Process and System for the Addition of Promoter Metal In Situ in a Catalytic Reforming Unit

a technology of catalytic reforming unit and promoter metal, which is applied in the direction of catalyst regeneration/reactivation, thermal naphtha reforming, physical/chemical process catalysts, etc., can solve the cost of replacing a large volume of catalyst, and achieve the effect of improving the selectivity of catalyst particles, improving the activity of catalyst particles, and improving the conversion rate of hydrocarbon feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

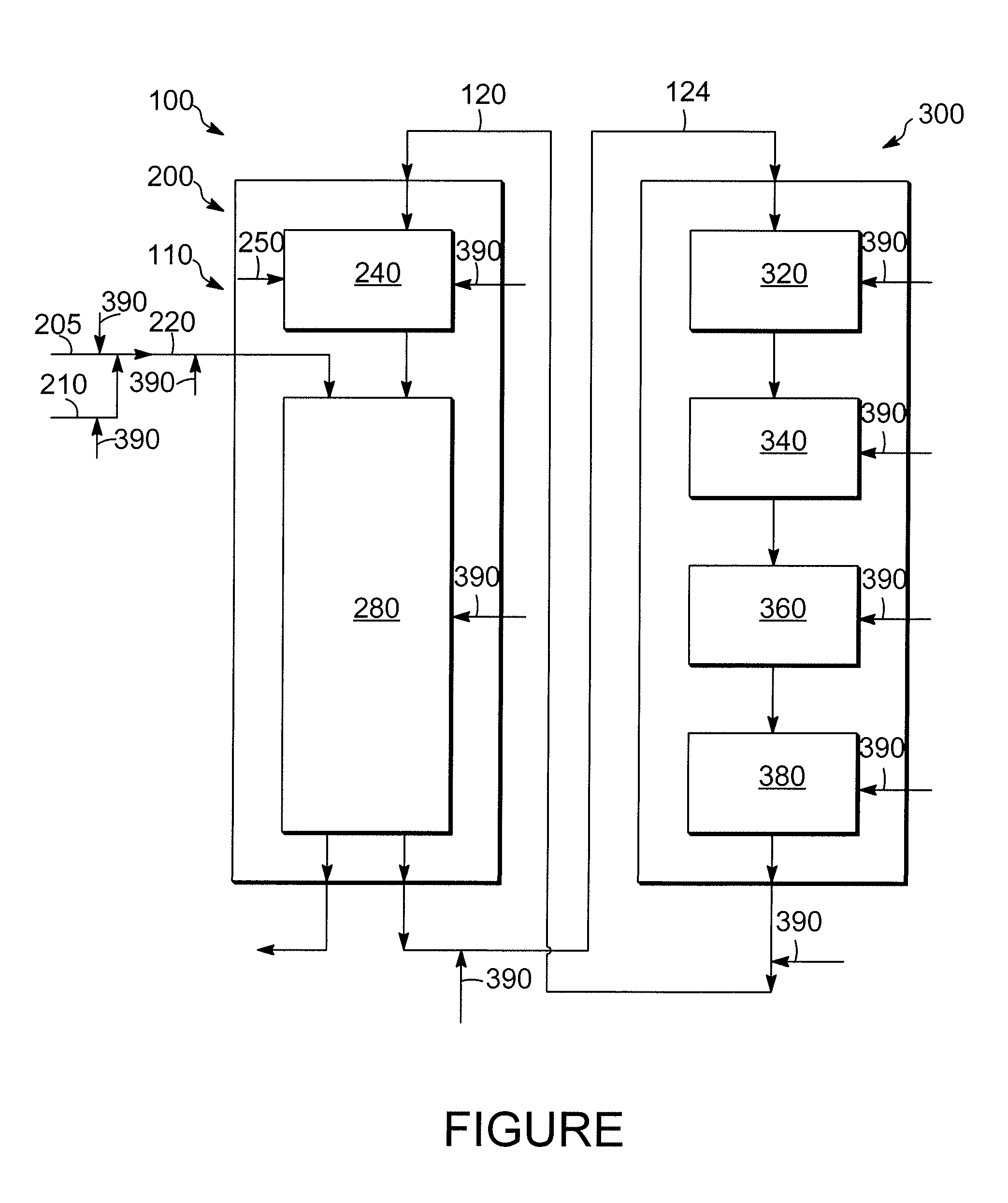

Image

Examples

example

[0055]200 cc of a fresh commercial continuous regeneration catalyst comprising Pt, Sn, and Cl on gamma alumina was loaded into a quartz reactor in four beds containing 50 cc each of the catalyst. The beds were numbered sequentially with Bed 5 located nearest to the top of the reactor, and bed 2 located nearest to the bottom of the reactor. The beds were separated by quartz wool. At the bottom of the reactor, in bed 1, a bed of 200 cc of the gamma alumina support was loaded. The initial indium levels of the catalyst and of the support were zero wt. %. Spacers were located above the top bed.

[0056]A regeneration procedure was conducted in the reactor. The steps of the regeneration procedure included (1) a heat up period in air ramping the temperature from ambient to 510° C. at 1.4° C. / min. (2) introduction of Cl2 and a HCl-containing solution as described below, during an oxychlorination step for 8 hours at 510° C. (3) Cool down period with full air to reach 93° C. (4) a reheat / ramp pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com