Composite quantum dot, preparation method thereof and quantum dot light-emitting diode

A quantum dot luminescence and quantum dot technology, which is applied in the direction of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of photoelectric performance inactivation, short service life, quenching, etc., and achieve good water resistance, The effect of improving photoelectric stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

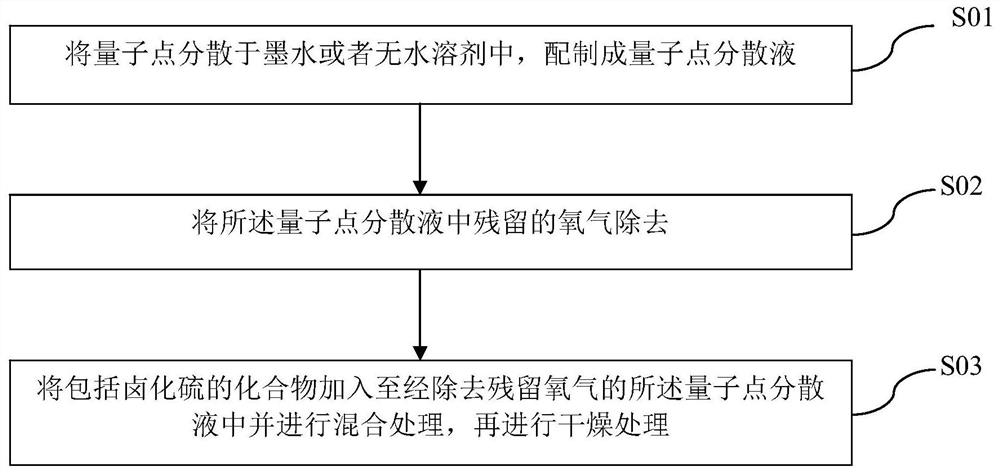

[0040] Correspondingly, the embodiment of the present invention provides the preparation method of the above composite quantum dots. The technological process of the preparation method of composite quantum dots is as figure 1 As shown, it includes the following steps:

[0041] S01: dissolving the quantum dots and preparing a quantum dot dispersion;

[0042] S02: adding the sulfur halide compound into the quantum dot dispersion liquid and performing mixing treatment.

[0043] Wherein, in the step S01, the prepared quantum dot dispersion liquid should be such that the quantum dots are fully and uniformly dispersed to form a dispersion system in which the quantum dots are uniformly dispersed. Therefore, in an embodiment, the solution for dissolving quantum dots may be a common solvent for preparing quantum dots or a solvent for preparing quantum dot inks. In a specific embodiment, the solvent is selected from at least one of n-octane, n-dodecane, decane and n-hexane.

[0044]...

Embodiment 11

[0071] This embodiment provides a composite quantum dot and its preparation method. The composite quantum dots include green core-shell type CdSe / ZnSe quantum dots, which are combined and coated with disulfide dichloride (S 2 Cl 2 ).

[0072] Composite quantum dot preparation steps include:

[0073] S11: Dissolve the green core-shell type CdSe / ZnSe quantum dots in n-octane solvent to prepare a CdSe / ZnSe quantum dot dispersion; wherein, control the concentration of CdSe / ZnSe quantum dots in the CdSe / ZnSe quantum dot dispersion to 20 mg / mL;

[0074] S12: Bubble the CdSe / ZnSe quantum dot dispersion prepared in step S11 with argon in an argon atmosphere, and stir at 20-30 degrees Celsius at a speed of 3000 rpm for 30 minutes until the quantum dots are completely dissolved;

[0075] S13: Add disulfur dichloride S to the CdSe / ZnSe quantum dot dispersion after the bubbling treatment in step S11 at a ratio of 2.0 mg / mL 2 Cl 2, continue to stir for 30 minutes, and dry it.

Embodiment 12

[0077] This embodiment provides a composite quantum dot and its preparation method. The composite quantum dots include green core-shell type CdSe / ZnSe quantum dots, which are combined and coated with disulfide dibromide (S 2 Br 2 ).

[0078] Composite quantum dot preparation steps include:

[0079] S11: Dissolve the green core-shell type CdSe / ZnSe quantum dots in n-octane solvent to prepare a CdSe / ZnSe quantum dot dispersion; wherein, the concentration of CdSe / ZnSe quantum dots in the CdSe / ZnSe quantum dot dispersion is controlled to 20mg / mL;

[0080] S12: Bubble the CdSe / ZnSe quantum dot dispersion prepared in step S11 with argon in an argon atmosphere, and stir at 20-30 degrees Celsius at a speed of 3000 rpm for 30 minutes until the quantum dots are completely dissolved;

[0081] S13: Add S to the CdSe / ZnSe quantum dot dispersion after the bubbling treatment in step S11 at a ratio of 2.0 mg / mL 2 Br 2 , continue to stir for 30 minutes, and dry it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com