Patents

Literature

56results about "Thermal naphtha reforming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

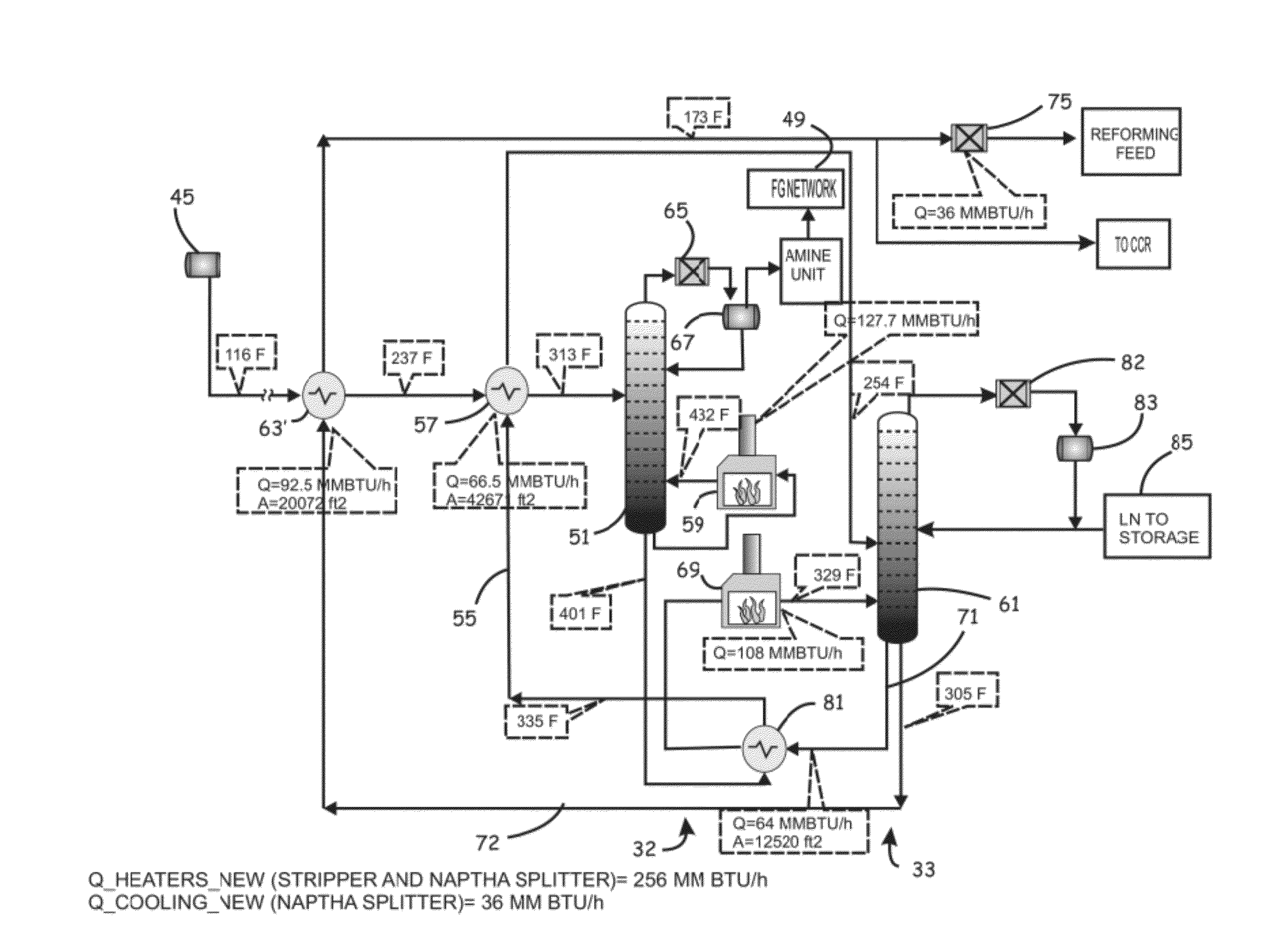

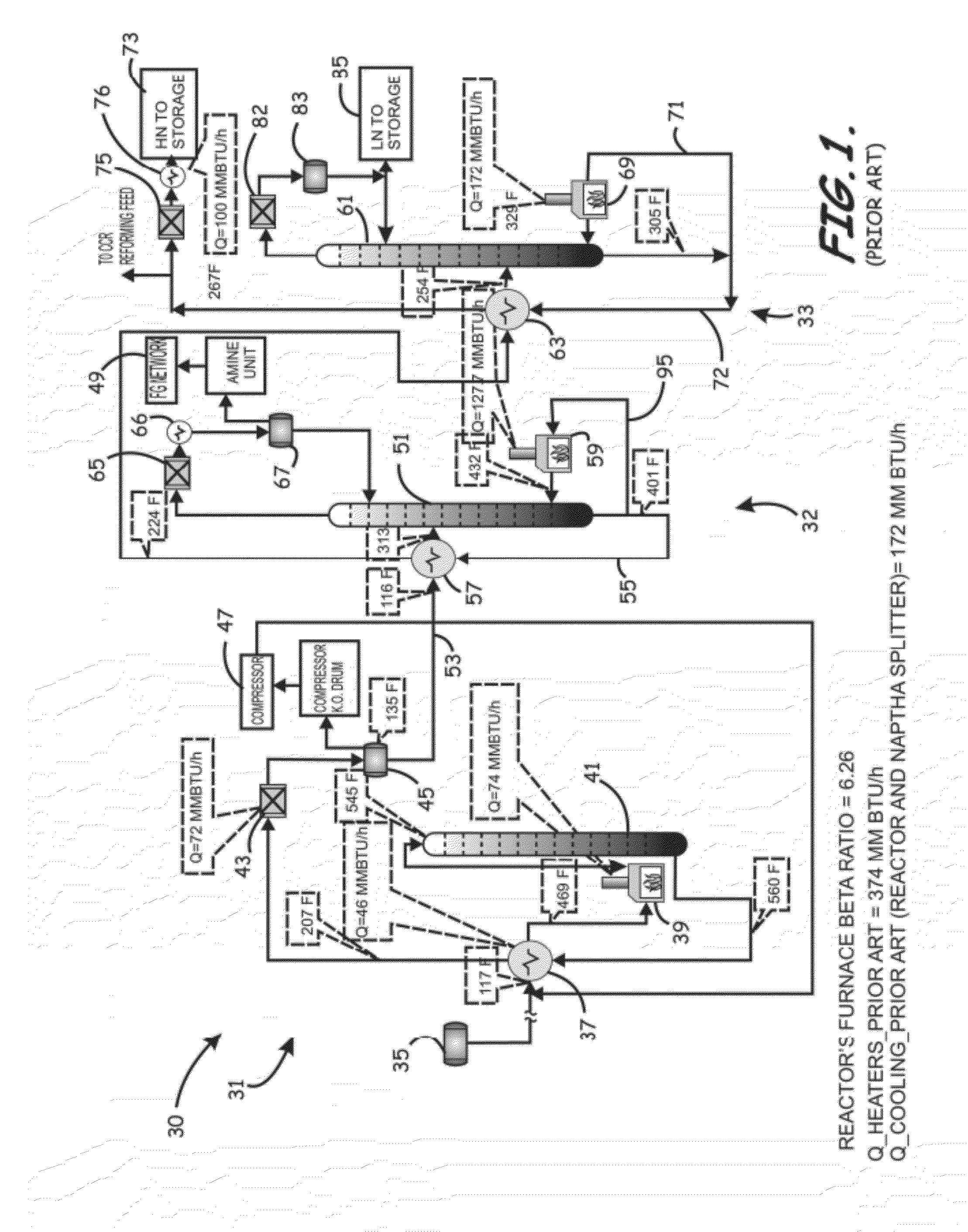

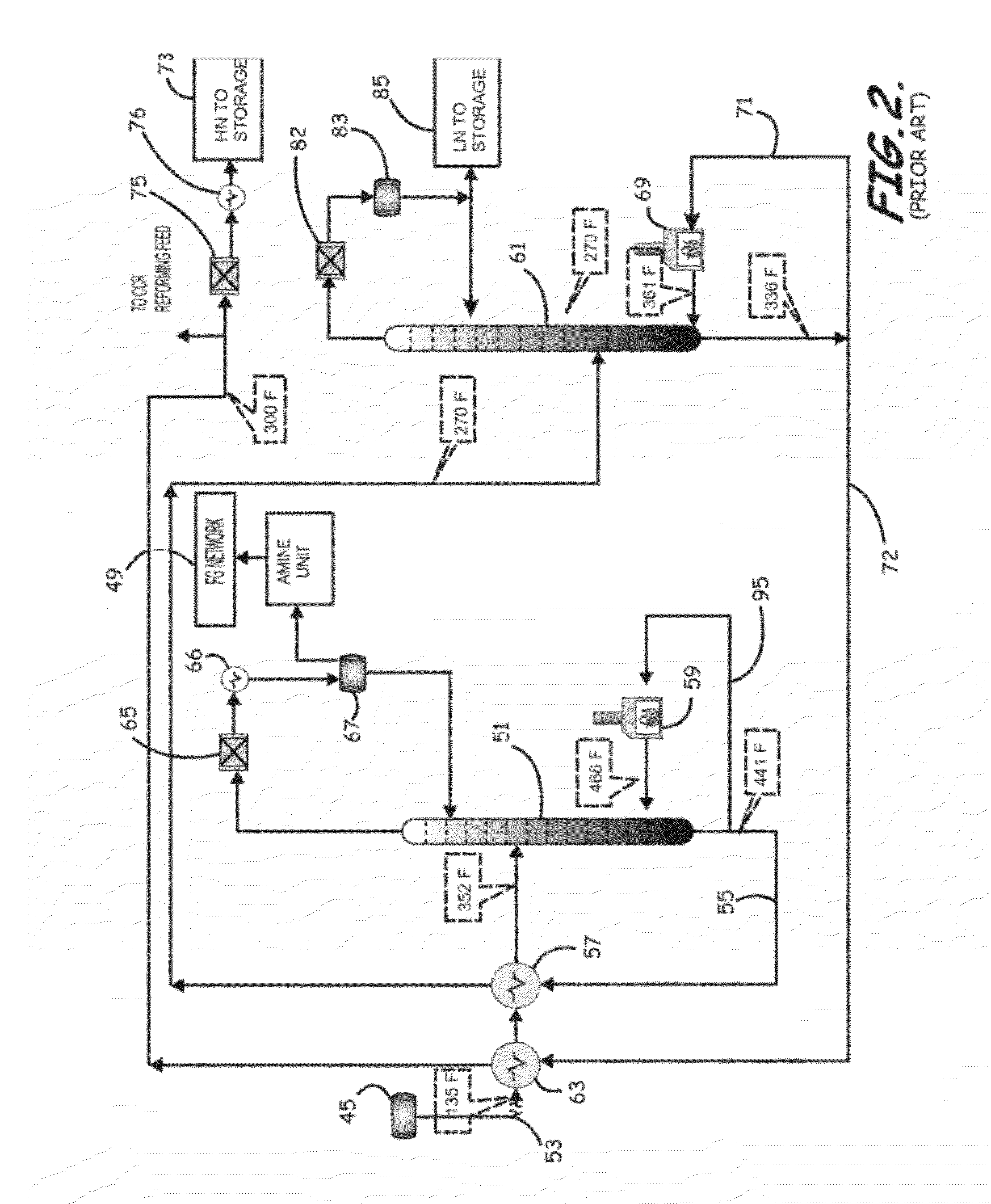

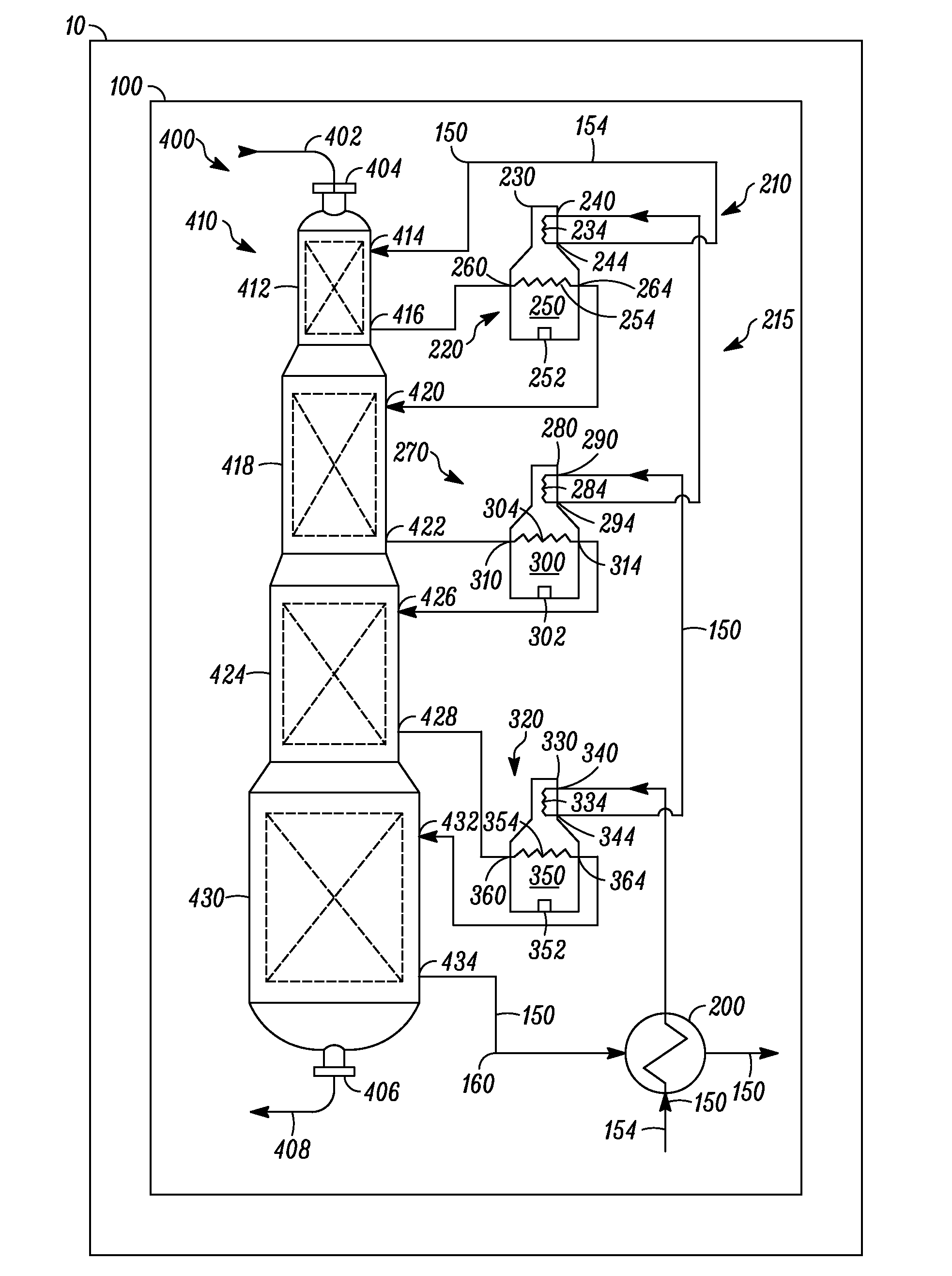

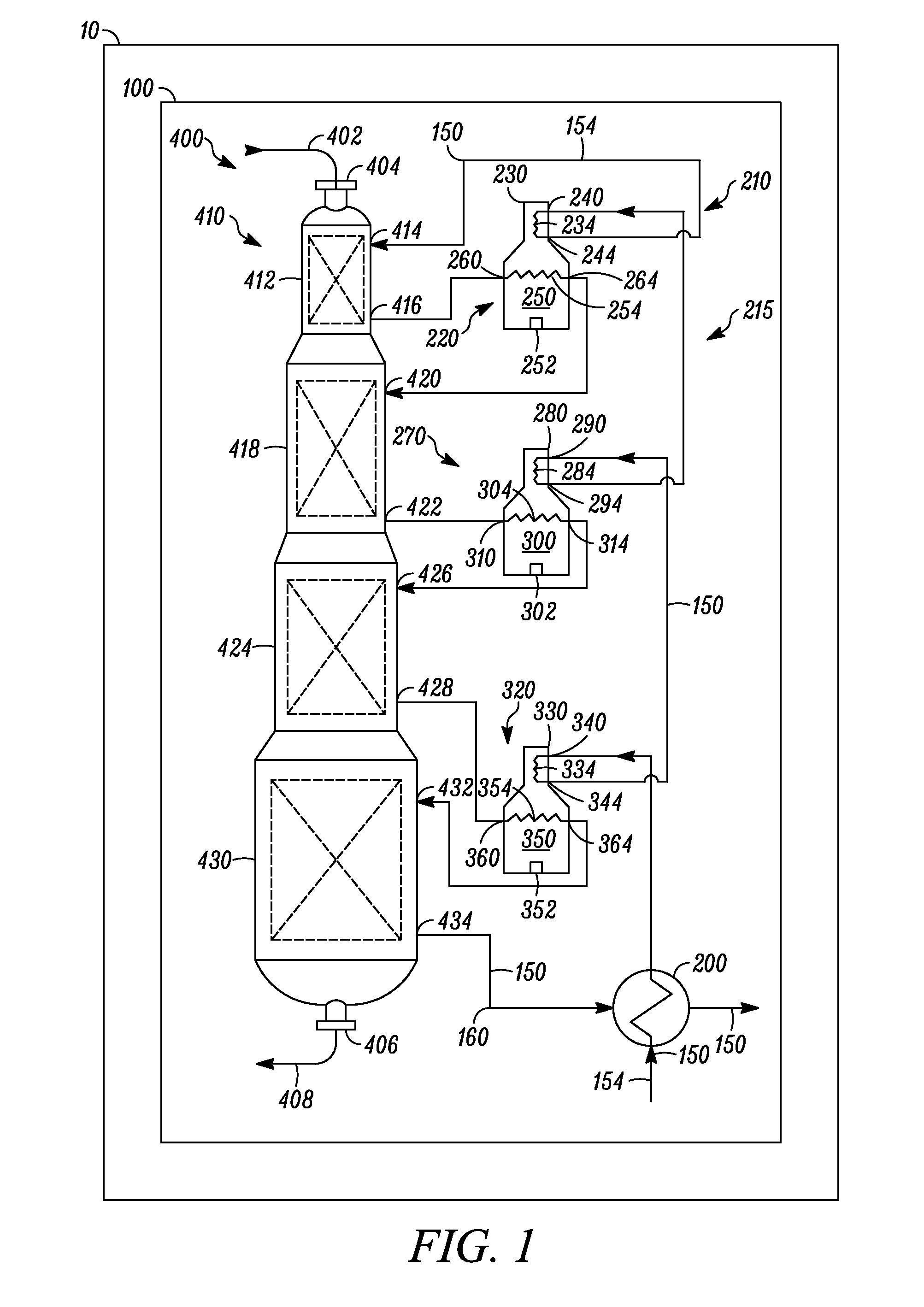

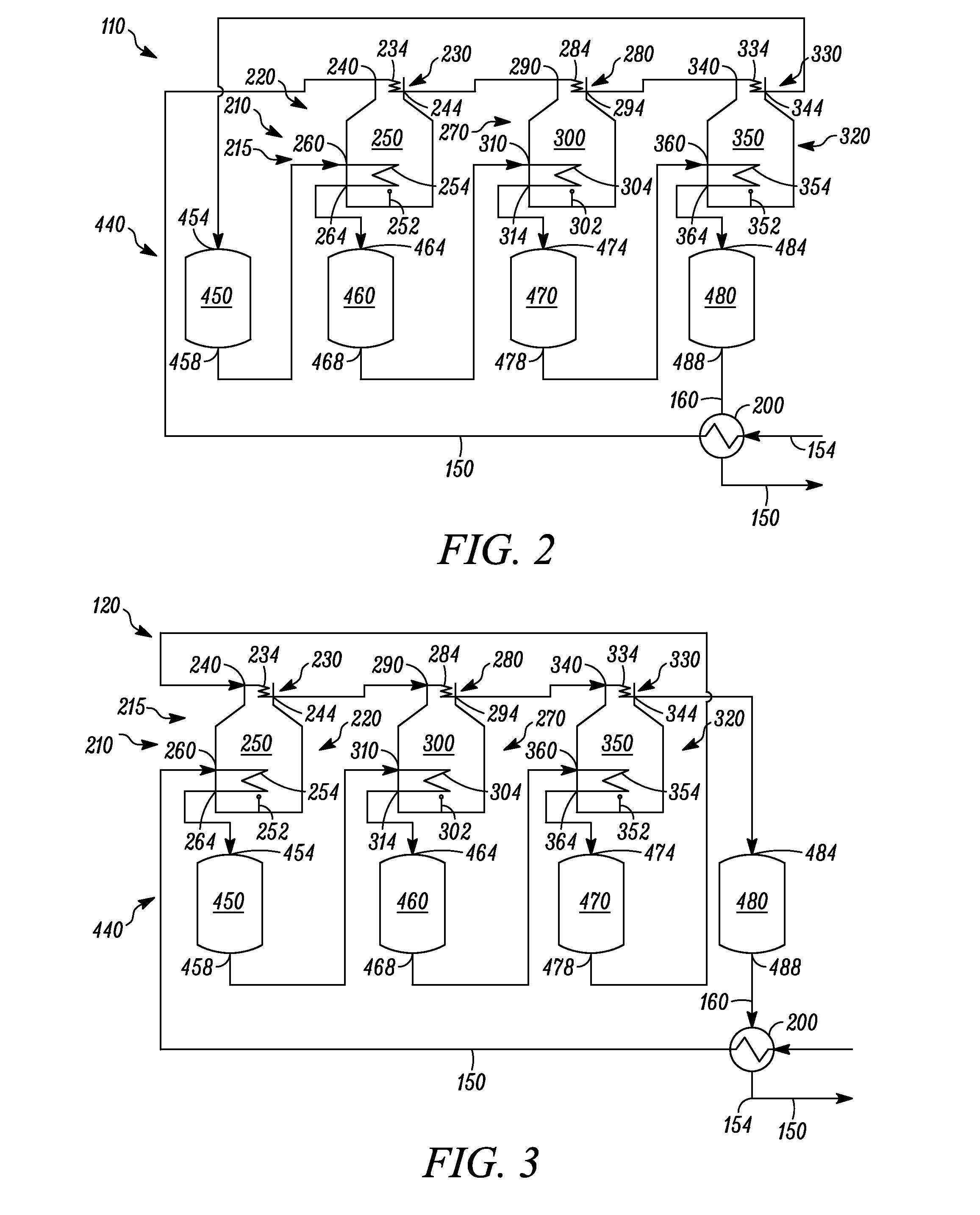

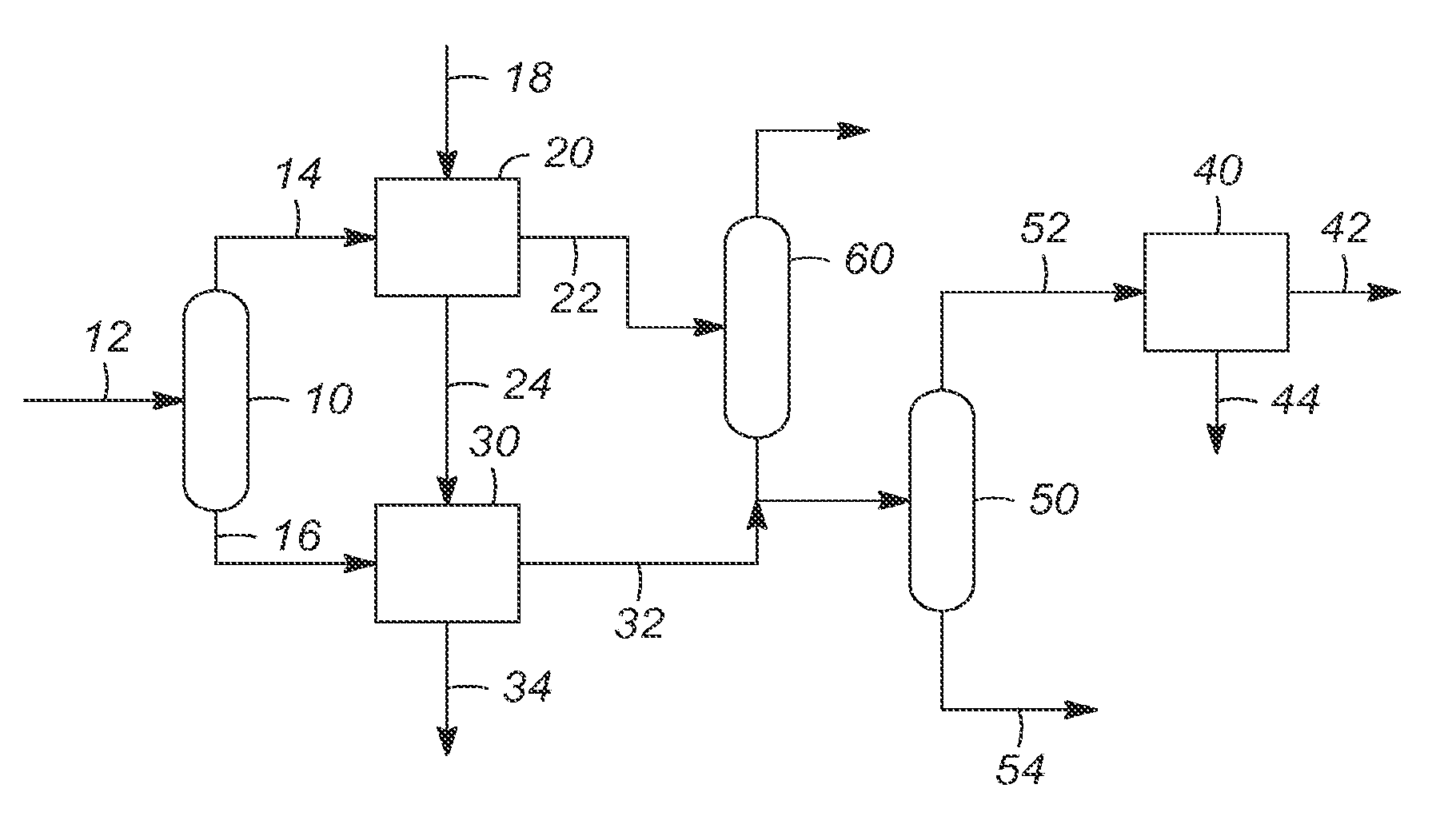

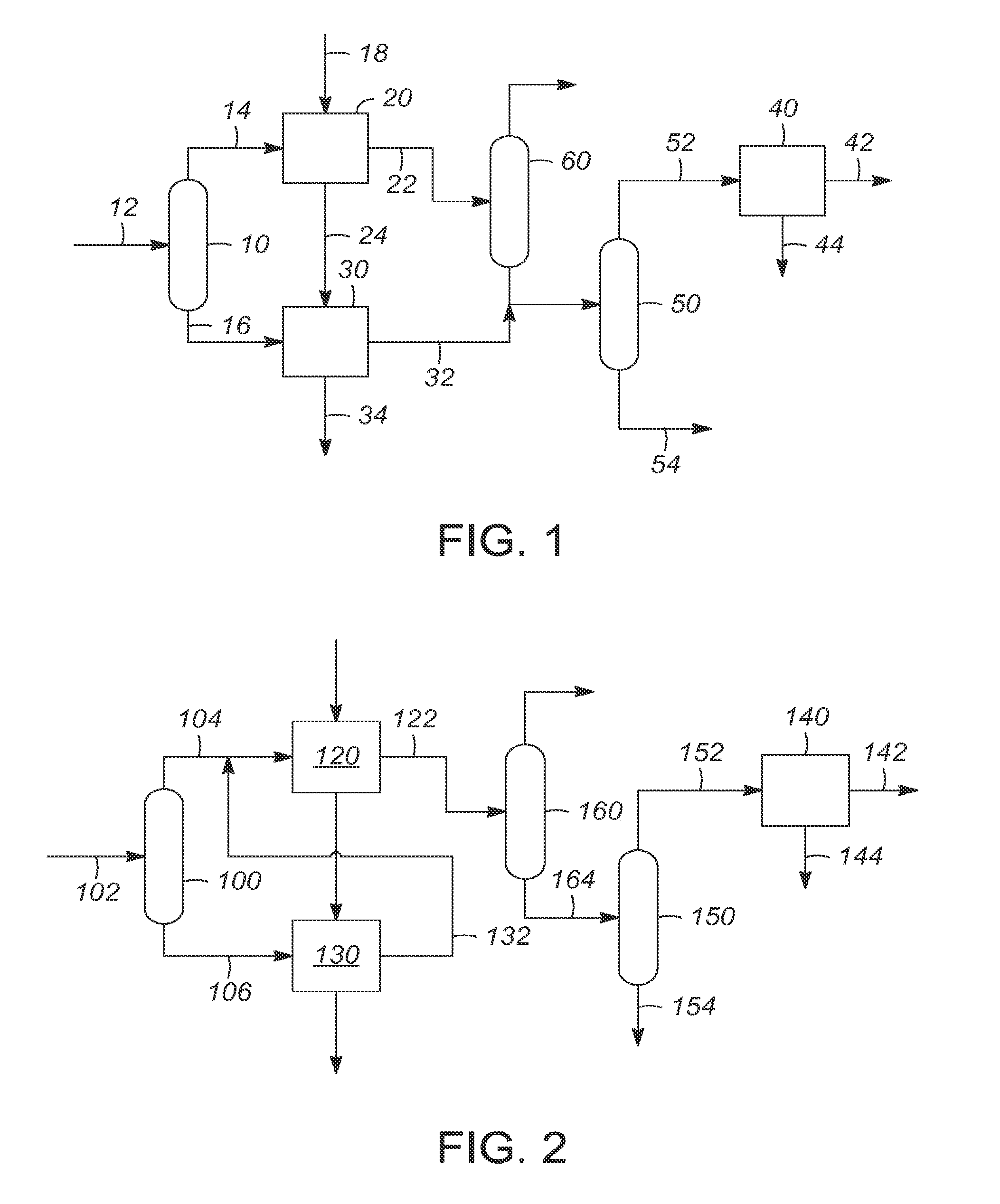

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

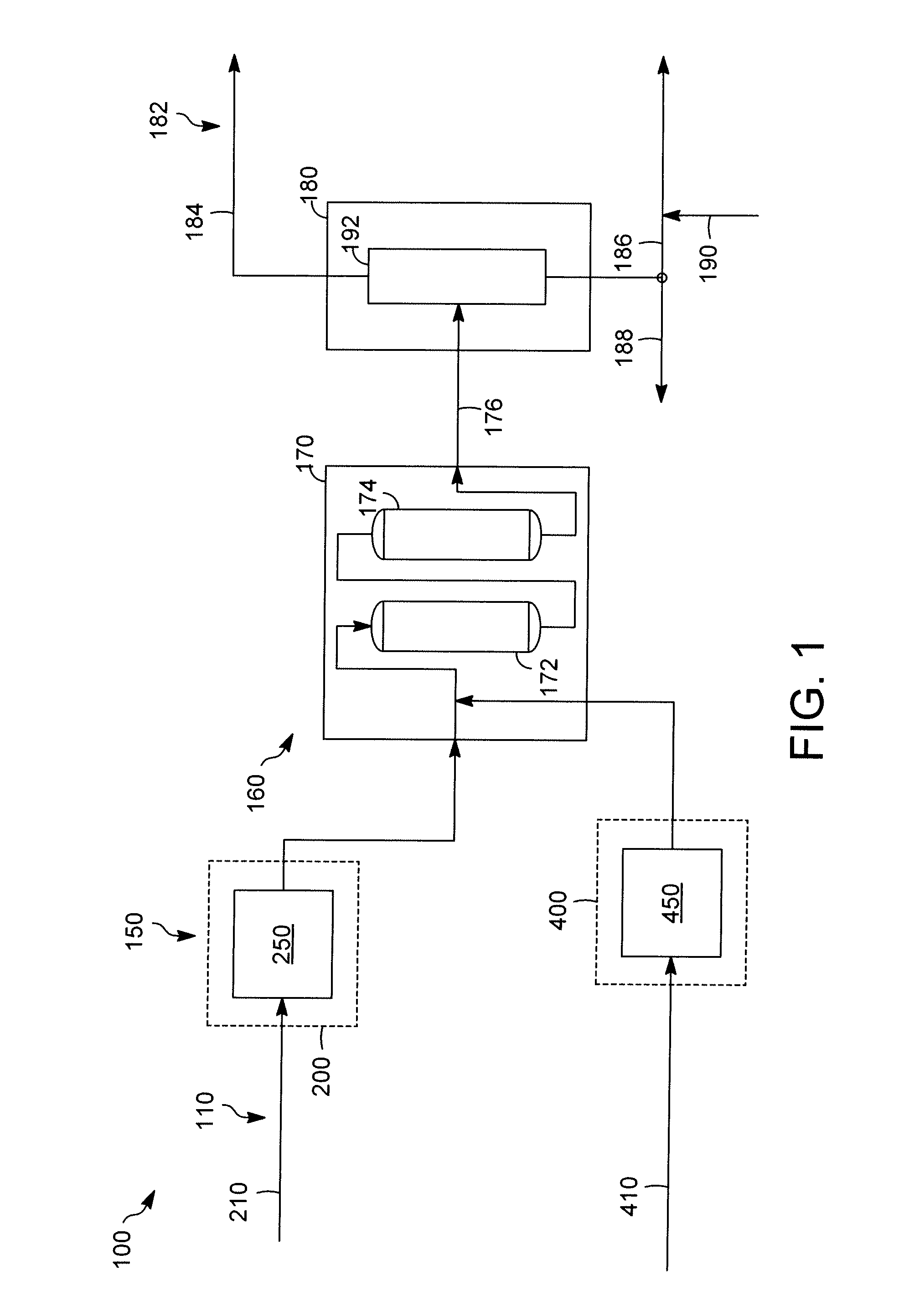

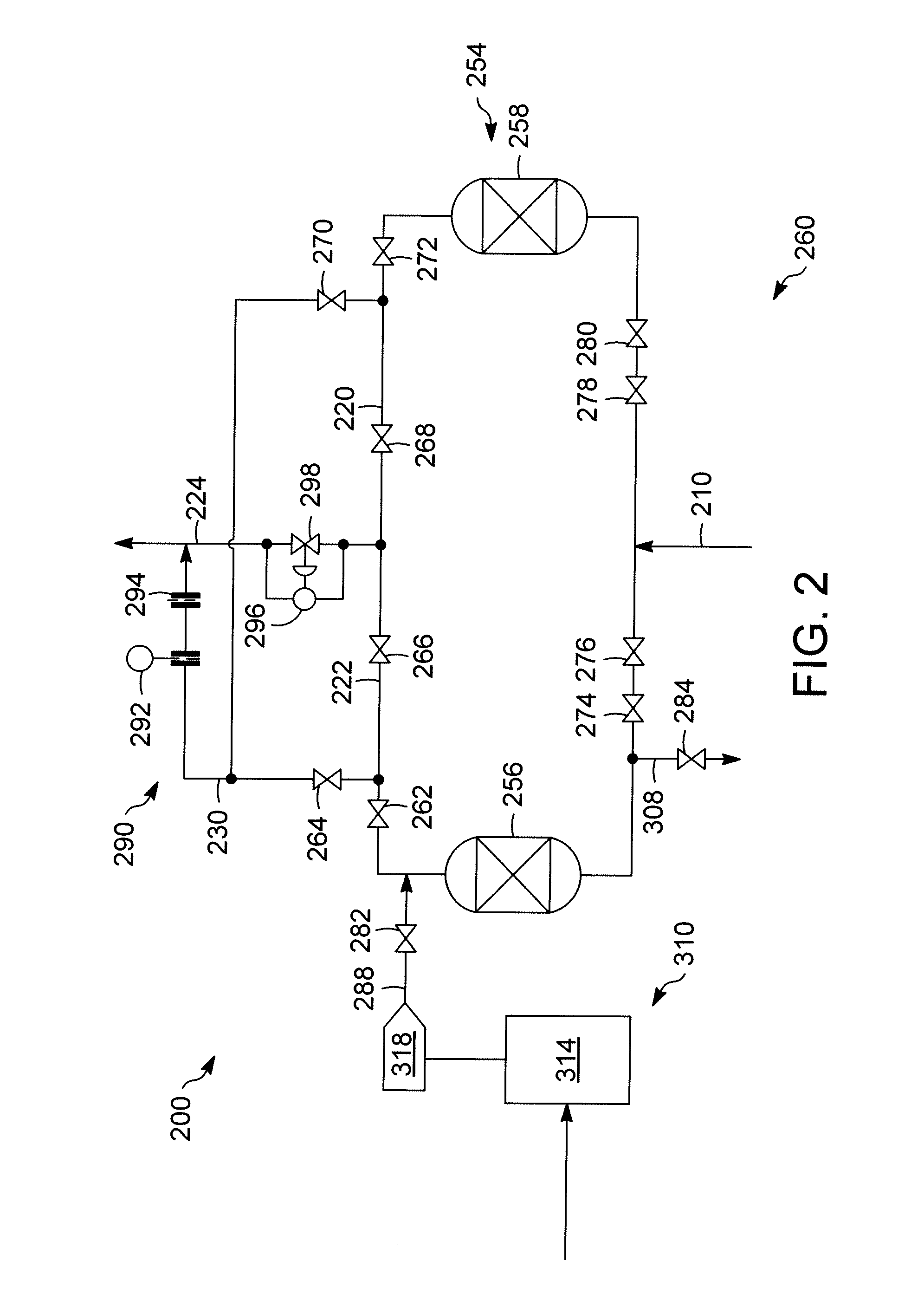

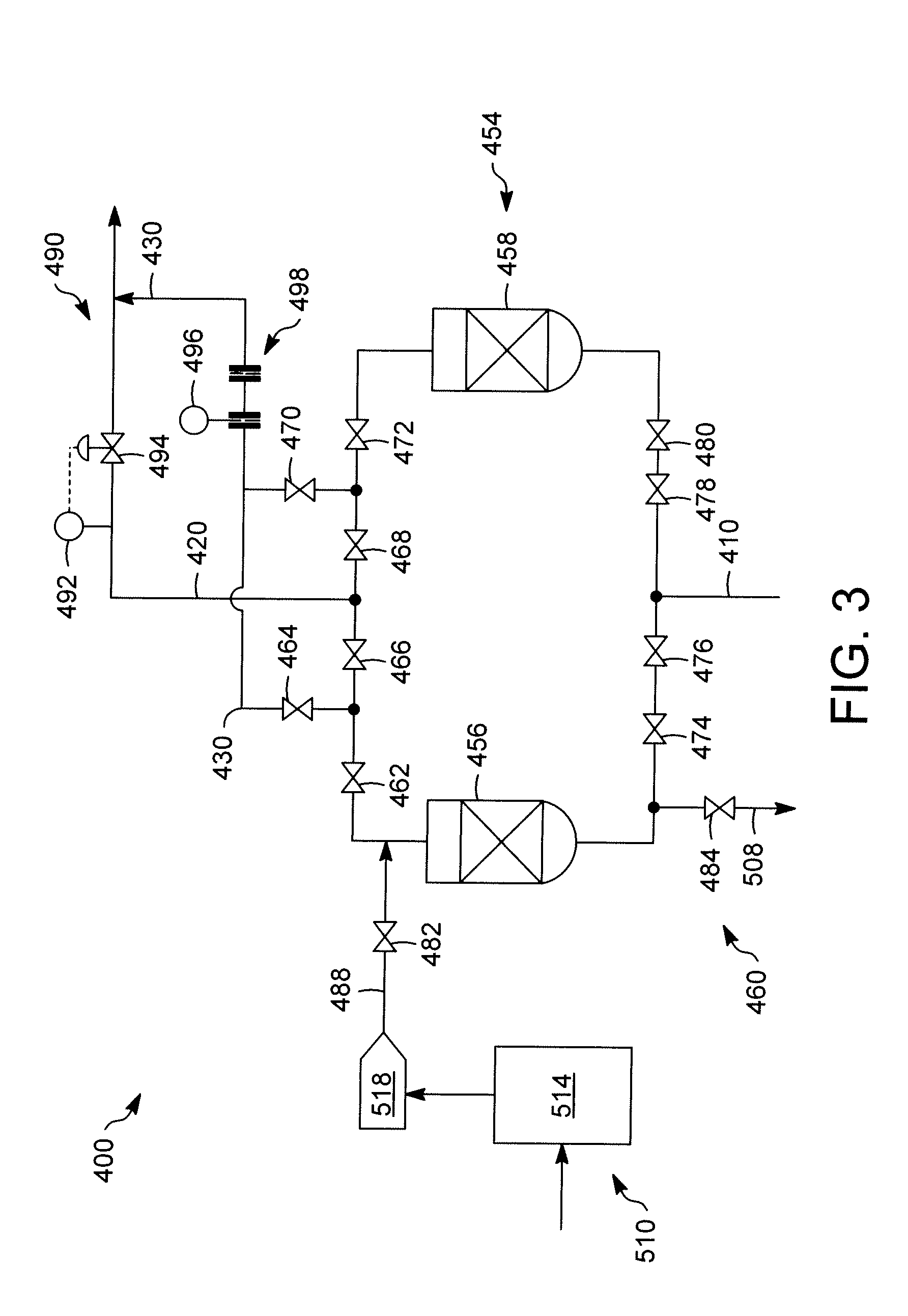

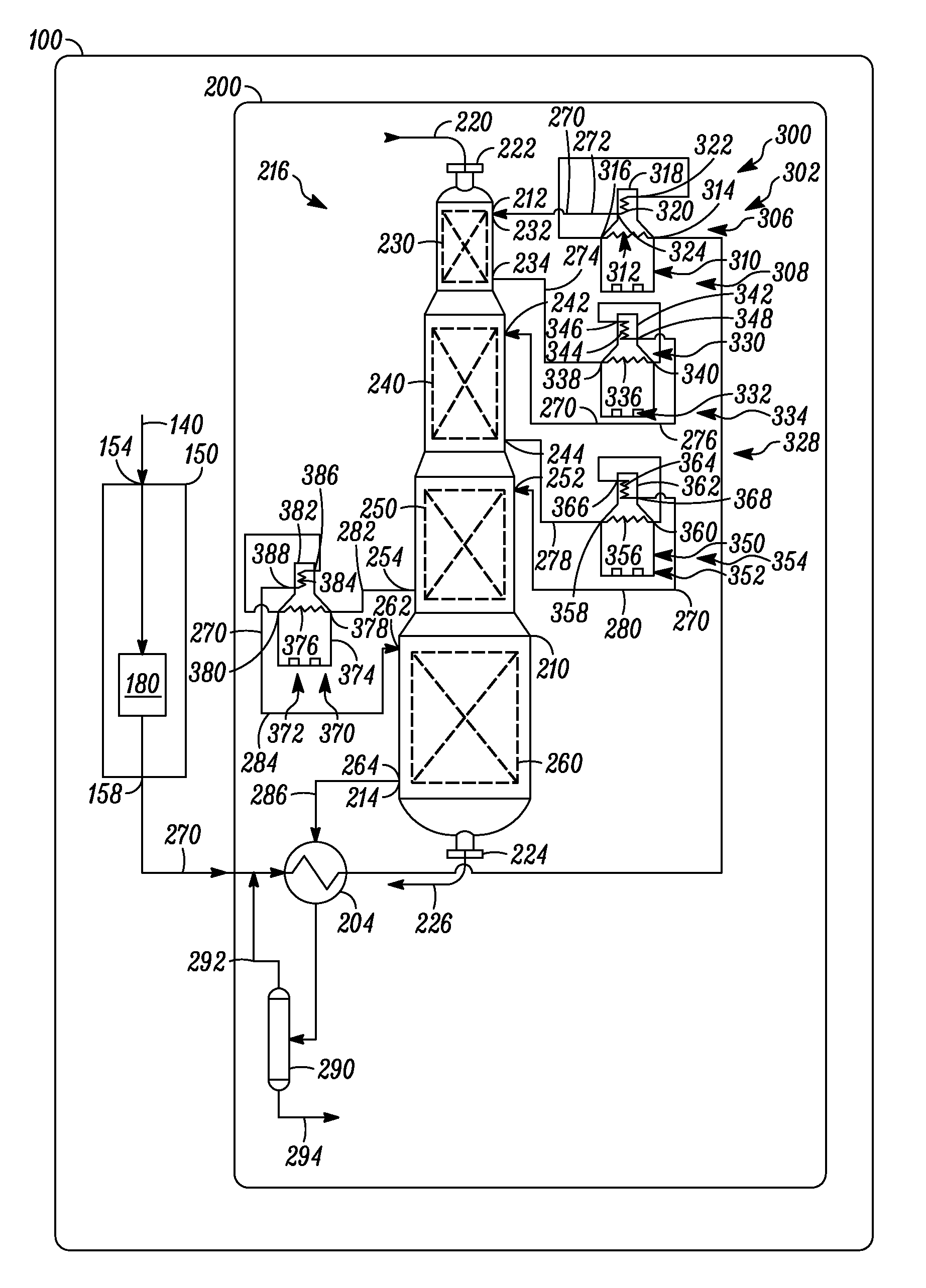

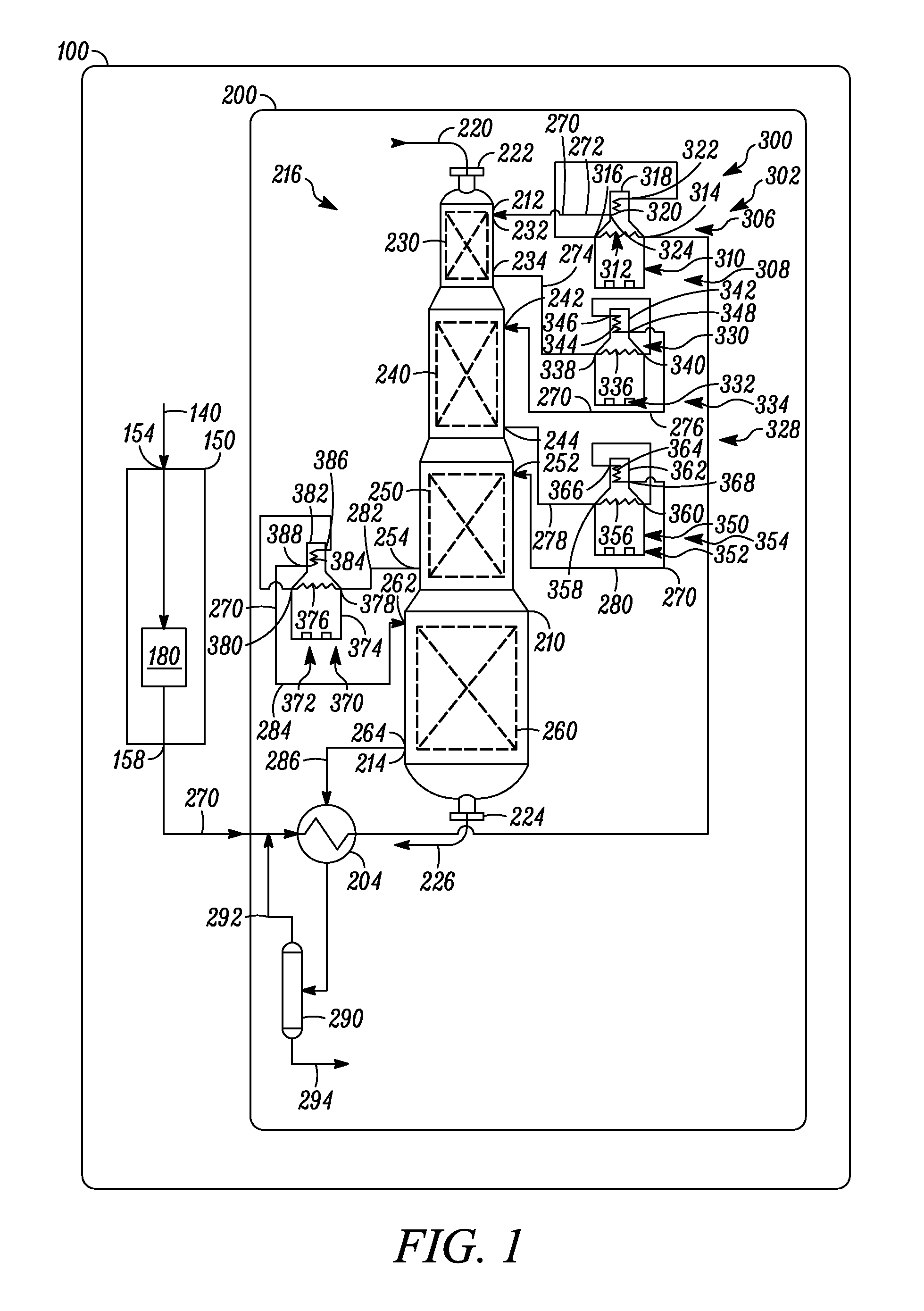

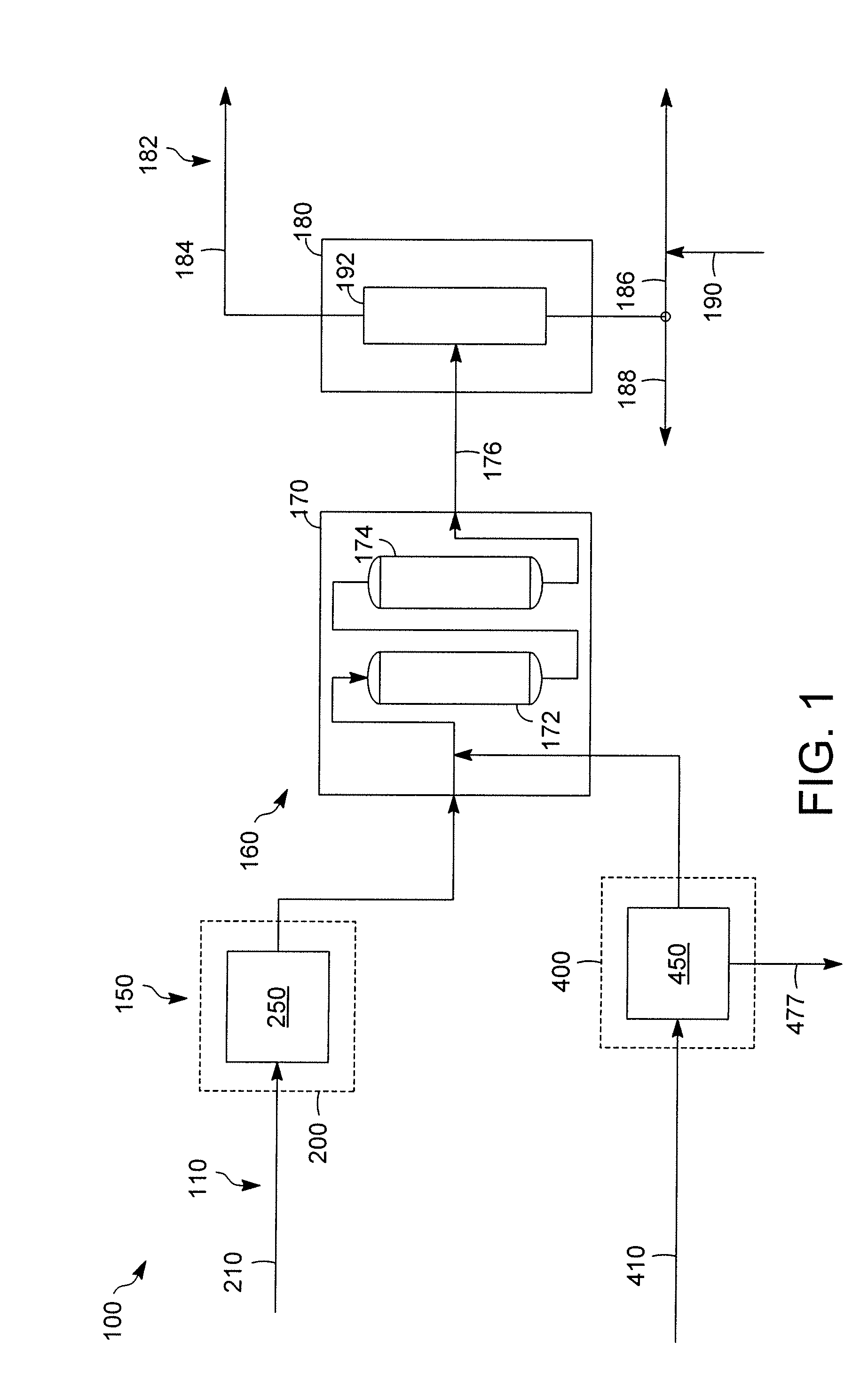

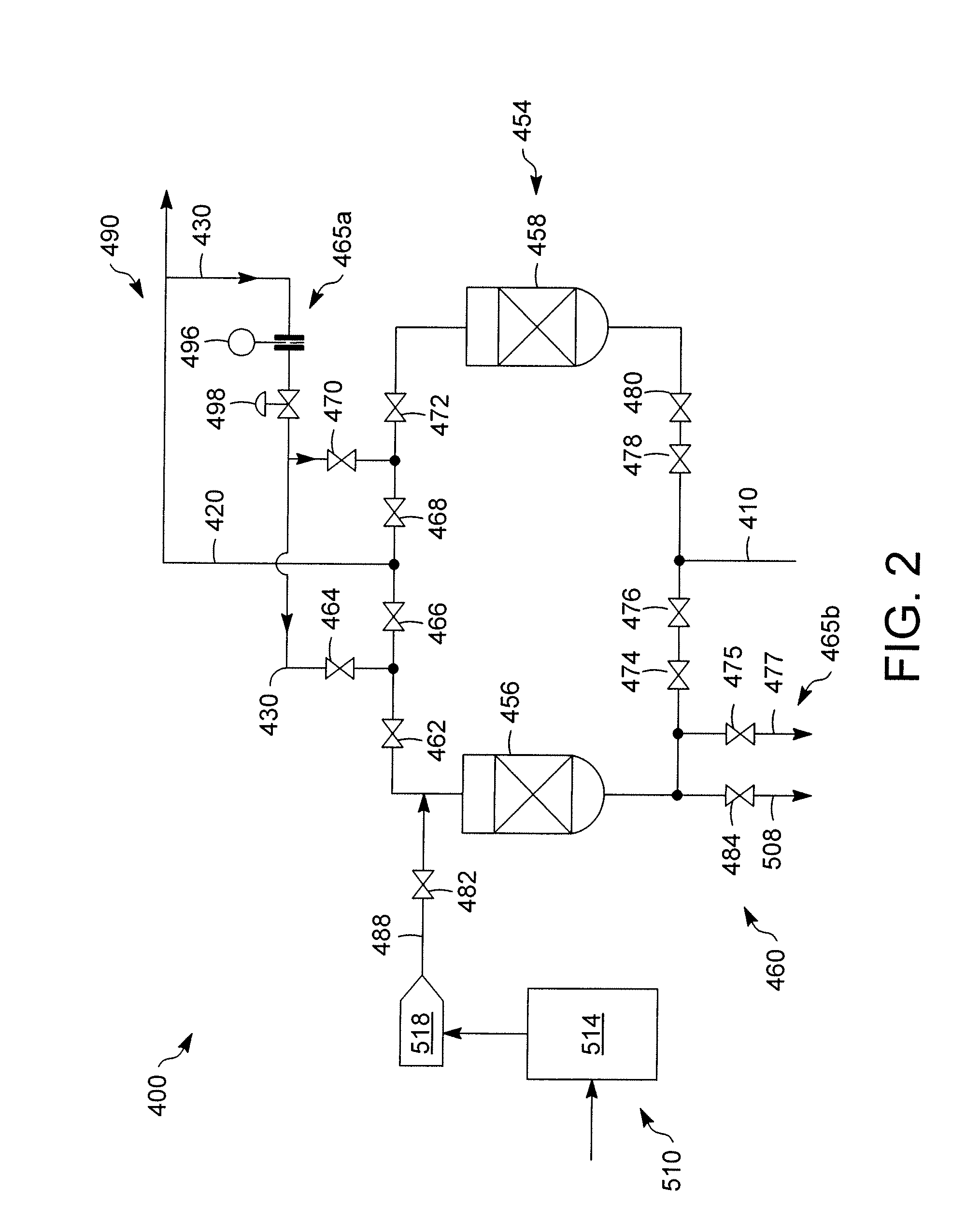

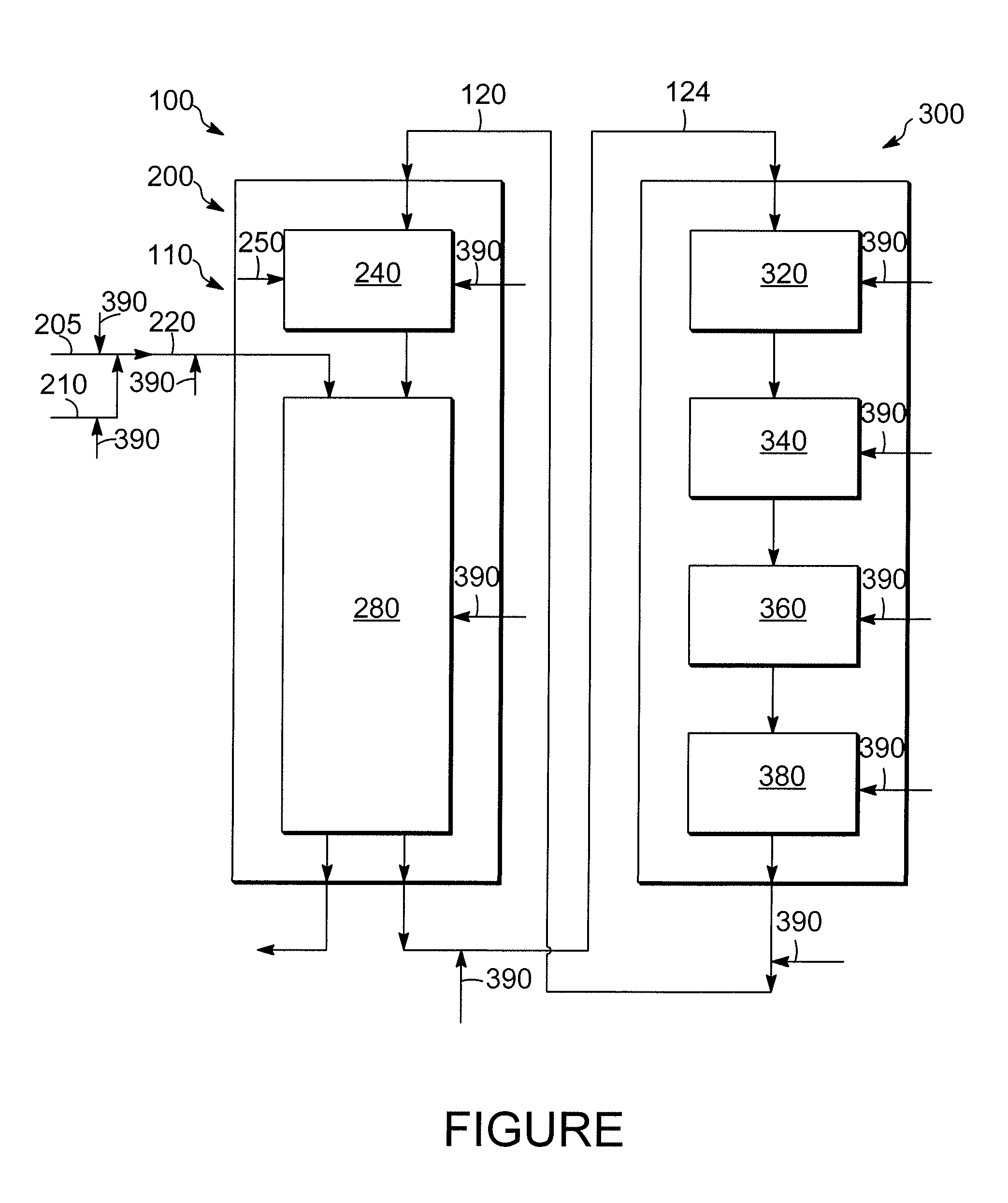

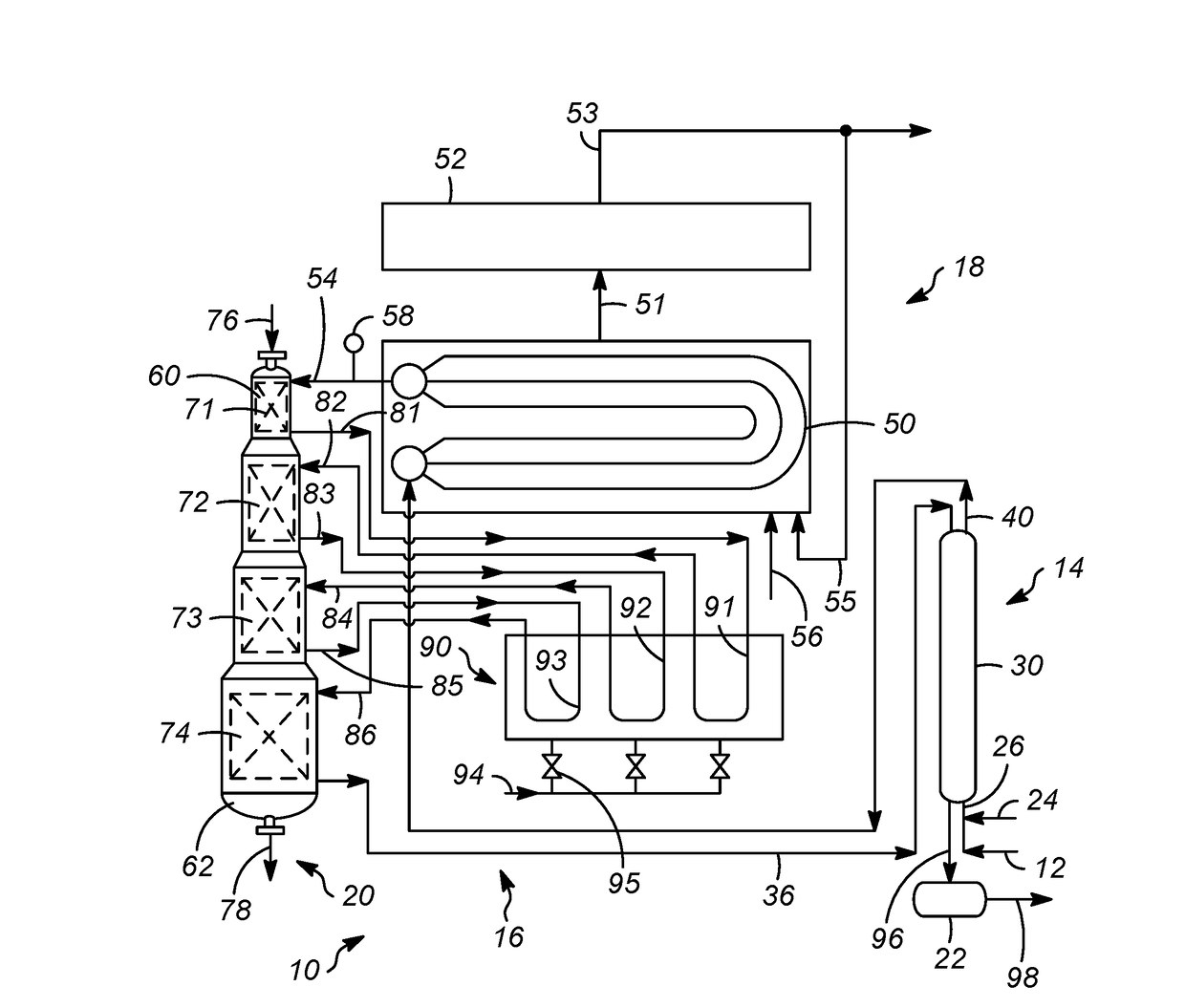

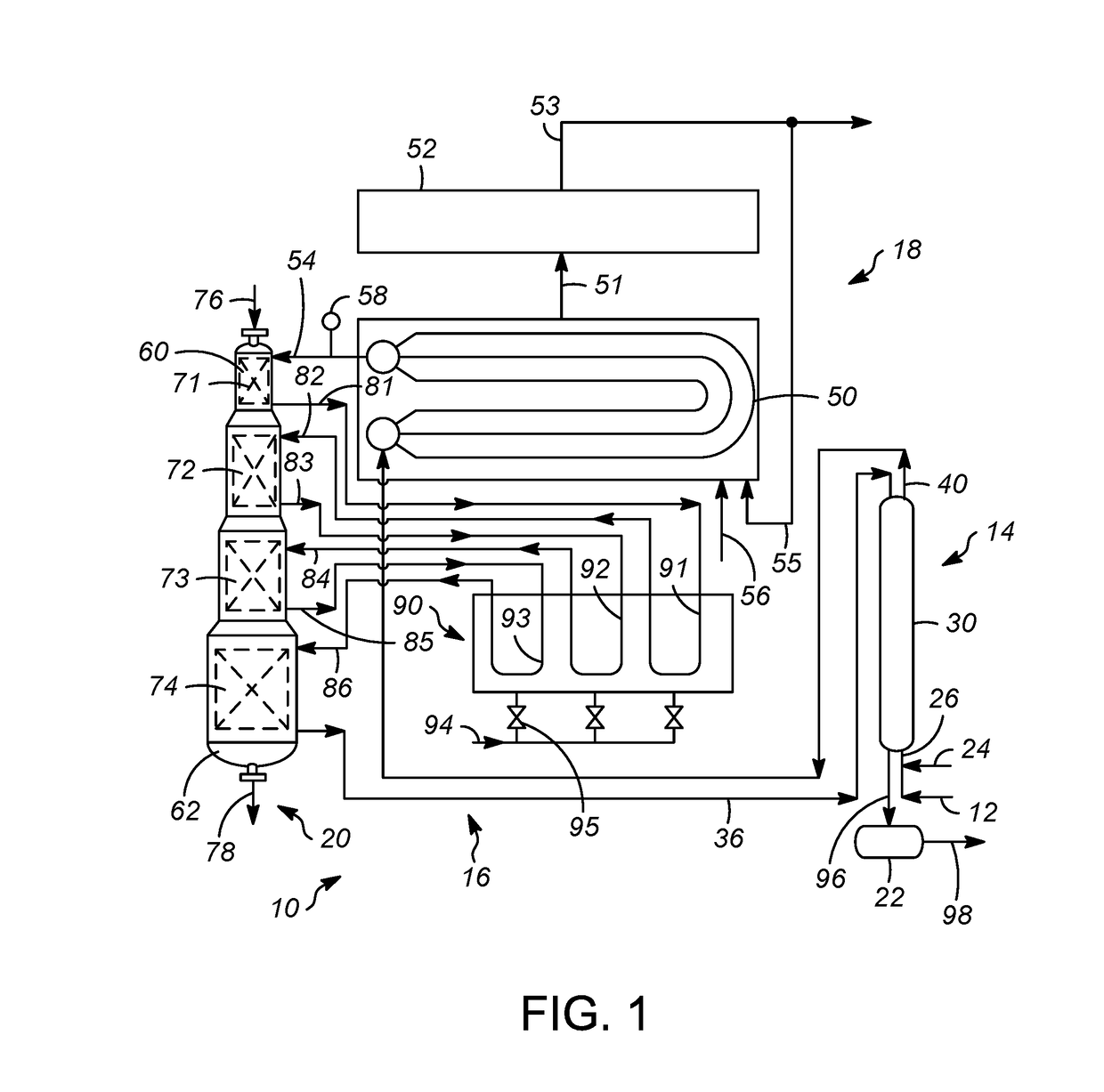

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

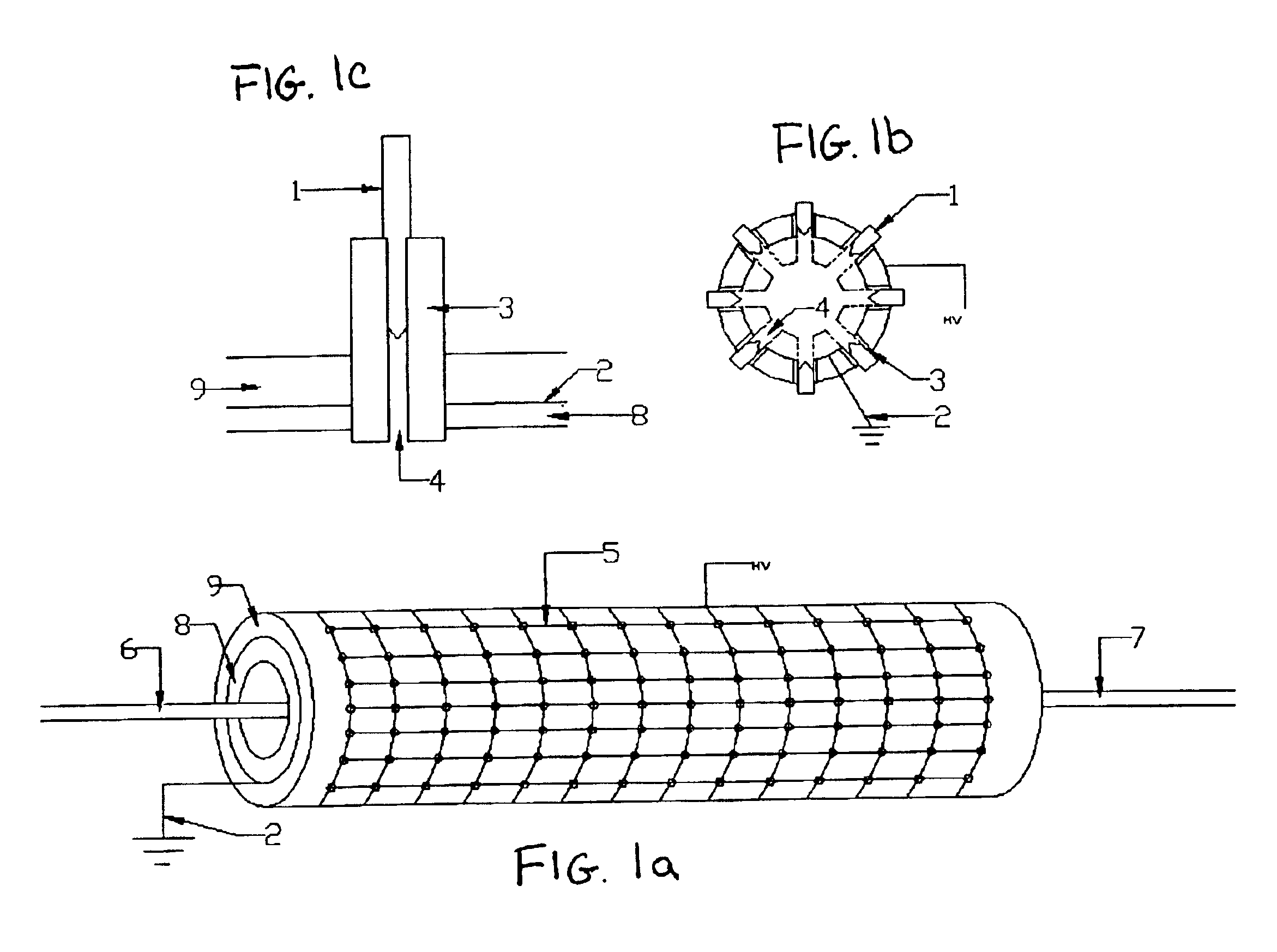

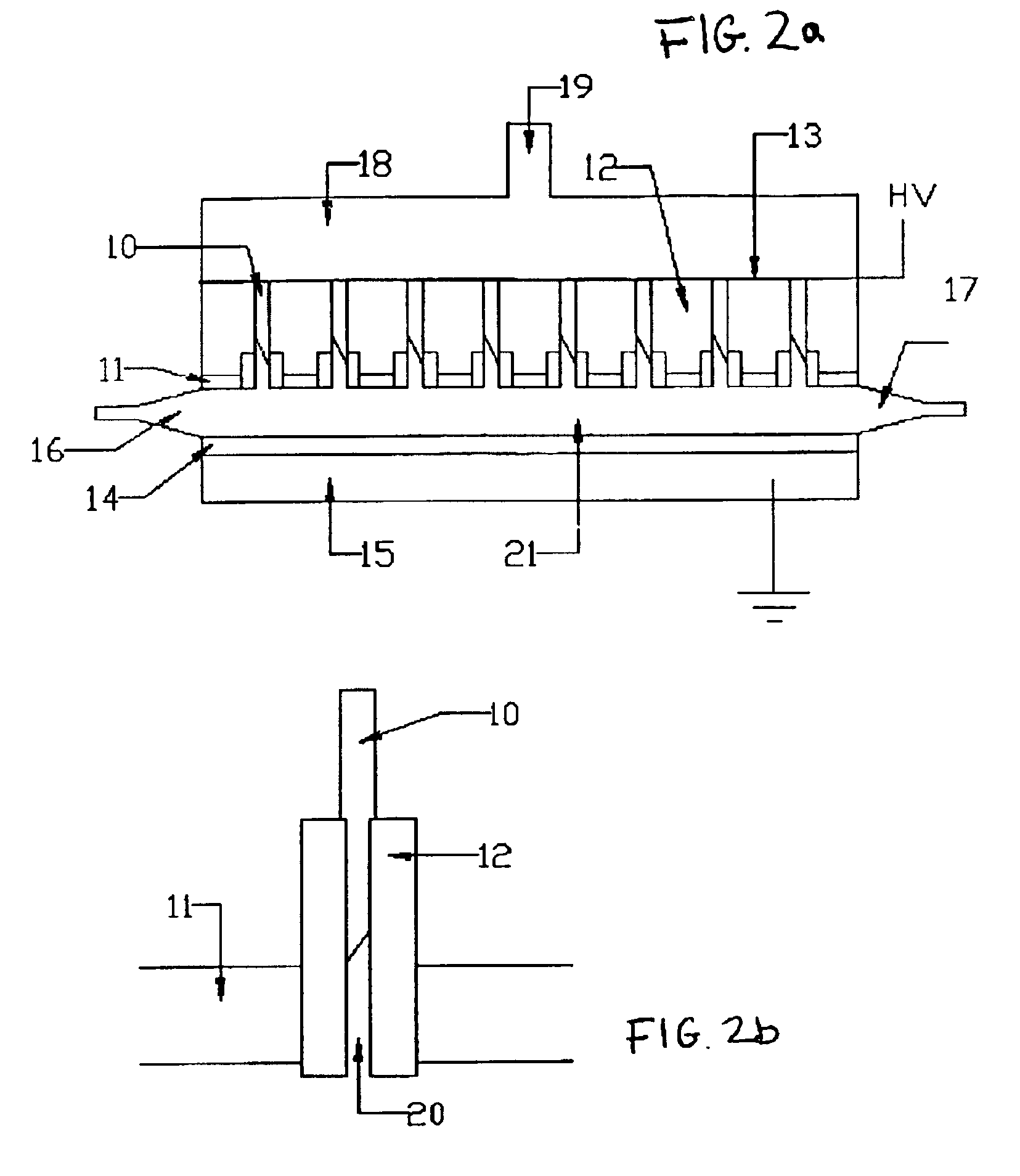

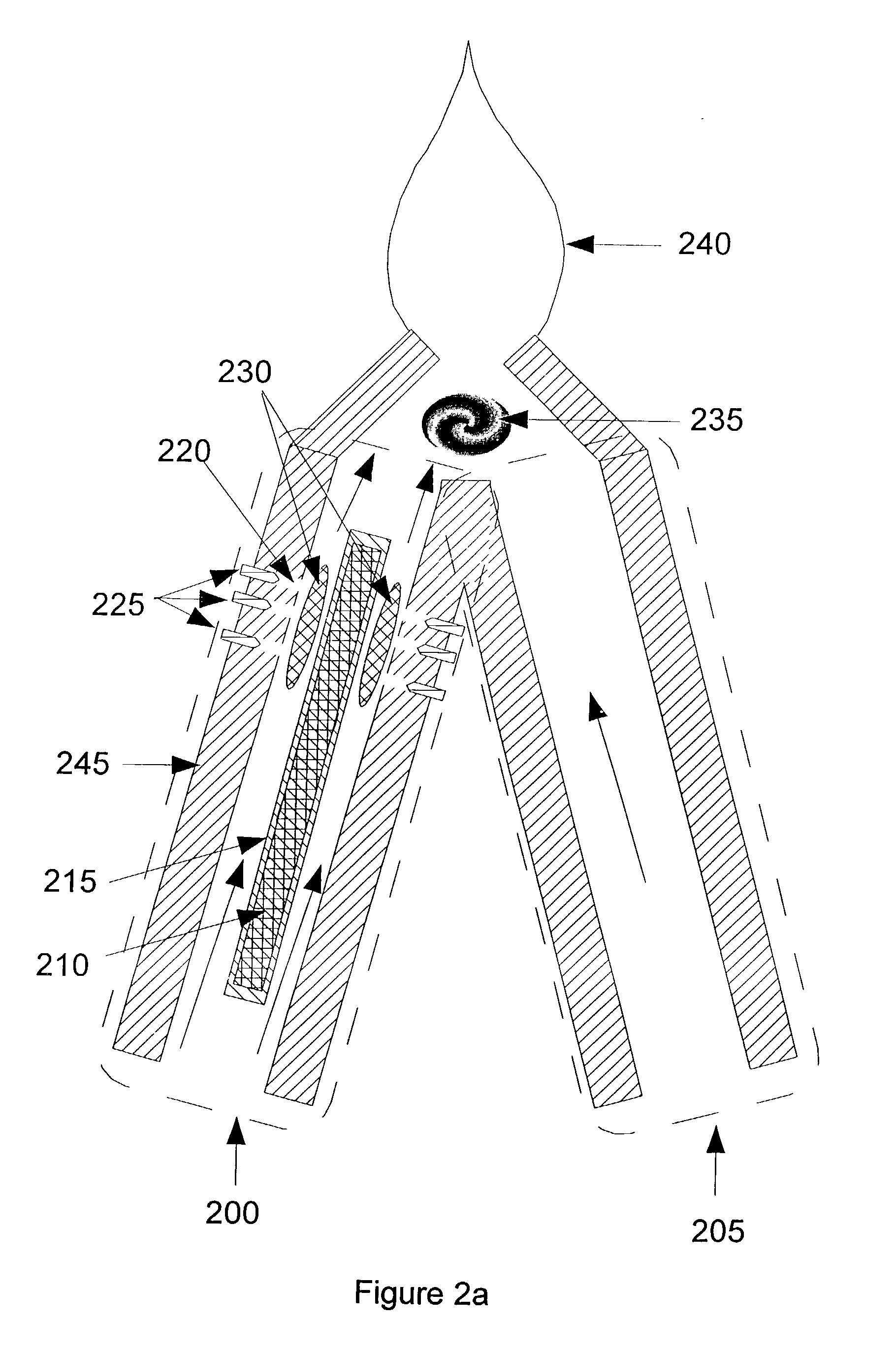

Chemical processing using non-thermal discharge plasma

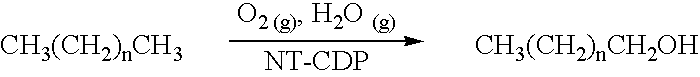

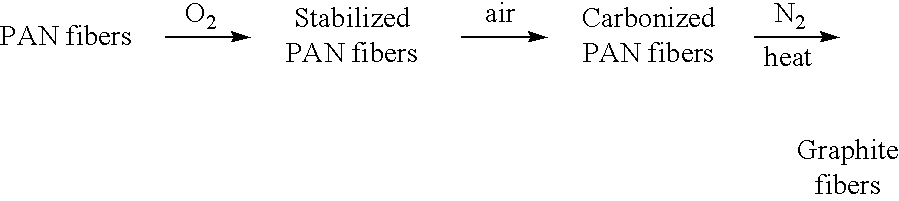

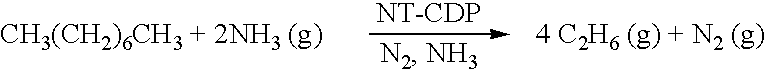

InactiveUS6923890B2Simple processEnhanced water gas shiftingHydrogenMolecular sieve catalystsChemical treatmentFiber

A method for activating chemical reactions using a non-thermal capillary discharge plasma (NT-CDP) unit or a non-thermal slot discharge plasma (NT-SDP) unit (collectively referred to as “NT-CDP / SDP”). The NT-CDP / SDP unit includes a first electrode disposed between two dielectric layers, wherein the first electrode and dielectric layers having at least one opening (e.g., capillary or a slot) defined therethrough. A dielectric sleeve inserted into the opening, and at least one second electrode (e.g., in the shape of a pin, ring, metal wire, or tapered metal blade) is disposed in fluid communication with an associated opening. A non-thermal plasma discharge is emitted from the opening when a voltage differential is applied between the first and second electrodes. Chemical feedstock to be treated is then exposed to the non-thermal plasma. This processing is suited for the following exemplary chemical reactions as (i) partial oxidation of hydrocarbon feedstock to produce functionalized organic compounds; (ii) chemical stabilization of a polymer fiber (e.g., PAN fiber precursor in carbon fiber production; (iii) pre-reforming of higher chain length petroleum hydrocarbons to generate a feedstock suitable for reforming; (iv) natural gas reforming in a chemically reducing atmosphere (e.g., ammonia or urea) to produce carbon monoxide and Hydrogen gas; or (v) plasma enhanced water gas shifting.

Owner:PLASMASOL CORP

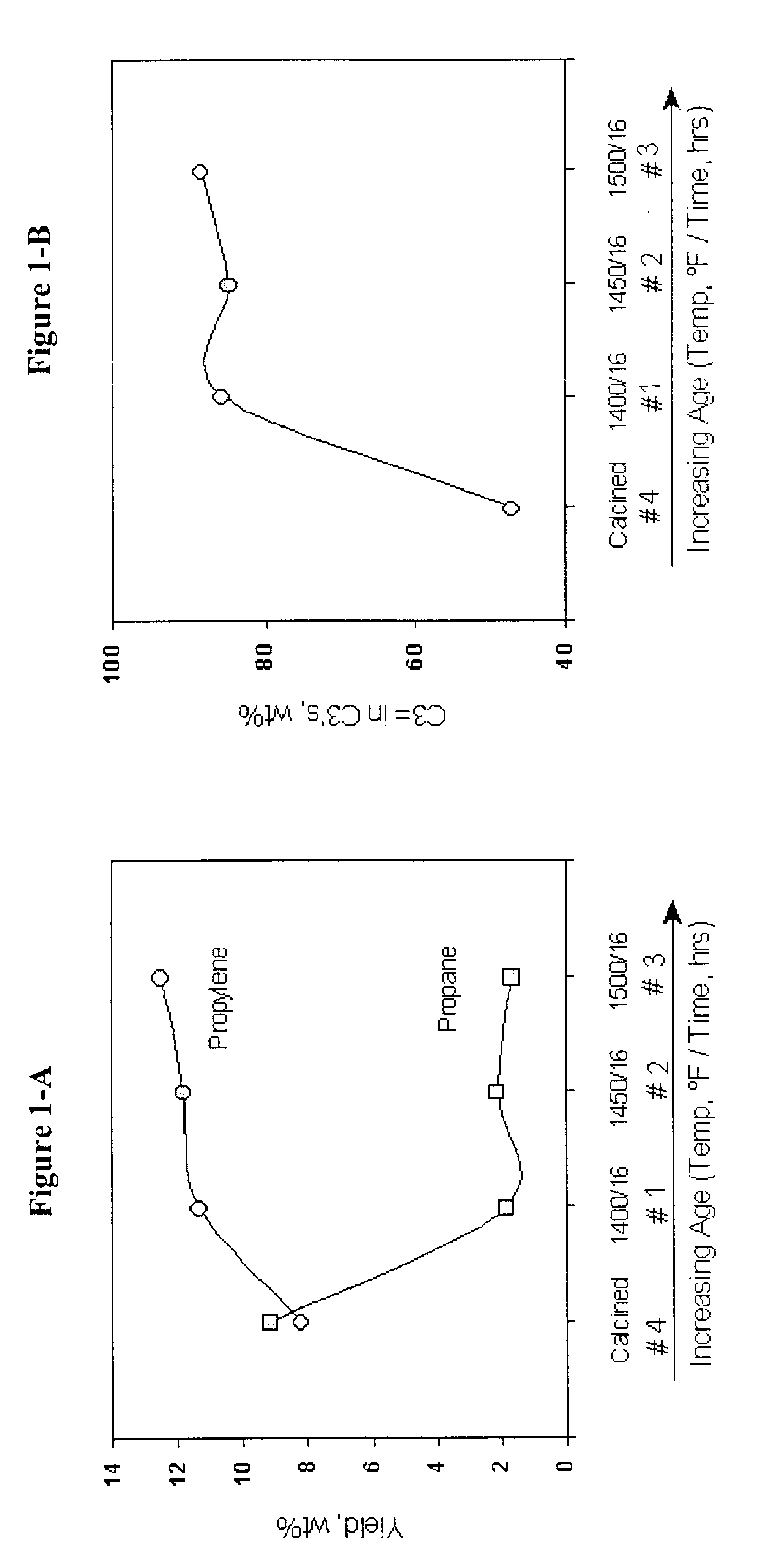

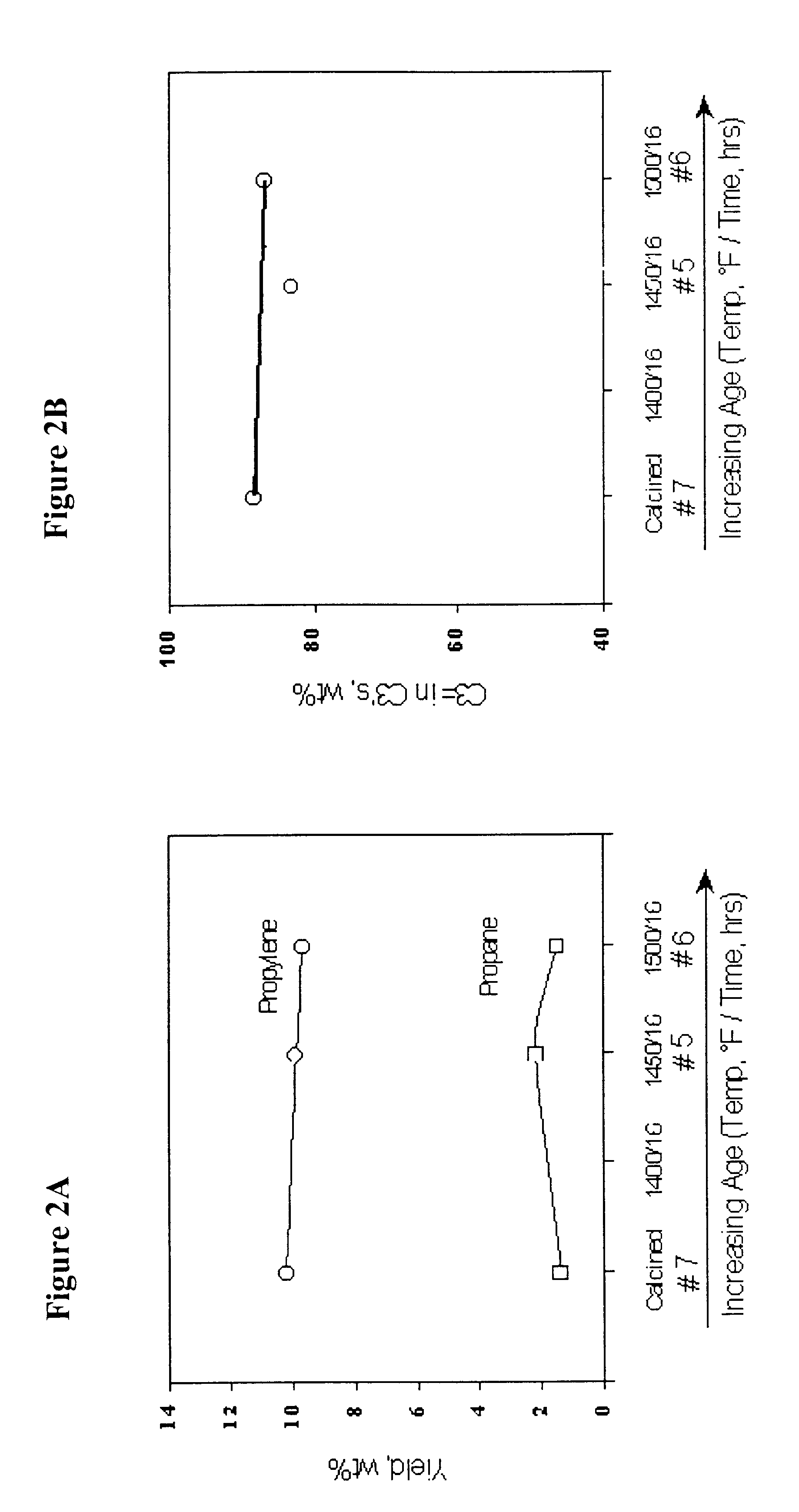

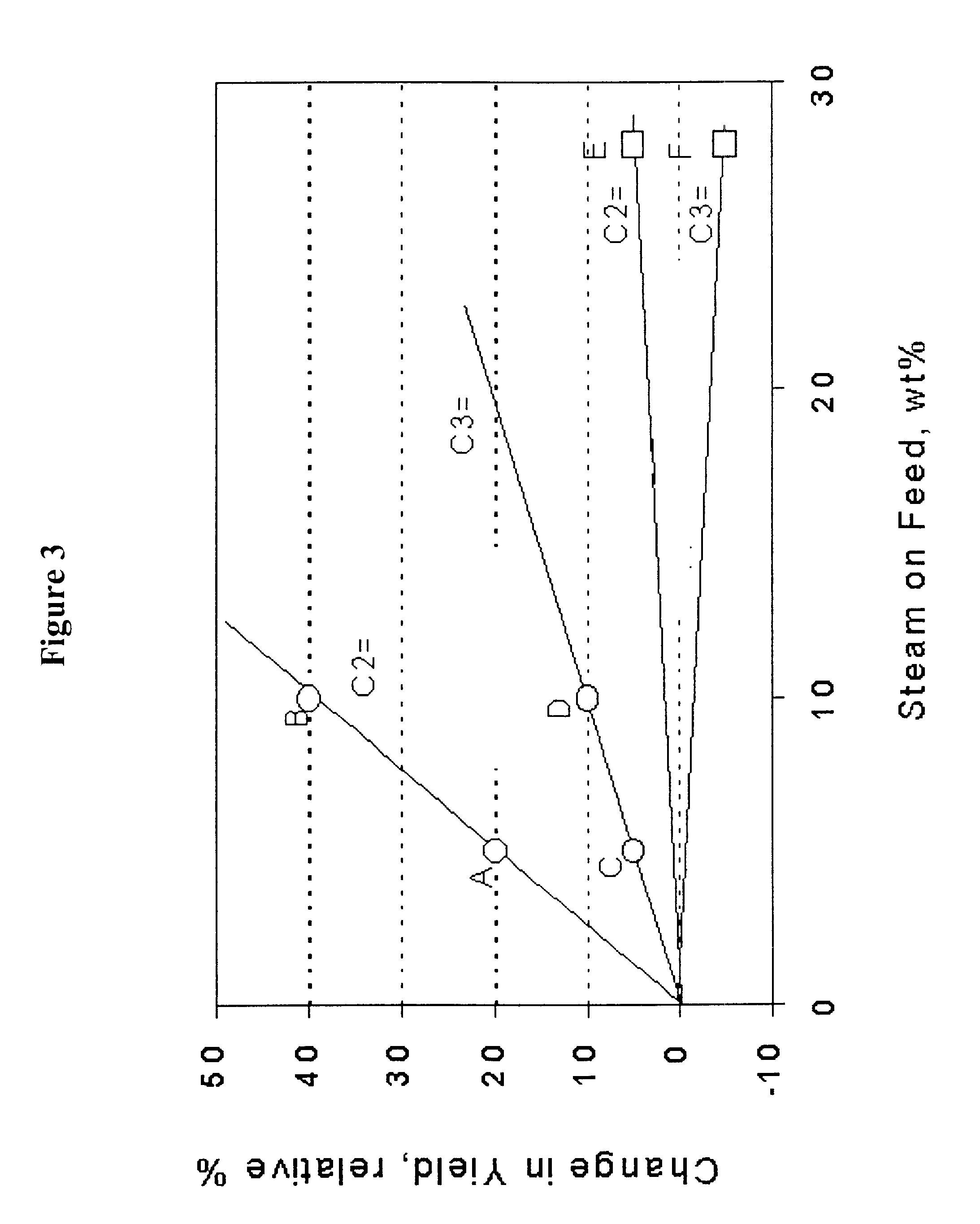

Process for selectively producing light olefins

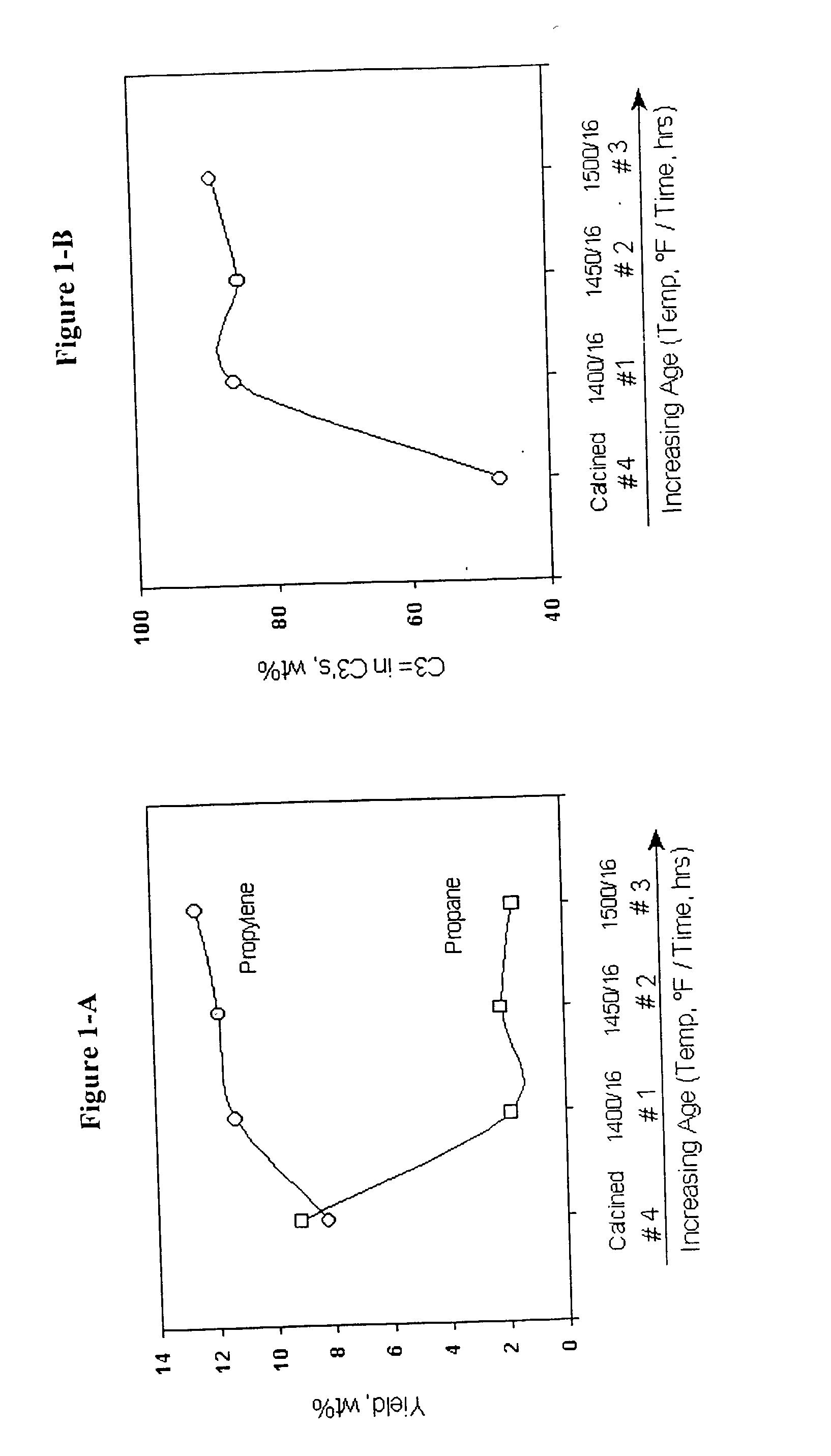

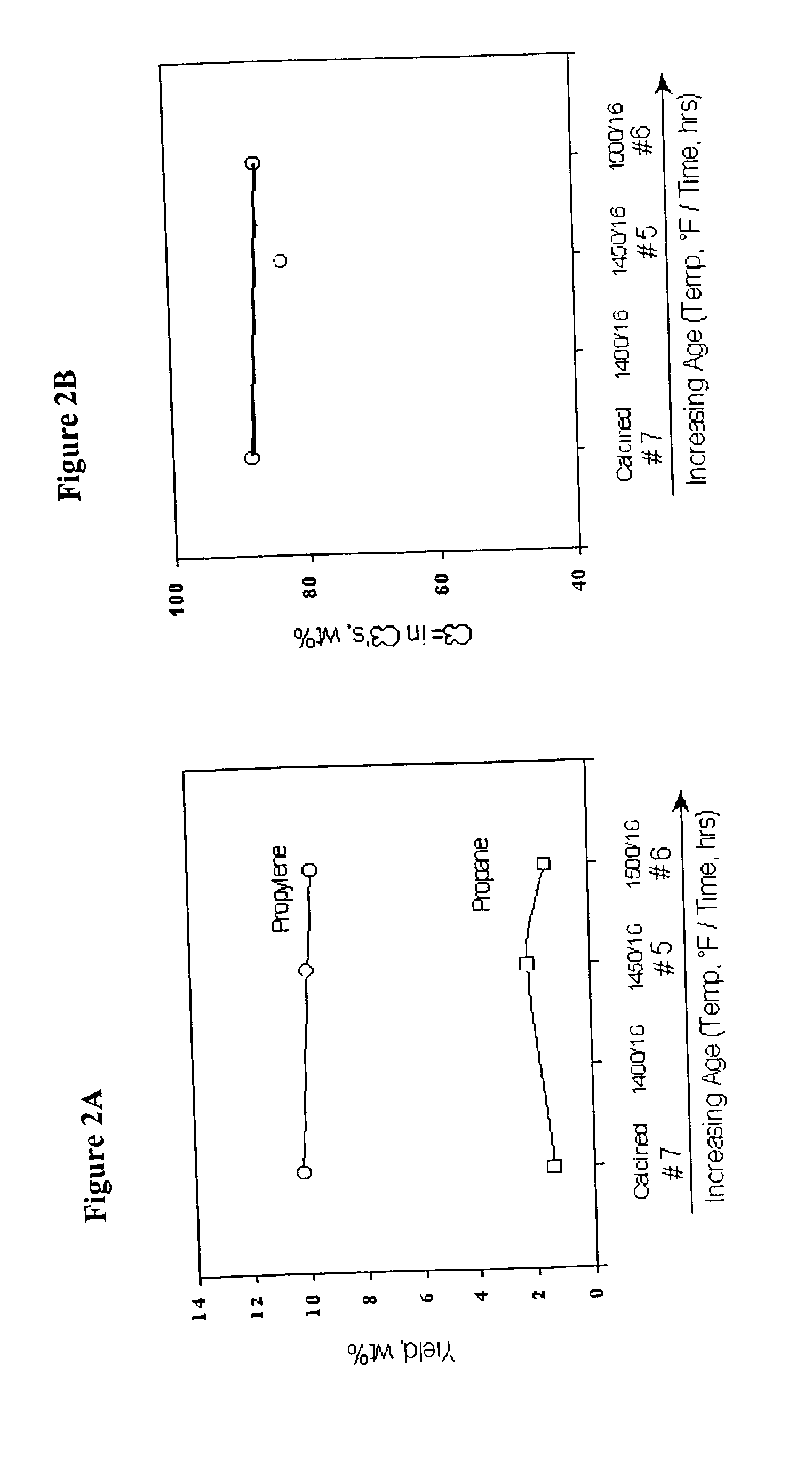

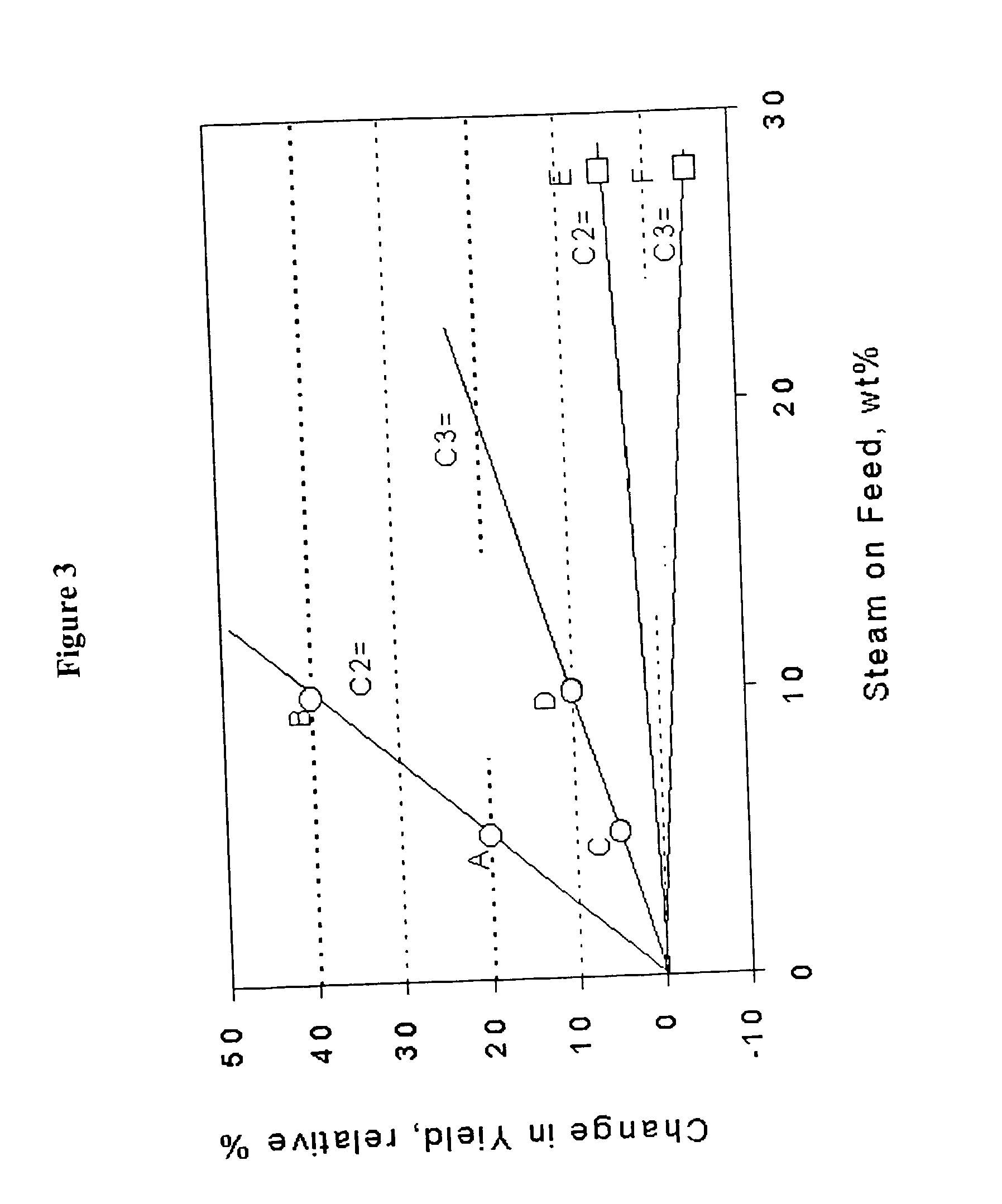

InactiveUS6455750B1Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaSteam activation

The invention is related to a catalyst and a process for selectively producing light (i.e., C2-C4) olefins from a catalytically cracked or thermally cracked naphtha stream. The naphtha stream is contacted with a catalyst containing from about 10 to 50 wt. % of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions. The catalysts do not require steam activation.

Owner:EXXONMOBIL CHEM PAT INC

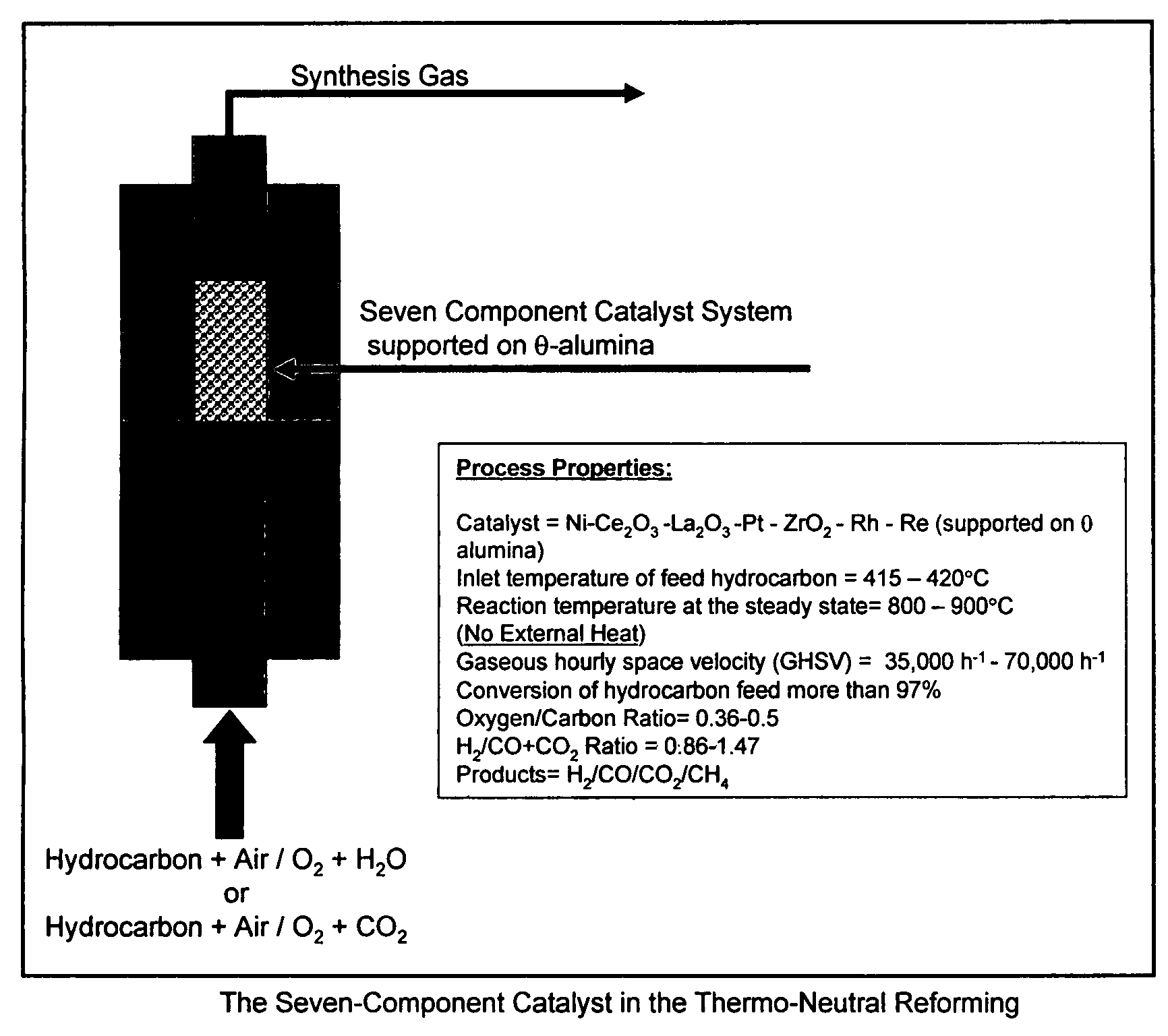

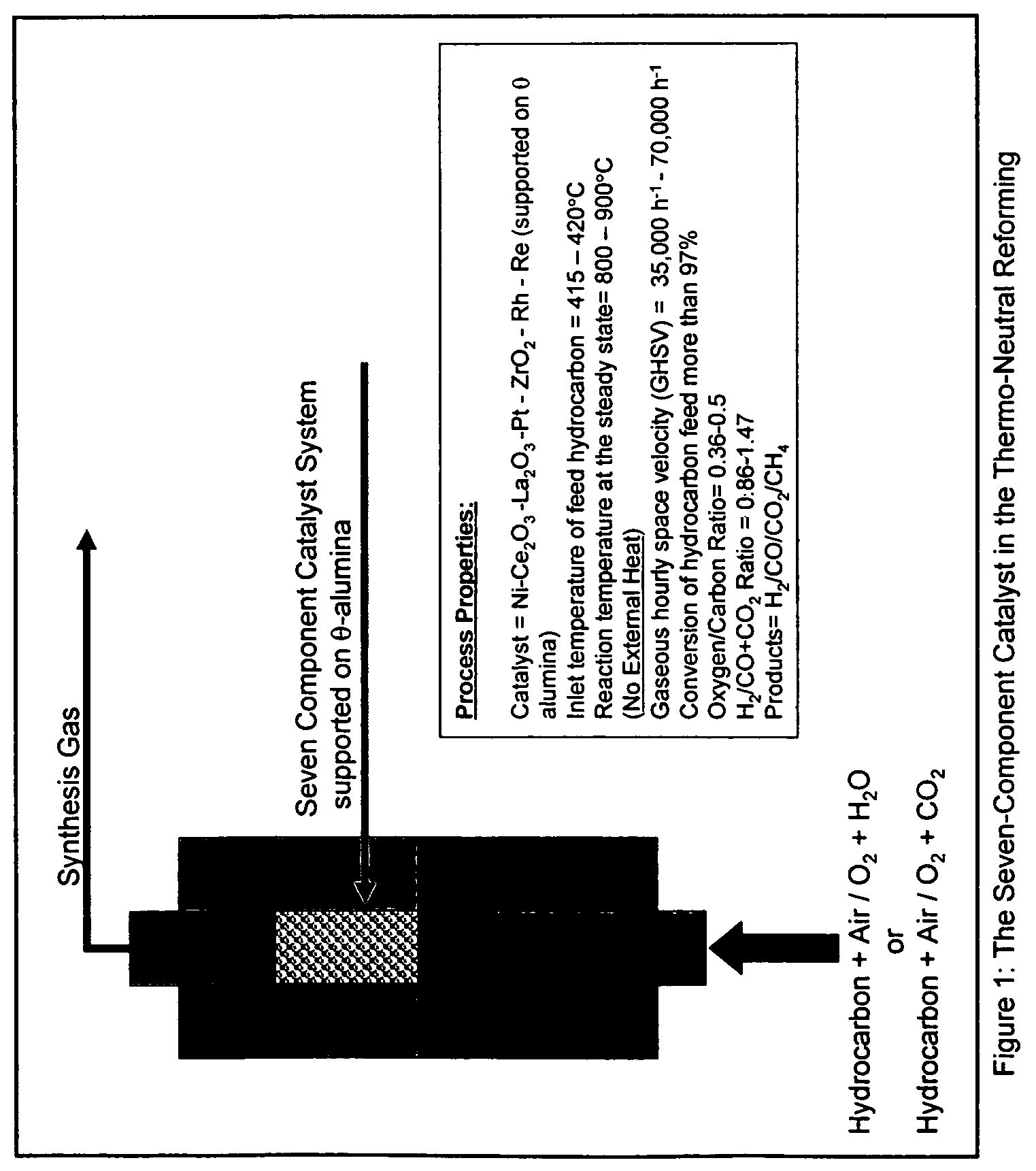

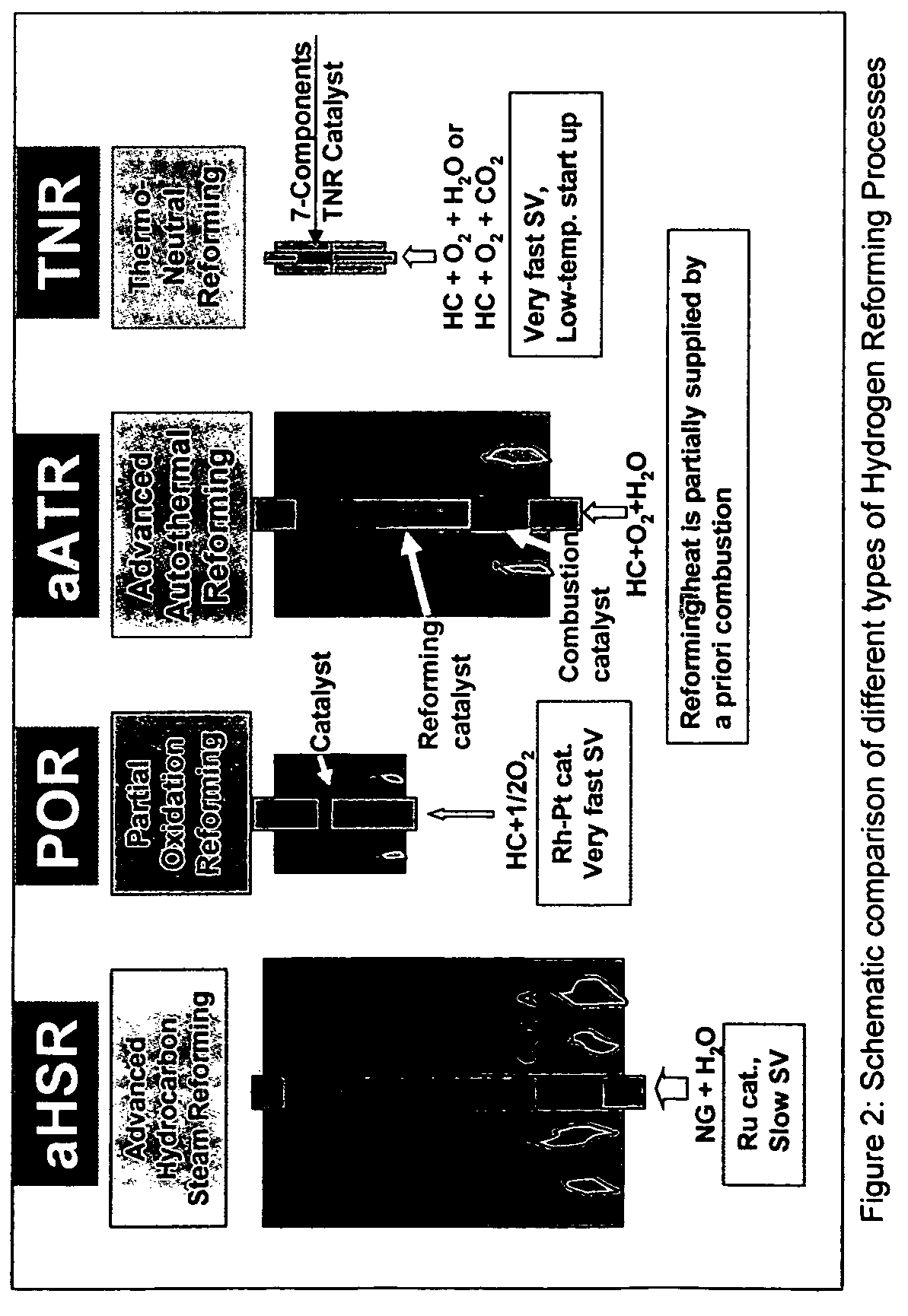

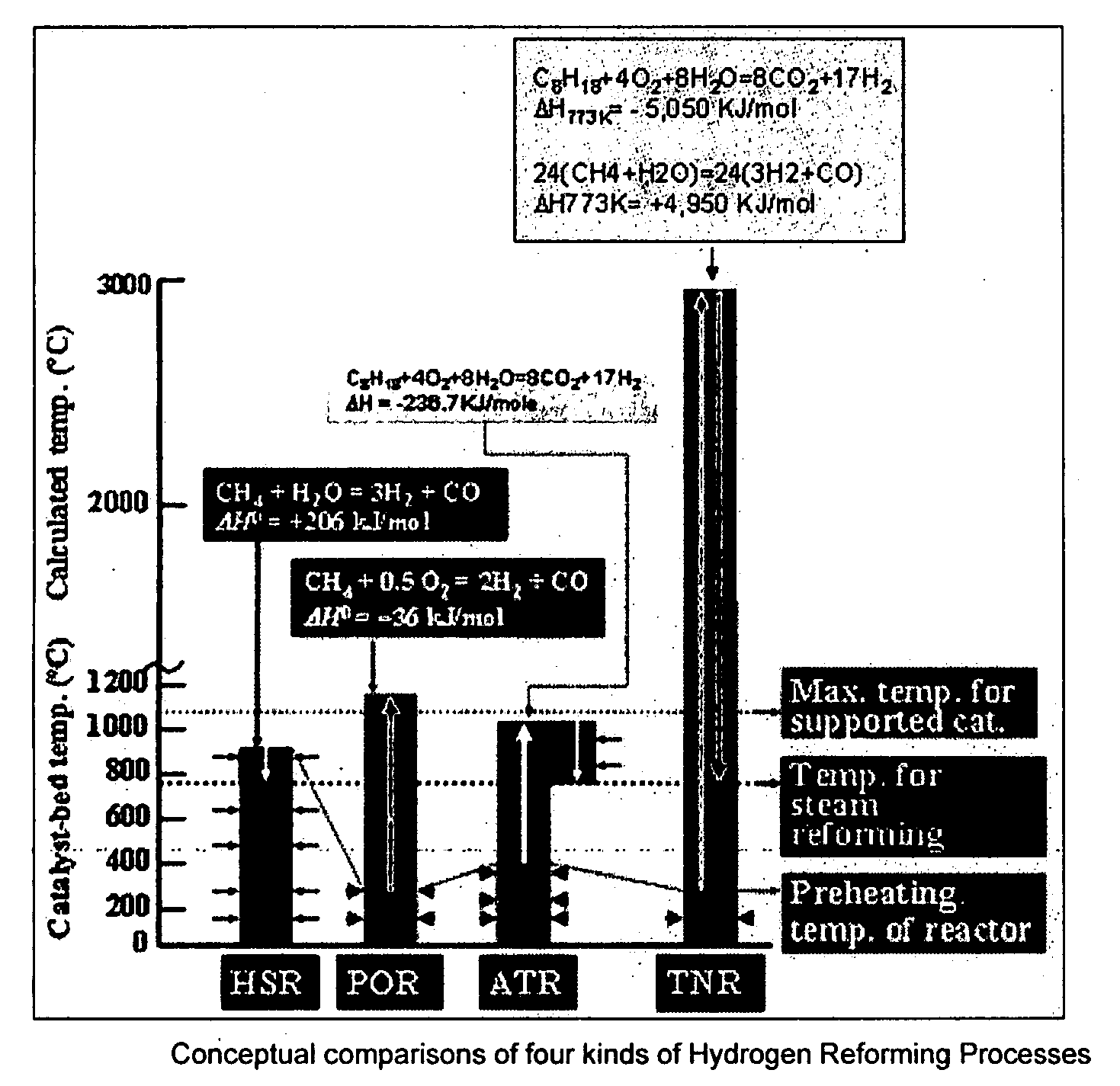

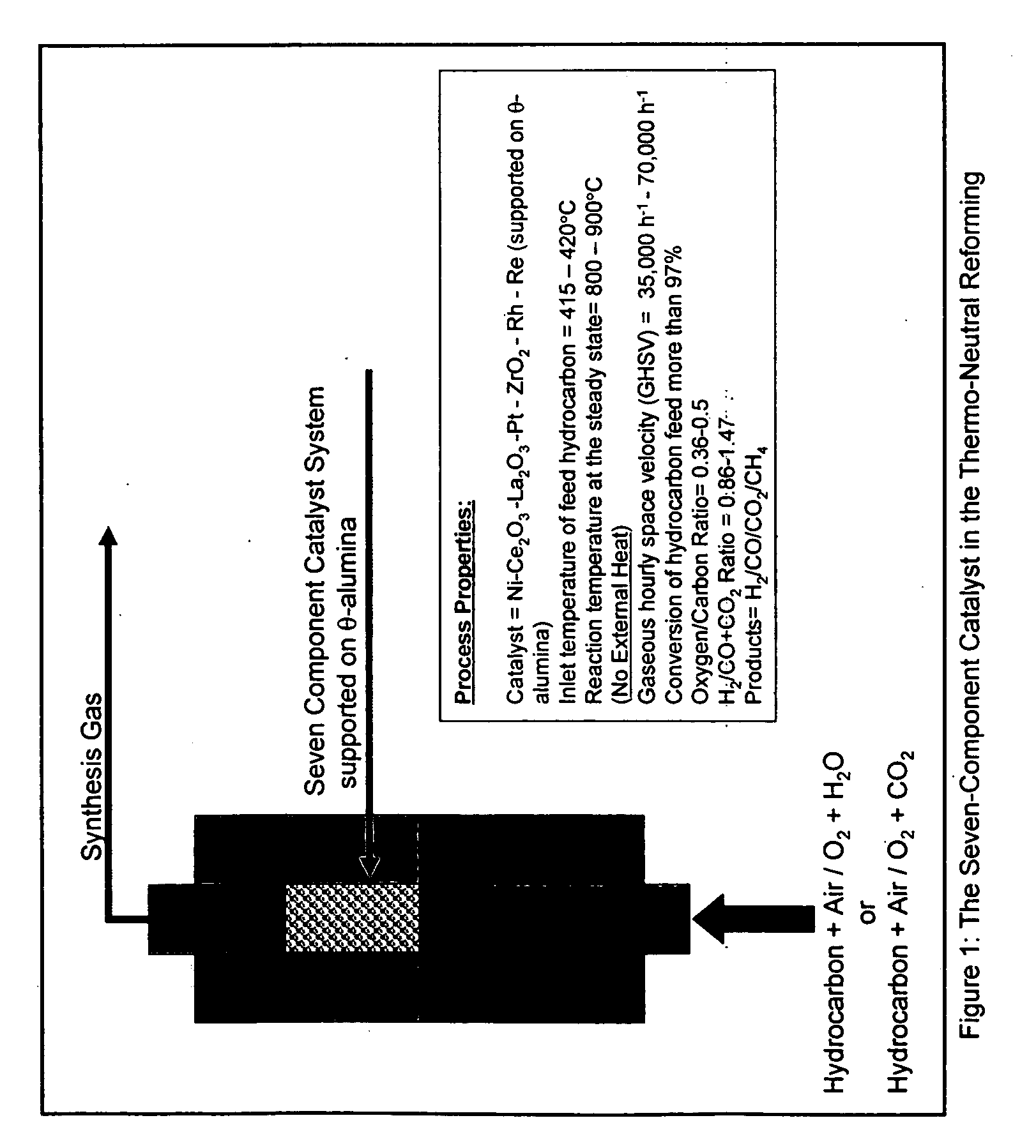

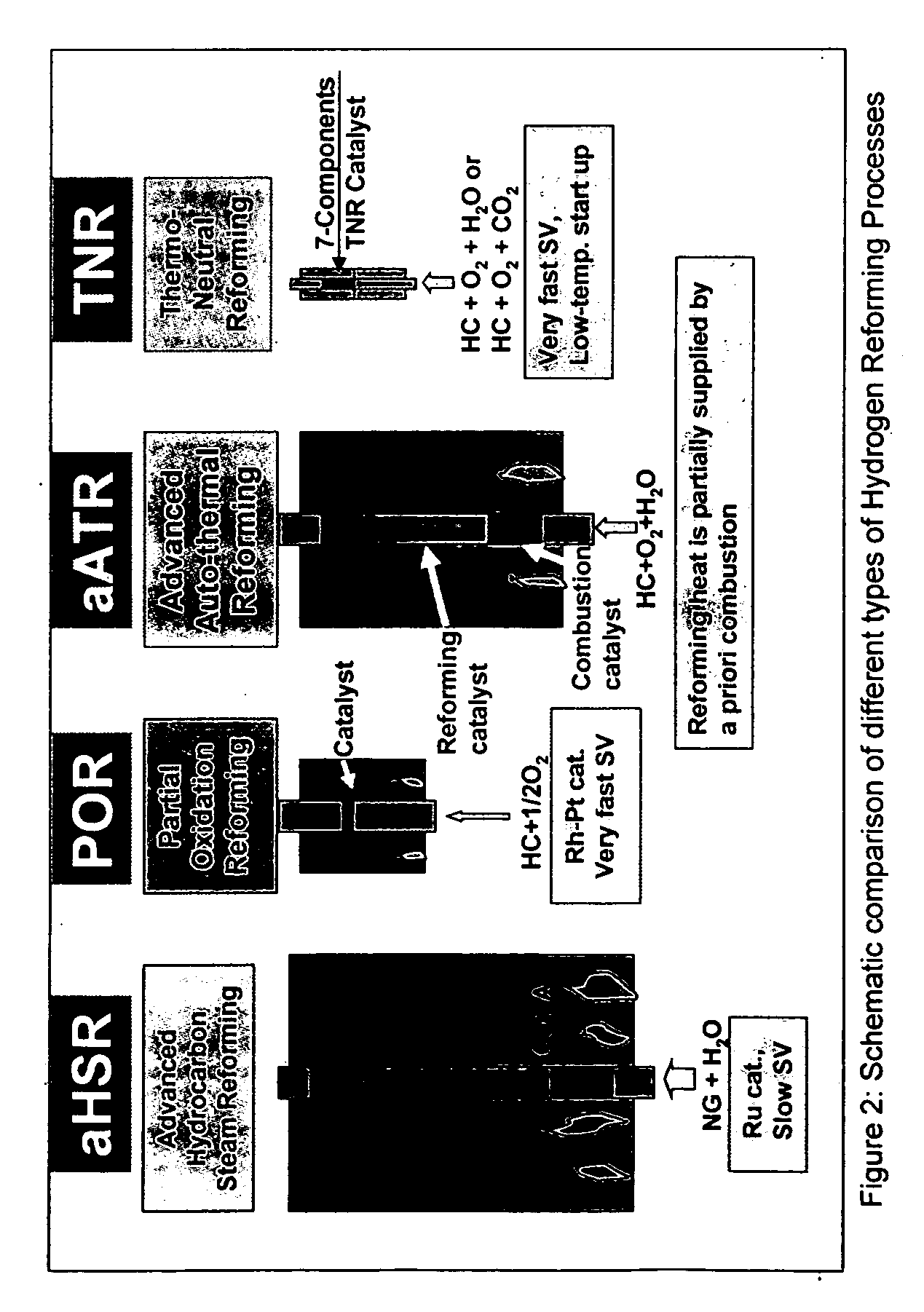

Oil-based thermo-neutral reforming with a multi-component catalyst

ActiveUS7700005B2Enhance the activity of the base metal-supported thermo-neutral reforming catalystProcesses liquid hydrocarbon fuels efficiently and reliablyHydrogenHydrocarbon from carbon oxidesSteam reformingCombustion

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Process for selectively producing propylene in fluid catalytic cracking process

InactiveCN1380898ATreatment with plural serial cracking stages onlyCatalytic crackingPtru catalystNaphtha

The invention discloses a method for selectively producing olefins from catalytic cracking or thermal cracking naphtha streams and producing polypropylene from the olefins. The naphtha stream is contacted with a catalyst containing 10-50 wt% crystalline zeolites having an average pore size of less than 0.7 nm under reaction conditions comprising a temperature of 500-650°C and a hydrocarbon partial pressure of 10-40 psia. The catalyst may be pre-coked with a carbonaceous feedstock. Additionally, carbonaceous feedstock for coking the catalyst may be added with the naphtha feedstock.

Owner:EXXONMOBIL CHEM PAT INC

Chemical processing using non-thermal discharge plasma

A method for activating chemical reactions using a non-thermal capillary discharge plasma (NT-CDP) unit or a non-thermal slot discharge plasma (NT-SDP) unit (collectively referred to as "NT-CDP / SDP"). The NT-CDP / SDP unit includes a first electrode disposed between two dielectric layers, wherein the first electrode and dielectric layers having at least one opening (e.g., capillary or a slot) defined therethrough. A dielectric sleeve inserted into the opening, and at least one second electrode (e.g., in the shape of a pin, ring, metal wire, or tapered metal blade) is disposed in fluid communication with an associated opening. A non-thermal plasma discharge is emitted from the opening when a voltage differential is applied between the first and second electrodes. Chemical feedstock to be treated is then exposed to the non-thermal plasma. This processing is suited for the following exemplary chemical reactions as (i) partial oxidation of hydrocarbon feedstock to produce functionalized organic compounds; (ii) chemical stabilization of a polymer fiber (e.g., PAN fiber precursor in carbon fiber production; (iii) pre-reforming of higher chain length petroleum hydrocarbons to generate a feedstock suitable for reforming; (iv) natural gas reforming in a chemically reducing atmosphere (e.g., ammonia or urea) to produce carbon monoxide and Hydrogen gas; or (v) plasma enhanced water gas shifting.

Owner:PLASMASOL CORP

Naphtha cracking and hydroprocessing process for low emissions, high octane fuels

InactiveUS6315890B1Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaLow emission

The invention is related to a two step process wherein the first step comprises cracking an olefinic naphtha resulting in a cracked product having a diminished total concentration of olefinic species. The second step comprises hydroprocessing at least a portion of the cracked product, especially a naphtha fraction, to provide a hydroprocessed cracked product having a reduced concentration of contaminant species but without a substantial octane reduction.

Owner:EXXONMOBIL CHEM PAT INC

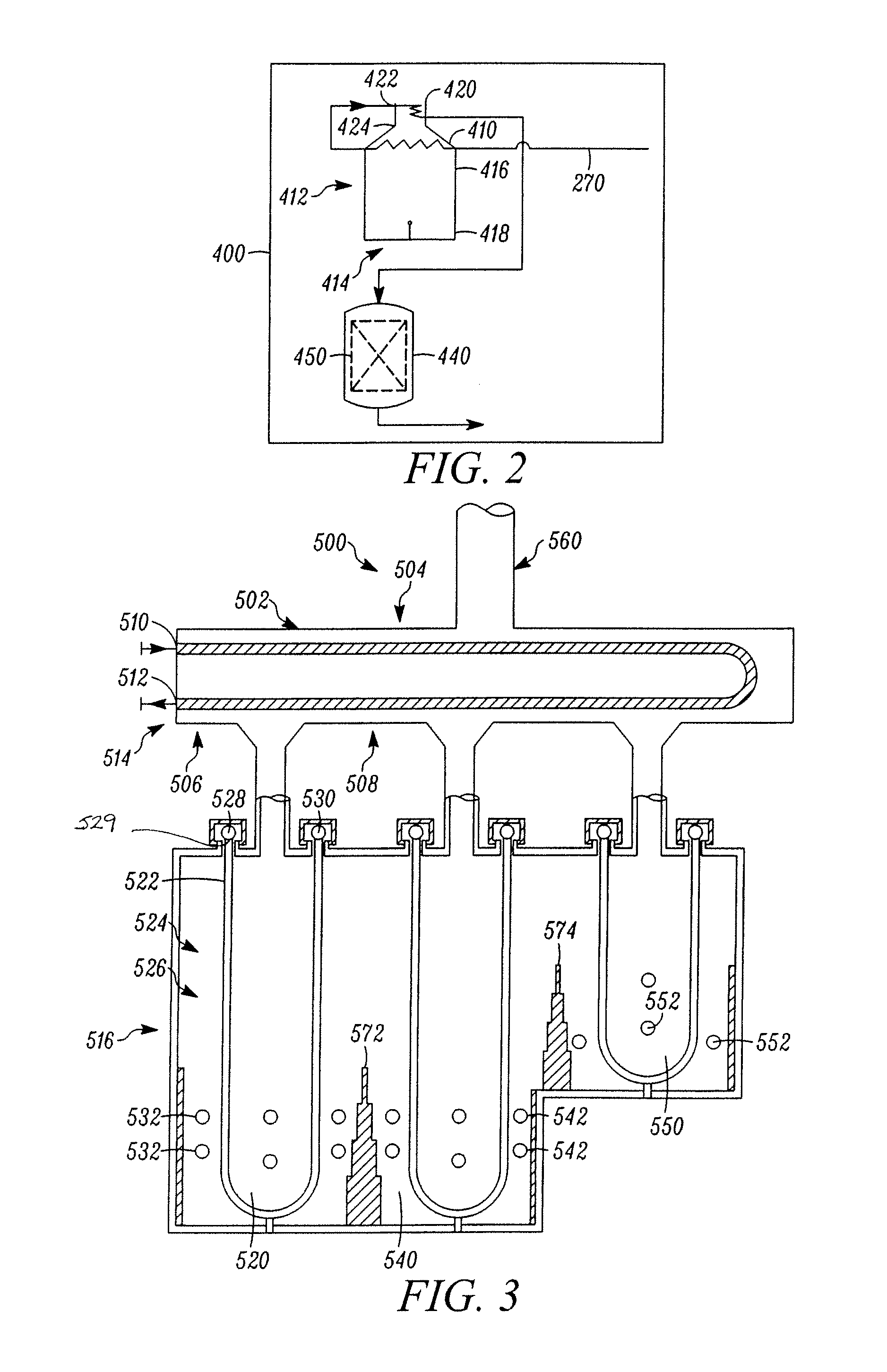

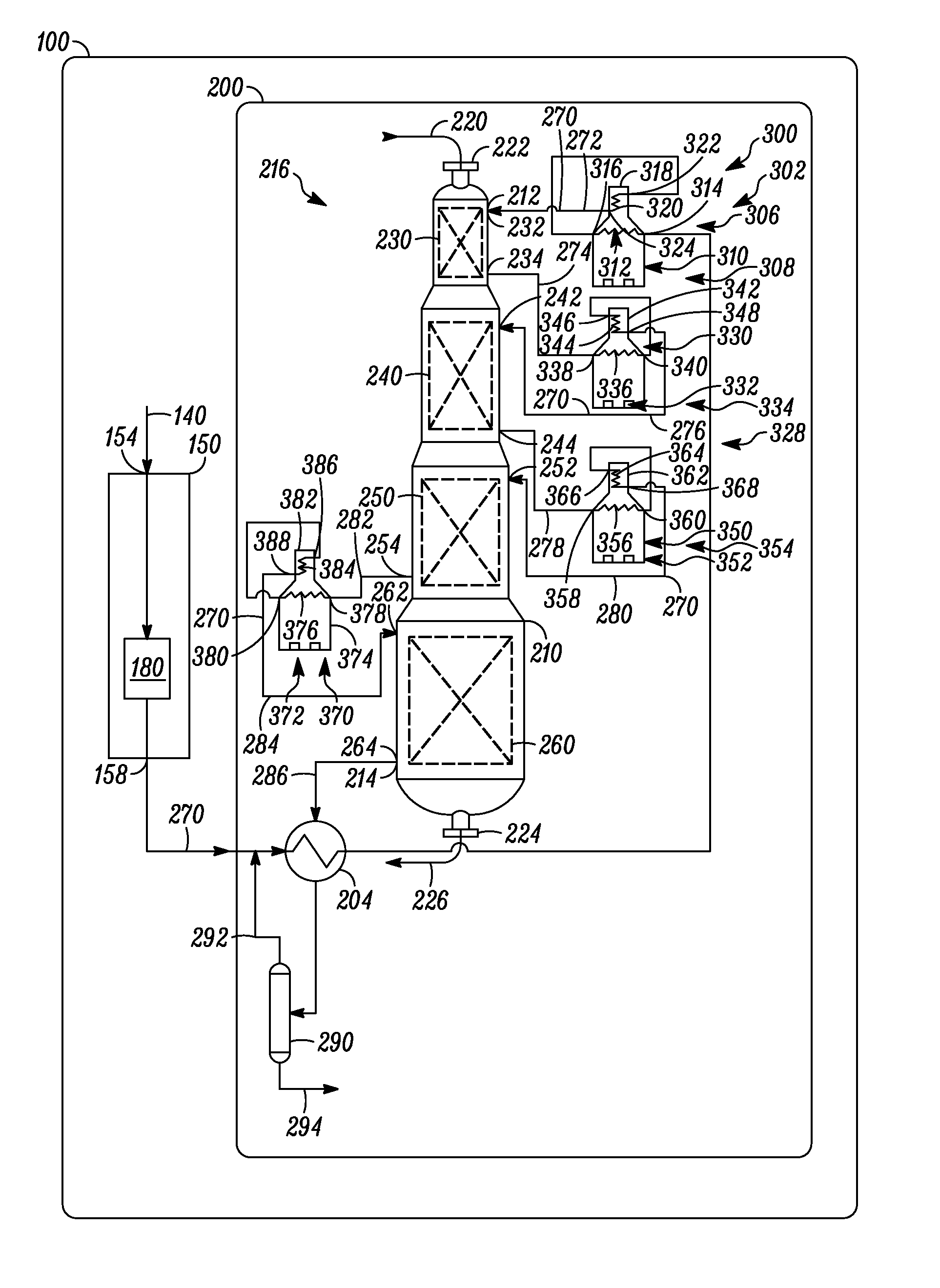

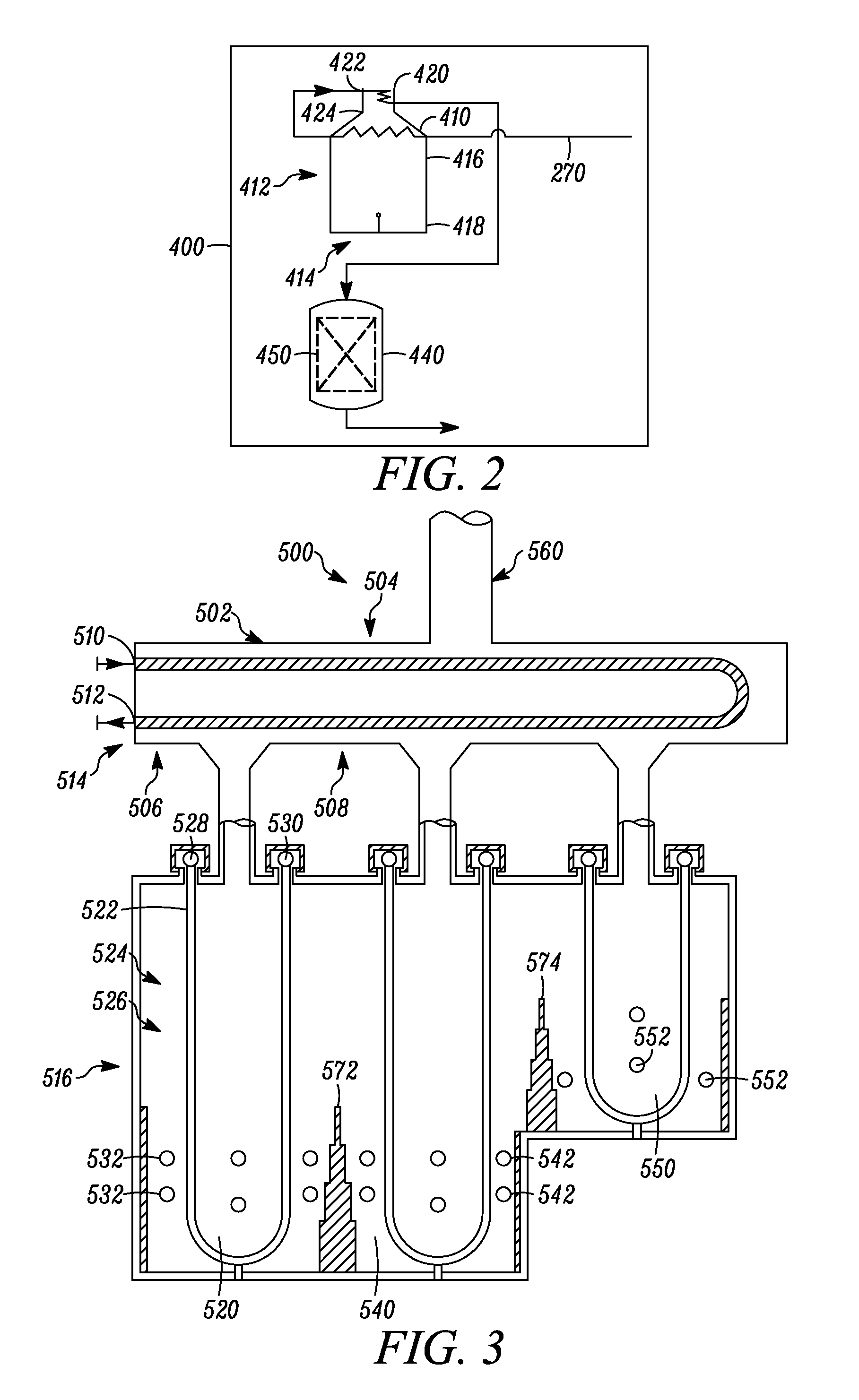

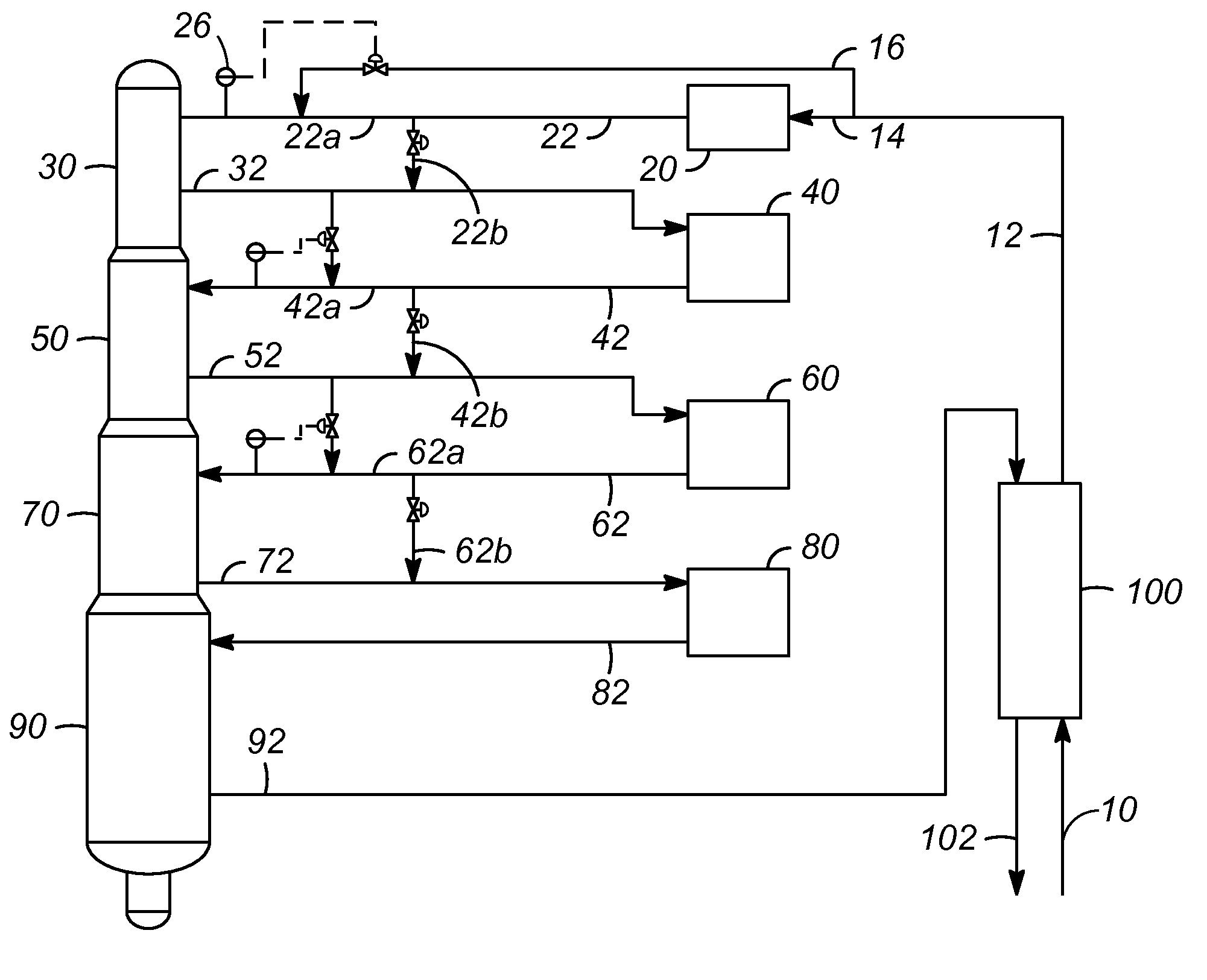

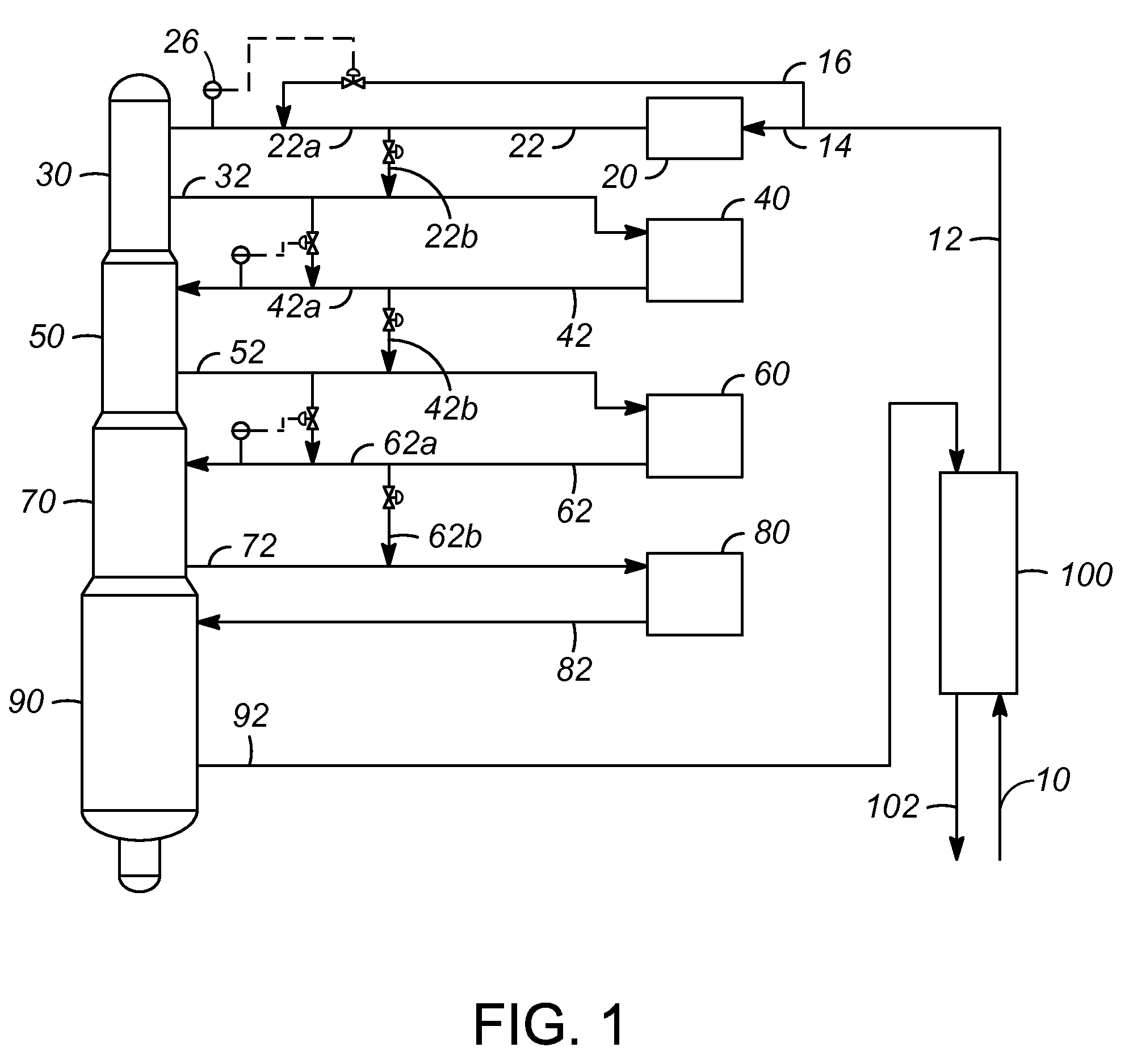

Process For Heating A Hydrocarbon Stream Entering A Reaction Zone With A Heater Convection Section

InactiveUS20080110801A1Lower cost of capitalLower catalyst costsCatalytic naphtha reformingThermal naphtha reformingReaction zoneConvection

An exemplary process can include passing a hydrocarbon stream through a reforming unit. The reforming unit may include a heater, which in turn generally includes a convection section and a radiant section, and a plurality of reforming reaction zones. Generally, the hydrocarbon stream is heated in the convection section for reacting in one of the reforming reaction zones to which the hydrocarbon stream is sent and the hydrocarbon stream is heated in the radiant section of the heater for reacting in the other reforming reaction zone to which the hydrocarbon stream is sent.

Owner:UOP LLC

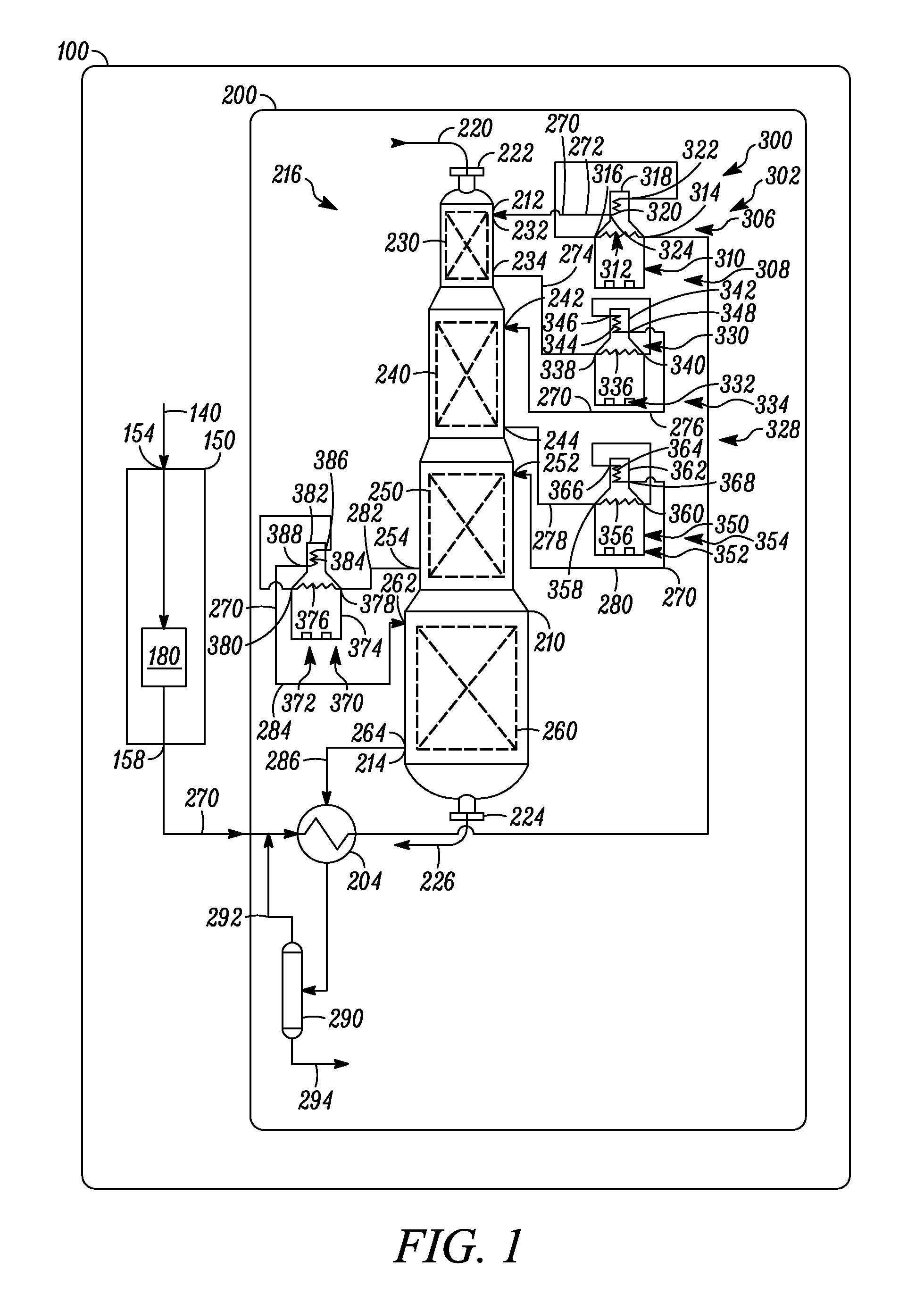

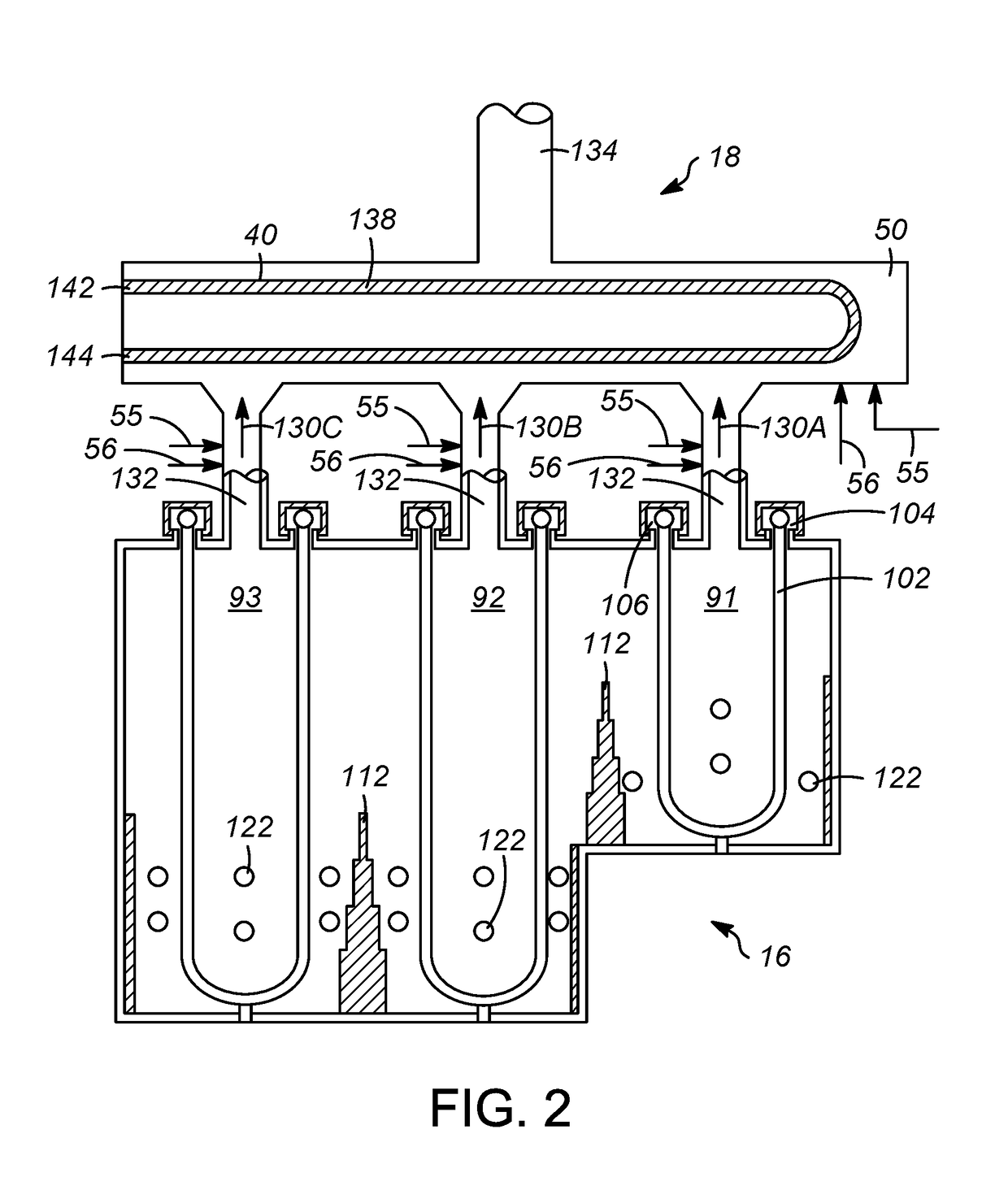

Fired heater for a hydrocarbon conversion process

ActiveUS8282814B2Low costShorten the timeThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonEngineeringInlet manifold

One exemplary embodiment of the present invention can be a fired heater for a hydrocarbon conversion process. The fired heater includes inlet and outlet headers or manifolds, a set of heater tubes with each heater tube having an inlet and an outlet, at least one restriction orifice adjacent the inlet of at least one heater tube. The restriction orifice may be within the inlet manifold and adjacent the inlet of a heater tube, or between the inlet manifold and the inlet to the heater tube. A process may include passing a hydrocarbon stream through the fired heater described herein during the course of operating a hydrocarbon conversion process.

Owner:UOP LLC

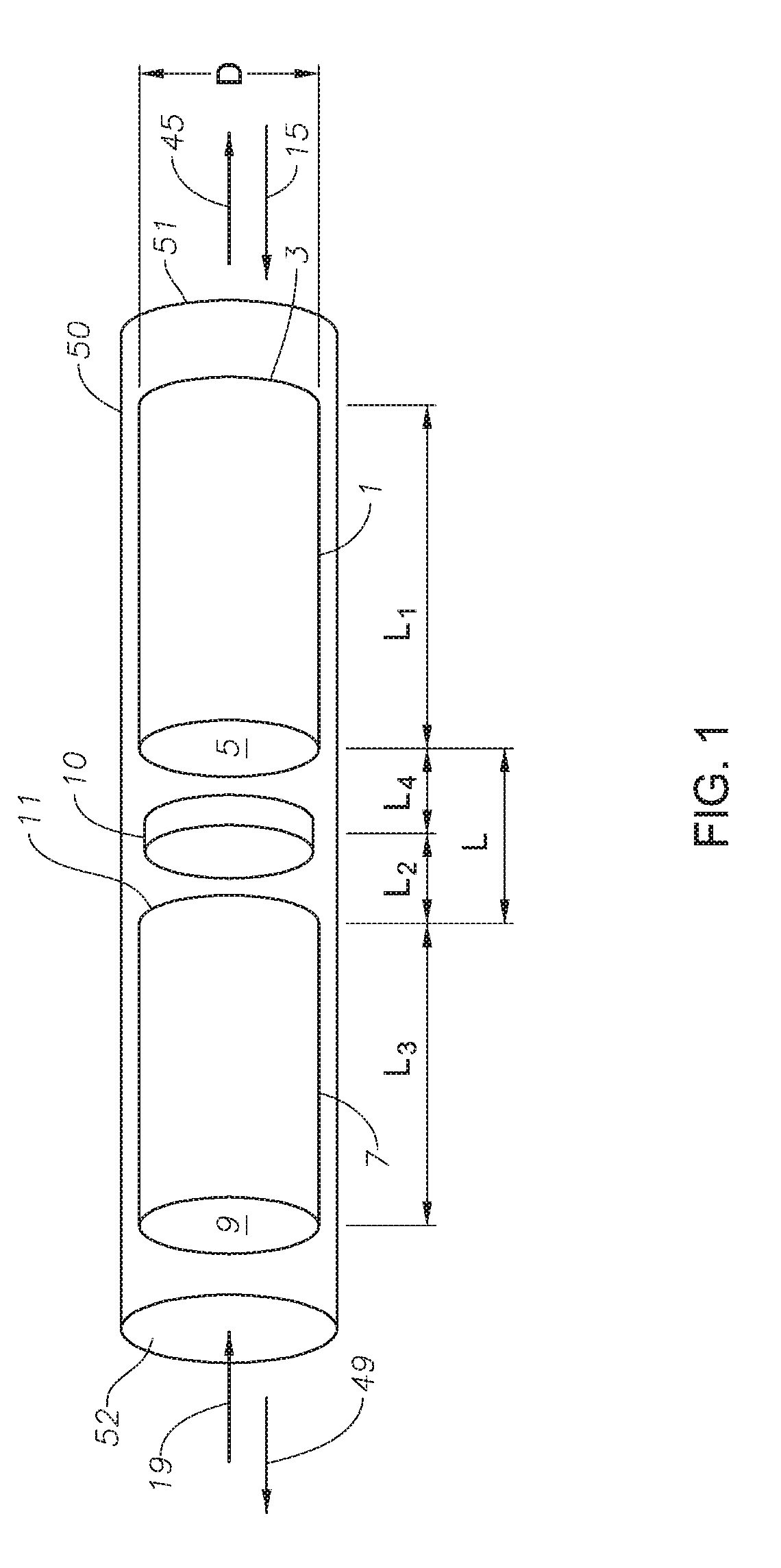

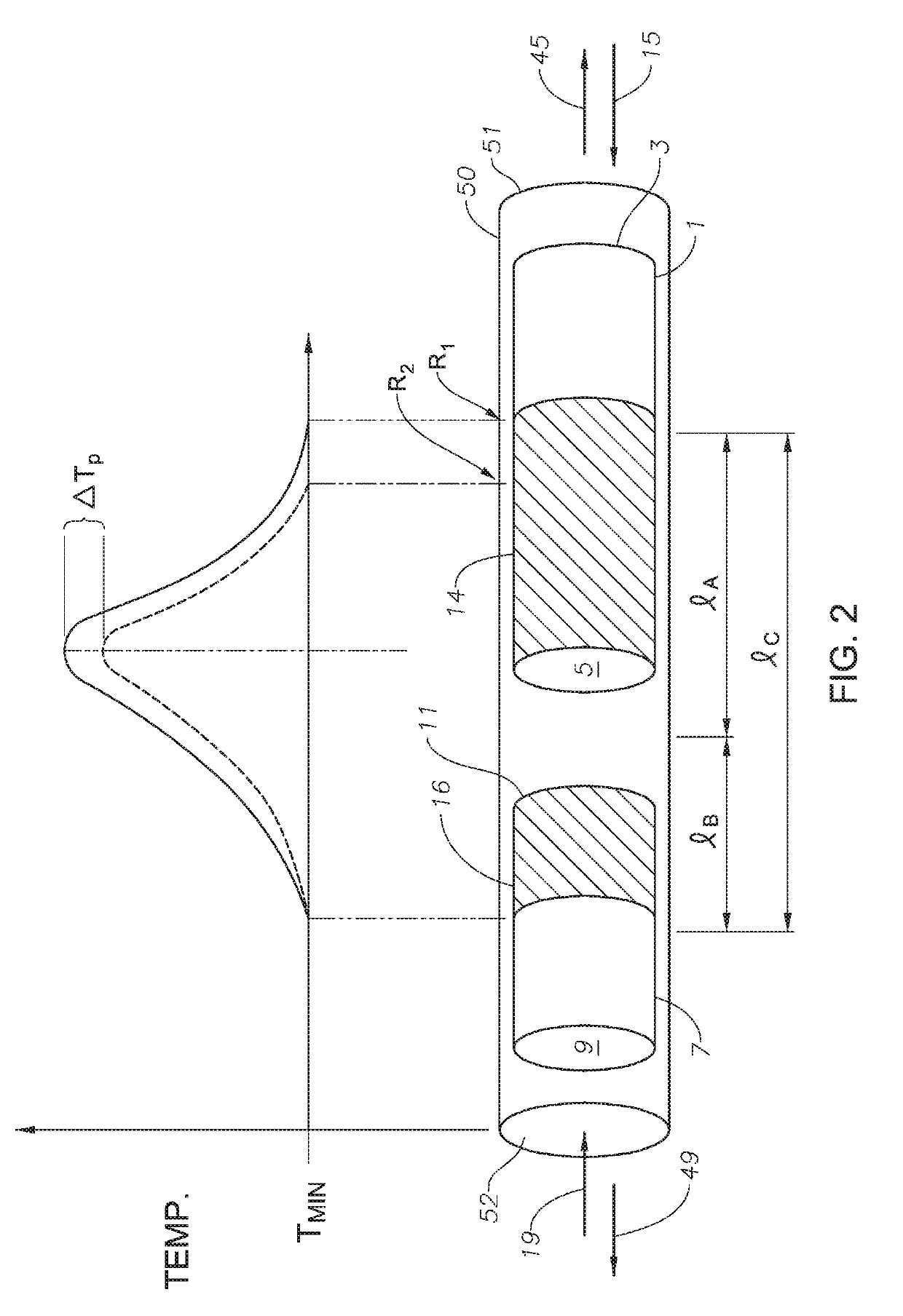

Process for heating a stream for a hydrocarbon conversion process

ActiveUS7740751B2Increase feed rateReduce wall temperatureCatalytic naphtha reformingThermal naphtha reformingThermodynamicsProcess engineering

One exemplary embodiment of the present invention can be a hydrocarbon conversion process. The process may include passing a hydrocarbon stream through at least one heater including at least one burner, a radiant section, and a convection section. Generally, the stream passes through the radiant section and then through the convection section before exiting the heater. Desirably, the hydrocarbon stream includes, in percent or parts by weight based on the total weight of hydrocarbons in the stream:C4 or less: less than about 0.5%,sulfur or sulfur containing compounds: less than about 1 ppm, andnitrogen or nitrogen containing compounds: less than about 1 ppm.Preferably, the sulfur or sulfur containing compounds and the nitrogen or nitrogen containing compounds are measured as, respectively, elemental sulfur or nitrogen.

Owner:UOP LLC

Apparatus and Process for Isomerizing a Hydrocarbon Stream

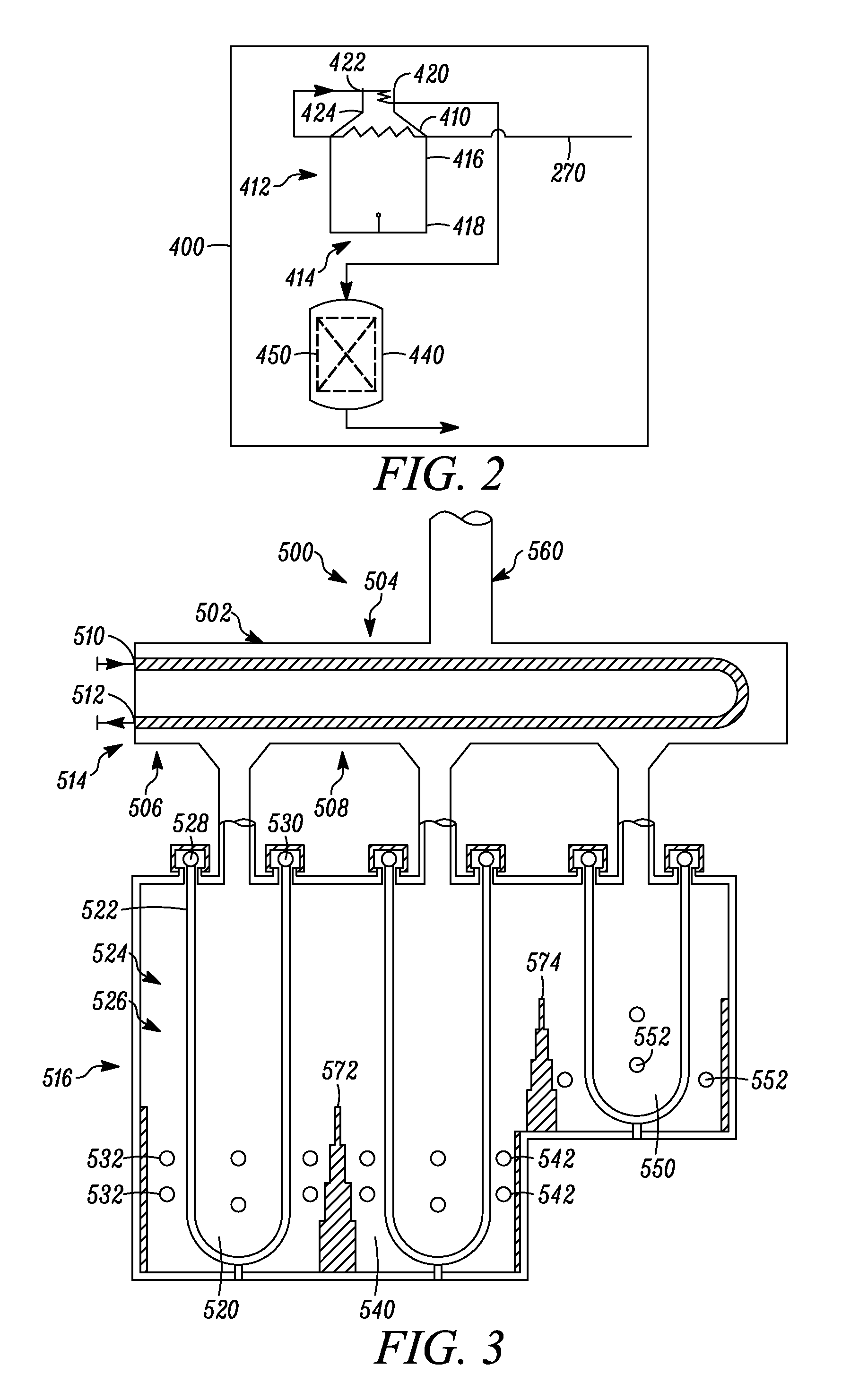

ActiveUS20100314292A1MiniaturizationMinimize upsetDewatering/demulsification with chemical meansRefining to change hydrocarbon structural skeletonReaction zoneHydrocarbon

One exemplary embodiment can be an apparatus for isomerizing a hydrocarbon stream rich in a C4 hydrocarbon and / or at least one of a C5 and C6 hydrocarbon. The apparatus can include: a first drier and a second drier adapted to receive a fluid including at least one reactant; and a reaction zone communicating with the first drier to receive the fluid including at least one reactant and with the second drier to receive the regenerant. Generally, the first drier operates at a first condition to dry the fluid including at least one reactant and the second drier operates at a second condition during regeneration with a regenerant. The regenerant can pass through a fluid tapering device for regulating the flow of the regenerant to the reaction zone.

Owner:UOP LLC

Process For Heating A Stream For A Hydrocarbon Conversion Process

ActiveUS20080110800A1Increase feed rateReduce pipe wall temperatureCatalytic naphtha reformingThermal naphtha reformingCombustorNitrogen

One exemplary embodiment of the present invention can be a hydrocarbon conversion process. The process may include passing a hydrocarbon stream through at least one heater including at least one burner, a radiant section, and a convection section. Generally, the stream passes through the radiant section and then through the convection section before exiting the heater. Desirably, the hydrocarbon stream includes, in percent or parts by weight based on the total weight of hydrocarbons in the stream:C4 or less: less than about 0.5%,sulfur or sulfur containing compounds: less than about 1 ppm, andnitrogen or nitrogen containing compounds: less than about 1 ppm. Preferably, the sulfur or sulfur containing compounds and the nitrogen or nitrogen containing compounds are measured as, respectively, elemental sulfur or nitrogen.

Owner:UOP LLC

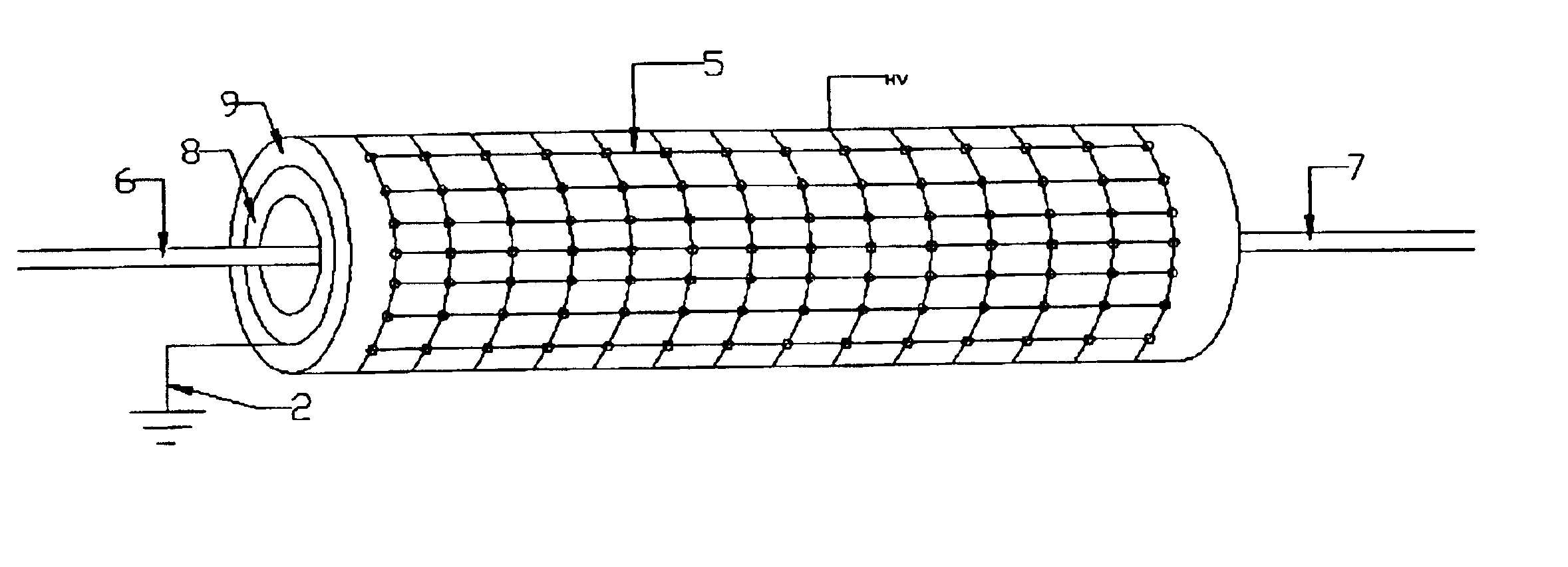

Electrode discharge, non-thermal plasma device (reactor) for the pre-treatment of combustion air

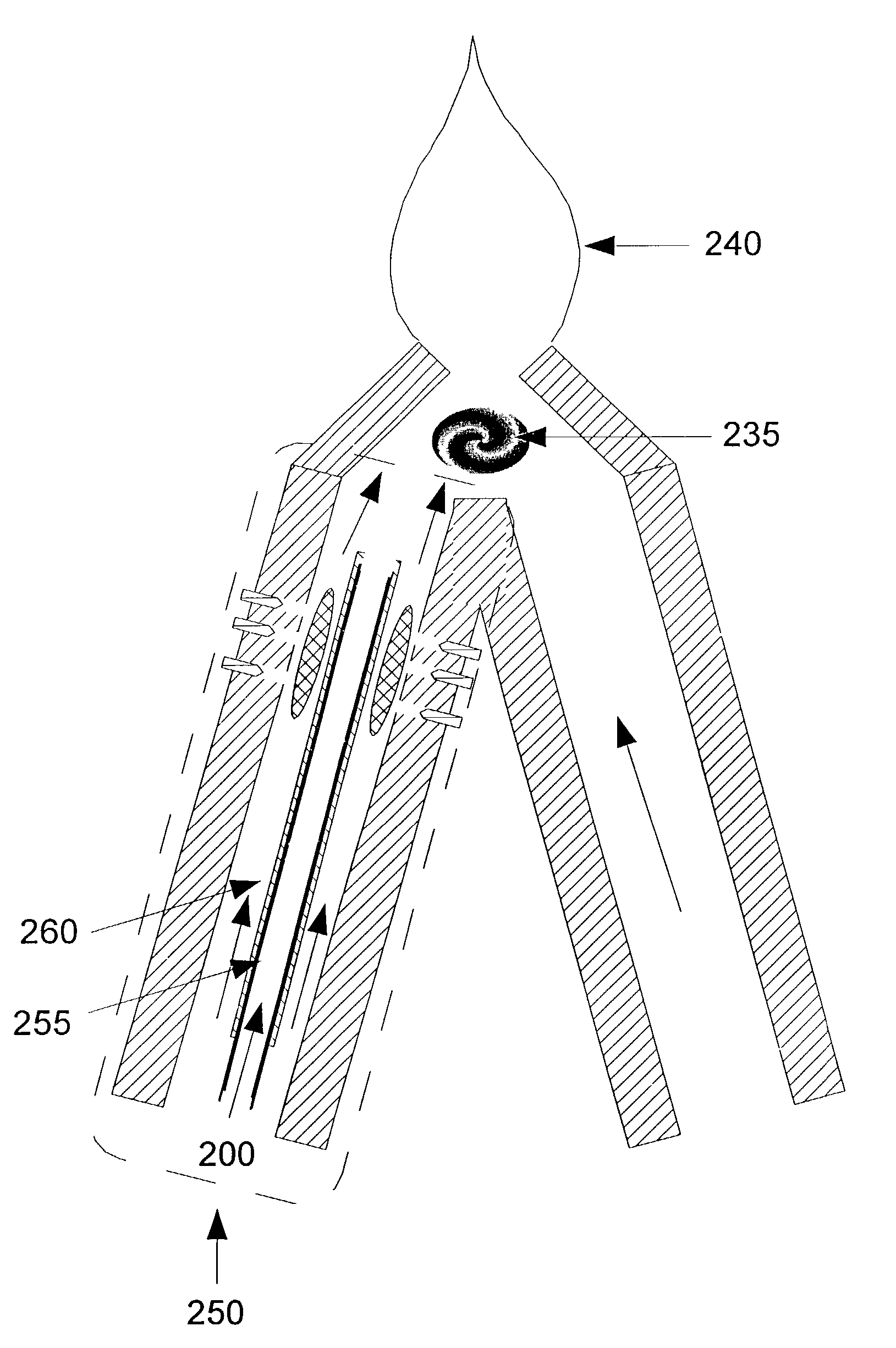

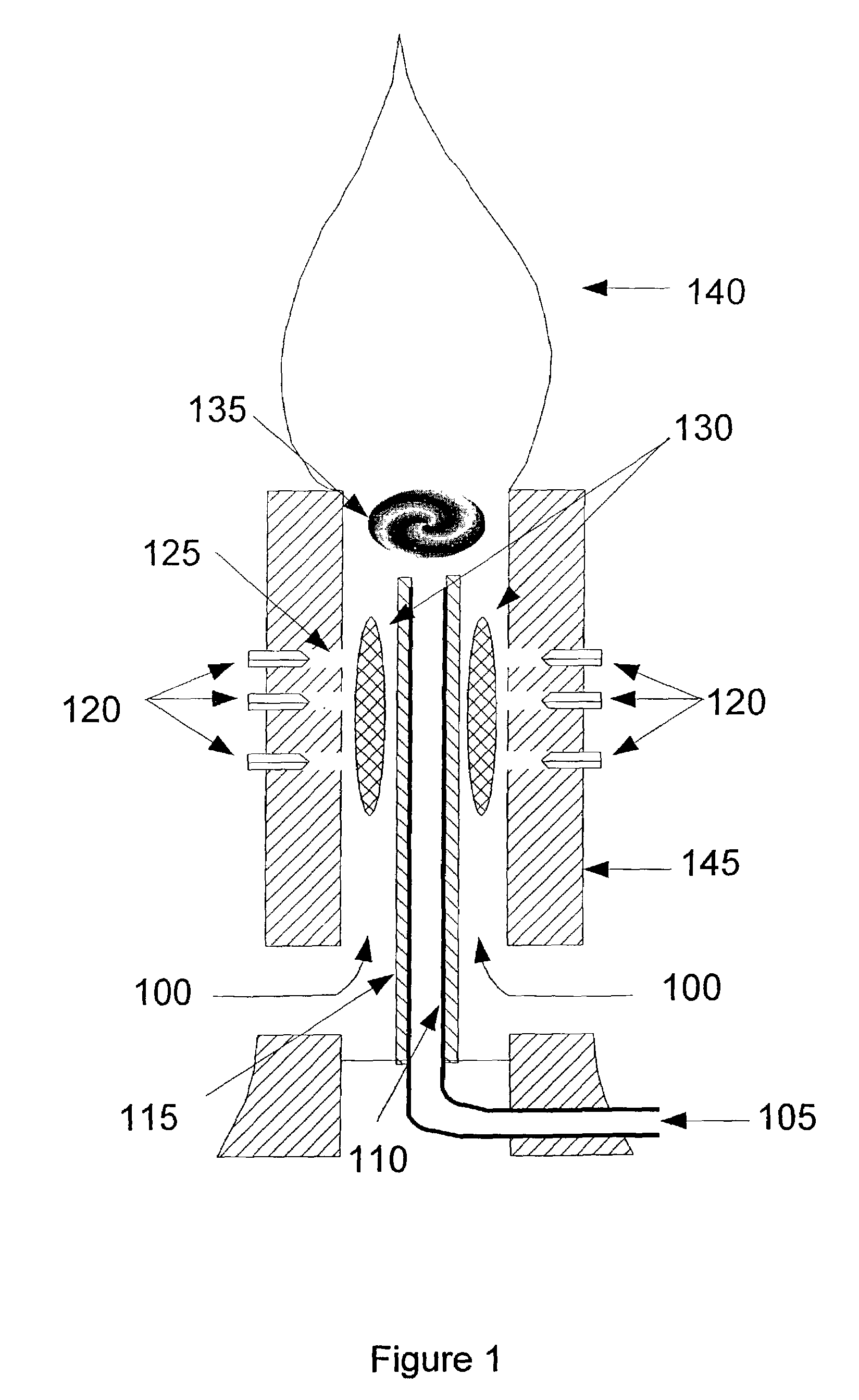

InactiveUS7029636B2Improve energy efficiencyImprove scalabilityHydrogenNitrogen compoundsElectricityCombustor

A device for the pre-treatment of combustion air by exposure to non-thermal plasma at substantially atmospheric pressure and a method for operating the same. The device includes an inner electrode having a longitudinal channel defined therein to receive a fuel. An outer dielectric layer is separated a predetermined distance from the inner electrode so as to form a non-thermal atmospheric pressure plasma region therebetween for receiving the combustion air to be treated. The outer dielectric has at least one opening (e.g., capillaries or slots) defined therethrough from which the non-thermal plasma is emitted. At least one outer electrode (e.g., in the shape of a pin or ring) is disposed in fluid communication with the at least one opening. The treated combustion air and fuel are combined in a mixing region. The pretreatment device may be disposed in an unsealed or a sealed combustion burner.

Owner:PLASMASOL CORP

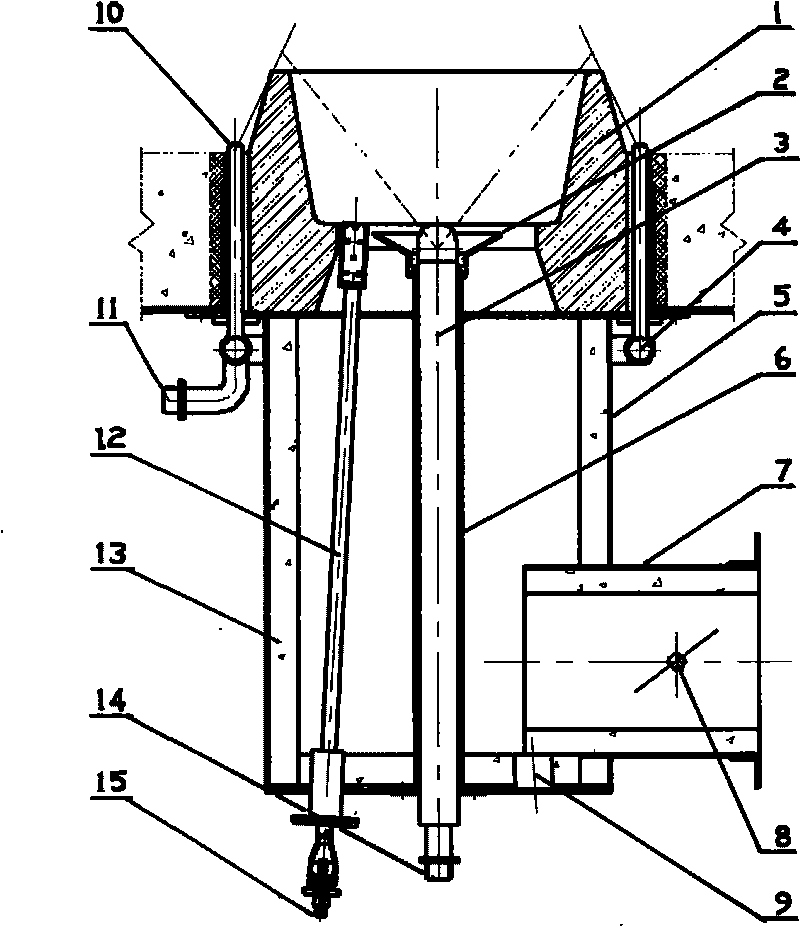

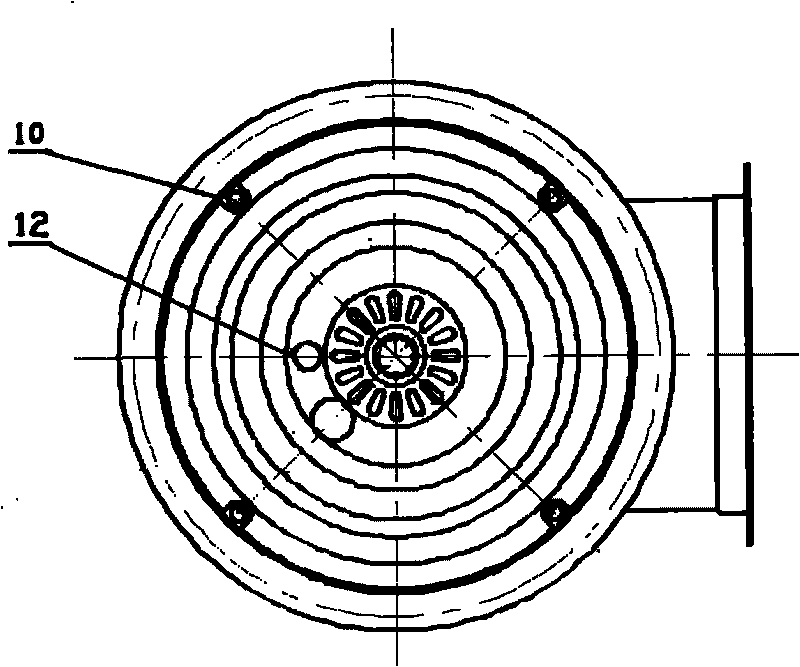

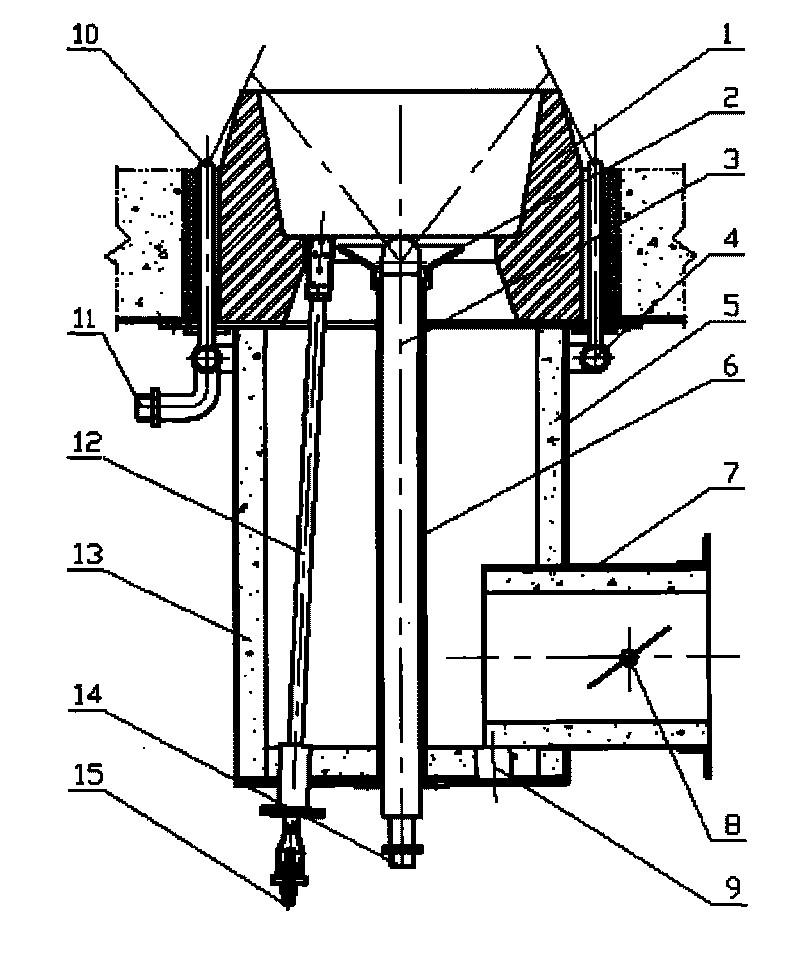

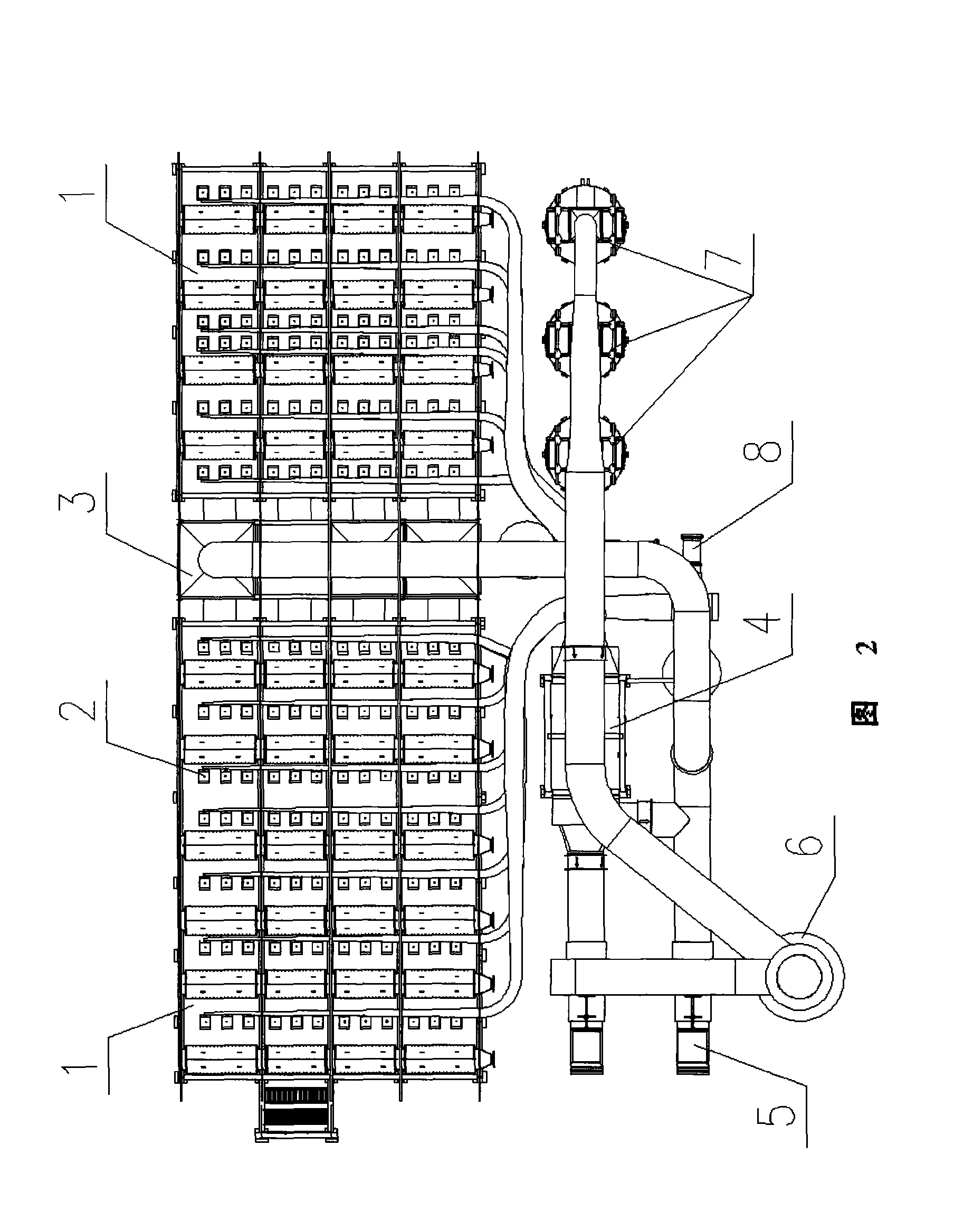

Forced-draft burner and method for regularizing side-combustion high-temperature preheated air of square-box furnace

InactiveCN101694297AReduce the maximum temperatureReduce generationThermal naphtha reformingIndirect carbon-dioxide mitigationCombustorBrick

The invention discloses forced-draft burner and method for regularizing side-combustion high-temperature preheated air of a square-box furnace. The burner is provided with two independent grades of gas wheels; a main gas gun 3 is arranged in the center of the burner and the gas blower of the gas gun is communicated with a combustion channel consisting of flam path bricks 1, that is to say, the gas blower of the gas gun is communicated with a primary combustion area; a combustion air channel is communicated with the center of the burner; and an air adjustment butterfly vale 8 is arranged for controlling the quantity of combustion air; all combustion air enters the burner via the combustion air channel and is mixed with the gas blown out of the main gas gun 3 for combustion together in the combustion channel consisting of the flame path bricks 1; a second-level gas distribution ring 4 is arranged and communicated with a second-level gas source; and a plurality of second-level gas guns 10 are arranged on the second-level gas distribution ring 4 and around the outer wall of the flame bricks of the burner. By adopting graded combustion and flue backflow technologies, the invention can reduce the generation of nitric oxides and has the advantages of full combustion, energy saving, environmental protection and high efficiency.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

Apparatus and Process for Isomerizing a Hydrogen Stream

ActiveUS20100314291A1MiniaturizationMinimize upsetRefining to change hydrocarbon structural skeletonHydrocarbon distillationHydrogenReaction zone

One exemplary embodiment can be an apparatus for isomerizing a hydrocarbon stream rich in a C4 hydrocarbon and / or at least one of a C5 and C6 hydrocarbon. The apparatus can include: a first drier and a second drier adapted to receive a fluid including at least one reactant; and a reaction zone communicating with the first drier to receive the fluid including at least one reactant and with the second drier to receive the regenerant. Generally, the first drier operates at a first condition to dry the fluid including at least one reactant and the second drier operates at a second condition during regeneration with a regenerant. The regenerant is displaced from the drier using a down-flow regenerant displacement assembly.

Owner:UOP LLC

Process for selectively proudcing C3 olefins in fluid catalytic cracking process

InactiveCN1380899ATreatment with plural serial cracking stages onlyCatalytic crackingNaphthaPartial pressure

The invention discloses a method for producing propylene from catalytic cracking or thermal cracking naphtha stream. The naphtha stream is contacted with a catalyst comprising 10-50 wt% crystalline zeolites having an average pore size of less than 0.7 nm under reaction conditions comprising a temperature of 500-650°C and a hydrocarbon partial pressure of 10-40 psia. A separate stream containing aromatics can be fed with the naphtha stream.

Owner:EXXONMOBIL CHEM PAT INC

Process for selectively producing light olefins in a fluid catalytic cracking process

InactiveCN1299341ATreatment with plural serial cracking stages onlyCatalytic crackingNaphthaFluidized bed

Disclosed is a process for selectively producing C2-C4 olefins from a catalytically cracked or thermally cracked naphtha stream. The naphtha stream is contacted with a catalyst containing from about 10 to 50 wt.% of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions which include temperatures from about 500 to 650 DEG C and a hydrocarbon partial pressure from about 10 to 40 psia.

Owner:EXXON RES & ENG CO

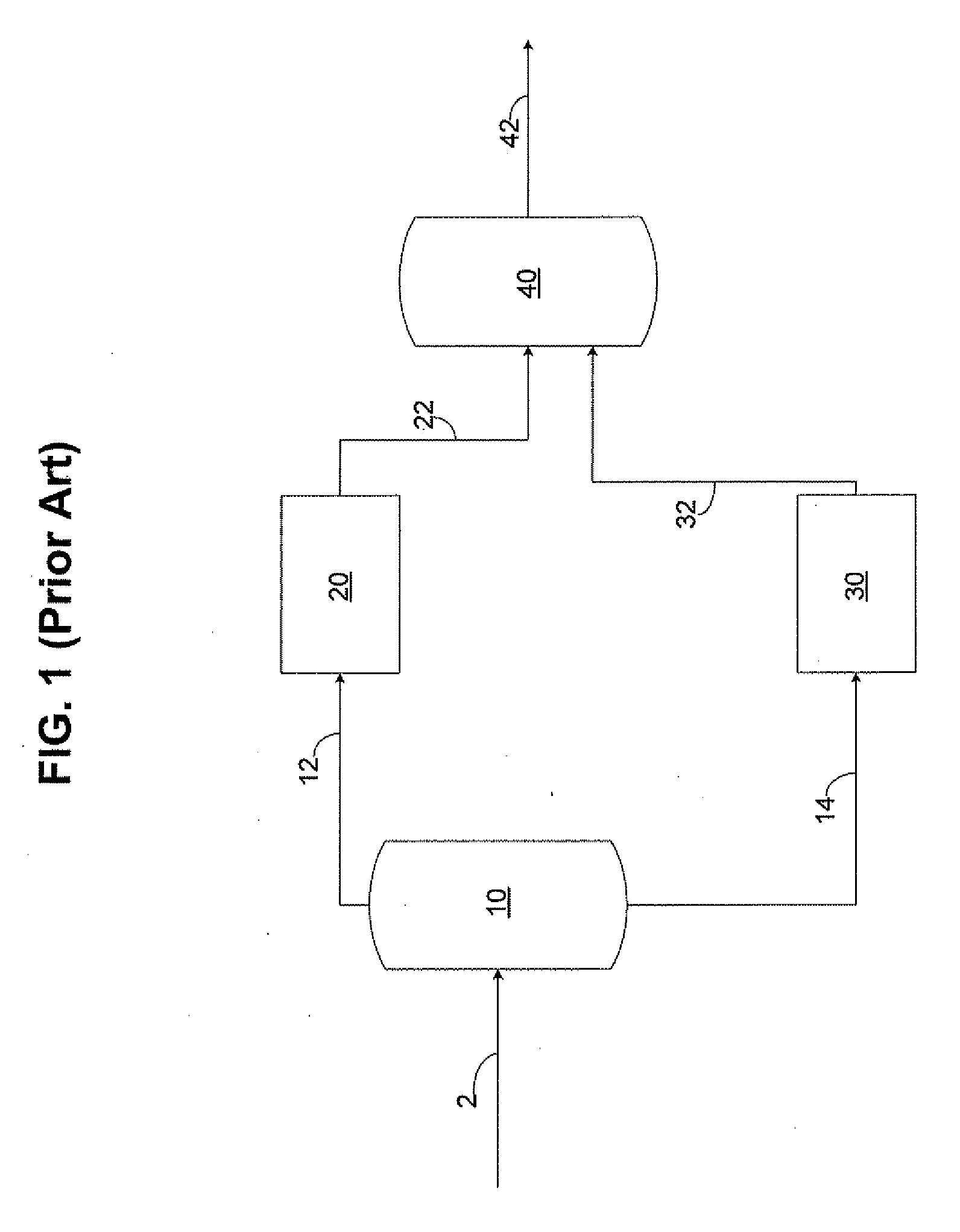

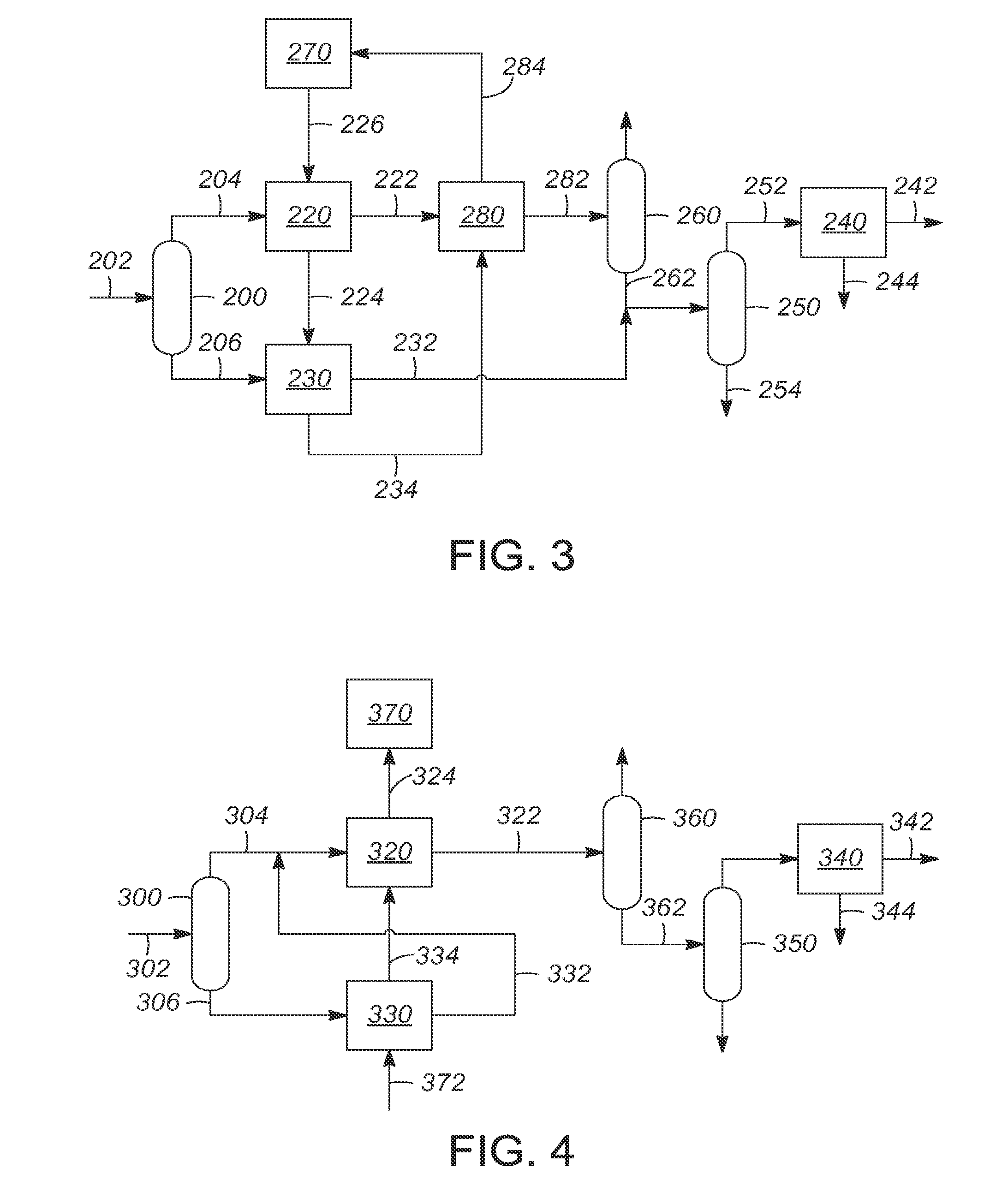

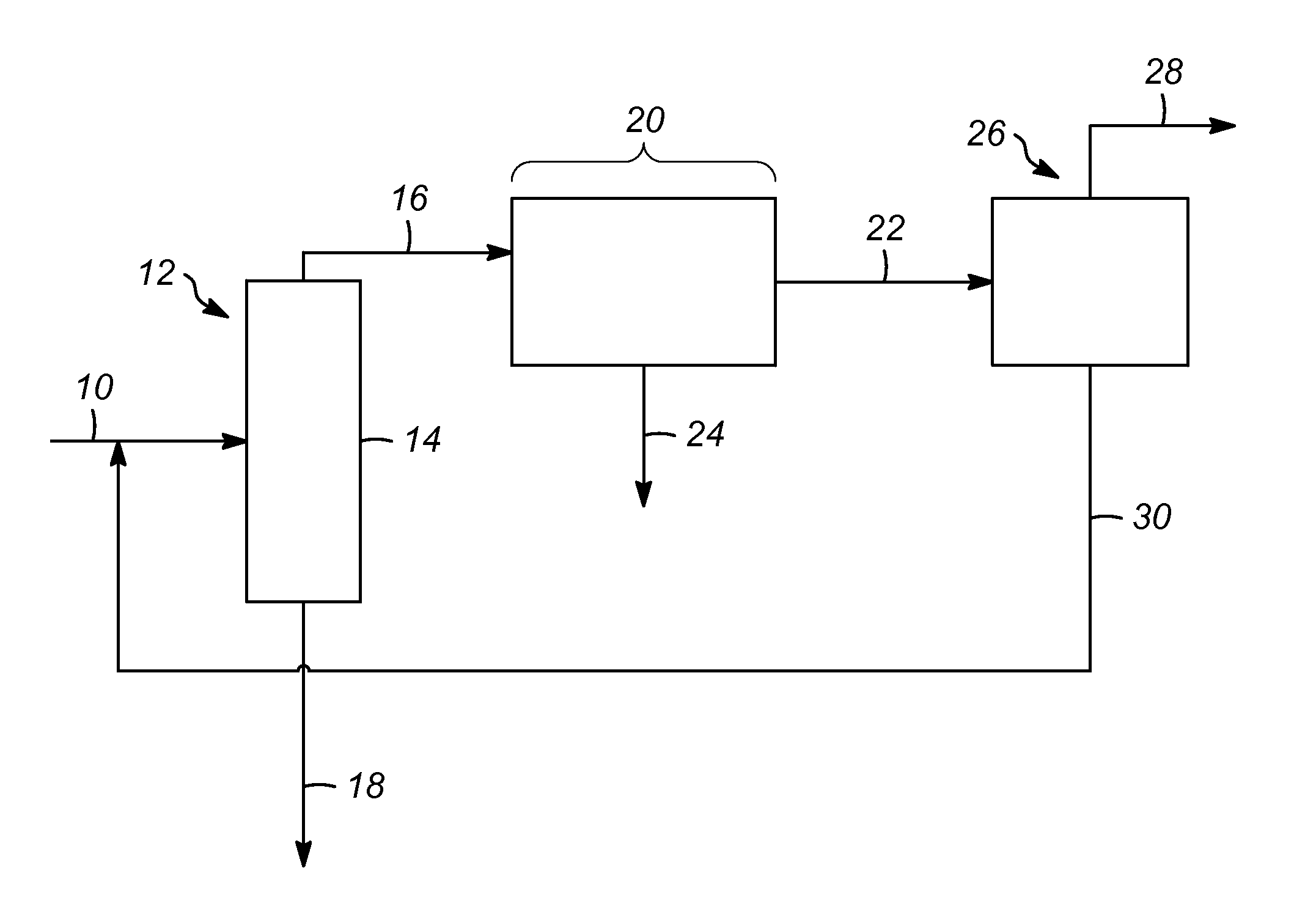

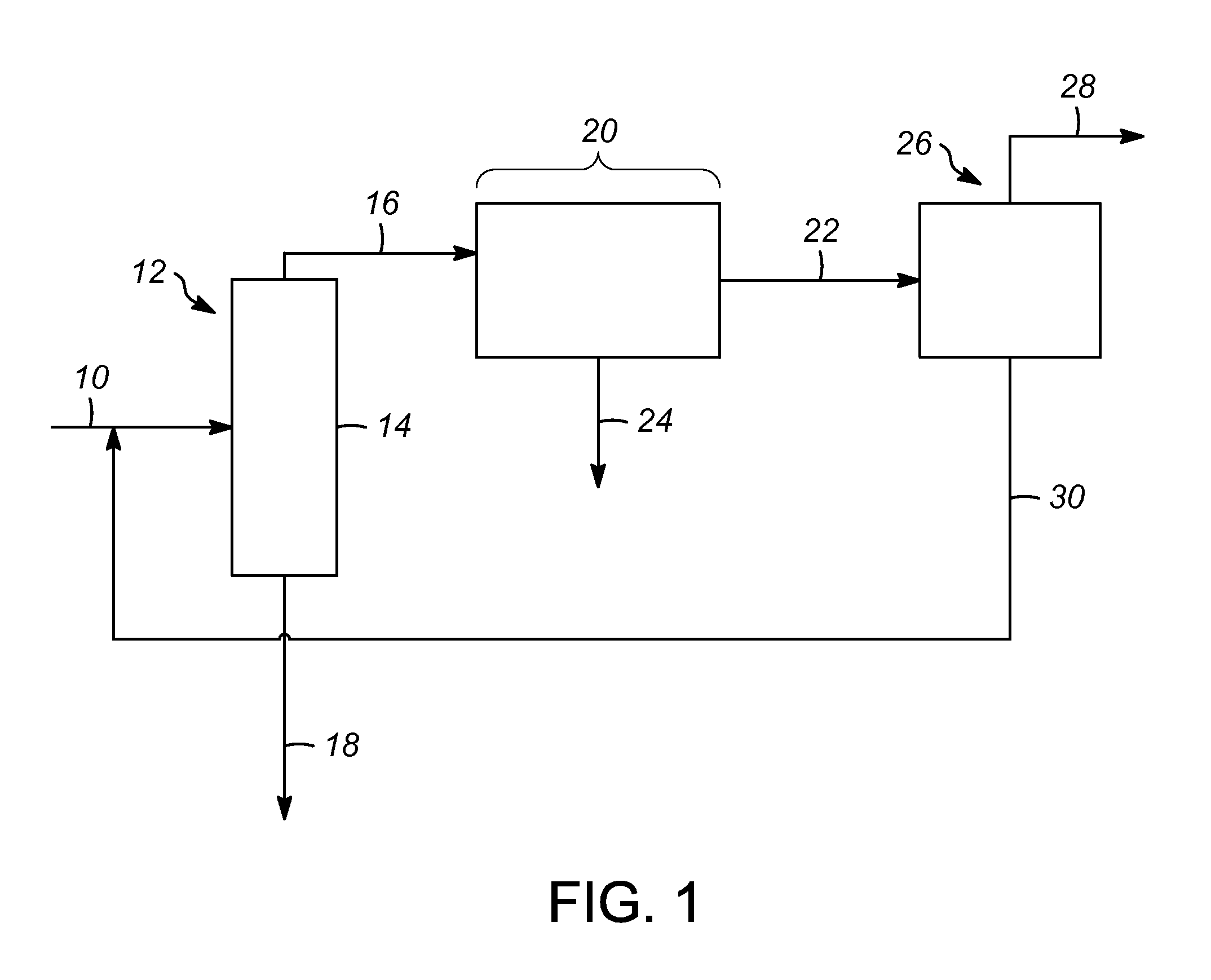

Process Development By Parallel Operation Of Paraffin Isomerization Unit With Reformer

ActiveUS20130026066A1Improve featuresCatalytic naphtha reformingThermal naphtha reformingParaffin waxNaphtha

A process for refining naphtha that results in an improved octane value in a subsequent gasoline blend. Certain embodiments include separating a naphtha feed into light naphtha and heavy naphtha; separating the heavy naphtha into a paraffin stream and non-paraffin stream; introducing the light naphtha to a first isomerization unit, introducing the paraffin stream to a second isomerization unit; introducing the non-paraffin stream to a reforming unit and combining the resulting effluents to form a gasoline blend. The resulting gasoline blend has improved characteristics over gasoline blends that are made without introducing the paraffin stream to a second isomerization unit.

Owner:SAUDI ARABIAN OIL CO

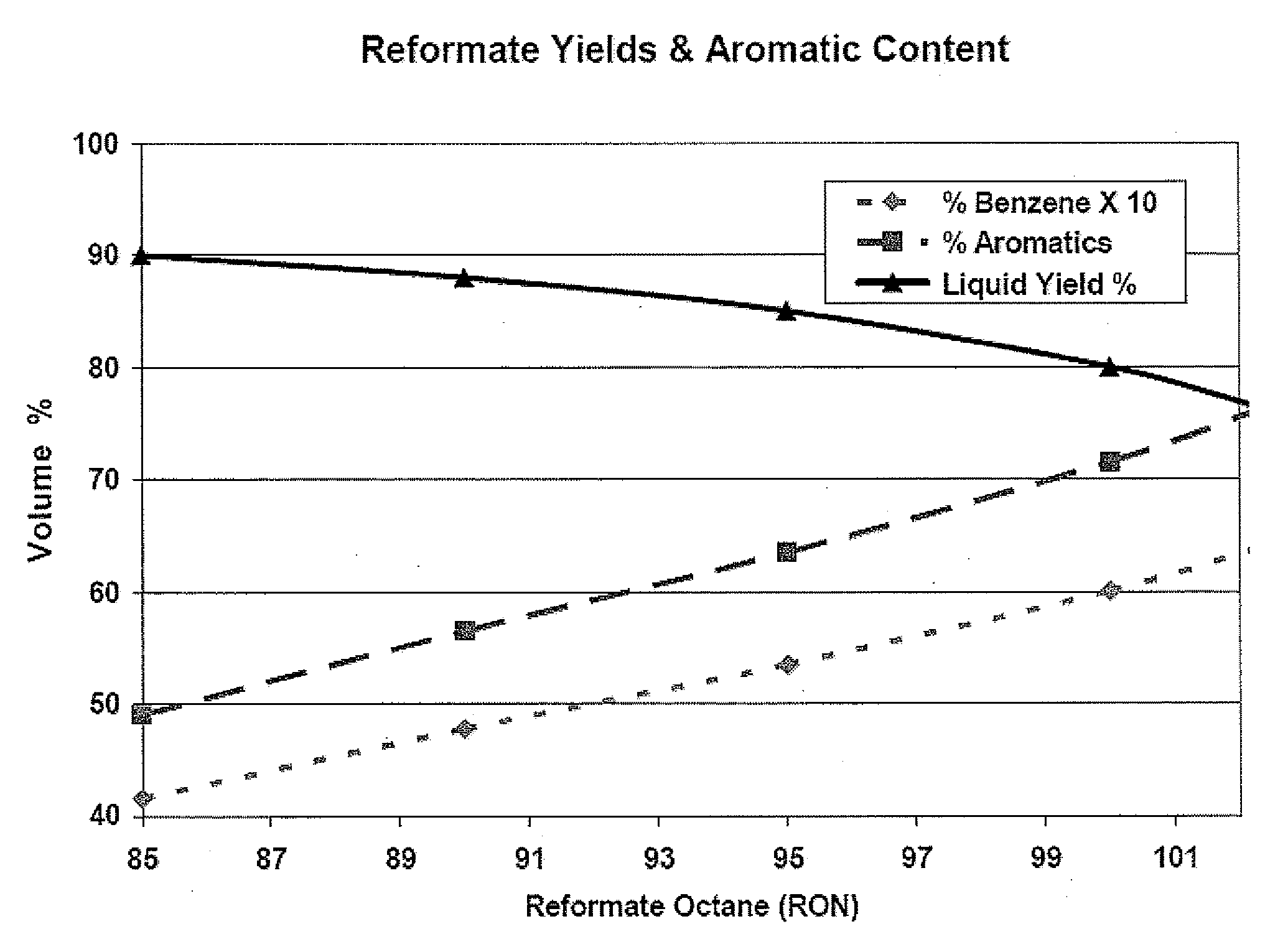

PROCESS AND APPARATUS FOR PRODUCING A REFORMATE BY INTRODUCING n-BUTANE

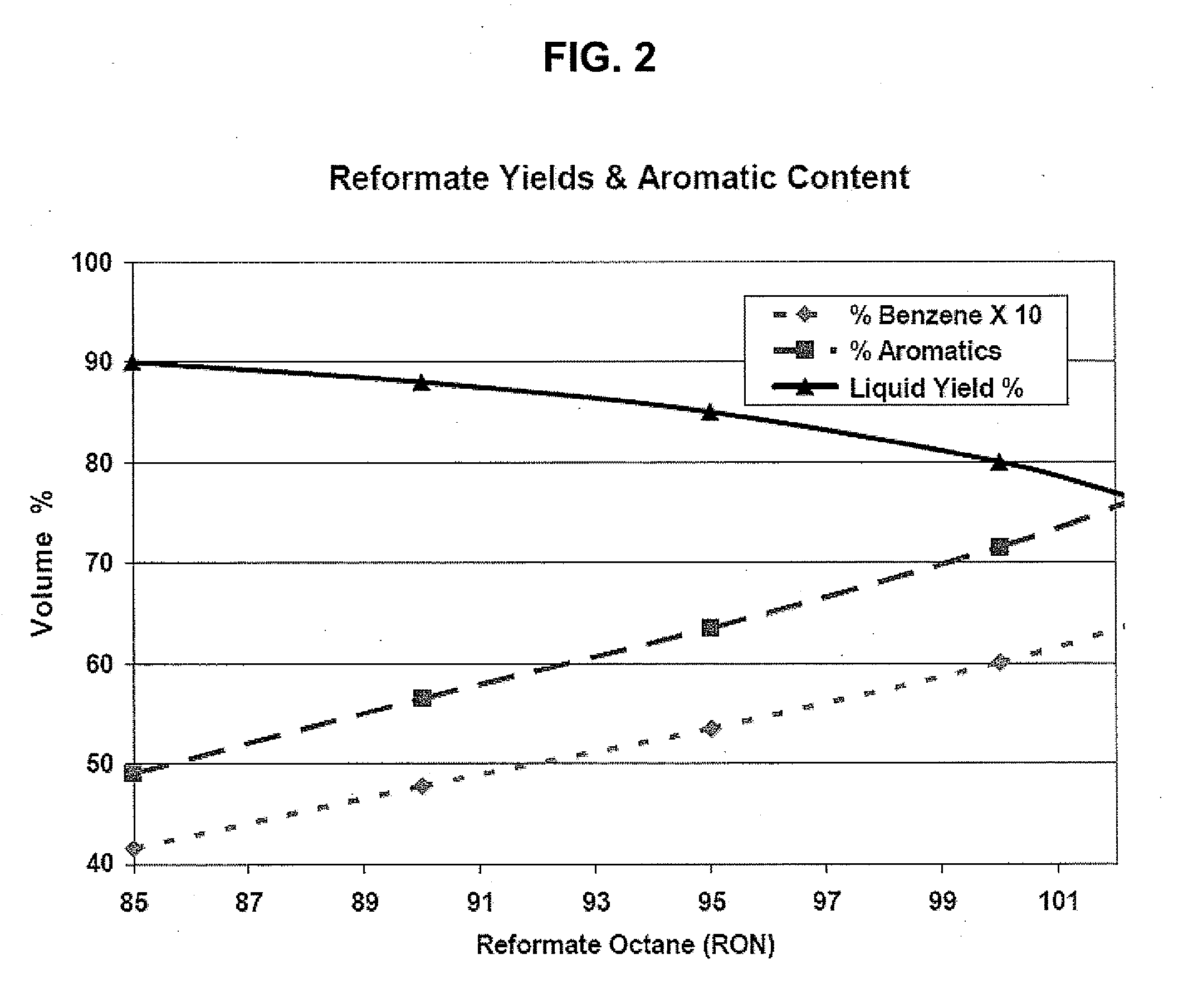

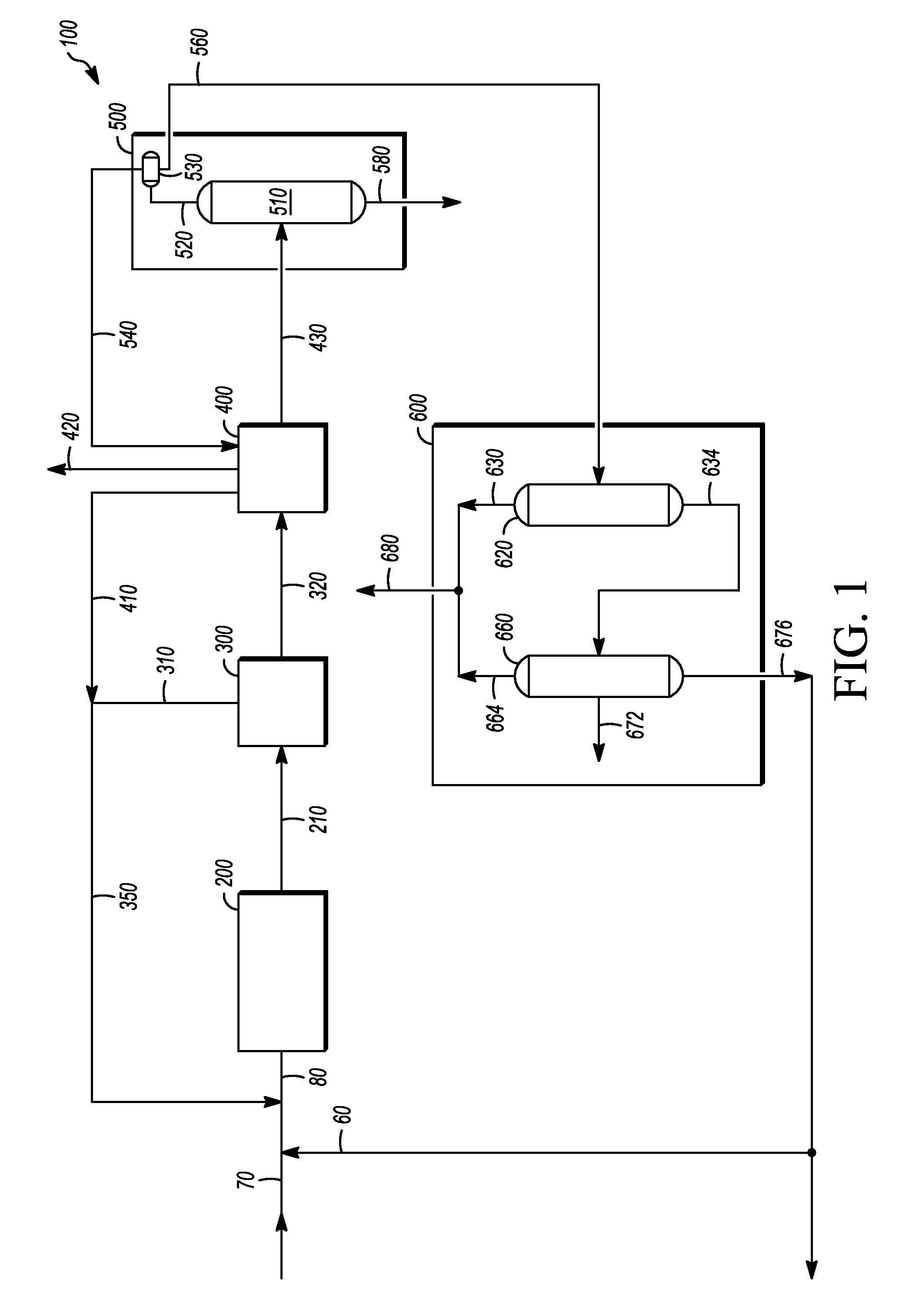

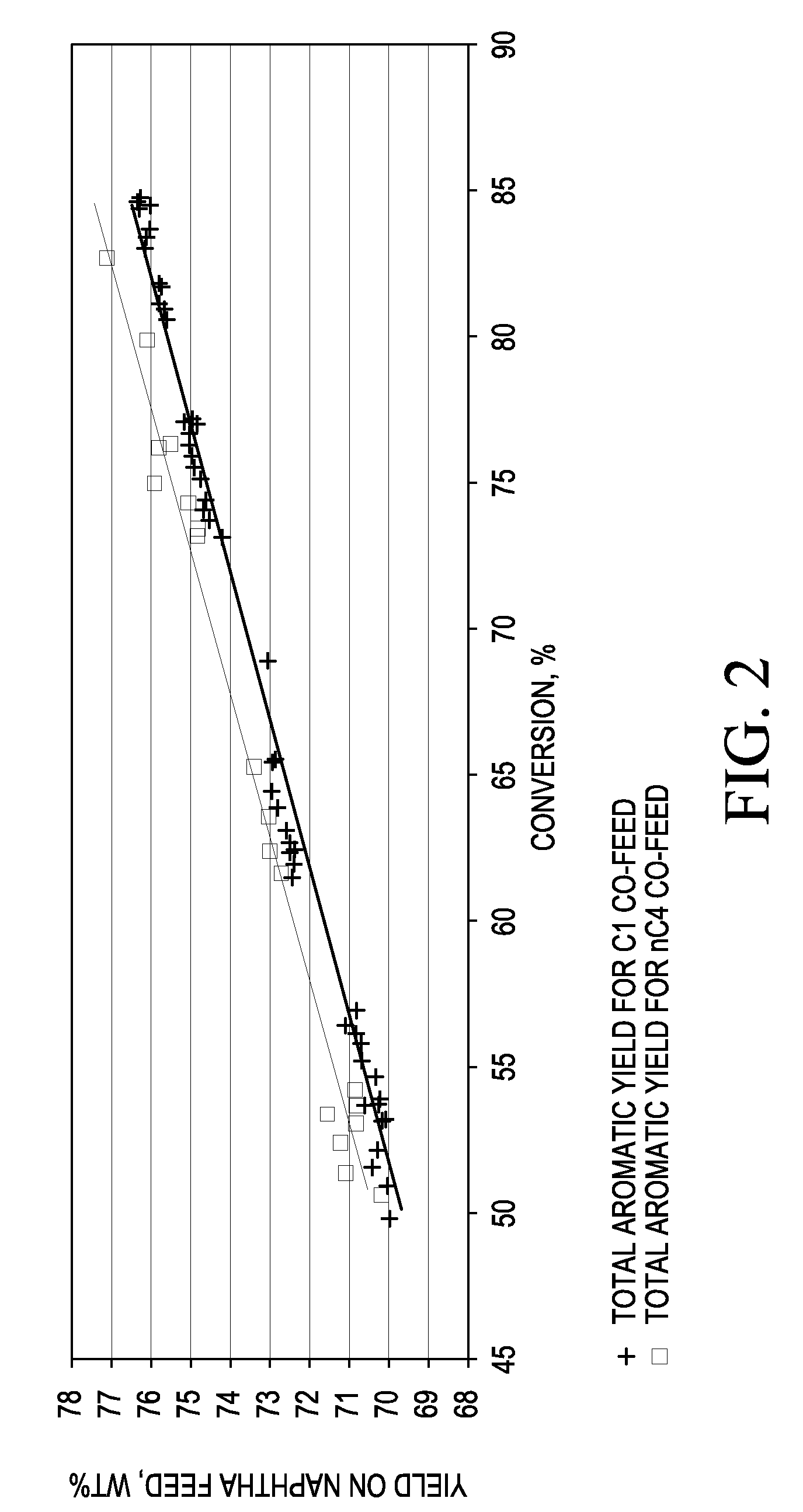

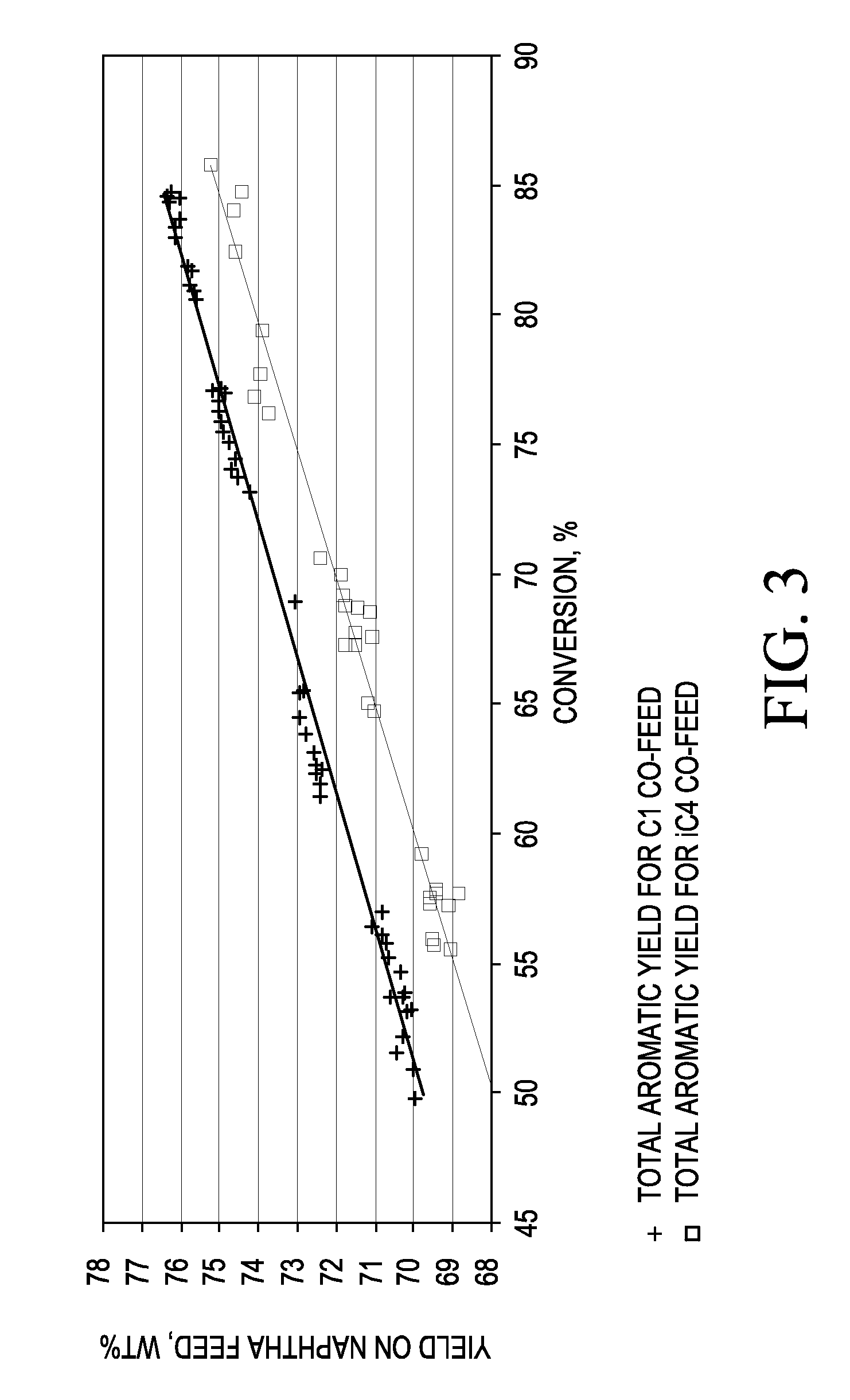

InactiveUS20100018900A1Reduce productionIncrease in total aromatic yieldCatalytic naphtha reformingThermal naphtha reformingNaphthaBoiling point

One exemplary embodiment can be a process for producing a reformate by combining a stream having an effective amount of n-butane and a stream having an effective amount of naphtha for reforming. Generally, the naphtha has not less than about 95%, by weight, of one or more compounds having a boiling point of about 38—about 260° C. as determined by ASTM D86-07. The process can include introducing the combined stream to a reforming reaction zone. Typically, the combined stream has an n-butane:naphtha mass ratio of about 0.10:1.00—about 1.00:1.00.

Owner:UOP LLC

Process for increasing aromatics production

ActiveUS20130225886A1High selectivityEasy to crackHydrocarbonsThermal naphtha reformingNaphthaFractionation

Processes for producing aromatics from a naphtha feedstream are provided. An exemplary process includes passing the feedstream to a fractionation unit, thereby generating a first stream including hydrocarbons having less than 8 carbon atoms and a second stream including hydrocarbons having at least 8 carbon atoms. The first stream is passed to a first reformer operated at a first set of reaction conditions to generate a first product stream. The first set of reaction conditions includes a first temperature and a first pressure. The second stream is passed to a second reformer operated at a second set of reaction conditions to generate a second product stream. The second set of reaction conditions includes a second temperature and a second pressure. The first pressure is lower than the second pressure.

Owner:UOP LLC

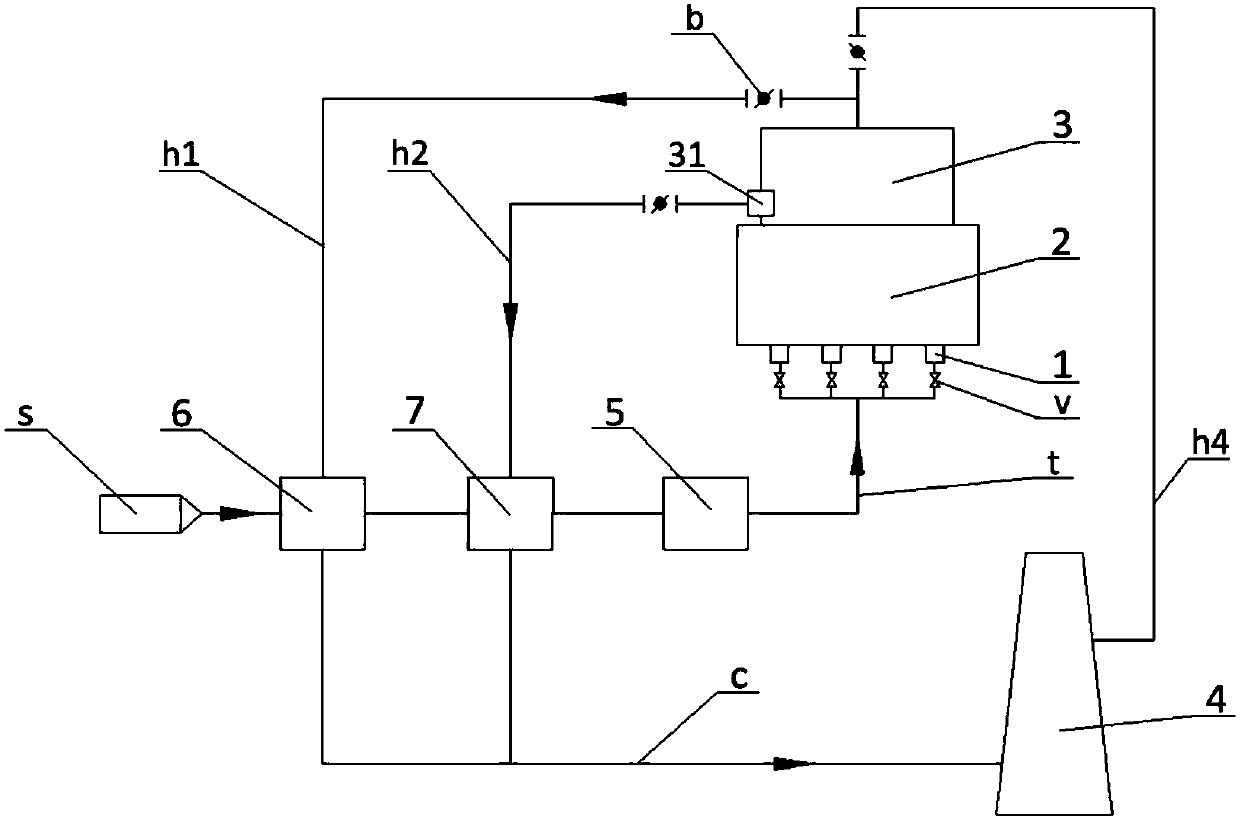

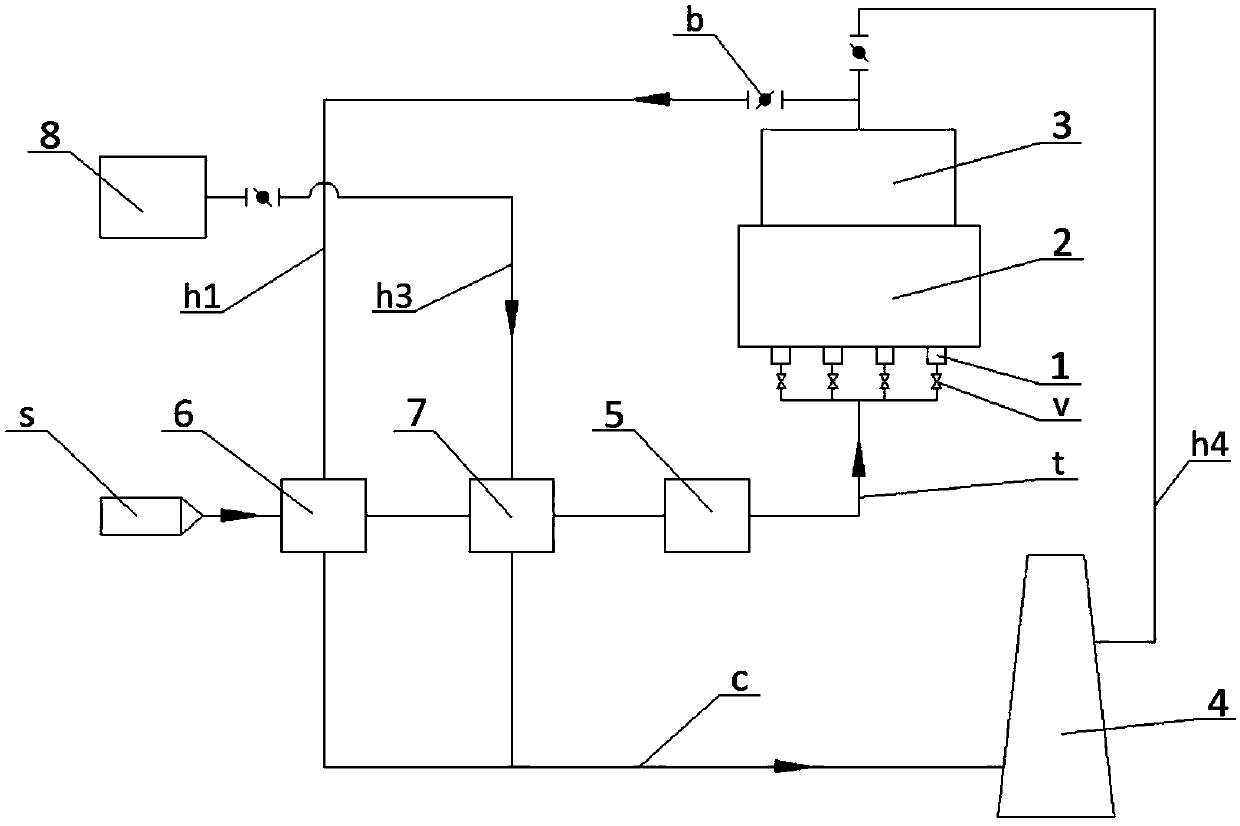

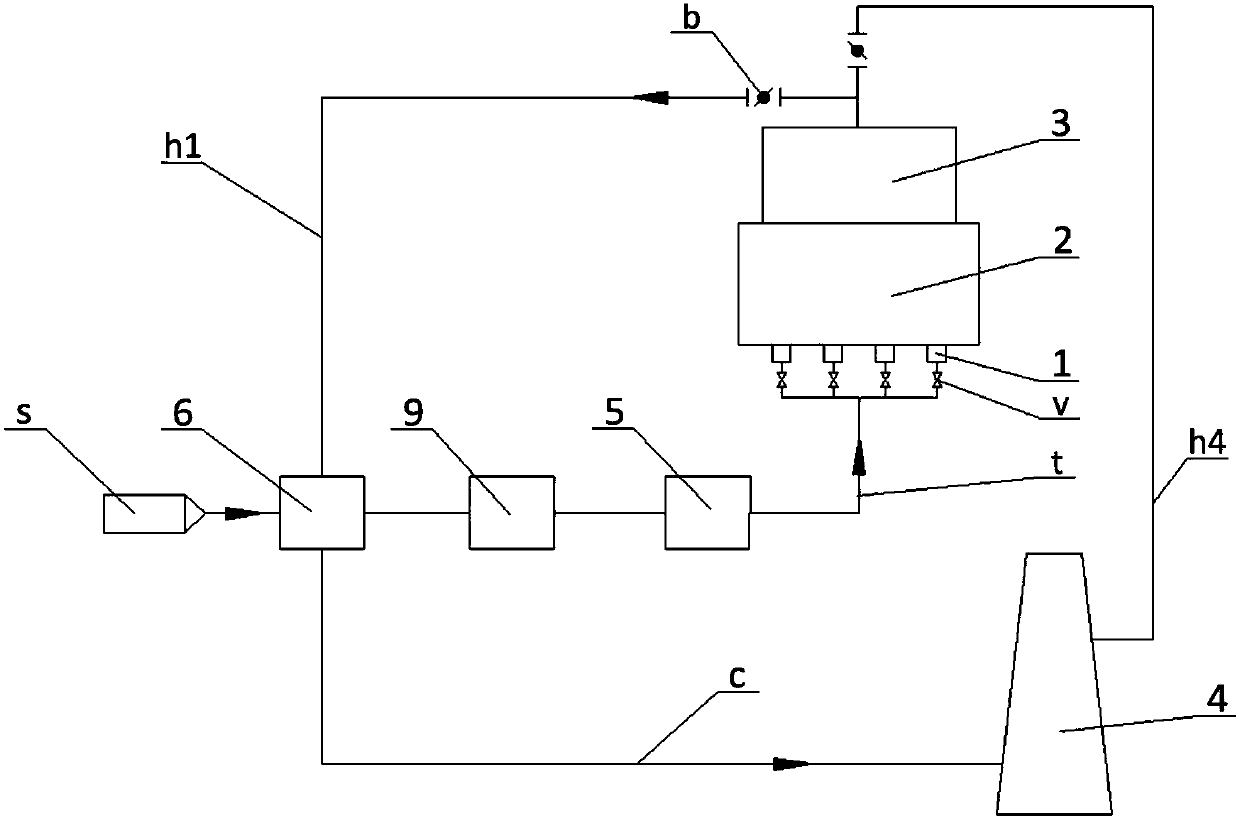

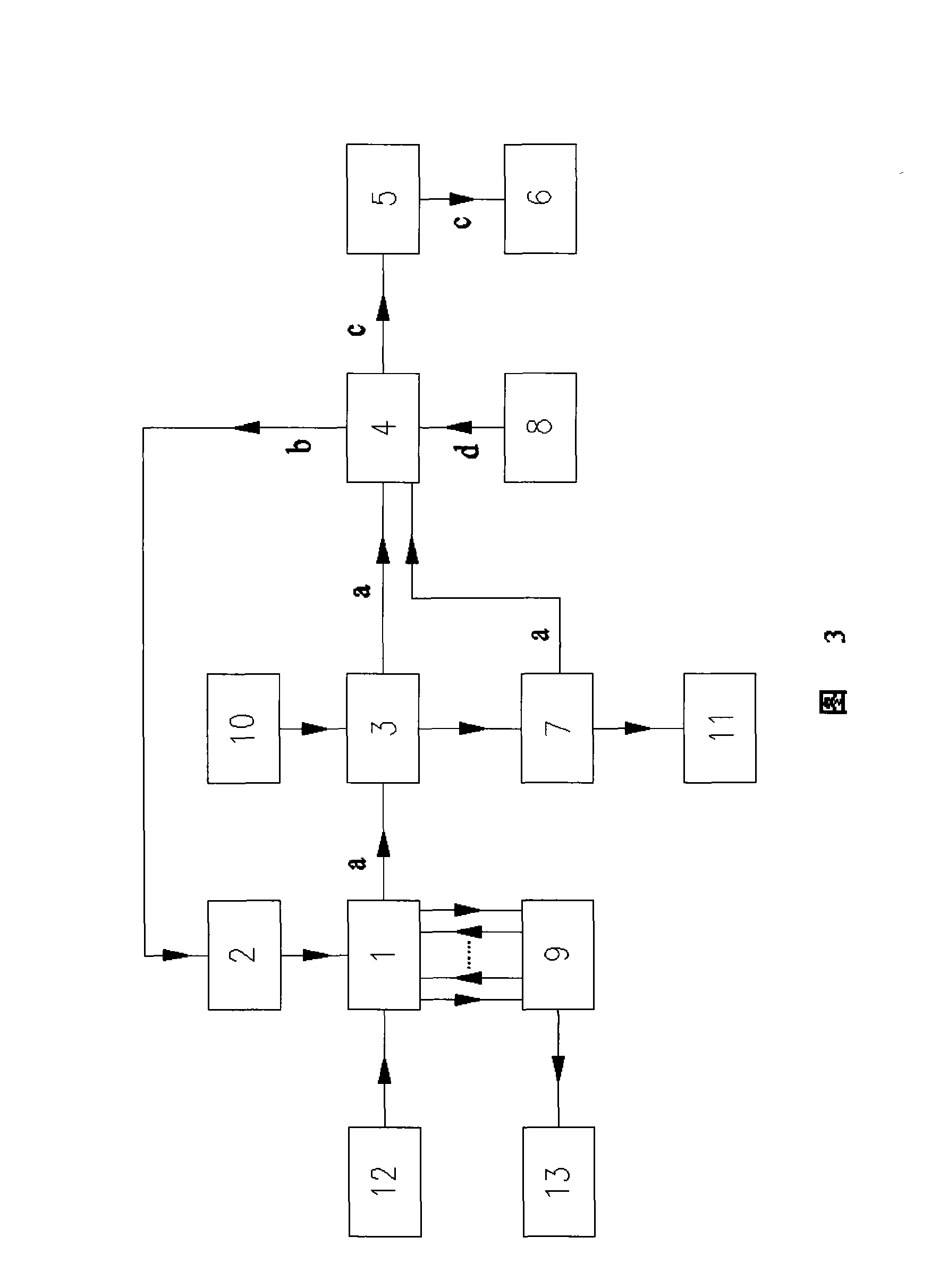

Preheating method for fuel gas of reforming heating furnace and reforming device

PendingCN107940461ASolve the problem of dew point corrosion after the thermal efficiency is improvedSolve the problem of exceeding the standardDispersed particle separationThermal naphtha reformingNitric oxideCorrosion

The embodiment of the invention provides a preheating method for fuel gas of a reforming heating furnace. The method comprises the steps that before the fuel gas enters the reforming heating furnace,primary preheating and secondary preheating are carried out; in the primary preheating process, the fuel gas and flue gas guided out are subjected to heat exchange in a first preheater; then the fuelgas is introduced into a secondary fuel gas preheating unit for secondary preheating; and the fuel gas subjected to secondary preheating is introduced into a fuel gas fine treatment unit for fine treatment and then is introduced into a combustor for combustion. The method has the advantages that the high-temperature flue gas entering the convection section is used for preheating the fuel gas, theamount of steam produced by the fuel gas can be decreased, and the energy utilization efficiency can be improved; and meanwhile, the fuel gas is preheated to the temperature meeting the finish treatment, and therefore the problem that sulfuric acid dew point corrosion occurs after the heat efficiency of the heating furnace is improved can be solved, the problem that the content of sulfur dioxide exceeds the standard when the fuel gas coarse desulfurization system fluctuates can be solved, and the emission concentration of nitric oxide can be further decreased. The embodiment of the invention further provides a reforming device based on the preheating method for the fuel gas of the reforming heating furnace.

Owner:上海浩用工业炉有限公司

Process for increasing the yield of an isomerization zone

ActiveUS20150315101A1Promote disproportionation reactionHigh overall conversionHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonIsomerizationHydrocarbon

A process for increasing a yield of an isomerization zone by removing at least a portion of the C6 cyclic hydrocarbons from a stream having iC4 hydrocarbons, iC5 hydrocarbons, and iC6 hydrocarbons prior to the stream being passed into the same isomerization zone. Suppression of the iC4 hydrocarbons does not occur, allowing the iC4 hydrocarbons to be isomerized in the same isomerization zone as the iC5 hydrocarbons and iC6 hydrocarbons.

Owner:UOP LLC

Process for selectively producing light olefins

InactiveUS20020169350A1Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaSteam activation

The invention is related to a catalyst and a process for selectively producing light (i.e., C2-C4) olefins from a catalytically cracked or thermally cracked naphtha stream. The naphtha stream is contacted with a catalyst containing from about 10 to 50 wt. % of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions. The catalysts do not require steam activation.

Owner:STEFFENS TODD R +1

Process and System for the Addition of Promoter Metal In Situ in a Catalytic Reforming Unit

InactiveUS20100116714A1Improve conversion of hydrocarbonImprove catalytic selectivityCatalytic naphtha reformingCatalyst regeneration/reactivationCatalytic reformingNaphtha

One exemplary embodiment can be a process for facilitating adding a promoter metal to at least one catalyst particle in situ in a catalytic naphtha reforming unit. The process can include introducing a compound comprising the promoter metal to the catalyst naphtha reforming unit and adding an effective amount of the promoter metal from the compound comprising the promoter metal to the catalyst particle under conditions to effect such addition and improve a conversion of a hydrocarbon feed.

Owner:UOP LLC

Oil-based thermo-neutral reforming with a multi-component catalyst

ActiveUS20080152572A1Enhance the activity of the base metal-supported thermo-neutral reforming catalystProcesses liquid hydrocarbon fuels efficiently and reliablyHydrogenHydrocarbon from carbon oxidesSteam reformingCombustion

A method is provided for the thermo-neutral reforming of liquid hydrocarbon fuels which employs a Ni, Ce2O3, La2O3, Pt−ZrO2, Rh and Re catalyst having dual functionalities to achieve both combustion and steam reforming.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

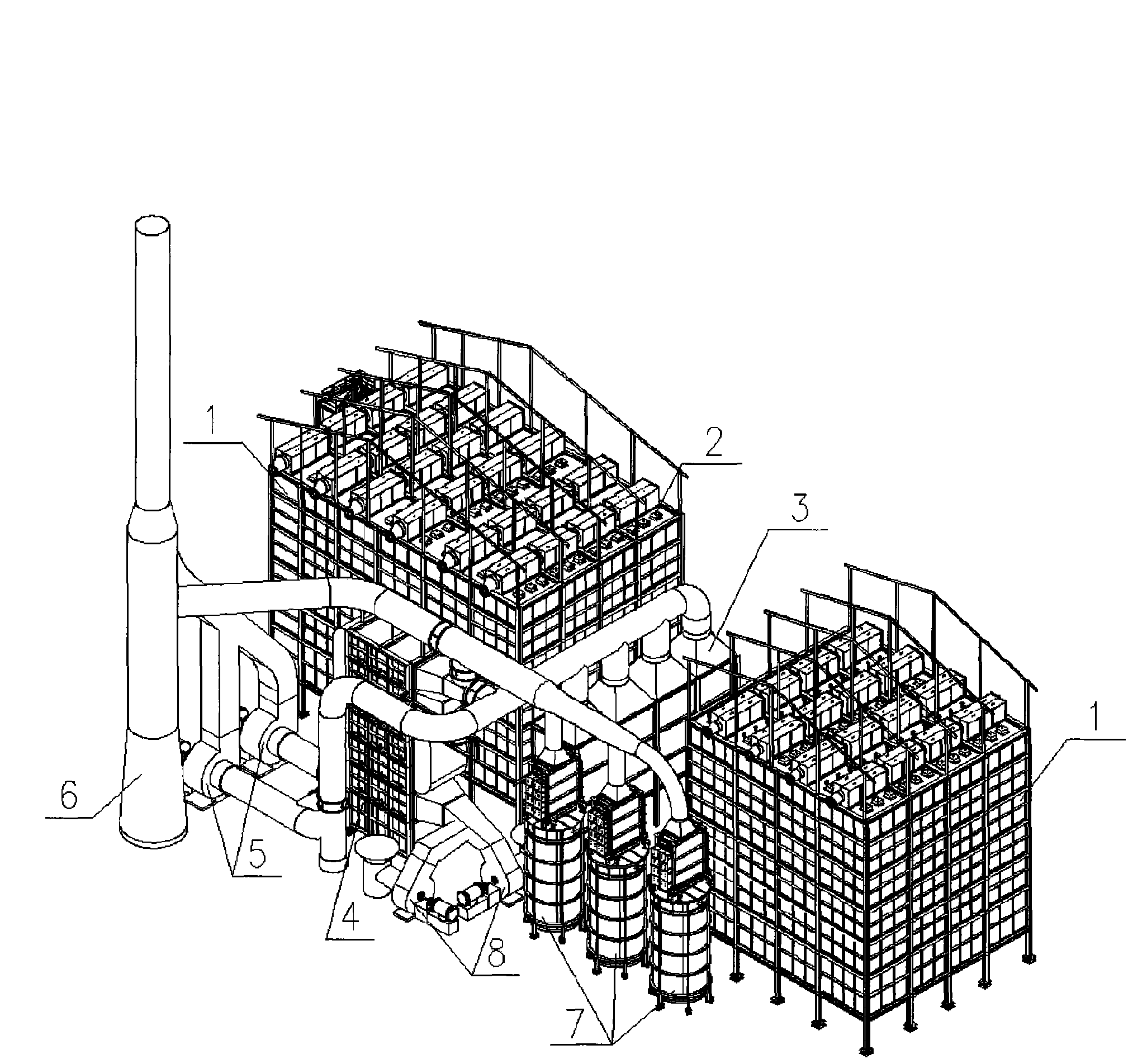

Process for reforming relay heat of heating furnace and equipment thereof

ActiveCN101514297AImprove qualitySignificant energy saving benefitsThermal naphtha reformingAir preheaterProcess engineering

The invention discloses a process for reforming relay heat of a heating furnace and equipment thereof. The process for reforming relay heat of the heating furnace is characterized in that a reformed radiation chamber and a relay heating furnace are integrated together to form a heating system; process mediums to be heated in a reforming device are heated together, and the part with deficient heat adopts relay heat. The equipment for reforming relay heat of the heating furnace mainly comprises the radiation chamber, a floor convention chamber, an air preheater, a relay heating furnace, a draft blower, a draft fan and a chimney, the parts are connected through pipelines; the upper part of the radiation chamber is provided with a tipburn burner; the floor convention chamber is positioned between two radiation chambers; three relay heating furnaces and the air preheater are arranged in front of the radiation chamber in parallel; the draft fan and the draft blower are respectively positioned on two sides of the air preheater; and the chimney is arranged in front of the draft fan. The process and the equipment can reduce consumption of fuel oil or fuel gas, and reduces pressure of a steel structure and steel consumption.

Owner:HENAN FANGYUAN IND FURNACE DESIGN & MFG CO LTD

Hydrocarbon Conversion

ActiveUS20190169088A1Solve the lack of resistanceImprove stabilityThermal non-catalytic crackingCatalytic crackingNon oxide ceramicsOxide ceramic

The invention relates to hydrocarbon conversion, to equipment and materials useful for hydrocarbon conversion, and to processes for carrying out hydrocarbon conversion, e.g., hydrocarbon pyrolysis processes. The hydrocarbon conversion is carried out in a reactor which includes at least one channeled member that comprises refractory and has an open frontal area ≤55%. The refractory can include non-oxide ceramic.

Owner:EXXONMOBIL CHEM PAT INC

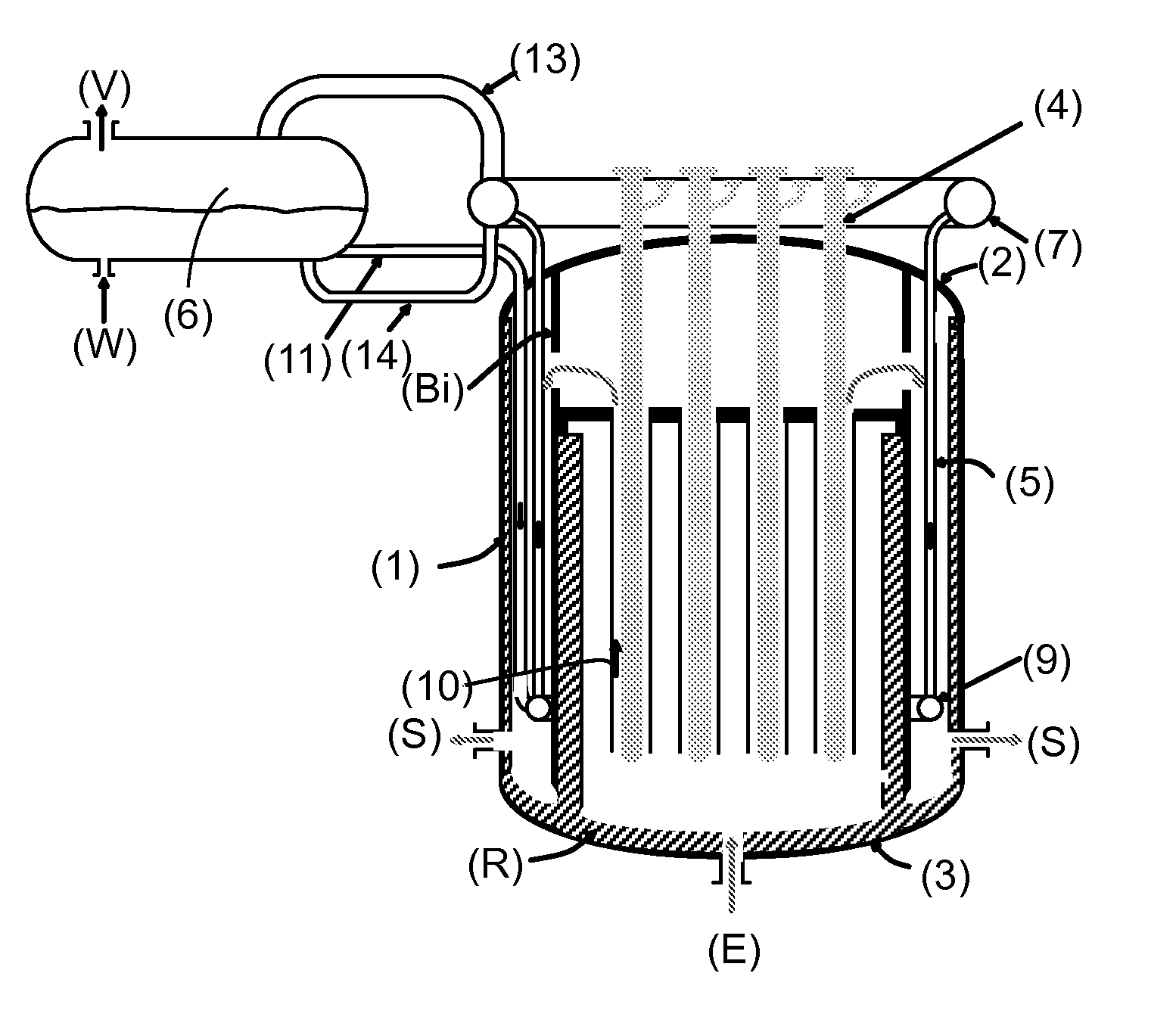

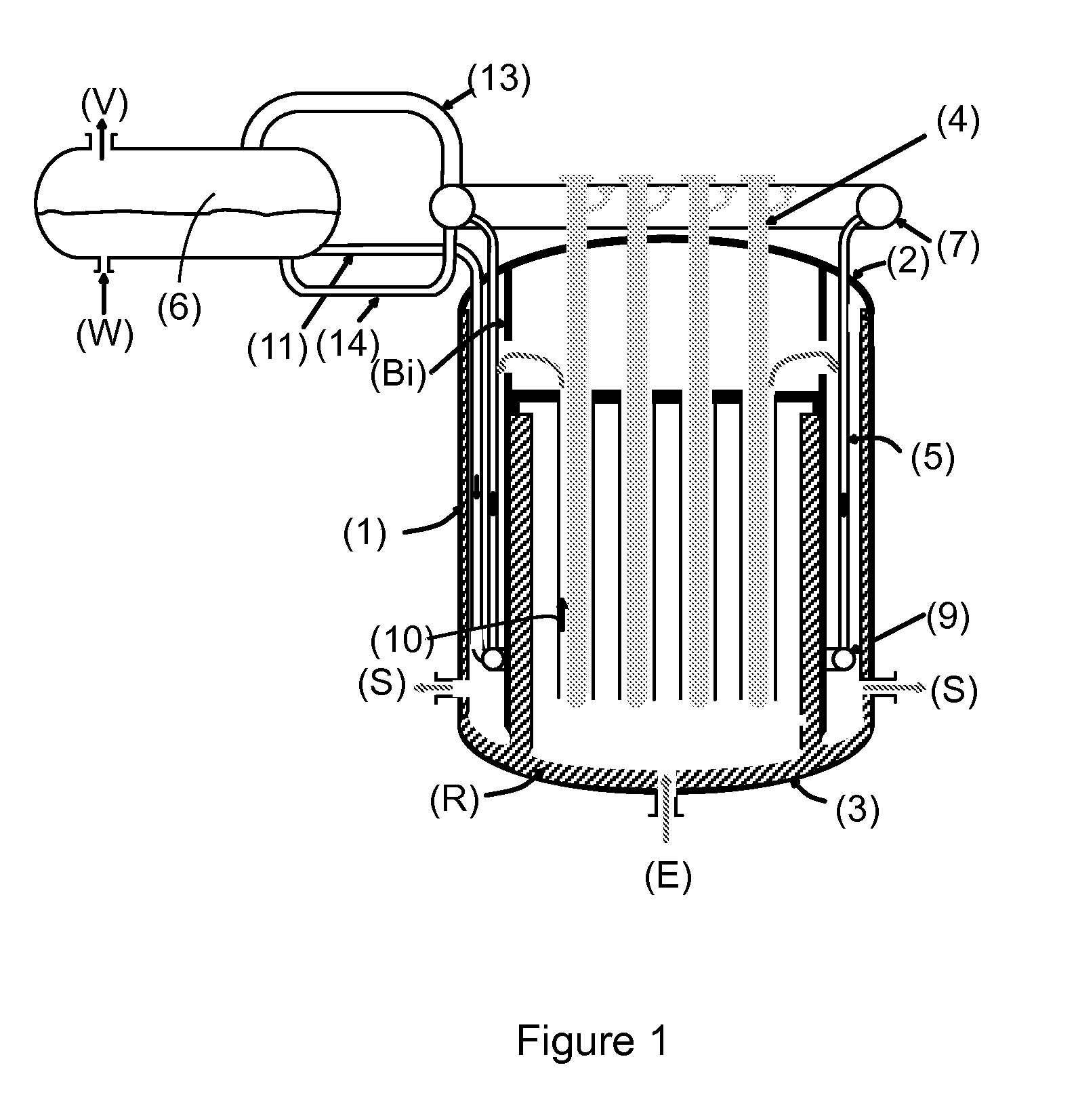

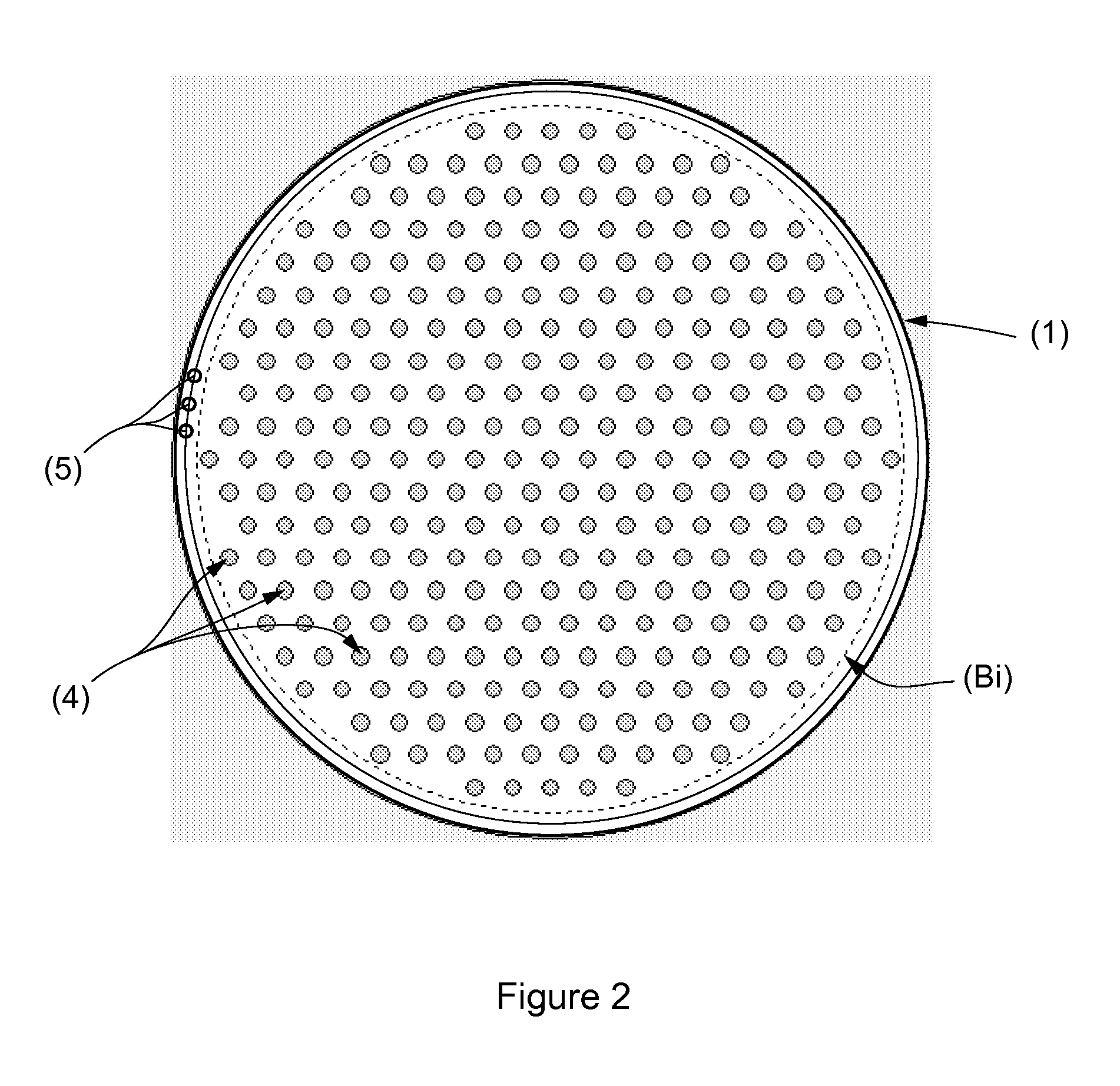

Exchanger-reactor for the production of hydrogen with an integrated steam generation bundle

InactiveUS20130053604A1Pressurized chemical processThermal naphtha reformingSteam reformingProcess engineering

The present invention describes an exchanger-reactor for carrying out endothermic reactions such as steam reforming oil cuts or alcohols integrating a steam generation bundle which can thereby increase the thermal efficiency.

Owner:INST FR DU PETROLE

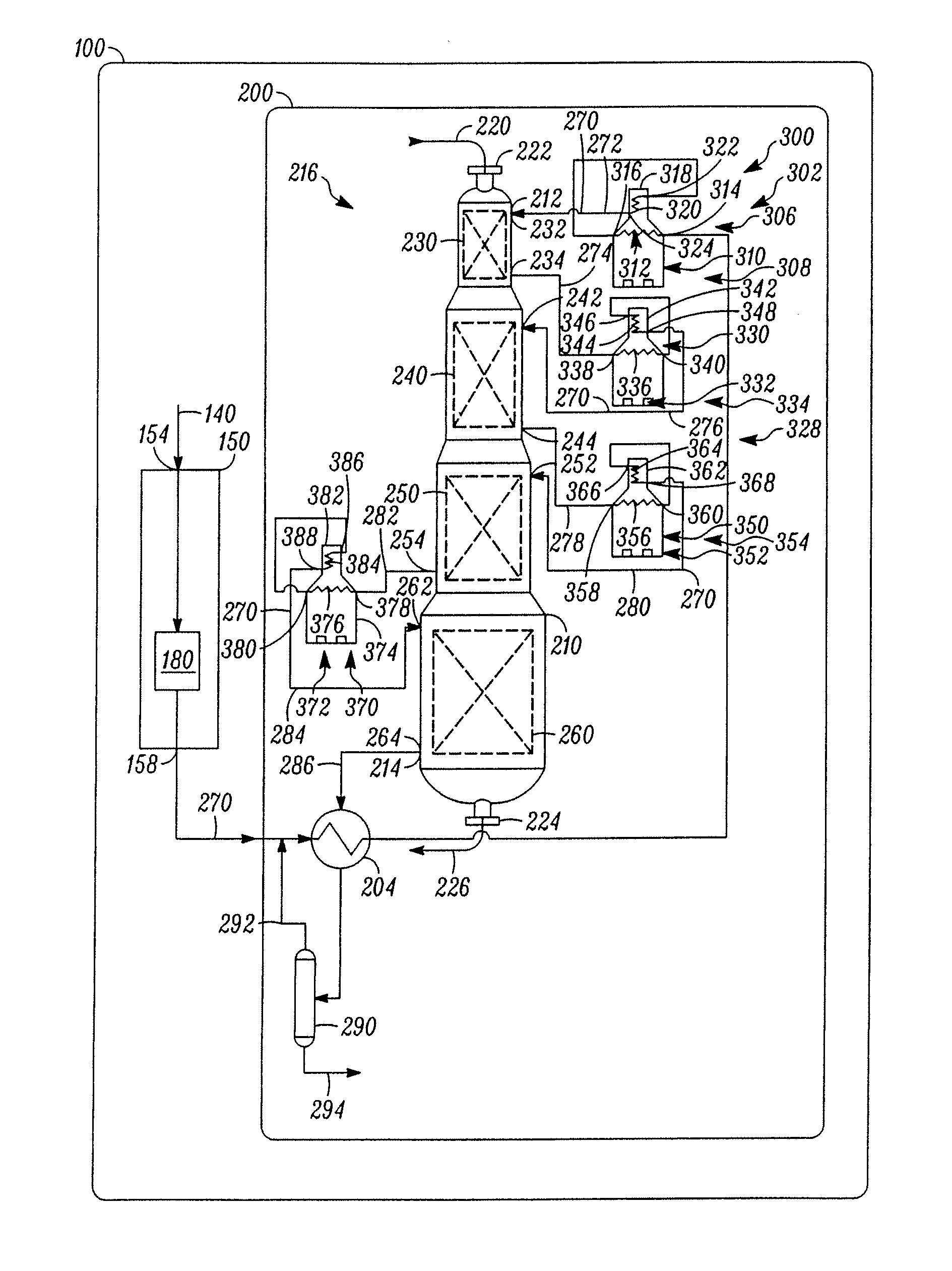

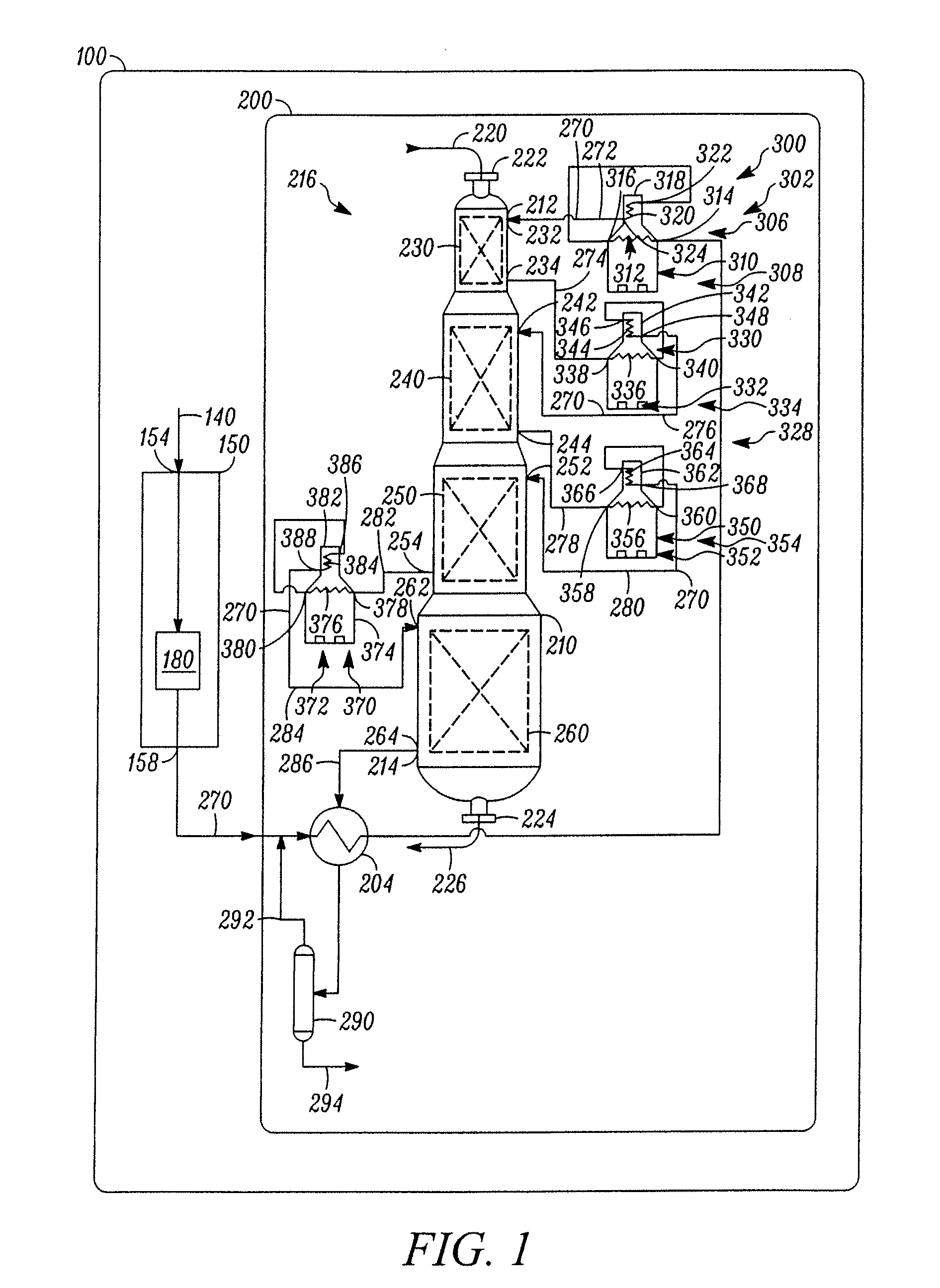

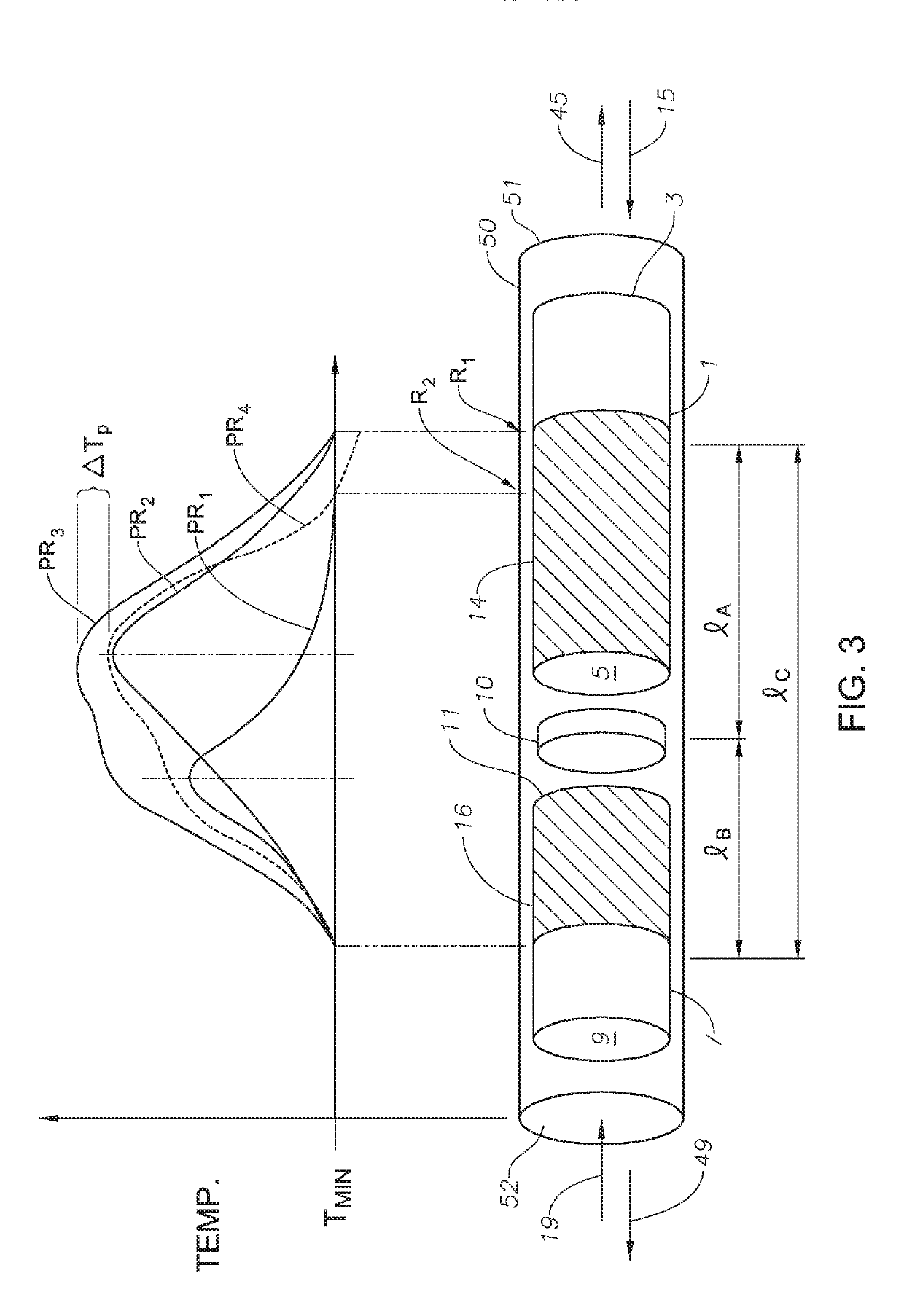

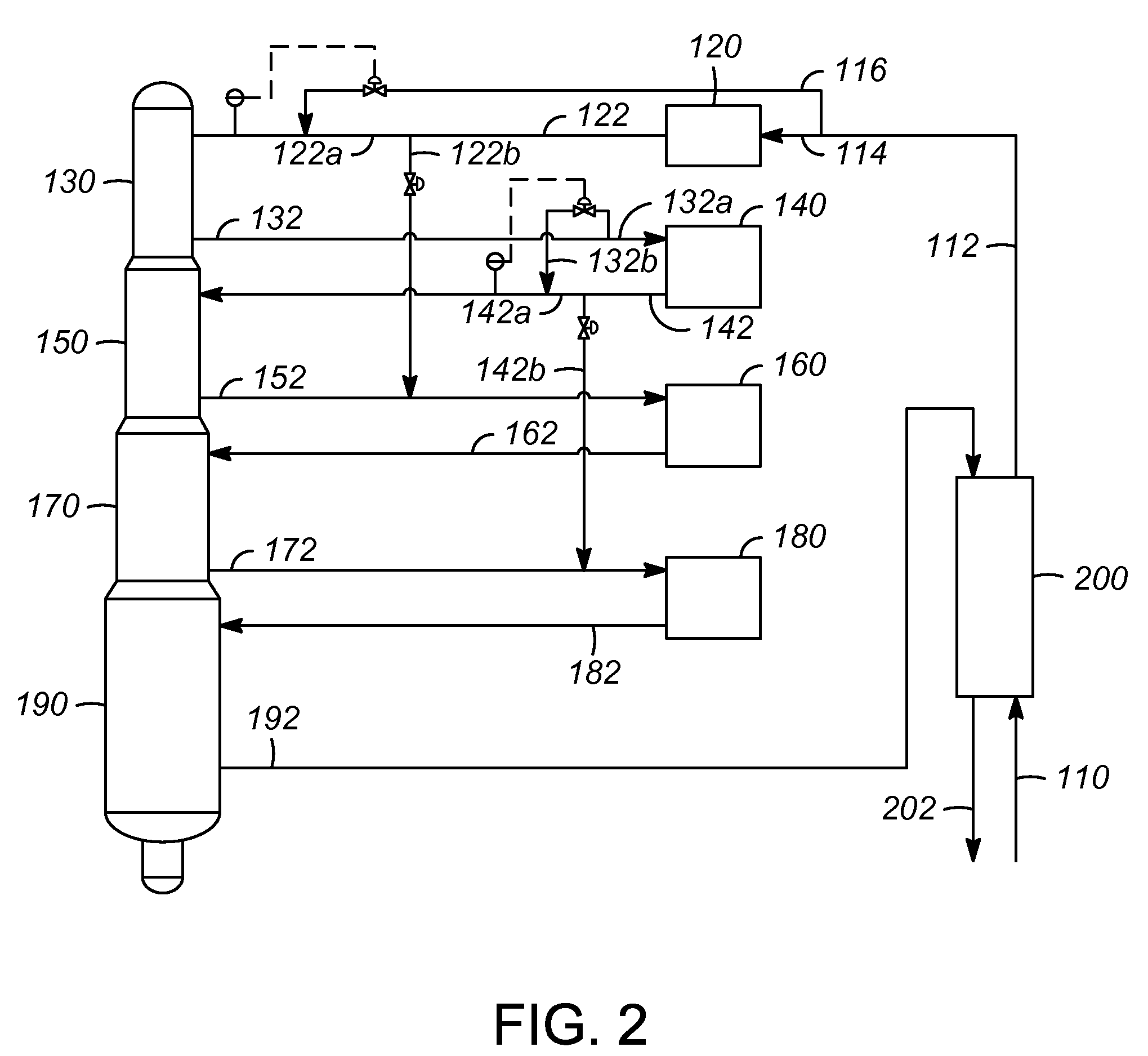

Reforming process with improved heater integration

ActiveUS20170327755A1Thermal non-catalytic crackingThermal naphtha reformingRadiant heaterProcess engineering

A method and apparatus for processing a hydrocarbon stream are described. The method includes heating a feed stream in a convective bank. The heated feed stream is reacted in a first reaction zone to form a first effluent, which is heated in a first radiant cell. The first radiant cell combusts fuel to heat the first effluent and forms a first exhaust gas. The first exhaust gas is contacted with the convective bank to heat the feed stream. The outlet temperature the heated feed stream from the convective bank is controlled by introducing an additional gas stream into the convective bank. There can be additional reaction zones and radiant heaters.

Owner:UOP LLC

High temperature CCR process with integrated reactor bypasses

A process is presented for increasing the aromatics content in a reformate process stream. The process modifies existing processes to change the operation without changing the reactors or heating units. The process includes bypasses to utilize heating capacity of upstream heating units, and passes the excess capacity of the upstream heating units to downstream process streams.

Owner:UOP LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com