Patents

Literature

90results about How to "Solve the problem of exceeding the standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound agent for repairing heavy metal contaminated soil and application thereof

ActiveCN108641726AMitigation of cadmium leachingImprove stability efficiencyOther chemical processesContaminated soil reclamationContaminated soilsSodium lignosulfonate

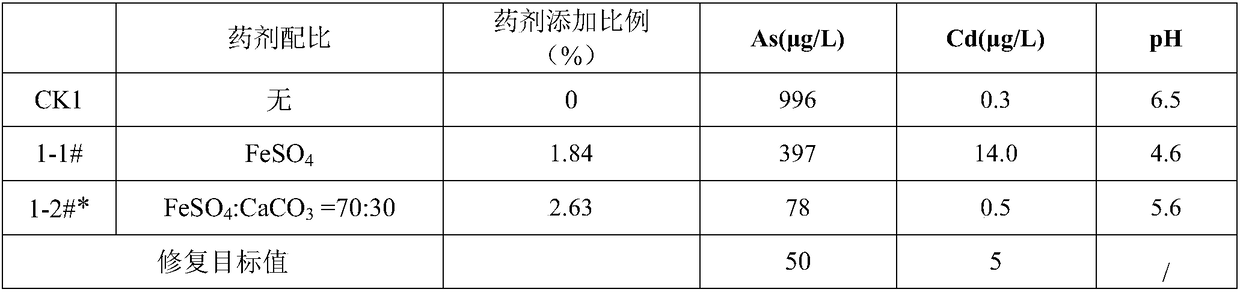

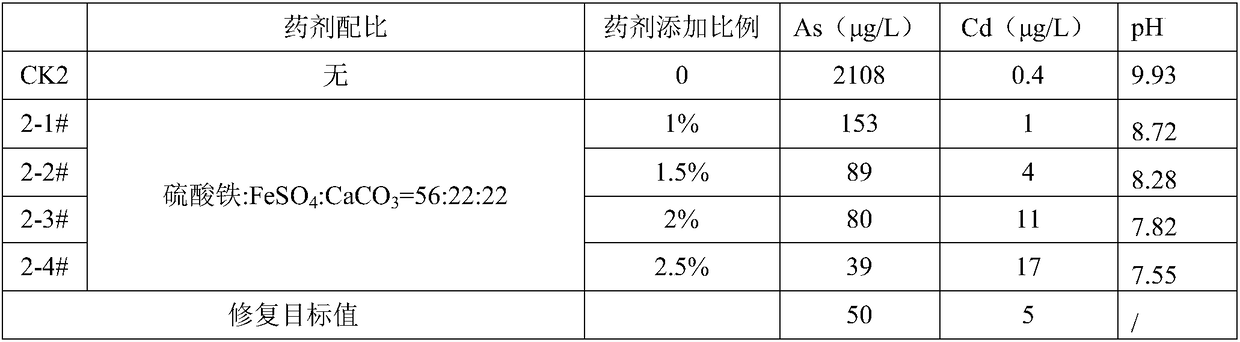

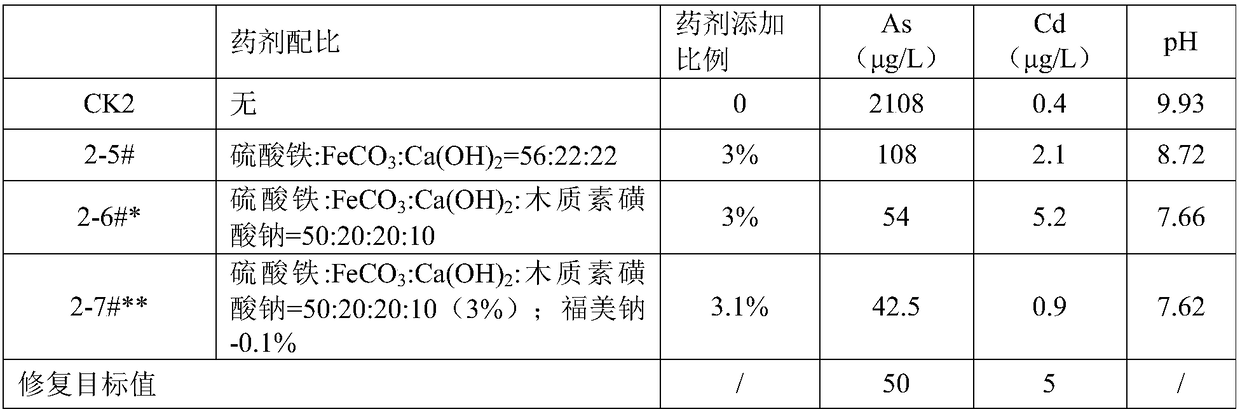

The present invention discloses a compound agent for repairing heavy metal contaminated soil and an application thereof. The compound agent comprises the following components in parts by mass: 30-75 parts of soluble ferric salts and / or ferrous salts, 10-60 parts of calcium-based compounds, 5-20 parts of sodium lignosulfonate and 2-10 parts of an organic sulfur chelating agent. The soluble ferric salts and / or ferrous salts, calcium-based compounds, sodium lignosulfonate, and organic sulfur chelating agent of sodium dimethyl dithiocarbamate, etc. can effectively repair the compound contaminatedsoil by heavy metals of arsenic, cadmium, etc.

Owner:YONKER ENVIRONMENTAL PROTECTION

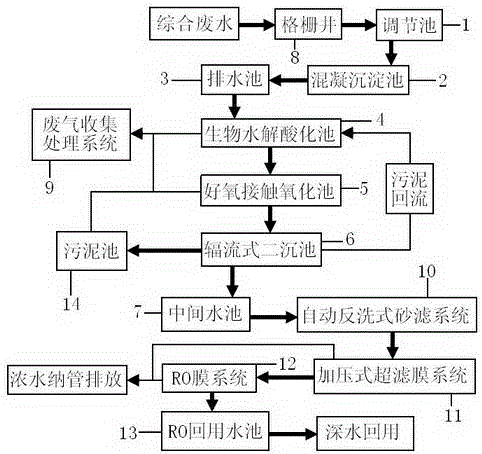

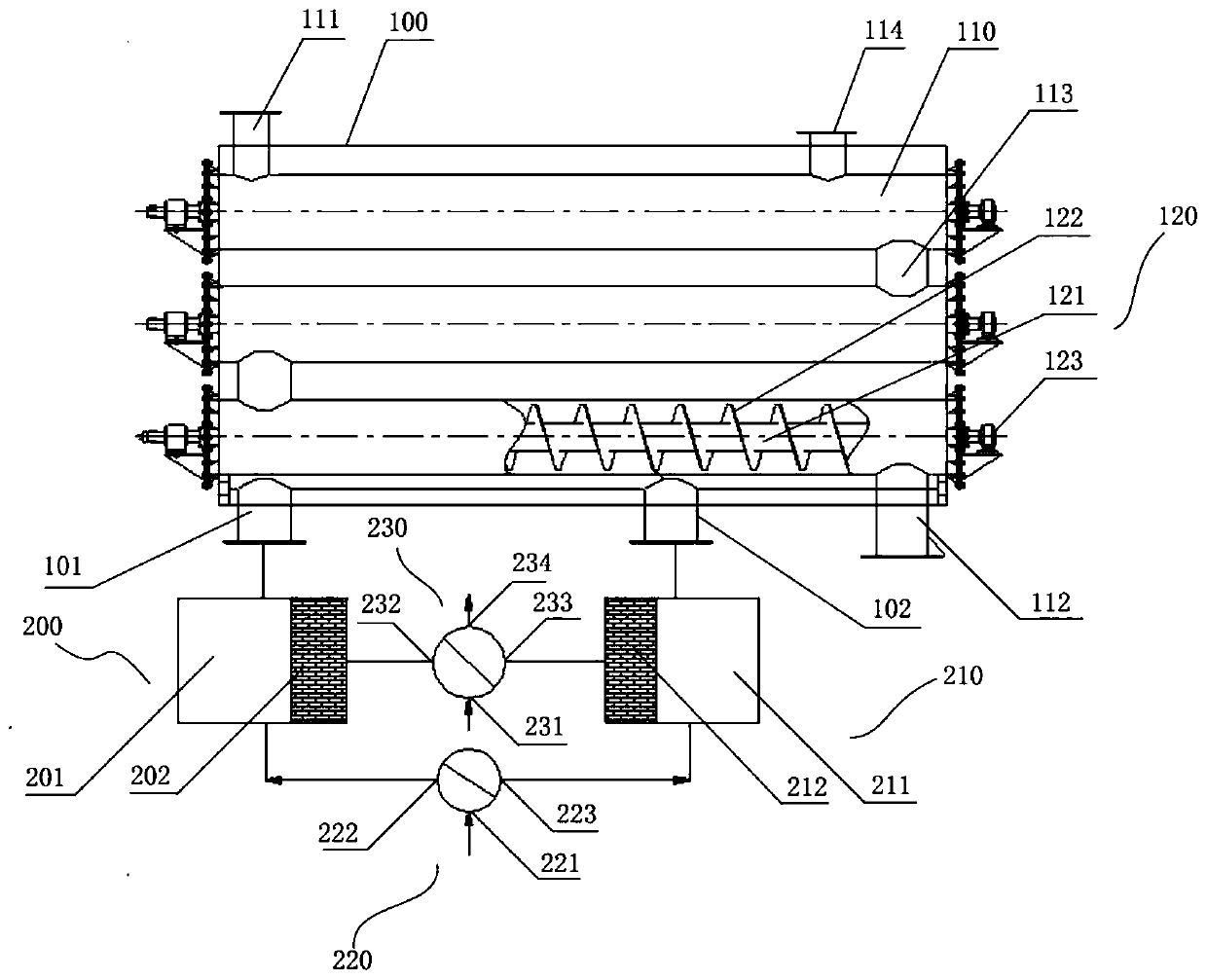

Printing and dyeing wastewater processing system

InactiveCN102616978ASolve the problem of exceeding the standardIncrease water reuseSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWater dischargeSludge

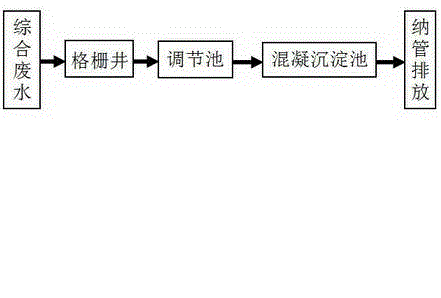

The invention discloses a printing and dyeing wastewater processing system. The printing and dyeing wastewater processing system comprises a comprehensive wastewater preprocessing system, a depth reuse processing system and a sludge processing system, wherein the sludge processing system comprises a sludge pool; the comprehensive wastewater preprocessing system comprises an adjustment pool, a coagulative precipitation pool, a water discharging pool, a biological hydrolysis-acidification pool, an aerobic contact oxidation pool, a radial flow type secondary sedimentation pool and an intermediate water pool which are sequentially connected; the depth reuse processing system comprises an automatic backwashing sand filtration system, a pressure type ultrafilter membrane system, an RO membrane system and an RO reuse water pool which are sequentially connected; the sludge outlet of the radial flow type secondary sedimentation pool is communicated with the sludge pool; and the water outlet of the intermediate water pool is communicated with the automatic backwashing sand filtration system. According to the invention, the quality of the depth reuse water reaches outlet water quality standards; and the deepwater reuse can saves the water resource, and COD discharge is reduced year by year, so the content of discharged ammonia nitrogen can reach standards.

Owner:SHANGHAI ZHANGHUA FILM PURIFICATION

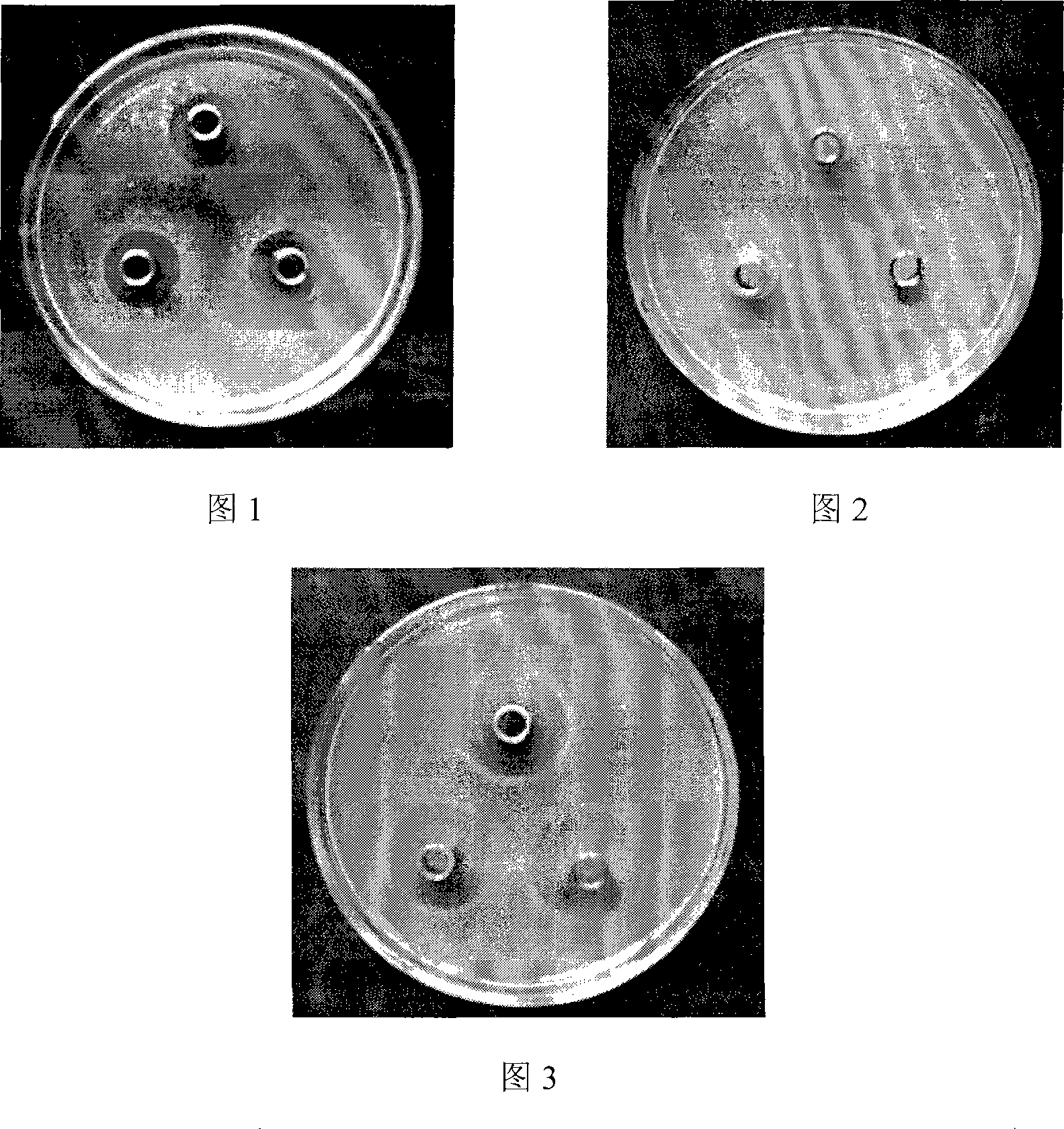

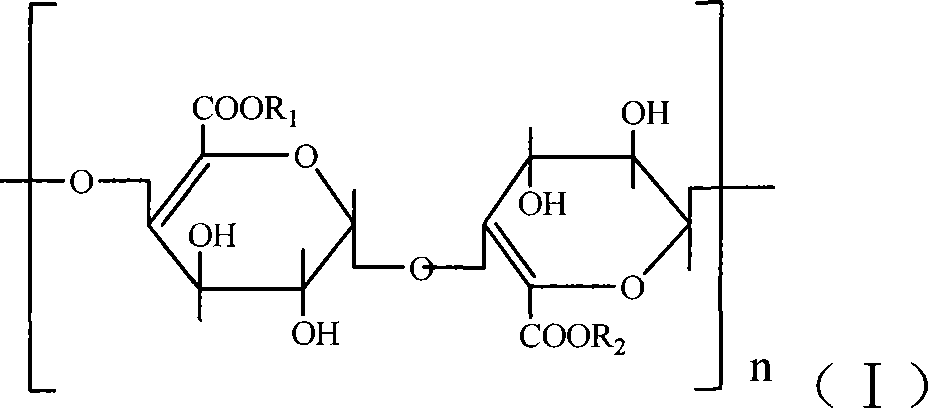

Unsaturated pectin oligosaccharide and compound biological preservatives

The invention relates to a preparation and application of unsaturated pectic oligosaccharide and a compound biological preservative combined with the unsaturated pectic oligosaccharides, which is characterized in that: pectin is extracted from pericarps or fruit residues, pectate lyase produced by the fermentation of aspergillus niger-wz003 is added into the pectin, and then the unsaturated pectic oligosaccharide is obtained by centrifugal separation, monosaccharide removal by yeast, decoloration by active carbon, polyether sulfone membrane and membrane separation of regenerated cellulose, and the unsaturated pectic oligosaccharide can be obtained by a further drying step. The preparation method of unsaturated pectic oligosaccharide and a compound biological preservative combined with the unsaturated pectic oligosaccharides has the advantages that: self-made pectate lyase is utilized, so the raw materials are easy to obtain and the cost is low; meanwhile, the pectic oligosaccharide and the compound biological preservative has the advantages of innocuity, high efficiency, broad spectrum and wide application range and can reduce the addition of chemical preservatives.

Owner:重庆檬泰生物科技有限公司

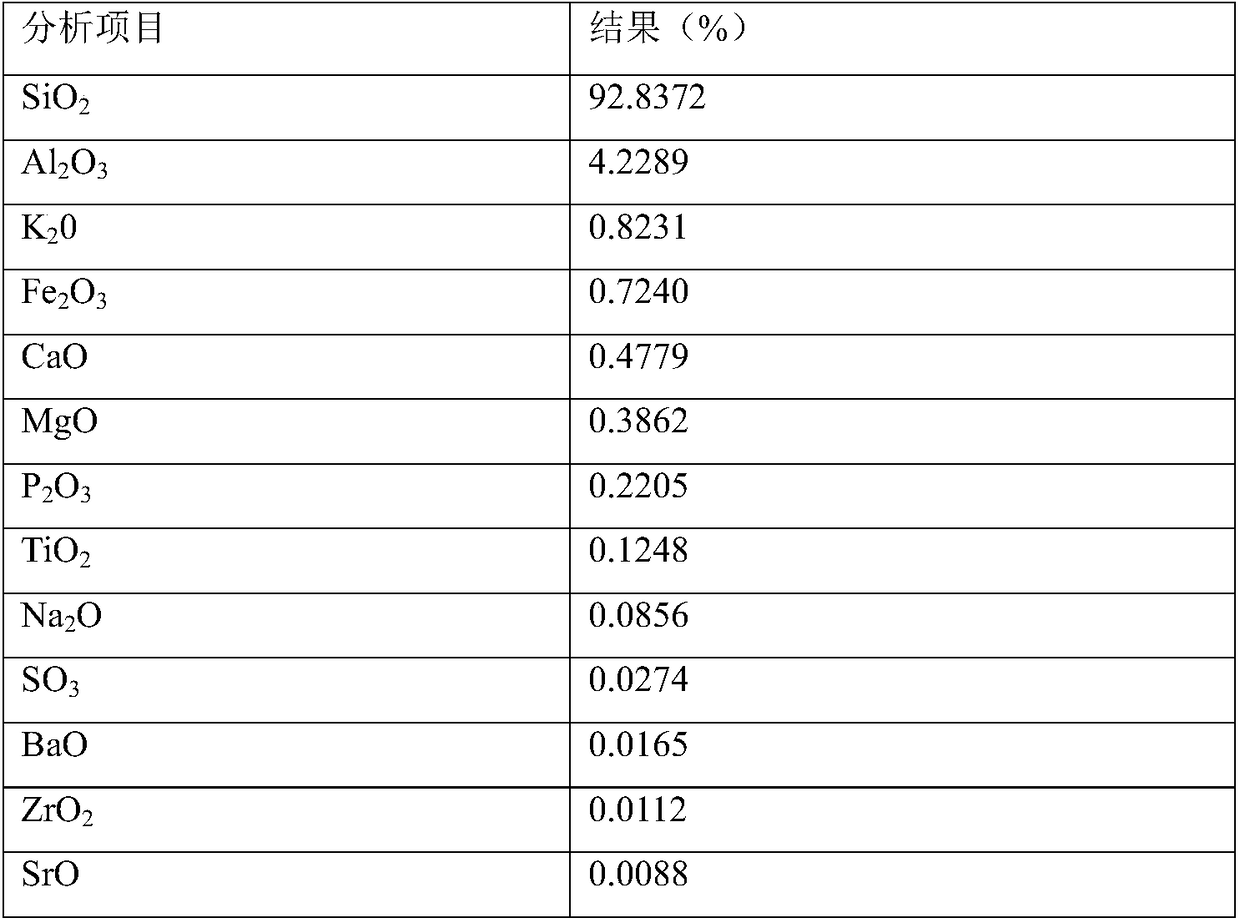

Nano porous ceramic for atomizing core and preparation method of nano porous ceramic

ActiveCN112592200AUnbreakableSolve the problem of cracking and oil leakageMedical atomisersTobaccoParaffin waxMolten state

The invention discloses nano porous ceramic for an atomizing core and a preparation method. The ceramic is prepared from 1 to 60 parts of nano silicon oxide, 10 to 80 parts of ceramic powder, 1 to 50parts of a pore-forming agent and 1 to 40 parts of a sintering aid. The preparation method comprises the steps of (1) weighing raw materials including nano silicon dioxide, ceramic powder, a pore forming agent and a sintering aid, and putting the raw materials into a ball milling device for mixing and ball milling; (2) baking and drying the ball-milled mixture to obtain mixed powder; (3) heating paraffin to a molten state, adding the mixed powder while stirring, and continuously stirring for 1-8 hours after the addition is finished so as to obtain paraffin slurry; (4) injecting the paraffin slurry into a pre-prepared mold, cooling and molding, and demolding to obtain a wax mold; (5) preheating the wax mold to remove wax to obtain a dewaxed sample; and (6) sintering the dewaxed sample, andcooling to obtain the nano-porous ceramic. The preparation method has the beneficial effects that the problem that the requirements of high porosity and high strength cannot be met simultaneously in the prior art is solved, and the problem that impurities and heavy metals are easy to separate out is solved.

Owner:HUIZHOU HAPPY VAPING TECH LTD

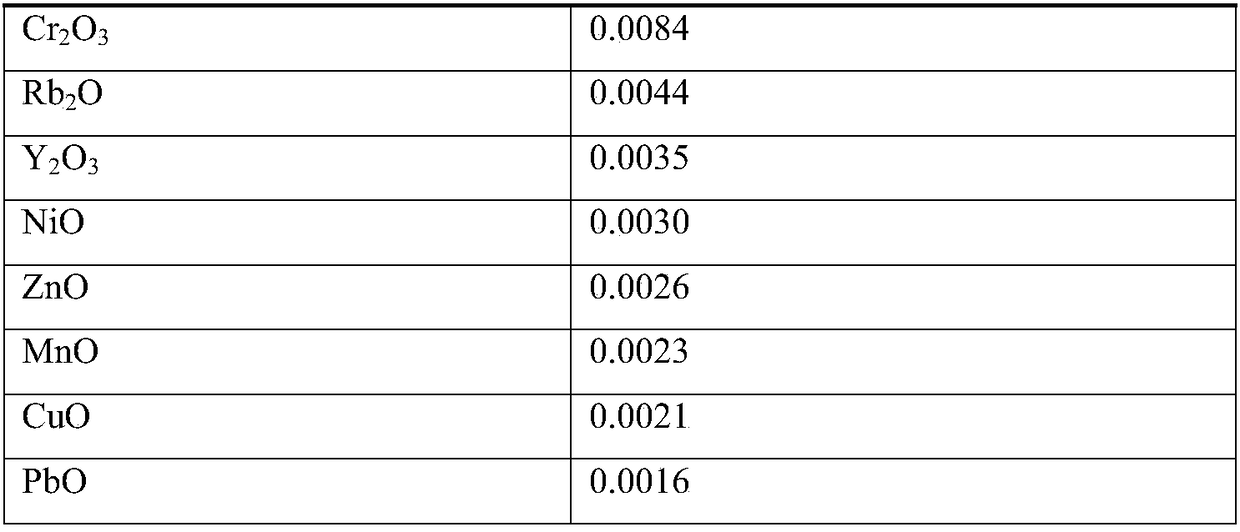

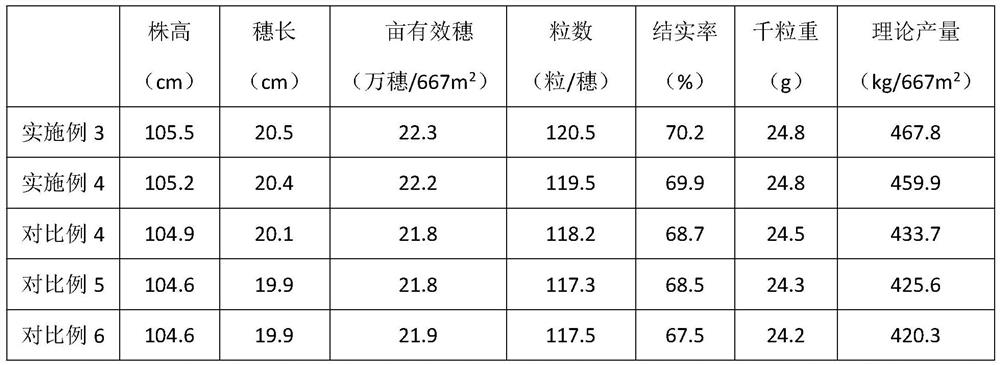

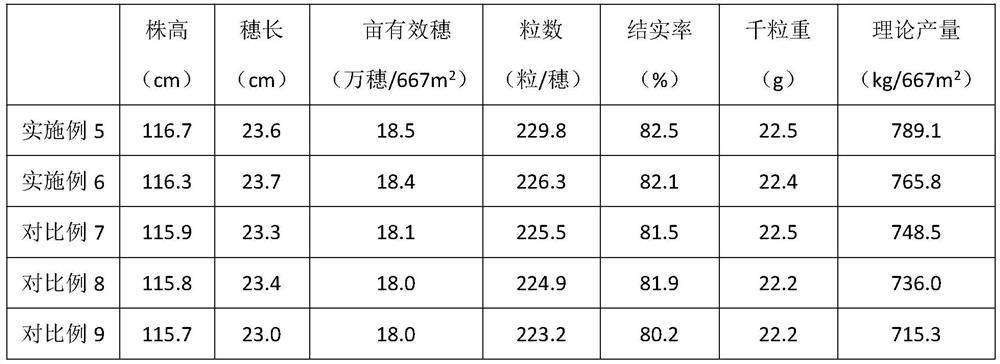

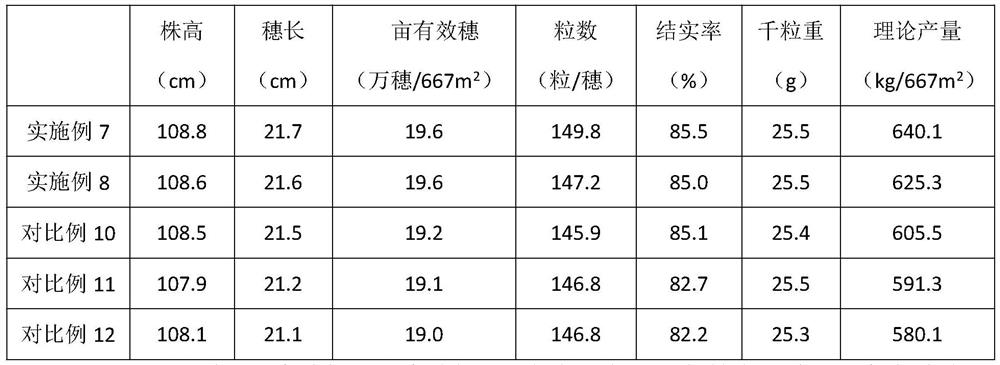

Method for planting rice to reduce absorption of heavy metal cadmium

ActiveCN103688813AReduce absorptionBarrier absorptionFertilising methodsRice cultivationWater qualityOrganic fertilizer

The invention relates to a method for planting rice to reduce absorption of heavy metal cadmium, comprising the following steps: 1. feeding water in a rice field, scattering and applying biological cadmium-reduction element-containing compound bio-organic fertilizer into the rice field based on the usage amount of 35kg per mu; ploughing through a rooter so as to enable the biological cadmium-reduction element-containing compound bio-organic fertilizer to be evenly distributed in the soil of the rice field; finally transplanting rice seedlings; 2. after rice seedlings are transplanted for eight days, and water is fed into the rice field for three days, scattering and applying biological cadmium-reduction element-containing compound bio-organic fertilizer into the rice field according to the usage amount of 20kg per mu; 3. after paddy rice ears for eight days, keeping the soil of the rice field moistened; adding water into biological cadmium-reduction element for diluting by 20 times and spraying leaf surfaces according to the usage amount of 1kg per mu. According to the method, the compound bio-organic fertilizer is evenly distributed in the soil, the absorption of rice roots on the heavy metal can be reduced, the method is especially suitable for planting rice seedlings at regions, with water and soil seriously polluted by heavy metals, in Xiang river and Dongting lake drainage basins, not only can the working hours be saved, but also the problem that the heavy metal cadmium in the rice exceeds the standard can be solved.

Owner:傅胤超

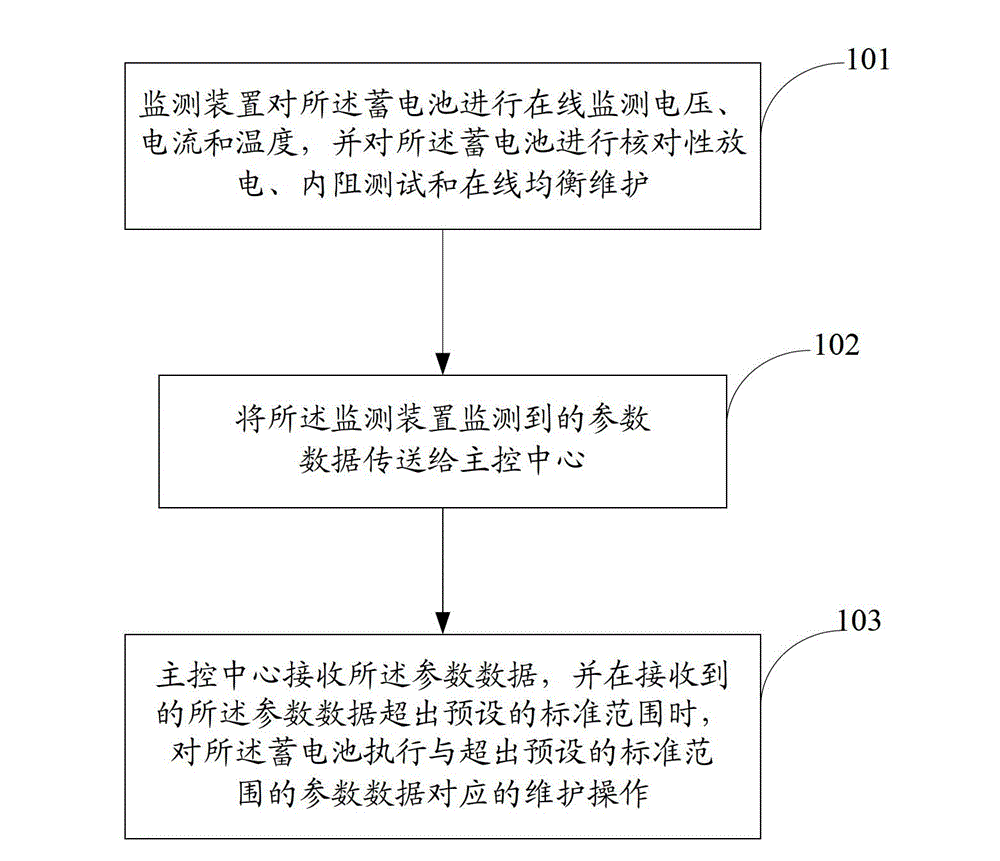

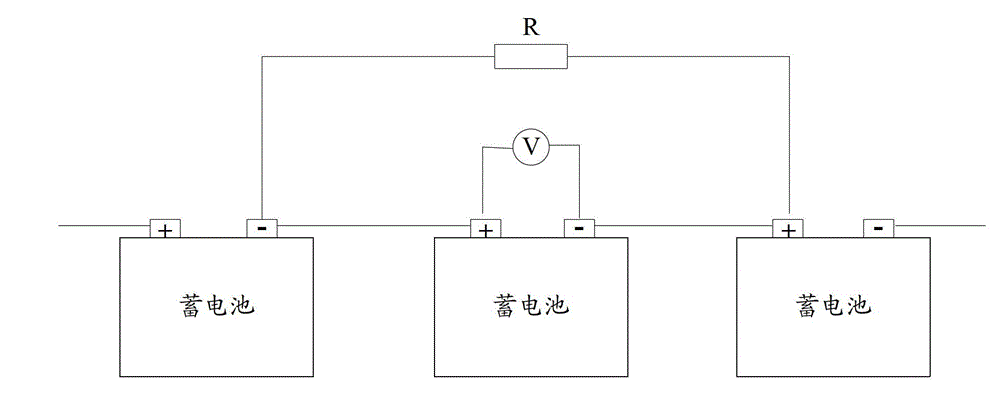

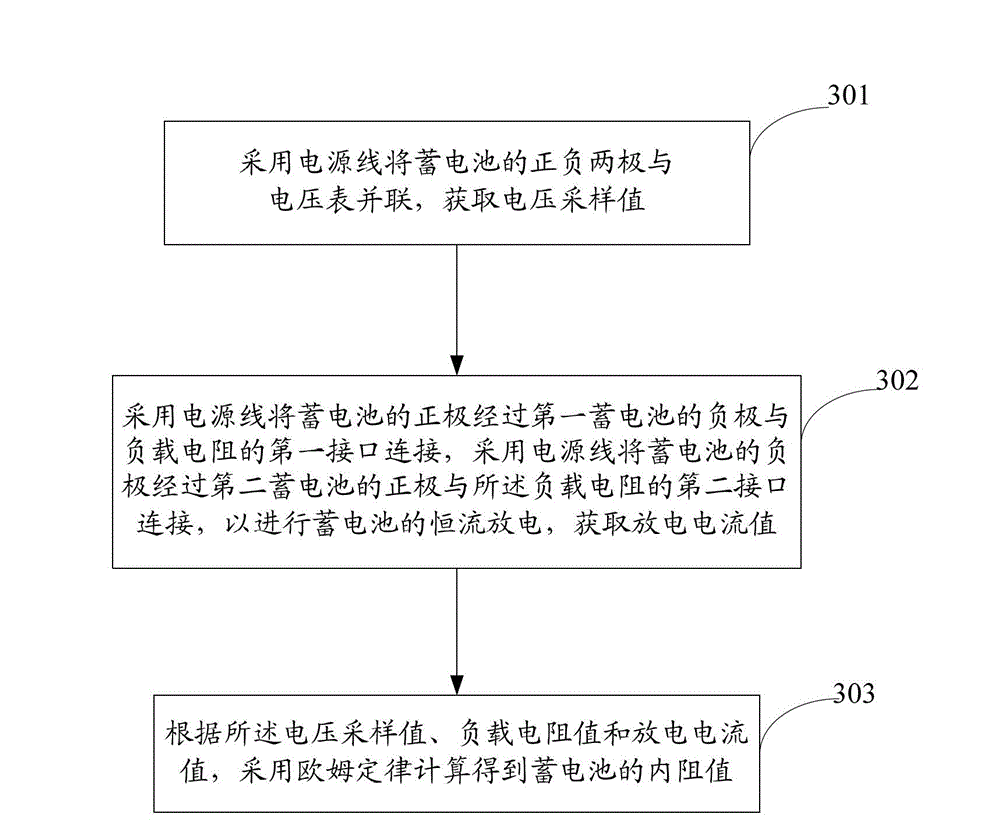

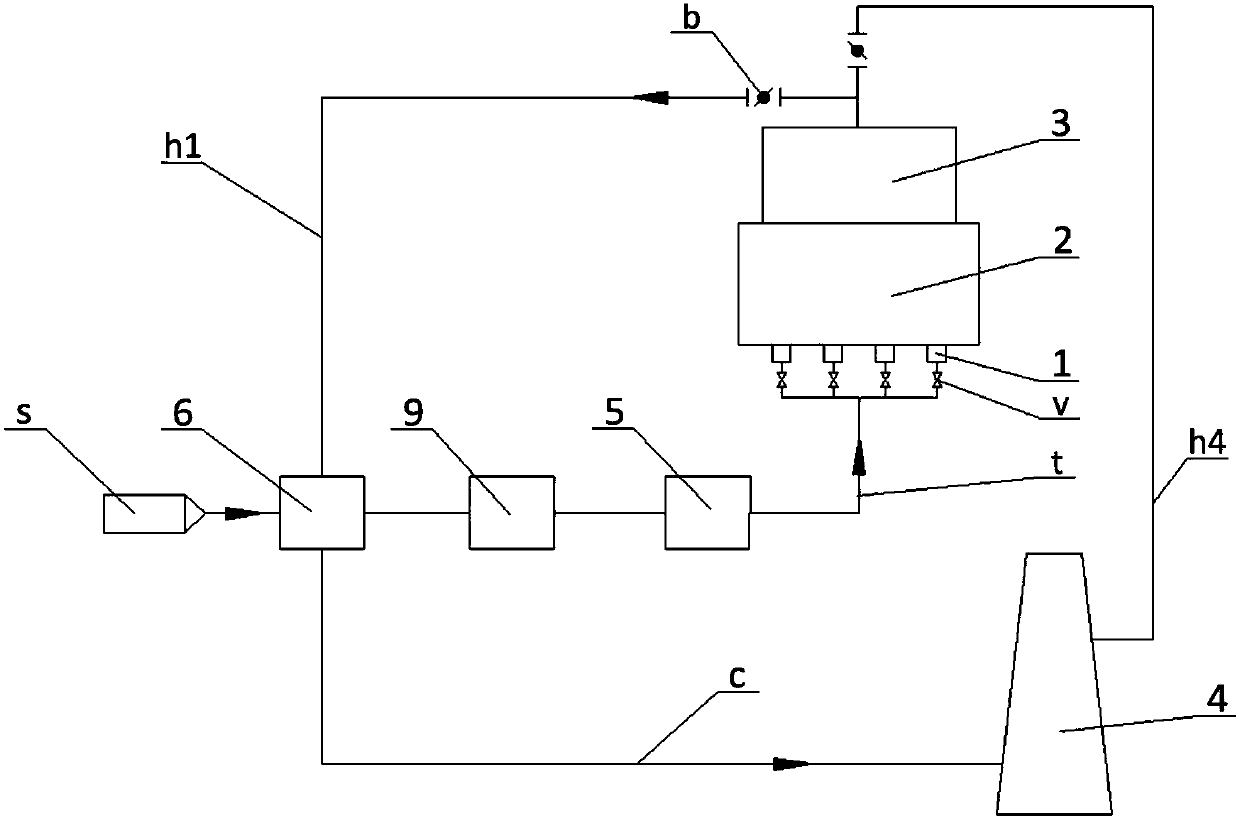

Method and system for on-line maintenance of storage battery

ActiveCN102916232ASolve the problem of exceeding the standardReal-time responseSecondary cells servicing/maintenanceWorking environmentEmbedded system

The invention discloses a method and a system for on-line maintenance of a storage battery. By means of the method, various parameters of the storage battery, such as inner resistance, voltage and current values can be monitored in on-line mode, the storage battery can be maintained in on-line balanced mode, and when parameters exceed a preset range, maintenance operations can be carried out in terms of the parameters exceeding the preset range, so that the problem of standard exceeding of the parameters can be solved, and qualified working environment and state of the storage battery can be recovered. By means of the method and the system for on-line maintenance of the storage battery, measures for solving the occurred or discovered storage battery problems can be provided, and the problem of the storage battery can be solved timely.

Owner:YUYAO POWER SUPPLY BUREAU +1

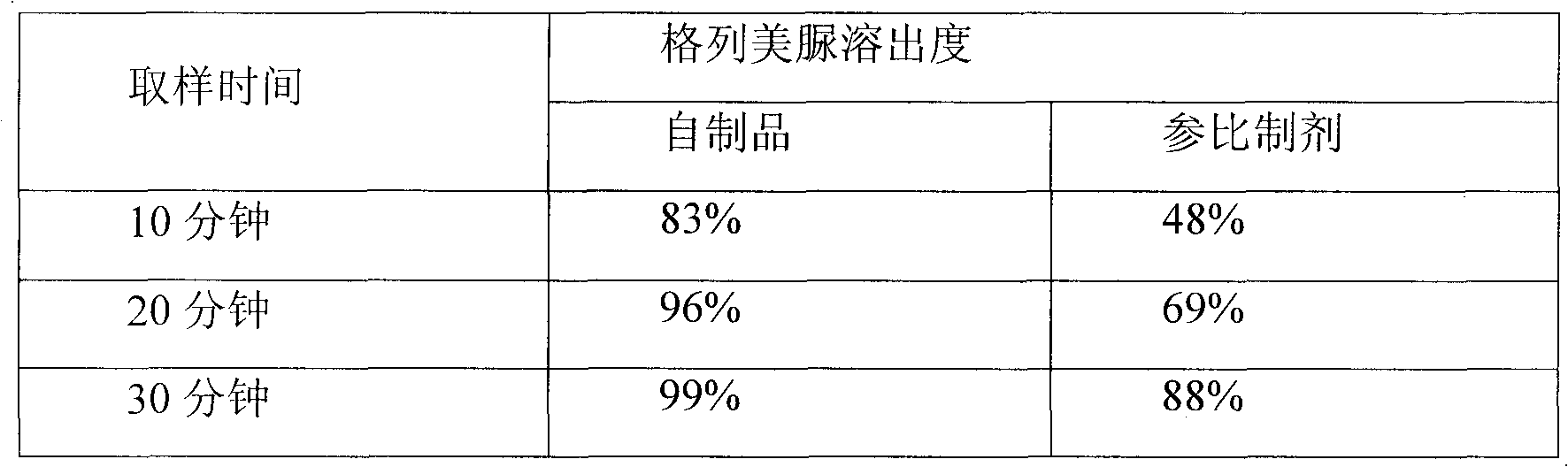

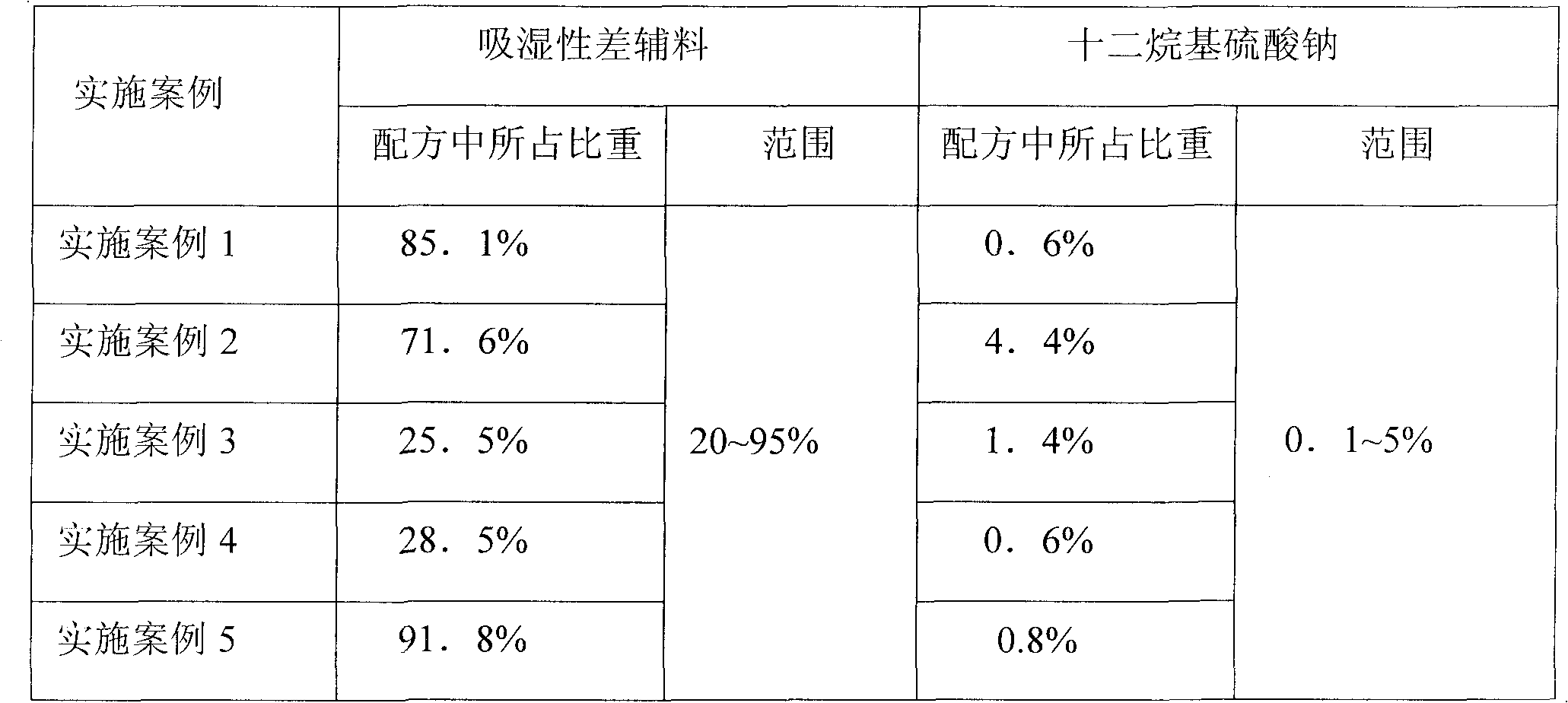

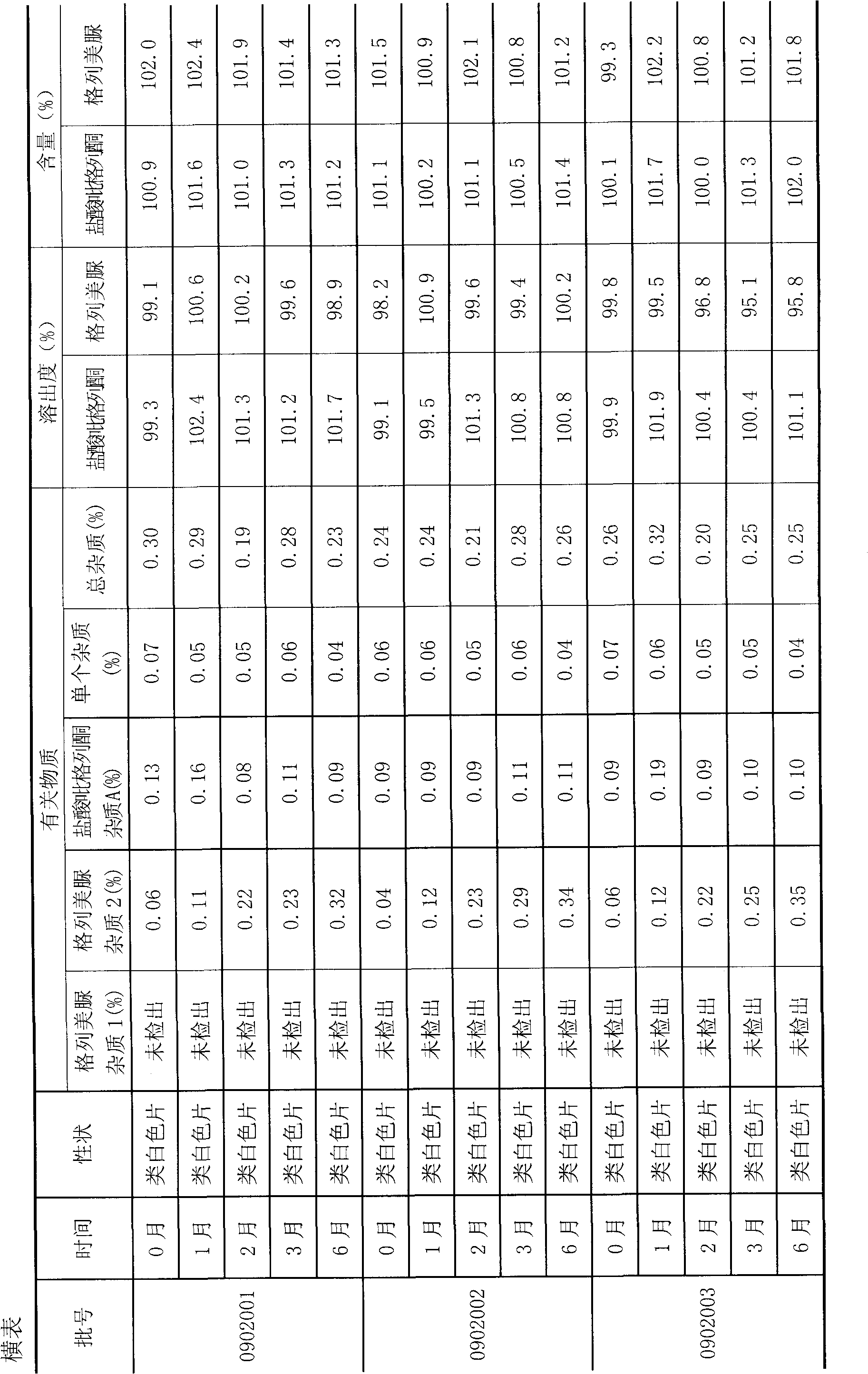

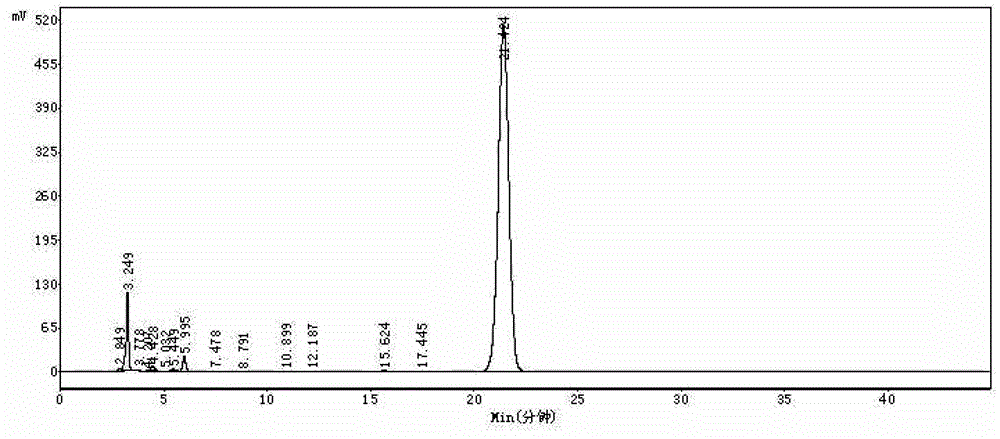

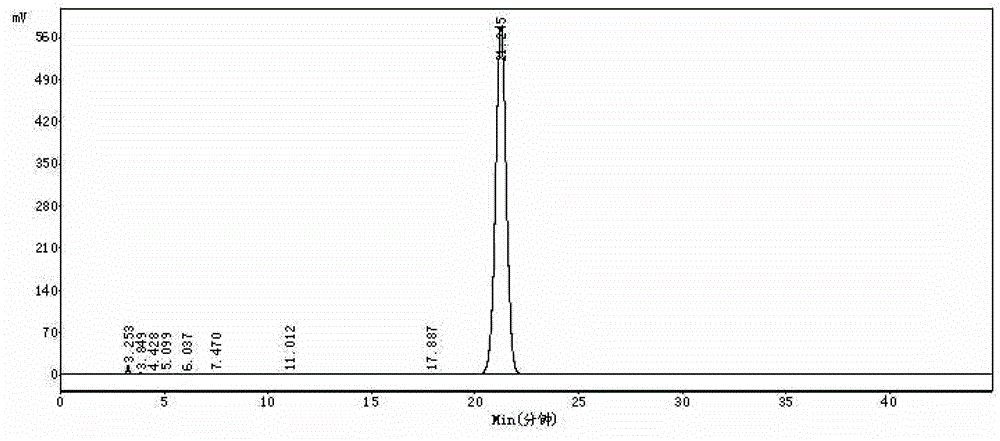

Compound tablet of pioglitazone hydrochloride, glimepiride and preparation method thereof

InactiveCN101804056ASolve the problem of exceeding the standardReduce moisture contentOrganic active ingredientsMetabolism disorderGlimepirideDissolution

The invention relates to a compound tablet of pioglitazone hydrochloride, glimepiride and a preparation method thereof. The compound tablet contains sodium dodecyl sulfate and auxiliary with poor hygroscopicity, wherein the weight ratio of glimepiride to pioglitazone hydrochloride is 1-4:33; the content of sodium dodecyl sulfate by weight percent is 0.1-5%, and the content of the auxiliary with poor hygroscopicity by weight percent is 20-95%. The preparation method comprises the steps: the raw material of glimepiride, pioglitazone hydrochloride and the auxiliary with poor hygroscopicit are mixed into smashed mixing powder, the mixing powder, the raw material of pioglitazone hydrochloride, filler, disintegrant and lubricator are evenly mixed, and the mixture is subject to tabletting. The compound tablet solves the problems of imperfect dissolution of glimepiride, inferior stability and large industrialization difficulty of glimepiride. The preparation method according to the invention has the advantages of simple process, easy operation and better suitability for industrial production.

Owner:SHANDONG XINHUA PHARMA CO LTD

Method for preparing strontium carbonate in high purity from celestite ore in mid and low grades

InactiveCN1872695AIncrease profitImprove product qualityCalcium/strontium/barium carbonatesDecompositionInorganic salts

This invention provides a method for manufacturing high purity strontium carbonate from medium- and low-grade celestite ore. The method comprises: (1) decomposing celestite ore into crude strontium carbonate; (2) calcining to obtain crude strontium oxide; (3) immersing in water to obtain strontium hydroxide solution; (4) recrystallizing to obtain high purity strontium hydroxide; (5) carbonizing to obtain high purity strontium carbonate. The method decreases the content of impurities such as barium, sodium, calcium and chlorine in the final product. The mother liquor of recrystallization can be used to manufacture industrial strontium chloride by double decomposition with bischofite, and magnesium hydroxide can be obtained as a byproduct. The method can increase the utilization rate of salt lake resources.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Purification method of cefotiam hydrochloride and aseptic powder injection of cefotiam hydrochloride

ActiveCN102746324AHigh yieldLow organic residueAntibacterial agentsOrganic active ingredientsPurification methodsNitrogen gas

The invention relates to the technical field of medicaments, and particularly relates to a purification method of cefotiam hydrochloride and an aseptic powder injection of cefotiam hydrochloride. The method comprises the steps of: dissolving cefotiam sodium hydrochloride crude product with water, adding activated carbon for injection to remove pyrogen, then adding acetone, recrystallizing, washing obtained crystal with ethyl ether or methyl tert-butyl ether, filtering, carrying out suction filtering water-saturated nitrogen gas, drying under reduced-pressure to obtain cefotiam aseptic powder which is low in organic residue, pyrogen-free and high in purity.

Owner:HAINAN JINXING PHARMA

Multiple-effect composite refining flux for removing impurities in aluminum and aluminum alloy melt and application

ActiveCN105803215AEvenly dispersedAccelerates the process of adsorbing slag inclusionsPowder mixtureSlag

The invention discloses a multiple-effect composite refining flux for removing impurities in aluminum and aluminum alloy melt. Raw materials of the multiple-effect composite refining flux comprise, by weight, 50%-70% of aluminum fluoride AlF3, 15%-25% of magnesium chloride MgCl2, 2%-10% of sodium borate Na2B4O7 and 1%-15% of potassium chloride KCl2. All the raw materials are dried industrial grade powder products, and the purities of all the raw materials reach 99.5% or above. After the matched raw materials are added into a ball mill for ball milling for 10-15 min, the raw materials are screened through a screen with the meshes being 100-325, and the powder mixture grain size distribution requirements are that 35%-50% of powder with the grain size being 90-125 [mu]m, 20%-25% of powder with the grain size being 60-90 [mu]m, 8%-10% of powder with the grain size being 40-60 [mu]m, and 35%-50% of powder with the grain size being smaller than or equal to 40 [mu]m. The prepared flux is packaged in a sealed mode for standby application after inspection. The multiple-effect composite refining flux provided by the invention has the good capacity for removing the metal impurities and oxide inclusion, the problem that metal impurities in the aluminum and aluminum alloy melt are over standard is solved, and the flux has the better impurity and slag inclusion removing capacity, and has the multiple effects and the multiple purposes.

Owner:广元中孚高精铝材有限公司

Formula of pregnant sow compound feed added with kelp fiber and production method

PendingCN107080081AImprove stereotyped behaviorImprove early embryo survivalAnimal feeding stuffAccessory food factorsAnimal scienceDisease

The invention discloses pregnant sow compound feed added with kelp fiber. The feed overcomes the defect that a fiber source in existing feed is simplex, the problem of environment pollution generated after kelp degumming is solved, and comprehensive development and utilization of marine product waste and unification of the development of the livestock breeding industry are achieved. The feed has the advantages that the kelp fiber has strong water-holding capacity and expansion capacity, sows have stronger satiety after eating the feed, stereotyped behaviors of the pregnant sows can be remarkably reduced, and the constipation problem, caused by long-time intestinal retention of chime, of the sows is solved; the problem of environmental pollution of a glue extraction factory is solved, a new fiber raw material is provided for the feed industry, and the novel fiber raw material is compounded with enteromorpha powder to achieve the synergistic effect between seaweeds; a micro-ecological preparation, composite vitamins, motherwort, radix astragali and the like are added into the feed, so that the health care function of the product is improved, the immunity of pregnant sow bodies is improved, and the risk of disease infection is reduced.

Owner:青岛旺海源生物科技有限公司

Device and method for desulfuration and decyanation treatment of waste liquid generated in vacuum potassium carbonate desulfurization process

InactiveCN105776675AReduce contentReduce the impactSludge treatment by de-watering/drying/thickeningWater treatment parameter controlLiquid wasteCyanide

The invention discloses a device for desulfuration and decyanation treatment of waste liquid generated in the vacuum potassium carbonate desulfurization process.The device comprises a desulfuration and decyanation agent tank, a coagulant tank, a reaction pond, a settling pond and a catalytic oxidation reaction tank, wherein the desulfuration and decyanation agent tank and the coagulant tank are both communicated with the reaction pond, an inlet of the reaction pond is communicated with a waste liquid pipeline, and an outlet of the reaction pond is communicated with the settling pond; the upper portion of the settling pond is communicated with the coagulant tank, a sludge outlet of the settling pond is communicated with a sludge treatment system, a liquid outlet of the settling pond is communicated with the top of the catalytic oxidation reaction tank, and the lower portion of the catalytic oxidation reaction tank is communicated with an ozonator.The invention further discloses a method for desulfuration and decyanation treatment of waste liquid generated in the vacuum potassium carbonate desulfurization process.The device and method have the advantage that by additionally arranging a first aeration plate and a second aeration plate, waste liquid can fully react, the problem that the cyanide group and thiocyanate group in waste liquid exceed the standard is solved, and engineering application value is quite high.

Owner:武汉钢铁有限公司

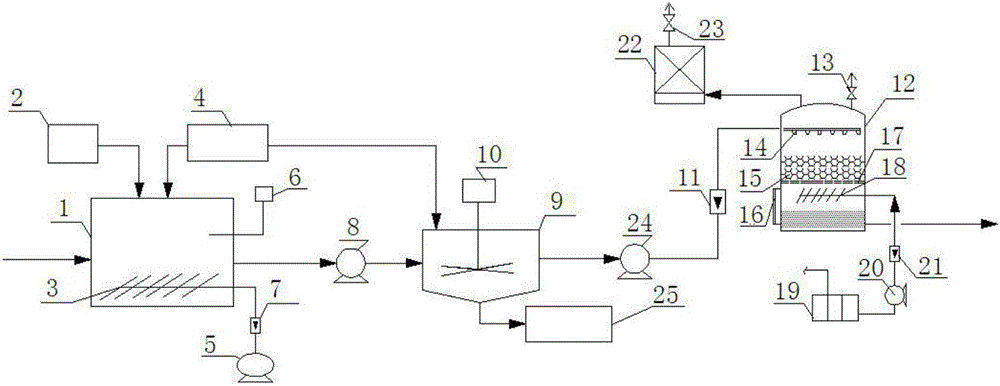

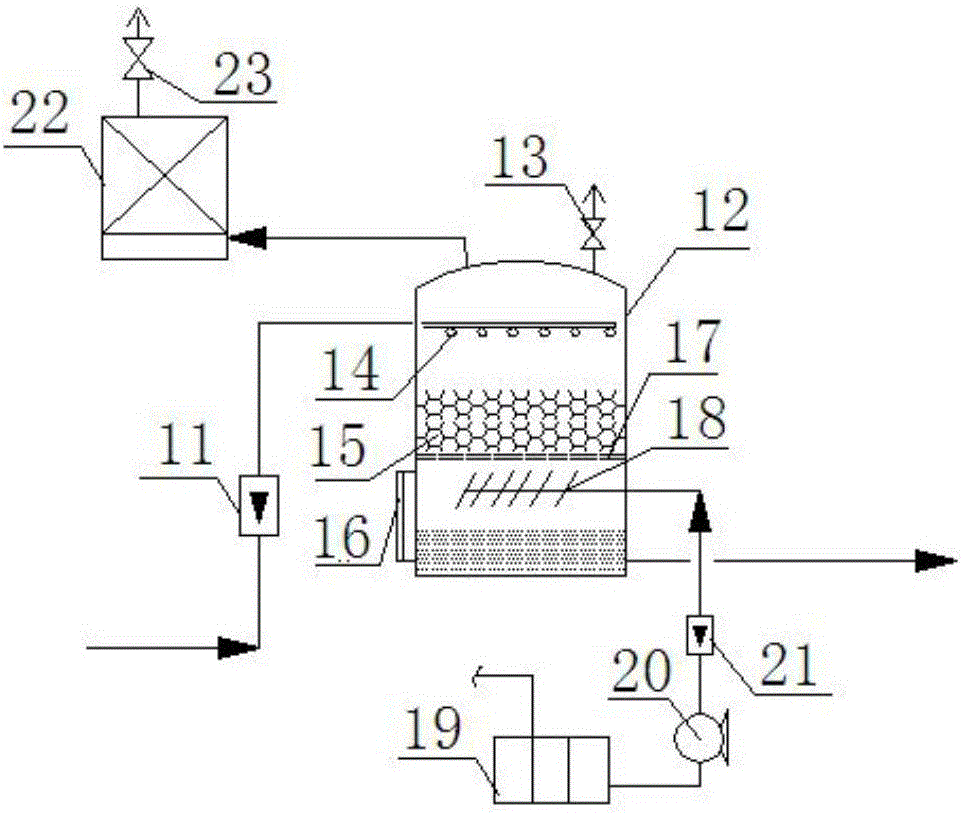

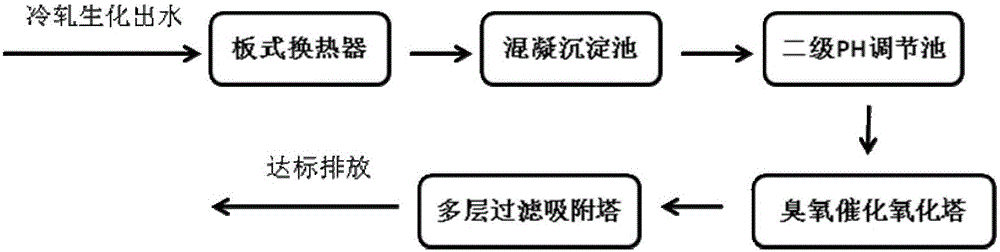

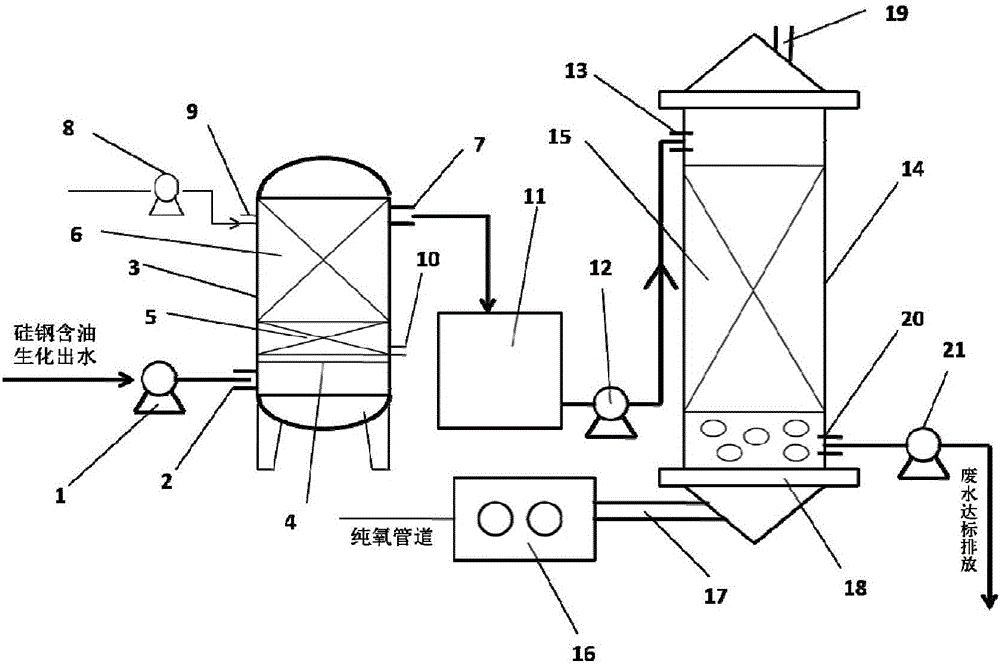

Cold rolling thin alkali biochemical effluent depth treatment method and system

ActiveCN106277426ASolve the problem of exceeding the standardEasy to handleMultistage water/sewage treatmentTreatment effectTower

The invention provides a cold rolling thin alkali biochemical effluent depth treatment method and system. The method comprises the following steps that cold rolling thin alkali biochemical effluent passes through a heat exchanger, then enters a coagulative precipitation tank, then enters a two-level pH regulating tank and then enters an ozone catalytic oxidizing tower, wherein the ozone adding amount is 250-600 mg / L; the cold rolling thin alkali biochemical effluent passing through the ozone catalytic oxidizing tower enters a multilayer filtering adsorption tower and then is discharged up to the standard. The system solves the problem of standard exceeding of cold rolling waste organic pollutants, and the cold rolling thin alkali biochemical effluent treated with the method and the system can reach the new national discharging standard; the cold rolling thin alkali biochemical effluent treatment technology is stable in treatment effect, low in production operation cost, easy and convenient to implement and high in automation degree.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of water-retaining agent for grass carp and water-retaining method

ActiveCN103989234AAvoid uncertaintySimple preparation processMeat/fish preservation by coatingFish filletUmami

The invention discloses a preparation method of a water-retaining agent for a grass carp and a water-retaining method. The preparation method comprises the following steps: removing the head, the tail, the scales and the skin of the fresh grass carp and taking out the viscera of the grass carp for later use; mincing the viscera of the grass carp by using a meat mincer at 4 DEG C, adding purified water, and homogenizing; adjusting the pH value by edible sodium hydroxide, and filtering for removing insoluble substances to obtain grass carp viscera protein liquid; adding the grass carp viscera protein liquid and composite phosphate into de-ionized water to prepare the water-retaining agent; and cutting the fresh grass carp into fish fillets, soaking the fish fillets in the water-retaining agent for 0.5-2 hours, taking out the soaked fish fillets, and quickly freezing for storage. The water-retaining agent has the advantages of low phosphorus content, good water-retaining effect, low unfreezing loss rate and capability of keeping the umami and the mouth feel of the grass carp; in addition, the preparation method is simple, easy to operate and suitable for industrialized production.

Owner:BOHAI UNIV

Method and device for removing nitrates from drinking water

InactiveCN102126789AAvoid excess electron donors and microbial overgrowthReduce processing difficultyWater contaminantsTreatment with anaerobic digestion processesChemistryActivated carbon

The invention relates to environmental protection, in particular to a method and a device for removing nitrates from drinking water. The method comprises the following steps that: organic micromolecules generated by the anaerobic digestion of strains in an anaerobic fermentation unit permeate through a separating diffusion layer and are diffused to enter a denitrification unit to serve as a reducing agent for strains subjected to habituated culture in the denitrification unit, namely an electron donor source, wherein for 30 to 50 mg / L of NO3<->-N nitrates at the temperature of between 20 and 25 DEG C, water is cut for 24 to 36 hours; and voltage difference between the denitrification unit and the anaerobic fermentation unit forms microbial current through activated carbon fibers, and the microbial current is transmitted to the denitrification unit from the anaerobic fermentation unit to promote bio-electrochemical denitrification, so that heterotrophic denitrification and bio-electrochemical denitrification are synchronously and synergetically to remove the nitrates from the drinking water. By the method and the device, an electron dornor is prevented from being excessive, and theproblem that the nitrates in the drinking water exceed the standard is solved economically and reliably. The method is suitable for removing the nitrates in the drinking water in large scale and is also suitable for the in-situ treatment of the nitrate pollution in a drinking water source.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

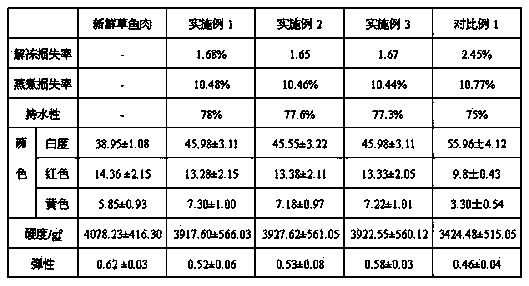

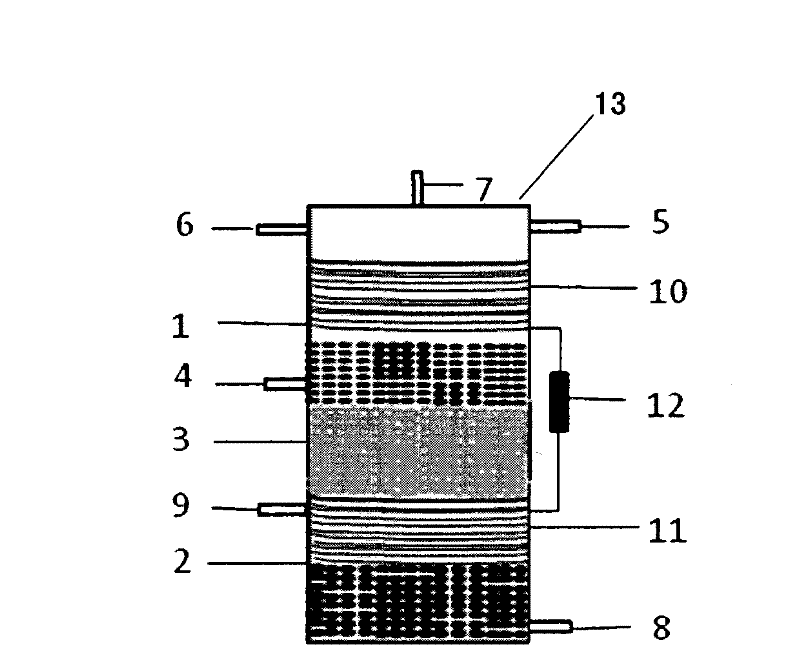

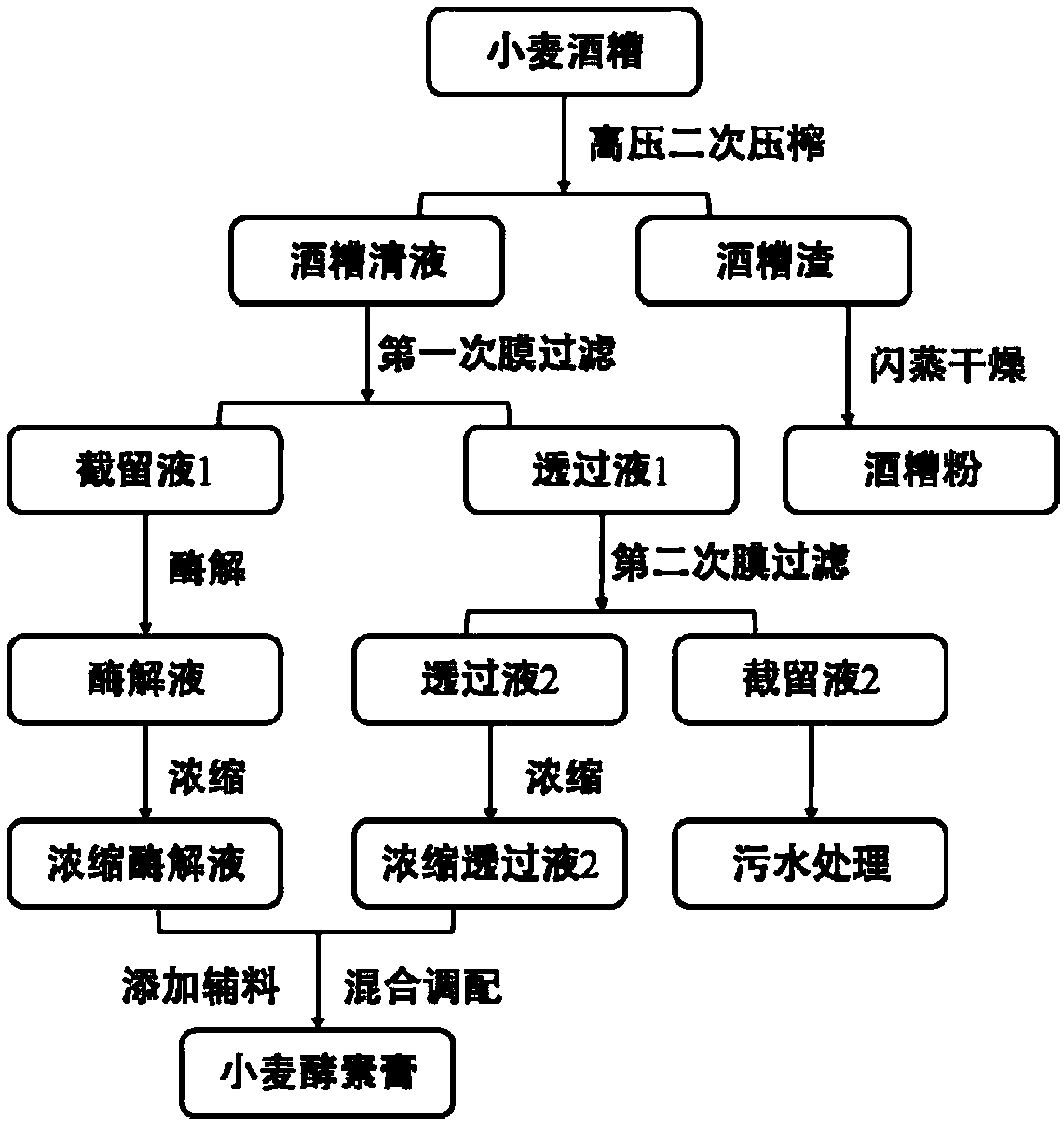

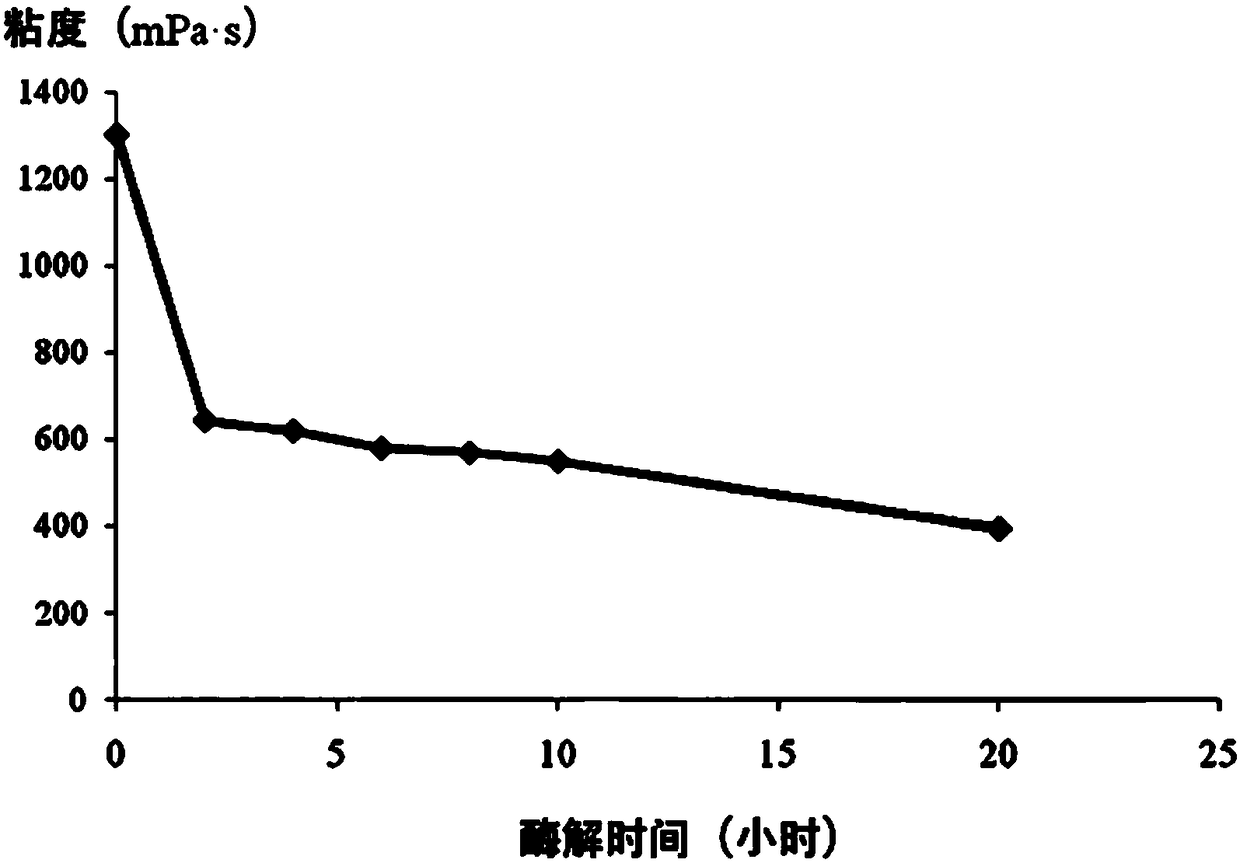

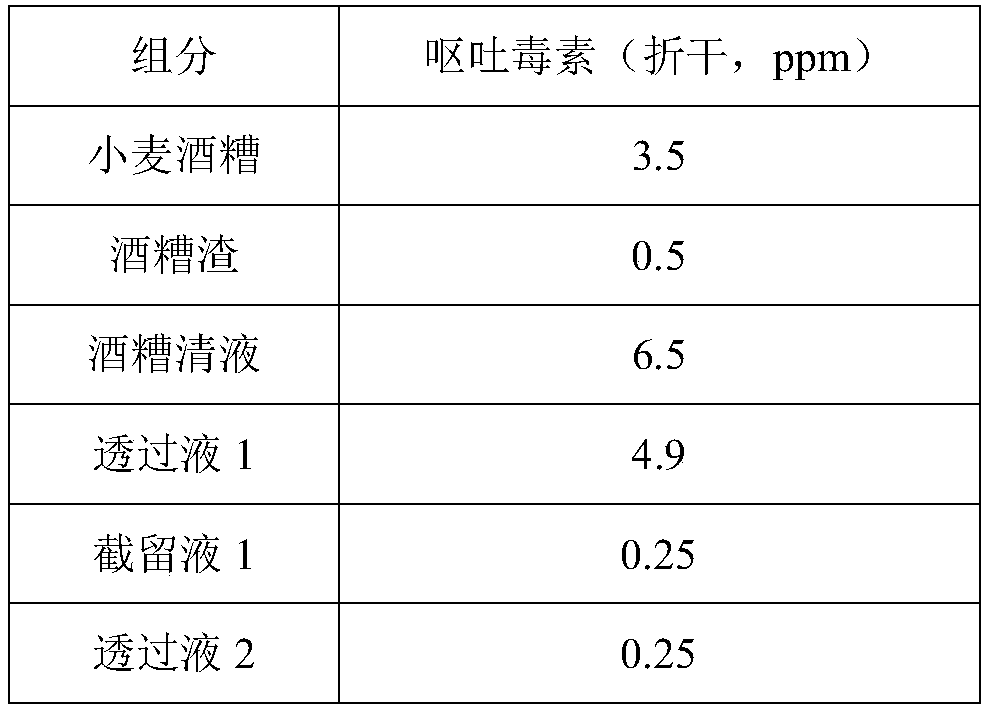

Method for producing distillers' grain powder and wheat enzyme paste by using wheat distillers' grains

InactiveCN109170266AEliminate anti-nutritional factorsSolve the problems that affect the effect of animal feedingFood processingAnimal feeding stuffEnzymatic hydrolysisFiltration

The invention discloses a method for producing distillers' grain powder and wheat enzyme paste by using wheat distillers' grains. The method comprises the following steps: acquiring wheat distillers'grain raw materials; performing solid-liquid separation; performing expansion drying; performing primary filtration by a nanofiltration membrane; performing enzymatic hydrolysis; performing concentration; performing secondary filtration by a nanofiltration membrane; and acquiring the wheat enzyme paste. The method has the following beneficial effects: by using a high pressure secondary pressing technique, solid-liquid separation of the wheat distillers' grains is realized, and vomitoxin is transferred into liquid by secondary pressing deep dehydration; by an enzyme preparation technique, anti-nutritional factors in the wheat distillers' grains are eliminated, the anti-nutritional factors are transformed into prebiotics, and a wheat enzyme type product is prepared by concentration and blending; and by secondary filtration by the nanofiltration membrane, the problem of excessive vomitoxin in the wheat distillers' grains is solved. The method solves the problem of treatment of the wheat distillers' grains in starch enterprises, derives two kinds of wheat distillers' grain products for feed enterprises, realizes optimization utilization of the wheat distillers' grains, and has extensive popularization application potential and huge commercial value.

Owner:梁耀培 +3

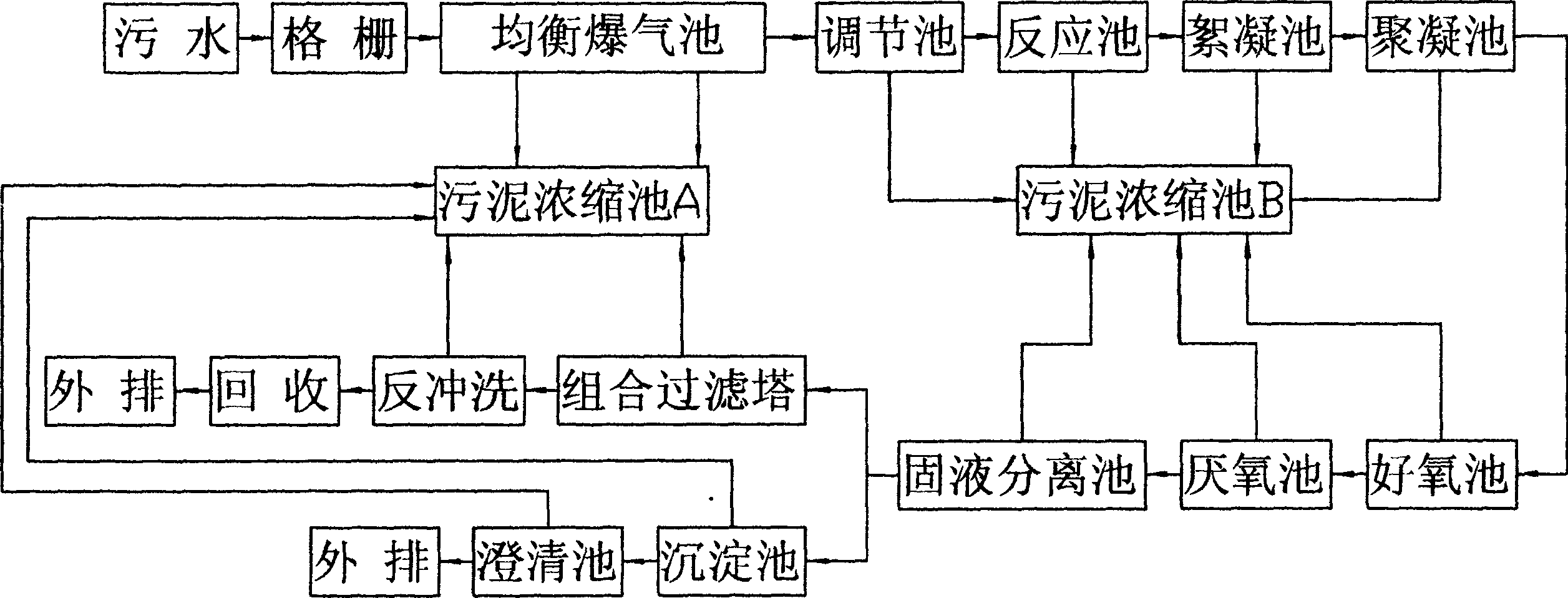

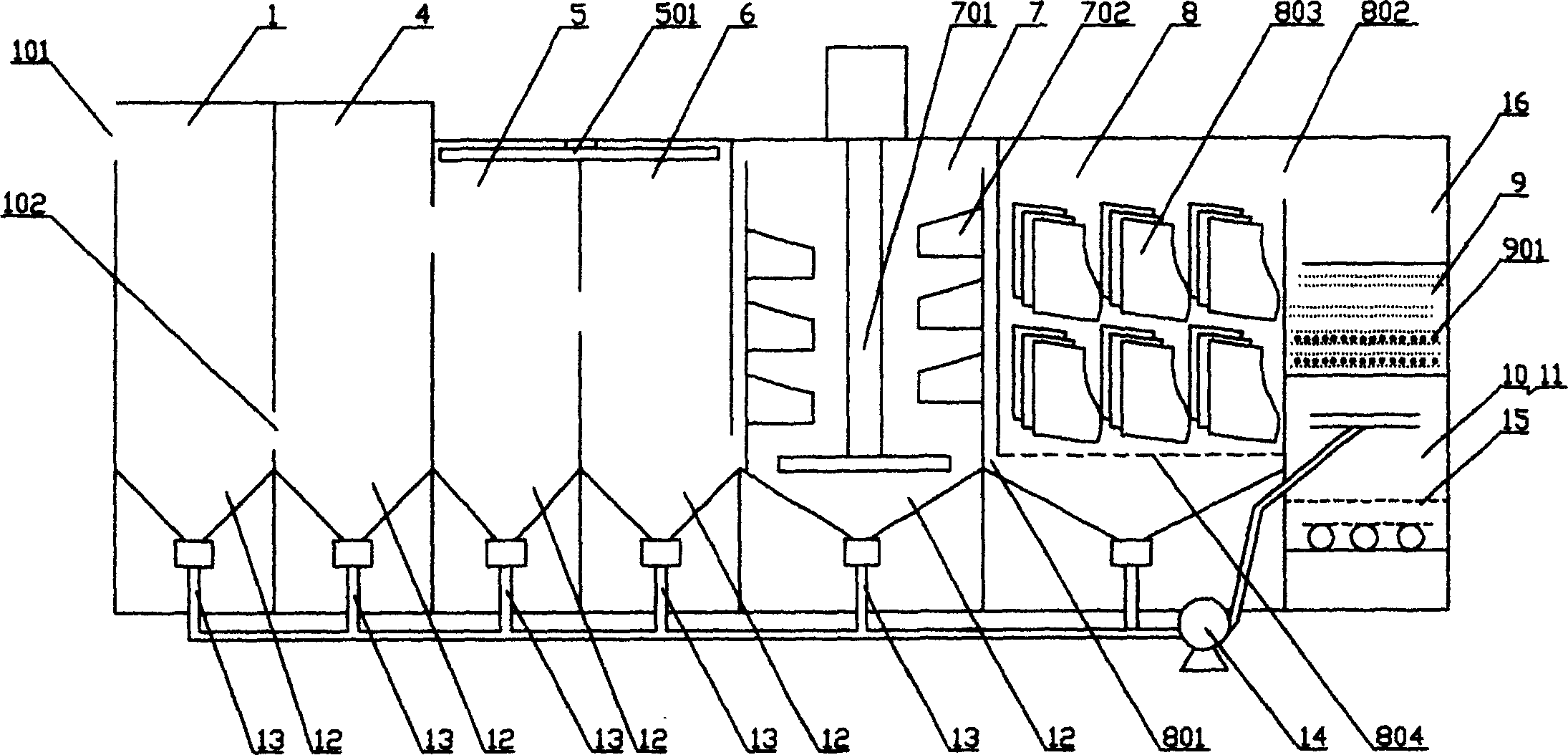

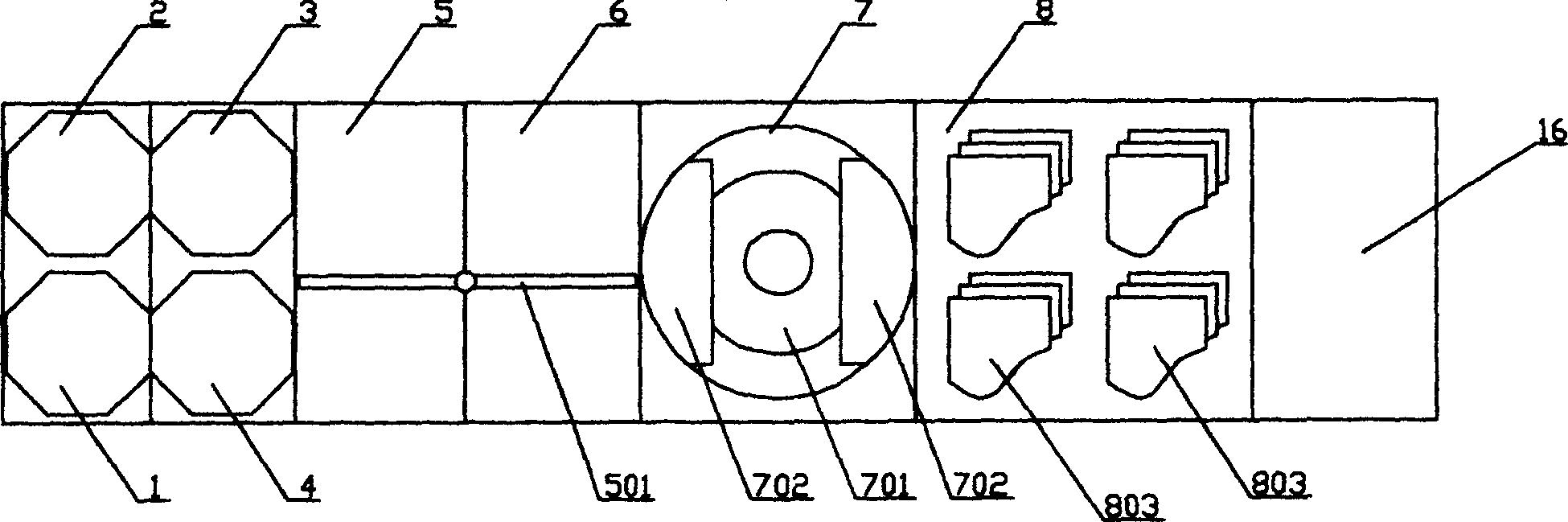

Rapid treatment process for middle-small sewage source, and integrated rapid sewage treatment station thereof

InactiveCN1699226ABalanced Pooling ComponentsImprove oxidation effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFlocculationSludge

The invention discloses a rapid treatment process for middle-small sewage source which comprising the waste water is treated through the procedures conducted in grid pool, balanced aeration tank, regulating reservoir, reaction tank, flocculation tank, coagulation tank, aerobic tank, anaerobic tank, liquid-solid separation tank, combined type filtration tower / sedimentation tank, and clarifying tank. The invention discloses an integrated effluent fast treatment station which integrates each tanks into one integral portion, each tanks are connected in sequence and are provided with sludge collection buckets on the bottoms, each sludge collection bucket is provided with a mud discharging pipe on the bottom, the mud discharging pipe is provided with a pump.

Owner:FOSHAN XILUN CHEM +1

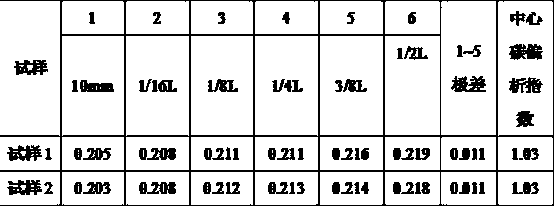

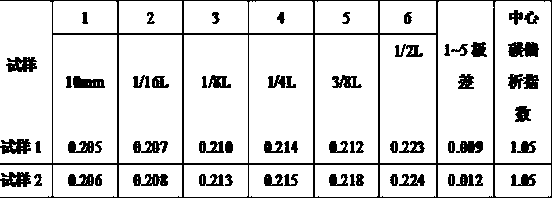

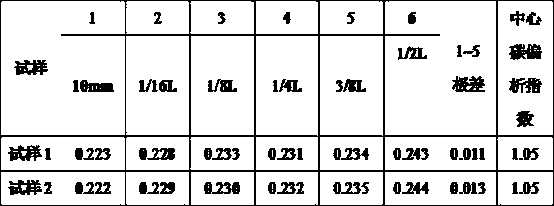

Method for reducing segregation during casting process of continuous-casting square billet for gear

The invention discloses a method for reducing segregation during a casting process of a continuous-casting square billet for a gear. The method comprises the following steps: before the end of LF refining, the temperature of molten steel is increased to the continuous-casting molten steel overheating degree of 20-30 DEG C; a relatively large amount of water is utilized for primary cooling and secondary cooling of the continuous-casting square billet of 150x150 mm; the proportion of the water volume of a foot roller section reaches 40%; the electromagnetic stirring function of a crystallizer isdisabled; the electromagnetic stirring at the tail end is performed at a relatively low electric current; and the casting is performed at a withdrawing speed of 2.00 m / min. According to the method, the electromagnetic stirring function of the crystallizer is disabled, and thus the circumstance that the molten steel purity is influenced when entrapped slag is generated due to excessive stirring inthe crystallizer during the molten steel casting process can be avoided; the cooling water volume can be increased, the cooling strength can be improved, the withdrawing speed can be reduced, and thecasting billet can be sufficiently cooled, the effects that the growth of columnar crystals is promoted and the central equiaxed crystal ratio is reduced can be achieved, the aggregation of solute elements towards the space among the crystals and the center can be avoided, and then the segregation of elements in the casting billet can be reduced; the carbon range from the surface to 3 / 8 of a diagonal of the continuous-casting square billet for the gear can be controlled to be within 0.015%; the central carbon segregation index can be within 1.05; and the steel performance stability can be improved.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Environment-friendly industrial cleaning agent

ActiveCN105331995AEliminate Nutritional ProblemsImprove cleaning efficiencySodium silicatePolypropylene

The invention discloses an environment-friendly industrial cleaning agent which comprises, by weight, 4-7 parts of fatty alcohol-polyoxyethylene ether A, 10-13 parts of fatty alcohol-polyoxyethylene ether B, 5-7 parts of polyoxyethylene-polypropylene oxide block polymer, 6-9 parts of coconut oil fatty acid diethanol amide, 5-7 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 3-5 parts of triethanolamine oleic soap, 12-15 parts of sodium gluconate, 11-14 parts of sodium silicate, 5-7 parts of sodium borate, 7-9 parts of sodium molybdate and 17-19 parts of water. The fatty alcohol-polyoxyethylene ether A is a polymer obtained by mixing and addition of fatty alcohol, fatty amine and ethylene oxide, wherein the mass of fatty alcohol is larger than that of fatty amine. The fatty alcohol-polyoxyethylene ether A is fatty alcohol and ethylene oxide. The cleaning agent has the beneficial effects of being low in use concentration, high in cleaning efficiency, long in solution service life and the like and is particularly suitable for cleaning before electroplating of steel, aluminum, aluminum alloy, copper, copper alloy and other base material parts or cleaning between machining processes.

Owner:江南工业集团有限公司

Deep processing method and device of cold rolling oil-containing wastewater

ActiveCN106315908AEasy to handleReduce production and operation costsWater contaminantsMultistage water/sewage treatmentOzone generatorSlag

The invention provides a deep processing method and device of cold rolling oil-containing wastewater. The method comprises the following steps: introducing cold rolling oil-containing biochemical effluent into a multi-medium filter; after the effluent goes through a ceramsite filler area and a water granulated slag filler area, introducing the effluent into a medium water pool, then pumping the wastewater in the medium water pool into an ozone catalyst tower through a secondary water feed pump, wherein the ozone catalyst tower is filled with a diatomite catalyst filler, ozone generated by an ozone generator is introduced into the bottom of the ozone catalyst tower and is diffused to the whole ozone catalyst tower through an ozone diffuser, and wastewater is mixed with ozone in the ozone catalyst tower and then catalytically oxidized by the diatomite catalyst; and finally discharging qualified cold rolling oil-containing wastewater. The provided method and system have the advantages that the processing effect is stable, the production and operation cost is low, the operation is convenient, and the automation degree is high. The provided steel green production system is environment-friendly.

Owner:BAOSHAN IRON & STEEL CO LTD

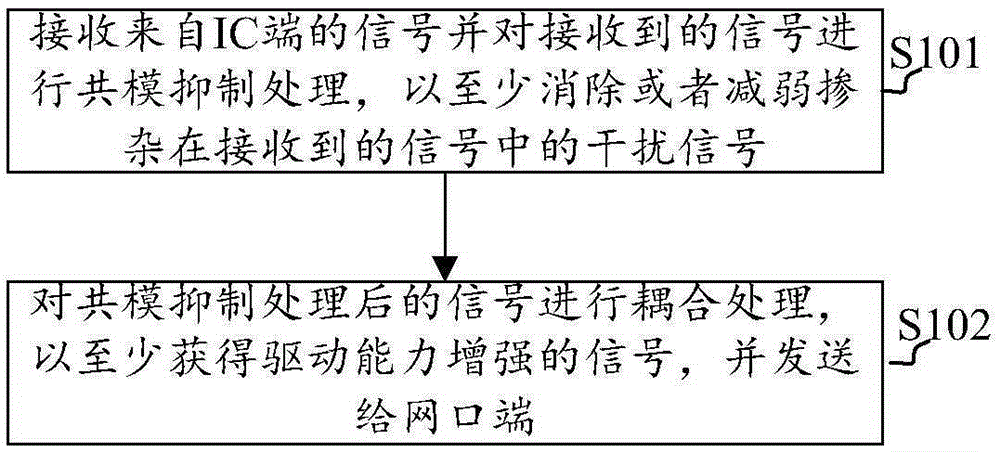

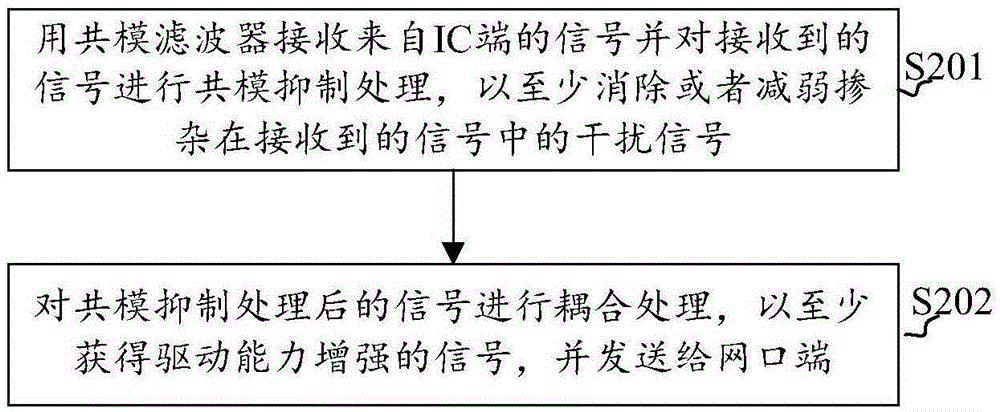

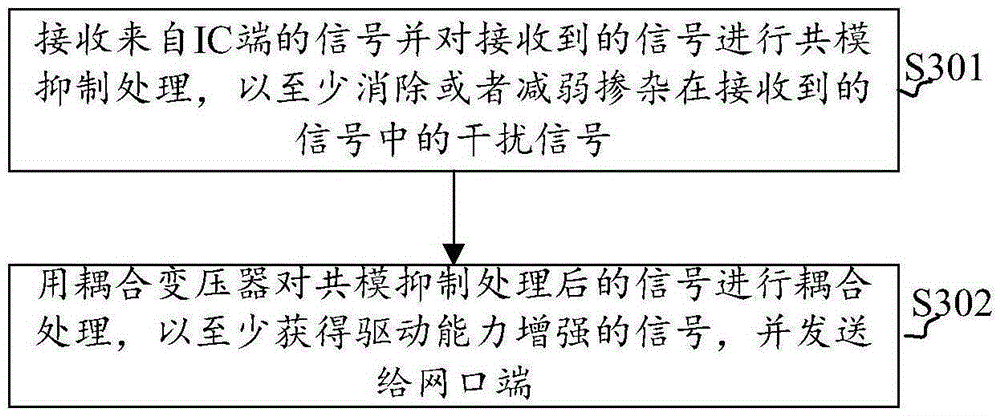

Electromagnetic interference suppression method and device

InactiveCN105897212AEliminate or suppress electromagnetic interferenceImprove driving abilityMultiple-port networksElectromagnetic interferenceEngineering

The invention provides an electromagnetic interference suppression method and device. The electromagnetic interference suppression method comprises the steps that signals from an IC terminal are received, and common mode suppression is carried out on the received signals to at least eliminate or weaken interference signals doped in the received signals; the signals after common mode suppression are coupled to at least acquire a signal with enhanced drive capability, and the signal is sent to a network port side. According to the invention, the signals from the IC terminal are received, and common mode suppression is carried out on the received signals to at least eliminate or weaken the interference signals in advance; the signals after common mode suppression are coupled to at least acquire the signal with enhanced drive capability, and the signal is sent to the network port side; the problem that amplified interference signal is difficultly or hardly eliminated in the prior art is solved; electromagnetic interference is eliminated or suppressed; and the problems of excessive electromagnetic interference and the like are effectively solved.

Owner:LE SHI ZHI XIN ELECTRONICS TECH TIANJIN

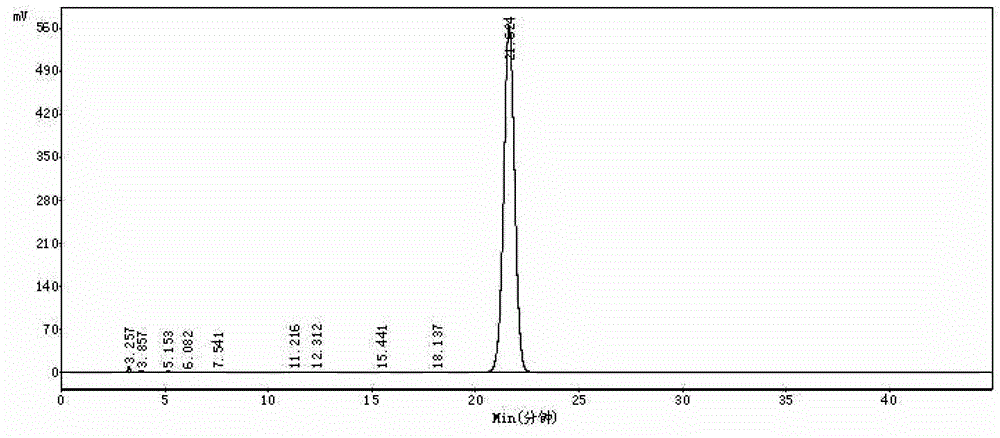

Method for preparing nalmefene compound

InactiveCN102584840ASafety and Product Yield ImprovementImprove product quality and safetyOrganic chemistrySolventEthyl acetate

The invention discloses a method for preparing a nalmefene compound, which comprises the steps as follows: a conventional method is adopted to prepare the nalmefene compound at first so as to obtain a brown solution reaction system, and then the brown solution reaction system is extracted and purified by adopting methyl tert-butyl ether to obtain dried off-white nalmefene solids; and then ethyl acetate is adopted to obtain the white solid nalmefene compound through refining. The method has the advantages as follows: (1) methyl tert-butyl ether is applied creatively during the preparation process of nalmefene, ether that is explosive solvent in the traditional technology is abandoned, and safety and product yield coefficient are improved greatly during the preparation process; and (2) ethyl acetate is adopted to refine nalmefene for the first time, so that the content of naltrexone that is impurities is less than 0.1 percent, the purity of nalmefene is more than 99.5 percent, the requirements of injection grade can be achieved, the problem that naltrexone that is main impurities in the traditional technology exceeds standard can be well solved, product quality and safety can be improved, excellent practicability is achieved, and excellent economic benefits and social effects can be realized.

Owner:NANJING YOKO PHARMA GRP CO LTD

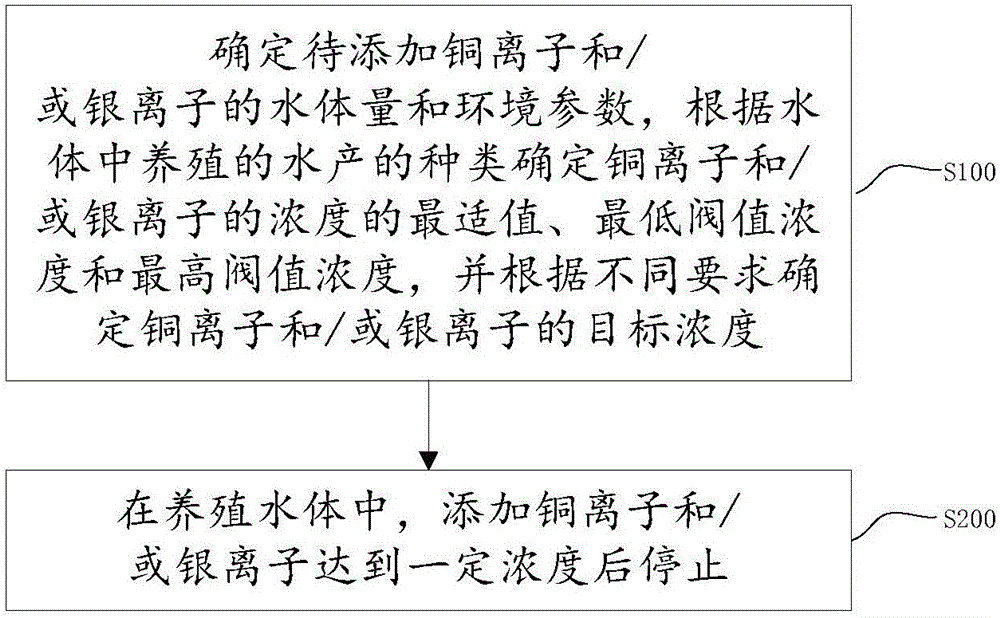

Method for killing bacteria, viruses and microorganisms in aquaculture water by using copper and silver ions

InactiveCN105923720ASolve the problem of exceeding the standardGuaranteed uninterrupted generationWater treatment parameter controlWater/sewage treatment using germicide/oligodynamic-processMicroorganismAquatic product

The invention provides a method for killing bacteria, viruses and microorganisms in aquaculture water by using copper and silver ions. The method is characterized by comprising the following steps: adding copper ions and / or silver ions into aquaculture water, and stopping addition after a certain concentration is reached. By the method, harmful bacterial florae, viruses, and microorganisms comprising parasites in water, especially in the aquaculture water, can be killed, so that the safety of a water environment is ensured and the growth of aquatic products is facilitated.

Owner:SANTONG BIOENG WEIFANG

Preheating method for fuel gas of reforming heating furnace and reforming device

PendingCN107940461ASolve the problem of dew point corrosion after the thermal efficiency is improvedSolve the problem of exceeding the standardDispersed particle separationThermal naphtha reformingNitric oxideCorrosion

The embodiment of the invention provides a preheating method for fuel gas of a reforming heating furnace. The method comprises the steps that before the fuel gas enters the reforming heating furnace,primary preheating and secondary preheating are carried out; in the primary preheating process, the fuel gas and flue gas guided out are subjected to heat exchange in a first preheater; then the fuelgas is introduced into a secondary fuel gas preheating unit for secondary preheating; and the fuel gas subjected to secondary preheating is introduced into a fuel gas fine treatment unit for fine treatment and then is introduced into a combustor for combustion. The method has the advantages that the high-temperature flue gas entering the convection section is used for preheating the fuel gas, theamount of steam produced by the fuel gas can be decreased, and the energy utilization efficiency can be improved; and meanwhile, the fuel gas is preheated to the temperature meeting the finish treatment, and therefore the problem that sulfuric acid dew point corrosion occurs after the heat efficiency of the heating furnace is improved can be solved, the problem that the content of sulfur dioxide exceeds the standard when the fuel gas coarse desulfurization system fluctuates can be solved, and the emission concentration of nitric oxide can be further decreased. The embodiment of the invention further provides a reforming device based on the preheating method for the fuel gas of the reforming heating furnace.

Owner:上海浩用工业炉有限公司

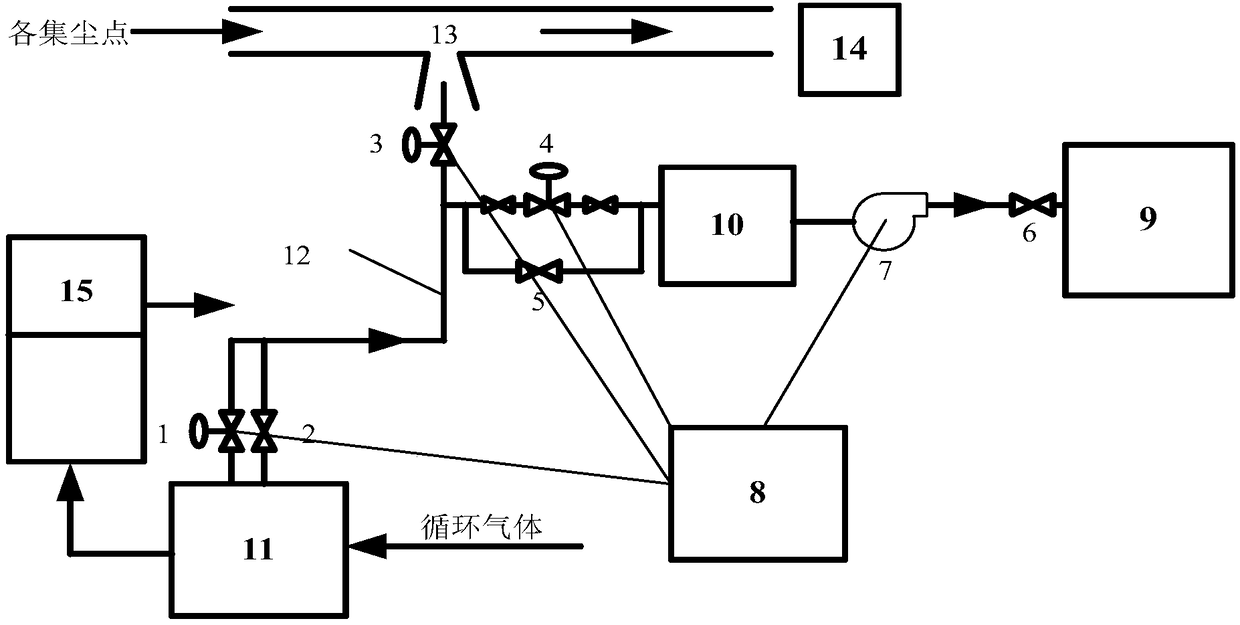

Device and method for reducing sulfur dioxide of chimney of dry quenching environment ground dust removal system

PendingCN108379996ACompact and reasonable layoutEmission reductionCoke quenchingGas treatmentQuenchingAutomatic control

The invention provides a device and method for reducing sulfur dioxide of a chimney of a dry quenching environment ground dust removal system. The device comprises a first automatic valve, a second automatic valve, a third automatic valve, a dust removal station, a variable-frequency fan, a smoke gas desulfurization device and an automatic control system, wherein the first automatic valve and thesecond automatic valve are arranged onto a pre-storing chamber discharging pipeline between a sub coal saver and a dust removal negative pressure pipeline; a tee joint is also arranged on the pre-storing chamber discharging pipeline between the first automatic valve and the second automatic valve; the tee joint is connected with the dust removal station through the third automatic valve via a pipeline; the dust removal station is connected with the smoke gas desulfurization device through a pipeline; the variable-frequency fan is positioned onto a pipeline between the dust removal station andthe smoke gas desulfurization device; the automatic control system is electrically connected with the first automatic valve, the second automatic valve, the third automatic valve and the variable-frequency fan. The device and the method mainly solve the problem of sulfur dioxide standard exceeding of the chimney of a dry quenching environment ground dust removal station; the pollutant discharge can be further reduced.

Owner:JINNENG SCI & TECH

Advanced treatment technology for oilfield reinjection water

ActiveCN105330061ASolve the problem of exceeding the standardImprove removal efficiencyWater contaminantsTreatment involving filtrationActivated carbonPtru catalyst

The invention discloses an advanced treatment technology system for oilfield reinjection water. The advanced treatment technology system is characterized by comprising a first-stage water inlet pump, a filter water inlet, a multi-medium filter, a water distributor, a ceramic filler area, an activated carbon filler area, a filter water outlet, a backwashing pump, a backwashing water inlet, a backwashing water outlet, a middle pool, a second-stage water inlet pump, a catalysis tower water inlet, an ozone catalysis tower, a kaolin ozone catalyst, an ozone generator, an ozone pipeline, an ozone inlet, an ozone diffuser, an ozone quencher, an ozone outlet, a catalysis tower water outlet and a draining pump. According to the advanced treatment technology system, a technical scheme for advanced treatment of oil producing wastewater is presented, the problem that organic pollutants in the oilfield reinjection water exceed the standard is systematacially solved, and the oil producing wastewater treated by the system can meet the oilfield reinjection requirements; in addition, the treatment effect is stable, the production operation cost is low, and operation is easy and convenient.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

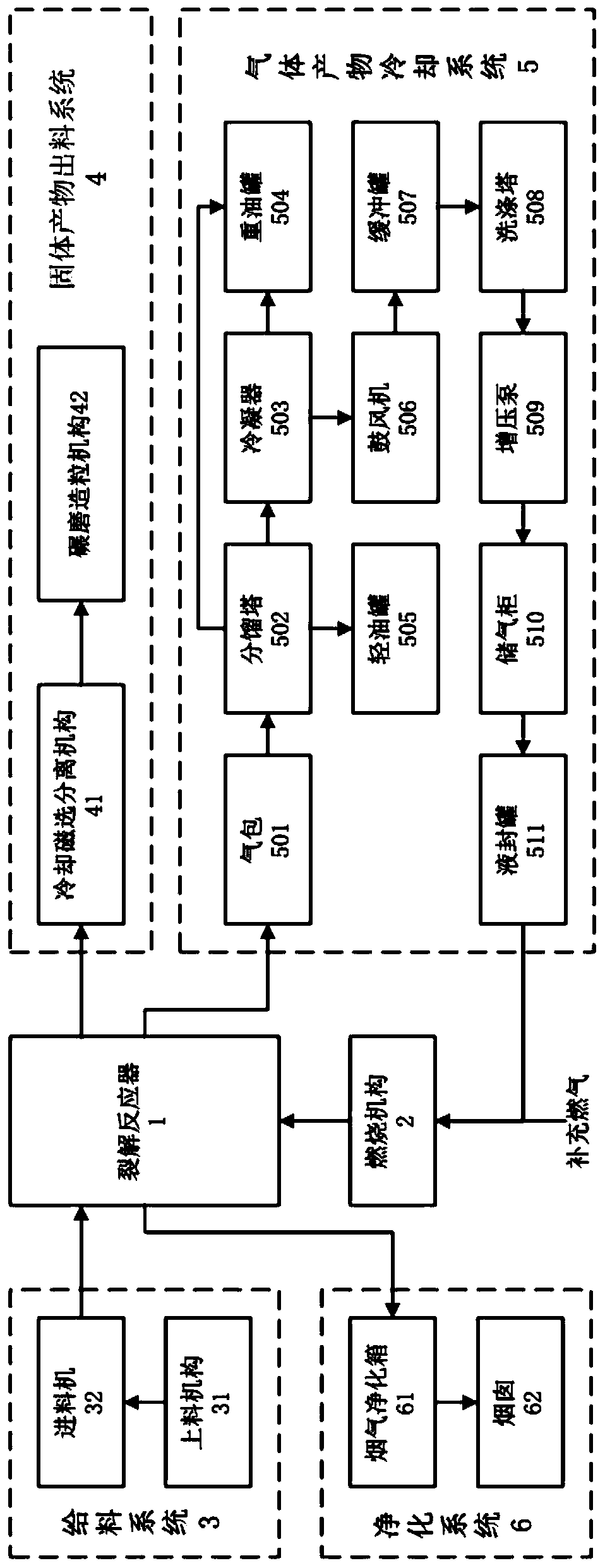

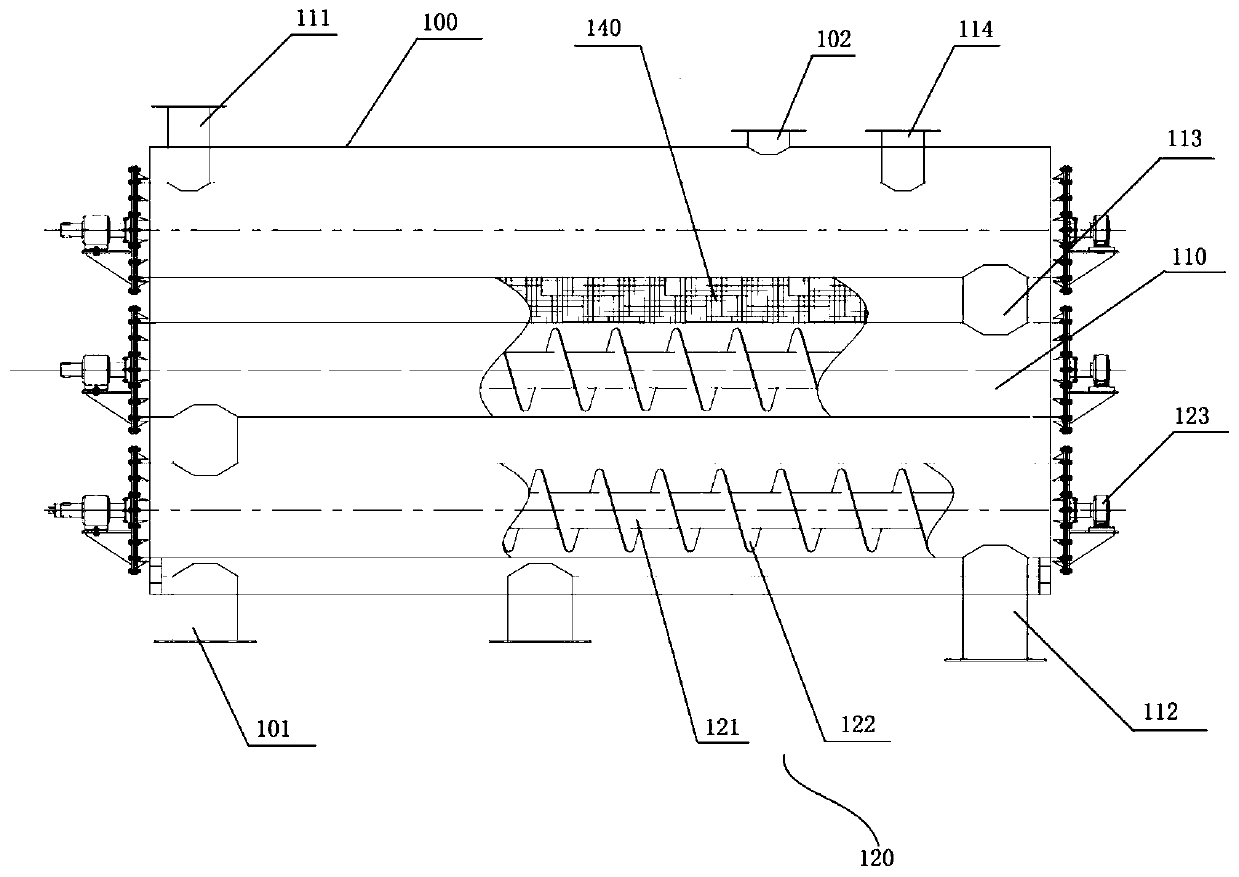

Novel rubber block pyrolysis oil production system

PendingCN110129085AStable combustionGuarantee self-sufficiencyLiquid hydrocarbon mixture productionEnvironmental resistanceCombustion

The invention discloses a novel rubber block pyrolysis oil production system, and relates to the technical field of environment-friendly equipment. The novel rubber block pyrolysis oil production system comprises a cracking reactor, a combustion mechanism, a material feeding system, a solid product discharging system, a gas product cooling system and a purification system, wherein the material feeding system is used for sending crushed rubber blocks into the cracking reactor, the cracking reactor is used for heating and cracking the rubber blocks, and the solid product discharging system is used for collecting and filtering carbon black generated in the cracking reactor, grinding the filtered carbon black, and performing granulation, drying and packaging; the gas product cooling system isused for collecting oil-gas products produced in the cracking reactor, and separating the oil-gas products so as to obtain an oil product and flammable non-condensable gas, the combustion mechanism isused for introducing and burning the flammable non-condensable gas, and sending the generated high-temperature flue gas into the cracking reactor so as to provide heat for cracking of the rubber blocks, and the purification system is used for purifying exhausted flue gas.

Owner:武汉兴泰荣达科技有限公司

Biological organic mineral fertilizer and processing method thereof

InactiveCN108314590AScientific and effective useControl accessAnimal corpse fertilisersFertilizer mixturesPowder mixtureSoil organic matter

The invention provides biological organic mineral fertilizer and a processing method thereof and belongs to the field of biological fertilizer. Aiming at the problems of current biological fertilizerthat the fertilizer efficiency is low, the application amount is great and the like, the invention provides the biological organic mineral fertilizer; the processing method comprises the following steps: carrying out low-temperature calcination on diatomaceous shale powder and volcanic rock powder at 600 to 800 DEG C to obtain an ore powder mixture; crushing and mincing animal organic matters intominced meat; then adding humic acid and soybean meal to form an organic matter mixture; after mixing the ore powder mixture and the organic matter mixture, granulating to form particles; after drying, spraying a bacillus subtilis bacterium agent; or mixing the ore powder mixture and the organic matter mixture, and adding bacillus subtilis and uniformly mixing to finally prepare the biological organic mineral fertilizer. The processing method is applicable to processing and utilization of the biological organic mineral fertilizer.

Owner:黑龙江沃坤农业科技有限公司

Chinese herbal medicine extraction nutrient solution, preparation method and ecological planting method

PendingCN112273172AIncrease productionQuality improvementFertilising methodsNitrogenous fertilisersSmoked PlumMicrobial agent

The invention discloses a Chinese herbal medicine extraction nutrient solution, a preparation method and an ecological planting method. The Chinese herbal medicine extraction nutrient solution is prepared from the following raw materials in parts by weight of 10-15 parts of fermentation liquor, 1-5 parts of trace elements, 5-10 parts of amino acid and 300-400 parts of RO water. The fermentation liquor comprises elecampane, scutellaria baicalensis, dandelion, fructus forsythiae, coptis chinensis, cortex pseudolaricis, galangal, golden cypress, cinnamon, clove, mangnolia officinalis, radix sophorae flavescentis, radix salviae miltiorrhizae, rosemary, radix stemonae, radix gentianae, quisqualis indica, artemisia apiacea, dendrobium officinale, herba violae, smoked plums, euphorbia helioscopia, saccharomycetes, bifidobacteria, bacillus subtilis and pseudomonas. The planting method comprises the steps of applying base fertilizer to a farmland; after crops are transplanted, mixing a microbial agent with water for root irrigation; and spraying the Chinese herbal medicine extraction nutrient solution to crop leaves. The method has the advantages that less pesticide is sprayed or even no pesticide is sprayed, the crops using the nutrient solution can appear on the market in advance, the harvesting period is prolonged, the quality of agricultural products is greatly improved, and the problems of soil acidification, heavy metal pollution and the like in the planting environment can be remarkably solved.

Owner:JIANGXI RUIBOTE FERTILIZER CO LTD

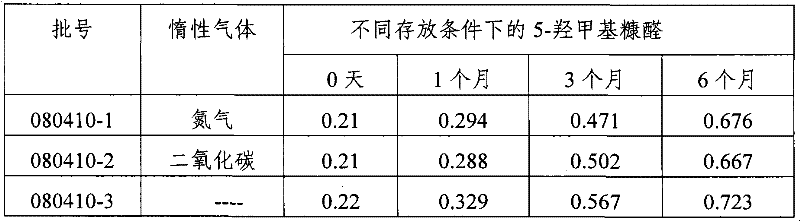

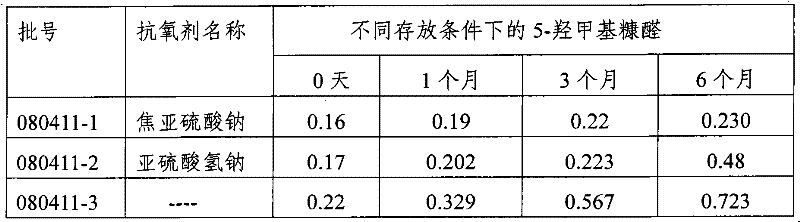

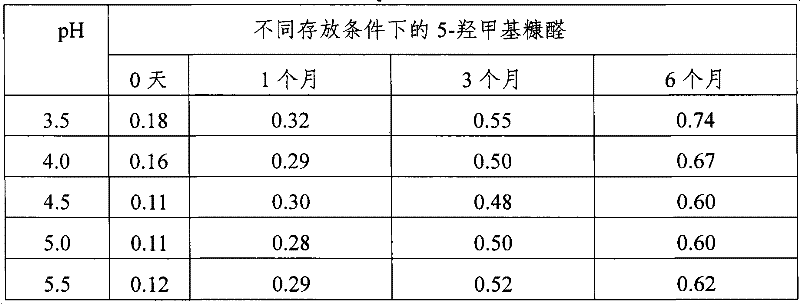

Mannitol sodium chloride injection and preparation method thereof

InactiveCN102526099AGood quality and stabilitySolve the problem of exceeding the standardHydroxy compound active ingredientsBlood disorderAntioxidantGlycerol

The invention discloses a mannitol sodium chloride injection and a preparation method thereof. The mannitol sodium chloride injection comprises the following components in percentage by weight: 5-10 percent of glycerol, 5-10 percent of fructose, 0.9 percent of sodium chloride and 0.01-0.05 percent of an antioxidant. The mannitol sodium chloride injection provided by the invention has high quality stability, the general problem of quick rising of 5-hydroxymethylfurfural existing in a mannitol sodium chloride injection product is solved, and safe clinical use is ensured effectively. Moreover, the preparation method provided by the invention is simple and convenient and is convenient for clinical use, and the product quality is stable and reliable.

Owner:蚌埠丰原涂山制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com