Composite ceramic powder, flow guide nozzle and preparation method of composite ceramic powder

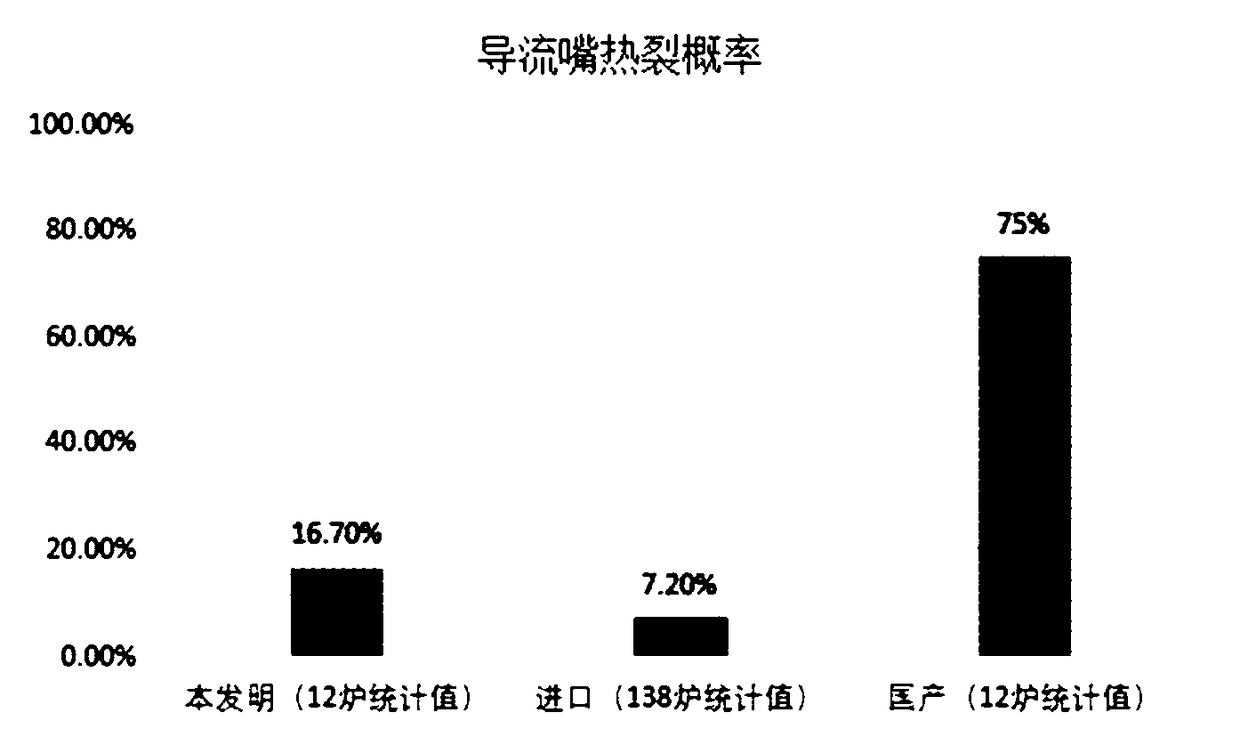

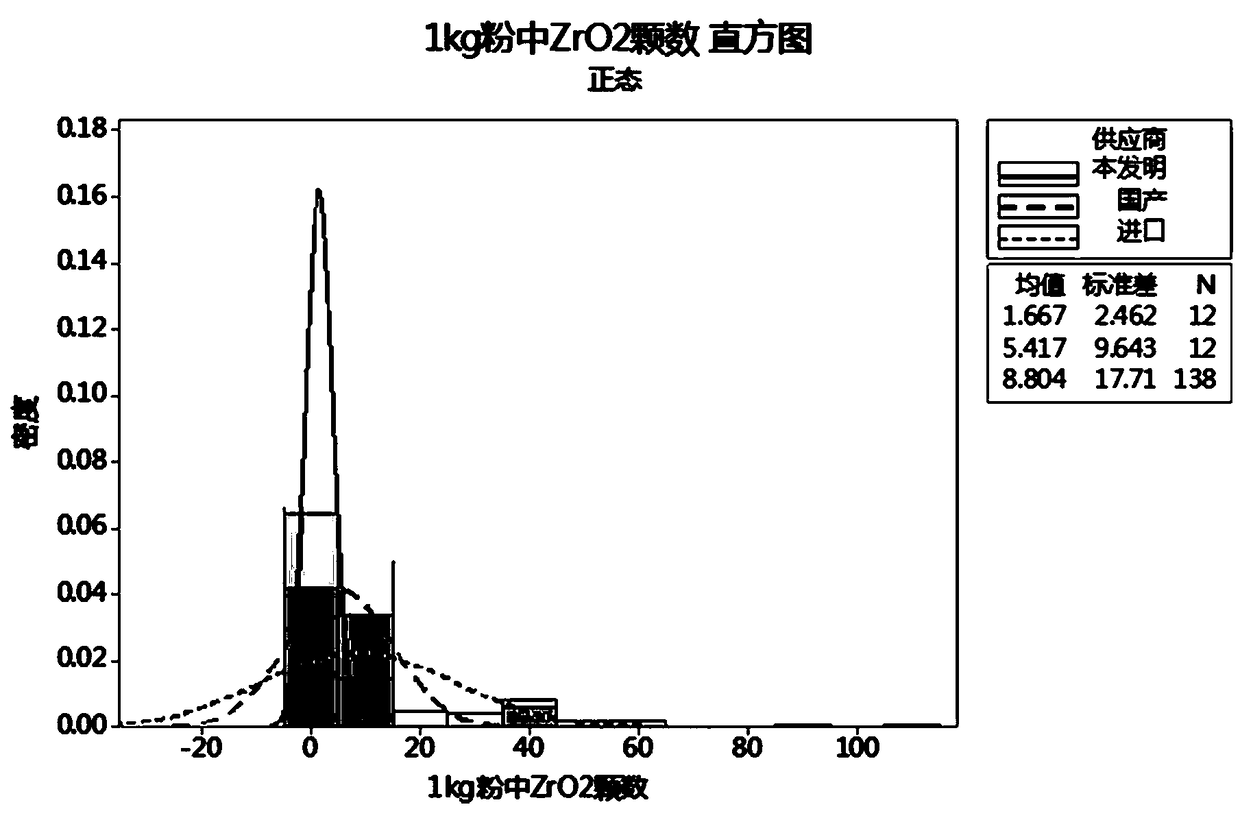

A composite ceramic and guide nozzle technology, applied in the field of materials, can solve the problems of easy thermal cracking, easy peeling, poor thermal shock resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and embodiments.

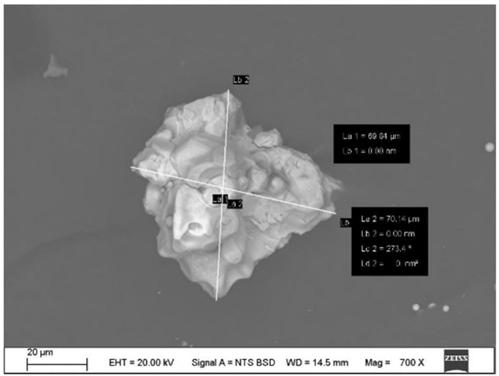

[0029] The present invention provides a method for preparing composite ceramic powder, and a method for preparing composite ceramic powder, such as Figure 5 Shown, including steps:

[0030] S1, configuration with ZrO 2 +HfO 2 The composite ceramic powder is a matrix, wherein the weight percentage of the composition ratio in the composite ceramic powder is:

[0031] ZrO 2 +HfO 2 : 92~96, Y 2 O 3 +CeO 2 : 2~6, SiO 2 +TiO 2 +Fe 2 O 3 +Al 2 O 3 +CaO+MgO:1~3;

[0032] S2. The composite ceramic powder is mixed with deionized water and dispersant and then ball milled to form a slurry, wherein the mass ratios of the composite ceramic powder, deionized water and dispersant are respectively 1:1 to 2:0.001 to 0.002;

[0033] S3, adding a binder to the slurry to continue ball milling;

[0034] S4, spraying and granulating the slurry obtained in the step S3 to obtain a finished composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com