A heavy rail steel converter smelting method capable of reducing oxygen content during tapping

A technology of converter smelting and oxygen content, which is applied in the manufacture of converters, etc., can solve problems such as unfavorable temperature, stable control of steel material consumption, large dependence on experience operation, and influence on the stability of production process, so as to solve unstable factors and improve Effect of control level, improvement of service fatigue life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A heavy rail steel converter smelting method for reducing oxygen content of steel, the steps:

[0032] 1) In the initial stage of smelting, the oxygen gun is continuously blowing oxygen at 1.65m during this period, and the oxygen pressure is controlled at 0.8 MPa and oxygen flow at 3.0 nm. 3 / min · ton steel; lime is added in accordance with 30kg / ton steel; the first addition of lime is added when starting smelting, and its addition is not less than 60% of the total amount; the first lime is added after the end, Immediately, add a light burning dolomite according to 12kg / ton steel; when smelting to 180s, the remaining lime is added for the second time. After the remaining lime is added, the iron ore is added according to 10kg / ton steel;

[0033] 2) In the middle of the converter smelting, the end of the 750S is smelted. During this time, the oxygen gun is still maintained at 1.65m, and the oxygen pressure is controlled at 0.7 MPa, and the oxygen flow is 2.6 nm. 3 / m...

Embodiment 2~6

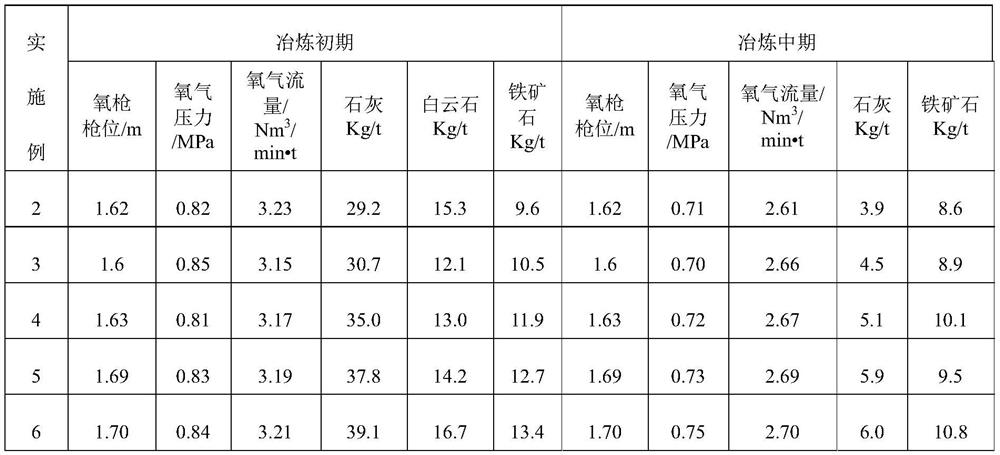

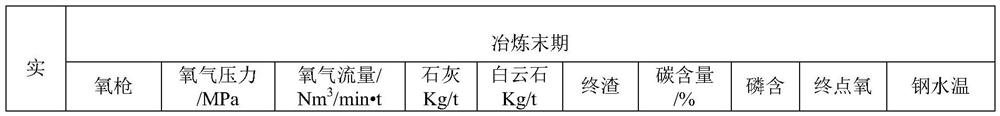

[0037] The implementation process except that the rest is the same as in Example 1, Table 1 shows the main process parameters of the embodiments and the finite oxygen, carbon content and steel temperature control levels.

[0038] Table 1 Main Process Parameters of Embodiments of the Invention

[0039]

[0040] Continued table 1

[0041]

[0042]

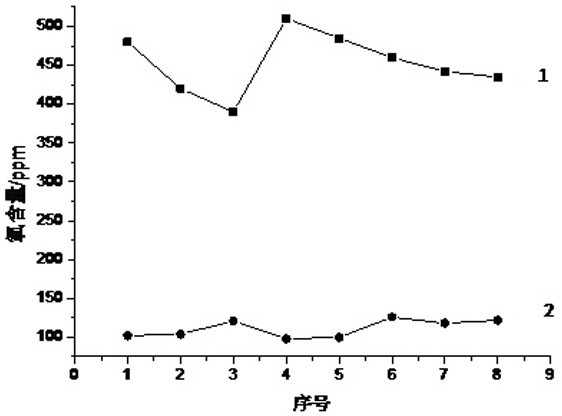

[0043] Examples 2 to 6 In the production method of the present invention, the temperature of the end point is controlled above 1630 ° C, and the phosphorus content is controlled at 0.015% or less, and the carbon content is 0.35 ~ 0.50%, the oxygen content is less than 120 ppm, and the amount of carbonaceous agent is used in 42.3. % ~ 52.9%, reducing the amount of deoxidation alloy is 11.7% to 15.8%, thereby reducing the number of internal oxide inclusions in steel, improving the level of steel clean and cleanness control level and the use of fatigue life and safety of rails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com