxidation is mainly used; the intermingling number of large aluminum oxide in steel is reduced; and such strong oxide forming elements as Zr / Mg / REM are not added.

Owner:SHANDONG IRON & STEEL CO LTD

A method for smelting nanoparticle dispersion strengthened steel

Owner:SICHUAN UNIV

Method for reducing segregation during pouring of continuous casting billets for gears

The invention discloses a method for reducing segregation in the pouring process of continuous casting billets for gears, which comprises the following steps: before the end of LF refining, the temperature of molten steel is raised until the superheat of continuous casting molten steel is 20-30°C, and continuous casting of 150×150mm billets The first cooling and the second cooling use a large amount of water, and the proportion of water in the foot roll section reaches 40%. Turn off the electromagnetic stirring of the crystallizer, use a lower current for the electromagnetic stirring at the end, and use a casting speed of 2.00m / min. The present invention avoids excessive stirring in the mold during pouring of molten steel by not using electromagnetic stirring of the crystallizer, resulting in slag entanglement affecting the purity of molten steel, increasing the amount of cooling water, improving the cooling intensity, reducing the casting speed, and fully cooling the slab to achieve the promotion of columnar The effect of crystal growth and reduction of central equiaxed crystal ratio can avoid the accumulation of solute elements to the intergranular and center, reduce the segregation of slab elements, and enable the gear to be used on the diagonal of the continuous casting billet from the surface to the 3 / 8 diagonal. The carbon range is controlled within 0.015%, and the central carbon segregation index is within 1.05, which improves the stability of steel performance.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com