Method for reducing segregation during pouring of continuous casting billets for gears

A continuous casting and gear technology, applied in the field of alloy steel, can solve the problems of severe segregation, achieve the effects of avoiding segregation aggregation, reducing electricity consumption, and increasing cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) When SAE8620H is smelted in the LF refining process, after the alloy element composition of the molten steel is adjusted to the target value in the mid-stage of refining, the electrode is energized to raise the temperature of the molten steel to the liquidus temperature +70°C for vacuum treatment;

[0029] 2) Continuous casting 150×150mm billet crystallizer uses 150m 3 / h water volume, turn off the electromagnetic stirrer of the crystallizer, the stirring parameters of the end electromagnetic stirrer are: 60A / 10Hz (alternate mode), the casting speed is 2.00m / min, the specific water volume of the secondary cooling is 0.60L / kg, and the water volume ratio of the foot roll section 40%;

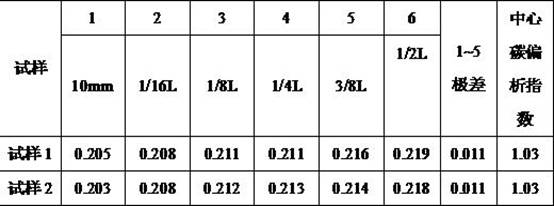

[0030] 3) Use a Φ6mm alloy drill bit to sample the cuttings at 6 points from the surface, 10mm, 1 / 16L, 1 / 8R, 1 / 4L, 3 / 8L, 1 / 2L, on the diagonal line of the billet transverse low-magnification sample, And use the infrared carbon sulfur analyzer carbon content, after analysis, from the sur...

Embodiment 2

[0036] 1) When 20CrMnTiH3 / RT smelting is carried out in the LF refining process, after the alloy element composition of the molten steel is adjusted to the target value in the mid-stage of refining, the electrode is energized to raise the temperature of the molten steel to the liquidus temperature +70°C for vacuum treatment;

[0037] 2) Continuous casting 150×150mm billet crystallizer uses 150m3 / h water volume, turn off the electromagnetic stirrer of the crystallizer, the stirring parameters of the end electromagnetic stirrer are: 60A / 10Hz (alternate mode), the casting speed is 2.00m / min, the specific water volume of the secondary cooling is 0.60L / kg, and the water volume ratio of the foot roll section 40%;

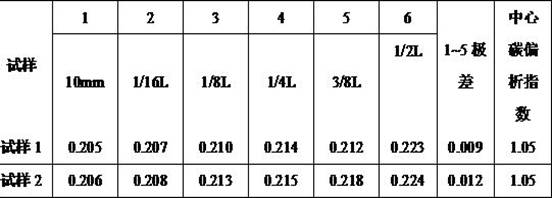

[0038] 3) Use a Φ6mm alloy drill bit to sample the cuttings at 6 points from the surface, 10mm, 1 / 16L, 1 / 8R, 1 / 4L, 3 / 8L, 1 / 2L, on the diagonal line of the billet transverse low-magnification sample, And use the infrared carbon sulfur analyzer carbon content, after analys...

Embodiment 3

[0044] 1) When 22CrMoH is smelted in the LF refining process, after the alloy element composition of the molten steel is adjusted to the target value in the mid-stage of refining, the electrode is energized to raise the temperature of the molten steel to the liquidus temperature +70°C for vacuum treatment;

[0045] 2) Continuous casting 150×150mm billet crystallizer uses 150m 3 / h water volume, turn off the electromagnetic stirrer of the crystallizer, the stirring parameters of the end electromagnetic stirrer are: 60A / 10Hz (alternate mode), the casting speed is 2.00m / min, the specific water volume of the secondary cooling is 0.60L / kg, and the water volume ratio of the foot roll section 40%;

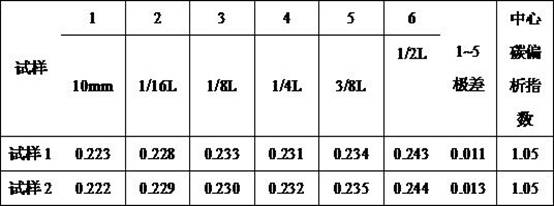

[0046] 3) Use a Φ6mm alloy drill bit to sample the cuttings at 6 points from the surface, 10mm, 1 / 16L, 1 / 8R, 1 / 4L, 3 / 8L, 1 / 2L, on the diagonal line of the billet transverse low-magnification sample, And use the infrared carbon sulfur analyzer carbon content, after analysis, from the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com