Process For Heating A Hydrocarbon Stream Entering A Reaction Zone With A Heater Convection Section

a technology of hydrocarbon stream and heater, which is applied in the direction of catalytic naphtha reforming, naphtha treatment, and thermal naphtha reforming, can solve the problems of insufficient heat generation of combined feed stream to the desired inlet temperature of the first reactor, and the combined feed stream often requires additional heating, so as to reduce the capital and catalyst cost, increase yield, and reduce the effect of capital cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

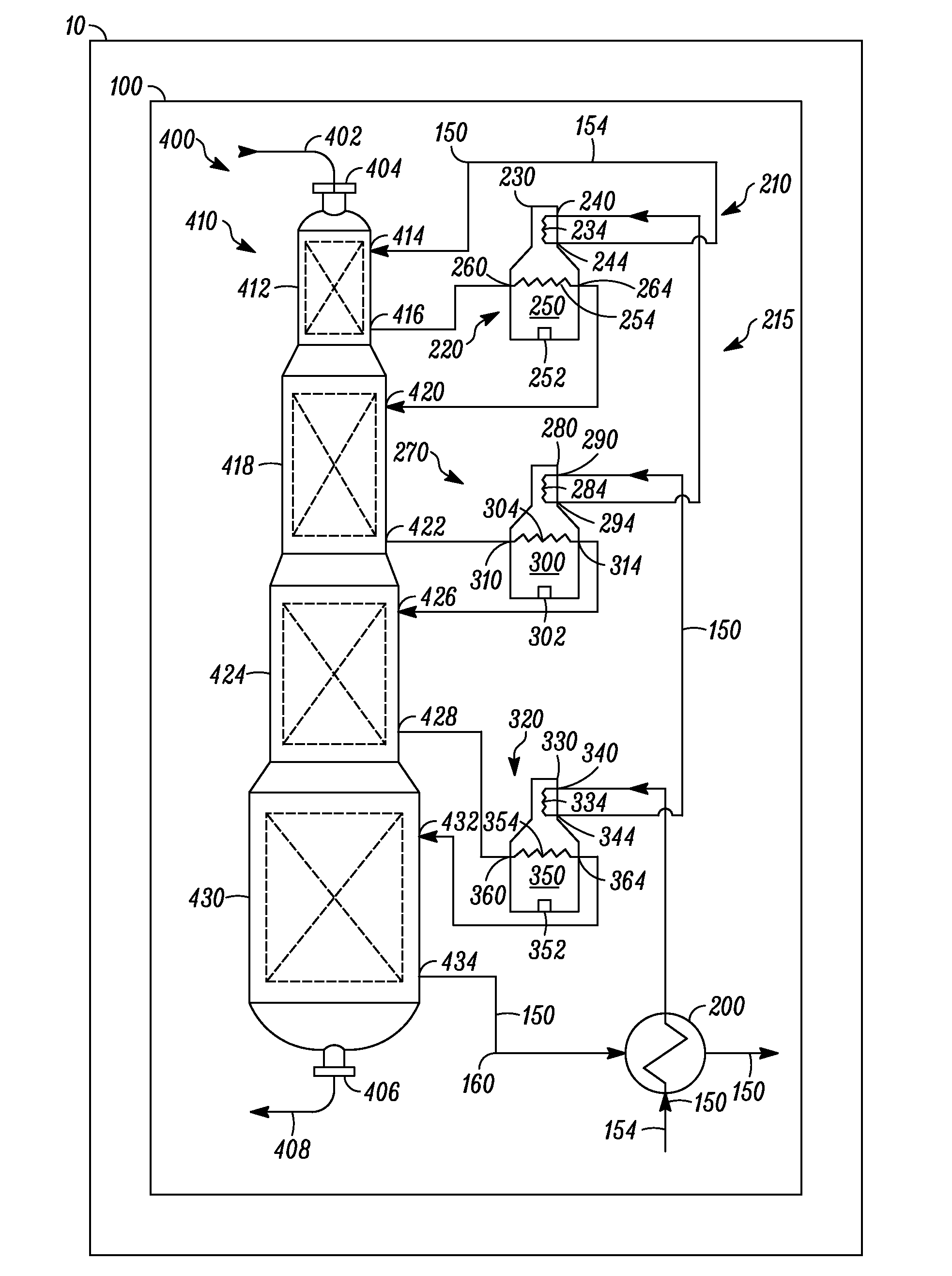

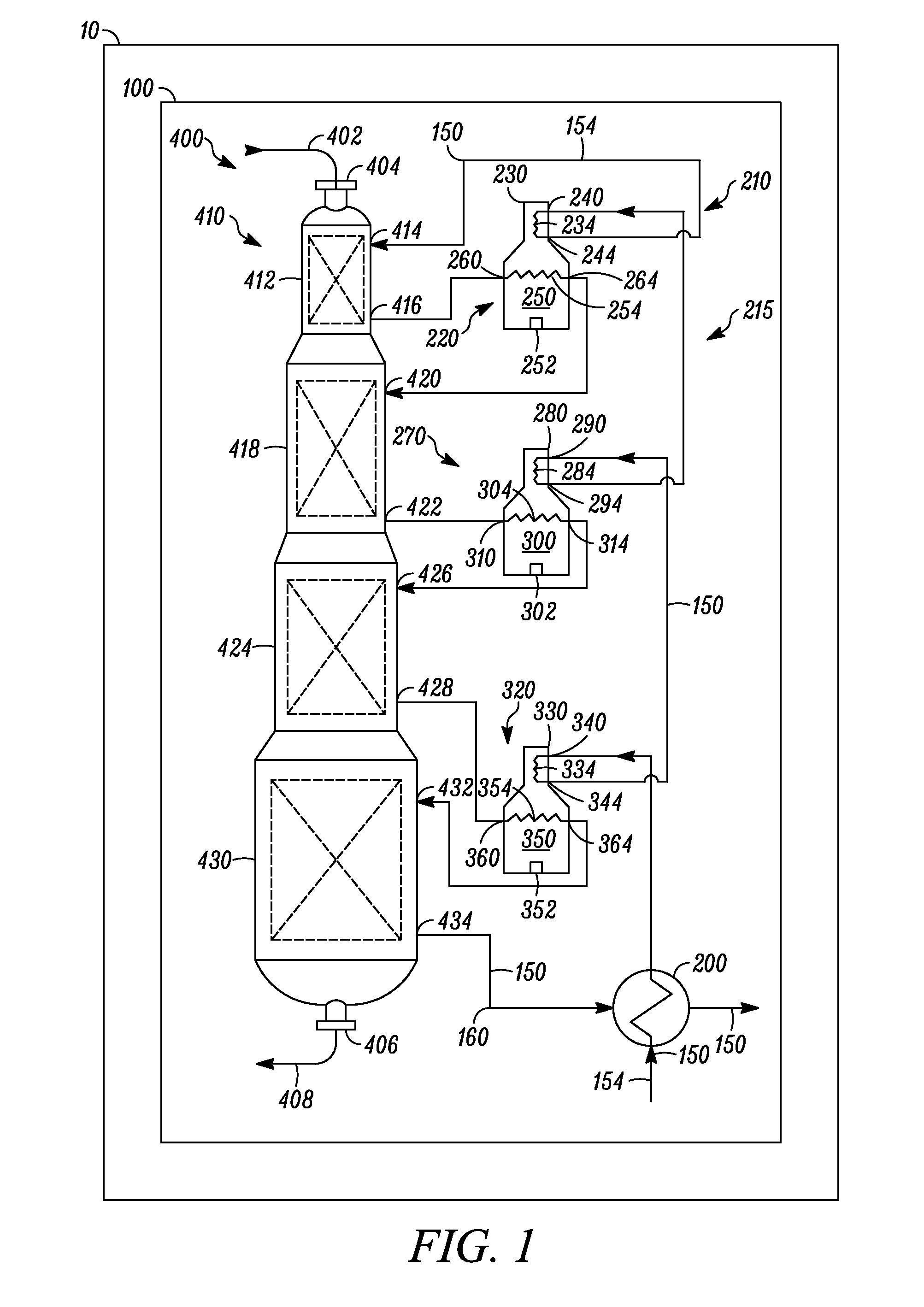

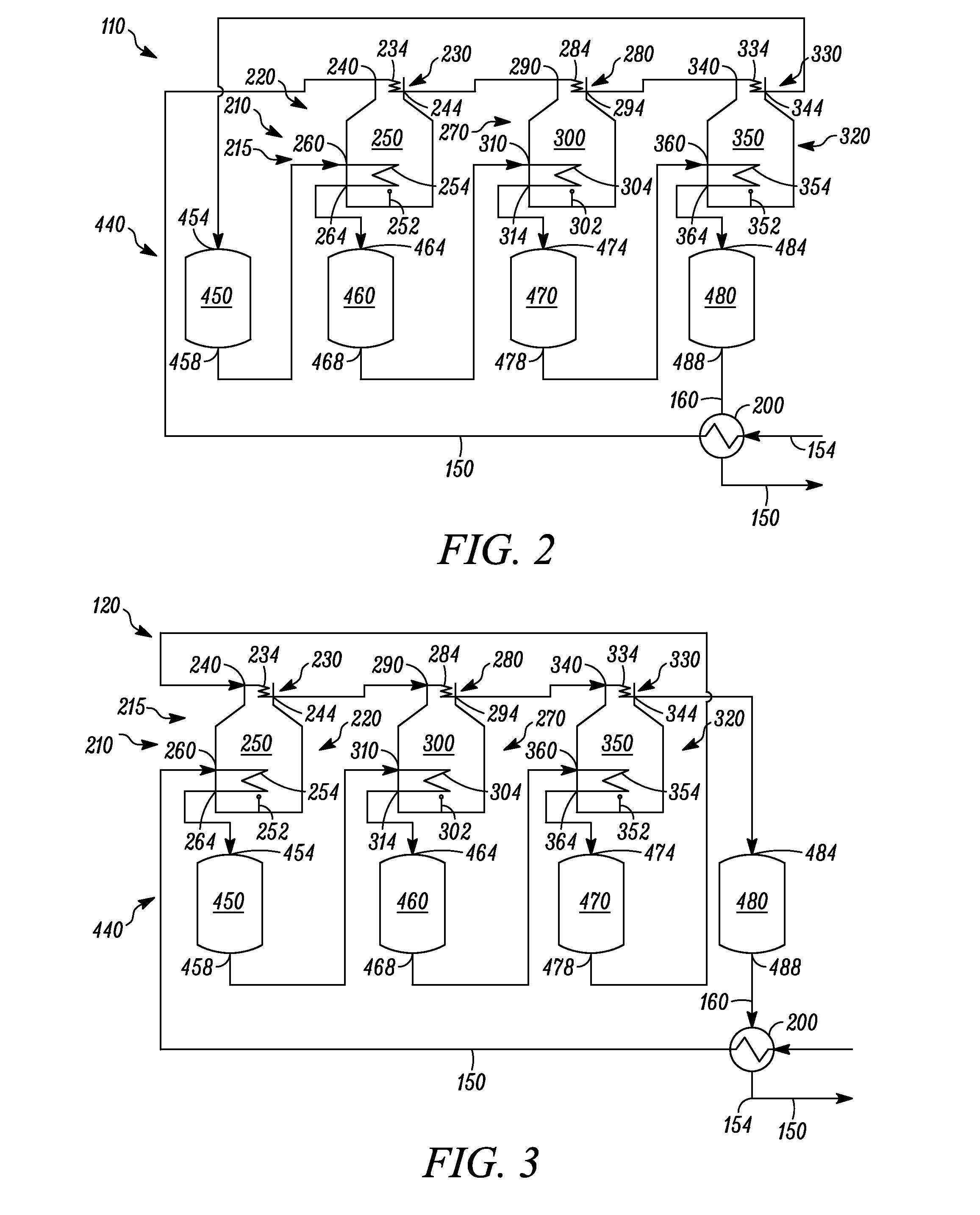

[0035]Generally, the embodiments disclosed herein are applicable to multiple reaction systems with multiple heaters, such as various hydrocarbon conversion processes, including those that are exothermic and endothermic. As an example, the embodiments of the invention could be applicable for an exothermic process with multiple reaction zones where an ascending temperature profile would be desirable. Preferably, the embodiments disclosed herein are applicable for endothermic reforming processes.

[0036]Generally, a hydrocarbon feedstock that is charged for a reforming process includes naphthenes and paraffins that boil within the gasoline range. The preferred charge stocks are naphthas consisting principally of naphthenes and paraffins, although, in many cases, aromatics also can be present. This preferred class includes straight-run gasolines, natural gasolines, synthetic gasolines, and the like. As an alternative embodiment, it is frequently advantageous to charge thermally or catalyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com