A steel plate for ocean engineering that can be welded with large heat input and its manufacturing method

A technology for high-line energy welding and marine engineering, applied in the field of structural steel for ships and marine engineering, can solve the problems of narrow composition control window, clogging of continuous casting nozzles, difficult production control, etc., to prolong reheating time and reduce reheating. Temperature, the effect of easy on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

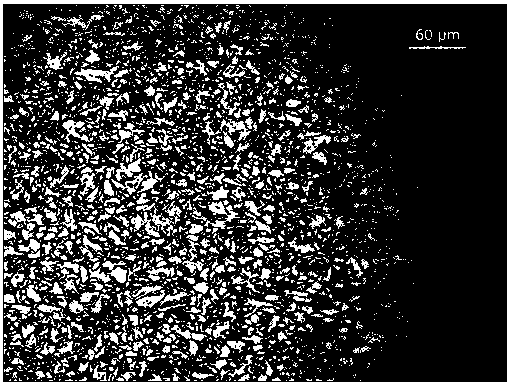

Image

Examples

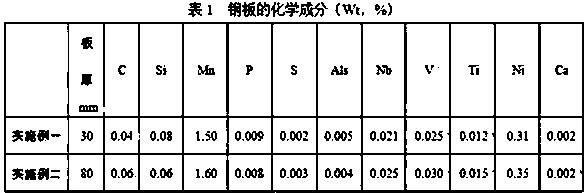

Embodiment 1

[0022] The production process of a steel plate for marine engineering that can be welded with large heat input is: blast furnace hot metal→hot metal pretreatment→converter smelting→LF refining→RH refining→slab continuous casting→slab reheating→rolling→water cooling→sampling inspection ; P ≤ 0.08%, Cr ≤ 0.06%, As ≤ 0.006% of the blast furnace molten iron, the pretreatment of molten iron is desulfurization and slag removal of molten iron, after the molten iron pretreatment, the exposed area of molten iron is 77%, the S content is 0.002%, and the converter When tapping after smelting, add ferrosilicon to the ladle for deoxidation when 1 / 4 of the tapping is reached, then add manganese metal for alloying, add 850Kg of lime and 240Kg of fluorite during tapping, and then proceed to the CAS station after tapping Argon blowing, argon blowing time 11 min, argon blowing time includes steel tapping argon blowing, LF refining with ferrosilicon to adjust the oxygen content of molten steel ...

Embodiment 2

[0024] The production process of a steel plate for marine engineering that can be welded with large heat input is: blast furnace hot metal→hot metal pretreatment→converter smelting→LF refining→RH refining→slab continuous casting→slab reheating→rolling→water cooling→sampling inspection ; P ≤ 0.08%, Cr ≤ 0.06%, As ≤ 0.006% of the blast furnace molten iron, the pretreatment of the molten iron is desulfurization and slag removal of the molten iron, the exposed area of the molten iron is greater than 76% after the pretreatment of the molten iron, S = 0.002%, the converter When tapping after smelting, add ferrosilicon to the ladle for deoxidation when 1 / 4 of the tapping is reached, then add manganese metal for alloying, add 900Kg of lime and 380Kg of fluorite during tapping, and carry out CAS station after tapping Argon blowing, argon blowing time 15 min, argon blowing time includes tapping argon blowing, during LF refining, use ferrosilicon to adjust the oxygen content of molten s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com