CdS/metallic organic frame composite photocatalysis material as well as preparation method and application thereof

A metal-organic framework, composite photocatalysis technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. , CdS instability, weak adsorption capacity and other problems, to achieve the effect of improving photoelectric stability, improving photostability, and photocurrent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

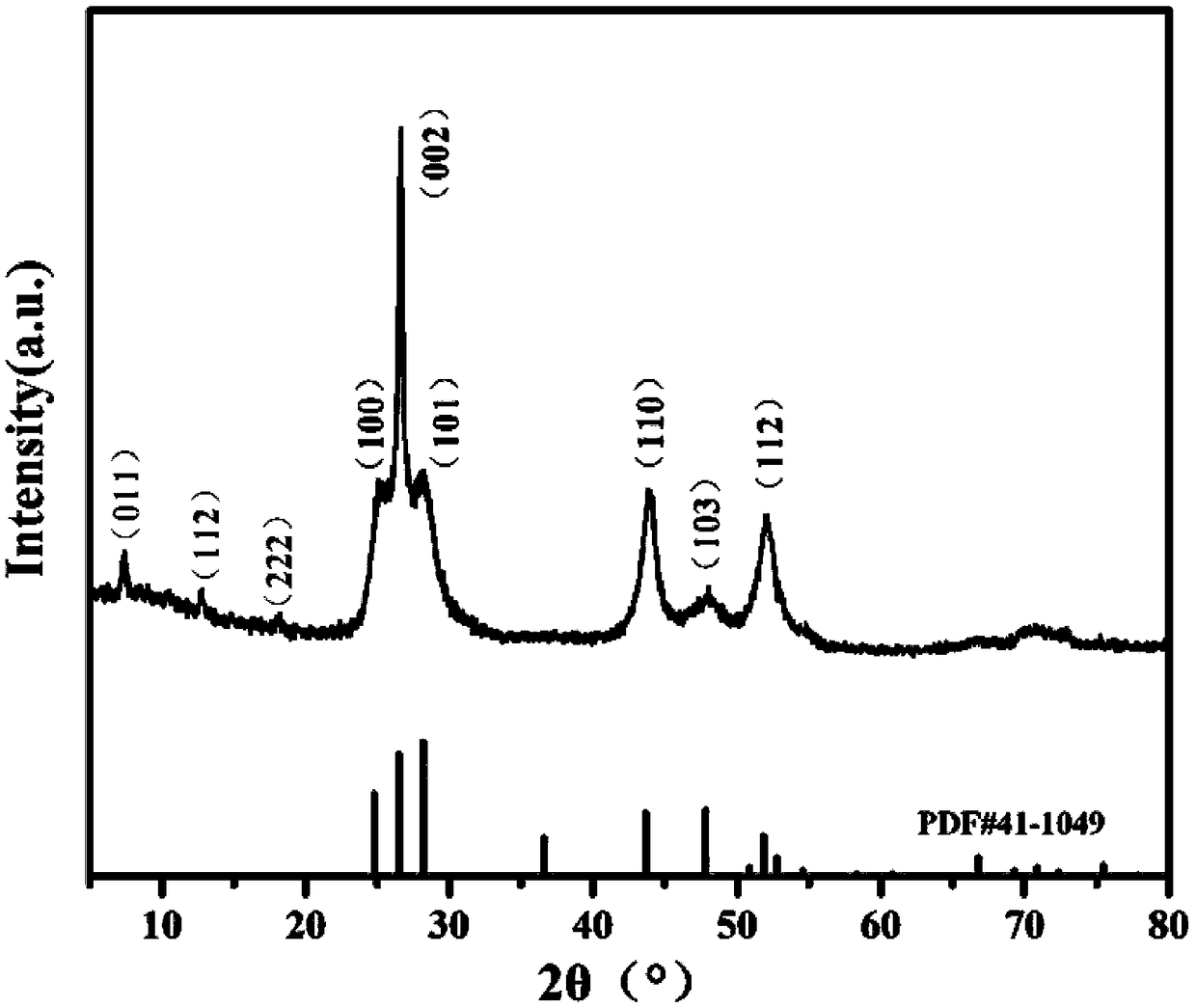

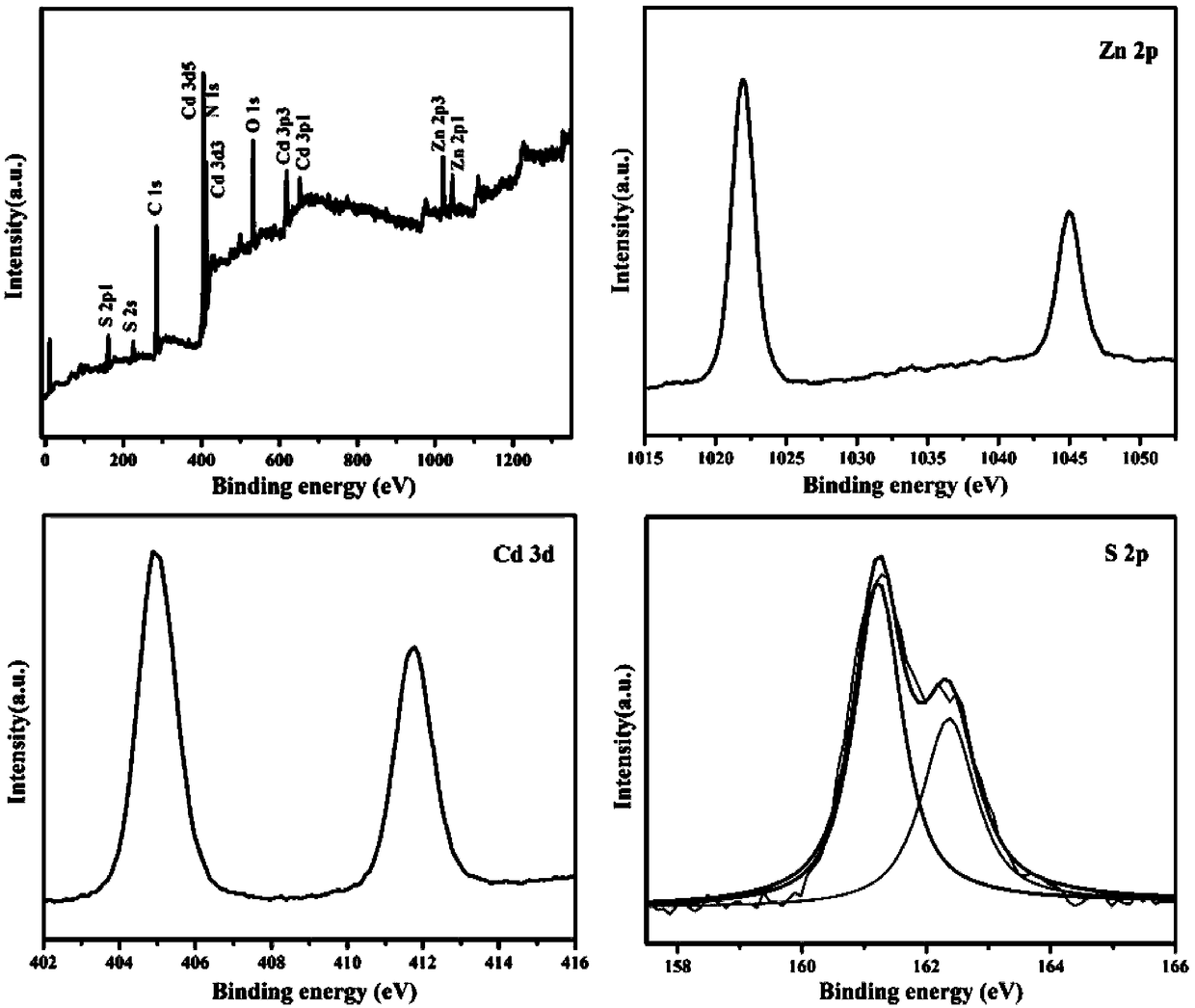

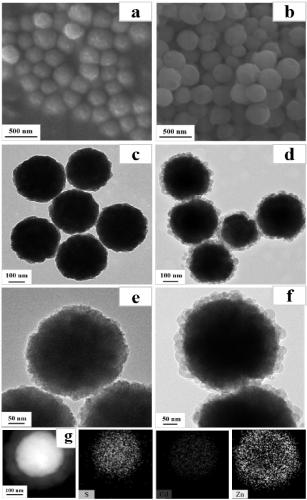

[0049] Preparation of CdS / ZIF-8 and Its Photocatalytic Reduction of CO 2 Performance Testing

[0050] Step (1): Preparation of CdS nanomaterials

[0051] 7mmol thiourea, 7mmol Cd(NO 3 ) 2 4H 2 O and 7mmol PVP were dissolved in 70ml ethylene glycol to obtain a clear solution, then, the mixed solution was transferred to a 100ml tetrafluoroethylene-lined stainless steel autoclave, and kept at 120°C for 12h. After cooling the autoclave to room temperature, a certain amount of methanol was added to the resulting solution to make the CdS nanoparticles easier to precipitate. The solution is centrifuged, the precipitate is collected, washed and freeze-dried to obtain the CdS nanoparticles.

[0052] Step (2): Preparation of CdS / ZIF-8 composite material

[0053] First, 32 mg of CdS nanoparticles were dispersed in 10 ml of methanol and homogenized by ultrasonication, and then 0.2974 g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of methanol, the two were mixed while stirring and...

Embodiment 2

[0057] Preparation of CdS / ZIF-67 and Its Photocatalytic Reduction of CO 2 Performance Testing

[0058] Step (1): Preparation of CdS nanomaterials

[0059] 7mmol thiourea, 7mmol Cd(NO 3 ) 2 4H 2 O and 7mmol PVP were dissolved in 70ml ethylene glycol to obtain a clear solution, then, the mixed solution was transferred to a 100ml tetrafluoroethylene-lined stainless steel autoclave, and kept at 120°C for 12h. After cooling the autoclave to room temperature, a certain amount of methanol was added to the resulting solution to make the CdS nanoparticles easier to precipitate. The solution is centrifuged, the precipitate is collected, washed and freeze-dried to obtain the CdS nanoparticles.

[0060] Step (2): Preparation of CdS / ZIF-67 composite material

[0061] First, 32 mg of CdS nanoparticles were dispersed in 10 ml of methanol and homogenized by ultrasonication, and then 0.2379 g of CoCl 2 6(H 2 O) Dissolve in 50ml methanol, mix the two while stirring and continue to stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com