A method for smelting nanoparticle dispersion strengthened steel

A dispersion strengthening and nanoparticle technology, applied in the field of iron and steel metallurgy, can solve the problems of difficult removal of modified products, hinder denaturation reaction, and deterioration of steel performance, and achieve the effects of fast melting rate, refined structure, and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

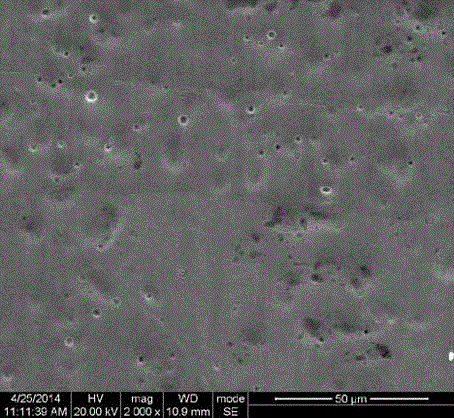

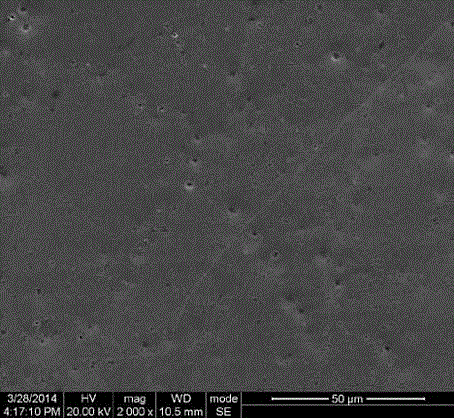

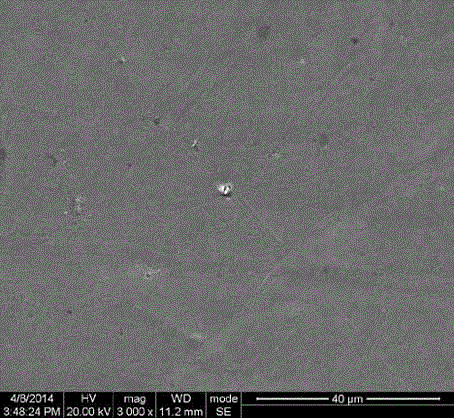

Image

Examples

Embodiment 1

[0071] Embodiment 1 is to add deoxidation modifier Ti, deoxidizer Al and typical inclusion Al to pure iron powder 2 o 3 Melting experiments.

[0072] The specific operation steps are as follows:

[0073] S100: Al, Al 2 o 3 , ferro-titanium powder and pure iron powder are ground evenly, and then compacted to obtain the original steel sample. The pure iron powder in this step is atomized iron powder, the composition is calculated by weight percentage, and the Fe content is more than 99%. Wherein the mass percentage composition of titanium iron powder is 5%, and the mass percentage composition of Al is 3% in the present embodiment, and Al 2 o 3 The mass percentage content is 3%.

[0074] S200: placing the original steel sample in a crucible, and putting the crucible in a magnetic levitation furnace for melting to obtain molten steel. During the melting process, the temperature of the magnetic levitation furnace is above 1500° C., and the melting time is 4 minutes. Melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com