Patents

Literature

179results about How to "Lower catalyst costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for effectively hydrolyzing cellulose in ion liquid

InactiveCN101289817ALower catalyst costsReduce acid consumptionCation exchanger materialsOrganic anion exchangersIonSolvent

The invention relates to cellulosic hydrolysis, in particular to a method for high-efficiently hydrolyzing celluloses in ionic liquid. In the method, the ionic liquid in which celluloses are dissolved is used as solvent, and water, the equivalent weight of which is more than or equal to 1 mol, is used as reactant, and inorganic acids, the catalytic amount of which is the stoichiometric amount, are used as catalyst, and celluloses are reacted under the conditions of the normal pressure and the temperature of between 70 to 100 DEG C for 2min to 9hr; after the reaction is over, celluloses undergo the cold water quenching reaction and the alkali neutralization reaction, and the cellulose hydrolysate is obtained; total reducing sugar and glucose in the cellulose hydrolysate are taken with quantitative chemical analysis, and results of which show that the highest yield of reducing sugar is 73 percent, and correspondingly the yield of glucose is 53 percent. Compared with the conventional hydrolysis method, the method of the invention has the advantages of unnecessary pretreatment, mild reaction conditions, high hydrolytic activity, quick reaction speed, little acid consumption, low requirement on corrosion resistance of a reactor and easy tracking and controlling of the extent of reaction; the method opens a new road for resolving the lasting problem of the complete utilization of lignocelluloses.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

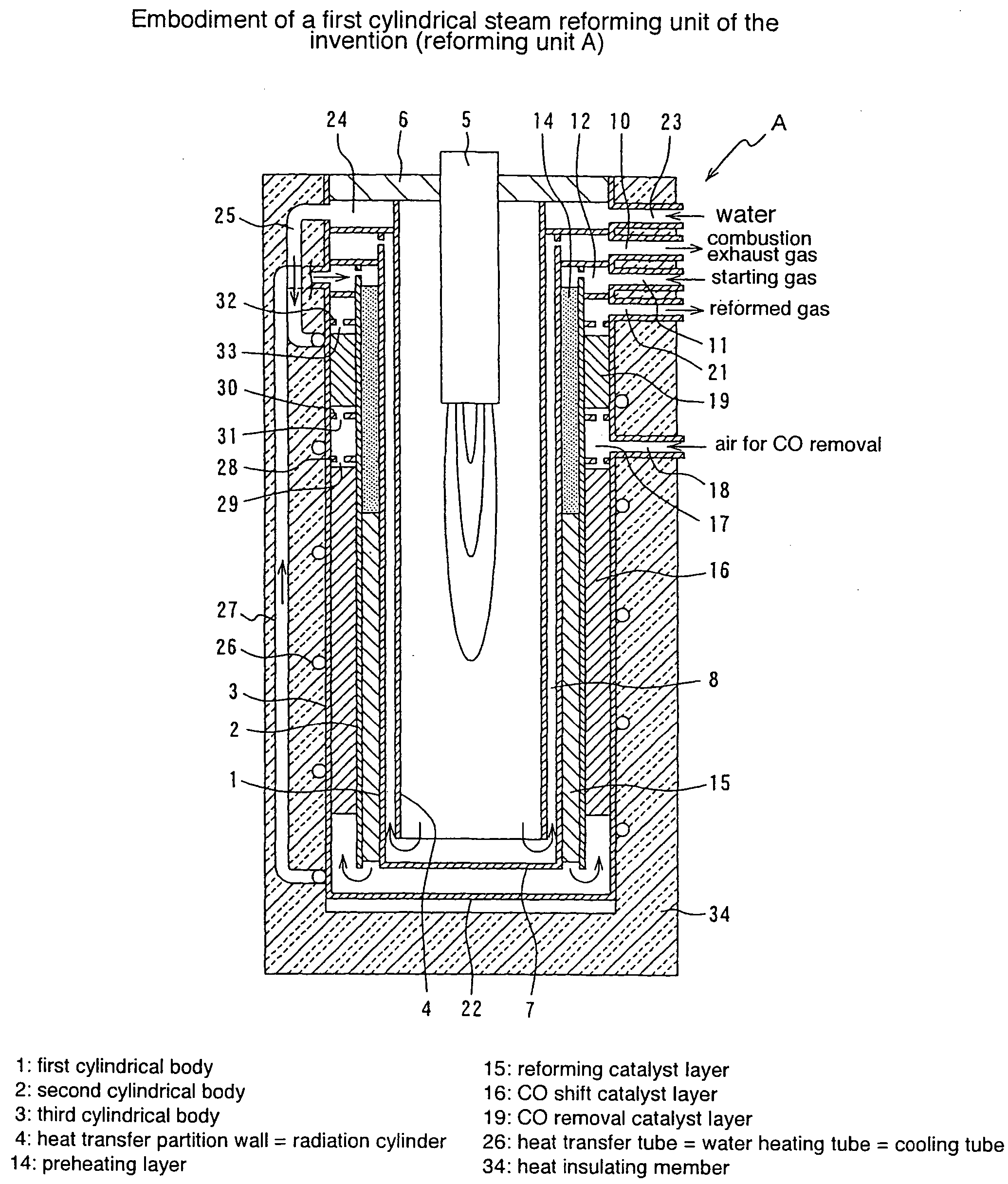

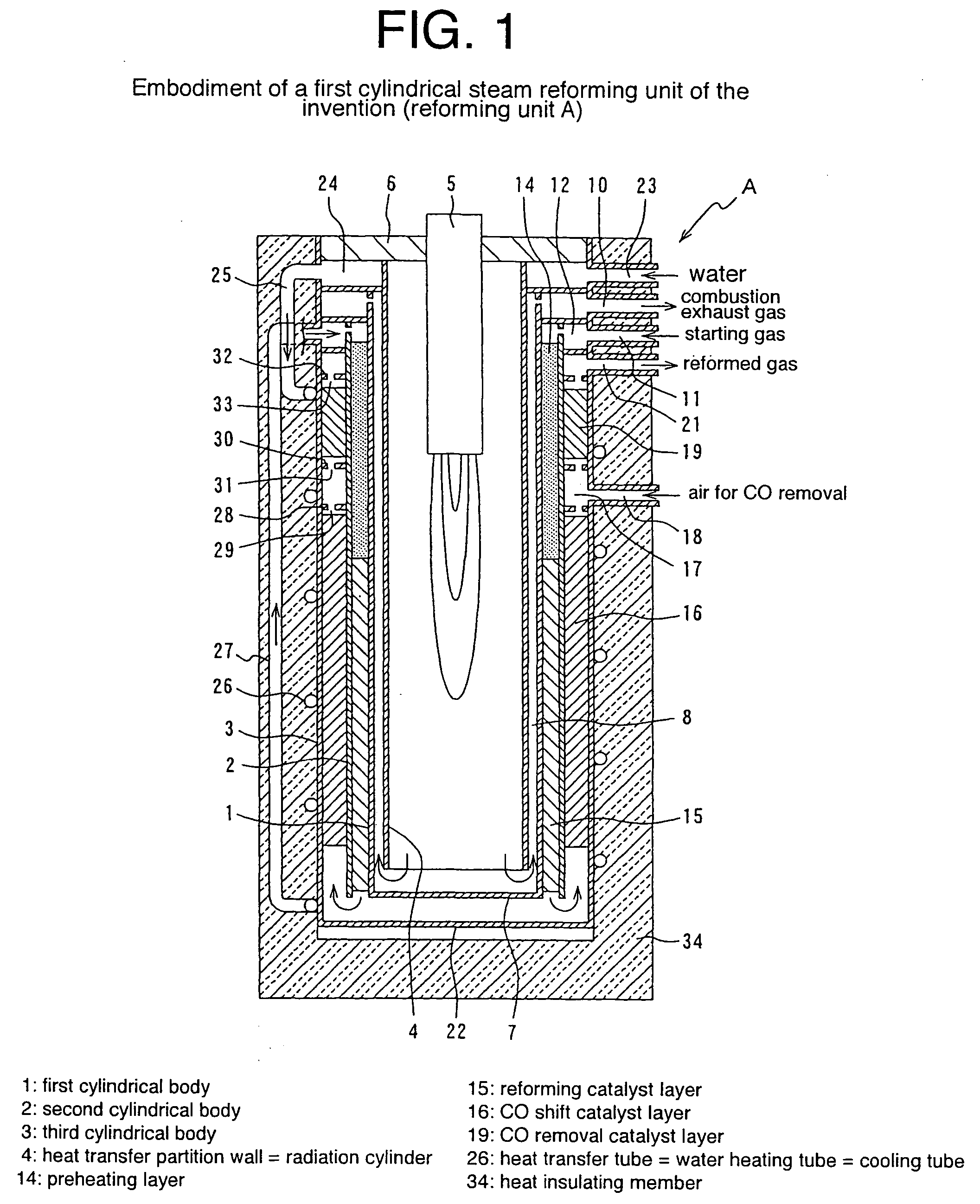

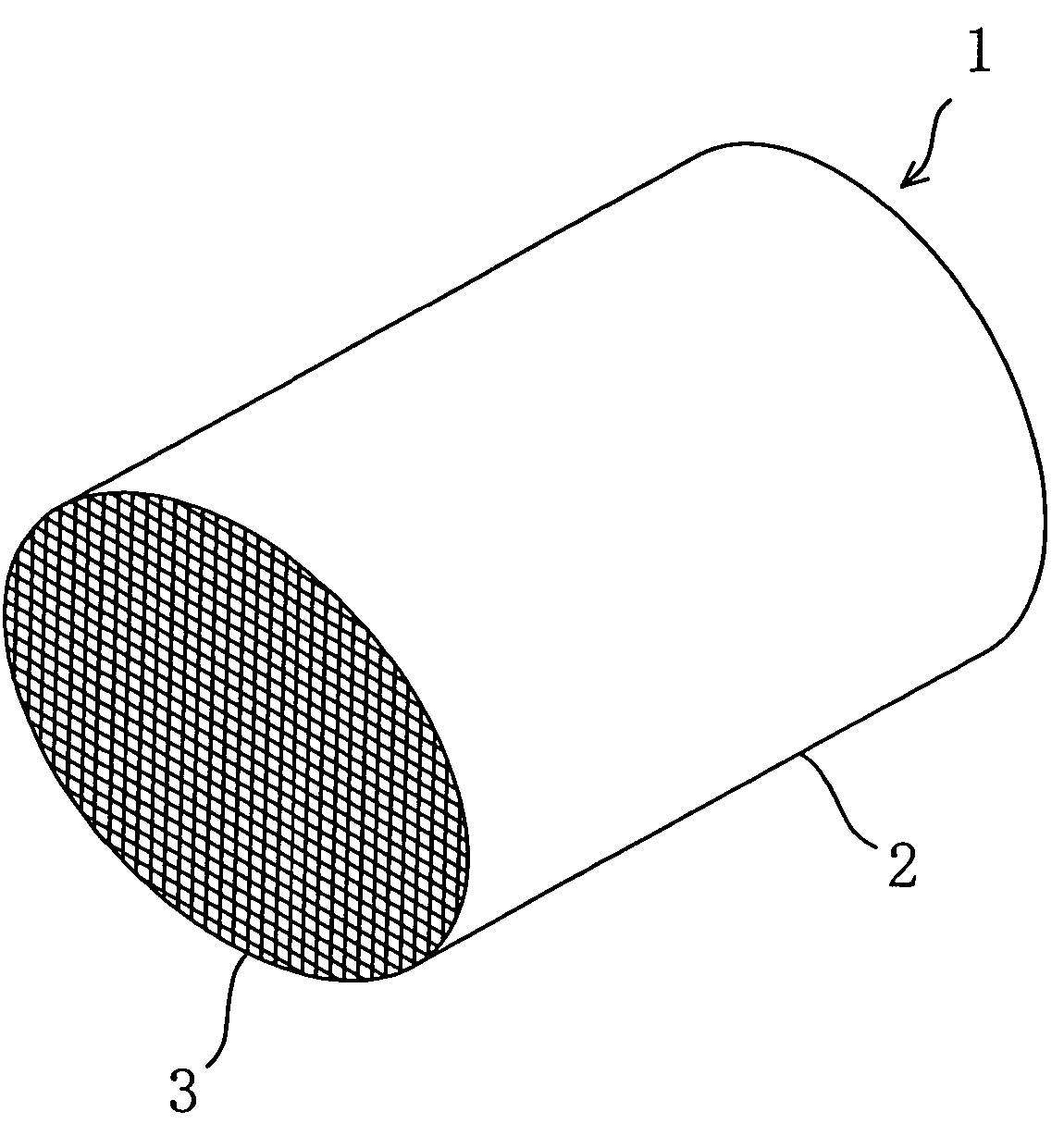

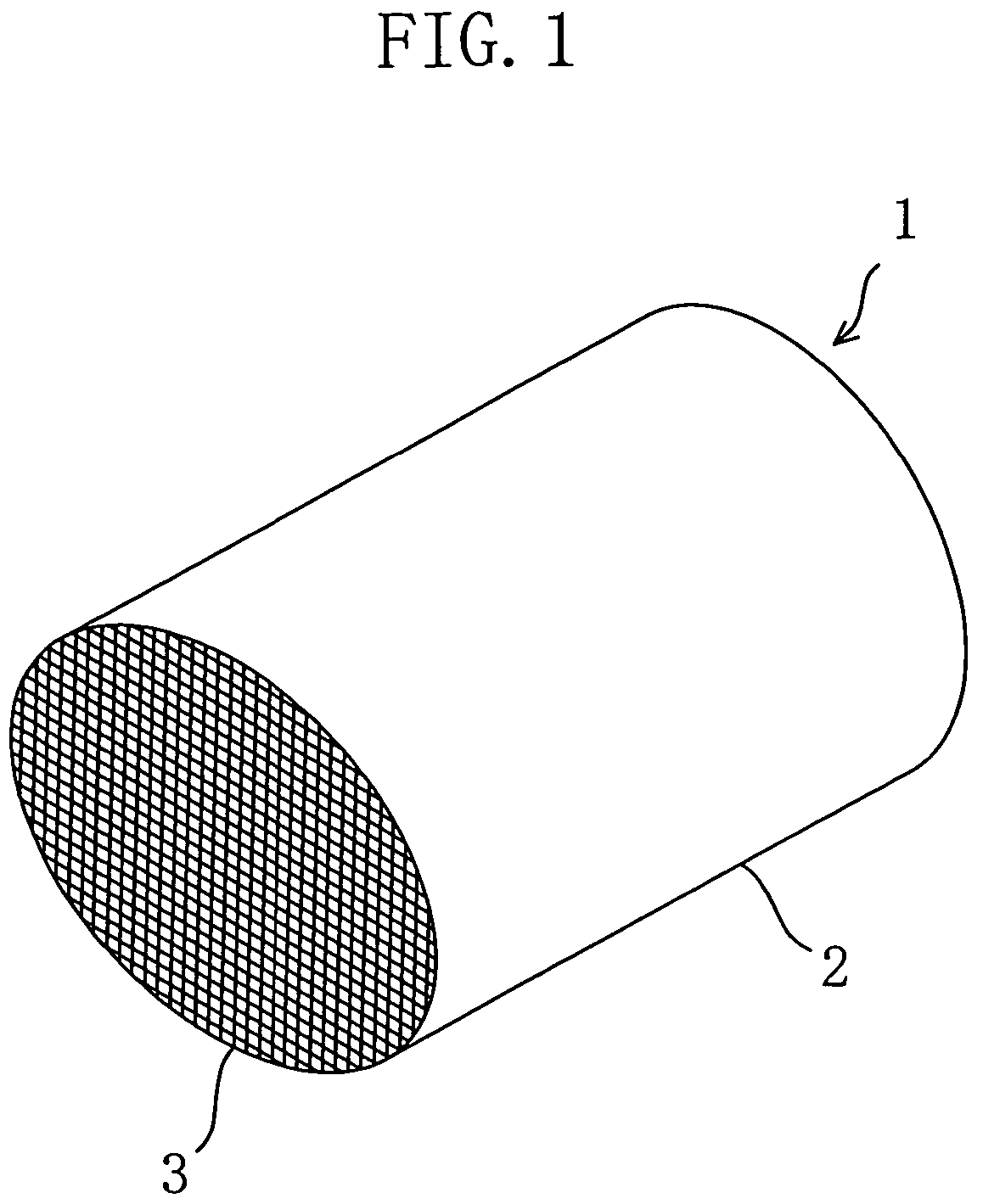

Cylindrical water vapor reforming unit

InactiveUS20040144029A1Small sizePass smoothlyHydrogen/synthetic gas productionChemical/physical/physico-chemical processesSteam reformingInsulation layer

A cylindrical steam reforming unit comprising a plurality of cylindrical bodies consisting of a first cylindrical body, a second cylindrical body and a third cylindrical body of successively increasing diameters disposed in a concentric spaced relation, a radiation cylinder disposed within and concentrically with the first cylindrical body, a burner disposed in the radial central portion of the radiation cylinder, and a reforming catalyst layer with a reforming catalyst filled in a gap between the first and second cylindrical bodies, wherein a CO shift catalyst layer and a CO removal catalyst layer are disposed in a gap between the second and third cylindrical bodies, the CO shift catalyst layer being formed in a gap with the direction of flow reversed at one axial end of the reforming catalyst layer and through a heat recovery layer of predetermined length. According to this reforming unit, without internally disposing a heat insulation layer, a cooling mechanism or the like, the reforming catalyst layer, CO shift catalyst layer, and CO removal catalyst layer can be integrated, achieving various useful effects, including size and weight reductions and the shortening of startup time.

Owner:TOKYO GAS CO LTD

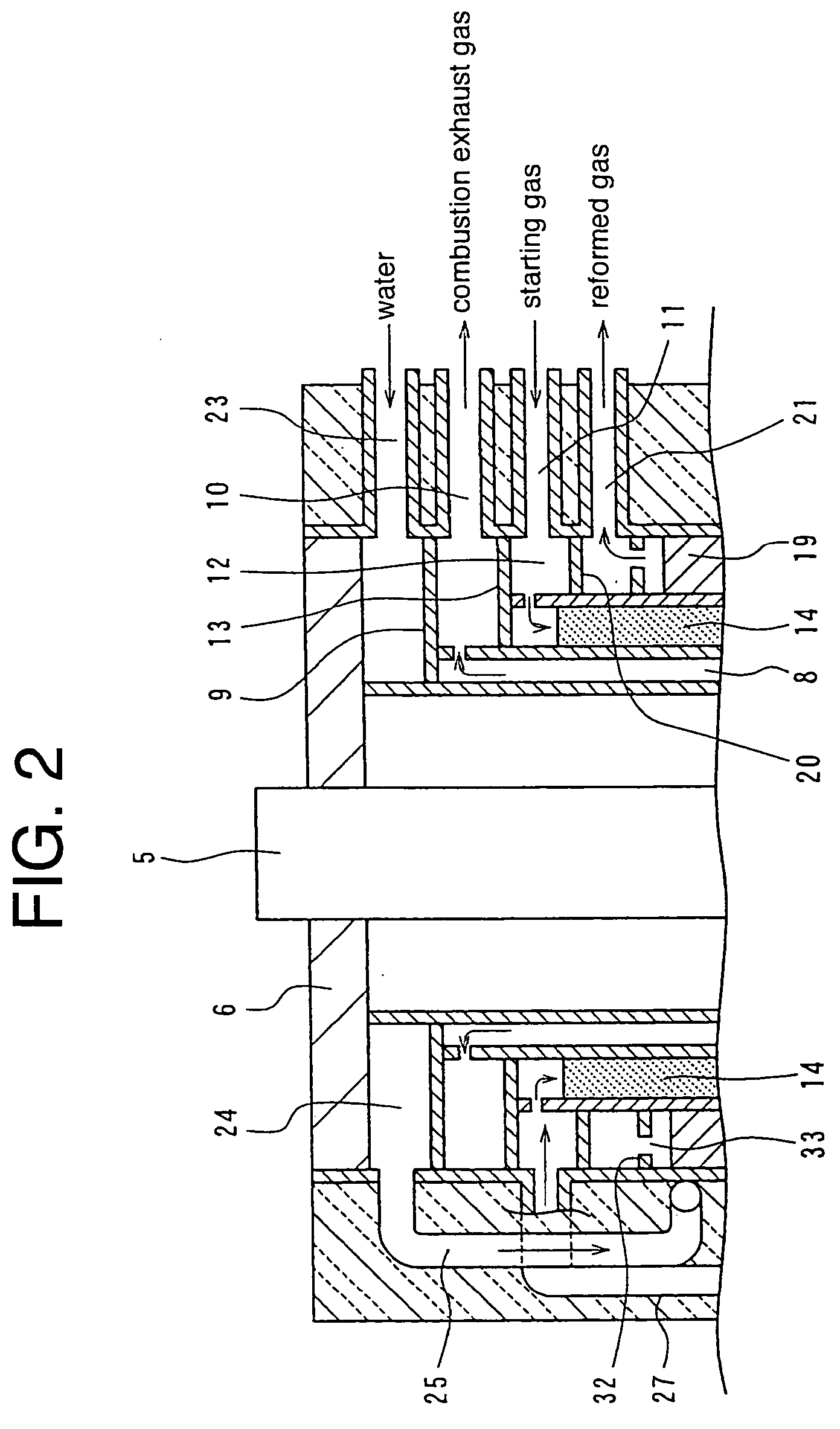

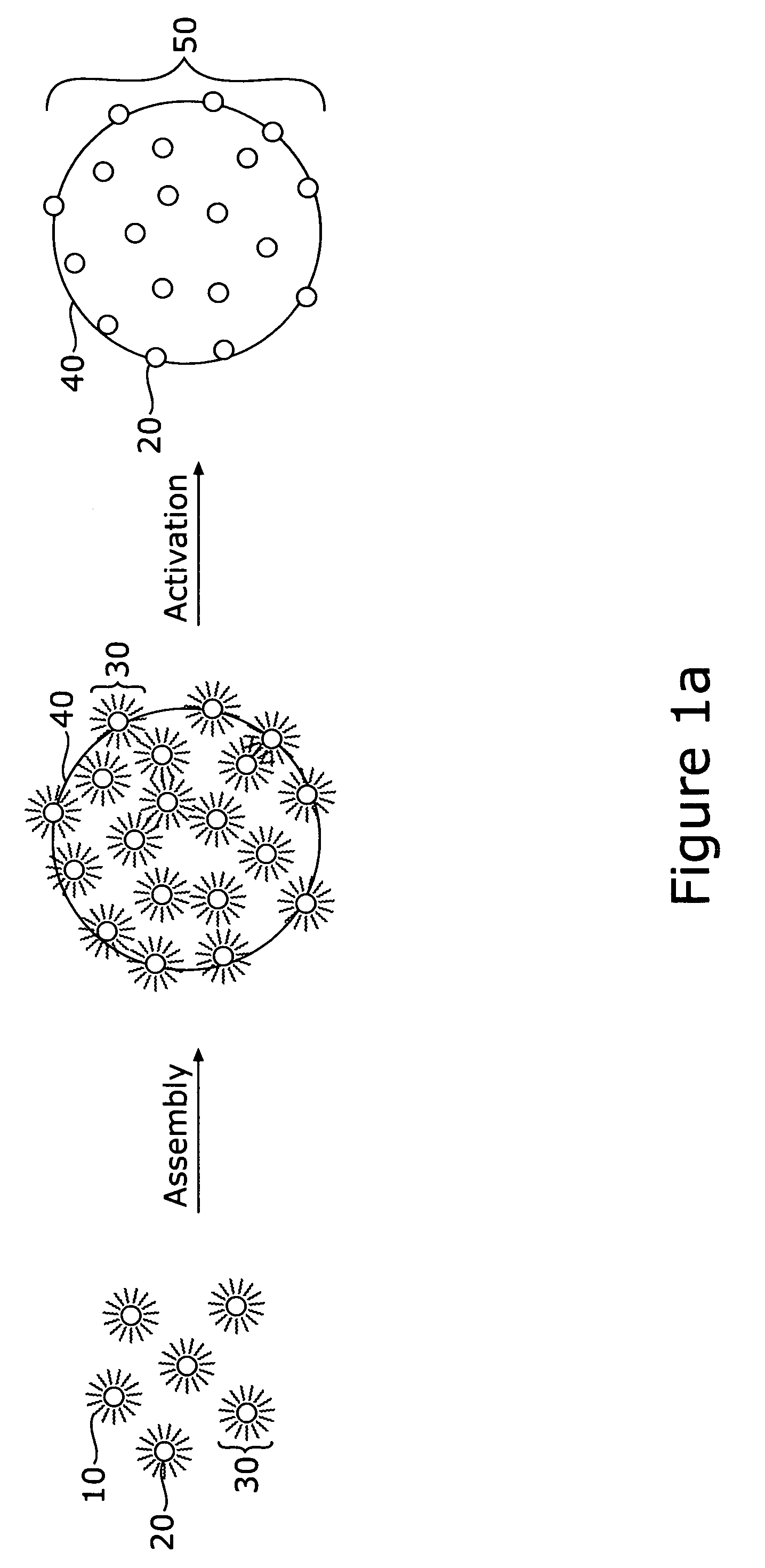

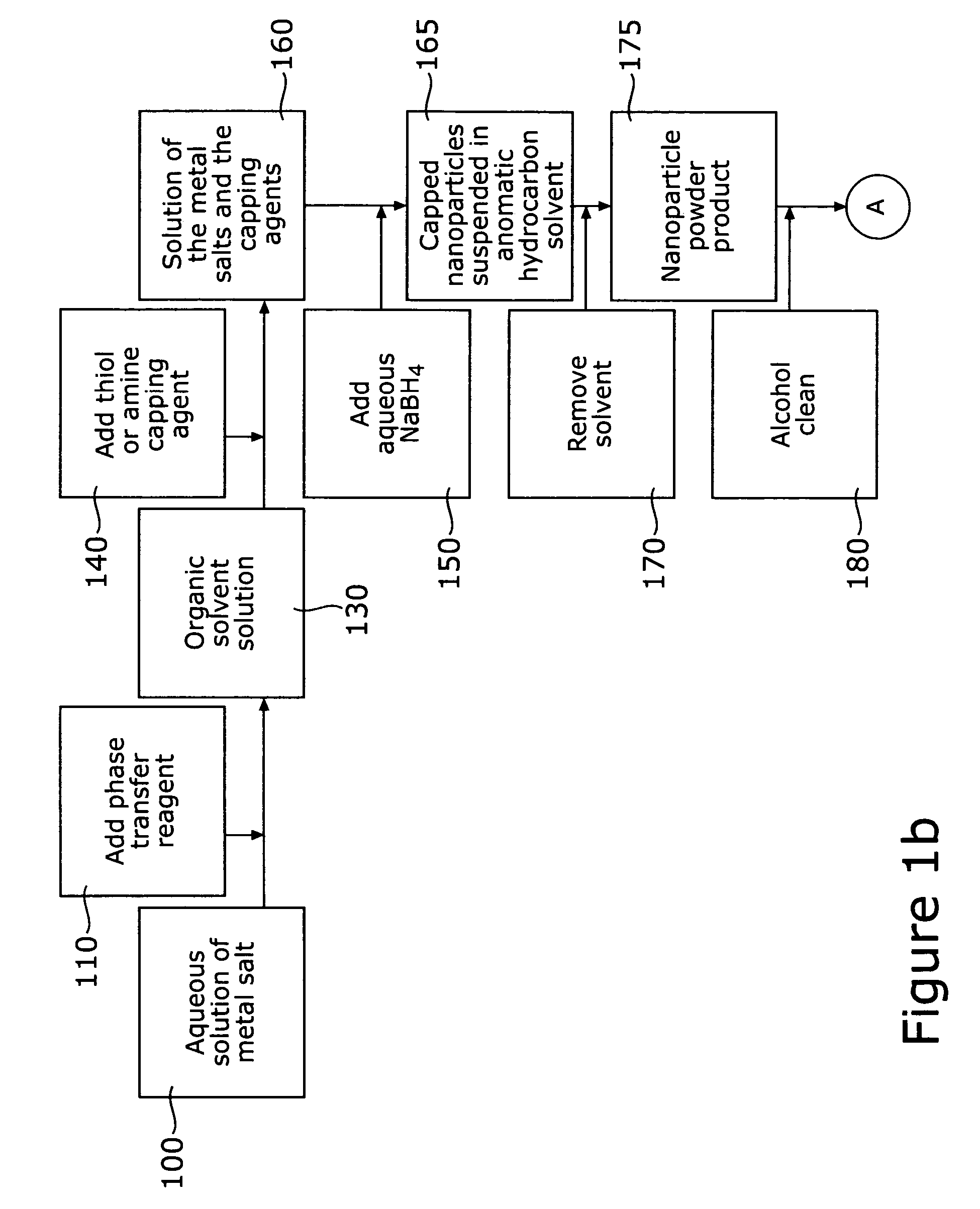

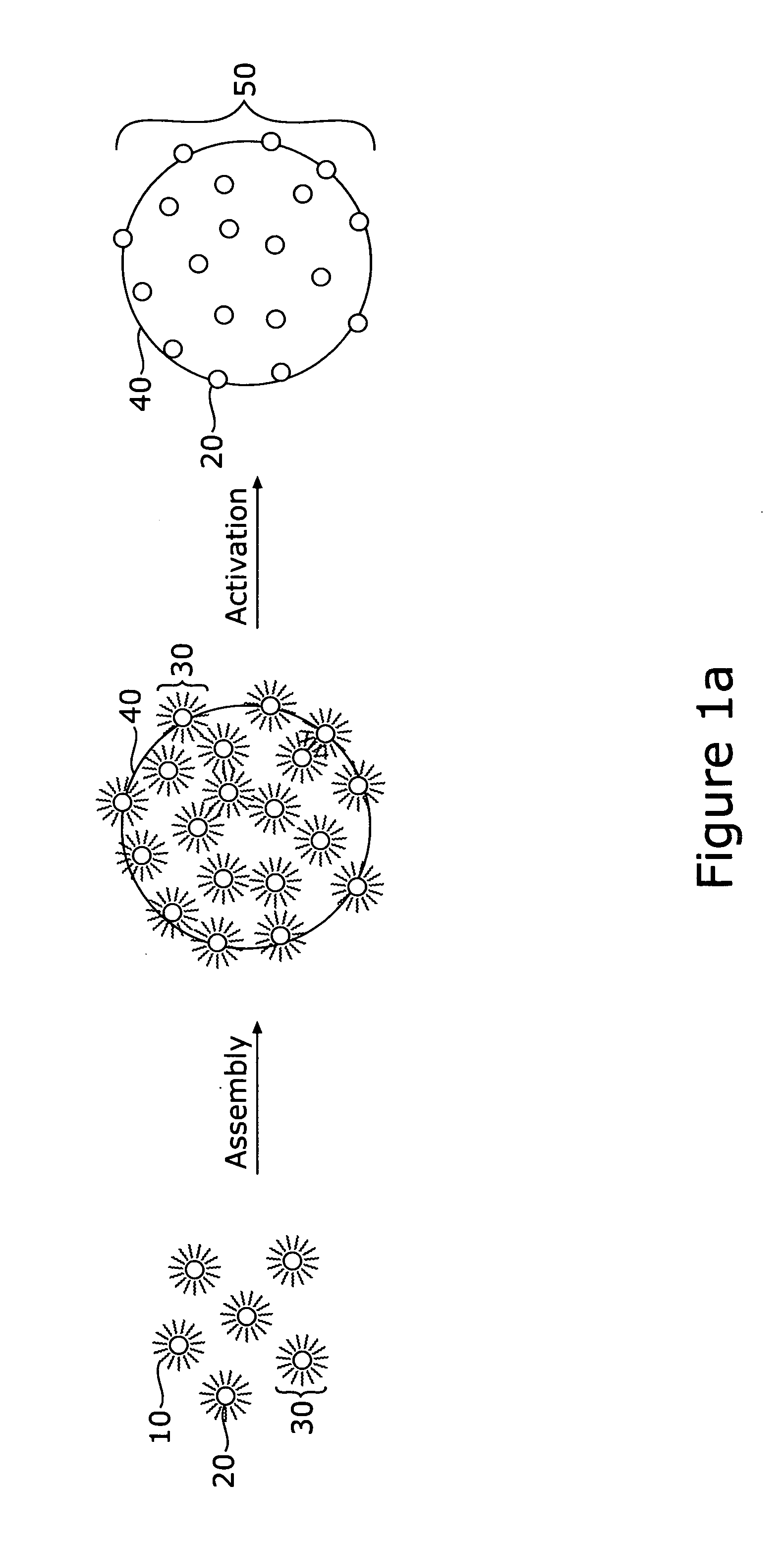

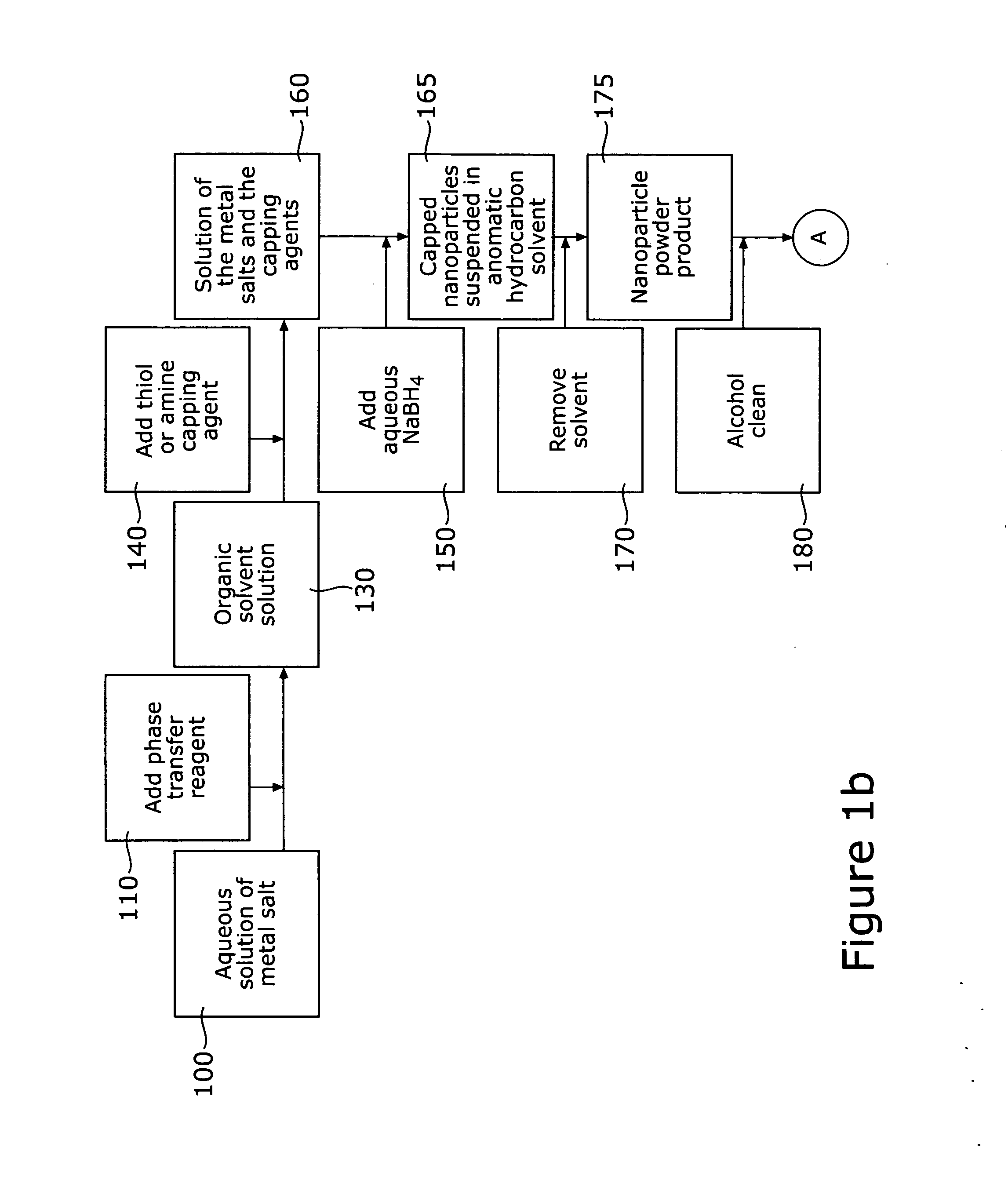

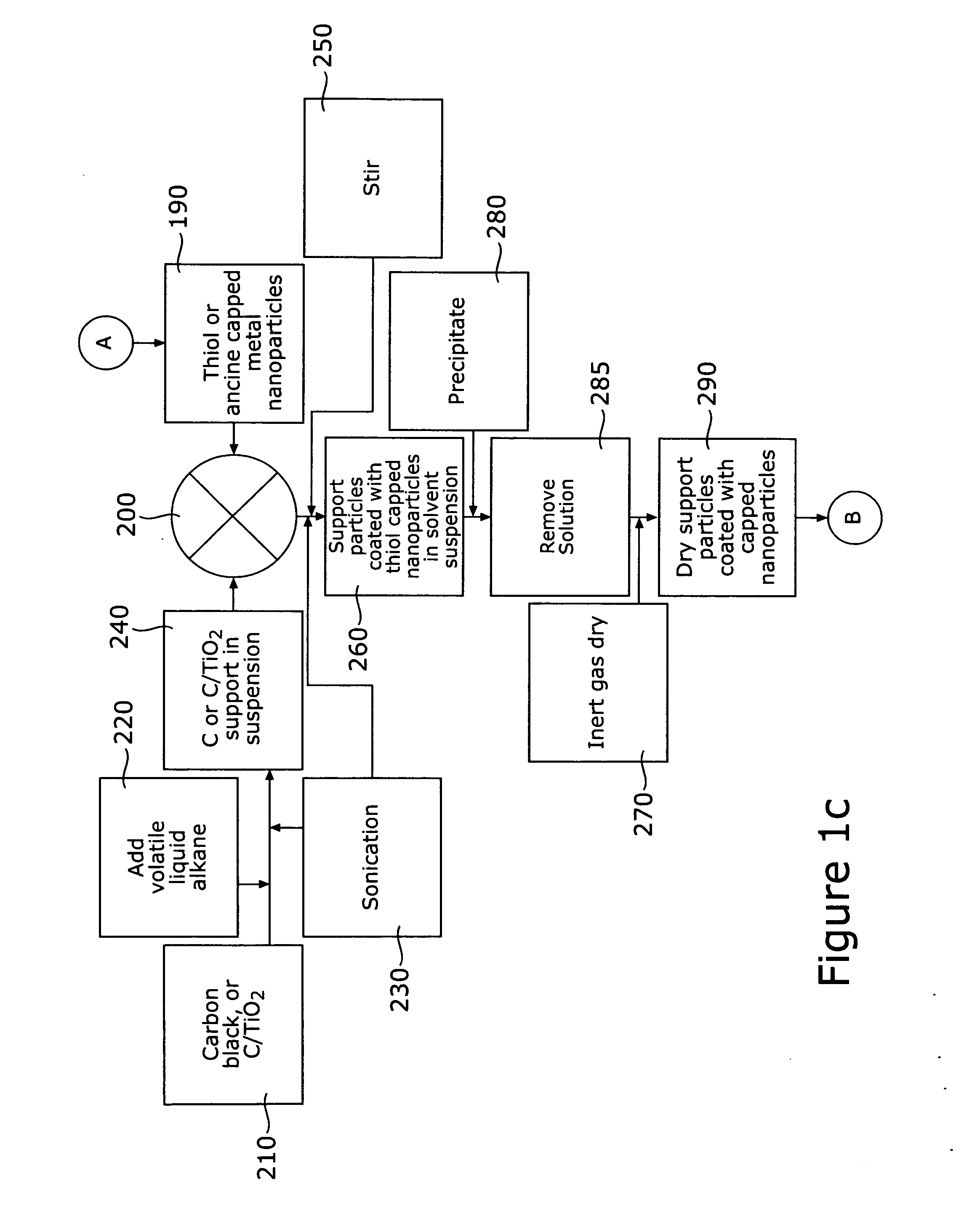

Gold-based alloy nanoparticles for use in fuel cell catalysts

InactiveUS7208439B2Lower catalyst costsLarge specific surface areaMaterial nanotechnologyCell electrodesFuel cellsMethanol

A method is featured for fabricating Carbon-supported AuPt nanoparticle catalysts for fuel cells, and particularly fuel cells using methanol as the fuel. The method prepares AuPt-based fuel cell catalysts having a wide range of controllable Au:Pt ratios. The AuPt catalysis are supportable on both carbon black (C) and C / TiO2 support materials. These materials demonstrate electro-catalytic activity towards CO and methanol oxidation, and O2 reduction. The same catalyst material is useful in constructing both anodes and cathodes, and demonstrates bifunctional activity.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

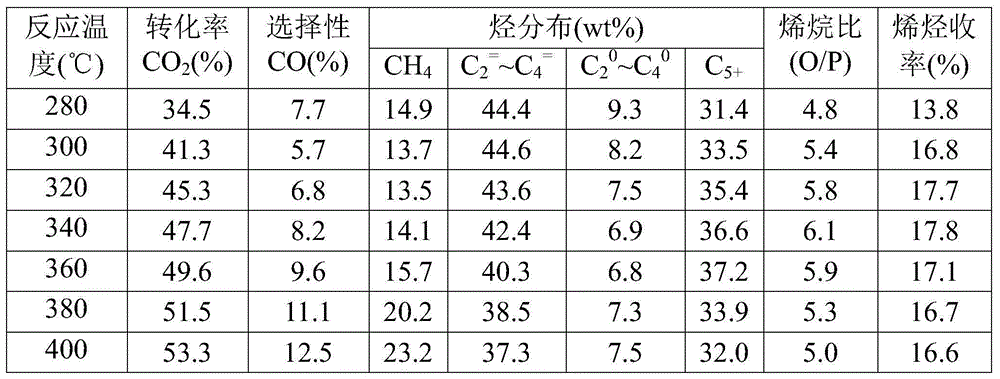

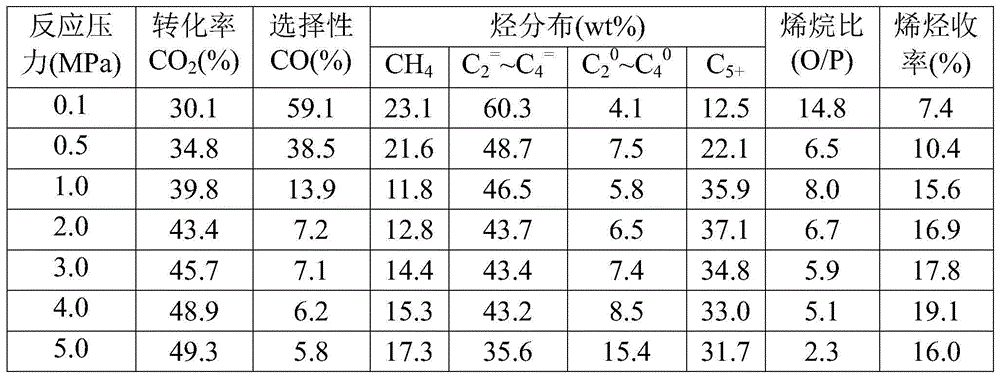

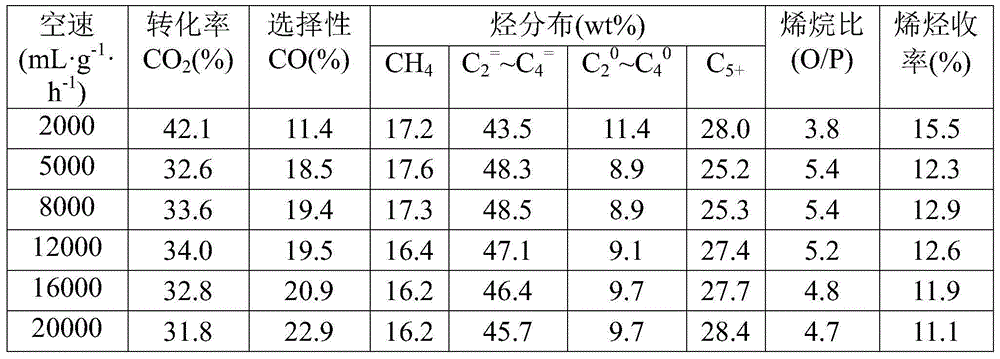

Iron-based catalyst for low-carbon olefin production through CO2 hydrogenation, and preparation and applications thereof

ActiveCN106031871AEasy to prepareLower catalyst costsHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsOxideFixed bed

The present invention provides an iron-based catalyst for low-carbon olefin production through CO2 hydrogenation, wherein the main active component of the catalyst is Fe3O4, the auxiliary agent is added or is not added, and is an oxide, the content of the auxiliary agent accounts for 0-30% of the total mass of the catalyst, and the auxiliary agent is one or more than two selected from the oxide of Si, Al, Mn, K, Cu, Na, Zr, V, Zn and Ce. The present invention further provides a preparation method and applications of the catalyst. According to the present invention, the catalyst has the following beneficial effects that 1) the particles have characteristics of regular spherical shape, uniform spatial distribution, and narrow size distribution; 2) the raw materials are inexpensive and easy to obtain, and the preparation method has characteristics of simpleness and low cost, and is suitable for industrial production; 3) the catalyst has characteristics of high mechanical strength, good wear resistance and compression resistance, and is suitable for the fixed bed, the fluidized bed and the slurry bed; 4) the CO2 hydrogenation activity and the low-carbon olefin selectivity are high, the single-pass conversion rate can achieve more than 40%, the methane selectivity in the hydrocarbon product is lower than 15%, the low-carbon olefin selectivity is higher than 40%, the alkene / alkane ratio (O / P) is 2-12, and the yield of the low-carbon olefin can achieve 10-60 g / m<3> (CO2+H2).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Gold-based alloy nanoparticles for use in fuel cell catalysts

InactiveUS20060178260A1Improve energy efficiencyLower catalyst costsMaterial nanotechnologyTransportation and packagingFuel cellsMethanol

A method is featured for fabricating Carbon-supported AuPt nanoparticle catalysts for fuel cells, and particularly fuel cells using methanol as the fuel. The method prepares AuPt-based fuel cell catalysts having a wide range of controllable Au:Pt ratios. The AuPt catalysis are supportable on both carbon black (C) and C / TiO2 support materials. These materials demonstrate electro-catalytic activity towards CO and methanol oxidation, and O2 reduction. The same catalyst material is useful in constructing both anodes and cathodes, and demonstrates bifunctional activity.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Anion modified mercury-free catalyst for ethyne hydrochlorination reaction, and preparation method thereof

InactiveCN103272619AHarm reductionAvoid inactivationPhysical/chemical process catalystsPreparation by halogen halide additionPhosphatePyrophosphate

The invention discloses an anion modified mercury-free catalyst for an ethyne hydrochlorination reaction, and a preparation method thereof. The catalyst comprises a catalyst carrier and an active component, wherein the catalyst carrier is active carbon, the active component is a sulfate, a chloride, a phosphate or a pyrophosphate of copper or tin, and the carrier is acid-washed active carbon or phosphorus doped active carbon. The preparation method comprises preparing an active component impregnating solution, adding a catalyst carrier to carry out equivalent volume impregnation, drying, baking and other process steps. According to the present invention, acetylene and hydrogen chloride are mixed and then are subjected to a reaction in the catalyst system, wherein the catalysis system of the present invention has characteristics of environmental protection and safety compared with the current mercury catalyst in the industry; and the catalyst prepared by the preparation method has characteristics of high activity, high selectivity, good stability, and longer service life, and is more suitable for ethyne hydrochlorination reactions for producing vinyl chloride through a calcium carbide method compared with the general mercury-free catalyst.

Owner:TIANJIN UNIV

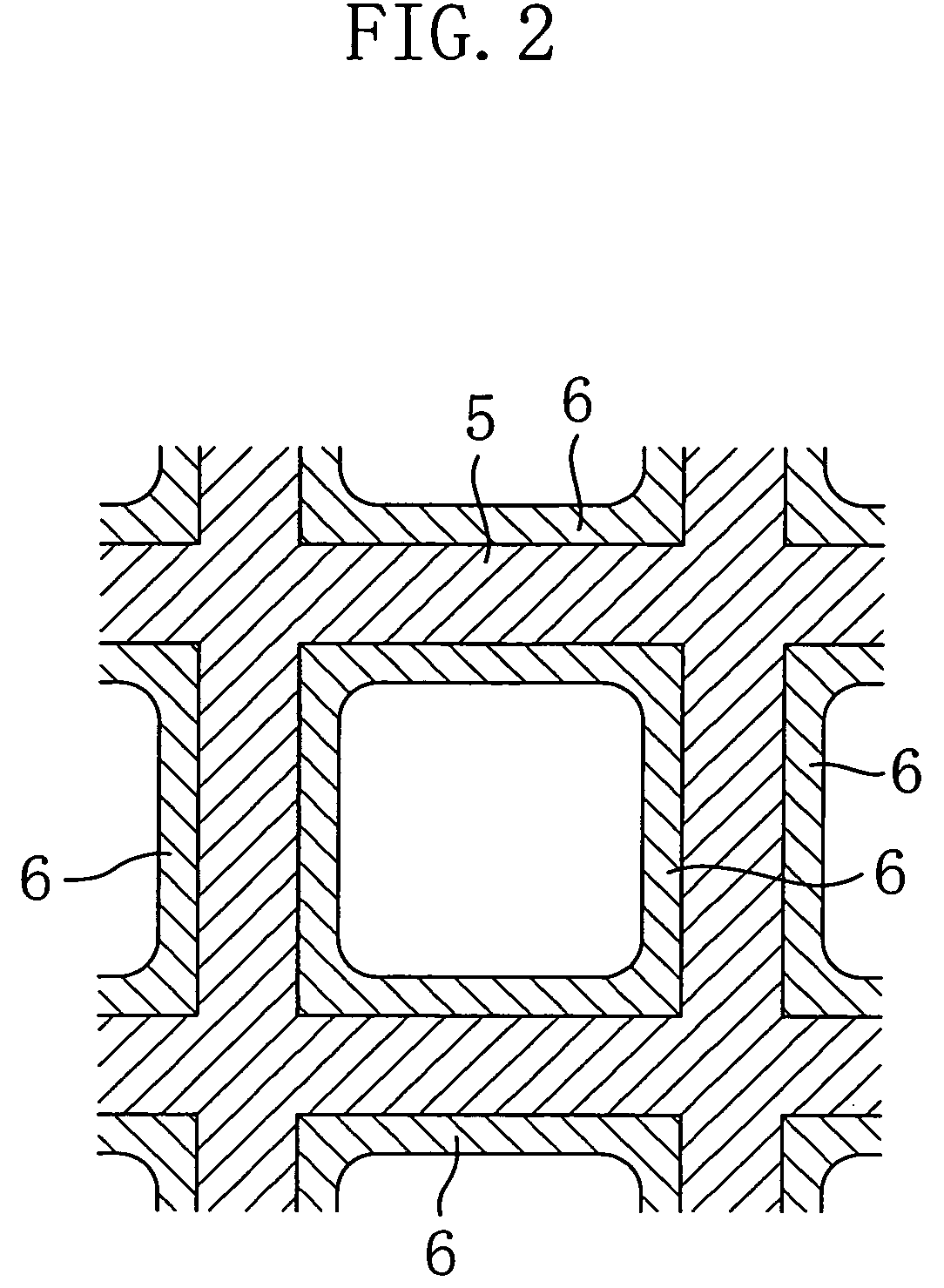

Exhaust gas purification catalyst and oxygen storage component for the same

InactiveUS7307039B2Improve exhaust gas purification performanceDeteriorating exhaust gas purification performanceInternal combustion piston enginesZirconium compoundsMixed oxideHoneycomb

In an exhaust gas purification catalyst comprising a honeycomb support and a catalytic layer that is formed on wall surfaces of each cell of the honeycomb support and contains active alumina and a mixed oxide containing Ce, Zr and Nd and doped with catalytic precious metal, the mixed oxide has a CeO2 / ZrO2 mass ratio of 1.4 or more and the ratio of Nd2O3 / (CeO2+ZrO2+Nd2O3) in the mixed oxide is 20 mass % or less.

Owner:MAZDA MOTOR CORP

Nitrogen and phosphorous doped carbon supported nanoparticle platinum electrocatalyst and method of making

ActiveUS20180272320A1Simple structureIncreased durabilityMembranesSemi-permeable membranesPlatinumPhosphate

A platinum-carbon electrocatalyst material comprising a carbon support having a minimum BET surface area of 1000 m2 / g, a nitrogen content of at least 2.5 weight percent, which is present in the form of pyridine, pyridone or pyrrole, a phosphorous content of at least 3 weight percent, which is present in the form of phosphate and phosphonate, and a plurality of platinum nanoparticles dispersed on the carbon support having a maximum average particle diameter of 1.5 nm.

Owner:TDA RES

Chlorination aromatic hydrocarbon waste gases catalytic purification method

InactiveCN101185796ALower catalyst costsApplication prospect of environmental protectionDispersed particle separationDecompositionEnvironmental chemistry

The invention discloses a catalytic purification method of chlorobenzene waste gas. The invention includes the following steps: the reaction is carried out by introducing humid air into the waste gas containing chlorobenzene in the presence of the catalyst; the catalyst is composed of a carrier which is stable in humid air, transition metal oxide which is carried on the carrier, rare earth oxide and phosphoric acid; the using method of the invention is that, the invention can stably convert the chlorobenzene in the waste gas into carbon dioxide and hydrogen chloride in a long time in humid air, at lower reaction temperature and in the presence of oxidation decomposition catalyst, while the activity of the catalyst is not reduced; the catalyst is composed of transition metal oxide and rare earth oxide, so the cost of the catalyst is low. The invention uses the extremely economical method for eliminating chlorohydrocarbon in the waste gas, has no formation of polychlorinated by-products and does not cause secondary pollution, so the invention is a very effective method for the treatment of the waste gas containing chlorohydrocarbon and has greater environmental protection application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalysts for maleic acid hydrogenation to 1,4-butanediol

ActiveUS20060004212A1Good bdo productionCost reductionOrganic compound preparationOxygen compounds preparation by reductionTitanium dioxideGamma-Butyrolactone

This invention relates to a process for catalytically hydrogenating a hydrogenatable precursor in contact with a hydrogen-containing gas and a hydrogenation catalyst comprising one or more active hydrogenation catalyst components on a support comprising titanium dioxide in the rutile crystalline phase to produce 1,4-butanediol and, optionally, gamma-butyrolactone and / or tetrahydrofuran.

Owner:BP CORP NORTH AMERICA INC

Preparation method for magnesia-alumina spinel

ActiveCN103204528ASimple structureStable structureCatalyst carriersAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCrystal structureSpinel

The invention relates to a preparation method for magnesia-alumina spinel. The preparation method comprises the steps of: firstly, evenly mixing alumina-containing compound and magnesium-containing compound according to the mole ratio of Al:Mg being 3.2:1-3.92:1; then adding acid solution, and stirring evenly into size; then neutralizing the size with alkali liquor; and finally, filtering the neutralized product, washing, drying and roasting a filter cake to obtain the magnesia-alumina spinel. According to the preparation method for the magnesia-alumina spinel, the alkali liquor can be added after the acid solution is added, the aluminum source can be directly doped into crystal lattices of the aluminum-magnesium crystals in the crystal nucleus growth process of the aluminum-magnesium crystals, so that the strength of the prepared magnesia-alumina spinel compound is larger, the crystal structure is more stable, thereby better meeting the strength requirement of a hydrogenated desulfurization catalyst to a carrier.

Owner:SHENYANG SANJUKAITE CATALYST

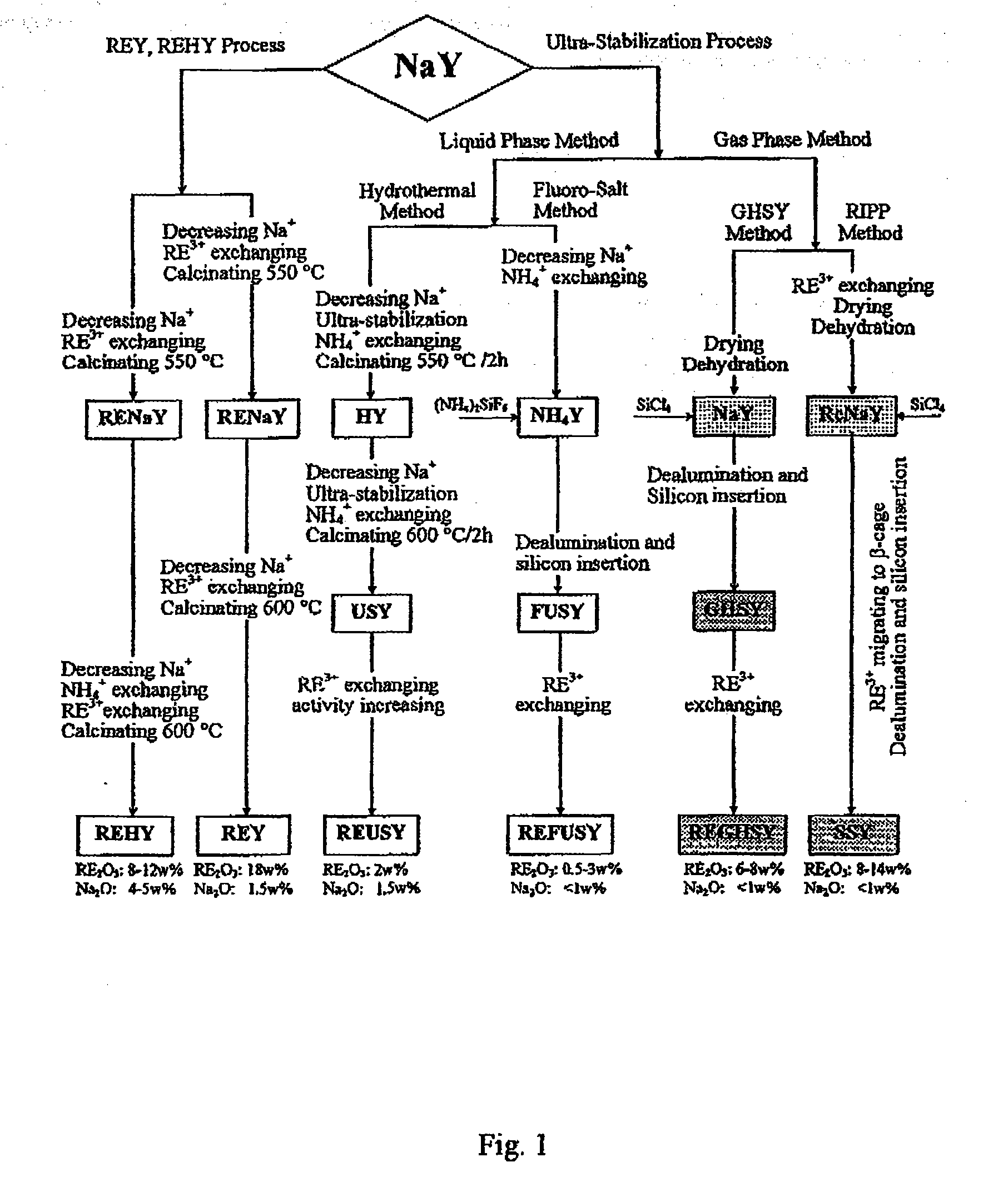

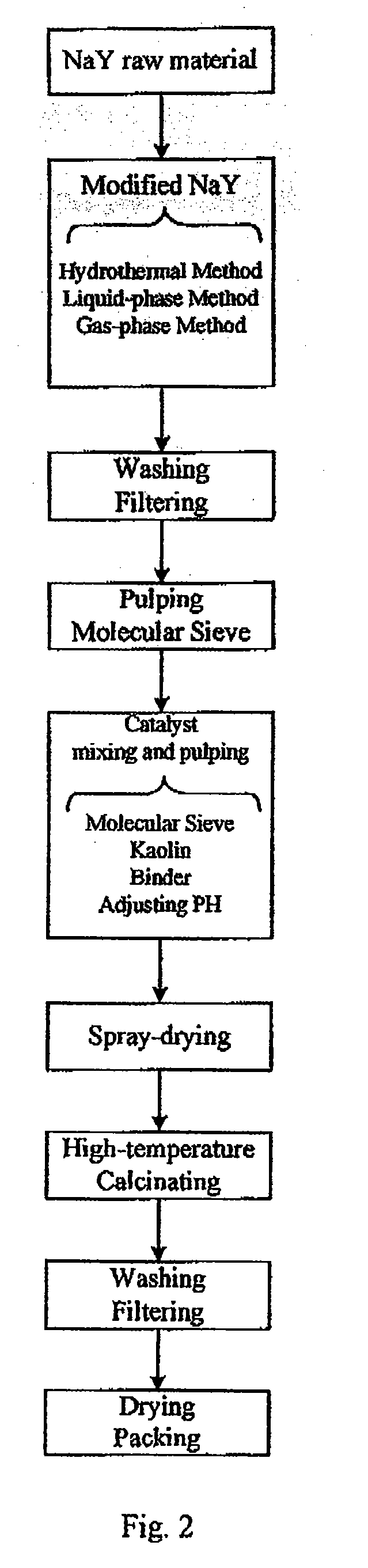

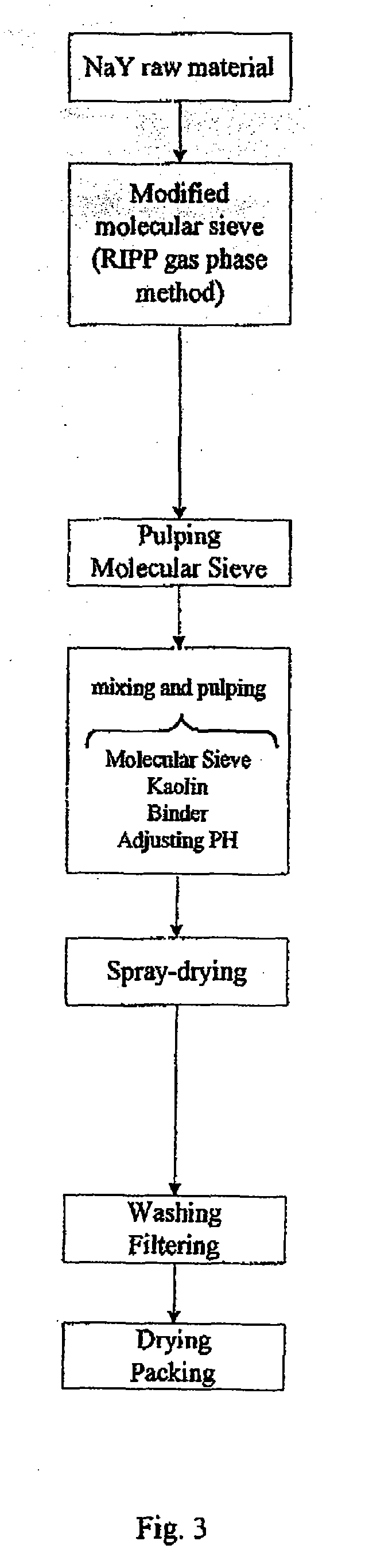

Cracking Catalyst and a Preparation Process for the Same

ActiveUS20080261802A1Improve catalyst binding propertyImprove catalyst strengthCatalytic crackingMolecular sieve catalystsRare earthCell size

The present invention provides a cracking catalyst, containing a rare-earth Y-zeolite and a support, which is characterized in that the rare-earth content in crystal lattice of the rare-earth Y-zeolite is 4-15 wt % of RE2O3; the original unit cell size is 2.440-2.465 nm; the equilibrium unit cell size of the catalyst after 100% stream-aging at 800° C. for 17 hours is larger than 2.435 nm; the rare-earth atom content in the support is 1.0-8.0 wt % of the support. The present invention also relates to a preparation process for the same catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

Supported gold-PGM alloy catalyst with stable storage property and preparation method thereof

InactiveCN101698149AHigh activityInhibit migrationCatalyst carriersDispersed particle separationAmbient humidityAlloy catalyst

The invention relates to a supported gold-PGM alloy catalyst with stable storage property and a preparation method thereof. An active component is Au, an accessory ingredient is Pd or Pt in PGM, and a carrier is a Al2O3 composite oxide modified by Al2O3 or MIOx and MIIOx, wherein the atomic ratio of Au to PGM is 1.0:1.0-1.0:1.0*10<-2>; the atomic ratio of Au to MI+MII is 1.0:1.0-1.0:10; the atomic ratio of MI to MII is 2.0:1.0-0.2:1.0; the atomic ratio of Au to Al is 1.0:1.0*10<3>-1:0:10; MI is La; and MII is Fe, Co or Ni. The composite oxide carrier is prepared by an impregnation method or a coprecipitation method. After being supported with MIOx and MIIOx, Al2O3 is roasted at a temperature of between 800 and 1,000 DEG C to generate a spinelle or perovskite structure. The catalyst of the invention catalytically oxidizes micro CO (0.1 percent to 1.5 percent) in the air into CO2 at ambient temperature and in ambient humidity, and has the advantages of stable catalysis property, pressure drop meeting the requirements of a gas mask and a mining self-rescuer and low cost.

Owner:安立敦

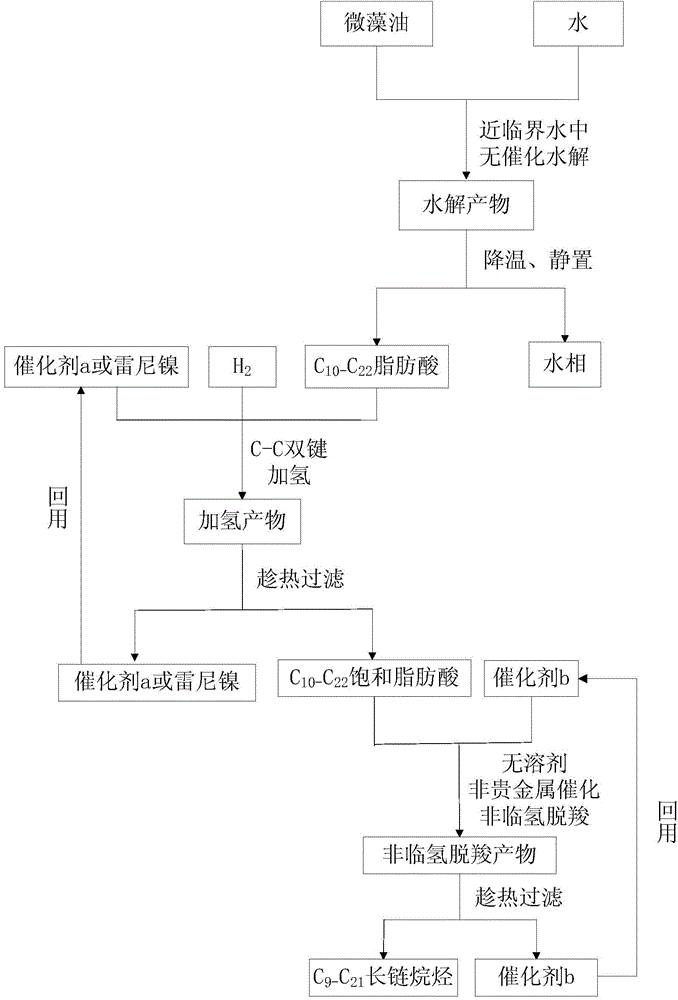

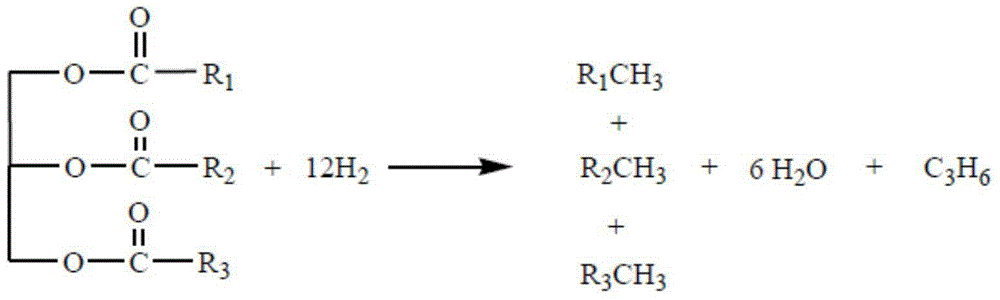

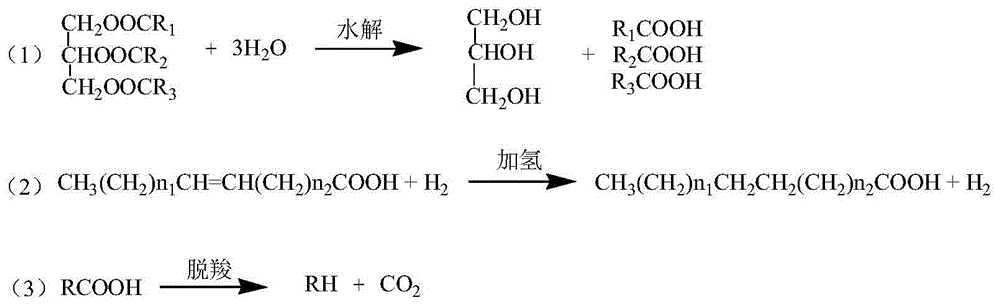

Method for preparing long-chain alkane with microalg al oil as raw material in low hydrogen consumption

ActiveCN104610004ALower Catalytic CostsReduce hydrogen consumptionHydrocarbonsHydrocarbon preparationRaney nickelChemistry

The invention discloses a method for preparing long-chain alkane with microalg al oil as raw material in low hydrogen consumption. The method comprises the following steps: (1) mixing microalg al oil with water, heating to generate a hydrolysis reaction, and treating to obtain C10-C22 fatty acids; (2) generating a hydrogenation reaction on the C10-C22 fatty acids and hydrogen under the action of a non-noble metal supported catalyst a or raney nickel, and treating to obtain C10-C22 saturated fatty acids; and (3) generating a decarboxylic reaction on the C10-C22 saturated fatty acids under the action of a non-noble metal supported catalyst b, and treating to obtain C9-C21 long-chain alkane. The method disclosed by the invention is cheap and easily available in raw materials and lower in hydrogen consumption, and the adopted non-noble metal supported catalysts a and b can be recycled to reduce the catalytic cost. The reaction process of the method provided by the invention is simple to operate, and the products are convenient and quick to separate, so that the method is a quite ideal method for degrading the microalg al oil to prepare the long-chain alkane.

Owner:ZHEJIANG UNIV +1

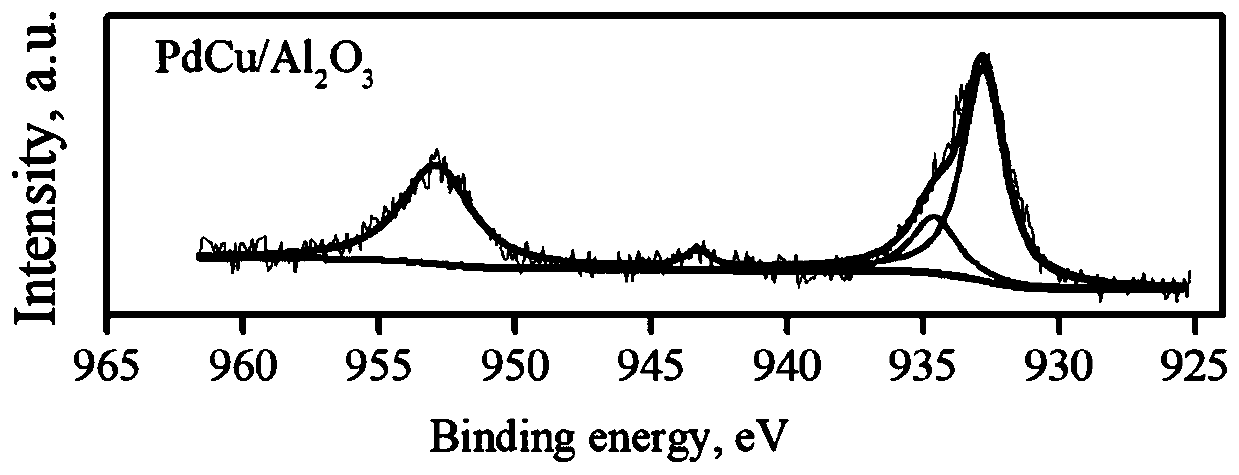

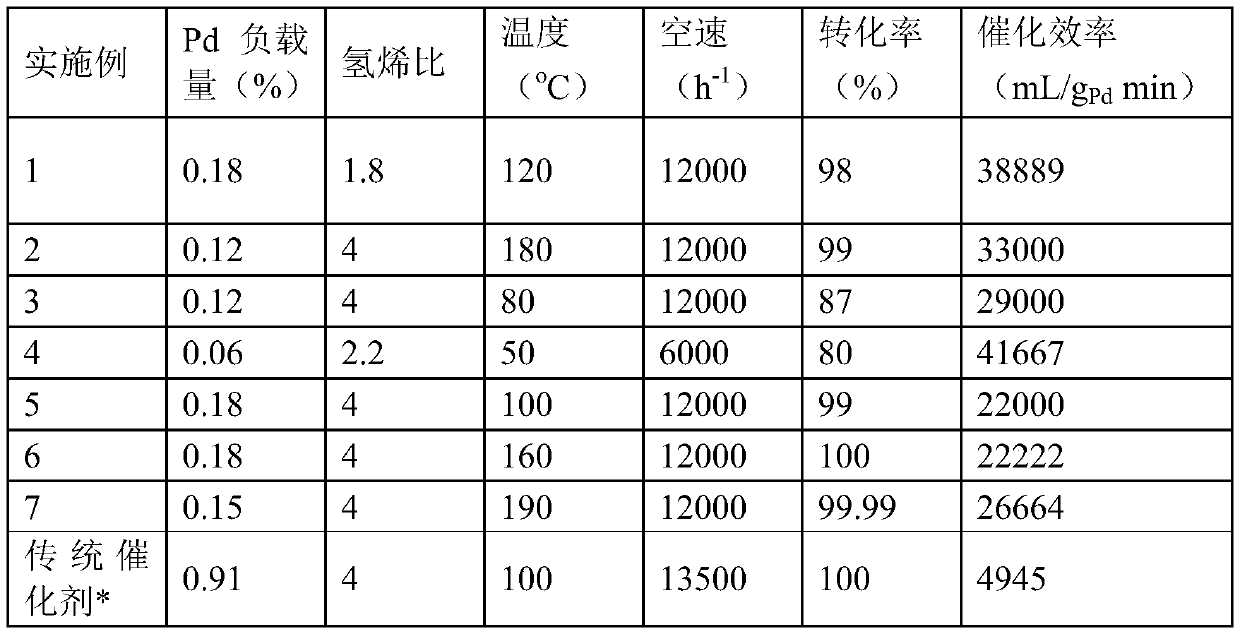

Pdx/Cu monatomic catalyst for selective hydrogenation of C4 and preparation method for Pdx/Cu monatomic catalyst

InactiveCN109806885ATemperature controlEasy to removeHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsButeneAlkyne

The invention relates to an unsaturated C4 selective hydrogenation catalyst and a preparation method and application thereof. The catalyst is prepared from Pd, Cu and a carrier. The catalyst is used for selective hydrogenation removal of C4 alkynes and dienes, unsaturated C4 molecules are converted into butene through hydrogenation, and therefore the purpose of removing unsaturated C4 is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

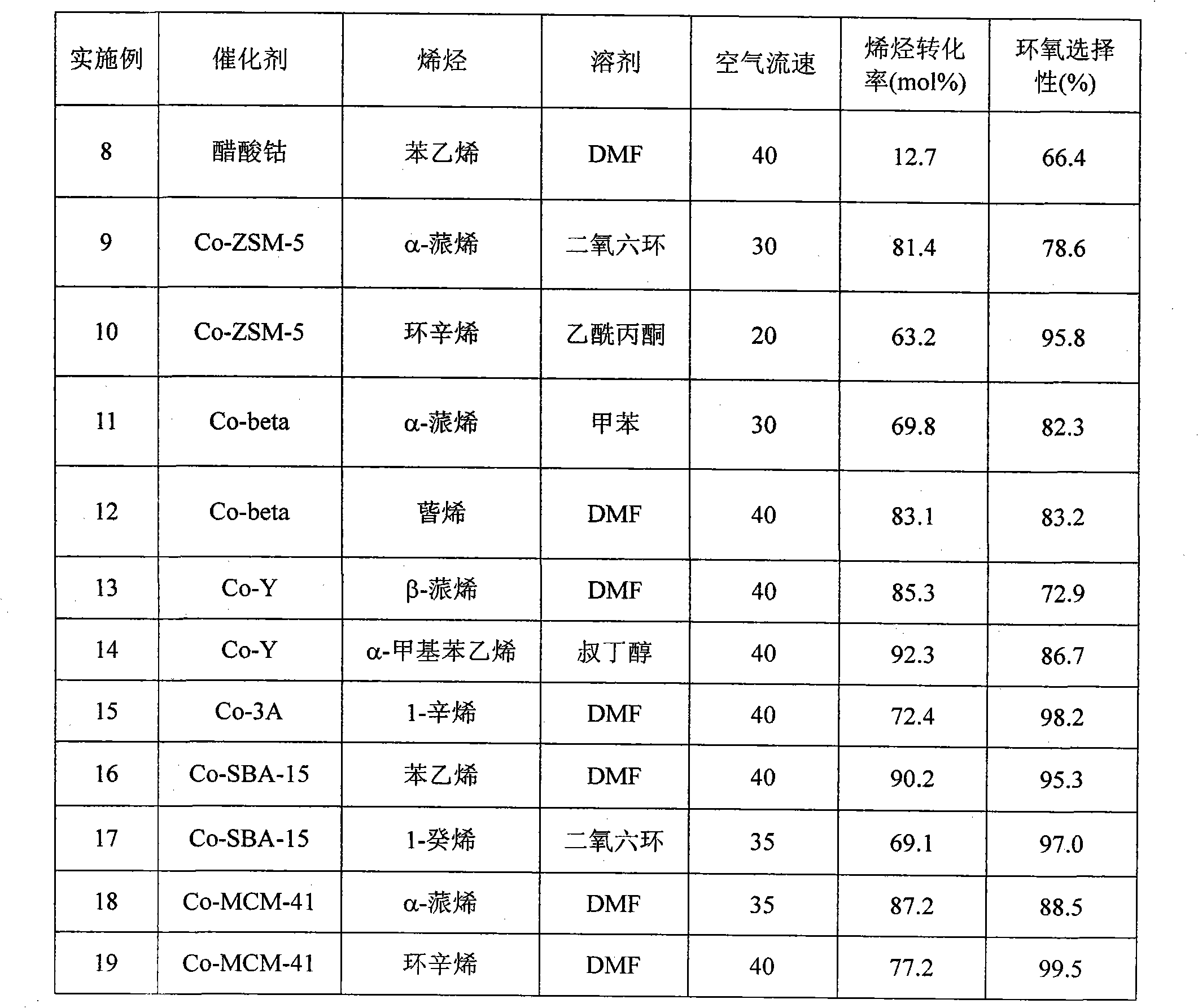

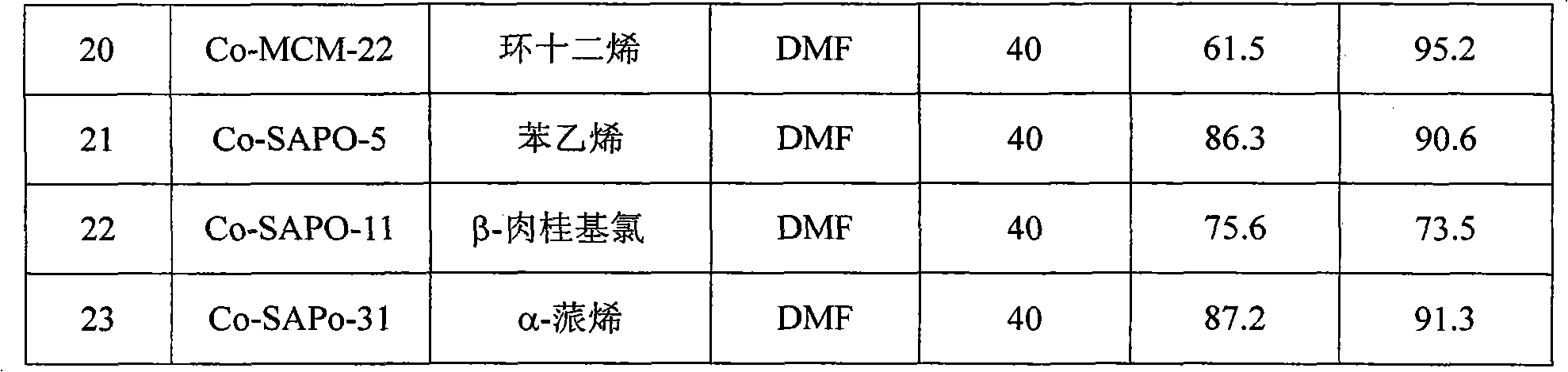

Method for highly selectively catalyzing epoxidation between olefin and air by cobalt-loaded zeolite molecular sieve

The invention relates to a chemical reaction process for preparing an epoxide by multi-phase catalytic oxidation, in particular to a method for highly selectively catalyzing epoxidation between olefin and air by a cobalt-loaded zeolite molecular sieve. Cobalt which is a non-precious transition metal and has a catalytic activity is exchanged to zeolite molecular sieve frameworks of different apertures and structures according to a certain loading proportion by an ion exchange method to prepare a cobalt-loaded zeolite molecular sieve based catalyst; and such olefine compounds as styrene class, Alpha, Beta-pinene class, cycloolefin class, Beta-cinnamyl chloride class and linear olefin class are catalyzed to perform epoxidation reaction in a solvent at a certain reaction temperature for a certain reaction time by taking air at a certain flowing rate as an oxidant (a small amount of t-butylhydroperoxide (TBHP) as initiators) without adding any reducing agent. The method has the advantages that the catalyst is simple in preparation, the raw material is high in conversion rate, the target product is high in selectivity, the reaction is short in time, high in efficiency and mild in condition, the operation is easy to control, the cost is low and the whole environment is environment-friendly.

Owner:HUBEI UNIV

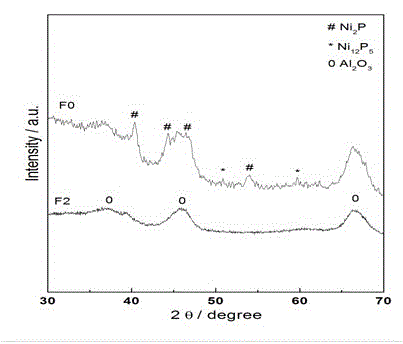

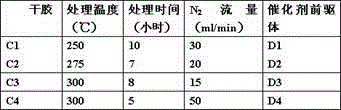

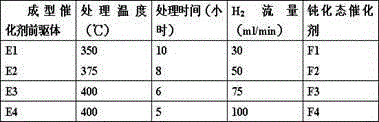

Non-noble metal selective hydrogenation catalyst, preparation method and application thereof

ActiveCN105642324ALower catalyst costsLow hydrogenation loss rate of butenePhysical/chemical process catalystsHydrocarbon purification/separationLanthanumMetallic Nickel

The invention discloses a non-noble metal selective hydrogenation catalyst, which is composed of an active component amorphous nickel phosphide, an alumina carrier and an assistant X. In a final catalyst, in terms of metal nickel, the weight content of nickel in the active component amorphous nickel phosphide accounts for 10-15% of the total catalyst weight, the mole ratio of phosphorus to nickel is 2.0-2.4, the mole ratio of X to nickel is 0.01-0.05:1, and the balance is the carrier, the assistant X is one or more of lanthanum, cerium, praseodymium, samarium, ytterbium and other rare earth elements, preferably cerium. The non-noble metal catalyst has catalytic activity equivalent to that of noble metal catalysts when used in a reaction process for selective hydrogenation of a C4 raw material to remove butadiene, can greatly reduce the catalyst cost, and at the same time has low 1-butene isomerization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

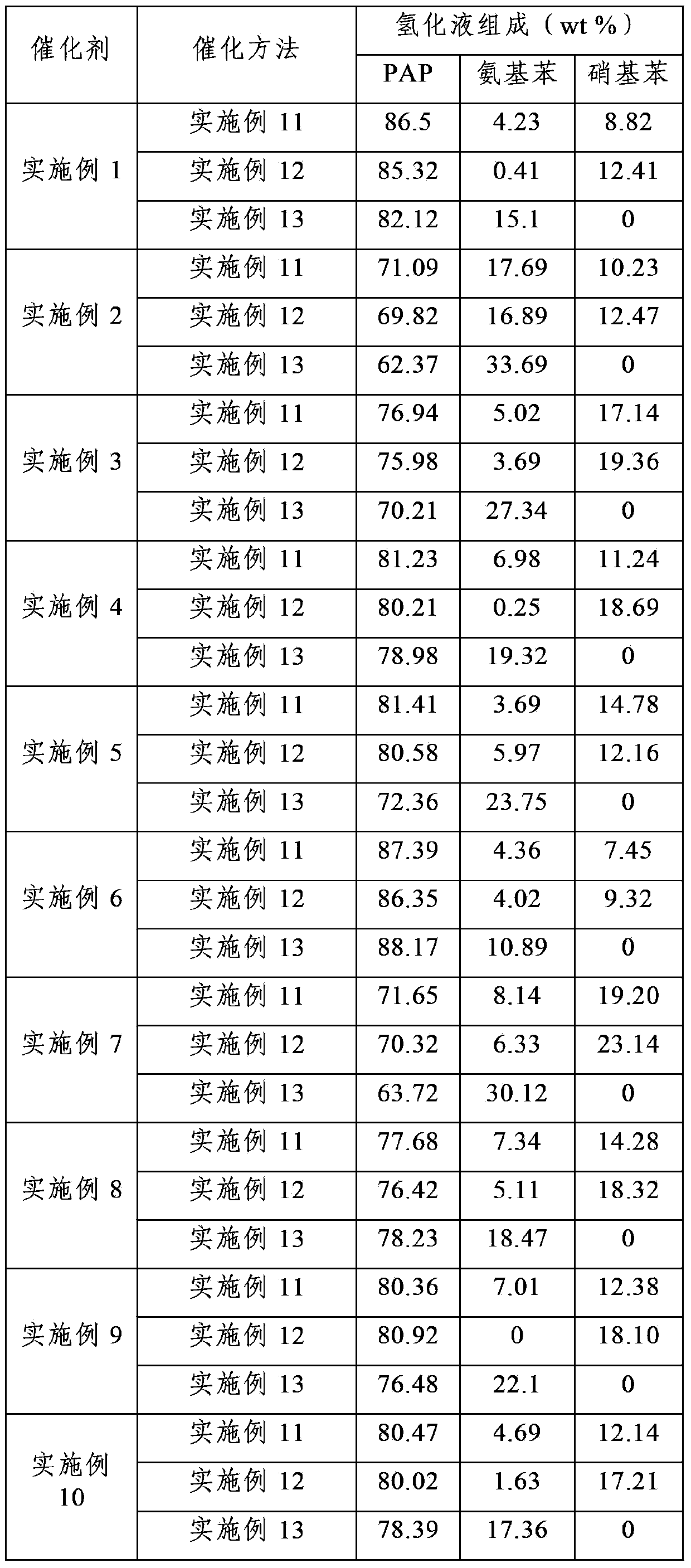

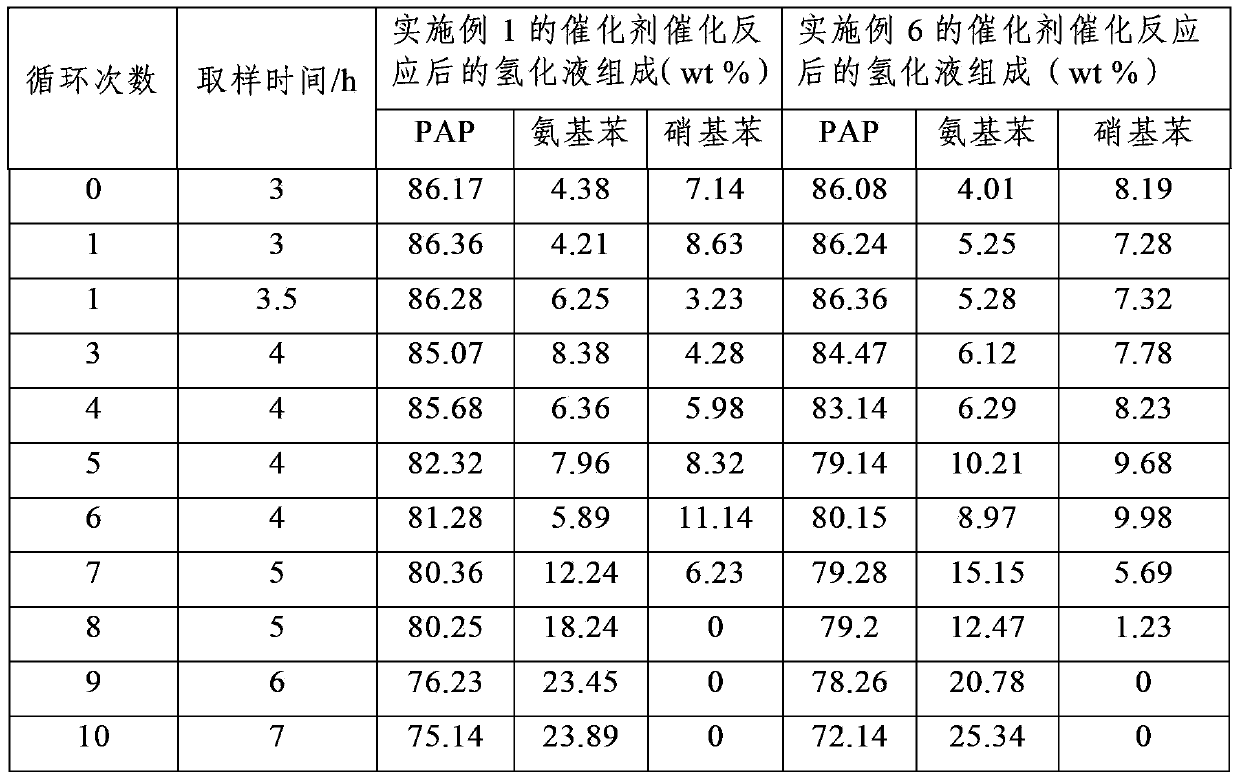

Preparation method and application of catalyst for one-step preparation of p-aminophenol from nitrobenzene

InactiveCN103357407AExtended service lifeHigh catalytic activityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsPlatinum saltsP-Aminophenol

The invention discloses a preparation method of a catalyst for the one-step preparation of p-aminophenol from nitrobenzene. The method comprises the following steps: preprocessing active carbon; loading a platinum salt; loading a vanadate; and reducing a catalyst, wherein the mass percentage contents of platinum and vanadium in the catalyst are 0.5-5% and 0.05-0.2% respectively. The invention also discloses a method for the one-step preparation of p-aminophenol from nitrobenzene through utilizing the catalyst. The addition of a certain amount of metallic vanadium to the Pt / C catalyst reduces the poisoning effect of sulfides in the nitrobenzene raw material to platinum, prolongs the service life of the catalyst and also improves the catalysis activity and selectivity of the catalyst; and the prepared catalyst has stable performances and very good repeatability, can be used for catalyzing the one-step preparation of p-aminophenol from nitrobenzene, reduces the purity requirement of the raw material nitrobenzene and reduces the catalysis cost.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Method for preparing oxidized rosin

InactiveCN101077960AReduce dosageHigh catalytic efficiencyNatural resin chemical modificationCatalytic oxidationPapermaking

The present invention is Schiff' s base-metal complex catalyzed rosin oxidizing process for preparing oxidized rosin. After it is dissolved in alcohol solvent, rosin is oxidized with H2O2 under the catalysis of Schiff' s base-metal complex so as to prepare oxidized rosin. The process has the advantages of low catalyst consumption, high catalysis efficiency, low catalysis cost, high rosin converting rate, simple product post-treatment, etc. and is suitable for industrial production. The oxidized rosin has softening point raised to about 98 deg.c, and may be applied widely in adhesive, paint, papermaking, ink, plastic, rubber, etc.

Owner:GUANGXI UNIV FOR NATITIES

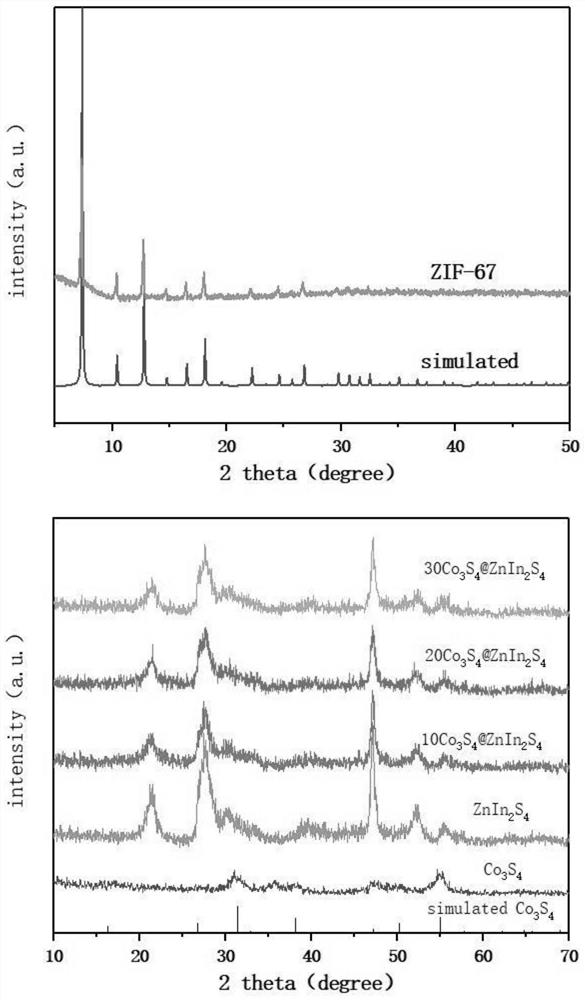

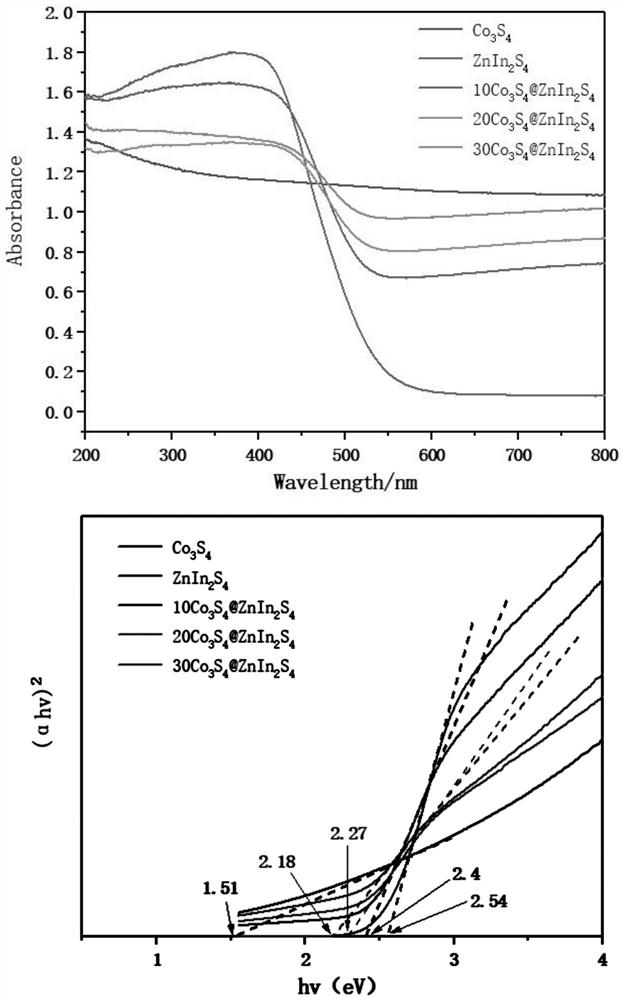

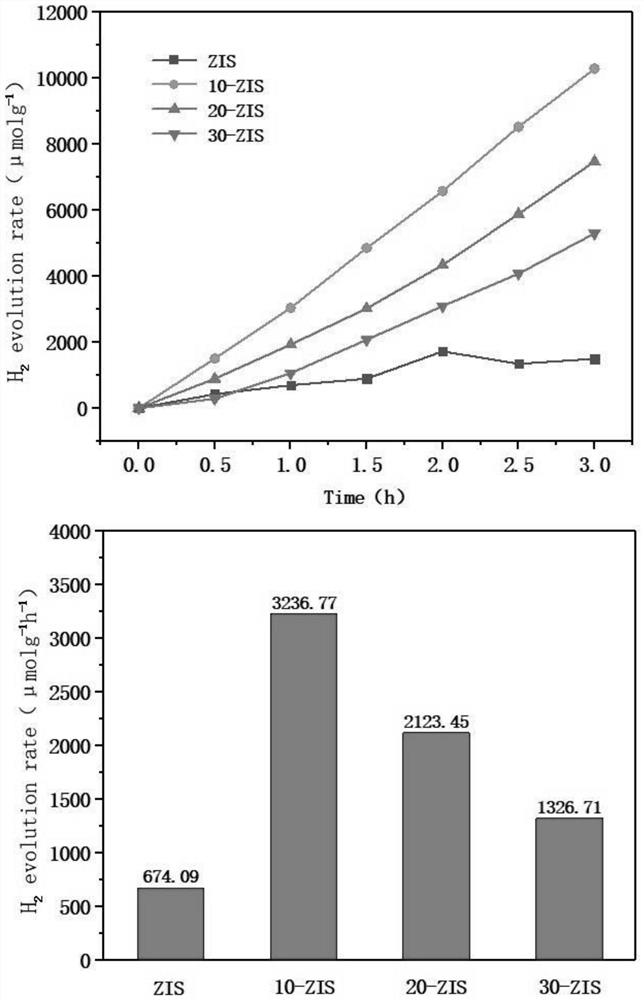

Preparation method and application of composite photocatalyst formed by Co3S4 derived from ZIF-67 and ZnIn2S4

ActiveCN111729675ALower catalyst costsHigh catalytic efficiencyCatalyst activation/preparationHydrogen productionHydration reactionThio-

The invention discloses a preparation method and an application of a composite photocatalyst formed by ZIF-67 derived Co3S4 and ZnIn2S4. The preparation method comprises the following steps: a, weighing cobalt nitrate hexahydrate and 2-methylimidazole, respectively dissolving the cobalt nitrate hexahydrate and the 2-methylimidazole in methanol, uniformly mixing the obtained two solutions, and washing and drying the obtained product; b, weighing ZIF-67 and thioacetamide, respectively dissolving ZIF-67 and thioacetamide in ethanol, uniformly mixing the two obtained solutions, carrying out ultrasonic treatment, pouring the reactant into a reaction kettle, carrying out a reaction at a high temperature, washing the obtained product, and drying and grinding the product; c, weighing the empty Co3S4 in the step b, and adding deionized water; adding Zn(NO3)2.6H2O, In(NO3)3.4.5H2O and thioacetamide, and carrying out a reaction at a high temperature; washing and drying the product and grinding the prodcut into powder. The Co3S4 and ZnIn2S4 prepared by the method are used for hydrogen production by photolysis of water, so that the catalytic cost is reduced, and the catalytic efficiency is improved.

Owner:SHANGHAI UNIV

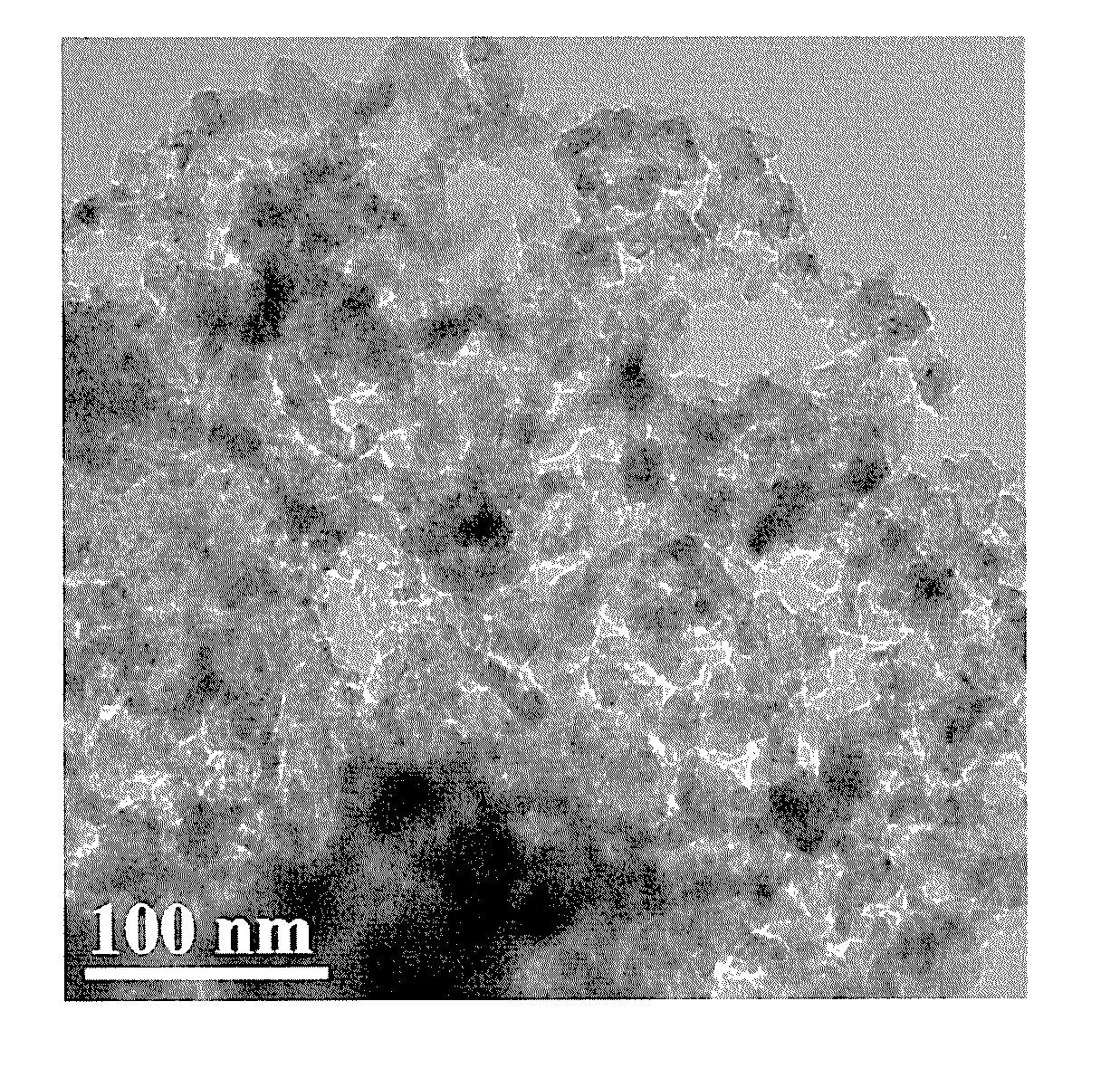

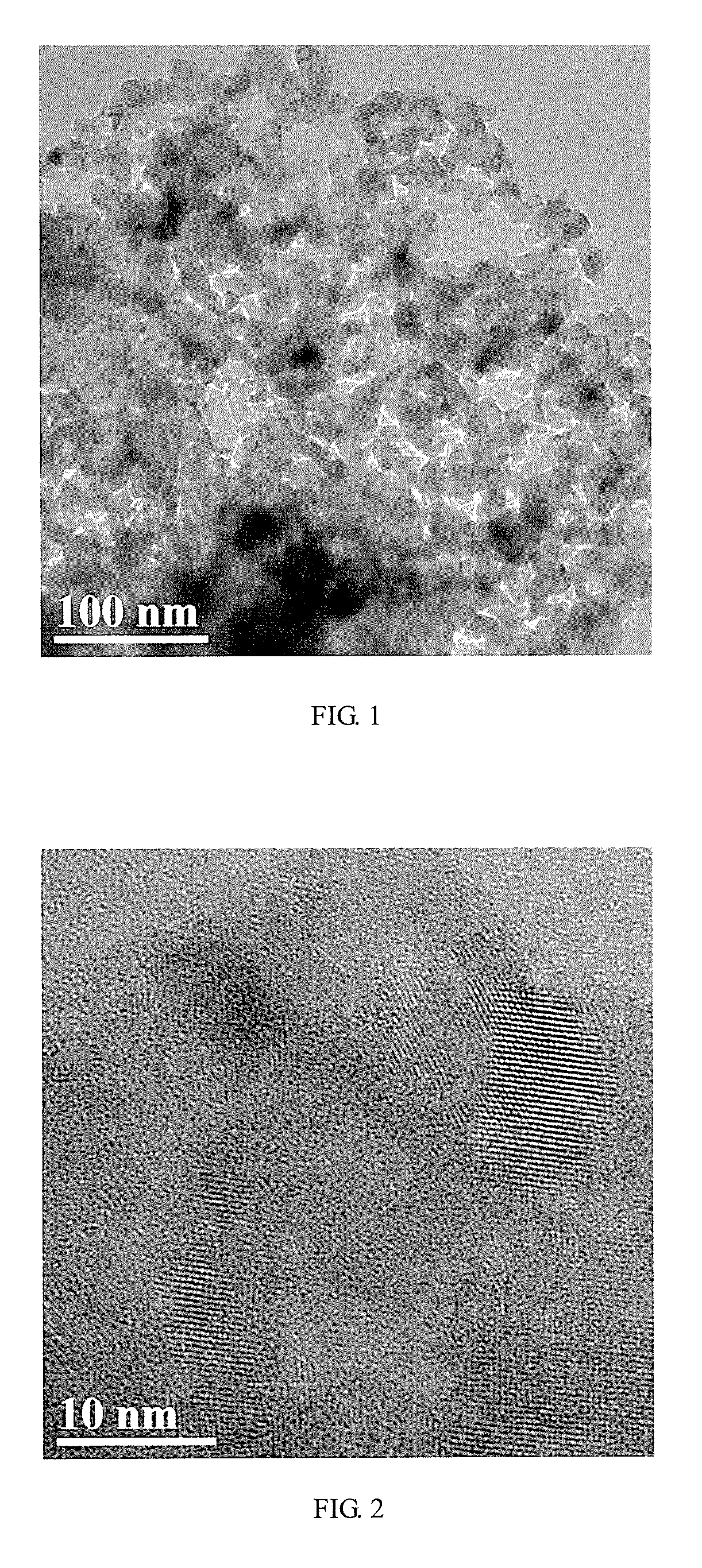

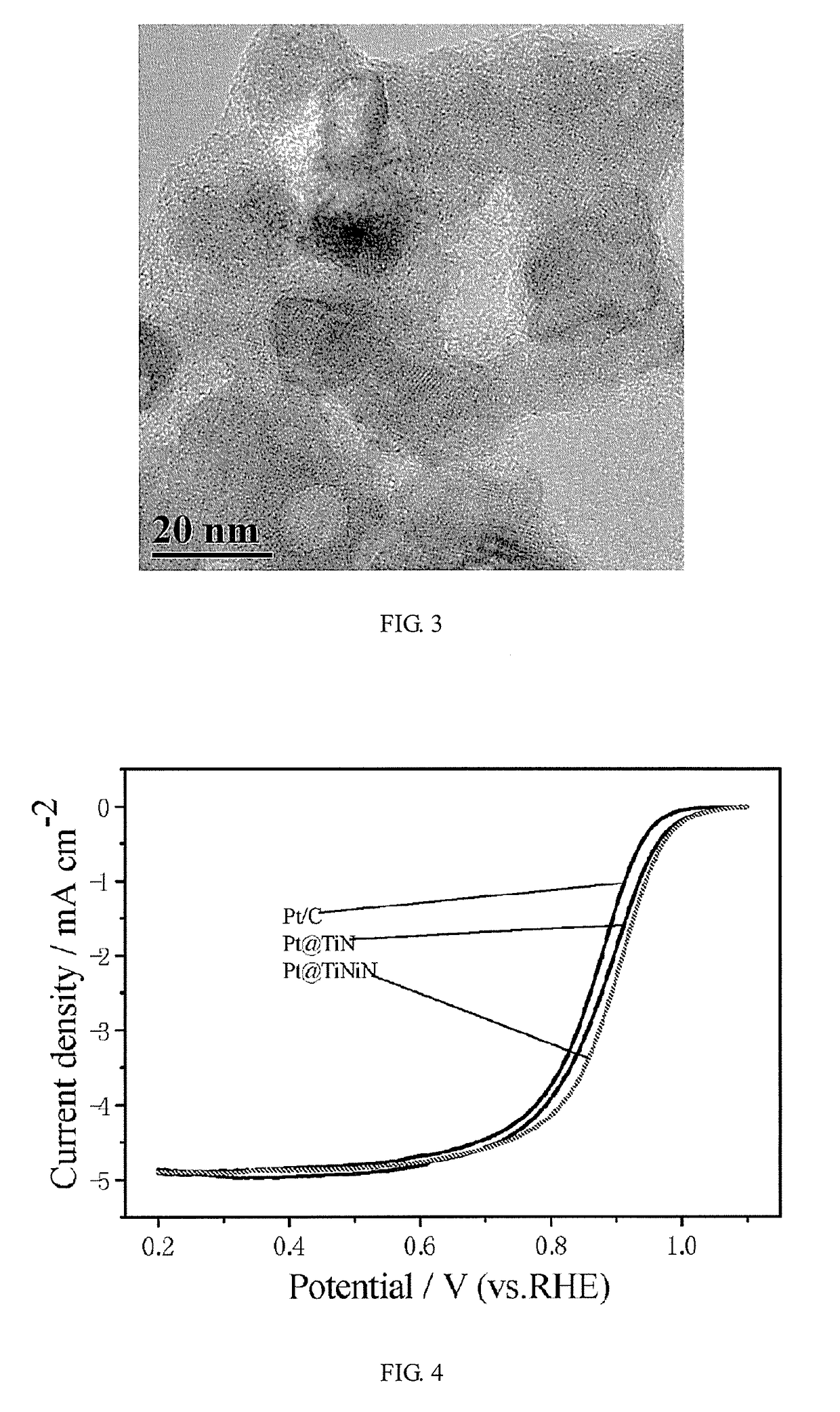

Low-platinum catalyst based on nitride nanoparticles and preparation method thereof

ActiveUS20180185825A1Improve performanceLower catalyst costsMaterial nanotechnologyCell electrodesPt elementPlatinum catalyst

A low-platinum catalyst based on nitride nanoparticles and a preparation method thereof. A component of an active metal of the catalyst directly clades on a surface of nitride particles or a surface of nitride particles loaded on a carbon support in an ultrathin atomic layer form. Preparation steps including: preparing a transition-metal ammonia complex first, nitriding the obtained ammonia complex solid under an atmosphere of ammonia gas to obtain nitride nanoparticles; loading the nitride nanoparticles on a surface of a working electrode, depositing an active component on a surface of the nitride nanoparticles by pulsed deposition, to obtain the low platinum loading catalyst using a nitride as a substrate. The catalyst may be used as an anode or a cathode catalyst of a low temperature fuel cell.

Owner:SOUTH CHINA UNIV OF TECH

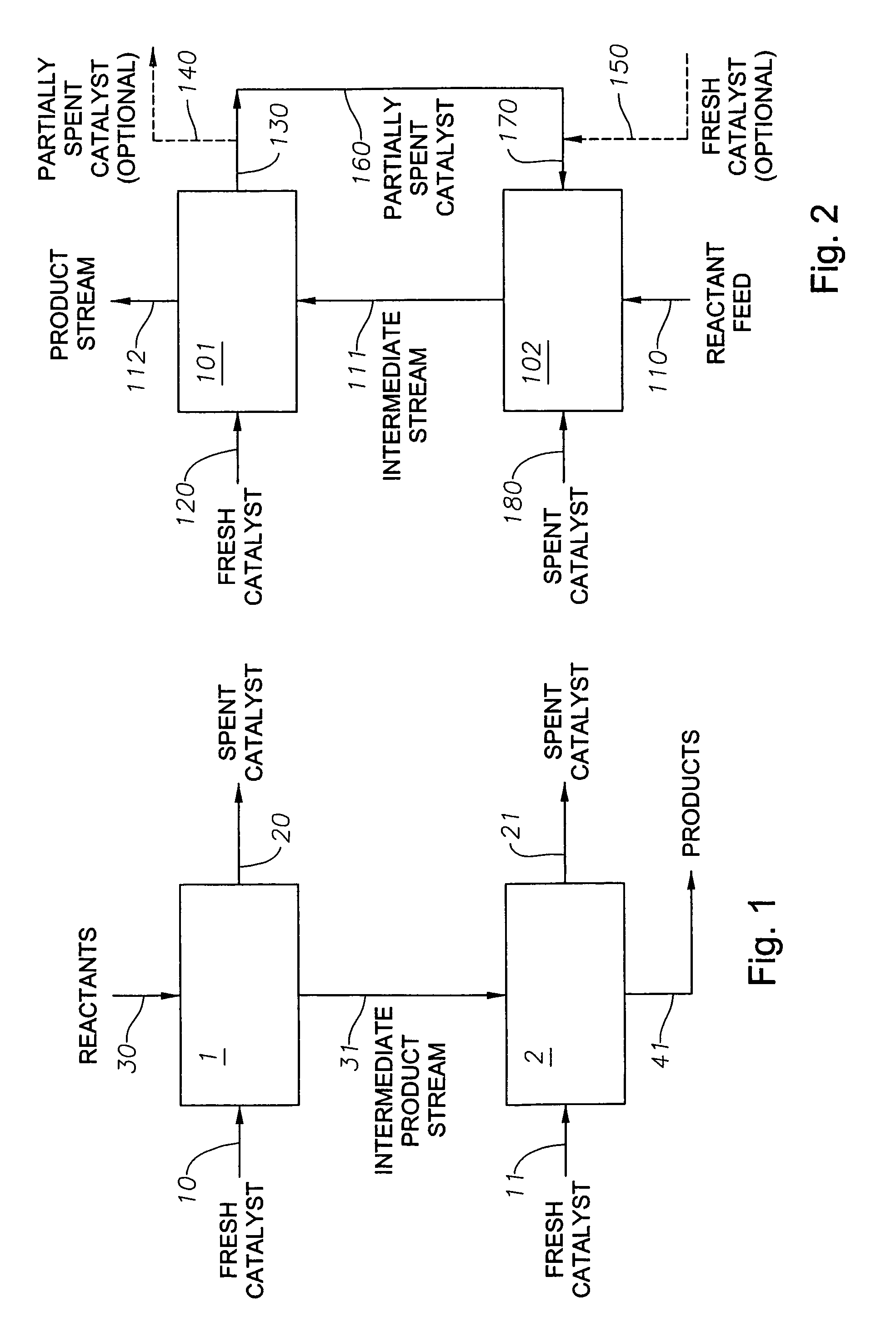

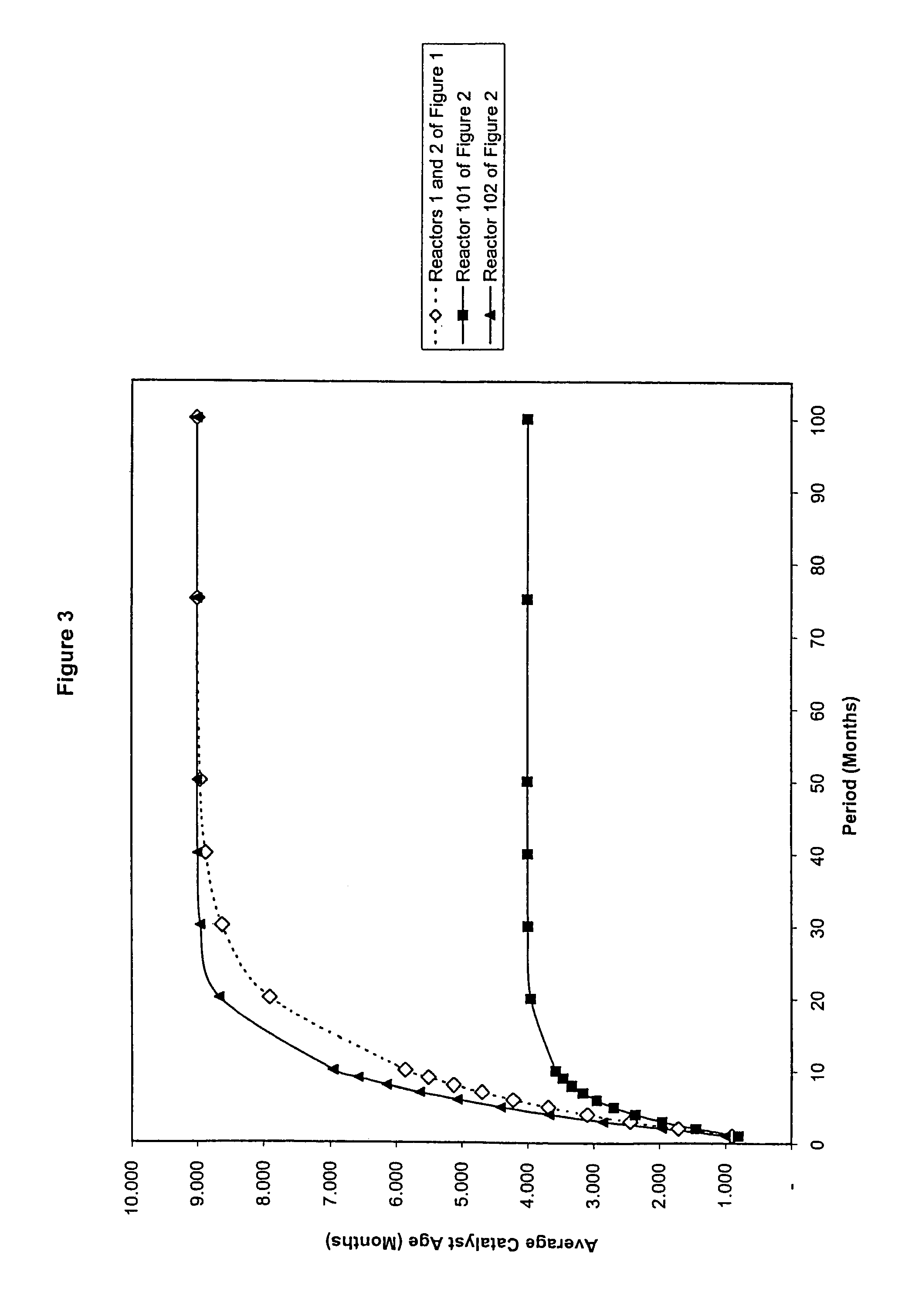

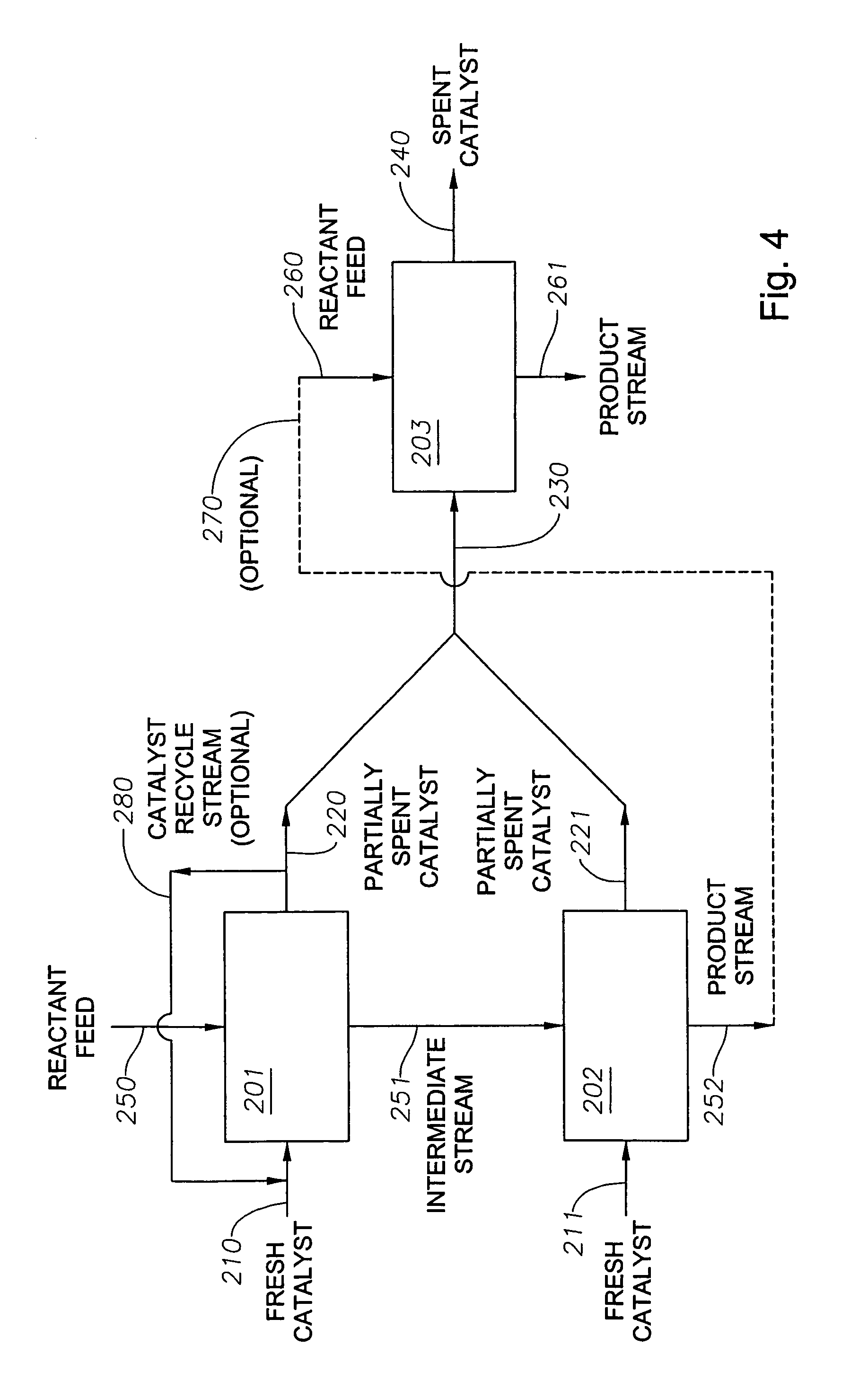

Method of removing and replacing catalyst in a multi-reactor cascade configuration

InactiveUS7033488B2Reduce frequencyGood removal effectTreatment with plural serial cracking stages onlyCatalytic crackingProduction rateReactor system

A defined catalyst withdrawal and replacement program for optimizing the productivity and the economics of catalyst consumption in a multi-reactor system is disclosed. Catalyst cost is reduced by minimizing removal of the newest catalyst and maximizing removal of older catalyst to achieve an overall reduction of catalyst age in the multi-reactor system.

Owner:CONOCO INC

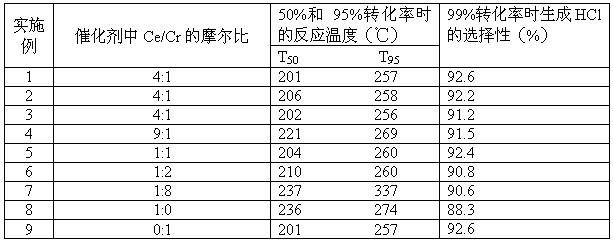

Preparation method of Cr-Ce composite oxide catalyst

InactiveCN102416319ASimple preparation processLower catalyst costsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSide productComposite oxide

The invention provides a preparation method of a Cr-Ce composite oxide catalyst. The preparation method of the Cr-Ce composite oxide catalyst is characterized in that chromium nitrate and cerium nitrate as raw materials are prepared into the Cr-Ce composite oxide catalyst through a coprecipitation technology, wherein a mole ratio of Ce to Cr in the Cr-Ce composite oxide catalyst is in a range of (9: 1) to (1: 8). The preparation method of the Cr-Ce composite oxide catalyst is easy and has a low cost. The Cr-Ce composite oxide catalyst obtained by the preparation method has good chlorine-containing organic compound catalytic degradation activity and stability, high selectivity of CO2 and HCl, and no by-product such as polychlorocarbon and the like.

Owner:ZHEJIANG UNIV

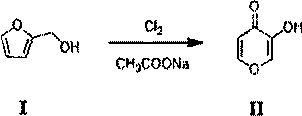

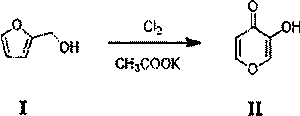

Synthesis method of 3-(benzyloxy)-4-oxo-4H-pyran-2-carboxylic acid

PendingCN109438405ALower catalyst costsNovel synthetic routeOrganic chemistryBulk chemical productionFurfuryl alcoholBatch production

The invention discloses a synthesis method of 3-(benzyloxy)-4-oxo-4H-pyran-2-carboxylic acid. The synthesis method takes furfuryl alcohol as a starting raw material and four-step reaction including rearrangement, addition, hydroxyl protection and oxidization is carried out; the total mol yield of a synthesis route is greater than 32 percent; the synthesis method has the characteristics of relatively moderate reaction conditions and the like, and the yield and purity of the 3-(benzyloxy)-4-oxo-4H-pyran-2-carboxylic acid are remarkably improved; meanwhile, the synthesis method has the advantagesof detailed technological operation steps, specific parameters, controllable conditions and stable technology, and can realize industrial large-batch production.

Owner:RAFFLES PHAMRMATECH CO LTD

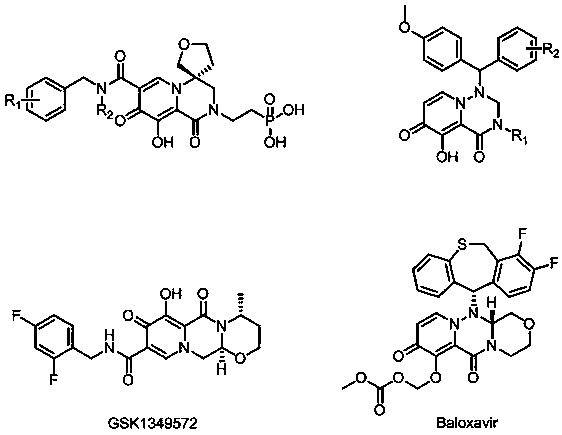

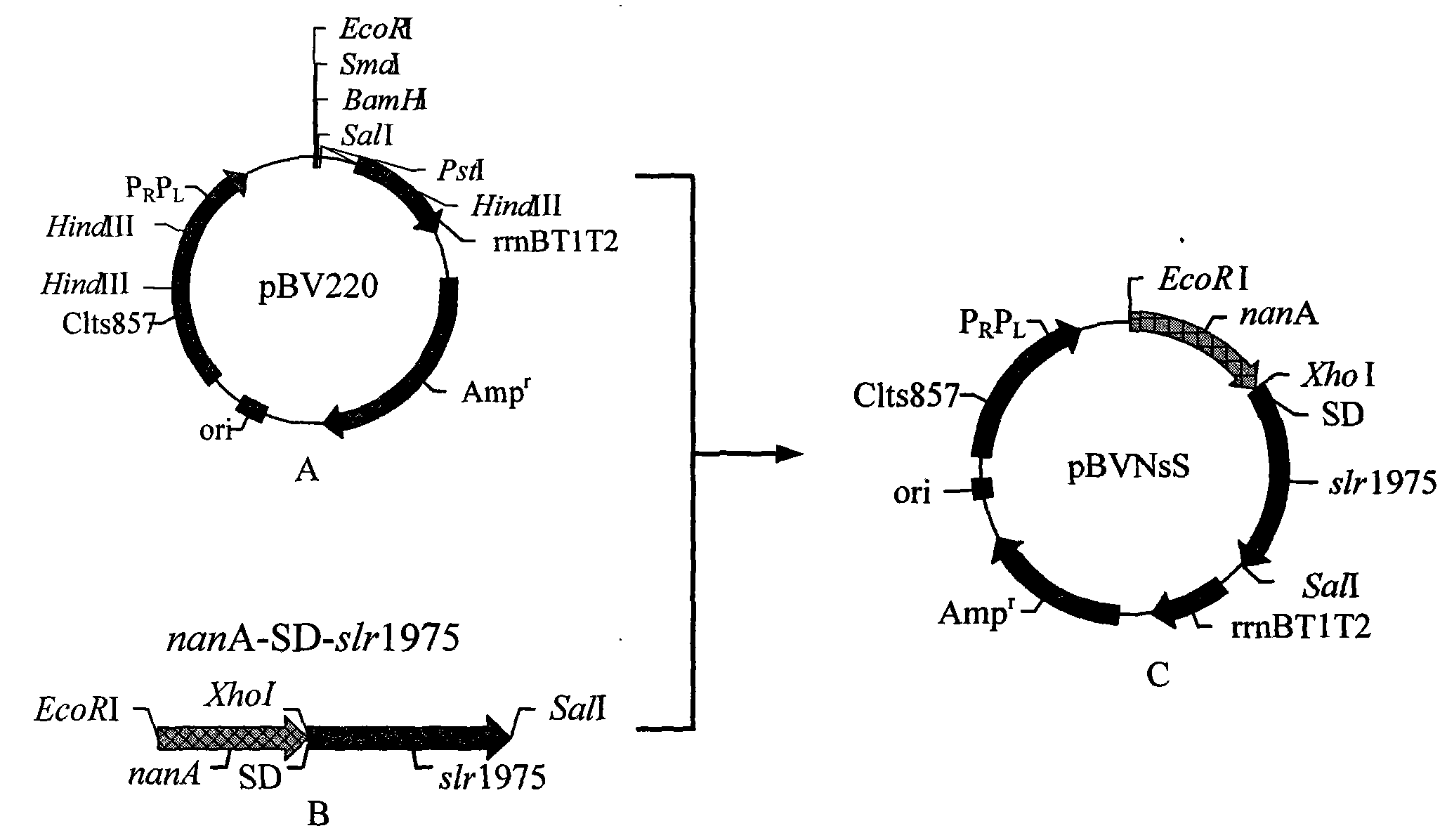

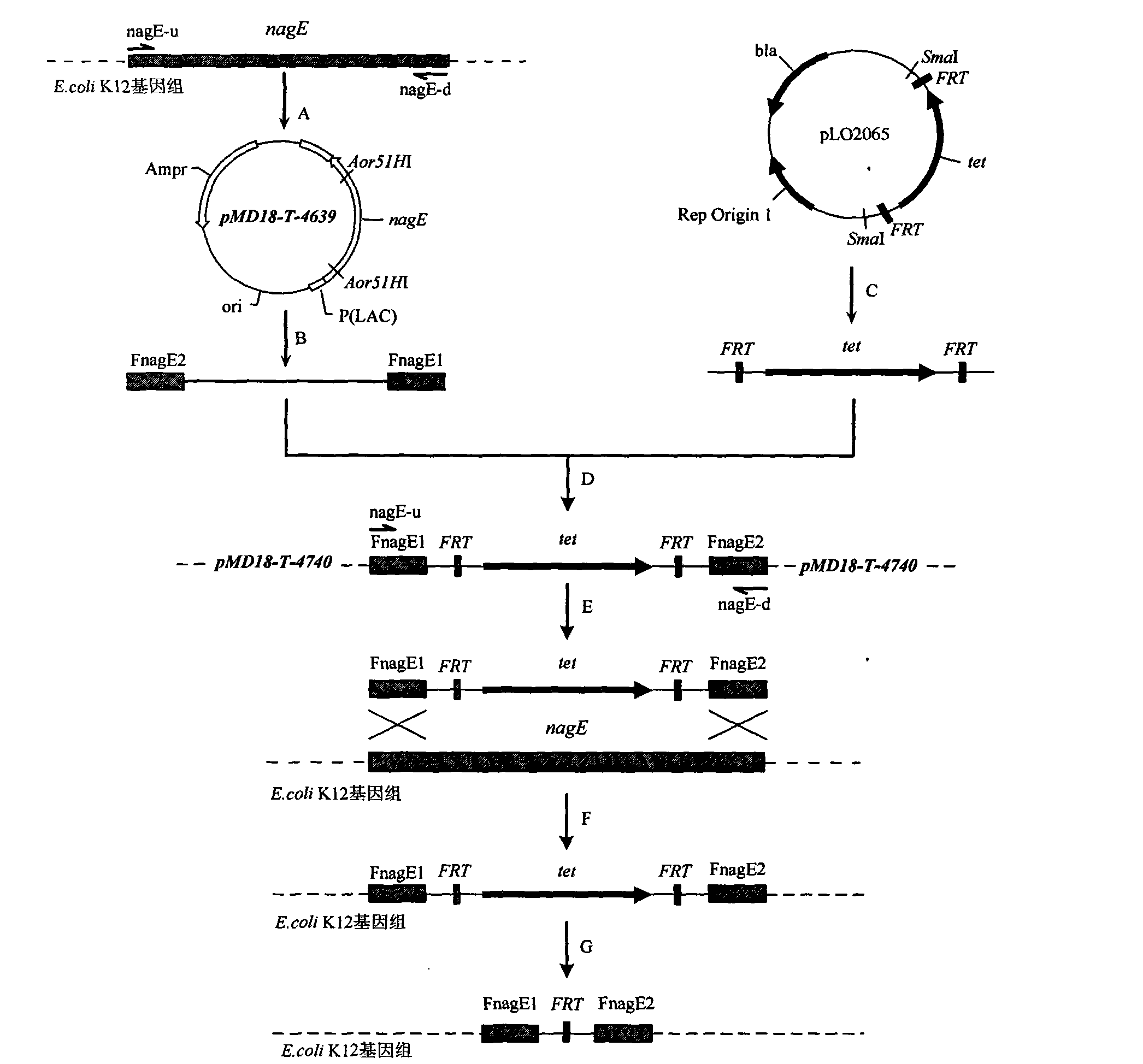

Recombinant escherichia coli of temperature-control coexpression exogenous gene and application thereof

InactiveCN101603023ASuitable for repeated usePost-processing is simpleBacteriaMicroorganism based processesEscherichia coliTemperature control

The invention discloses recombinant escherichia coli of a temperature-control coexpression exogenous gene, which is named as Escherichia coli DT26 (pBVNsS) CCTCC NO:M 209018. The genotype of the recombinant escherichia coli is delta nagE::FRT; and the recombinant escherichia coli contain a temperature-control coexpression carrier pBVNsS. Simultaneously, the invention also discloses the application of the recombinant escherichia coli used as a catalyst for the complete cell catalytic preparation of N-acetylneuraminic acid. In the process of the large-scale catalytic production of the N-acetylneuraminic acid, the recombinant escherichia coli of the temperature-control coexpression exogenous gene has the characteristics of safe and convenient preparation of the catalyst, simple operation of the catalytic process, cheap price, higher efficiency, easy extraction and the like.

Owner:SHANDONG UNIV

Method for preparing benzhydrol by hydrogenation of benzophenone

PendingCN111233626ALower catalyst costsGood conversion and selectivityMolecular sieve catalystsOrganic compound preparationActivated carbonTitanium oxide

The invention discloses a method for preparing benzhydrol by hydrogenation of benzophenone, which adopts a supported heterogeneous catalyst, and comprises the following components in percentage by mass: 0.1-60% of a main active component, 0-15% of an assistant and the balance of a carrier, wherein the main active component is one or more of Cu, Ni and Co, the assistant is one or more simple substances of Pd, Pt, Ru, Rh, Ir, Au, Re, Al, B, Cr, Mg, Mn, La, Ag, Li, Zn and Ce, or oxides, and the carrier is one or more of activated carbon, silicon oxide, aluminum oxide, titanium oxide, a molecularsieve, diatomite and zirconium oxide. According to the invention, a cheap metal is used as a main active component, so that the cost of the catalyst is reduced, a protective agent is not required to be added in the benzhydrol preparation process, an excellent conversion rate and selectivity can be achieved under mild conditions, the catalyst preparation method is simple, and large-scale industrialproduction is easy to realize.

Owner:ZHEJIANG NORMAL UNIVERSITY

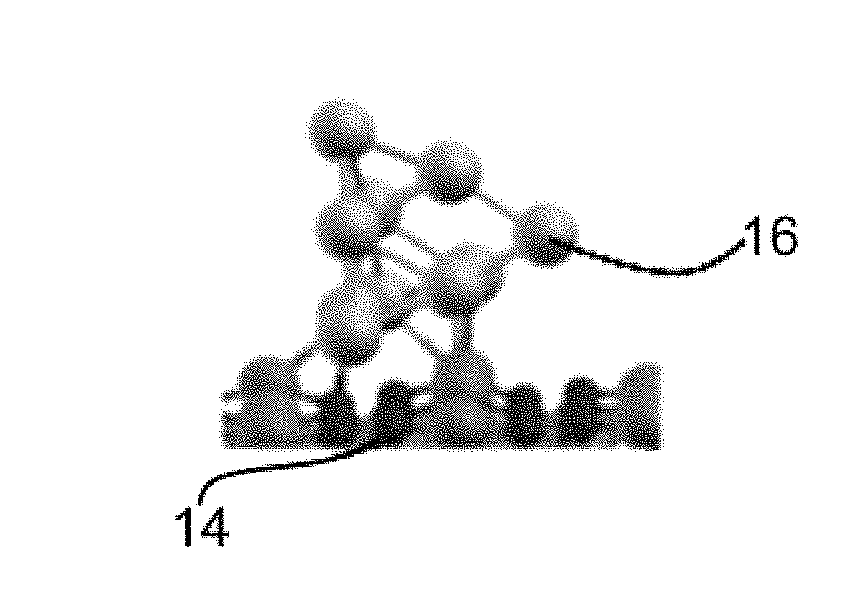

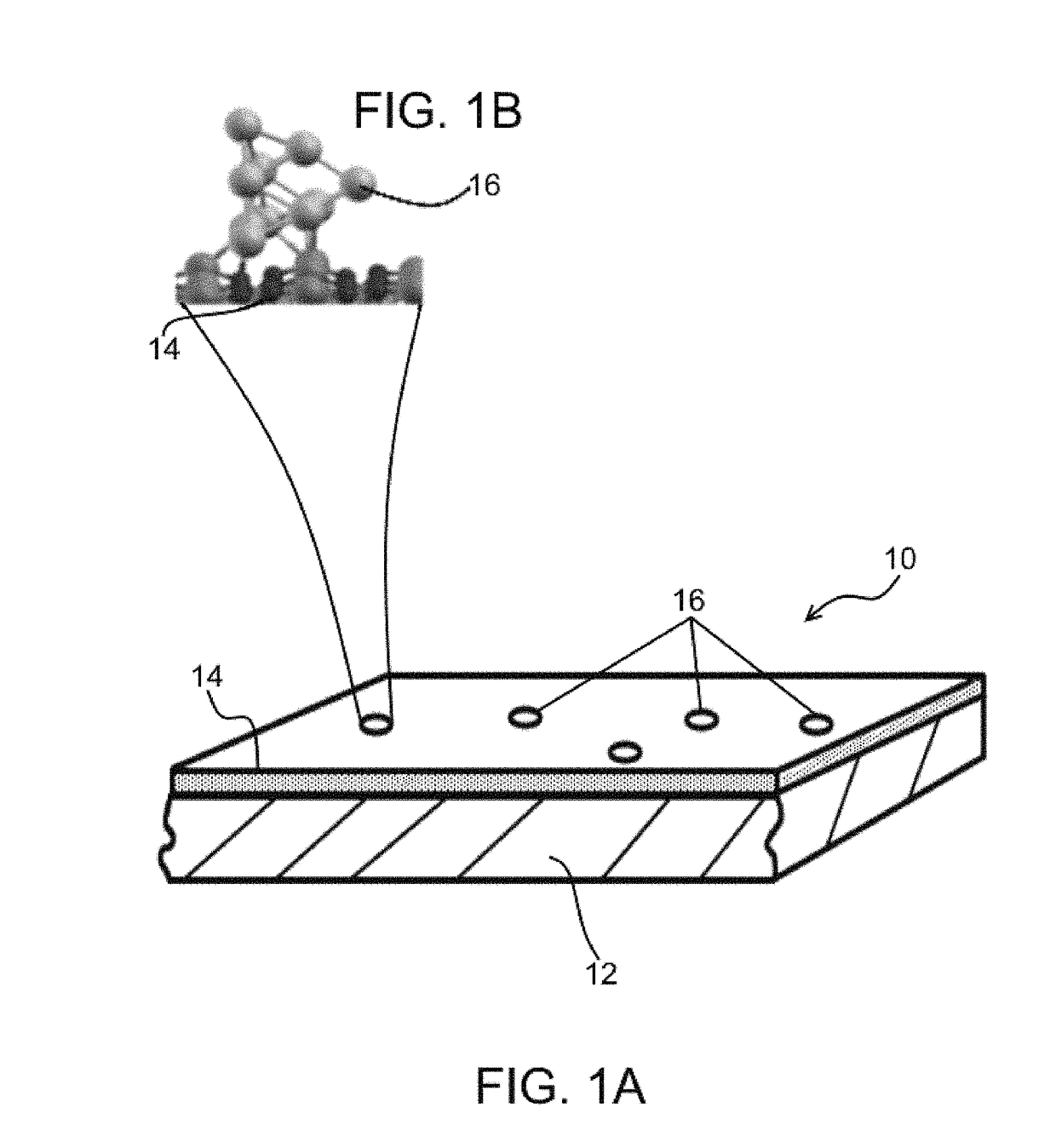

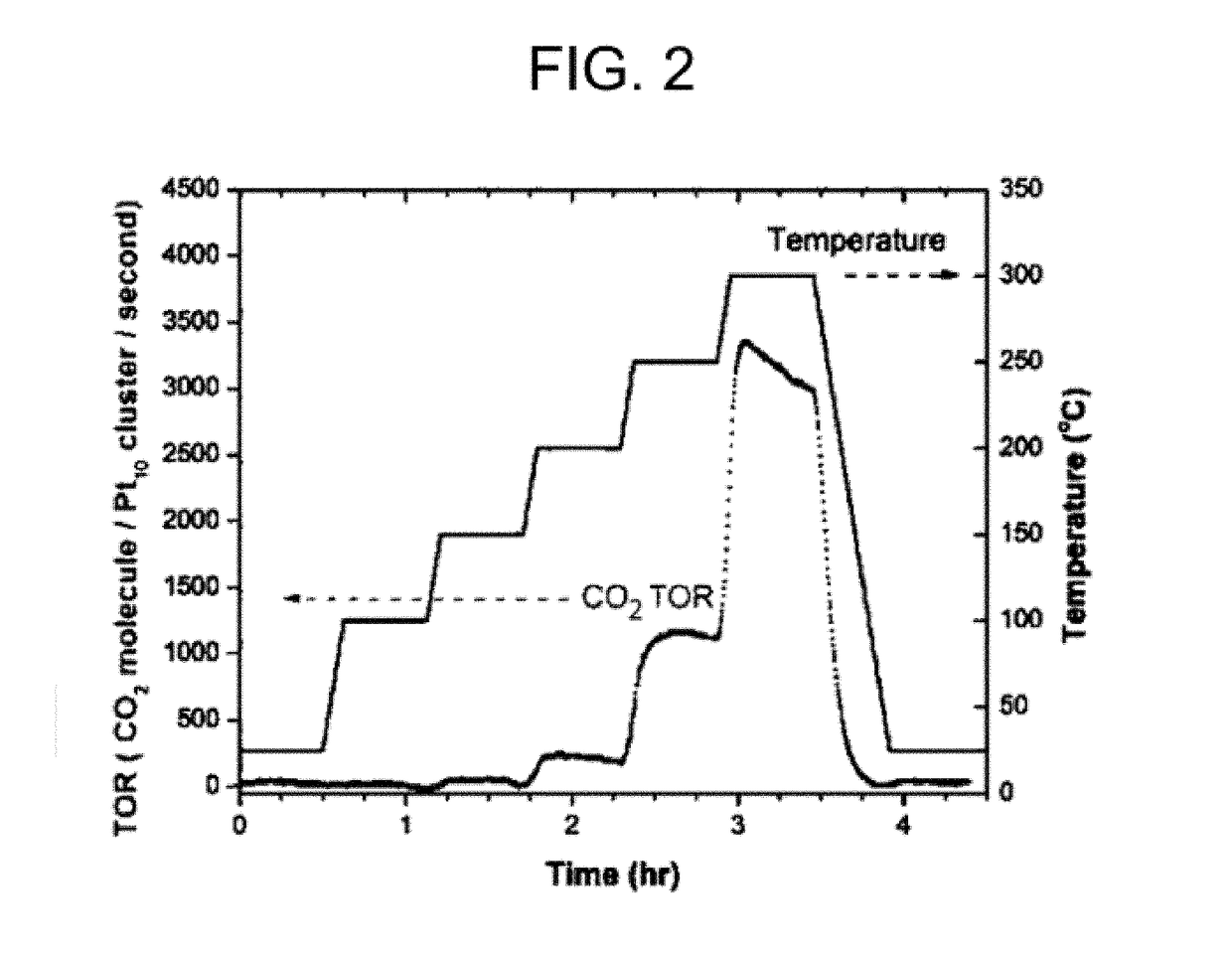

Subnanometer to nanometer transition metal CO oxidation catalysts

ActiveUS9849445B2Low costEliminate poisonCarbon compoundsDispersed particle separationMetal clustersChemistry

The present invention provides a catalyst defined in part by a conductive substrate; a film overlaying a surface of the substrate; and a plurality of metal clusters supported by the layer, wherein each cluster comprises between 8 and 11 atoms. Further provided is a catalyst defined in part by a conductive substrate; a layer overlaying a surface of the substrate; and a plurality of metal clusters supported by the layer, wherein each cluster comprises at least two metals.

Owner:UCHICAGO ARGONNE LLC

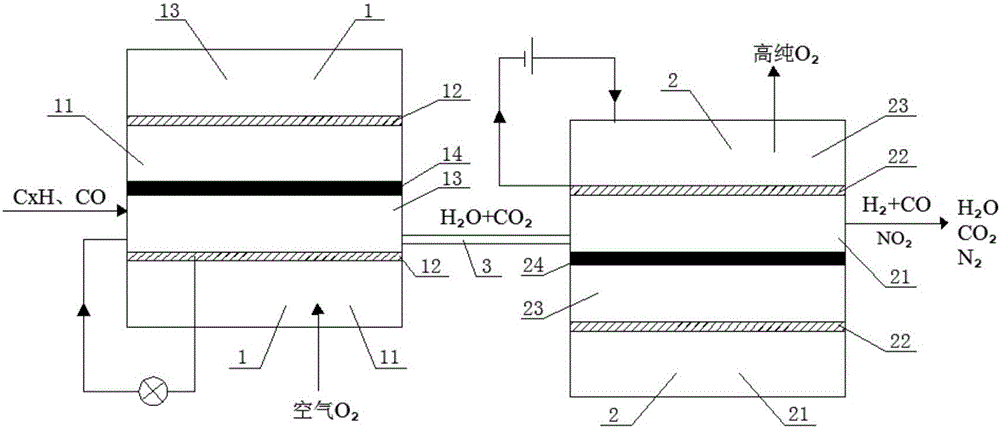

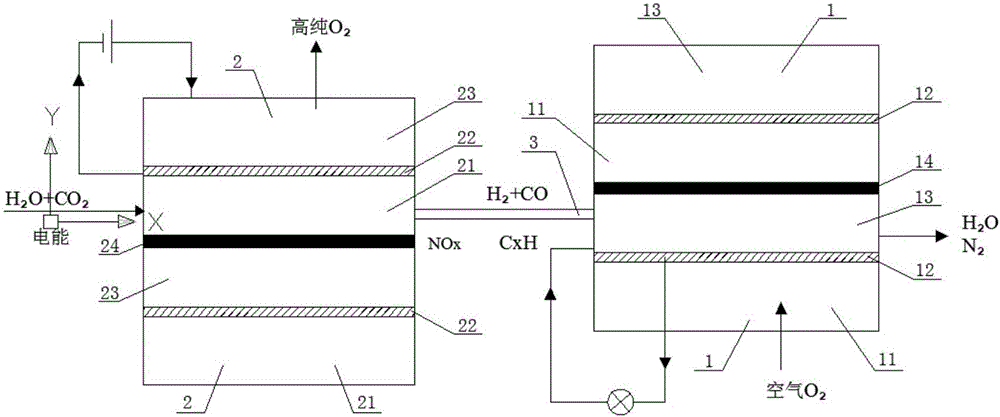

Device for automobile exhaust treatment and preparation method thereof

ActiveCN105888787AEasy to industrializeLow cost of three-way catalysisFuel cells groupingExhaust apparatusFuel cellsEngineering

The invention provides a device for automobile exhaust treatment. The device comprises a solid oxide fuel cell stack and a solid oxide electrolytic cell stack, wherein a function sealing material is arranged between the solid oxide fuel cell stack and the solid oxide electrolytic cell stack; the solid oxide fuel cell stack comprises at least two solid oxide fuel single cells which are connected in series or in parallel; and the solid oxide electrolytic cell stack comprises at least two solid oxide fuel single electrolytic cells which are connected in series or in parallel. According to the treatment device, the solid oxide fuel cells are subjected to industrialized application, the application field of the solid oxide fuel electrolytic cells is exploited, and the solid oxide fuel cells and the solid oxide fuel electrolytic cells are firstly combined and utilized in the study of aftertreatment of automobile exhaust. The invention further provides a preparation method of the treatment device. The preparation method is simple in operation and low in cost, and the industrial production is easy to achieve.

Owner:HUAINAN NORMAL UNIV

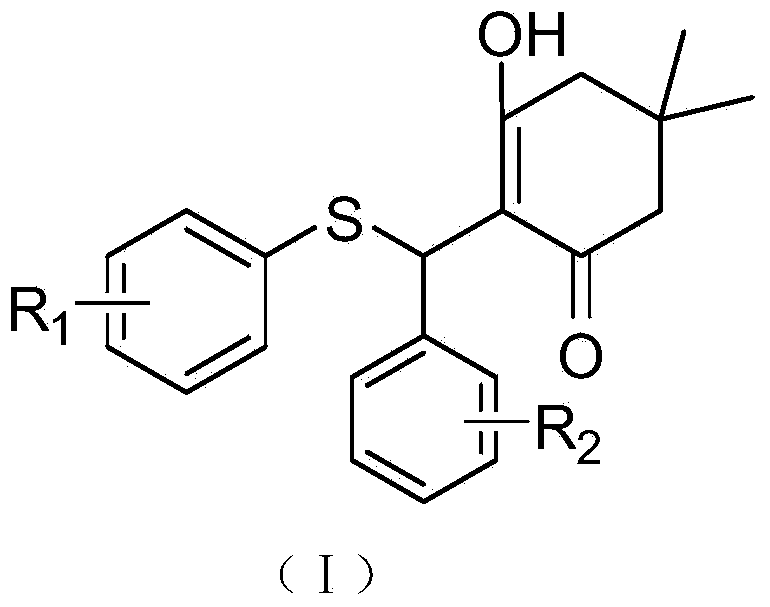

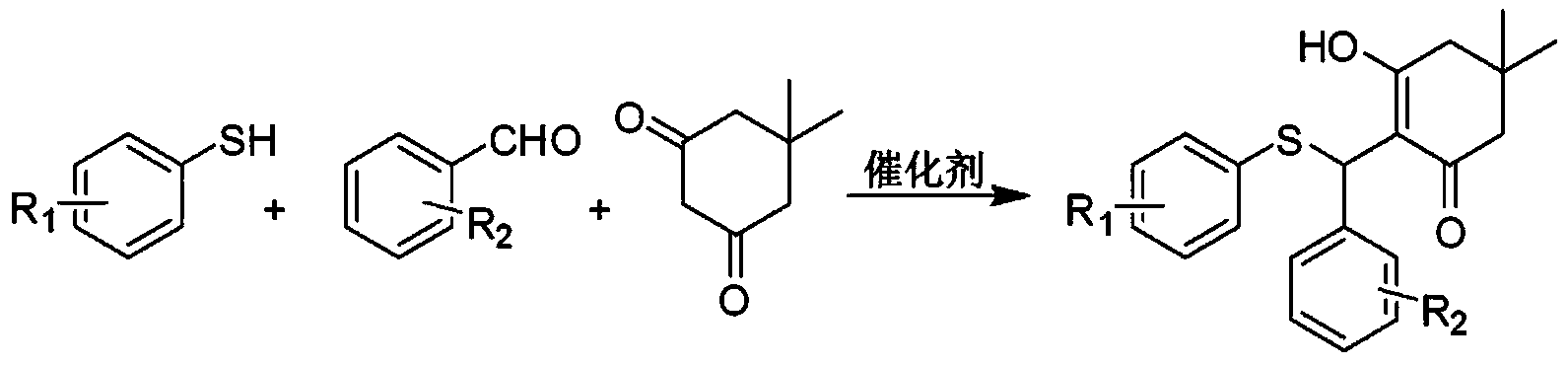

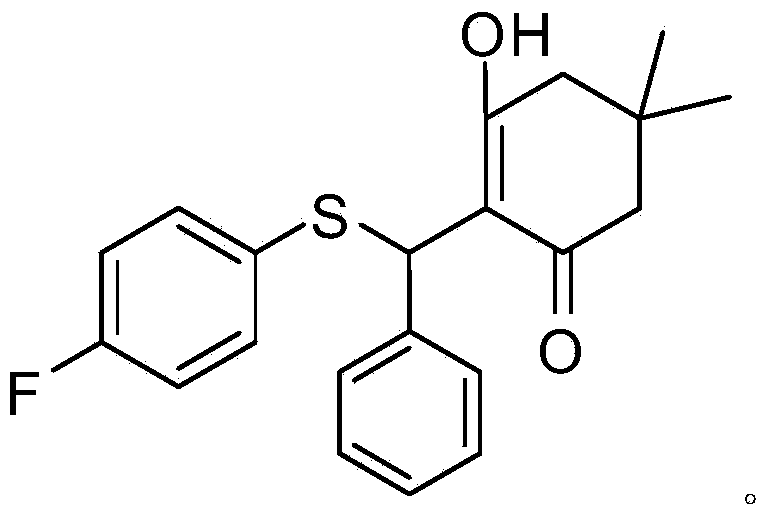

Mono-aryl thioether compound as well as preparation method and application thereof

InactiveCN103408476ARaw materials are easy to getLower catalyst costsAntimycoticsSulfide preparationArylDimedone

The invention discloses a mono-aryl thioether compound: 2-((substituted thiophenyl) benzyl)-3-hydroxy-5,5-dimethylcyclohexyl-2-ketene. According to the compound, a benzyl side chain of the compound has 3-hydroxy-5,5-dimethylcyclohexyl-2-ketene, so that the compound has antifungal activity and can be used for preparing antifungal pharmaceutical preparations. The invention also discloses a preparation method of the mono-aryl thioether compound, and the preparation method comprises the following steps of taking aromatic aldehyde, thiophenol or substituted thiophenol and 5,5-dimethyl-1,3-cyclohexanedione, and performing heating reaction under the catalysis of catalysts including silica gel sulfuric acid and the like to generate a target product. The catalysts used in the preparation method disclosed by the invention are low in cost, the reaction conditions are mild, the operation is simple, and the problems of the existing thioether preparation method are solved, so that the mono-aryl thioether compound is suitable for large-scale application.

Owner:HEBEI UNIVERSITY

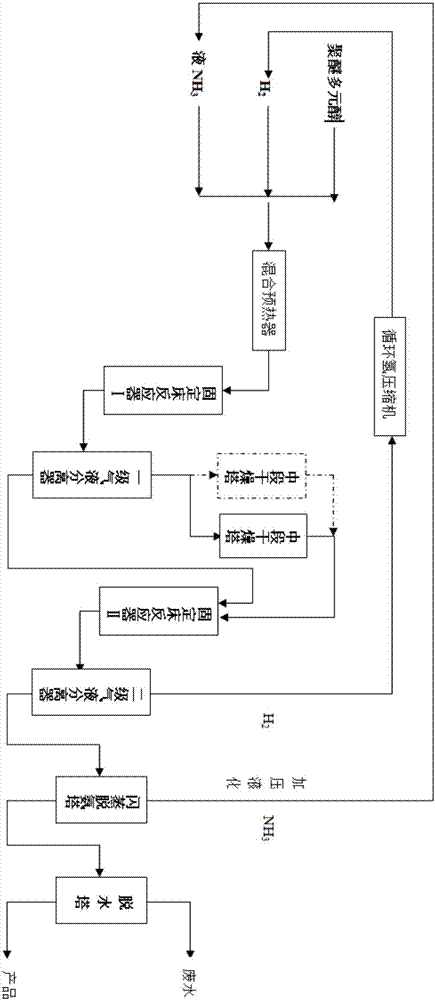

Continuous preparation device of small molecular weight amine-terminated polyether and preparation method

PendingCN107880260ARaise the feed space velocityReduce usageOrganic compound preparationAmino-hyroxy compound preparationFixed bedAmination

The invention discloses a continuous preparation device of small molecular weight amine-terminated polyether and a preparation method. The continuous preparation device of small molecular weight amine-terminated polyether comprises a hydrogen storage device, a liquid ammonia storage tank, a polyether polyol storage tank, a mixing preheater, a fixed bed reactor I, a fixed bed reactor II, a primarygas-liquid separator, an intermediate drying tower, a secondary gas-liquid separator, a circulating hydrogen compressor, a flash ammonia stripping tower, a pressurized liquefaction plant, a dehydrating tower, a wastewater pool and a product storage tank. The preparation method comprises the following steps: by taking small molecular weight polyether polyol, H2 and liquid NH3 as raw materials, respectively carrying out 'two-step' hydrogen present ammonolysis reactions in the presence of a catalyst in a manner of connecting the two fixed bed reactors in series, thereby obtaining the small molecular weight amine-terminated polyether. The operation process is continuous, the product quality is stable and controllable, and the reaction conditions are mild; recycling of the H2 and liquid NH3 isrealized, and the device is environmentally friendly and economical; and the reaction conversion rate is more than or equal to 99.0%, and the primary amine selectivity is more than or equal to 98.5%.

Owner:HONGBAOLI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com